Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Andrussow process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

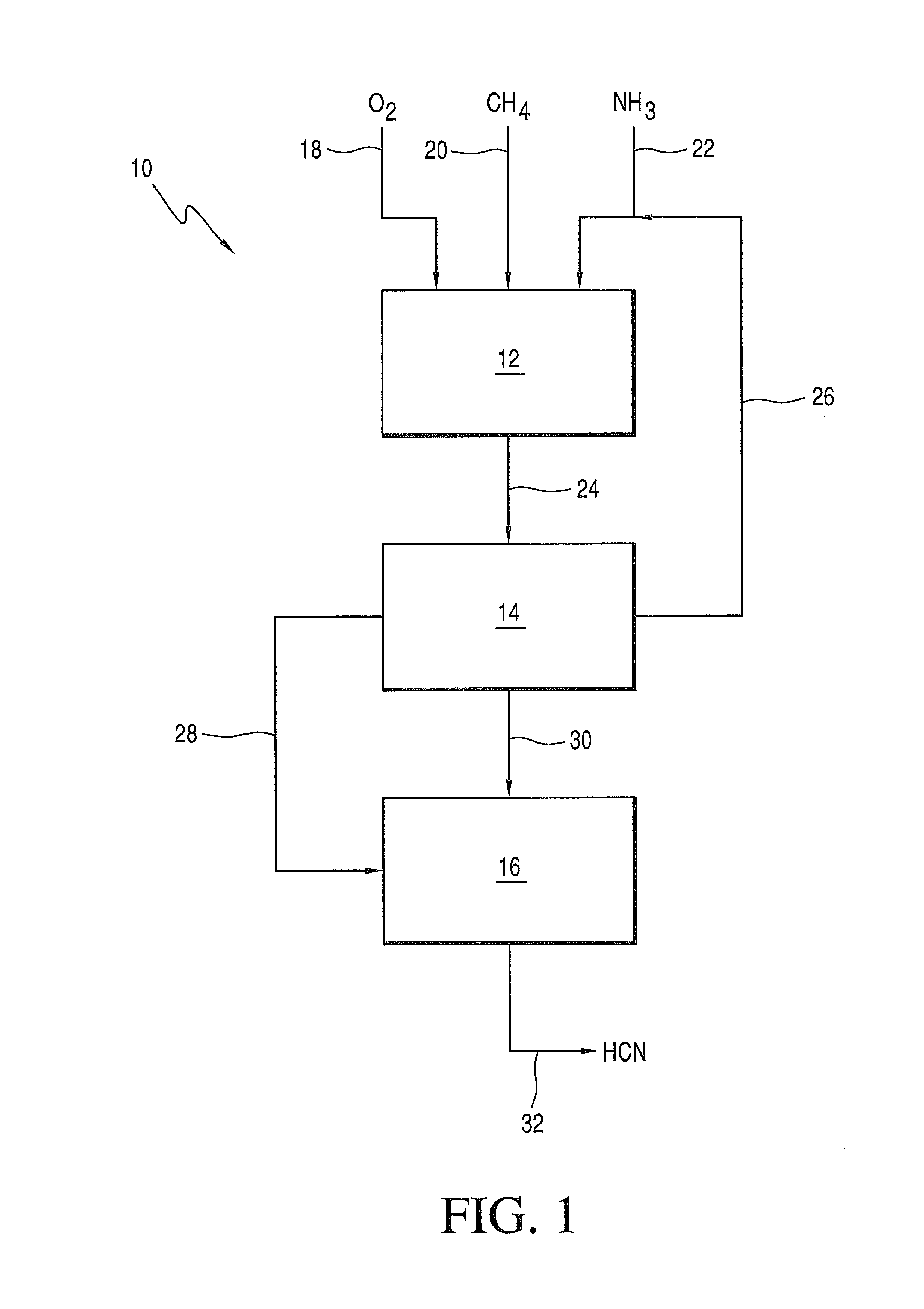

The Andrussow process is an industrial process for the production of hydrogen cyanide from methane and ammonia in the presence of oxygen and a platinum catalyst. The process is based on a reaction that was discovered by Leonid Andrussow in 1927. In the following years he developed the process that is named after him. HCN is also produced in the BMA process.

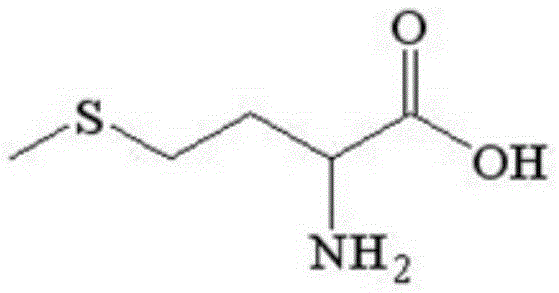

Cheap preparation method for high purity D,L-methionine

ActiveCN103641758AAvoid it happening againShorten production timeOrganic compound preparationSulfide preparationMethionine biosynthesisPressure reduction

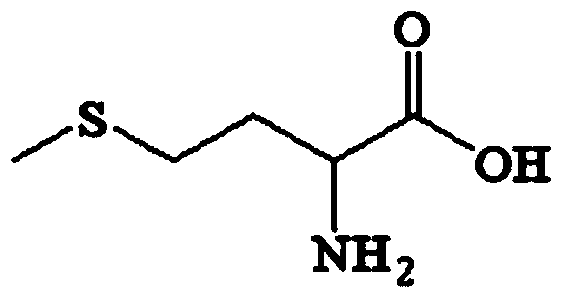

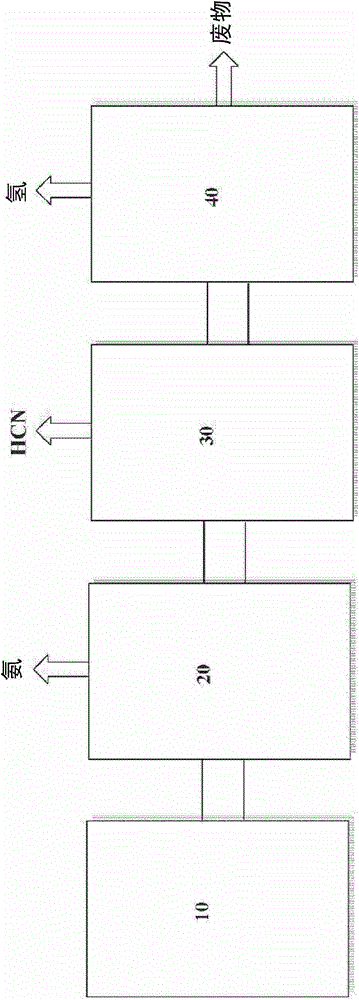

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for producing hydrocyanic acid (HCN)

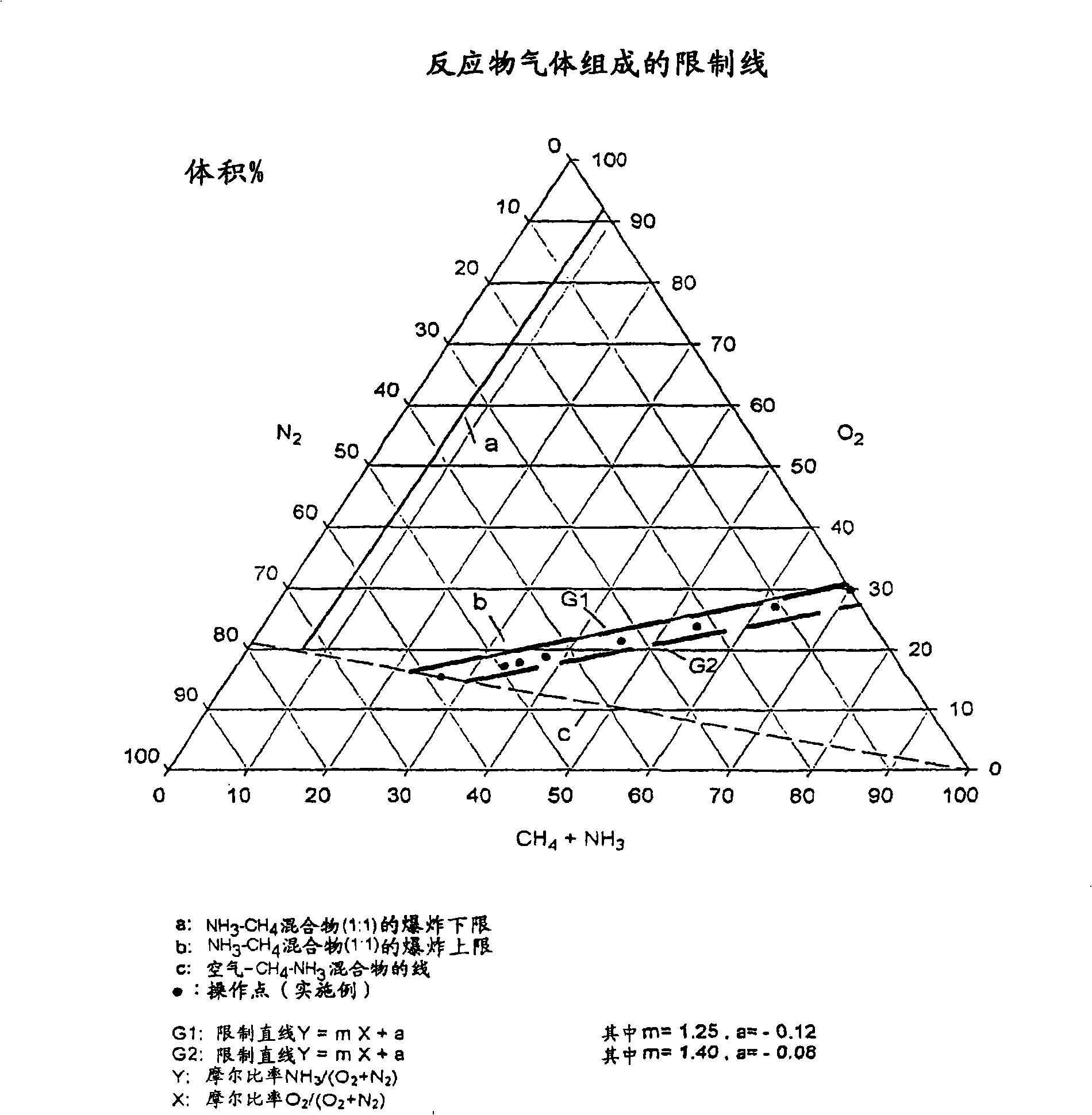

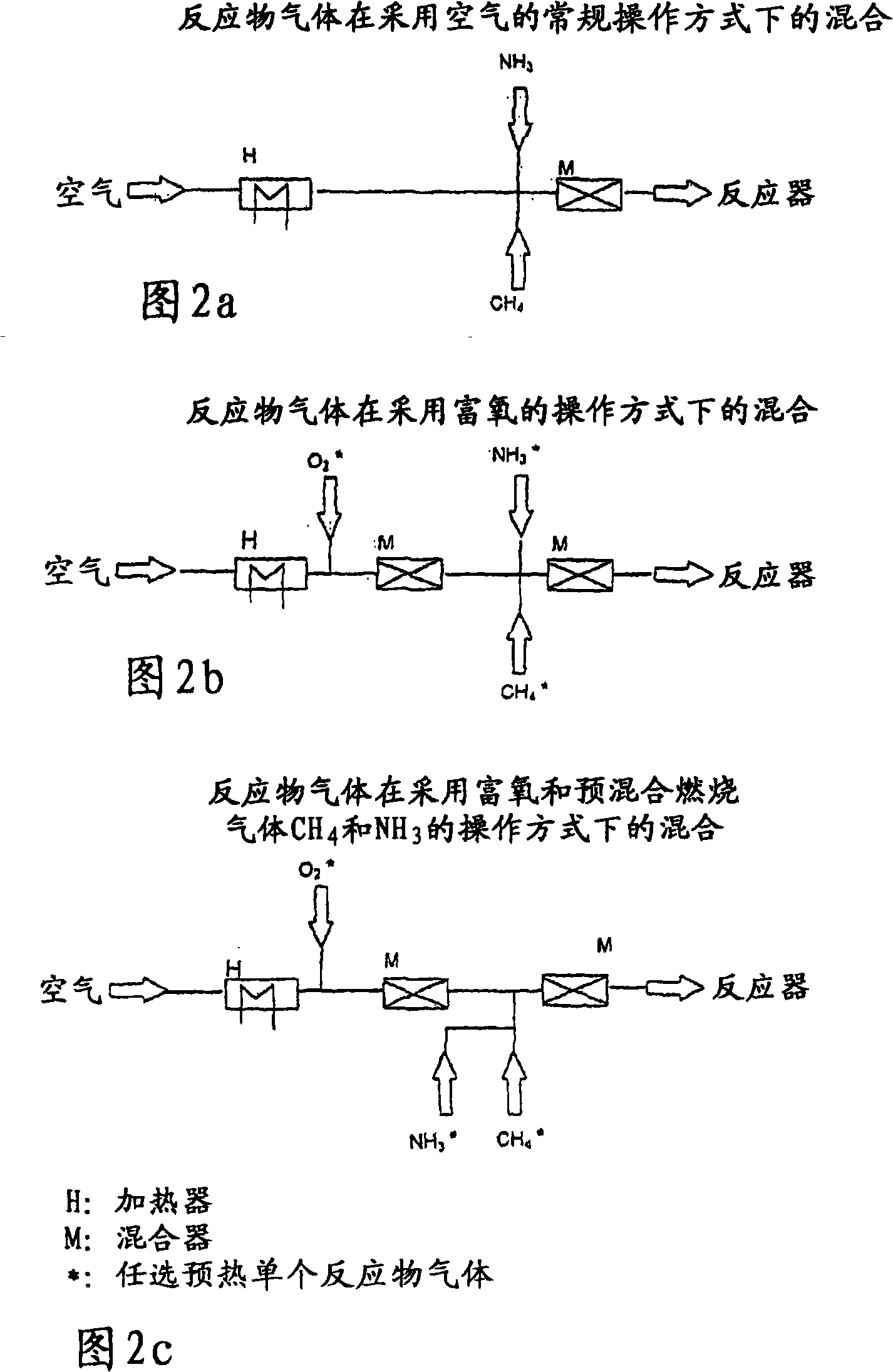

InactiveCN101269824AHigh yieldIncrease production capacityHydrogen cyanide preparation/purification/separationNitrogenMethane gas

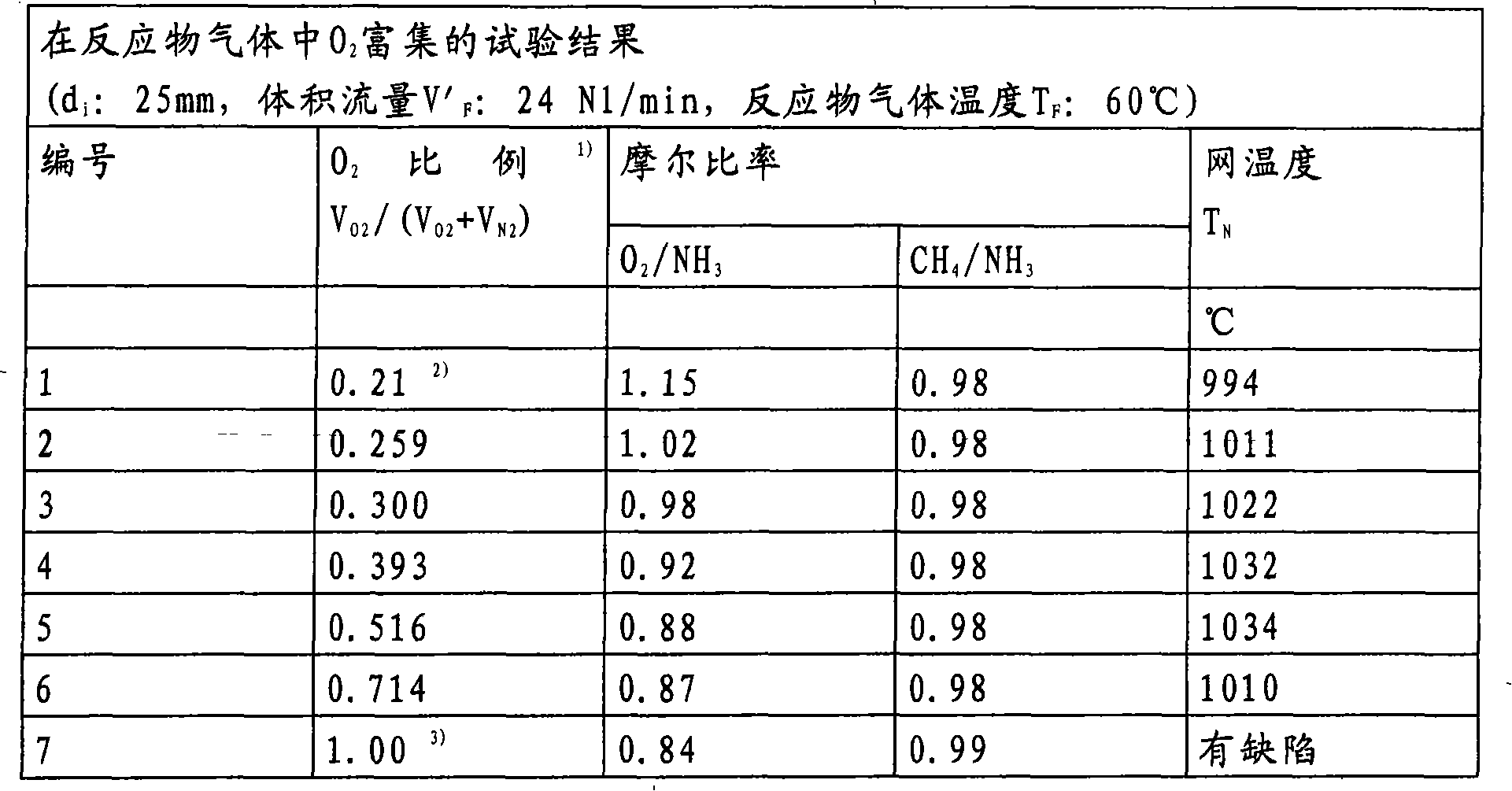

The invention relates to a method for preparing hydrogen cyanide according to andrussow process, which is carried out by reacting methane gas, ammonia gas and oxygen-containing gas at rising temperature on catalyst. Oxygen has a volume proportion (O<2> / (O<2>+N<2>) of 0.2 to 1.0 corresponding to total volume of nitrogen and oxygen, and the reaction is carried out by adopting mixture of incombustible reactant gas.

Owner:EVONIK ROEHM GMBH

Preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate

ActiveCN103641757AStable in natureShorten production timeSulfide preparationTrace element2-hydroxy-4-methylthiobutyrate

The invention is directed at the field of chemical engineering and provides a preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; preparing a 2-hydroxy-4-methylthiobutyronityile system with the hydrocyanic acid gas mixture and methylthiopropionaldehyde as starting raw materials; hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system with inorganic base so as to obtain D,L-2-hydroxy-4-methylthiobutyrate; and chelating D,L-2-hydroxy-4-methylthiobutyrate with a soluble calcium salt so as to produce calcium D,L-2-hydroxy-4-methylthiobutyrate. The method has the advantages of a few processing step, cheap and easily available raw materials, stable intermediate properties and low total production cost. Prepared calcium D,L-2-hydroxy-4-methylthiobutyrate has the advantages of high yield, high purity, a powder crystal form and great bulk density, can be used as an animal feed additive for effective mixing with a feed so as to supplement trace elements and amino acid in daily ration and improve production performance and immune performance of animals and can also be used as a medicine reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

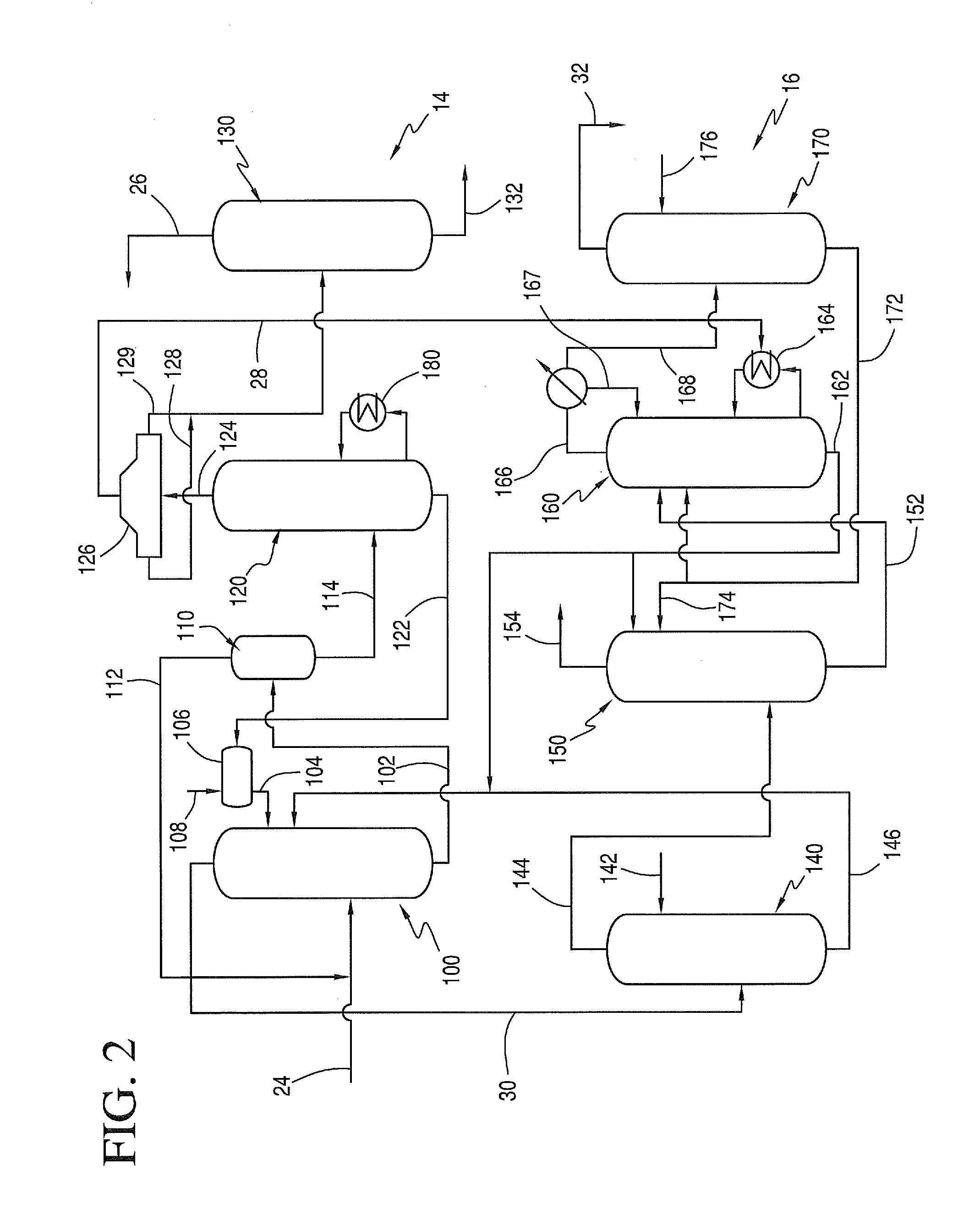

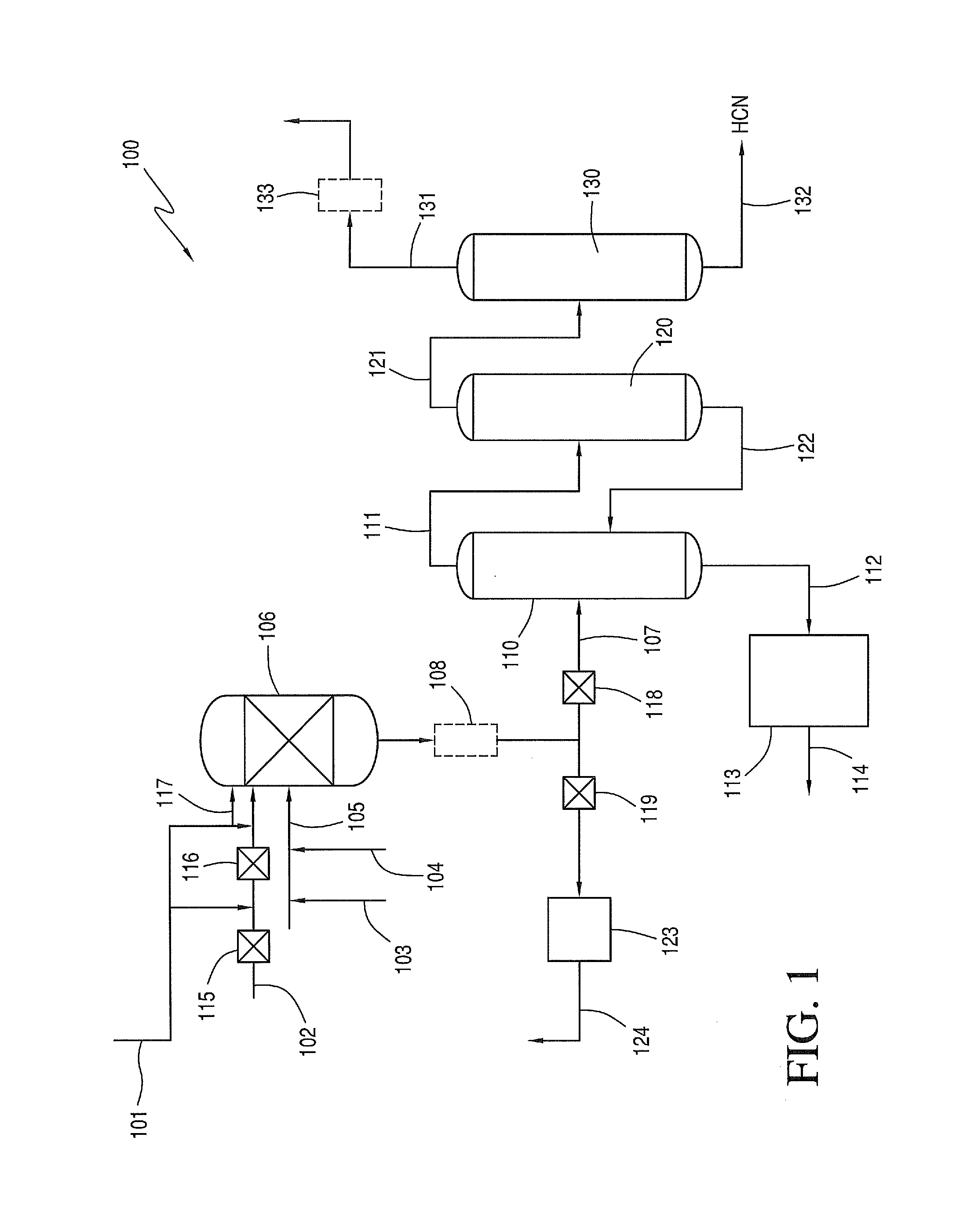

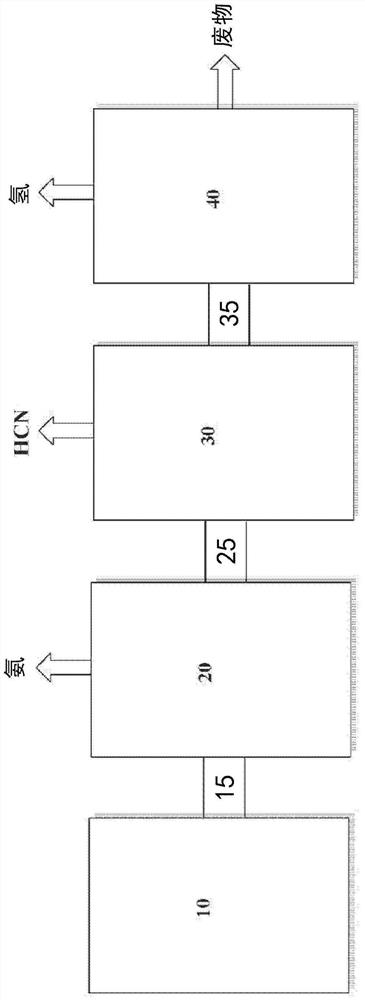

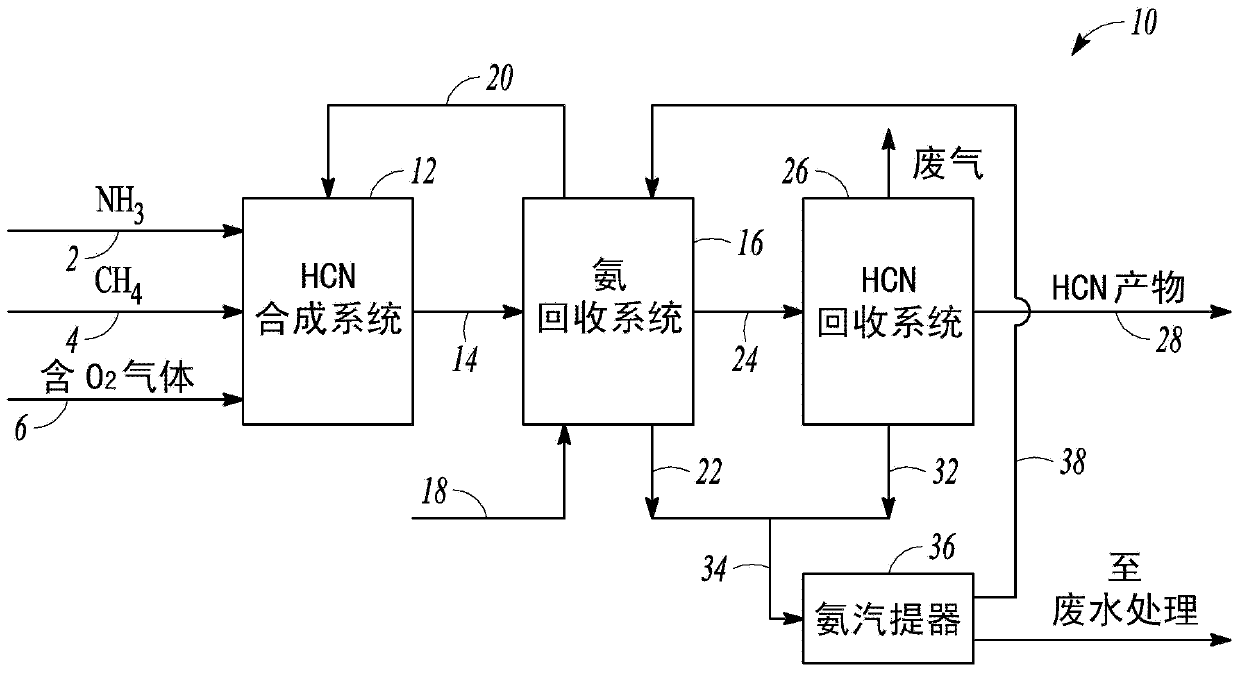

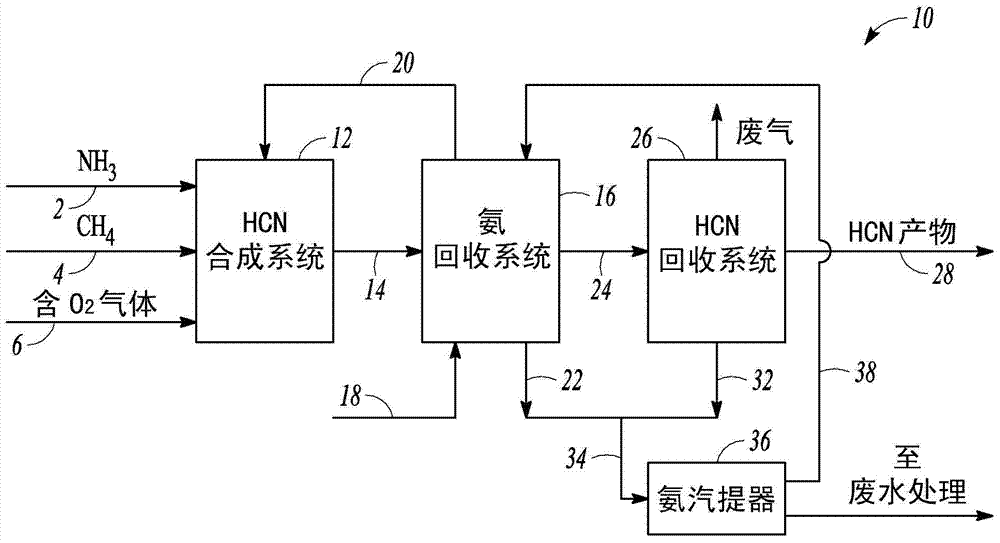

Process for heat recovery from ammonia stripper in andrussow process

InactiveUS20160068404A1Reduce concentrationEasy to adaptGas treatmentDispersed particle separationAndrussow processNH3 compound

A hydrogen cyanide production process that recovers ammonia and hydrogen cyanide from a crude hydrogen cyanide product comprising from 25 to 50 vol. % water. When heat is recovered from the ammonia stripper, in the form of low pressure steam, and the steam can be integrated with the refining of hydrogen cyanide.

Owner:INVISTA NORTH AMERICA R L

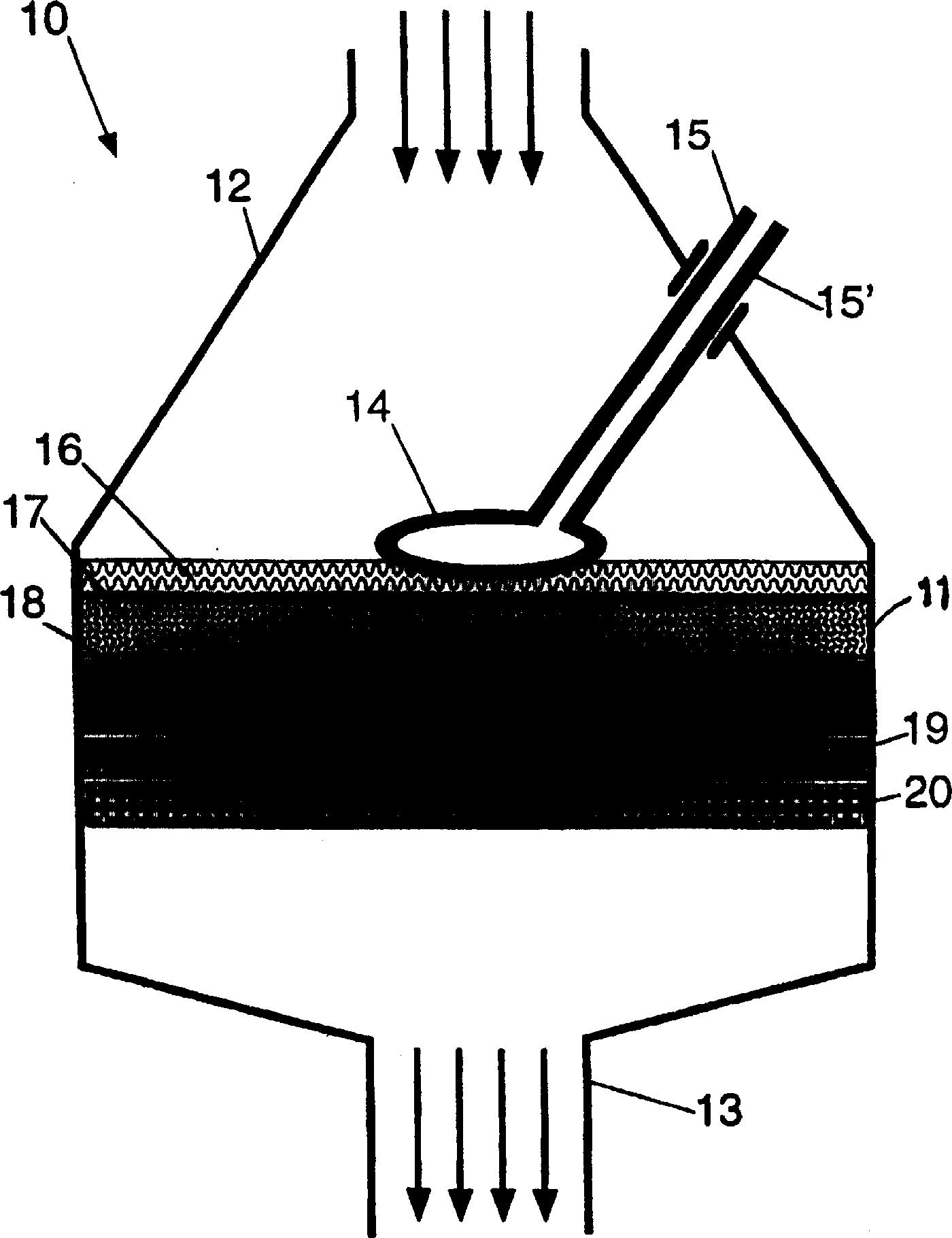

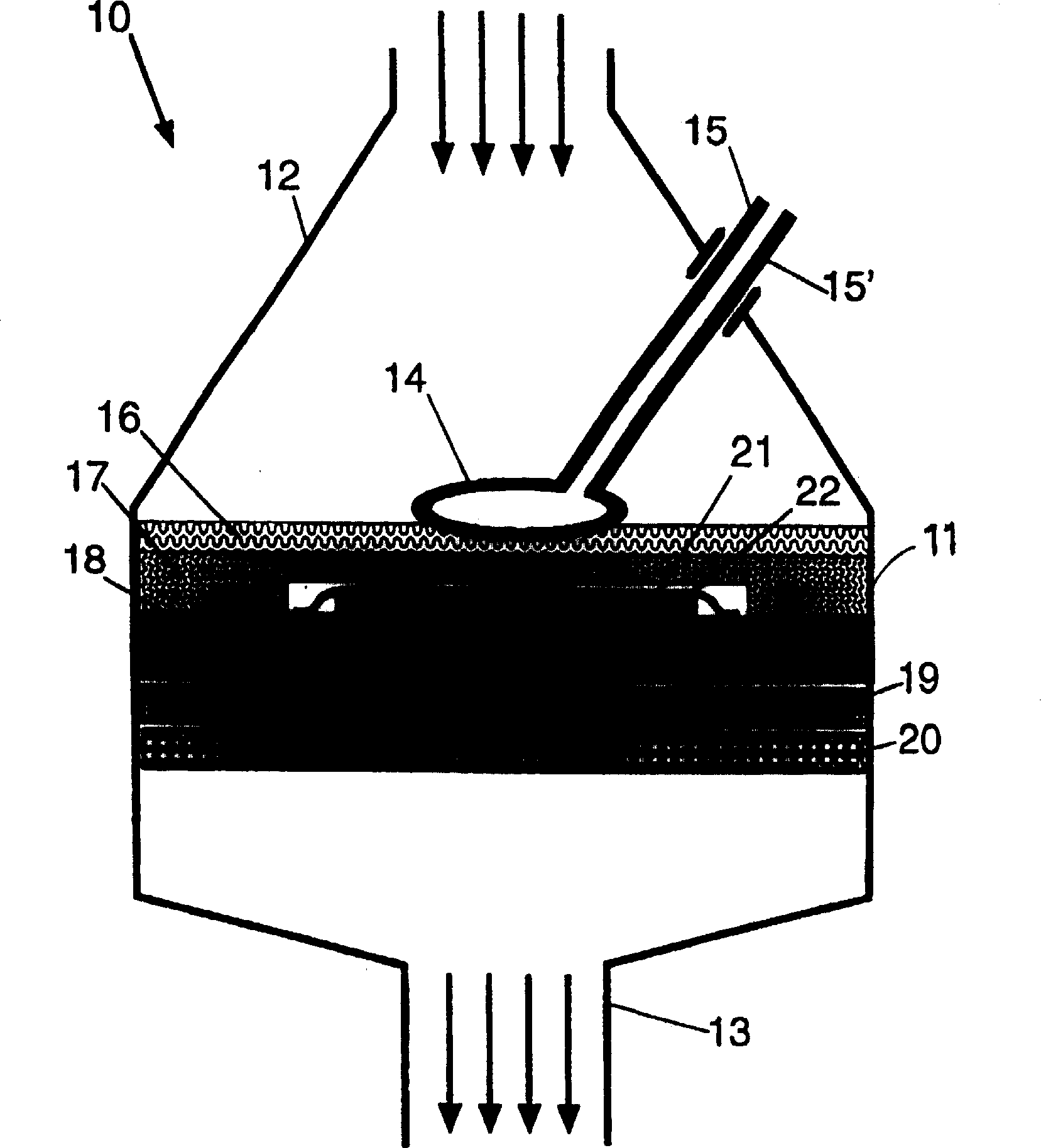

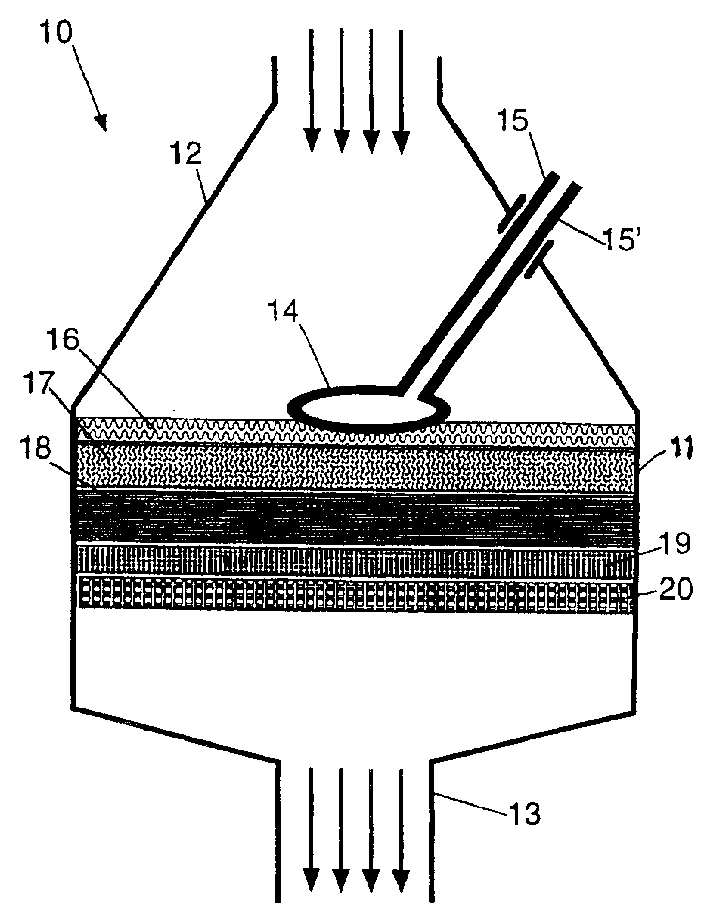

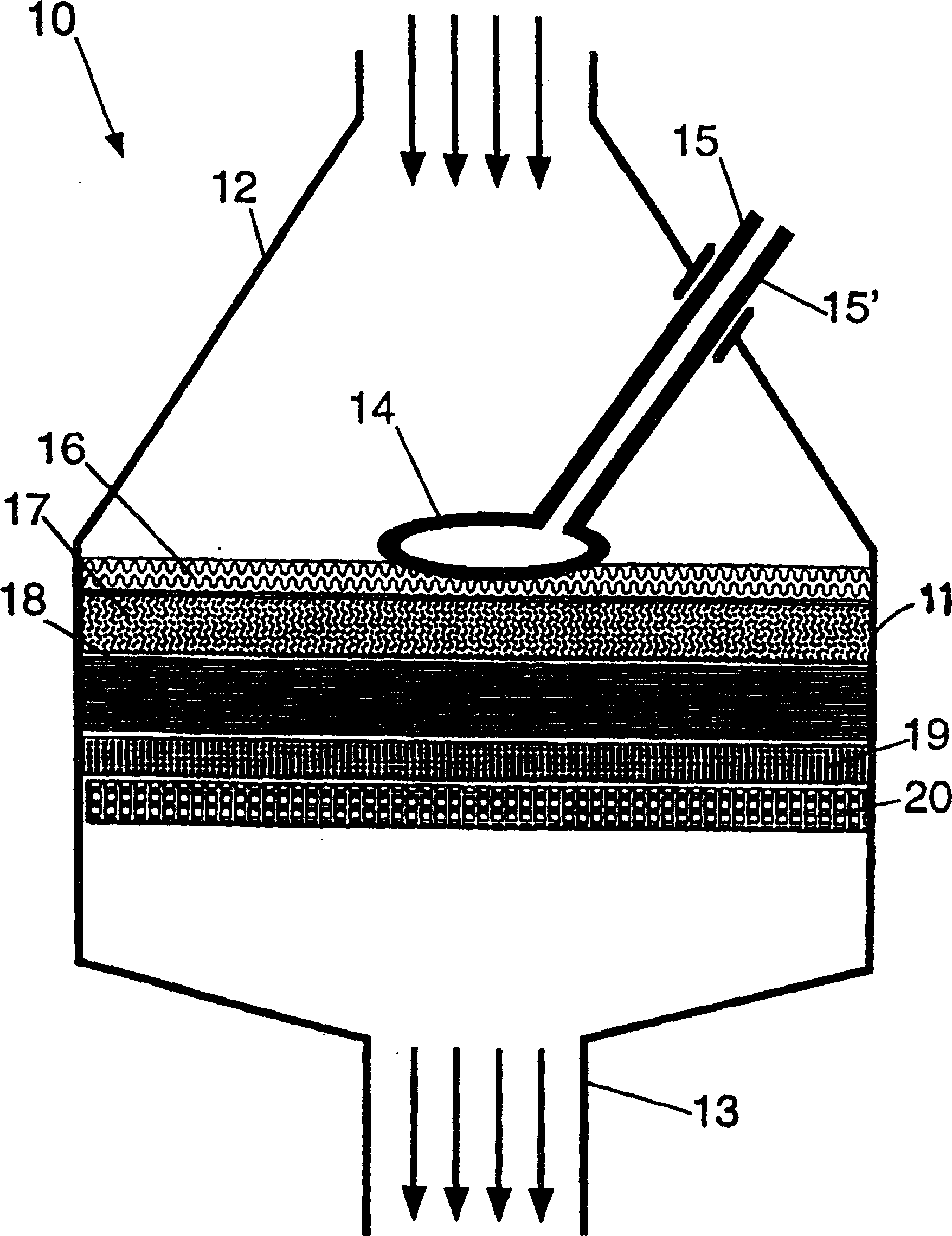

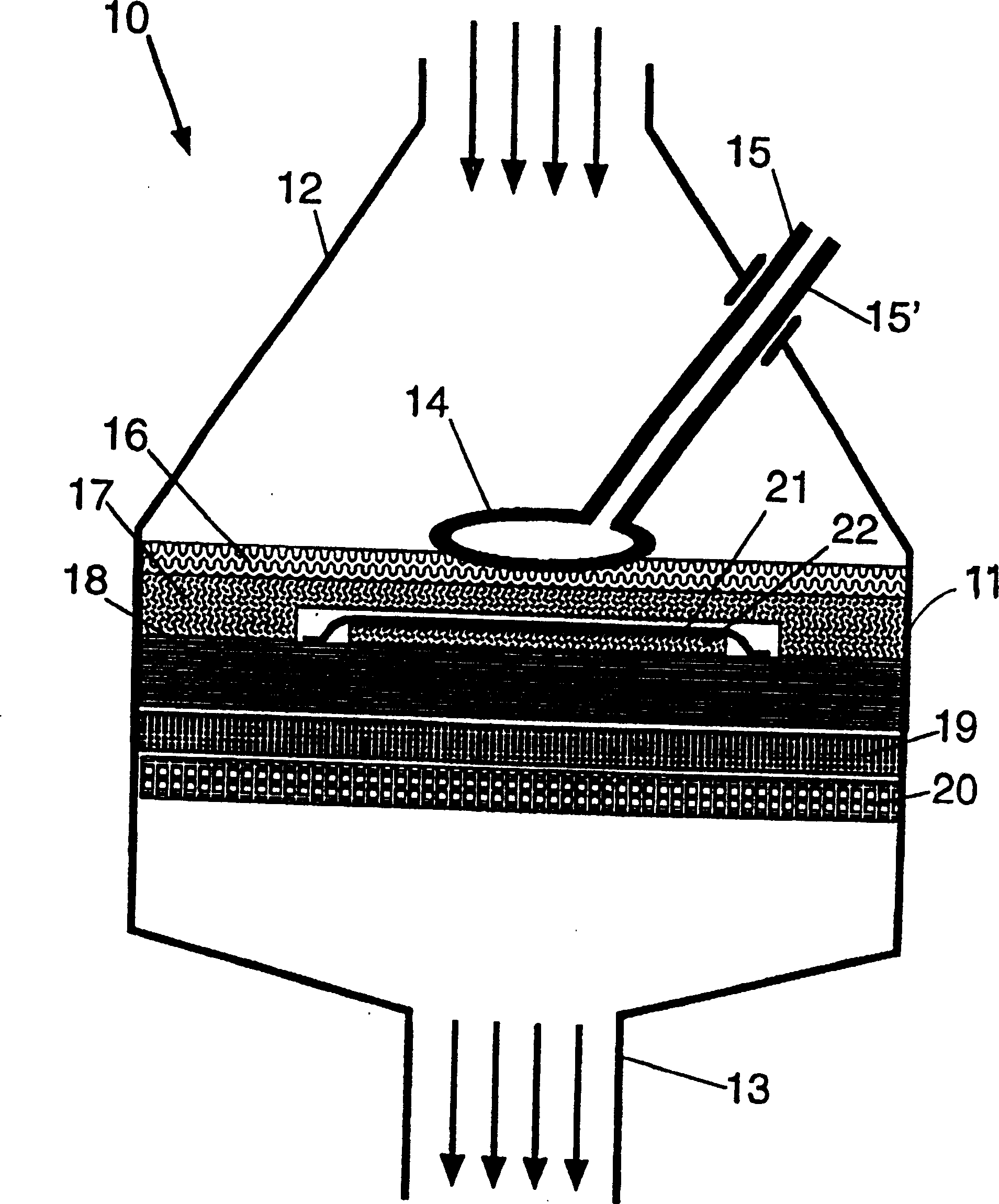

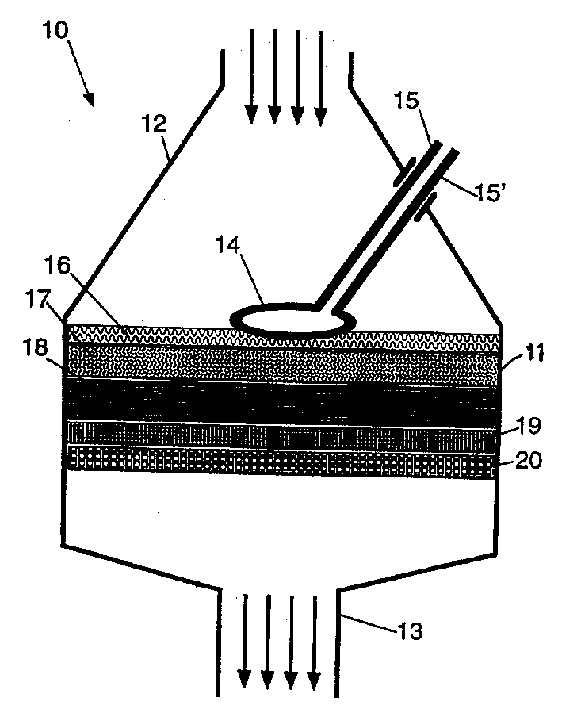

Method of inductively igniting a chemical reaction

InactiveCN1261822AImprove induction efficiencyCatalytic gas-gas reactionEnergy based chemical/physical/physico-chemical processesChemical reactionGas phase

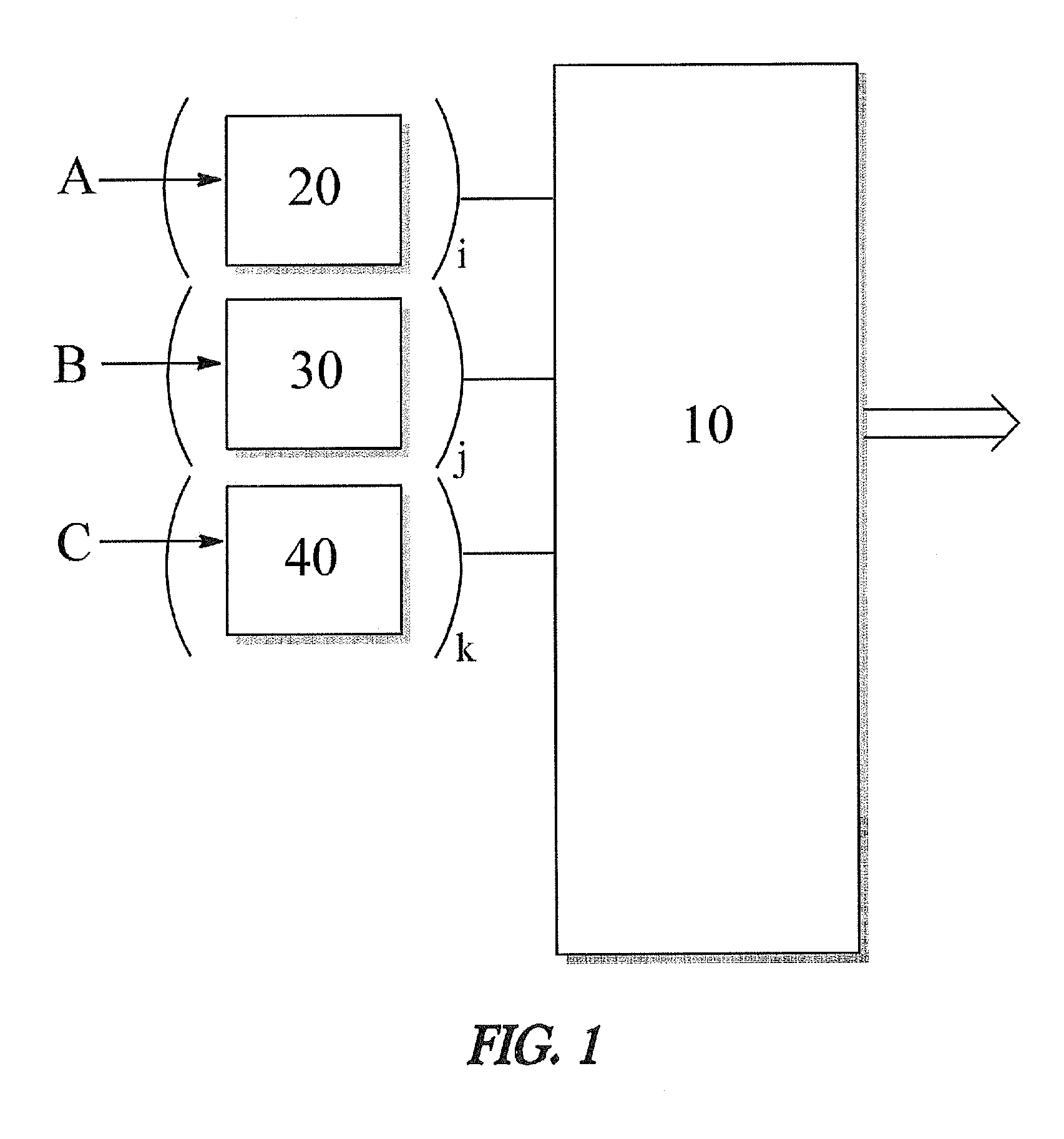

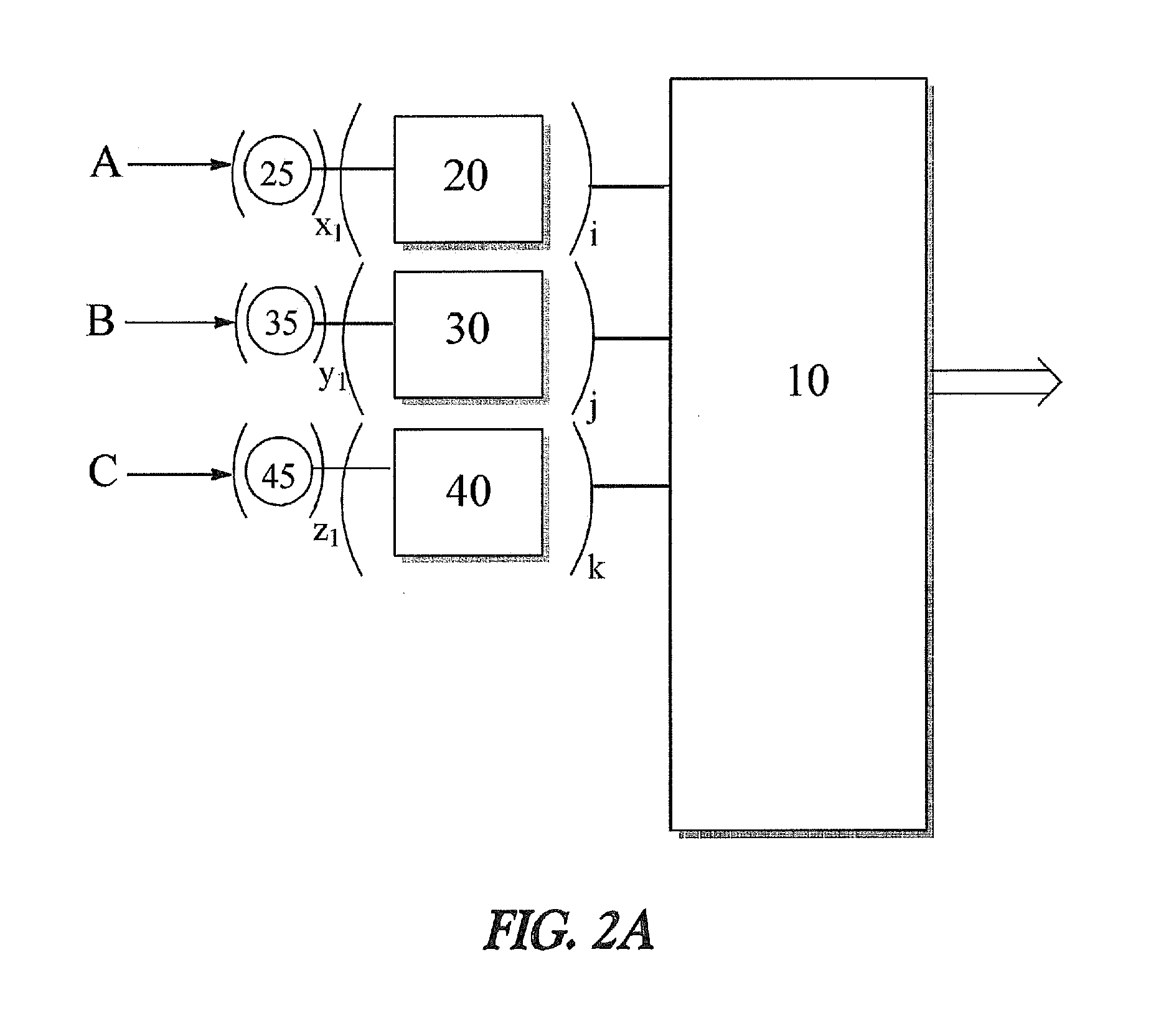

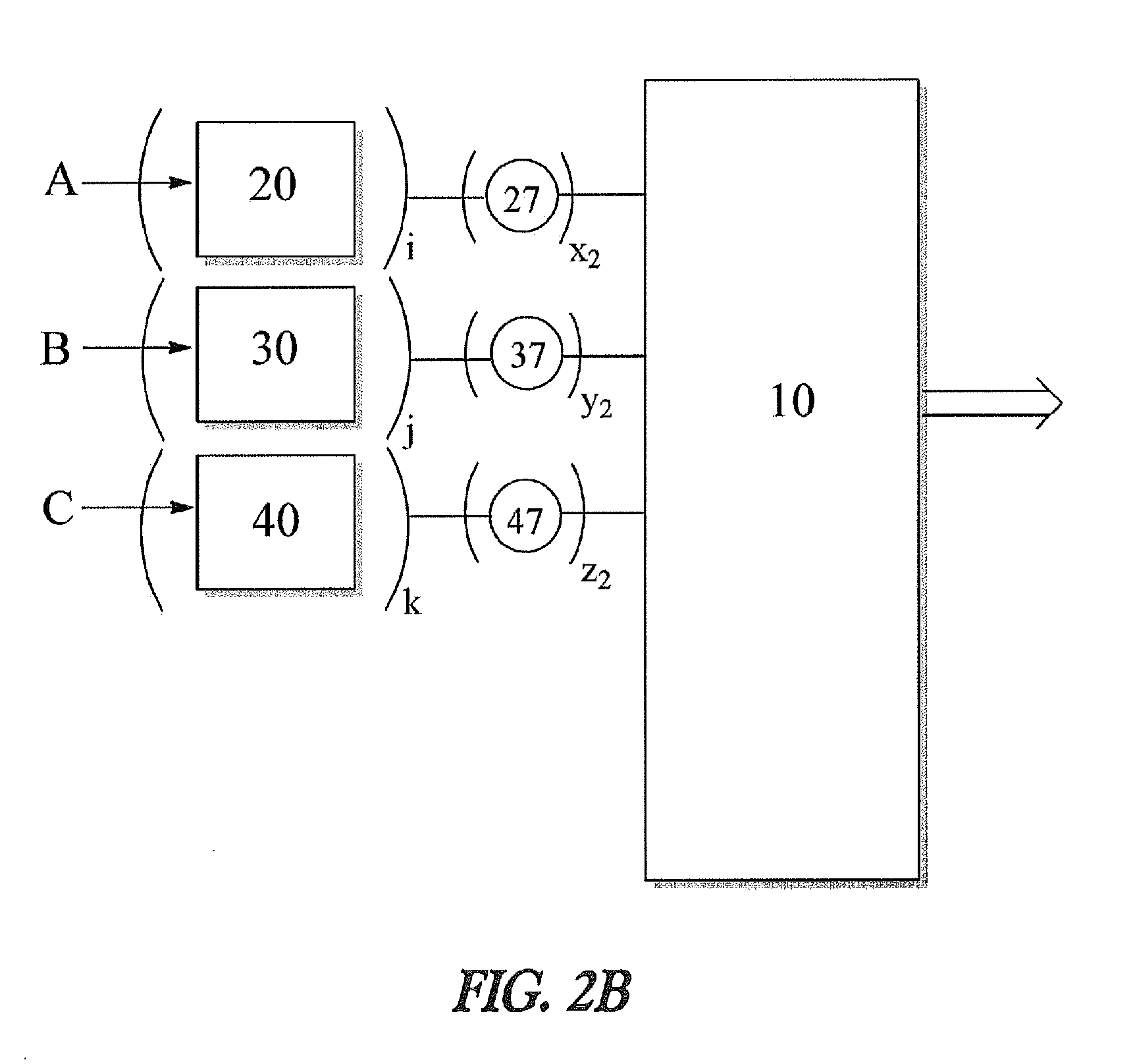

An improved method of igniting a catalyzed gas phase chemical reaction involving the act of providing a reactor vessel (10), wherein the gaseous reactant, continuously passing through the reactor, makes contact with a solid phase metallic catalyst media (18), with an inductive coil (14) within the reactor (10) on the inlet side of the catalyst and a porous thermal, spark and radiation barrier (17) between the induction coil (14) and solid catalyst (18). According to the improved method of ignition, the metallic catalyst media (18) is inductively heated in order to ignite the chemical reaction and after ignition the inductive heating is suspended and the exotherm of the chemical reaction is thereafter relied upon to sustain the reaction temperature. Such a reactor and method of operation is particularly useful for continuous production of hydrogen cyanide by the Andrussow process.

Owner:INVISTA TECHNOLOG IES S A R L

Preparation method of medicinal D,L-2-hydroxy-4-methylthiobutyric acid metal chelate

ActiveCN103641754AStable in natureLong storage timeOrganic compound preparationSulfide preparationChemical industryMetal chelate

The invention aims at the chemical industry field, and relates to a preparation method of a medicinal D,L-2-hydroxy-4-methylthiobutyric acid metal chelate. The method comprises the following steps: carrying out a reaction of a hydrocyanic acid mixed gas prepared through an Andrussow process and methylthiopropionaldehyde as initial raw materials to obtain a 2-hydroxy-4-methylthiobutyronityile system, hydrating the 2-hydroxy-4-methylthiobutyronityile system to obtain D,L-2-hydroxy-4-methylthiobutyramide, and hydrolyzing to obtain D,L-2-hydroxy-4-methylthiobutyrate; and chelating D,L-2-hydroxy-4-methylthiobutyrate with a trace metal element salt to obtain the D,L-2-hydroxy-4-methylthiobutyrate. The method has the advantages of mild technological conditions, few side reactions, low production cost and simple purifying operation, and the obtained D,L-2-hydroxy-4-methylthiobutyrate has a high purity and a large bulk density, and can be used as an animal feed additive or a medicinal reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

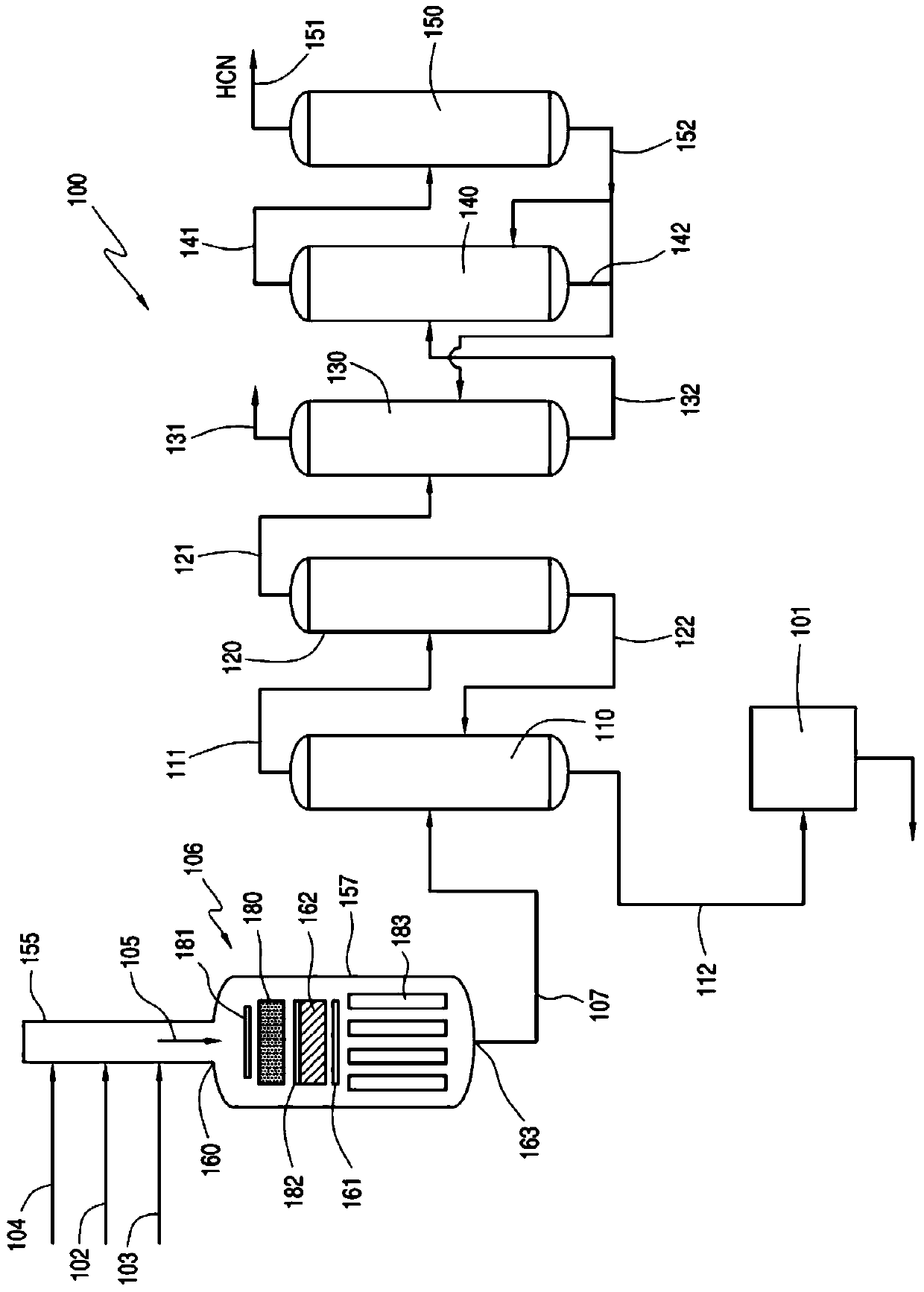

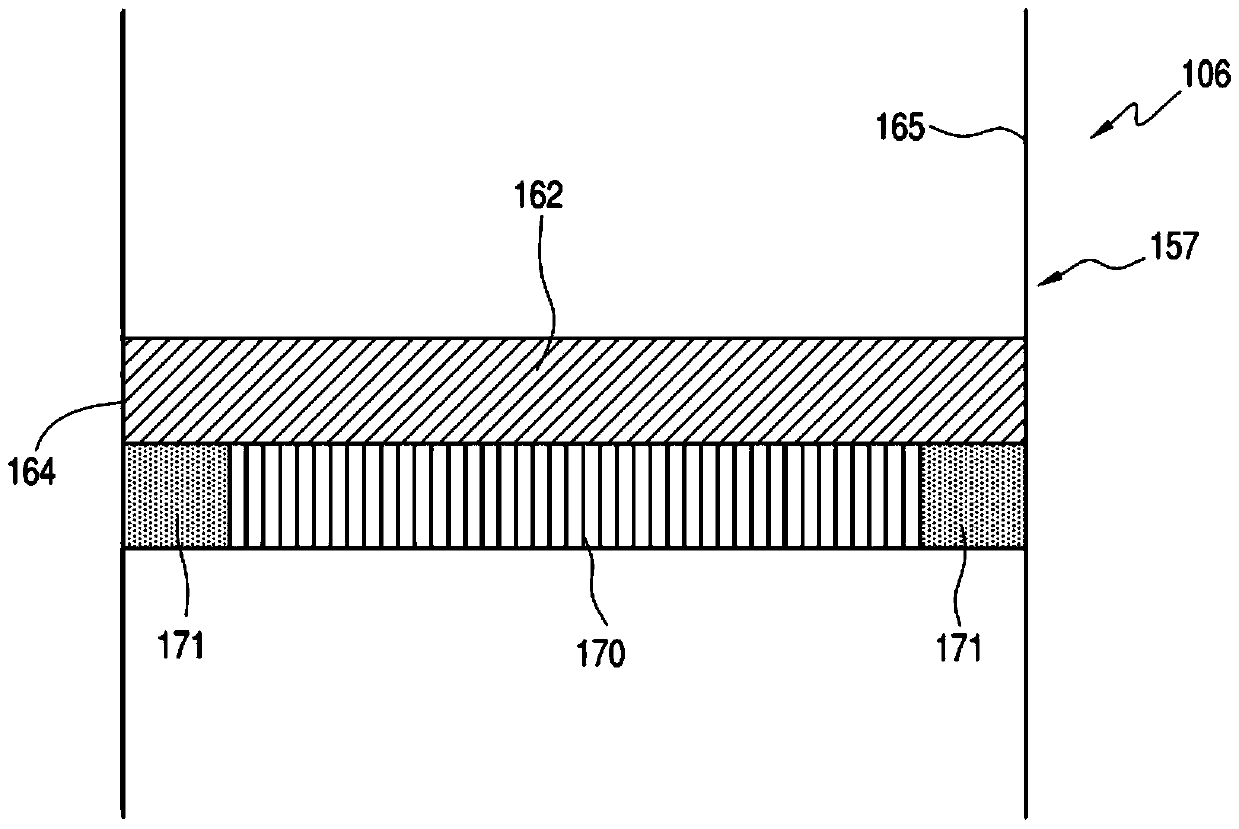

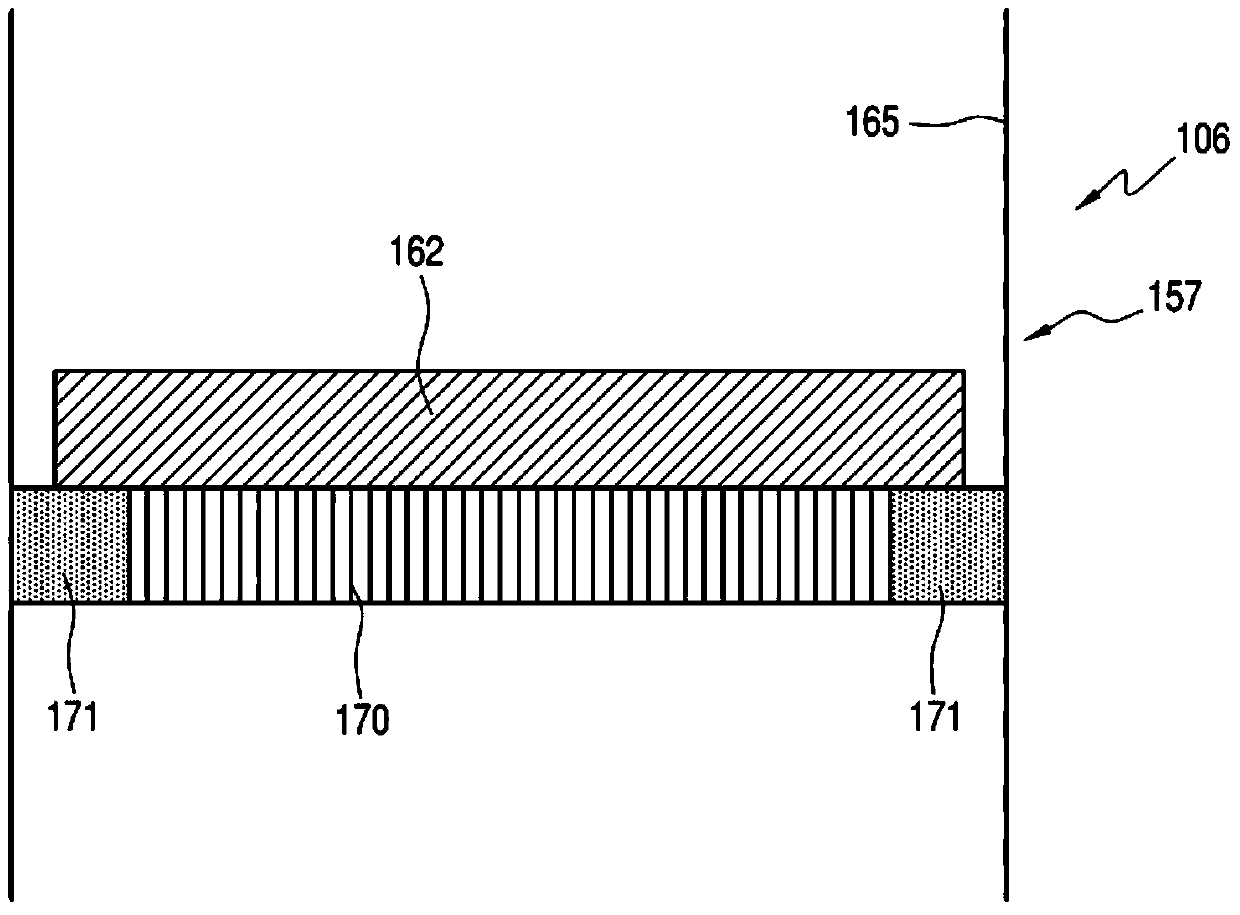

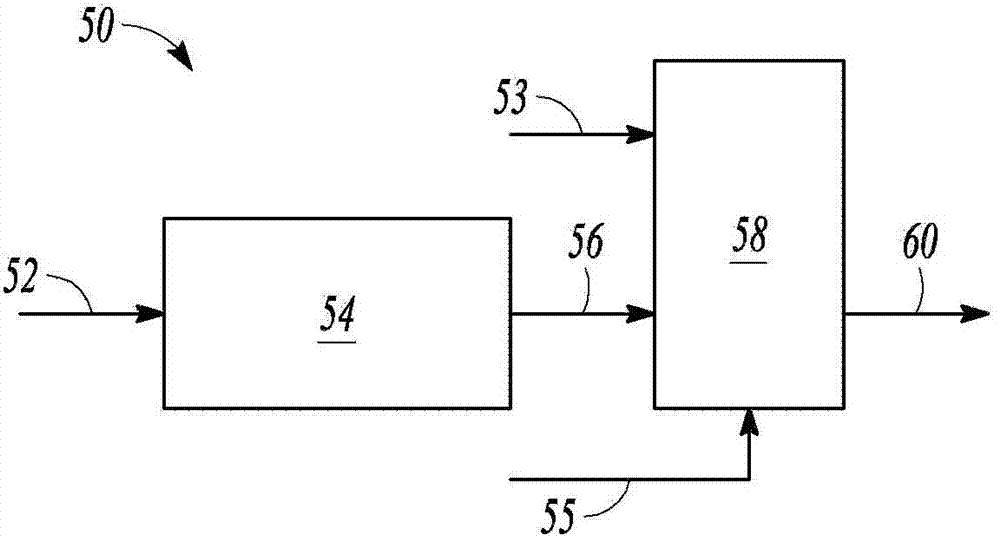

Apparatus and method for decreasing humidity during an andrussow process

InactiveUS20150360965A1Large heat capacityLow conversion efficiencyDispersed particle separationHydrogen cyanide preparation/purification/separationAndrussow processReagent

The system and methods described herein solve problems of inaccurate flow control, loss of optimum reactant gas feed ratios, and the associated inefficiencies brought on by variable humidity in reactant feedstream gases during production of hydrogen cyanide by an Andrussow process.

Owner:INVISTA NORTH AMERICA R L

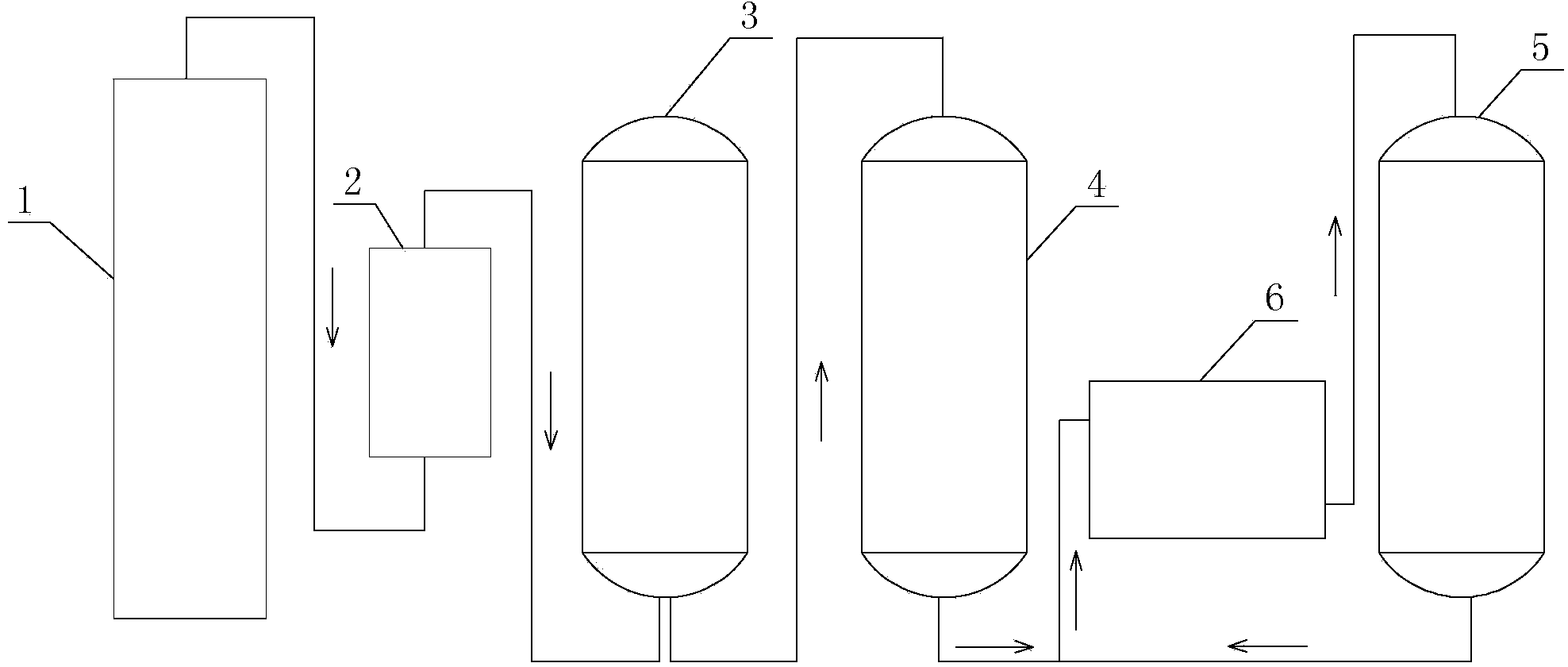

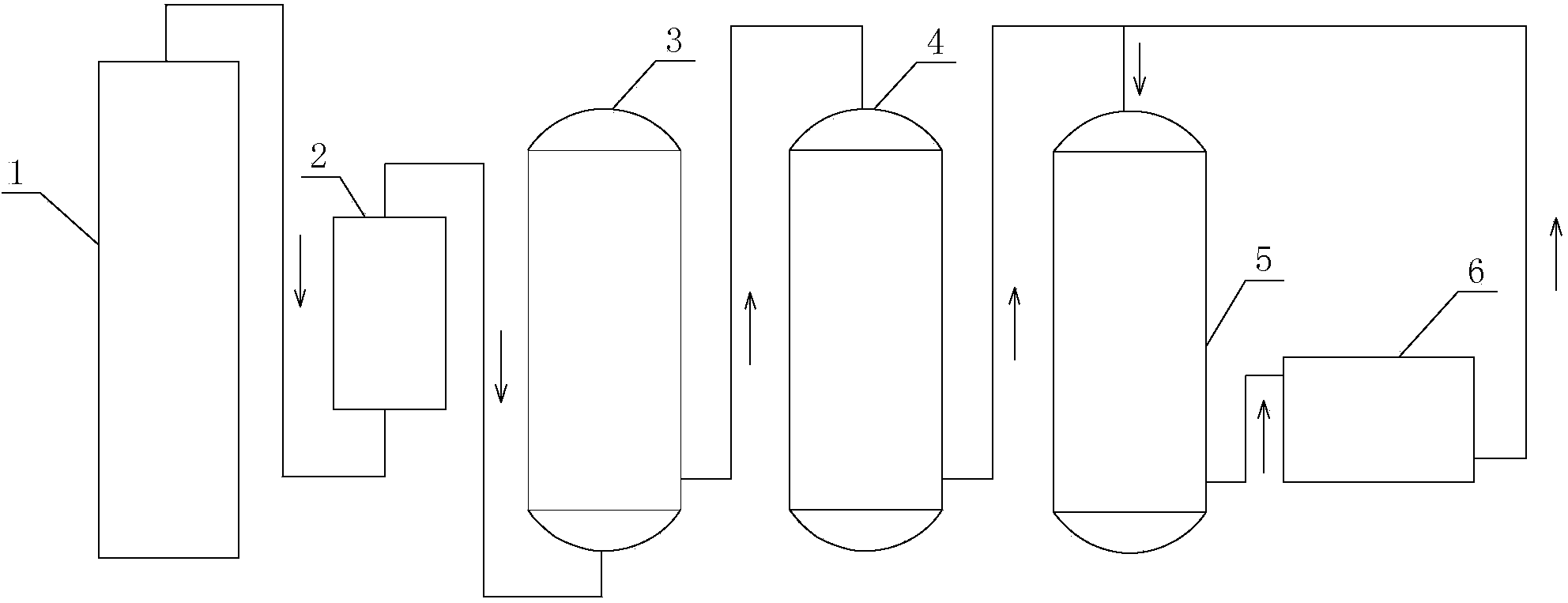

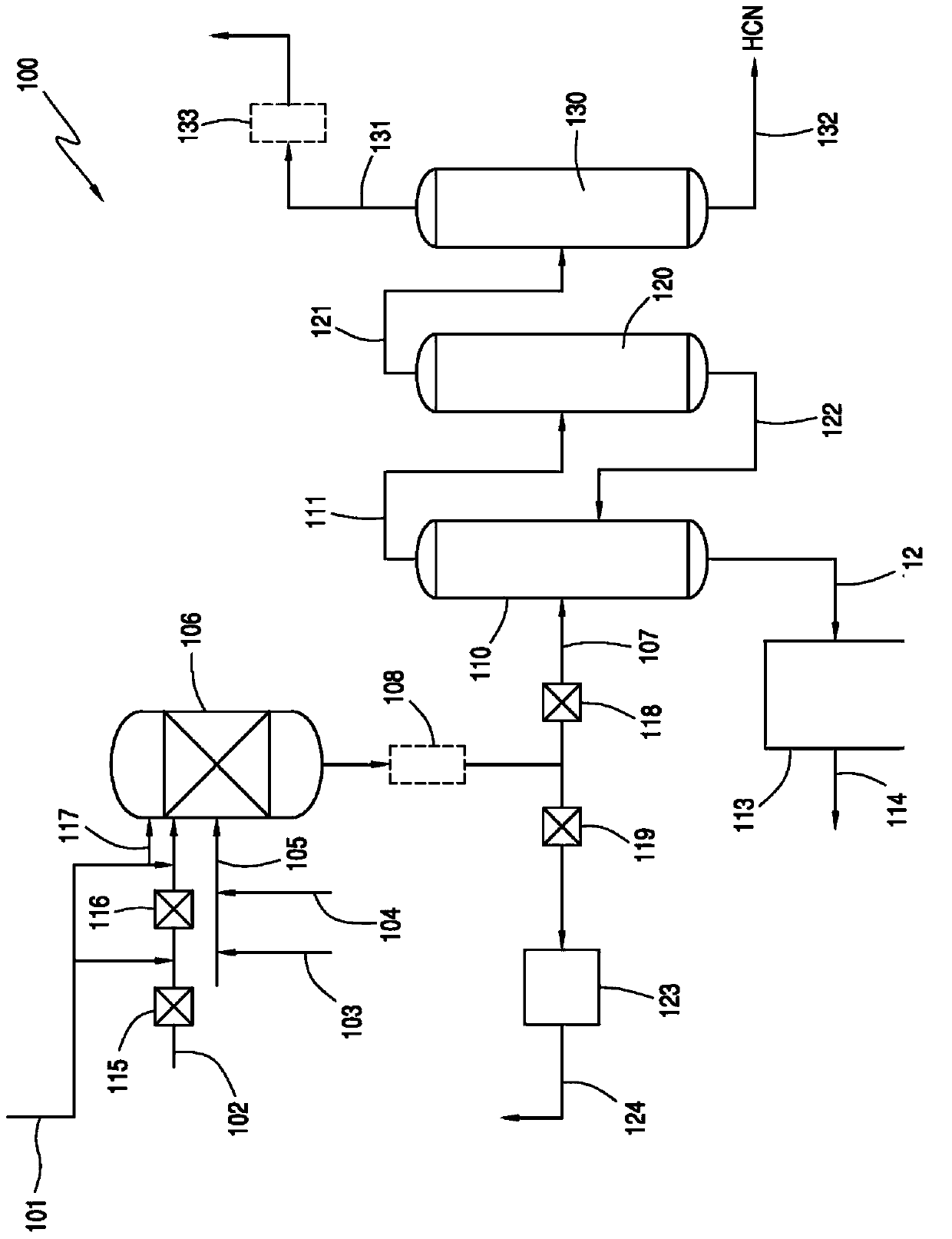

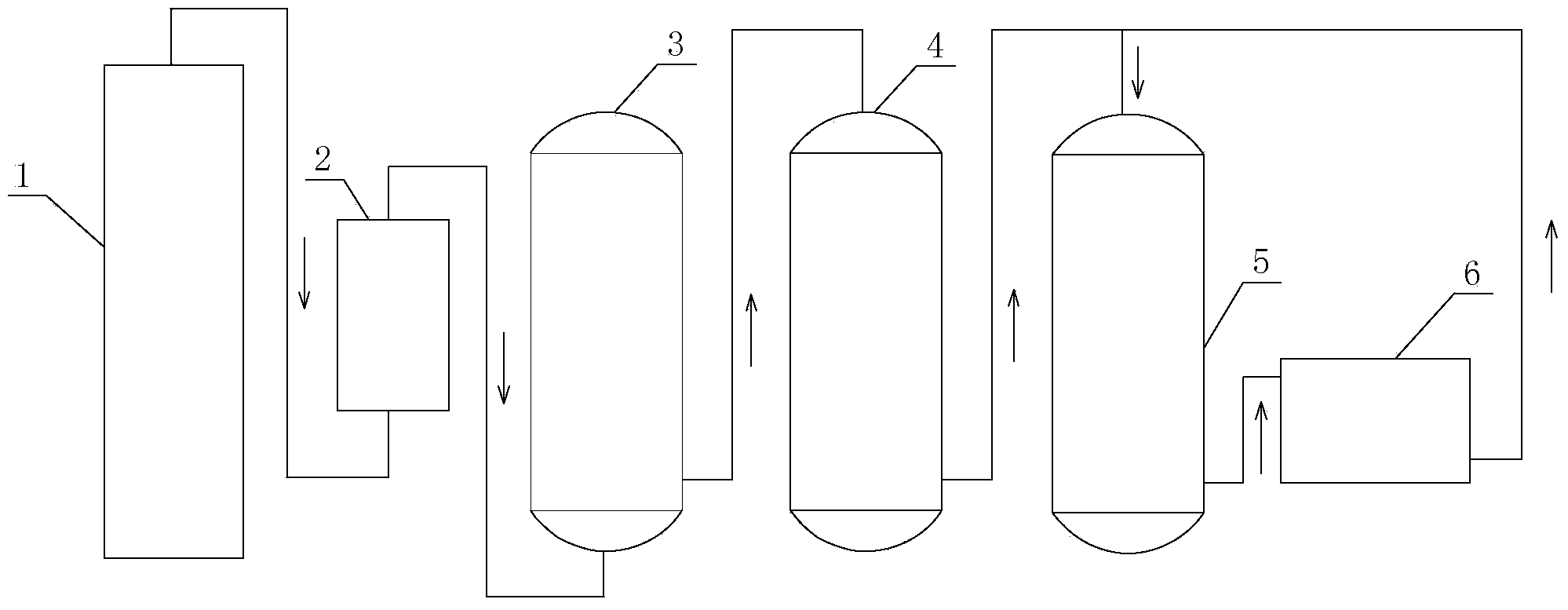

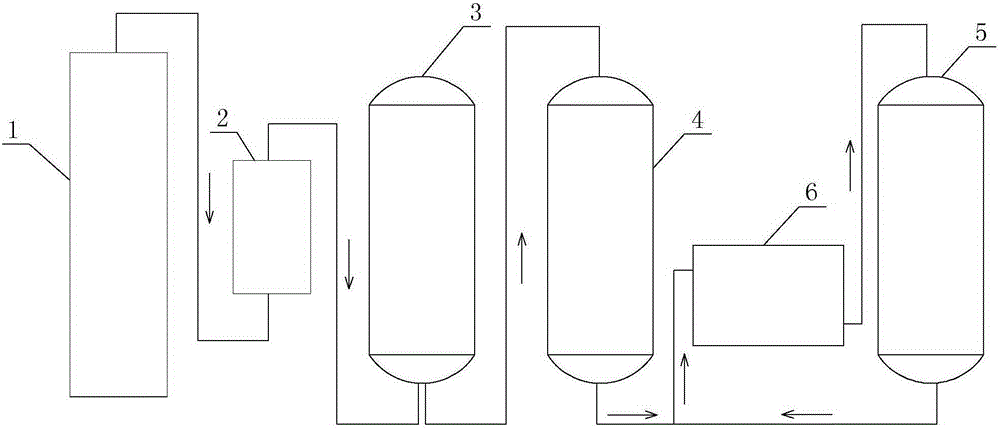

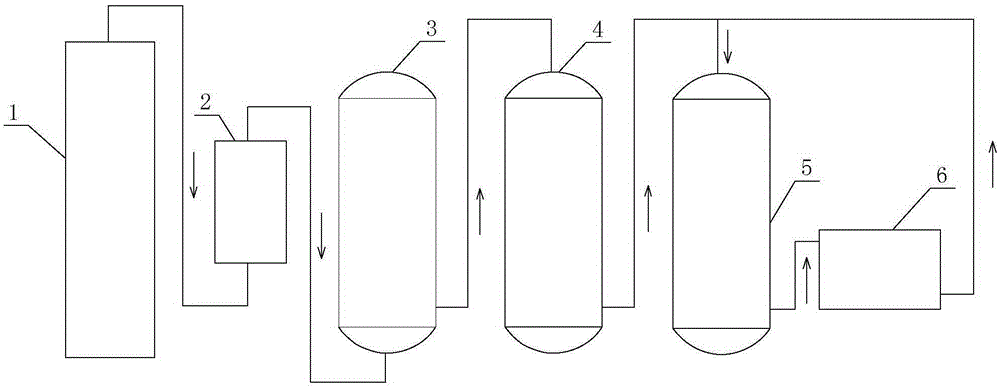

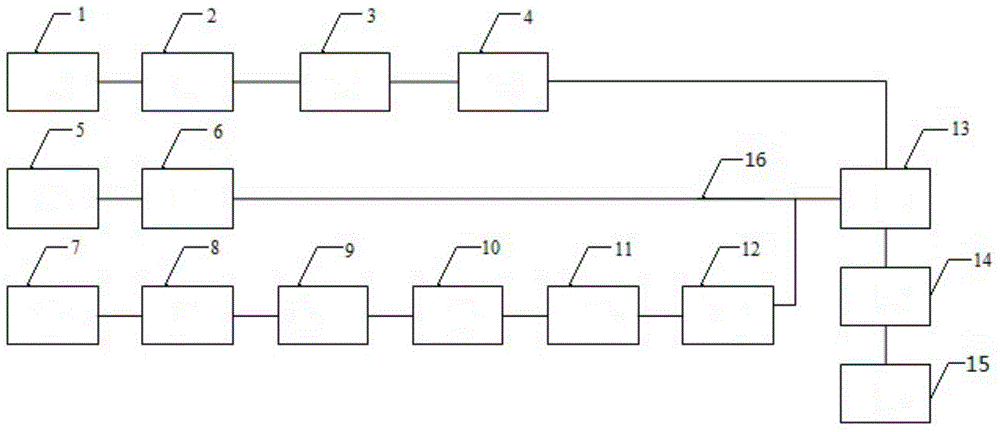

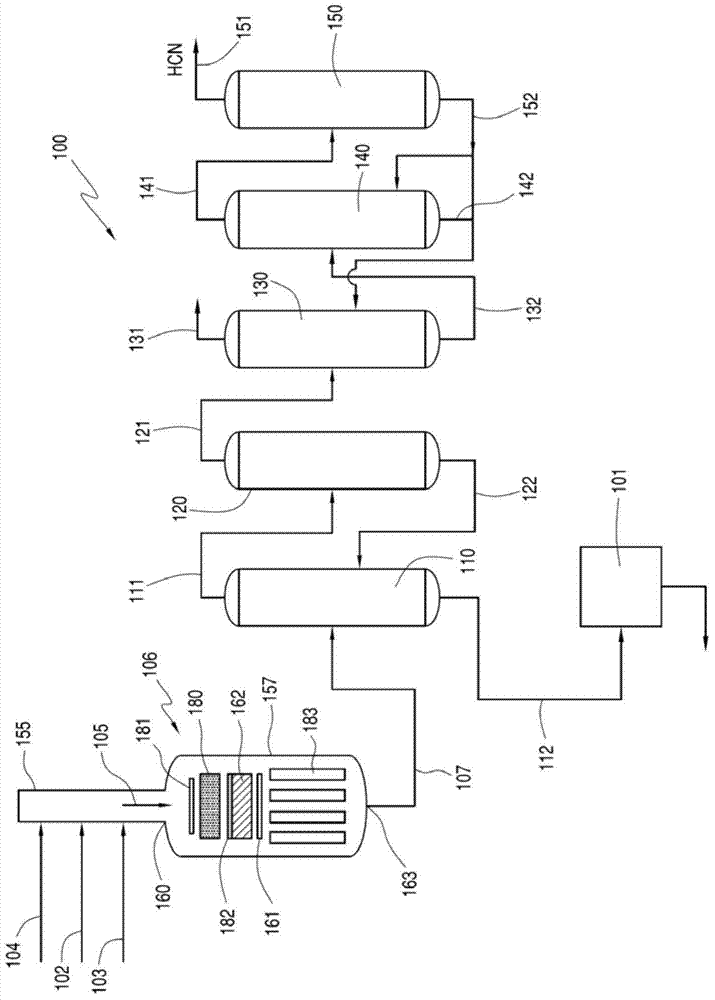

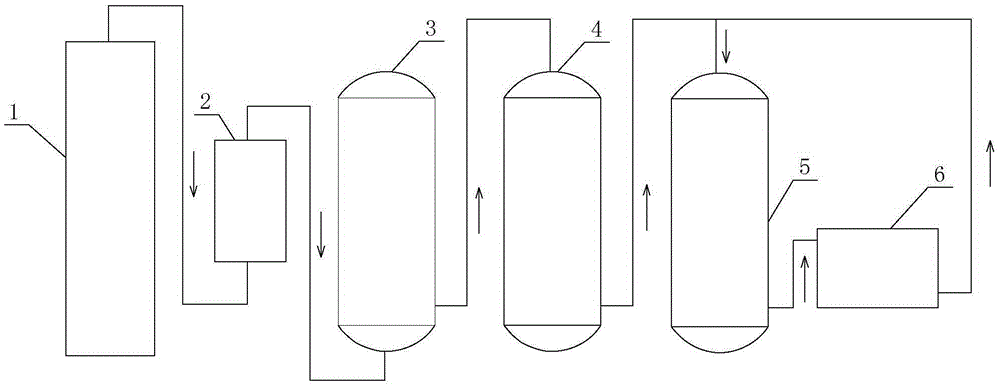

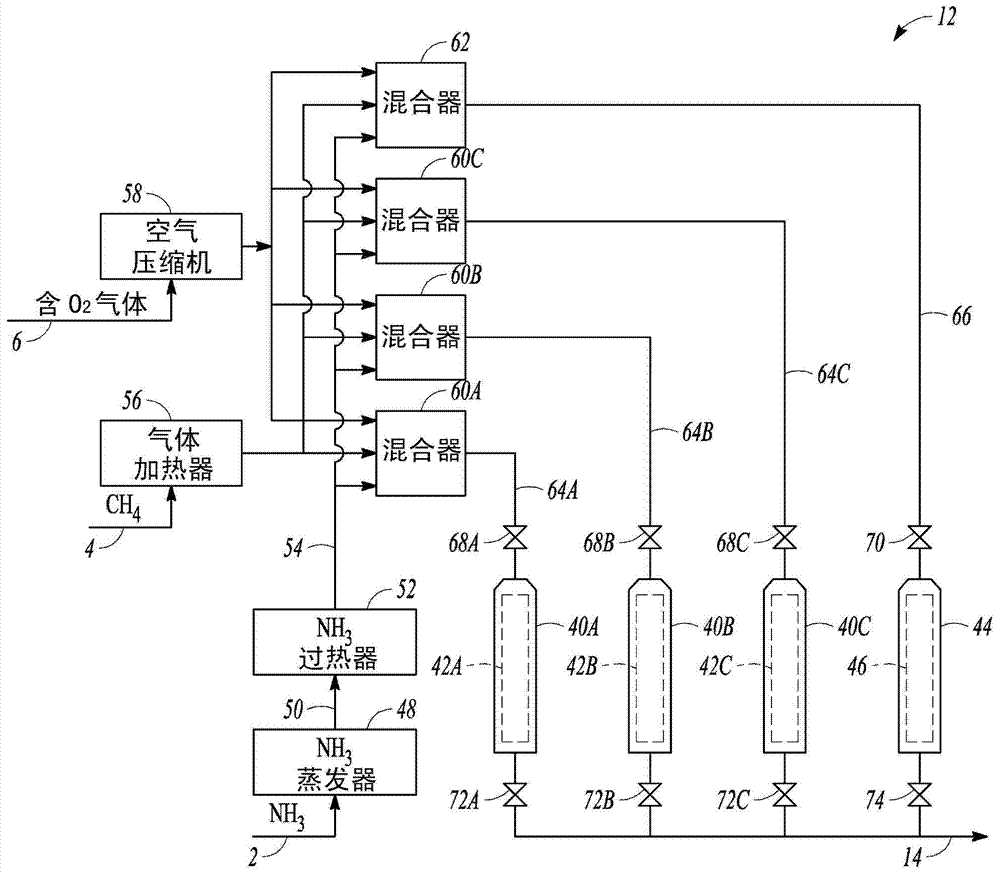

Production system and production method for synthesizing hydrocyanic acid by Andrussow process

ActiveCN103539158ASmall pressure lossSimple process routeHydrogen cyanide preparation/purification/separationFlame arresterProcess equipment

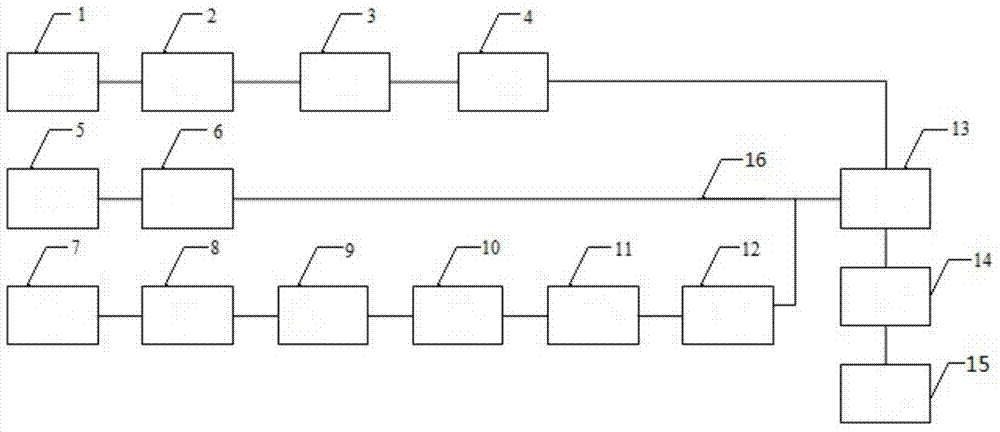

The invention provides a production system and a production method for synthesizing hydrocyanic acid by an Andrussow process. The production system comprises a natural gas conveying system, an air conveying system, an ammonia gas conveying system and mixed reaction equipment, wherein an outlet of the air conveying system and an outlet of the ammonia gas conveying system are joined at one place and communicated with an inlet of the mixed reaction equipment; an outlet of the natural gas conveying system is communicated with an inlet of the mixed reaction equipment. The production method comprises the following steps: mixing air and ammonia gas; mixing the mixed gas with natural gas; and introducing the mixture into a reactor for reaction through a flame arrester. According to the production system and production method provided by the invention, hot ammonia gas and hot air are mixed on an air pipeline, three materials are separately preheated respectively, the burst points of the three gases can be avoided in a large range, the process route and process equipment are simplified, the reaction efficiency is improved, the energy consumption is reduced, the raw material natural gas can be saved by 10-15%, and 5-5.5 million yuan can be saved per year.

Owner:CHONGQING UNISPLENDOUR INT CHEM

Operational controls for inert gas blanketing for Andrussow process

ActiveCN103964471AHydrogen cyanide preparation/purification/separationControl systemOperational stability

The present invention relates to a system and a process for producing hydrogen cyanide and more particularly, to a process for controlling operational stability of the system and process by blanketing the system with inert gas. More particularly, the present invention relates to the flushing of the system with an inert gas when a crude hydrogen cyanide product exceeds a threshold of oxygen, such as greater than 0.4 vol.% oxygen.

Owner:INVISTA TEXTILES (U K) LTD

Method of inductively igniting a chemical reaction

InactiveCN1112962CSuitable for induction heatingImprove induction efficiencyCatalytic gas-gas reactionEnergy based chemical/physical/physico-chemical processesChemical reactionGas phase

An improved method of igniting a catalyzed gas phase chemical reaction involving the act of providing a reactor vessel (10), wherein the gaseous reactant, continuously passing through the reactor, makes contact with a solid phase metallic catalyst media (18), with an inductive coil (14) within the reactor (10) on the inlet side of the catalyst and a porous thermal, spark and radiation barrier (17) between the induction coil (14) and solid catalyst (18). According to the improved method of ignition, the metallic catalyst media (18) is inductively heated in order to ignite the chemical reaction and after ignition the inductive heating is suspended and the exotherm of the chemical reaction is thereafter relied upon to sustain the reaction temperature. Such a reactor and method of operation is particularly useful for continuous production of hydrogen cyanide by the Andrussow process.

Owner:INVISTA TECHNOLOG IES S A R L

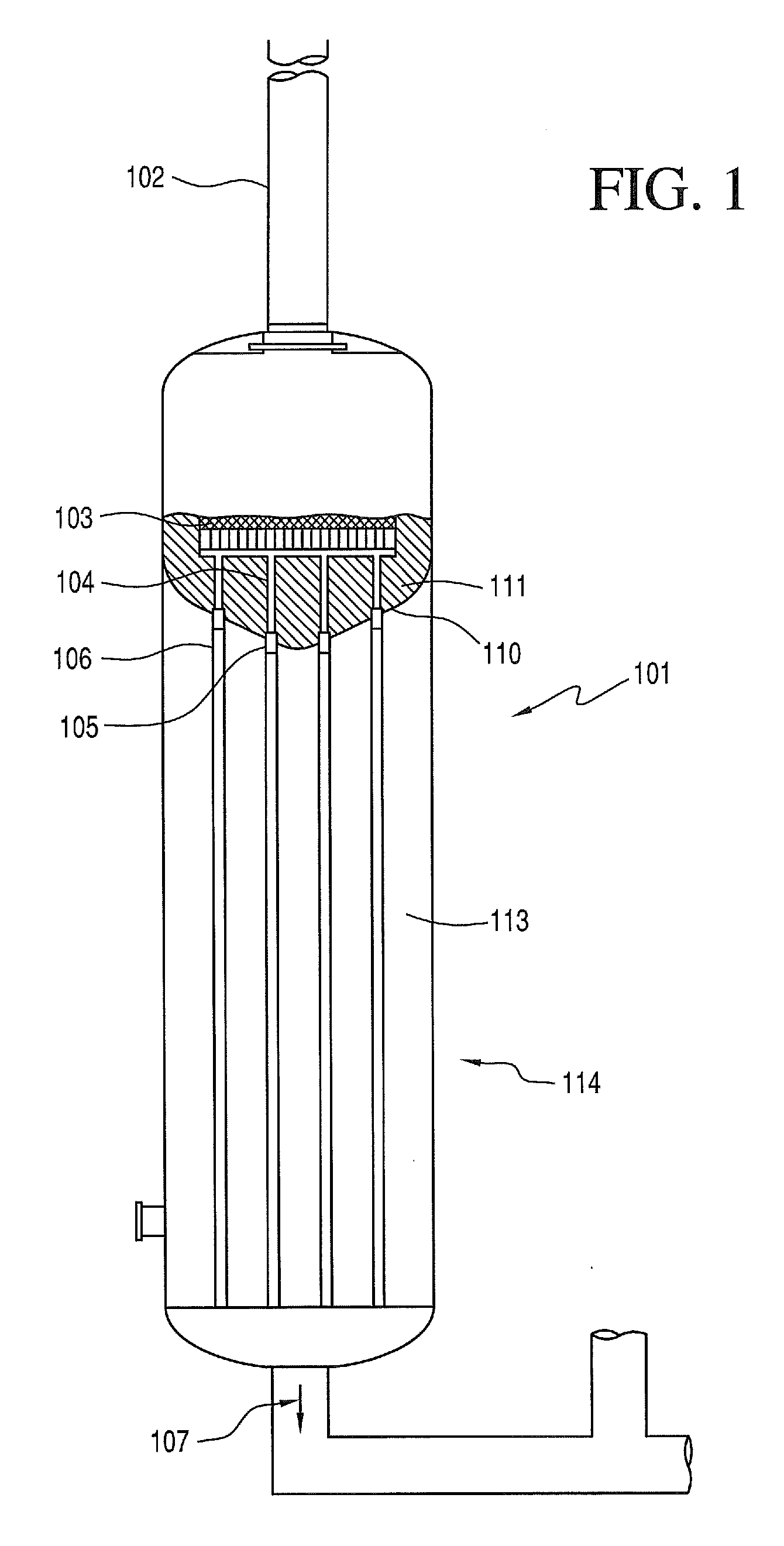

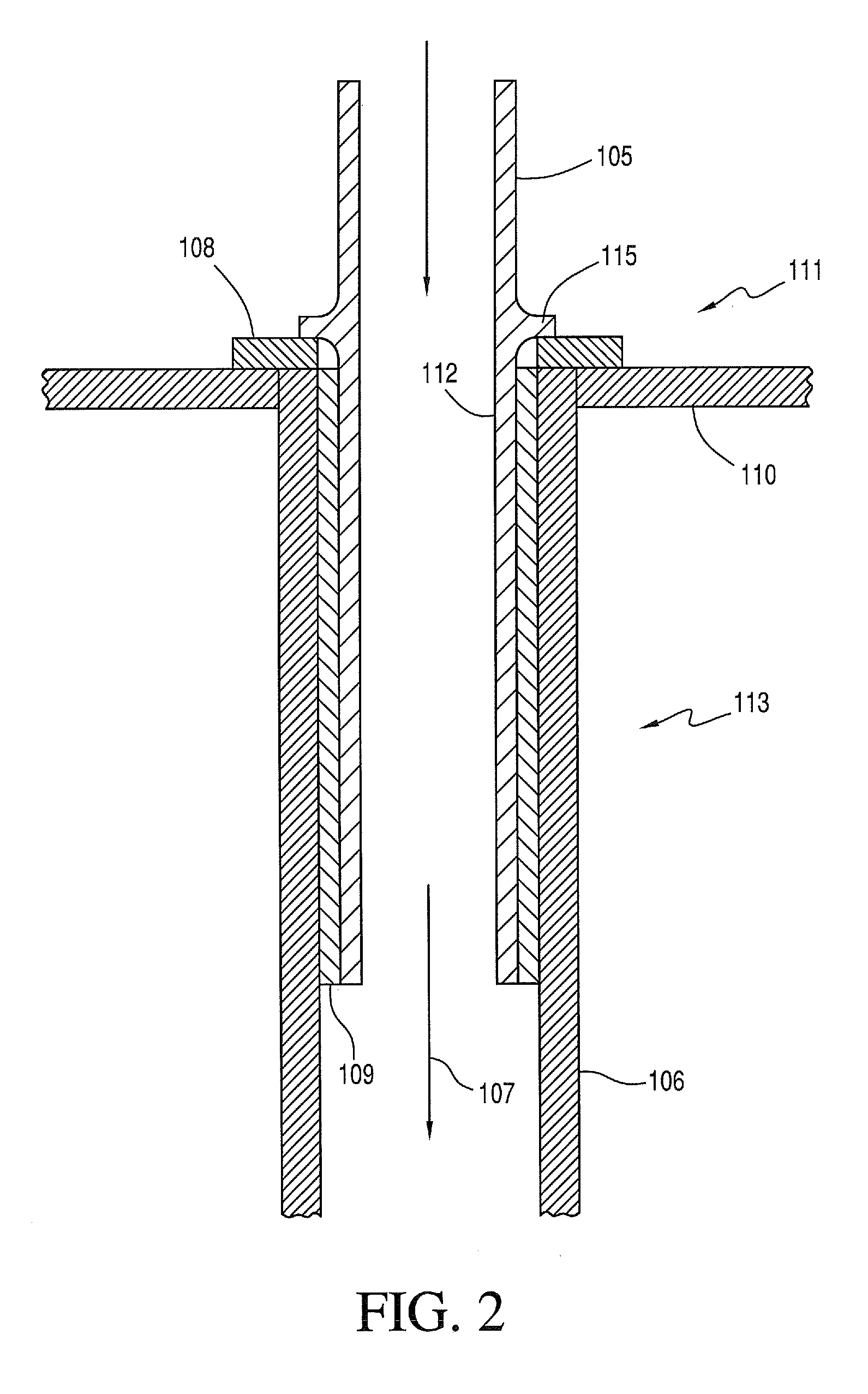

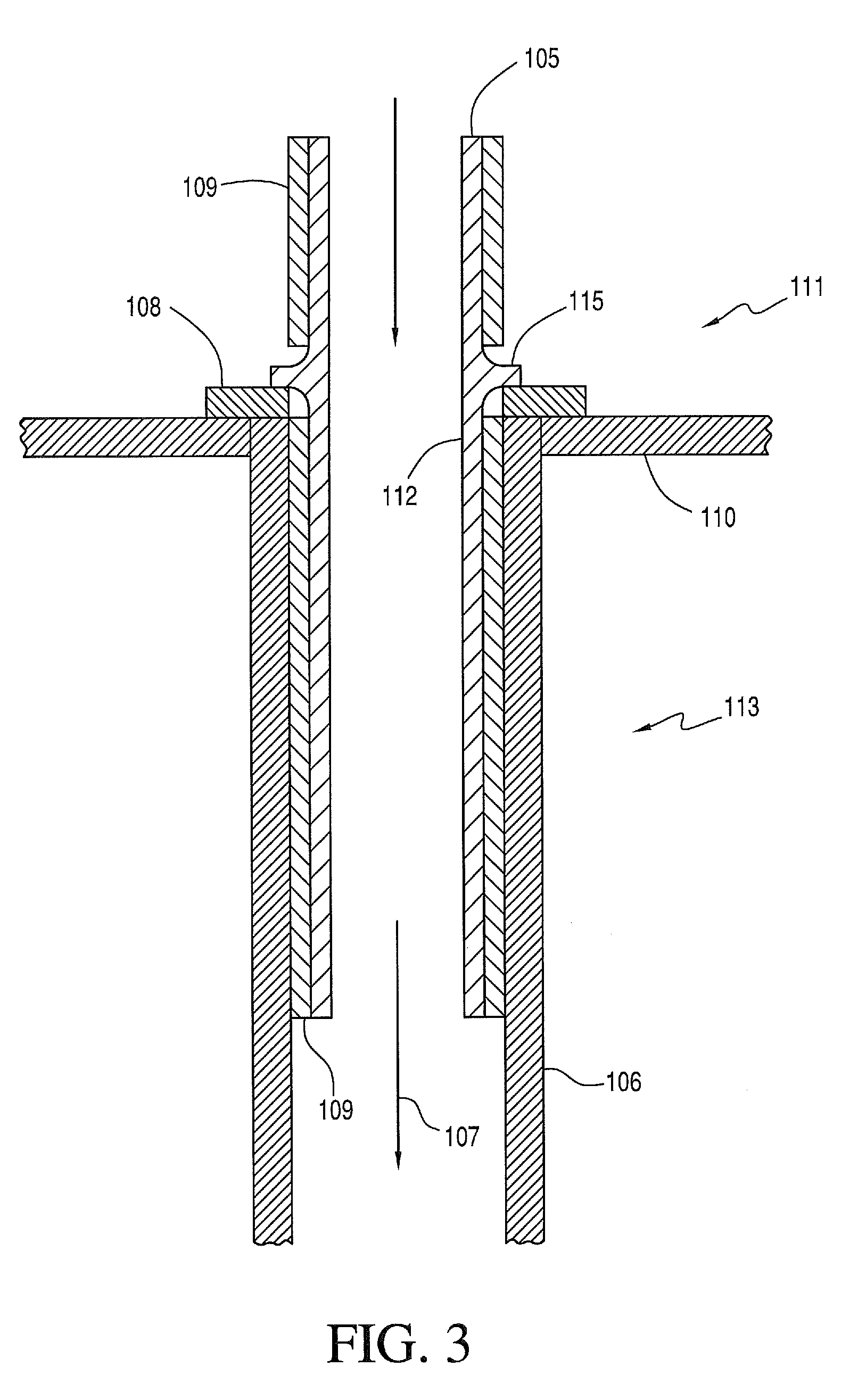

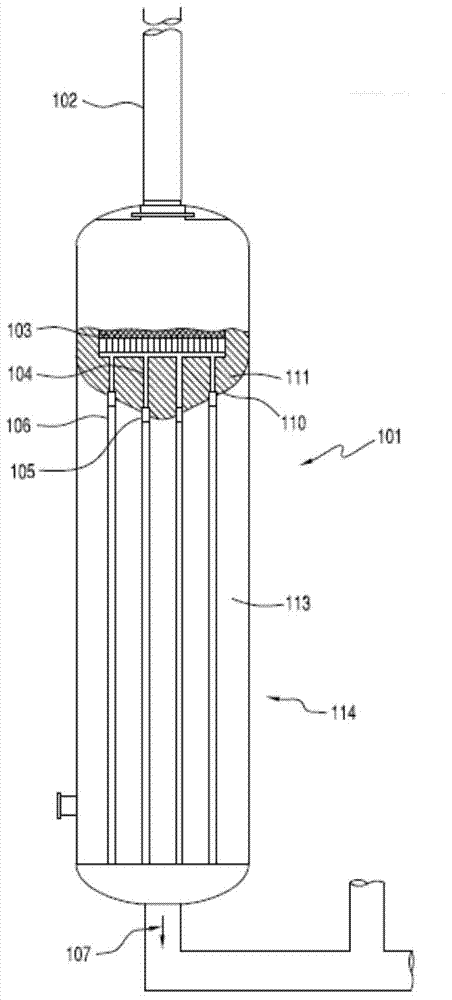

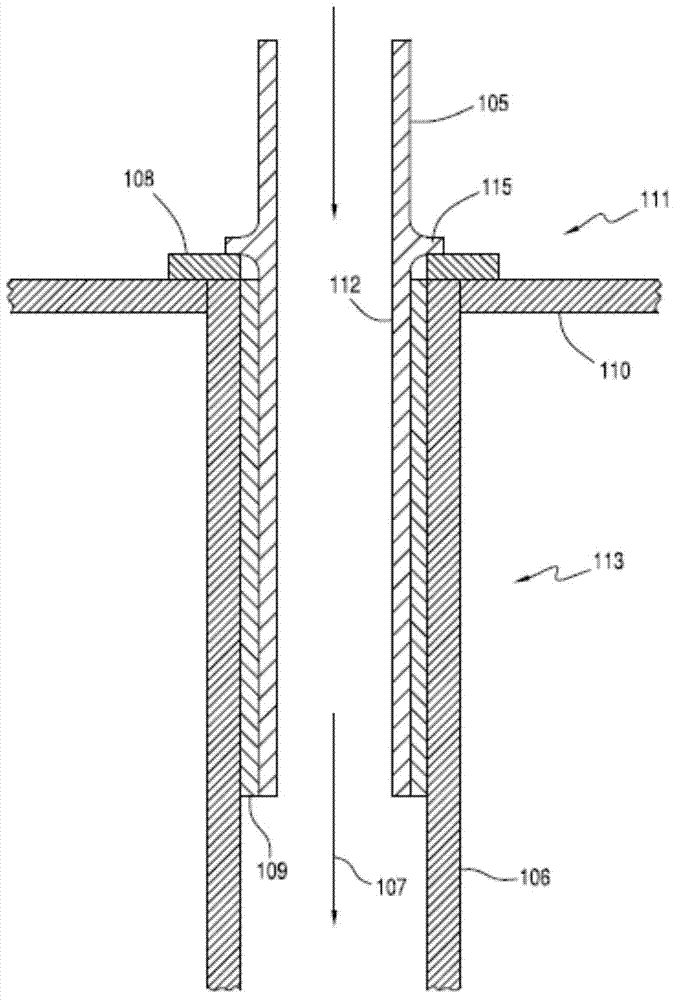

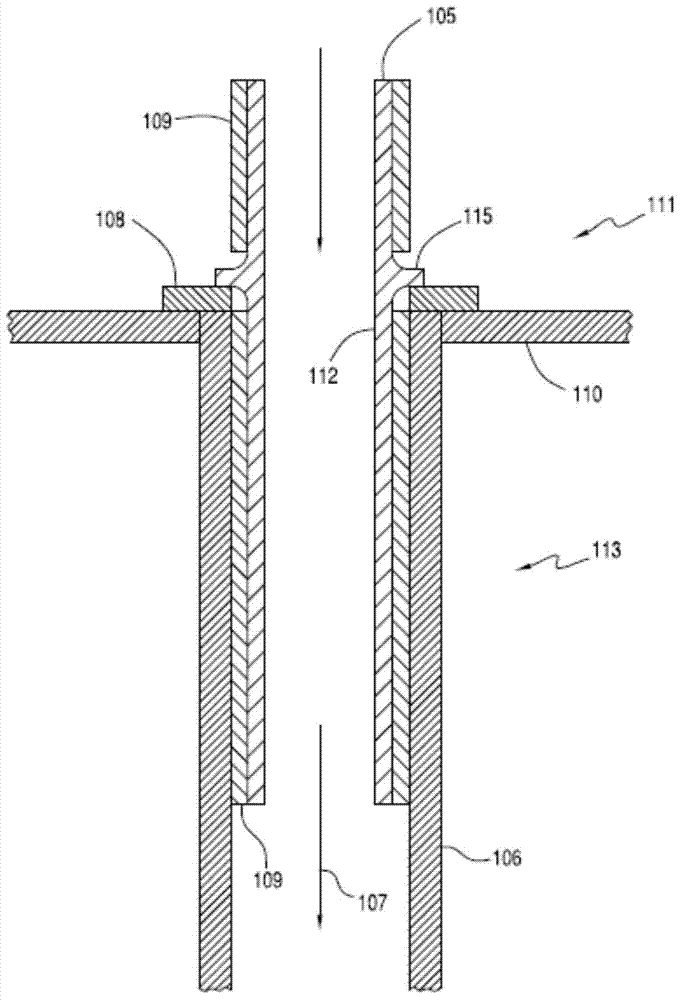

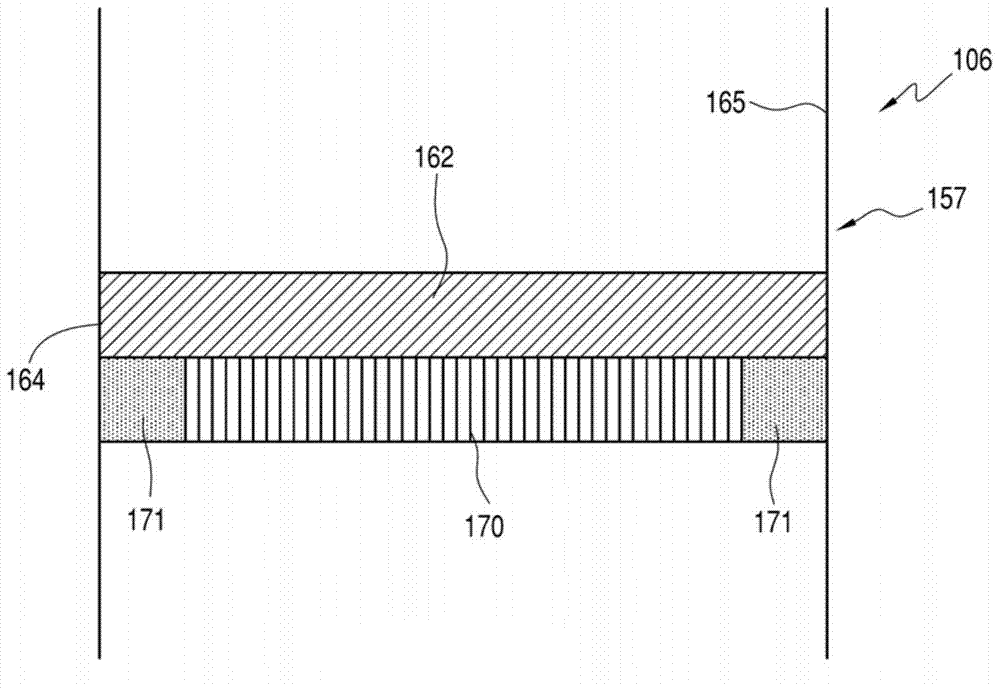

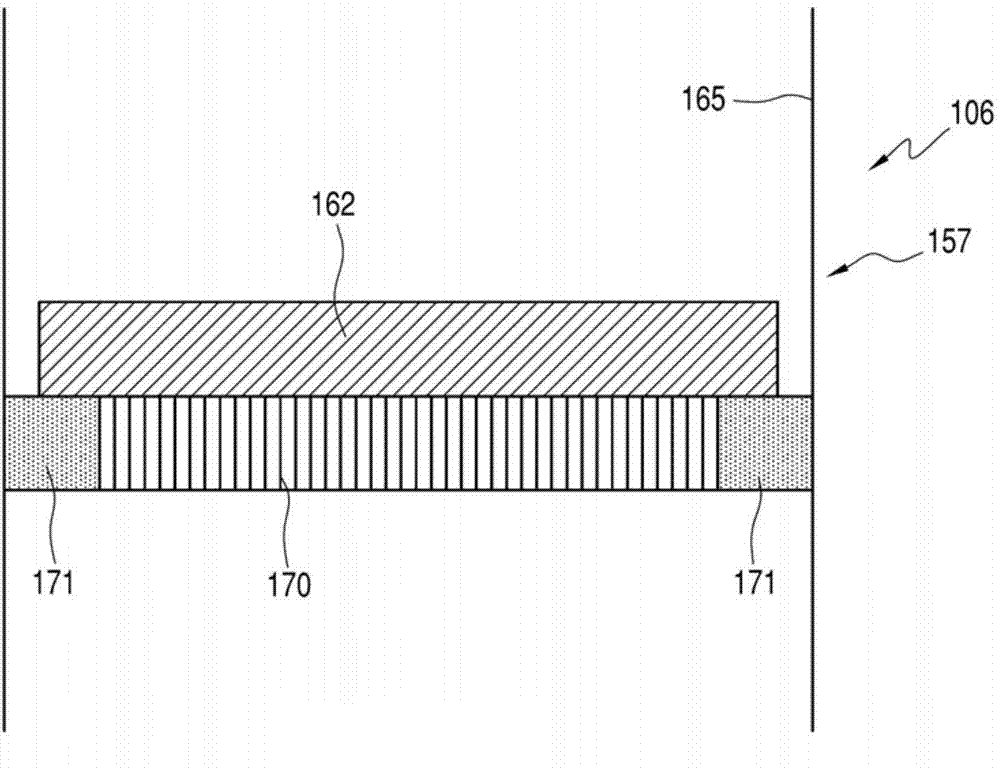

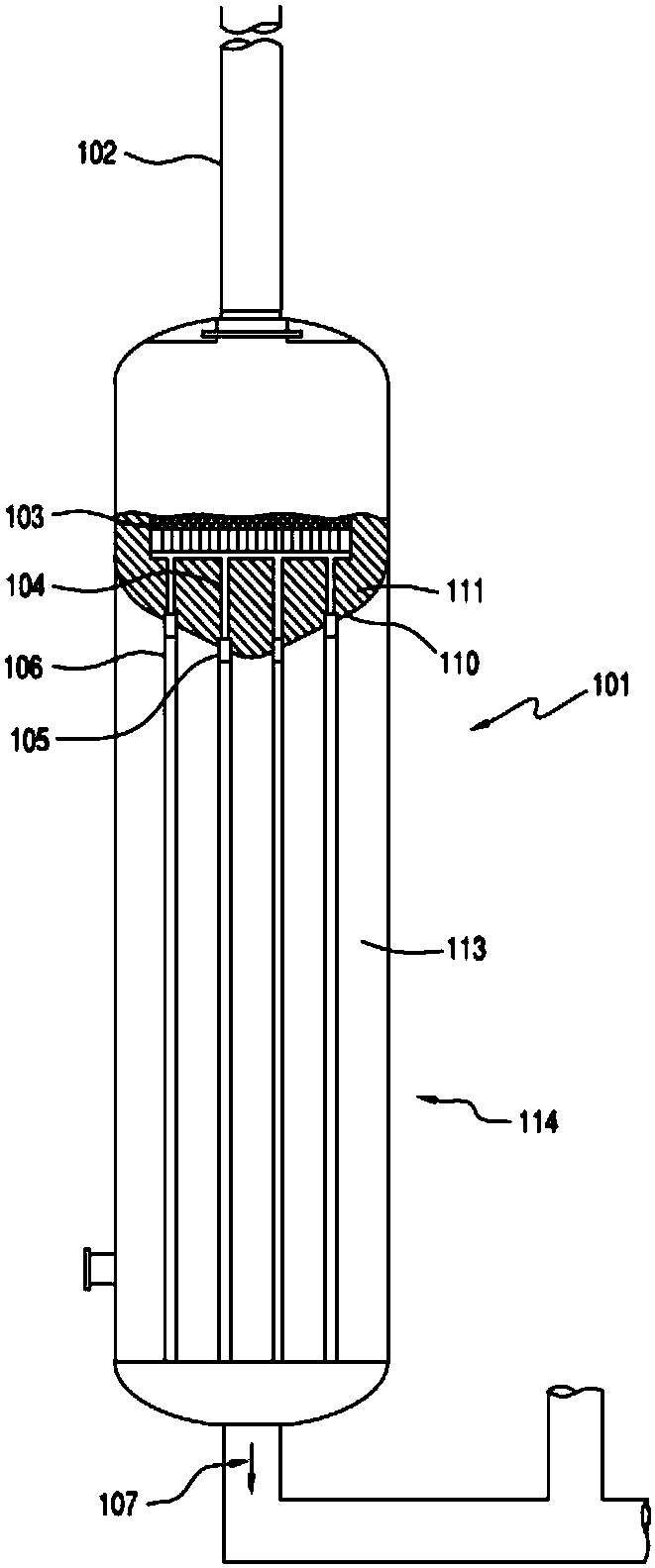

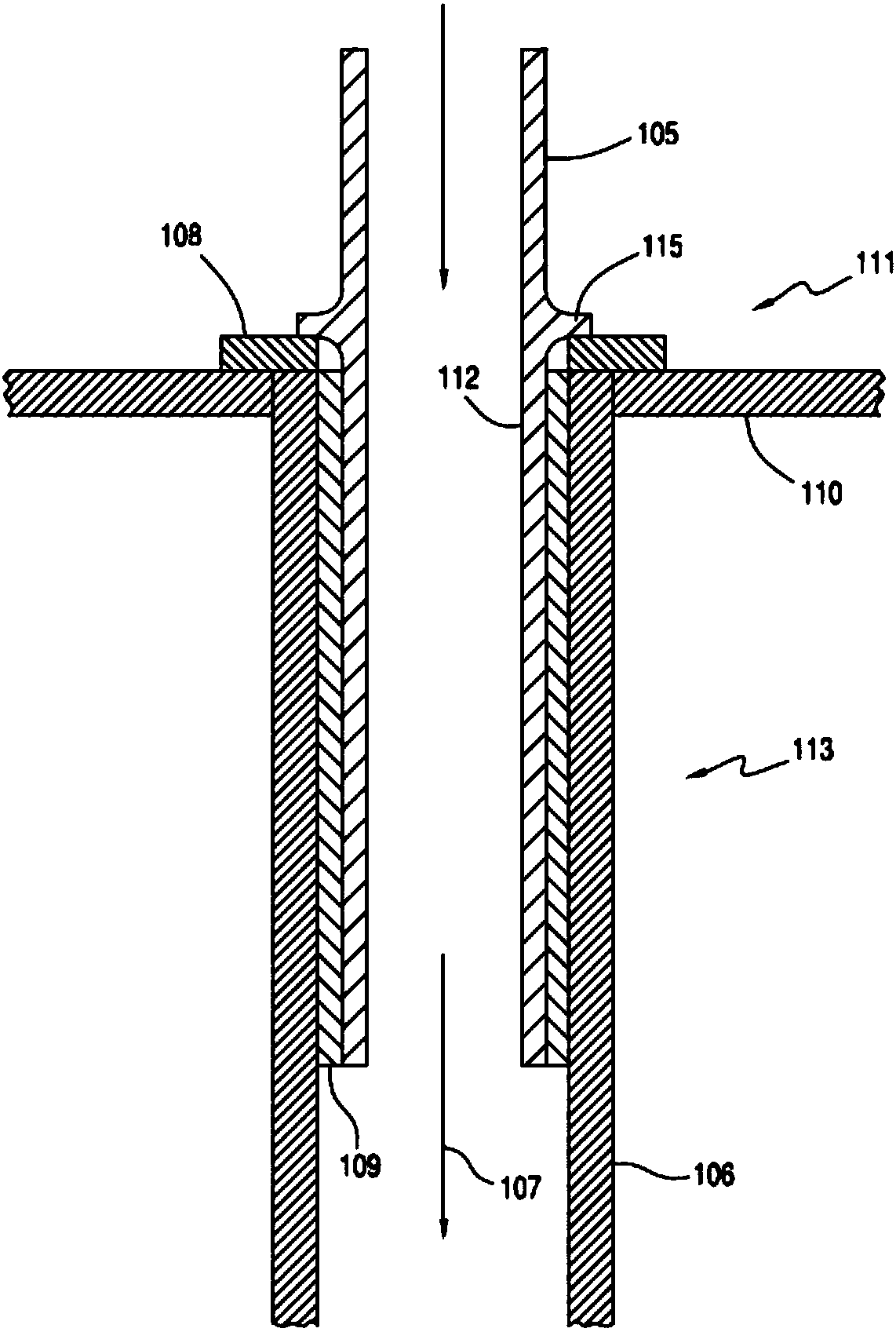

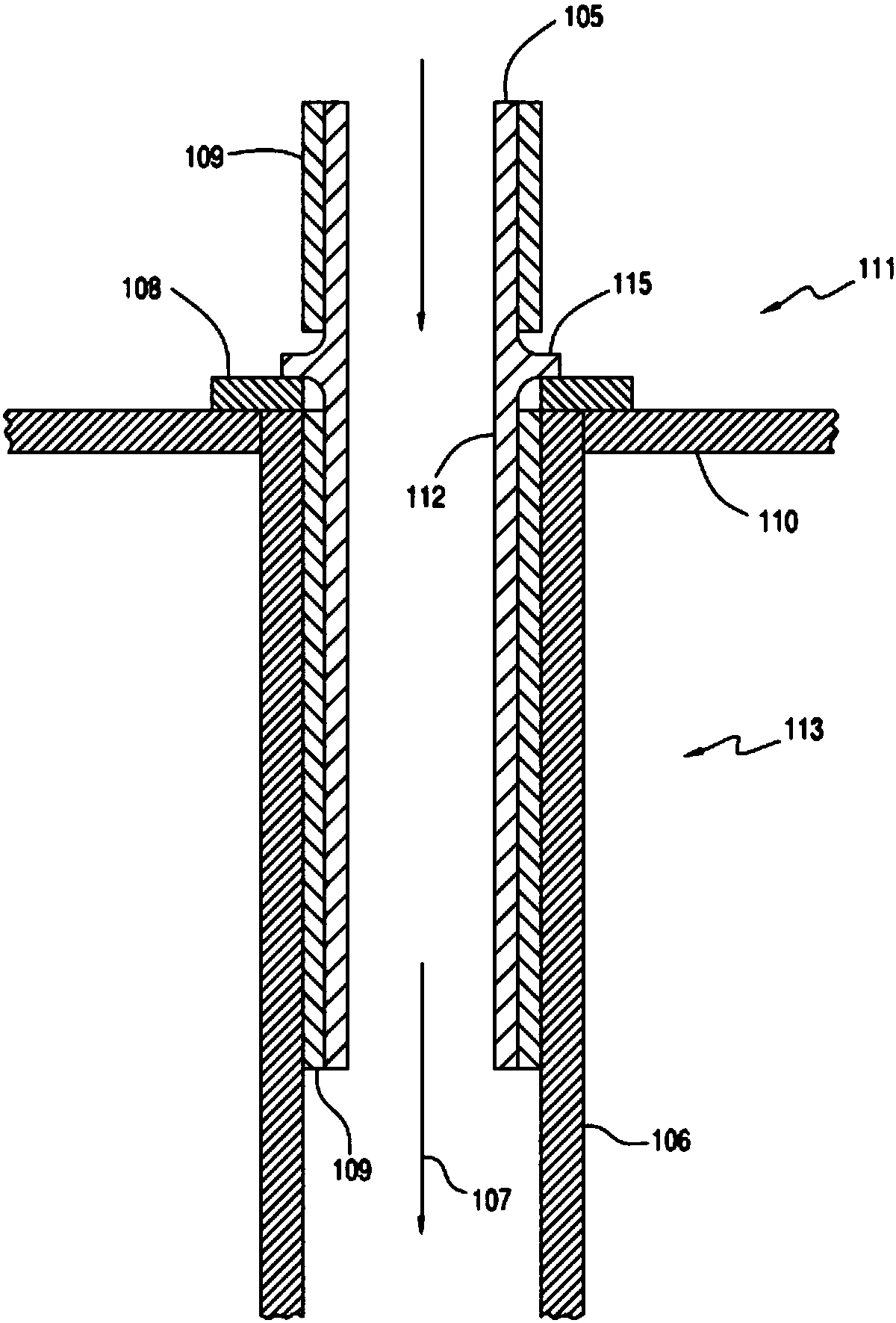

Process for stabilizing heat exchanger tubes in andrussow process

InactiveUS20160046498A1Control degradationEnergy inputCorrosion preventionInsulation layerEngineering

The present invention relates to an improved process for producing hydrogen cyanide involving a heat exchanger comprising a plurality of tubes, wherein each of the plurality of tubes comprises a ceramic ferrule extending through the entrance of the tube, each ferrule comprising an insulation layer surrounding at least a portion of the ferrule, and one or more washers, wherein at least one of the one or more washers surrounds the ferrule above the entrance of the tube, wherein the ceramic ferrule is spaced apart from the tube. It further relates to a reaction apparatus for producing hydrogen cyanide involving a heat exchanger comprising a plurality of tubes, wherein each of the plurality of tubes comprises a ceramic ferrule extending through the entrance of the tube, each ferrule comprising an insulation layer surrounding at least a portion of the ferrule, and one or more washers, wherein at least one of the one or more washers surrounds the ferrule above the entrance of the tube, wherein the ceramic ferrule is spaced apart from the tube. It further relates to the heat exchanger for use in this improved process and reaction apparatus.

Owner:INVISTA NORTH AMERICA R L

Preparation method of D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate

ActiveCN103641755AStable in natureShorten production timeSulfide preparationChemical industryChelation

The invention aims at the chemical industry field, and relates to a preparation method of a D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method comprises the following steps: preparing a hydrocyanic acid mixed gas by adopting an Andrussow process, and reacting the hydrocyanic acid mixed gas with methylthiopropionaldehyde to obtain a 2-hydroxy-4-methylthiobutyronityile system, hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system by an inorganic alkali to obtain D,L-2-hydroxy-4-methylthiobutyrate, and chelating the D,L-2-hydroxy-4-methylthiobutyrate with a trace metal element salt to generate the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method has the advantages of few technological steps, cheap and easily available raw materials, stable properties of the above intermediate, and low total production cost; the obtained D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate has the advantages of high yield, high purity and large bulk density; and the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate can be effectively mixed with feeds as an animal feed additive to supplement trace elements and amino acids in the daily ration and improve the endozoic production and immunity performances, and can also be used as a medicinal reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

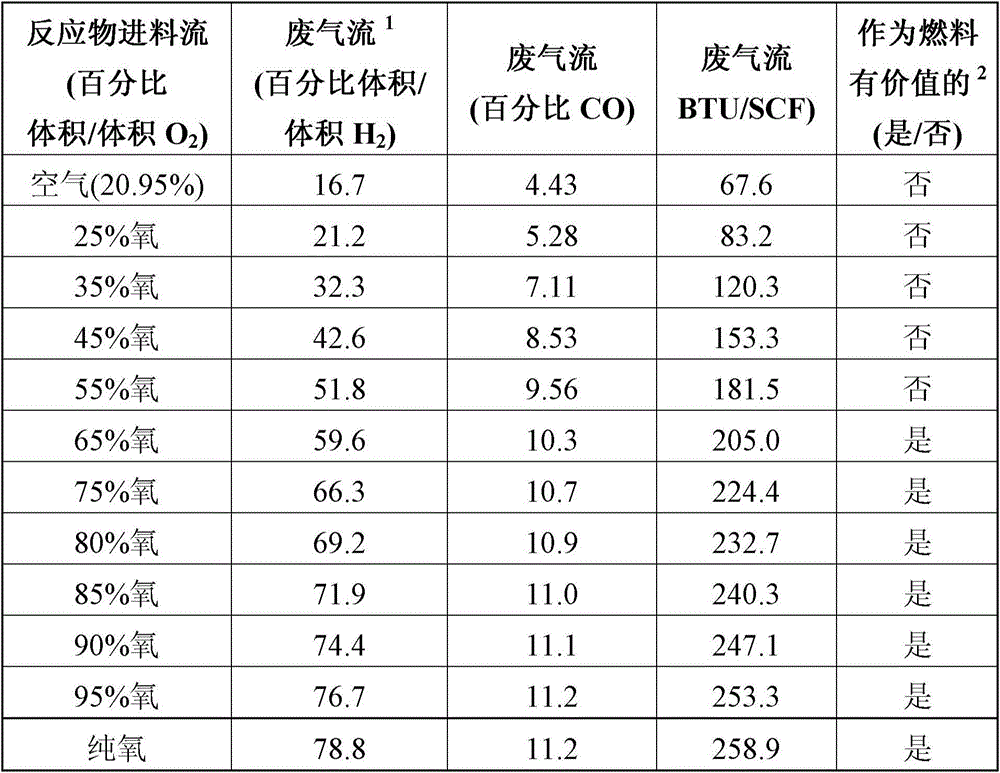

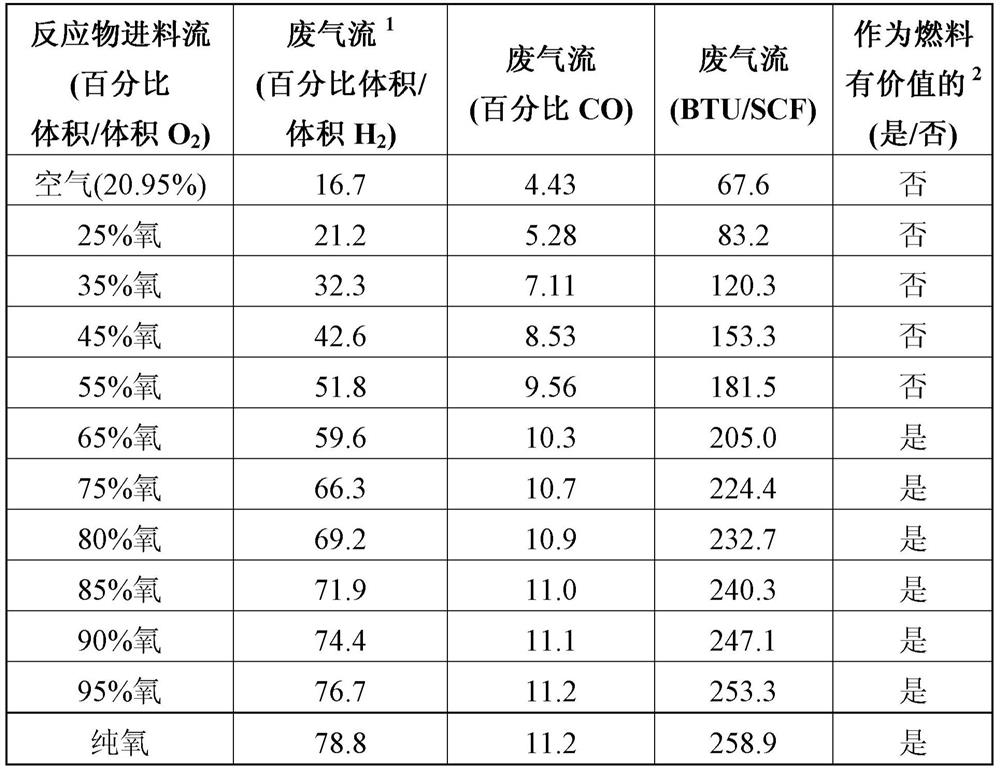

Apparatus And Method For Hydrogen Recovery In Andrussow Process

ActiveCN103910331ALow costGas treatmentHydrogen separation using solid contactRecovery methodHydrogen

The application provides an apparatus and a method for hydrogen recovery in an andrussow process. The present invention relates to the hydrogen recovery from the andrussow process for making hydrogen cyanide via methane, ammonia and oxygen. The method comprises the following steps: (a) adjusting a reaction mixture comprising methane, ammonia and oxygen to provide the reaction mixture with sufficient oxygen to generate a gaseous waste stream that has at least 40% hydrogen after removal of ammonia and recovery of hydrogen cyanide; and(b) removing components from the gaseous waste stream to generate recovered hydrogen. The apparatus comprises an actor and a hydrogen recovery system. According to the present invention, by the described hydrogen recovery method and system, the waste and loss problems of the hydrogen rich in oxygen and oxygen andrussow outcome stream are solved safely.

Owner:INVISTA TEXTILES (U K) LTD

Process for stabilizing heat exchanger tubes in Andrussow process

The invention relates to an improved process for producing hydrogen cyanide involving a heat exchanger comprising a plurality of tubes, wherein each of the plurality of tubes comprises a ceramic ferrule extending through the entrance of the tube, each ferrule comprising an insulation layer surrounding at least a portion of the ferrule, and one or more washers, wherein at least one of the one or more washers surrounds the ferrule above the entrance of the tube, wherein the ceramic ferrule is spaced apart from the tube. The invention further relates to a reaction apparatus for producing hydrogen cyanide involving a heat exchanger comprising a plurality of tubes, wherein each of the plurality of tubes comprises a ceramic ferrule extending through the entrance of the tube, each ferrule comprising an insulation layer surrounding at least a portion of the ferrule, and one or more washers, wherein at least one of the one or more washers surrounds the ferrule above the entrance of the tube, wherein the ceramic ferrule is spaced apart from the tube. The invention further relates to the heat exchanger for use in this improved process and reaction apparatus.

Owner:INVISTA TEXTILES (U K) LTD

Operational controls for inert gas blanketing for andrussow process

InactiveUS20160194211A1Easy to adaptPhysical/chemical process catalystsSamplingOperational stabilityAndrussow process

The present invention relates to a system and a process for producing hydrogen cyanide and more particularly, to a process for controlling operational stability of the system and process by blanketing the system with inert gas. More particularly, the present invention relates to the flushing of the system with an inert gas when a crude hydrogen cyanide product exceeds a threshold of oxygen, such as greater than 0.4 vol. % oxygen.

Owner:INVISTA NORTH AMERICA R L

Preparation method of cheap and high-purity d,l-methionine

ActiveCN103641758BStable in natureLong storage timeOrganic compound preparationSulfide preparationCombinatorial chemistrySulfuryl

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

d, the preparation method of l-2-hydroxyl-4-methylthiobutyrate calcium

ActiveCN103641757BStable in natureShorten production timeSulfide preparationTrace element2-hydroxy-4-methylthiobutyrate

The invention is directed at the field of chemical engineering and provides a preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; preparing a 2-hydroxy-4-methylthiobutyronityile system with the hydrocyanic acid gas mixture and methylthiopropionaldehyde as starting raw materials; hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system with inorganic base so as to obtain D,L-2-hydroxy-4-methylthiobutyrate; and chelating D,L-2-hydroxy-4-methylthiobutyrate with a soluble calcium salt so as to produce calcium D,L-2-hydroxy-4-methylthiobutyrate. The method has the advantages of a few processing step, cheap and easily available raw materials, stable intermediate properties and low total production cost. Prepared calcium D,L-2-hydroxy-4-methylthiobutyrate has the advantages of high yield, high purity, a powder crystal form and great bulk density, can be used as an animal feed additive for effective mixing with a feed so as to supplement trace elements and amino acid in daily ration and improve production performance and immune performance of animals and can also be used as a medicine reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

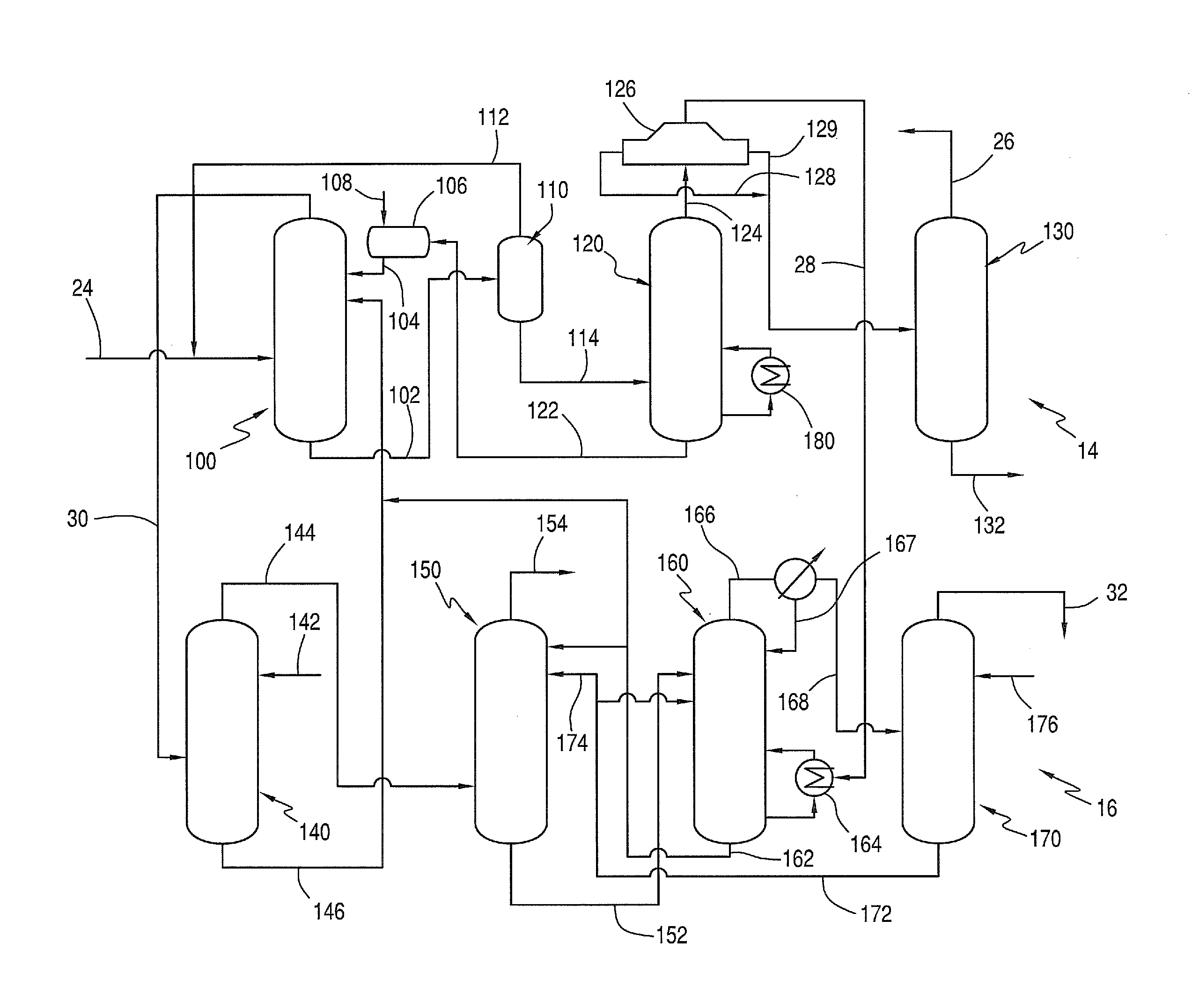

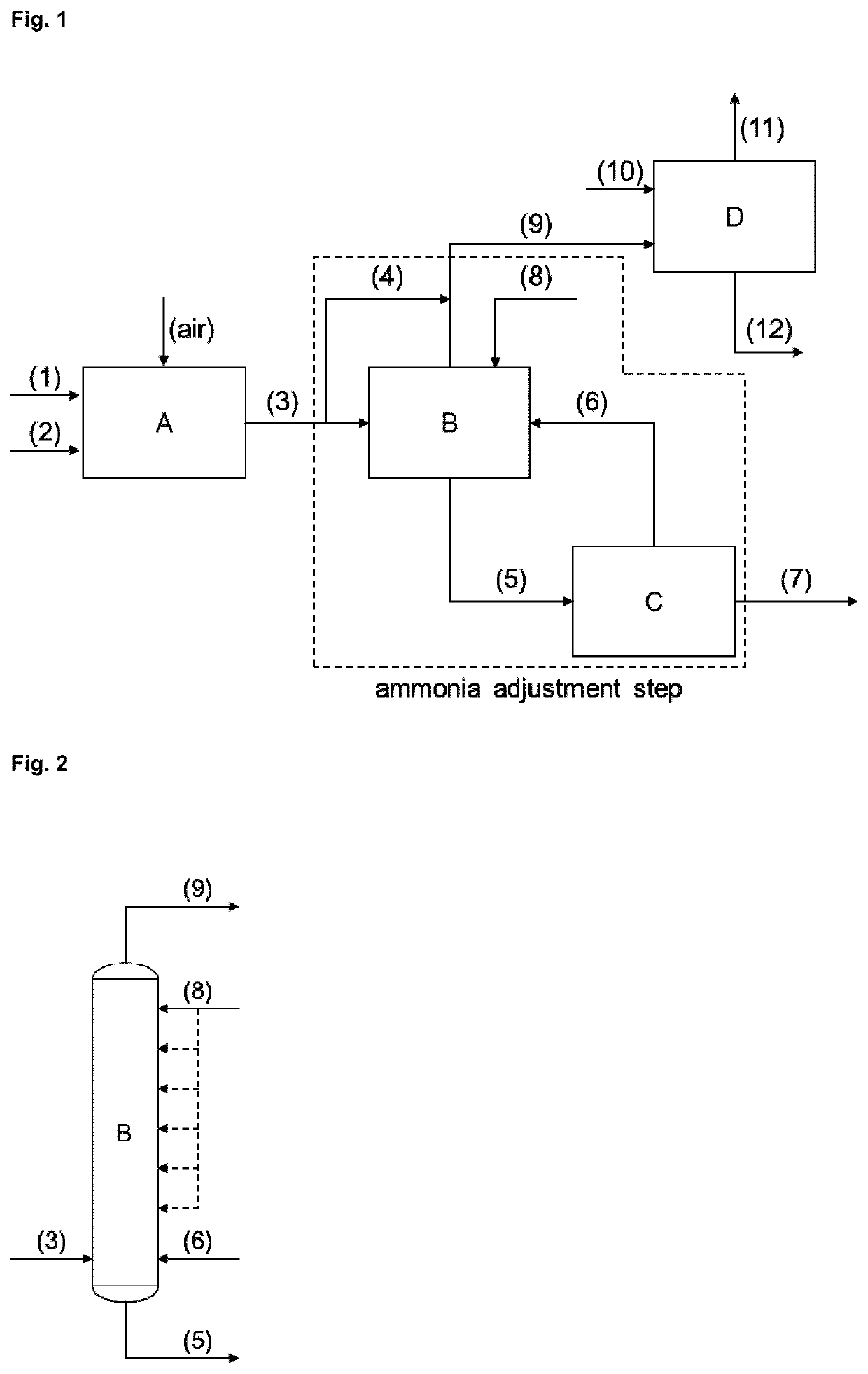

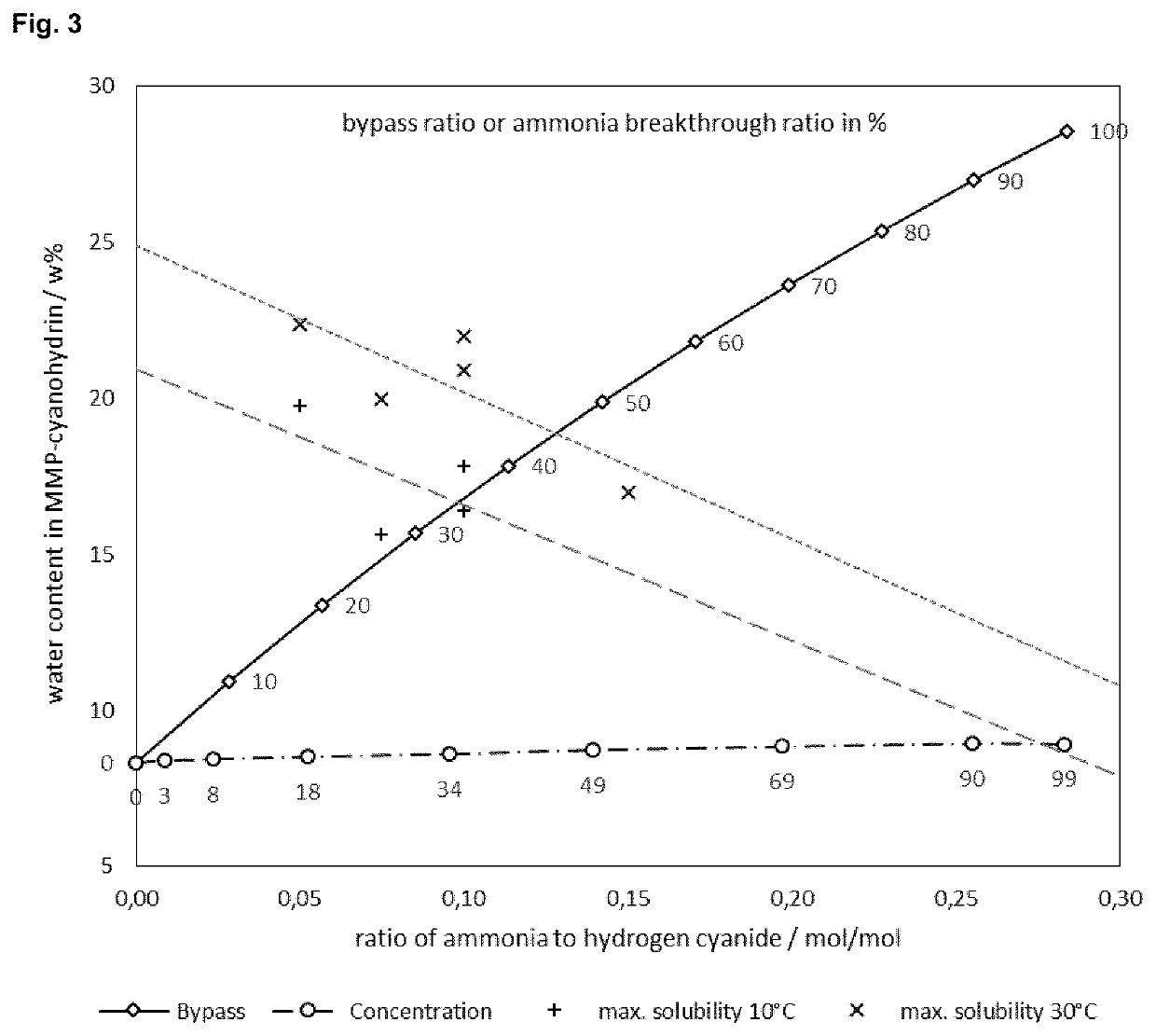

Method for producing methionine

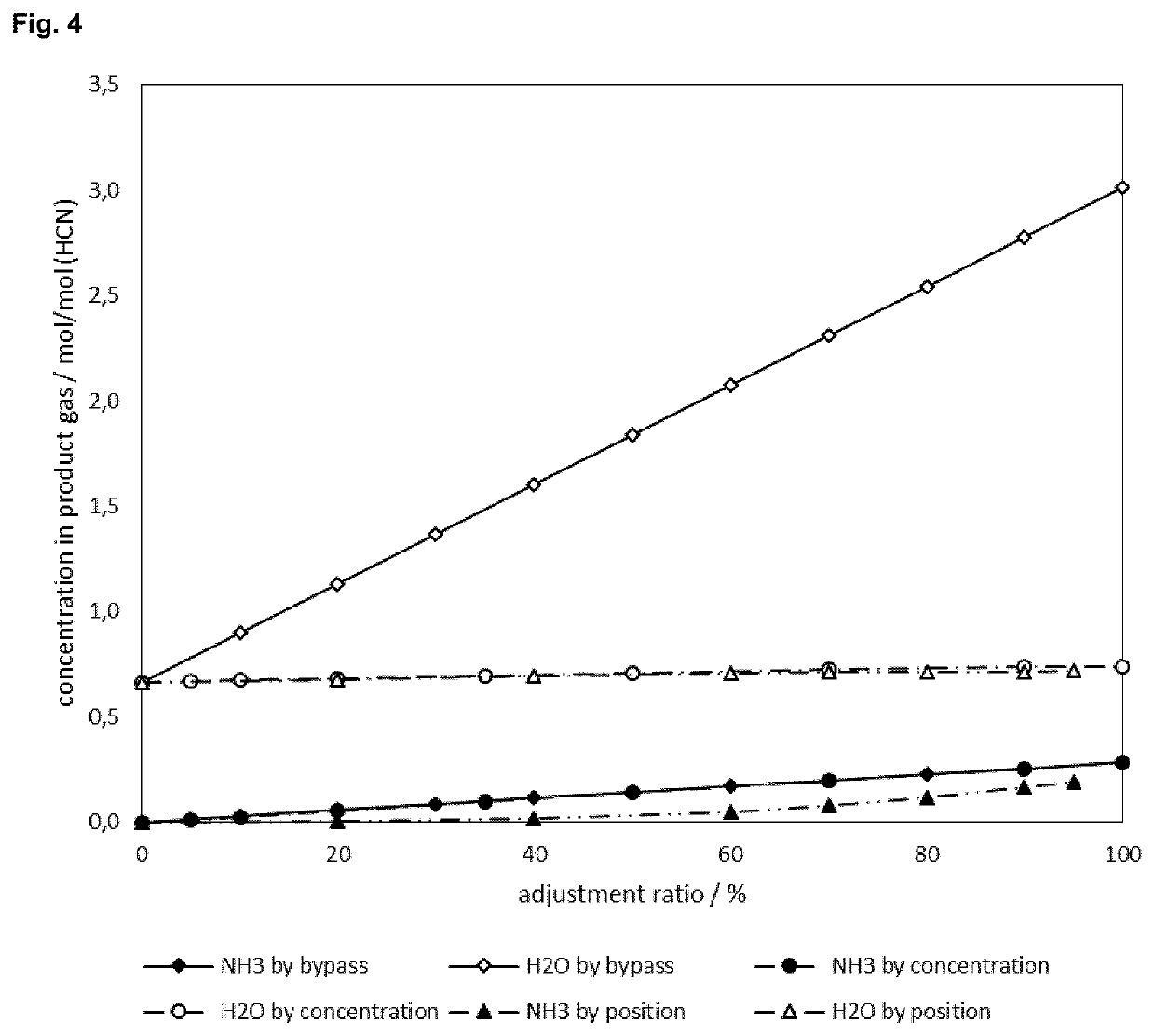

The present invention pertains to a method for producing methionine or salts or derivatives thereof from hydrogen cyanide (HCN), the method comprising a step of producing 2-hydroxy-4-(methylthio)butyronitrile (MMP-CN), or a crude product mixture comprising MMP-CN, by contacting a hydrogen cyanide (HCN) process gas mixture prepared according to the Andrussow process from methane, ammonia and oxygen, with 3-methylmercaptopropionaldehyde (MMP), wherein the HCN process gas mixture is obtained from the crude HCN process gas mixture by adjusting the amount of ammonia to between 20% (v / v) and 60% (v / v) of the amount of the ammonia in the crude HCN process gas mixture.

Owner:EVONIK OPERATIONS GMBH

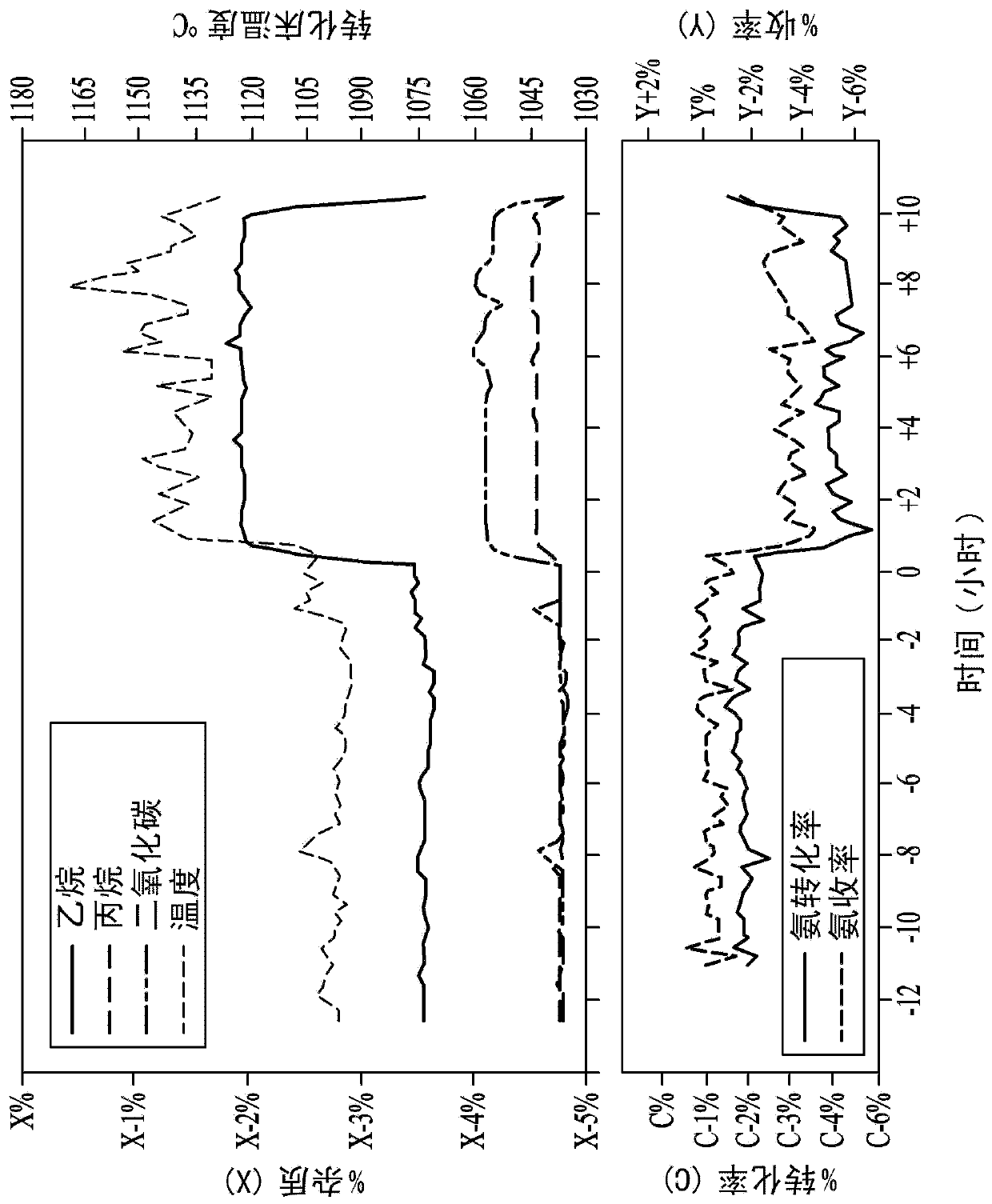

Enhanced methane control for the andrussow method

The present invention relates to a process for the production of hydrogen cyanide, more particularly to a process for the production of crude hydrogen cyanide comprising 0.05-1% by volume of methane. The invention also relates to a reactor for the production of crude hydrogen cyanide product, said reactor having a catalyst bed supported by an annular support providing a passage zone having an area of at least 90% of the cross-sectional area of the reactor, and wherein The annular support substantially prevents catalyst bed bypass. The invention also relates to a crude hydrogen cyanide comprising 0.05-1% by volume of methane.

Owner:INVISTA TEXTILES (U K) LTD

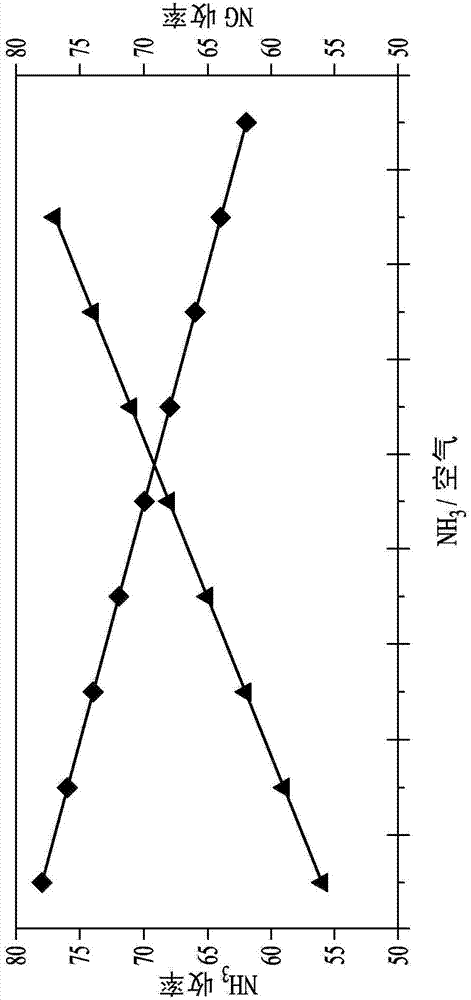

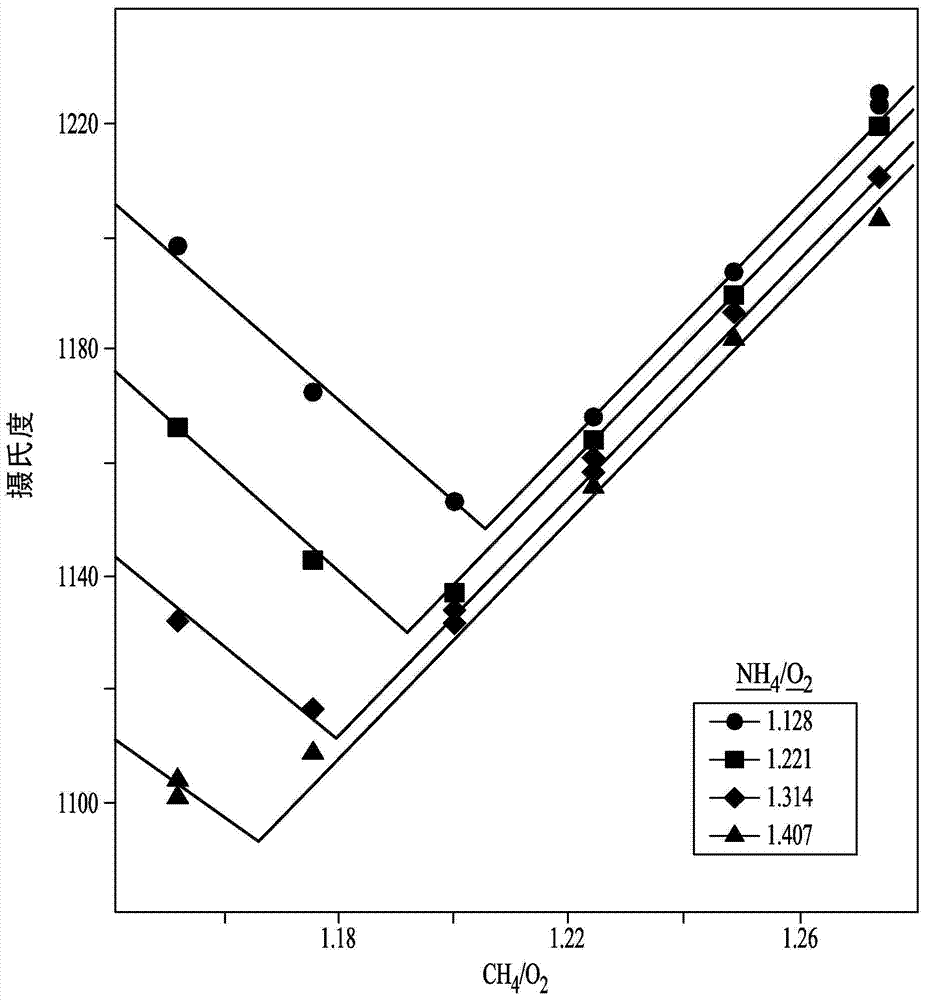

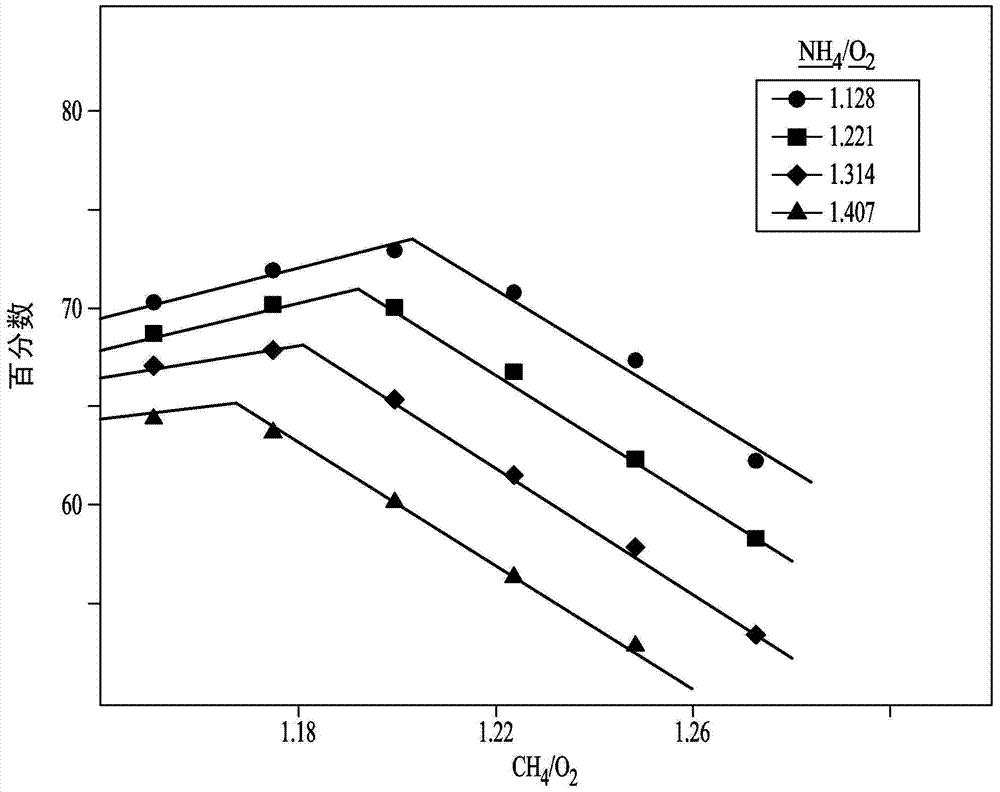

Variation of ammonia ratio in Andrussow process

ActiveCN103864106AAddress or improve prepared higherFix or improve costsSolidificationLiquefactionAndrussow processChemistry

Owner:INVISTA TEXTILES (U K) LTD

The production system and the production method of Angle's method for synthesizing hydrocyanic acid

ActiveCN103539158BSmall pressure lossSimple process routeHydrogen cyanide preparation/purification/separationFlame arresterProcess equipment

The invention provides a production system and a production method for synthesizing hydrocyanic acid by an Andrussow process. The production system comprises a natural gas conveying system, an air conveying system, an ammonia gas conveying system and mixed reaction equipment, wherein an outlet of the air conveying system and an outlet of the ammonia gas conveying system are joined at one place and communicated with an inlet of the mixed reaction equipment; an outlet of the natural gas conveying system is communicated with an inlet of the mixed reaction equipment. The production method comprises the following steps: mixing air and ammonia gas; mixing the mixed gas with natural gas; and introducing the mixture into a reactor for reaction through a flame arrester. According to the production system and production method provided by the invention, hot ammonia gas and hot air are mixed on an air pipeline, three materials are separately preheated respectively, the burst points of the three gases can be avoided in a large range, the process route and process equipment are simplified, the reaction efficiency is improved, the energy consumption is reduced, the raw material natural gas can be saved by 10-15%, and 5-5.5 million yuan can be saved per year.

Owner:CHONGQING UNISPLENDOUR INT CHEM

Enhanced methane control for Andrussow process

The invention relates to a process for producing hydrogen cyanide and more particularly, to a process for producing a crude hydrogen cyanide product comprising from 0.05 to 1 vol.% methane. The invention also relates to a reactor for producing a crude hydrogen cyanide product having a catalyst bed that is supported by an annular shelf that provides a pass-through area of at least 90% of the area of the cross-sectional area of the reactor and the annular shelf substantially prevents catalyst bed bypass. The invention also relates to a crude hydrogen cyanide product comprising from 0.05 to 1 vol.% methane.

Owner:INVISTA TEXTILES (U K) LTD

Apparatus and method for reducing catalyst poisoning in an andrussow process

ActiveCN103864102ADispersed particle separationHydrogen cyanide preparation/purification/separationPlatinumSulfur

Processes and systems for the production of hydrogen cyanide via the Andrussow process are described. A reaction zone, wherein oxygen, ammonia, and methane can be allowed to react in the presence of a catalyst comprising platinum to provide hydrogen cyanide. A desulfurization zone, wherein a feed stream comprising sulfur and at least one of the oxygen, the ammonia, and the methane can be contacted with a desulfurization material to produce a sulfur- reduced feed stream that is provided to the reaction zone. In an example, the desulfurization material includes zinc oxide.

Owner:INVISTA TEXTILES (U K) LTD

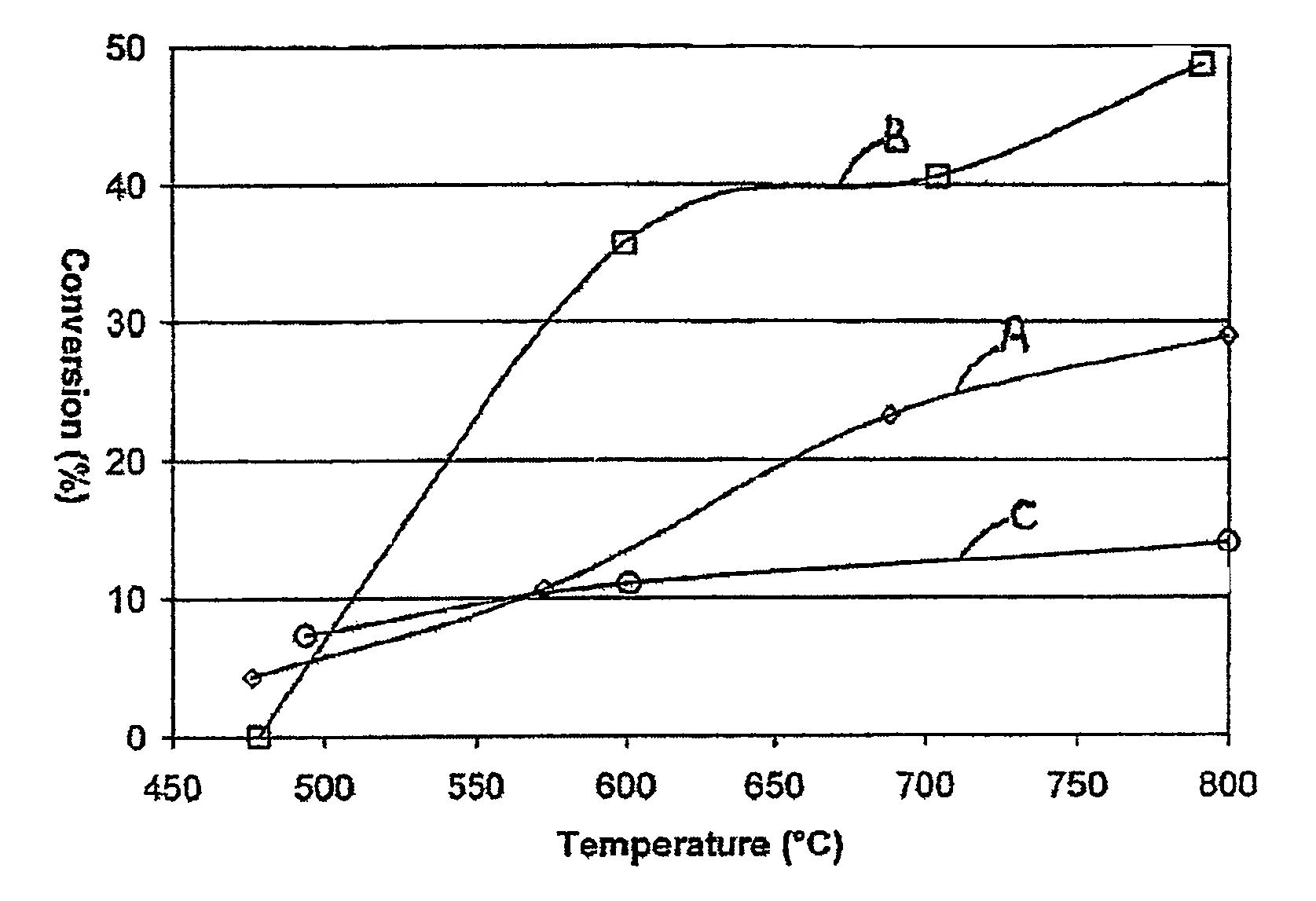

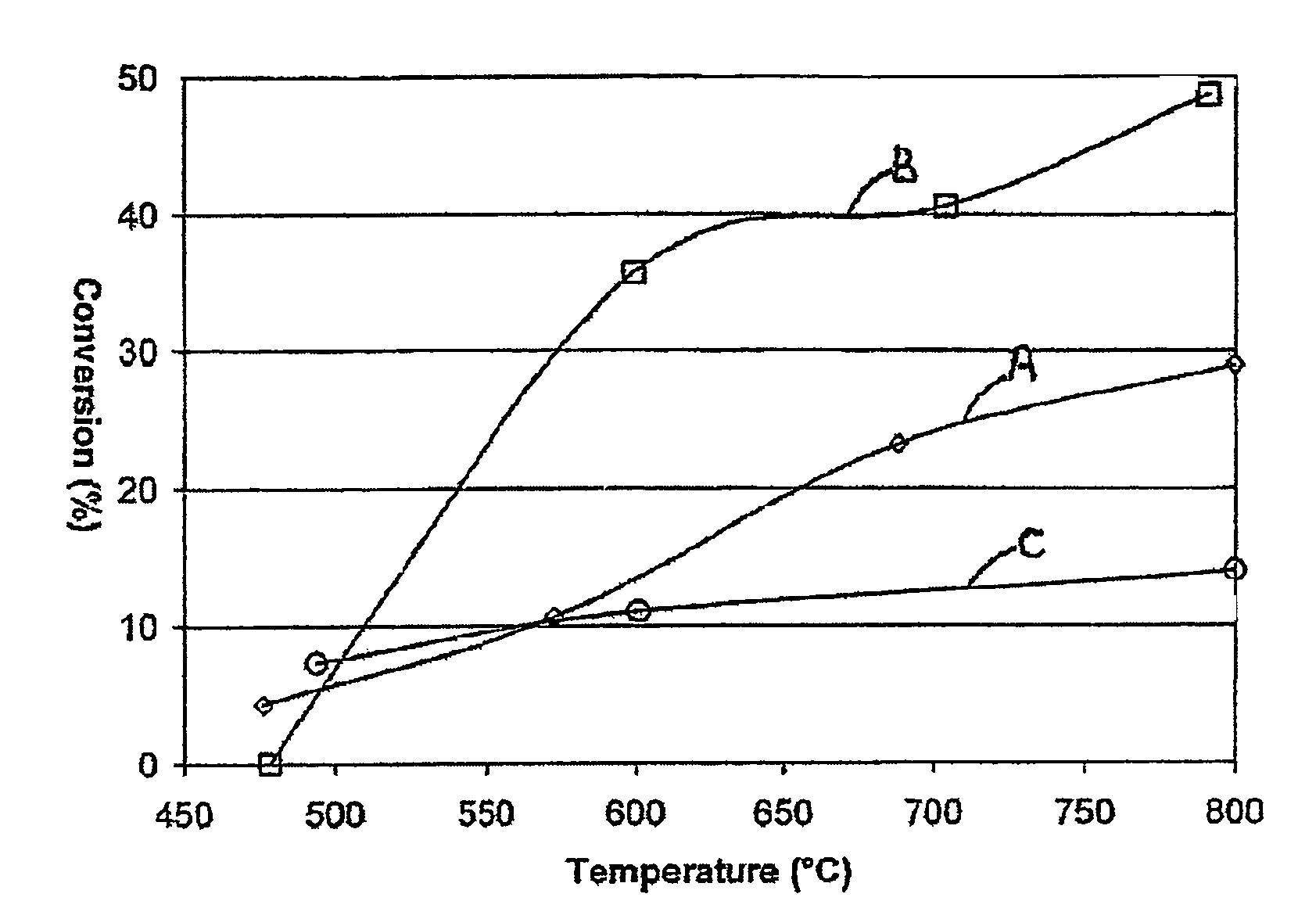

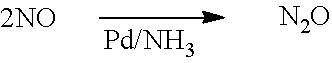

Catalyst charge design

InactiveUS8178068B2Avoid destructionEasy to manufactureAmmonium nitratesAlkali metal nitratesProduct gasNitrogen oxide

A catalyst charge for ammonia oxidation, including the Andrussow process, comprises a first stage ammonia oxidation catalyst capable of oxidizing 20 to 99% of designed ammonia throughput, to produce a first stage product gas comprising unreacted ammonia, oxygen and nitrogen oxides, and a second stage ammonia oxidation catalyst capable of completing the oxidation of unreacted ammonia. Low levels of nitrous oxide are produced an extended campaign lengths may be seen.

Owner:JOHNSON MATTHEY PLC

Apparatus and method for hydrogen recovery in the Andrussow process

ActiveCN103910331BLow costGas treatmentHydrogen separation using solid contactCyanidePhysical chemistry

The present application provides devices and methods for hydrogen recovery in the Andrussow process. The present disclosure relates to hydrogen recovery for the Andrussow process for the production of hydrogen cyanide (HCN) from methane, ammonia and oxygen. The method comprises (a) conditioning a reaction mixture comprising methane, ammonia, and oxygen to provide sufficient oxygen to the reaction mixture to produce a gaseous waste product having at least 40% hydrogen after removal of ammonia and recovery of hydrogen cyanide stream; and (b) removing components from said gaseous waste stream to produce recycled hydrogen. The device includes a reactor and a hydrogen recovery system. The present invention safely solves the problem of wasteful losses of hydrogen from oxygen-enriched or oxygen Andrussow process product streams through the use of the hydrogen recovery methods and systems described herein.

Owner:INVISTA TEXTILES (U K) LTD

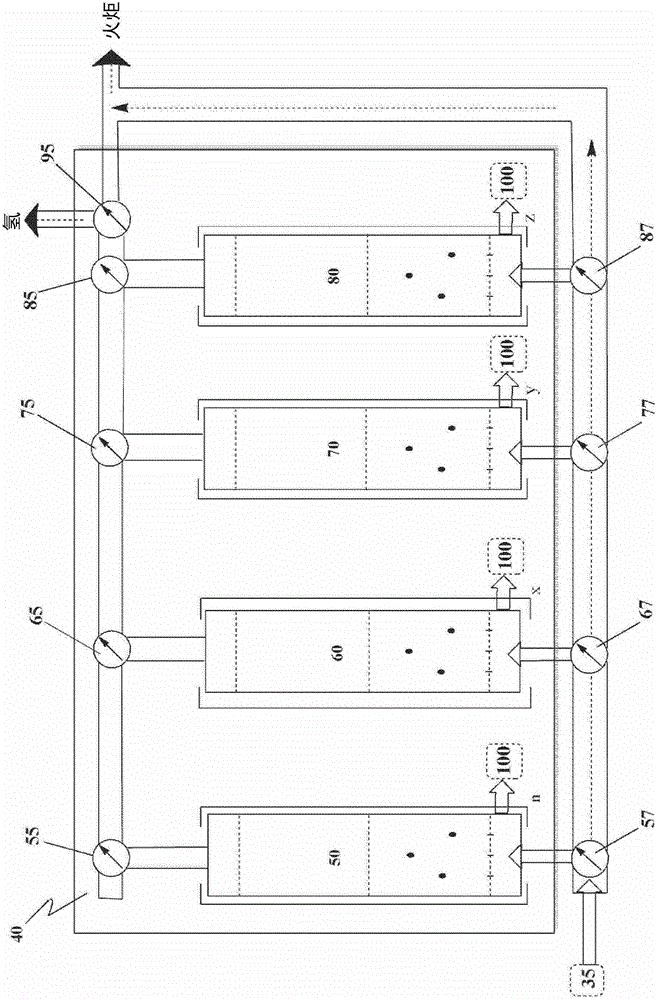

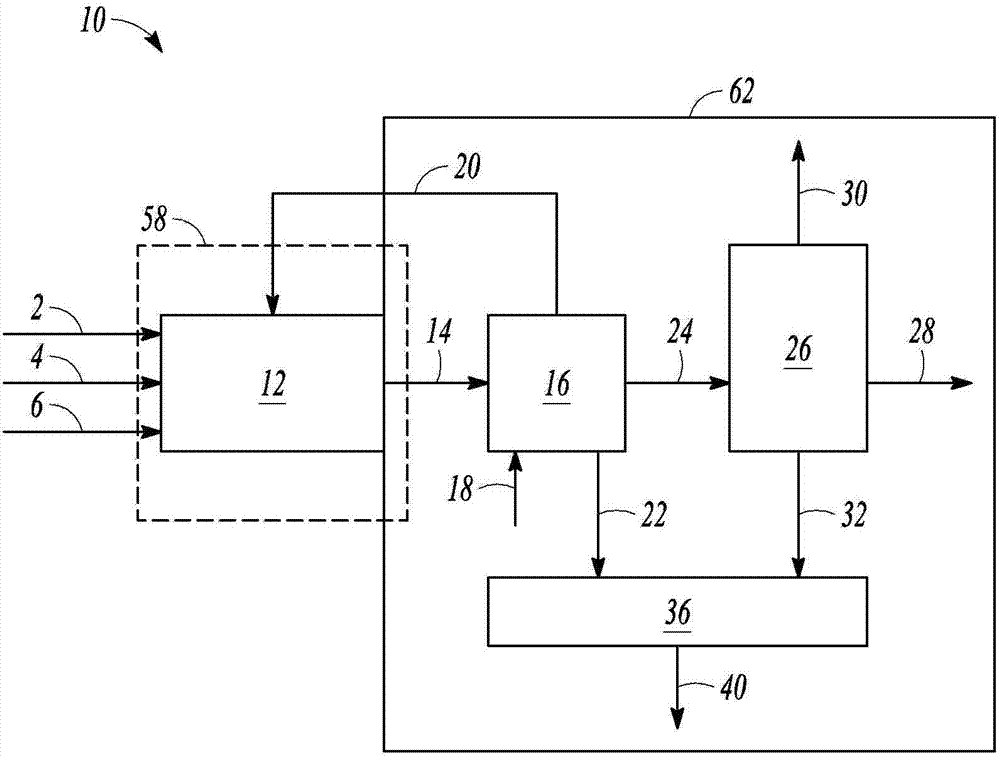

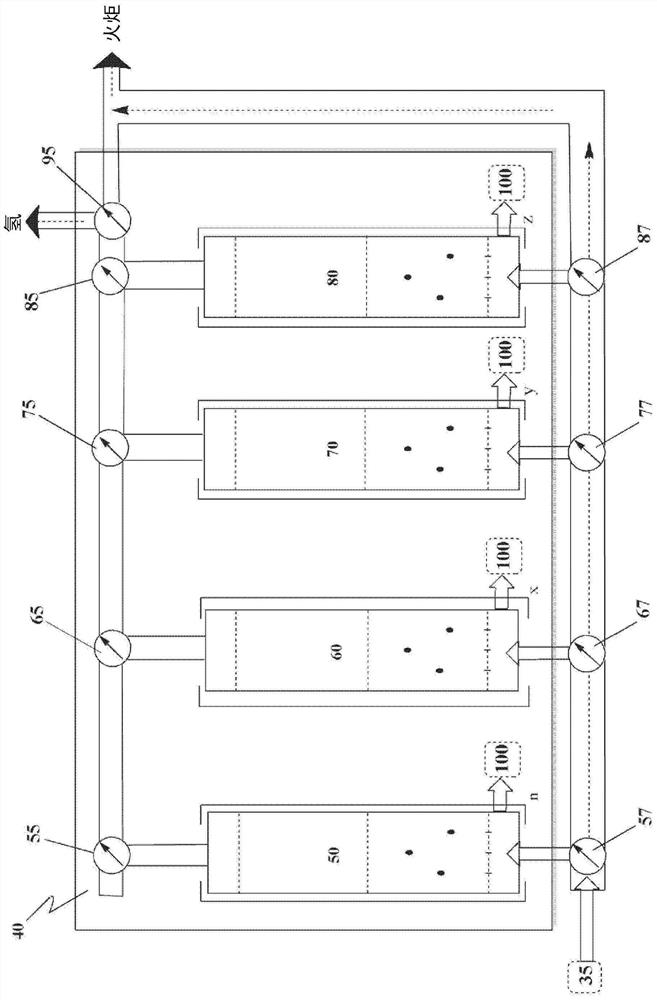

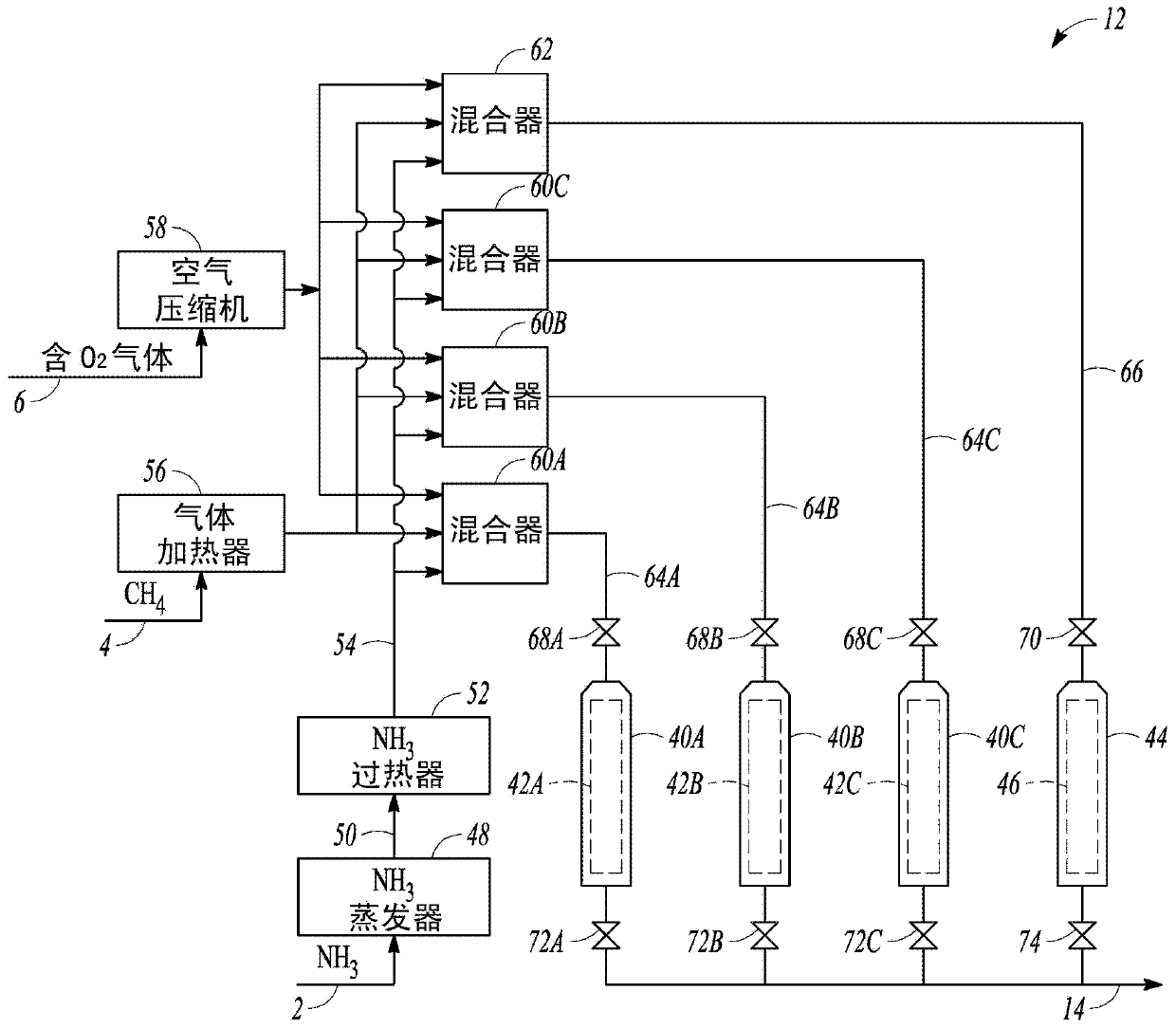

Reactor Scheme in the Andrussow Process

ActiveCN103864111BRate of consistent preparationConsistent and predictable rates of preparationCatalytic gas-gas reactionEnergy inputProduction rateGaseous ammonia

A method for producing hydrogen cyanide comprising: feeding a reaction mixture feed comprising gaseous ammonia, methane and oxygen to a plurality of main reactors each comprising a platinum-containing catalyst bed; determining the whether the percent yield of hydrogen cyanide in any one of the plurality of primary reactors is at or below a threshold; when the percent yield of hydrogen cyanide in any one of the plurality of primary reactors is at or below at said threshold, identifying one or more suboptimal reactors among said plurality of primary reactors; and when said one or more suboptimal reactors are identified, supplementing said reaction mixture feed Feed to one or more supplementary reactors, wherein each of the one or more supplementary reactors includes a platinum-containing catalyst bed. The supplemental feeding may be performed in place of the feed of the reaction mixture to the one or more suboptimal reactors, or in addition to the feed of the reaction mixture to the one or more suboptimal reactors In addition to the feed, the supplementary feed is also carried out. The overall process is sufficient to maintain the total measured hydrogen cyanide production rate in the one or more supplementary reactors and the main reactor within a desired total hydrogen cyanide production rate range.

Owner:INVISTA TEXTILES (U K) LTD

Preparation method of d,l-2-hydroxy-4-methylthiobutyric acid trace element chelate

ActiveCN103641755BStable in natureShorten production timeSulfide preparationChemical industryChelation

The invention aims at the chemical industry field, and relates to a preparation method of a D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method comprises the following steps: preparing a hydrocyanic acid mixed gas by adopting an Andrussow process, and reacting the hydrocyanic acid mixed gas with methylthiopropionaldehyde to obtain a 2-hydroxy-4-methylthiobutyronityile system, hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system by an inorganic alkali to obtain D,L-2-hydroxy-4-methylthiobutyrate, and chelating the D,L-2-hydroxy-4-methylthiobutyrate with a trace metal element salt to generate the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method has the advantages of few technological steps, cheap and easily available raw materials, stable properties of the above intermediate, and low total production cost; the obtained D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate has the advantages of high yield, high purity and large bulk density; and the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate can be effectively mixed with feeds as an animal feed additive to supplement trace elements and amino acids in the daily ration and improve the endozoic production and immunity performances, and can also be used as a medicinal reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for stabilizing heat exchange tubes in the andrussow process

The present invention relates to an improved method of producing hydrogen cyanide, said method involving a heat exchanger comprising a plurality of tubes, wherein each of said plurality of tubes comprises: a ceramic sleeve, each of said sleeves comprising an isolation layer surrounding at least a portion of said sleeve; and one or more spacers, wherein at least one of said one or more ceramic spacers is placed between said tubes The upper part of the inlet surrounds the sleeve, and the ceramic sleeve is spaced apart from the tube. The invention further relates to a reaction apparatus for the production of hydrogen cyanide, said apparatus relating to a heat exchanger comprising a plurality of tubes, wherein each of said plurality of tubes comprises: a ceramic ceramic extending through the inlet of said tube a sleeve, each of the sleeves comprising an isolation layer surrounding at least a portion of the sleeve; and one or more spacers, wherein at least one of the one or more ceramic spacers is located between the The upper portion of the inlet surrounds the sleeve, and the ceramic sleeve is spaced from the tube. The invention further relates to heat exchangers used in the improved process and reaction apparatus.

Owner:INVISTA TEXTILES (U K) LTD

Reactor scheme in Andrussow process

ActiveCN103864111ARate of consistent preparationConsistent and predictable rates of preparationProcess control/regulationCatalytic gas-gas reactionPlatinumProduction rate

A method for preparing hydrogen cyanide comprises the following steps: feeding a reaction mixture feed material to a plurality of main reactors of catalyst beds respectively containing platinum, wherein the feeding reaction materials contains gaseous ammonia, methane and oxygen; determining whether the percentage yield of the hydrogen cyanide in any one of the main reactors is at or below a threshold value; when the percent yield of any one of the main reactors is at or below the threshold value, identifying one or more subprime reactors from the main reactors; and, when one or more subprime reactor is identified, complementally feeding the reaction mixture feed material to one or more complementary reactors, wherein each of the one or more complementary reactors comprises the catalyst bed containing the platinum. Complementary material feeding capable of replacing material feeding of the reaction mixture feed material to the one or more subprime reactors is performed, or, besides the material feeding of the reaction mixture feed material to the one or more subprime reactors, the complementary material feeding is also performed. The total method can enough to keep the total measurement hydrogen cyanide production rate in the one or more complementary reactors and the main reactors within a scope of the required total hydrogen cyanide production rate.

Owner:INVISTA TEXTILES (U K) LTD

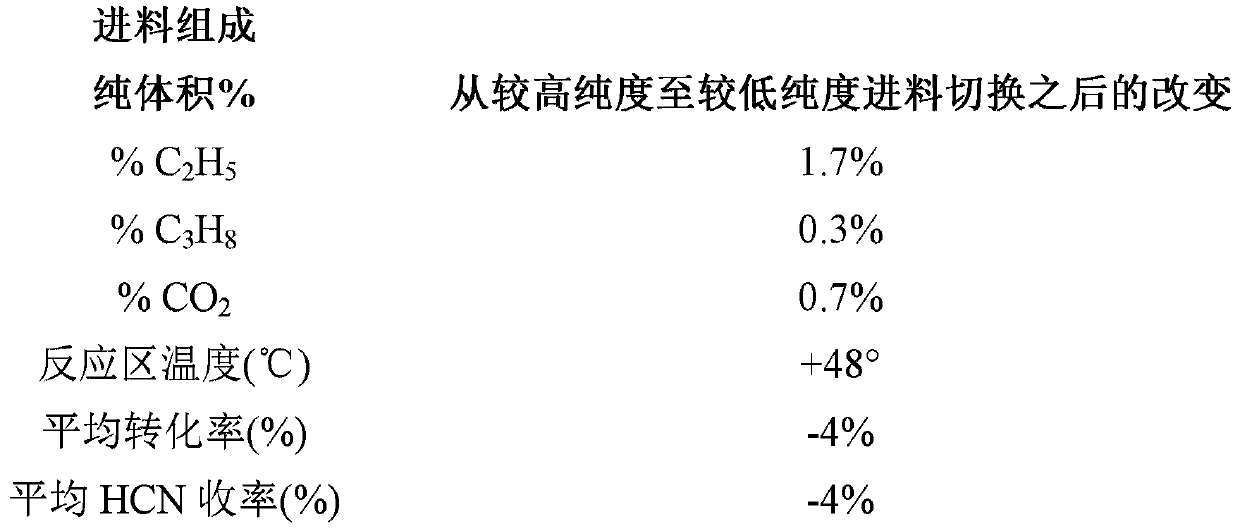

Reduction of organonitrile impurity levels in HCN from an oxygen Andrussow process

PendingCN111268695ALower levelReduce contentHydrogen cyanide preparation/purification/separationProcess equipmentPtru catalyst

The invention provides an oxygen Andrussow process for production of hydrogen cyanide from a methane-containing feedstock such as natural gas in the presence of oxygen and ammonia over a platinum catalyst, wherein the production of byproduct organonitrile impurities, such as acrylonitrile, is reduced. Limiting the content of C2+ hydrocarbons in the methane feedstock in the oxygen Andrussow process, in contrast to the air Andrussow process, has been found to reduce formation of organonitriles, such as acrylonitrile. The organonitrile impurities can require additional processing for removal, cause fouling of equipment, and can also contribute to hydrogen cyanide polymerization. Reduction of C2+ hydrocarbon levels to less than 2 wt%, or 1 wt%, or less than 0.1 wt%, in the methane can providean improved yield of higher purity HCN. Reduction of C2+ hydrocarbon levels also solves the problem of polymer buildup in process equipment, reducing downtime required for cleaning when higher C2+ hydrocarbon levels are present in the reaction feed.

Owner:INVISTA TEXTILES (U K) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com