Activated clay dry preparation process

A preparation process and soil drying technology, applied in the field of decolorizers, can solve the problems of low product activity, inability to completely remove clay acid, inability to apply in the field of food oil decolorization, etc., and achieve the effect of low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of activated clay dry method preparation process comprises the following steps:

[0025] S1. Prepare materials, select calcium-based bentonite with montmorillonite content > 70% as raw material, crush it into particles with a diameter of no more than 1 cm with a crusher, and pulverize the crushed calcium-based bentonite to a particle size of more than 200 mesh;

[0026] S2. Activation, the pulverized calcium-based bentonite powder is put into a heating mixer, the heating mixer adopts a high-speed heating mixer, and dilute sulfuric acid with a concentration of 5-7% is added, and the amount of dilute sulfuric acid added is 20% of the total amount of calcium-based bentonite ~25%, heat up to 90~95℃ and knead for 1~3 hours;

[0027] S3, neutralize and remove acid, the kneading reaction is completed, stop heating and cool down to below 50°C, gradually add 20% concentration of amphoteric oxide, keep stirring during the addition process, stop adding until t...

Embodiment 2

[0031] Embodiment 2: a kind of activated clay dry method preparation process comprises the following steps:

[0032] S1. Prepare materials, select calcium-based bentonite with montmorillonite content > 70% as raw material, crush it into particles with a diameter of no more than 1 cm with a crusher, and pulverize the crushed calcium-based bentonite to a particle size of more than 200 mesh;

[0033] S2. Activation, the pulverized calcium-based bentonite powder is put into a heating mixer, the heating mixer adopts a high-speed heating mixer, and dilute sulfuric acid with a concentration of 5-7% is added, and the amount of dilute sulfuric acid added is 20% of the total amount of calcium-based bentonite ~25%, heat up to 90~95℃ and knead for 1~3 hours;

[0034] S3, neutralize and remove acid, the kneading reaction is completed, stop heating and cool down to below 50°C, gradually add 20% concentration of amphoteric oxide, keep stirring during the addition process, stop adding until t...

Embodiment 3

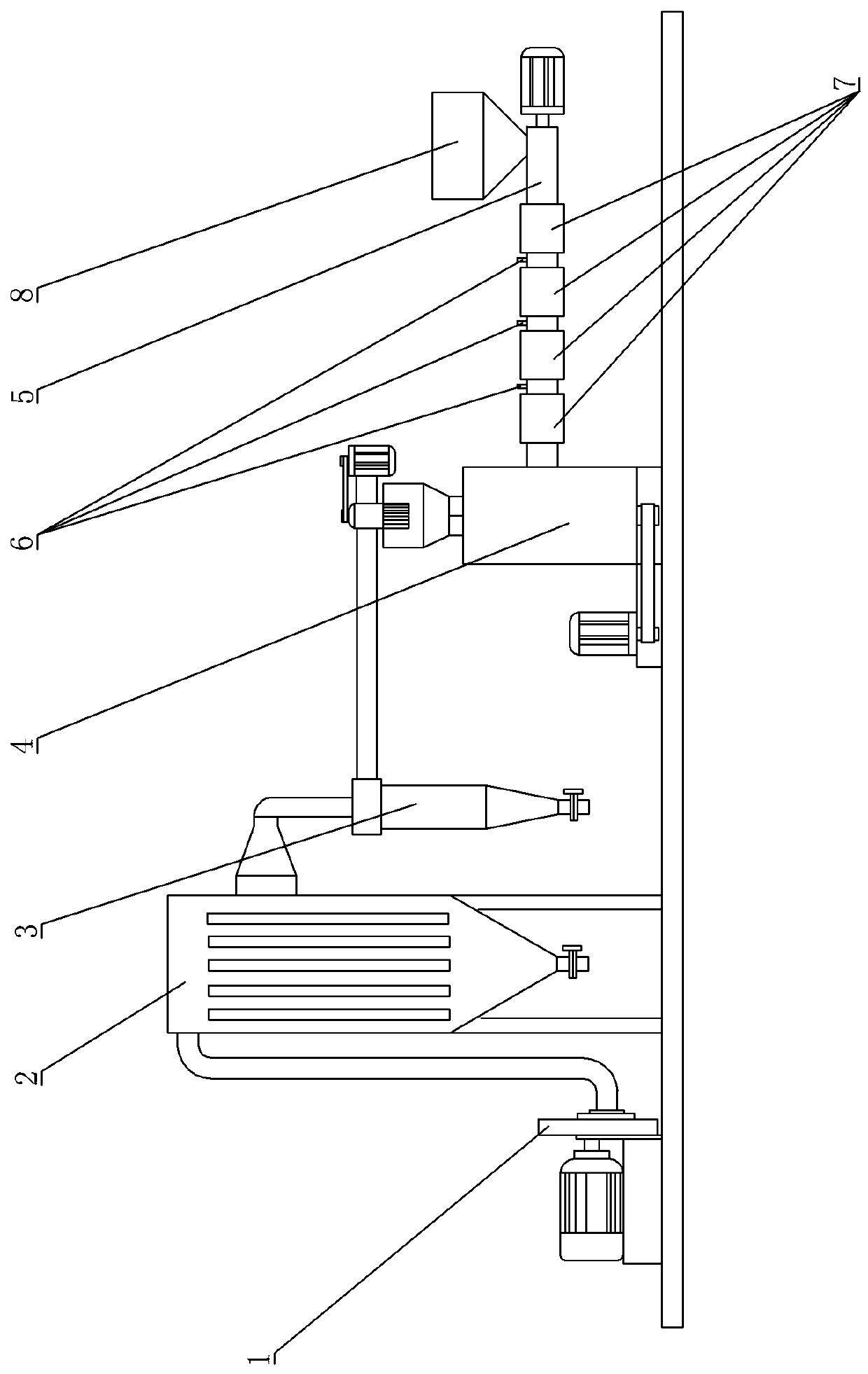

[0037] Embodiment 3: a kind of activated clay drying pulverizer, is used for one-time drying and pulverizing of activated clay in step S4 in embodiment 2, comprises high-speed pulverizer 4, and the feeding port of described high-speed pulverizer 4 is connected with drying Feed device, described drying feed device comprises feed cylinder 5, and feed cylinder 5 is provided with feed hopper 8 at one end far away from high-speed pulverizer 4, and described feed cylinder 5 is set with feed auger, so The outer periphery of the feed cylinder 5 is surrounded by several constant temperature electric heaters 6, and the side wall of the feed cylinder 5 is provided with an exhaust hole 6, and the exhaust hole 6 is arranged between two adjacent constant temperature electric heaters 6. between. The constant temperature electric heater 6 can be composed of a simple electric heating tube and a mechanical thermostat. The structure is simple and the cost is low, but the temperature control accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com