Method for producing aluminum oxide using industrial solid waste rich in aluminum oxide

A technology for industrial solid waste and alumina, which is applied in the comprehensive utilization of mineral resources and metallurgy to achieve the effects of mild process conditions, low free acid content, and high aluminum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: The method for producing alumina from industrial solid waste rich in alumina is as follows:

[0040] (1) Crush the coke through a 180-mesh sieve, with a sieve allowance of less than 5%, and set aside; the coal gangue is dried, crushed, and ground until the sieve allowance of an 80-mesh sieve is less than 10%;

[0041] (2) For the first production, add water with 40% of the mass of gangue to 10kg of coal gangue, after mixing, add sulfuric acid with a mass concentration of 98% to the mixture according to 1.4 times the amount of acid used in theory, and then react at 120°C for 4 hours , after the reaction is over, add 2.6 times the mass of coal gangue to the reaction product to dissolve in water, filter to obtain acid solution and acid slag, and wash the acid slag twice with water, the amount of water is 3.0 times the mass of the aluminum-rich powder, after washing The liquids are the first washing liquid and the second washing liquid respectively, the acid s...

Embodiment 2

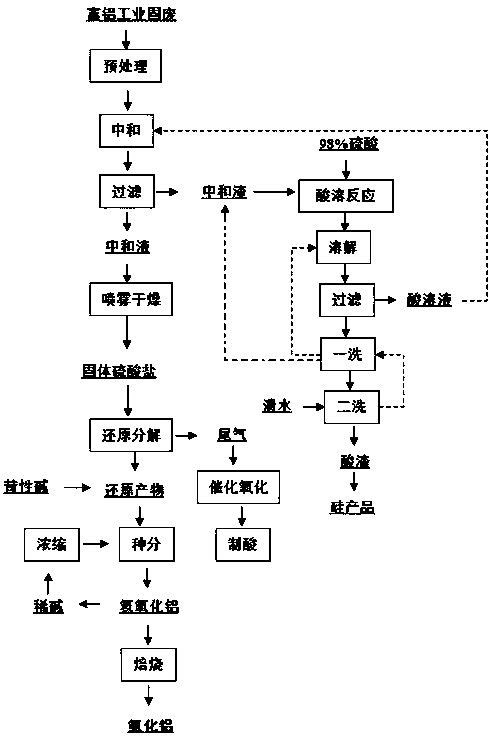

[0049] Embodiment 2: as figure 1 As shown, the method for producing alumina from industrial solid waste rich in alumina is as follows:

[0050] (1) Crush the anthracite through a 180-mesh sieve, with a sieve balance of less than 5%, and set aside; dry, crush, and grind the red mud until the 80-mesh sieve has a sieve balance of less than 10%;

[0051] (2) Add step 1 of Example 1 to 10 kg of ground red mud (3) Obtain the filtrate after solid-liquid separation for neutralization reaction to obtain neutralization liquid and neutralization slag, and add step 1 to the neutralization slag ( 3) Part of the three-wash liquid is mixed until the water content of the slurry is about 45wt%. The slurry is pumped into the acid-dissolving tank, and acid-dissolved with 1.1 times the amount of acid plus 98% concentrated sulfuric acid according to the theory of acid-soluble substances in red mud. Reaction, the dissolution temperature is 110°C, and the time is 4h. After the acid dissolution rea...

Embodiment 3

[0058] Embodiment 3: as figure 1 As shown, the method for producing alumina from industrial solid waste rich in alumina is as follows:

[0059] (1) Crush the semi-coke through a 180-mesh sieve, with a sieve balance of less than 5%, and set aside; the aluminum ash is dried, crushed, and ground until the sieve through an 80-mesh sieve, and the sieve balance is less than 10%;

[0060](2) Add the acid solution (filtrate) obtained in step (2) of Example 2 to 10 kg of ground aluminum ash for neutralization reaction to obtain neutralization liquid and neutralization slag, and add the neutralization slag for implementation Example 2 Step (2) Part of the five washing liquids is mixed until the water content of the slurry is about 50wt%, and the slurry is pumped into the acid-dissolving tank, and the acid content of the acid-soluble matter in aluminum ash is 1.2 times the amount of acid plus a mass concentration of 98%. Sulfuric acid was subjected to acid-dissolution reaction, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com