Alcohol-free concentrated fountain solution and preparation method thereof

A technology of fountain solution and concentrated solution, which is applied in the preparation and printing of printing surface, can solve the problems of large amount of alcohol or isopropyl alcohol added, high requirements for operation proficiency, and cannot be universally applied, and achieves spreading. Fast speed, wide adaptability, and the effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

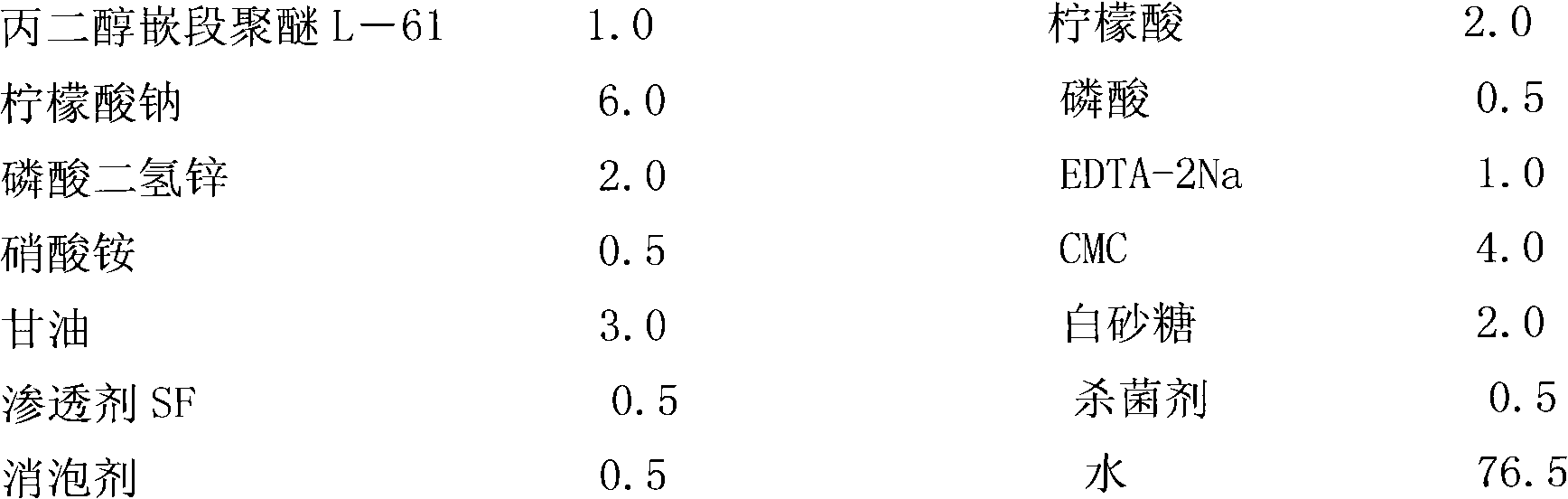

[0037] A fountain solution concentrate composition for lithography comprises the following components (amounts are parts by weight):

[0038]

[0039] Weigh the above-mentioned raw materials in proportion, add water into the reaction kettle first, and then add solid raw materials in turn. The adding method is: the former raw material to be added is completely dissolved, and then the latter raw material is added. Then use the same method to add liquid raw materials sequentially. After adding all the raw materials, stir for 1 hour to make the finished product. Add water to the prepared dampening solution concentrate composition to dilute it into a 2-3% aqueous solution for direct use. The dampening solution is added to the water tank of the printing machine, and the printing can be started normally.

Embodiment 2

[0041] A fountain solution concentrate composition for lithography comprises the following components (amounts are parts by weight):

[0042]

[0043] Weigh the above-mentioned raw materials in proportion, add water into the reaction kettle first, and then add solid raw materials in turn. The adding method is: the former raw material to be added is completely dissolved, and then the latter raw material is added. Then use the same method to add liquid raw materials in sequence. After adding all the raw materials, stir for 1.5 hours to make the finished product. The prepared dampening solution concentrate composition is diluted with water to a 2-3% aqueous solution for direct use. The dampening solution is added to the water tank of the printing machine, and the printing can be started normally.

Embodiment 3

[0045] A fountain solution concentrate composition for lithography comprises the following components (amounts are parts by weight):

[0046]

[0047] Weigh the above-mentioned raw materials in proportion, add water into the reaction kettle first, and then add solid raw materials in turn. The adding method is: the former raw material to be added is completely dissolved, and then the latter raw material is added. Then use the same method to add liquid raw materials sequentially. After adding all the raw materials, stir for 2 hours to make the finished product. Add water to dilute the fountain solution concentrate composition to a 2-3% aqueous solution for direct use. The dampening solution is added to the water tank of the printing machine, and the printing can be started normally.

[0048] In order to verify the use effect of alcohol-free fountain solution of the present invention, a comparative test with traditional alcohol fountain solution has been carried out:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com