Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Solve inseparable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

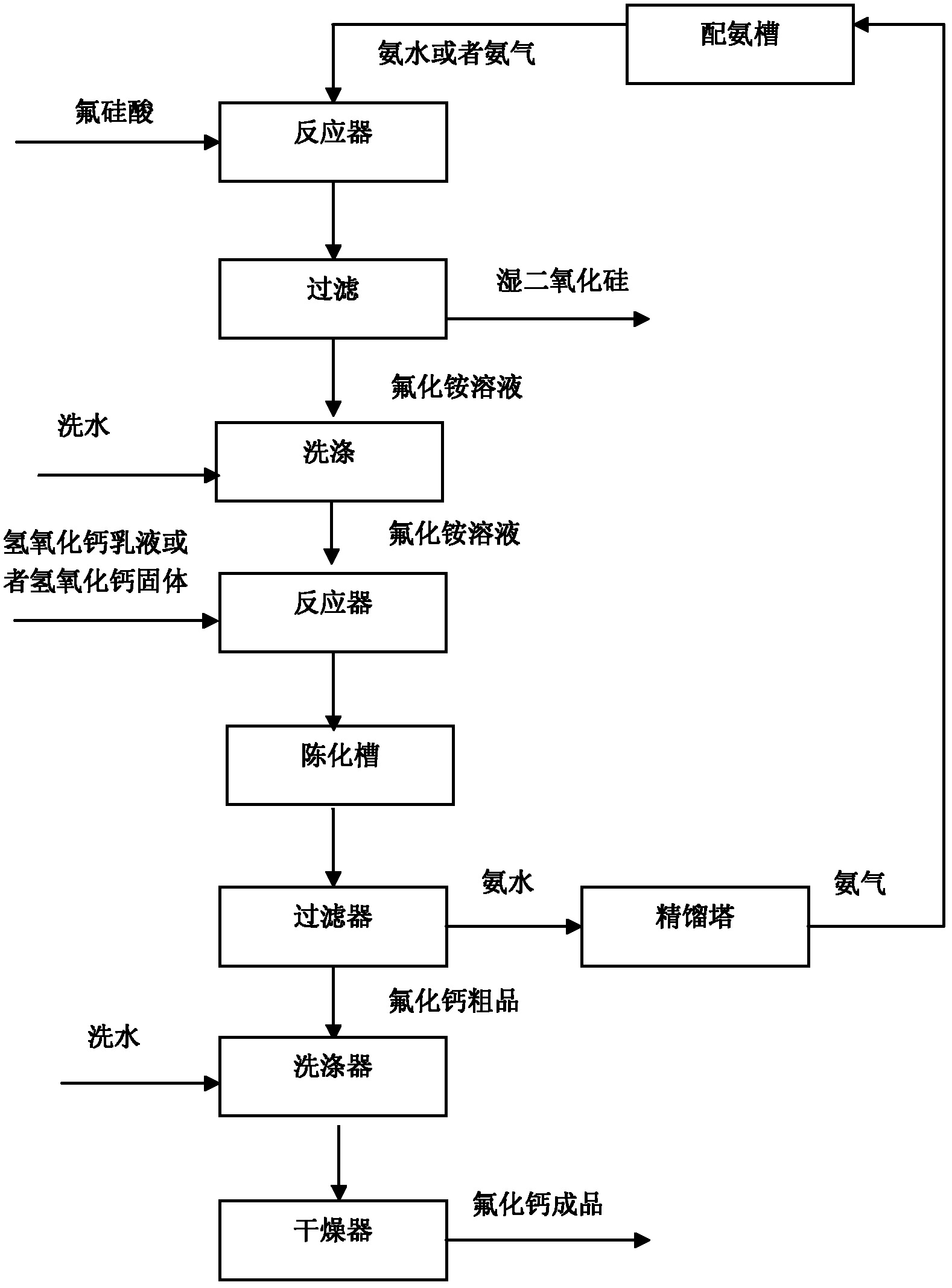

Synthetic method of calcium fluoride

ActiveCN102502753AImprove solubilityAchieve separationCalcium/strontium/barium fluoridesSolubilityTwo step

The invention relates to a synthetic method of calcium fluoride, hydrofluosilicic acid produced during a phosphate fertilizer production process is adopted as raw materials so as to synthesize calcium fluoride through two steps of reaction, the first step of reaction is that ammonium fluoride and silicon dioxide are produced through the reaction of fluosilicic acid and ammonia gas or ammonia water, the solubility of ammonium fluoride is high, and the separation of ammonium fluoride from silicon dioxide is achieved through the method of filtering and washing; the second step of reaction is that calcium fluoride and ammonia water are produced through the reaction of ammonium fluoride solution and calcium hydroxide, the separation of calcium fluoride from ammonia water is achieved through the filtering way, ammonia gas is obtained by rectifying the ammonia water, and calcium fluoride is produced by taking ammonium fluoride as an intermediate product. Therefore, the invention overcomes defects of insufficient reaction during the process of synthesizing calcium fluoride through the reaction of hydrofluosilicic acid and calcium hydroxide, and mass of calcium fluosilicate contained in calcium fluoride products, further solves the problem of difficulty separation of calcium fluoride from silicon dioxide mixture, and achieves efficient utilization of by-product hydrofluosilicic acid ofphosphate fertilizer.

Owner:KUNMING DAOERSEN TECH

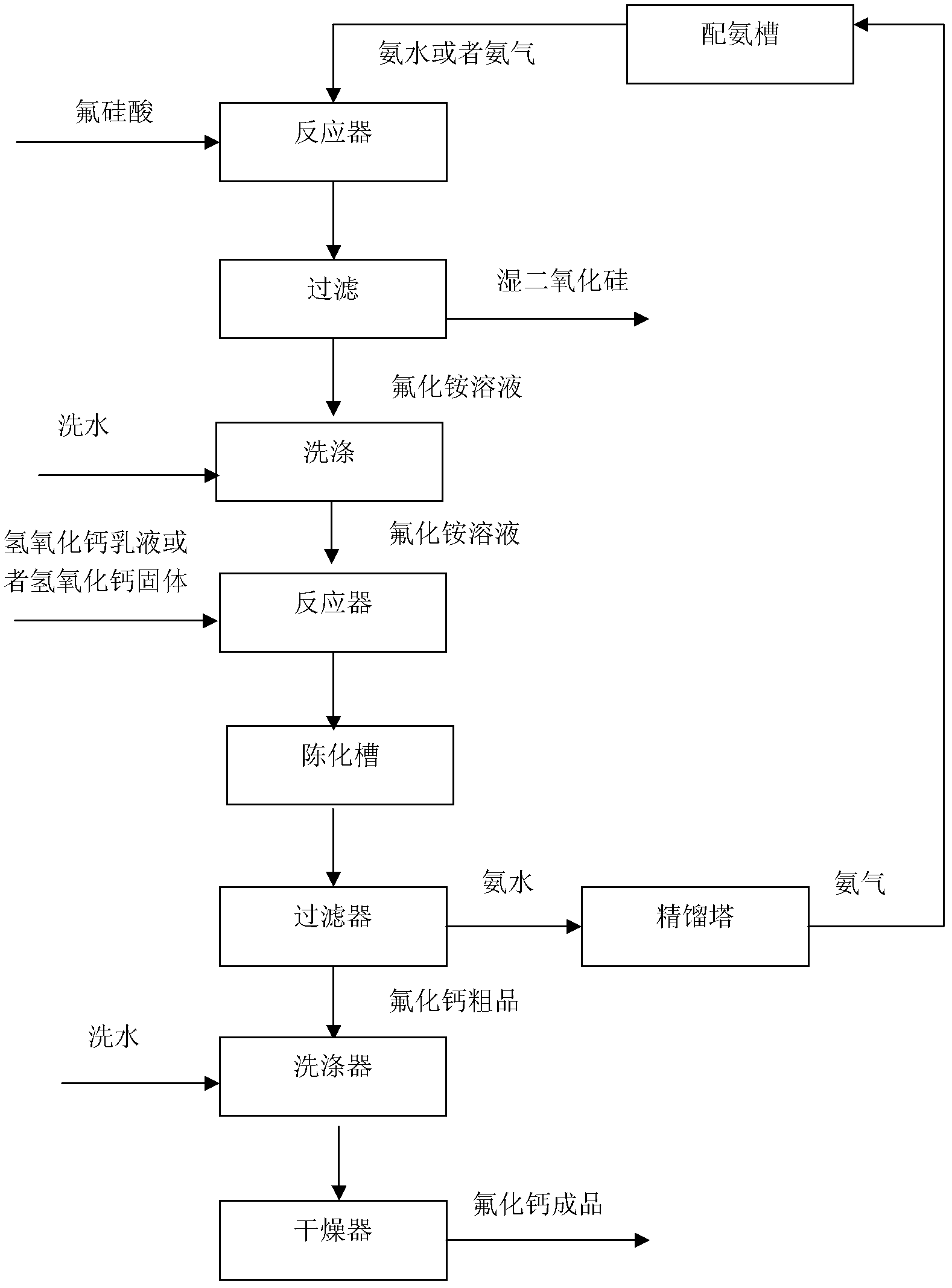

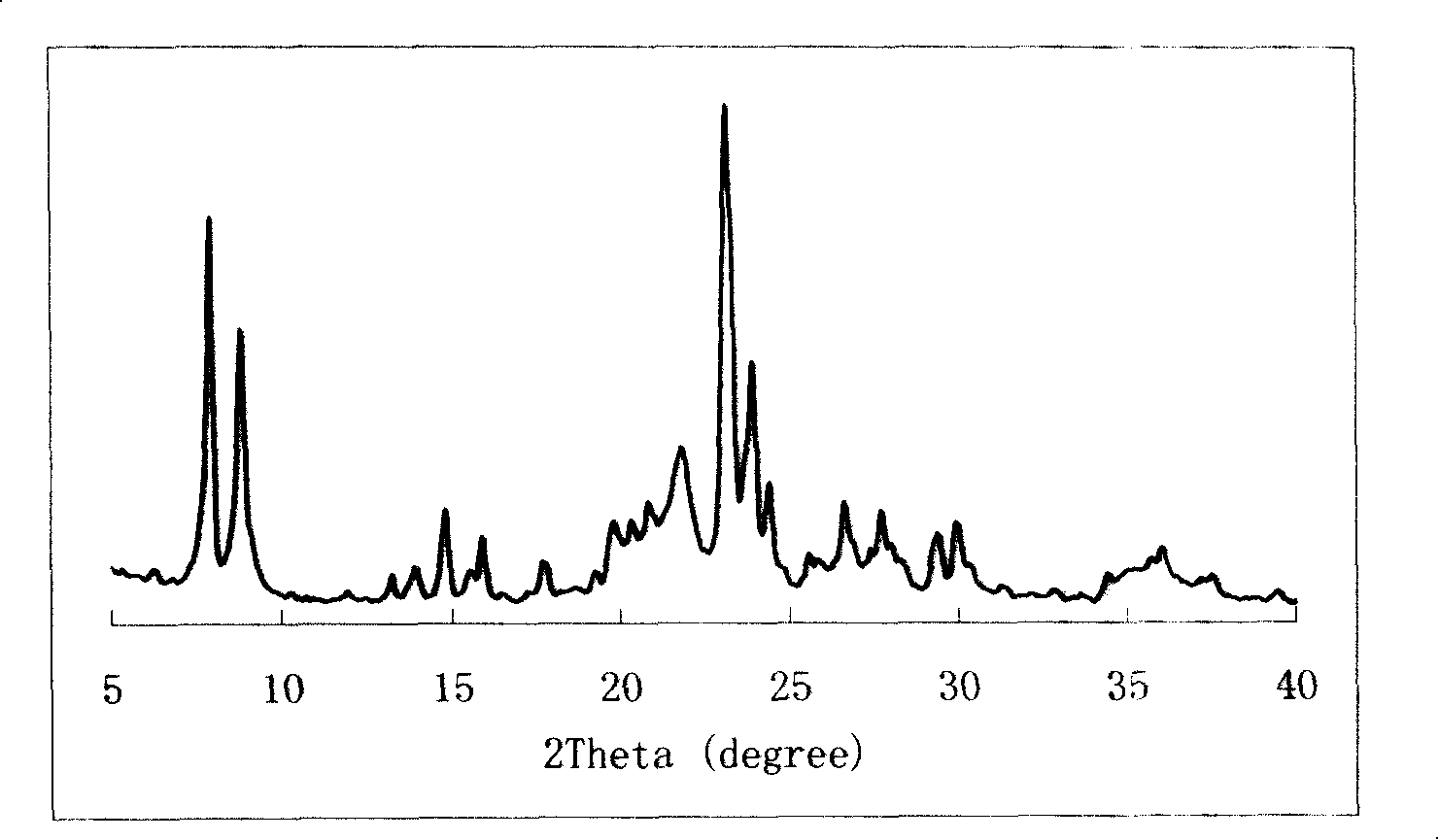

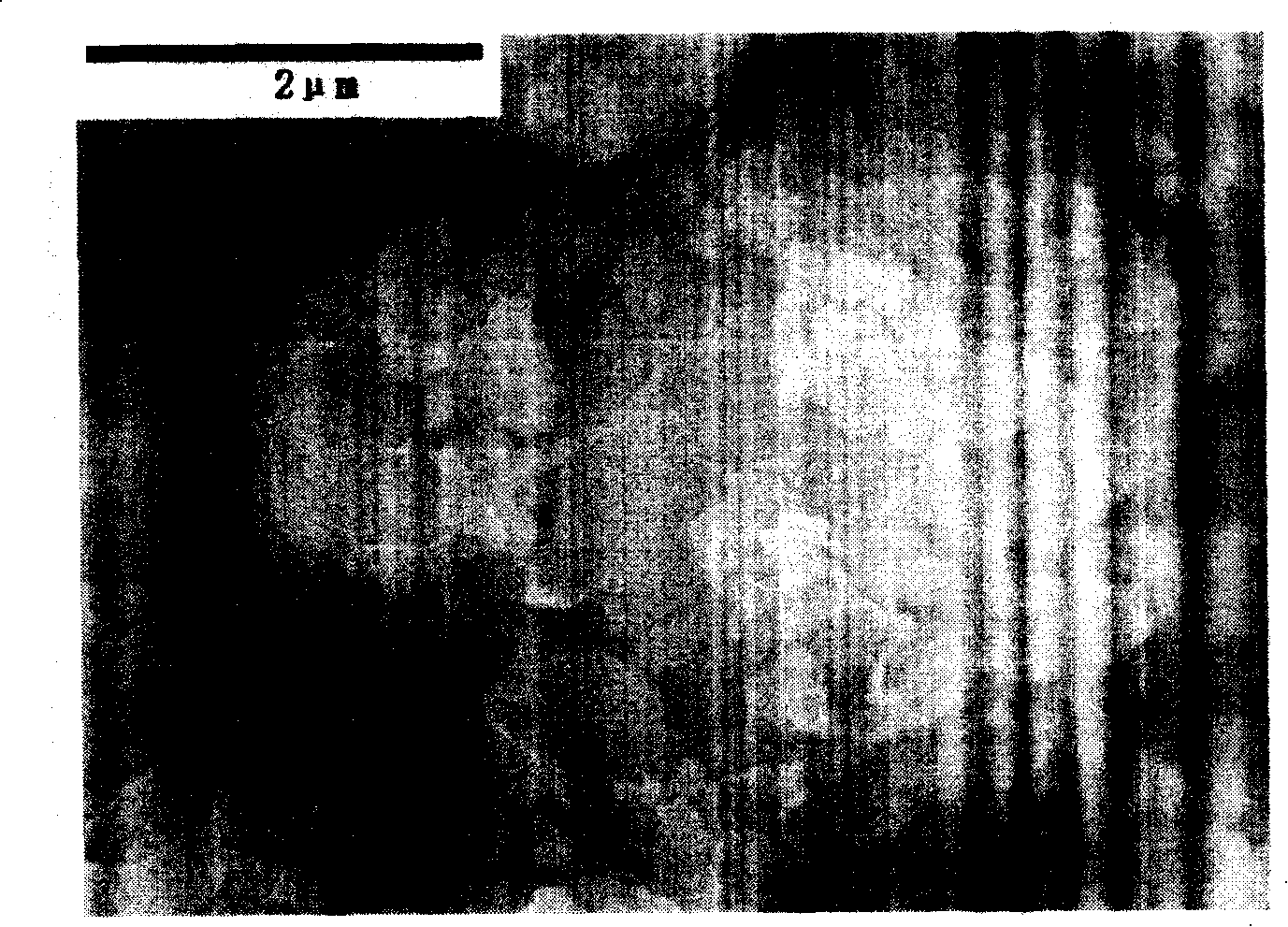

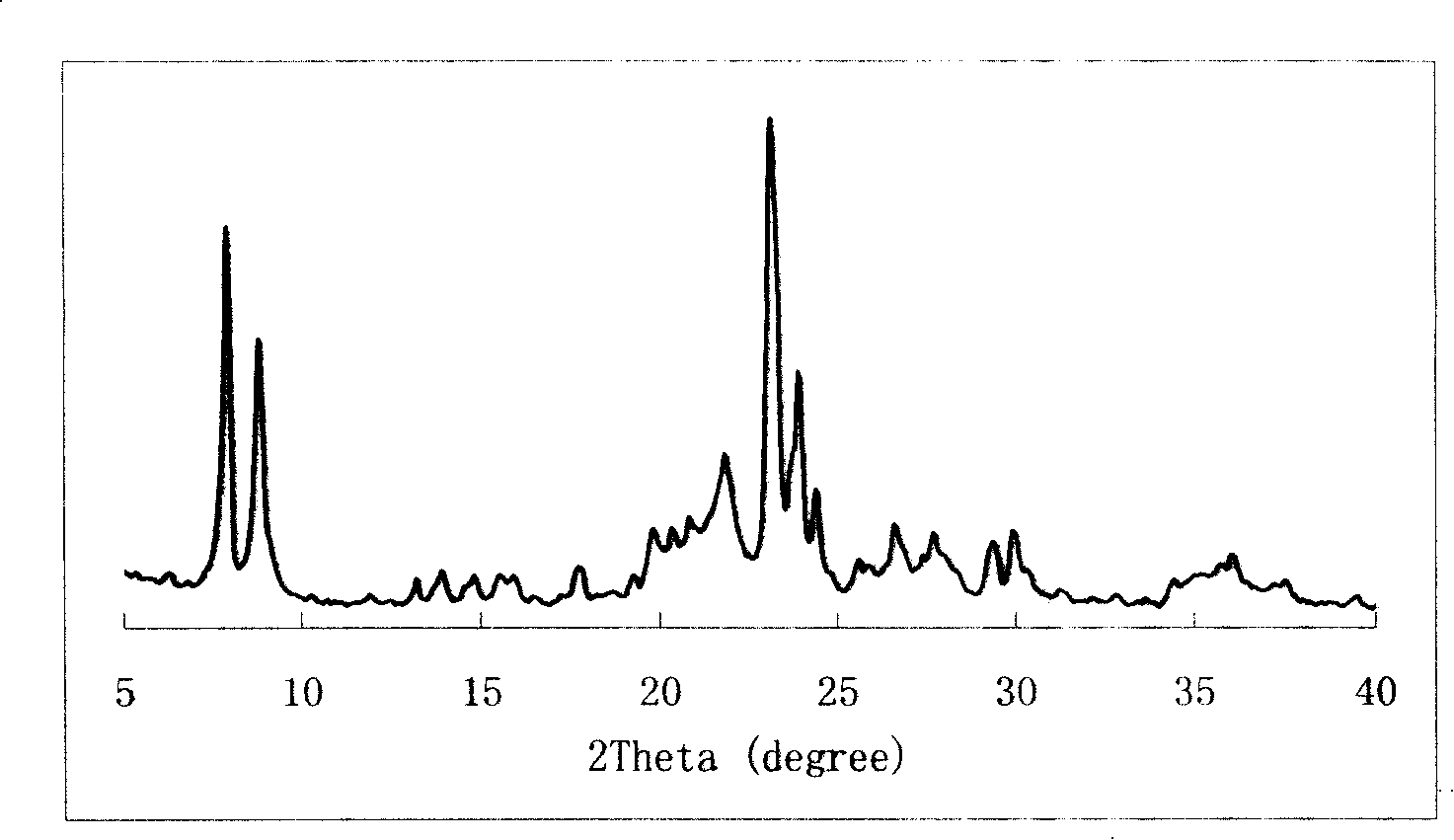

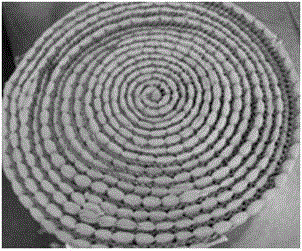

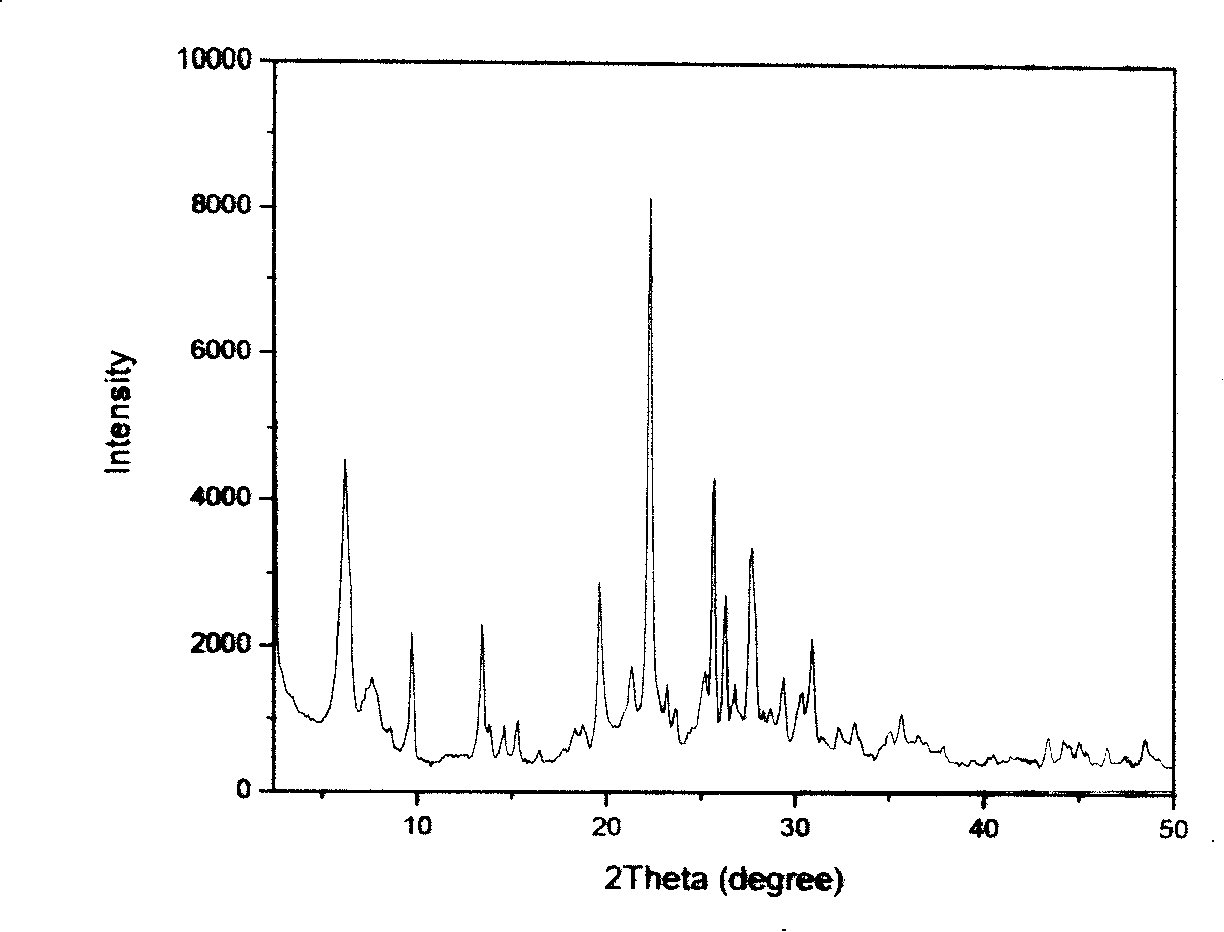

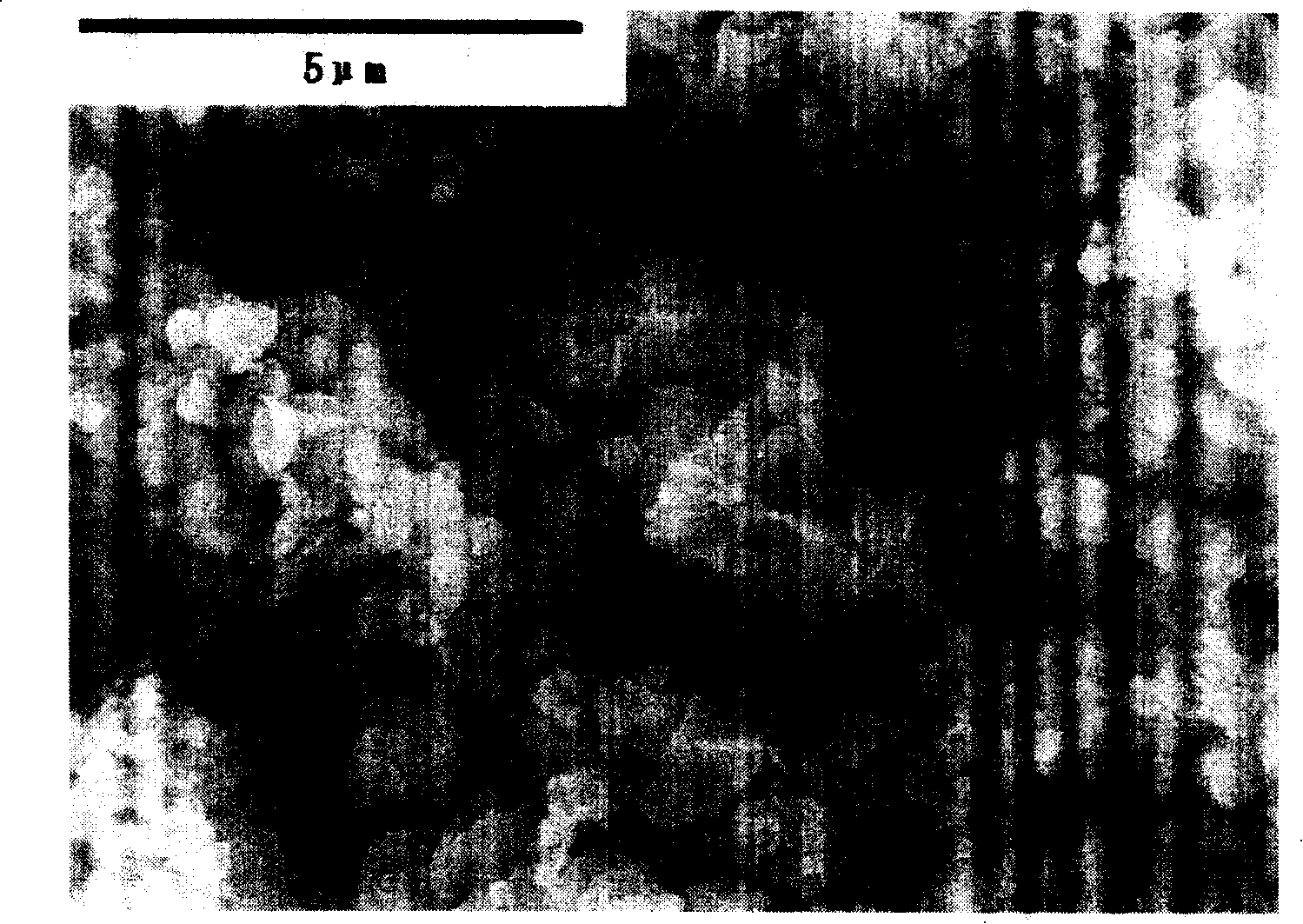

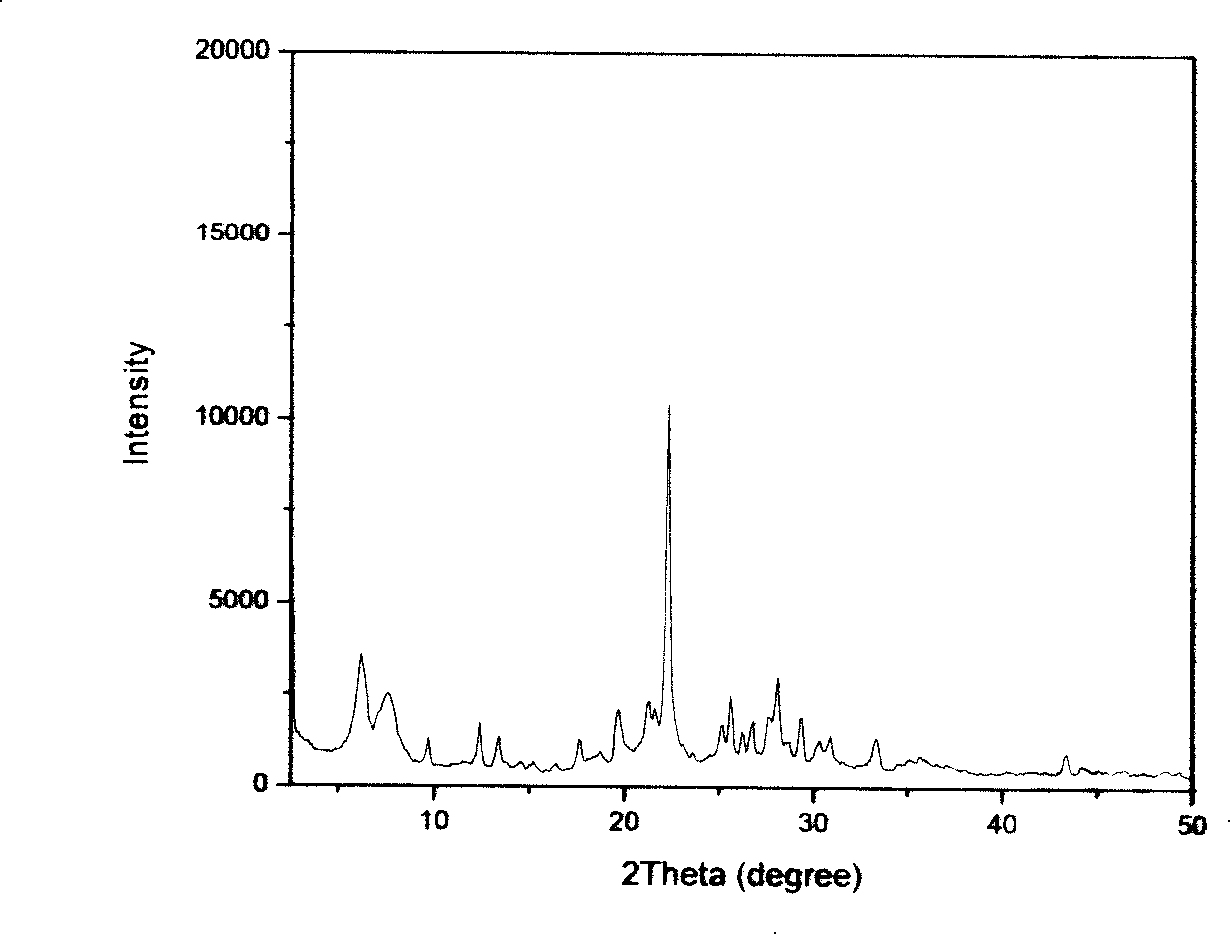

Montmorillonite/ZSM-5 molecular sieve composite material and preparation thereof

ActiveCN101239325ASimple processImprove thermal stabilityMolecular sieve catalystsSorbentHeat stability

The present invention provides a montmorillonite / ZSM-5 molecular sieve composite material and its preparing method. The montmorillonite / beta molecular sieve composite material is prepared by evenly mixing montmorillonite with ZSM-5 molecular sieve gelatin, then processing home position crystallization, and via filtering, washing and drying. The composite material have structure characteristics of the montmorillonite and the molecular sieve at the same time, the montmorillonite and the molecular sieve are alternative. The synthetic montmorillonite / ZSM-5 molecular sieve have characteristics of small crystal grain molecular sieve by controlling the synthetic course and the conditions. The preparing method is simple, the easily separating, the molecular sieve composite material has better water-heat stability. The composite material are mainly used for all kinds of catalysts and absorption agents, especially the preparing of hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

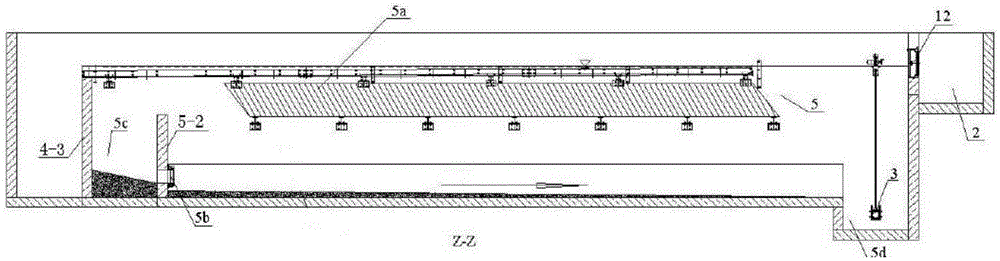

Region sectioning rainwater treatment system based on separate-system pipe network

ActiveCN105625545AAvoid delayRelieve stressFatty/oily/floating substances removal devicesSewerage structuresStormwater pollutionWater treatment system

The invention relates to the field of urban rainwater treatment systems, in particular to a region sectioning rainwater treatment system based on a separate-system pipe network.The region sectioning rainwater treatment system comprises multiple sections divided according to area and a sewage manifold communicated with a sewage treatment plant, a sewage branched pipe, a rainwater branched pipe and at least one rainwater treatment facility are arranged in each section, each rainwater treatment facility is communicated with a discharging end of the corresponding rainwater branched pipe, a discharging end of each rainwater treatment facility is communicated with a natural water body, and a discharging end of each sewage branched pipe is communicated with the sewage manifold.The region sectioning rainwater treatment system is simple in structure, an urban water treatment system is divided into independent sections, and each rainwater treatment facility which is independent is arranged in the corresponding section, so that the delay problem in the process of long-distance delivery of early-stage rainwater in the prior art is solved, treatment pressure of the sewage treatment plant is reduced, the early-stage rainwater is avoided causing pollution to natural water, discharging treatment of rainwater is more reasonable and more efficient, and the region sectioning rainwater treatment system has high popularization value.

Owner:WUHAN SHENGYU DRAINING SYST

Catalyst for preparing aldehyde by two-phase catalytic hydrogen formylation reaction and application thereof

ActiveCN101722048AEliminate emulsificationReduce rhodium loss in organic phaseOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionSolventSurface-active agents

The invention relates to a catalyst which uses alcohol and water as a solvent and contains water soluble phosphine ligands and rhodium compounds and a method for preparing high-carbon aldehyde by a two-phase catalytic hydrogen formylation reaction by using alpha-olefin above C5 as a raw material. The invention overcomes the defects that the reaction rate of a hydrogen formylation reaction of high-carbon alpha-olefin above C5 is low, and the addition of a surface active agent for improving the reaction rate can generate two-phase emulsification and dissolution and cause phase separation difficulty and the increase of rhodium catalyst loss in a traditional two-phase water soluble rhodium-phosphine catalytic process. The invention can improve the reaction rate or avoid the emulsification, thereby reducing the rhodium catalyst loss. The innocuous and environment-friendly mixed solvent of the alcohol and the water is adopted and can be recycled, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

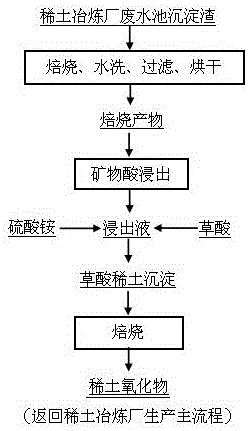

Method for extracting rare earth from precipitation sludge of rare earth wastewater pool

ActiveCN106636689ASimple processEasy to operateProcess efficiency improvementSolid phasesAmmonium sulfate

The invention discloses a method for recovering rare earth from precipitation sludge of a rare earth wastewater pool, comprising the main steps: firstly, preroasting the precipitation sludge of the rare earth wastewater pool, then leaching the roasted product with mineral acid to obtain a leach solution containing rare earth, and sequentially adding ammonium sulfate and oxalic acid to the leach solution so the rare earth is separated from soluble impurities in a manner of solid phase precipitation. The method has a simple process, convenient operation and low cost, solves the problem of difficult complete separation in a condition of coexistence of rare earth and calcium in a solution, can efficiently recover the rare earth in the precipitation sludge of the rare earth wastewater pool, and realizes separation of rare earth from calcium, aluminum and iron; the recovery rate of rare earth reaches above 99%; and the recovered rare earth oxide can be returned to a production main flow of a rare earth smeltery.

Owner:JIANGXI UNIV OF SCI & TECH

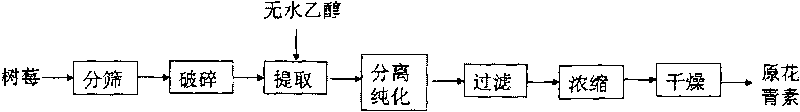

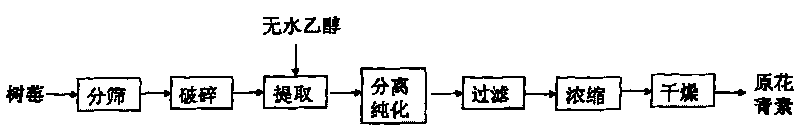

Method for extracting proanthocyanidins from raspberry

InactiveCN101712673AHigh dissolution rateSolve inseparableOrganic chemistryBiotechnologyChemical synthesis

The invention relates to a method for extracting proanthocyanidins from a raspberry, which is characterized in that the method adopts ethanol as an extracting agent; and the extracting process comprises the following steps: controlling the four conditions of ethanol concentration, extraction temperature, material-to-liquid ratio and extraction time under normal pressure, and then filtering, refining, purifying, concentrating and drying the extracted solution to obtain a finished product, wherein the refining and the purifying adopt a macroporous adsorption resin. The method has the following advantages that: the content of the proanthocyanidins in the raspberry is high, and the efficiency of adopting an extracting method is high, so the dissolution rate of the proanthocyanidins can be obviously improved, the primary structure and activity are kept, more byproducts in a chemical synthesis method are avoided, and particularly the problem that the isomer of the product is difficult to separate to cause low purity of the product is solved; therefore, the method has broad application in the fields of food, medicine and the like. The method has low cost and high extracting efficiency, and can obviously improve the dissolution rate of the proanthocyanidins and keep the primary structure and activity; and the process is simple, efficient and quick, and has little waste liquid emission.

Owner:XINJIANG ACADEMY OF FORESTRY SCI +1

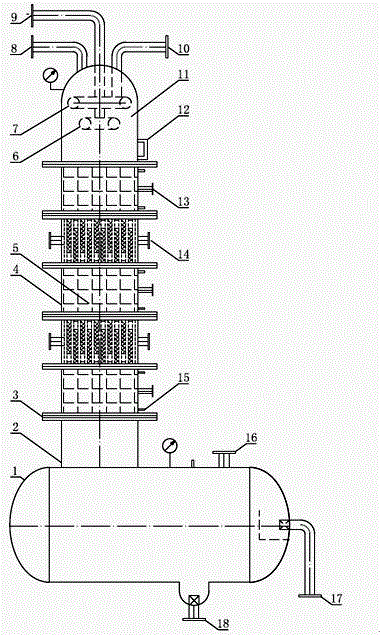

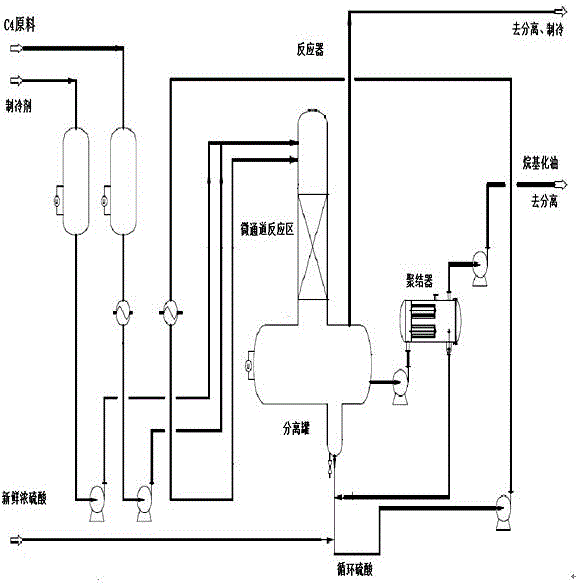

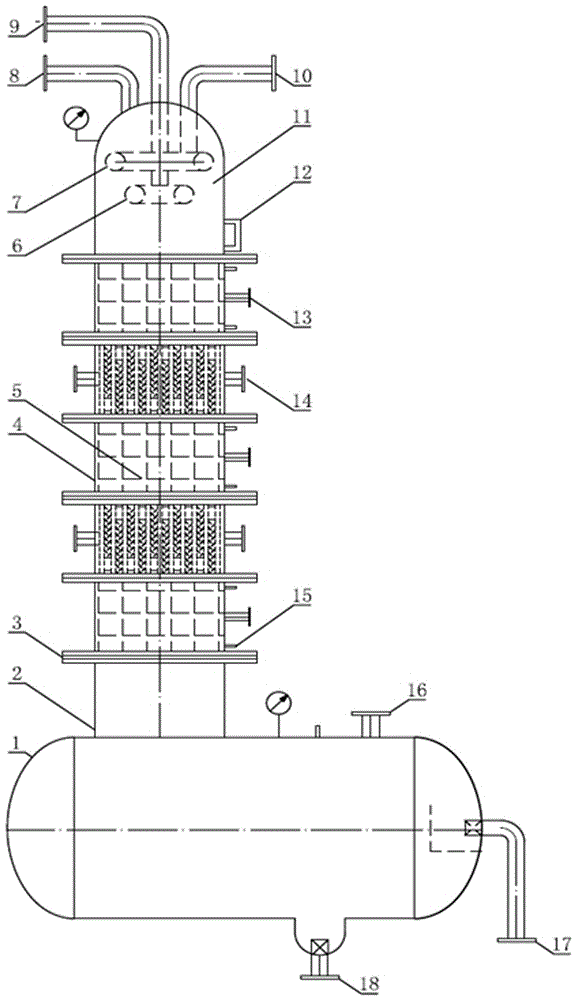

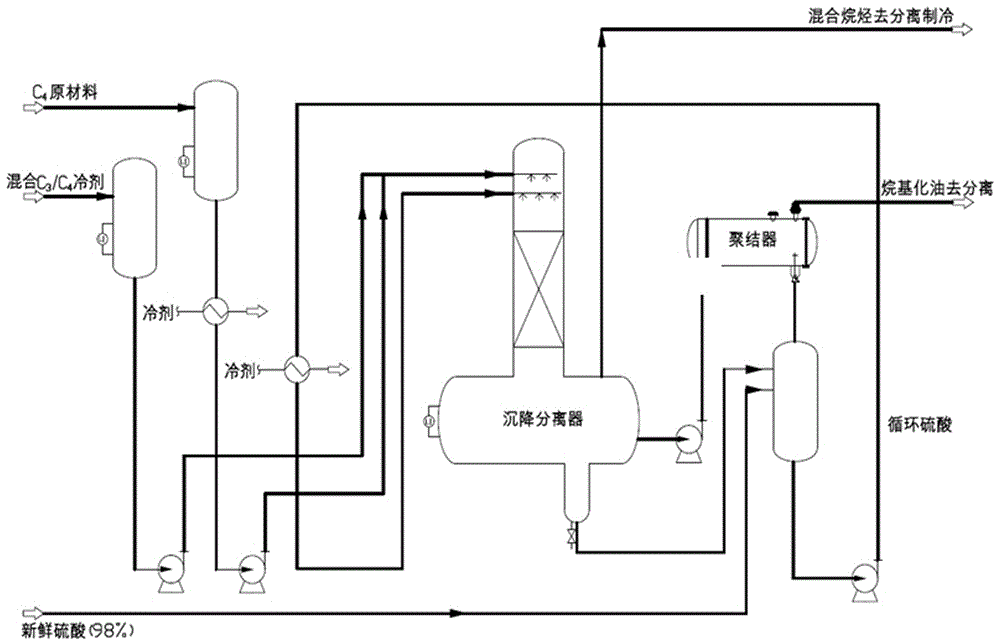

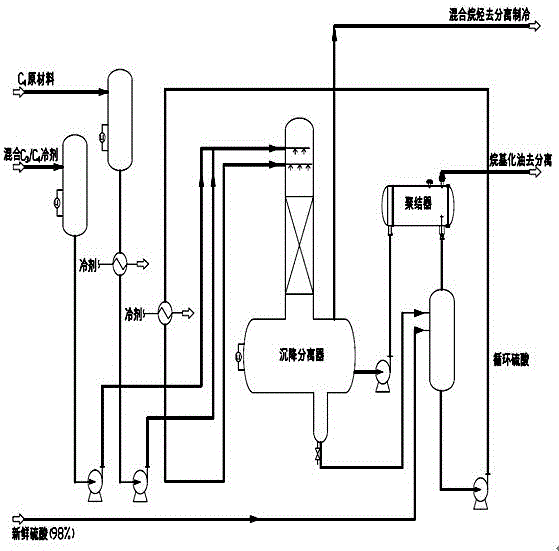

Alkylation method and apparatus using novel microchannel reactor

ActiveCN107519828AWell mixedImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsLiquid carbonaceous fuelsAlkyl transferReaction temperature

The invention discloses an alkylation method adopting a novel microchannel reactor. A reactor used in the invention is designed to be the microchannel reactor; a microchannel reaction zone is composed of a tubular microchannel reaction zone and a planar microchannel reaction zone, wherein the tubular microchannel reaction zone is composed of an inorganic or organic polymeric material having a fiber-grade dense porous structure and the planar microchannel reaction zone is composed of flaps liable to heat transfer. The alkylation method in the invention uses isobutane and C3-C5 olefins as raw materials and further utilizes a considerable amount of propane as a cooling agent and an entrainer to realize vaporization for heat extraction, so low reaction temperature is ensured; and a knockout drum with a hydrocyclone separation function is arranged on the bottom of the reactor for separation of products. The alkylation method and apparatus provided by the invention have the characteristics that alkylation can be carried out at a low temperature; no pre-mixing is needed for reaction raw materials; bed pressure drop is small; good energy-saving effect is obtained; high product quality is ensured and the like. The alkylation method and apparatus can realize high-efficiency energy-saving safe low-carbon environment-friendly continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

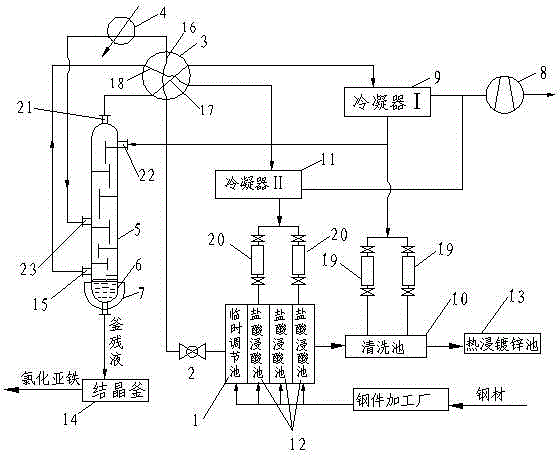

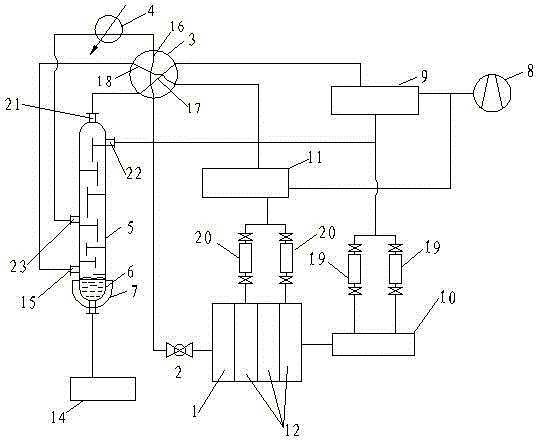

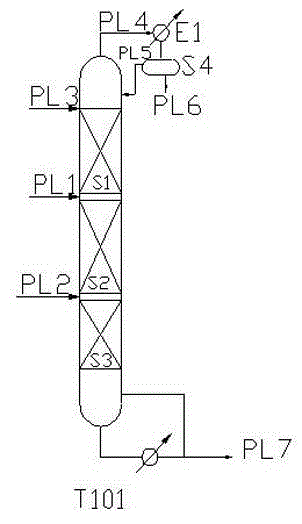

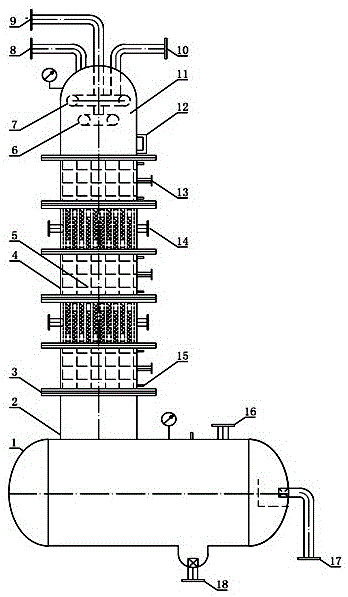

Recycling treatment process for chlorohydric acid pickling liquid waste

InactiveCN103553256ASolve inseparableVolatileChlorine/hydrogen-chlorideWaste water treatment from metallurgical processLiquid wasteChloride

The invention discloses a recycling treatment process for chlorohydric acid pickling liquid waste. The process comprises the following steps: adjusting the acidity of CaCO3 of the chlorohydric acid pickling liquid waste to 99.65-124.56g / L; adding ferrous chloride so as to enable ferrite to be in a saturation condition; heating to the bubble point, then feeding the mixture into a rectifying tower and separating, wherein the pressure in the rectifying tower is 61.05-67.50Kpa; recovering a 10-15% diluted hydrochloric acid liquid and ferrous chloride crystals. Through reasonable parameter control and decompressing and rectifying processes, hydrochloric acid liquor applicable to acid pickling steel pieces as well as a coagulant capable of being used for sewage and wastewater treatment or a chemical raw material ferrous chloride can be recovered just by means of materials generated in the steel piece acid pickling process without spending other raw materials, so that the cost is greatly saved. The process is process-investment-saving, low in energy consumption and easy for mastering of operation, and can be continuously operated or intermittently operated in batches, thereby realizing automatically controlled operation.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

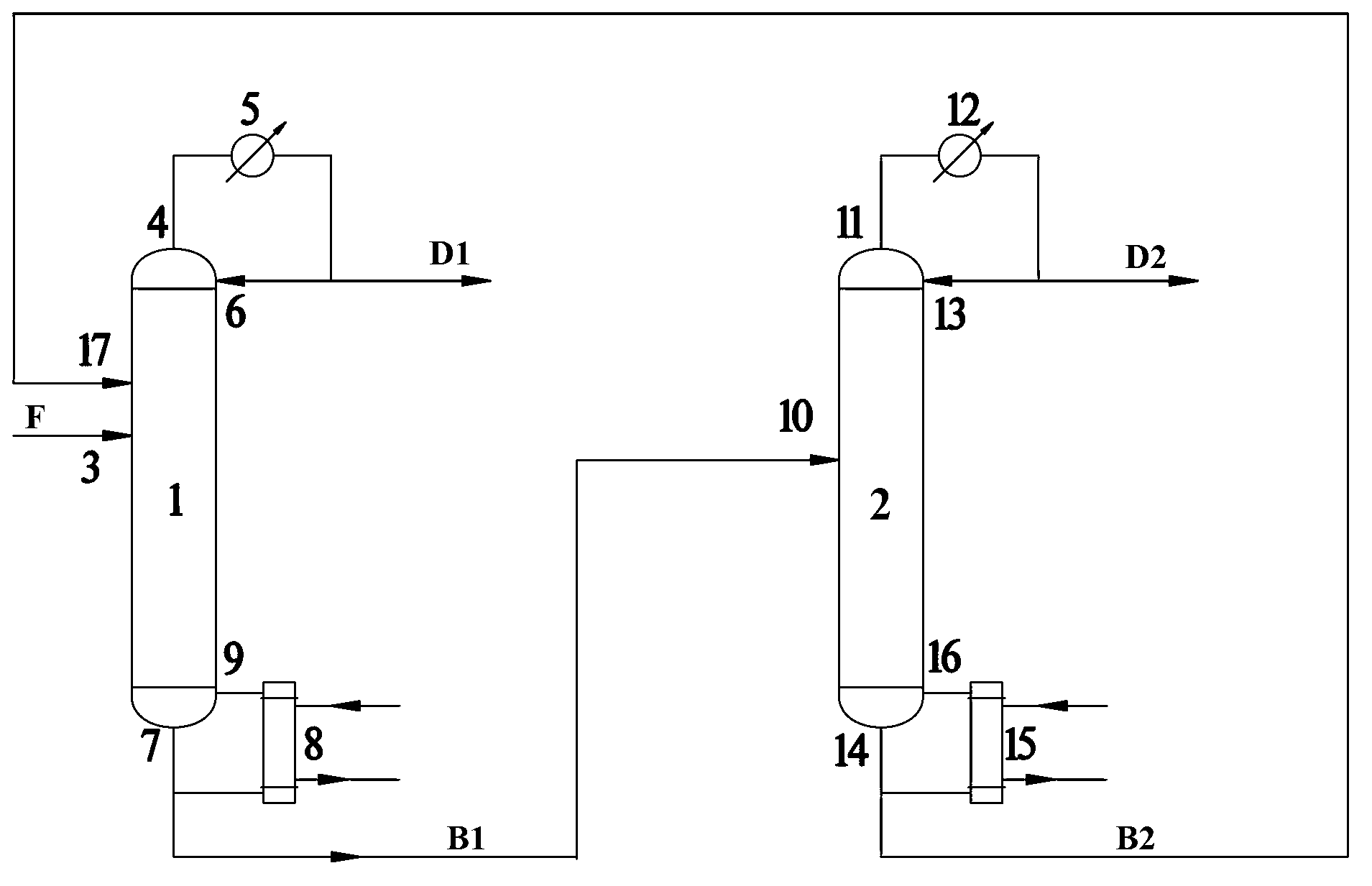

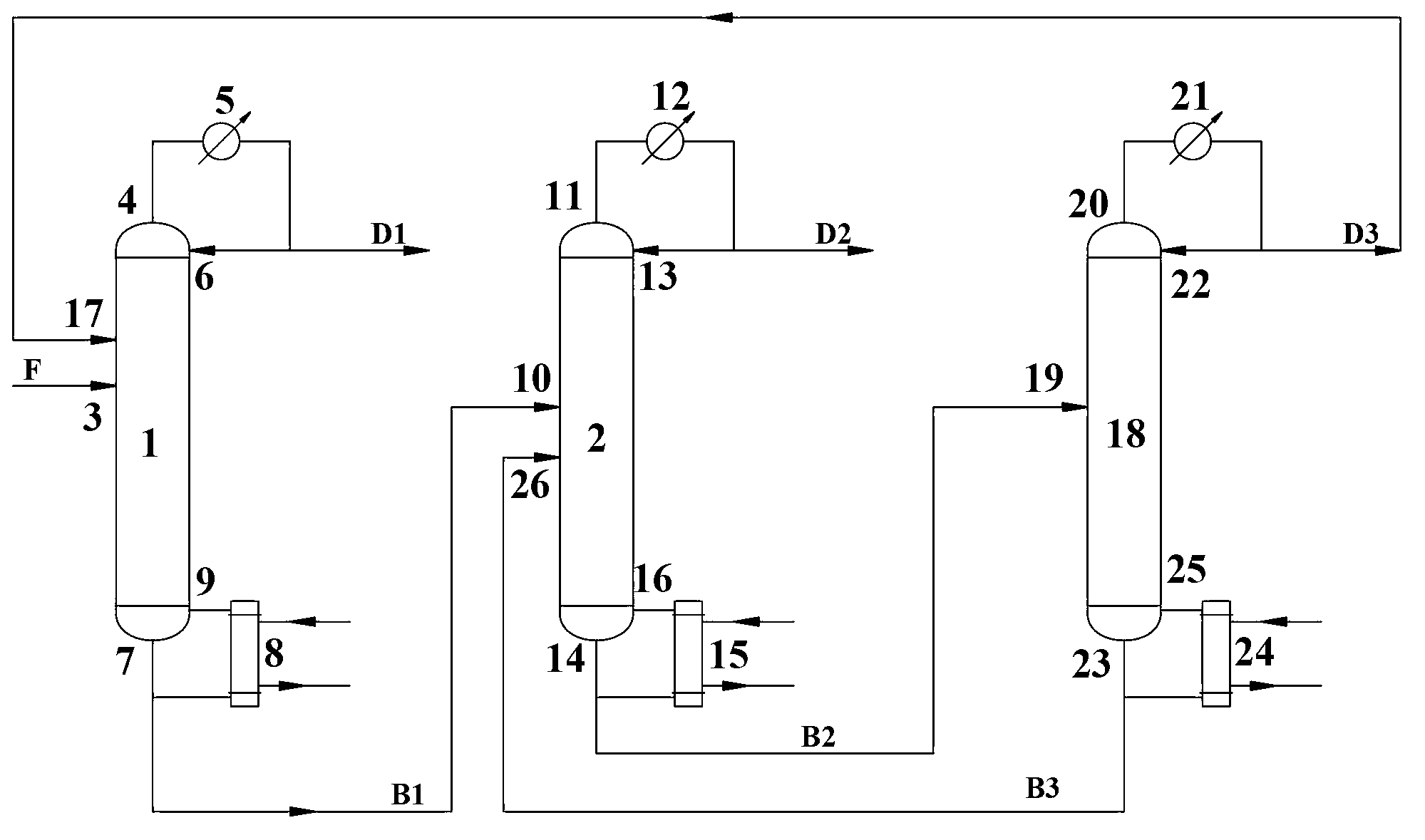

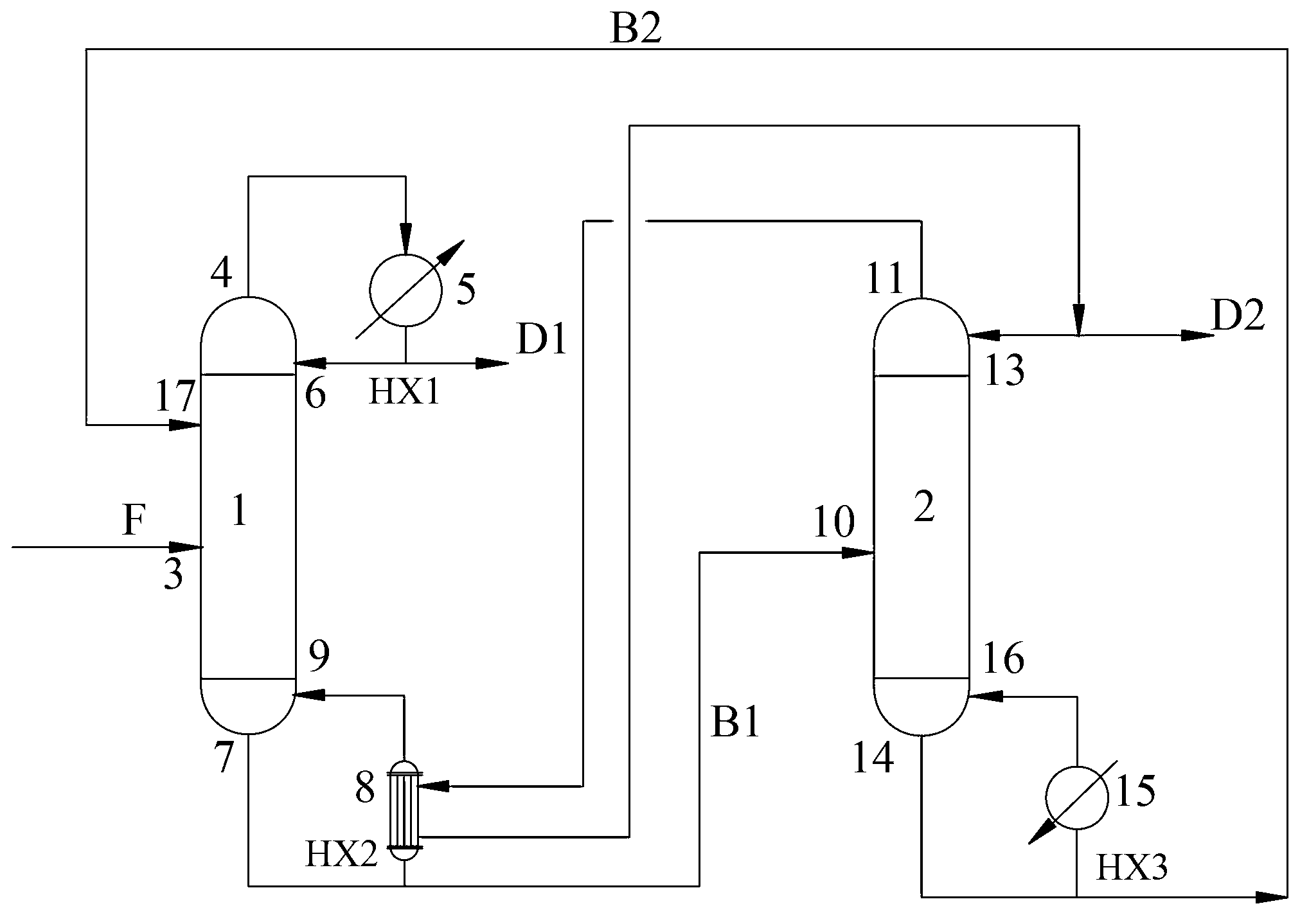

Solvent reinforced transformation thermal coupling rectification system for separating cyclohexanone and phenol

ActiveCN103055530AImprove protectionRealize continuous rectification separation operationOrganic compound preparationDistillation regulation/controlCyclohexanoneReflux

The invention discloses a solvent reinforced transformation thermal coupling rectification system for separating cyclohexanone and phenol, wherein a feed port of a first low pressure rectification tower is connected with a cyclohexanone and phenol mixed solution raw material, one low pressure steam outlet of the first low pressure rectification tower is connected with a liquid phase reflux inlet and the other low pressure steam outlet is a cyclohexanone outlet after the low pressure steam outlets pass through a condenser of the low pressure rectification tower, a low pressure tower kettle outlet of the first low pressure rectification tower is connected with a first feed port of a high pressure rectification tower and an inlet of a reboiler of the first low pressure rectification tower respectively, an outlet of the reboiler of the first low pressure rectification tower is connected with a steam inlet of the first low pressure rectification tower, one high pressure steam outlet of the high pressure rectification tower is connected with a liquid phase reflux inlet of the high pressure rectification tower and the other high pressure steam outlet is a phenol outlet after the high pressure steam outlets pass through a condensation mechanism, a high pressure tower kettle outlet of the high pressure rectification tower is connected with a solvent circulation feed port and an inlet of a reboiler of the high pressure rectification tower respectively, and an outlet of the reboiler of the high pressure rectification tower is connected with a steam inlet of the high pressure rectification tower. According to the thermal coupling rectification system, the overall energy saving efficiency is up to 30-50%.

Owner:TIANJIN UNIV

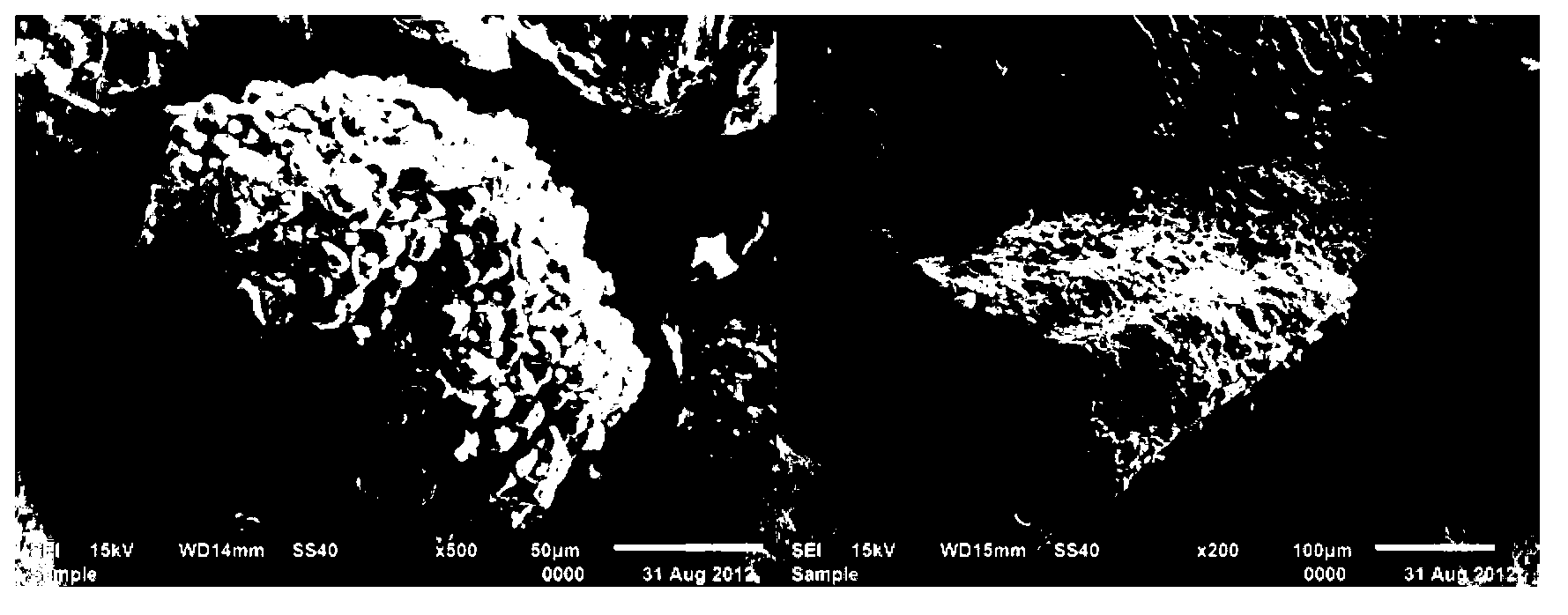

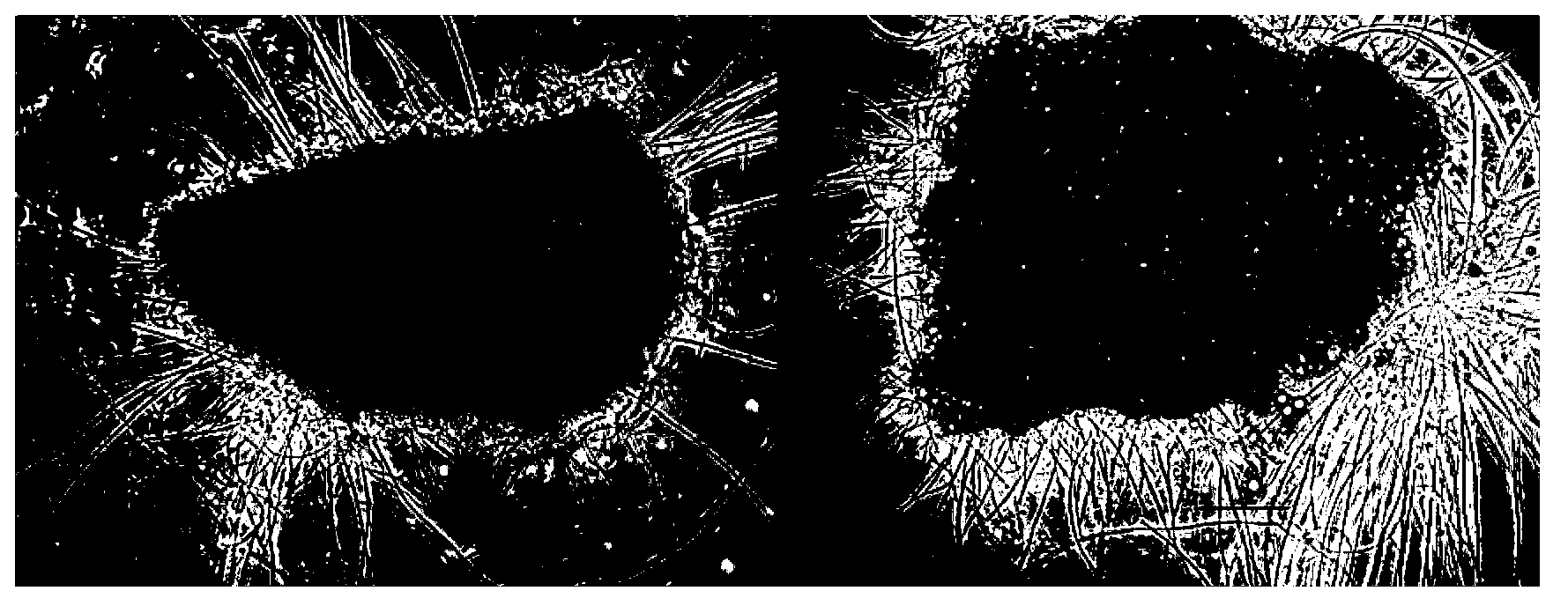

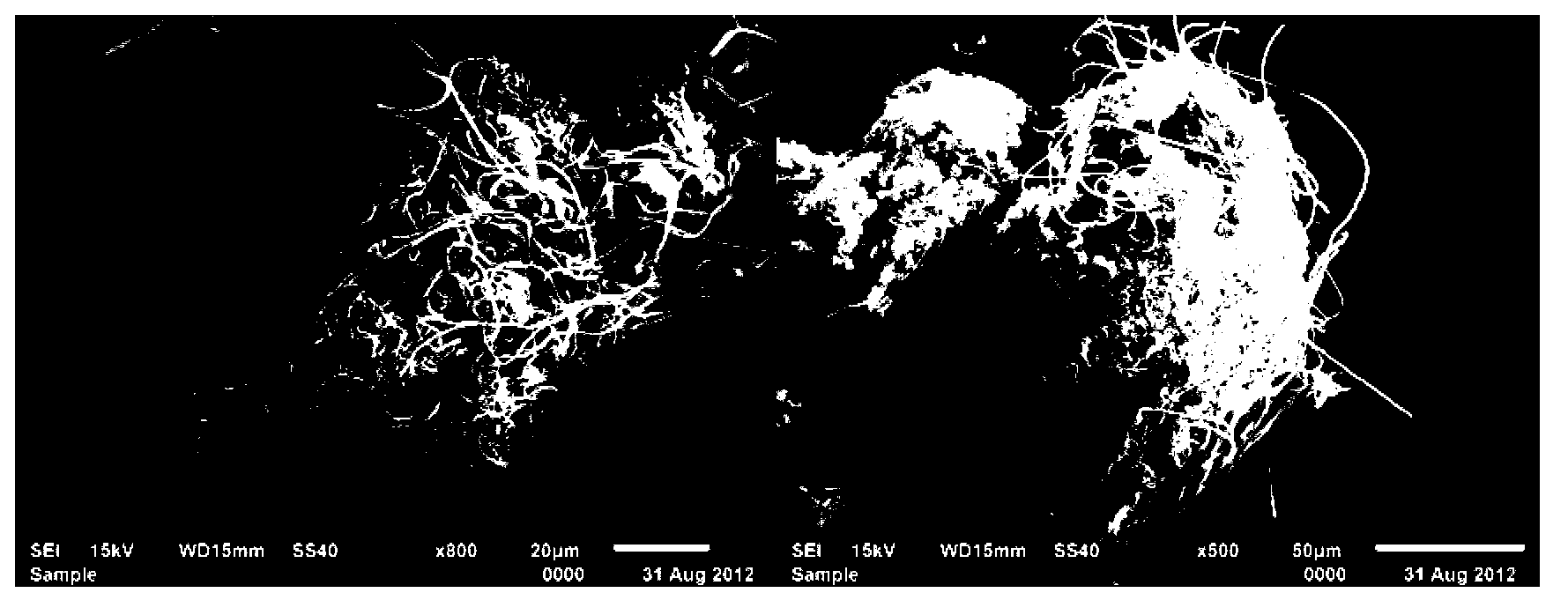

Method for improving precipitation performance of filamentous bulking sludge

InactiveCN103011392AImprove precipitation effectIncrease concentrationSustainable biological treatmentBiological water/sewage treatmentMixed liquor suspended solidsGram

The invention discloses a method for improving precipitation performance of filamentous bulking sludge. The method comprises the steps of 1), crushing and screening organics, such as corn, wheat, sorghum and rice; 2), measuring the concentration of activated sludge in a biological reaction tank such as an aeration tank and a precipitation tank, and quantifying filamentous bacteria for the bulking sludge; 3), putting into the filamentous bulking sludge according to the weight ratio for preparing the screened organics per gram of the sludge or the weight ratio for preparing the organics per meter of the length of each filamentous bacterium; 4), keeping other conditions in the biological reaction tank unchanged, and increasing stirring; and 5), measuring the MLSS (mixed liquor suspended solid) value and the SVI (sludge volume index) value in the biological reaction tank, so that the improvement of the precipitation performance of the filamentous bulking sludge is achieved. The method can enable the filamentous bacteria causing sludge bulking to grow in adhering and twining manners and change a spreading growing manner of the filamentous bacteria, so that the filamentous bacteria grow densely, the problem that solids and liquid are hard to separate is solved, and the effluent quality of sewage treatment is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Solid super acid for catalytically synthesizing PMA (2-acetoxy-1-methoxypropane), and catalytic rectification technique and apparatus thereof

ActiveCN104549372ASolve inseparableEasy to usePhysical/chemical process catalystsOrganic compound preparationPropanediolEsterification reaction

The invention discloses a solid super acid for catalytically synthesizing PMA (2-acetoxy-1-methoxypropane), and a catalytic rectification technique and apparatus thereof. The solid super acid is prepared by the following steps: reacting TiO2 powder with a H2SO4 solution to prepare solid super acid TiO2 / SO4<2-> powder, kneading with an adhesive, an enhancer, a pore forming agent, a lubricant and deionized water to obtain a formed precursor, carrying out extrusion forming, drying and roasting. The obtained solid super acid has the advantages of stable catalytic activity, low shedding loss tendency of the active component, and favorable repetitiveness, and can be easily separated from the reaction product. Propylene glycol monomethyl ether and acetic acid used as raw materials can be subjected to esterification reaction in a catalytic rectification tower under the catalytic action of the solid super acid to obtain the PMA. The method can implement the continuous catalytic rectification process, avoids the problems of recovery, equipment corrosion and the like in the liquid acid catalyst, and has the characteristics of low energy consumption, high reaction conversion rate, stable product quality and the like.

Owner:FUZHOU UNIVERSITY

Montmorillonite/beta molecular sieve composite material and preparation thereof

ActiveCN101239321ASimple processEasy to prepareMolecular sieve catalystsMolecular sieveGelatin product

The present invention provides a montmorillonite / beta molecular sieve composite material and its preparing method. The montmorillonite / beta molecular sieve composite material is prepared by evenly mixing montmorillonite with beta molecular sieve gelatin, then processing home position crystallization, and via filtering, washing and drying. The composite material have structure characteristics of the montmorillonite and the molecular sieve at the same time, the montmorillonite and the molecular sieve are alternative. The synthetic montmorillonite / beta molecular sieve have characteristics of small crystal grain molecular sieve by controlling the synthetic course and the conditions. The preparing method is simple, the easily separating, the molecular sieve composite material has better water-heat stability. The composite material are mainly used for all kinds of catalysts and absorption agents, especially the preparing of hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

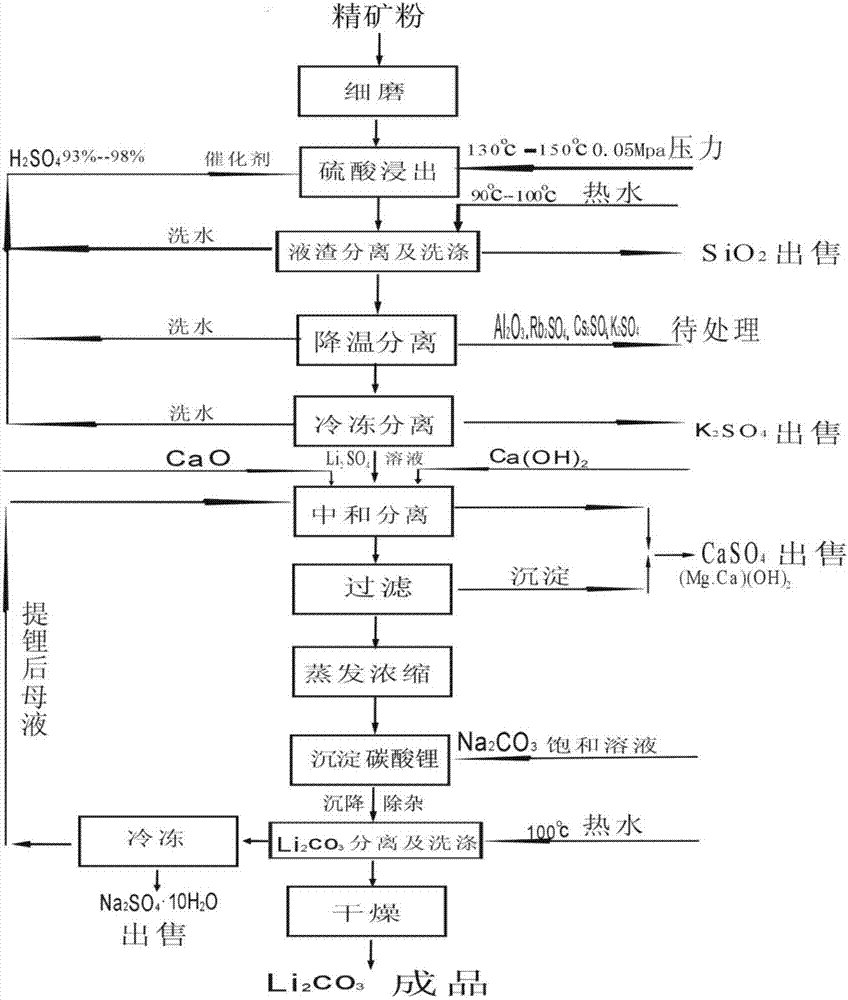

Preparation technology for extracting lithium element from lithium ore by virtue of sulfuric acid direct dipping process

ActiveCN107344725AAvoid energy consumptionAvoid environmental problemsSilicaAlkali metal sulfites/sulfatesHigh energyLithium carbonate

The invention discloses a preparation technology for extracting a lithium element from a lithium ore by virtue of a sulfuric acid direct dipping process. The preparation technology comprises the following steps: 1) grinding the lithium ore into particles; 2) carrying out sulfuric acid leaching, namely putting the particular lithium ore obtained in the step 1), sulfuric acid and water into a reaction kettle in proportion, adding sodium fluoride as a catalyst, reacting for 6-8 hours, and cooling, so that a leached material is obtained; 3) sequentially separating other elements in the leached material, and reserving filtrate; and 4) separating lithium from the filtrate obtained in the step 3) and preparing lithium carbonate. The preparation technology disclosed by the invention has the advantages that the problems of high energy consumption and poorer environmental friendliness of an existing roasting method are solved and the preparation technology can be applicable to different types of lithium ores.

Owner:成都茂岩矿业有限责任公司

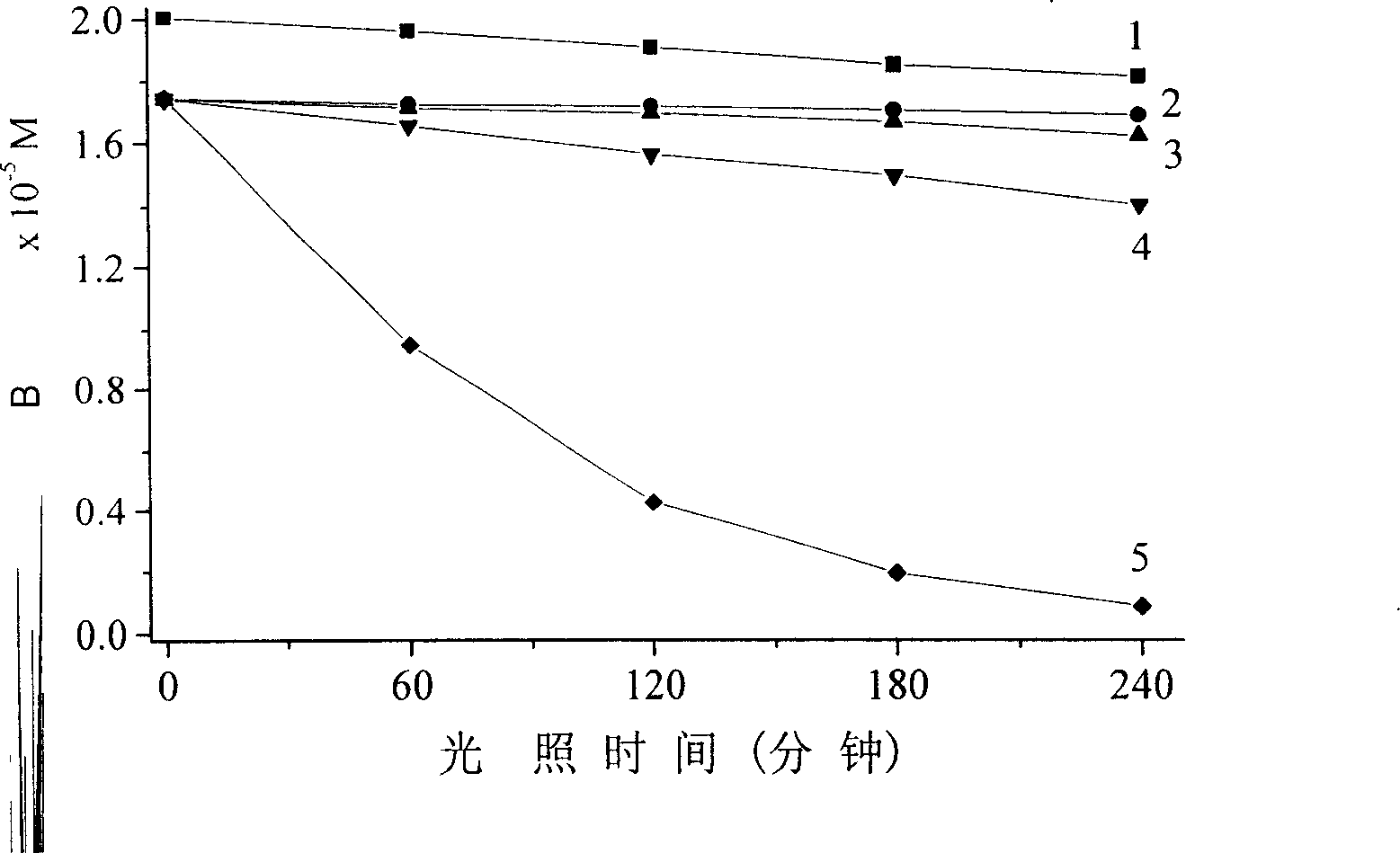

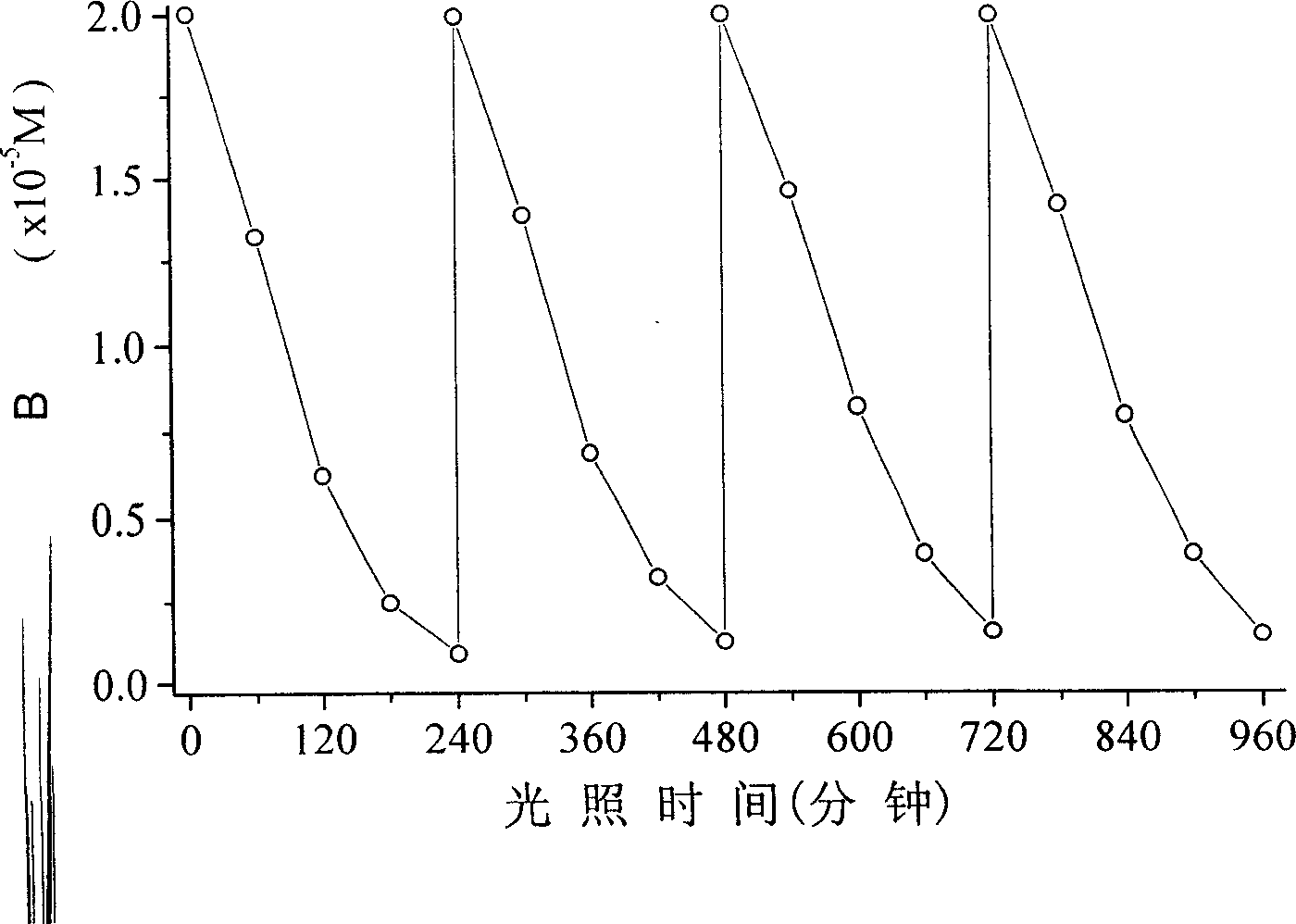

Solid-phase photocatalyst utilizing visible light and its preparing method

InactiveCN1814348ASolve inseparableAvoid secondary pollutionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsIndustrial waste waterOrganic dye

This invention belongs to solid phase catalyst field, especially relates to solid phase catalyst consisted by carrier and yang collaterals transition metal compound with photocatalysis activity. The catalyst is consisted by negative ion exchange resin and yang collaterals transition metal compound, they linkage with each other and there quality ratio is 1:0.01-1.5. The compound is isopoly acid, heteropoly acid or tertiary heteropoly acid, and they all have light activity. The catalyst can use visible light activate H2O2 to clear and process the organic fuel pollutant in dye printing industrial waste water.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Magnetic sludge carbon biological filler with core-at-shell structure and preparation method and application thereof

InactiveCN104961228ASolve inseparableSolving Corrosion ProblemsSustainable biological treatmentBiological water/sewage treatmentMicroorganismMicrosphere

The invention discloses magnetic sludge carbon biological filler with a core-at-shell structure and preparation method and application thereof. The magnetic sludge carbon biological filler is prepared by using Fe3O4 magnetic microsphere as a magnetic core, iron-containing sludge as an intermediate layer raw material and common sludge or zinc-containing sludge (preferred) as a shell raw material, adopting a repetitive impregnation-drying method to sequentially wrap the intermediate layer raw material and the shell raw material on the Fe3O4 magnetic microsphere to form a precursor of the core-at-shell structure, and then performing pyrolysis and after-treatment. Since the magnetic material is used as the core and the sludge carbon is used as the shell material, the prepared magnetic sludge carbon biological filler with the core-at-shell structure not only can solve the problem that a powder magnetic material is difficult to separate, and can also solve the problem that ferrite used as a magnetic matrix is corroded by microorganisms; the specific surface of the porous sludge carbon in a shell layer is large, a magnetic environment for growth can be provided for more microorganisms, the metabolic efficiency of the microorganisms is improved and the tail water treatment efficiency of domestic sewage plants is greatly improved.

Owner:SUN YAT SEN UNIV

Environment-friendly method for metronidazole synthesis

The invention discloses an environment-friendly method for metronidazole synthesis. Formic acid is replaced with acetic acid, alcohol is added for esterification, neutralization is performed for three times, sodium sulfate and ethylene glycol are recovered, a nitration product is effectively recovered from a metronidazole mother solution, derivatives such as acetic ester, anhydrous sodium sulfate and the like are obtained, by-products such as ethylene glycol and the like are chemical raw materials with wide applications, resources are recycled, the raw materials are greatly saved, the production cost is reduced, and the whole novel process adopts simple steps and is convenient to operate.

Owner:WUHAN WUYAO PHARMA

Process for selectively extracting valuable metals in waste power lithium battery and repreparing ternary positive electrode material

InactiveCN110615486ANothing producedEasy to operatePositive electrodesWaste accumulators reclaimingResource utilizationManganese

The invention discloses a process for selectively extracting valuable metals in a waste power lithium battery and repreparing a ternary positive electrode material. The method comprises the followingsteps: (1) carrying out complete discharge, disassembly, ultrasonic stripping, calcination and grinding treatment on a recycled waste lithium battery to obtain a required LiNi1 / 3Mn1 / 3CoO2 positive electrode material; (2) leaching the LiNi1 / 3Mn1 / 3CoO2 positive electrode material through a wet metallurgy method by using mild acid and reducing agent, wherein the ratio of the positive electrode material to the added acid is controlled to be 20-60 mL / g, so as to obtain a leaching solution rich in lithium and a precipitate containing nickel-cobalt-manganese; (3) leaching the precipitate again by using a trace amount of acid and reducing agent, wherein the ratio of the precipitate to the added acid is controlled to be 20-60mL / g to obtain a metal-rich salt solution; and (4) carrying out coprecipitation on the metal salt solution to obtain a ternary precursor, adding excessive 3-10% of a lithium source according to the amount of substance of the precursor, and calcining the material at a selected temperature to obtain the ternary positive electrode material with good electrochemical performance. According to the method, metal resource utilization can be achieved, the problem of harmful garbage pollution is solved, and the cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

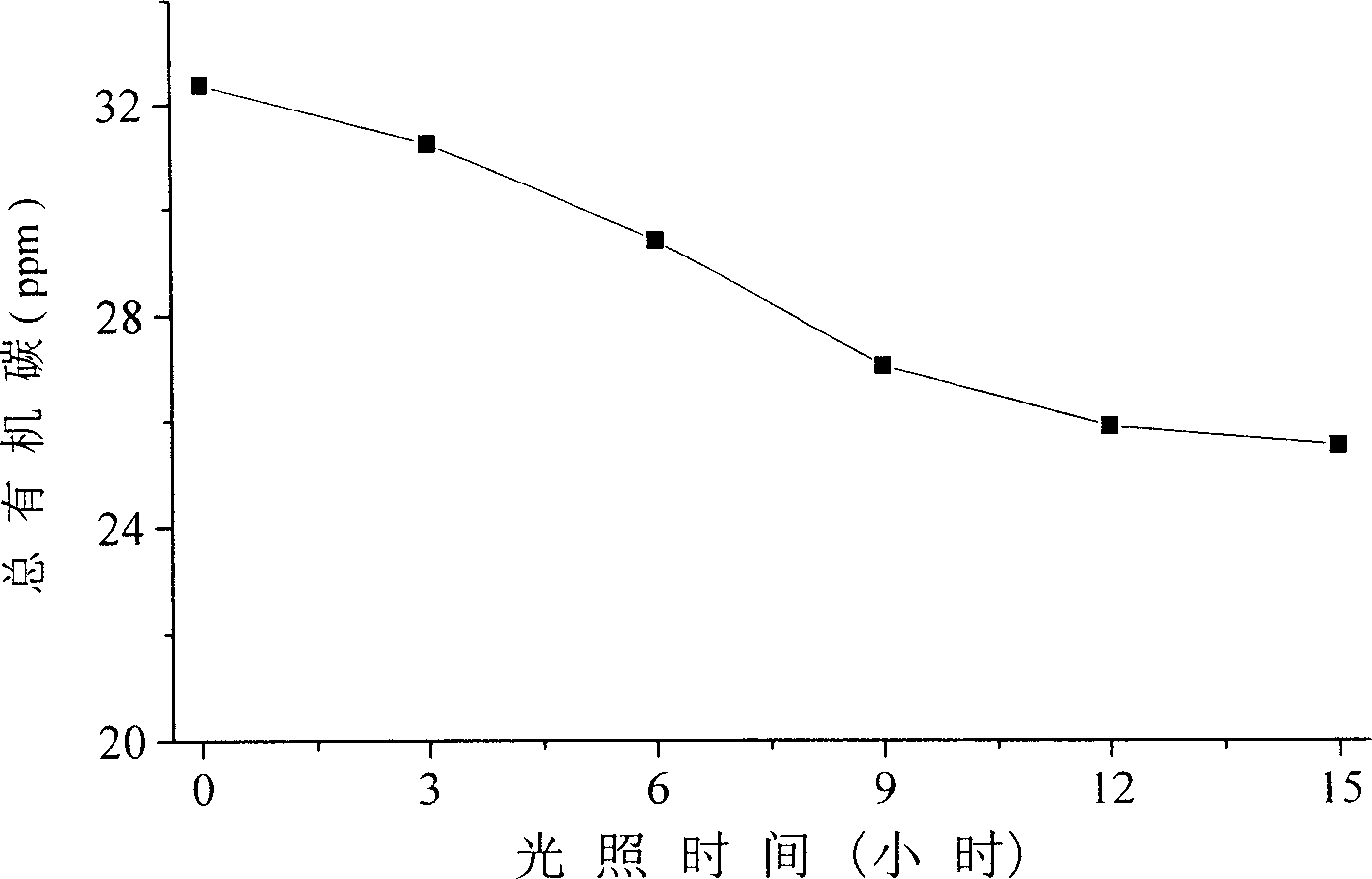

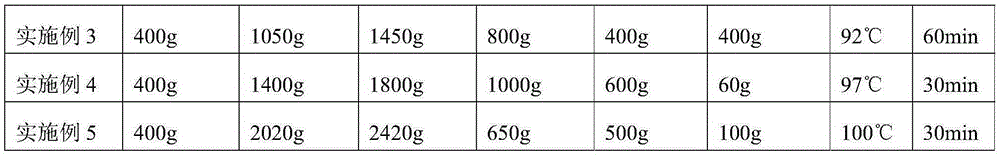

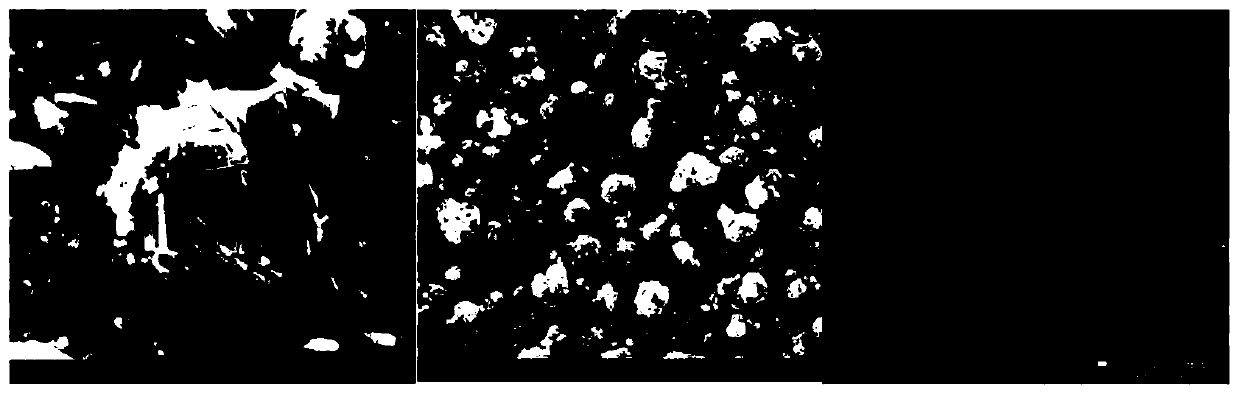

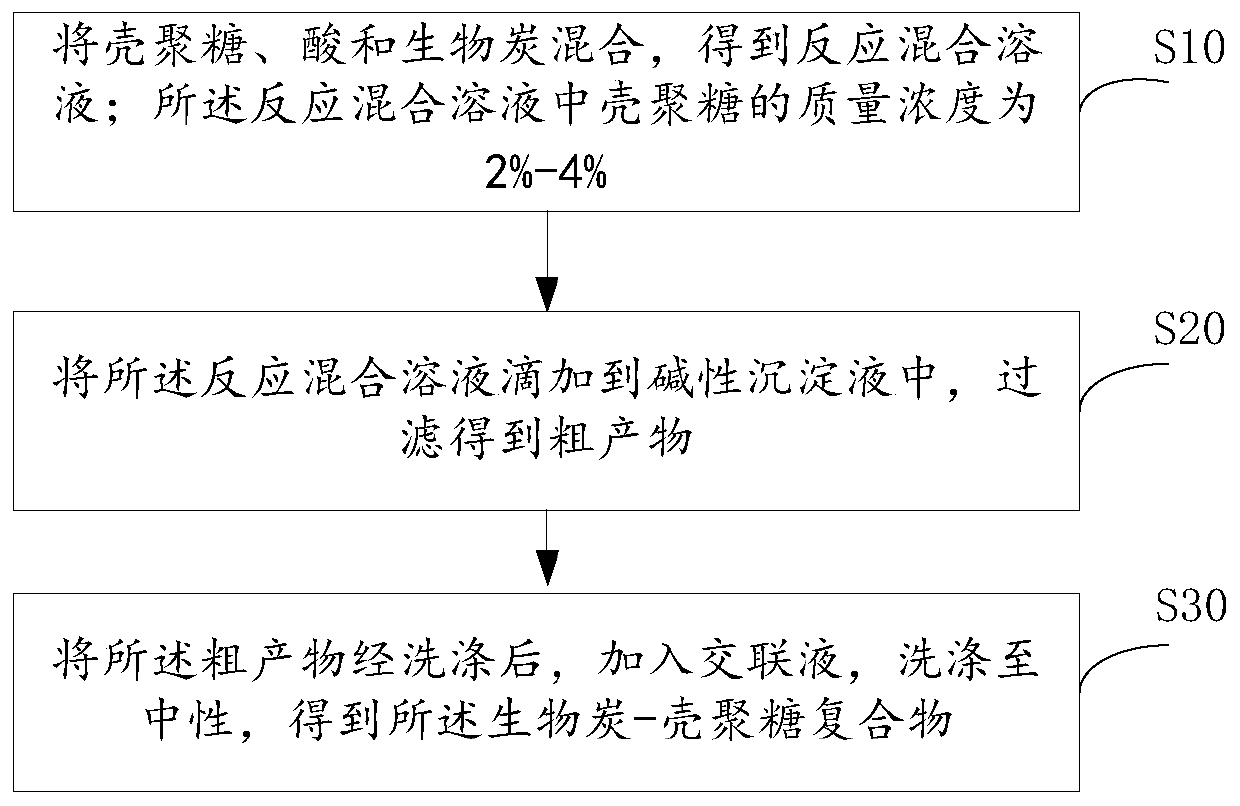

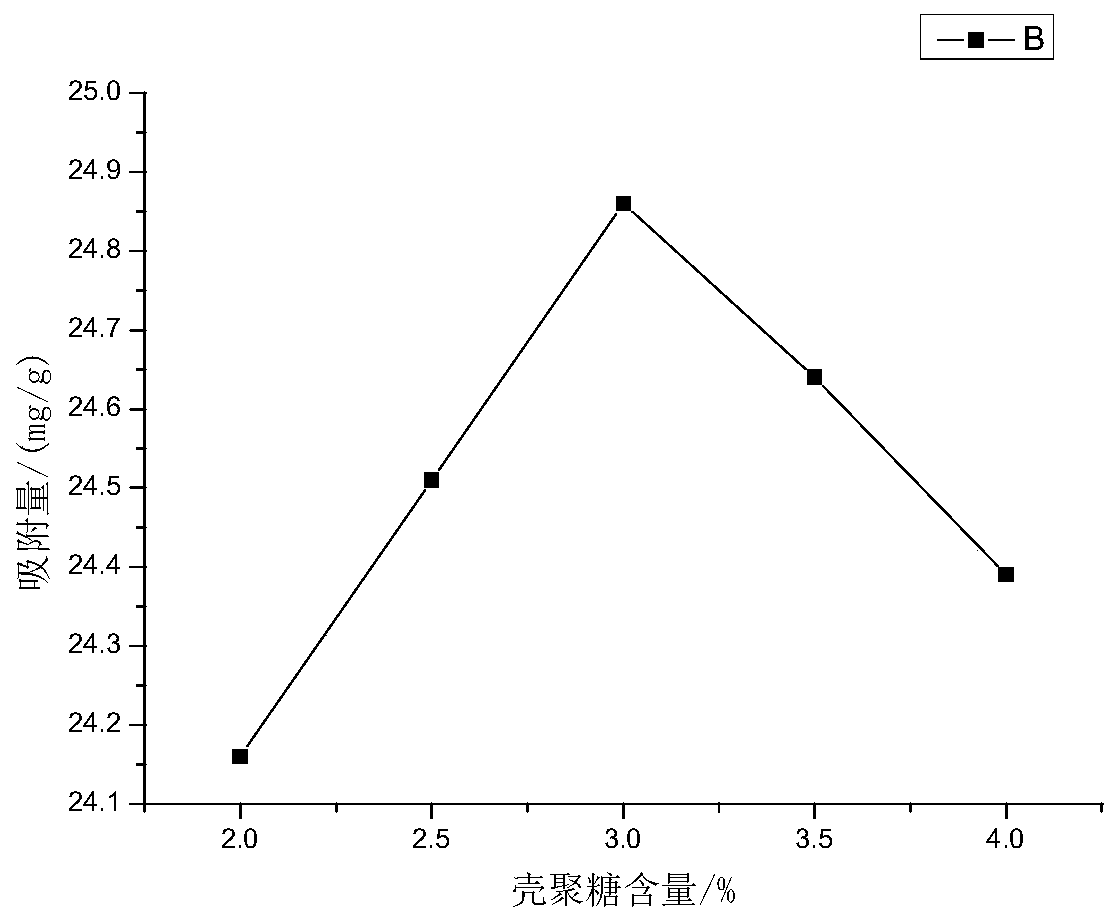

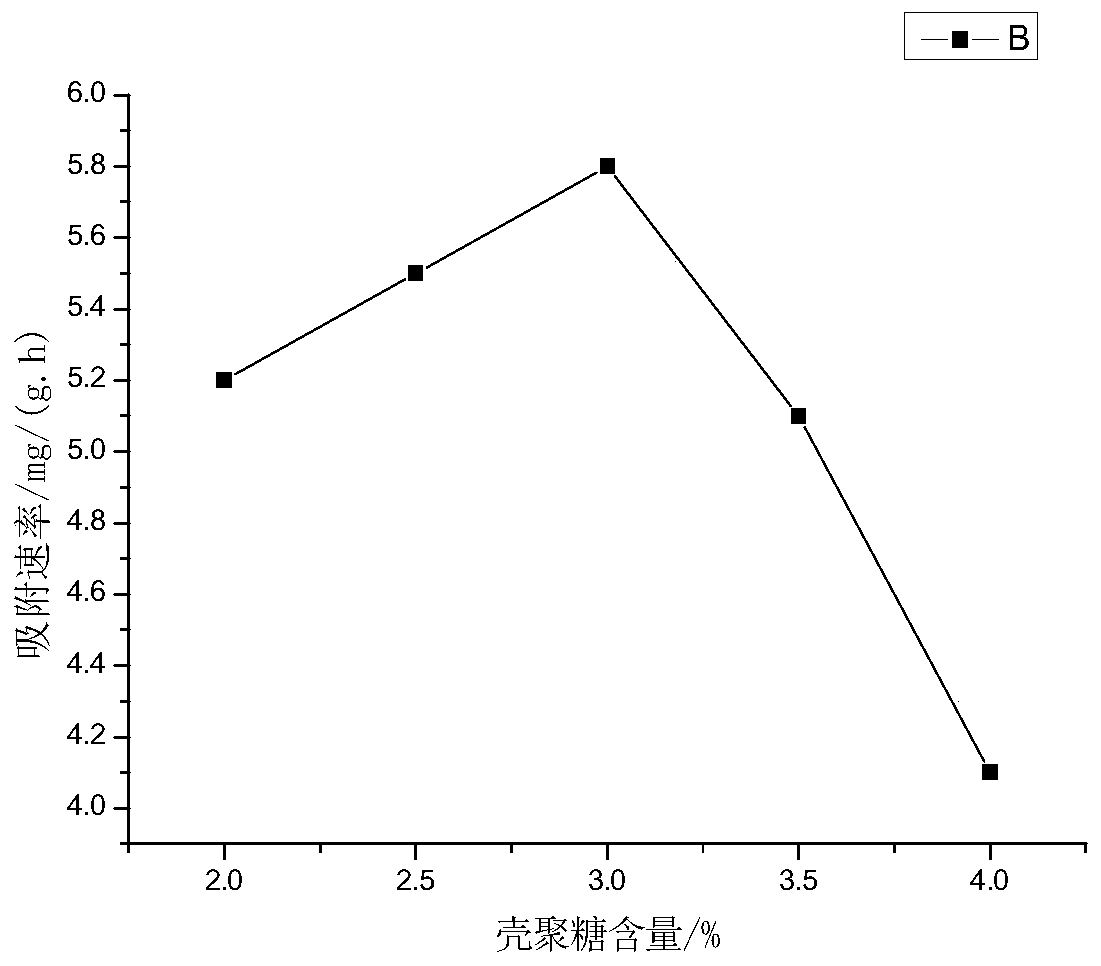

Biochar-chitosan compound as well as preparation method and application thereof

InactiveCN110918070AImprove adsorption capacityEasy to degradeOther chemical processesWater contaminantsCongo redEngineering

The invention relates to a biochar-chitosan compound as well as a preparation method and application thereof, and the method comprises the following steps: mixing chitosan, acids and biochar to obtaina reaction mixed solution; wherein the mass concentration of chitosan in the reaction mixed solution is 2-4%; dropwise adding the reaction mixed solution into an alkaline precipitation solution, andfiltering to obtain a crude product; and washing the crude product, adding a cross-linking solution, and washing to be neutral to obtain the biochar-chitosan compound. According to the biochar-chitosan compound obtained by the preparation method disclosed by the invention, after biochar microparticles are added into a loose and porous chitosan microsphere structure; the surface area of the microspheres is obviously increased, the adsorption and decolorization efficiency of dye wastewater is further improved, the problem that mother liquor is difficult to separate can be avoided, so that second-stage pollution is avoided, and the biochar-chitosan compound shows excellent adsorption performance after adsorbing an azo dye Congo red reagent solution.

Owner:FOSHAN UNIVERSITY

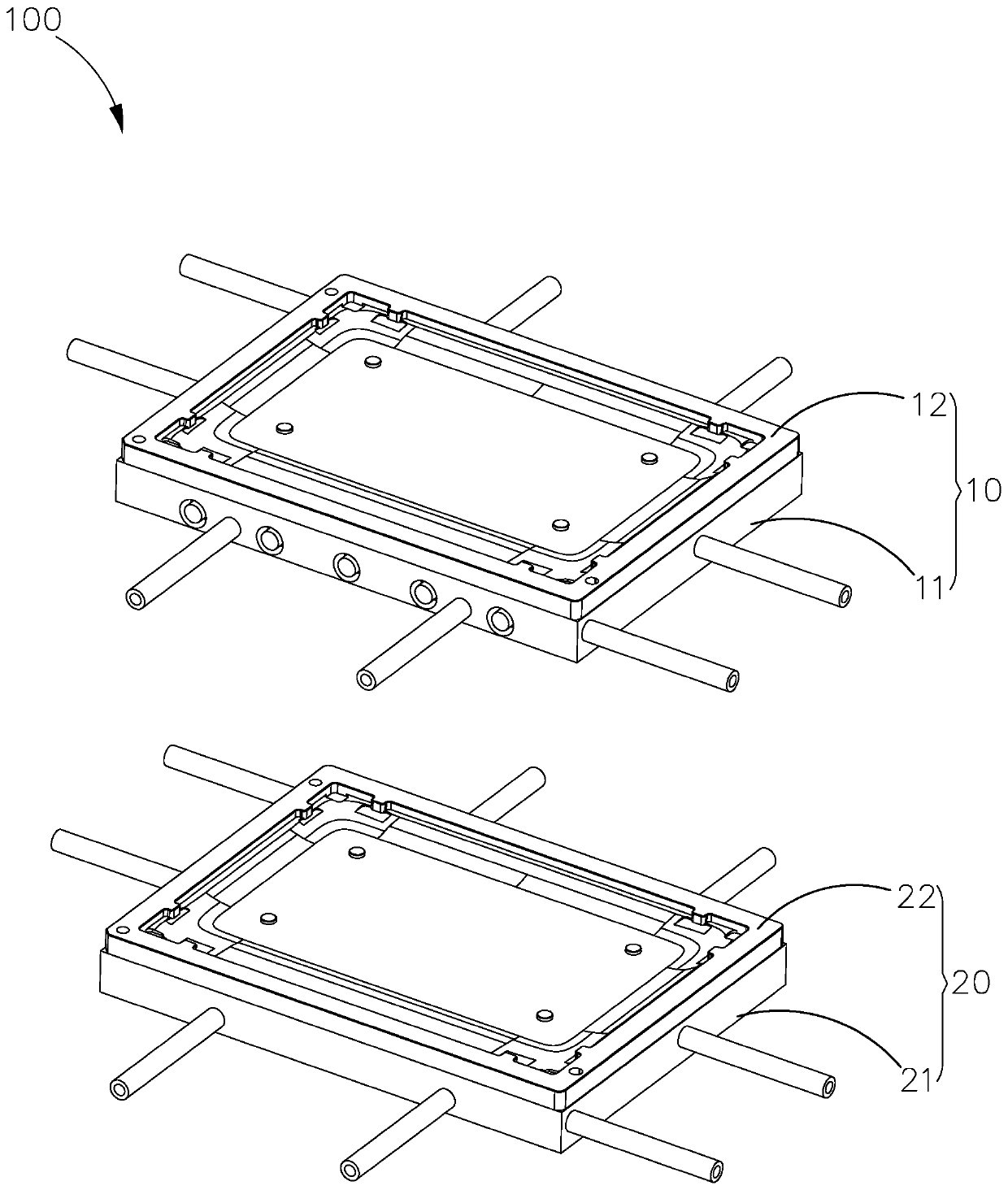

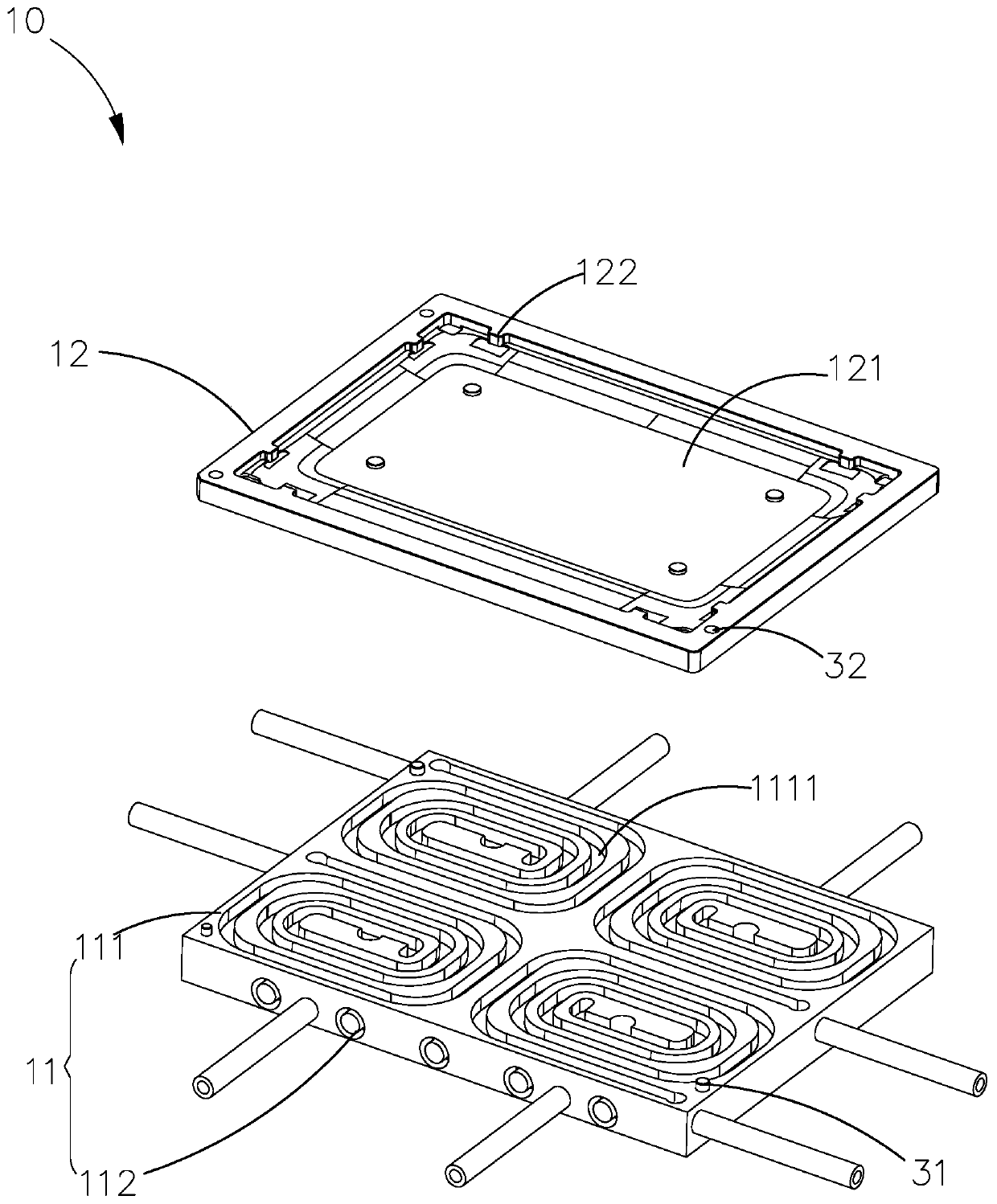

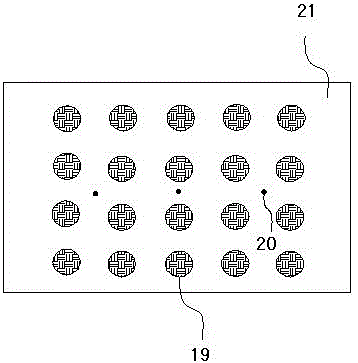

Freezing positioning device and freezing positioning method

The invention relates to a freezing positioning device which comprises a first freezing positioning clamp and a second freezing positioning clamp. The first freezing positioning clamp comprises a first heat exchange assembly and a first positioning plate; the first heat exchange assembly includes a first freezing disc detachably connected with the first positioning plate and a heater connected with the first freezing disc; the first freezing disc is provided with a first cooling flow channel; the first positioning plate is provided with an accommodating groove; the second freezing positioningclamp comprises a second heat exchange assembly and a second positioning plate; the second heat exchange assembly includes a second freezing disc detachably connected with the second positioning plate; the second freezing disc is provided with a second cooling flow channel; and the second positioning plate has the same structure as the first positioning plate. Meanwhile, the invention also provides a freezing positioning method. The freezing positioning device and the freezing positioning method have the beneficial effects that by means of freezing and fixing of positioning liquid, accurate positioning of a product in CNC machining is realized, waiting time spend by freezing and thawing the product is reduced, the working period is compressed, and working efficiency of CNC machining is improved.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD +1

Method and device for simulating pure oxygen iron-making and blast furnace gas recycling

ActiveCN111485044AHigh volume loadEasy to separateBlast furnace componentsBlast furnace detailsCo2 storageDust control

The invention discloses a method and a device for simulating pure oxygen iron-making and blast furnace gas recycling. The device comprises oxygen production equipment, a hot blast stove, a blast furnace, dust removal equipment, pressurizing equipment, CO2 separating equipment, a CO2 compressor, a CO2 storage tank, a CO storage tank and a valve component. In an original blast furnace iron-making process, oxygen is prepared by adding the oxygen production equipment and CO2 is separated from CO by adding the CO2 separating equipment; part CO2 obtained by separating is mixed with the oxygen in a certain proportion to serve as a combustion-supporting gas for the blast furnace iron-making, so that a large amount of N2 in a blast furnace gas is avoided; the difficulty in purifying the CO is reduced; the utilization value of the blast furnace gas is improved; the consumption of coke and coal for the blast furnace iron-making is reduced; and therefore, the purposes of saving energy and reducingthe emission of the CO2 are achieved.

Owner:BEIJING PEKING UNIV PIONEER TECH

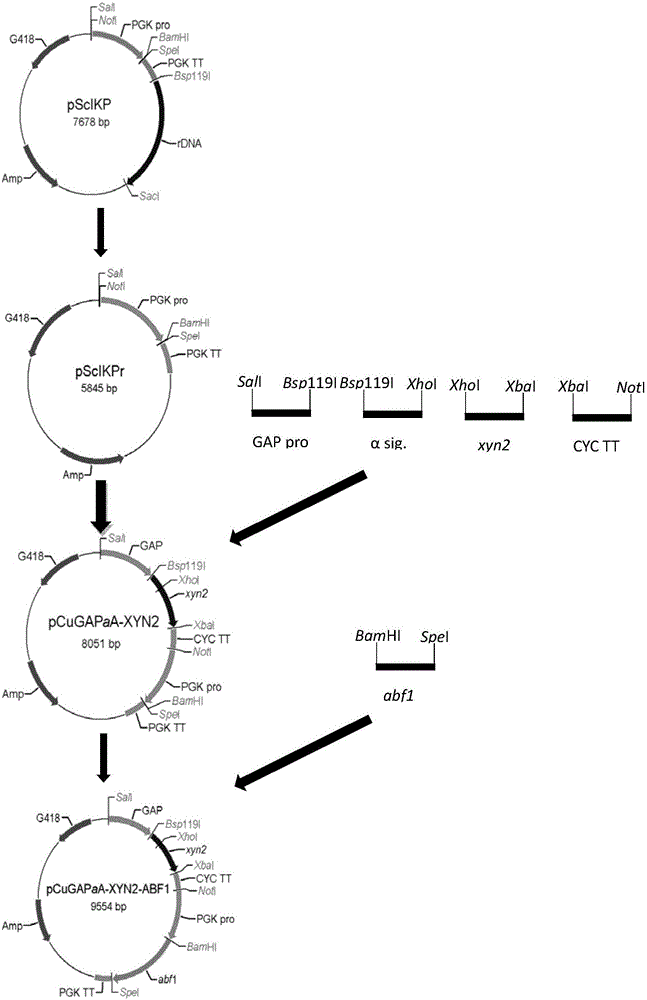

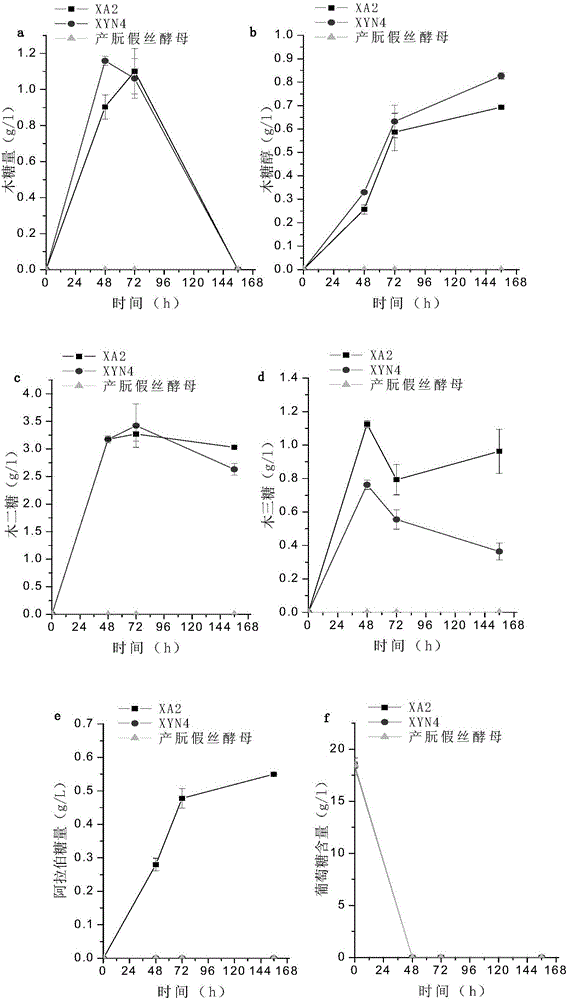

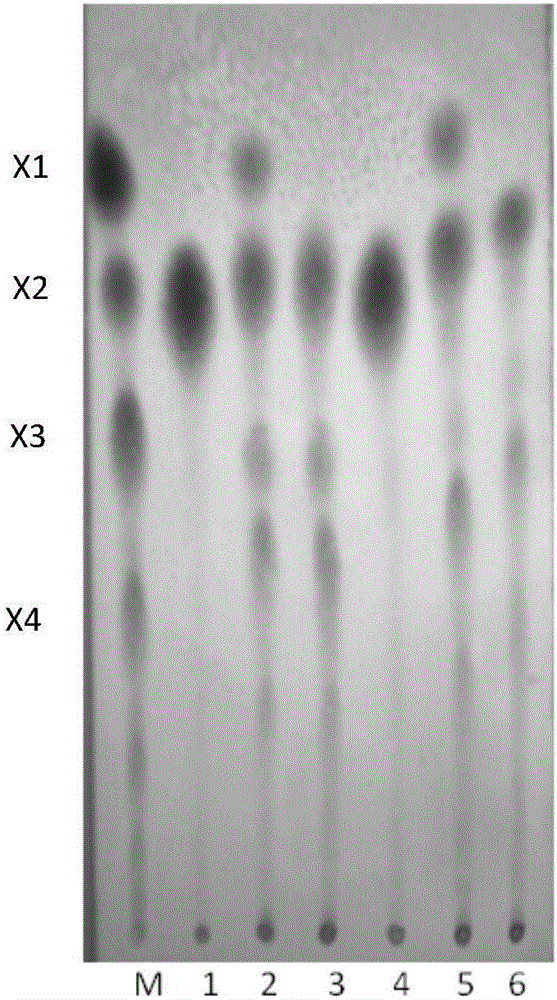

Gene recombined candida utilis capable of degrading and utilizing hemicellulose and applications of gene recombined candida utilis

The invention discloses gene recombined candida utilis capable of decomposing hemicellulose and applications of the gene recombined candida utilis. The gene recombined candida utilis can stably express xylanase coming from trichoderma reesei and Arabinfuranosidease. With the gene recombined yeast, an integrated biotechnology capable of degrading hemicellulose for co-producing xylooligosaccharide, arabinose and newtol is established. According to the process, 20g / l bagasse hemicellulose is taken as a substrate, after culture for 156h, xylose produced in the middle process is consumed up by the yeast, the yield of xylooligosaccharide is 20%, at the time, the highest yields of newtol and arabinose, namely, 3.5% and 2.7% are achieved, and the hydrolysis rate of hemicellulose is 40.4%. The integrated biotechnology belongs to a co-production technology which is environmentally friendly, convenient and rapid, and effective.

Owner:GUANGDONG QIZHI BIOTECHNOLOGY CO LTD

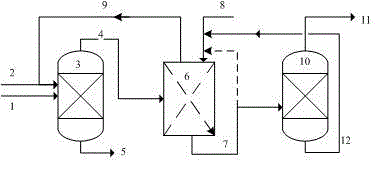

Alkylation method adopting novel microchannel reactor

ActiveCN107523328AReduce lossSmall pressure dropLiquid hydrocarbon mixtures productionHydrocarbon oils treatmentAlkyl transferSurface type

The invention discloses an alkylation method adopting a novel microchannel reactor. According to the method, iso-butane and olefin serving as raw materials are added with a proper amount of dimethylmethane serving as refrigerant and entrainer to perform an alkylation reaction to obtain an alkylate oil; the raw materials and catalyst perform the alkylation reaction in a microchannel reaction zone in the microchannel reactor, and are settled and layered in a settling section; then the reacting materials continuously enter a horizontal separation tank, lower catalyst is extracted, upper gas is exhausted, and the intermediate product is delivered to a coalescing separator; and the microchannel reaction zone is formed by a tube-type microchannel reaction zone and a surface-type microchannel reaction zone. The method has the characteristics of low temperature performance, no premix requirement for reacting raw materials, small bed pressure drop, good energy-saving effect, high product quality and the like, and can realize efficient, energy-saving, safe, low carbon and environment-friendly continuous production.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY +2

Method for refining polyoxymethylene dimethyl ether (PODE)

ActiveCN104557484ASolve inseparableEasy to recycleOrganic chemistryOrganic compound preparationPolyoxymethyleneAlkane

The invention relates to a method for refining polyoxymethylene dimethyl ether (PODE). The method is mainly used for solving the problem that the property of a PODE product is affected due to the presence of methanol. The problem of the influence of methanol on the separation of the PODE product is well solved by adopting the technical scheme of the method for refining PODE; according to the method, alkane or halogenated alkane having a boiling point of 30-100 DEG C is used as an azeotropic agent to remove methanol in the PODE crude product by virtue of azeotropic distillation; and the method comprises the following steps: adding the azeotropic agent and the crude product into an azeotropic distillation tower, carrying out azeotropic distillation to distill an azeotrope formed by methanol and the azeotropic agent out from the tower top and enabling purified PODE to flow out from the tower bottom; enabling the azeotrope obtained at the tower top to enter a solvent recovery tank and be in contact with water and naturally layering to obtain an oil layer containing the azeotropic agent and a water layer containing methanol. The method can be used in the refining production of polyoxymethylene dimethyl ether as a diesel additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

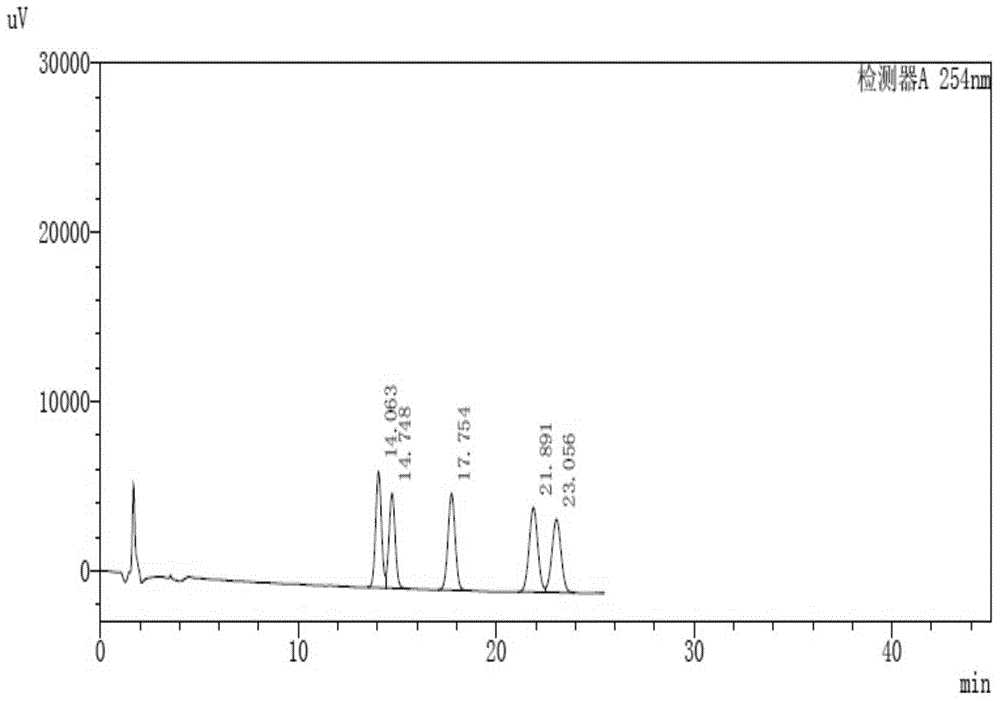

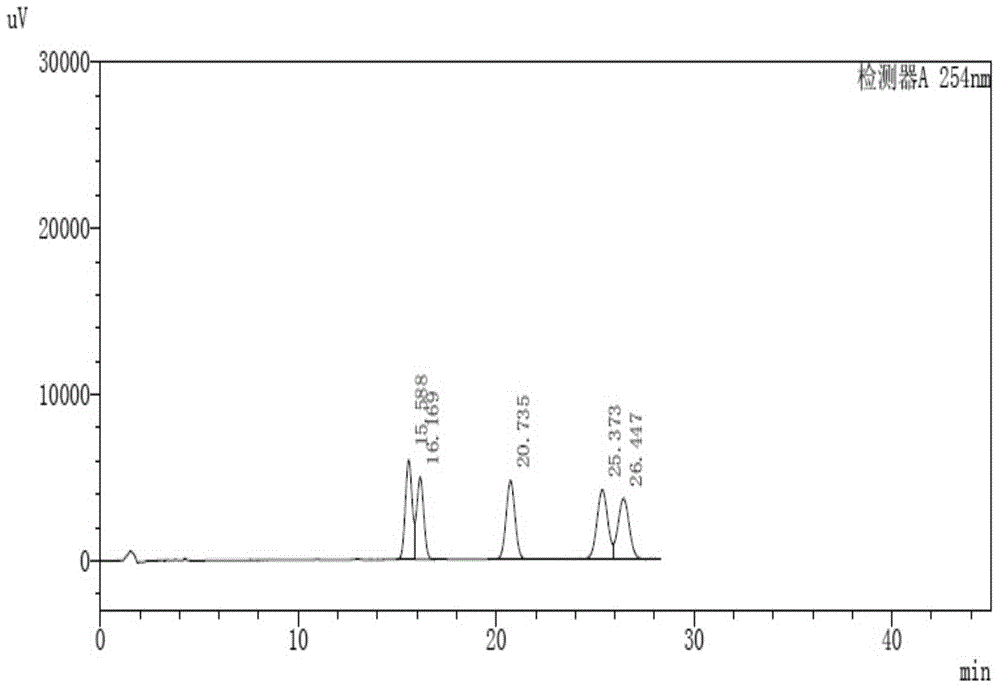

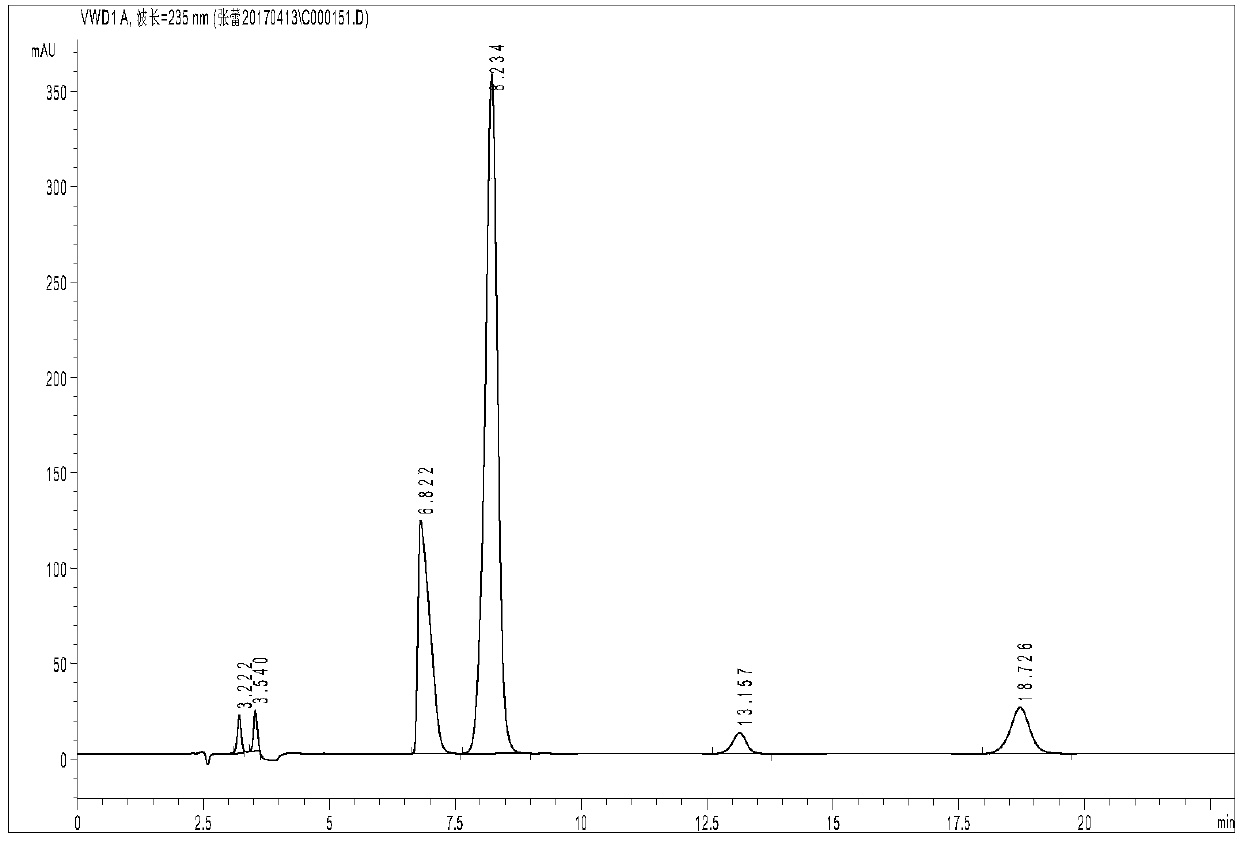

Liquid chromatographic method for separating and determining multiple impurities in tolvaptan

ActiveCN105004803AStrong specificityThe measurement results are accurate and reliableComponent separationChromatographic columnTolvaptan

The invention discloses a liquid chromatographic method for separating and determining multiple impurities in tolvaptan. High performance liquid chromatographic detection conditions are that detection wavelength is 230 to 280 nm, a chromatographic column is Symmetry shield RP18 and a mobile phase is acetonitrile-aqueous solution containing 0.2% phosphoric acid, wherein the volume fraction of acetonitrile is 43 to 47%. The method provided by the invention overcomes problems in separation and determination of tolvaptan and five impurities thereof, especially problems in separation and determination of positional isomer impurities of tolvaptan and positional isomer impurities of tolvaptan intermediates; and the method has the advantages of good specificity, simplicity, rapidness, accuracy and accurate and reliable determination results, so the quality of tolvaptan can be effectively monitored, and drug security is improved.

Owner:CHENGDU BAIYU PHARMA CO LTD

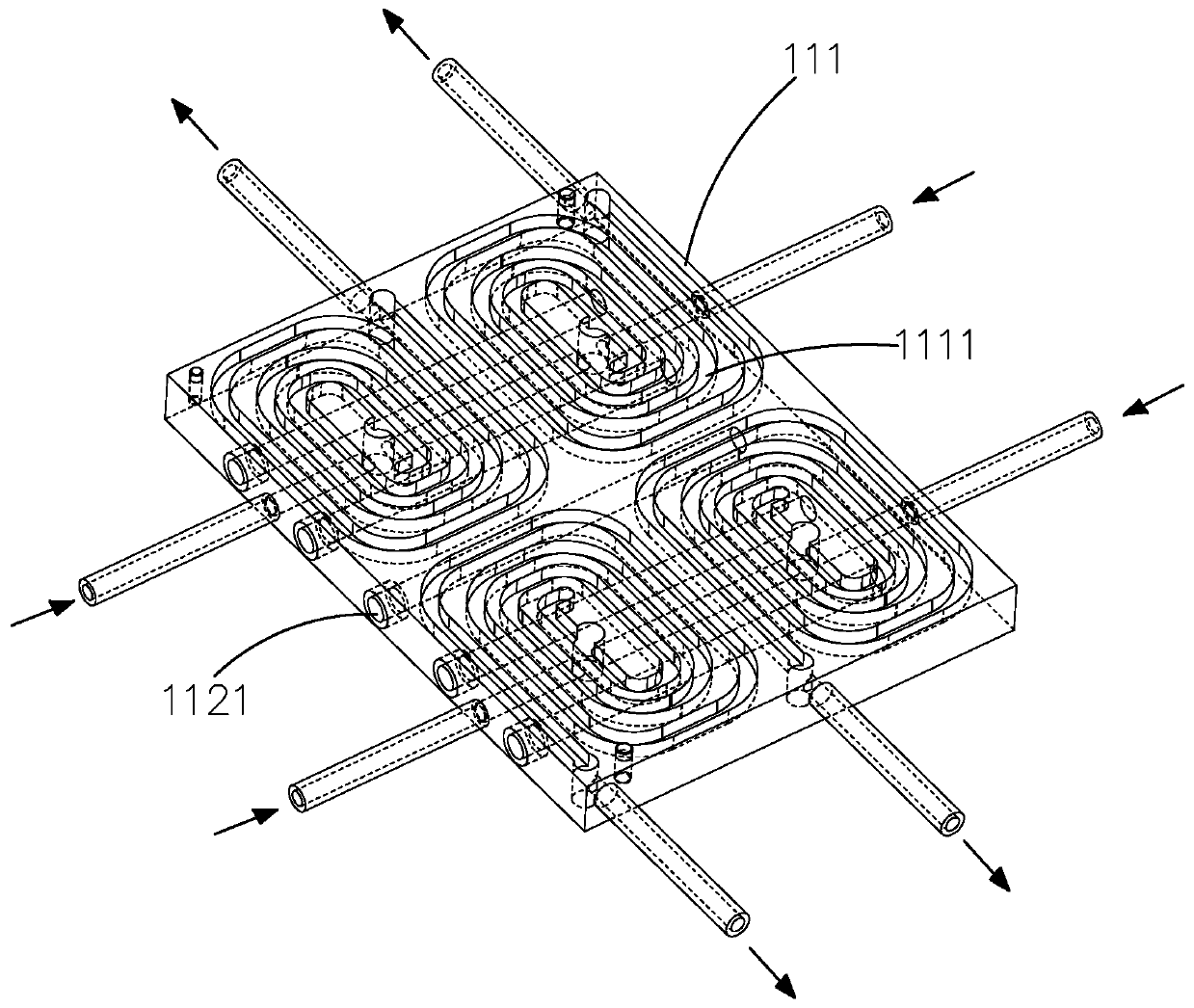

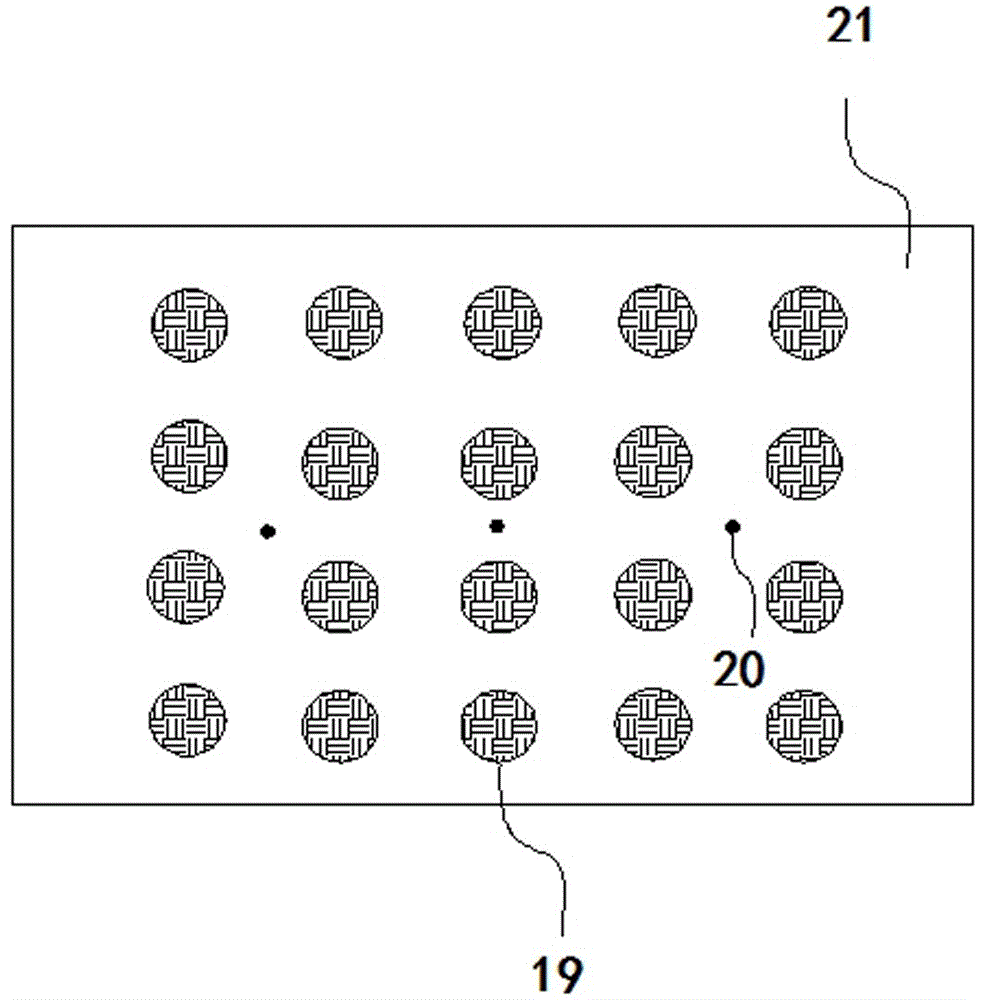

Microchannel reactor

ActiveCN107519835ALess side effectsImprove mass transfer efficiencyLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical stationary reactorsContinuous productionAlkyl transfer

The invention discloses a microchannel reactor. According to the invention, a microchannel reaction zone is arranged in a reactor shell and is at least provided with a tubular microchannel reaction zone and a planar microchannel reaction zone; the tubular microchannel reaction zone is composed of a tubular microchannel member; the planar microchannel reaction zone is composed of a planar microchannel member; the planar microchannel member is composed of multiple groups of plates, and a channel gap between two plates is 0.1 to 10 mm and compose a planar microchannel; tubular microchannels of the tubular microchannel reaction zone are arranged to be perpendicular to a horizontal plane; and the planar microchannels of the planar microchannel reaction zone are arranged to be perpendicular to the horizontal plane. The microchannel reactor provided by the invention is applicable to alkylation and has the characteristics that alkylation can be carried out at a low temperature, reaction raw materials do not need premixing, bed pressure drop is small, good energy-saving effect can be obtained, high product quality is realized, etc.; and the microchannel reactor can realize high-efficiency, energy-saving, safe, low-carbon, environment-friendly and continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

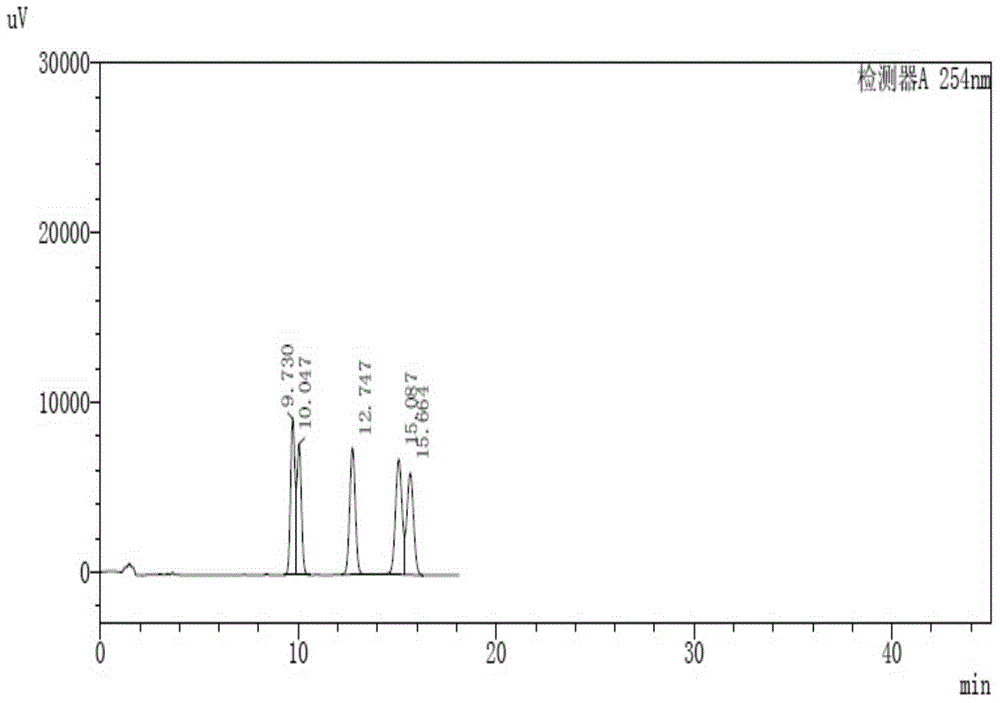

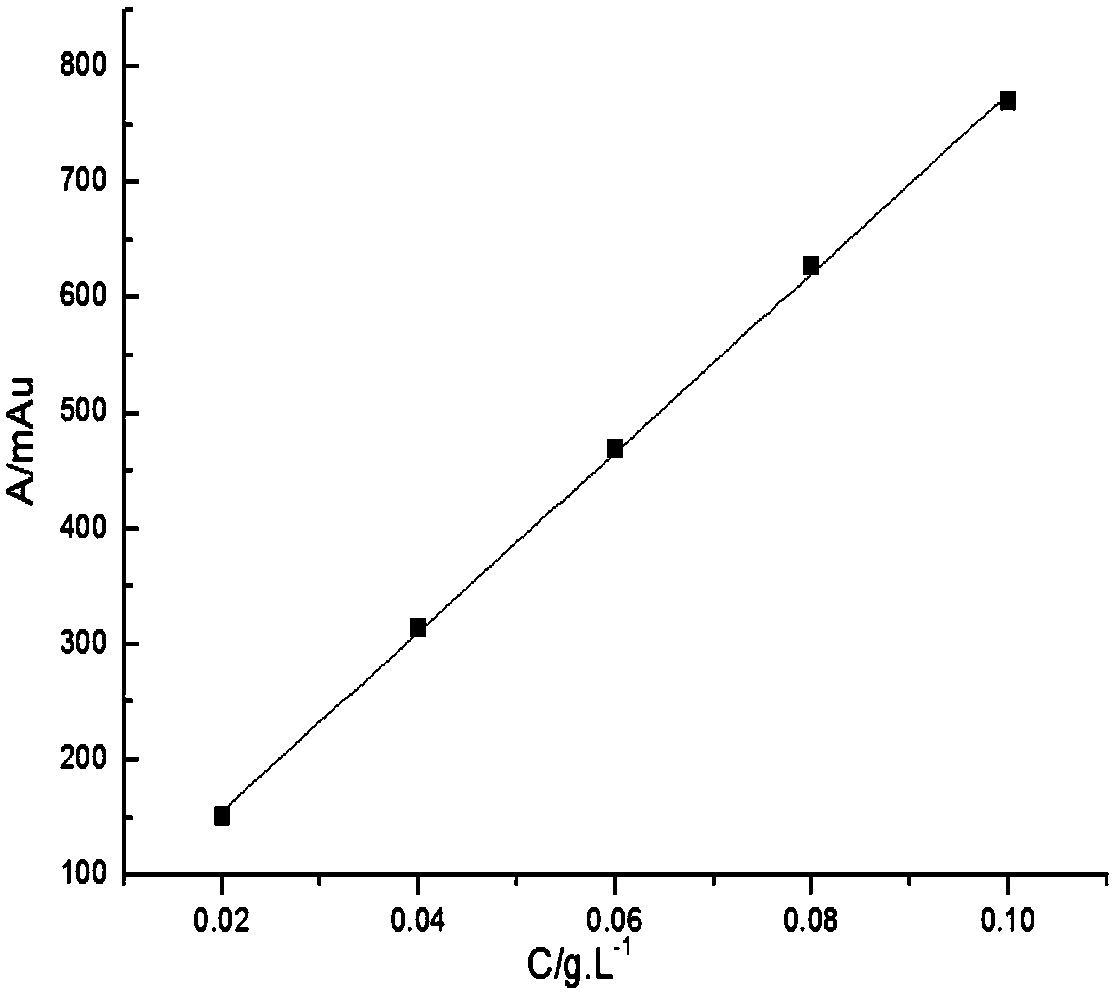

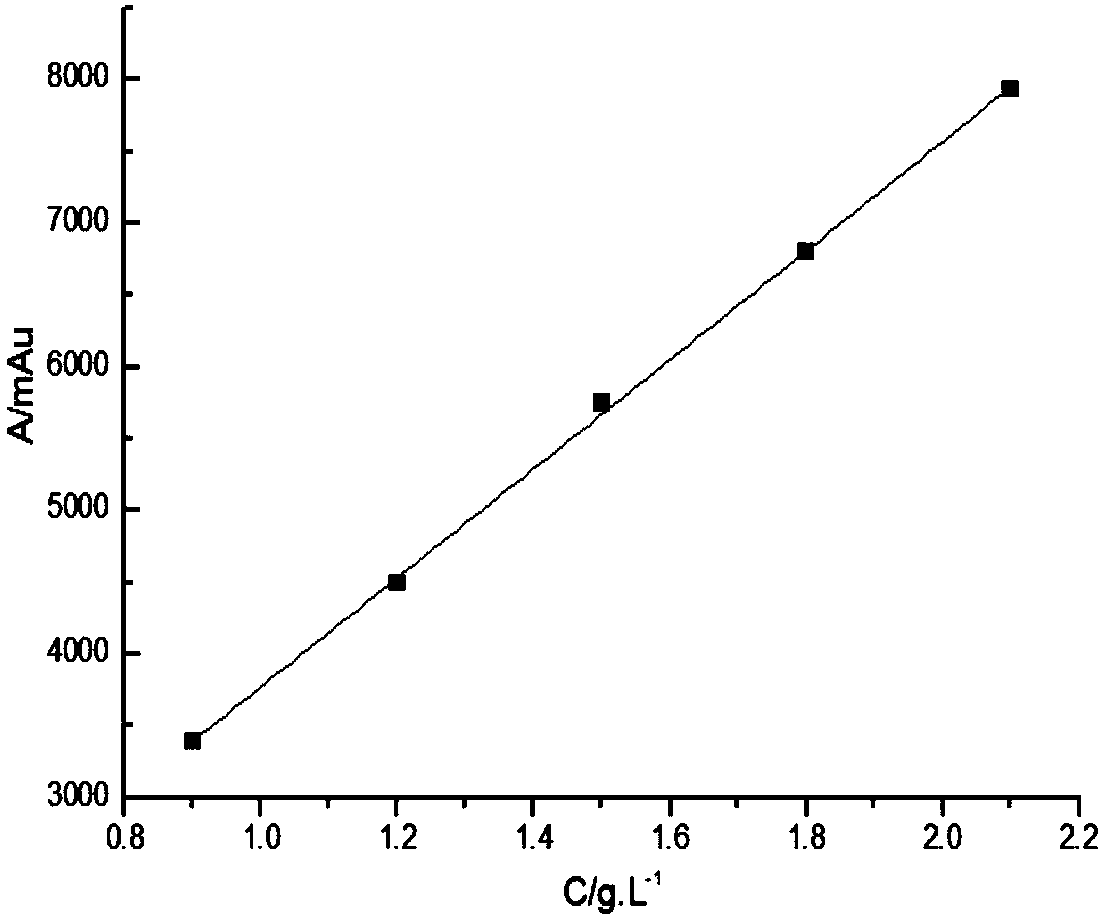

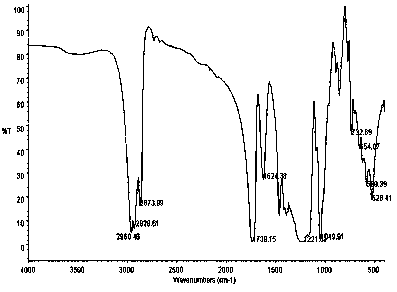

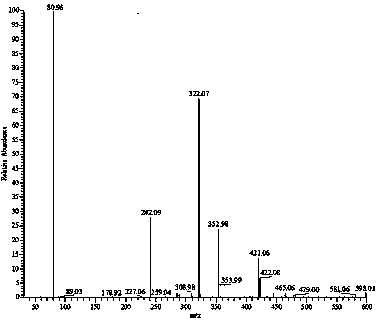

Liquid chromatographic analysis method for simultaneously quantifying glycine and iminodiacetic acid from diethanol amine dehydrogenation product

ActiveCN107621507AHigh reactivityLow priceComponent separationSulfonyl chlorideRelative standard deviation

The invention discloses a liquid chromatographic analysis method for simultaneously quantifying glycine and iminodiacetic acid from a diethanol amine dehydrogenation product. The method comprises thefollowing steps: taking toluene sulfonyl chloride acetonitrile as a derivating agent; carrying out derivative reaction on the toluene sulfonyl chloride acetonitrile and amino acid in the diethanol amine dehydrogenation product, and then carrying out liquid chromatographic analysis; and separately drawing standard curves for the concentration of the iminodiacetic acid and the glycine by taking thepeak area of an iminodiacetic acid derivative and the peak area of a glycine derivative. The peak area of an iminodiacetic acid (IDA) standard substance and the concentration of a standard substance have linear dependence in the range of 0.5 g / L-2.500 g / L, the peak area of a glycine (Gly) standard substance and the concentration of a standard substances have linear dependence in the range of 0.01g / L-0.15 g / L, the coefficients of association are greater than 0.9990, and the relative standard deviation is smaller than 1.3%. The analysis result is accurate, analysis steps are simple and convenient, analysis sensitivity is high, the method can be used for quantitative analysis on the iminodiacetic acid as a product and the glycine as a by-product in diethanol amine dehydrogenation reaction, can also be used for liquid chromatography-mass spectrometry qualitative analysis of a product, and has important guidance significance on scientific research and industrial production on preparation of the iminodiacetic acid by diethanol amine catalytic dehydrogenation.

Owner:XIANGTAN UNIV

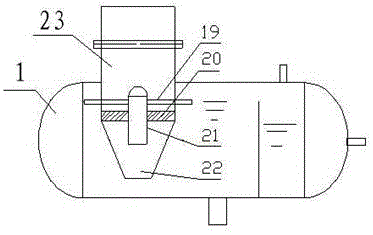

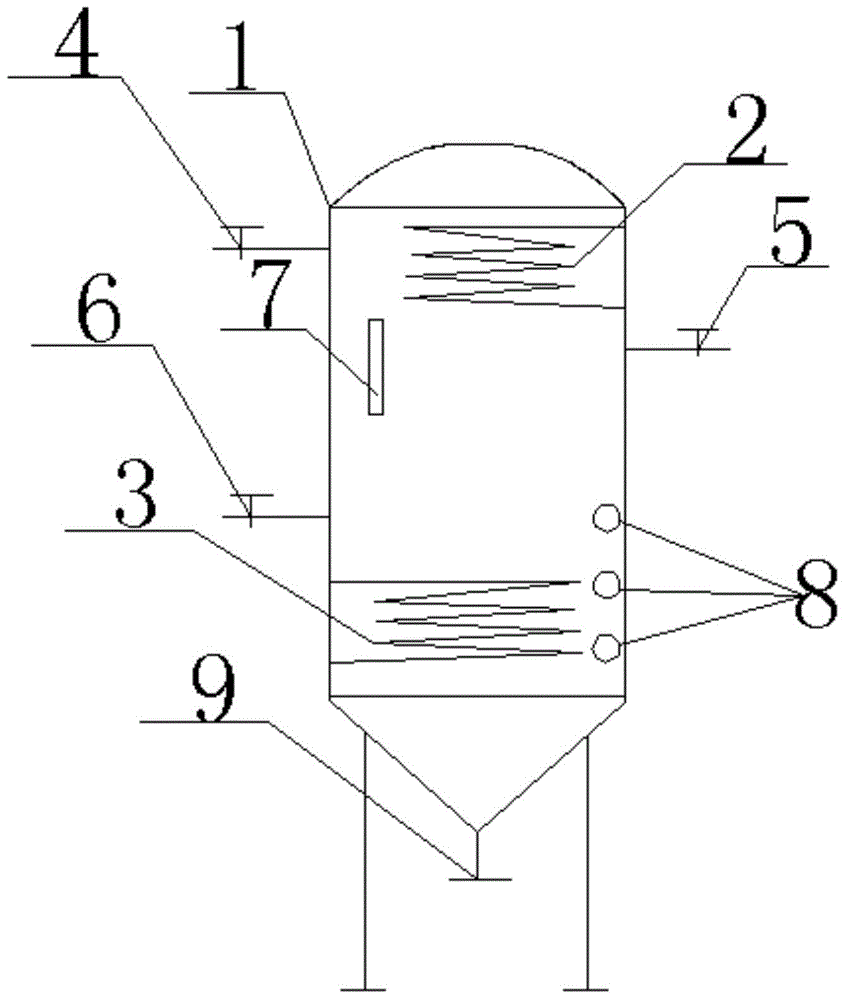

Oil-water separation tank

InactiveCN104307209ASimple and Effective Liquid TemperatureRaise the temperature of the liquidLiquid separation by thermal diffusionLiquid temperatureSight glass

The invention provides an oil-water separation tank. The oil-water separation tank comprises an oil tank, a condensation coiled pipe, a heating coiled pipe, an emptying valve, a feeding hole, a discharging hole, sight glass and a water shearing opening, wherein the oil tank is divided into three parts, namely a heating region, a condensation region and an observation region; the oil tank is divided into inner and outer layers; the inner layer is a sealed space when the emptying valve, the feeding hole, the discharging hole and the water shearing opening are closed; the condensation coiled pipe is wound in an outer layer cavity at the top end of the oil tank to form a condensation region; the heating coiled pipe is wound in an outer layer cavity at the bottom end of the oil tank to form a heating region; the feeding hole is formed in the upper half part of the right side of the oil tank and the discharging hole is formed in the lower half part of the left side of the oil tank; the water shearing opening is formed in the bottom end of the oil tank; the emptying valve is mounted at the upper half part of the left side of the oil tank; and the surface of the tank wall of the condensation region is coated by a smooth coating so that oil drops can slide off. According to the oil-water separation tank, a simple and efficient method for improving the temperature of liquid is adopted and the density difference of an oil phase and a water phase is changed so that the oil and the water can be rapidly separated, so that the oil-water separation time is shortened, and furthermore, the good separation effect is realized; and most importantly, the problem that the oil and the water cannot be separated in winter is solved, the production efficiency is improved and the loss of crude oil can be reduced, so that the production cost is reduced.

Owner:QINGDAO KANGHEWEIYE COMML

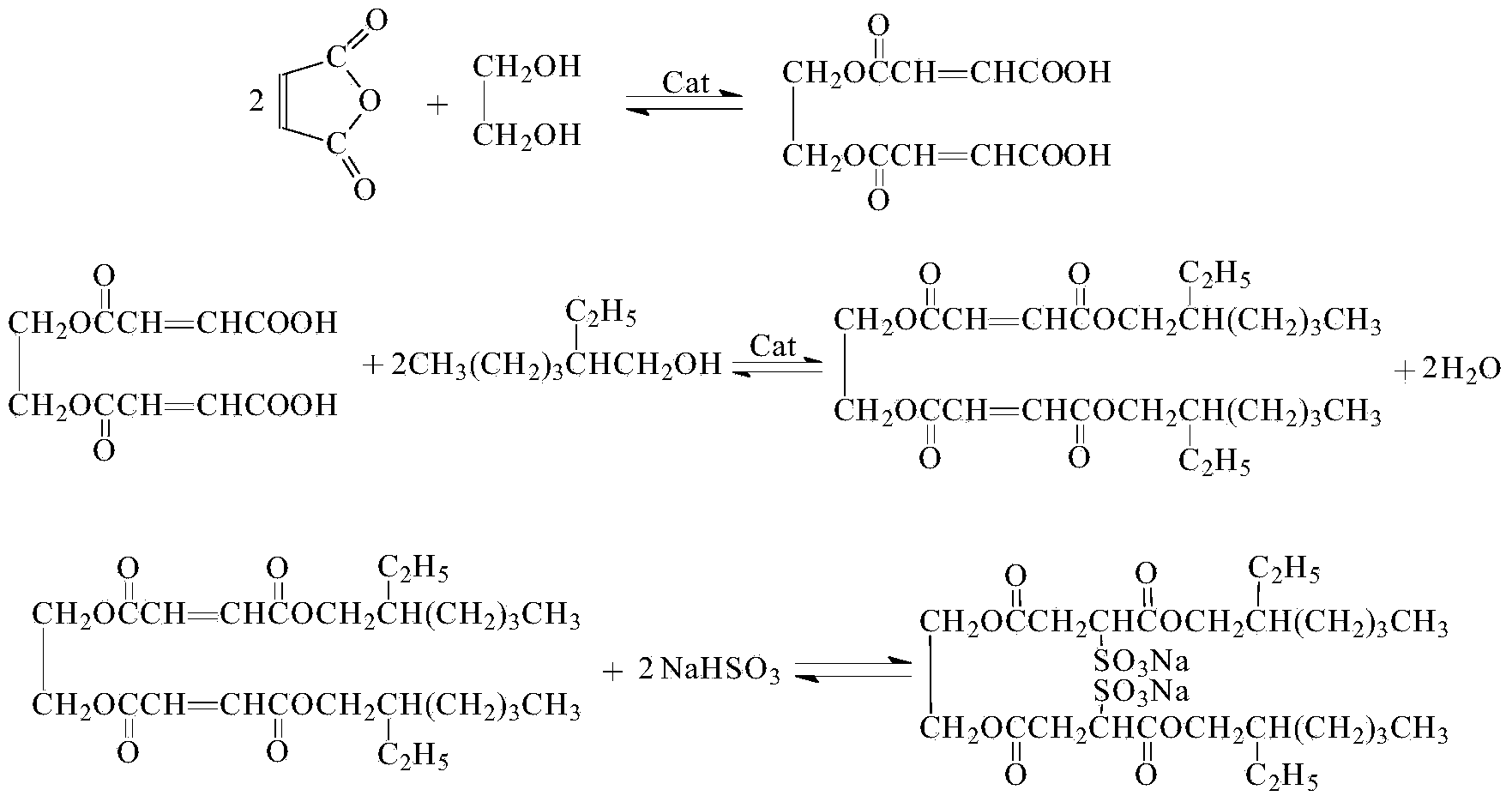

Preparation method of ethylene glycol gemini di-isooctyl succinate sodium sulfonate

InactiveCN103450053AEasy to operateThe method is simpleSulfonic acids salts preparationMaleic anhydridePolyethylene glycol

The invention discloses a preparation method of ethylene glycol gemini di-isooctyl succinate sodium sulfonate. The preparation method comprises the steps that maleic anhydride and two hydroxy groups on ethylene glycol are bonded to carry out mono-esterification reaction to generate ethylene glycol monoester dimaleate; then ethylene glycol monoester dimaleate and isooctyl alcohol carry out di-esterification reaction to obtain ethylene glycol di-isooctyl dimaleate; finally ethylene glycol di-isooctyl dimaleate and sodium hydrogen sulfite carry out conjugate addition sulfonation reaction to prepare a product, wherein a catalyst for mono-esterification reaction is a carbon-based solid acid and directly serves as a catalyst for di-esterification reaction after mono-esterification. The method is easy to operate, is simple and convenient and has good environment friendliness.

Owner:NANTONG UNIVERSITY

Clean and environment-friendly production method for methionine hydroxyl analogue

InactiveCN109232336ASolve inseparableHigh purityOrganic compound preparationSulfide preparationOrganic solventMethionine hydroxy analog

The invention relates to a clean and environment-friendly production method for a methionine hydroxyl analogue, aiming at solving the problems in a traditional production technological method that themethionine hydroxyl analogue and ammonium salt are difficult to separate and more methionine hydroxyl analogues are carried in the byproduct ammonium salt; the purity of the obtained ammonium salt ishigh; in a whole process, less odor is generated; the whole production process is safe, clean and environmentally friendly, and nearly no wastewater is discharged; the problem of extracting by utilizing an organic solvent in a traditional production technology is solved or the problem that a mixture of the methionine hydroxyl analogue and the ammonium salt are concentrated at high temperature sothat the methionine hydroxyl analogue is decomposed to generate odorous gas is solved; the content of a monomer in an obtained product is greater than that of a traditional production technology and the quality of the product is relatively high.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

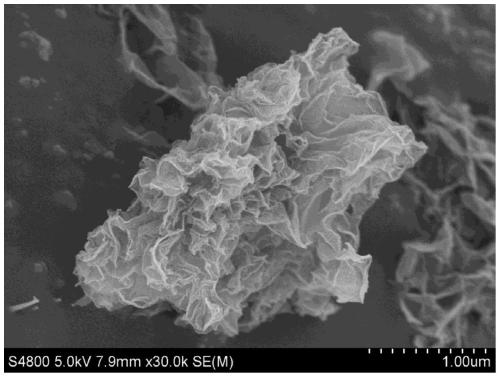

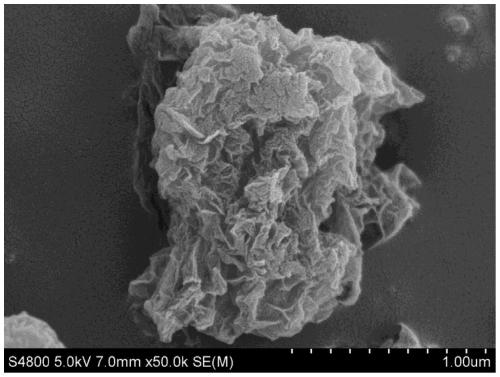

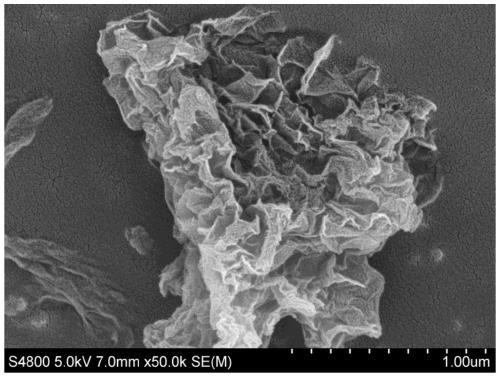

Single-layer wrinkled graphene and production method and application thereof

ActiveCN110436445AInhibit stackingImprove filtering effectSingle layer grapheneWrinkled structureCentrifugation

The invention relates to single-layer wrinkled graphene and a production method and application thereof. The production method comprises the following steps of mixing and heating graphene oxide dispersion liquid and an alkaline solution to obtain an alkaline dispersion solution of graphene oxide; subjecting the alkaline dispersion solution of the graphene oxide to centrifugal separation and clearwater washing, and dispersing solid sediment in a hydrochloric acid solution again to obtain a mixed solution; then conducting heating acidification, after cooling is conducted, conducting centrifugalseparation and clear water washing, and dispersing a solid subjected to centrifugation in water to obtain wrinkled graphene oxide dispersion liquid subjected to alkali washing and acidification treatment; and then mixing the wrinkled graphene oxide dispersion liquid subjected to alkali washing and acidification treatment and an acidic reducer, and conducting heating to obtain the single-layer wrinkled graphene. The single-layer wrinkled graphene is distributed in a single layer mode, a graphene nanosheet layer has a good wrinkled structure, and stacking of graphene nanosheet layers can be effectively inhibited, so that more fluffy graphene powder is obtained, and the density is small; and the wrinkled graphene powder is more liable to be filtered out from reduced dispersion liquid, so that the problem that in practical application, graphene powder is hard to separate out is solved, and production and the utilization rate of graphene are greatly improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com