Method for refining polyoxymethylene dimethyl ether (PODE)

A technology of dimethyl ether and polyoxymethylene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high cost, high cost, and low product yield, and achieve good economy and feasibility The effect of high stability, mild operating conditions, and simple recovery methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

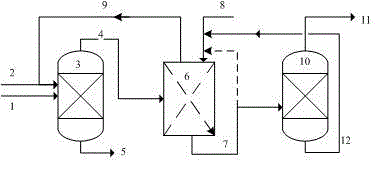

Image

Examples

Embodiment 1

[0030] With cyclohexane as entrainer, PODE 2 The crude product is a raw material (composed by weight: 13.84wt% methanol, 1.02wt% DMM, 84.85wt% PODE 2 and the remainder of other impurities) for azeotropic distillation. Take cyclohexane 75g respectively, PODE 2 300g of the crude product (containing 41.5g of methanol) was added to the rectification tower, heated under normal pressure, the reflux ratio was 2, the temperature of the top of the azeotropic rectification tower was 54~56°C, and the temperature of the bottom of the tower was 105°C. Light component 1 and bottom liquid 1. After the light component 1 is fully mixed with an equal amount of water, it is allowed to stand and separate into layers. The upper layer liquid is recovered entrainer cyclohexane, and the lower layer is aqueous methanol solution.

[0031] The light component 1 and the bottom liquid 1 were sampled respectively, and gas chromatography analysis was carried out after standing and cooling. The results a...

Embodiment 2

[0037] With n-hexane as entrainer, PODE 2 The crude product is a raw material (composed by weight: 13.84wt% methanol, 1.02wt% DMM, 84.85wt% PODE 2 and the remainder of other impurities) for azeotropic distillation. Take 110g of n-hexane, PODE 2 300g of the crude product (containing 41.5g of methanol) was added to the rectification tower, heated under normal pressure, the reflux ratio was 5, the temperature of the top of the azeotropic rectification tower was 50~52°C, and the temperature of the bottom of the tower was 100°C to obtain the Light component 2 and bottom liquid 2. After the light component 2 is fully mixed with an equal amount of water, it is allowed to stand and separate into layers. The upper layer liquid is recovered entrainer n-hexane, and the lower layer is aqueous methanol solution.

[0038] The light component 2 and the tower bottom liquid 2 were sampled respectively, and gas chromatographic analysis was carried out after standing and cooling. The results...

Embodiment 3

[0041] With n-heptane as entrainer, PODE 2 The crude product is a raw material (composed by weight: 13.84wt% methanol, 1.02wt% DMM, 84.85wt% PODE 2 and the remainder of other impurities) for azeotropic distillation. Take 45g of n-heptane respectively, PODE 2 300g of the crude product (containing 41.5g of methanol) was added to the rectification tower, heated under normal pressure, the reflux ratio was 8, the temperature of the top of the azeotropic rectification tower was 59~61°C, and the temperature of the bottom of the tower was 120°C. Light component 3 and bottom liquid 3. After the light component 3 is fully mixed with an equal amount of water, it is allowed to stand and separate into layers. The upper layer liquid is recovered entrainer n-heptane, and the lower layer is aqueous methanol solution.

[0042] The light component 3 and the tower bottom liquid 3 were sampled respectively, and gas chromatographic analysis was carried out after standing and cooling. The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com