Microchannel reactor

A technology of microchannel reactor and microchannel reaction, applied in chemical/physical/physicochemical stationary reactors, chemical instruments and methods, production of liquid hydrocarbon mixtures, etc. Problems such as flow distribution and unbalanced alkylation rate can be achieved to reduce the occurrence of side reactions, solve the problem of large equipment size, and improve quality and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

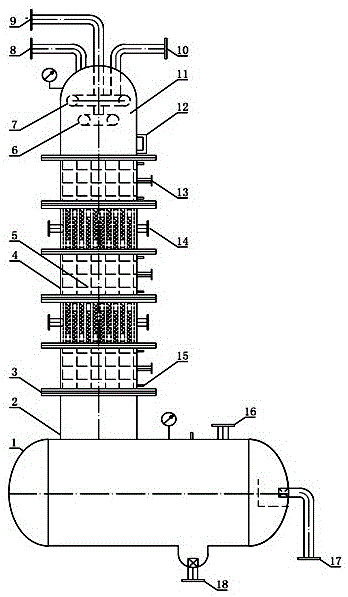

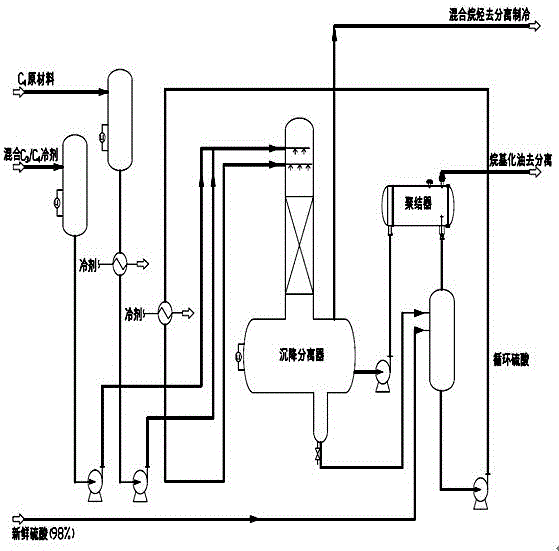

[0060] use as figure 1 The reactor with the structure shown and figure 2 In the alkylation reaction process shown, the bed pressure drop in the microchannel reaction zone is 0.1-1.0 MPa, preferably 0-0.5 MPa. Using isobutane and butene as raw materials, sulfuric acid as catalyst, and propane as refrigerant for alkylation reaction.

[0061]The acid hydrocarbon volume ratio of the sulfuric acid feed to the mixture feed of isobutane and butene is 0.1-5:1, preferably 0.5-3:1. The molar ratio of alkene is 1-50:1, preferably 5-20:1. The molar ratio of isobutane to propane is 1~100:1, preferably 10~30:1, and the reaction pressure is maintained at 0MPa~1.0MPa, preferably 0MPa~0.5MPa. The side reaction is suppressed, the acid consumption is reduced, the selectivity and yield of the reaction process are improved, and the octane number of the alkylated oil is improved at the same time. The residence time of the reaction materials in the reactor is 1-200 min, preferably 10-90 min.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Channel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com