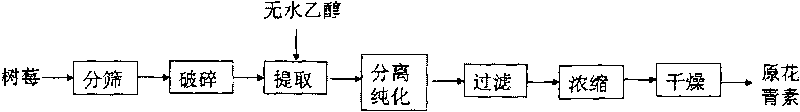

Method for extracting proanthocyanidins from raspberry

A technology for proanthocyanidins and raspberries is applied in the field of raspberry development and utilization, and achieves the effects of high efficiency, less waste liquid discharge and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Freeze the screened raspberry raw materials at -30~-35°C for 30 minutes, crush them until they are all smaller than 1mm, and then put them into an extractor. Slowly add 40% ethanol solvent into the extractor, the weight ratio of solid to liquid = 6:1, and heat it to 60°C with a hot water bath at the same time, as the solvent continues to vaporize and condense, it enters the extractor for extraction. The extraction time is 2h, and the solution Filtrate through medium-speed qualitative filter paper, concentrate in a rotary evaporator with a vacuum degree of 0.09MPa for 1h, and dry in a vacuum oven at 50°C for 2-4h to obtain a crude proanthocyanidin extract.

[0019] Soak the macroporous resin in absolute ethanol for 24 hours, wet-pack the column, wash it with distilled water until it is free of alcohol, then pass it through the resin column with a 5% hydrochloric acid solution at a flow rate of 2mL / min, soak it for 2 hours, and then flush it with distilled water until Neu...

Embodiment 2

[0022] Freeze the screened raspberry raw materials at -30~-35°C for 30 minutes, crush them until they are all smaller than 1mm, and then put them into an extractor. Slowly add 50% ethanol solvent into the extractor, the weight ratio of solid to liquid is = 9:1, and heat it to 50°C with a hot water bath at the same time, as the solvent continues to vaporize and condense into the extractor, the extraction time is 3h, and the solution passes through Filtrate with medium-speed qualitative filter paper, concentrate in a rotary evaporator with a vacuum degree of 0.09MPa for 2h, and dry in a vacuum oven at 50°C for 2-4h to obtain a crude proanthocyanidin extract.

[0023] Soak the macroporous resin in absolute ethanol for 24 hours, wet-pack the column, wash it with distilled water until it is free of alcohol, then pass it through the resin column with a 5% hydrochloric acid solution at a flow rate of 2mL / min, soak it for 2 hours, and then flush it with distilled water until Neutral, ...

Embodiment 3

[0026] Freeze the screened raspberry raw materials at -30~-35°C for 30 minutes, crush them until they are all smaller than 1mm, and then put them into an extractor. Slowly add 50% ethanol solvent into the extractor, the weight ratio of solid to liquid is = 7:1, and at the same time, heat it to 40°C with a hot water bath, and enter the extractor as the solvent continues to vaporize and condense. The extraction time is 4 hours, and the solution passes through Filtrate with medium-speed qualitative filter paper, concentrate in a rotary evaporator with a vacuum degree of 0.09MPa for 2h, and dry in a vacuum oven at 50°C for 2-4h to obtain a crude proanthocyanidin extract.

[0027] Soak the macroporous resin in absolute ethanol for 24 hours, wet-pack the column, wash it with distilled water until it is free of alcohol, then pass it through the resin column with a 5% hydrochloric acid solution at a flow rate of 2mL / min, soak it for 2 hours, and then flush it with distilled water until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com