Recycling and treatment technology for hydroxylamine hydrochloride mother liquor

A technology for the recovery and treatment of hydroxylamine hydrochloride mother liquor, which is applied in the direction of hydroxylamine, nitrogen and non-metallic compounds, etc., can solve the problems of difficult storage and difficult treatment of hydroxylamine hydrochloride mother liquor, and achieve the effect of reducing waste discharge and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

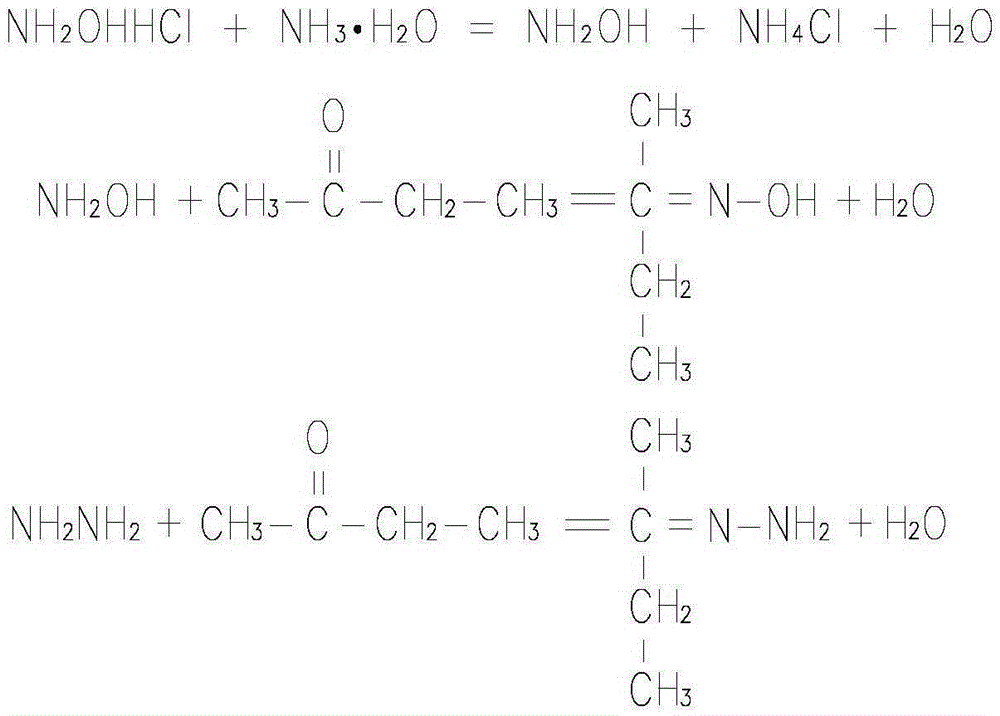

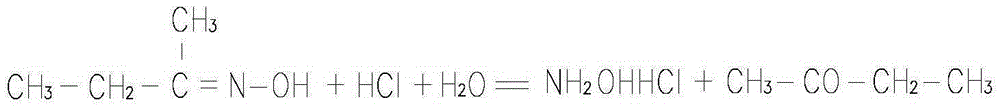

Method used

Image

Examples

Embodiment 1

[0029] The composition of the hydroxylamine hydrochloride mother liquor is: hydroxylamine hydrochloride accounts for 61.5wt%, hydrochloric acid accounts for 5.25wt%, ammonium chloride accounts for 19.3wt%, hydrazine salt accounts for 8.75wt%, and water accounts for 5.2wt%. The recycling process of hydroxylamine hydrochloride mother liquor is as follows:

[0030] (1) Oximation:

[0031] According to the mass ratio of methyl ethyl ketone, hydroxylamine hydrochloride mother liquor is the ratio of 1:1.8, 320kg butanone and 576kg hydroxylamine hydrochloride mother liquor are joined in the reaction kettle that has added water in advance and stir, heat up, drip concentration is the ammoniacal liquor of 25wt% at 45 The reaction is carried out at ℃, and the pH value at the end of the reaction is controlled to be 3.0, and then the heat preservation reaction is continued for 1 hour to obtain a reaction solution containing butanone oxime, hydrazone and ammonium chloride;

[0032] (2) Pur...

Embodiment 2

[0039] The composition of the hydroxylamine hydrochloride mother liquor is: hydroxylamine hydrochloride accounts for 61.5wt%, hydrochloric acid accounts for 5.25wt%, ammonium chloride accounts for 19.3wt%, hydrazine salt accounts for 8.75wt%, and water accounts for 5.2wt%. The recycling process of hydroxylamine hydrochloride mother liquor is as follows:

[0040] (1) Oximation:

[0041] According to the mass ratio of methyl ethyl ketone, hydroxylamine hydrochloride mother liquor is the ratio of 1:1.6, 320kg methyl ethyl ketone and 512kg hydroxylamine hydrochloride mother liquor are joined in the reactor that has added water in advance and stir, heat up, drip concentration is the ammoniacal liquor of 25wt%, in Carry out the reaction at 50°C, control the pH value at the end of the reaction to 3.5, and then continue the heat preservation reaction for 1.2h to obtain a reaction solution containing butanone oxime, hydrazone and ammonium chloride;

[0042] (2) Purification:

[0043]...

Embodiment 3

[0049] The composition of the hydroxylamine hydrochloride mother liquor is: hydroxylamine hydrochloride accounts for 61.5wt%, hydrochloric acid accounts for 5.25wt%, ammonium chloride accounts for 19.3wt%, hydrazine salt accounts for 8.75wt%, and water accounts for 5.2wt%. The recycling process of hydroxylamine hydrochloride mother liquor is as follows:

[0050] (1) Oximation:

[0051]According to the mass ratio of methyl ethyl ketone, hydroxylamine hydrochloride mother liquor is the ratio of 1:1.9, 320kg methyl ethyl ketone and 608kg hydroxylamine hydrochloride mother liquor are joined in the reaction kettle that has added water in advance and stir, heat up, drip concentration is the ammoniacal liquor of 25wt% at 55 The reaction was carried out at ℃, and the pH value at the end of the reaction was controlled to be 4.5, and then the reaction was continued for 1.5 hours to obtain a reaction solution containing butanone oxime, hydrazone and ammonium chloride;

[0052] (2) Purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com