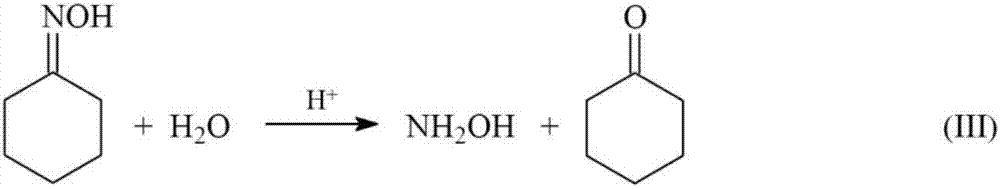

Method for generating hydroxylamine by cyclohexanone-oxime through hydrolyzing

A technology of cyclohexanone oxime and hydroxylamine, which is applied in the field of preparation of hydroxylamine by the hydrolysis of cyclohexanone oxime catalyzed by solid acid, can solve the problems of difficult separation of catalyst and product, difficult recycling of waste acid liquid, difficulty of continuous production, etc., and achieves environmental protection Friendly process, avoid equipment corrosion, mild condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

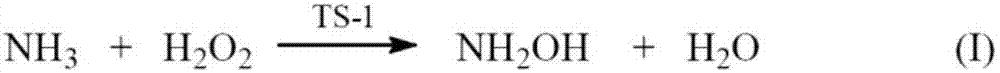

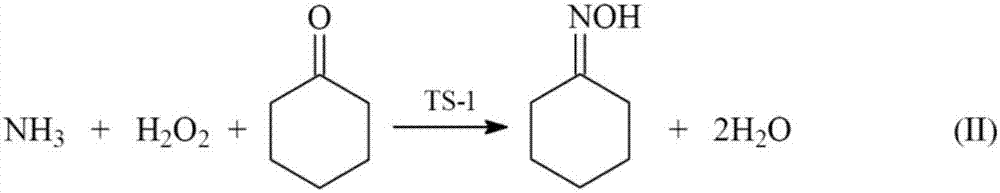

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 1g (0.0088mol) of cyclohexanone oxime, 20mL (1.111mol) of deionized water, and HZSM-5 catalyst (2g) with a silicon-aluminum ratio of 25 into a 100mL three-necked bottle, stir, reflux and condense, and react at 60°C The reaction was stopped after 1 h. At the reaction temperature, toluene is added for extraction, and the organic phase in the reaction liquid is separated to obtain cyclohexanone; the raffinate aqueous phase is centrifuged to obtain the product hydroxylamine aqueous solution and catalyst respectively.

[0021] Hydroxylamine in the aqueous phase was analyzed by potassium permanganate redox titration; the organic phase was qualitatively analyzed by the retention value method of pure substances and chromatographic-mass spectrometry, and the cyclohexanone in the organic phase was quantitatively analyzed by gas chromatography oxime conversion. The experimental results are shown in Table 1.

Embodiment 2

[0023] Step is with embodiment 1, and difference is that the catalyst that adds is silicotungstic acid (H 4 SiW 12 o 40 ). The experimental results are shown in Table 1.

Embodiment 3

[0025] Step is with embodiment 1, and difference is that the catalyst that adds is phosphotungstic acid (H 3 o 40 PW 12 ). The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com