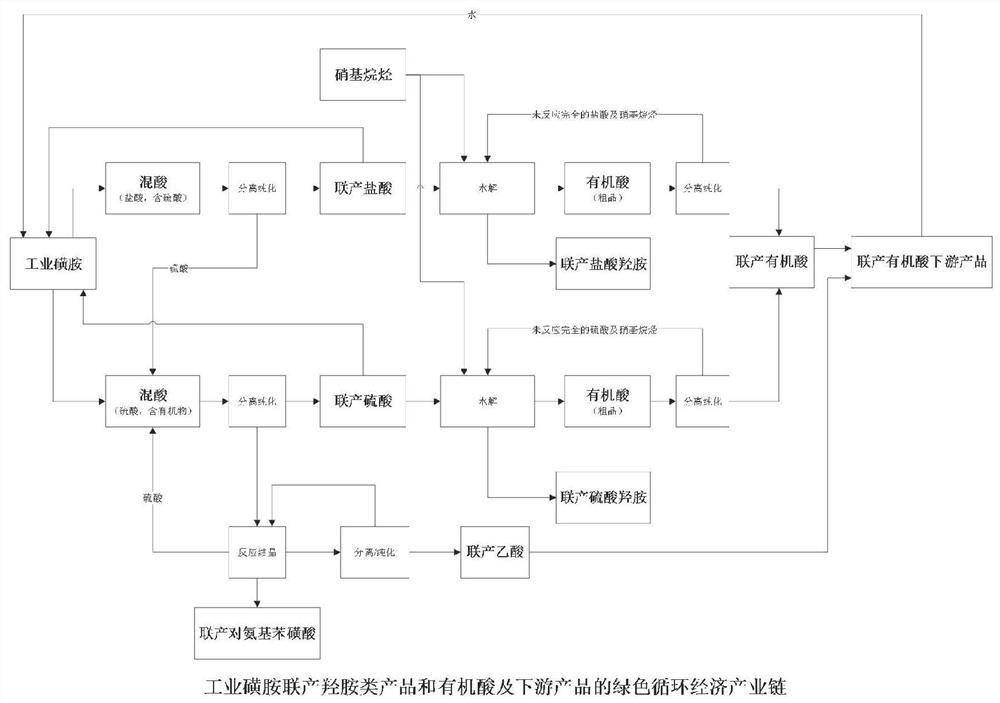

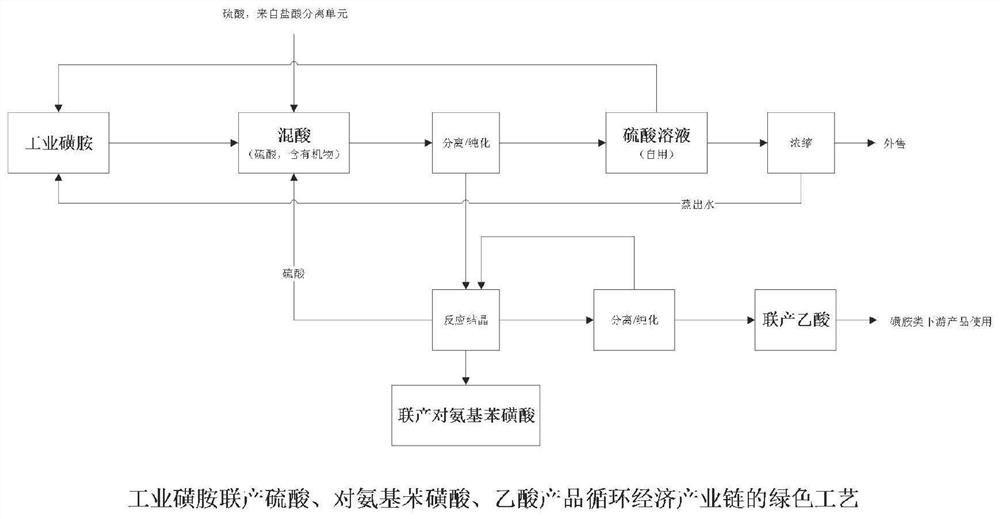

Green process of circular economy industry chain for co-production of industrial sulfanilamide and hydroxylamine products and organic acid downstream products

An industrial sulfonamide and green process technology, applied in the preparation of organic compounds, hydroxylamine, organic chemistry, etc., can solve the problems of waste of resources and energy, limited consumption of surrounding enterprises, and restrict the development of sulfonamide pharmaceutical companies, etc., and achieve high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example provides a green process for the circular economy industrial chain of industrial sulfonamide co-production of hydroxylamine products and organic acid downstream products. Its specific process is as figure 1 shown, including the following steps.

[0049] The industrialization of the circular economy industry chain with industrial sulfonamide-hydroxylamine hydrochloride-calcium propionate as the main product line, such as figure 2 shown.

[0050] Separation and purification of a small amount of sulfuric acid from hydrochloric acid (mixed acid) produced by industrial sulfonamides: Selective absorption process is adopted, normal pressure, 20°C -30°C, the absorption medium is water, selective absorption adopts pre-absorption + energy-saving absorption, and the pre-absorption tower is high-efficiency packing tower, an energy-saving absorption tower has been disclosed, and can be referred to CN202020276073. The separated sulfuric acid enters the sulfuric acid ...

Embodiment 2

[0061] This example provides a green process for the circular economy industrial chain of industrial sulfonamide co-production of hydroxylamine products and organic acid downstream products. Include the following steps.

[0062] Industrialization of circular economy industrial chain with industrial sulfonamide-hydroxylamine hydrochloride-calcium propionate as the main product line.

[0063] Separation and purification of a small amount of sulfuric acid from hydrochloric acid (mixed acid) produced by industrial sulfonamide: Selective absorption process is adopted, normal pressure, 35°C -45°C, absorption medium is water, selective absorption adopts pre-absorption + energy-saving absorption, and the pre-absorption tower is high-efficiency packing tower, an energy-saving absorption tower has been disclosed, and can be referred to CN202020276073. The separated sulfuric acid enters the sulfuric acid (mixed acid) separation and purification unit. The co-produced hydrochloric acid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com