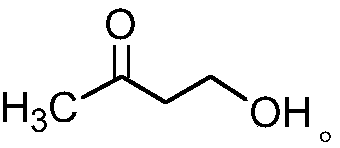

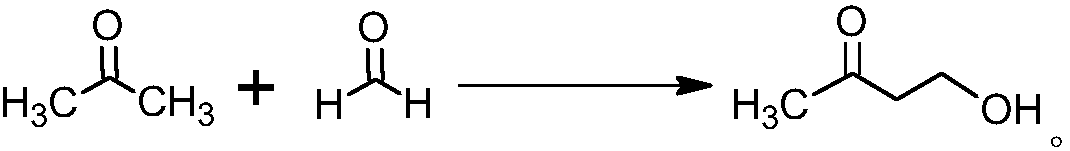

Method and device for synthetizing 4-hydroxy-2-butanone through catalytic reaction rectification

A technology for synthesizing butanone alcohol and catalyzing reaction, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problem of high energy consumption for separation and purification of fractionation tower, large loss of acetone, and long process flow and other problems, to achieve the effect of high temperature, reducing acetone loss and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

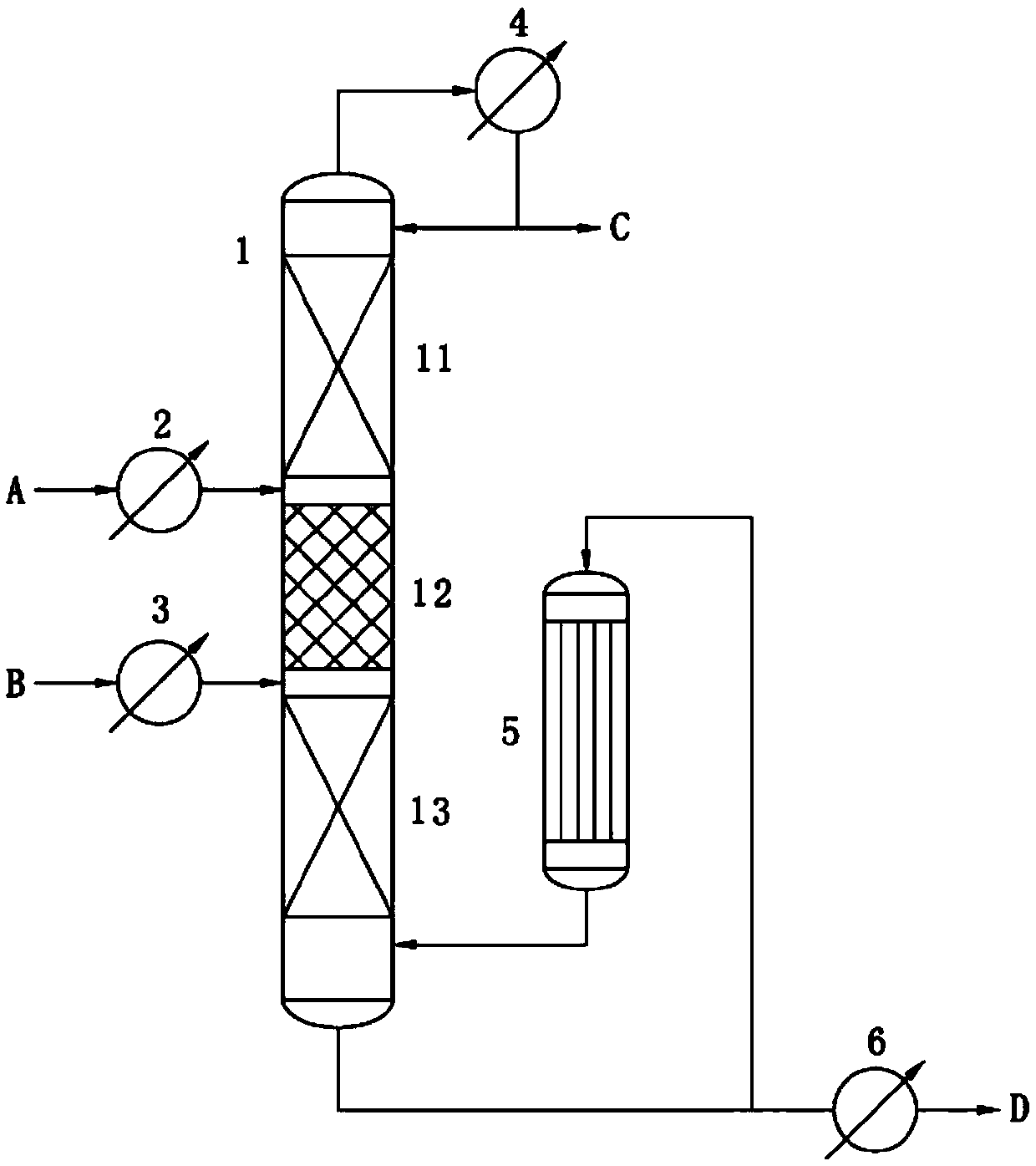

[0043]According to a preferred embodiment of the present invention, the method for synthesizing butanone alcohol by catalytic reaction rectification also includes condensing the unreacted acetone separated and purified from the rectifying section 11, and then partially returning it to the catalytic reaction The tower top of the rectifying tower 1 can provide cooling capacity for gas-liquid mass transfer and heat transfer in the catalytic reaction rectifying tower 1 tower, so as to ensure the purity of the acetone produced at the tower top. At this time, the reflux ratio of the catalytic reaction distillation column 1 is preferably (0.8-2):1, more preferably (1-1.6):1, and most preferably (1.2-1.4):1. The term "reflux ratio" refers to the ratio of the reflux flow to the production flow.

[0044] According to a preferred embodiment of the present invention, the method for synthesizing butanone alcohol by catalytic reaction rectification also includes returning the part of butano...

Embodiment 1

[0054] The diameter of the catalytic reaction rectification tower 1 is 300mm, wherein, the rectification section 11 is filled with BX500 wire mesh corrugated packing and the filling height is 5000mm, and the calculated theoretical plate number is 12; the catalytic section 12 is filled with packed KF / Al 2 o 3 MULTIPAK catalytic rectification structured packing with solid base catalyst (KF / Al 2 o 3 The weight ratio of the solid base catalyst to the MULTIPAK catalytic rectification structured packing is 1.7:1), the packing height is 3000 mm, and the calculated theoretical plate number is 5; the stripping section 13 is filled with BX500 wire mesh corrugated packing and the packing height is 2400 mm, The calculated theoretical plate number is 6. Formaldehyde enters from the upper part of the catalytic section 12 after being preheated to 80°C by the first preheater 2, and the flow rate is 100kg / h; acetone enters from the lower part of the catalytic section 12 after being preheated...

Embodiment 2

[0056] The diameter of the catalytic reaction rectification tower 1 is 300mm, wherein, the rectification section 11 is filled with BX500 wire mesh corrugated packing and the filling height is 4000mm, and the calculated theoretical plate number is 10; the catalytic section 12 is filled with packed KF / Al 2 o 3 KATAPAK Catalytic Distillation Structured Packing with Solid Base Catalyst (KF / Al 2 o 3 The weight ratio of the solid base catalyst to the KATAPAK catalytic rectification structured packing is 1.6:1), the packing height is 3200mm, and the calculated theoretical plate number is 5; the stripping section 13 is filled with BX500 wire mesh corrugated packing and the packing height is 2800mm, The calculated number of theoretical plates is 7. Formaldehyde enters from the upper part of the catalytic section 12 after being preheated to 80°C by the first preheater 2, and the flow rate is 100kg / h; acetone enters from the lower part of the catalytic section 12 after being preheated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com