Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1741results about "Heat-activated film/foil adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

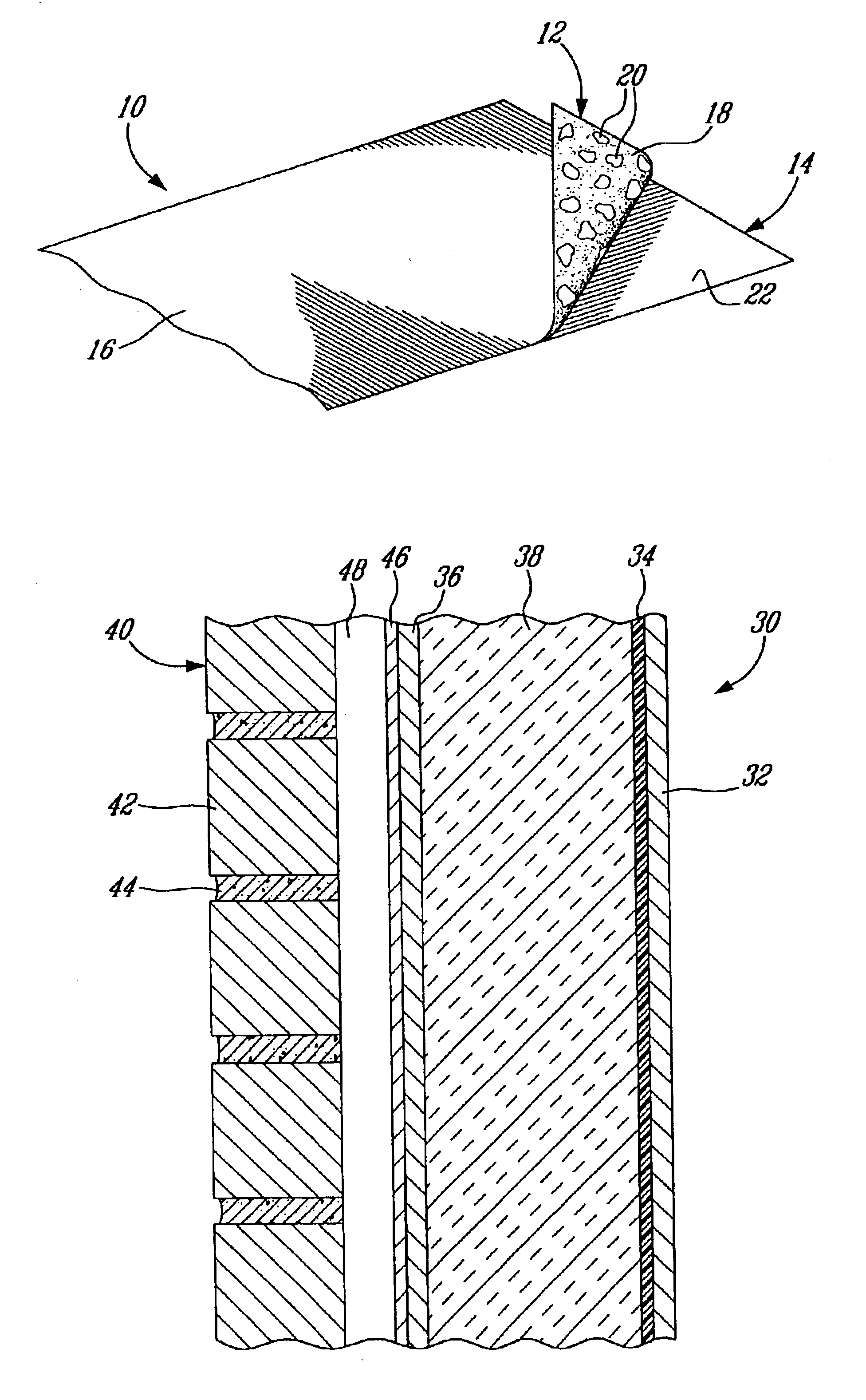

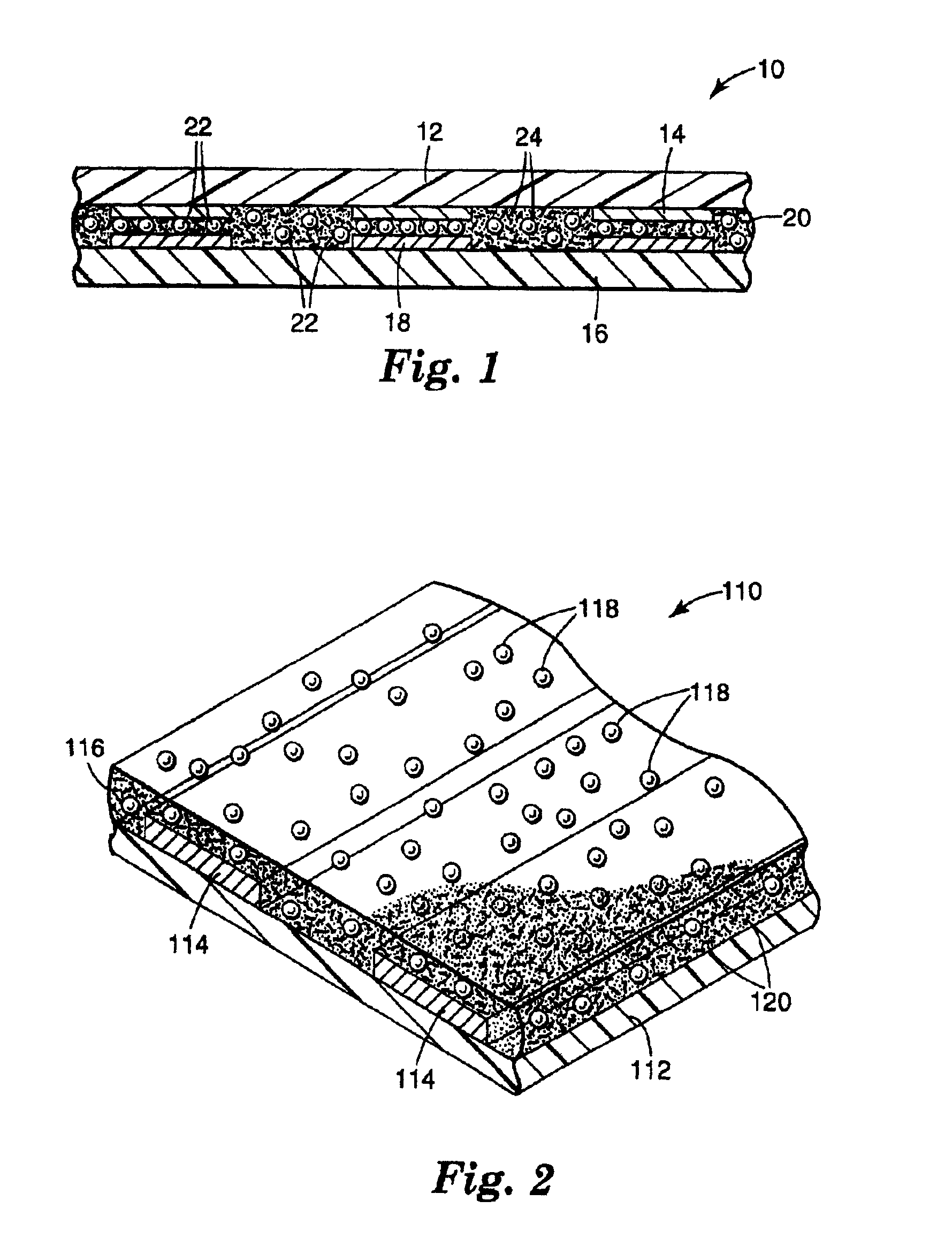

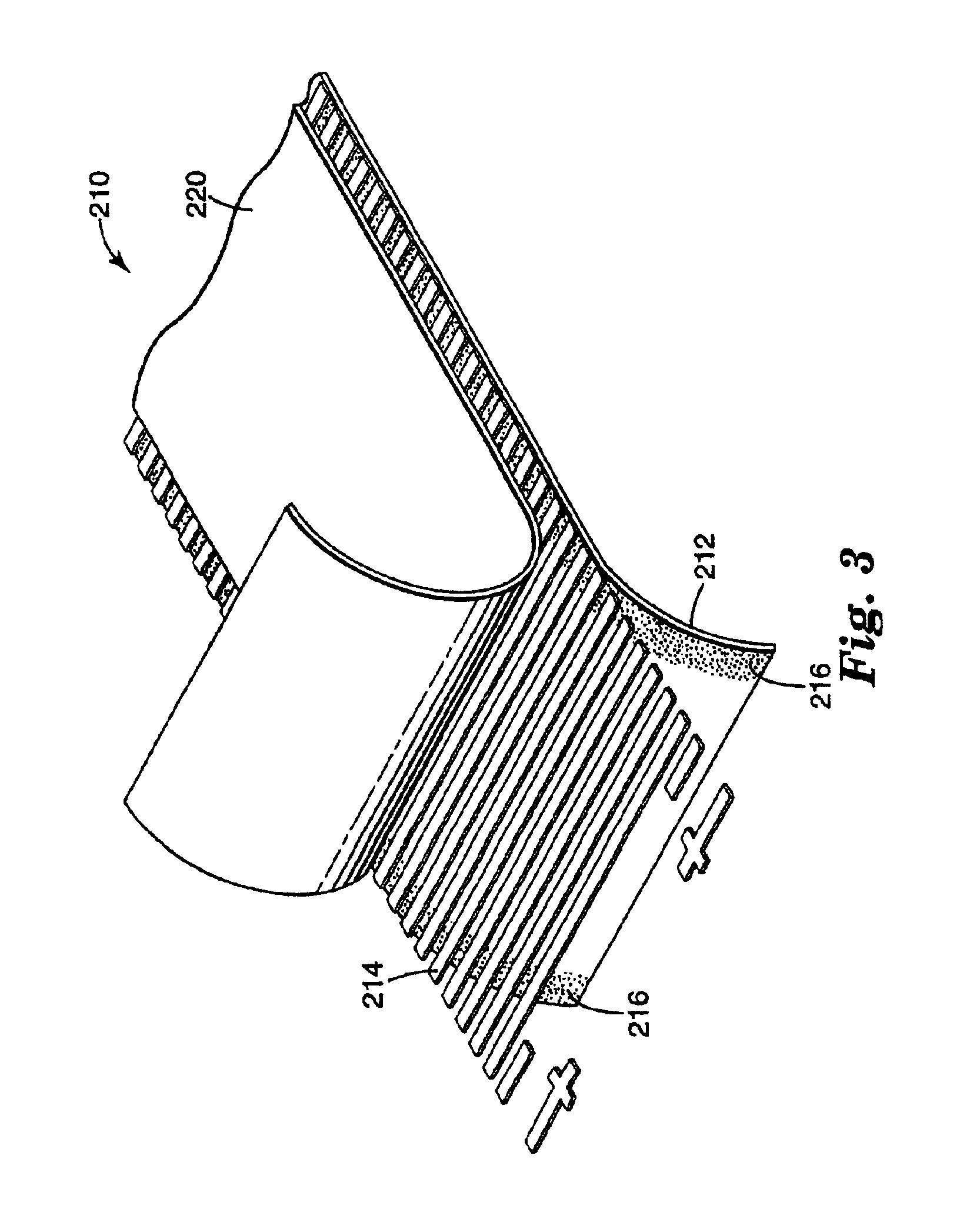

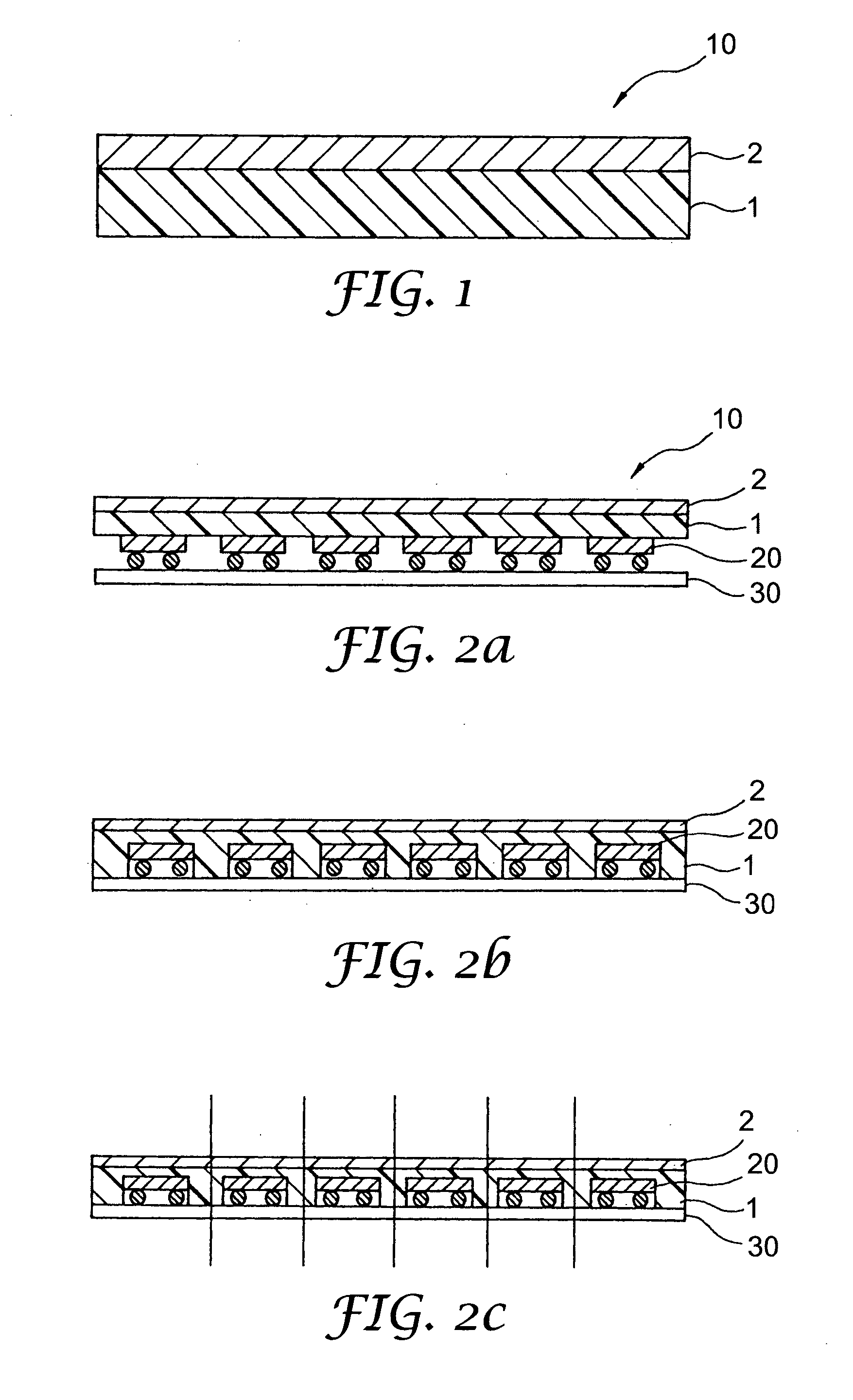

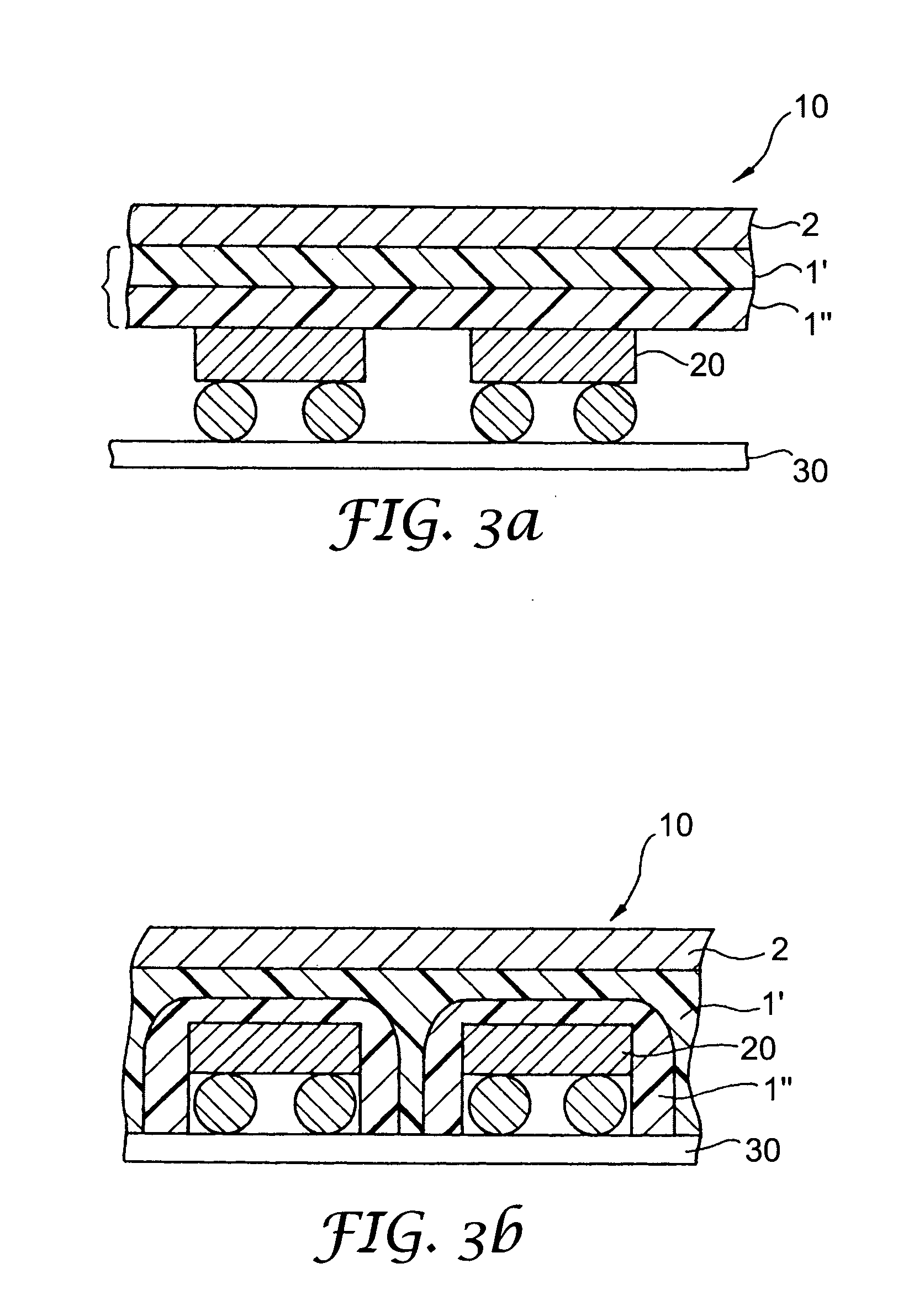

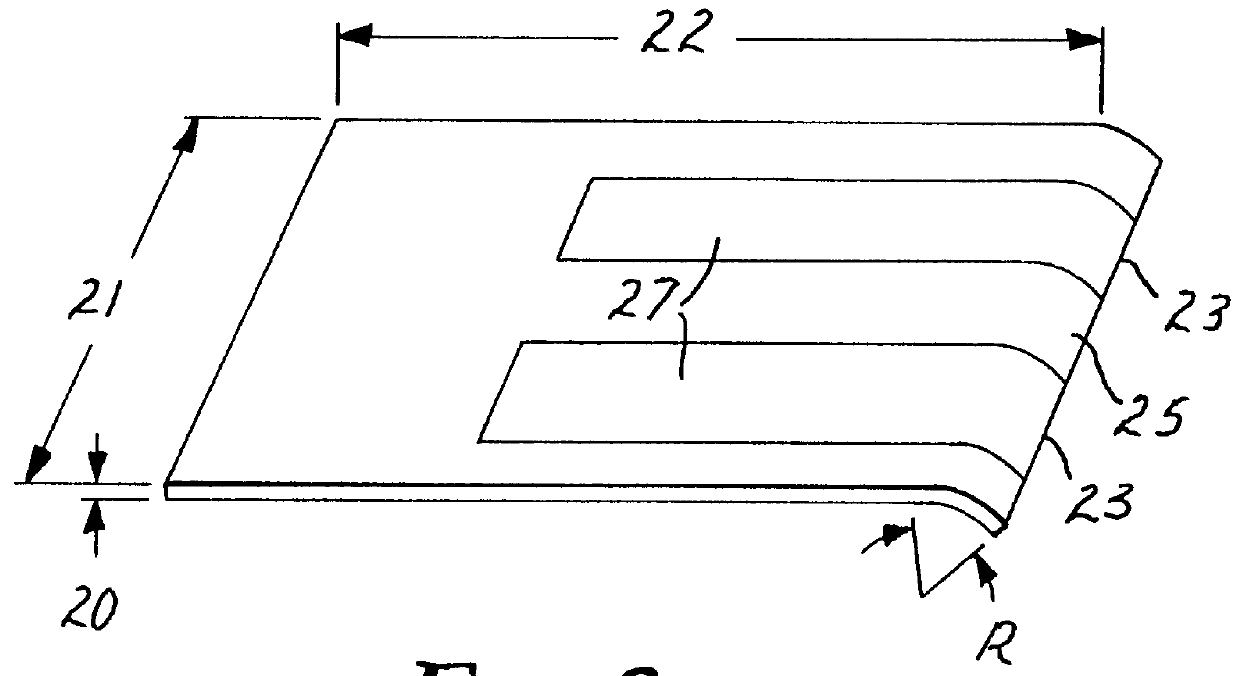

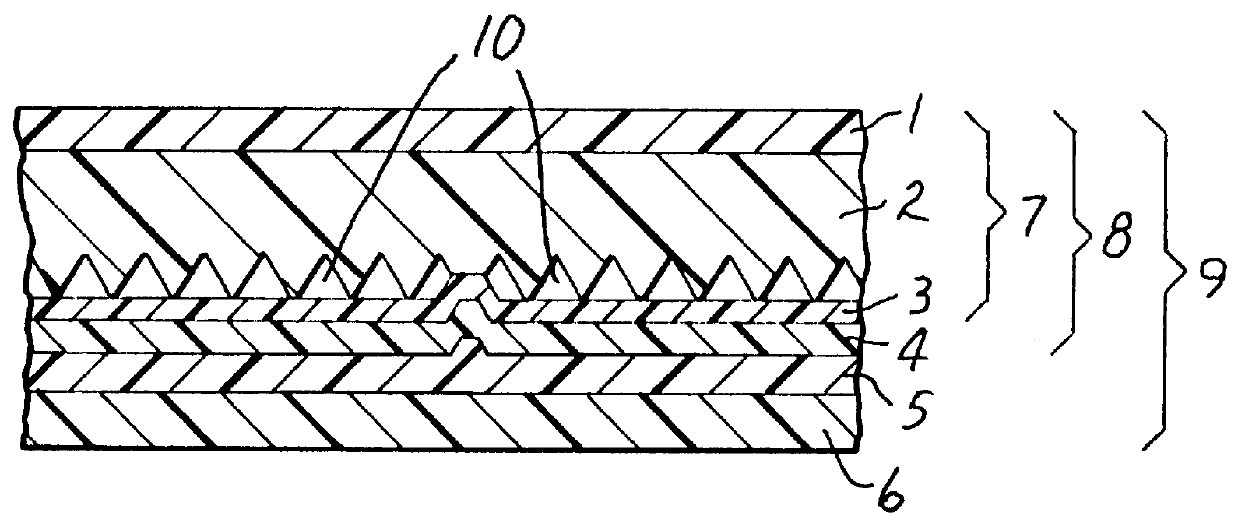

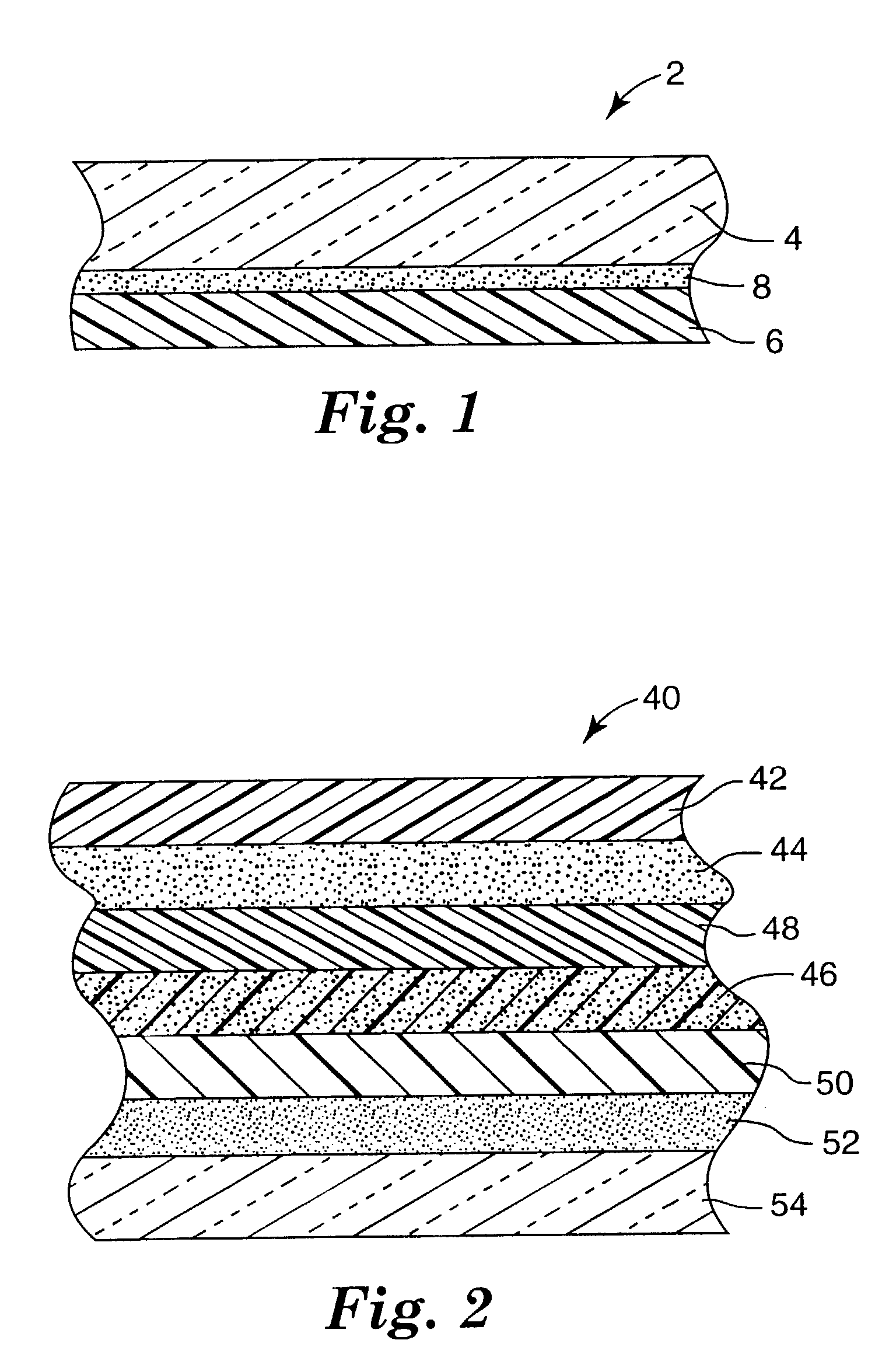

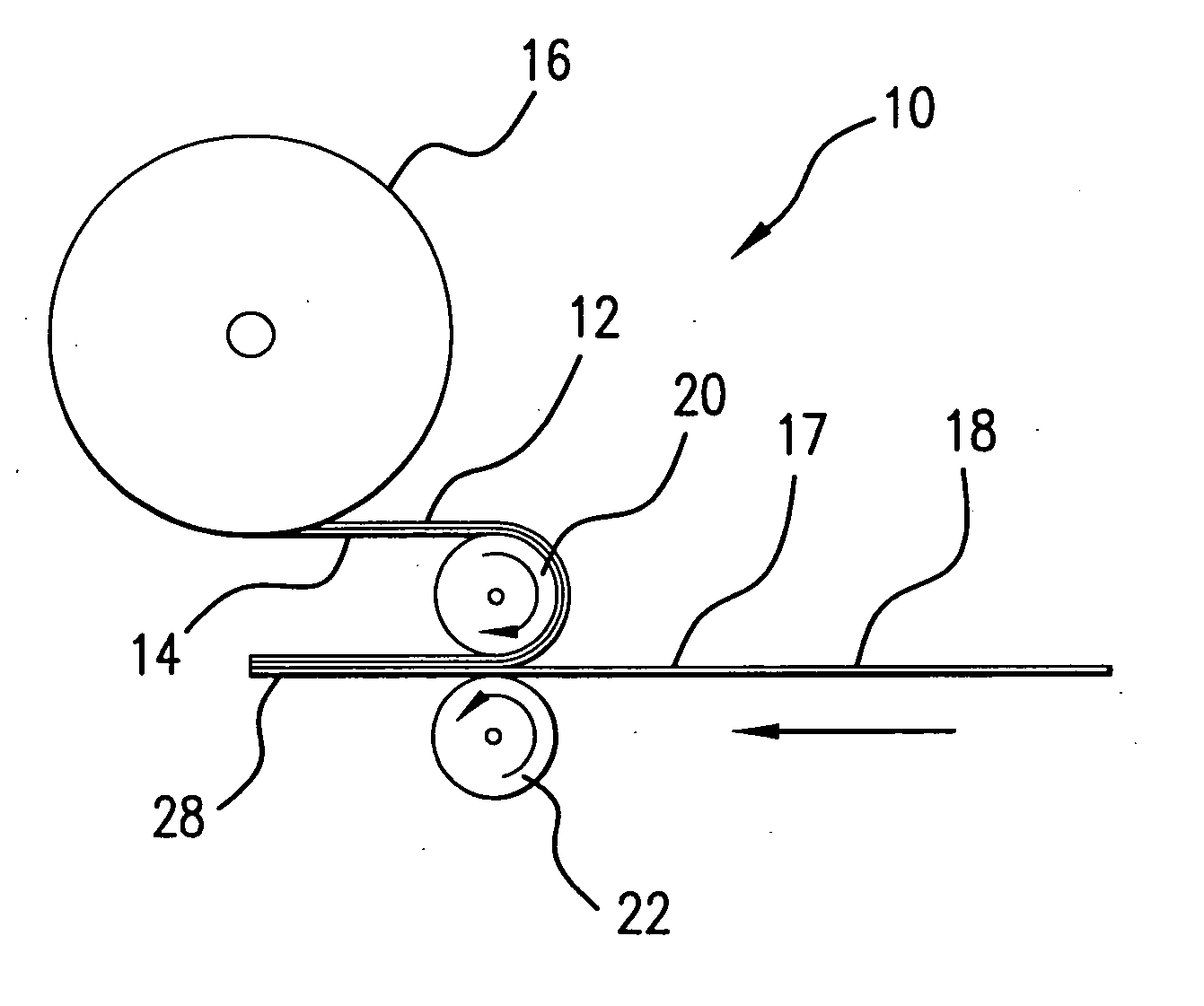

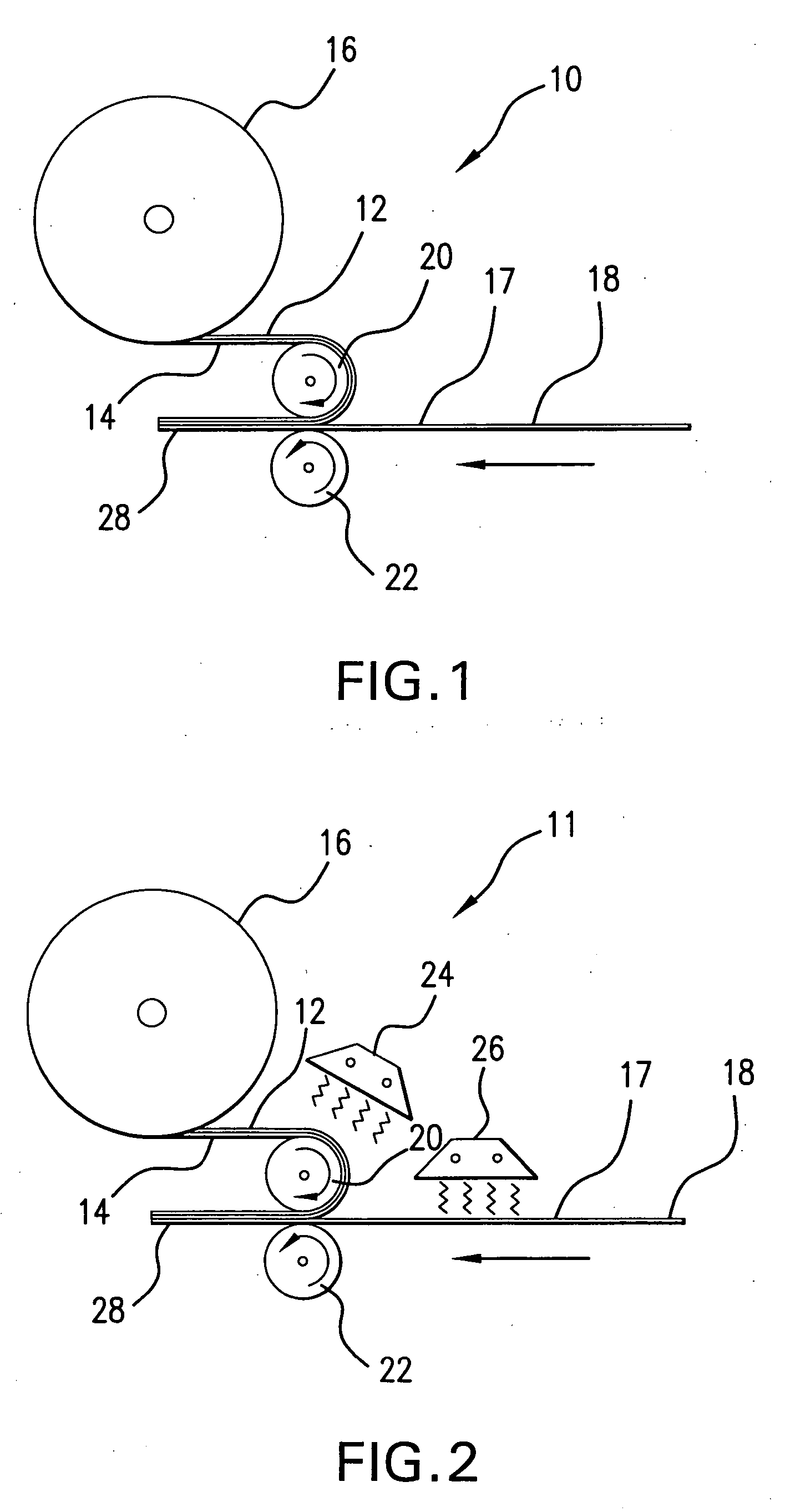

Self-adhering vapor permeable air and moisture barrier membrane

InactiveUS6901712B2Prevent lateral movementEliminate channelingCovering/liningsWallsAdhesiveWater vapor

Owner:HENRY COMPANY CANADA

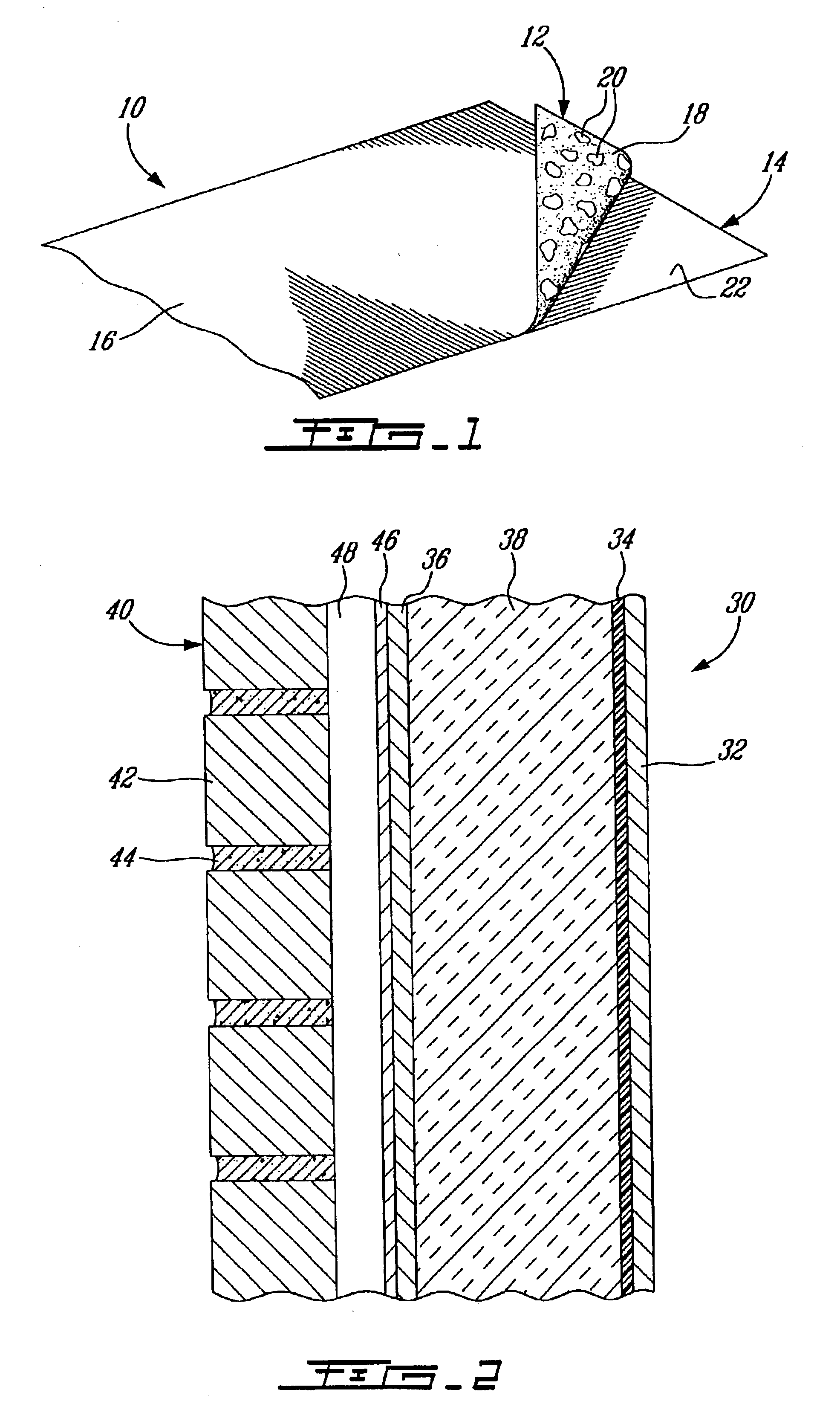

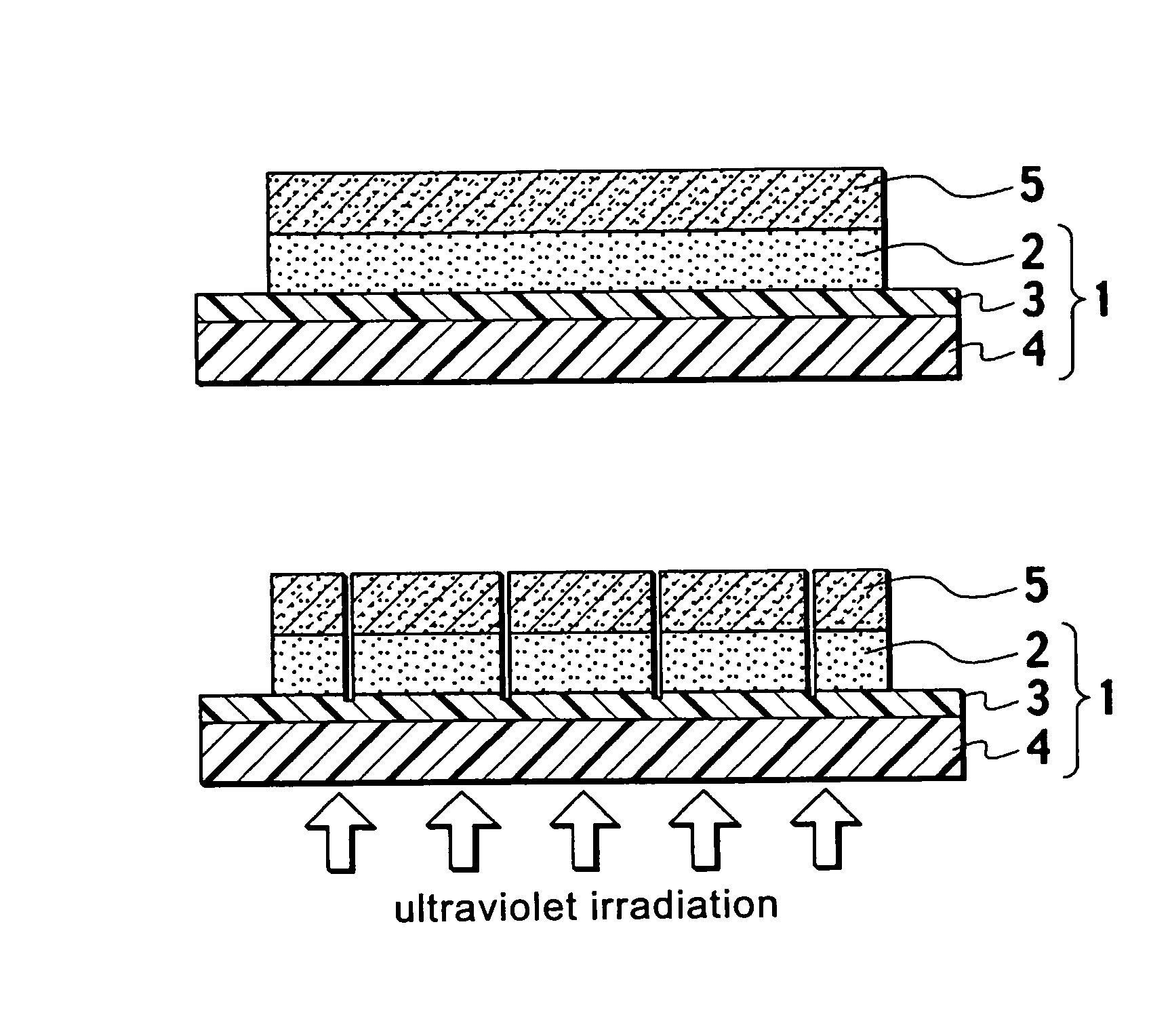

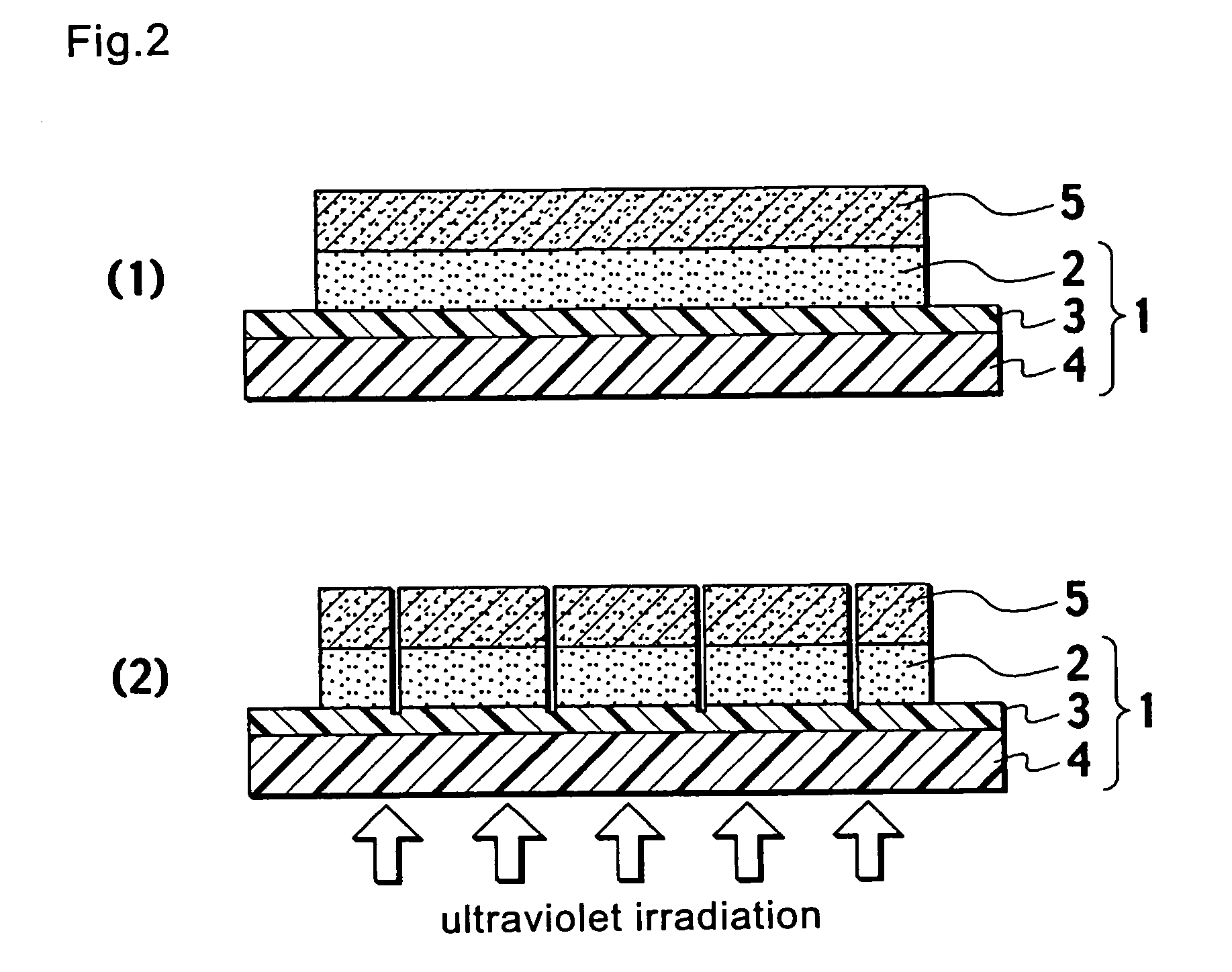

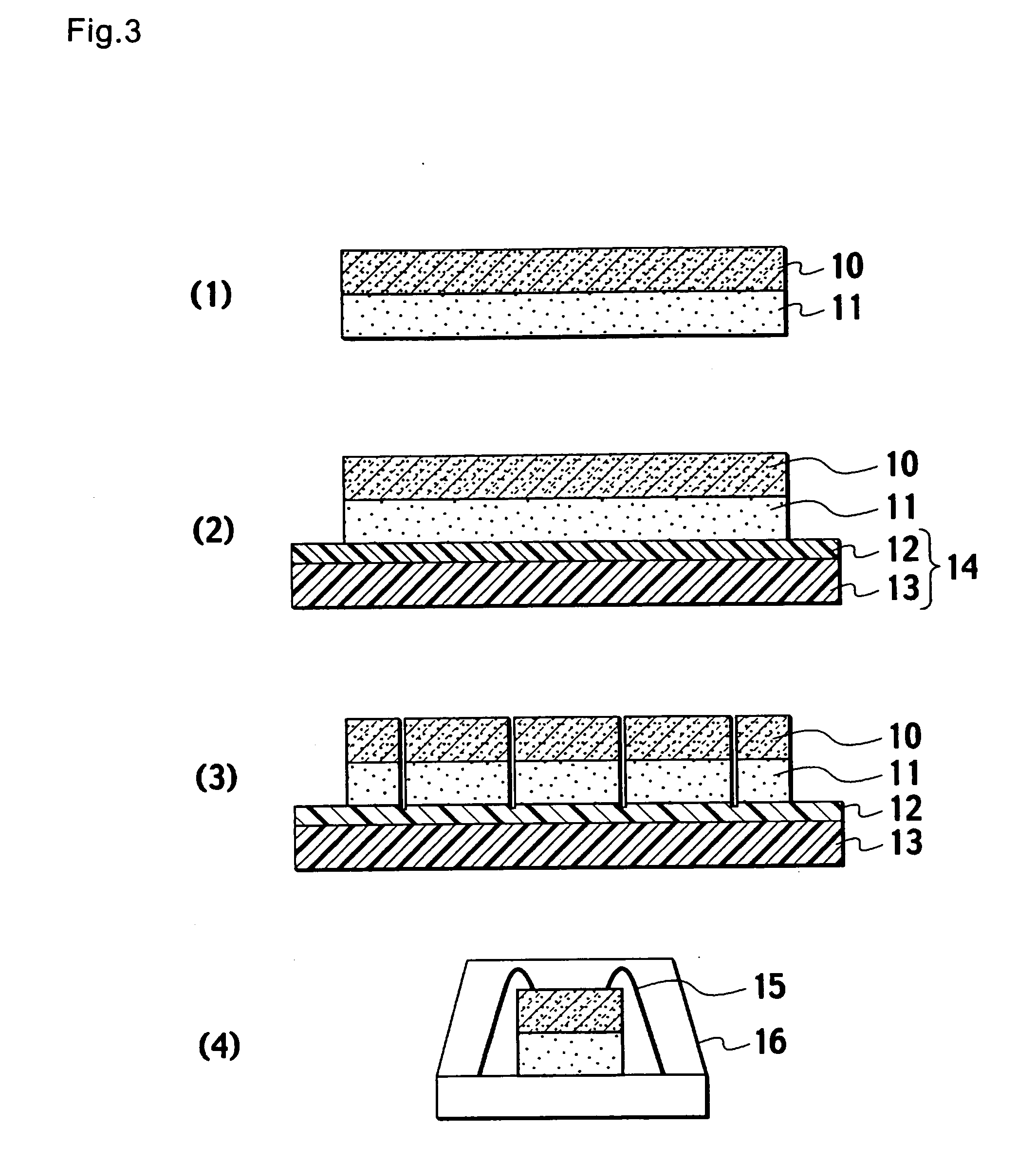

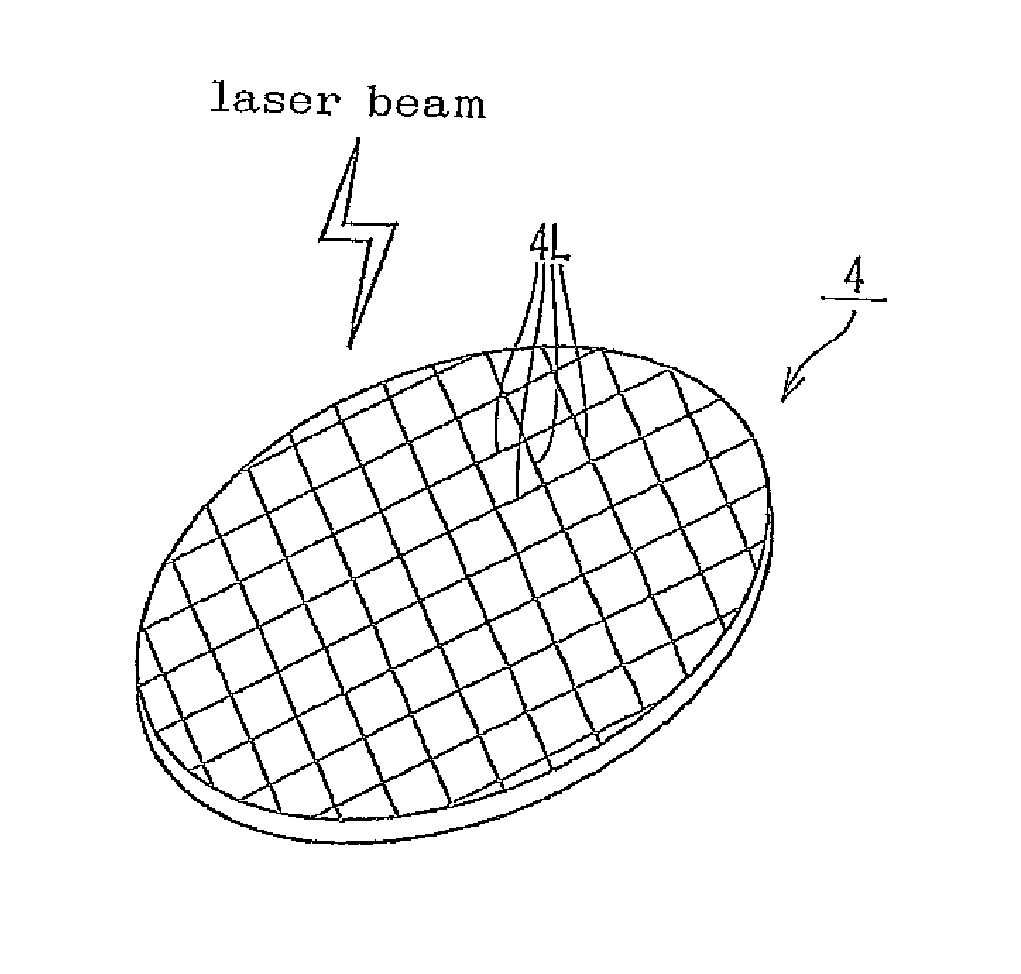

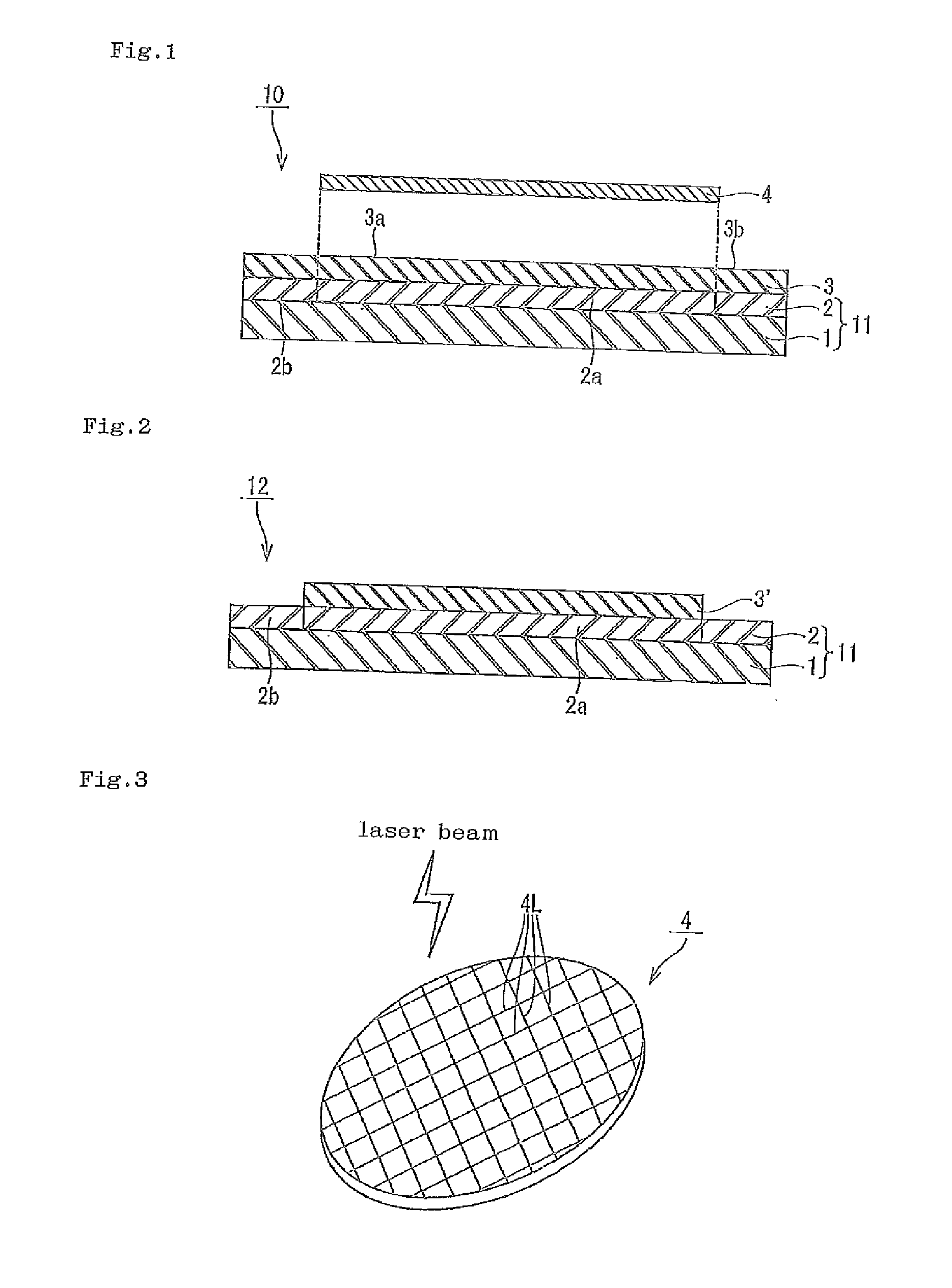

Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

InactiveUS20060128065A1Efficient cuttingImprove bond reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeDevice material

The invention provides an adhesive sheet which can be stuck to a wafer at low temperatures of 100° C. or below, which is soft to the extent that it can be handled at room temperature, and which can be cut simultaneously with a wafer under usual cutting conditions; a dicing tape integrated type adhesive sheet formed by lamination of the adhesive sheet and a dicing tape; and a method of producing a semiconductor device using them. In order to achieve this object, the invention is characterized by specifying the breaking strength, breaking elongation, and elastic modulus of the adhesive sheet in particular numerical ranges.

Owner:HITACHI CHEM CO LTD

Curing resin composition, adhesive epoxy resin paste, adhesive epoxy resin sheet, conductive connection paste, conductive connection sheet, and electronic component joined body

ActiveUS20060154078A1Adhesion reliability is highIncrease flexibilityNon-insulated conductorsSynthetic resin layered productsEpoxyHeat resistance

It is an object of the invention to provide a curable resin composition excellent in mechanical strength, heat resistance, moisture resistance, flexibility, resistance to thermal cycles, resistance to solder reflow, dimensional stability, and the like after curing and providing high adhesion reliability and conduction reliability and an adhesive epoxy resin paste, an adhesive epoxy resin sheet, a conductive connection paste, and a conductive connection sheet using the curable resin composition, and an electronic component joined body. The invention relates to a curable resin composition, which contains an epoxy resin, a solid polymer having a functional group to react with the epoxy group and a curing agent for an epoxy resin, no phase separation structure being observed in a matrix of a resin when a cured product is dyed with a heavy metal and observed with a transmission electron microscope.

Owner:SEKISUI CHEM CO LTD

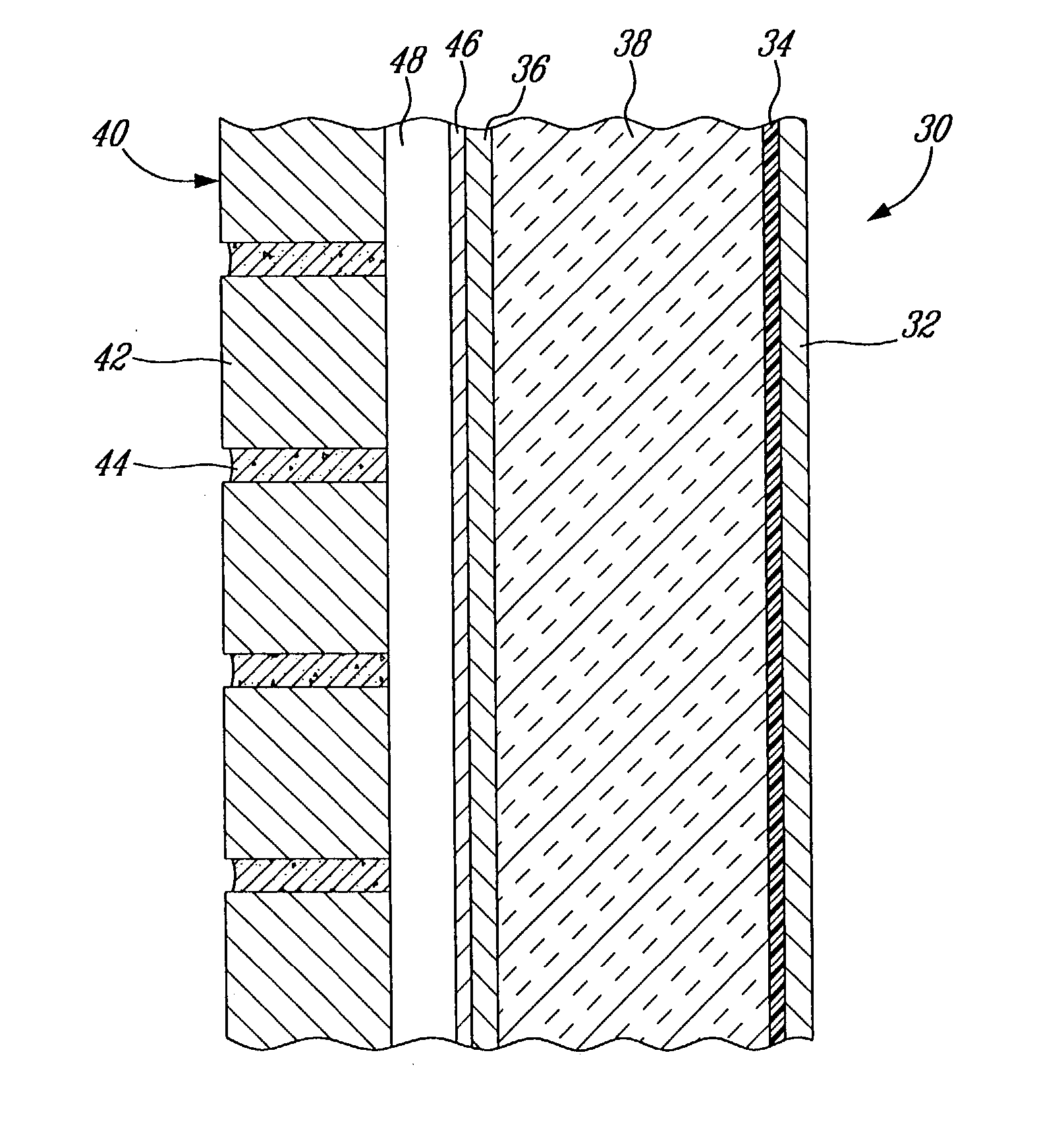

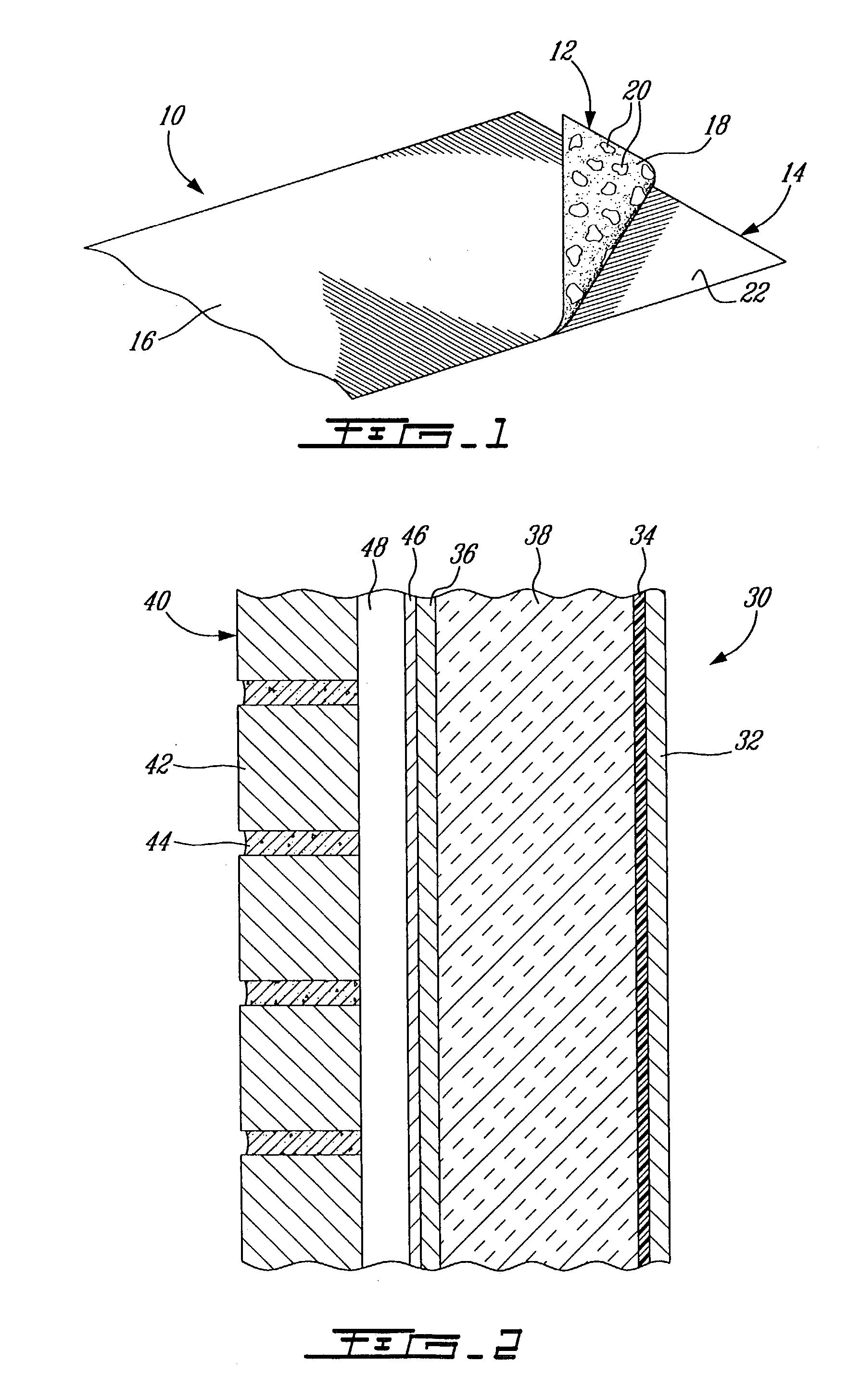

Self-adhering vapor permeable air and moisture barrier membrane

A self-adhering air and moisture barrier sheet membrane for structural surfaces of buildings, which is permeable to the passage of water vapor, is comprised of a water vapor permeable sheet onto one surface of which is applied an adhesive in a non-continuous film.

Owner:HENRY COMPANY CANADA

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

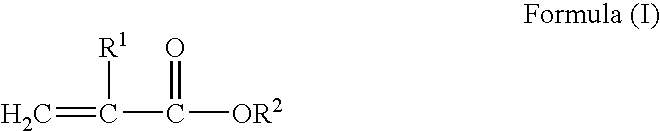

Block copolymer hot-melt processable adhesives, methods of their preparation, and articles therefrom

Hot-melt processable adhesive, such as pressure-sensitive-adhesive (PSA) or heat-activatable adhesive, compositions of the present invention possess a broad formulation latitude and adequate cohesive strength after application for use in high performance applications. Hot-melt processable adhesives of the invention comprise at least one block copolymer comprising at least two A blocks and at least one B block. The A and B blocks are derived from monoethylenically unsaturated monomers, which monomers result in saturated polymer backbones without the need for subsequent hydrogenation upon their polymerization. Preferably, the block copolymer is a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

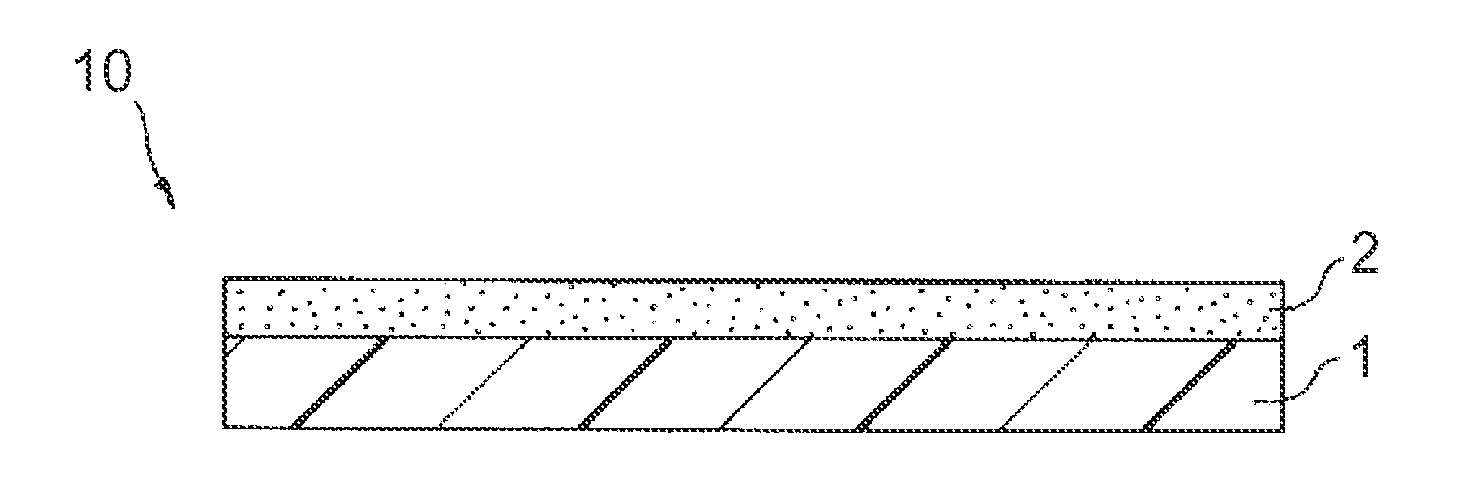

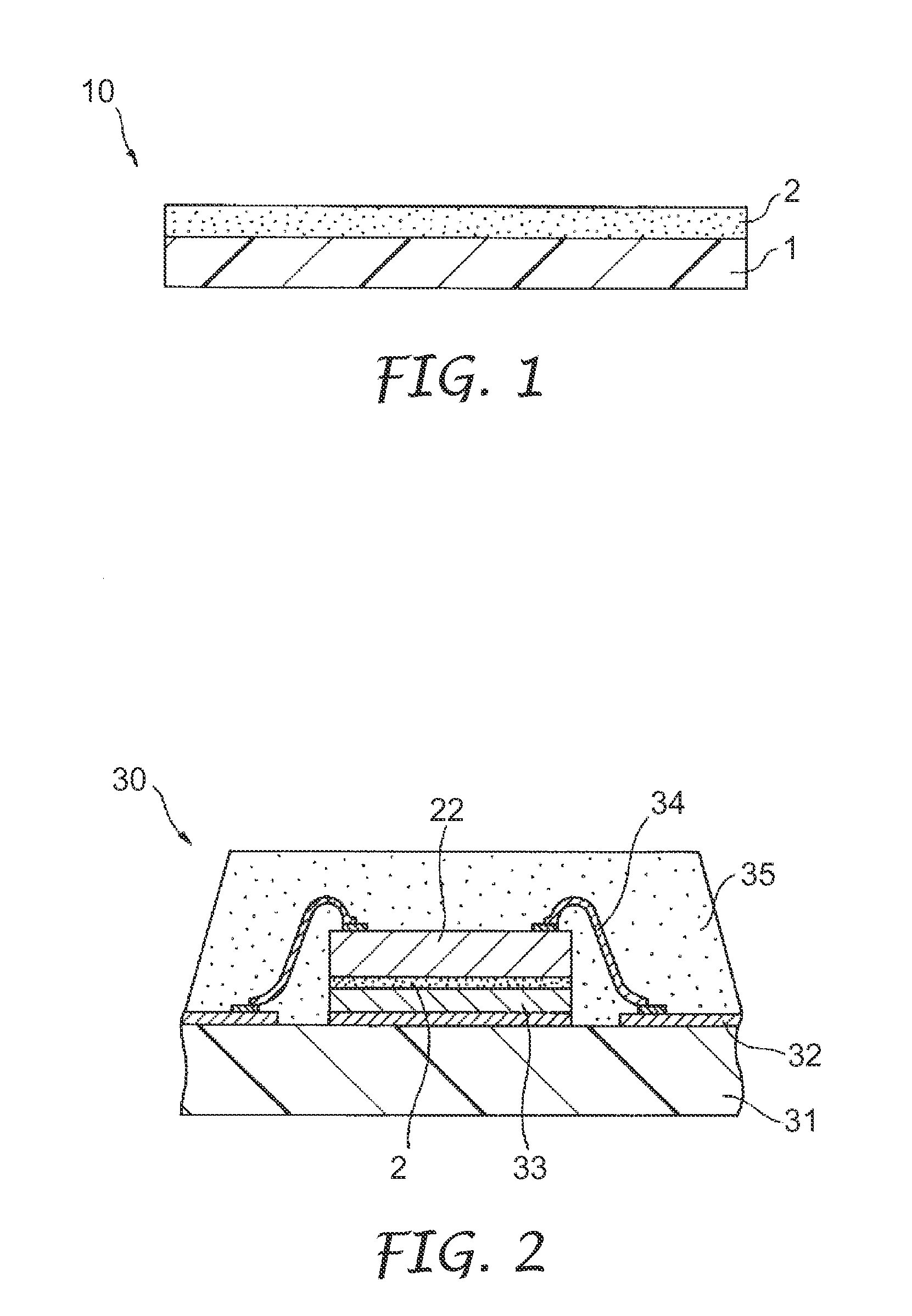

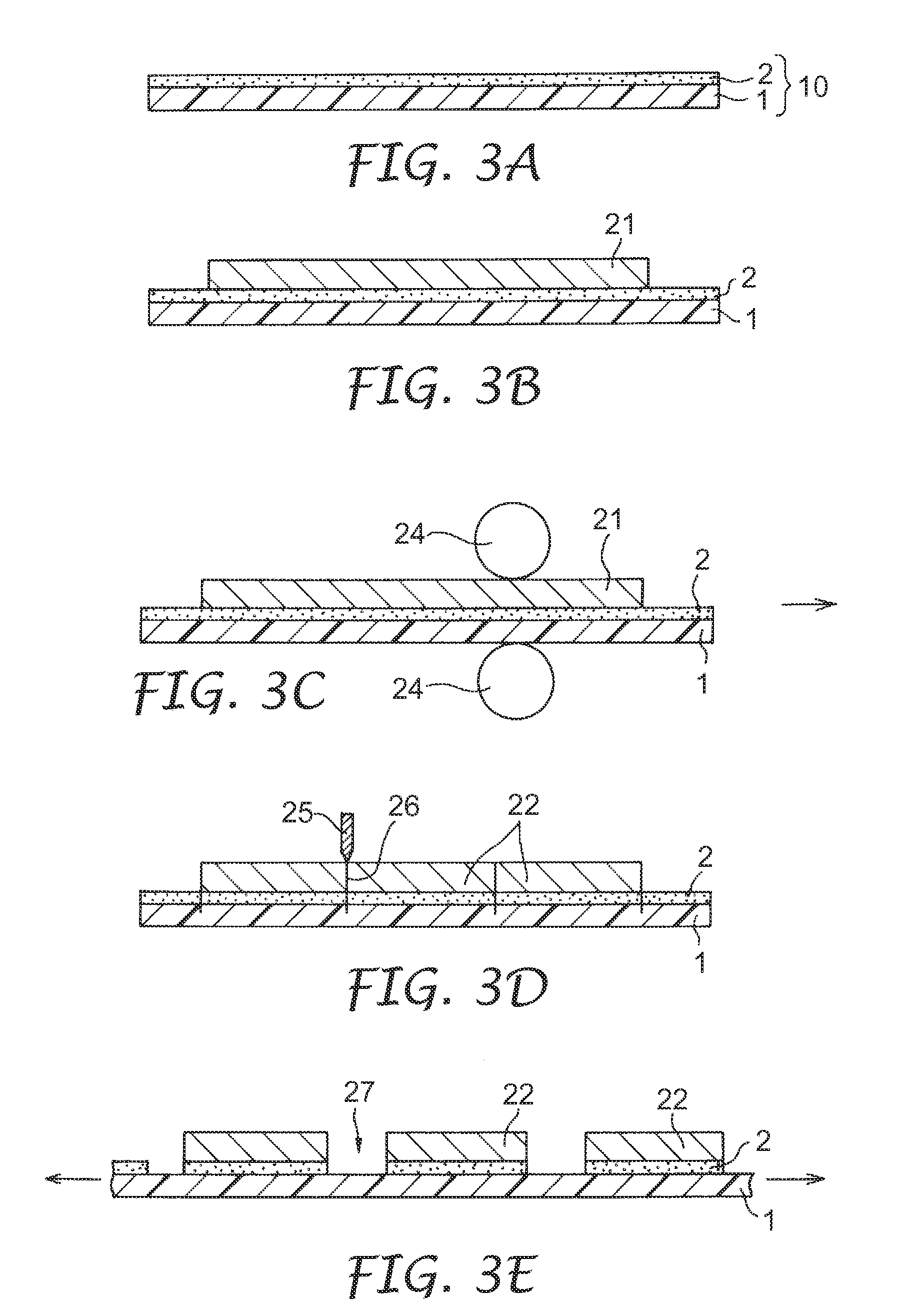

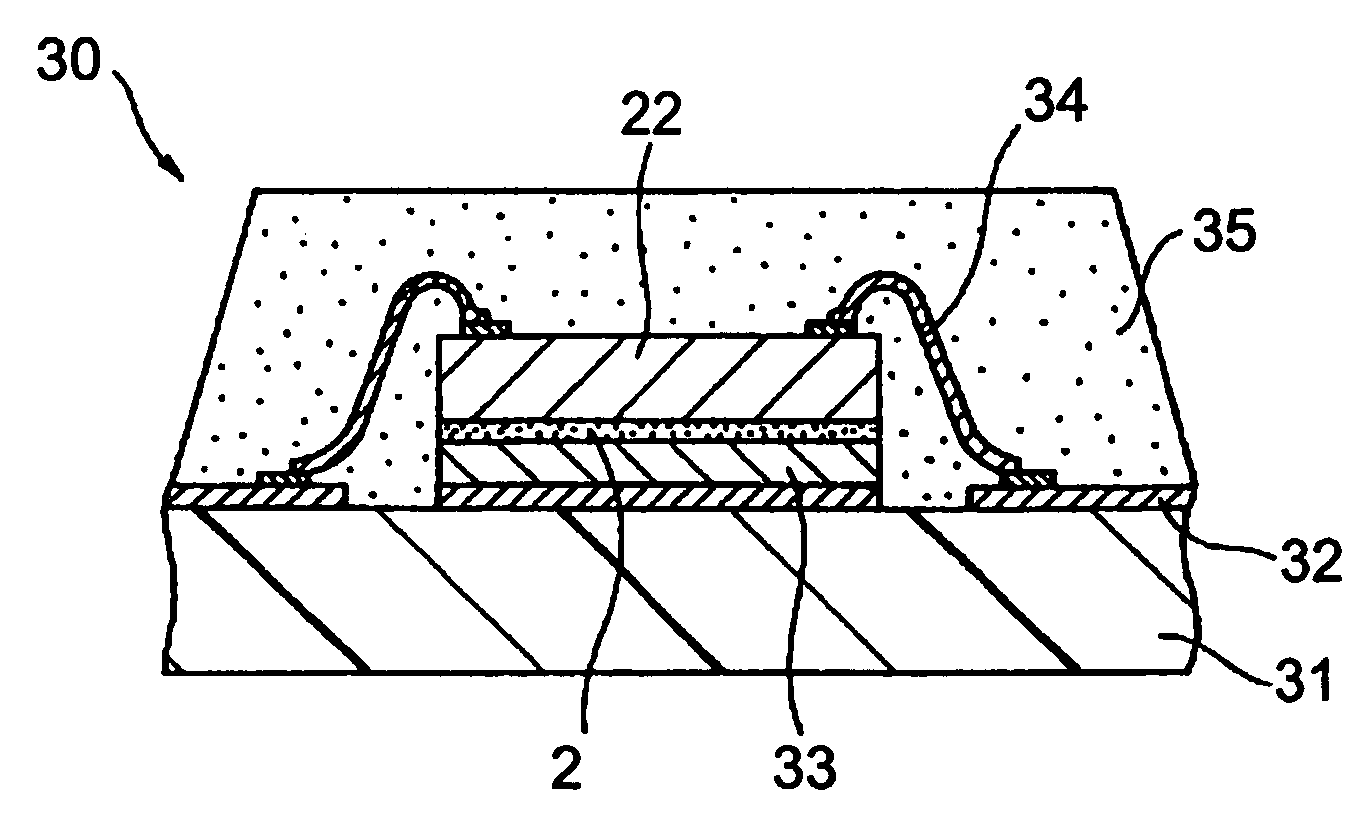

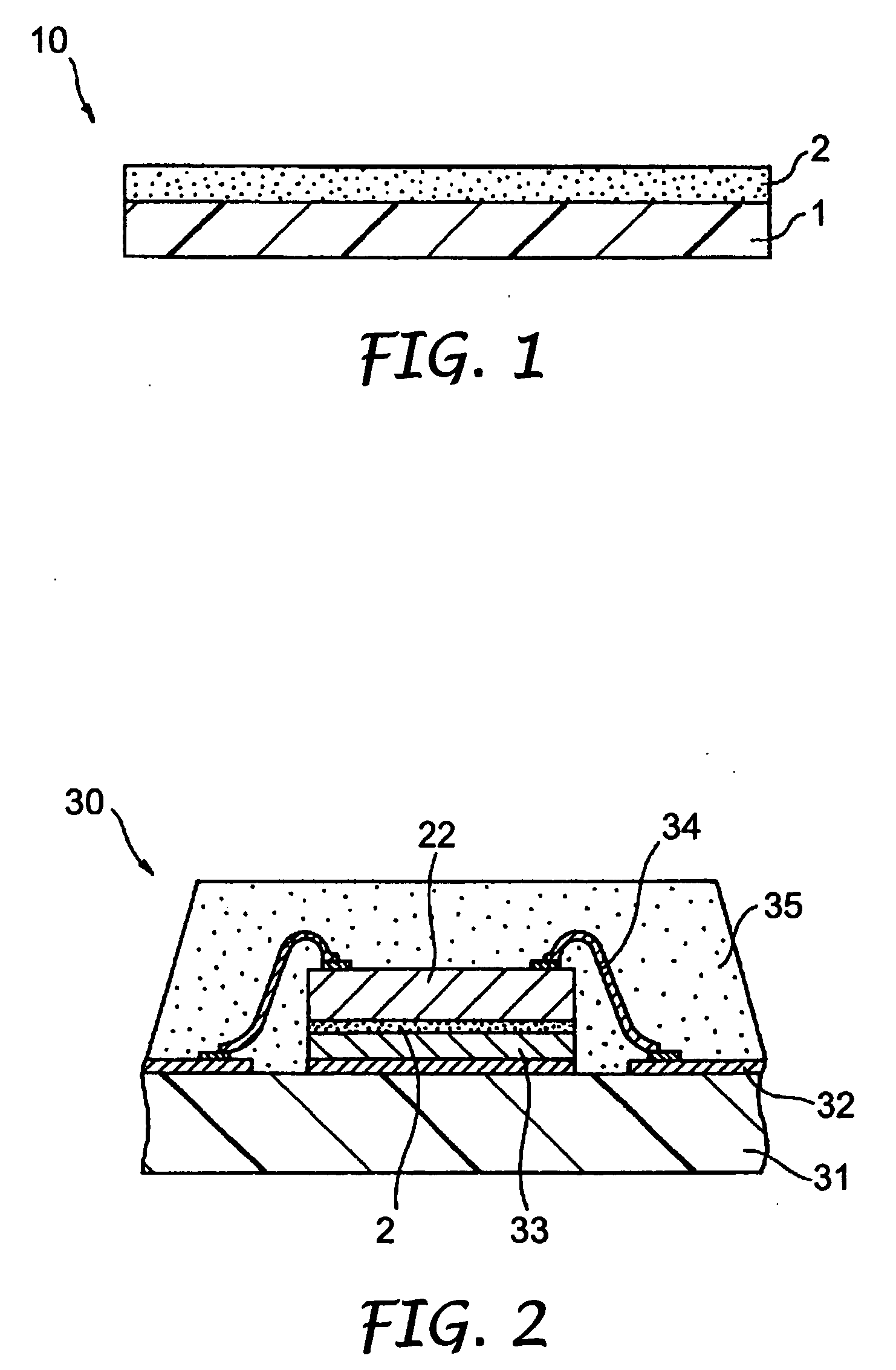

Heat curable adhesive composition, article, semiconductor apparatus and method

InactiveUS20080090085A1Lose resistanceLose strengthSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxySemiconductor chip

Provided are a heat curable adhesive composition and an adhesive article suited for dicing of a semiconductor and die-bonding of the diced semiconductor chip, and a semiconductor apparatus and a process for preparing a semiconductor apparatus using the adhesive composition and article. In one embodiment, the present invention provides a heat curable adhesive composition comprising a caprolactone-modified epoxy resin and a tack reducing component. Another embodiment of the present invention provides an adhesive article comprising a heat curable adhesive layer of a heat curable adhesive composition comprising a caprolactone-modified epoxy resin, a tack reducing component, and a backing layer carrying said adhesive layer on at least a portion of the backing layer.

Owner:3M INNOVATIVE PROPERTIES CO

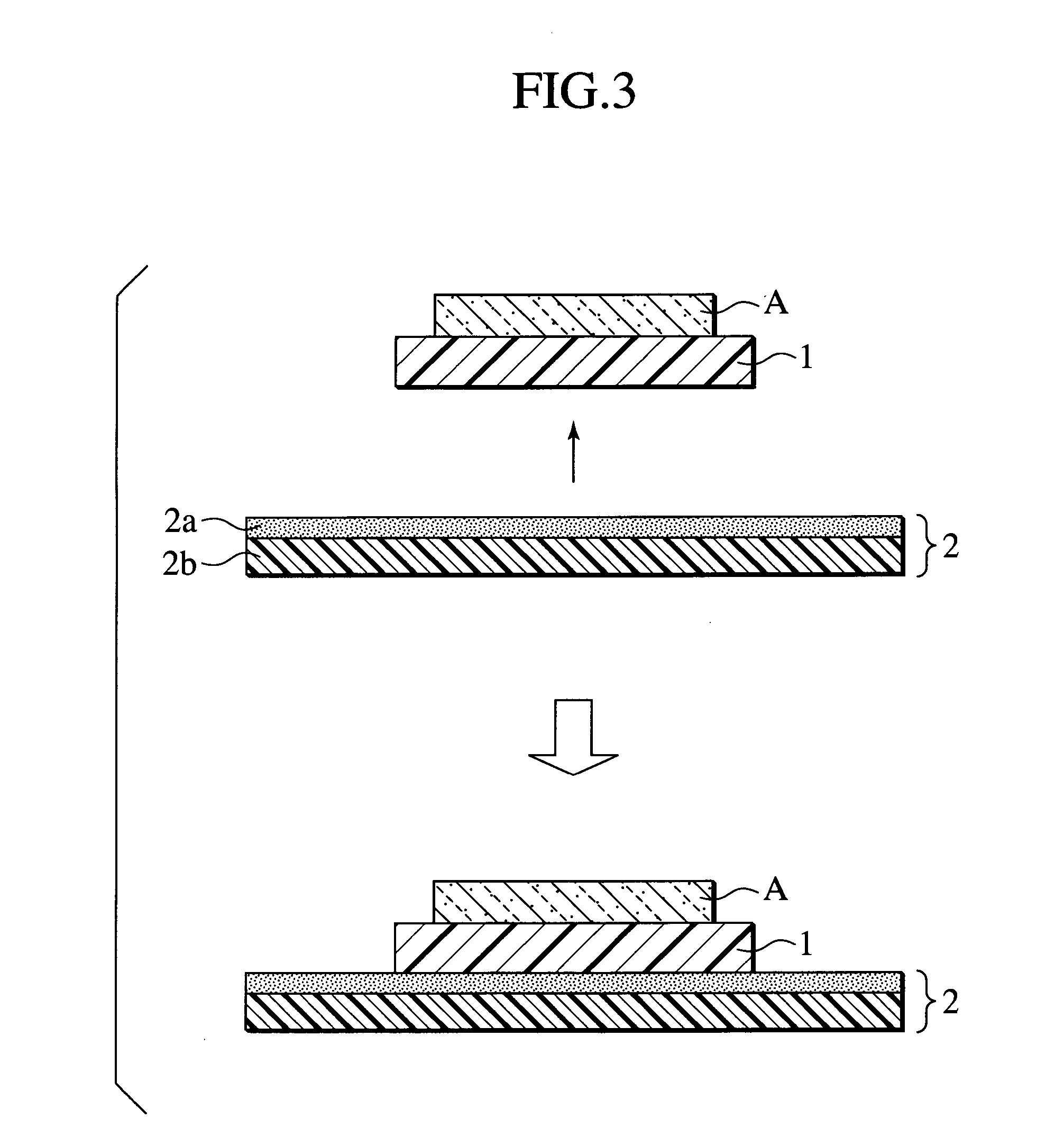

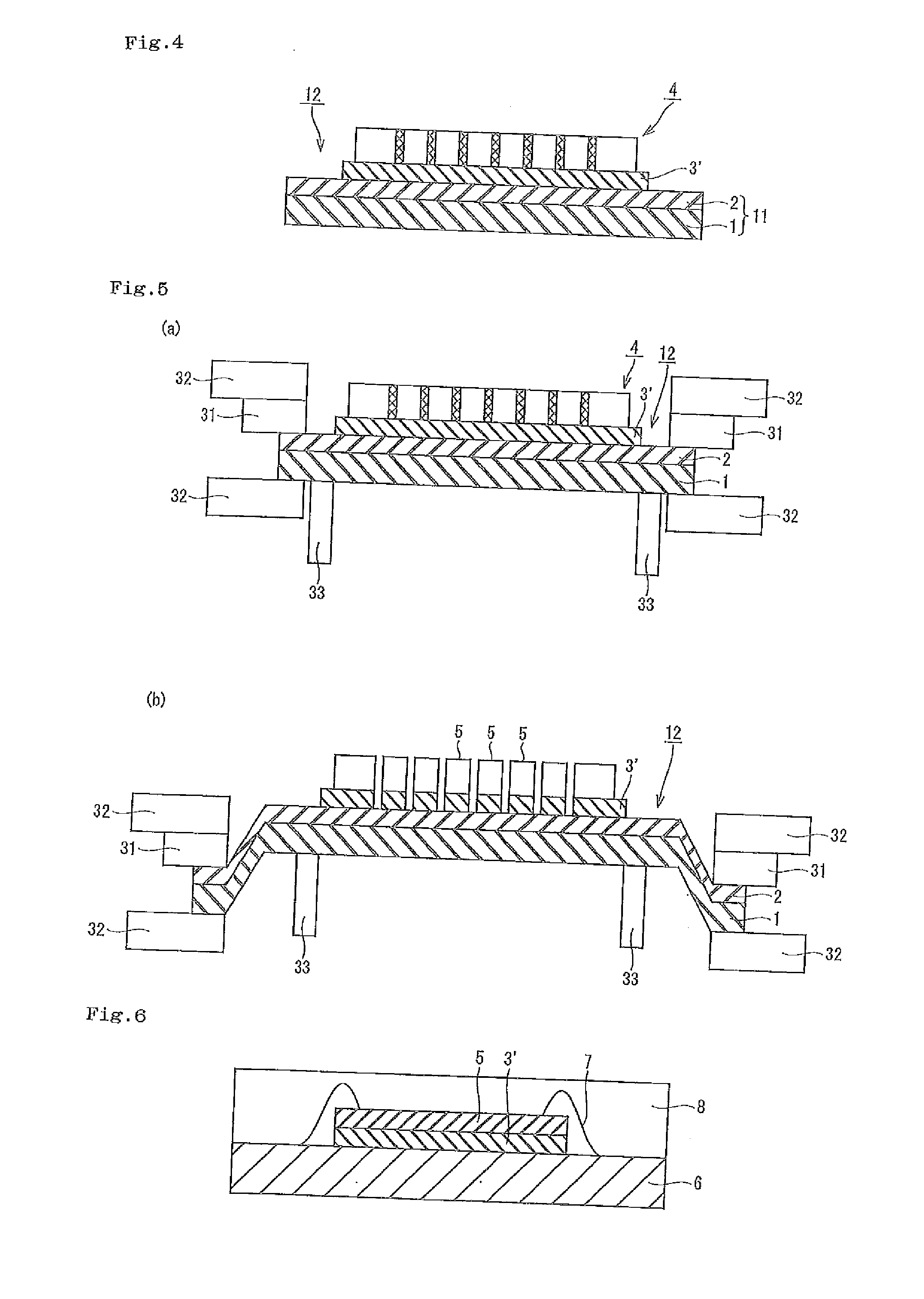

Dicing/die bonding sheet

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

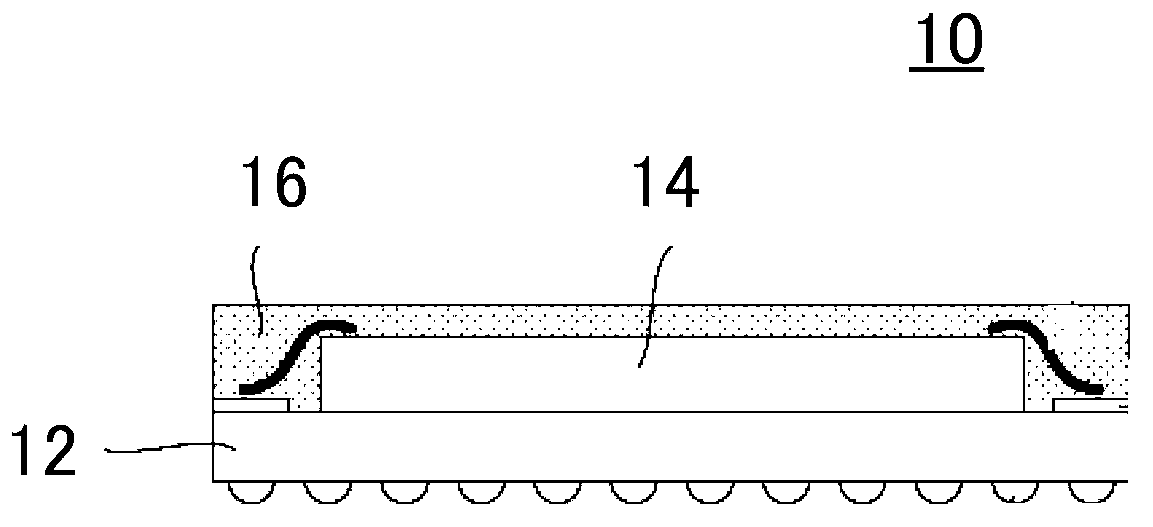

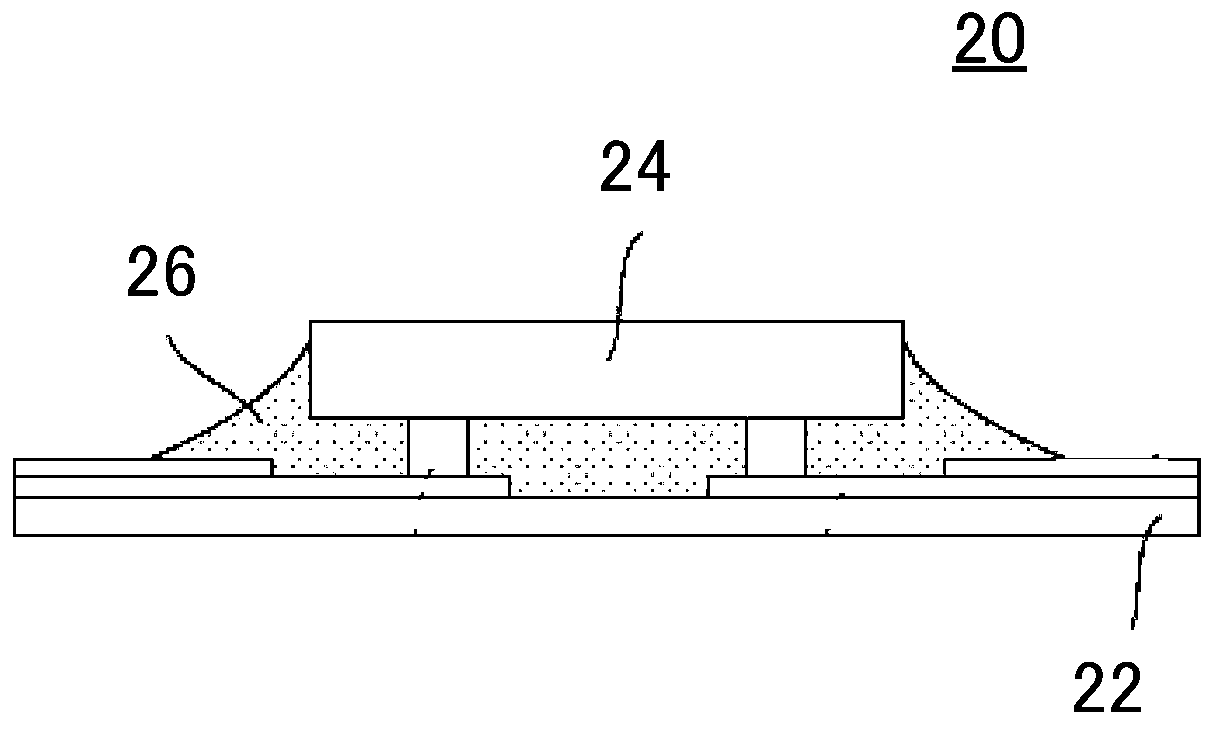

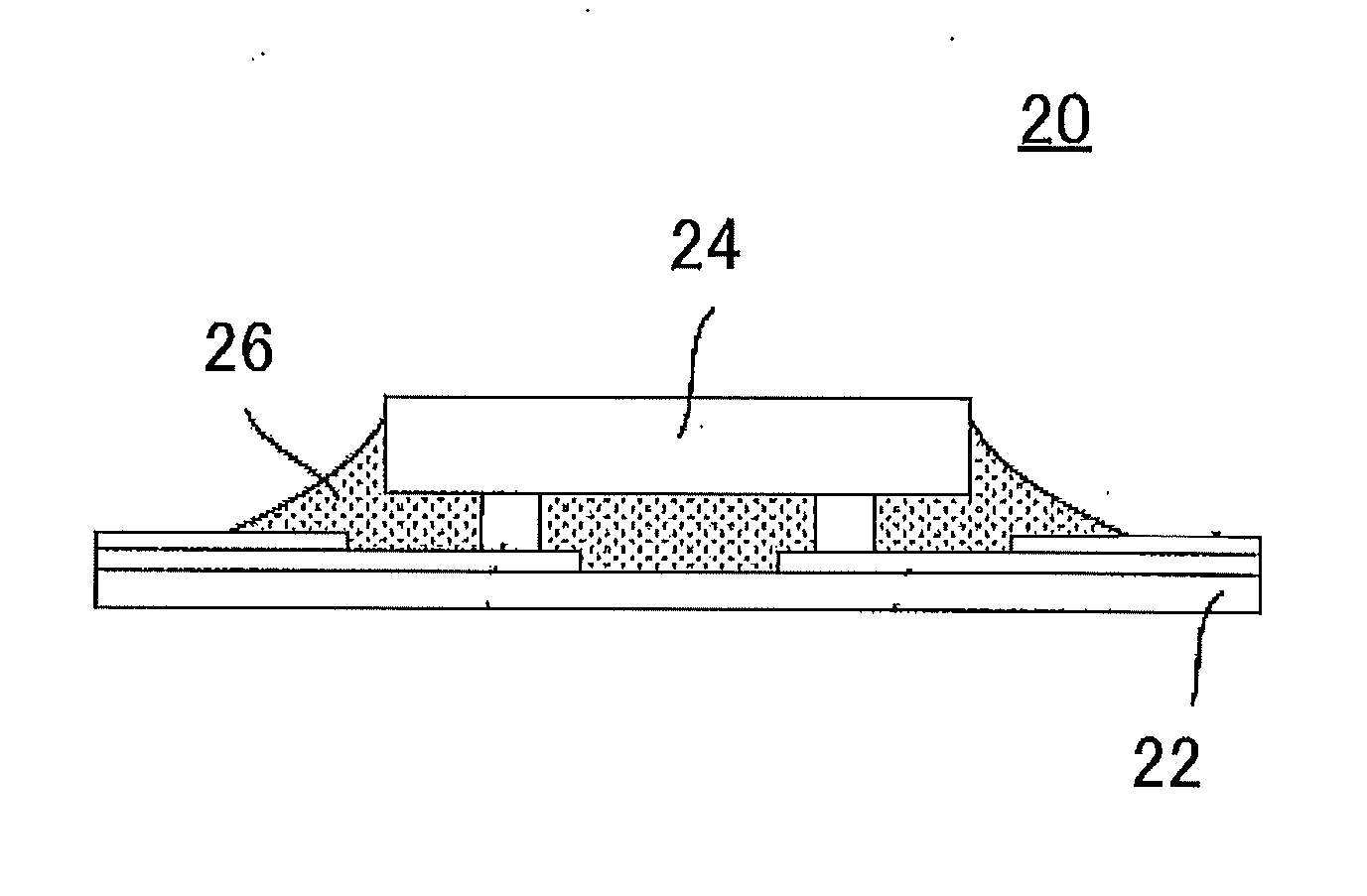

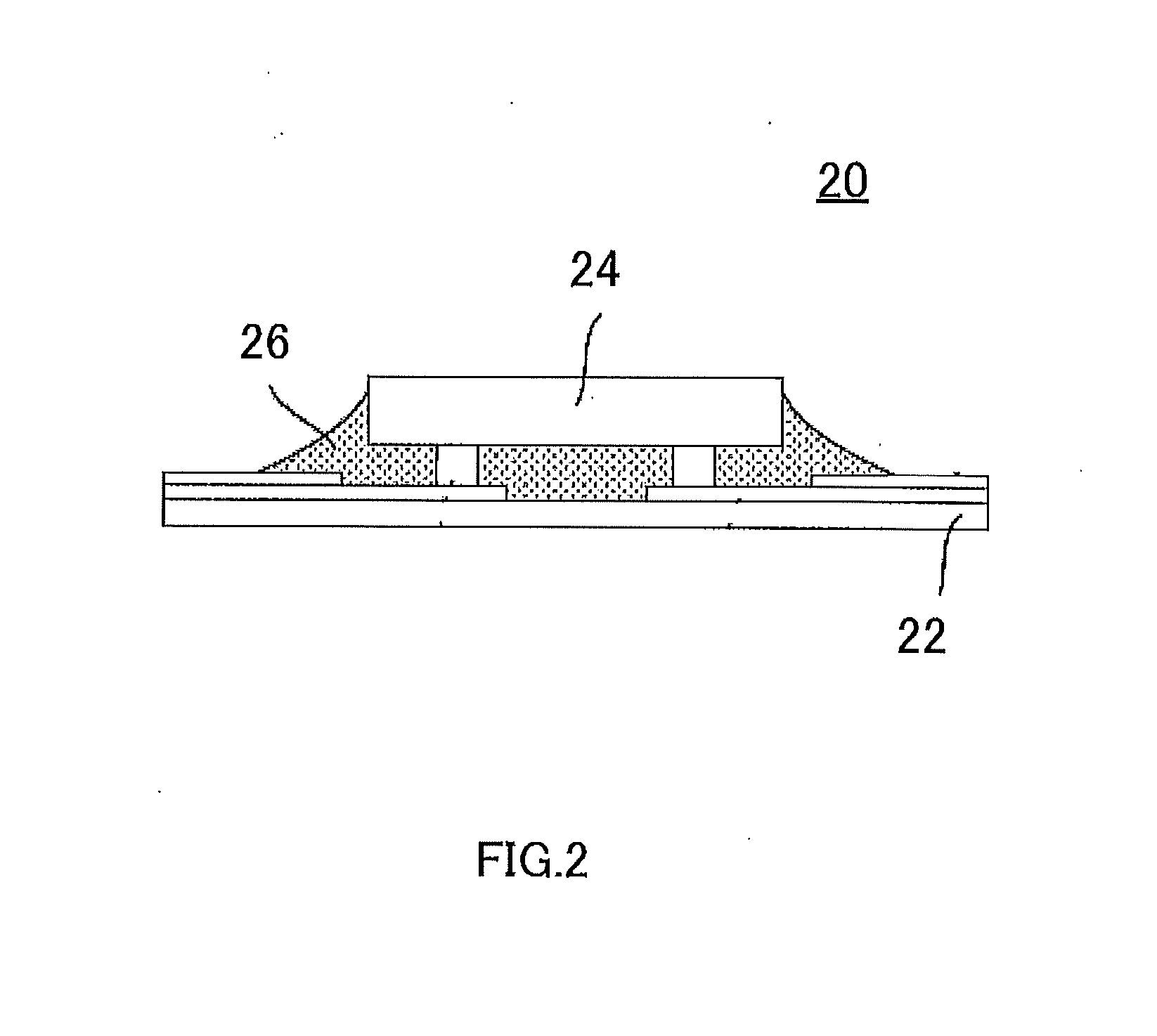

Film adhesive for sealing, film laminate for sealing and sealing method

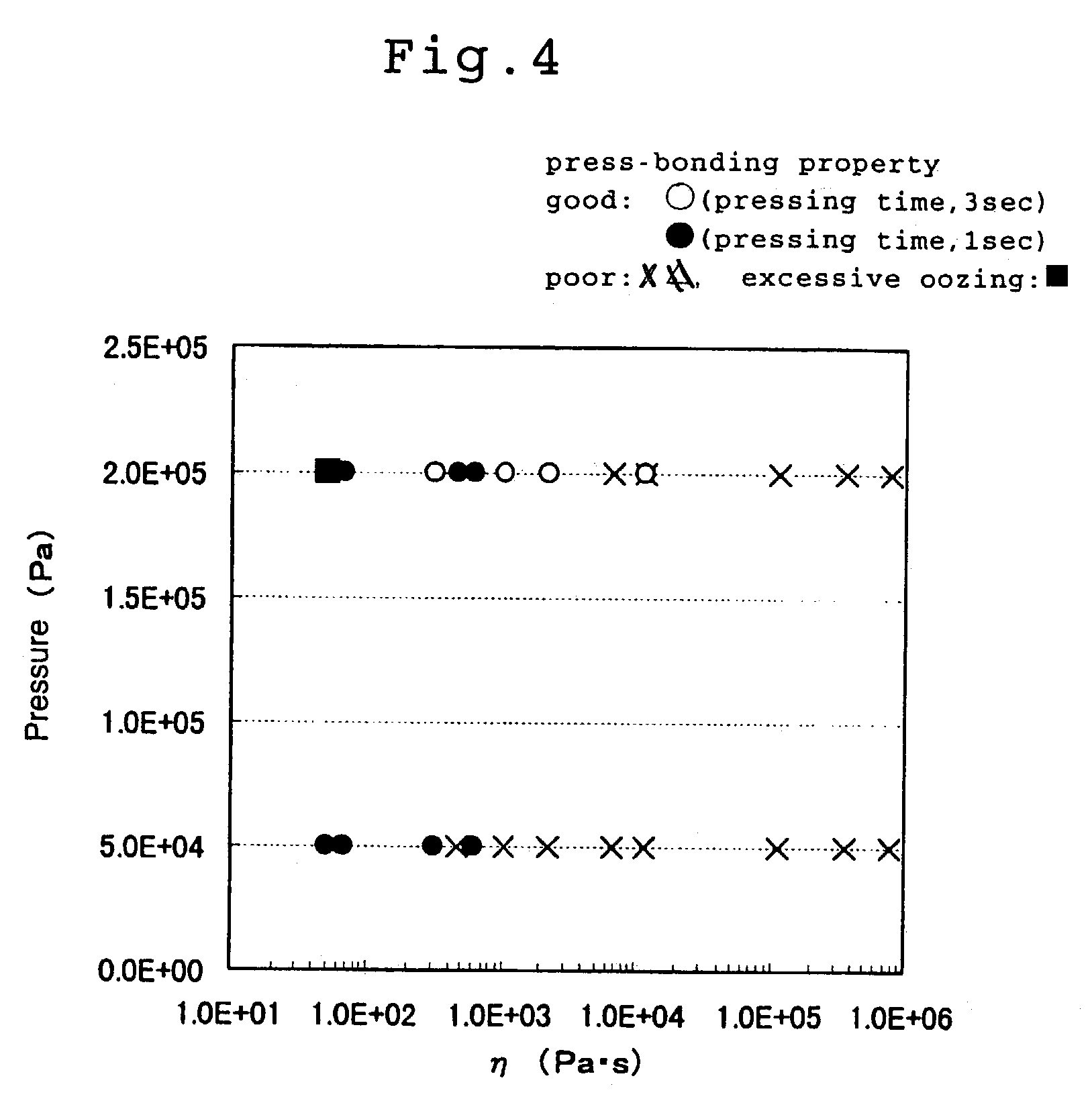

InactiveUS20040213973A1Poor compatibilityReduce adhesionImpedence networksSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

A film adhesive for sealing a plurality of chip-type devices on a substrate at one time, including an adhesive layer of an adhesive composition which exhibits a minimum value of a storage modulus of elasticity before curing from 1x10<3 >to 5x10<5 >Pa measured by using a dynamic visco-elasticity measuring apparatus while elevating the temperature from 80° C. to 150° C. at an elevating temperature rate of 2.4° C. / min and at a shearing rate of 6.28 rad / sec and a storage modulus of elasticity after curing from 5x10<5 >to 5x10<7 >Pa measured by using a dynamic visco-elasticity measuring apparatus at a sample temperature of 150° C. in a tensile mode at a measuring frequency of 6.28 rad / sec.

Owner:3M INNOVATIVE PROPERTIES CO

Adhesive, adhesive member, interconnecting substrate for semiconductor mounting having adhesive member, and semiconductor device containing the same

InactiveUS6673441B1Low elastic modulusLower the heatPrinted circuit assemblingSemiconductor/solid-state device detailsEpoxyMeth-

An adhesive which comprises (1) 100 parts by weight of an epoxy resin and a hardener therefor, (2) 75 to 300 parts by weight of an epoxidized acrylic copolymer having a glycidyl (meth)acrylate unit content of 0.5 to 6 wt. %, a glass transition temperature of -10° C. or higher and a weight average molecular weight of 100,000 or more and (3) 0.1 to 20 parts by weight of a latent curing accelerator; an adhesive member having a layer of the adhesive; an interconnecting substrate for semiconductor mounting having the adhesive member; and a semiconductor device containing the same.

Owner:RESONAC CORPORATION

Retroreflective sheeting articles

InactiveUS6012818ASuitable flexibility and transparencyReduce cohesionLayered productsAldehyde/ketone condensation polymer adhesivesDynamic viscoelasticityAdhesive

A retroreflective sheet comprises a film having a substantially flat surface and a large number of pyramidal projections having retroreflectivity on the opposite surface, and a colored layer and an adhesive layer disposed on the surface of the film having the projections. The adhesive layer comprises a heat-sensitive adhesive containing an acrylic polymer and a phenolic resin, and exhibits an elastic modulus (by dynamic viscoelasticity measurement, compression mode) at 30 DEG C. ranging from about 1x106 to 1x108 dyn / cm2.

Owner:3M INNOVATIVE PROPERTIES CO

Tackified thermoplastic-epoxy pressure sensitive adhesives

InactiveUS7005394B1Retains porosityPoor extrusion propertySynthetic resin layered productsWoven fabricsEpoxyThermoplastic

A pressure sensitive adhesive composition comprised of: a) 75 to 99.9 weight percent of a tackified thermoplastic polymer component comprising 1) 1–99 weight percent of a thermoplastic polymer substantially without epoxy-binding or ester functions, and 2) 1–99 weight percent of a tackifier; and b) 0.1 to 25 weight percent of an epoxy component comprising a cured epoxy and non-woven webs made of this adhesive composition.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure sensitive adhesive sheet, method of protecting semiconductor wafer surface and method of processing work

InactiveUS20060134406A1Solid-state devicesSemiconductor/solid-state device manufacturingHeat resistanceEngineering

Provided is a pressure sensitive adhesive sheet that does not adhere to other apparatuses, even when it is used in a manufacturing scheme using heat treatment or treatment involving heat generation. More particularly, the pressure sensitive adhesive sheet is suited for semiconductor wafer processing, possessing unprecedented high-temperature heat resistance. The pressure sensitive adhesive sheet can be used as a surface protective sheet, a dicing sheet or a pickup sheet, by imparting properties such as a protective function of an uneven circuit surface or expanding properties. The pressure sensitive adhesive sheet comprises a base material obtained by film-forming and curing a first curable resin, a top coat layer formed on the base material by coating and curing a second curable resin, and a pressure sensitive adhesive layer formed on the opposite side of the base material.

Owner:LINTEC CORP

Heat curable adhesive composition, article, semiconductor apparatus and method

InactiveUS20050224978A1Lose heat resistanceLose shear strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxySemiconductor chip

Provided are a heat curable adhesive composition and an adhesive article suited for dicing of a semiconductor and die bonding of the diced semiconductor chip, and a semiconductor apparatus and a process for preparing a semiconductor apparatus using the adhesive composition and article. In one embodiment, the present invention provides a heat curable adhesive composition comprising a caprolactone-modified epoxy resin and a tack reducing component. Another embodiment of the present invention provides an adhesive article comprising a heat curable adhesive layer of a heat curable adhesive composition comprising a caprolactone-modified epoxy resin, a tack reducing component, and a backing layer carrying said adhesive layer on at least a portion of the backing layer.

Owner:3M INNOVATIVE PROPERTIES CO

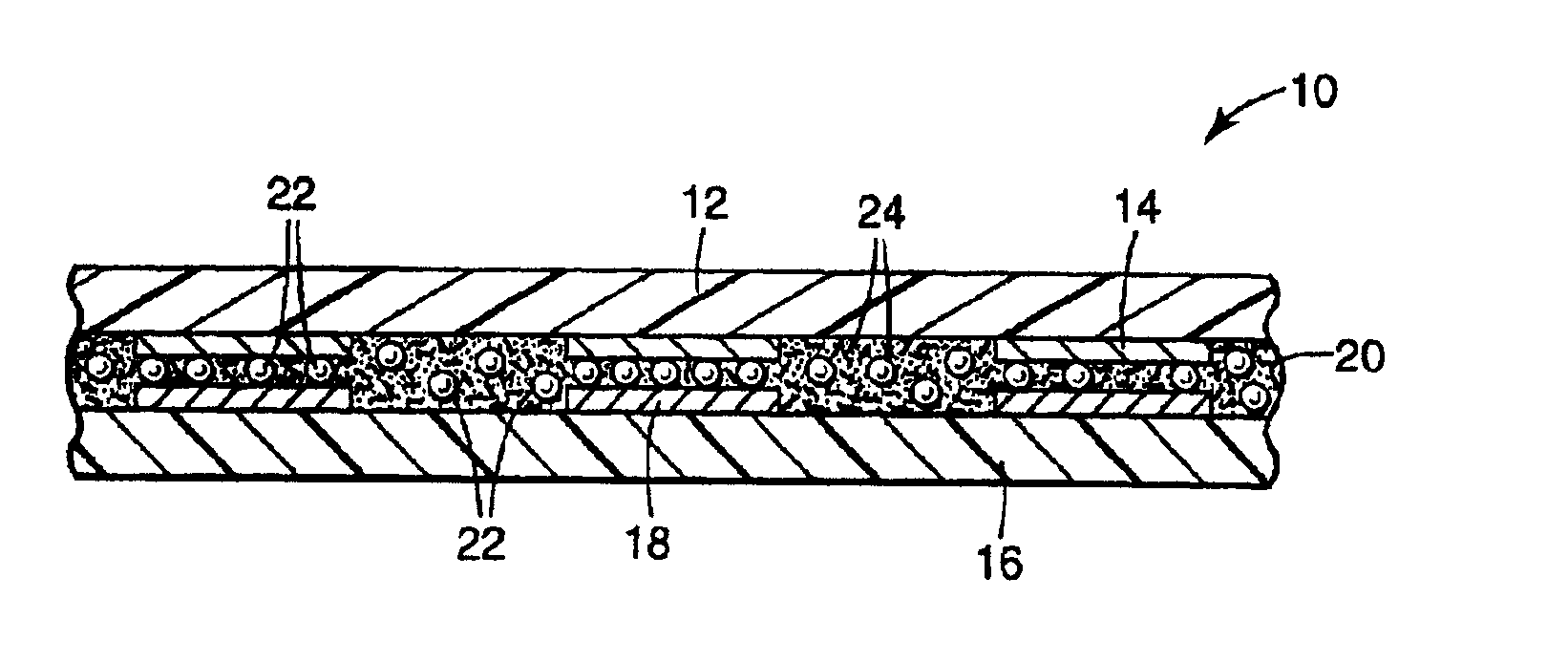

Patch repair system for collapsible fuel and water tanks

InactiveUS20050112968A1High crystallinityHighly elasticMedical patchesPolyureas/polyurethane adhesivesPolyesterElastomer

The invention is a patch system for repairing collapsible fuel tanks, water tanks, inflatable boats, and other articles fabricated from a flexible structural fabric coated with a polymer. The coated structural fabric is made of nylon or polyester synthetic fibers or a blend thereof, which are coated with a thermoplastic elastomer. The structural coated fabric is coated with a thermoplastic elastomer that is a urethane (TPU), or a TPU alloy polymer. Likewise, the patch is a urethane adhesive having a latent cure coated on a TPU film. The patch can also have an integral reinforcing fabric for applications requiring a higher tensile patch. In the invention, the urethane adhesive of the patch is solvent activated by the application of a thin coating of a volatile, substantially low odor, fugitive solvent like acetone or MEK. While in the activated state, the adhesive has much less cyrstallinity and a lot more tack. The solvent activated adhesive has good wetting, and aggressively wets out and adheres to the surface of the TPU coating on the tank. The activated adhesive side of the patch is pressed against the surface of the tank. The solvent will also partially etch the thermoplastic urethane polymer coating on the tank fabric, and rapidly diffuses therein, ultimately evaporating to the surroundings. The cross-linkable urethane adhesive contains a blocked isocyanate and, preferably, an uretdione. The reduced cyrstallinity in the adhesive imparts greater freedom to the blocked isocyanate that can, depending on the equilibrium of the system, begin to cross-link the adhesive. The curing process can be accelerated through the application of heat, albeit will slowly progress to a cured state at ambient conditions.

Owner:COOLEY

Adhesive composition, method for preparing the same, adhesive film using the same, substrate for carrying semiconductor and semiconductor device

There are disclosed an adhesive composition comprising: (a) an epoxy resin, (b) a curing agent and (c) a polymer compound with a weight average molecular weight of 100,000 or more, wherein a ratio of A / B exceeds 1 and is 10 or less, where A represents the total weight of (a) the epoxy resin and (b) the curing agent and B represents a weight of (c) the polymer compound; an adhesive composition, whose compositions are separated into a sea phase and an island phase, when viewed at a section in a cured state, and a ratio X / Y is in a range of 0.1 to 1.0, where X is an area of the sea phase and Y is an area of the island phase; a process for producing said adhesive composition; an adhesive film wherein said adhesive composition is formed into a film form; an adhesive film for bonding a semiconductor chip and a wiring board for mounting a semiconductor or for bonding semiconductor chips themselves, wherein the adhesive film can perform bonding by heat-pressing with a pressure of 0.01 to 0.5 MPa; a wiring board for mounting a semiconductor equipped with said adhesive film on a surface for mounting a semiconductor chip; and a semiconductor device using said adhesive film or said wiring board for mounting a semiconductor.

Owner:HITACHI CHEM CO LTD

Adhesive blends, articles, and methods

Described are adhesive compositions containing a mixture of a pressure sensitive adhesive, a high Tg polymer, and a crosslinker to form a compatibilized blend that is optically clear. Methods of using the adhesive compositions, and multilayer assemblies such as optical elements prepared using the adhesives, are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

Image transfer material and polymer composition

InactiveUS20070172609A1Raise transfer toDecorative surface effectsTransfer printing processImage transferCrosslinked polymers

Provided is an image transfer material, comprising a support, optionally at least one barrier layer, a melt transfer layer, and an image receiving layer. Also provided is a process for preparing the image transfer material. Further provided is a heat transfer process using the disclosed material. In the heat transfer process, after imaging, the image receiving layer and melt transfer layer are peeled away from the optionally barrier-coated support material and placed, preferably image side up, on top of a receptor element. A non-stick sheet is then optionally placed over the imaged peeled material and heat is applied to the top of the optional non stick sheet. The melt transfer layer then melts and adheres the image to the receptor element. A composition comprising: at least one self-crosslinking polymer; and at least one dye retention aid.

Owner:SCHWENDIMANN JODI

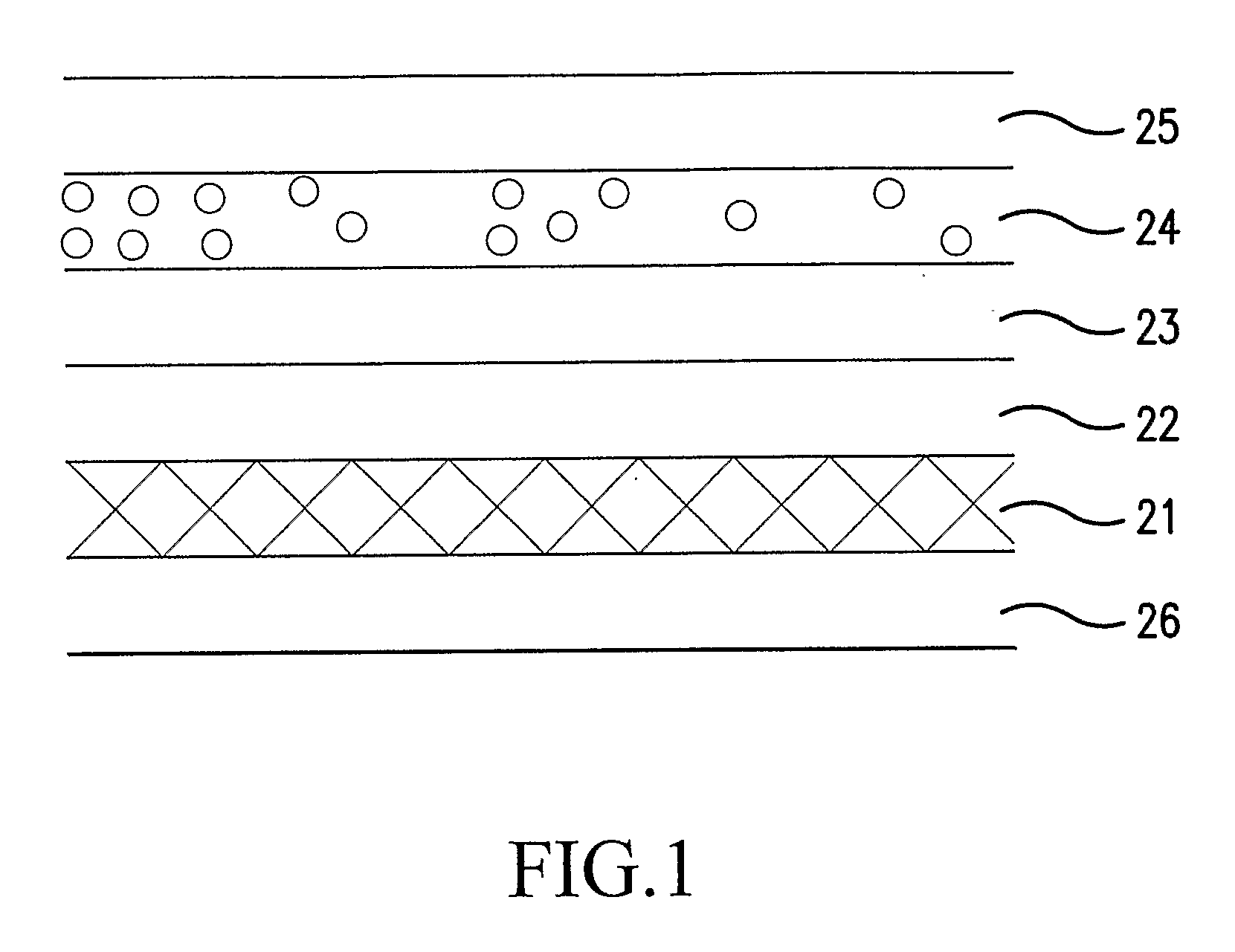

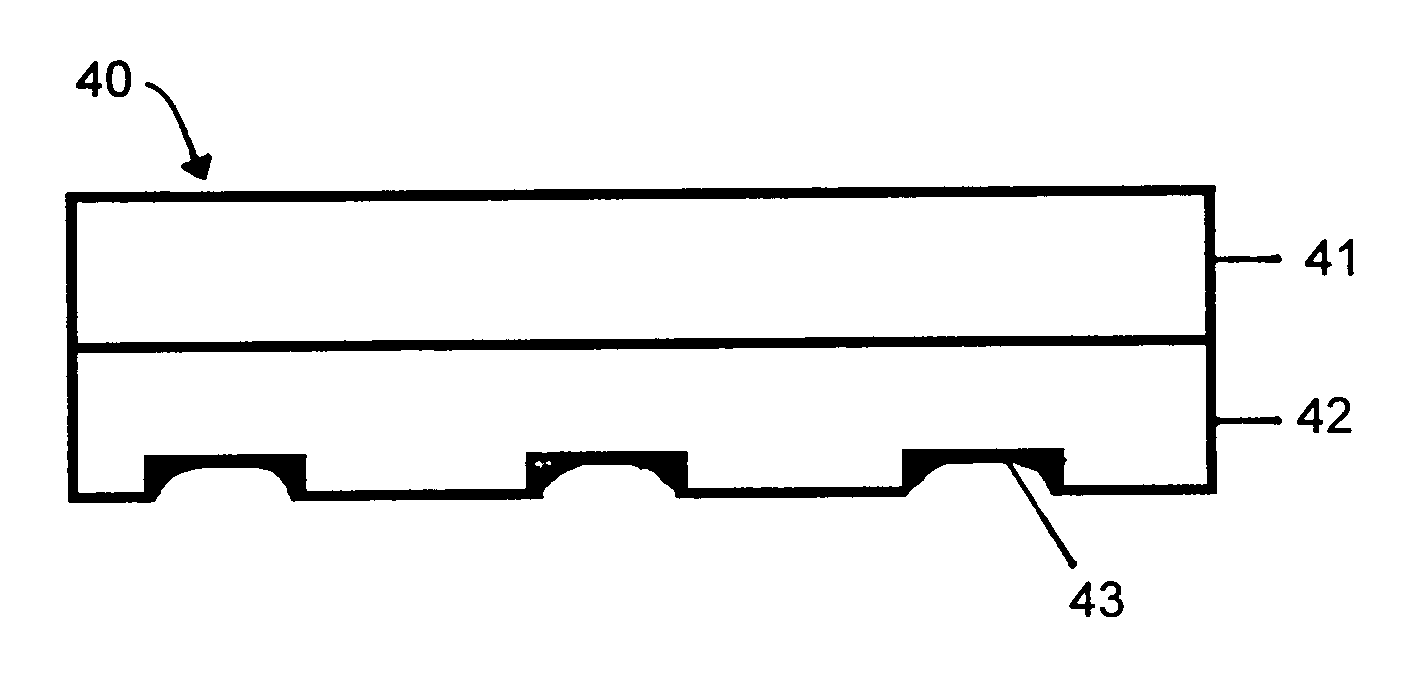

Dicing die bond film

InactiveUS20120061805A1Good tackinessImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDie bondingPolymer chemistry

The present invention provides a dicing die bond film in which peeling electrification hardly occurs and which has good tackiness and workability. The dicing die bond film of the present invention is a dicing die bond film including a dicing film and a thermosetting type die bond film provided thereon, wherein the thermosetting type die bond film contains conductive particles, the volume resistivity of the thermosetting type die bond film is 1×10−6 Ω·cm or more and 1×10−3 Ω·cm or less, and the tensile storage modulus of the thermosetting type die bond film at −20° C. before thermal curing is 0.1 to 10 GPa.

Owner:NITTO DENKO CORP

Adhesive article with improved air egress

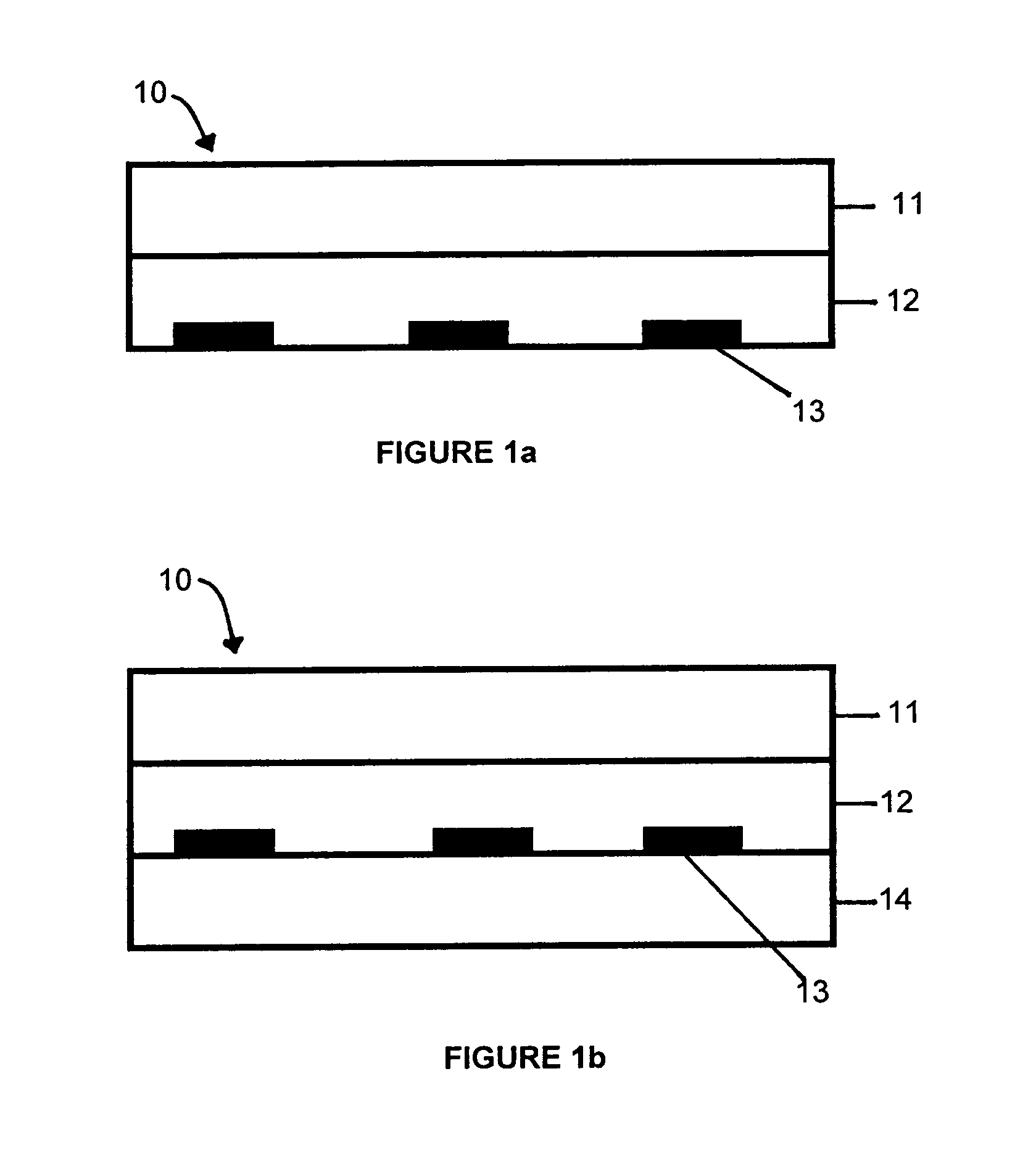

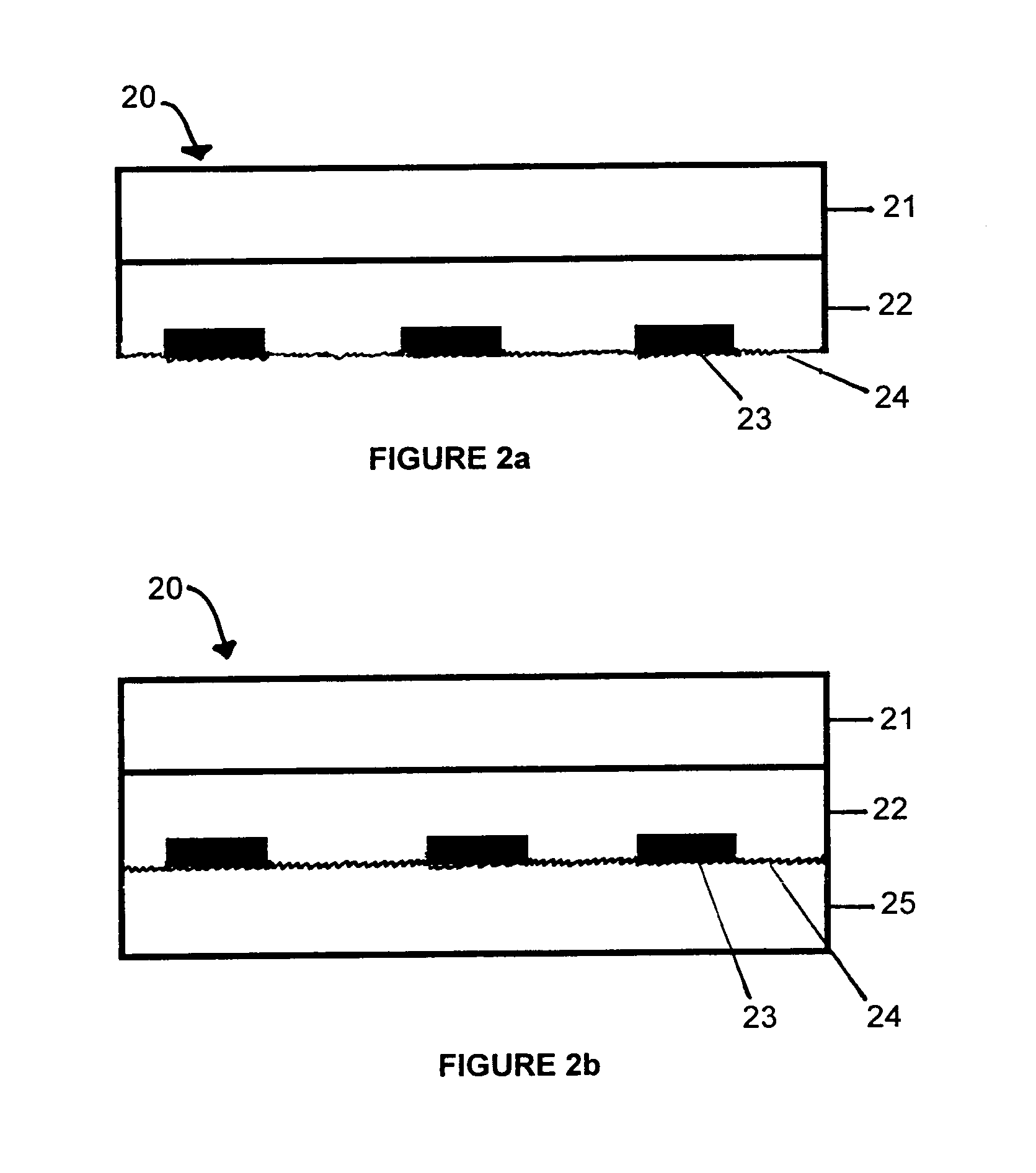

This invention relates to an adhesive article which provides air egress. Air egress is provided by supplying a mute, such as areas of no initial adhesion for the air to flow out from under the construction. The invention relates to an adhesive article comprising a facestock having a front surface and a back surface, a continuous layer of adhesive having an upper surface and a lower surface wherein the upper surface of the adhesive layer is adhered to the back surface of the facestock, and a plurality of spaced-apart non-adhesive material which is in contact with the lower surface of the adhesive layer wherein the lower surface of the adhesive layer has a Sheffield roughness of at least about 10 and the adhesive article provides air egress. The invention also relates to methods of preparing the adhesive articles, These articles have usefulness as industrial graphics images, as well as decorative coverings, etc. The articles provide air egress and optionally repositionability and slideability.

Owner:AVERY DENNISON CORP

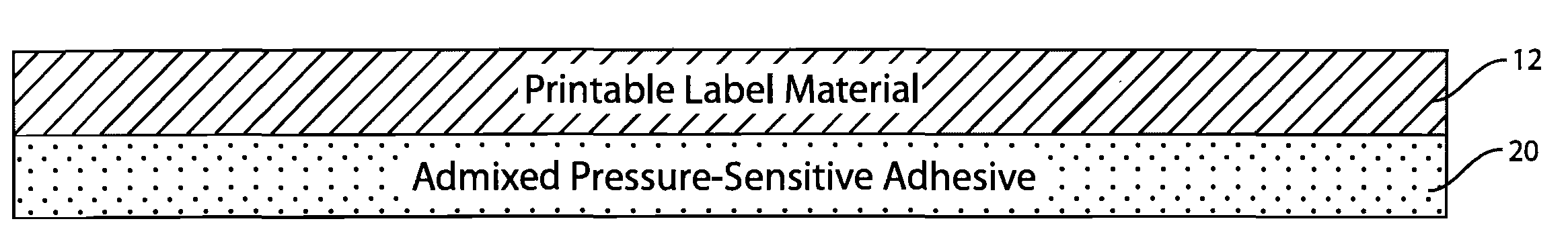

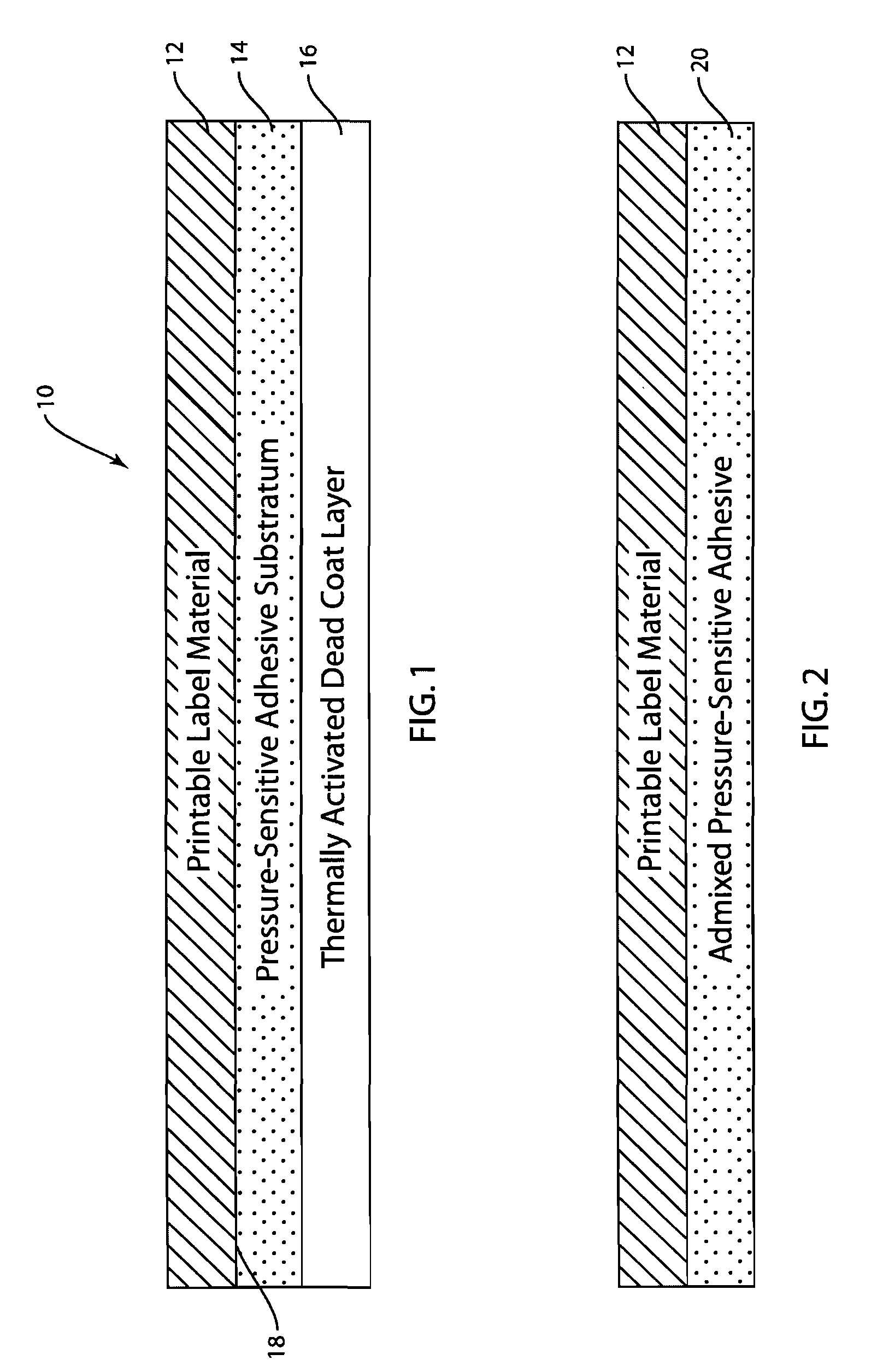

Heat-Activated Pressure-Sensitive Labels

A linerless pressure-sensitive label uses a heat-activated, non-tacky dead coat to cover a pressure sensitive substratum. Upon heat activation, the dead coat melts and admixes with an underlying pressure-sensitive adhesive substratum thereby resulting in an exposed pressure-sensitive adhesive. The label can then be applied to packaging or an end product by pressing the adhesive side of the label to the packaging or end product similar to a conventional pressure-sensitive label, however, no silicone-coated release liner is required. The elimination of the silicone-coated release liner results in lower material costs, lower shipping costs and less waste.

Owner:WAUSAU COATED PRODS

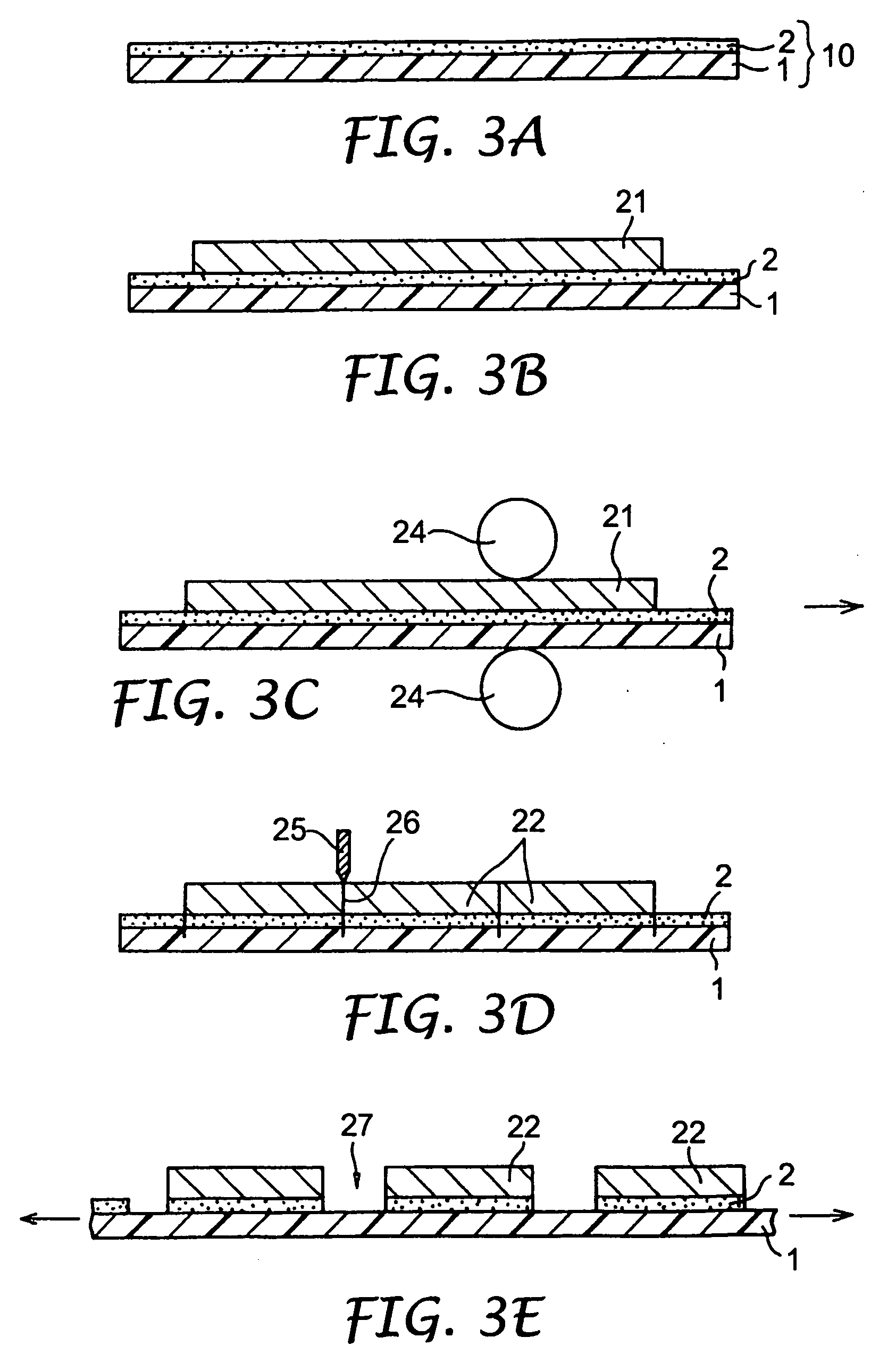

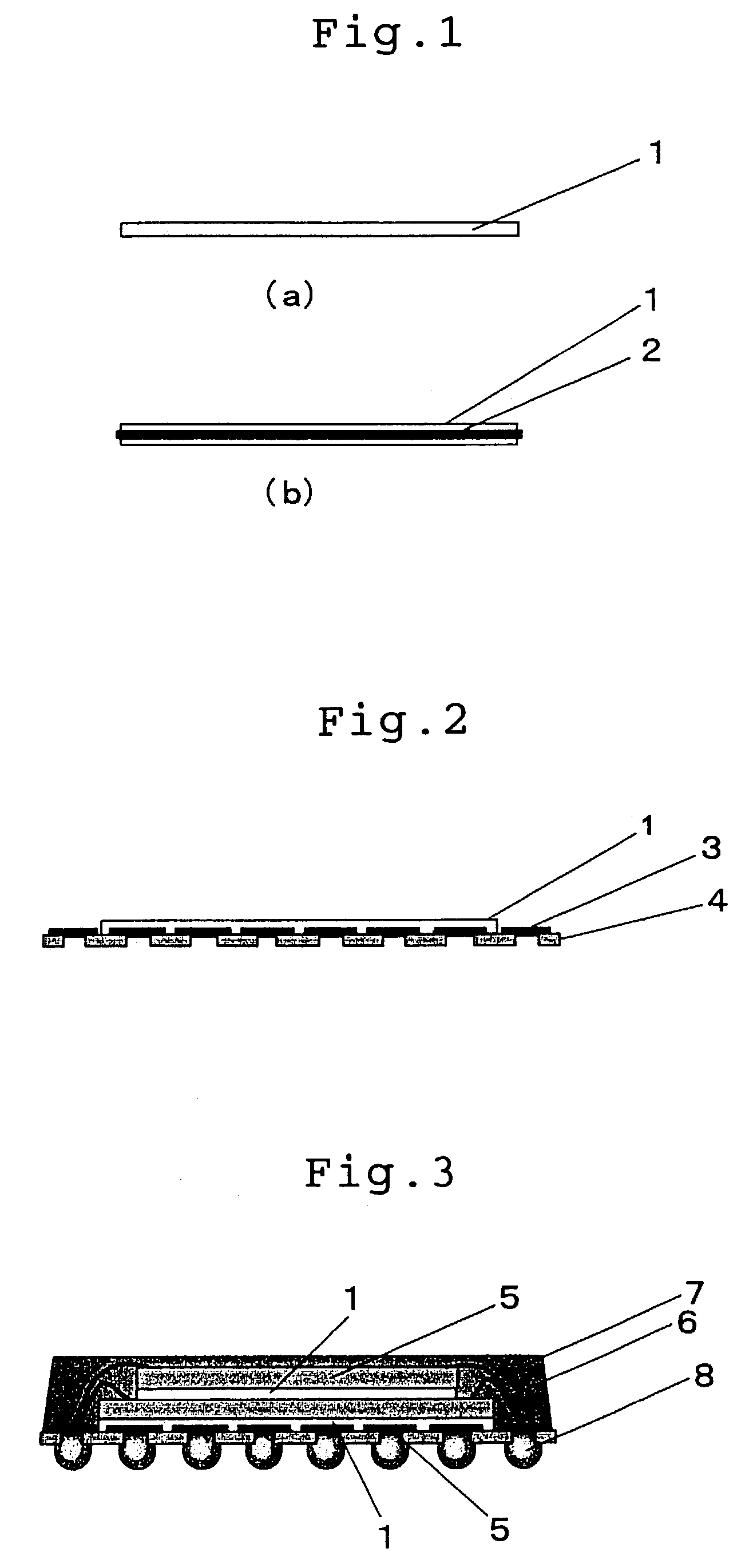

Adhesive film and process for preparing the same as well as adhesive sheet and semiconductor device

InactiveUS20070098995A1Improve workabilityLow heating temperatureNon-macromolecular adhesive additivesSynthetic resin layered productsHeat resistanceDicing tape

An object of the present invention is to provide a die-adhering adhesive film which can be laminated on a back of a wafer at a temperature lower than a softening temperature of a protecting tape for an ultra-thin wafer, or a dicing tape to be laminated, can reduce a thermal stress such as warpage of a wafer, can simplify a step of manufacturing a semiconductor device, and is excellent in heat resistance and humidity resistance reliance, an adhesive sheet in which the adhesive film and a dicing tape are laminated, as well as a semiconductor device.

Owner:HITACHI CHEM CO LTD

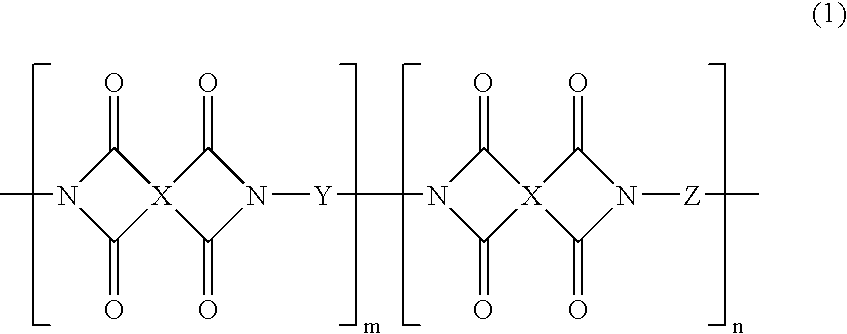

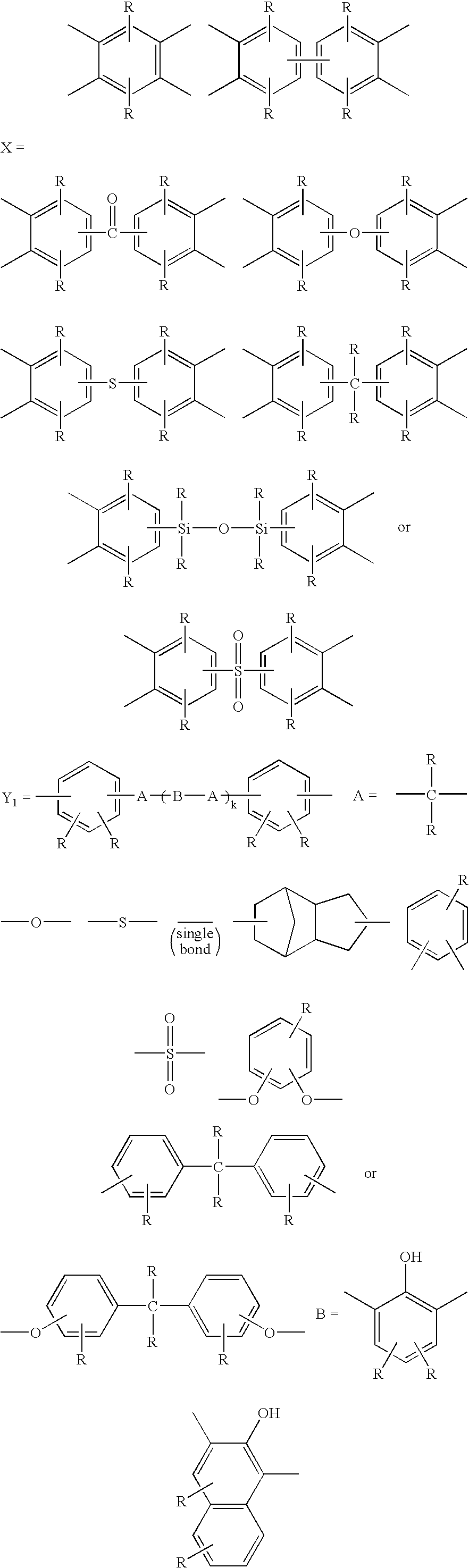

Polyimide resin composition and laminate including same

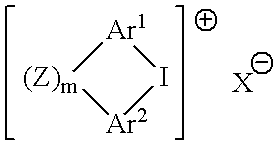

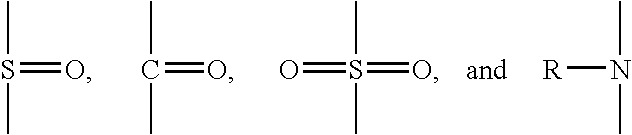

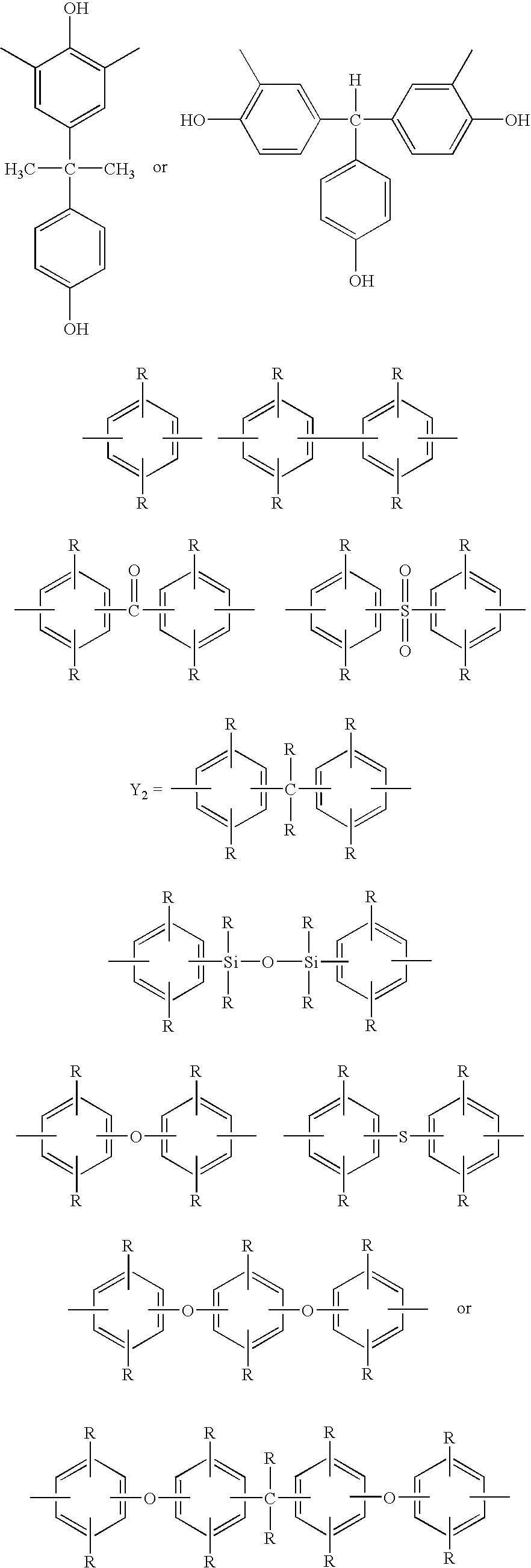

ActiveCN103298855AHigh viscosity elasticGood flexibilityImpression capsElectrolytic capacitorsPolyresinGreek letter alpha

The present invention addresses the problem of providing a resin composition including a polyimide that is soluble in a solvent and from which a resulting film will be highly viscoelastic and flexible at high temperatures. In order to resolve this problem, a polyimide resin composition includes a polyimide including polycondensate units of tetracarboxylic dianhydride and diamine, wherein either the tetracarboxylic dianhydride includes a dianhydride (alpha 1) represented by general formula (1) or the diamine includes an aromatic diamine (beta 1) represented by general formula (2) and the diamine includes an aliphatic diamine (beta 2) represented by general formula (3) or (4), the sum amount of the dianhydride (alpha 1) and aromatic diamine (beta 1) contained therein being 5-49 mol% with respect to the sum of the tetracarboxylic dianhydride and the diamine, and the amine equivalent thereof being 4,000-20,000. In the formula (3), R1 is an aliphatic chain; H2N-R2-NH2... (4), in the formula (4), R2 is an aliphatic chain.

Owner:MITSUI CHEM INC

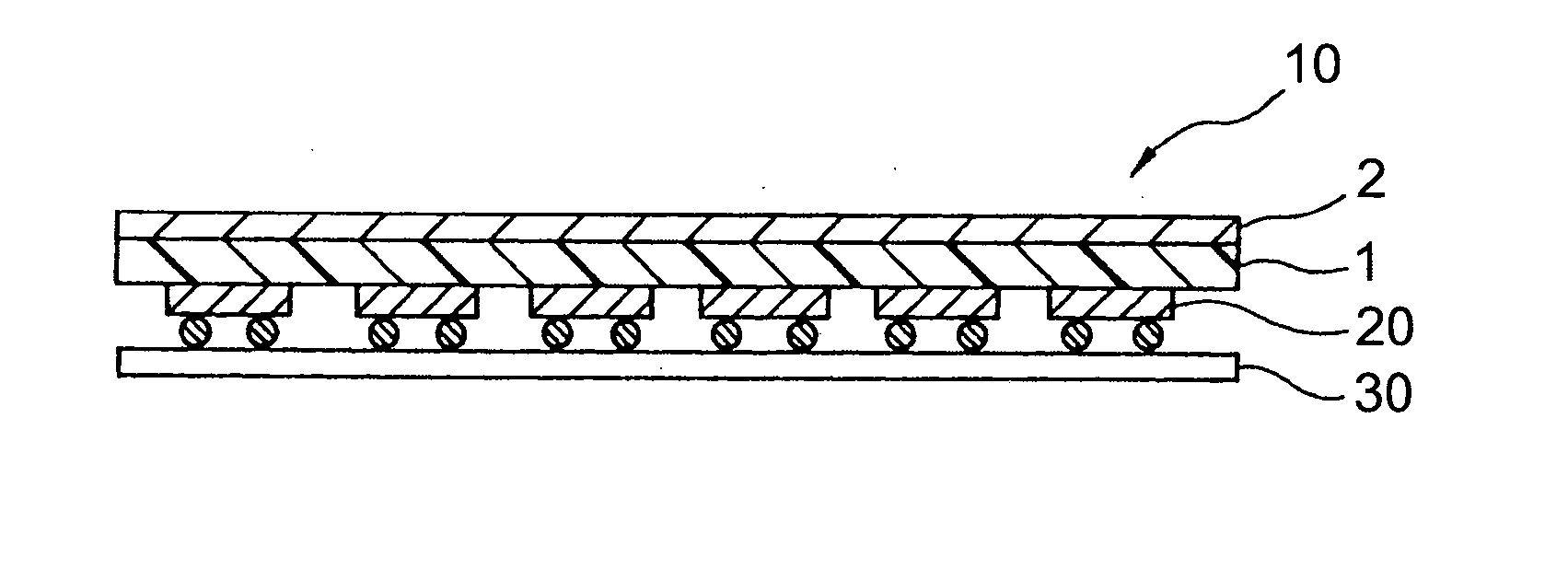

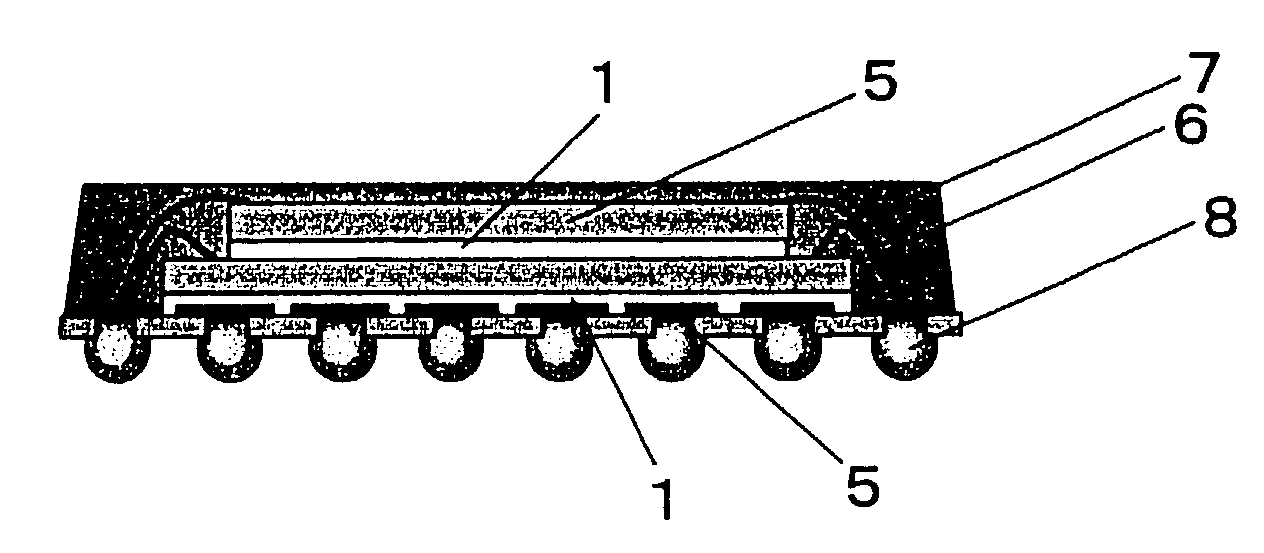

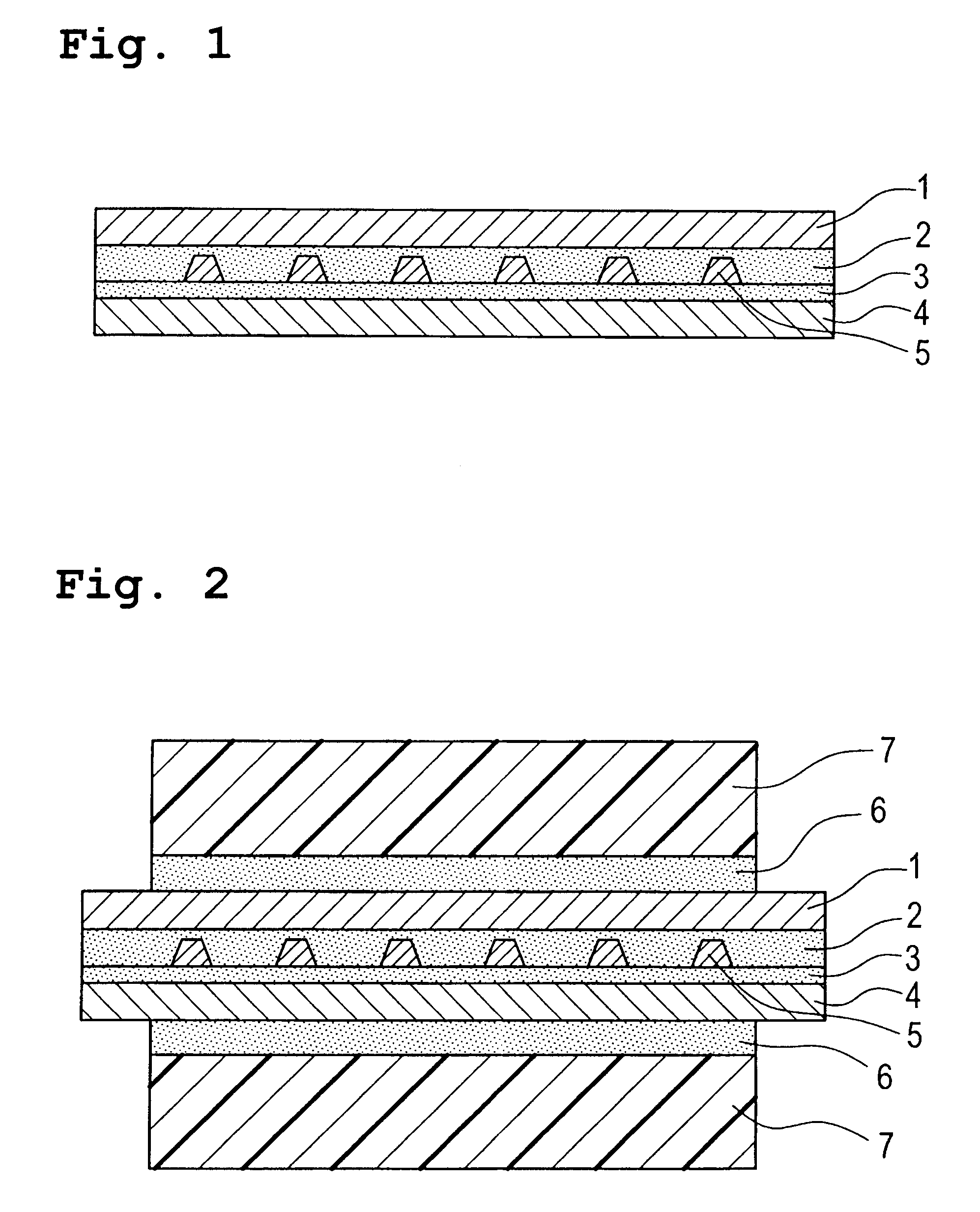

Wafer dicing/die bonding sheet

ActiveUS20040105990A1Avoid crackingAvoid separationSynthetic resin layered productsSolid-state devicesEpoxyHeat resistance

In a wafer dicing / die bonding sheet comprising a backing member, an adhesive layer, and a protective member, the adhesive layer is made of an adhesive composition comprising a phenolic hydroxyl radical-bearing polyimide resin, an epoxy resin, and an epoxy resin curing agent, the ratio of the total weight of the epoxy resin and the epoxy resin curing agent to the weight of the polyimide resin being from 0.1:1 to 3:1. Due to heat resistance, improved adhesive properties and a low modulus of elasticity, the wafer dicing / die bonding sheet is effective for reducing the warpage of a chip after die bonding.

Owner:SHIN ETSU CHEM IND CO LTD

Adhesive tape

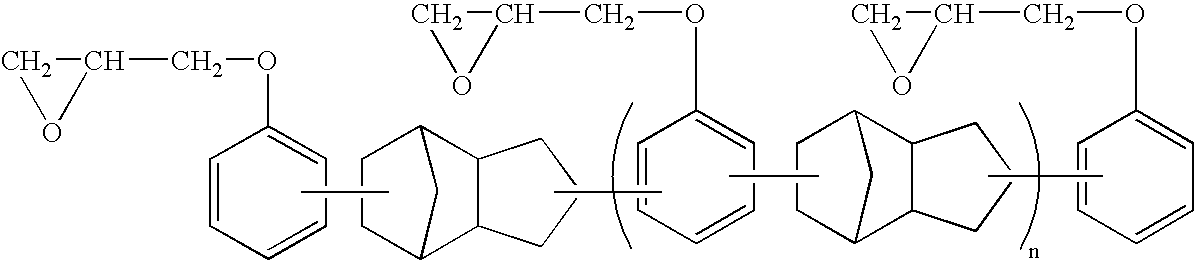

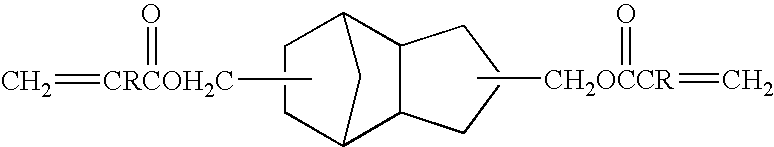

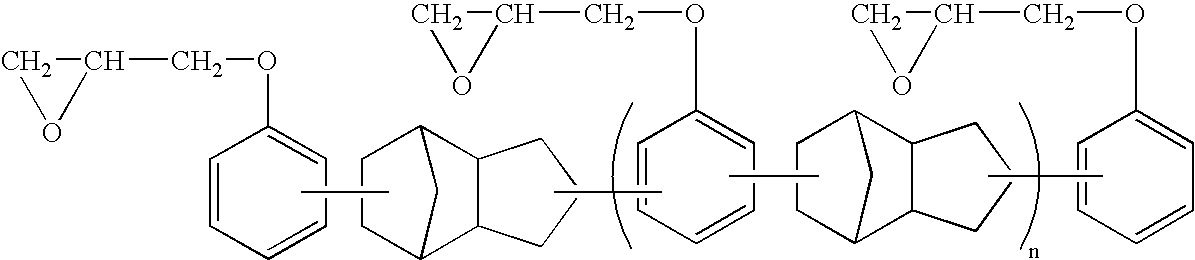

InactiveUS20040232563A1Improve abilitiesAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEpoxyElastic modulus

An adhesive tape comprising a base and, superimposed thereon, an adhesive layer, this adhesive layer comprising an adherent component (A), an epoxy resin (B), a thermally active latent epoxy resin curing agent (C), an energy radiation polymerizable compound (D) and a photopolymerization initiator (E), wherein either or both of the epoxy resin (B) and energy radiation polymerizable compound (D) have a dicyclopentadiene skeleton in its molecule or molecules thereof. The resultant adhesive tape has an adhesive layer which provides reduced water absorption of an adhesive curing product and which enables a lowering of the elastic modulus thereof during thermocompression bonding.

Owner:LINTEC CORP

Self-adhesive laminate and method of making it

InactiveUS20060062955A1High strengthSave materialLamination ancillary operationsDecorative surface effectsSolvent freeRoom temperature

A decorative laminate includes a laminate substrate coated with an adhesive layer. The adhesive layer is a layer of a physically setting, solvent-free adhesive material including an acrylic polymer. The adhesive layer is self-adhesive at room temperature. The adhesive-coated laminate substrate has a peeling-off force of at least 0.2 N / mm2, after application on a carrier. A method for the production of the adhesive-coated laminate substrate, its use as a coating material, and a composite of the adhesive-coated laminate substrate and a carrier material are also provided.

Owner:WILSONART

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20080241452A1Improve flame retardant performanceGood adhesivenessNon-macromolecular adhesive additivesGroup 5/15 element organic compoundsEpoxyScavenger

The present invention provides a halogen-free, flame retardant adhesive composition that exhibits excellent anti-migration properties, not only within single layer structures, but also within multilayer structures of much higher density such as copper-clad laminates.The flame retardant adhesive composition according to the present invention comprises: (A) a halogen-free epoxy resin, (B) a carboxyl group-containing acrylic resin and / or a carboxyl group-containing acrylonitrile-butadiene rubber, (C) a curing agent, (E) specific phosphinate and / or diphosphonate compounds, and (F) an ion scavenger and / or a heavy metal deactivator.

Owner:SHIN ETSU CHEM IND CO LTD

Polyimide resin composition and laminate including polyimide resin composition

InactiveUS20130288120A1Excellent solvent solubilityHigh viscoelasticityImpression capsElectrolytic capacitorsViscoelasticityHigh heat

To provide a resin composition that contains a solvent-soluble polyimide and can provide a film exhibiting high viscoelasticity and flexibility at high temperatures. To attain this, a polyimide resin composition is provided that includes a polyimide having a polycondensation unit of a tetracarboxylic acid dianhydride and a diamine, wherein the tetracarboxylic acid dianhydride includes an (α1) tetracarboxylic acid dianhydride represented by general formula (1), or the diamine includes an (β1) aromatic diamine represented by general formula (2), the diamine includes an (β2) aliphatic diamine represented by general formula (3) or (4), a total amour of the (α1) tetracarboxylic acid dianhydride and the (β1) aromatic diamine is 5 to 49 mol % with respect to a total amount of the tetracarboxylic acid dianhydride and the diamine, and an amine equivalent of the polyimide is 4,000 to 20,000.

Owner:MITSUI CHEM INC

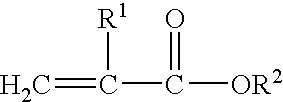

Weatherstrip tape and method for producing the same

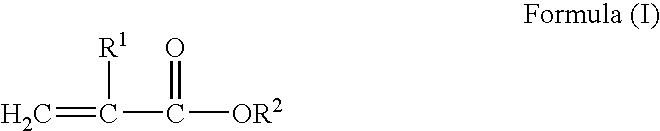

InactiveUS7217455B2Reduce stickingReliably used in bondingFilm/foil adhesives without carriersSpecial surfacesMonomerPressure sensitive

The present invention relates to an adhesive tape and to a method for its manufacture, the tape comprising: (A) a heat-activatable adhesive resin layer, wherein the resin is a polymer of one or more monomers selected from the group consisting of olefins, and (B) a pressure-sensitive adhesive layer, comprising an acrylic-type pressure sensitive adhesive, wherein said pressure sensitive adhesive layer is permanently and directly bonded to a first major surface of said heat-activatable adhesive layer. The present invention also relates to an intermediate article comprising the heat-activatable adhesive resin layer (A) releasably bonded to a support layer, to a composite article comprising the adhesive tape and a rubber article bonded to the second major surface of the heat-activatable layer (A), and to a vehicle comprising the composite article.

Owner:3M INNOVATIVE PROPERTIES CO

Resin composition and adhesive film for multi-layered printed wiring board

ActiveUS20050019554A1High mechanical strengthEasy to manufactureLayered product treatmentAdhesive articlesBenzoxazolePolyetherimide

Resin compositions, which contain: (a) a heat-resistant resin which is soluble in organic solvents wherein the heat-resistant resin is one or more heat-resistant resin(s) selected from the group consisting of a polyimide resin, a polyamide-imide resin, a polyamide resin, a polyether imide resin, a polybenzoxazol resin, a polybenzimidazole resin, copolymers thereof, and mixtures thereof; (b) a thermosetting resin; (c) a filler; and (d) resin having a polybutadiene structure and / or a polysiloxane structure, wherein: the heat-resistant resin (a) and the thermosetting resin (b) are present in a weight ratio of heat-resistant resin (a) to thermosetting resin (b) of from 100:1 to 1:1; the heat-resistant resin (a), thermosetting resin (b), and filler (c) are present in relative amounts such that weight ratio of the total amount of heat-resistant resin (a) and thermosetting resin (b) to filler (c) by weight is from 100:1 to 3:2; the resin having a polybutadiene structure and / or a polysiloxane structure (d) is present in an amount of 0.1 to 15 parts by weight based on 100 parts by weight of the heat-resistant resin (a); and the heat-resistant resin (a), thermosetting resin (b), filler (c), and resin having a polybutadiene structure and / or a polysiloxane structure (d) are present in a total amount of not less than 70% by weight, based on the total weight of the resin composition, are useful for preparing adhesive films, which are, in turn, useful for forming interlayer insulation layers for multi-layered printed wiring boards having an excellent mechanical strength and capable of being roughened by an oxidizing agent.

Owner:AJINOMOTO CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com