Epoxy resin modified two-component silicone rubber adhesive

A technology of epoxy resin and epoxy modification, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc. It can solve the problem that the adhesion is not as good as that of one-component room temperature vulcanized silicone rubber, and the adhesion is poor. Problems such as slow deep curing speed, to achieve the effect of meeting the production cycle, good bonding effect, and excellent performance retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

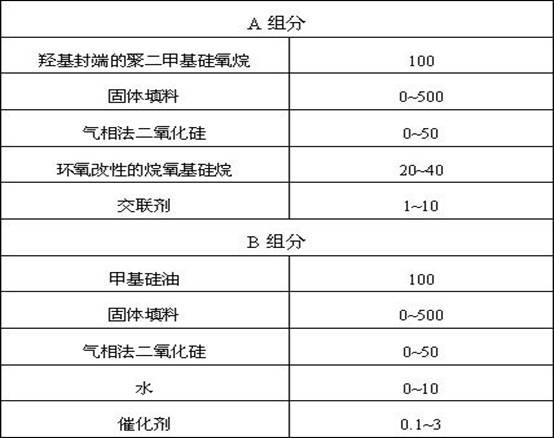

[0054]

[0055] The preparation method of epoxy-modified alkoxy coupling agent is as follows: 100 parts of epoxy resin E51, 200 parts of aminopropyltrimethoxysilane, under the catalysis of dibutyltin dilaurate, react at 70℃ 2 hours;

[0056] The mixing ratio of component A and component B is 4:1;

[0057] After the A component and the B component are evenly mixed, the operating time is more than 20 minutes, and the clearing time is less than 90 minutes; after fully cured, the tensile strength is greater than 3.5MPa, and the elongation at break is greater than 200%. The bonding strength can reach more than 2MPa; according to the aging conditions of the photovoltaic standard, the retention rate of tensile strength and bonding strength is more than 75% after being placed under the conditions of 85℃ and 85%RH for 1000 hours;

Embodiment 2

[0059]

[0060] The preparation method of epoxy-modified alkoxy coupling agent is as follows: 100 parts of bisphenol F epoxy resin (epoxy equivalent of 60~70), and 400 parts of N-β-aminoethyl-γ-aminopropyl Trimethoxysilane, under the catalysis of dibutyltin dilaurate, react at 70℃ for 2 hours;

[0061] The mixing ratio of component A and component B is 2:1;

[0062] After the A component and the B component are evenly mixed, the operating time is more than 30 minutes, and the clearing time is less than 120 minutes; after fully cured, the tensile strength is greater than 3.0MPa, and the elongation at break is greater than 350%. The bonding strength can reach more than 2MPa; according to the aging conditions of the photovoltaic standard, the retention rate of tensile strength and bonding strength is about 80% after being placed at 85°C and 85%RH for 1000 hours;

Embodiment 3

[0064]

[0065] The preparation method of epoxy-modified alkoxy coupling agent is as follows: 100 parts of bisphenol F epoxy resin (epoxy equivalent of 60~70), and 400 parts of N-β-aminoethyl-γ-aminopropyl Trimethoxysilane, under the catalysis of dibutyltin dilaurate, react at 70℃ for 2 hours;

[0066] The mixing ratio of component A and component B is 10:1;

[0067] After the A component and the B component are mixed uniformly, the operating time is more than 30 minutes, and the clearing time is less than 90 minutes. After fully cured, the tensile strength is greater than 3.0MPa, the elongation at break is greater than 300%, and the bonding strength to photovoltaic modules can reach more than 2MPa. According to the aging conditions of the photovoltaic standard, after standing for 1000 hours under the conditions of 85℃ and 85%RH, the retention rate of tensile strength and bonding strength is about 75%; the part of dibutyltin dilaurate is changed to 1.5, and The number of parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com