Nitrile-butadiene rubber NBR gear cover sealing material and preparation method thereof

A technology of nitrile rubber and sealing material, applied in the field of rubber materials, can solve the problems of low production efficiency, inability to meet price requirements and high performance requirements, shorten vulcanization molding time, improve high and low temperature resistance and medium resistance, and improve resistance Effects of Ozone Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

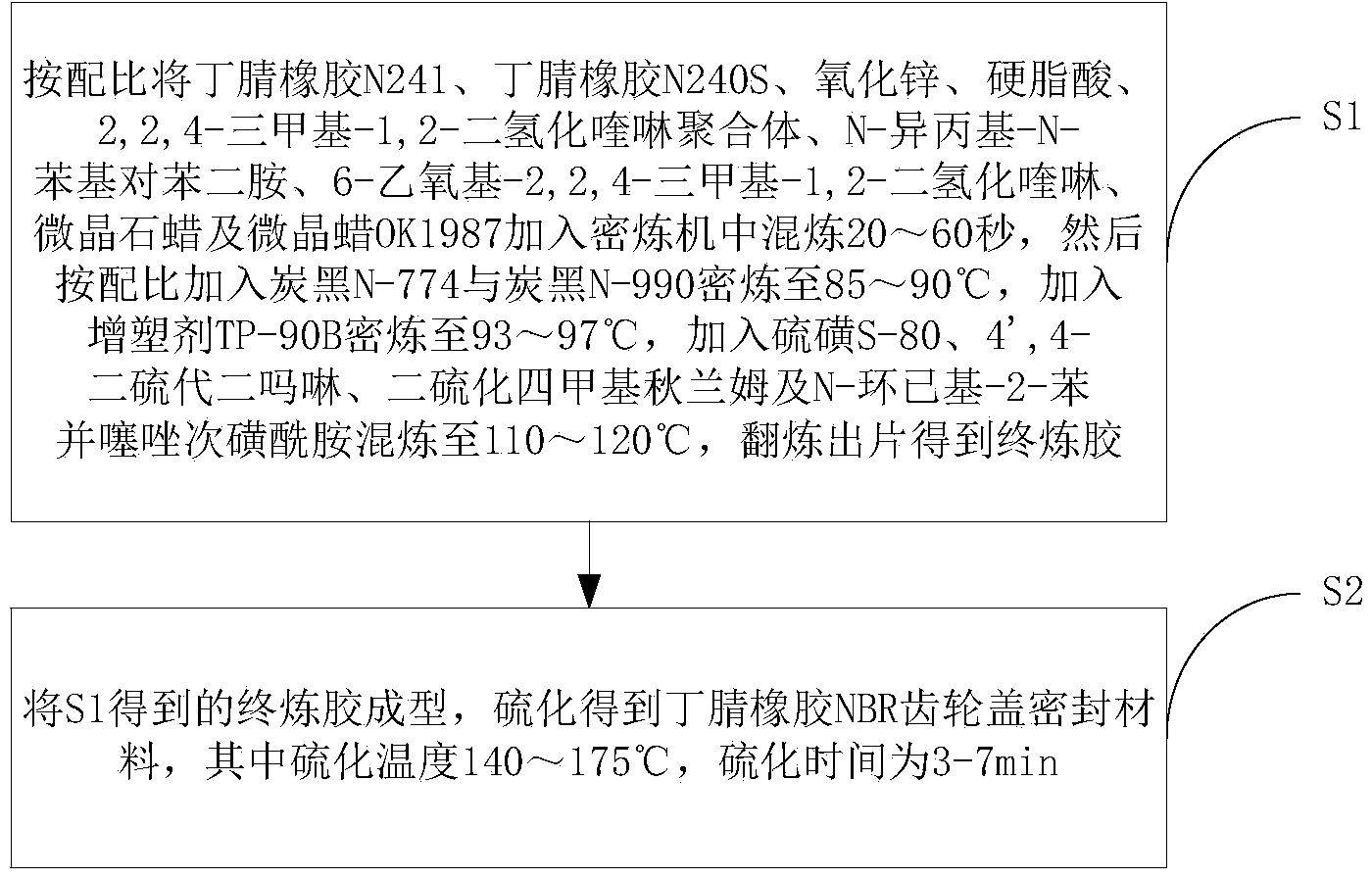

[0027] In the specific implementation process, refer to figure 1 , the preparation method of above-mentioned nitrile rubber NBR gear cover sealing material comprises the steps:

[0028] S1. Mix nitrile rubber N241, nitrile rubber N240S, zinc oxide, stearic acid, 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-isopropyl-N -Phenyl-p-phenylenediamine, 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, microcrystalline paraffin and microcrystalline wax OK1987 were added to the internal mixer and mixed for 20~ 60 seconds, then add carbon black N-774 and carbon black N-990 according to the proportion and banbury to 85~90℃, add plasticizer TP-90B banbury to 93~97℃, add sulfur S-80, 4', 4-dithiodimorpholine, tetramethylthiuram disulfide, and N-cyclohexyl-2-benzothiazole sulfenamide are mixed to 110-120°C, and kneaded to obtain the final compound rubber;

[0029] S2. Molding the final mixing rubber obtained in S1, and vulcanizing to obtain a nitrile rubber NBR gear cover sealing material...

Embodiment 1

[0032] A kind of nitrile rubber NBR gear cover sealing material, its raw material comprises by weight:

[0033]

[0034] In the present embodiment 1, the preparation method of above-mentioned nitrile rubber NBR gear cover sealing material comprises the steps:

[0035] S1. Mix nitrile rubber N241, nitrile rubber N240S, zinc oxide, stearic acid, 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-isopropyl-N -Phenyl-p-phenylenediamine, 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, microcrystalline paraffin and microcrystalline wax OK1987 were added to the internal mixer and mixed for 20 seconds , then add carbon black N-774 and carbon black N-990 according to the proportion and banbury to 90°C, add plasticizer TP-90B and banbury to 97°C, add sulfur S-80, 4',4-dithiodi Morpholine, tetramethylthiuram disulfide, and N-cyclohexyl-2-benzothiazole sulfenamide were mixed to 120°C, and kneaded to obtain the final compound rubber;

[0036] Among them, the top bolt was lifted 2 times in...

Embodiment 2

[0039] A kind of nitrile rubber NBR gear cover sealing material, its raw material comprises by weight:

[0040]

[0041]

[0042] In the present embodiment 2, the preparation method of above-mentioned nitrile rubber NBR gear cover sealing material comprises the steps:

[0043] S1. Mix nitrile rubber N241, nitrile rubber N240S, zinc oxide, stearic acid, 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-isopropyl-N -Phenyl-p-phenylenediamine, 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, microcrystalline paraffin and microcrystalline wax OK1987 were added to the internal mixer and mixed for 50 seconds , then add carbon black N-774 and carbon black N-990 according to the proportion and banbury to 87°C, add plasticizer TP-90B and banbury to 95°C, add sulfur S-80, 4',4-dithiodi Morpholine, tetramethylthiuram disulfide and N-cyclohexyl-2-benzothiazole sulfenamide were kneaded to 115°C, kneaded and rolled out to obtain the final rubber mix;

[0044] Among them, the top bolt wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com