Lithium ion battery positive electrode sheet and battery comprising positive electrode sheet

A technology for lithium-ion batteries and positive pole pieces, which is applied in the direction of non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve problems such as reducing battery costs, and achieve the effect of improving rate performance and improving charge-discharge rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

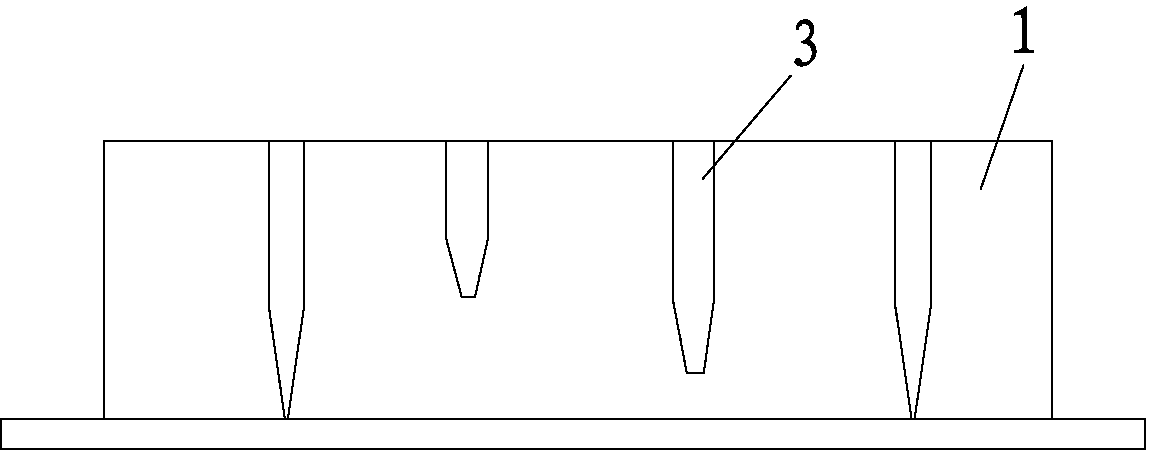

[0022] Example 1, such as figure 1 As shown, a positive pole piece of a lithium ion battery, the positive pole piece 1 is provided with a crack structure, the opening of the crack structure is arranged on the surface layer of the pole piece, and the surface density of the crack 3 of the crack structure is 100m / mm 2 , the width of the crack 3 is 5um, the length of the crack 3 is 5um, the cross-sectional shape of the crack 3 is triangular, and the thickness of the pole piece is completely penetrated by the crack 3. The positive pole piece 1 is obtained by stirring, coating and preparing cracks. The positive pole piece 1 used is to use lithium cobaltate as the active material, and prepare the positive electrode slurry according to the positive electrode formula (lithium cobaltate: polyvinylidene fluoride: superconducting carbon = 96.0%:2.0%:2.0%), and then The positive electrode slurry is coated on the aluminum foil current collector to prepare the positive electrode sheet 1, an...

Embodiment 2

[0023] Example 2, such as figure 2 As shown, the difference from Example 1 is: the surface density of the crack 3 of this example is 1000m / mm 2 , the width of the crack 3 is 12um, the length of the crack 3 is 8um, the cross-sectional shape of the crack 3 is trapezoidal, and the thickness of the pole piece is completely penetrated by the crack 3 . The positive electrode sheet 1 used is cobalt nickel cobalt manganese as the active material, and the distribution ratio of each component in the positive electrode sheet 1 is: nickel cobalt manganese: polyvinylidene fluoride: superconducting carbon=96.0%:2.0%:2.0%. The positive electrode sheet 1 is cold-pressed (compacted density 4.20g / cc), and assembled with the negative electrode sheet, separator, electrolyte and packaging bag to form a finished cell.

[0024] Others are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0025] Example 3, such as image 3 Shown, and embodiment 2 is different: the surface density of the crackle 3 of this embodiment is 10m / mm 2 , the width of the crack 3 is 1um, the length of the crack 3 is 9um, the cross-sectional shape of the crack 3 is rectangular, and the thickness of the pole piece is not completely penetrated by the crack. The positive electrode sheet 1 used is to use lithium iron phosphate as the active material, according to the positive electrode formula (lithium iron phosphate: polyvinylidene fluoride: superconducting carbon = 96.0%: 2.0%: 2.0%) to prepare the positive electrode slurry by stirring, and then The positive electrode slurry is coated on the aluminum foil current collector to prepare the positive electrode sheet 1, and then the positive electrode sheet 1 is cold-pressed (the compaction density is 4.20g / cc), and assembled with the negative electrode sheet, separator, electrolyte and packaging bag. Finished batteries.

[0026] Others are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com