Slit type coating method for manufacturing patterned coating layer

A coating method and slit-type technology are applied in the field of slit-type coating to achieve the effects of simple use, controllable pattern and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

[0021] A kind of slit type coating method of manufacturing patterned coating layer, comprises the steps:

[0022] S1. Provide substrate;

[0023] In the present invention, the type of substrate is not specifically limited, and may be various substrates that need to be coated.

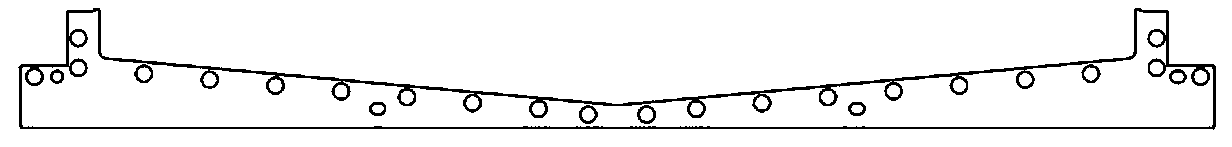

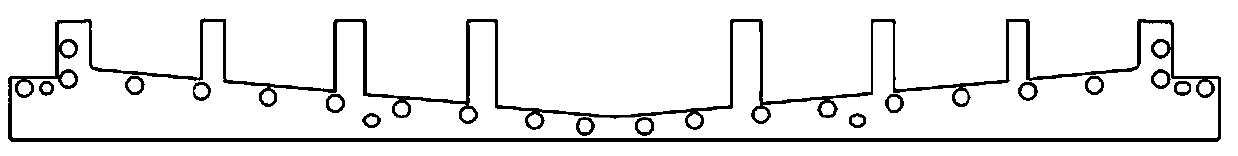

[0024] S2. Provide a slit coating head, the slit coating head includes an upper mold, a lower mold, and a gasket sandwiched between the upper mold and the lower mold, the gasket has a pattern forming portion, It is formed with several slit channels through which the coating liquid passes;

[0025] The present invention does not specifically limit the number of slit channels, it is set according to the shape of the required pattern, preferably, the number of the slit channels is 2-10, more pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com