Ceramic laser material distribution method and ceramic laser printing material distribution device

A cloth device, laser printing technology, applied in the direction of the supply device, manufacturing tools, etc., can solve the problems of heating ink, easy to block nozzles, unstable properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiment:

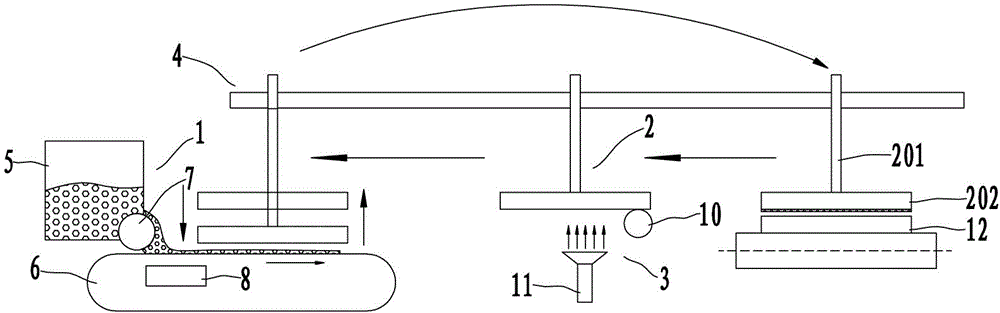

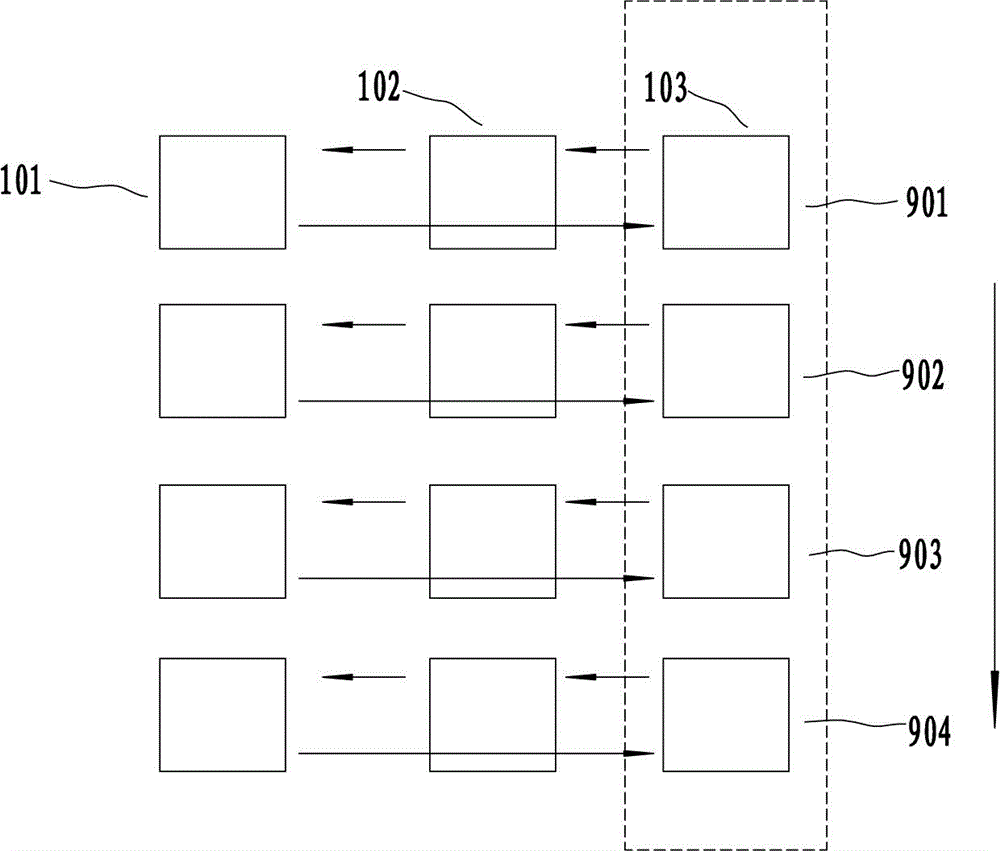

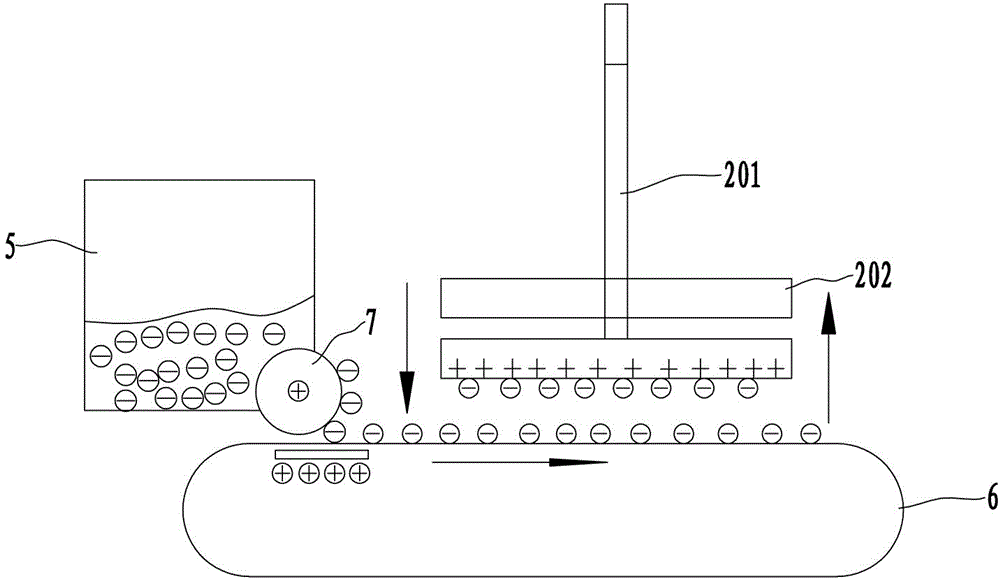

[0019] This embodiment provides a ceramic laser distributing method, which includes at least two ceramic pattern distributing stations that are sequentially arranged successively. When each ceramic pattern distributing station performs ceramic distributing, first charge the photosensitive surface on the powder distributing device used for powder distributing, and then irradiate the photosensitive surface with laser to form the required pattern on the surface pattern; then the powder distributing device absorbs powder; after the powder absorbing action is completed, the powder distributing device distributes the ceramic tile adobe on the station, and releases the patterned powder adsorbed on the photosensitive surface to the On the ceramic tile adobe; after the distribution of this station is completed, the powder distribution device returns to repeat the above distribution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com