Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Rich texture effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

Electronic cleaning agent special for solar energy photovoltaic component

InactiveCN101735903AEasy to cleanRich texture effectOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsCleansing AgentsSURFACTANT BLEND

The invention provides an electronic cleaning agent special for a solar energy photovoltaic component. The electronic cleaning agent comprises the following components by weight percent: 0.01-0.5% of surfactant, 0.2-2% of alkaline substance and the balance deionized water. The electronic cleaning agent of the invention is used to control the residual substance of the reaction between alkaline solution and silicon wafer; and the surfactant is used to avoid the poor decontamination ability caused by low reactivity of the weakly alkaline solution, increase the cleaning performance of the cleaning agent to the silicon wafer and ensure that no residue exists after the silicon wafer is cleaned, thus increasing the texture-preparing effect.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Preparation method of aqueous two-component super wear-resistant lusterless paint

InactiveCN105713496AImprove high temperature resistanceExcellent super wear resistancePolyurea/polyurethane coatingsMicrosphereWear resistant

The invention relates to a preparation method of aqueous two-component super wear-resistant lusterless paint. The lusterless paint comprises an ingredient A and an ingredient B and a mole ratio of OH to NCO in the ingredients A and B is 1: 1.0-1.5. The ingredient A comprises a hydroxyl-containing aqueous resin, SMA resin, PMMA microspheres, aqueous color paste, auxiliary agents and water. The ingredient B is an aqueous polyurethane curing agent. A film of the aqueous two-component super wear-resistant lusterless paint has excellent high temperature resistance, super wear resistance, water resistance, weatherability and chemical stability. The preparation method improves paint surface texture, fullness, flexibility, smoothness and delustring effects and does not influence paint film texture and a brilliant degree. The aqueous two-component super wear-resistant lusterless paint has low VOC, does not contain heavy metals, is environmentally friendly, can be widely used for surface coating and protection of a base material with high temperature resistance, wear and scratch resistance and lusterless effect requirements and can be used for aqueous floor paint, aqueous high-grade woodenware paint, aqueous plastic cement paint, aqueous mobile phone paint and aqueous industrial paint.

Owner:UNION FOSHAN CHEM +1

Cleaning method of diamond wire cut silicon wafer

InactiveCN102294332AEfficient removalMeet surface requirementsCleaning using liquidsMetallurgySolar battery

Owner:江西金葵能源科技有限公司

Texture etching method for single crystalline silicon solar cell

InactiveCN101431124AImprove conversion efficiencyIncrease short circuit currentFinal product manufactureSemiconductor devicesHydrofluoric acidEtching

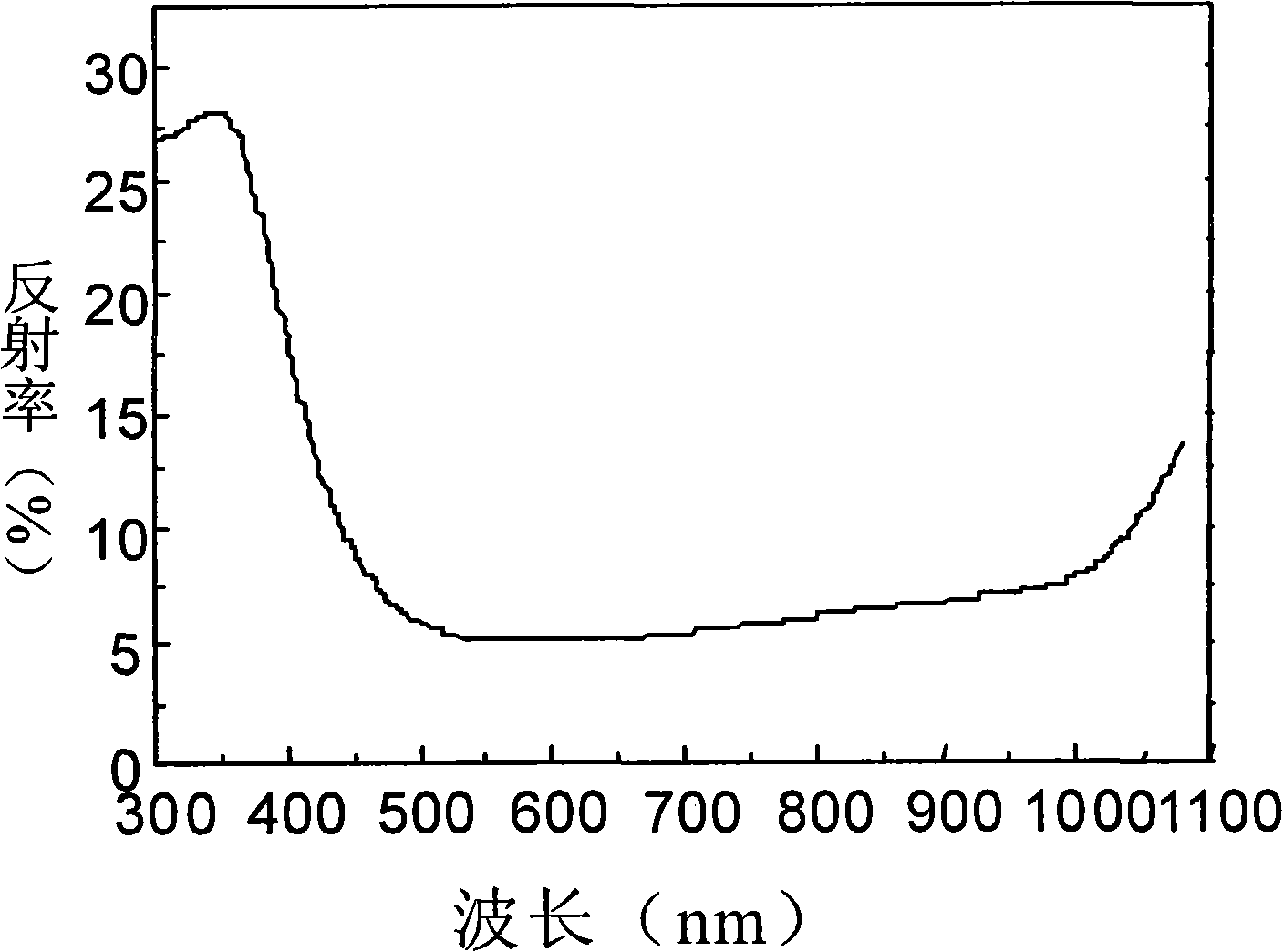

The invention discloses a preparation method of a monocrystalline silicon solar cell texture, the process is as follows: a monocrystalline silicon wafer which is rinsed cleanly by pure water after the chemical pre-cleaning in the former step is put in an ultrasonic tank of an ultrasonic cleaning machine with the power of 1,800-2,400w and the frequency of 25-40kHz, mixed water solution with 1 percent-2 percent NaOH and 3 percent-6 percent isopropyl alcohol according to the weight percentage is prepared in the ultrasonic tank, the temperature of the mixed water solution is set to be 75-85 DEG C, the ultrasound time is 30-35min, then the monocrystalline silicon wafer is taken out and put in hydrochloric acid water solution with the volume percentage of 10 percent for soaking for 4-6min, hydrofluoric acid water solution with the volume percentage of 10 percent is further used for soaking for 4-6min after the rinsing, then deionized water is used for cleaning, and drying is finally carried out. The silicon wafer texture prepared by the preparation method is even and low in reflection rate; furthermore, the preparation method reduces the fragmentation rate and improves the production efficiency and the production capacity.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

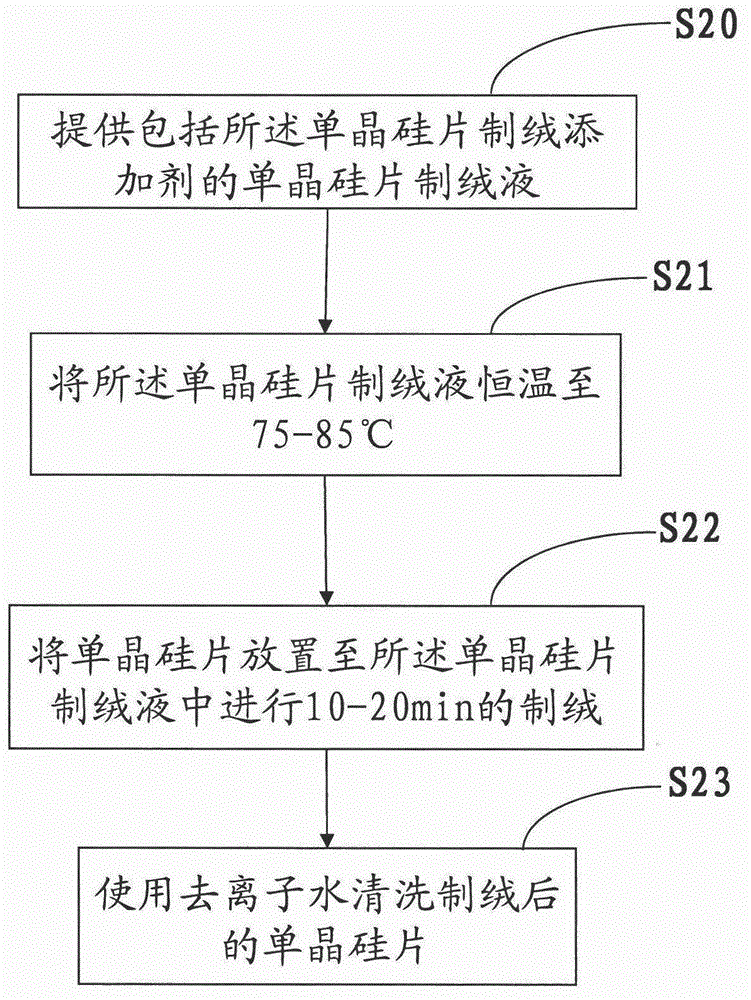

Monocrystalline silicon wafer texturing additive, texturing solution and corresponding texturing method

InactiveCN103938276AReduce usageImprove interfacial tensionAfter-treatment detailsSodium acetateOrganic solvent

The invention provides a monocrystalline silicon wafer texturing additive, a texturing solution and a corresponding texturing method. In the prior art, sodium silicate and the like are taken as monocrystalline silicon wafer texturing additives, a silicon wafer is bad in defoaming performance, and the defoaming effect can be guaranteed only by increasing the amount of a defoaming organic solvent, and thus the manufacturing cost is high and a pyramid texture surface is relatively large and not uniform in density at texturing later period. The monocrystalline silicon wafer texturing additive comprises terpilenol, polyglycol ether, lactic acid, sodium acetate and an alkali. The monocrystalline silicon wafer texturing solution comprises the above monocrystalline silicon wafer texturing additive and a texturing primary liquid, and the texturing primary liquid comprises an alkali, a defoaming organic solvent and deionized water. The monocrystalline silicon wafer texturing method comprises firstly providing the above monocrystalline silicon wafer texturing solution, controlling the texturing solution to have a constant temperature of 75-85 DEG C, placing a monocrystalline silicon wafer into the solution to make texture for 10-20 min, and finally using deionized water to clean the monocrystalline silicon wafer subjected to texturing. According to the technical scheme, the size of the pyramid texture surface can be effectively reduced, the technology stability and consistency are improved, the texture surface density is improved, and the production cost is reduced.

Owner:선테크파워컴퍼니리미티드 +1

Printing process of paper having pattern with three-dimensional laser effect

ActiveCN101823380AIncrease lossQuality assuranceOther printing apparatusPrinting after-treatmentEnvironmental resistancePrinting ink

The invention relates to a printing process of paper having a pattern with the three-dimensional laser effect, which is characterized by comprising the following steps: carrying out offset printing on one surface of the paper; leading an offset printing ink layer on the surface of the paper to obtain the laser effect; and carrying out screen varnish printing on the surface of the paper, wherein the offset printing in the step 1 and the treatment in the step 2 are sequentially carried out on the surface. The printing process has the benefits of reducing the cost by 20%-40%, being more environment-friendly, ensuring the product quality, leading the whole product to have beautiful appearance and strong three-dimensional sense, leading the printing effect to be more abundant and realizing stronger texture effect.

Owner:广西真龙彩印包装有限公司

Texturization method of monocrystalline silicon wafer

InactiveCN106835288AHigh boiling pointLow costAfter-treatment detailsFinal product manufactureChemistryMonocrystalline silicon

The invention belongs to the technical field of monocrystalline silicon wafer tools, and particularly relates to a texturization method of a monocrystalline silicon wafer. The method comprises the following steps: 1) preparing atexturizationadditive; 2) preparing atexturization solution; and 3) putting the monocrystalline silicon wafer into thetexturization solution prepared in the step 2), and carrying out texturization at 80-88 DEG C for 600-1200 seconds. The method has excellent texturization effect; and the pyramids on thetexturizedsurface have smaller size and narrower distribution, and can reduce the light reflection, thereby enhancing the photoelectric conversion efficiency of the assembled solar cell.

Owner:DEQING LIJING ENERGY TECH CO LTD

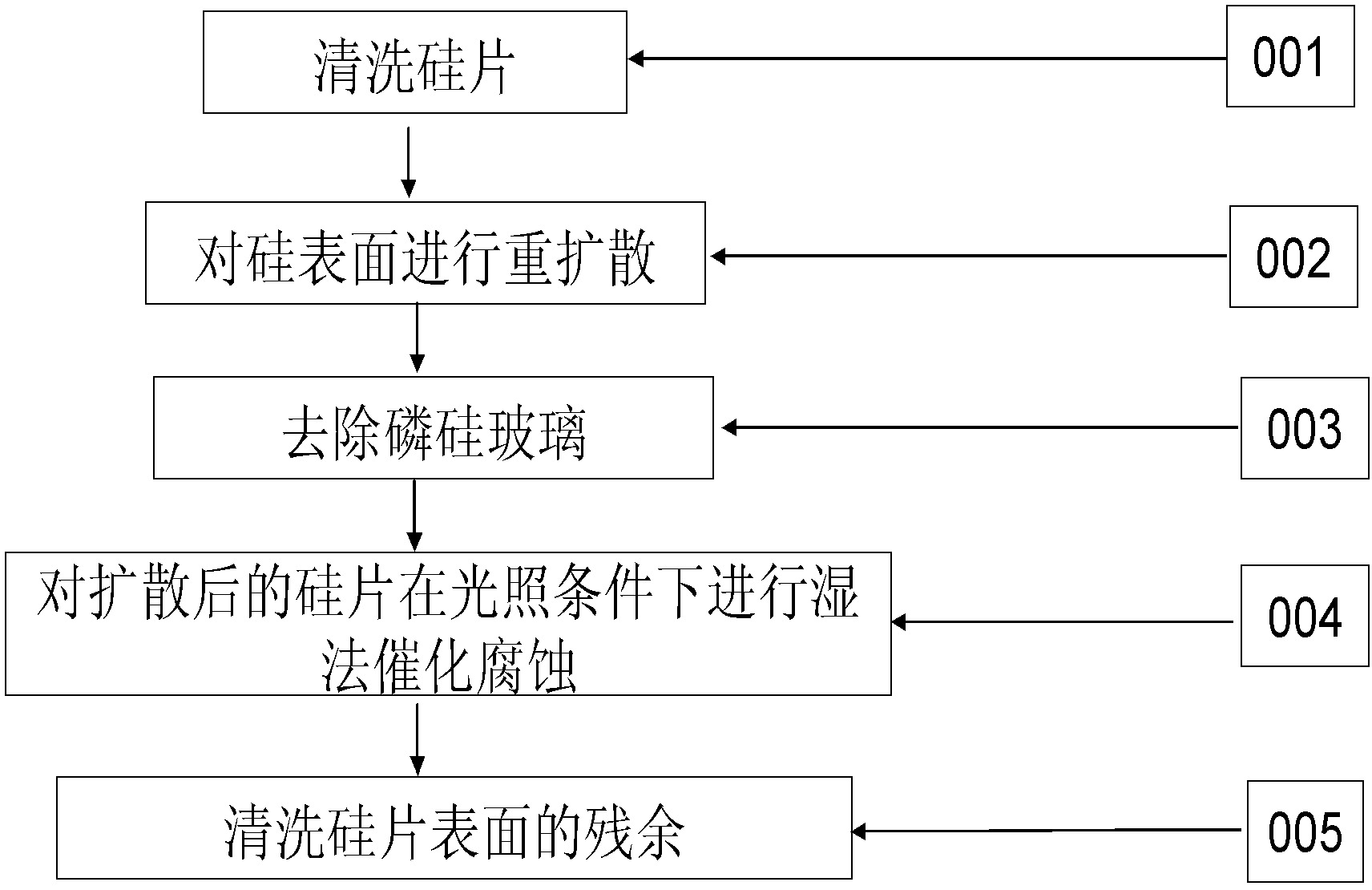

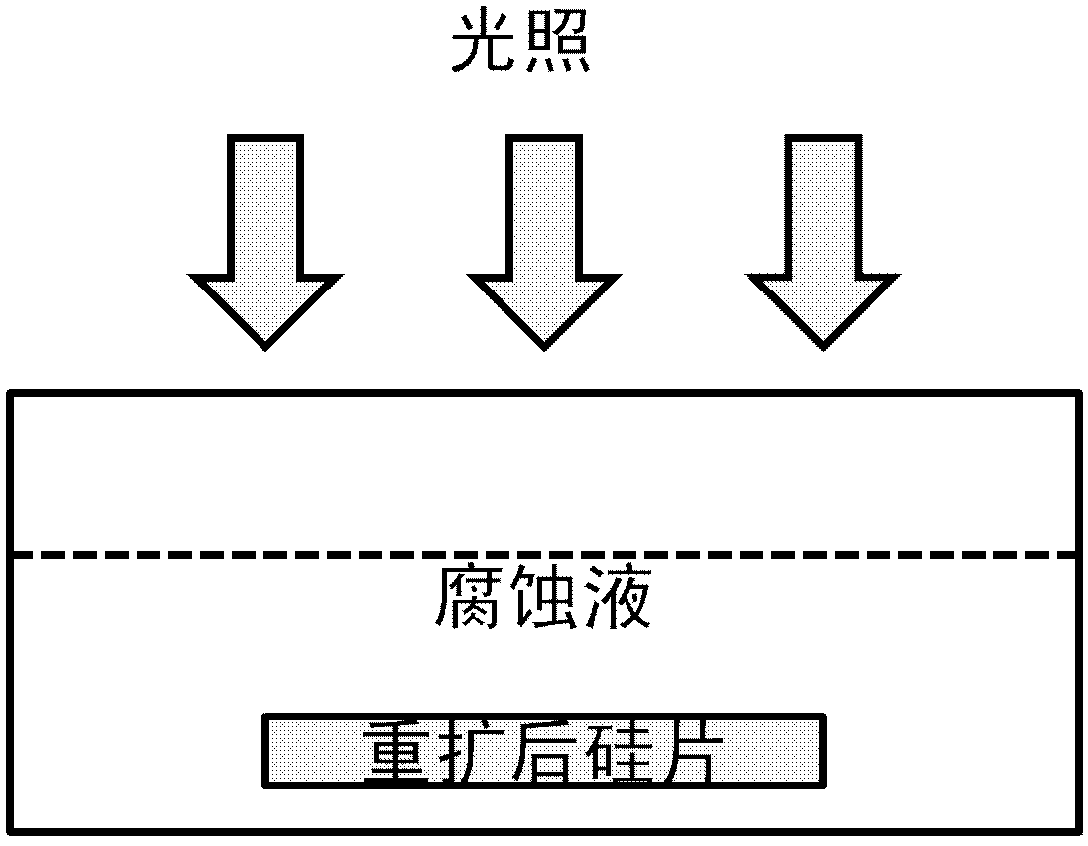

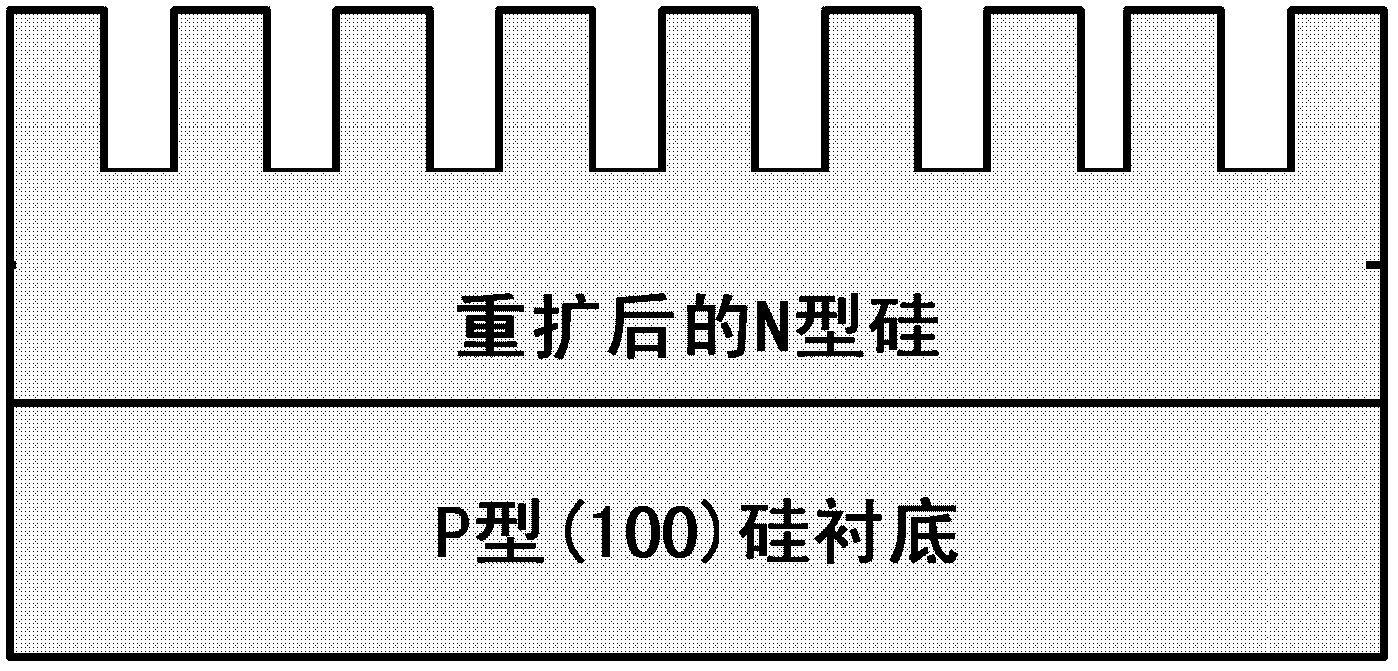

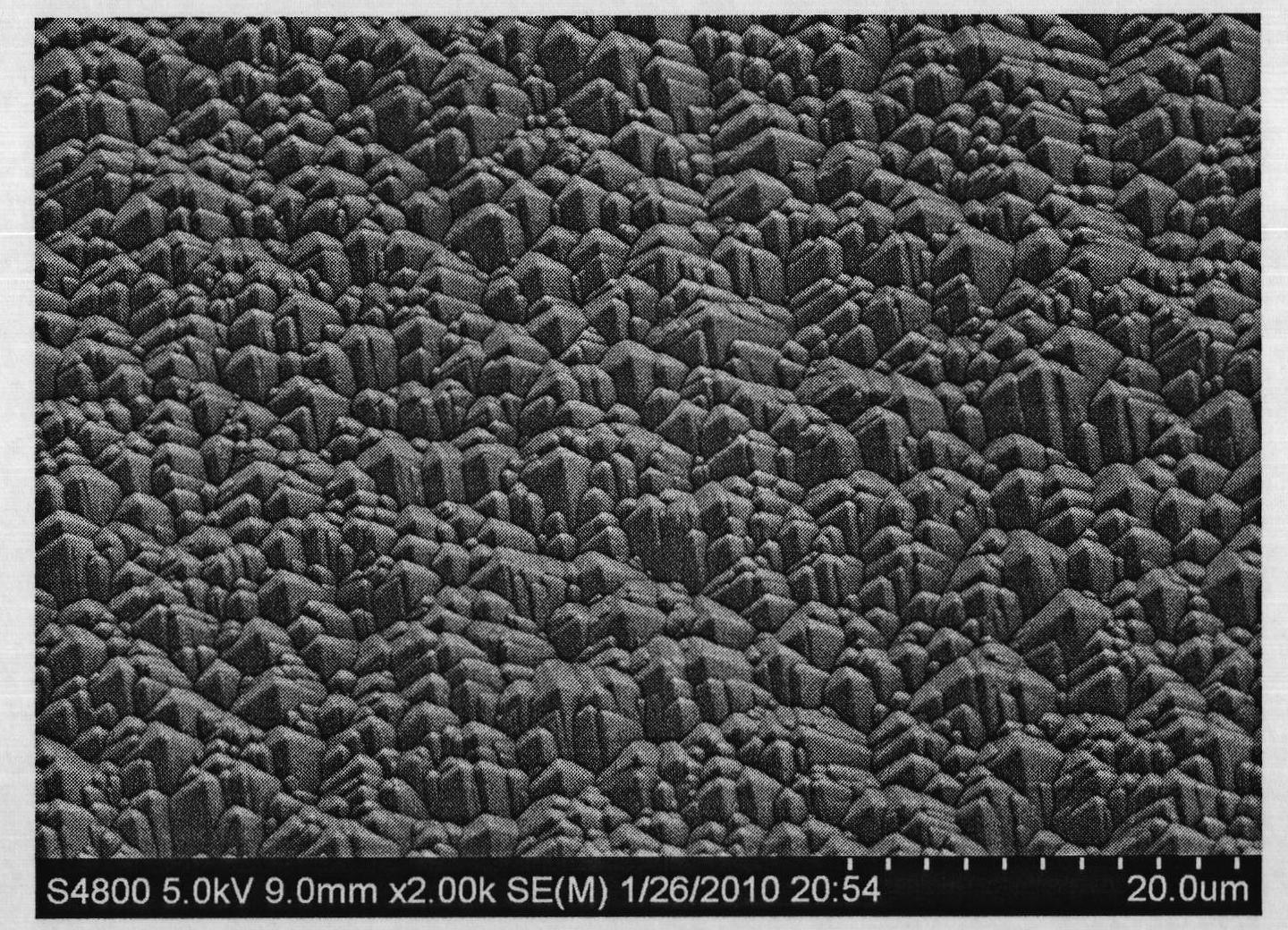

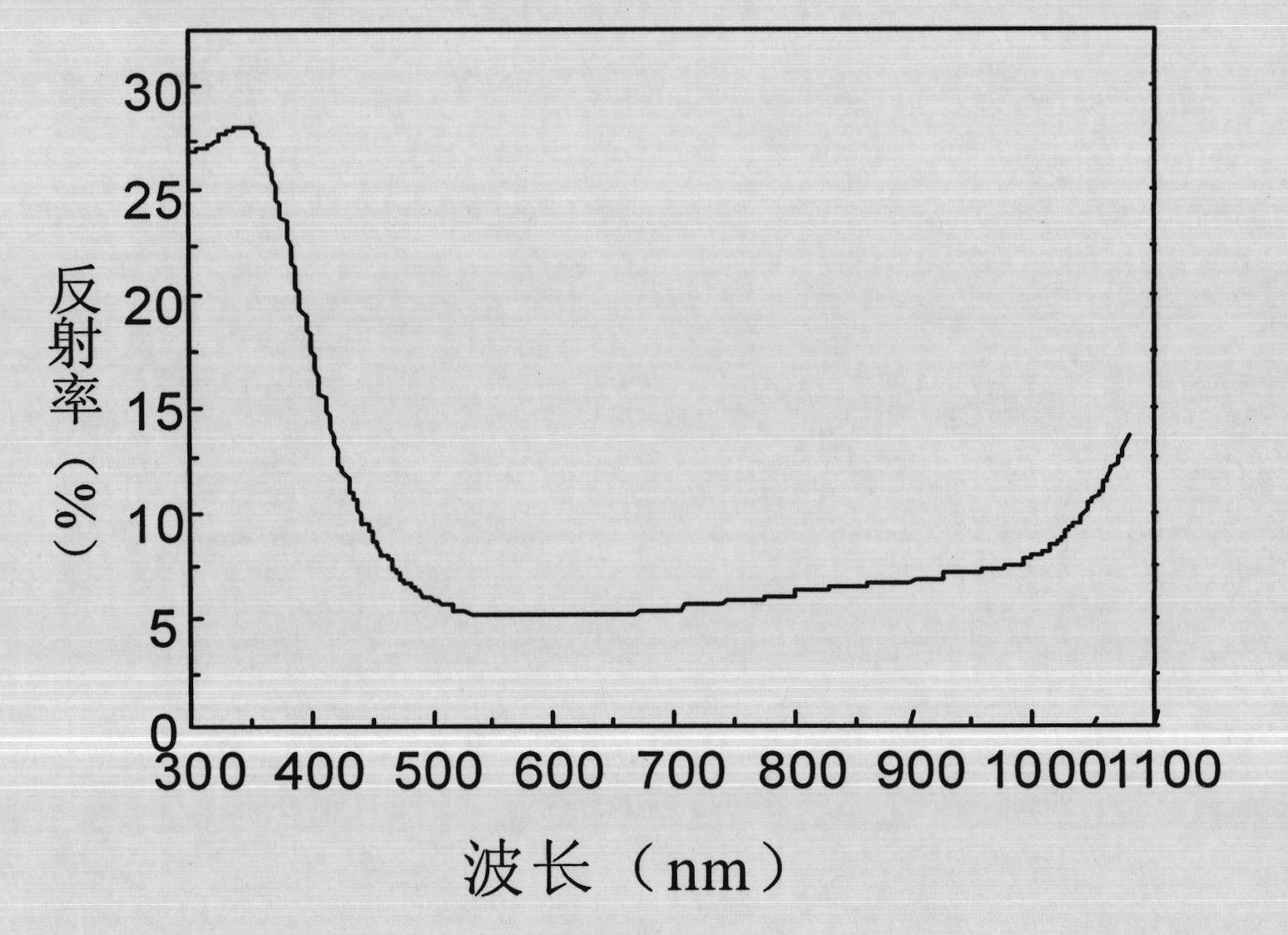

Method for realizing high-trapping-light nanostructure single-face texture surface making

InactiveCN103219427AObvious advantagesGood effectAfter-treatment detailsFinal product manufactureEtchingTrapping

The invention discloses a method for realizing high-trapping-light nanostructure single-face texture surface making. The method comprises the steps: cleaning a silicon wafer; conducting re-spreading to the surface of the silicon wafer; removing residues on the surface of the silicon wafer which is re-spread; coating TiO2 of a nanostructure on the surface of the silicon wafer or depositing Ti on the surface of the silicon wafer, and rapidly annealing; conducting wet etching on the silicon wafer to form the nanostructure; and removing oxide and titanium ions which are not completely reacted on the surface of the silicon wafer. Compared with the prior art, the method is adopted to prepare the high-trapping-light nanostructure, only technology sequence is changed, and under the premise that key equipment is not increased, only one light source needs to be added or only sun light needs to be led in so that the purpose of single-face texture surface making can be achieved. The nanostructure has a good light trapping effect. Besides, the method is simple in process step, and suitable for mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Texture etching method for quasi-monocrystalline silicon wafer

InactiveCN102034900AGood texture effectSimple processFinal product manufactureSemiconductor devicesEtchingMaterials science

The invention discloses a texture etching method for quasi-monocrystalline silicon wafer. In the method, quasi-monocrystalline silicon wafer with (100) crystalline grains predominantly are treated by a texture etching process of performing acid texture etching before performing alkali texture etching, and the degree of the acid texture etching and the alkali texture etching is regulated according to the rate of occupied areas of the (100) crystalline grains in the quasi-monocrystalline silicon wafer so as to achieve the optimal effect of comprehensive texture etching. The method has a simple process, and the integral texture etching effect is high.

Owner:JA SOLAR +2

Additive of wool making solution for monocrystalline silicon pieces and using method

ActiveCN101851757AReduce reflectivityImprove yieldFinal product manufactureSemiconductor devicesSolar cellVitamin

The invention relates to an additive of a wool making solution for monocrystalline silicon pieces, containing the components of lactic acid, vitamin and the balance of water. When the monocrystalline silicon pieces for solar cells are subjected to surface wool making, the additive is added in the alkali wool making solution so that an excellent wool making effect is achieved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Clear frit and method of producing the same, translucent grain, stone without hole and porcelain brick

The invention discloses a transparent frit, which comprises the following components: 50 to 70 portions of albite powder, 10 to 14 portions of burned talc, 6 to 10 portions of barium carbonate, 0 to 3 portions of zinc oxide, 6 to 8 portions of calcite and 6 to 12 portions of boric acid, wherein the components are measured by weight. The transparent frit provided by the invention has the advantage of good light transmittance. A light-transmitting crystal grain can be prepared by utilizing the transparent frit, and the light-transmitting crystal grain is good in light transmittance. A hole-free travertine porcelain tile prepared by utilizing a raw material comprising the light-transmitting crystal grain has visual holes but no actual holes; a part forming visual holes but no actual holes is the light-transmitting crystal grain; and the existence of the part having the visual holes but no actual holes ensures that the hole-free travertine porcelain tile is abundant in texture effects and strong in solid granular sense. The invention also provides a method for preparing the transparent frit, the light-transmitting crystal grain, hole-free travertine and the hole-free travertine porcelain tile, which belongs to the field of architectural ceramics.

Owner:霍镰泉

Water-base fluorocarbon imitation marble paint, preparation method thereof and method for spraying with imitation marble effect

ActiveCN101654578ASame decorative effectConsistent colorLiquid surface applicatorsNatural patternsWater basedCellulose

The invention discloses a water-base fluorocarbon imitation marble exterior wall paint, which comprises a white paint and more than one color paint, wherein the white paint comprises the following components in portion by weight: 12 to 20 portions of water-base fluorocarbon emulsion, 0.1 to 1 portion of cellulose, 0.1 to 1 portion of nano silicate, 0.1 to 1 portion of dispersing agent, 0.1 to 1 portion of pH conditioning agent, 0.1 to 1 portion of defoaming agent, 1.0 to 2.0 portions of film-forming agent, 1.0 to 2.5 portions of antiseptic mildew inhibitor, 1.0 to 2.0 portions of antifreezingagent, 10 to 12 portions of titanium pigment, 20 to 25 portions of calcium carbonate, 2.0 to 5.0 portions of barium sulfate, and 35 to 40 portions of water. The color paint is prepared by adding 0.01to 0.03 folds of color pigment paste on the basis of the white paint and stirring the mixture evenly. The invention also discloses a method for preparing the water-base fluorocarbon imitation marble exterior wall paint and a method for spraying an exterior wall with imitation marble effects by using the paint; and the water-base fluorocarbon imitation marble exterior wall paint keeps the same decorative effect as natural marbles, and simultaneously keeps the characteristics of consistent overall colors, energy saving, environmental protection, convenient construction and easy face lifting, andcan completely replace the natural marbles applied to the exterior wall and save two thirds of the cost at present.

Owner:珠海展辰新材料股份有限公司

Precleaning process of silicon wafer

InactiveCN102368468AReduce dosageLow costFinal product manufactureSemiconductor/solid-state device manufacturingDecompositionSilicon

The invention relates to a precleaning process of a silicon wafer, which comprises the following step of: precleaning the silicon wafer by sequentially performing procedures of soaking treatment, primary rinsing, oxidation treatment and secondary rinsing. In the oxidation process, the decomposition rate of hydrogen peroxide can be controlled in an alkalescence environment, the amount of the used hydrogen peroxide is reduced on the basis of not influencing the oxidation effect, and the cost is greatly reduced; in addition, in the oxidation process, a large amount of bubbles cannot be generatedin the decomposition process of the hydrogen peroxide, and the silicon wafer can be prevented from floating; and therefore the precleaning process disclosed by the invention is completely reliable and is high in finished product rate.

Owner:ZHEJIANG BEYONDSUN PV

Single crystal wafer texturing additive

InactiveCN106521636AReduce surface tensionGood texture effectPolycrystalline material growthAfter-treatment detailsSingle crystalP-toluenesulfonate

The invention belongs to the technical field of single crystal wafer tools and especially relates to a single crystal wafer texturing additive. The single crystal wafer texturing additive is characterized by comprising the following components in parts by weight: 0.01-1% of fluorocarbon surfactants, 1-5% of polyvinylpyrrolidone, 0.1-3% of crylic acid-maleic anhydride copolymer, 1-5% of propylene glycol monomethyl ether, 0.05-0.5% of sodium benzoate, 0.1-2% of sodium p-toluenesulfonate and the balance of water. The single crystal wafer texturing additive has the beneficial effects of excellent texturing effect, smaller size of flock pyramid after texturing, narrower distribution, capability of reducing light reflection and capability of increasing photoelectric conversion efficiency of an assembled solar cell.

Owner:DEQING LIJING ENERGY TECH CO LTD

Additive for polycrystalline silicon wafer texturization and application method thereof

InactiveCN106222755AReduce reflectivitySteady increase in conversion efficiencyPolycrystalline material growthAfter-treatment detailsCarboxylic acidContamination

The invention provides an additive for polycrystalline silicon wafer texturization and a method of applying the additive to perform texturization. The additive is prepared from polymer carboxylic acid, micromolecular organic acid, non-ionic surfactant and water, wherein the weight ratio of the polymer carboxylic acid to the water is 0.5-5 to 100, the weight ratio of the micromolecular organic acid to the water ratio is 1-10 to 100, and the weight ratio of the non-ionic surfactant to the water is 0.01-1 to 100. The texturization is performed by using the additive, the uniformity of suede can be improved, further polycrystalline silicon wafer reflectivity is reduced, and the side effects such as silicon wafer surface contamination and suede inside porous silicon are not produced.

Owner:杭州飞鹿新能源科技有限公司

Mineral crystal fancy glaze capable of releasing negative ions and ceramic tile produced by using mineral crystal fancy glaze

The invention provides a mineral crystal fancy glaze capable of releasing negative ions and a ceramic tile produced by using the mineral crystal fancy glaze. The mineral crystal fancy glaze capable of releasing the negative ions is prepared from the following components in parts by mass: 100 parts of mineral crystal dry pellets, 0 to 50 parts of transparent glaze, 1 to 3 parts of tourmaline powder, 0.01 to 0.05 part of light rare earth oxide, 60 to 80 parts of printing paste, 0.2 part of carboxymethylcellulose and 25 to 40 parts of water; the mineral crystal dry pellets are prepared from the following chemical components in parts by weight of oxides: 8 parts of SiO2, 3 parts of Al2O3, 20 parts of B2O3, 9 parts of Fe2O3, 46 parts of MnO and 8 parts of TiO2. The fancy glaze contains a large amount of color development oxides, the small amount of tourmaline powder and the trace amount of light rare earth oxides; electrostatic voltage difference of the fancy glaze can be improved; a higher release effect of the negative ions is realized at less dosage. The ceramic tile produced by using the mineral crystal fancy glaze capable of releasing the negative ions can release the negative ions.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

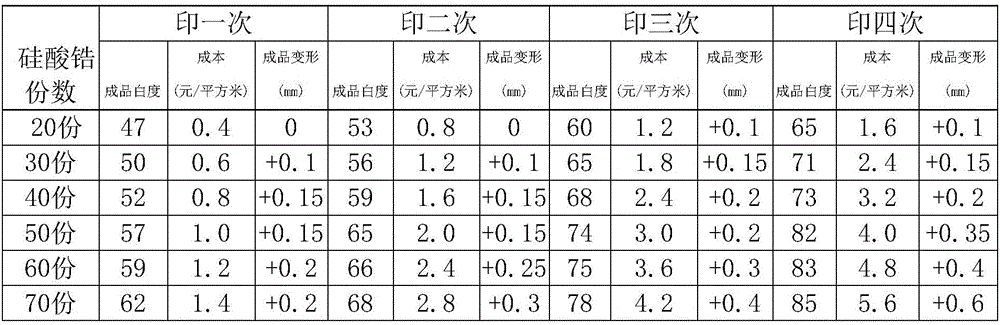

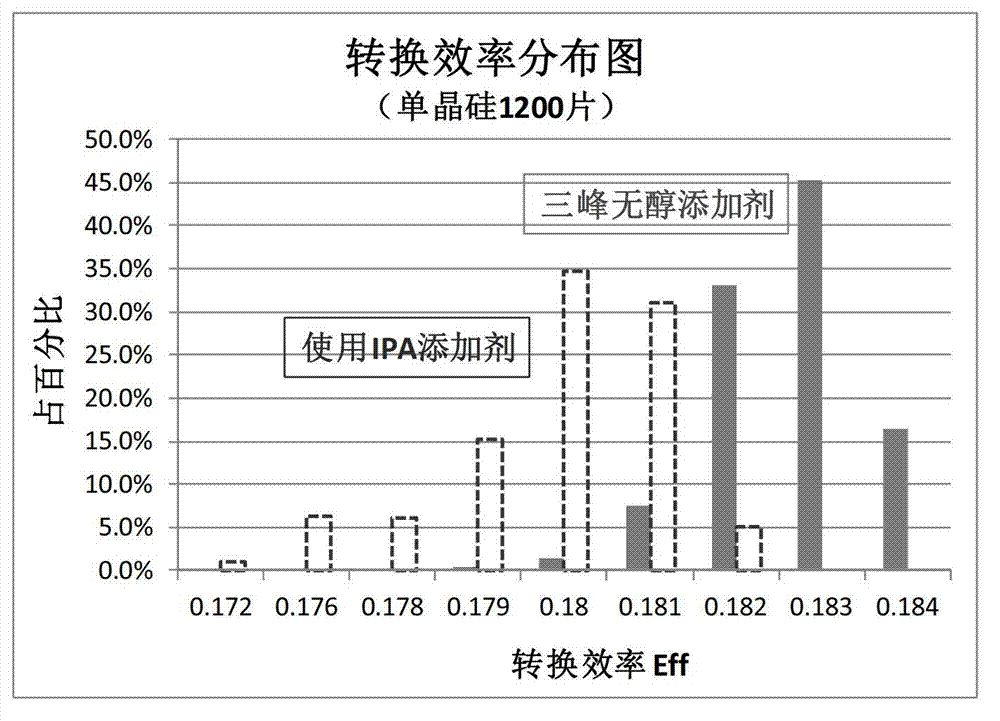

Additive for alkali environment-protecting type no-alcoholic felting liquid of mono-crystal silicone chip and using method thereof

ActiveCN102877135ALower the texturing temperatureShorten the time of texturingAfter-treatment detailsChemistryMonocrystalline silicon

The invention provides an additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, which comprises the following components in percent by weight: 0.05 to 1 percent of protein, 0.01 to 1 percent of detergent, 0.001 to 0.003 percent of vitamin, donkey-hide gelatin or tea polyphenol or the combination thereof, and the balance of water. After adopting the additive for the alkali environment-protecting type no-alcoholic solution of the mono-crystal silicone chip and the using method thereof, compared with the condition without the additive for an alkali environment-protecting type no-alcoholic felting liquid of a mono-crystal silicone chip, the felt temperature can be decreased, no isopropanol is required to be used, the felting time is shortened, and the felting effect is obviously improved.

Owner:湖州三峰能源科技有限公司

Pressure casting surface processing method and product produced through method

InactiveCN103623985AImprove corrosion resistanceBoth have a metallic texturePretreated surfacesSpecial surfacesPressure castingPre treatment

The invention discloses a pressure casting surface processing method and a product produced through the method. The method comprises the first step of casting and forming a workpiece, the second step of pre-processing the surface, the third step of carrying out cold spraying, and the fourth step of post-processing the surface. The product is the product processed through the method. According to the pressure casting surface processing method and the product produced through the method, the cold spraying technology and the surface post-processing technology are combined, the pressure casting finished product with the metallic texture effect or the high texture effect is manufactured on the surface of the pressure casting, the surface processing method is environmentally friendly in manufacturing process, simple in technology and suitable for being widely applied to the industry, and the yield of pressure casting finished products is greatly improved; the processed product is good in corrosion resistance, compact and attractive and has the metallic texture or high texture effect.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Cleaning and wool making technology for monocrystal silicon chip

InactiveCN103774239AStrong decontaminationEasy to cleanAfter-treatment detailsCleaning using liquidsPotassium hydroxideReaction temperature

The invention relates to a cleaning and wool making technology for a monocrystal silicon chip, and belongs to the technical field of chemical engineering. The technology particularly comprises the following step: (1) adopting a self-made silicon chip cleaning agent to perform precleaning on the silicon chip; (2) putting the pre-cleaned silicon chip into a wool making trough; preparing a wool making liquid in the wool making trough, and adding 0.1 to 5% of sodium hydroxide, 0.1 to 3% of potassium hydroxide, 1 to 5% of isopropyl alcohol and 0.02 to 5% of a self-made wool making additive in percentage by weight into the wool making liquid; rising temperature until the reaction temperature is 70 DEG C to 90 DEG C to make wool; turning on ultrasonic equipment during the wool making process; (3) when the wool is prepared, closing the trough body; before the chip is cast, stirring by adopting a stirring device, wherein the wool making reaction time is 15 to 40 min. According to the invention, through the adoption of the cleaning agent and the wool making additive, the technology is controlled to be simple and stable, the energy consumption is reduced, and the capability of process control is enhanced, so that the control quality of the product in various aspects is greatly improved, the production cost in various aspects is reduced, and the comprehensive economic benefit is increased.

Owner:HENAN INST OF SCI & TECH

Rinsing fluid used for removing organics on surface of monocrystalline silicon piece and cleaning method

InactiveCN104479913AEfficient removalImprove surface cleanlinessInorganic non-surface-active detergent compositionsCleaning using liquidsMegasonic cleaningPotassium hydroxide

The invention discloses a rinsing fluid used for removing organics on the surface of a monocrystalline silicon piece and a cleaning method. The rinsing liquid comprises the following compositions in parts by volume: 2.30 parts-4.5 parts of hydrogen peroxide, 0.20 parts-1.15 parts of potassium hydroxide, and 94.35 parts-97.5 parts of pure water, wherein the mass fraction of potassium hydroxide is 45% and pure water is 18 M pure water. The cleaning method comprises the following steps: (1) flushing with tap water; (2) immersing in a lactic acid solution; (3) rinsing with tap water; (4) using pure water for ultrasonic pre-cleaning; (5) using a cleaning liquid for ultrasonic cleaning; (6) using pure water for ultrasonic rinsing; (7) using the rinsing fluid for rinsing; (8) using pure water for rinsing; and (9) performing dip coating and baking. The rinsing fluid and the cleaning are capable of effectively removing organics left on the surface of the monocrystalline silicon piece, improving the clean degree of the monocrystalline silicon piece surface, effectively reducing the cleaning unqualified rate of the monocrystalline silicon piece and the adverse ratio of the monocrystalline silicon piece subjected to etching, improving the quality of the monocrystalline silicon piece and enhancing the market competiveness of the product.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

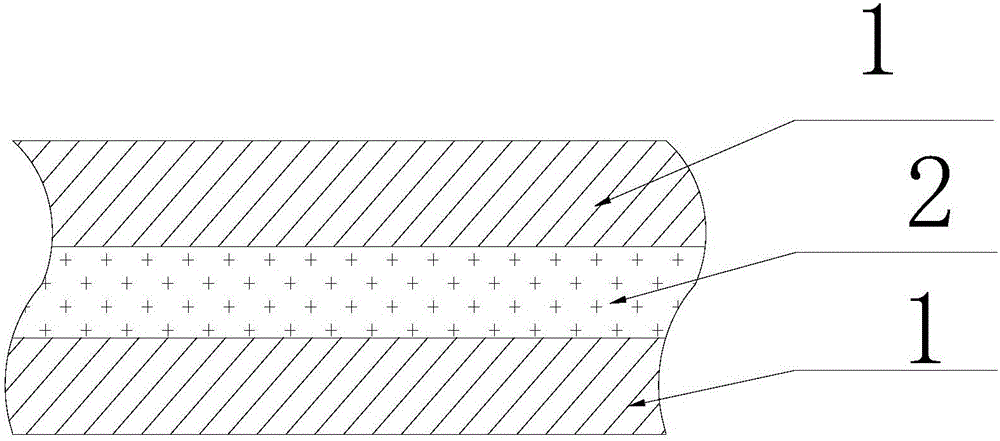

Soft hot-rolled non-woven fabric and preparation method thereof

The invention discloses a soft hot-rolled non-woven fabric and a preparation method thereof. The soft hot-rolled non-woven fabric comprises silk fiber non-woven fabric layers and a composite fiber non-woven fabric layer, wherein the composite fiber non-woven fabric layer is clamped between two silk fiber non-woven fabric layers in a hot-rolled bonding manner; the silk fiber non-woven fabric layers are formed by blending silk fibers with a small amount of ES bonding fibers; the composite fiber non-woven fabric layer is formed by blending polypropylene fibers, polyester three-dimensional crimp hollow fibers and the small amount of ES bonding fibers. According to the soft hot-rolled non-woven fabric disclosed by the invention, the polypropylene fibers of a traditional non-woven fabric are replaced with composite fibers consisting of the polypropylene fibers and the polyester three-dimensional crimp hollow fibers, so that the softness of the traditional non-woven fabric is improved; in addition, the silk fiber layers are additionally arranged on the surface of the traditional non-woven fabric, so that the texture effect of the traditional non-woven fabric is improved.

Owner:浙江晨阳无纺布科技有限公司

Production technology for T/R/H multielement functional fiber high textual quality yarn

The invention discloses a production technology for T / R / H multielement functional fiber high textual quality yarn. Heterotype cross-section Dacron, functional modified mucilage glue and Han jute fiber are selected as the raw materials or microporous modified dacron, functional modified mucilage glue and Han jute fiber are selected as the raw materials; the raw materials are prepared into clean, neat, puffy, soft, parallel and straight short fiber strands after going through opening and scutching, carding and edulcoration, combing and setting; then drawing decrement is carried out on the Heterotype cross-section dacron short fiber strands or microporous dacron short fiber strands; afterwards the drawing hybrid yarn principle is employed to enable the short fiber strands to be drawn with the functional modified mucilage glue and Han jute fiber; repeated drawing and gilling are performed to realize uniform blending of 3 functional fibers; the fiber strands after being blended and carded is processed into single yarn or plied yarn finished product yarn after going through processes of roving, spun yearn, spooling, doubling and wire twisting.The product of the invention features excellent conformality, bacterial resistance and moisture absorption and perspiration property, thus being an ideal new material of bionic function yarn.

Owner:SHAOXING UNIVERSITY

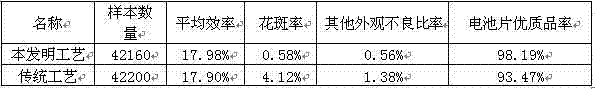

Texture surface making method for polycrystalline silicon solar battery

ActiveCN105040108AImprove stabilityImprove controllabilityAfter-treatment detailsPhotovoltaic energy generationPolyvinyl alcoholSolar battery

The invention relates to a texture surface making method for a polycrystalline silicon solar battery. A texture surface making aqueous solution comprises the following components in percentage by weight: 5-20% of hydrofluoric acid, 25-55% of nitric acid, 0.5-5% of silicofluoric acid, 0.1-0.5% of acetic acid, 0.5-1.5% of an additive and the balance of water, wherein the additive comprises the following components in percentage by weight: 0.2-0.8% of polyvinyl alcohol, 0.1-0.6% of triethanolamine, 1-6% of hydrolytic polymaleic anhydride, 0.05-0.1% of polyvinyl pyrrolidone and the balance of water, and the temperature of the texture surface making aqueous solution is 0-30 DEG C. The method comprises the following steps: putting silicon chips into the aqueous solution for 100-300s, performing ultrasonic vibration at the same time at an ultrasonic frequency of 40-60KHZ; and taking out the silicon chips, cleaning the silicon chips in a cleaning solution containing 0.2-0.5% of sodium hydroxide and 0.5-2% of sodium dodecyl benzene sulfonate, taking out the silicon chip and blow-drying. The method has the advantages of good stability, easily controllable temperature, good light-trapping effect on the surface of polycrystalline silicon, high photoelectric conversion rate of the battery, uniform texture surface and low reflectivity.

Owner:宁波乐丰新能源有限公司

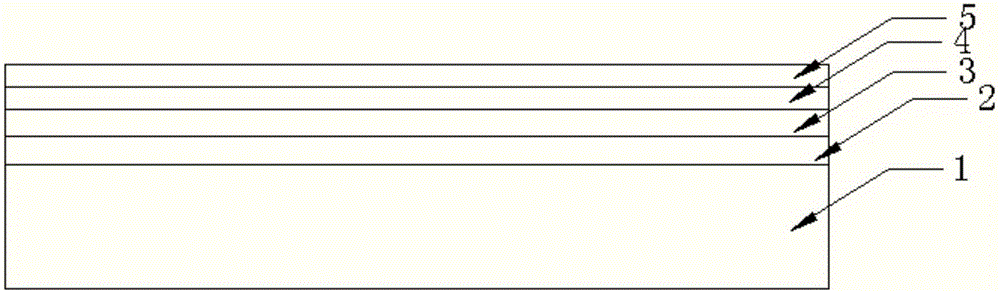

Ceramic tile with mineral crystal fancy glaze layer and preparation method thereof

The invention provides a ceramic tile with a mineral crystal fancy glaze layer and a preparation method thereof. The ceramic tile with the mineral crystal fancy glaze layer comprises a blank layer, a printing layer, a protection fancy glaze layer and the mineral crystal fancy glaze layer from bottom to top. The mineral crystal fancy glaze layer is formed by arranging a mineral crystal fancy glaze. The mineral crystal fancy glaze comprises, by mass, 100 parts of a mineral crystal dry granule, 0-50 parts of a clear glaze, 60-80 parts of printing paste, 0.2 part of carboxymethylcellulose and 25-40 parts of water. The mineral crystal dry granule comprises, by oxide weight, 8 parts of SiO2, 3 parts of Al2O3, 20 parts of B2O3, 9 parts of Fe2O3, 46 parts of MnO and 8 parts of TiO2. The ceramic tile is provided with the mineral crystal fancy glaze layer and can show the rich natural mineral crystal texture effect, and the decoration texture similar to natural stone is obtained.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

Focusing mirror active unordered device and method for roller laser-texturing lathe

InactiveCN101811226ASatisfy Matte RequirementsSimple productivityLaser beam welding apparatusOptical elementsMachine toolLaser beams

The invention discloses a focusing mirror active unordered device and a focusing mirror active unordered method for a roller laser texture lathe. A CO2 continuous laser or a YAG pulsed laser is utilized as an energy light source of roller texturing. A disturber is arranged on a focusing mirror support of a texturing head. Due to the use of the disturbing force generated by the disturber, the focusing mirror support is driven to change a tiny angle relative to a lathe support. Meanwhile, laser beams passing through the focusing mirror are subjected to angular change in random directions relative to the molded centerline of the laser; the laser beams passing through a chopper disk are scattered through the treatment of the chopper disk; and laser-texturing points in unordered distribution are generated on the roller surface so as to process sheet metals by using the textured roller. Due to the focusing mirror active unordered method, the matte effect of the surfaces of cold-rolled sheets can be achieved and the production efficiency of the roller laser-texturing lathe can be improved.

Owner:WUHAN HGLASER ENG CO LTD

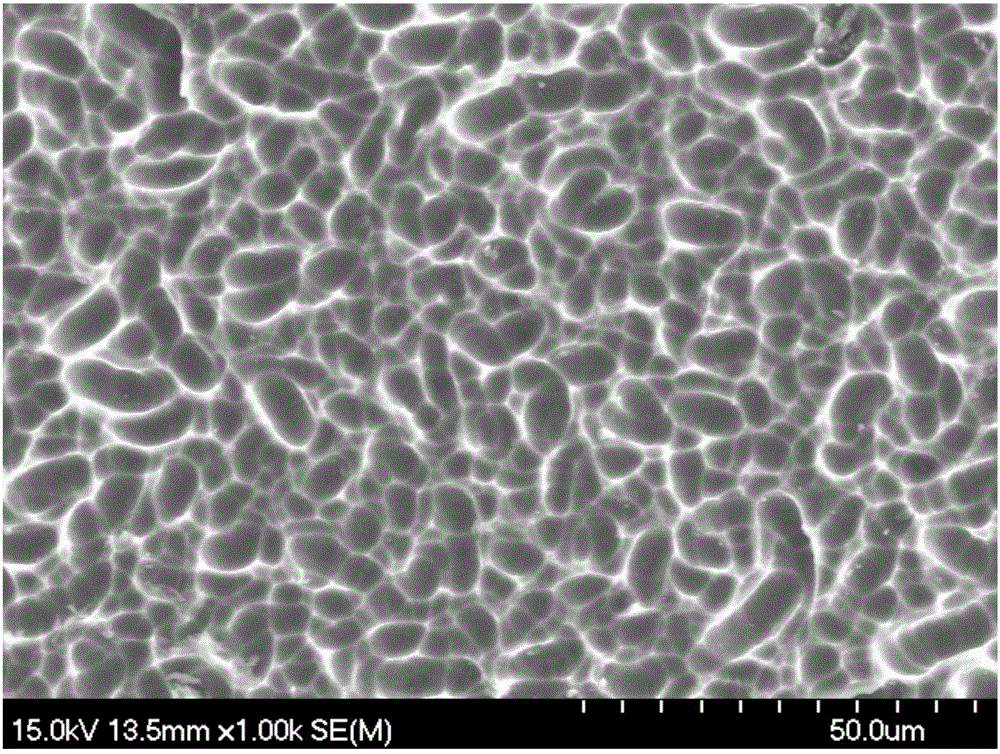

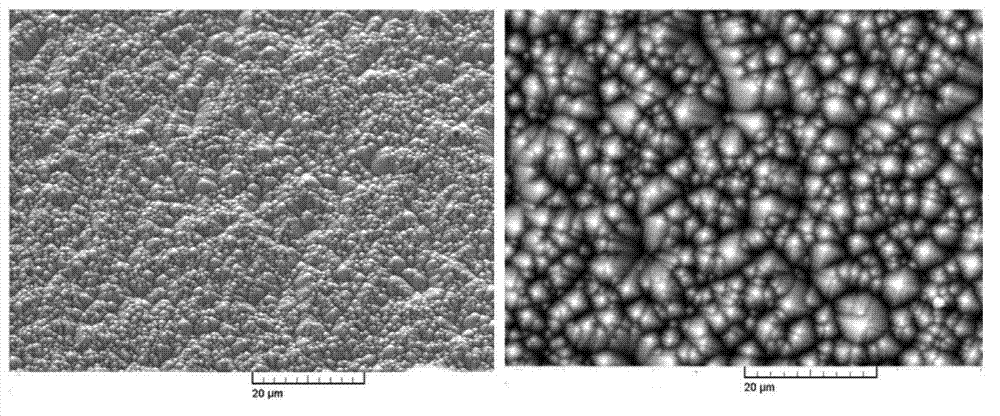

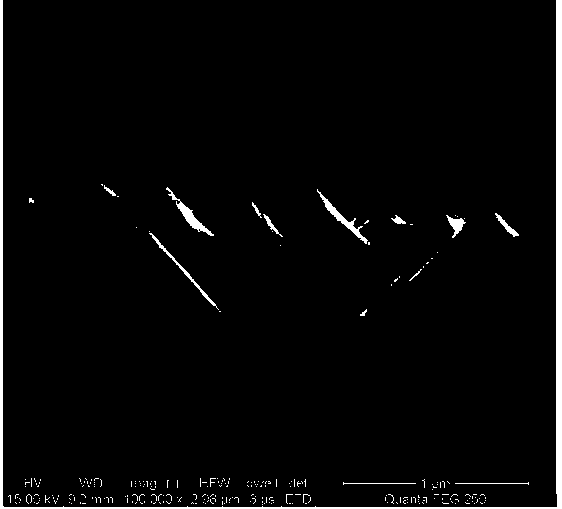

Formula of composite texturing additive for preparing maize-shaped monocrystal silicon textured surface as well as use method of additive

InactiveCN110644053AReduce reflectionImprove photoelectric conversion efficiencyPolycrystalline material growthAfter-treatment detailsPolyethylene glycolPyrrolidinones

The invention relates to a nonionic surfactant-containing additive of monocrystal silicon wafer texturing liquid. The additive comprises the following components: three nonionic surfactants such as polyethylene glycol (PEG), polyvinylpyrrolidone (PVP) and alkyl polysaccharide glycoside (APG), organic acid, inorganic salt and the balance of water. The invention also discloses a texturing method ofa monocrystal silicon wafer. The texturing method of the monocrystal silicon wafer comprises the following steps: 1) preparing a texturing additive; 2) preparing texturing liquid; 3) putting the monocrystal silicon wafer into the texturing liquid prepared in the step 2) and performing texturing at the texturing liquid temperature of 70 to 90 DEG C for 8 to 16 minutes; and 4) mixing the monocrystalsilicon wafer after texturing liquid with acid, cleaning with deionized water again and drying to obtain a product. The texturing effect is excellent; after texturing the texturing surface pyramids are arranged in a maize shape and the size distribution is 0.2 to 1.5 um; and reflection on light can be effectively reduced and the photoelectric conversion efficiency of a solar battery piece can besignificantly improved.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Environment-friendly biological texture etch solution and application method thereof

ActiveCN102181934AThe source of raw materials is stableEasy to sourceAfter-treatment detailsFinal product manufactureCitrate sodiumSodium carbonate

The invention discloses an environment-friendly biological texture etch solution and an application method thereof, particularly relates to application of the texture etch solution to a solar single wafer during processing and manufacturing of a solar silicon wafer, and belongs to the technical field of preparation of a monocrystalline silicon solar cell. The application method is characterized by comprising the following steps of: adding a non-ionic surfactant, sodium citrate, anhydrous sodium carbonate and deionized water into a cleaned texture etch groove, stirring, and mixing uniformly toprepare the environment-friendly biological texture etch solution; heating the environment-friendly biological texture etch solution to between 75 and 85 DEG C; placing cut monocrystalline silicon wafers in the environment-friendly biological texture etch solution for etching reaction after the temperature is completely stable, wherein the reaction time is between 10 and 30 minutes; and taking the silicon wafers out after texture etching, placing the silicon wafers in an ultrasound tank which is filled with the deionized water, and rinsing for 5 to 15 minutes by ultrasound. The texture surface with fine, uniform and high-coverage rate pyramids can be obtained after the solar single wafer is subjected to texture etching through the texture etch solution, and the mass difference of the wafer before etching and after etching is between 0.1 and 1.0g.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

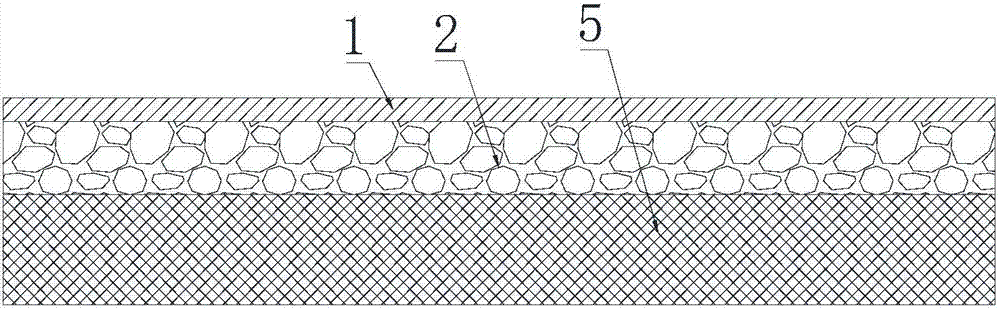

Burning-free imitating natural stone and preparation method thereof

PendingCN106869442ARich texture effectImprove visual effectsLamination ancillary operationsCovering/liningsTextile printerEngineering

The invention discloses burning-free imitating natural stone. The burning-free imitating natural stone is characterized by comprising a blank, a middle texture layer and a surface protection layer, wherein the middle texture layer and the surface protection layer are arranged on the blank, and the middle texture layer comprises at least one printed texture layer and / or cloth texture layer. The burning-free imitating natural stone is simple in structure and convenient to produce and process, and compared with products of the same type, the burning-free imitating natural is higher in plasticity, better in natural stone imitating effect and more excellent in performance.

Owner:FOSHAN SANSHUI YINGJIE PRECISION MACHINERY

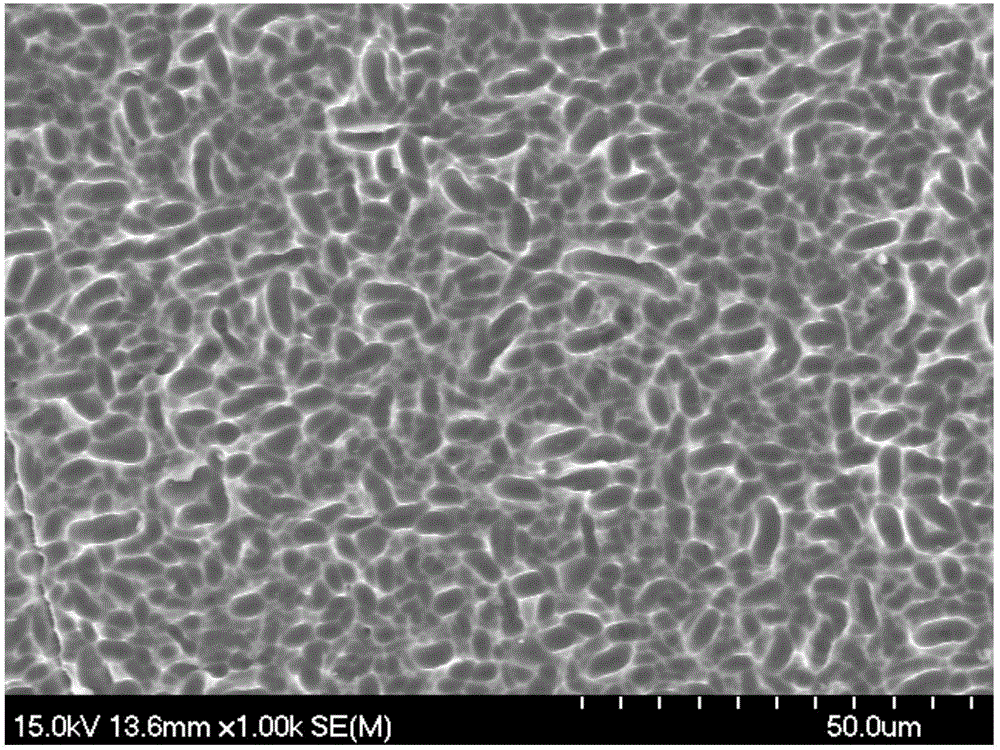

Special alkali texturing additive for diamond wire cutting single crystal silicon wafers, and using method of additive

InactiveCN108130598AImprove stabilityImprove consistencyPolycrystalline material growthAfter-treatment detailsPolyvinyl alcoholWire cutting

The invention relates to a special alkali texturing additive for diamond wire cutting single crystal silicon wafers. The additive is prepared from the following components by weight percent: 0.5-5% ofpolyols, 0.2-2% of polyvinyl alcohol, 0.02-0.2% of an anionic surfactant, 0.01-1% of a water-soluble silicone-based antifoaming agent, 0.5-5% of sodium silicate and the balance of deionized water. After the additive provided by the invention is used for alkali texturing of the diamond wire cutting single crystal silicon wafers, the time for the alkali texturing is shortened, uniform, fine and dense pyramid texture can be obtained, a better texturing effect is still maintained at the later use period of texturing liquid, the stability and consistency of a texturing process are improved, and the problems of line mark residue of the single crystal silicon wafers and the like after texturing can be effectively solved. The additive is non-toxic, easy to implement and good in stability, thus having a very good practical application value.

Owner:宁波道乐新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com