Burning-free imitating natural stone and preparation method thereof

A technology of imitating natural stone and base material, applied in the field of non-burning imitation natural stone and its preparation, can solve the problems of high production equipment requirements, large surrounding environment pollution, poor simulation, etc., and achieve the effect of rich texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 1 As shown, a non-fired imitation natural stone, its effect is like natural sandstone. It includes a surface protection layer 1, a cloth texture layer 2, a printed texture layer 3 and a ceramic plate 4 which are layered in sequence from top to bottom. The cloth texture layer is a three-dimensional texture layer formed by bonding glue and solid materials, and the solid materials are granular materials, such as sand grains. The thickness ratio of the ceramic plate 4, the cloth texture layer 2, the printed texture layer 3, and the surface protection layer 1 is 6:3:2:1.

[0037] The following is the preparation method of non-fired imitation natural stone. First, take a ceramic plate of specification and size as the base material according to the needs, clean it and dry it, then directly print the texture of imitation natural stone on the ceramic plate, dry it, and then print it on the surface of the texture. The cloth texture layer is laid, sent to a press ...

Embodiment 2

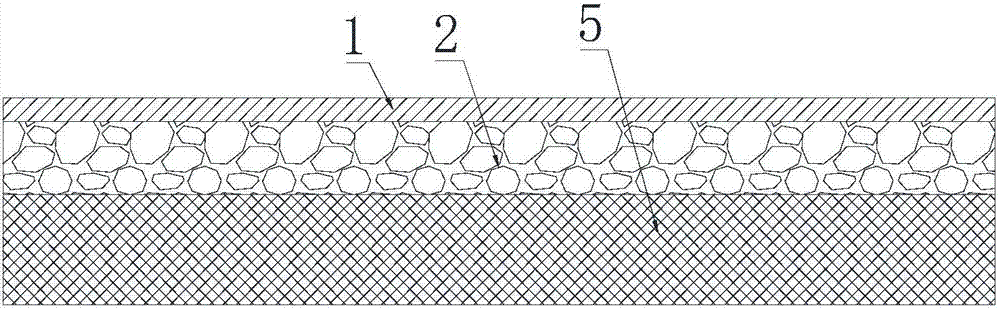

[0042] Such as figure 2 , In this embodiment, a non-fired imitation natural stone, including a surface protection layer 1, a printed texture layer 3, a cloth texture layer 2 and a silicon-calcium board 5, which are layered sequentially from top to bottom. The thickness ratio of the silicon-calcium board 5, the cloth texture layer 2, the printing texture layer 3, and the surface protection layer 1 is 7:2:1:1.

[0043] The following is the preparation method of non-fired imitation natural stone. First, take the calcium-silicon board of the specification and size as the base material, clean it and dry it, and then lay a cloth texture layer on the calcium-silicon board, send it to the press for pressing, and dry , and then print the texture imitating natural stone, and finally cover the surface protection layer on the printed texture layer.

[0044] Furthermore, in the process of printing the printed texture layer, the coloring agent used is inorganic pigments, and the pattern i...

Embodiment 3

[0046] Such as image 3 As shown, in this embodiment, a fire-free imitation natural stone material includes a surface protection layer 1 , a cloth texture layer 2 , and a ceramic plate 4 arranged in layers from top to bottom.

[0047] The following is the preparation method of non-fired imitation natural stone. First, take the ceramic plate of the specification and size as the base material according to the needs, clean it and dry it, then lay a cloth texture layer on the ceramic plate, send it to the press for pressing, dry, and finally Overlays the surface protection layer over the cloth texture layer.

[0048] Further, in the process of laying the cloth texture layer, a glue layer is first applied, and then solid materials are laid on the glue layer to form the texture. In order to improve production efficiency, the glue uses UV glue. After the process of laying the fabric texture layer is completed, it is sent to a UV ultraviolet lamp furnace to make the glue solidify qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com