Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Improve interfacial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of evaluating protein formulation stability and surfactant-stabilized insulin formulations derived therefrom

InactiveUS6737401B2Improve physical stabilityReliable timePeptide/protein ingredientsMicrobiological testing/measurementCell AggregationsProtein aggregation

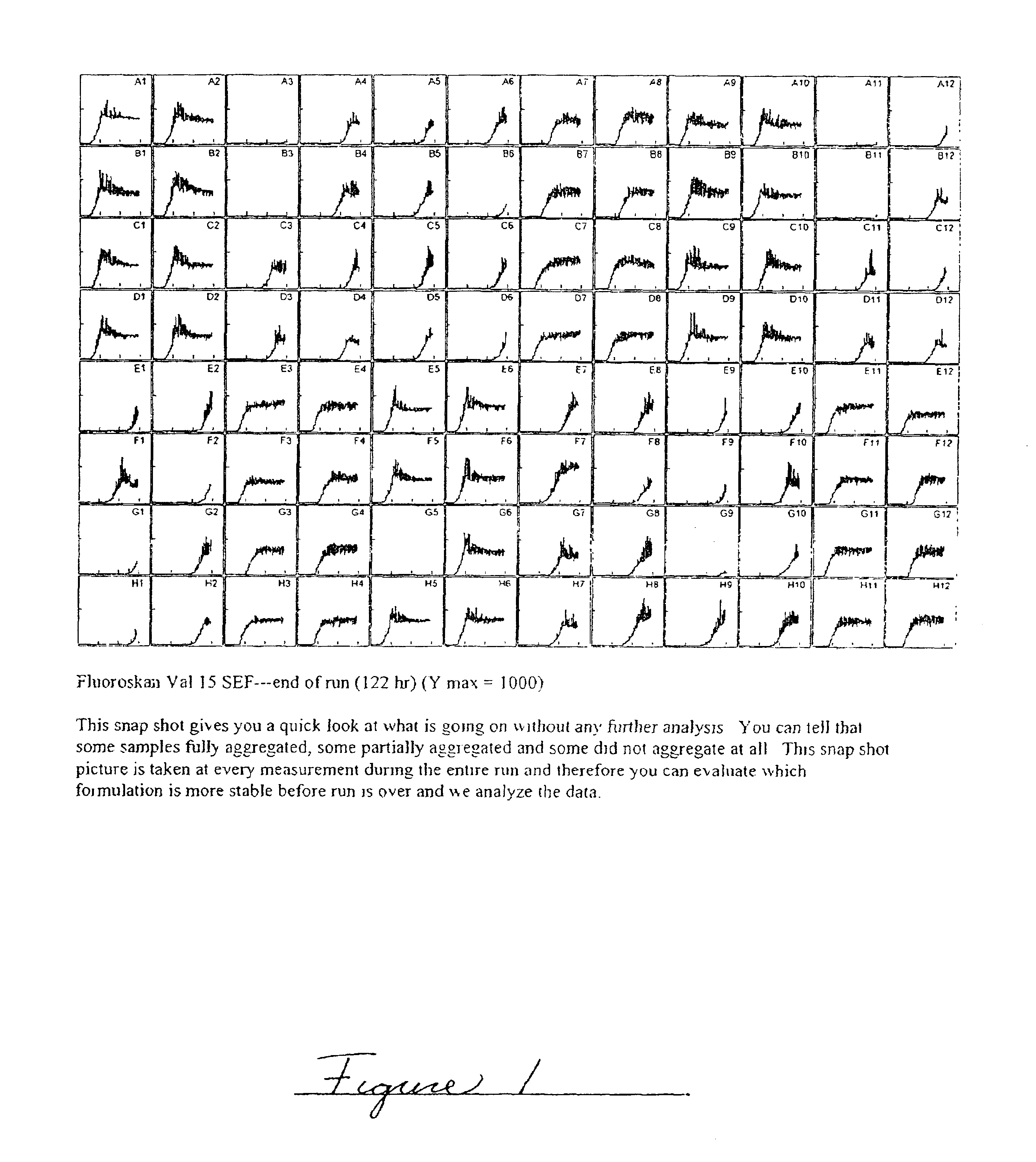

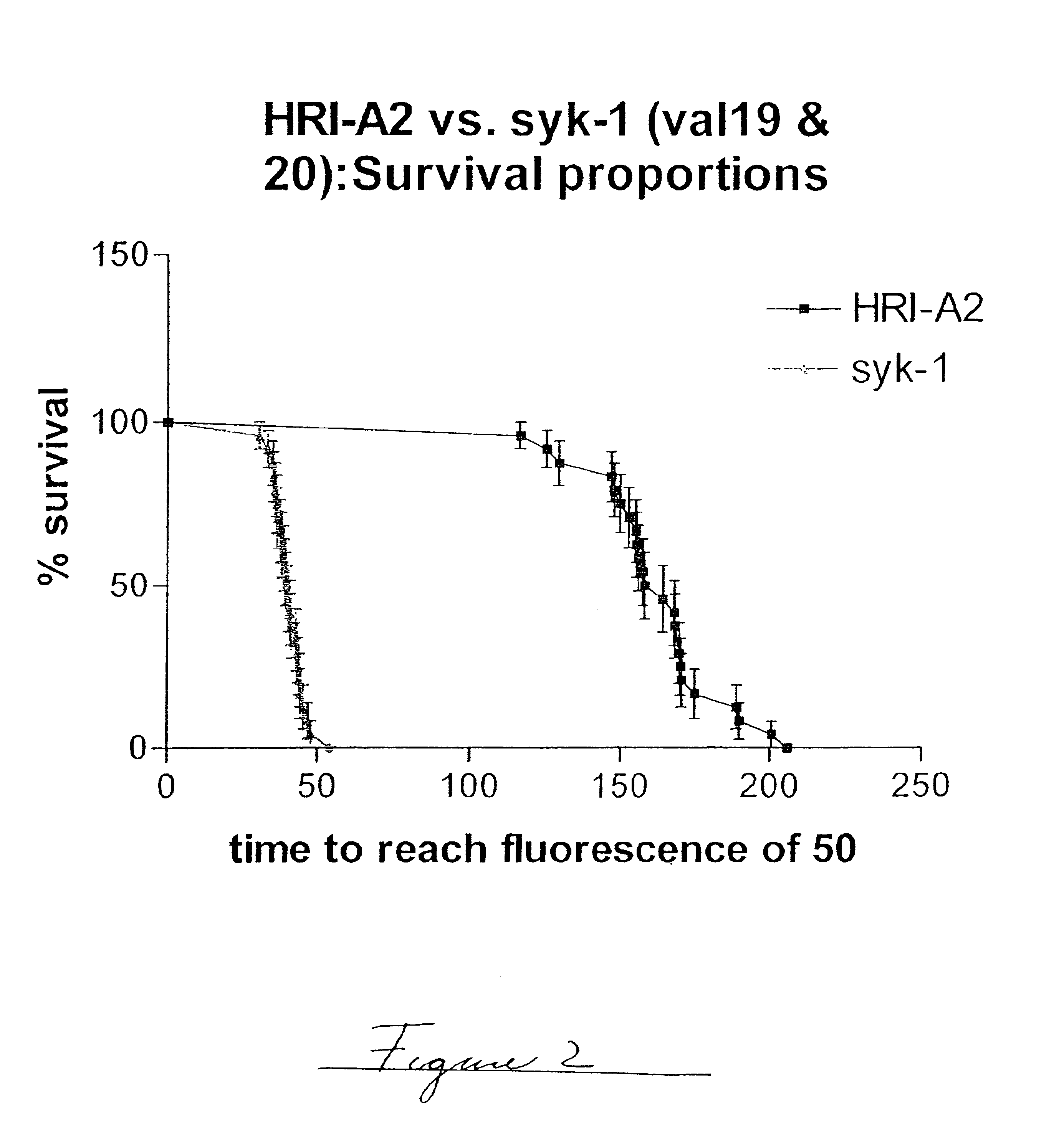

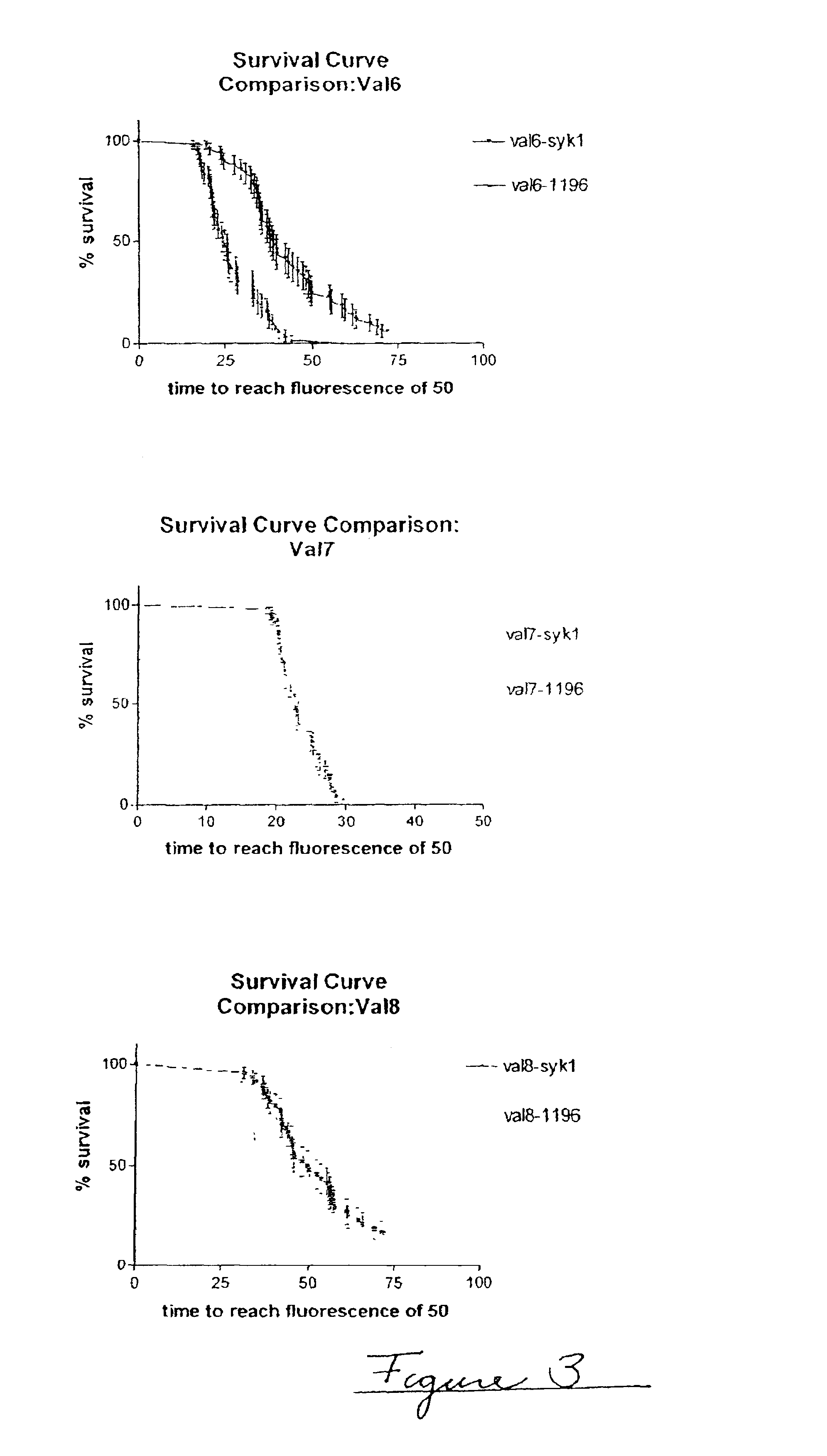

Embodiments of the invention are directed to a method of estimating the physical stability of a protein formulation. A particular embodiment of the invention places the protein formulation under an agitational stress that causes the protein to aggregate at an accelerated rate. In one embodiment, the change in protein aggregation is monitored spectroscopically using Thioflavin-T. Embodiments of the invention then utilize a survival curve analysis to ascertain the relative physical stability of the different protein formulations under study. This method was used to develop novel surfactant-stabilized insulin formulations in a rapid, cost efficient manner, thus illustrating the utility of the inventive method to the discovery and development of pharmaceutical protein formulations.

Owner:MEDTRONIC MIMIMED INC

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

Methods of using natural products as dewatering aids for fine particles

InactiveUS6526675B1Reduce moistureImprove hydrophobicityPigmenting treatmentDrying using combination processesLipid formationSlurry

A method of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic. A lipid of vegetable or animal origin is then added to the slurry in solutions of light hydrocarbon oils and short-chain alcohols, so that the hydrophobic lipid molecules adsorb on the moderately hydrophobic surface and, thereby, greatly enhance its hydrophobicity. By virtue of the enhanced hydrophobicty, the water molecules adhering to the surface are destabilized and more readily removed during the process of mechanical dewatering. The moisture reduction can be further improved using appropriate electrolytes in conjunction with the lipids, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and using combinations thereof.

Owner:YOON ROE HOAN

Hydroscopic polymer gel films for easier cleaning

InactiveUS6926745B2Reduce adhesionEasy to cleanLiquid surface applicatorsOrganic detergent compounding agentsWater dispersibleChemical reaction

Hydroscopic polymer gels can be formed by applying a water soluble or water dispersible polymer on a surface and allowing water to be sequestered from the atmosphere into the polymer. The polymer gels provides for easier next time cleaning. In addition, the surfaces of textiles and related materials can be engineered by the formation of polymer gel films thereon. Polymer gels also provide a vehicle by which sites of chemical reactions can be localized.

Owner:THE CLOROX CO

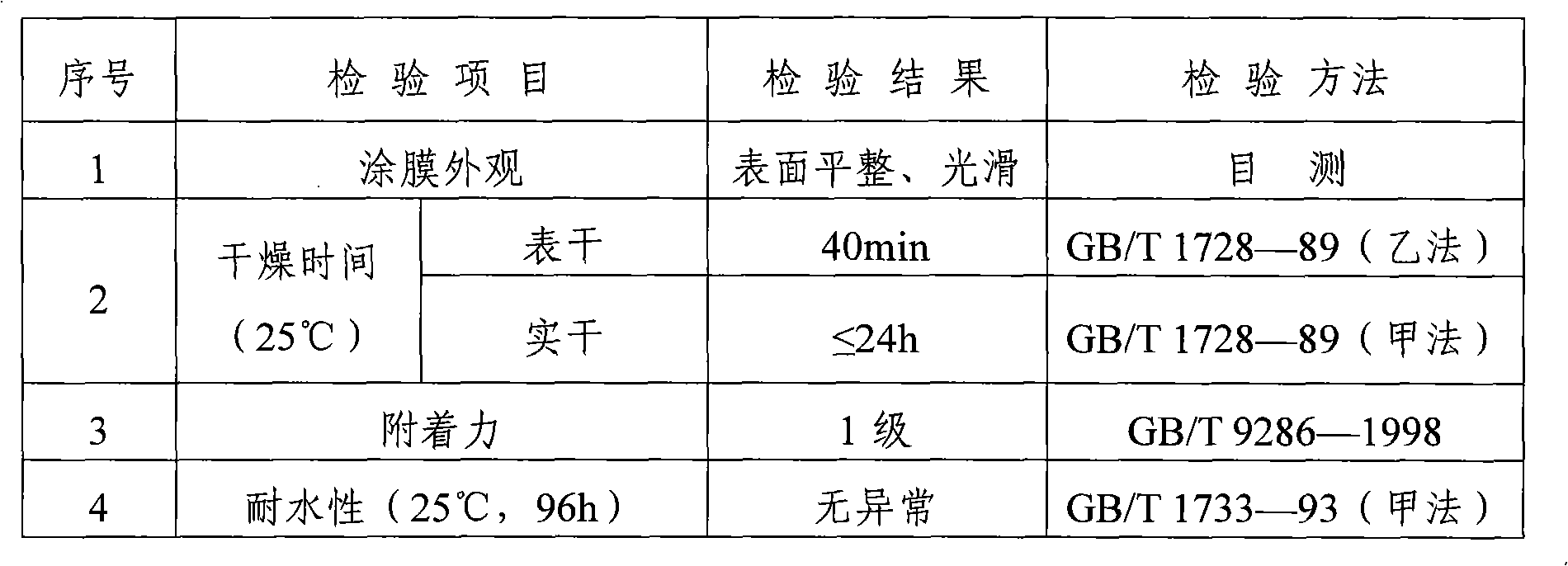

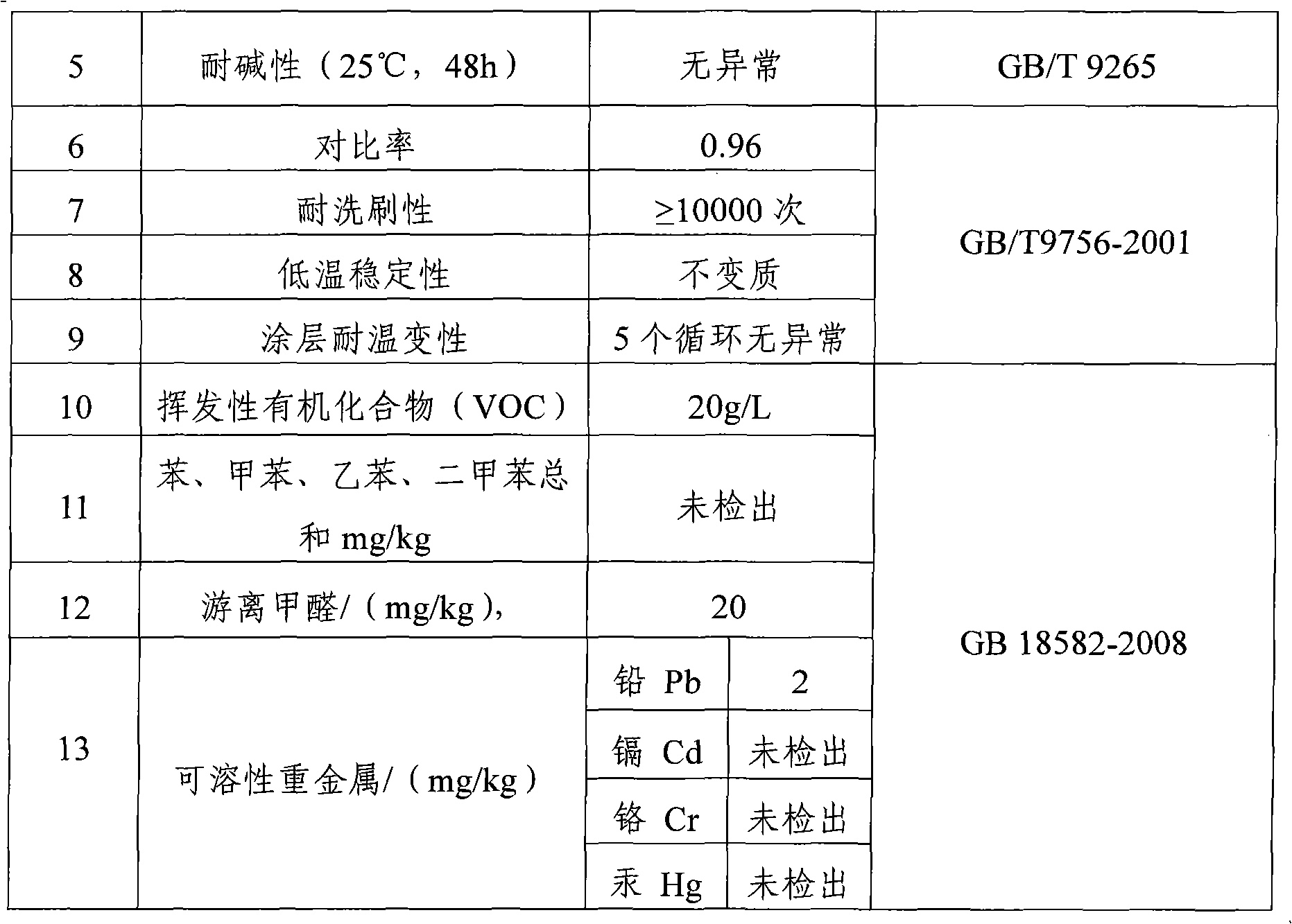

Emulsion paint for preventing mosquitoes and flies and preparation method thereof

ActiveCN101671509ALipophilicMosquito repellent for a long timeAntifouling/underwater paintsPaints with biocidesEmulsionMicrosphere

The invention relates to an emulsion paint for preventing mosquitoes and flies and a preparation method thereof. The emulsion paint comprises the components based on parts by weight: 100-400 parts ofnano waterborne resin with 48% of solid content, 2-5 parts of nano defoaming agent, 1-5 parts of preservative, 5-10 parts of dispersing agent, 200-500 parts of pigment filler, 1-10 parts of nano thickening agent, 1-10 parts of flatting agent, 0-10 parts of antifreeze agent, 0-10 parts of film formation auxiliary agent, 5-20 parts of nano inorganic anion antibacterial agent, 40-100 parts of nano polymer hollow microspheres, 20-80 parts of biological mosquito repellent and 0-350 parts of water. The emulsion paint for preventing the mosquitoes and the flies can be coated on the wall and the wood,has a paint film with the characteristics of good covering power, good adhesive force, scouring resistance and the like, can effectively prevent the mosquitoes and the flies from entering the room, and has the advantages of low cost, good construction property and excellent environmental protection performance, thus being taken as a product perfectly blending the three themes of decoration, functionality and environmental protection performance.

Owner:濮阳展辰新材料有限公司

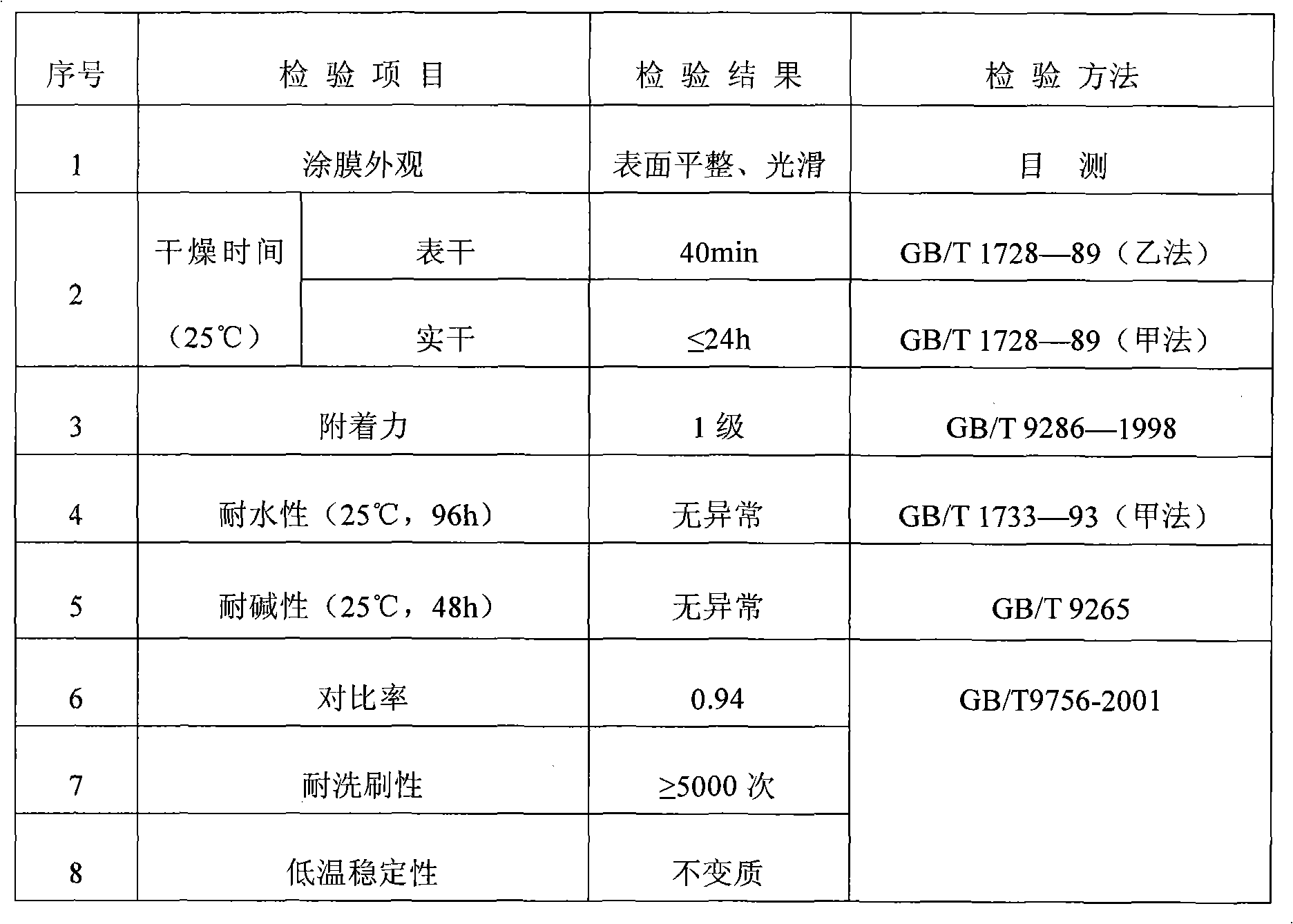

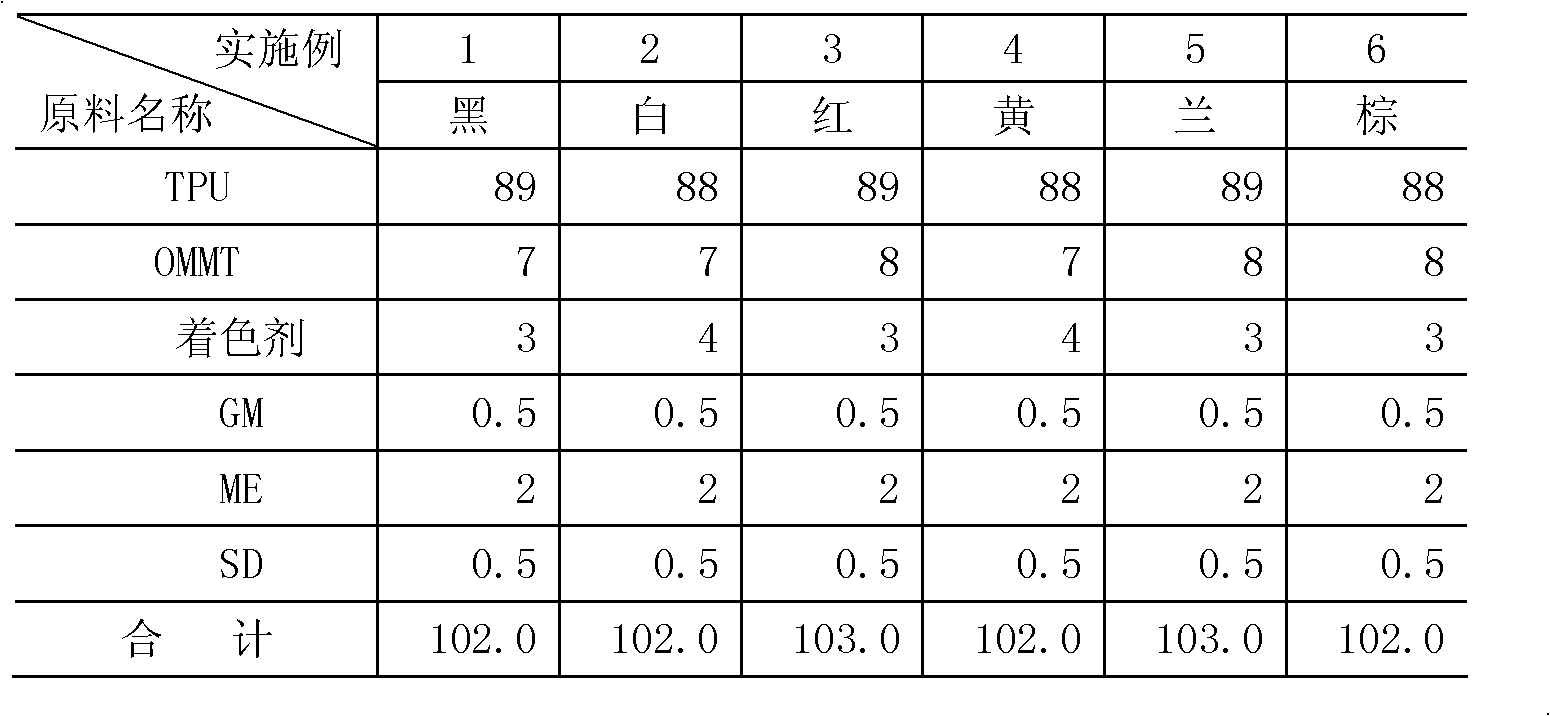

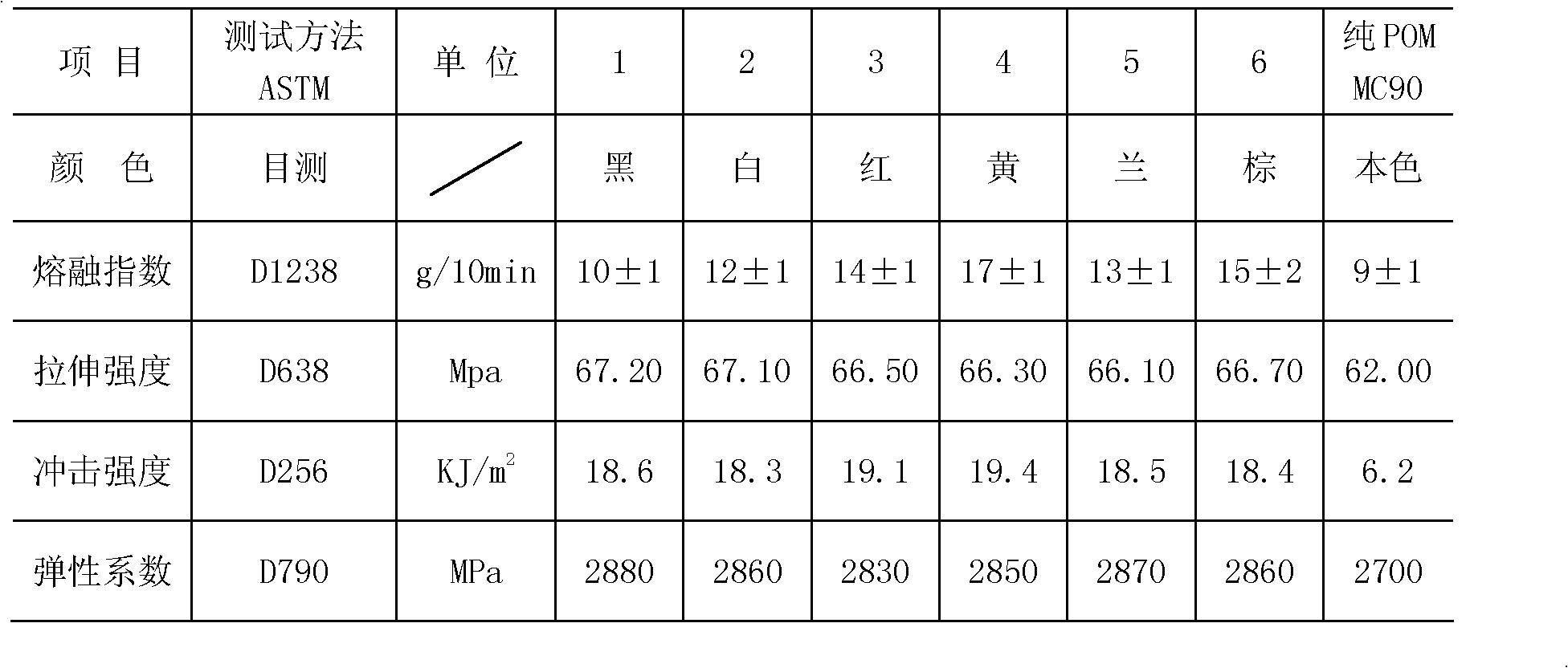

Polyformaldehyde masterbatch with double-function of toughening and coloring, and preparation method thereof

In the prior art, due to the structure characteristics of the polyformaldehyde, the coloring and the toughening of the polyformaldehyde are difficult compared to other plastics so as to provide a worldwide exploration problem. The present invention relates to a polyformaldehyde masterbatch with double-function of toughening and coloring, and a preparation method thereof. The polyformaldehyde masterbatch comprises, by weight, 70-90% of a thermoplastic polyurethane elastomer, 7-9% of nano-scale silicate, 0.8-2.5% of a nano-scale coloring agent, 1-3% of melamine, 0.3-0.8% of a surfactant polysiloxane, and 0.2-0.5% of an anti-aging agent, wherein the anti-aging agent is a mixture comprising styrenated phenol and diphenyl-p-phenylenediamine. The polyformaldehyde masterbatch of the present invention has the double functions of toughening and coloring, such that the strength and the stiffness of the material are not reduced while the notched impact strength of the POM is substantially improved, and the processing fluidity and the thermal deformation resistance are improved.

Owner:ZHEJIANG QISELU MASTERBATCH

Slag-forming constituents used for zinc and zinc-base alloy fusion casting

The invention relates to a slag-forming constituent in fusing zinc and zinc-base alloy, which is used to slag off zinc or zinc-base alloy and clarify molten metal when zinc-base alloy is used. The slag-forming constituent comprises 55-75wt% of CaF2, 3-8wt% of Na3AlF6, 3-8wt% of KCl, 5-10wt% of NaCl, 5-20wt% of ZnCl2 and 5-15wt% of C powder. The invention improves interfacial force and boundary tension of slag and metal by using chlorine saline to separate slag from liquid metal efficiently, and reduces evaporation of slag under high and low temperature to reduce environmental contamination. The invention has an extensive usage such as zinc ingot casting, zinc-base alloy product casting and zinc-base product later usage.

Owner:株洲冶炼集团有限责任公司

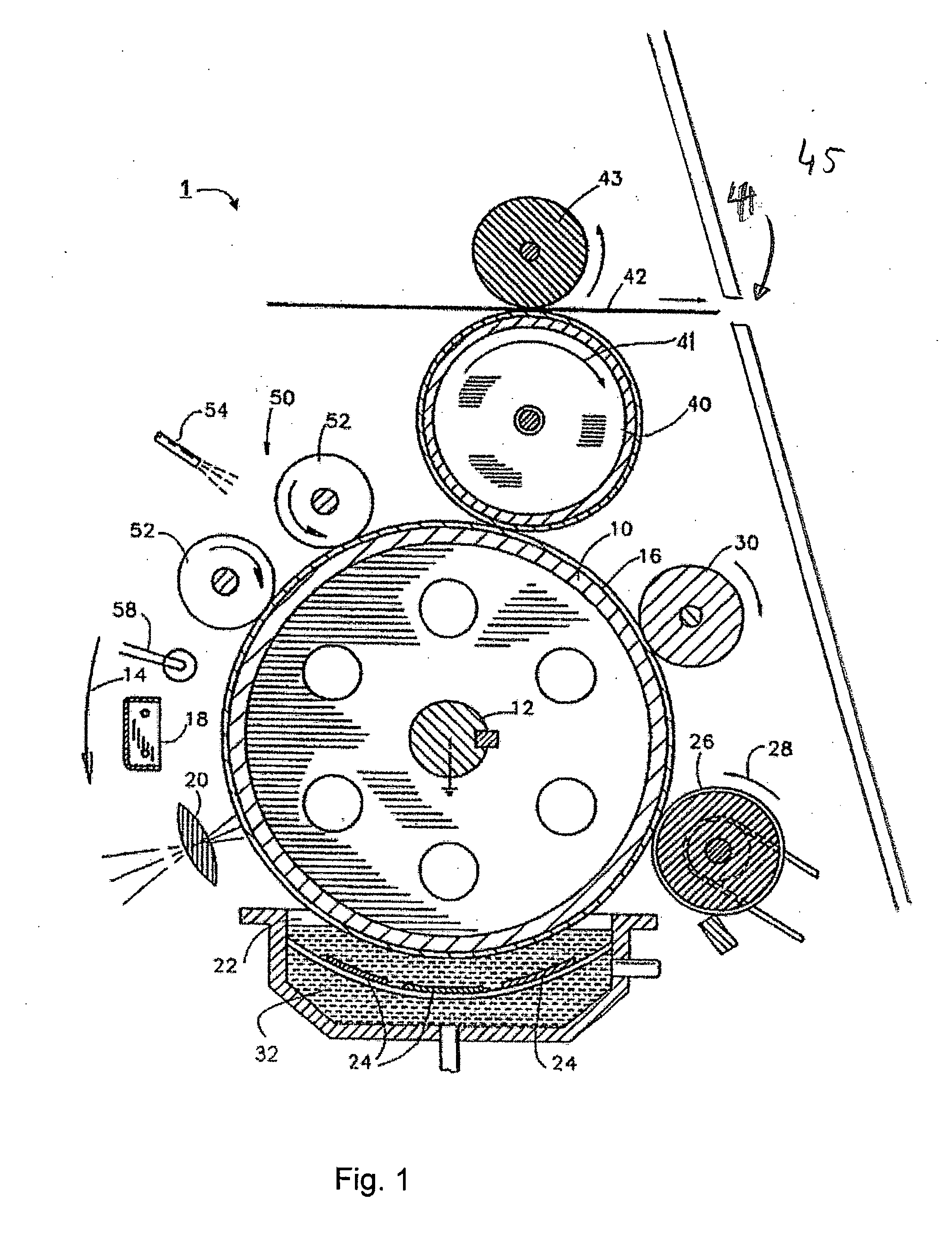

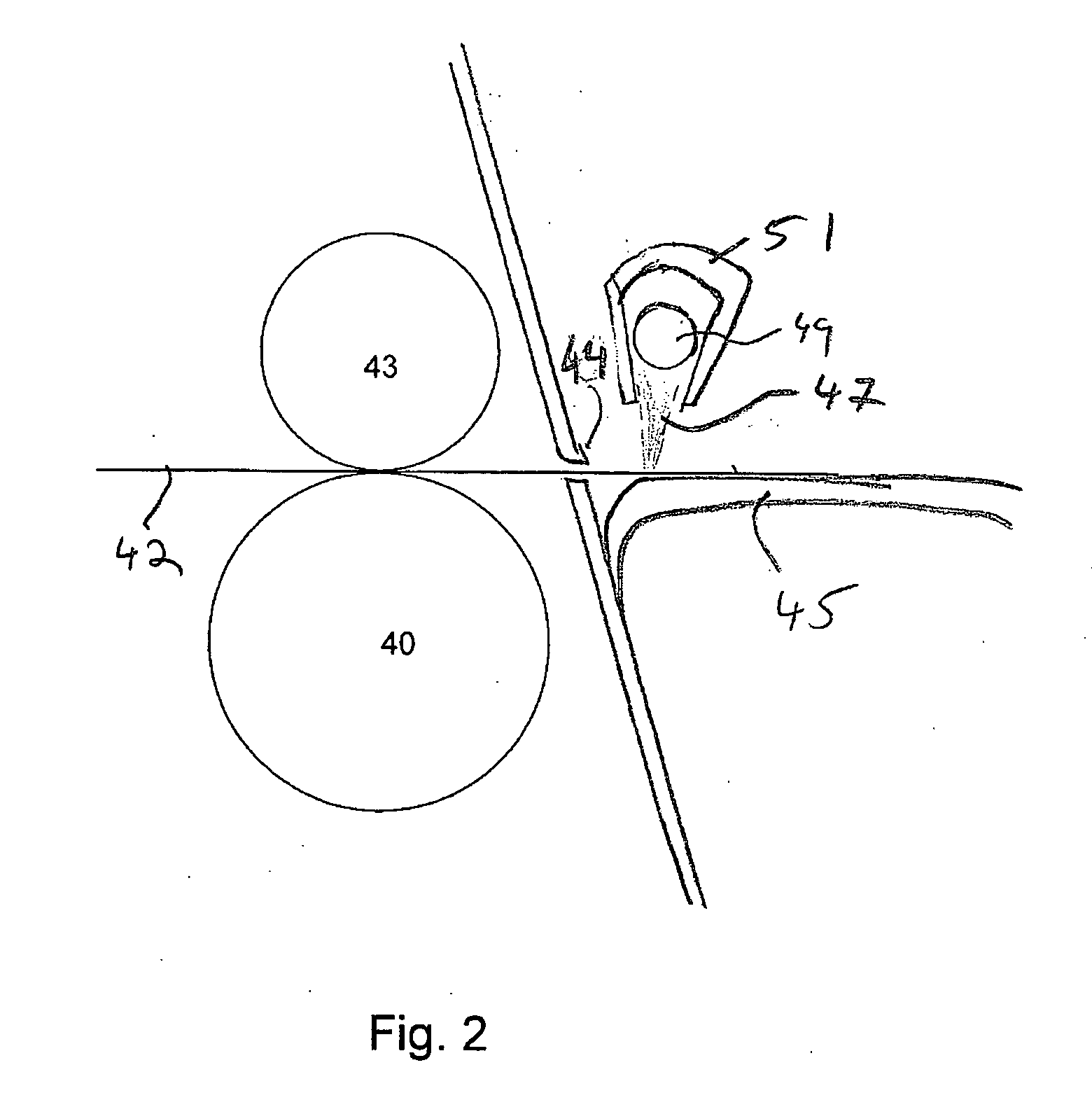

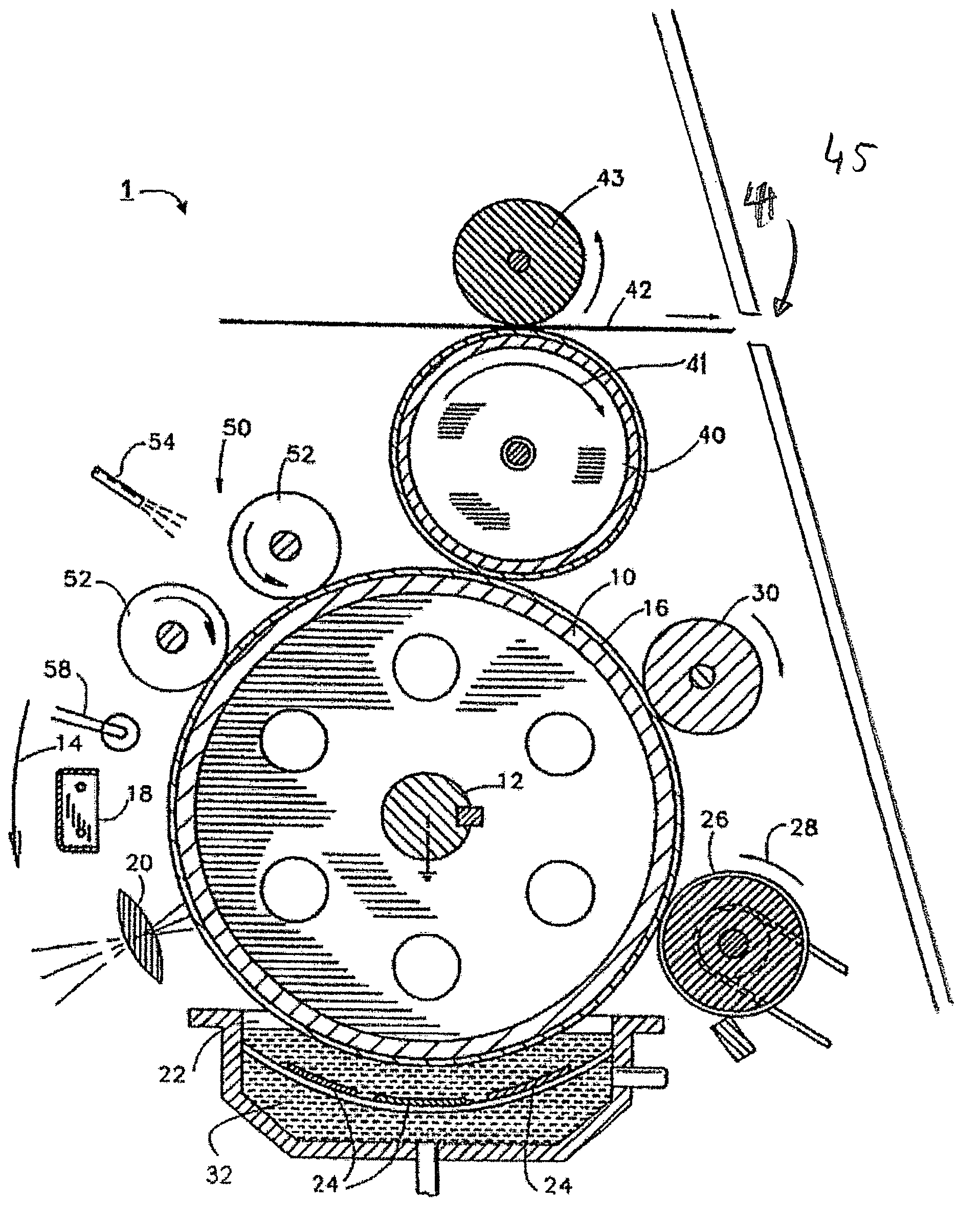

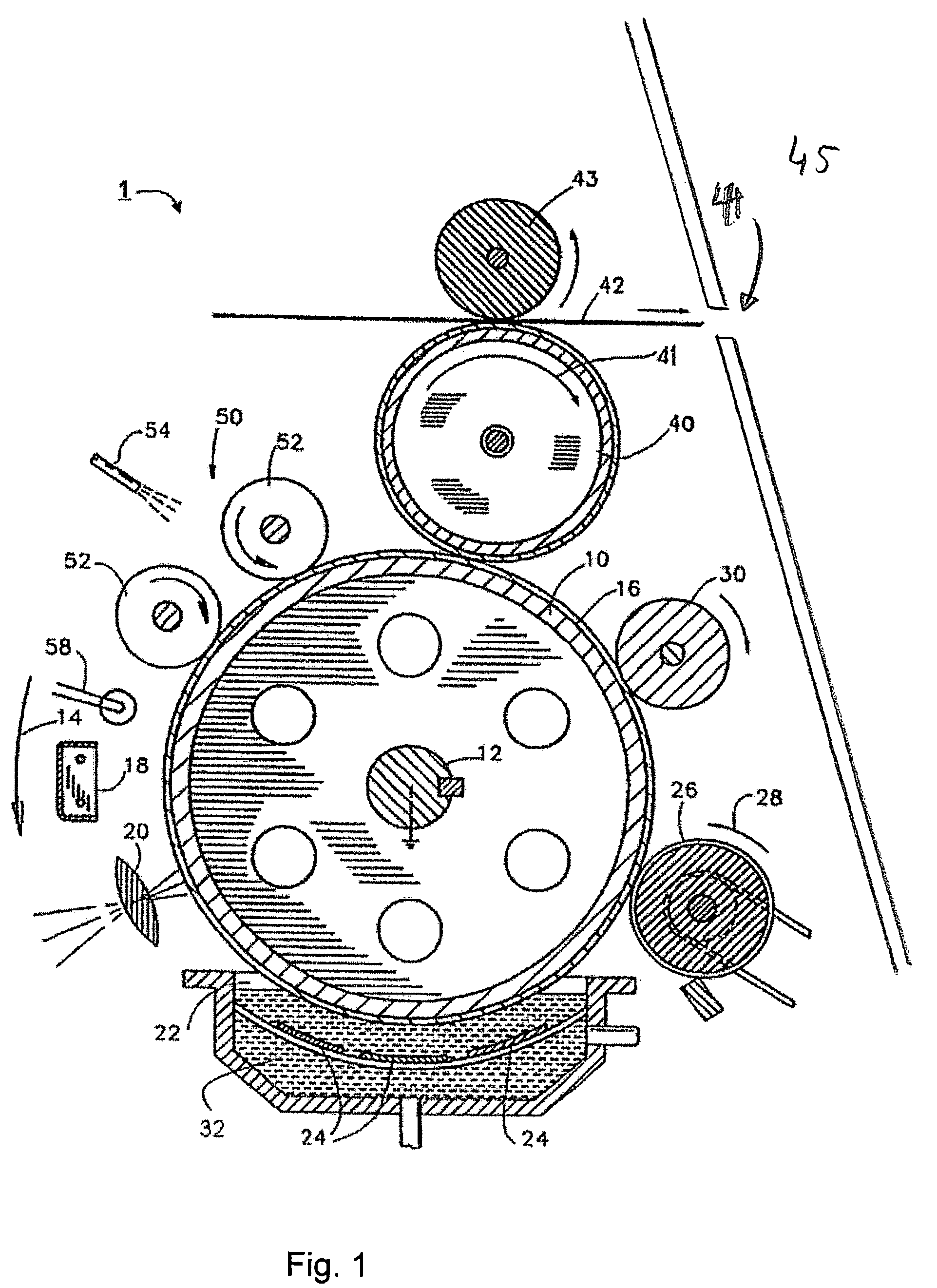

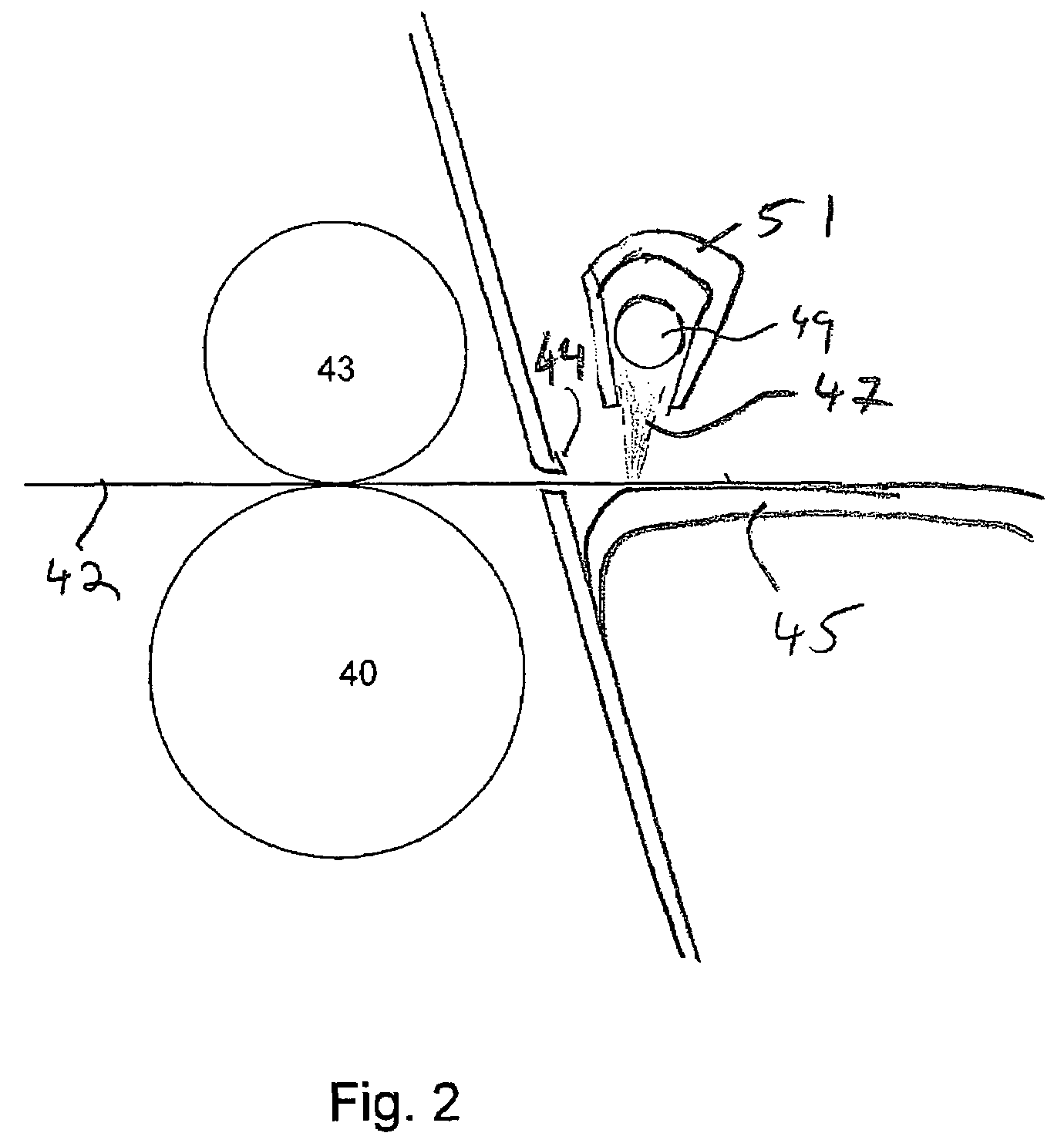

Composition, method and device for liquid electrophotographic printing

InactiveUS20070031751A1Reduce the smellLack of colorDevelopersElectrographic processes using charge patternTriacrylate esterElectrical and Electronics engineering

A UV-curable composition and liquid toner useful for electrophotographic printing, a method of electrophotographic printing and a device for electrophotographic printing are disclosed. A UV-curable composition and UV-curable liquid toner useful for electrophotographic printing includes a higher-acrylate, i.e. a triacrylate or higher. Such a composition and toner provide for scratch resistant print.

Owner:HEWLETT PACKARD DEV CO LP

Low-surface-tension solid-free reservoir protection drilling fluid

InactiveCN103589407AEnhanced inhibitory effectGood viscosity increaseDrilling compositionAntioxidantPetrochemical

The invention relates to a low-surface-tension solid-free reservoir protection drilling fluid, and belongs to the technical field of petrochemical engineering. The low-surface-tension solid-free reservoir protection drilling fluid comprises, by mass, 0.2-0.3 gram of sodium carbonate, 0.2-0.4 gram of PH-value conditioning agent, 0.8-1 gram of polymer emulsion powerful coat agent, 1.5-2.5 grams of fluid loss additive, 0.3-1 gram of shearing potentiator, 2-3 grams of polymeric alcohol, 0.5-1.5 grams of surfactant, 0.05-0.1 gram of antioxidant and 0-300 grams of soluble salt in every 100ml of water in an evenly-mixed mode. The low-surface-tension solid-free reservoir protection drilling fluid does not have the solid content, the surface tension is lower than 30mN / m, and the low-surface-tension solid-free reservoir protection drilling fluid has the good reservoir protection effect and is particularly suitable for horizontal well reservoir section drilling.

Owner:克拉玛依市金鑫科技有限公司

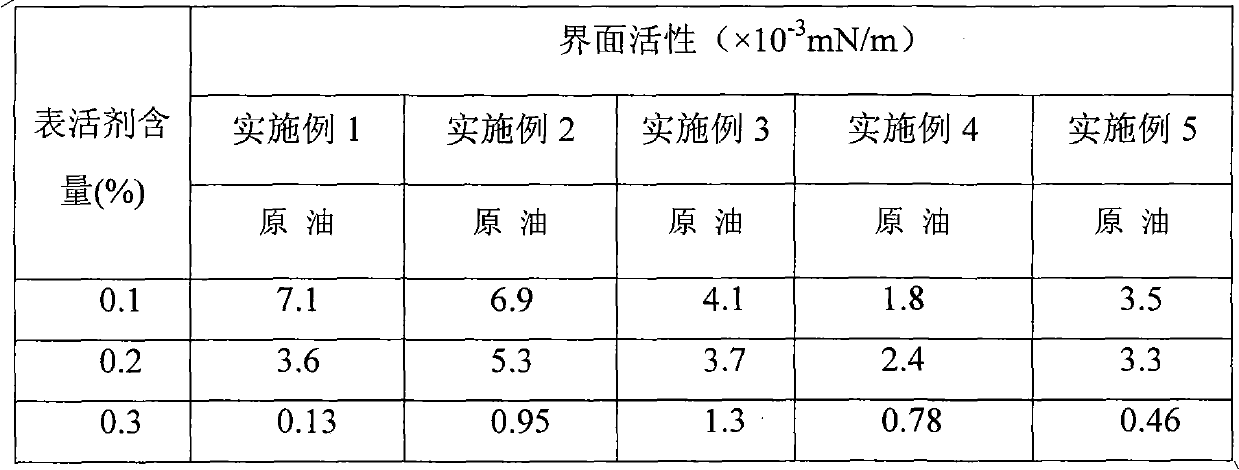

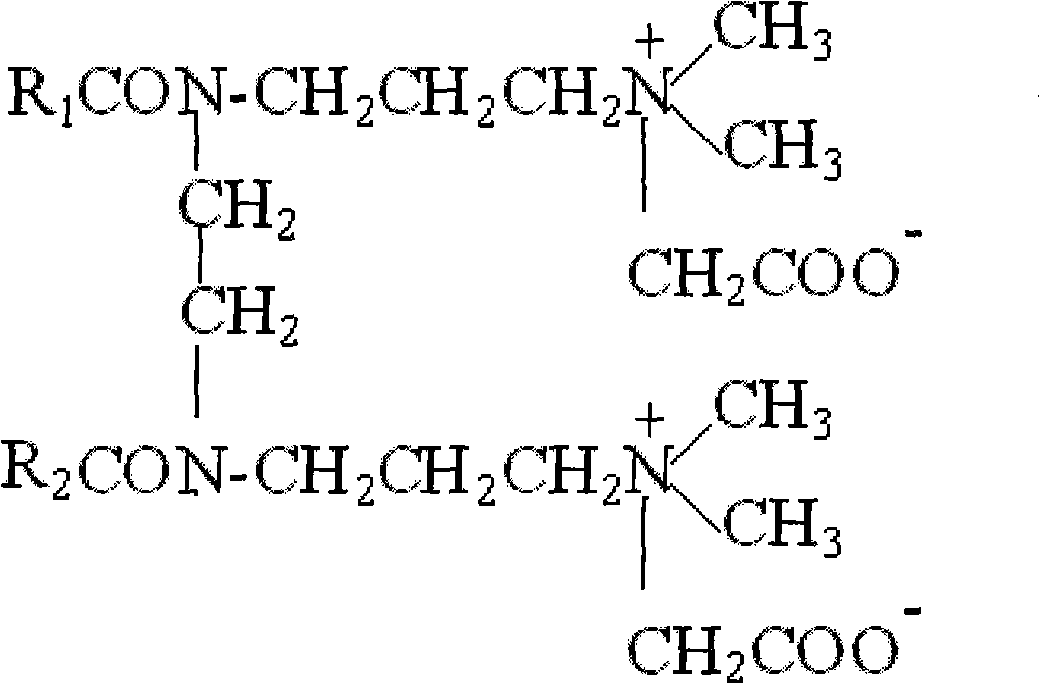

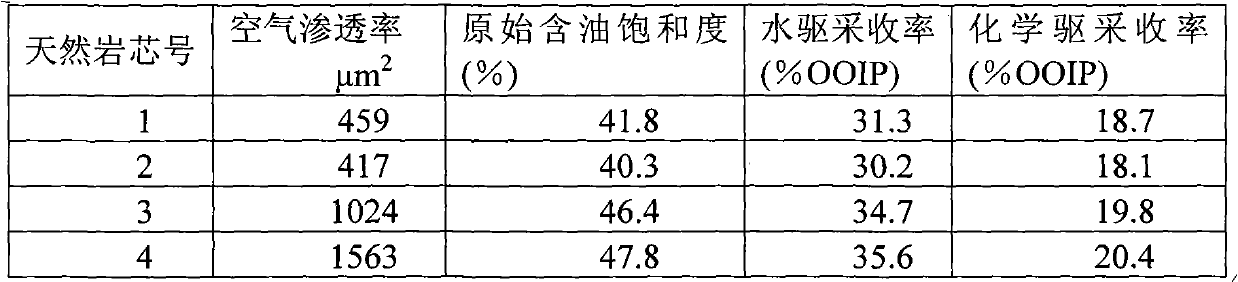

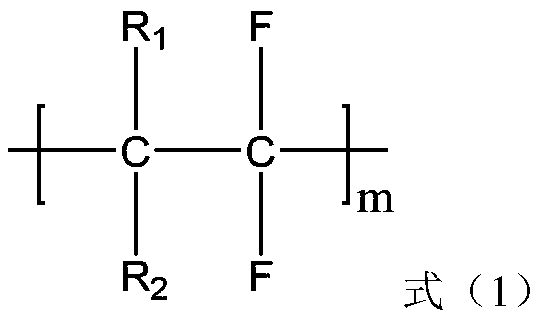

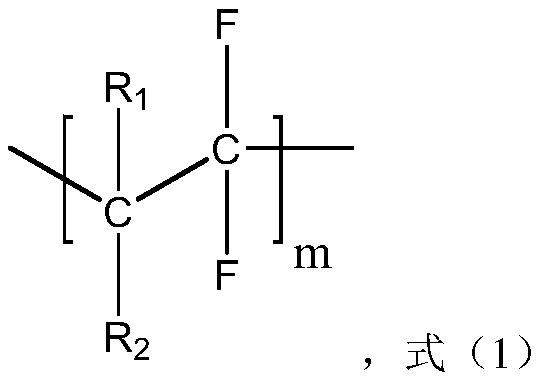

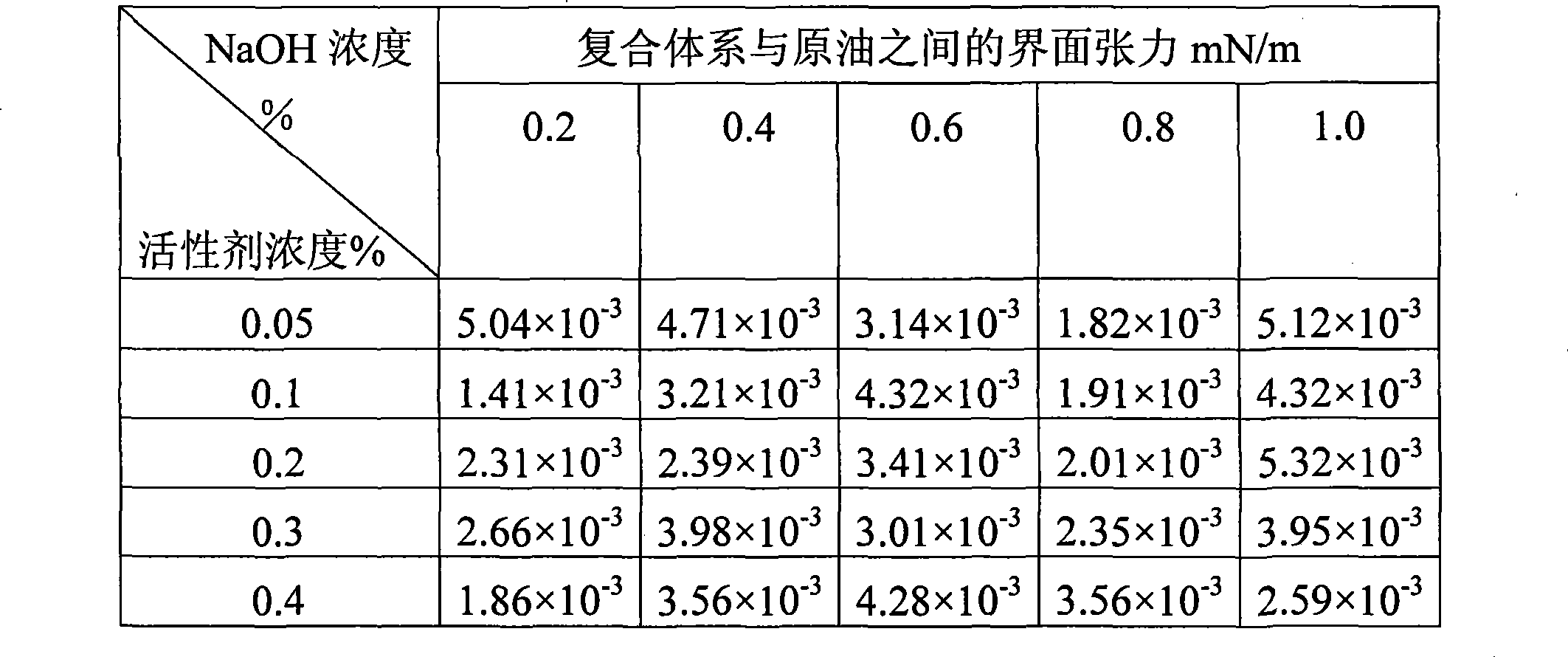

Gemini surfactant for tertiary oil recovery chemical oil-displacing agent and preparation method thereof

ActiveCN101955767ALow toxicityPromote degradationOrganic compound preparationCarboxylic acid amides preparationChromatographic separationStructural formula

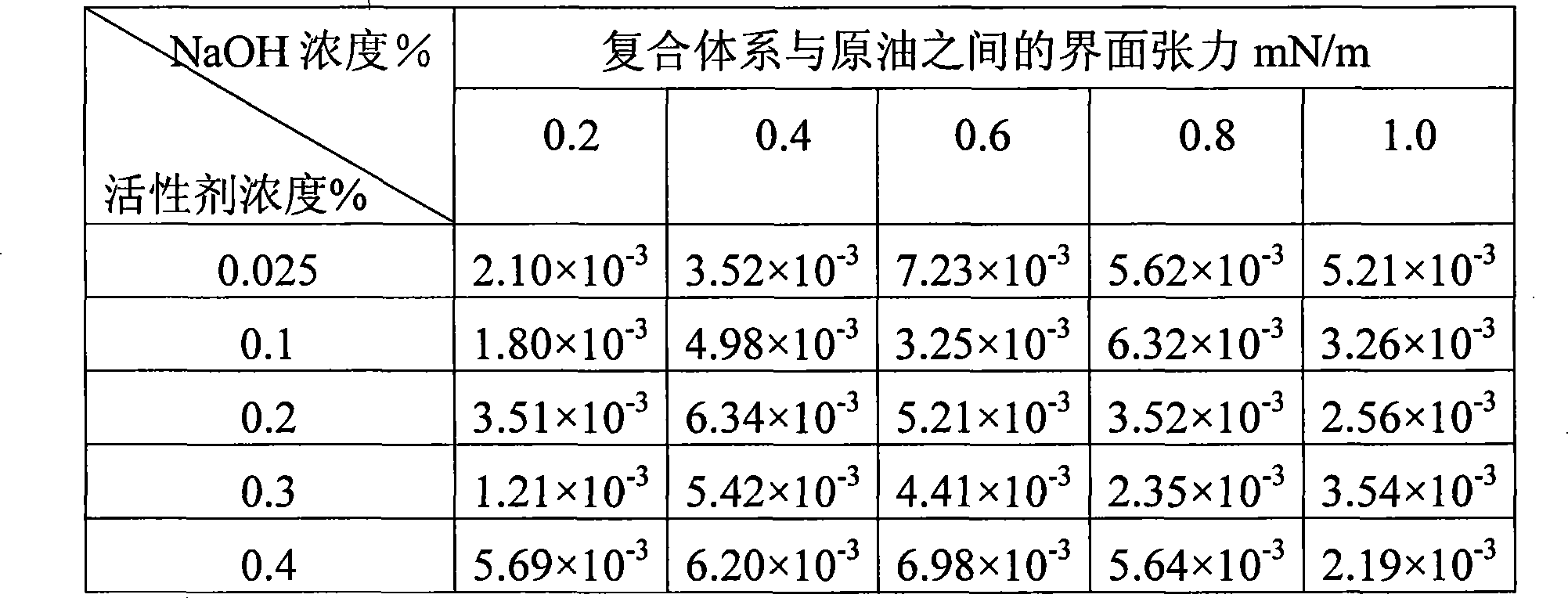

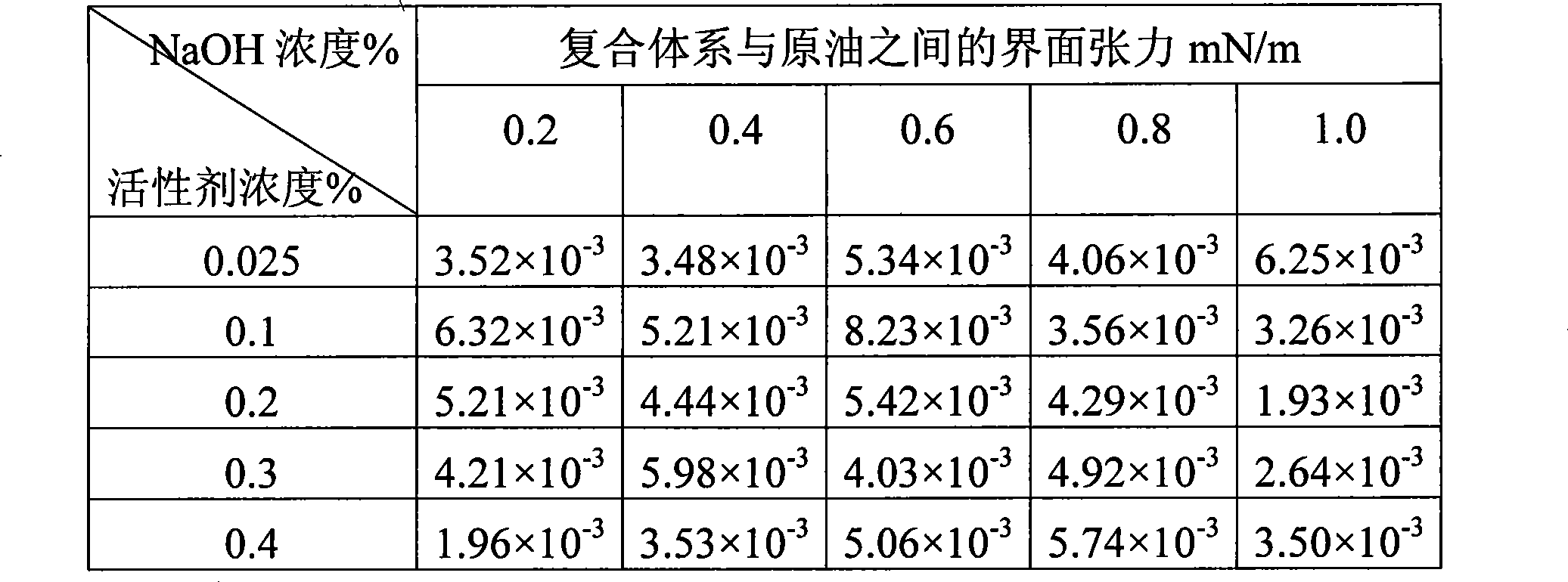

The invention discloses a gemini surfactant for a tertiary oil recovery chemical oil-displacing agent. The gemini surfactant has the structural formula shown in the specifications, wherein R1 and R2 are alkyl with 11 to 23 carbon atoms respectively. The surfactant of the invention has the advantages of single use without adding an alkali, harmlessness to a stratum, stable property, high capacity of reducing the oil / water interfacial tension and ensuring ultralow interfacial tension of 10<-3> to 10<-4>mN / m of crude oil / water in a wider range, and ideal oil displacing effect. The problem that the oil displacing efficiency of the conventional oil-displacing agent is reduced due to chromatographic separation is solved.

Owner:大庆高新区华龙祥化工有限公司

Insulating heat conducting cable material and preparation method thereof

InactiveCN105837911AImprove heat resistanceImprove cold resistancePlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an insulating heat conducting cable material. The insulating heat conducting cable material comprises the following raw materials in parts by weight: 60 to 70 parts of high-density polyethylene, 20 to 30 parts of modified polypropylene, 15 to 25 parts of heat conducting filler, 6 to 10 parts of polyolefin elastomers, 5 to 8 parts of glass fibres, 3 to 5 parts of a compatilizer, 3 to 8 parts of modified zinc borate, and 10 to 15 parts of ethylene-vinyl acetate copolymer. The insulating cable material is high in heat conductivity, high in insulating property, high in tensile strength, high in toughness, and convenient to process.

Owner:STATE GRID HENAN SHEQI POWER SUPPLY CO

Hydroscopic polymer gels for easier cleaning

InactiveUS20050245428A1Reduce adhesionEasy to cleanOrganic detergent compounding agentsFibre treatmentProtonationPolymer science

Hydroscopic polymer gels can be formed by applying a polymer to a surface and allowing water to be sequestered from the atmosphere into the polymer. The polymer gels are formed using methods and compositions employing water soluble or water dispersible copolymers having: (i) a first monomer that is acidic and is capable of forming an anionic charge in the composition; (ii) a second monomer that is amphipathic; (iii) optionally, a third monomer that is hydrophobic; and (iv) optionally, a fourth monomer that that has a permanent cationic charge or that is capable of forming a cationic charge on protonation. The polymer gels are particularly substantive and effective at modifying surfaces such as glass and hydrophobic polymeric substrates to provide soap scum and soil resistance, and easier next time cleaning benefits.

Owner:THE CLOROX CO

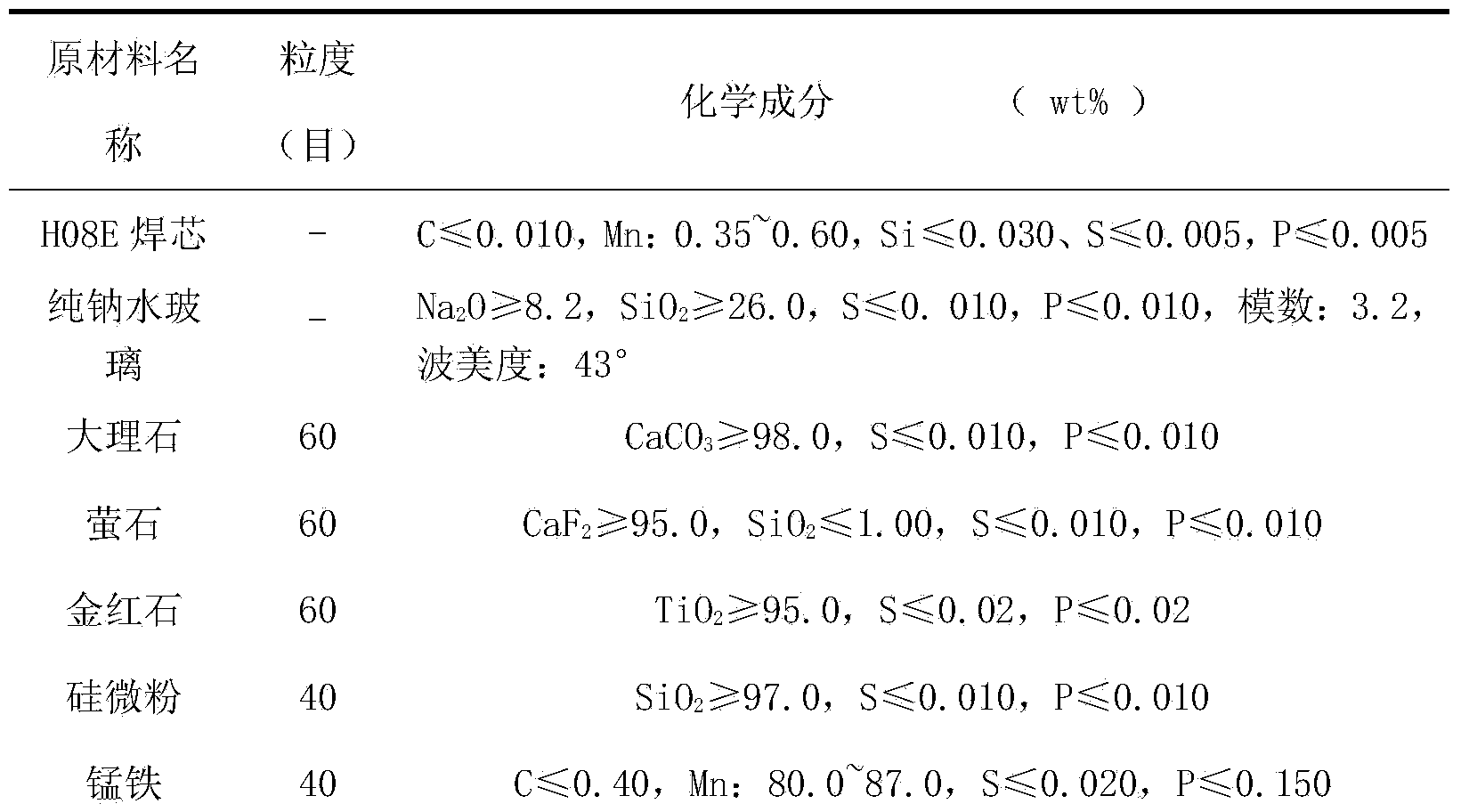

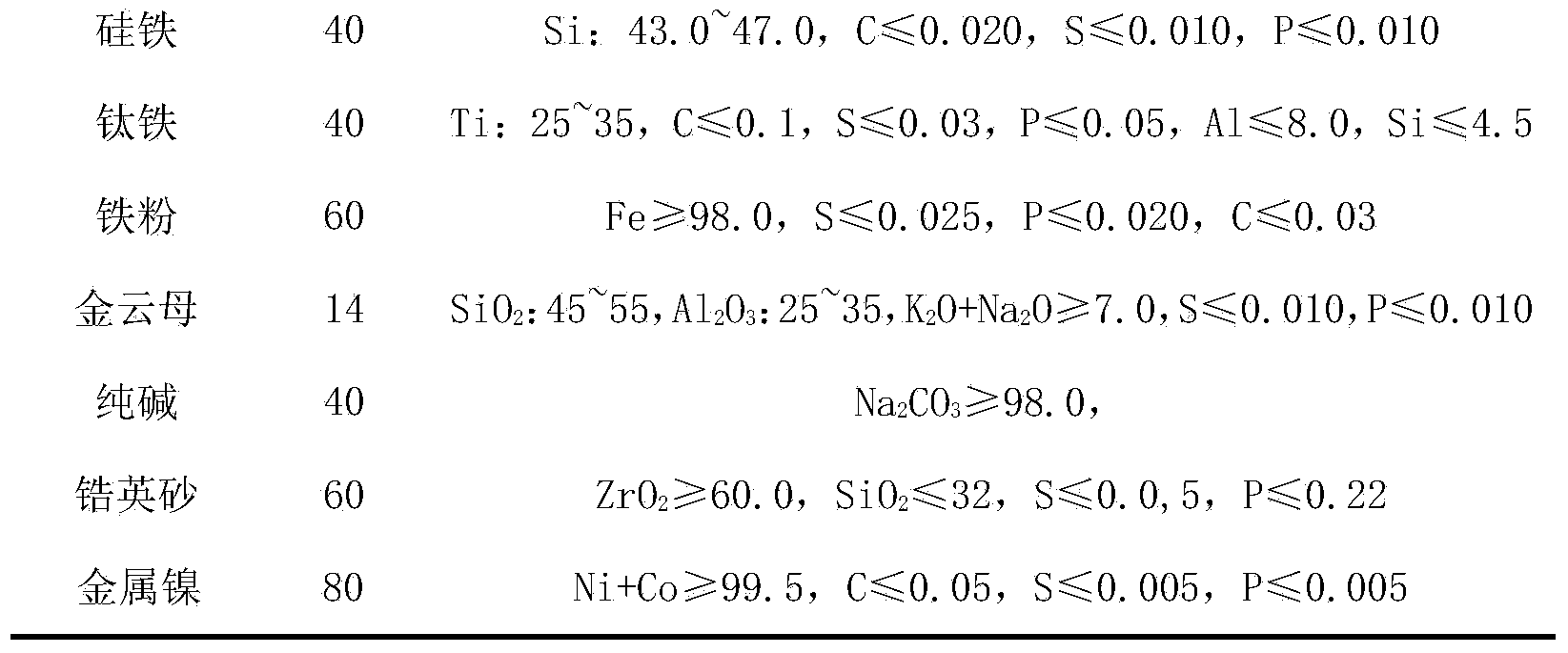

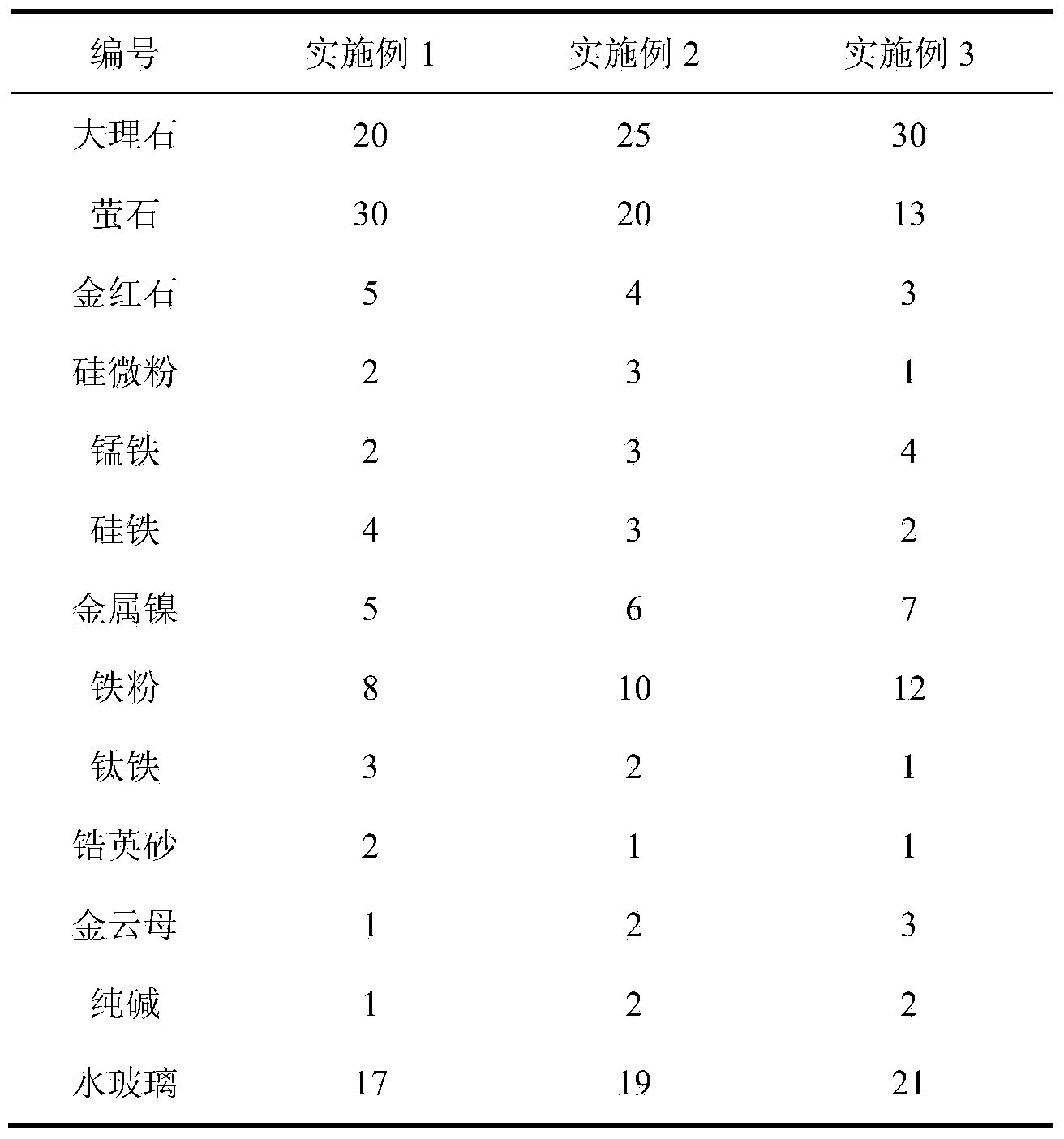

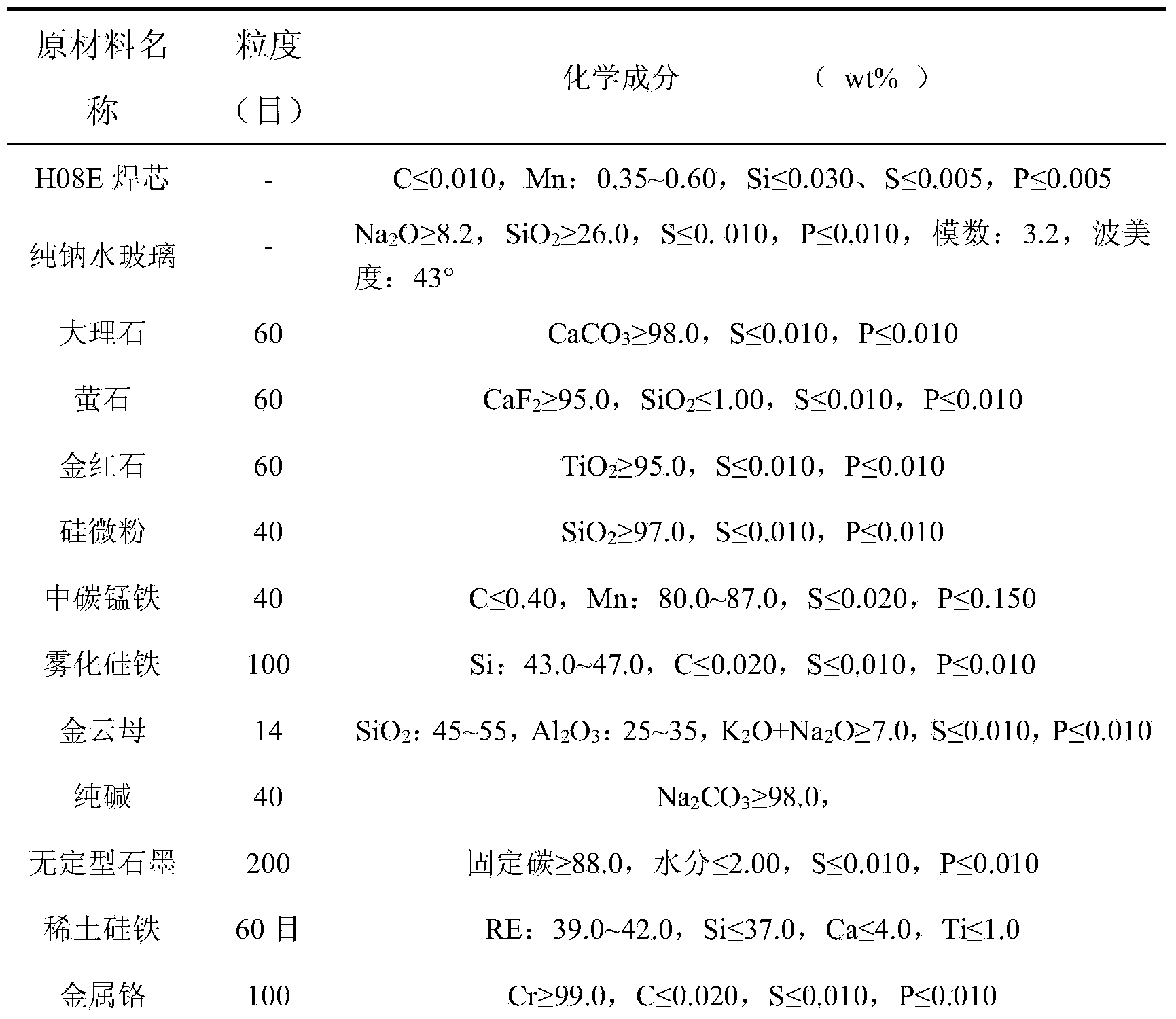

Welding electrode for Ni steel welding

InactiveCN103862201AStable mechanical propertiesModerate intensityWelding/cutting media/materialsSoldering mediaFerrosiliconZircon

The invention relates to a welding electrode for Ni steel welding. A heat-resistant steel welding electrode comprises an H08E welding core and a cover, wherein the cover contains the following components by weight percent: 20-30% of marble, 13-30% of fluorite, 3-5% of rutile, 8-12% of iron powder, 1-2% of sodium carbonate, 2-4% of silicon iron, 2-4% of ferromanganese, 5-7% of metallic nickel, 1-3% of ferrotitanium, 1-3% of silica powder, 1-3% of flogopite, 1-2% of zircon sand and 17-21% of pure sodium silicate. According to the invention, after the (620+ / -10 DEG C)*1h thermal treatment on the deposited metal, the mechanical property is stable, the strength is suitable, the toughness is better, the production processing property is excellent, the surface of the welding electrode is smooth, the eccentricity is stable, and the yield is high. The electrical arc is stable; the combustion is stable during a welding process; the spreadability and the fusing property are better; the formation of weld is attractive; the dregs-removing property is better.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Composition, method and device for liquid electrophotographic printing

InactiveUS7544458B2Reduce the smellLack of colorDevelopersElectrographic processes using charge patternEngineeringTriacrylate ester

A UV-curable composition and liquid toner useful for electrophotographic printing, a method of electrophotographic printing and a device for electrophotographic printing are disclosed. A UV-curable composition and UV-curable liquid toner useful for electrophotographic printing includes a higher-acrylate, i.e. a triacrylate or higher. Such a composition and toner provide for scratch resistant print.

Owner:HEWLETT PACKARD DEV CO LP

Outer glue material of rubber pneumatic bag for automobile air suspensions and preparation method thereof

The invention relates to an outer glue material of a rubber pneumatic bag for automobile air suspensions and a preparation method thereof. The outer glue material of the rubber pneumatic bag for automobile air suspensions comprises the following components in parts by weight: 20-80 parts of natural rubber (NR), 30-70 parts of chloroprene rubber (CR), 5-40 parts of butadiene rubber (BR), 4-6 parts of a surfactant, 0.3-10 parts of an antiager, 3-10 parts of a vulcanizing agent, 10-100 parts of nano inorganic filler, 20-40 parts of carbon black, and 2 parts of a homogenizing agent. The outer glue material disclosed by the invention has the following beneficial effects that in the outer glue material of a rubber pneumatic bag for automobile air suspensions, the rubber is high in strength, high in surrender and good in low temperature resistance, so that the endurance life of a finished rack product is greater than 4.5 million times, therefore, the outer glue material of a rubber pneumatic bag for automobile air suspensions disclosed by the invention meets and exceeds the requirements of operating conditions of outer glue materials of rubber pneumatic bags for automobile air suspensions.

Owner:BAOLONG ANHUI AUTO PARTS

Continuous casting mold flux for automobile sheet

The invention discloses continuous casting mold flux for an automobile sheet. The continuous casting mold flux is formed by mixing a base body and carbonaceous materials with the weight which is 1 percent to 2 percent of the total weight of the base body. The base body comprises, by weight, not more than 0.25 percent of Na2O, 0.5 percent to 4.5 percent of MgO, 0.3 percent to 1.0 percent of Fe2O3, 5 percent to 25 percent of Al2O3, 0.5 percent to 6.5 percent of Li2O, 0 percent to 16 percent of BaO, 5 percent to 9 percent of F, 20 percent to 40 percent of SiO2 and not more than 2 percent of impurities. The weight ratio of CaO to SiO2 ranges from 0.9 to 1.4. The base body meets the requirements that the proportion of a pre-melting portion is not less than 70 percent, the melting point of the base body ranges from 1100 DEG C to 1200 DEG C, the viscosity ranges from 0.25 Pa.s to 0.45 Pa.s at the temperature of 1300 DEG C, and the surface tension ranges from 0.43 N / m to 0.53 N / m at the temperature of 1400 DEG C. The continuous casting mold flux has the higher viscosity and the higher surface tension, and the slag inclusion occurrence rate of a continuous casting sheet billet of the automobile sheet is better reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

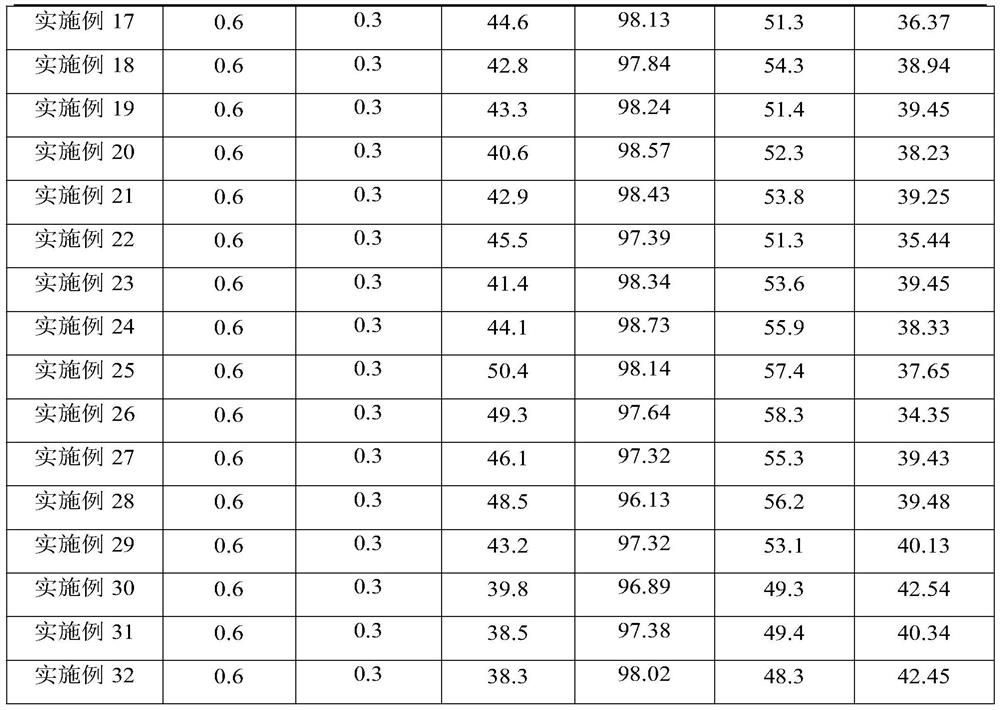

Polyamide composite nanofiltration membrane and preparation method thereof

PendingCN112076630AIncrease water fluxImprove wettabilitySemi-permeable membranesDiamineLithium bromide

The invention provides a polyamide composite nanofiltration membrane and a preparation method thereof.The polyamide composite nanofiltration membrane comprises a supporting base layer and a polyamidefunctional layer obtained on the supporting base layer through interfacial polymerization, and the polyamide functional layer comprises raw materials including diamine, inorganic salt, organic acid, polybasic acyl chloride, an oil-phase solvent and deionized water; wherein the diamine comprises at least one of piperazine, hexamethylenediamine, diaminopyridine and diaminopyrimidine; and the inorganic salt comprises at least one of lithium chloride, calcium chloride, sodium chloride, magnesium sulfate, lithium bromide and calcium bromide. The preparation method comprises the following steps: step 1, preparing a water-phase solution; step 2, preparing an oil-phase solution; and step 3, preparing the polyamide composite nanofiltration membrane. The water flux of the polyamide composite nanofiltration membrane prepared by the method is as high as 73.7 LMH, the rejection rate of divalent salt is as high as 99.31%, and the rejection rate of monovalent salt is as low as 31.83%. The preparationmethod is simple, short in technological process and low in cost.

Owner:HUNAN OVAY TECH CO LTD

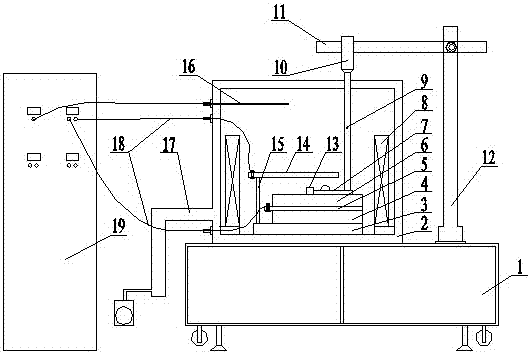

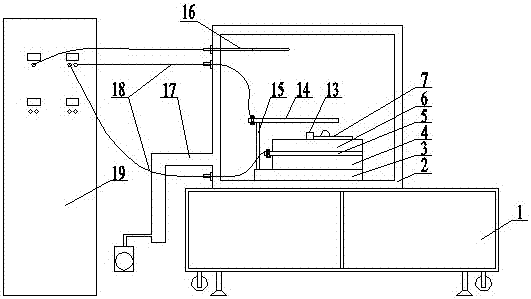

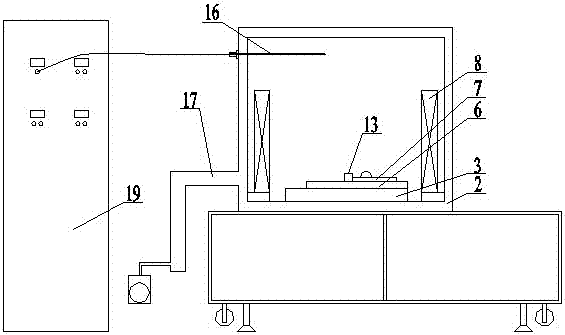

Material wettability improvement device and method based on multi-field coupling

ActiveCN107052494AImprove wettabilityWay to overcomeMuffle furnacesPreparing sample for investigationEngineeringMechanical engineering

The invention provides a material wettability improvement device and method based on multi-field coupling. The material wettability improvement device comprises an operation platform, a vacuum furnace stored on the operation platform, a high-voltage power supply control box, an ultrasonic auxiliary device, an electric field auxiliary device and a magnetic field auxiliary device. A rack on one side of the vacuum furnace is provided with a guide rail stand column. The upper end of the guide rail stand column is provided with a movable cross beam. An ultrasonic transducer is fixed to the cross beam. An ultrasonic variable-pressure rod stretches into the vacuum furnace through a corrugated pipe. The electric field auxiliary device is arranged below the ultrasonic variable-pressure rod. A sample is stored on an insulating ceramic plate and positioned through a stop block. The inner side of the vacuum furnace is further provided with a magnetic field power coil which generates a variable magnetic field after being applied with current. By adoption of the material wettability improvement device and method, the sample can be wetted under mutual assistance of an ultrasonic vibration load, an electric field and the magnetic field, and the problems that existing additionally arranged auxiliary equipment is simplex in applying mode, the ultrasonic applying mode is large in power loss, and simplex assistance is unobvious in sample wettability improvement effect are solved.

Owner:HENAN UNIV OF SCI & TECH

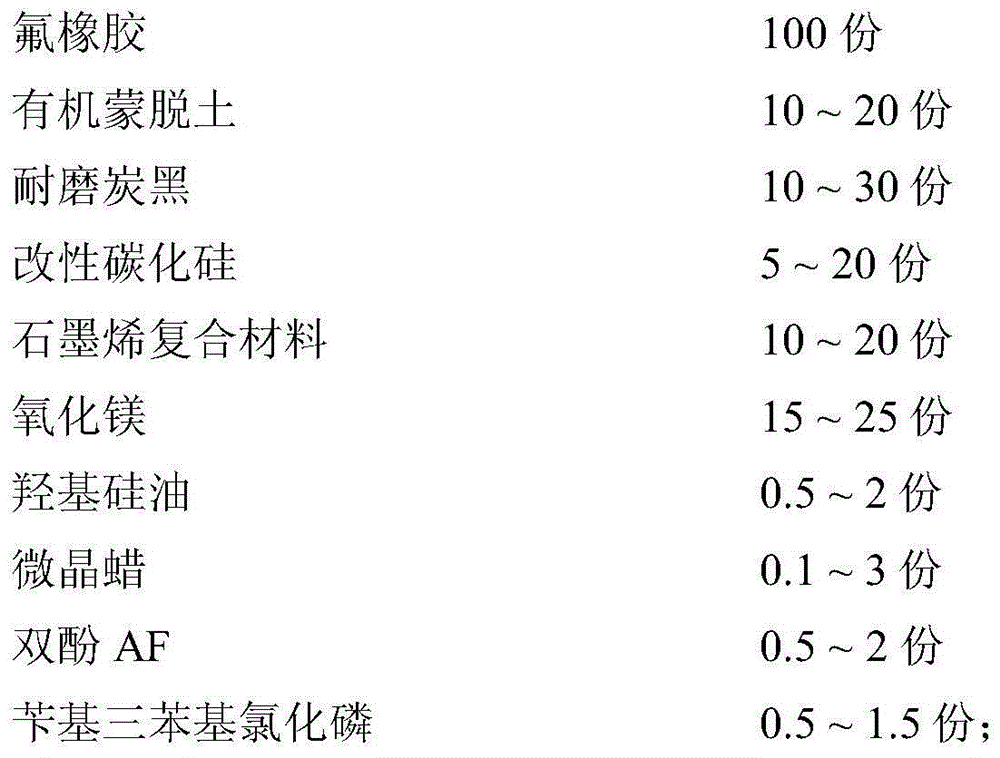

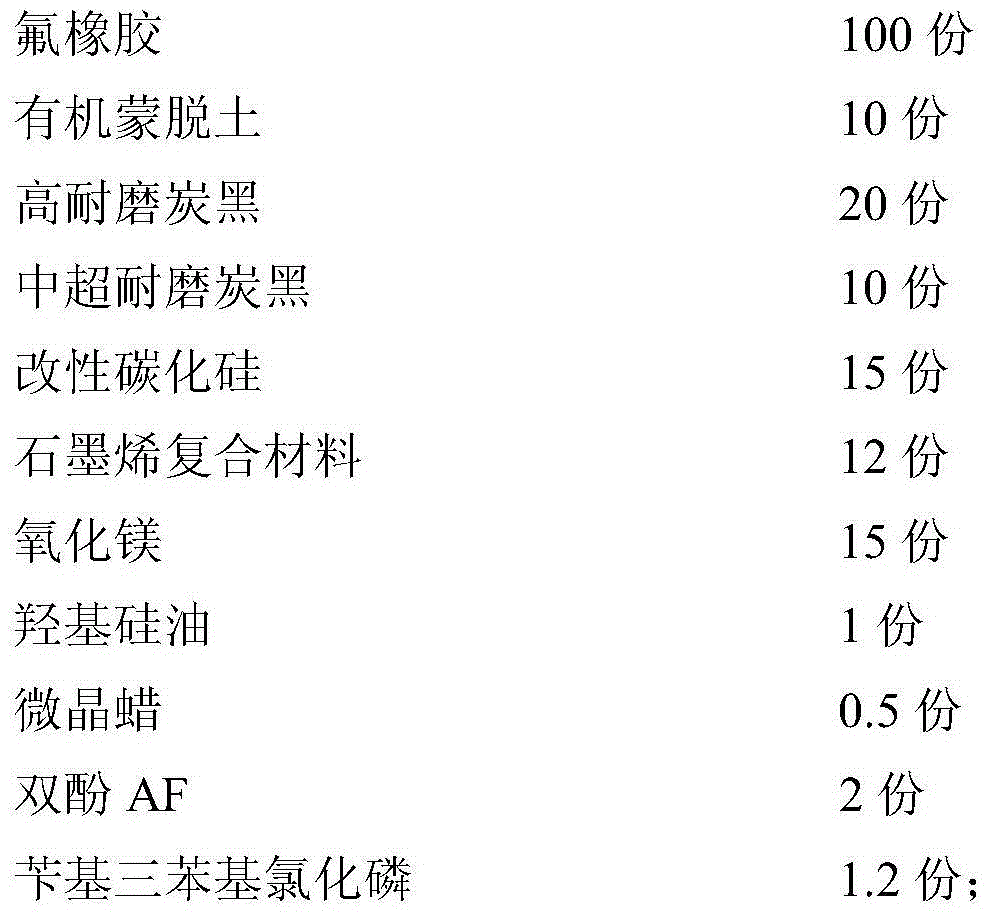

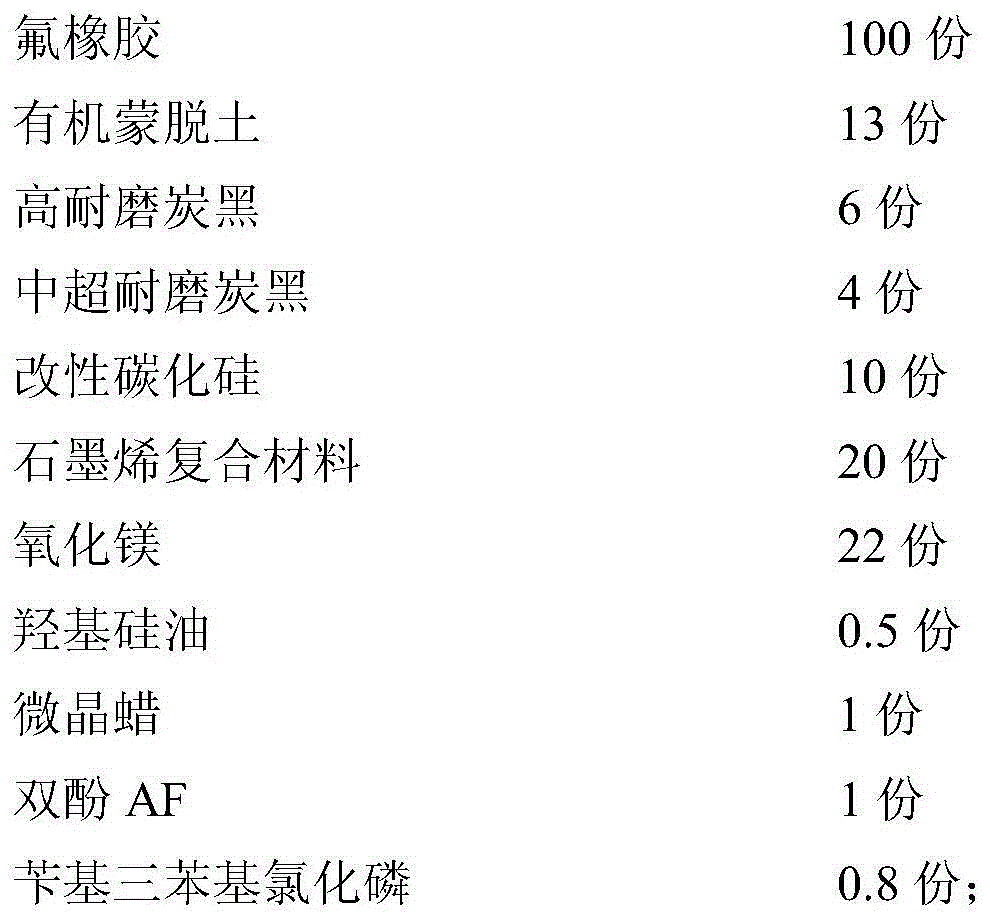

Grinding roller sealing ring materials and preparation method thereof

ActiveCN104530611ASolve difficult peelingSolve densityOther chemical processesMicrocrystalline waxBisphenol AF

The invention relates to grinding roller sealing ring materials. The grinding roller sealing ring materials are characterized by comprising, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. The graphene composites are graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction. The graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the grinding roller sealing ring materials, the function of the graphene is fully played, and the wear resistance and heat resistance of the grinding roller sealing ring materials are effectively improved.

Owner:宁波佳乐特橡塑机电有限公司

Paper improver

InactiveUS7547376B2Increase distanceImprove adsorption capacityNatural cellulose pulp/paperSpecial paperPolymer scienceOptical property

The invention provides a paper quality improver for papermaking that allows improvement in the bulky value and the optical properties such as brightness and opacity as well as in the paper strength of a sheet obtained by papermaking a pulp material. The paper quality improver for papermaking is a paper quality improver for papermaking containing a copolymer (A) having a constituent unit derived from at least one nonionic monomer having a solubility parameter of 20.5 (MPa)1 / 2 or less and a constituent unit derived from at least one anionic or cationic monomer and a surfactant (B) at a certain ratio, the quality improver providing at least one paper quality improving effect of: (i) standard improved bulky value: 0.02 g / cm or more; (ii) standard improved opacity: 1.0 point or more; and (iii) standard improved brightness: 0.5 point or more.

Owner:KAO CORP

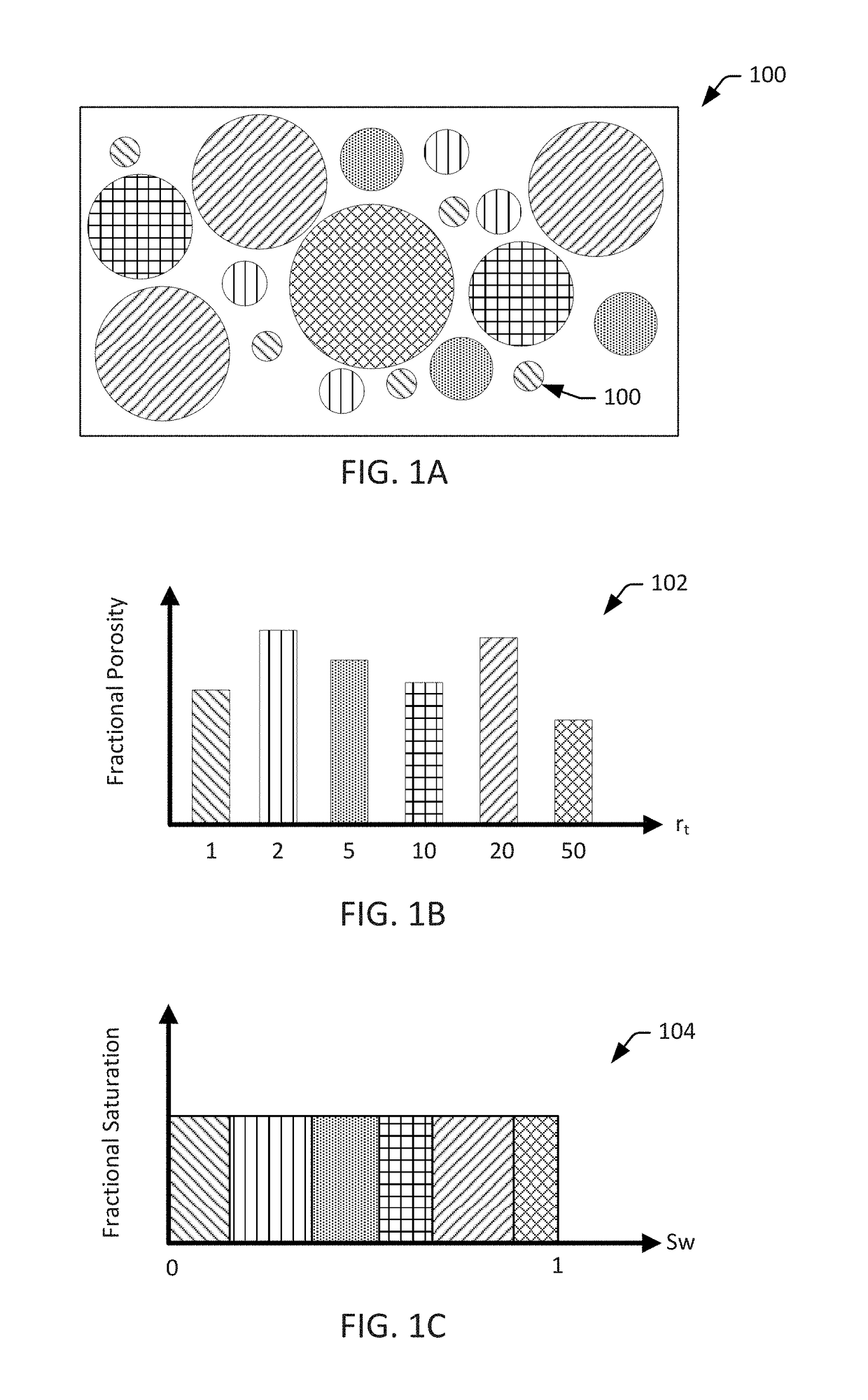

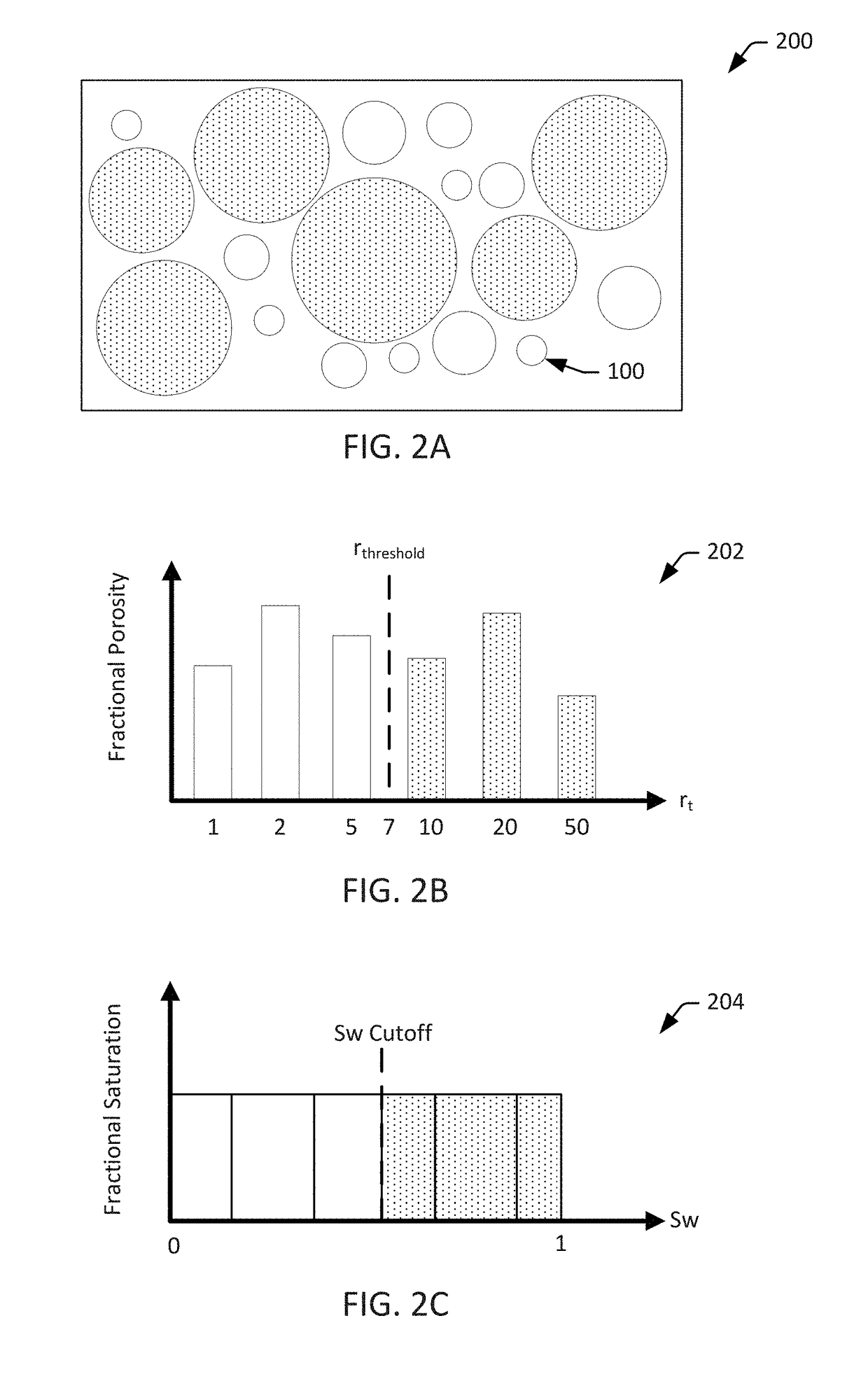

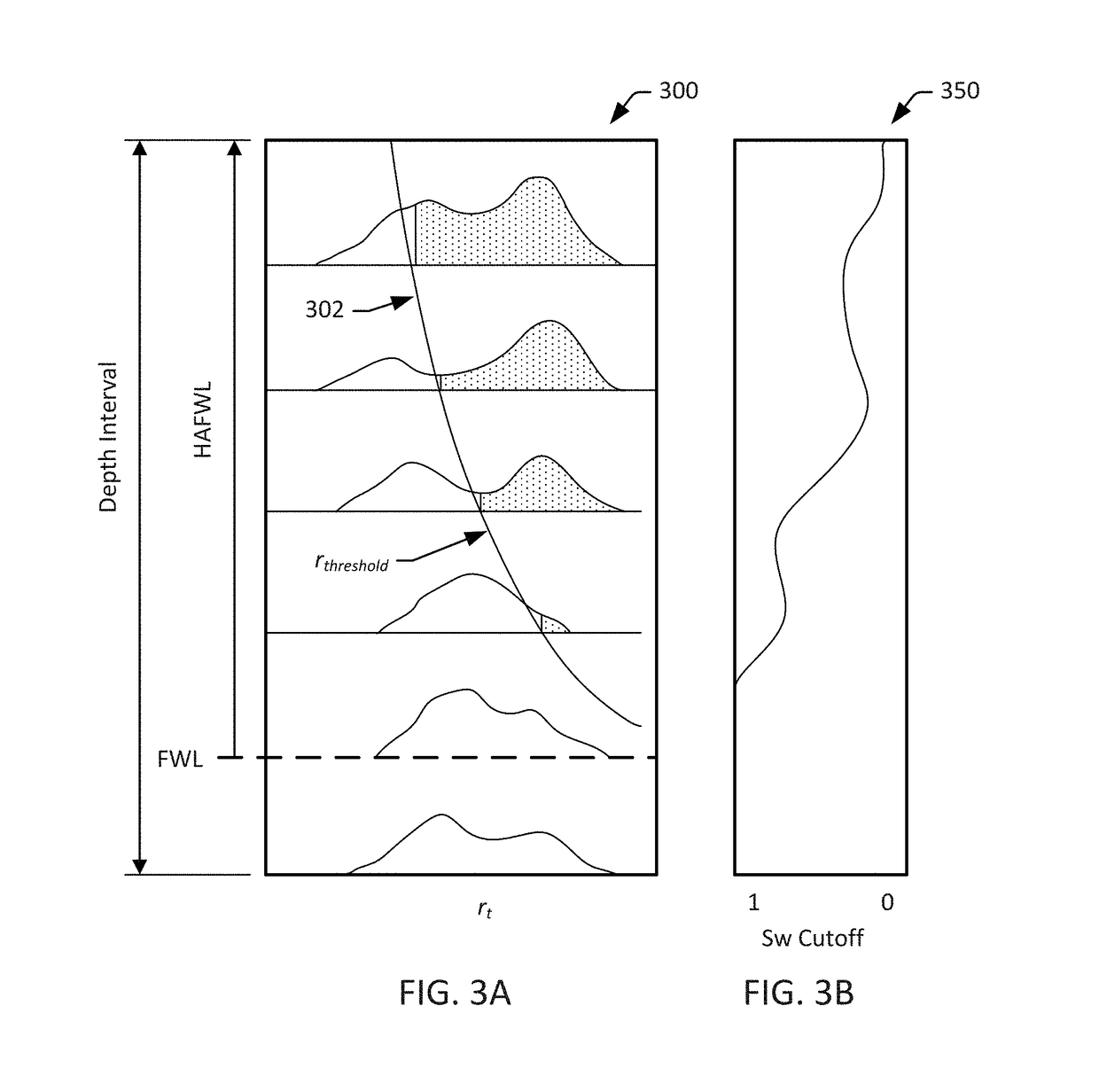

Nuclear magnetic resonance and saturation well logs for determining free water level and reservoir type

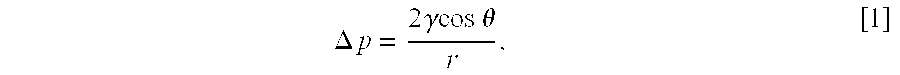

ActiveUS20170328847A1MiniaturizationImprove interfacial tensionElectric/magnetic detection for well-loggingWater resource assessmentReservoir typeSolid-state nuclear magnetic resonance

Provided in some embodiments are systems and methods for determining characteristics of a hydrocarbon reservoir. Embodiments include conducting a nuclear magnetic resonance (NMR) logging operation of a targeted reservoir section of a wellbore extending into a hydrocarbon reservoir to generate a NMR log of the targeted reservoir section, conducting a resistivity logging of the targeted reservoir section to generate an uninvaded water saturation (Sw) log of the targeted reservoir section, determining for each of a plurality of depths in the section, a T2 cutoff point based on values of the NMR and Sw logs, identifying a subset of the T2 cutoff points that exhibit a hyperbolic trend, determining a theoretical cutoff curve corresponding to the subset of the T2 cutoff points, determining a free water level (FWL) of the reservoir based on the theoretical cutoff curve, and determining a rock type of the reservoir based on the theoretical cutoff curve.

Owner:SAUDI ARABIAN OIL CO

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548AImproved particle morphology and molecular weight distributionImprove processing thermal stabilityChemistryPlasticizer

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products agingdue to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

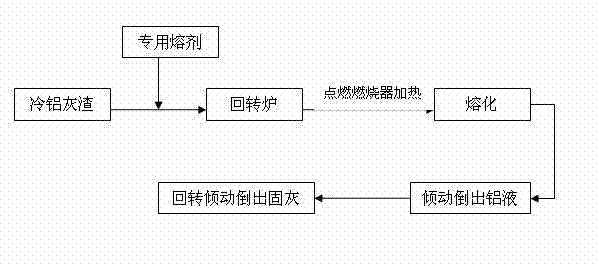

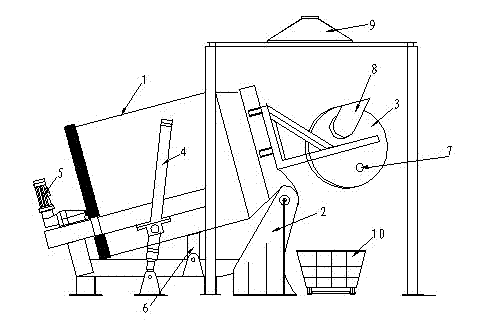

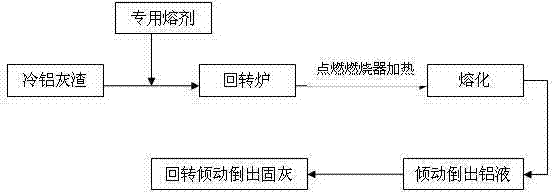

Technology for treating cold aluminous ash by utilization of tilting furnace

InactiveCN102392139AImprove interfacial tensionEasy to separateProcess efficiency improvementMetalChloride

The invention relates to a technology for treating cold aluminous ash by the utilization of a tilting furnace and is characterized in that the treatment technology comprises the following steps of: crushing the cold aluminous ash, screening to coarse grains for later use; adding a special fluxing agent which accounts for 5-20% of the total addition amount into the tilting furnace with a heating device arranged on the furnace mouth, wherein the special fluxing agent is made from 90-96% of chloride and 4-10% of fluoride; turning on a combustor, beginning heating, simultaneously rotating the tilting furnace, adding the cold aluminous ash coarse grains which account for 80-95% of the total addition amount after the special fluxing agent is melted in the tilting furnace; rotating and heating until an aluminium alloy liquid and the ash in the cold aluminous ash are separated, the aluminium alloy liquid is collected on the bottom and the ash flows on the surface of the aluminium alloy liquid, pouring out the aluminium liquid, and pouring out solid ash while rotating the tilting furnace. The special fluxing agent is used to improve the interfacial tension between the ash and the aluminium alloy and make it easy to separate the ash and the aluminium alloy. In the meantime, the covered aluminium will not be further oxidized. Therefore, the technology provided by the invention helps raise metal recovery rate and is suitable for scale production.

Owner:JIANGXI TANTAI ALUMINUM

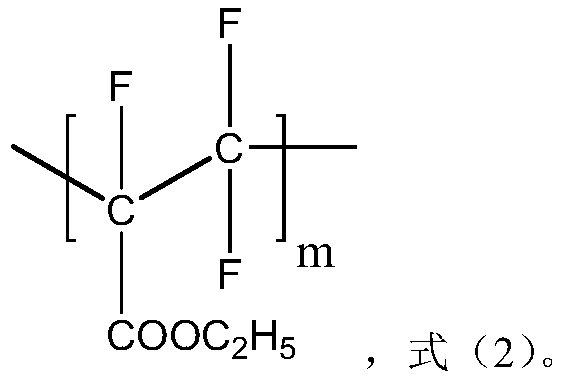

Modified PMMA optical film and preparation method thereof

The invention provides a modified PMMA optical film. The modified PMMA optical film contains the following components in parts by mass: 60-80 parts of PMMA resin, 20-40 parts of aromatic (co)polycarbonate and 5-14 parts of a compatibilizer, 0.5-8 parts of a flatting agent. The modified PMMA optical film has a flat and smooth surface, is uniform in thickness, high in light transmittance, low in haze level, colorless and transparent and has good heat resistance and tenacity. The invention further provides a preparation method of the modified PMMA optical film. The preparation method comprises the steps of sequentially preparing modified resin and modified coating liquid, forming a film through coating, and carrying out thermal stretch formation and the like. The method is simple in process,easy for industrial production and can be used for preparing the ultrathin and high-transparency modified PMMA optical film.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +2

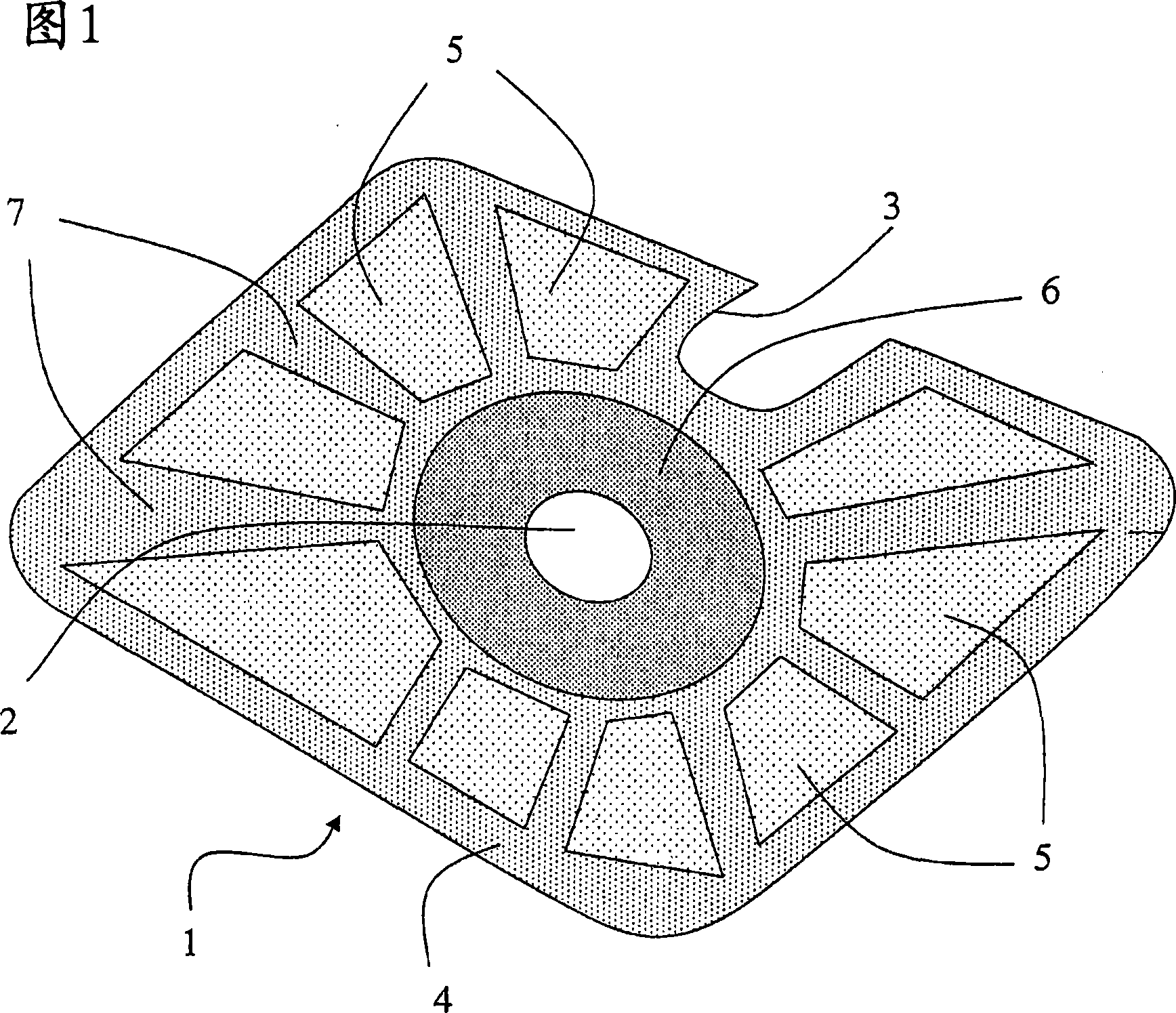

Sieve element for a dishwasher

InactiveCN101170938AAvoid blockingFacilitates capillary actionTableware washing/rinsing machine detailsEngineeringSieve area

Owner:ELECTROLUX HOME PROD CORP NV

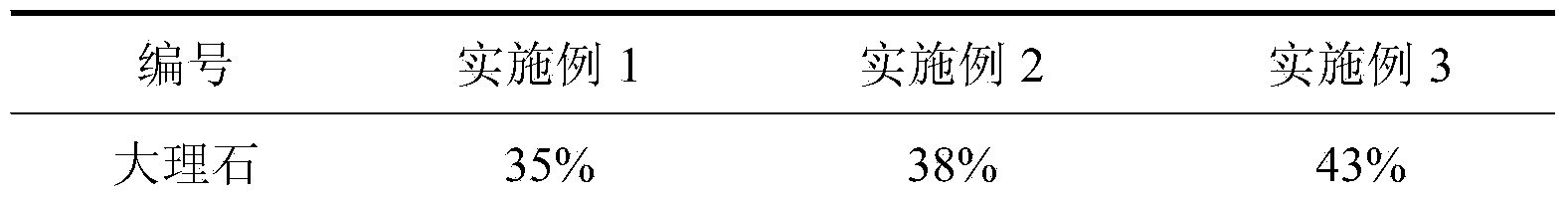

Low-strength high-toughness and heat-resistant steel welding rod

InactiveCN103878506AEccentricity is difficult to controlSuperiorWelding/cutting media/materialsWelding/soldering/cutting articlesAbsorbed energyRare earth

A low-strength high-toughness and heat-resistant steel welding rod comprises an H08E welding core and a coating. The coating is prepared by components including, by weight, 35-43% of marbles, 16-20% of fluorite, 3-5% of imported rutile, 1-2% of sodium carbonate, 2-4% of atomized ferrosilicon, 1-3% of flogopite, 3-5% of mid-carbon ferromanganese, 2.5-3% of Cr, 1.0-1.5% of molybdenum, 2-3% of ferrotitanium, 1-3% of silica powder, 1-2% of rare earth ferrosilicon and 17-21% of pure sodium silicate. After subjected to heat treatment at the temperature ranging from 675 + / -10 DEG C for 3 hours, the deposited metal is stable in mechanical property, low in strength (with room temperature tensile of 510-540Mpa), good in charpy impact absorbing energy at minus 20 DEG C is 180J above) and good in production process performance; the steel welding rod is smooth in surface, stable in eccentricity and high in yield.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

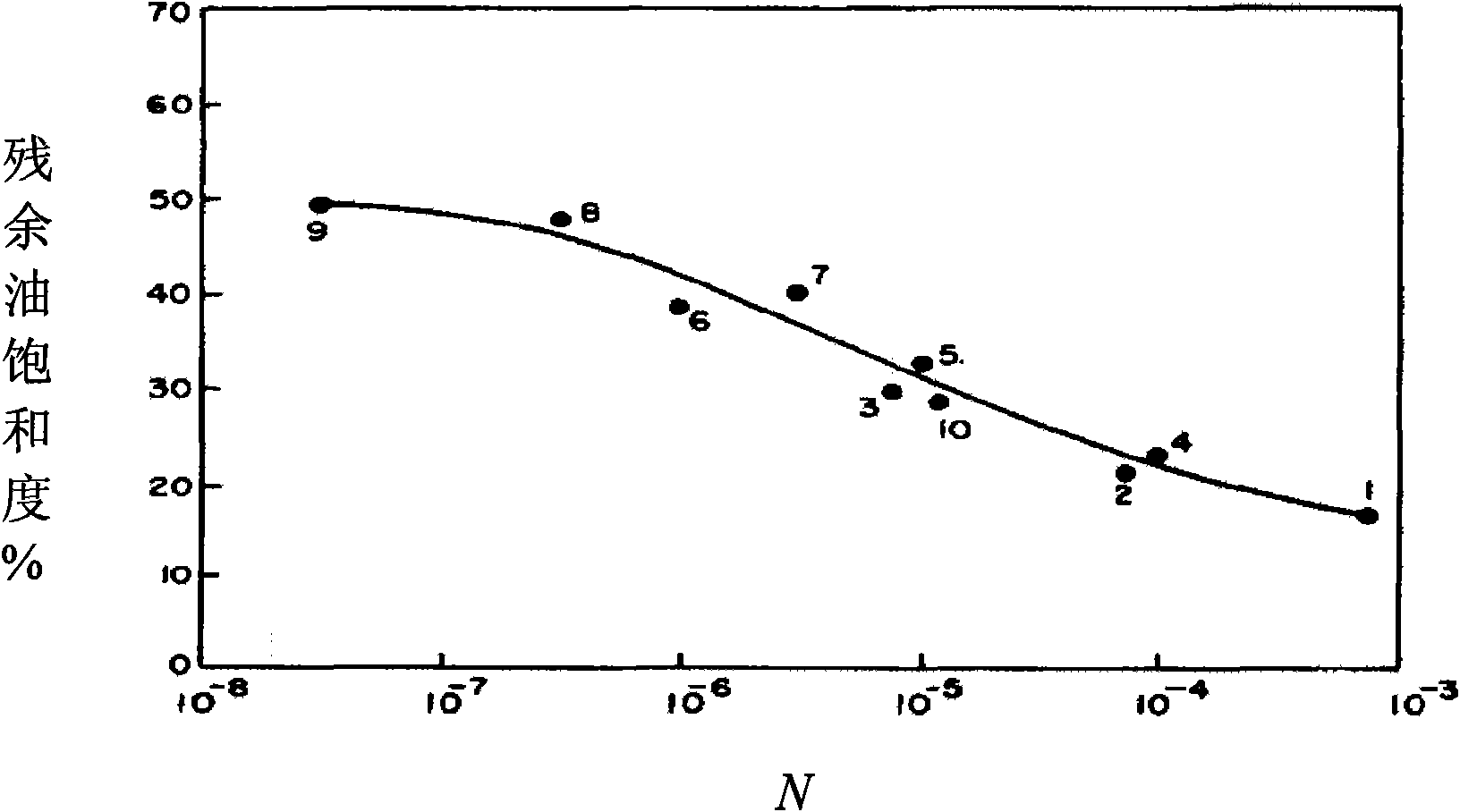

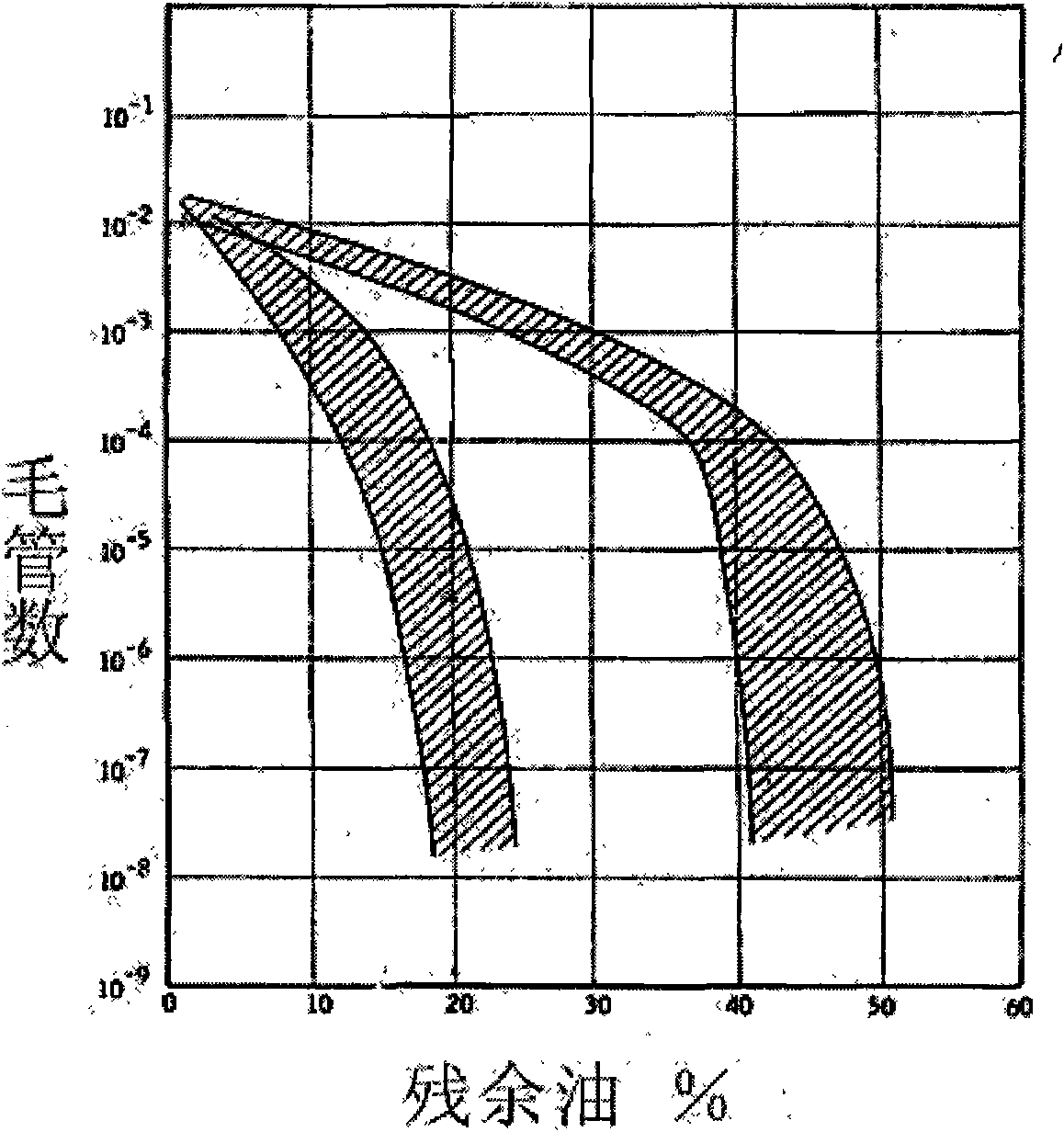

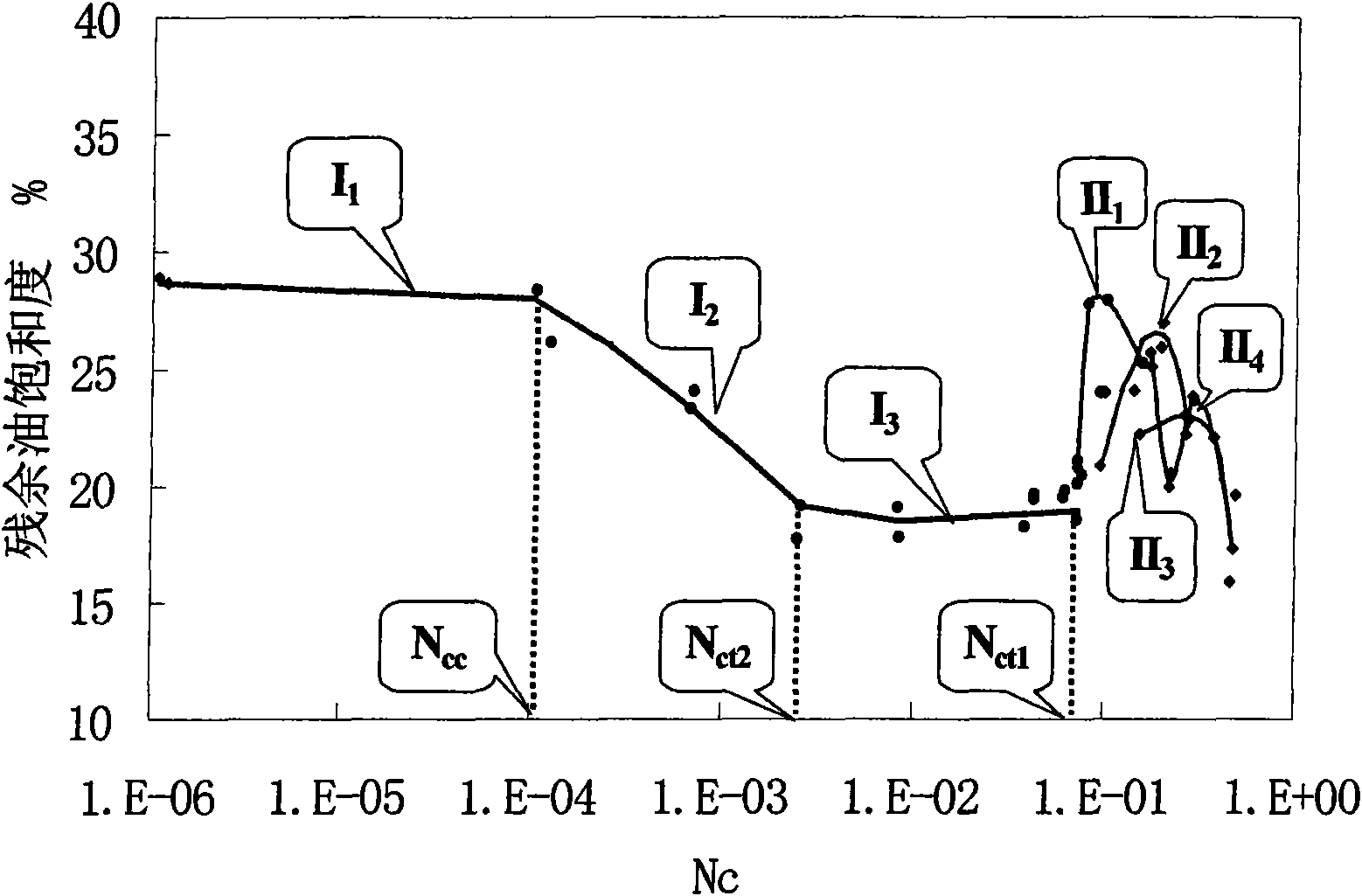

Complex oil displacing method suitable for large well spacing condition of offshore oil field

The present invention discloses a complex oil displacing method suitable for the large well spacing condition of the offshore field. The saturation relationship curve between the capillary number and the residual oil is produced through the oil displacing experiment for confirming optimization range of the capillary number, and furthermore the oil displacing elements are optimized according to the optimization range. In the process of optimizing the oil displaying elements, the fixed well spacing and the liquid injection speed are confirmed according to the characteristic of the offshore oil field, the underground seepage speed of the part which easily generates the driving state conversion is confirmed with an oil accumulation analyzing method. Then the reference area of the underground working viscosity is generated according to the field construction state. The interfacial tension and the underground working viscosity of the oil displacing system are optimized by the safety factor and the effect coefficient. Finally at the state that the well spacing and the liquid injection speed are confirmed, the complex oil displacing oil production is executed. The complex oil displacing method of the invention can combine the specific construction state for limiting the capillary number to an optimized range for guaranteeing the stability of the complex oil displacing method and a relatively high recovery factor increasing amplitude.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for improving the durability of an ink printed on a substrate and substrate formed from such a method

InactiveUS20120231237A1Increased durabilityReduce the smellLayered productsVacuum evaporation coatingNitrogenCoating

Owner:HEWLETT PACKARD INDIGO BV

Method for preparing surfactants for displacement of oil

InactiveCN101397494AEnhanced transfer processIncrease mass transfer rateTransportation and packagingMixingSulfonateSingle type

The invention relates to a preparation method of a surfactant used for oil displacement, belonging to the field of tertiary oil recovery. The previously researched single agent can achieve good interfacial activity only by being compounded and prepared by more than two types of surfactants, has poor field application effect, and can only carry out oil displacement under high injected alkali concentration. The invention overcomes the problems in the prior art that the speed of sulfonation reaction process is difficult to control, the mixing is uneven, and the like; applies high gravity technology into the sulfonation reaction process, meets the needs of fast response and micromixing of the sulfonation reaction, and provides a method for continuously and industrially preparing alkylbenzene sulfonate surfactant which has high efficiency, short production cycle and high product quality. The prepared alkylbenzene sulfonate is a single type surfactant used for oil displacement, and the single agent has good interfacial activity and low using concentration, and can lead the oil-water interfacial tension to be ultra-low (10<-3>mN / m order of magnitude) in wider and lower alkali concentration range.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com