Low-surface-tension solid-free reservoir protection drilling fluid

A low surface tension, reservoir protection technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of liquid phase intrusion into the reservoir and other problems, achieve excellent inhibition and lubricity, and reduce friction. resistance, good inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Basic performance of low surface tension solid-free reservoir protection drilling fluid

[0020] (1) Formula 1: Calculated according to the mass added per 100 ml of water: 0.2 grams of soda ash, 0.2 grams of pH value regulator, 0.8 grams of polymer emulsion strong coating agent, 1.5 grams of fluid loss reducer, 0.3 grams of shearing agent, polymer 2 grams of alcohol, 0.5 gram of surfactant, 0.05 gram of antioxidant, 0 gram of soluble salt. (2) Formula 2: Calculated according to the mass added per 100 ml of water: 0.3 grams of soda ash, 0.4 grams of pH regulator, 1 gram of polymer emulsion strong coating agent, 2.5 grams of fluid loss reducer, 1 gram of shearing agent, polymer 3 grams of alcohol, 1.5 grams of surfactant, 0.1 gram of antioxidant, 300 grams of soluble salt.

[0021] (3) Formula 3: Calculated according to the mass added per 100 ml of water: 0.25 grams of soda ash, 0.3 grams of pH regulator, 0.9 grams of polymer emulsion strong coating agent,...

Embodiment 2

[0026] Embodiment 2: This embodiment mainly evaluates the temperature resistance of the drilling fluid of the present invention

[0027] (1) Formula: Formula 3 in Example 1 is selected.

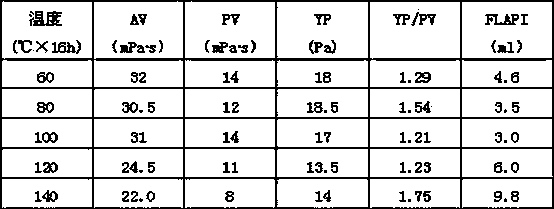

[0028] (2) According to the standard GB / T16783.1-2006, the apparent viscosity, plastic viscosity, dynamic shear force and fluid loss of the drilling fluid are tested. The test results are shown in Table 2:

[0029] Table 2: Rheology and water loss data table of drilling fluid of the present invention at different temperatures

[0030]

[0031] It can be seen from Table 2 that the drilling fluid of the present invention has excellent temperature resistance, and its performance is basically stable in a wide temperature range, indicating that it can be applied to oil wells with different depths and different formation temperatures.

Embodiment 3

[0032] Embodiment 3: This embodiment mainly evaluates the anti-salt pollution ability of the drilling fluid of the present invention

[0033] (1) Formula: select formula 3 in Example 1, add NaCl, CaCl on this basis 2 and MgCl 2 , to examine the salt resistance.

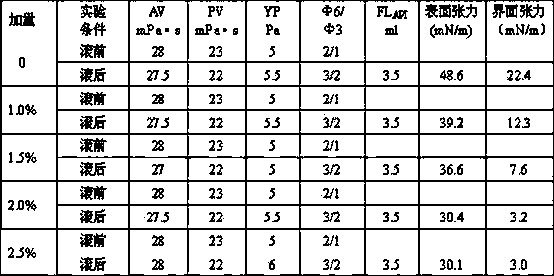

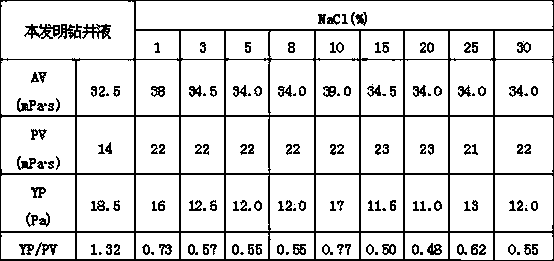

[0034] (2) According to the GB / T16783.1-2006 standard, the apparent viscosity, plastic viscosity and dynamic shear force of the drilling fluid are tested. The test results are shown in Table 3-Table 4:

[0035] Table 3: Evaluation data 1 of the salt resistance ability of the drilling fluid of the present invention

[0036]

[0037] Table 3: Evaluation data 2 of the salt resistance ability of the drilling fluid of the present invention

[0038]

[0039] It can be seen from Table 3 and Table 4 that the drilling fluid of the present invention has strong salt resistance and can resist high-content Na + , Ca 2+ , Mg 2+ Salt erosion, anti-calcium salt, magnesium salt can reach more than 10%, and anti-sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com