Material wettability improvement device and method based on multi-field coupling

A wettability and magnetic field technology, applied in the field of material performance testing, can solve the problems of single application method of external auxiliary equipment, large ultrasonic power loss, and insignificant effect of sample wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

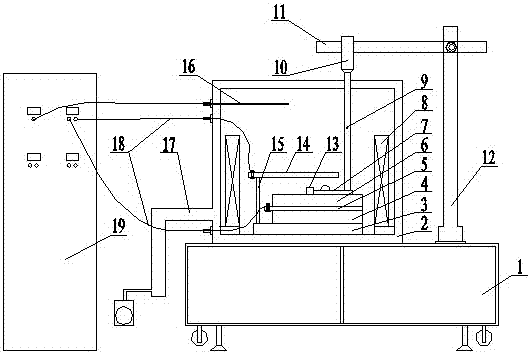

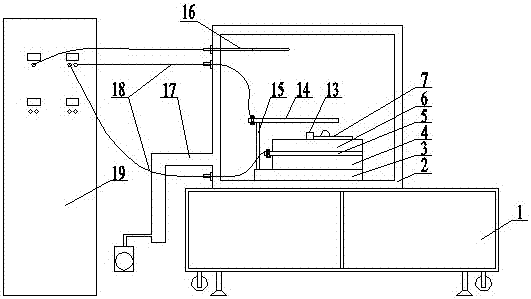

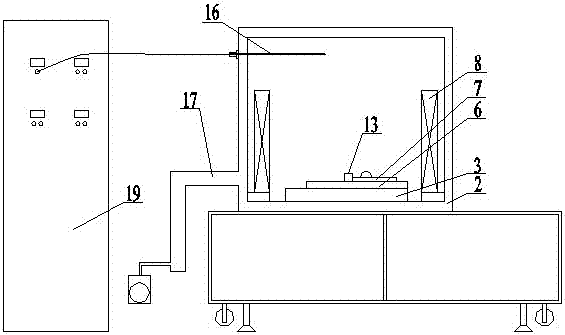

[0034] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions will be clearly and completely described below in conjunction with the drawings and embodiments of the present invention. Describe the scheme of the present invention in detail below in conjunction with specific embodiment:

[0035] A device and method for improving material wettability based on multi-field coupling according to the present invention comprises the following steps:

[0036] Step 1: Use sandpaper or grinding equipment to remove the burrs on the surface of sample A and sample B to be compounded respectively, and polish them smoothly, then put samples A and B into the ultrasonic cleaning machine, add alcohol or acetone to clean, The number of cleanings is 3~5 times, and the cleaning time is 15~20min each time. After cleaning to remove the oil and oxide impurities on the surface of the sample, take it out and dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com