Welding electrode for Ni steel welding

A technology of welding rod and welding rod, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve the effect of good spreadability, stable arc and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

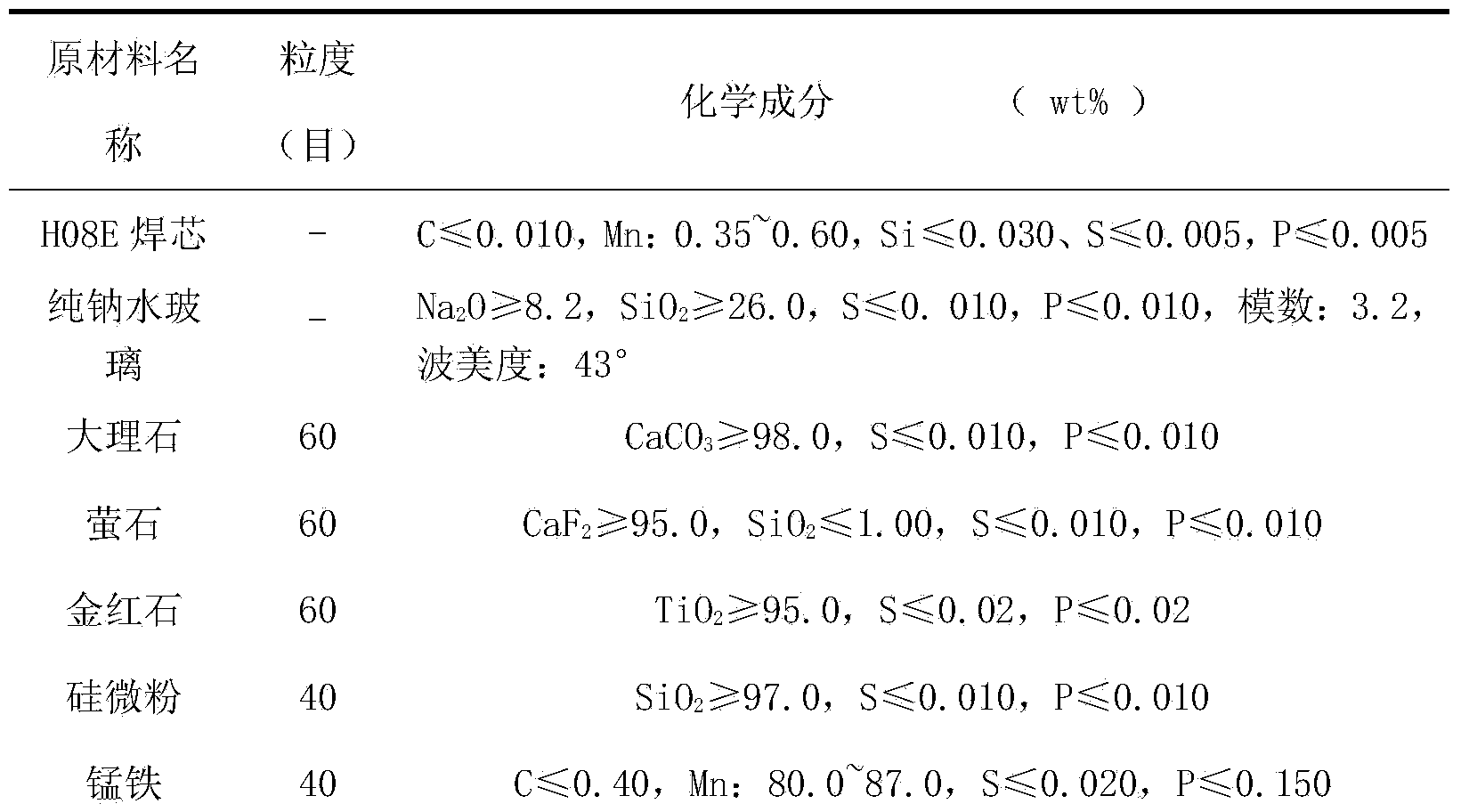

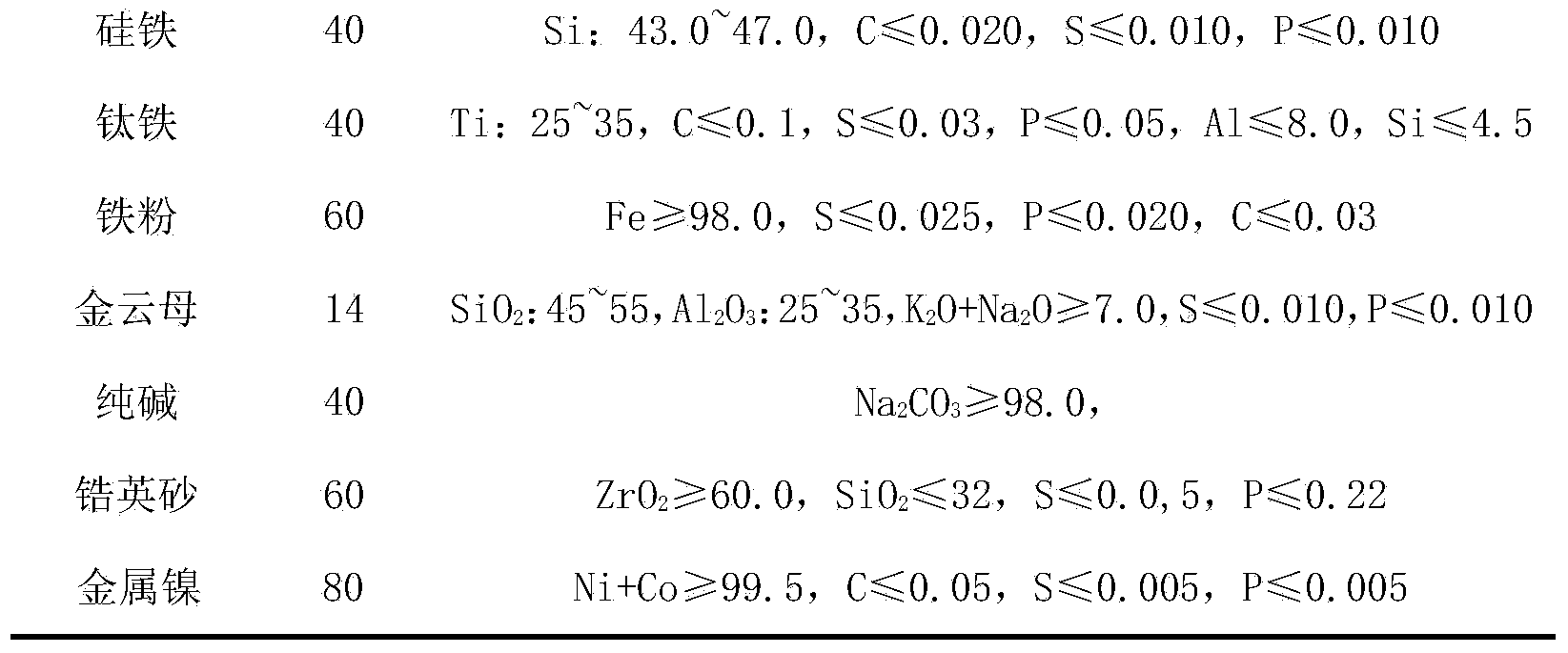

[0027] The chemical composition requirements of the main raw materials of this patent are shown in Table 1:

[0028] Table 1 Chemical composition requirements of main raw materials

[0029]

[0030]

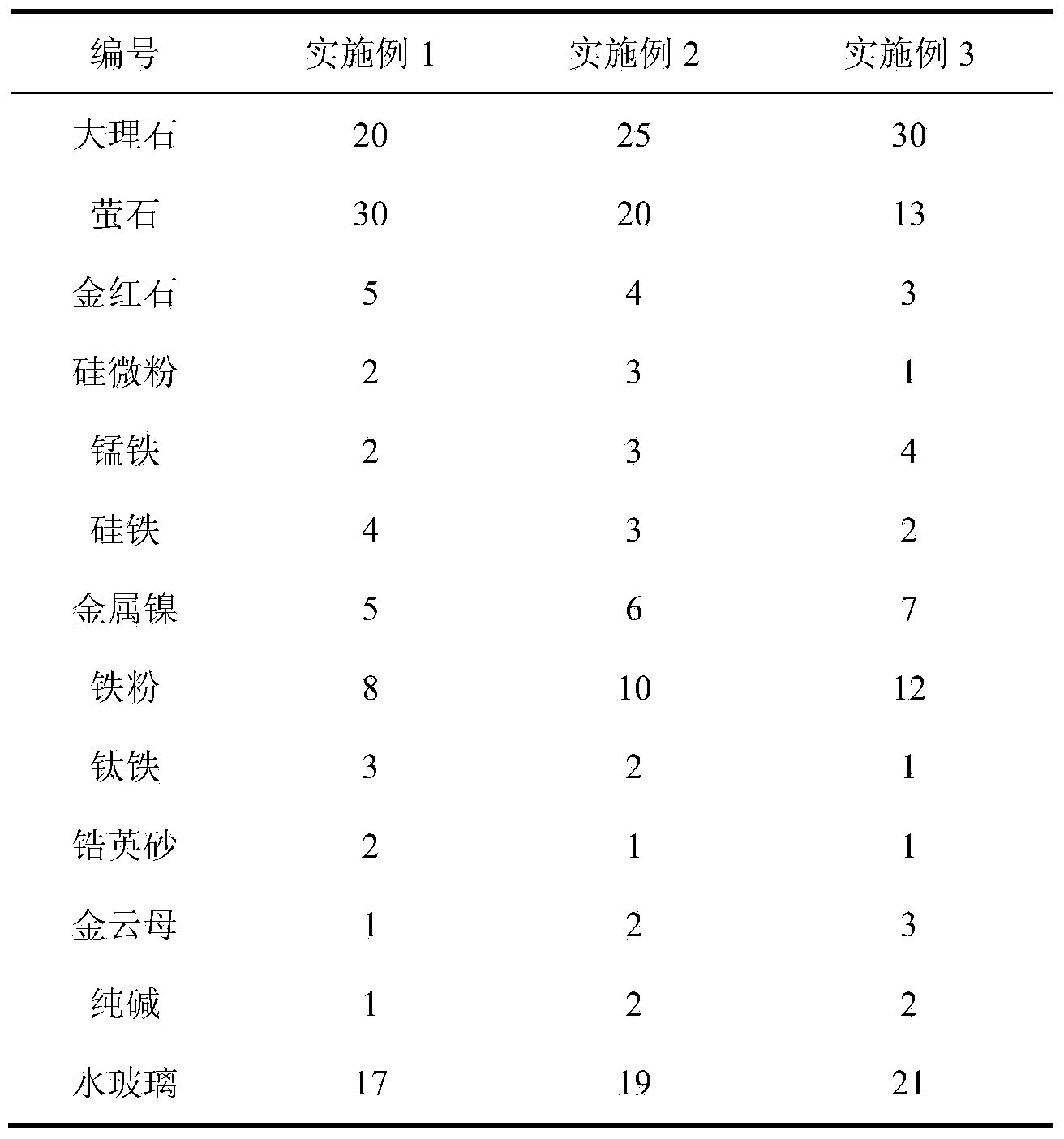

[0031] The concrete proportioning ratio of embodiment electrode coating composition is as shown in table 2:

[0032] Table 2 Example composition ratio (wt%)

[0033]

[0034] The chemical composition of the deposited metal is shown in Table 3.

[0035] Table 3 Example welding wire and deposited metal chemical composition (wt%)

[0036]

[0037]

[0038] The performance comparison of the embodiments of the present invention is shown in Table 4.

[0039] Table 4. Mechanical properties of the deposited metal in the example (620°C×1h heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com