Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Pattern effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

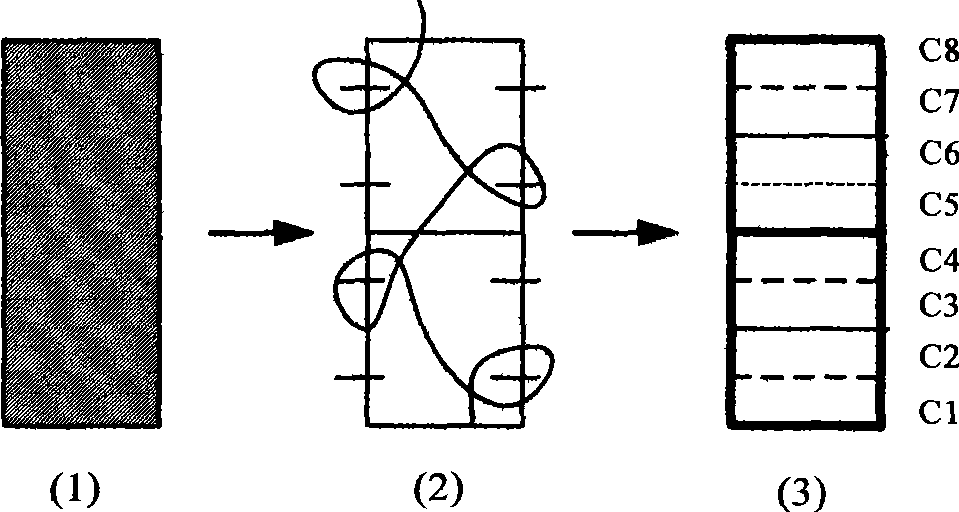

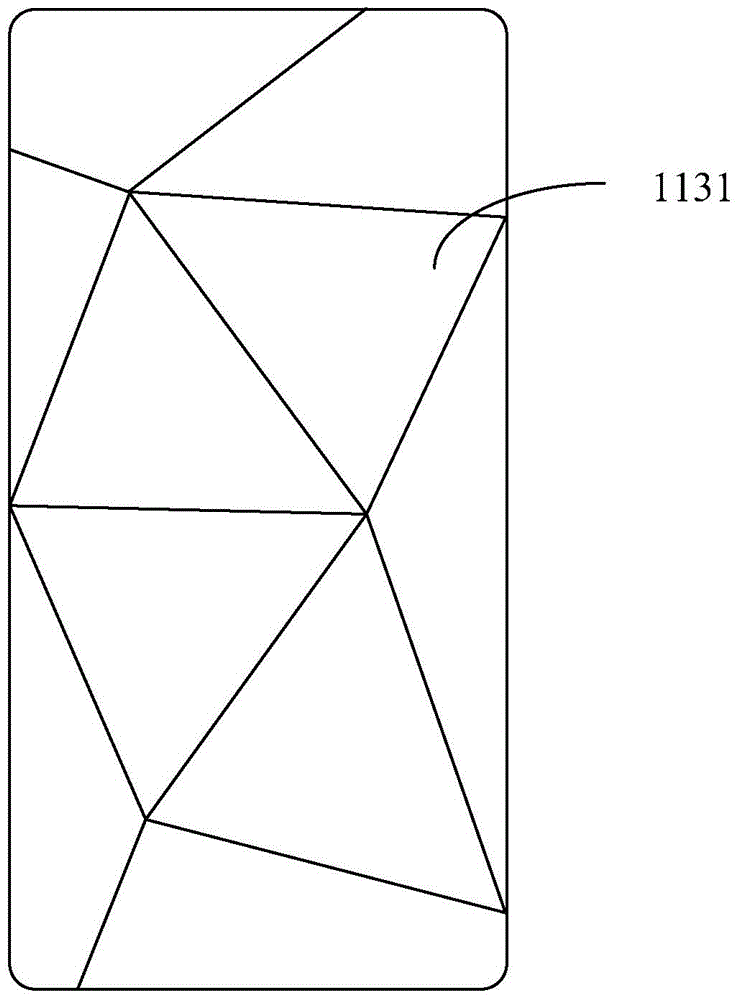

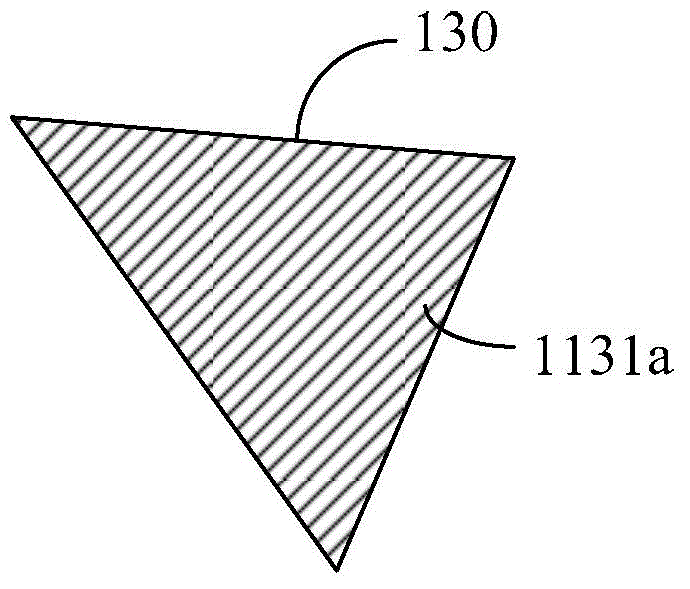

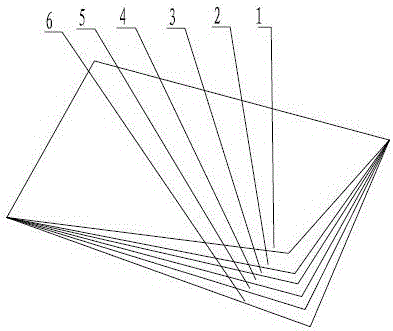

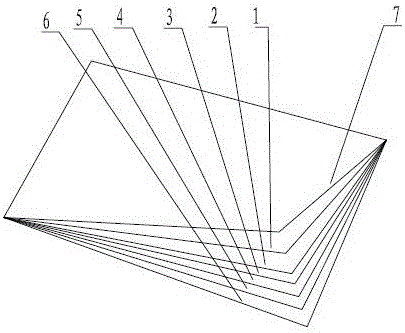

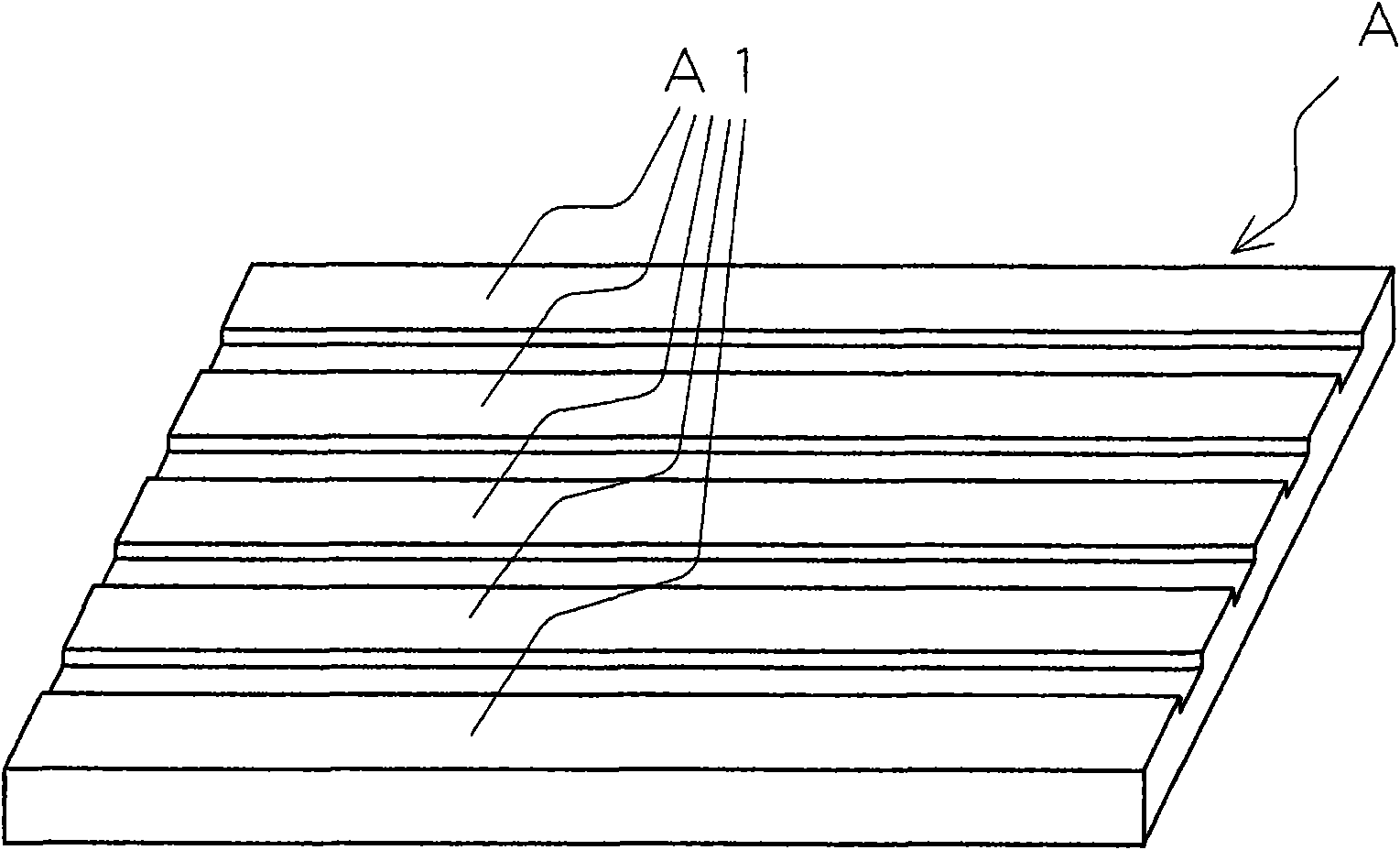

Knitting method for warp-knitting jacquard seamless fabric

InactiveCN101487164ARich organizational structurePattern effect is goodWarp knittingEngineeringMechanical engineering

The invention discloses a method for knitting warp-knitting jacquard-weave seamless textile, comprising the specific process flows as follows: firstly, a basic knitting process is determined; as for the general warp-knitting seamless jacquard-weave textile, a front needle bed and a rear needle bed respectively uses a guide bar to knit base fabric and respectively uses a jacquard weave guide bar to knit main jacquard weave patterns and tissues for connecting front sheets and rear sheets; secondly, information of main jacquard lapping movement and corresponding jacquard needle movement formed by the jacquard weave guide bar is determined; and finally, information of the lapping movement and jacquard weave needle action at the edge of the front garment piece and the rear garment piece is determined. The method utilizes specific process to lead certain needles at the jacquard weave guide bar to knit the edge connecting tissue and lead other jacquard weave needles to knit main patterns, thus forming the textile with natural connection and rich patterns; furthermore, additional guide bars are not used for connecting the edge, thus greatly simplifying the knitting method and improving the design efficiency and production benefits radically.

Owner:JIANGNAN UNIV

Curable composition for imprints, patterning method and pattern

ActiveUS20140154471A1Pattern effect is goodLess producedLayered productsCeramic shaping apparatusHydroxy groupSilicon

Disclosed is a to provide a curable composition for imprints capable of keeping a good patternability and of producing less defects even after repetitive pattern transfer. The curable composition for imprints comprising: a polymerizable compound (A); a photo-polymerization initiator (B); and anon-polymerizable compound (C) having a polyalkylene glycol structure having at least one terminal hydroxy group, or at least one etherified terminal hydroxy group, and containing substantially no fluorine atom and no silicon atom.

Owner:FUJIFILM CORP

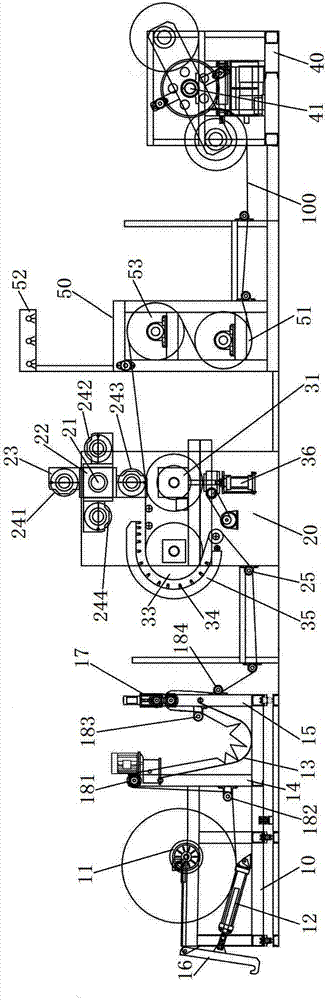

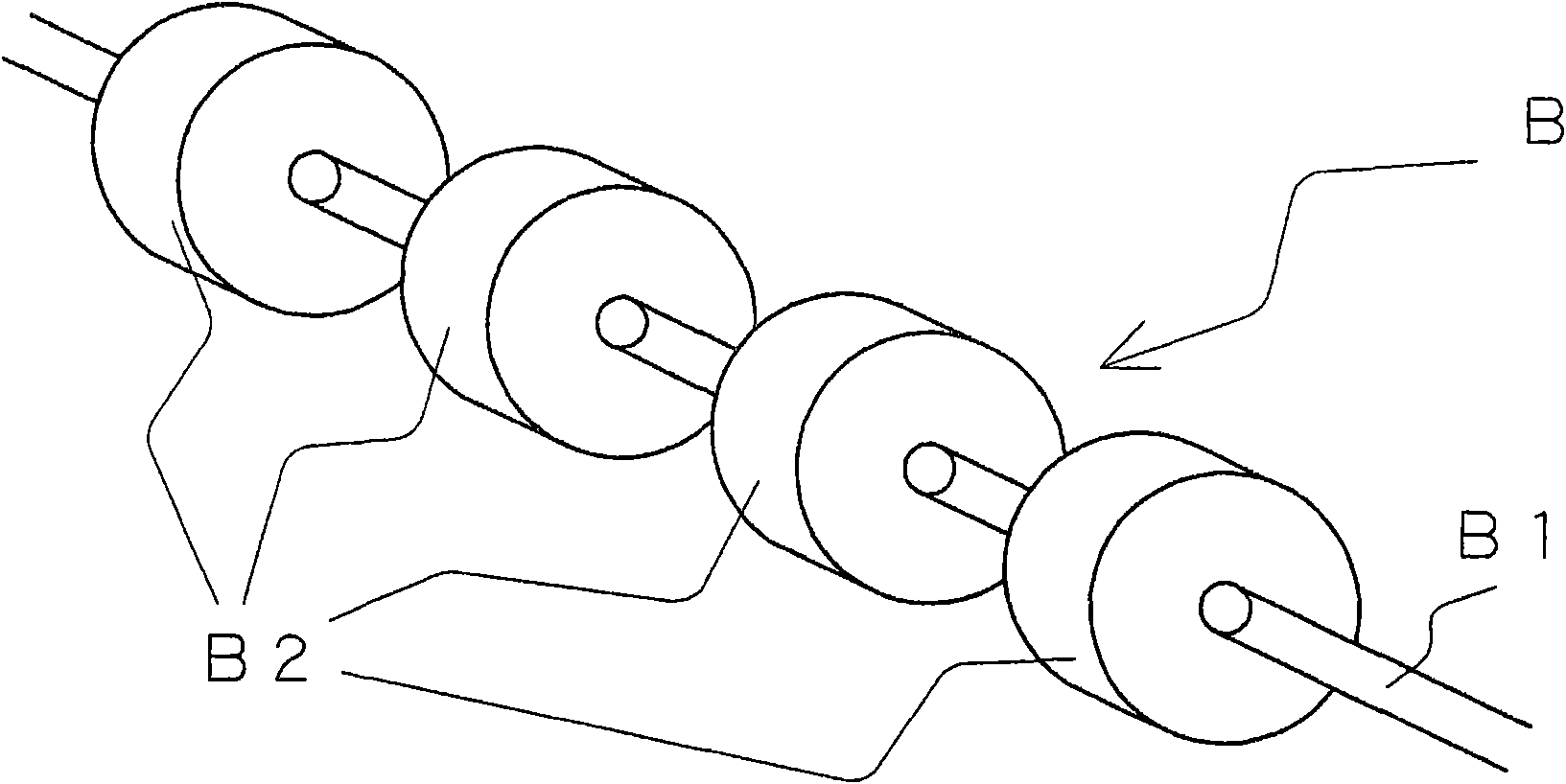

Embossing apparatus for garment material

The invention discloses an embossing apparatus for a garment material. The embossing apparatus comprises a feeding mechanism, an embossing mechanism, a material recovering mechanism and a drying mechanism, wherein the feeding mechanism comprises a feeding rack, a feeding roll, a feeding cylinder, a storage bin, a pressing and conveying assembly and a conveying roll; the embossing mechanism comprises an embossing frame, an embossing shaft, an embossing motor, an end plate, a station plate, a first embossing roll, a second embossing roll, a third embossing roll, a fourth embossing roll, a lower embossing roller, a conveying roller, a shell cover and a hot steam nozzle; the lower embossing roller is provided with concave patterns respectively matching with a first convex pattern, a second convex pattern, a third convex pattern and a fourth convex pattern; and the drying mechanism comprises a drying rack, a cold-air drier, a drying roller and an auxiliary roll. The embossing apparatus provided by the invention is simple to operate, high in an automation degree, capable of pressing complex and changeable patterns on fabrics, good in embossing quality and high in embossing efficiency.

Owner:JIAXING WANYUAN FASHION

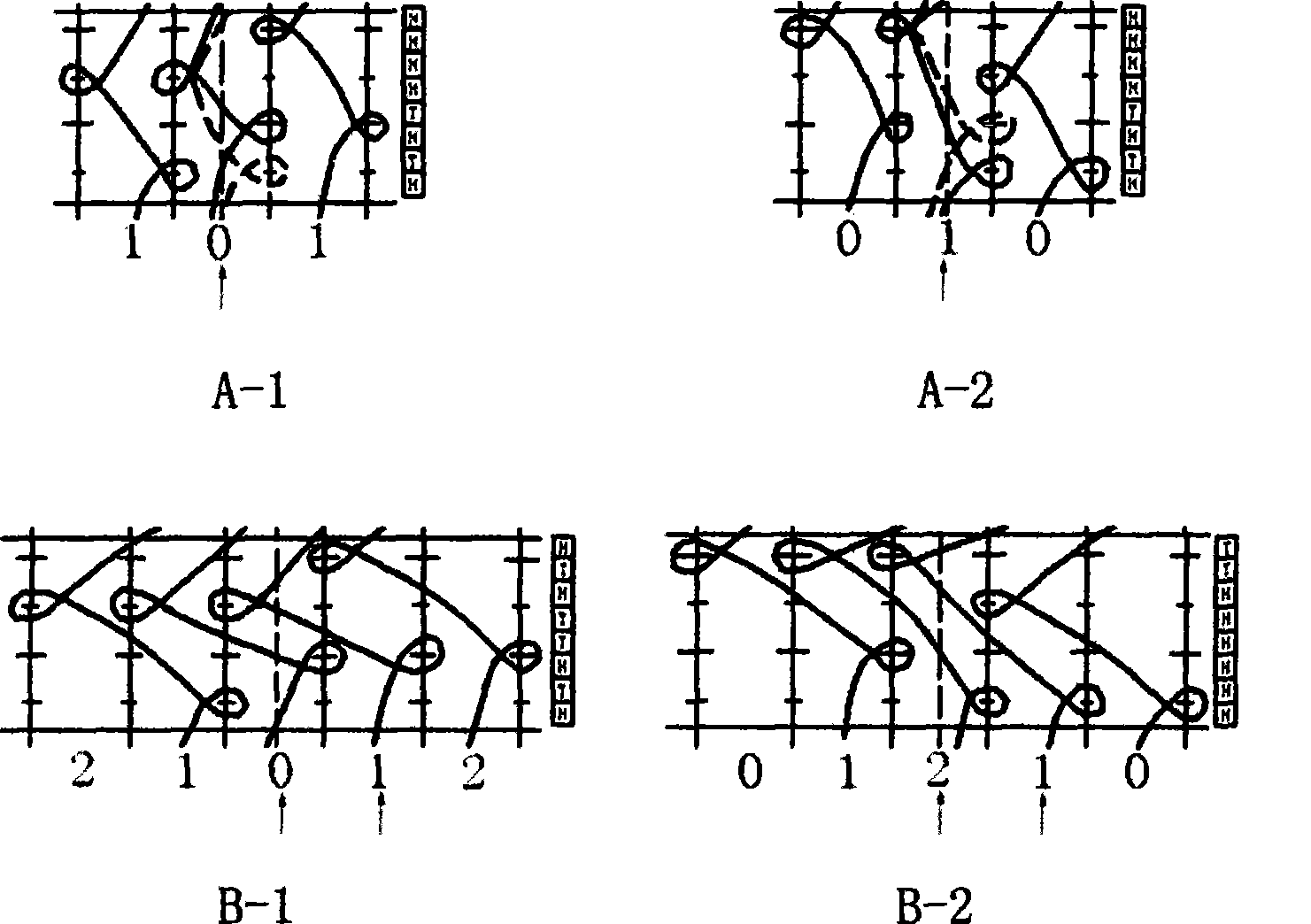

OPC method for mask preparation course in semiconductor manufacturing process

ActiveCN101498893AImprove conflicting issuesLarge OPC spaceOriginals for photomechanical treatmentEngineeringSemiconductor

The present invention provides a method for optical proximity correction (OPC), which can greatly prevent the problems appearing previously in optical proximity correction. The scheme provided by the present invention alters the shape of layout patterns before the existing optical proximity correction, generates other convex polygon patterns on the basis of existing layout patterns, and then conducts optical proximity correction with the convex polygon patterns as the target.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Production process of shoe fabric formed by flat knitting

InactiveCN104032468AExemption from cutting processEasy to process and manufactureWeft knittingShaping/stretching tubular fabricsPolyesterYarn

The invention relates to a production process of shoe fabric formed by flat knitting. The production process is characterized by including steps of (1) preparing raw materials, to be specifically, selecting low-melting-point leather-core color DTYs (draw texturing yarns) and Dacron color FDYs (fully drawn yarns) as raw materials; (2) stranding 3-4 low-melting-point leather-core color DTYs and 2-3 Dacron color FDYs to obtain yarns; knitting the obtained yarns on a computerized flat knitting machine to form mutually twisted loops and knitting the yarns to obtain the shoe fabric; (3) subjecting the shoe fabric to drying and ironing, to be more specifically, heating to 160-200 DEG C from the room temperature for 45-65 minutes and preserving heat for 30-45 minutes; naturally cooling to the room temperature. The low-melting-point leather-core colored DTYs comprise core layers and leather layers, the core layers are Dacron filaments and the leather layers are low-melting-point polyester. The joints of the yarn loops of the shoe fabric are adhered. The shoe fabric obtained is light and comfortable and good in shape maintenance and has good rigidity support.

Owner:JIANGNAN UNIV

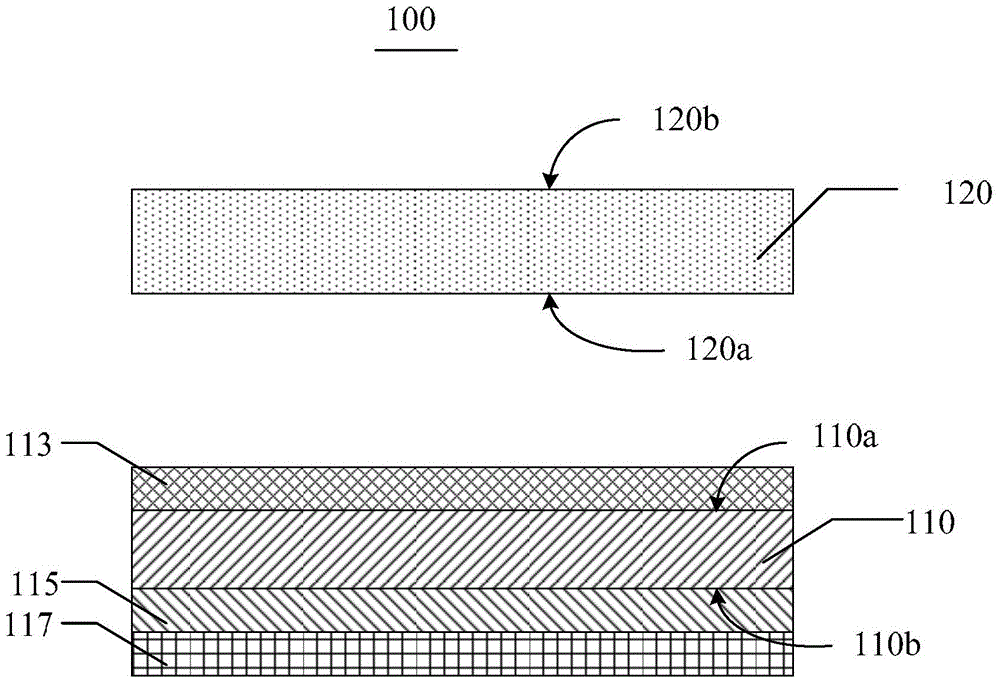

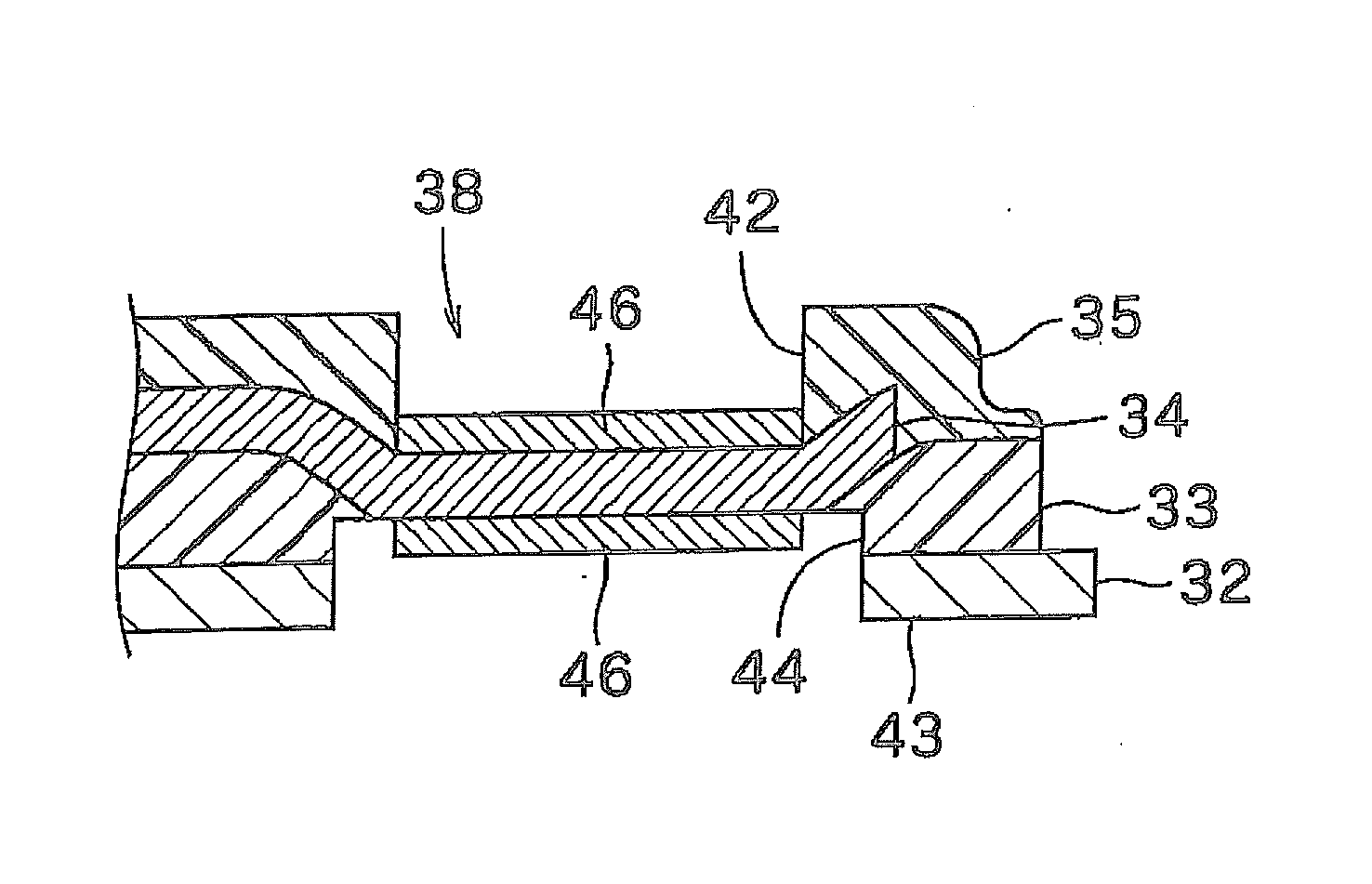

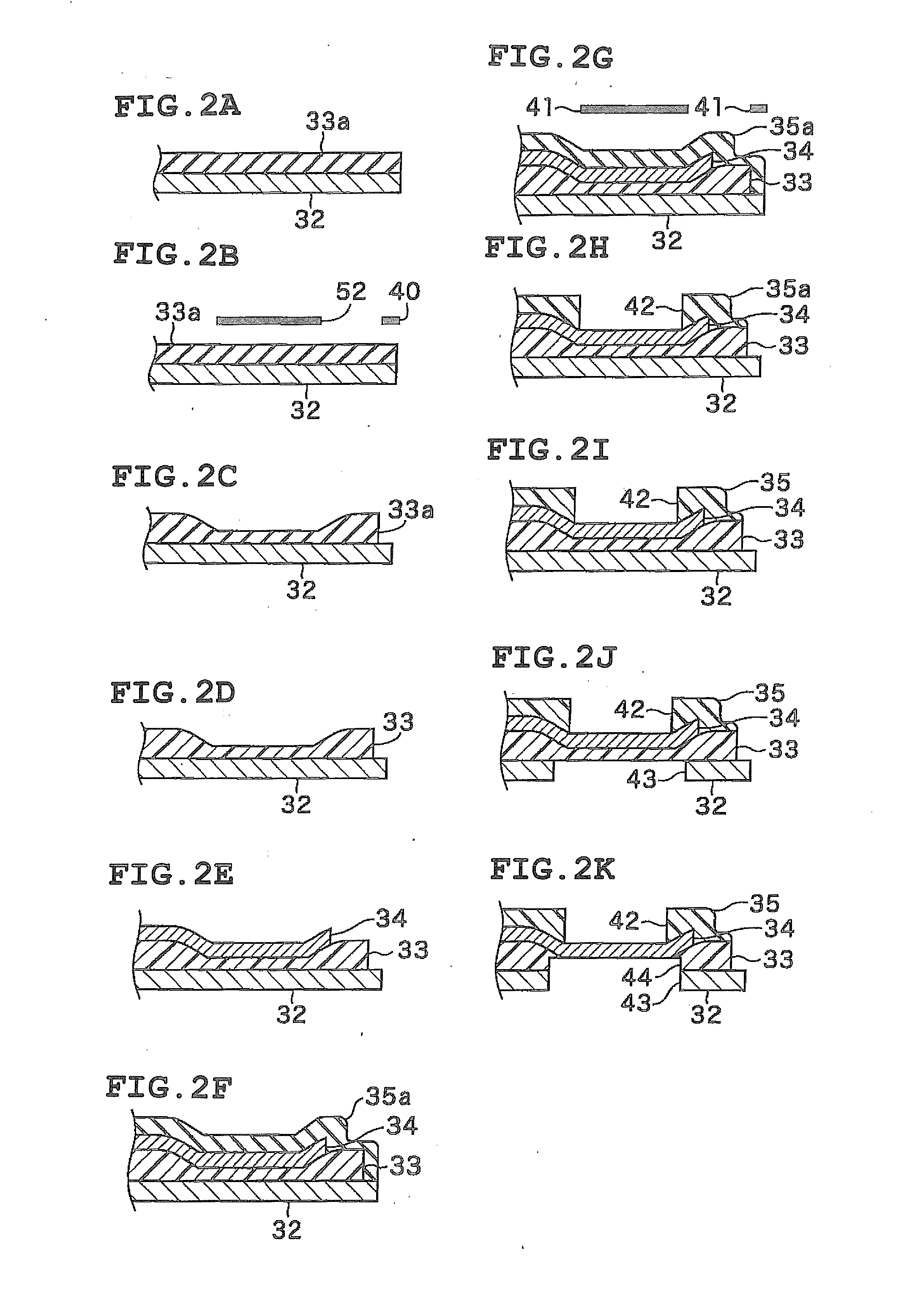

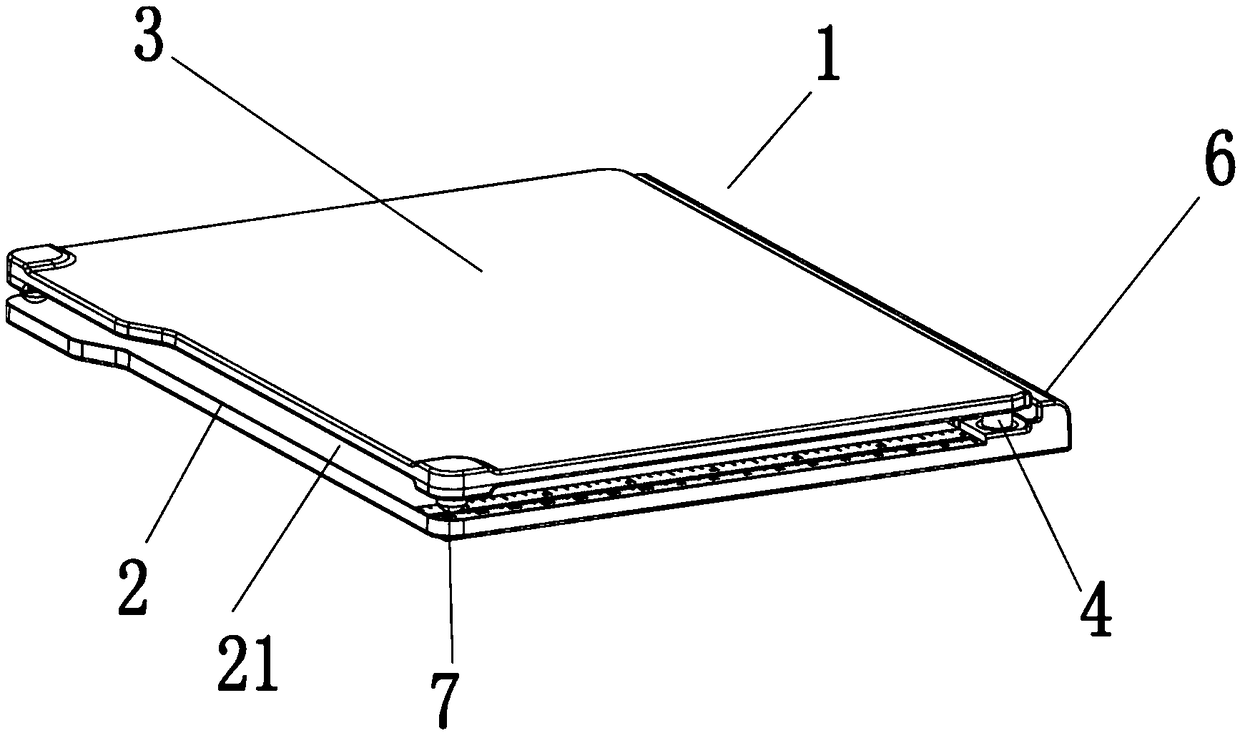

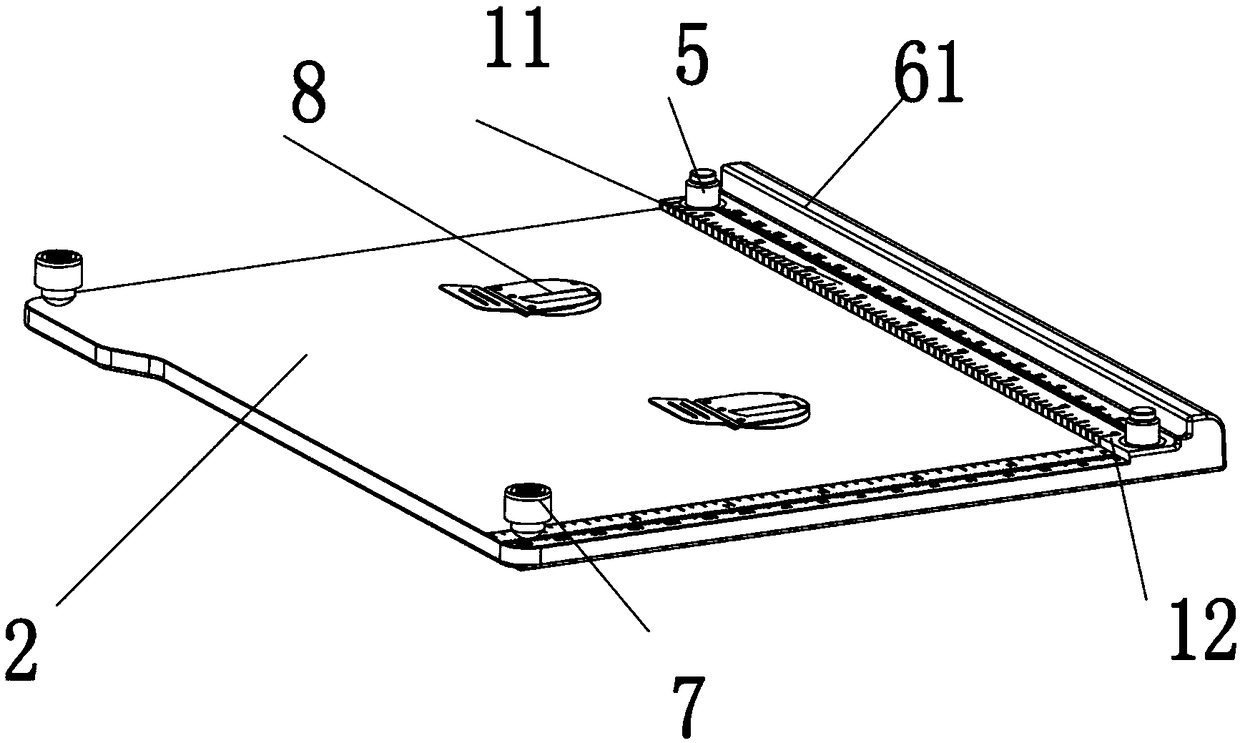

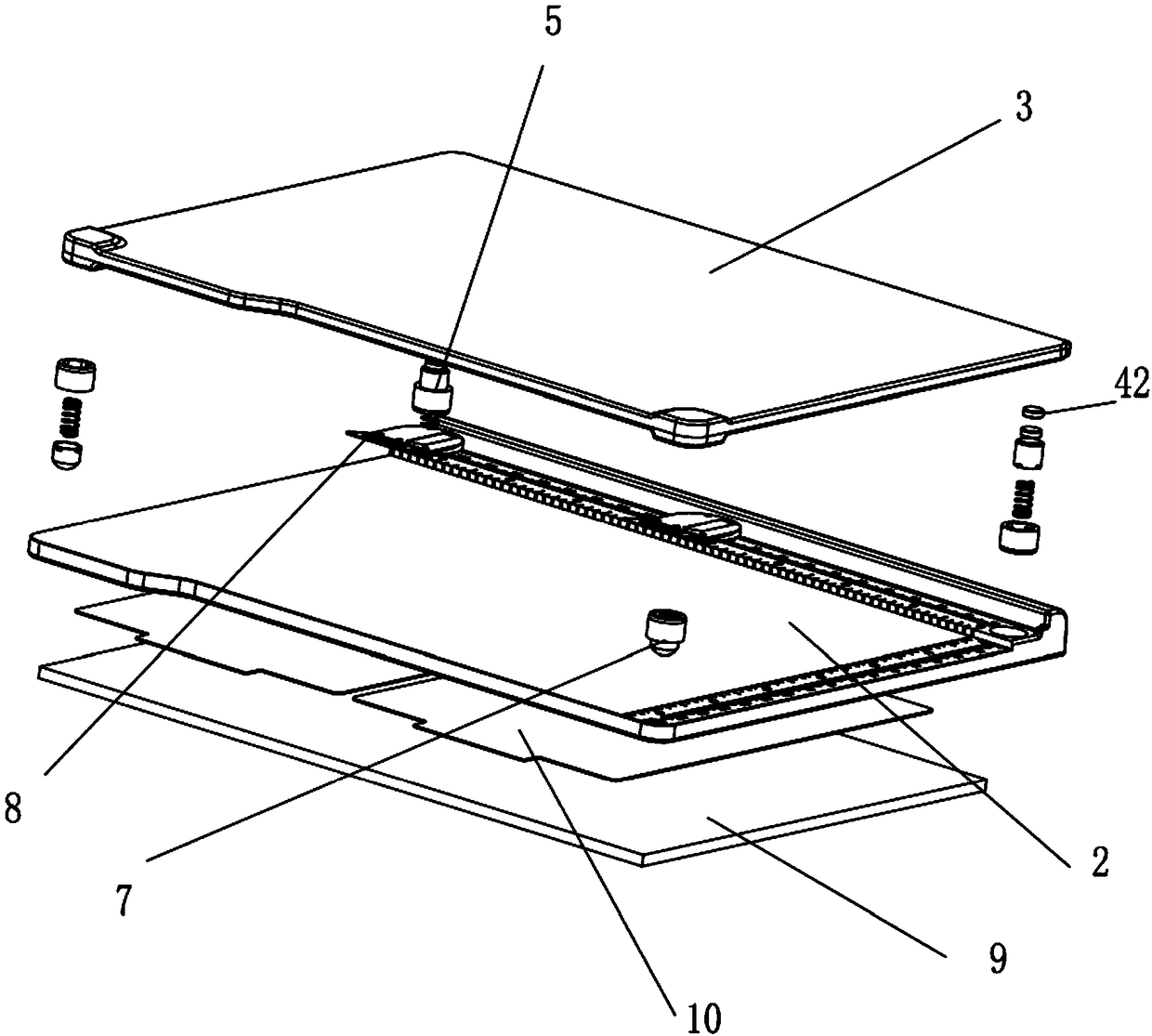

Housing, electronic apparatus, and manufacturing method of housing

InactiveCN104527166APattern effect is goodImprove experienceDigital data processing detailsLaminationBiochemical engineeringElectron

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

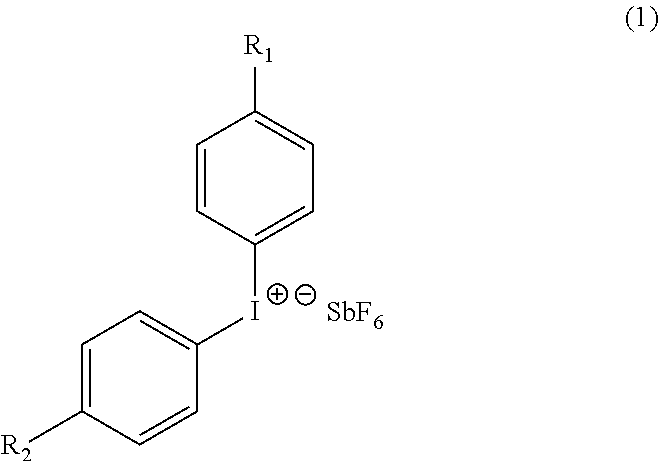

Negative photosensitive material, photosensitive board employing the negative photosensitive material, and negative pattern forming method

ActiveUS20100304298A1Improve etchabilityExcellent in patternabilityPhotosensitive materialsRadiation applicationsArylPolymer science

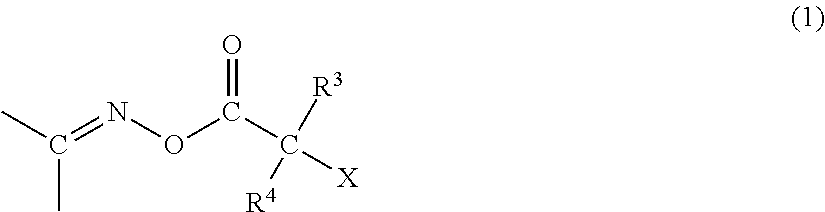

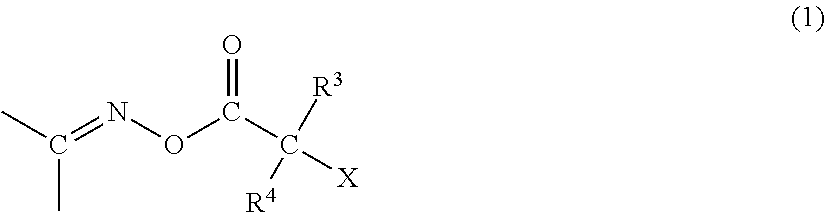

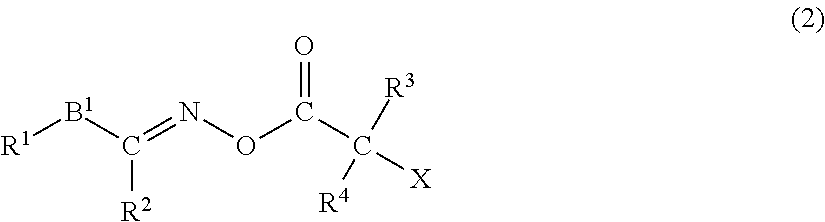

A negative photosensitive material is provided which has a lower linear expansion coefficient and a lower hygroscopic expansion coefficient and is excellent in gradational patternability and PI etchability in patterning. The negative photosensitive material comprises:(A) a polyimide precursor having a structural unit represented by the following general formula (1) and a structural unit represented by the following general formula (2), the structural unit represented by the general formula (2) being present in the polyimide precursor in a proportion of less than 30 mol % based on the overall amount of the polyimide precursor; and(B) at least one of a pyridine derivative represented by the following general formula (3) and a pyridine derivative represented by the following general formula (4):wherein R1, R2, R3, R4 and R5, which may be the same or different, are each a C1 to C4 alkyl group, and Ar is an aryl group having a nitro group at its ortho position,wherein R1, R2, R4 and R5, which may be the same or different, are each a C1 to C4 alkyl group, and Ar is an aryl group having a nitro group at its ortho position.

Owner:NITTO DENKO CORP

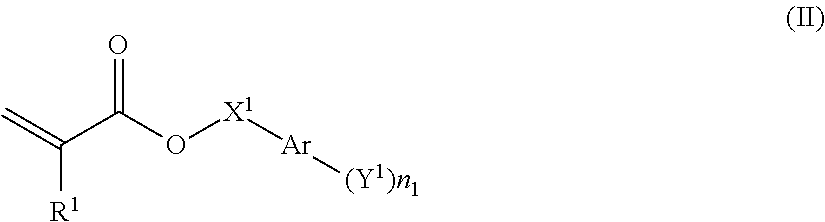

Photosensitive fluororesin composition, cured film obtained from the composition, and method of forming pattern

InactiveUS20060246371A1Pattern effect is goodEasy to solvePhotosensitive materialsPhotosensitive materials for photomechanical apparatusEpoxyMethacrylate

[PROBLEM TO BE SOLVED] To provide a cured product, which is excellent in the prevention of adherence of a water repellent oil component, finger prints and the like and wiping-off properties (anti-fouling properties) thereof, as well as in thermal shock properties, adhesion or other properties, and a photosensitive fluororesin composition for easily providing the above cured product. [SOLUTION] A photosensitive fluororesin composition comprising (A) a fluorocopolymer, (B) a compound having at least two alkyletherized amino groups in its molecule, (C) a photosensitive acid generating agent, and (D) a solvent, wherein the fluorocopolymer (A) is a copolymer comprising (A1) a structural unit derived from at least one monomer selected from fluoro(meth)acrylic esters, fluoroolefins, and fluoroolefin derivatives and (A2) a structural unit derived from at least one monomer selected from hydroxyl-containing monomers, epoxy-containing monomers, and carboxyl-containing monomers.

Owner:JSR CORPORATIOON

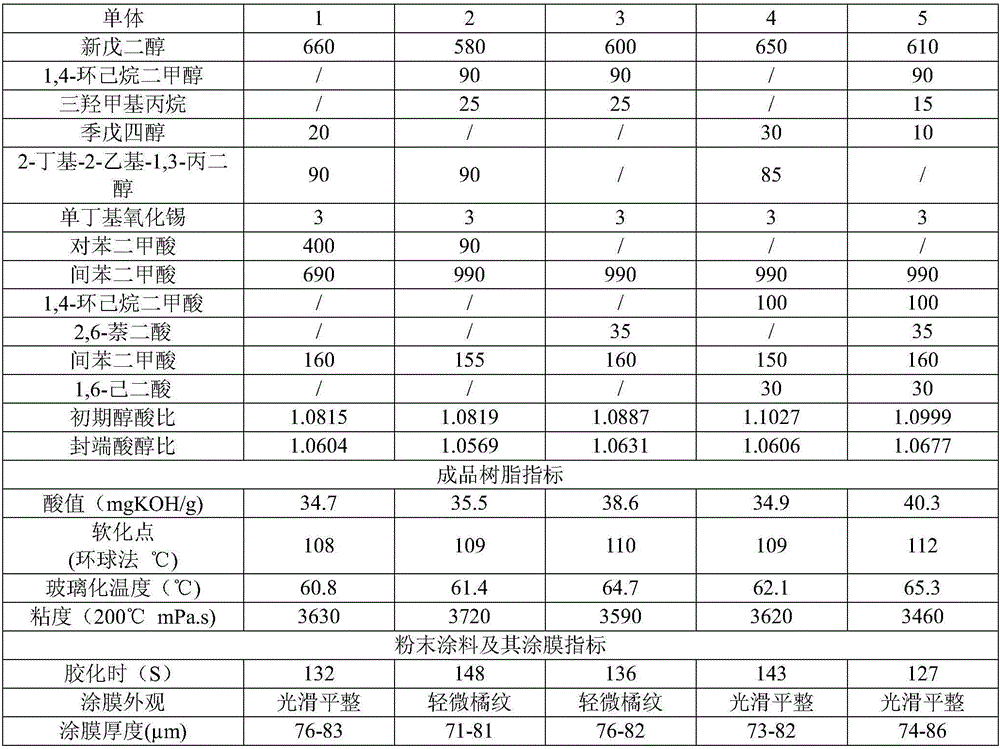

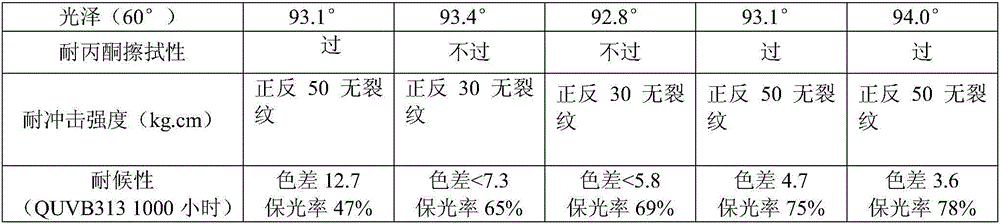

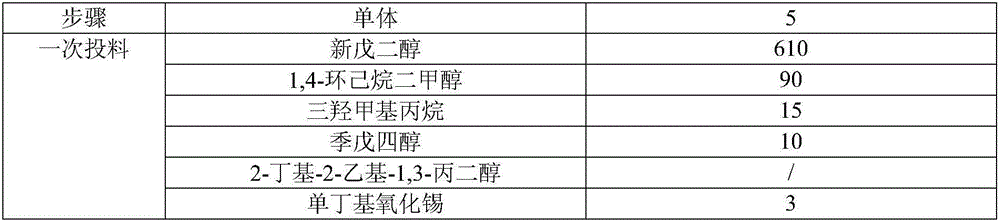

Weather-resisting type single-coating powder paint with metal pattern effect

ActiveCN106280914AHas super weather resistanceStrong three-dimensional sensePowdery paintsPolyester coatingsCyclohexanedimethanolPlasticizer

The invention relates to weather-resisting type single-coating powder paint with metal pattern effect. The weather-resisting type single-coating powder paint comprises bottom powder A and metal powder B; the bottom powder A is prepared from the following components in percentage by weight: 55 percent to 80 percent of weather-resisting type polyester resin, 4.0 percent to 6.2 percent of a curing agent, 0 to 40 percent of modified barium sulfate, 0.3 percent to 1.5 percent of a plasticizer, 0.02 percent to 2 percent of a curing accelerator, 1 percent to 5 percent of an auxiliary agent, 0 to 25 percent of pigment and 0.05 percent to 0.5 percent of a texturizing agent; the weather-resisting type polyester resin is synthesized from the following raw materials: neopentyl glycol, butylene glycol, 2-methyl-1,3-propylene glycol, cyclohexanedimethanol, 2-butyl-2-ethyl-propylene glycol, terephthalic acid and the like. By adopting modified polyester, the weather-resisting type single-coating powder paint with metal pattern effect has excellent weather resistance and also has a three-dimensional pattern effect; the weather-resisting type single-coating powder paint with metal pattern effect can be thickly applied and a thickly coated film with the thickness of 60UM to 120UM is formed by coating in one step; the coated film only needs to be cured for one time; the weather-resisting type single-coating powder paint with metal pattern effect has the characteristics of 10-year weather resistance, high metal stereoscopic impression, clear pattern effect, good coverage, good mechanical property, low cost, no pollution to the environment and the like.

Owner:ZHEJIANG CHAOLANG ADVANCED MATERIALS

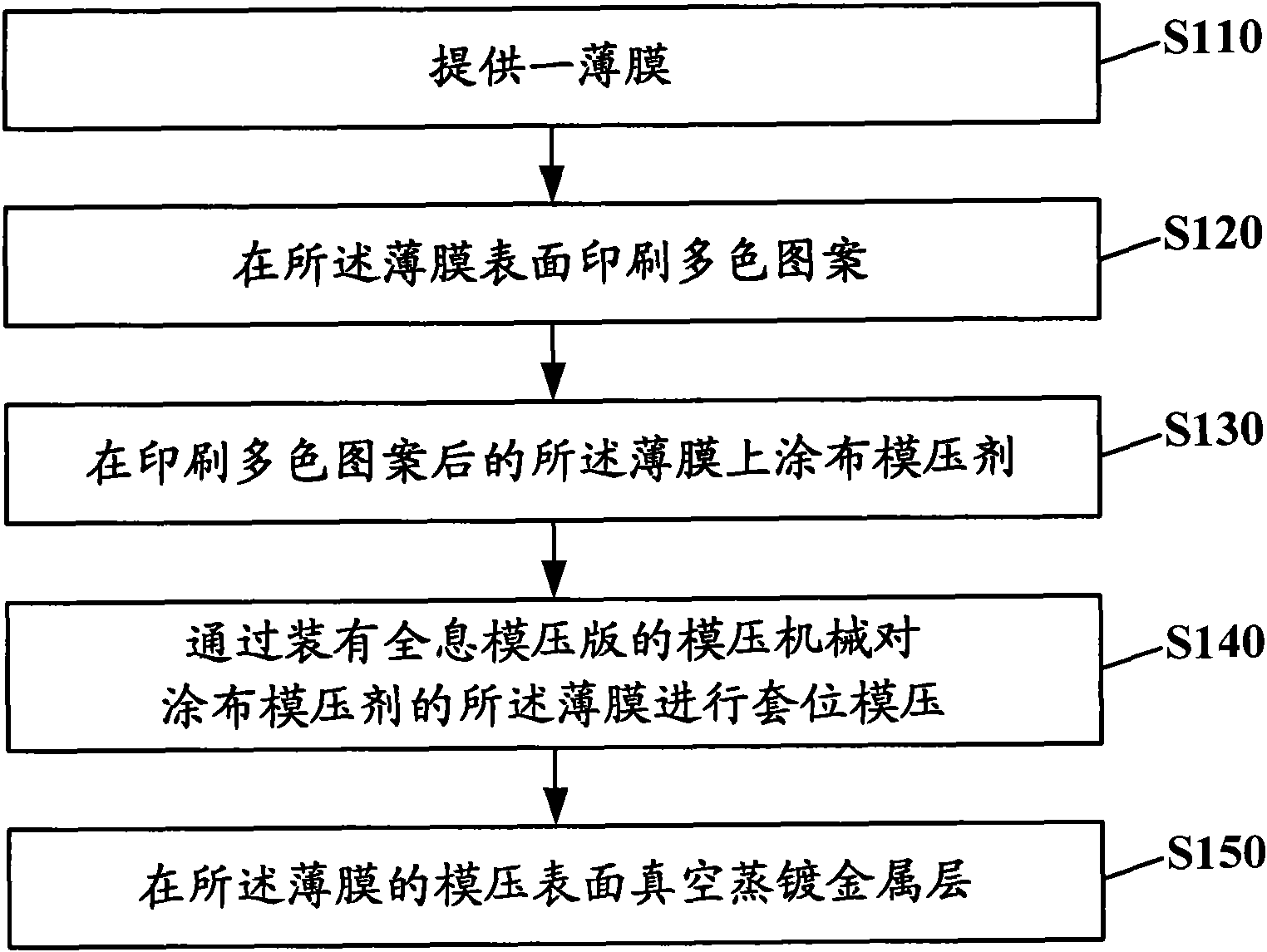

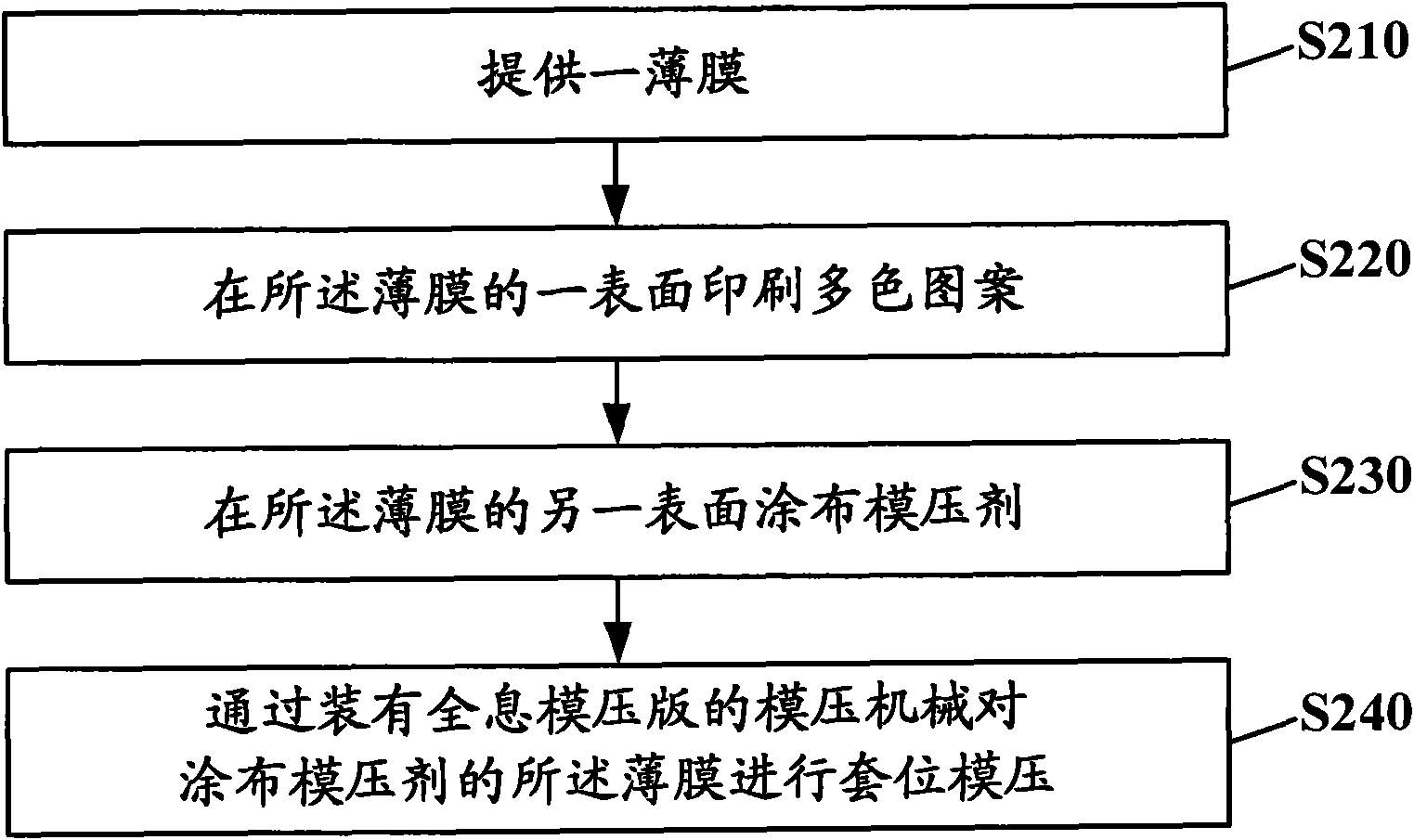

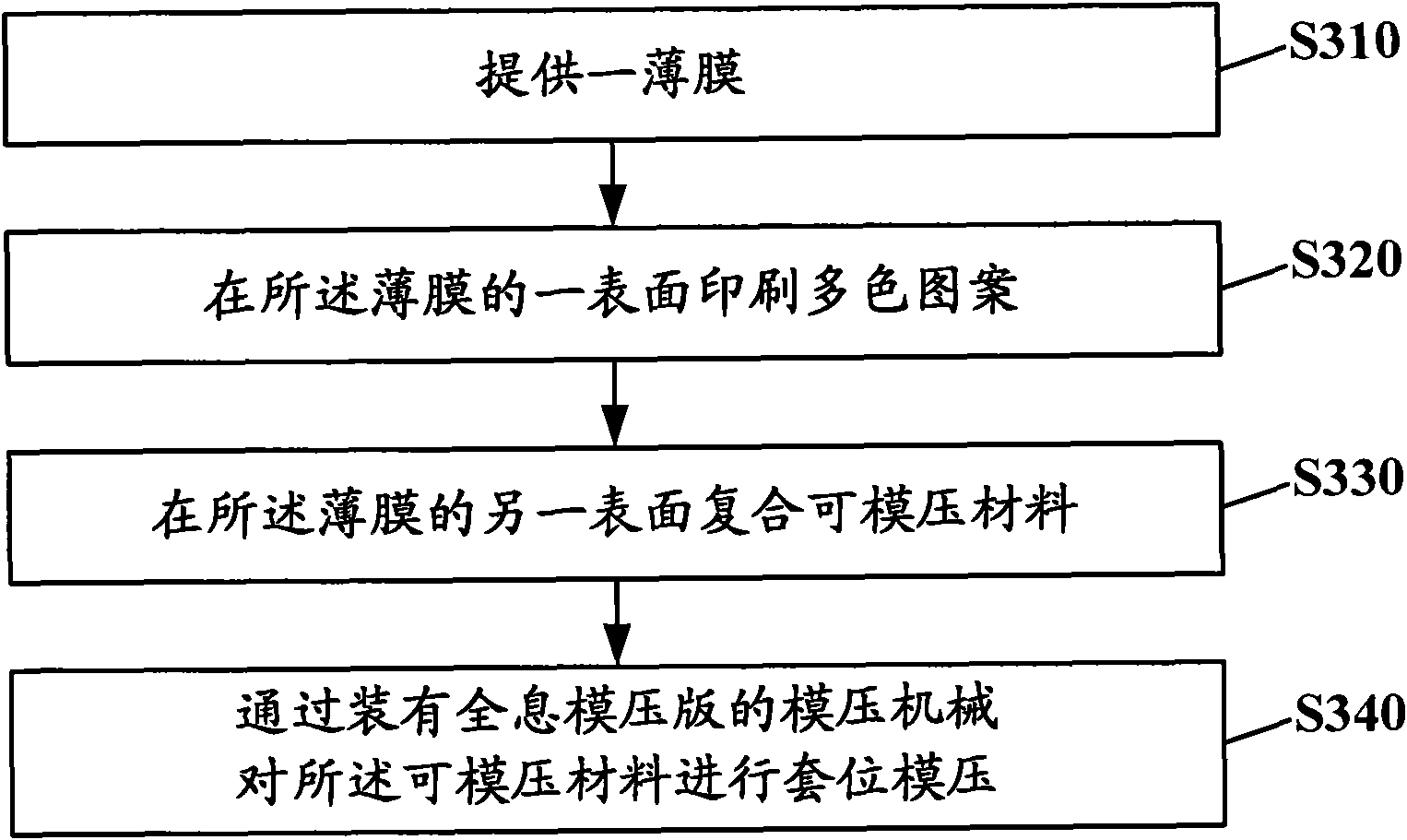

Method for acquiring colorized holographic pattern and colorized holographic pattern package paper structure

InactiveCN102700274ASimple processImprove pattern effectFlexible coversWrappersPaper sheetEngineering

The invention discloses a method for acquiring colorized holographic pattern and a colorized holographic pattern package paper structure. The method comprises the following steps of: supplying a thin film; printing a multi-color pattern on the surface of the thin film; coating a die-pressing agent on the thin film printed with the multi-color pattern; and performing sleeving die-pressing on the thin film coated with the die-pressing agent through die-pressing machinery with a holographic die-pressing plate, so that a holographic pattern is registered and matched with the multi-color pattern. According to the technical scheme, the holographic pattern and the printed pattern can be precisely matched, and the pattern effect is greatly enhanced.

Owner:李华容

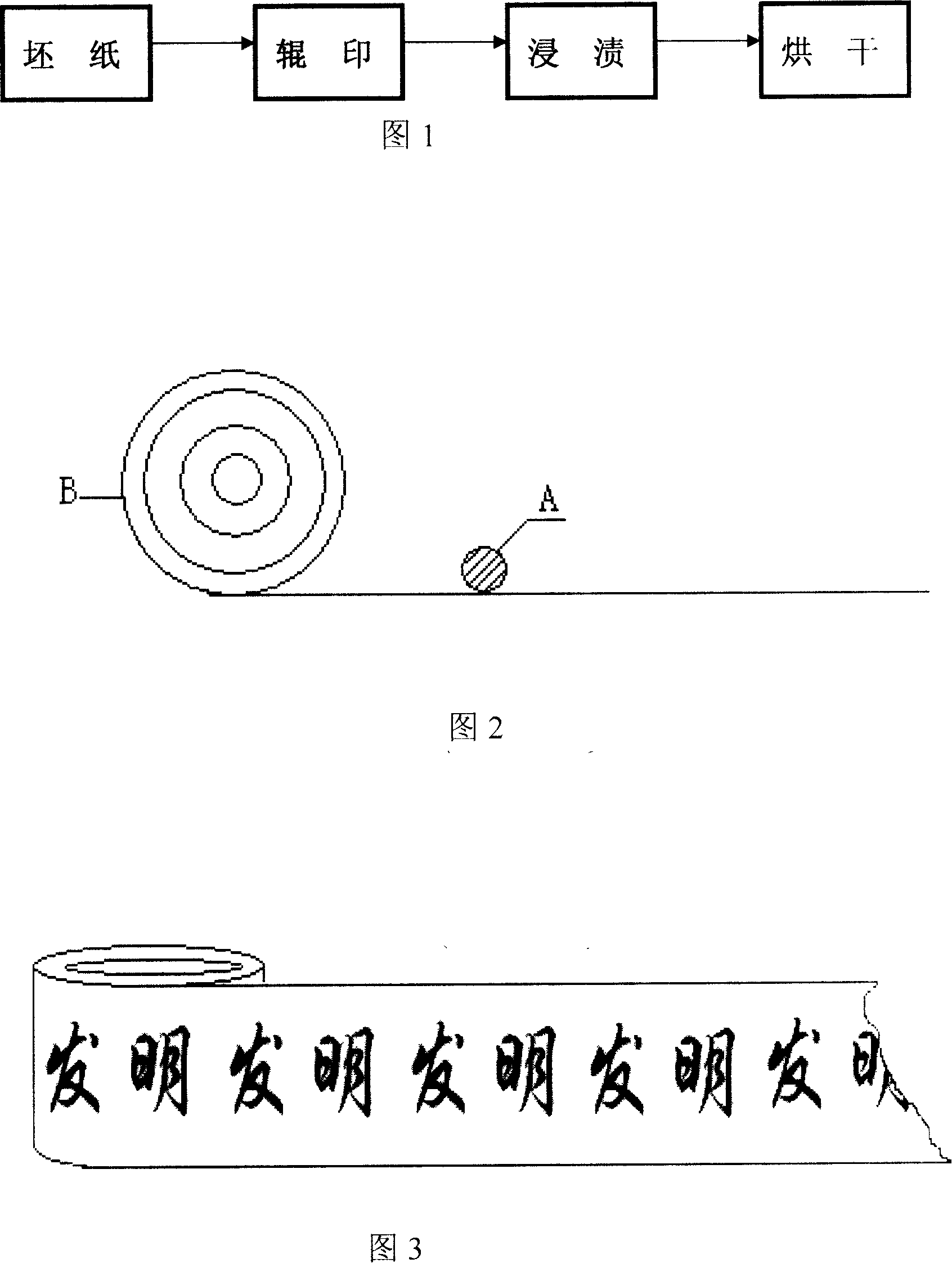

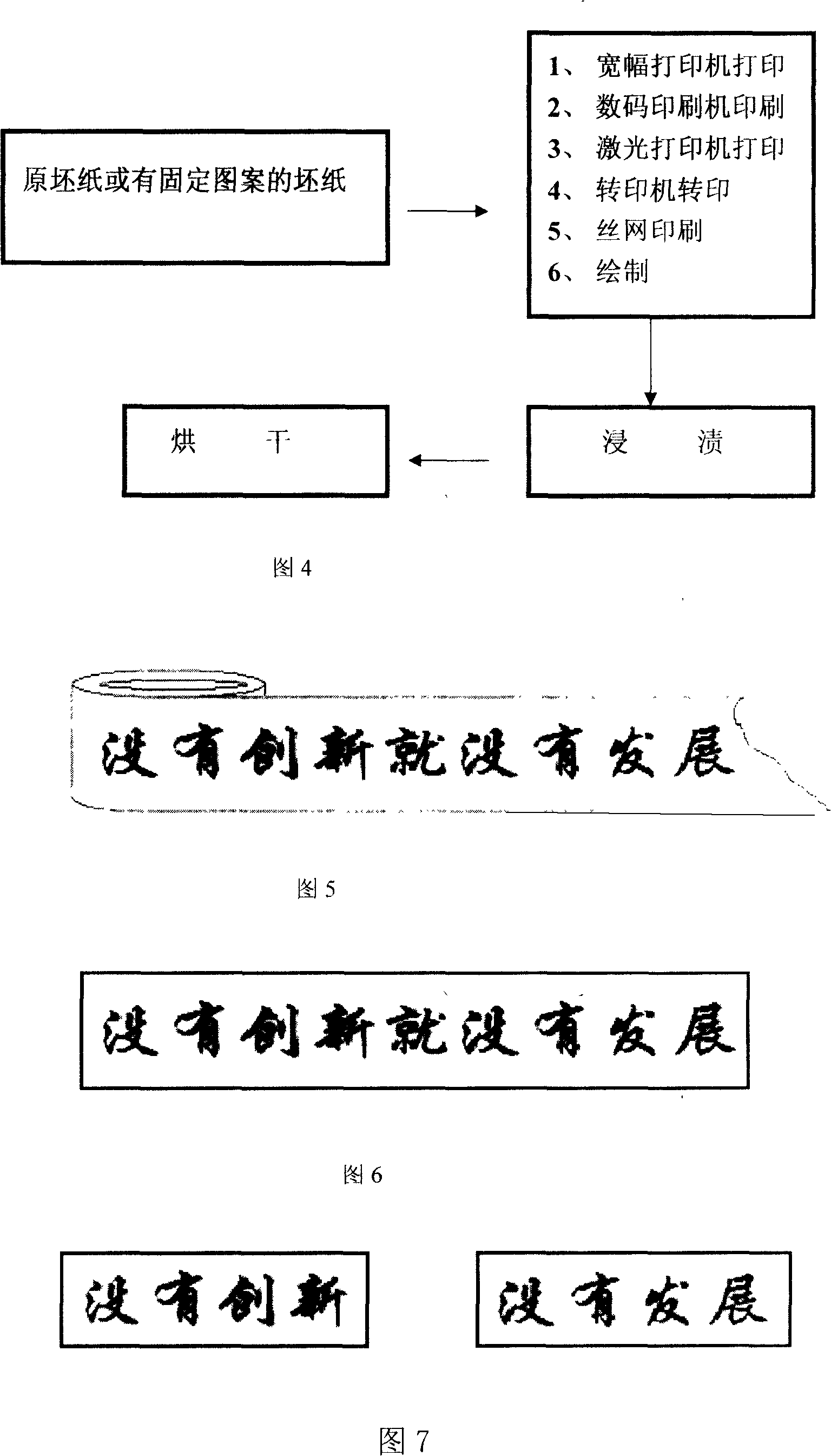

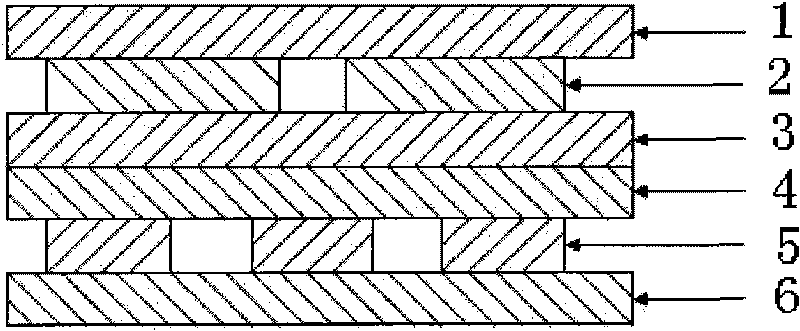

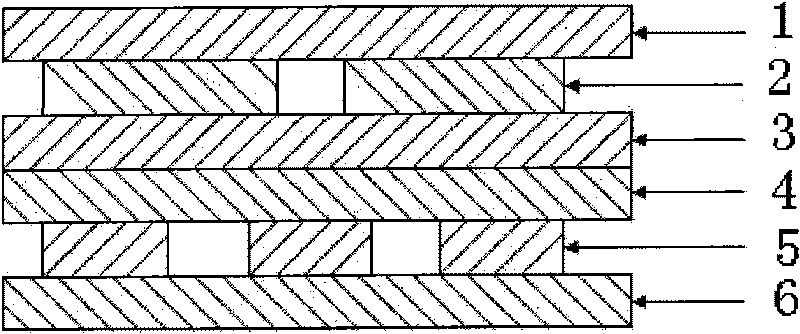

Multi-pattern melamine dipping decorative paper, manufacturing method and application thereof

InactiveCN101148848AFacilitate rearrangementEasy to combineNon-fibrous pulp additionSpecial paperMelamine resinPolyresin

The present invention is one kind of melamine dipped decoration paper with different patterns and its making process and application. The melamine dipped decoration paper with different patterns is made with a paper base of 5-5000 m length, and through printing and / or drawing to form texts and / or graphics, and dipping in urea-formaldehyde glue, melamine glue or melamine resin to form protective polymer layer. It is applied as the decoration material for furniture and artificial board.

Owner:赵国强

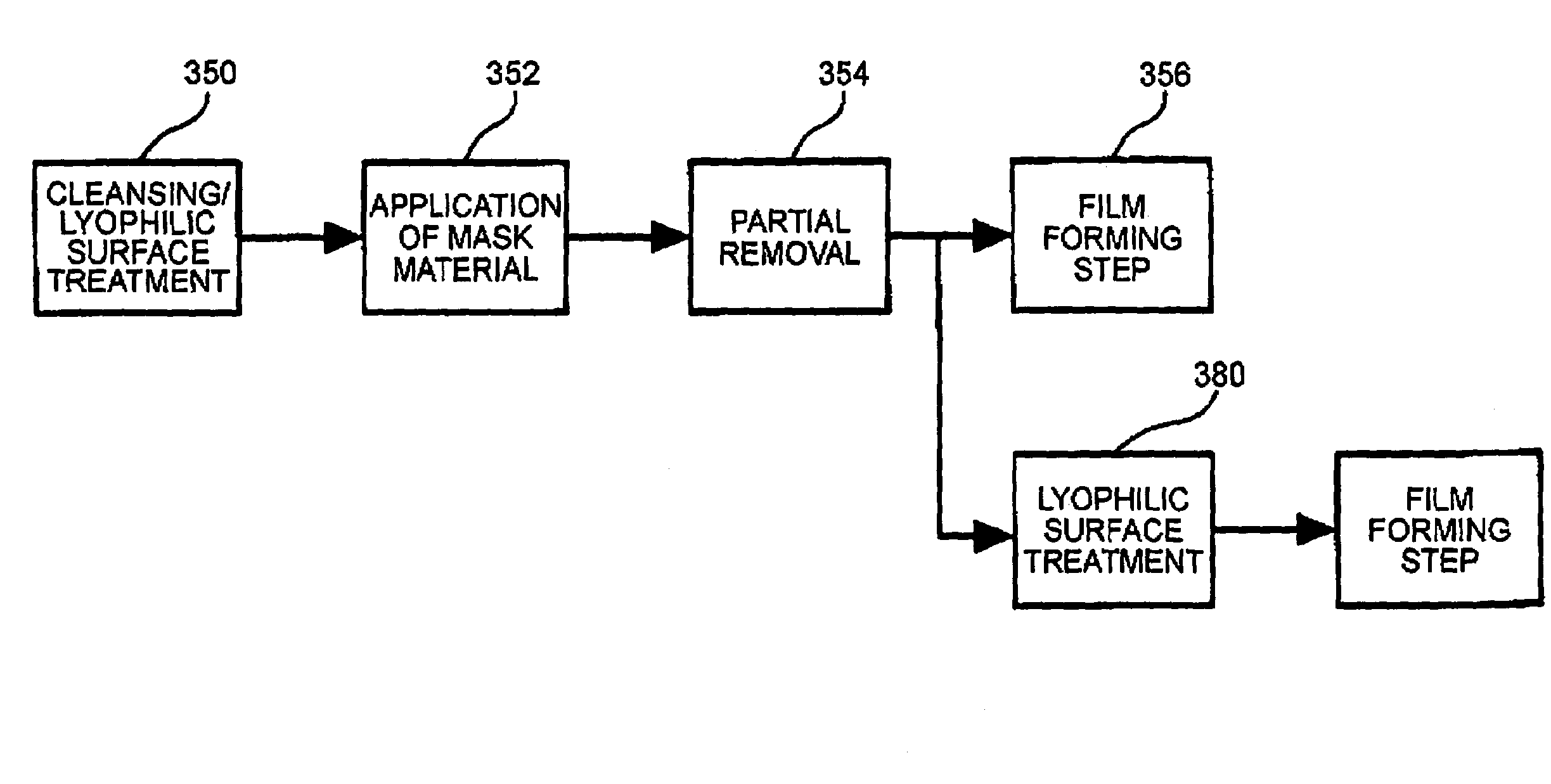

Mask forming and removing method, and semiconductor device, an electric circuit, a display module, a color filter and an emissive device manufactured by the same method

InactiveUS7148148B2Improve adhesionPattern effect is goodSemiconductor/solid-state device manufacturingSemiconductor devicesResistManufacturing cost reduction

A mask forming method that can reduce manufacturing cost is disclosed. The method forms a mask on the surface of a member to be processed in order to form a desired pattern using liquid material for patterning. The method also includes applying resist to the entire surface of the member to be processed, drying the applied resist, patterning by removing the resist in a pattern-formation area using photolithography, and heating the resist.

Owner:SEIKO EPSON CORP

Paper-aluminum-plastic composite aseptic packaging material

InactiveCN106364104ASuperior smoothnessSuperior scalabilityFlexible coversWrappersPolyolefinAluminum foil

The present invention discloses a paper-aluminum-plastic composite aseptic packaging material, which comprises an aluminum foil, wherein a first adhesion layer is coated on one surface of the aluminum foil in a film coating manner, a second adhesion layer and a polyethylene heat sealing layer are sequentially coated on the other surface of the aluminum foil in a film coating manner, a paper layer is adhered on the first adhesion layer surface away from the aluminum foil and is the paper incapable of directly providing the whiteness index and the smoothness index required by printing, and the paper layer surface away from the first adhesion layer is provided with a colored polyolefin layer. According to the present invention, the paper incapable of directly providing the whiteness index and the smoothness index required by printing is selected as the paper layer and the paper layer surface away from the first adhesion layer is provided with the colored polyolefin layer, such that the paper-aluminum-plastic composite aseptic packaging material with characteristics of breaking resistance, good printing effect and environmental protection is provided, and further has characteristics of clever idea, easy production, low production cost, and the like.

Owner:重庆市利慧包装有限公司

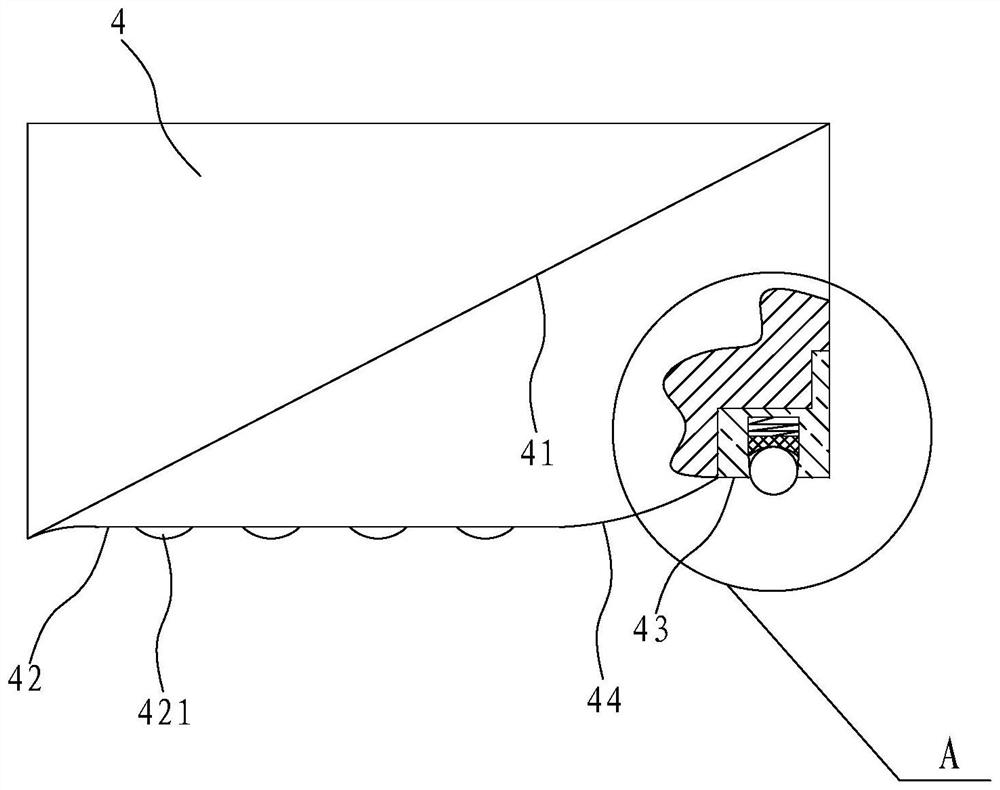

Seal marking machine

The invention discloses a seal marking machine. The machine comprises a body; the body comprises a bottom plate, a pressing plate and a magnetic attraction structure, wherein the bottom plate is usedfor placing a carrier and a seal, the pressing plate is matched with the bottom plate to press the carrier and the seal, and the magnetic attraction structure is used for limiting the transverse relative movement of the pressing plate and the bottom plate; and the upper surface of the bottom plate is provided with a working space for placing the carrier and the seal. According to the machine, theseal and carrier are pressed tightly through the seal and the carrier are tightly pressed by the pressing plate and the bottom plate so as to mark a pattern on the carrier, and the magnetic attractionstructure is arranged, so that the transverse movement of the pressing plate relative to the bottom plate is limited; and meanwhile, the pressing plate and an elastic telescopic structure can horizontally move downwards in the pressing process, so that the seal fixed on the pressing plate keeps the accurate positioning of the bottom plate, the seal can be repeatedly marked at the same position onthe carrier, meanwhile, the machine is adapted to the seals with different thicknesses, the seal is stressed uniformly, the printed patterns are complete and uniform, and the pattern is more attractive; and the machine is simple in structure, small in size, easy to operate, convenient to carry, low in manufacturing cost and suitable for any people.

Owner:PARRIC NINGBO STATIONERY & GIFTS MFG

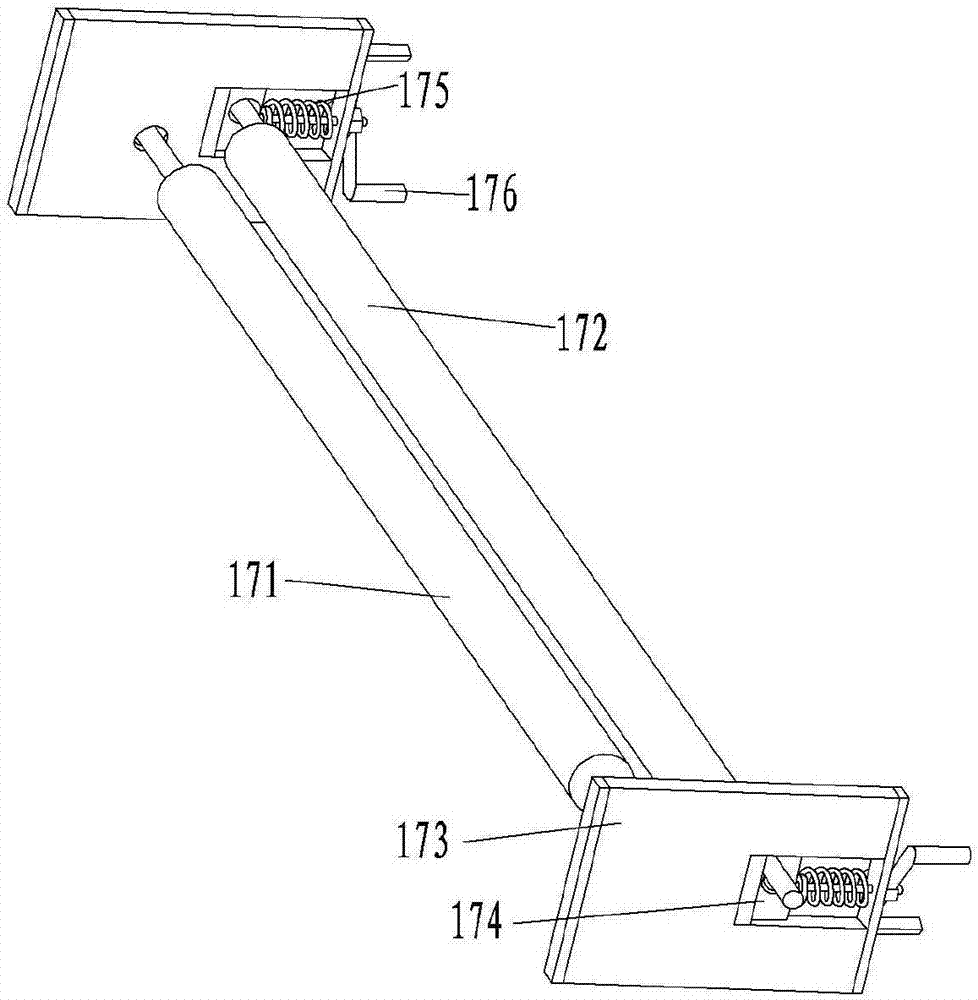

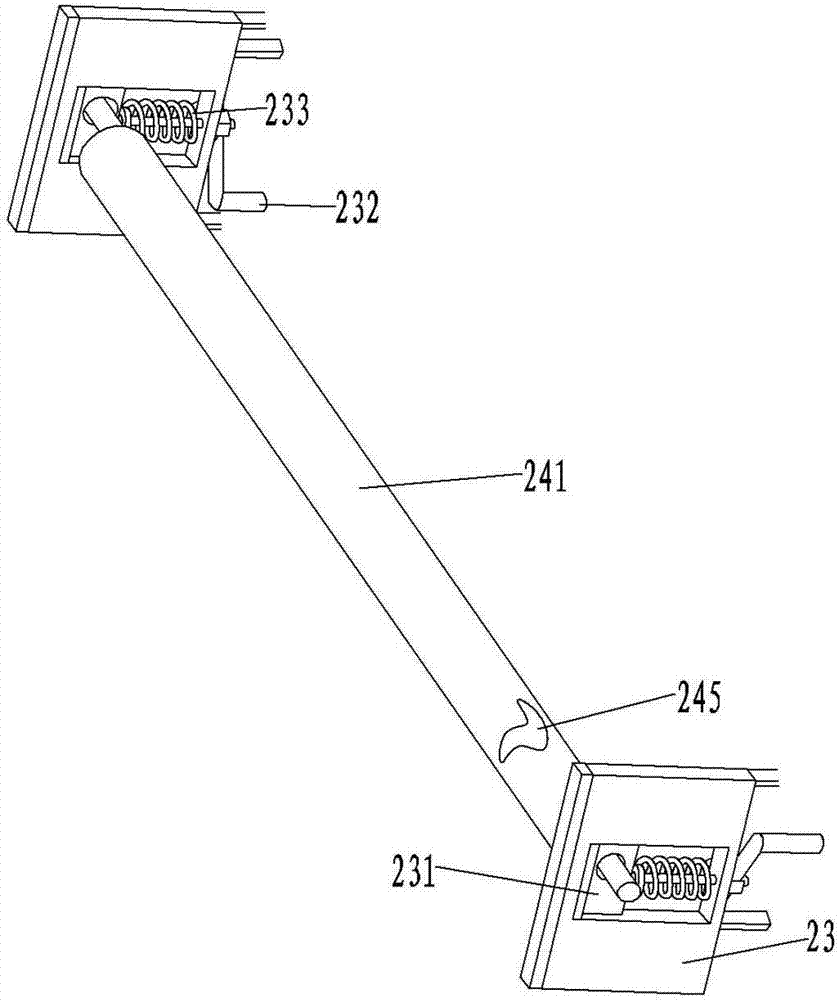

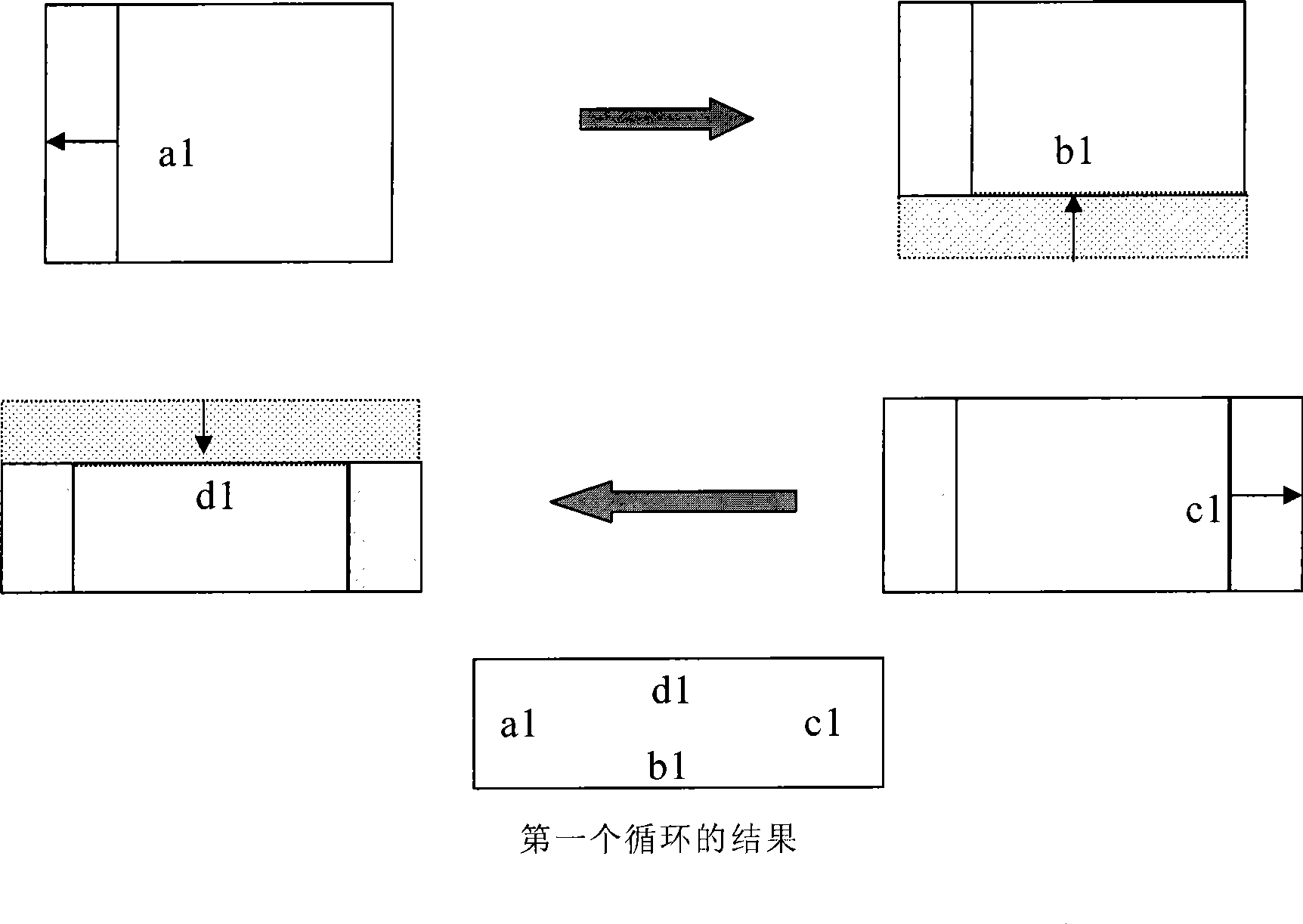

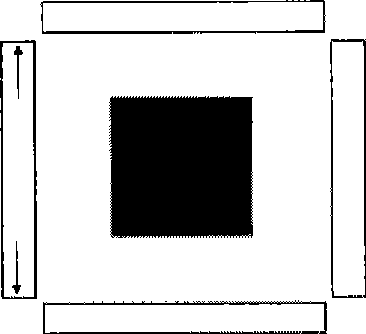

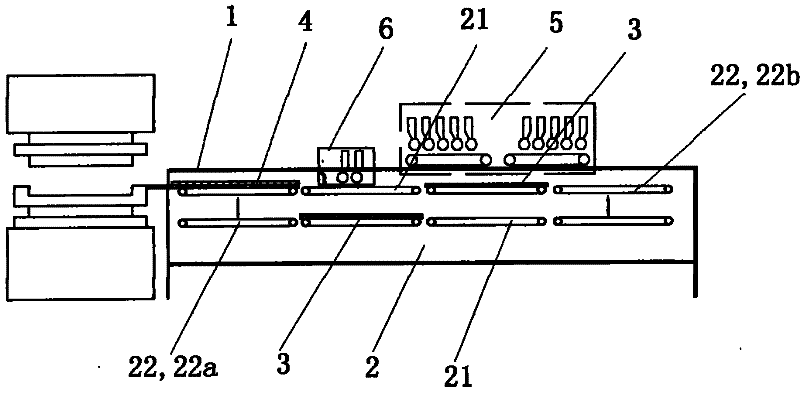

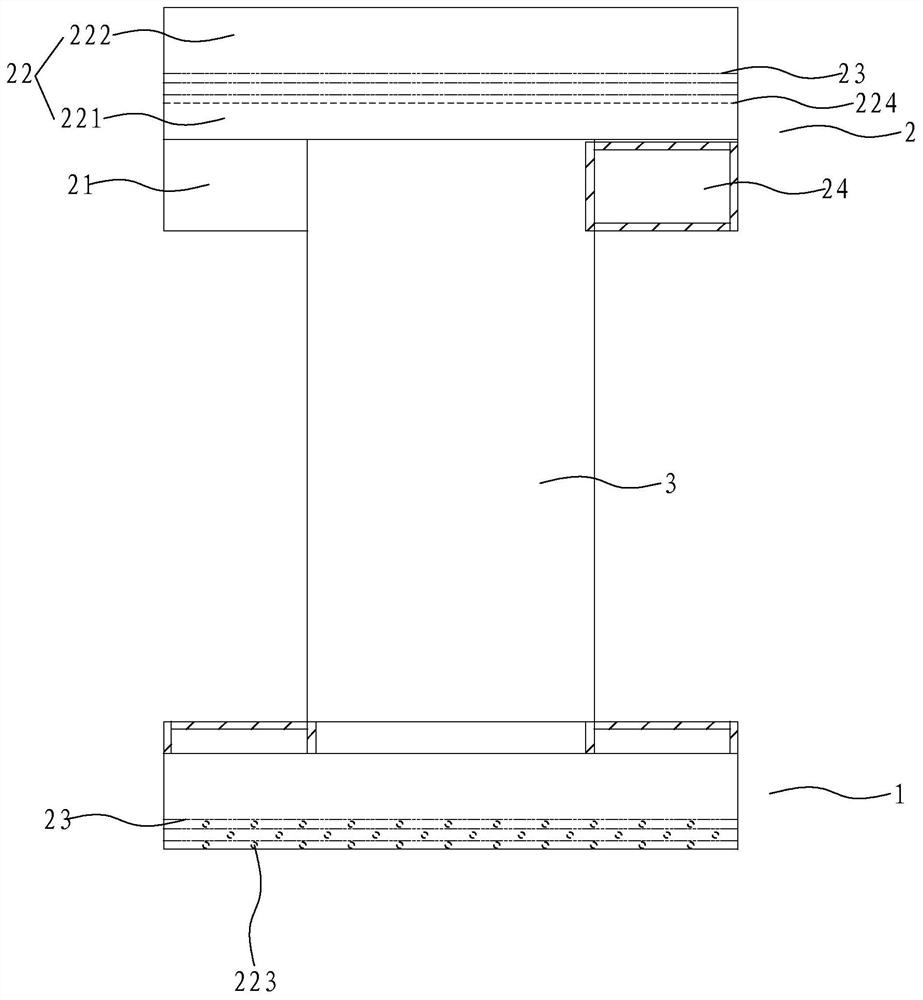

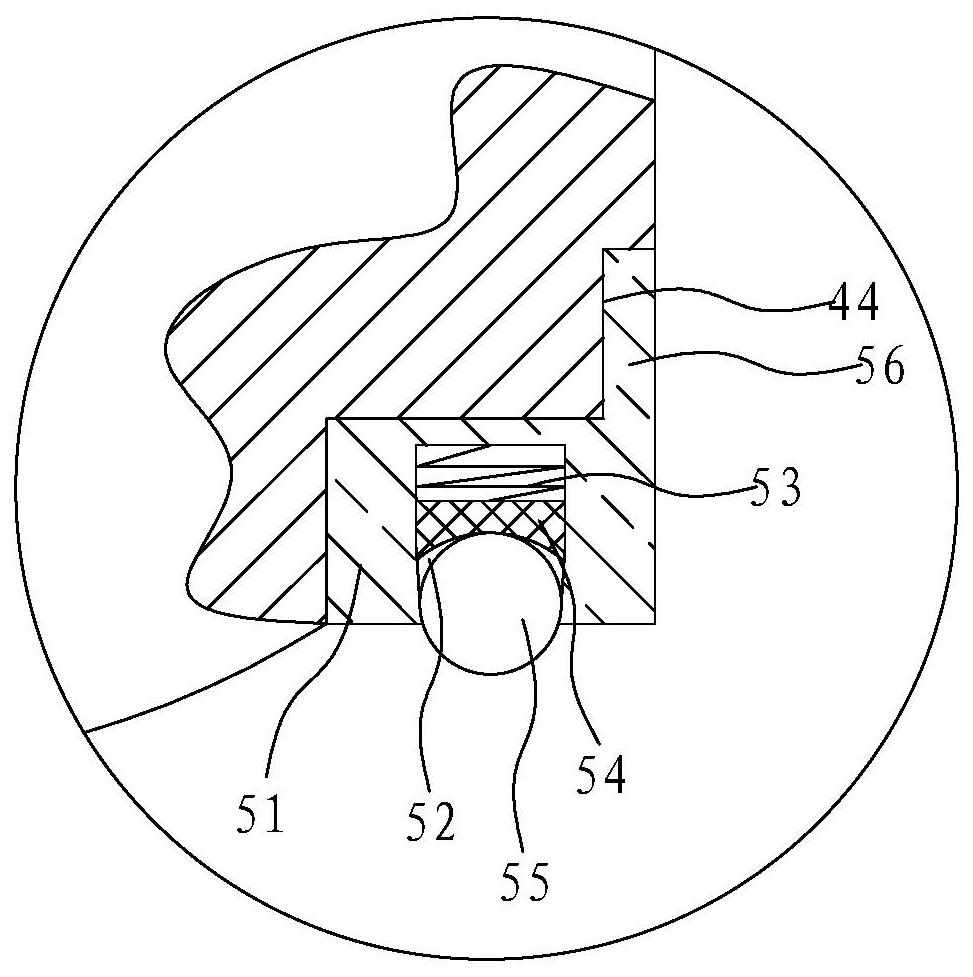

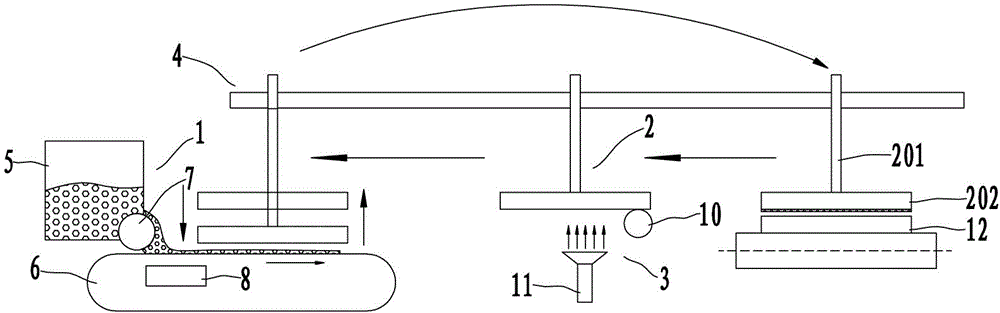

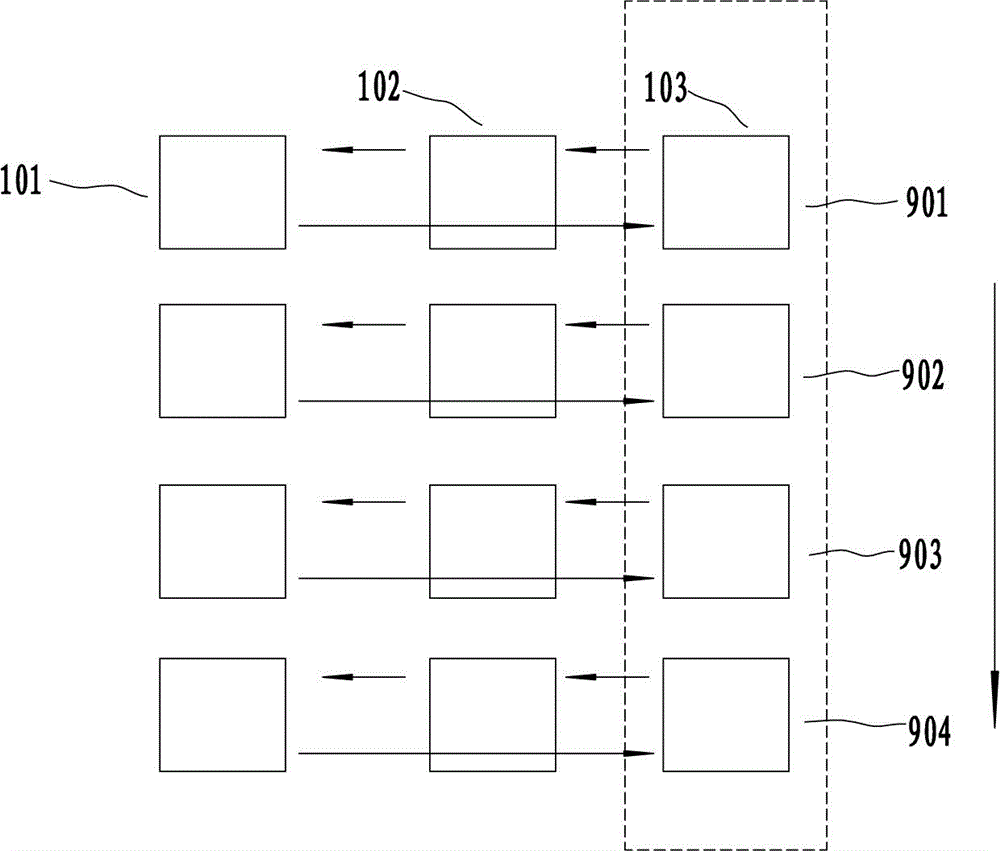

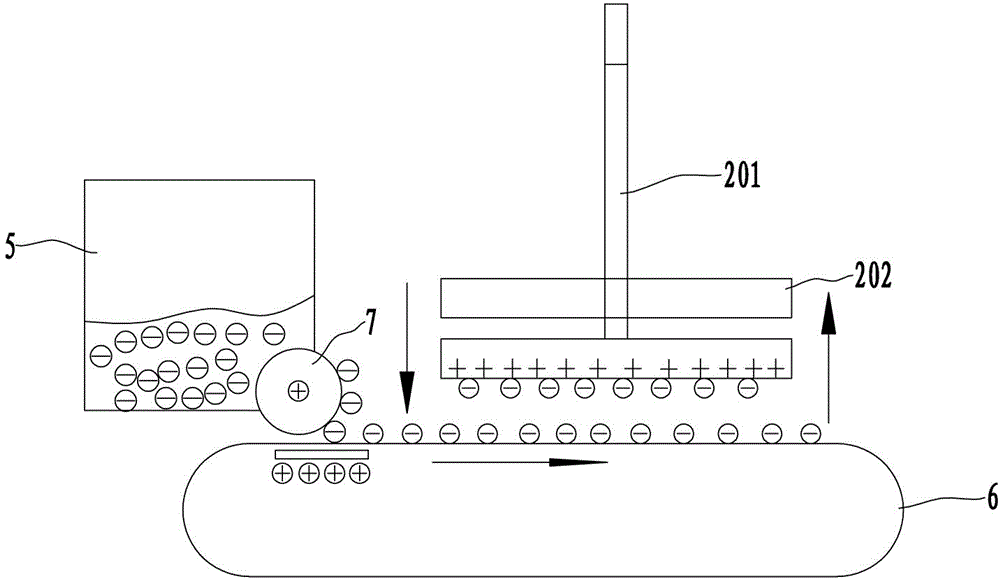

Circulating feeding system for producing ceramic wall and flow tiles

InactiveCN102229190AAchieve synchronous completionPattern effect is goodShaping conveyorsEngineeringDelivery system

The invention discloses a circulating cloth system for producing ceramic wall and flow tiles. The system comprises a rack, a delivery device, a supporting plate, a feeding device, a feeding station device and a supplementary material striking device; the delivery device comprises a horizontal delivery platform with an upper layer and a lower layer; the front end and rear end of the horizontal delivery platform are respectively provided with a liftable vertical delivery platform; and the horizontal delivery platform and the vertical delivery platforms form an enclosed circulating delivery device. Because a delivery system which is formed by the horizontal delivery platform and the vertical delivery platforms and the feeding device which is arranged above a front vertical lifting platform close to one end of a press are organically combined, and the synchronization implementation of multiple working procedures of feeding is realized, not only can the production efficiency be improved, but also the produced wall and floor tiles have abundant pattern effects.

Owner:FOSHAN DONGCHENGHUI TECH HLDG

Production method of heat transfer film imitating solid wood

ActiveCN101722781AProduction advantageLow curing temperatureDecorative surface effectsPretreated surfacesInformation layerSolid wood

The invention relates to a production method of a heat transfer film imitating solid wood, comprising the following steps of: (1) partially processing a carrier film in a coating way by using bi-component resin so as to obtain a partial processing layer, and forming solid wood pore patterns on the carrier film; (2) placing the film obtained in the step (1) into a drying oven at 60 DEG C-80 DEG C for curing for 24-48 hours; (3) sequentially coating a releasing layer and a protecting layer on the partial processing layer of the film obtained in the step (2); (4) printing an information layer onone surface of the protecting layer; and (5) coating a bonding layer on the information layer so as to obtain the heat transfer film imitating the solid wood. Compared with the prior art, the invention has less production procedure, convenient production, good transferring effect, and the like.

Owner:上海华工艾马尔新材料有限公司

UV curable offset printing scale ink for gold and silver cardboards

The invention discloses UV curable offset printing scale ink for gold and silver cardboards. The UV curable offset printing scale ink comprises the following ingredients (by weight): 33-37% of aldehyde ketone modified acrylate UV resin, 18-22% of bis-functional polyester acrylate UV resin, 7-12% of trimethylolpropane triacrylate, 1.5-2.5% of a cracked photoinitiator, 2.5-3.5% of a hydrogen abstracting type photoinitiator, 6.5-7.5% of an amine photoinitiator, 18-21% of wax and 3.3-4.7% of an auxiliary agent. The prepared one-component UV curable offset printing scale ink is solvent-free when in use, releases no toxic gas, is environment friendly and pollution-free, has characteristics of clear figure after curing, even coloring, good adhesion, fast curing speed and good fluidity, and can meet requirements of decorative ink.

Owner:广州市佳盛印刷有限公司

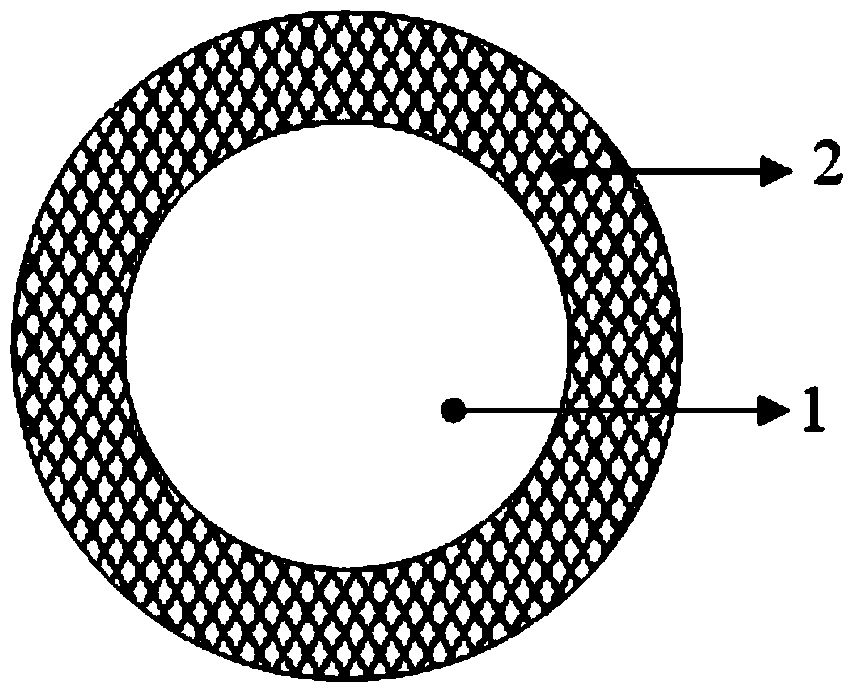

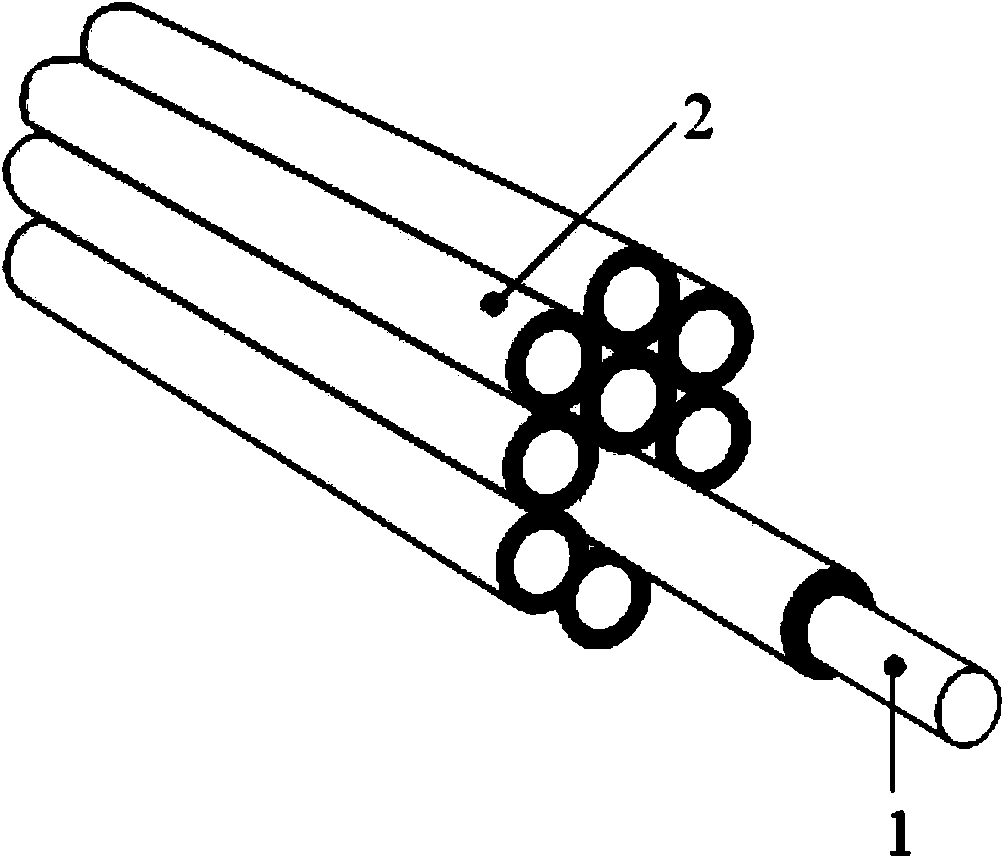

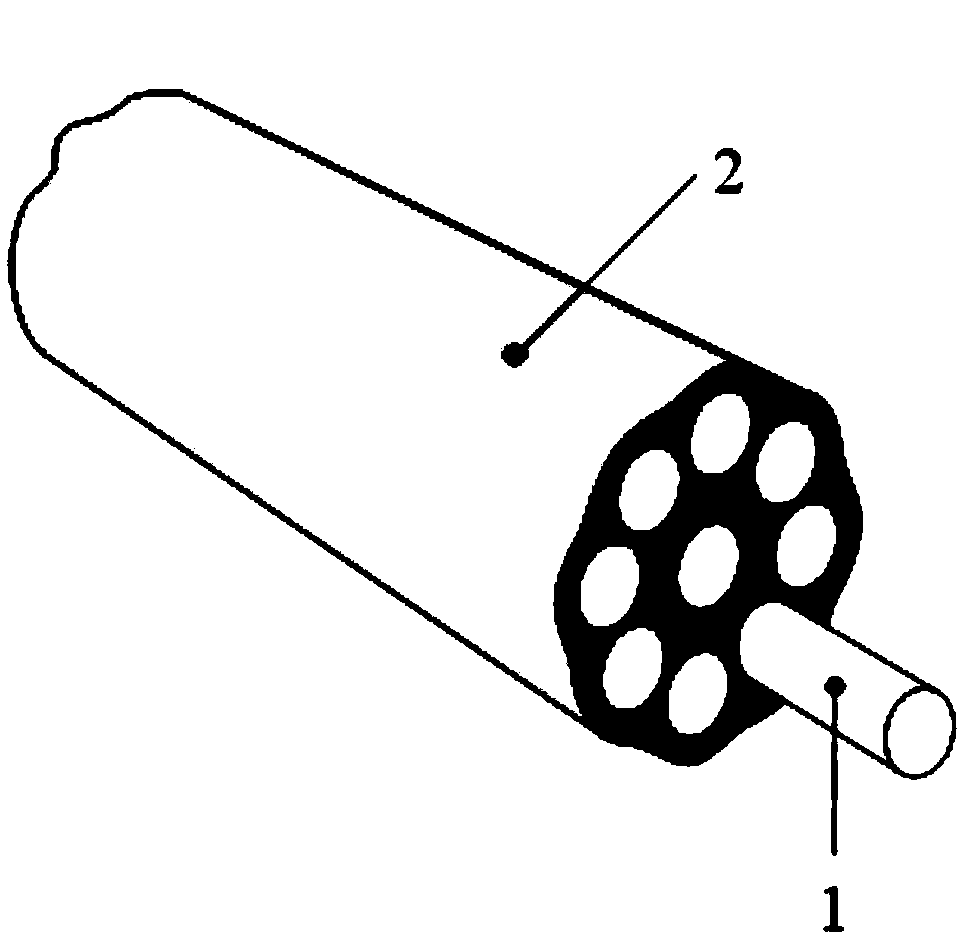

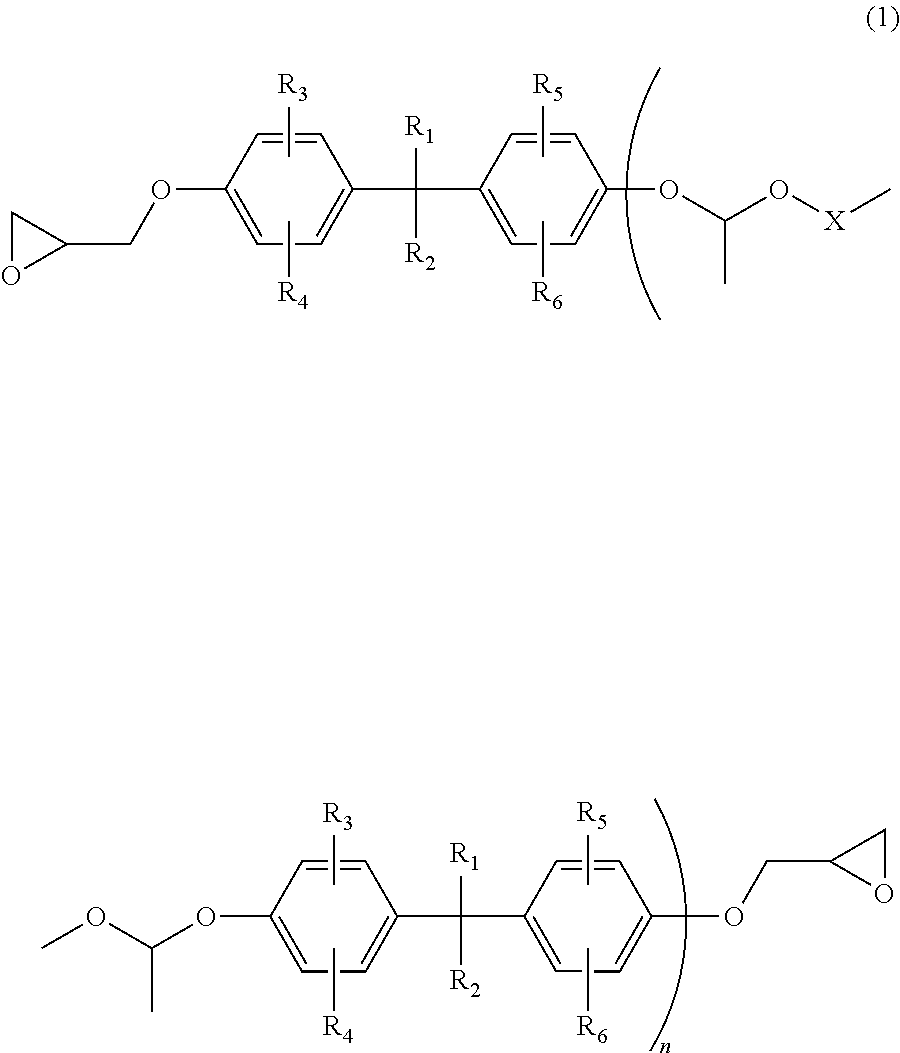

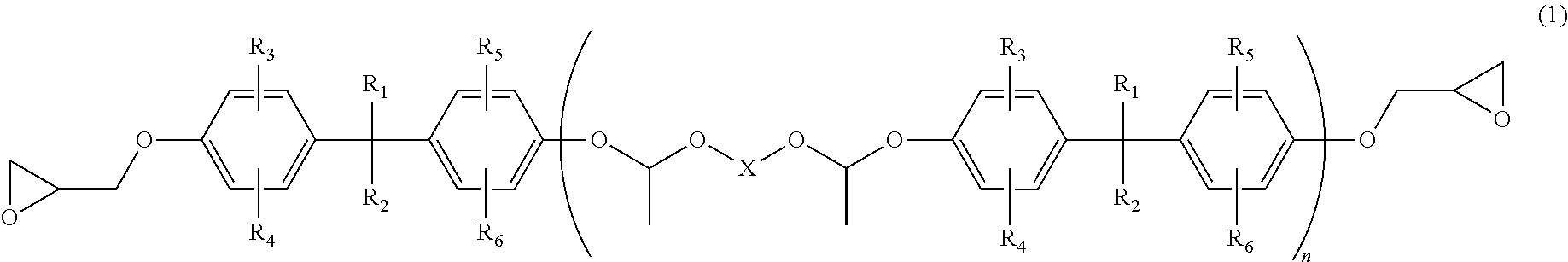

Optical waveguide forming epoxy resin composition, curable film formed from the epoxy resin composition for formation of optical waveguide, and light transmission flexible printed board

ActiveUS20130236149A1Increase temperatureIncrease flexibilityCladded optical fibrePhotosensitive materialsEpoxyBromine

An excellent optical waveguide forming epoxy resin composition is provided, comprising:(A) a liquid epoxy resin;(B) a solid resin; and(C) a photoacid generator;wherein the liquid epoxy resin (A) comprises a liquid epoxy resin represented by the following general formula (1) as a major component thereof in a proportion of 50 to 80 wt % based on an overall amount of a resin component of the resin composition:wherein R1 and R2 are each a hydrogen atom or a methyl group; R3 to R6 are each a hydrogen atom, a methyl group, a chlorine atom or a bromine atom; X is a C2 to C15 alkylene group, an ethyleneoxy group, a di(ethyleneoxy) group, a tri(ethyleneoxy) group, a propyleneoxy group, a propyleneoxypropyl group, a di(propyleneoxy) propyl group or a tri(propyleneoxy)propyl group; and n is a natural number and has an average value of 1.2 to 5.

Owner:NITTO DENKO CORP

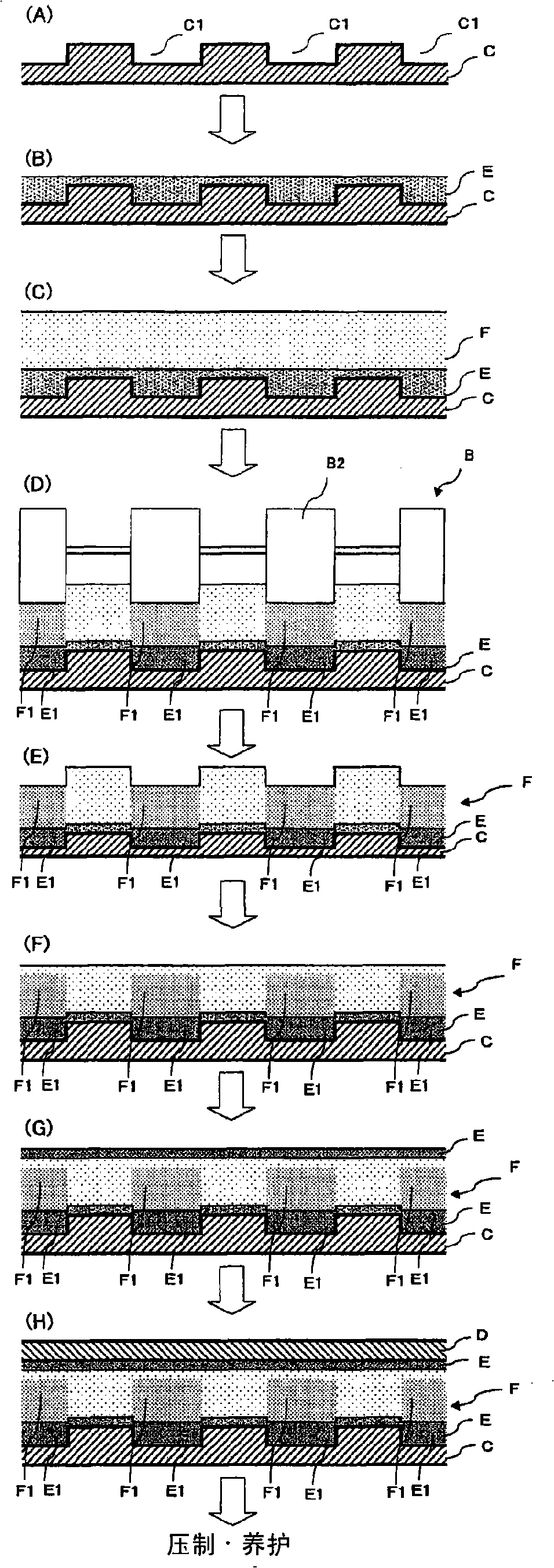

Wood cement board

ActiveCN101550743AAvoid crackingIncrease inhalationConstruction materialSolid waste managementCement boardMaterials science

Provided is a wood cement board that has a pattern of acute-angled and deep recesses and projections on its surface, and that tends not to cause cracking during a hardening and curing process, a drying process, a transportation process and so on. The wood cement board has a pattern of recesses and projections on its surface, in which the distance from the apex of the projections to the rear face is 9 mm or more, and the distance from the apex of the projections to the base point of the recesses is 2 mm or more, and is equal to or less than half the distance from the apex of the projections to the rear face. The average specific gravity of the wood cement board as a whole, and the specific gravities of the projections and the recesses are each 1.1 or more, and the difference between the specific gravity of the projections and the specific gravity of the recesses is less than 0.1.

Owner:NICHIHA CORP

Liquid shell powder coating as well as preparation method thereof

The invention discloses a liquid shell powder coating as well as a preparation method thereof, and relates to the technical field of building coatings. The coating is prepared from the following raw materials: 31.5 to 40.6 parts of sizing agent, 25 to 39 parts of filler, 13.3 to 18.4 parts of assistant, 0.6 to 1.3 parts of modifier and 10 to 15 parts of diluent A. The preparation method comprises the following steps: S1, preparing the sizing agent; S2, adding the filler into the sizing agent, and stirring to obtain a base material; S3, adding the assistant into the base material, and stirring to obtain a coating; S4, mixing the diluent A and the modifier to obtain a diluted modifier, adding the diluted modifier into the coating, and stirring to obtain a finished product. The coating has the advantages of rich color like that of emulsion paint, pattern effect like that of wall paper, environmental friendliness, decoration property, environmental friendliness like that of diatom ooze, low requirement on construction technology, convenience in construction, low cost, construction can be implemented without professional technicians, and an ideal pattern effect can be achieved.

Owner:秦皇岛美博士新型材料科技有限公司

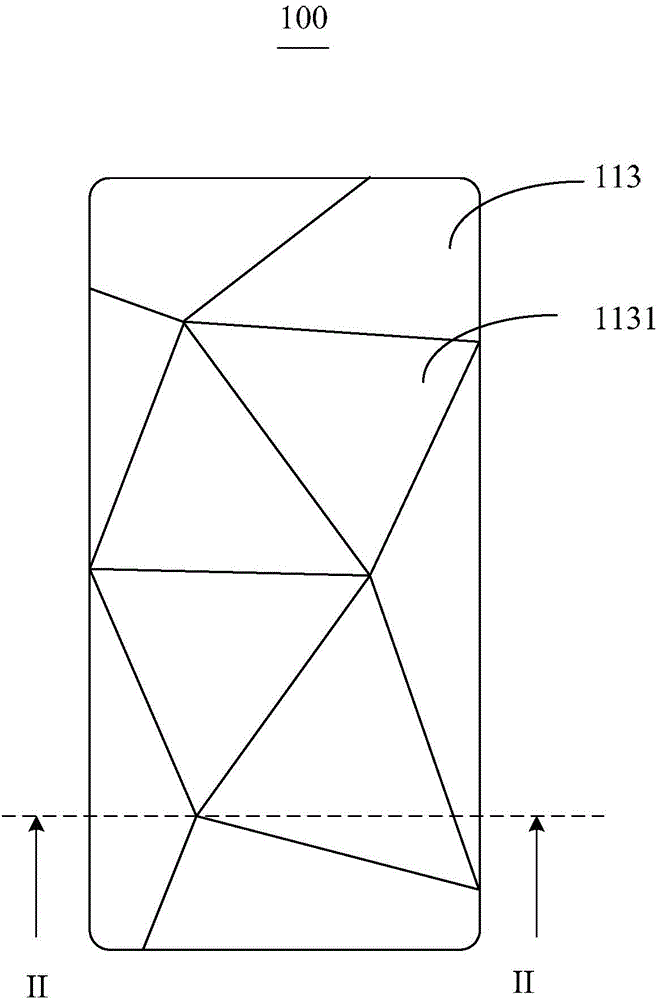

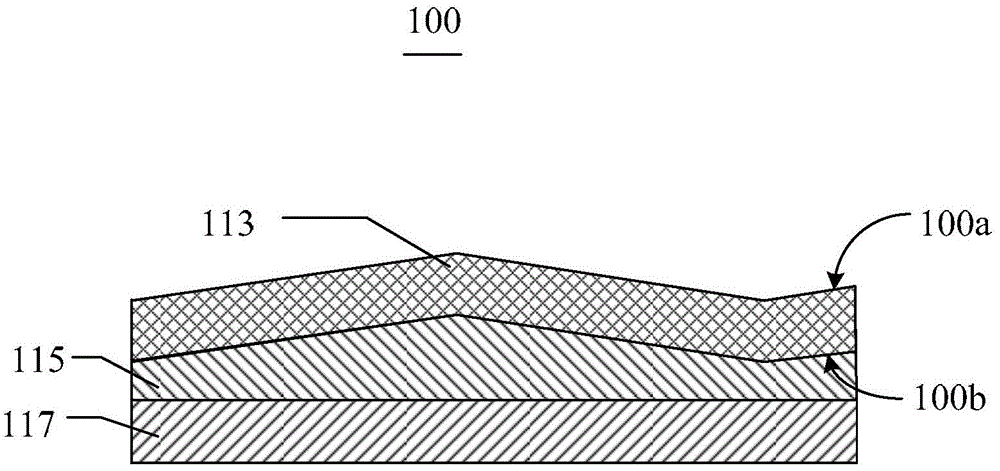

Shell, electronic device and manufacture method of shell

ActiveCN104540354AImprove user experienceImprove experienceCasings/cabinets/drawers detailsEngineeringFilm-coated tablet

The invention provides a shell, an electronic device and a manufacture method of the shell. The shell comprises a first surface and a second surface, wherein the first surface and the second surface are oppositely arranged; a three-dimensional pattern is formed on the first surface; a film coting layer and a silk printing layer are successively arranged on the second surface; and the film coating layer is arranged between the silk printing layer and the second surface, wherein the three-dimensional pattern and the shell are in integral forming. User experience can be improved by the shell.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Polymerizable composition, color filter, and method of producing the same, solid-state imaging device, and planographic printing plate precursor, and novel compound

InactiveUS20120176571A1High sensitivityImprove curing effectLiquid crystal compositionsOrganic chemistrySolid-statePhotochemistry

Disclosed is a photopolymerizable composition which contains a photopolymerization initiator (A) that has a partial structure represented by the following Formula (1) and a polymerizable compound (B). In General formula (1), R3 and R4 each independently represents a hydrogen atom, an alkyl group, an alkenyl group, an alkynyl group, an aryl group, a heteroaryl group or an alkoxy group; R3 and R4 may form a ring with each other; and X represents OR5, SR6, or NR17R18. The photopolymerizable composition is capable of forming a cured film that has high sensitivity, excellent intra-membrane curability and excellent adhesion to a support. The cured film is able to maintain a patterned shape even during post-heating after development and has good pattern formability, while coloring due to heating with passage of time being suppressed.

Owner:FUJIFILM CORP

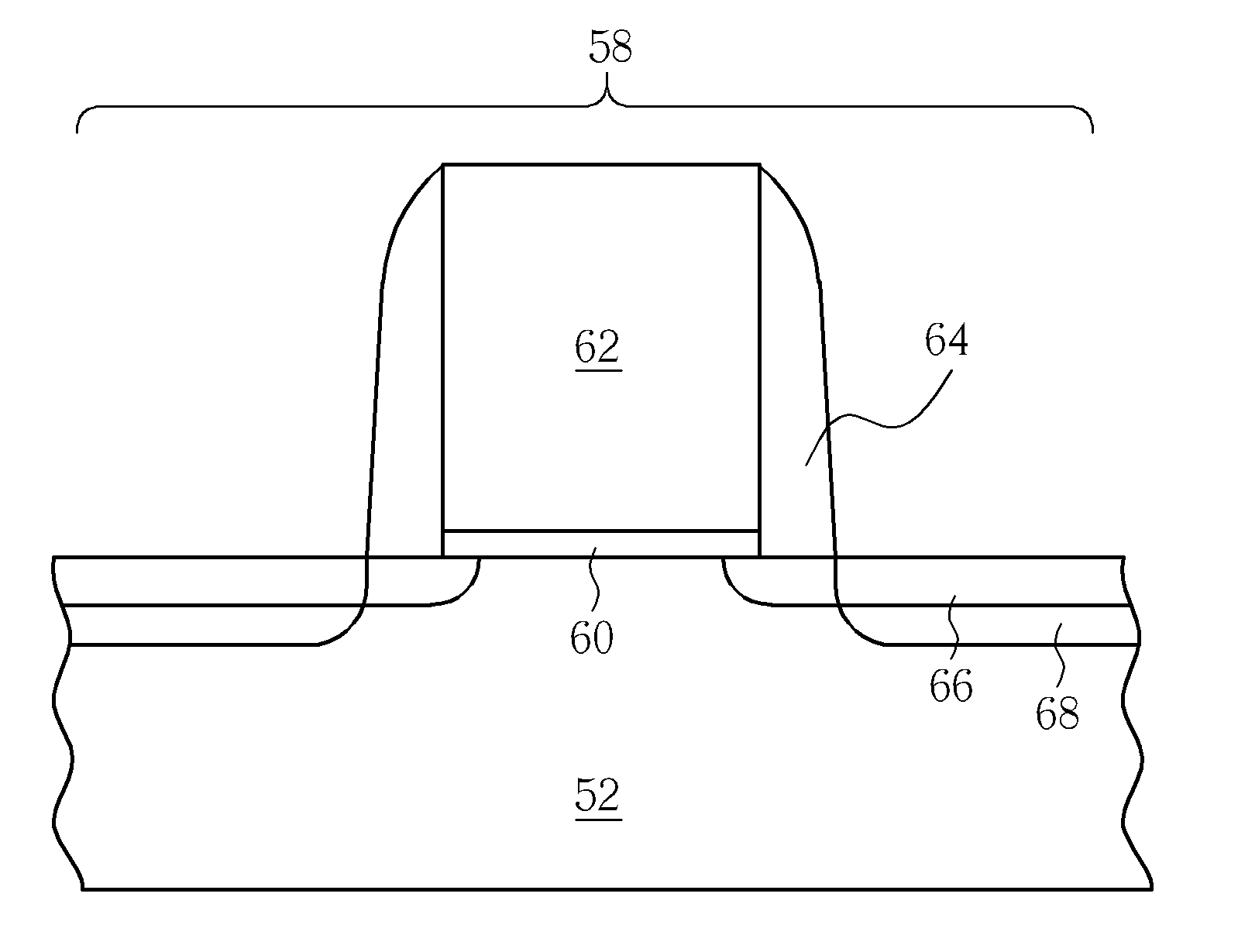

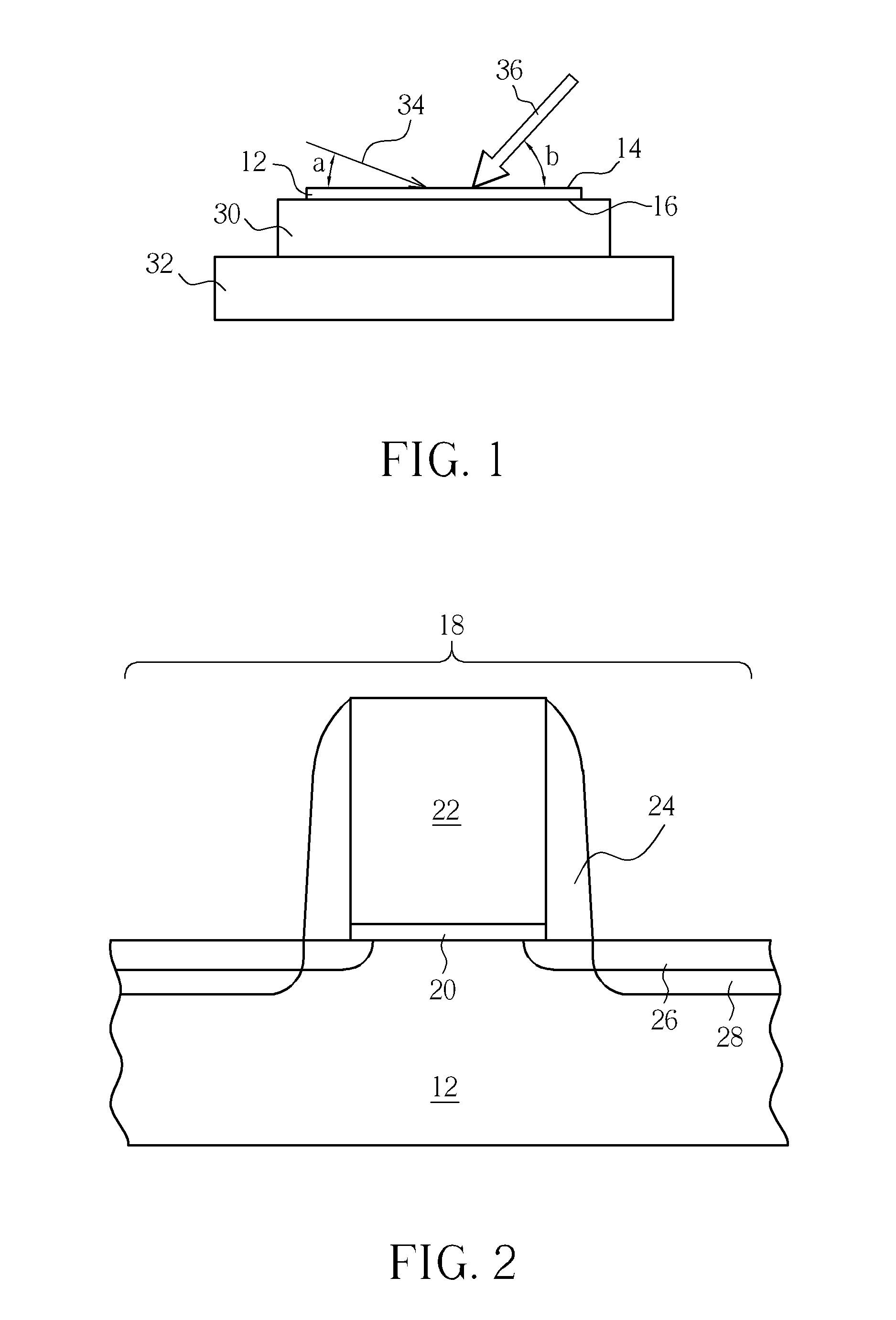

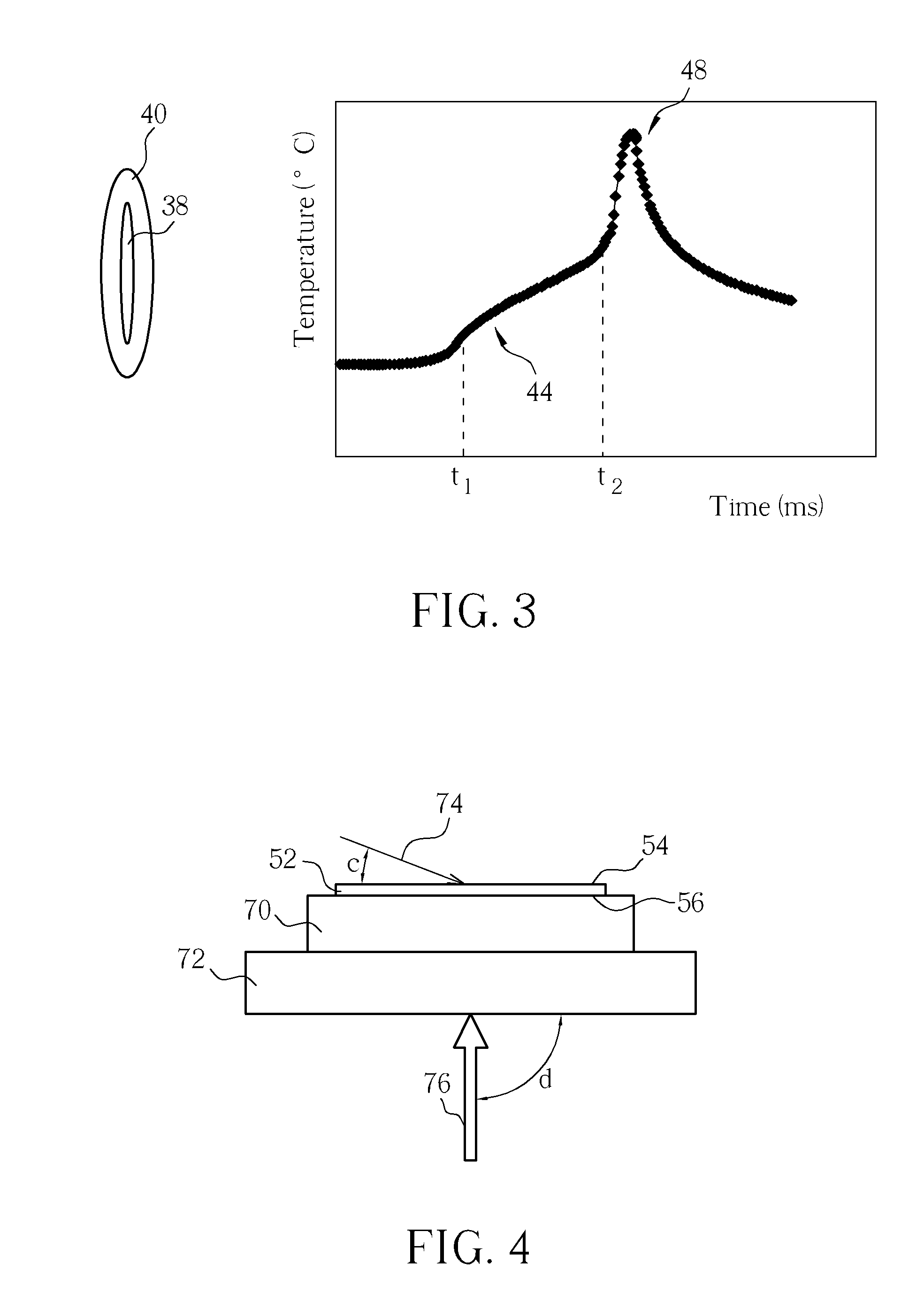

Thermal process

InactiveUS20110177665A1Shortens overall fabrication cycle timeImprove pattern effectTransistorSemiconductor/solid-state device manufacturingEnergy densityEngineering

A thermal process is disclosed. The thermal process preferably includes the steps of: providing a semiconductor substrate ready to be heated; and utilizing at least a first heating beam and a second heating beam with different energy density to heat the semiconductor substrate simultaneously. Accordingly, the present invention no only eliminates the need of switching between two different thermal processing equipments and shortens the overall fabrication cycle time, but also improves the pattern effect caused by the conventional front side heating.

Owner:UNITED MICROELECTRONICS CORP

Ink jet pattern seeping marble tile

ActiveCN106007662AReduce hygroscopic swellingSolution to short lifeClaywaresWear resistantWear resistance

The invention discloses an ink jet pattern seeping marble tile, which consists of a blank body and enamel seeped into the blank body, and is formed by firing a ceramic raw blank containing a nanometer stabilizing agent and the enamel layer containing a nanometer seeping aid, pattern seeping enamel and a nanometer color former. The color and the patterns of the ink jet pattern seeping marble tile are generated in a position being 1.5 to 2.0mm inside the ceramic blank body; the veins are clear; the colors are rich; the patterns are complete; the pattern effect is good; meanwhile, the surface wear-resistant performance of the ceramic tile is good; the anti-stain performance is good, so that the decoration and application effects are very good; the production steps are simple; the manufacturing cost is low.

Owner:四川省新万兴瓷业有限公司

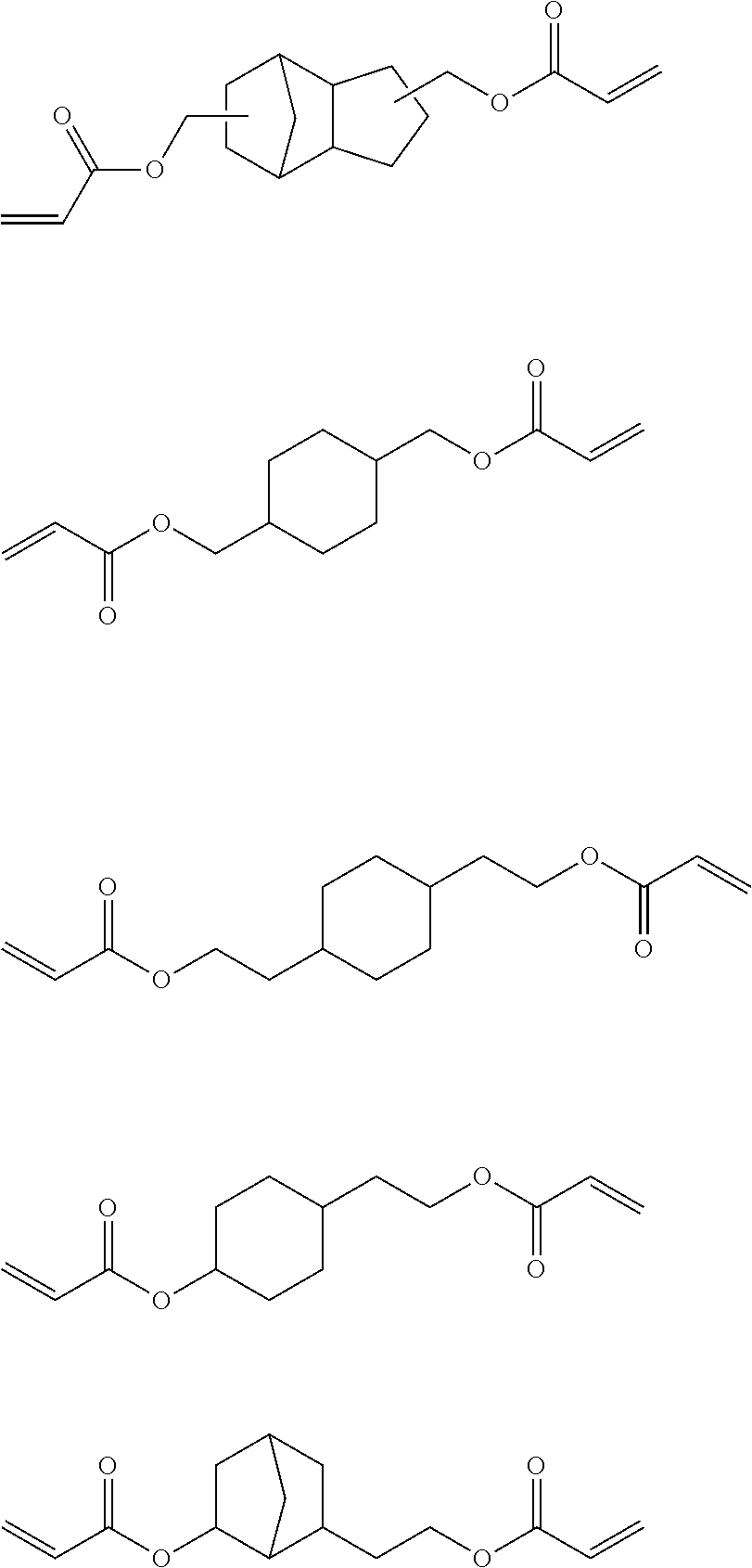

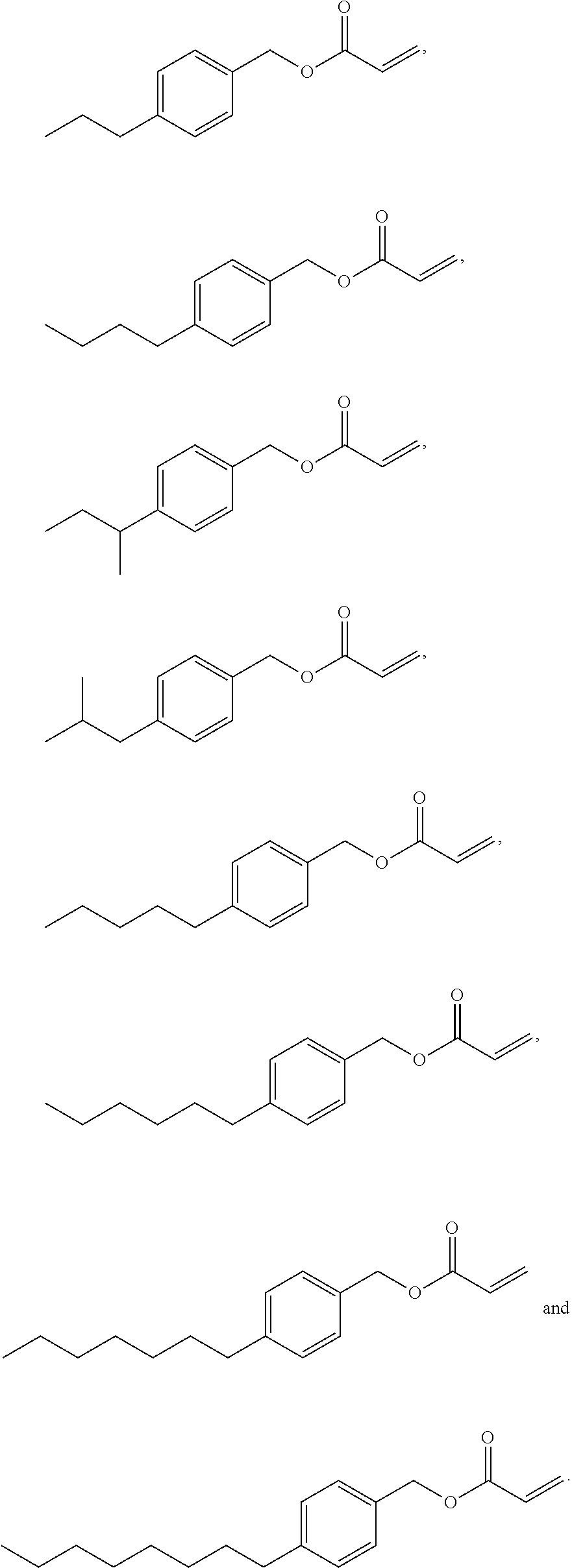

Curable composition for imprints, patterning method and pattern

Provided is a curable composition for imprints having good patternability and dry etching resistance. Disclosed is a curable composition for imprints comprising at least one kind of polymerizable monomer selected from the following compounds and a photopolymerization initiator;

Owner:FUJIFILM CORP

Optical waveguide photosensitive resin composition, photocurable film for forming optical waveguide core layer, optical waveguide using same, and mixed flexible printed circuit board for optical/electrical transmission

ActiveUS20160252655A1High transparencySatisfactory R-to-R compatibilityCircuit optical detailsPhotosensitive materials for photomechanical apparatusSide chainWaveguide

An optical waveguide photosensitive resin composition containing an aliphatic resin having a polymerizable substituent and a photopolymerization initiator, in which the aliphatic resin having the polymerizable substituent is formed of a side-chain polyfunctional aliphatic resin (A) and a bifunctional long-chain aliphatic resin (B), is provided. Accordingly, the composition brings together high transparency, satisfactory roll-to-roll compatibility, and a high resolution patterning property, and has excellent reflow resistance. Therefore, the composition is useful as a material for forming an optical waveguide, especially a core layer-forming material.

Owner:NITTO DENKO CORP

Anti-tightening pull-ups and manufacturing process thereof

ActiveCN111603314ANot easy to produce large areas of strangulationHigh expressionAbsorbent padsBaby linensMechanical engineeringRubber band

The invention relates to the field of disposable hygienic products, in particular to anti-tightening pull-ups. The anti-tightening pull-ups comprise a front waistline, a rear waistline and an absorption main body. The rear waistline comprises a base material layer; the upper end of the base material layer extends out of the absorption main body to form an extension part; the extension part is provided with a plurality of rubber bands along the width direction; elastic sheets are arranged at the left end and the right end of the absorption main body on the base material layer respectively; theelastic sheets extend to cover the two sides of the absorption main body and are bonded with the absorption main body; the portions, covering the absorption main body, of the elastic sheets achieve elasticity loss in a spot breaking mode, spot breaking areas are formed at the spot breaking portions; and the sides, away from the absorption main body, of the elastic sheets are bonded with the base material layer. The technical problems that in the prior art, the waistline of a pair of three-piece pull-ups needs to be subjected to rubber band breaking, consequently, perforation and wrinkling areirregular, and the appearance presentation degree is poor are solved. Correspondingly, the invention further provides a manufacturing process of the anti-tightening pull-ups.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Ceramic laser material distribution method and ceramic laser printing material distribution device

The invention provides a ceramic laser material distribution method and a corresponding material distribution device. The method comprises the following steps of arranging more than two ceramic pattern material distribution working stations which are sequentially connected, wherein when the material is distributed on each ceramic pattern material distribution working station, irradiating laser to the light sensitive surface of an electriferous powder material distribution device which is used for sucking powder material, so as to form a ceramic pattern; subsequently, enabling the powder material distribution device to suck the powder material; after the powder material is sucked, enabling the powder material distribution device to distribute the material onto a ceramic tile blank, and releasing the powder absorbed on the light sensitive surface onto the ceramic tile blank; after the material is distributed, enabling the powder material distribution device to return, and repeating the material distribution action of the previous working station on the next ceramic tile; meanwhile, when the material is distributed on the next adjacent ceramic pattern material distribution working station, repeating the action. Compared with the prior art, the method has the advantages that the ceramic laser printing type material distribution method is adopted, so the quality of the ceramic tile product and the pattern effect are obviously improved, and the obvious economic benefit is realized.

Owner:清远市升华建陶有限公司

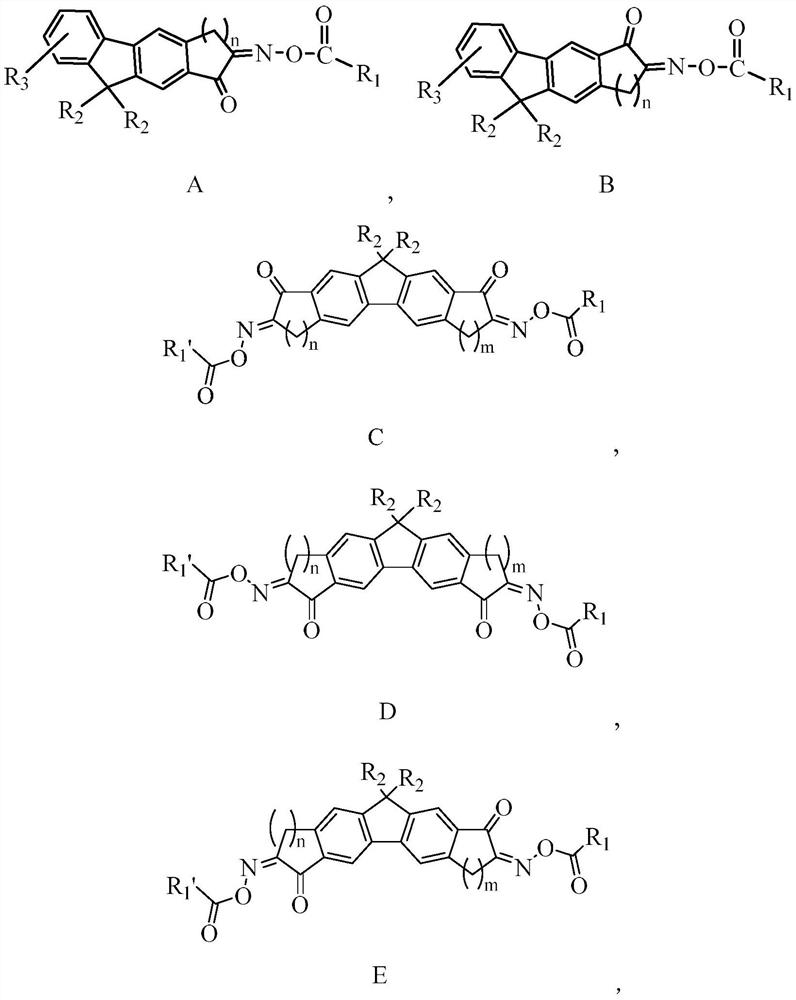

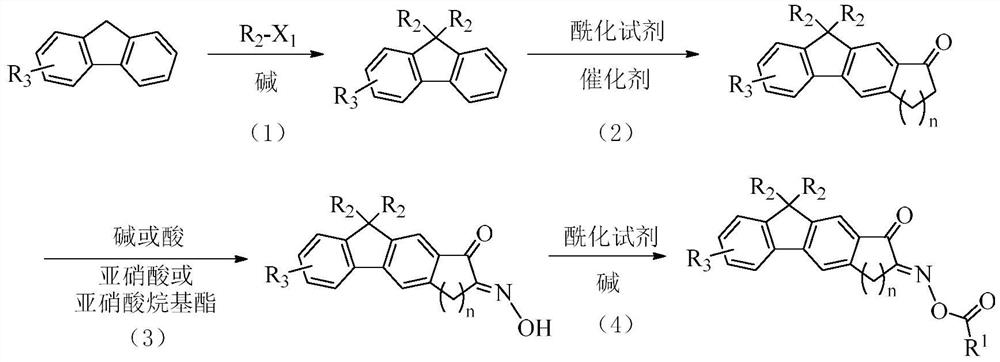

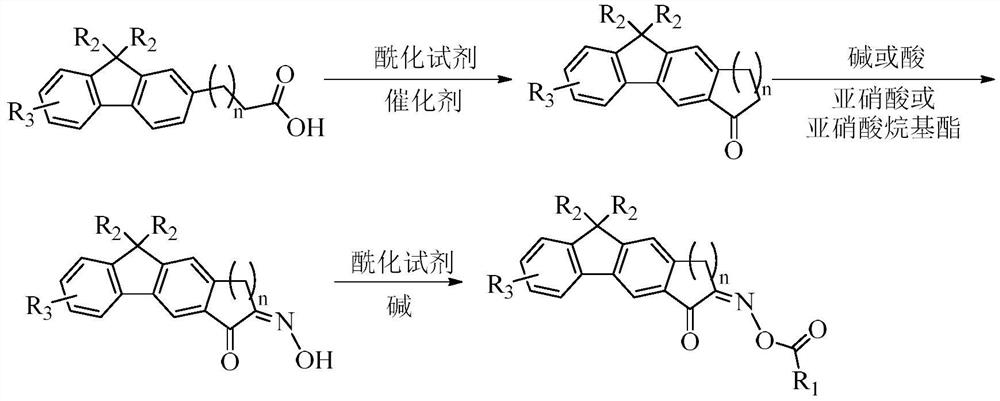

Fluorene oxime ester compound as well as preparation method and application thereof

ActiveCN112341359APattern effect is goodGood adhesionPhotomechanical apparatusOximes preparationPhotoinitiatorPolymer chemistry

The invention discloses a novel fluorene oxime ester compound, a preparation method thereof, a photoinitiator containing the fluorene oxime ester compound, and a photosensitive resin composition containing the fluorene oxime ester compound. The fluorene oxime ester compound has a chemical structure as shown in A, B, C, D or E, can prevent decomposers caused by exposure from being attached to a mask when used as a photoinitiator, has a good pattern effect, and is excellent in adhesiveness, alkali resistance and transparency.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

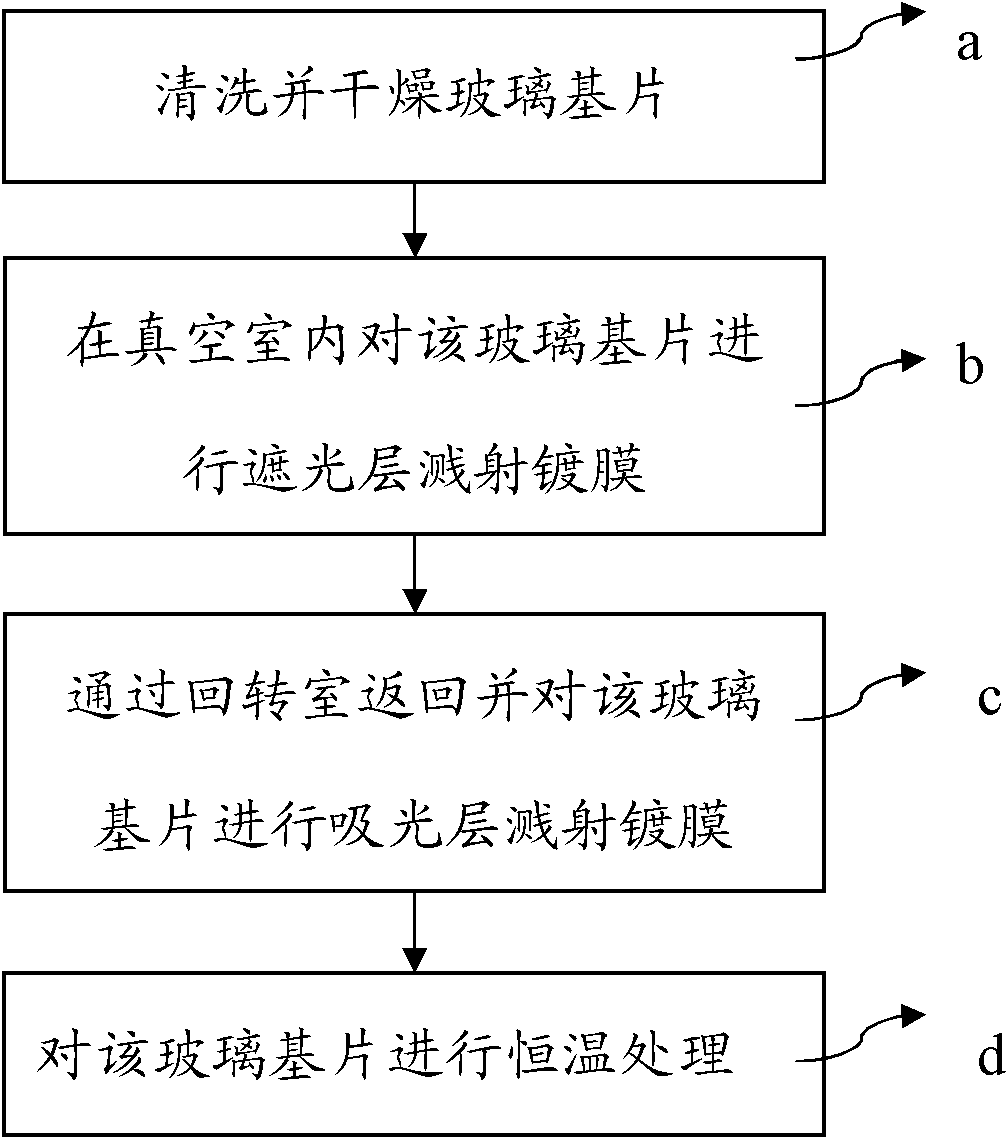

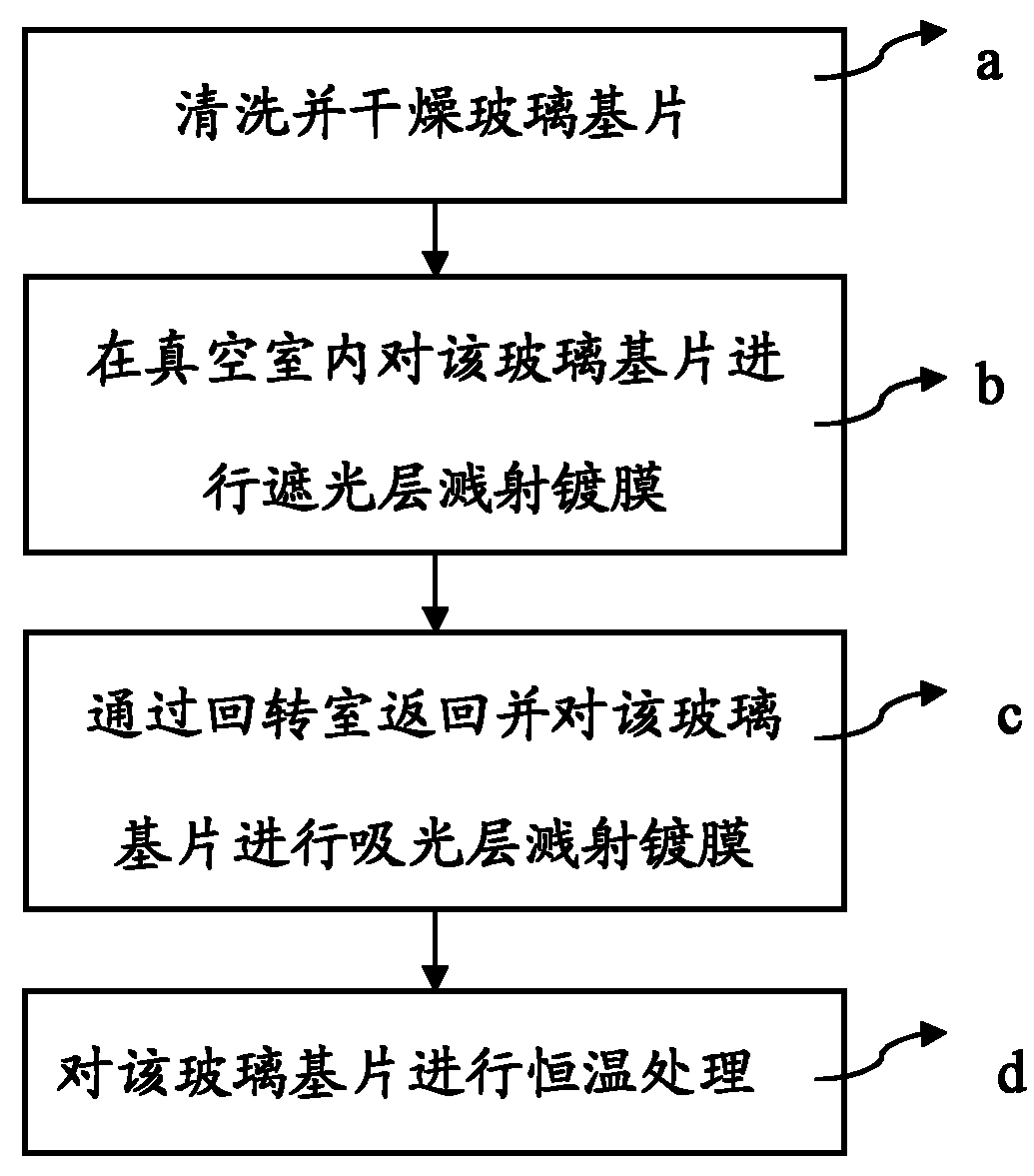

Chromium plate manufacturing process

ActiveCN102181838AHigh anti-static discharge damage characteristicsPattern effect is goodVacuum evaporation coatingSputtering coatingSputteringVacuum chamber

The invention discloses a chromium plate manufacturing process which comprises the following steps: step a, cleaning and drying a glass substrate; step b, sputtering and coating a shading layer on the glass substrate in a vacuum chamber; step c, returning through a rotation chamber, and sputtering and coating a light absorbing layer on the glass substrate; and step d, conducting constant temperature processing on the glass substrate. For the chromium plate manufacturing process, the parameters of the chromium plate manufacturing process are controlled, so that a chromium plate manufactured bythe invention has higher property of preventing the damage caused by the discharging of static electricity.

Owner:KELEAD PHOTOELECTRIC MATERIALS SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com