Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve embossing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

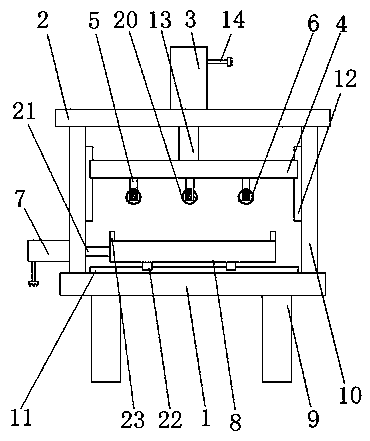

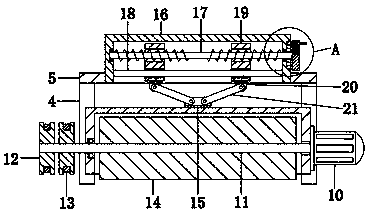

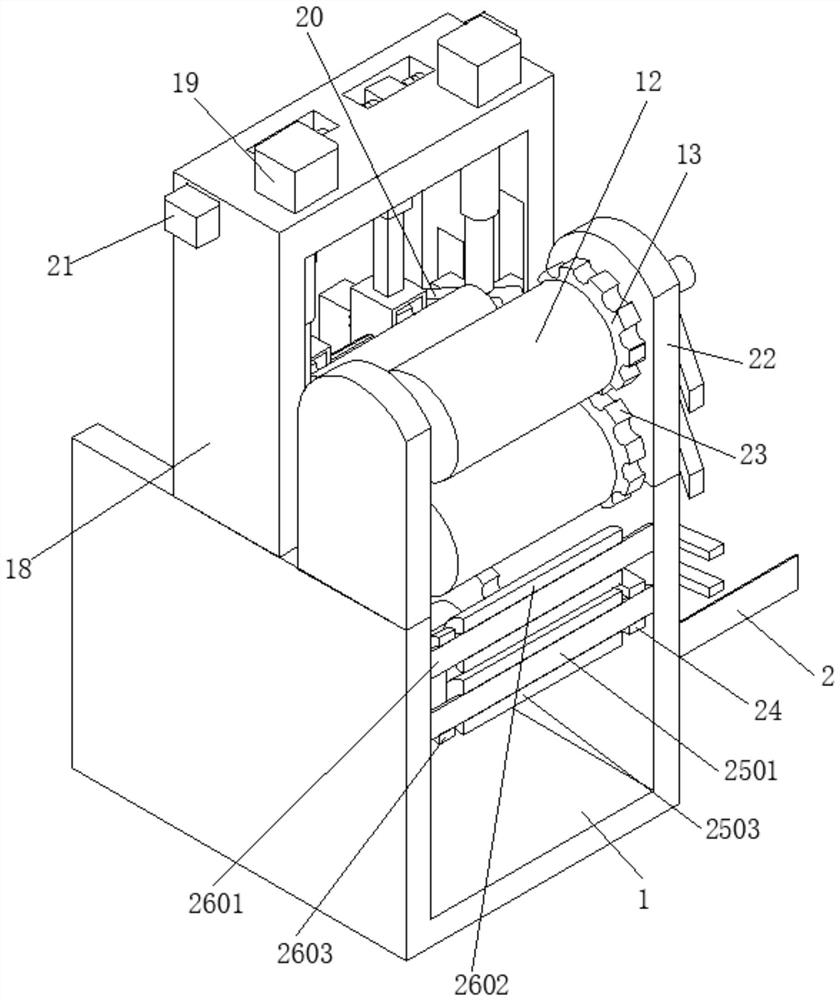

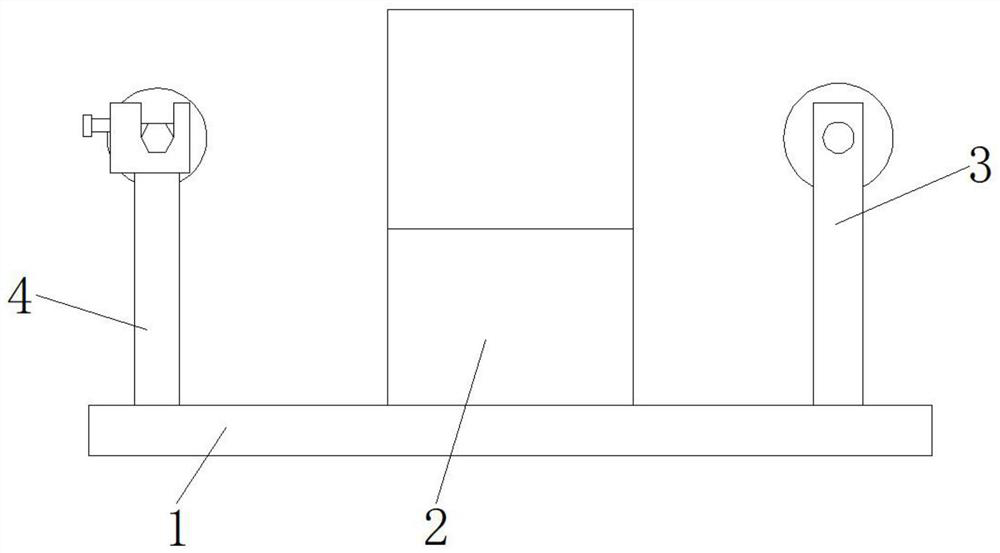

Waterproof aluminum-foil paper production equipment and production method thereof

InactiveCN109591383AFlat sizeUniform sizeMechanical working/deformationCleaning using toolsPaper productionPulp and paper industry

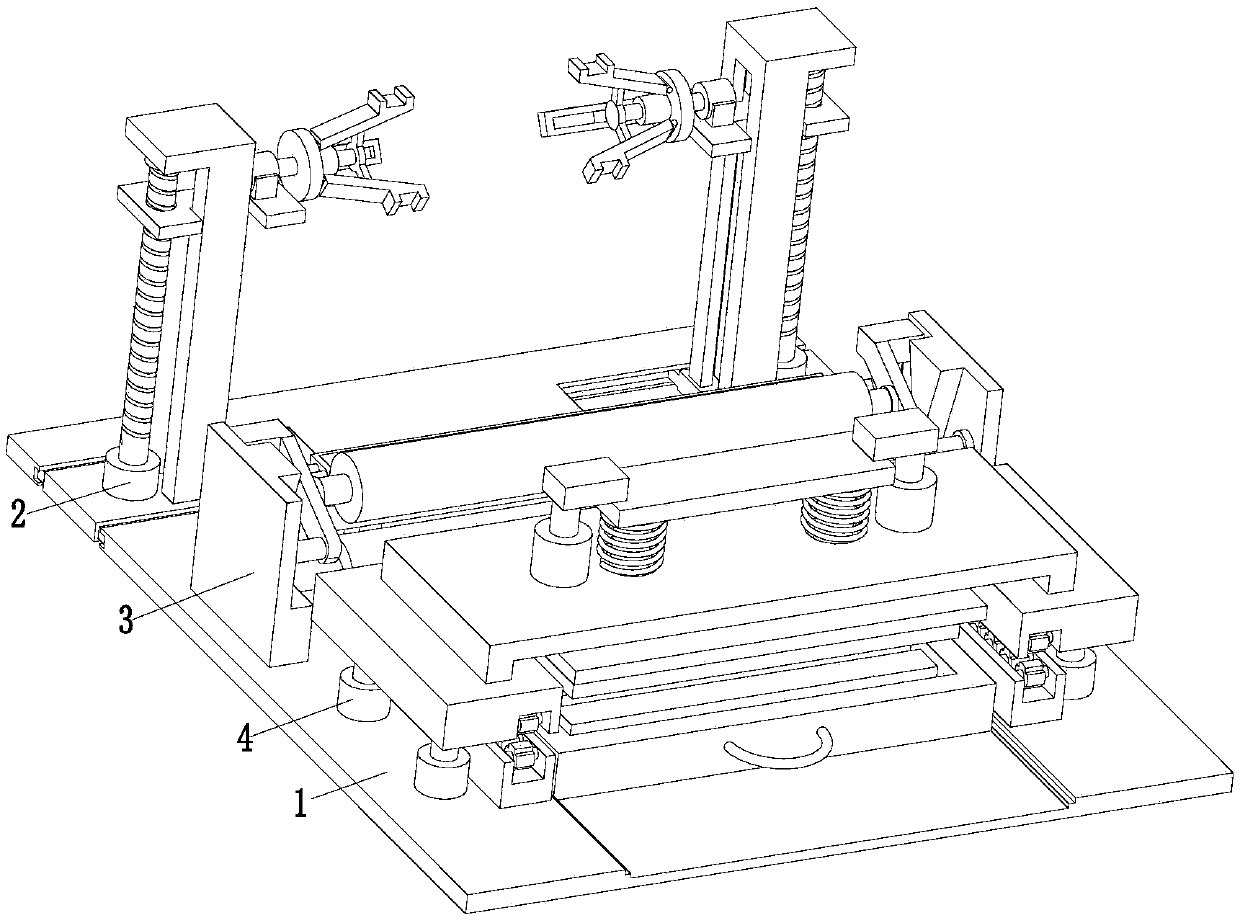

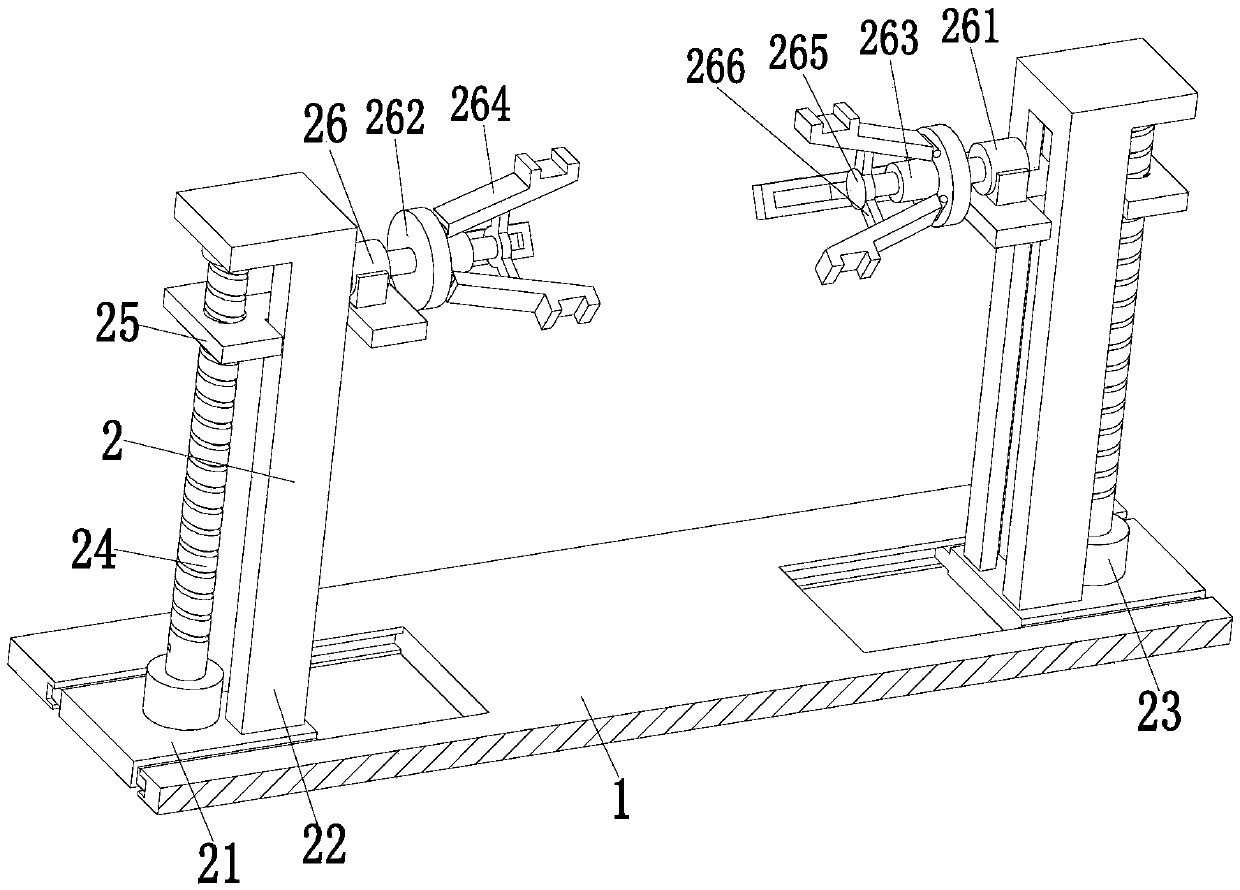

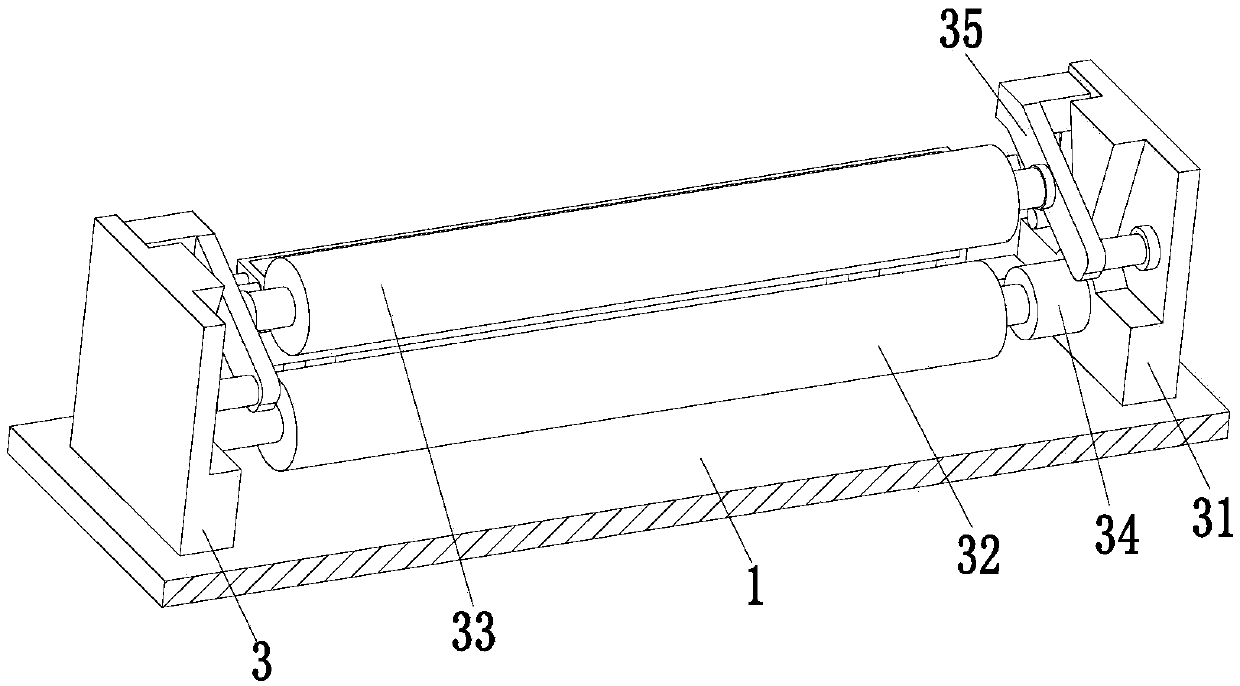

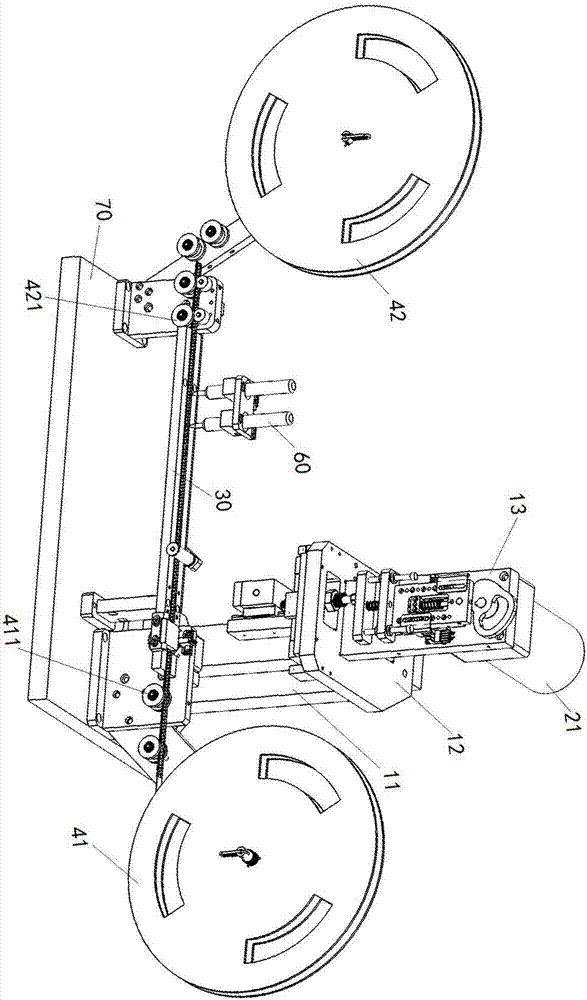

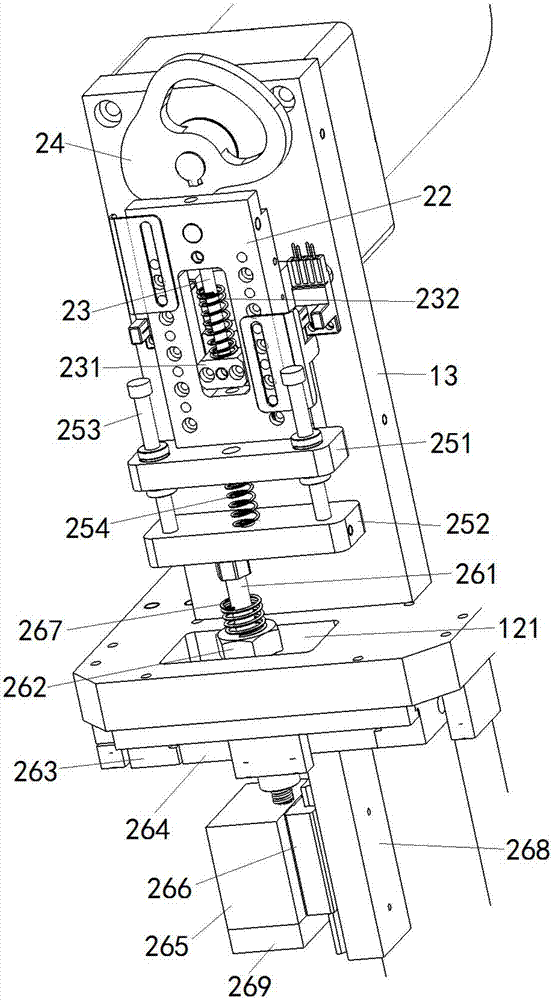

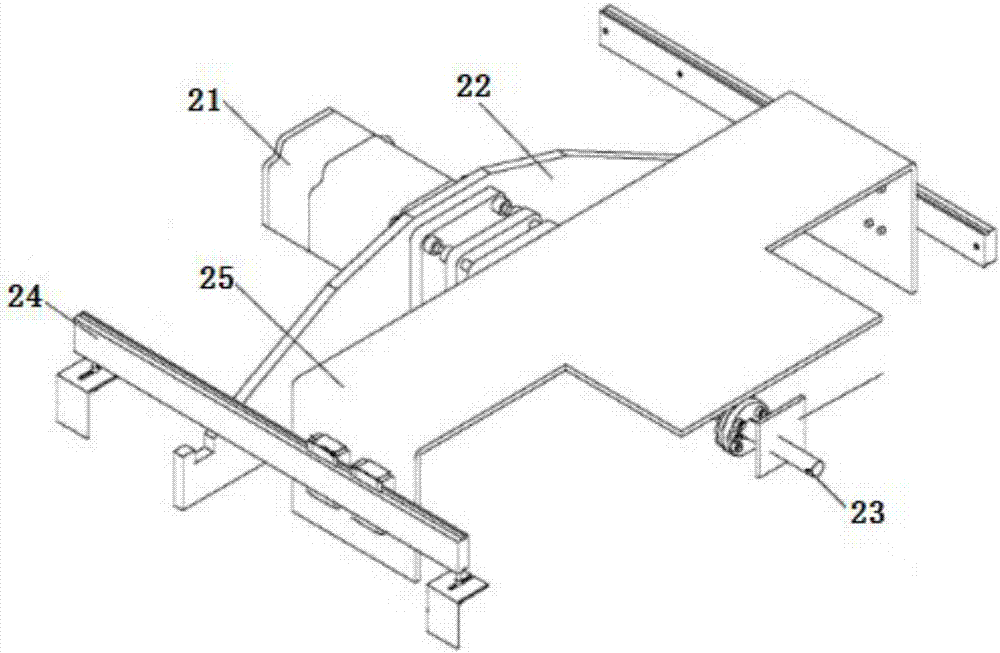

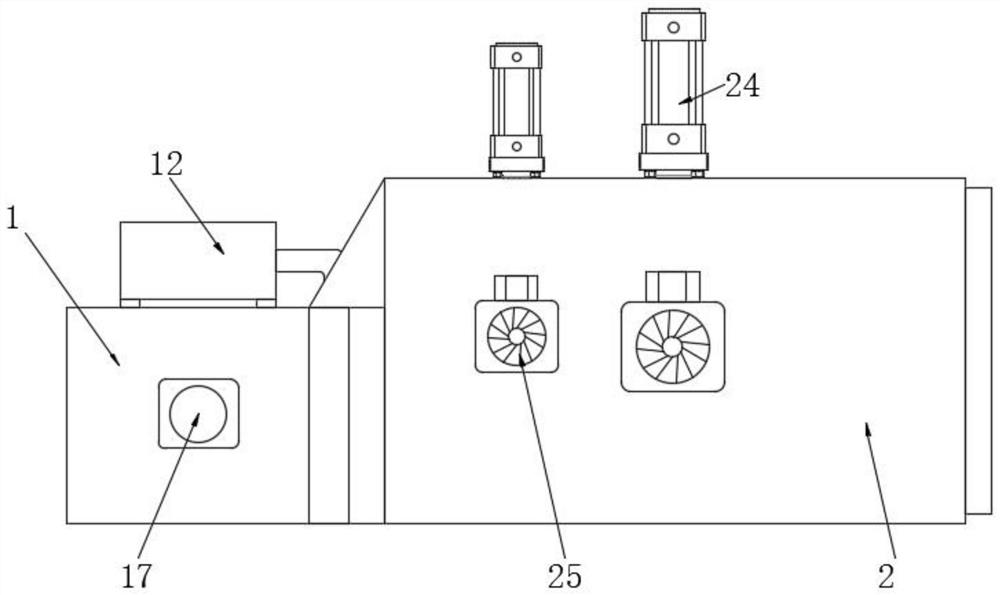

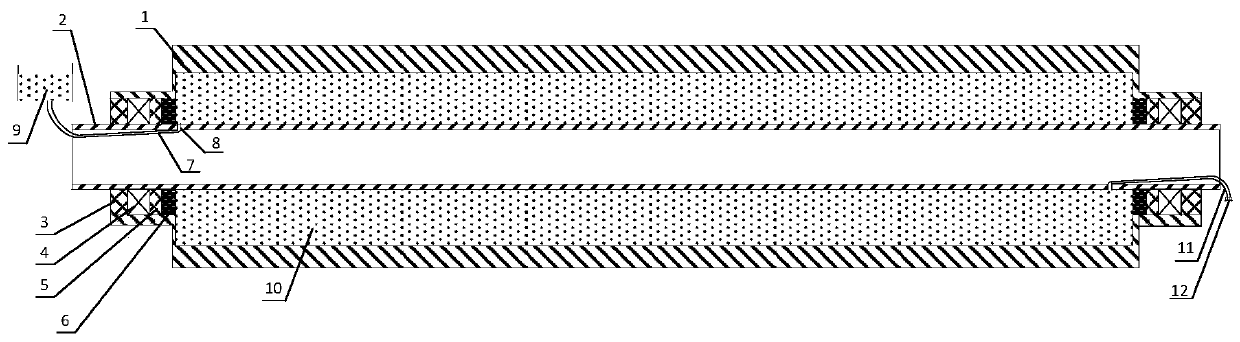

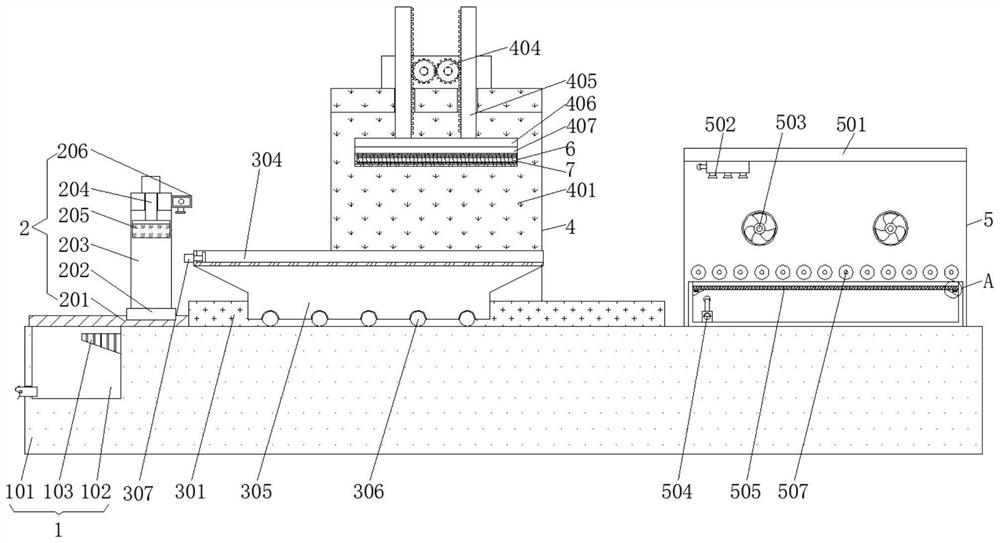

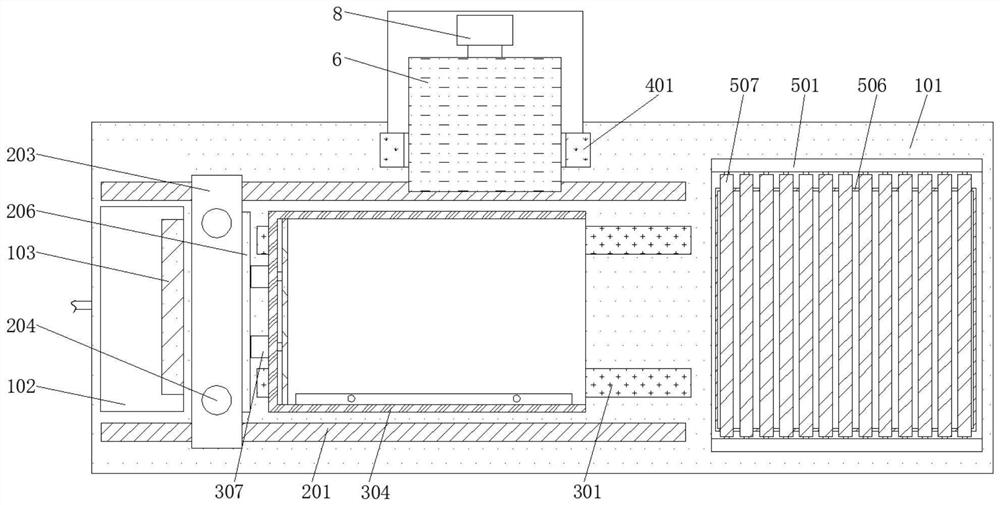

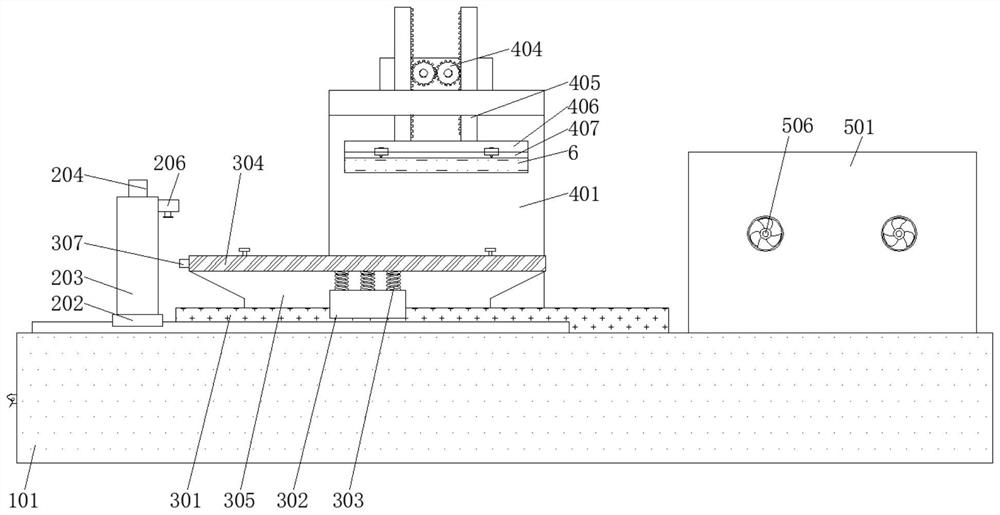

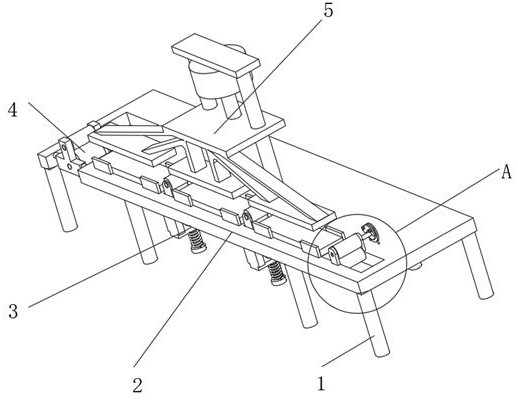

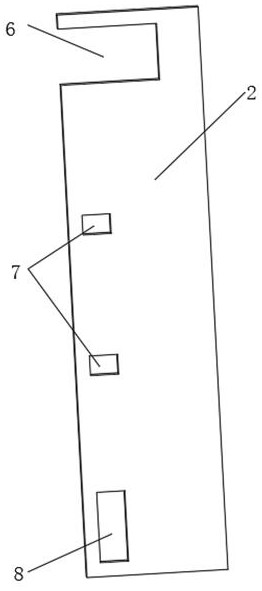

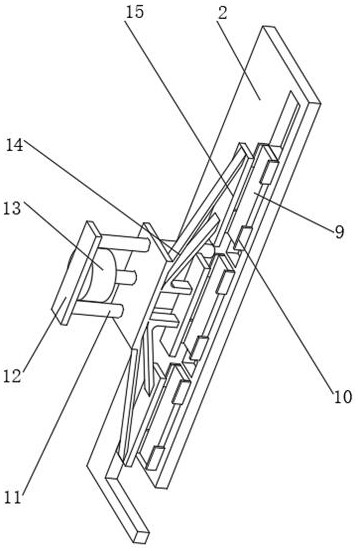

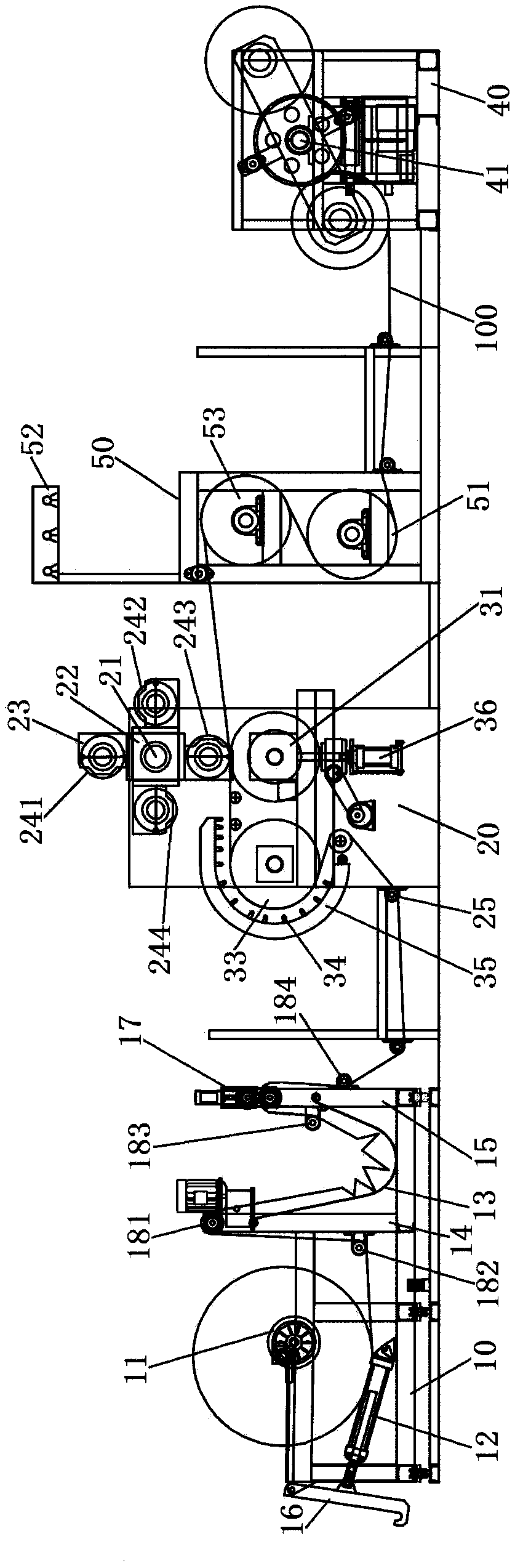

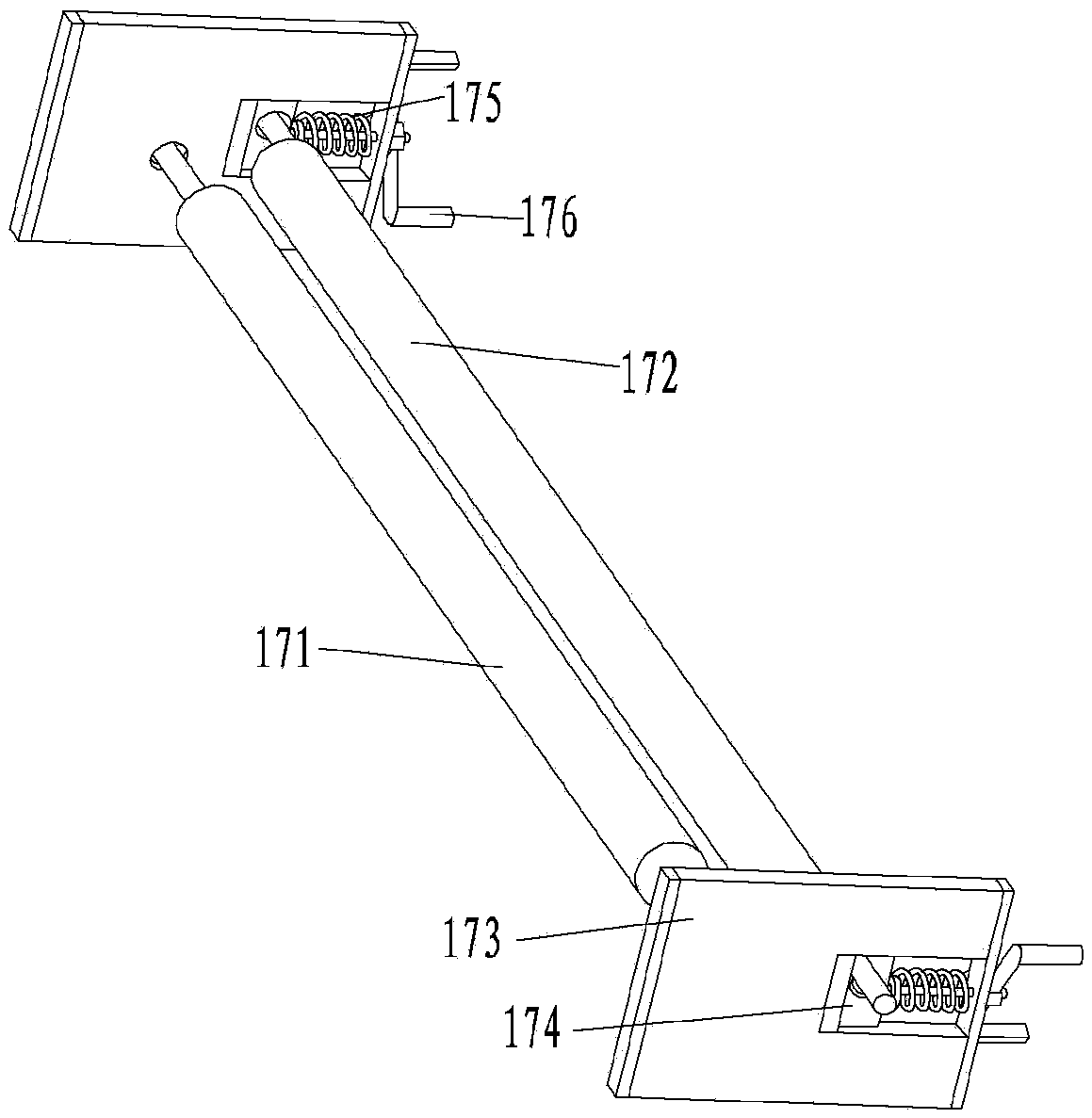

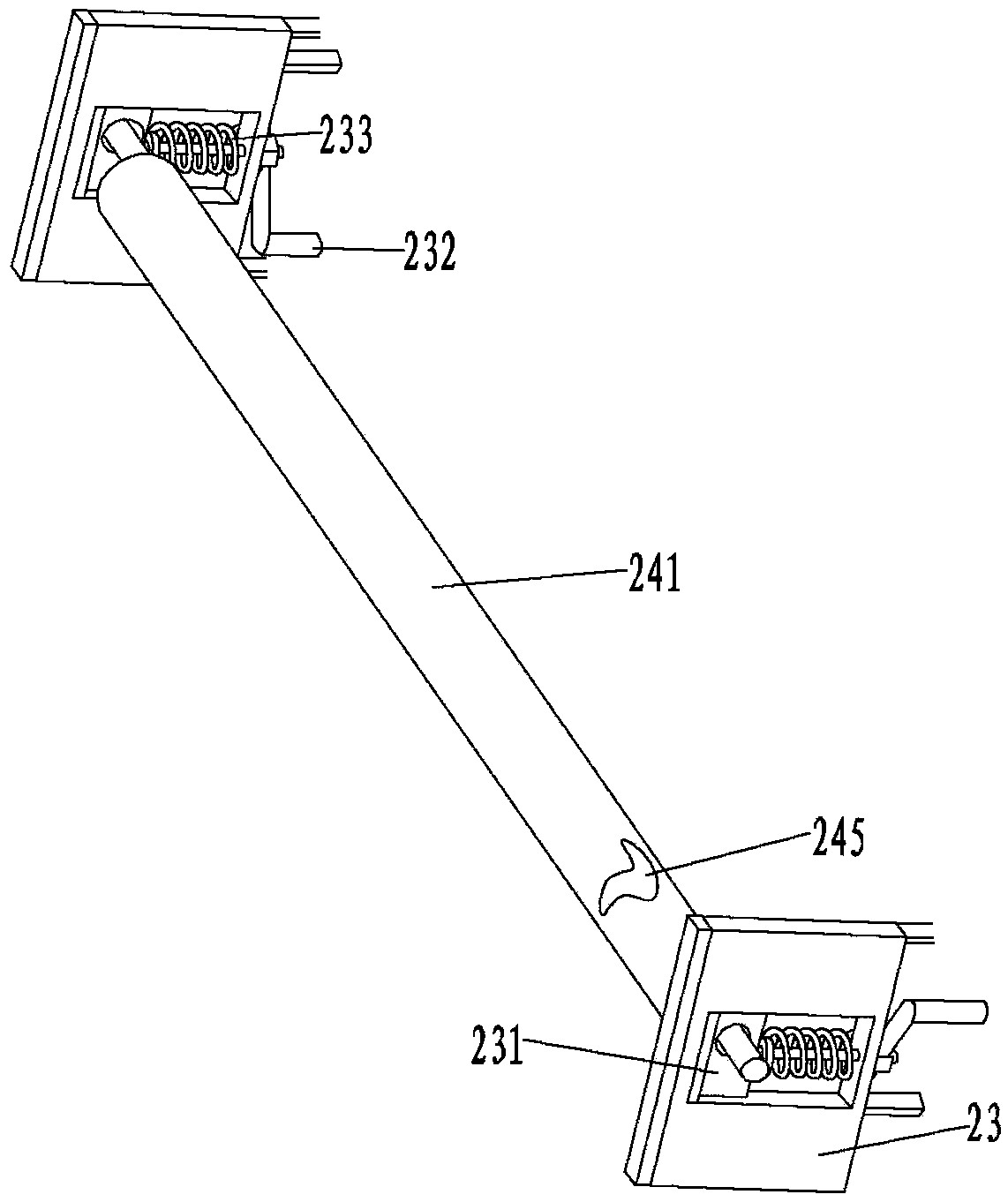

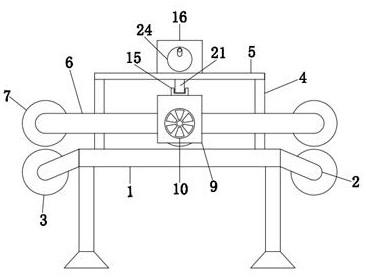

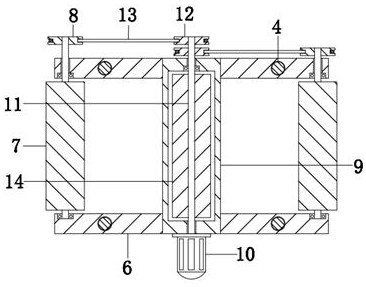

The invention provides waterproof aluminum-foil paper production equipment and a production method thereof. The waterproof aluminum-foil paper production equipment comprises a bottom plate, a windingdevice, an embossing device and a slitting device. The waterproof aluminum-foil paper production equipment and the production method thereof provided by the invention can solve the problems that a, during the volumed aluminum-foil paper embossing anti-fake production process, solid particles exist on the surface of volumed aluminum-foil paper, the aluminum-foil paper is easy to crush so as to be damaged due to direct embossing, and embossing equipment in the general market cannot adjust the appropriate pressure aiming at different aluminum-foil paper thicknesses, so that the application rangeis low; b, the volumed aluminum-foil paper is instable when being unwinded and is easy to shake, so that the production efficiency and the product quality are influenced; and c, when the aluminum-foilpaper is cut, the tension stressed on the aluminum-foil paper is instable, so that the cutting dimension of the aluminum-foil paper cannot be controlled when the aluminum-foil paper is cut, meanwhile, the cut aluminum-foil paper is easy to wrinkle, the product quality is influenced and the like.

Owner:FUYANG CIGARATE MATERIAL FACTORY

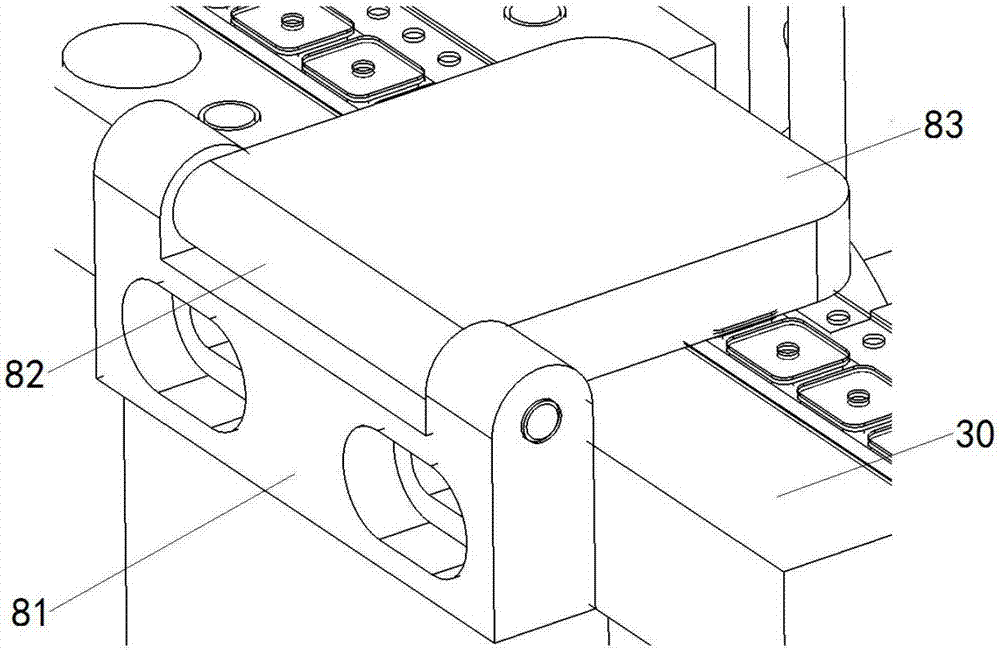

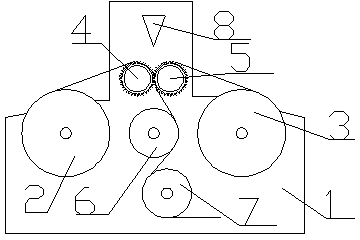

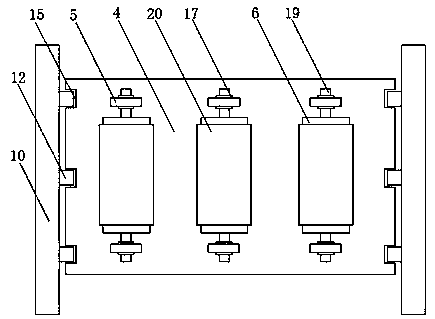

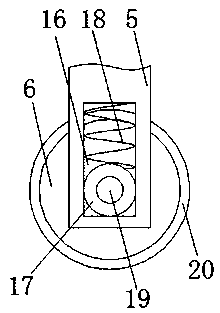

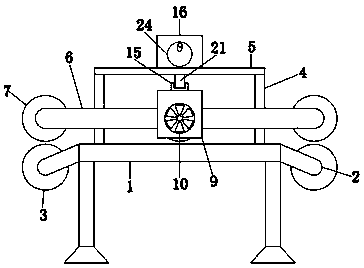

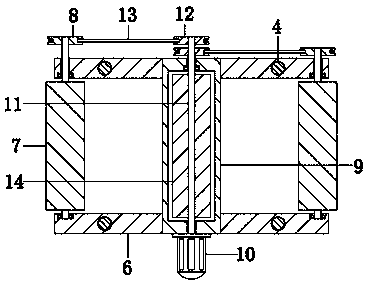

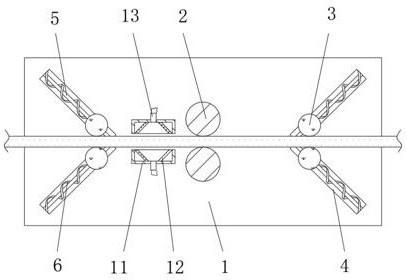

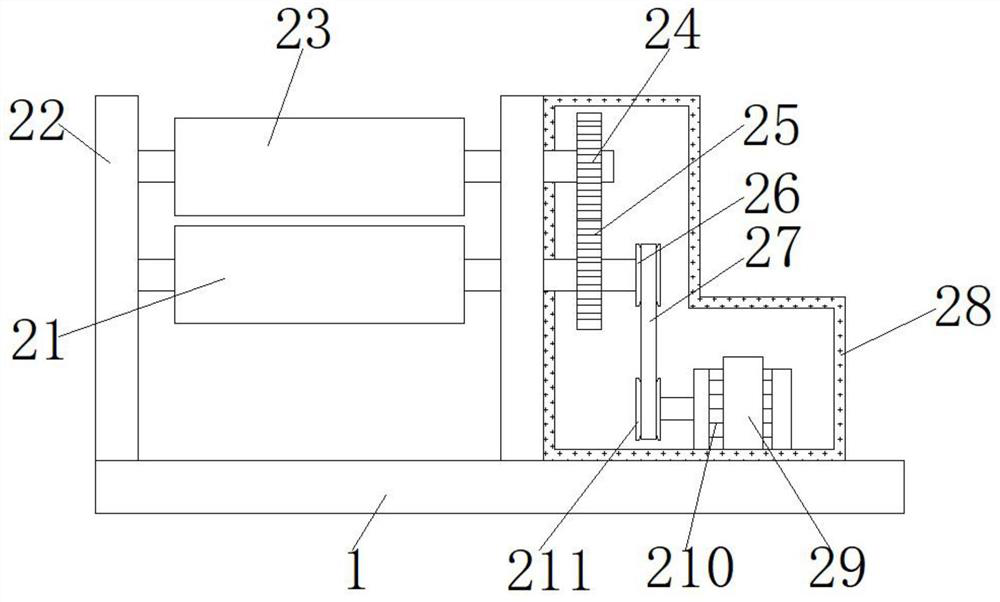

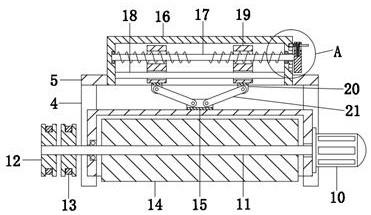

Paper surface groove embossing device

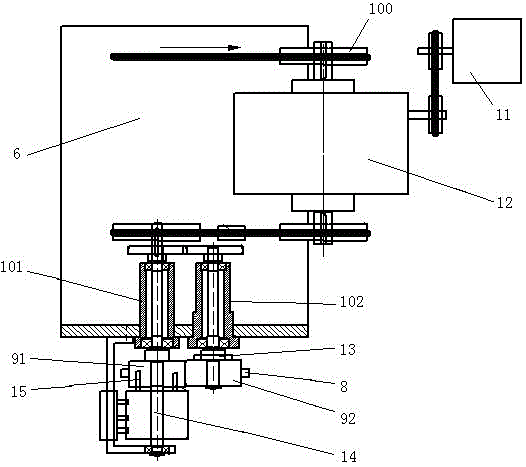

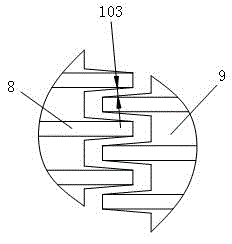

ActiveCN102873915AImprove embossing qualityIncrease production speedMechanical working/deformationControl systemPaper tape

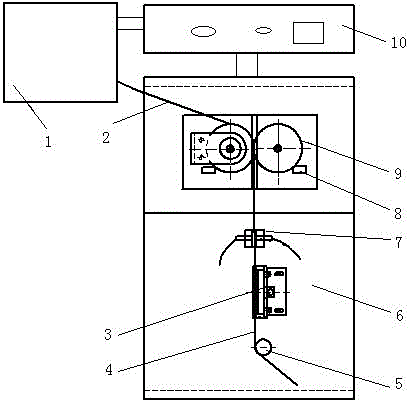

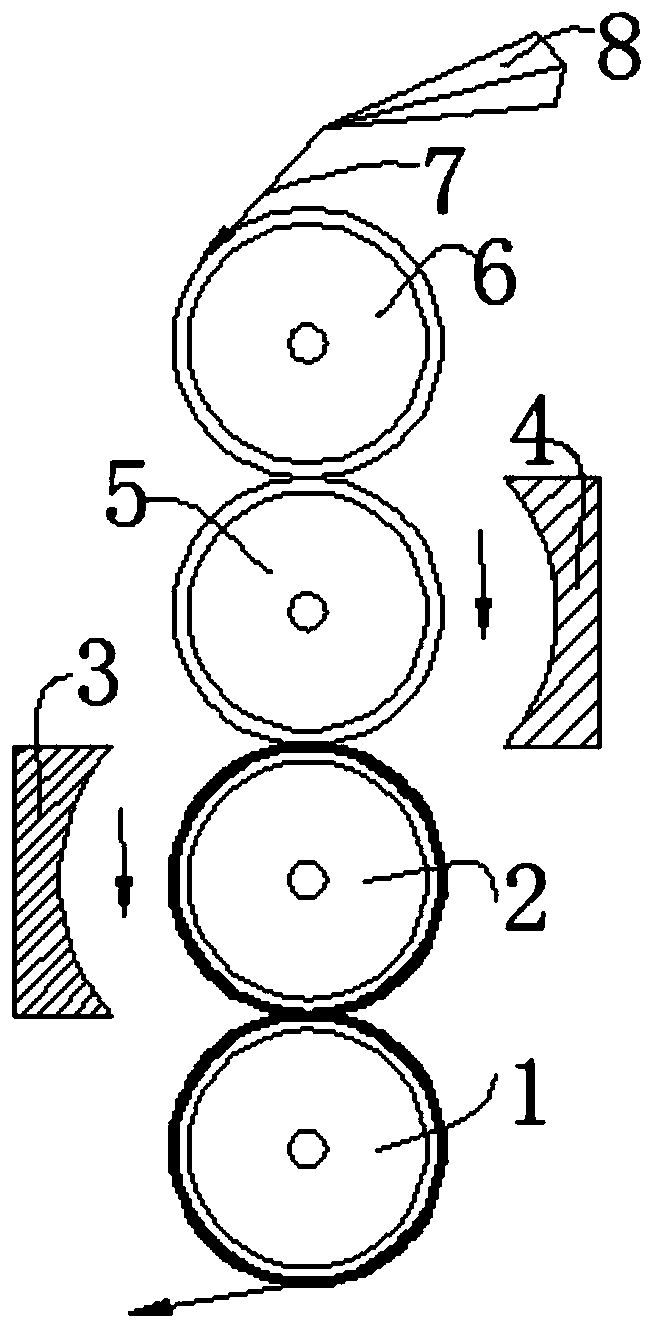

The invention provides a paper surface groove embossing device which is used for extruding concave-convex groove patterns on the surfaces of paper tapes. The paper surface groove embossing device comprises an electric control system, a paper tape conveying motor, a transmission mechanism, two split pattern pressing rolls, a paper guide roll, a mechanism base, an inching motor, a differential gearbox, a paper stopper and the like, wherein the inching motor can be started to finely adjust the rotation speeds of the two pattern pressing rolls, so that the lengths of the pattern pressing sections and the spacer sections on a paper tape can be adjusted; electro-thermal tubes are arranged in the pattern pressing rolls, so that the pattern pressing rolls can be heated to help the tooth shape forming of the paper tape; and a paper joint detector is arranged between the pattern pressing rolls and the paper guide roll, so that the thickness of the paper tape can be detected online. According to the paper surface groove embossing device, the production speed and the capacity of groove filter stick production equipment can be improved, the defective filter sticks can be automatically rejected, heating can be carried out to stabilize the tooth shapes on the paper surfaces and the quality of the groove filter stick products can be improved.

Owner:NANTONG CIGARETTE FILTER

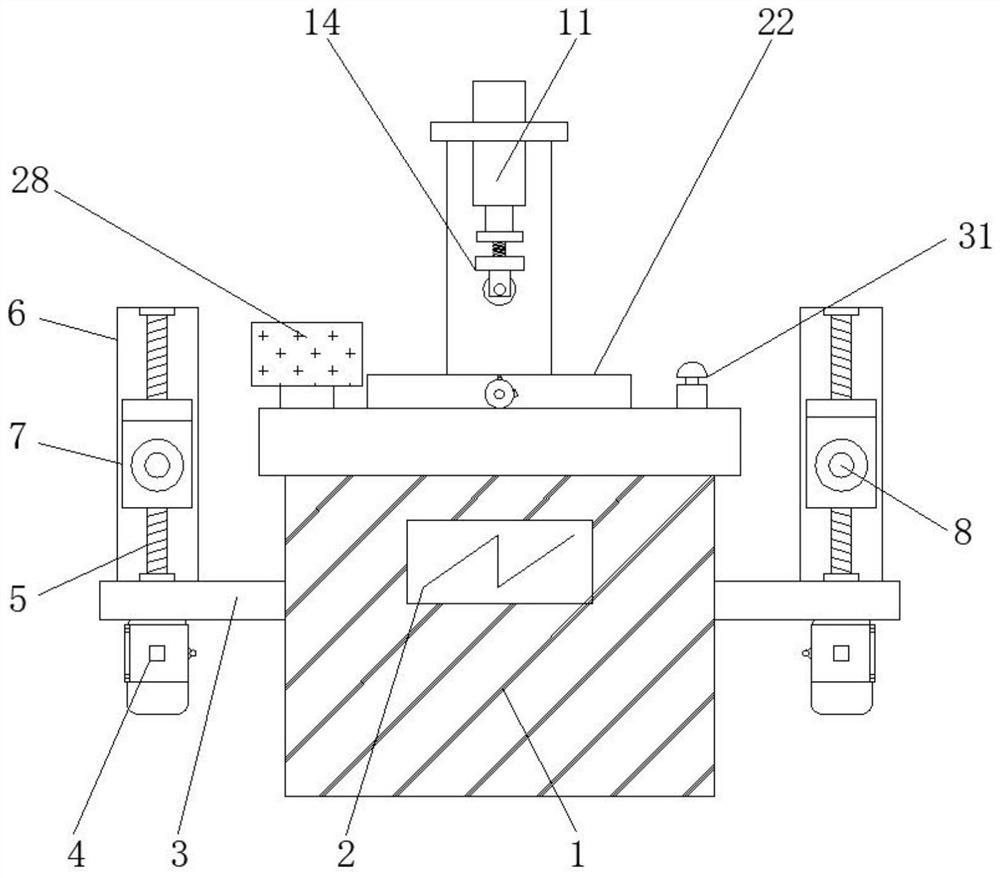

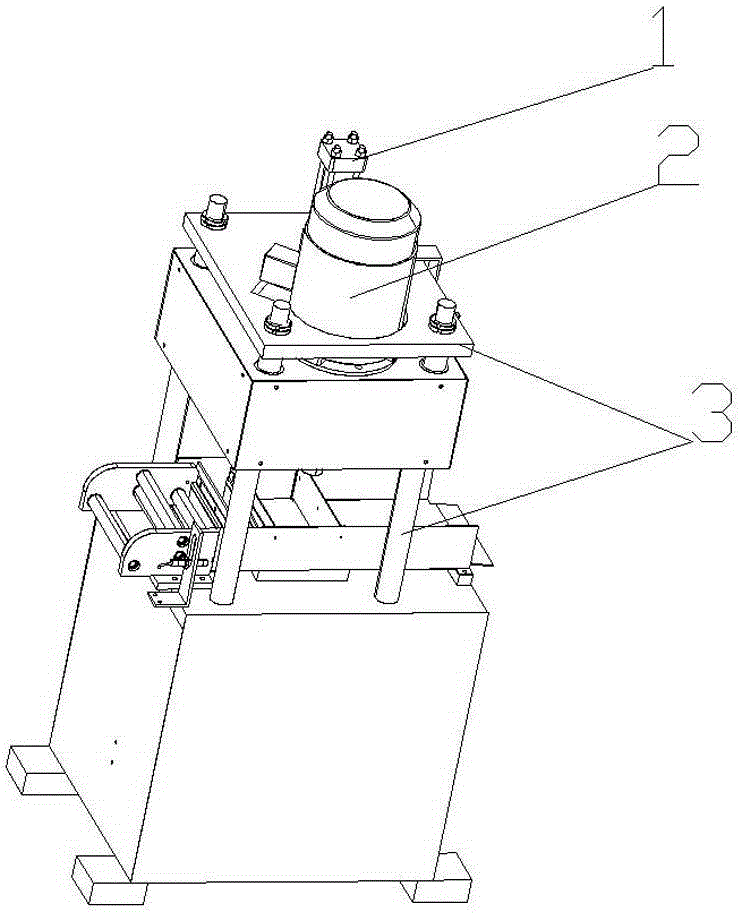

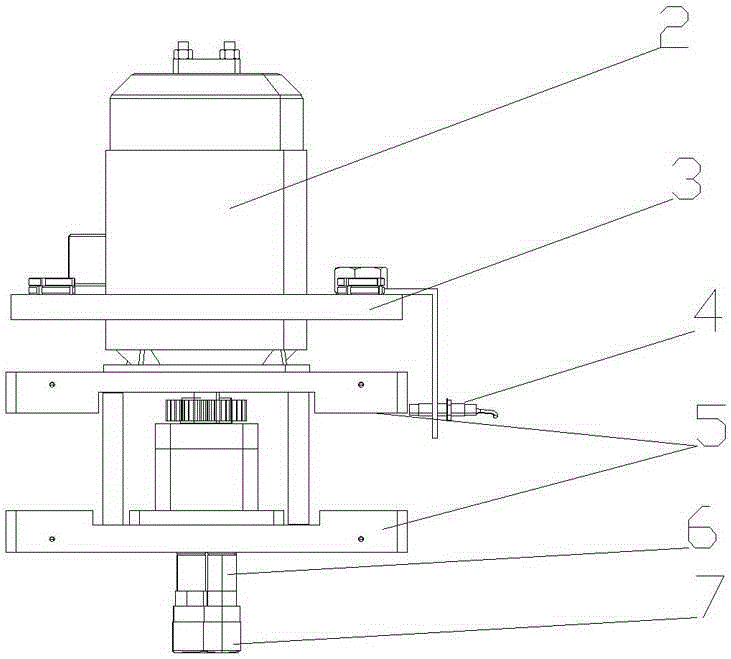

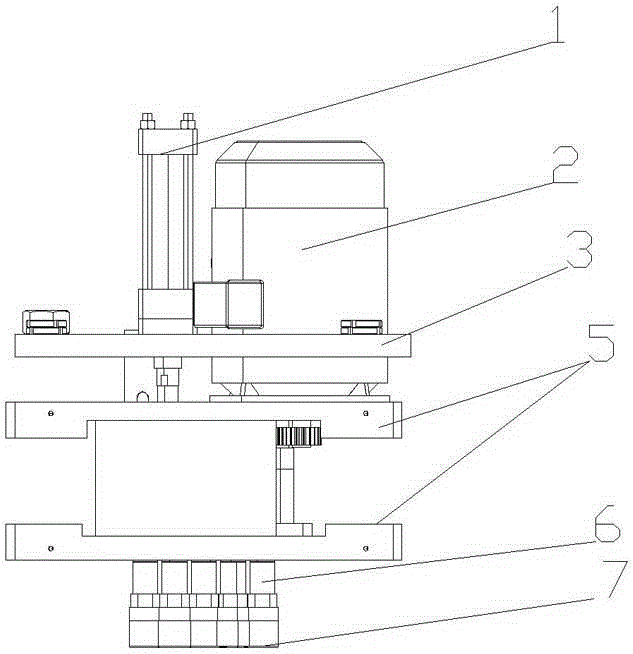

Embossing device adjustable in depth

ActiveCN107254758AImprove embossing qualityImprove the suppression effectPattern makingFrame basedEngineering

The invention discloses an embossing device adjustable in depth. The embossing device adjustable in depth comprises a laying table and an embossing mechanism, wherein the embossing mechanism comprises a driving motor, an embossing frame base, a driving rod and an embossing head, the embossing frame base is fixedly connected with a mounting vertical plate, and the driving motor drives a cam member to rotate, so that the embossing head is driven to operate by virtue of the driving rod and a pressing plate component; the embossing head comprises an adjusting bolt, an embossing sole piece, a longitudinal guide rail and a stop piece, a T-shaped hole and groove is formed in the bottom of a lower pressing plate, the top of the adjusting bolt is arranged in the T-shaped hole and groove, and the adjusting bolt can horizontally slide forward and backward in the T-shaped hole and groove; and the embossing sole piece is arranged below the adjusting bolt, and the top of the embossing sole piece is connected with the bottom of the adjusting bolt by virtue of a screw thread. The embossing device disclosed by the invention is compact in structure, continuous automatic embossing can be carried out on a garment material, and different floral designs and decorative patterns with different depths can be embossed on the same equipment, thereby being very convenient in use.

Owner:JIAXING WANYUAN FASHION

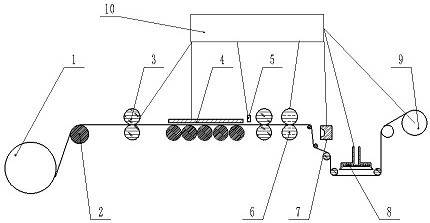

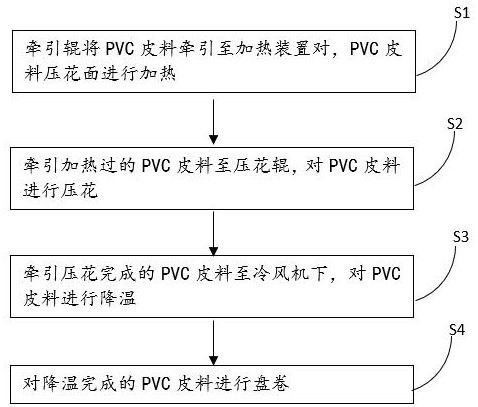

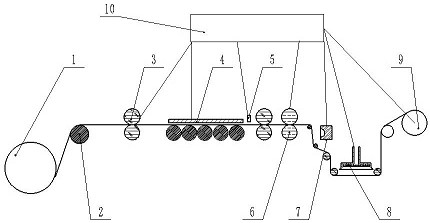

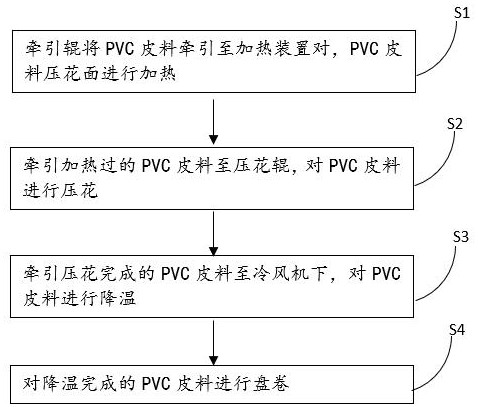

Automobile interior PVC leather embossing process

ActiveCN112406085AIntelligent control of the embossing processImprove embossing qualityDomestic articlesEngineeringMechanical engineering

The invention relates to an automobile interior PVC leather embossing process. The process comprises the following steps of pulling PVC leather to a heating device by a pulling roller, and heating anembossed surface of the PVC leather; pulling the heated PVC leather to an embossing roller, and embossing the PVC leather; pulling the embossed PVC leather to a position below an air cooler, and cooling the PVC leather; and coiling the cooled PVC leather. By arranging a central control module, the working states of all parts are intelligently adjusted, a temperature sensor detects the temperatureof the embossed surface of the PVC leather, the central control module adjusts the rotating speed of the pulling roller according to the temperature of the embossed surface of the PVC leather, and when the temperature of the embossed surface of the PVC leather is out of tolerance seriously, the central control module adjusts the temperature of the heating device; and by intelligently adjusting therotating speed of the pulling roller and the temperature of the heating device, the temperature of the embossed surface of the PVC leather is in the optimal range, the embossing process is intelligently controlled, and the embossing quality is improved.

Owner:温州市环球汽车衬垫有限公司

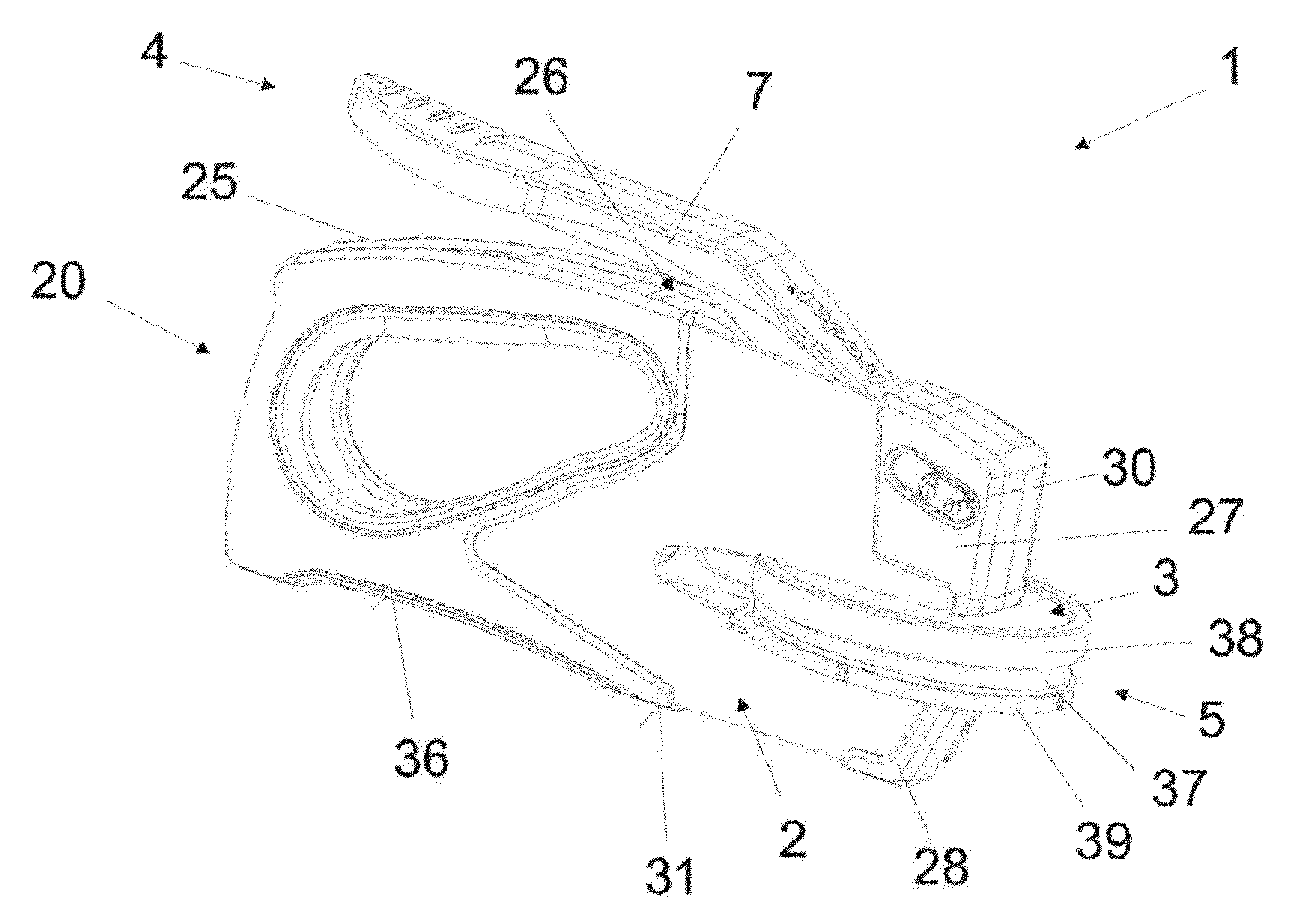

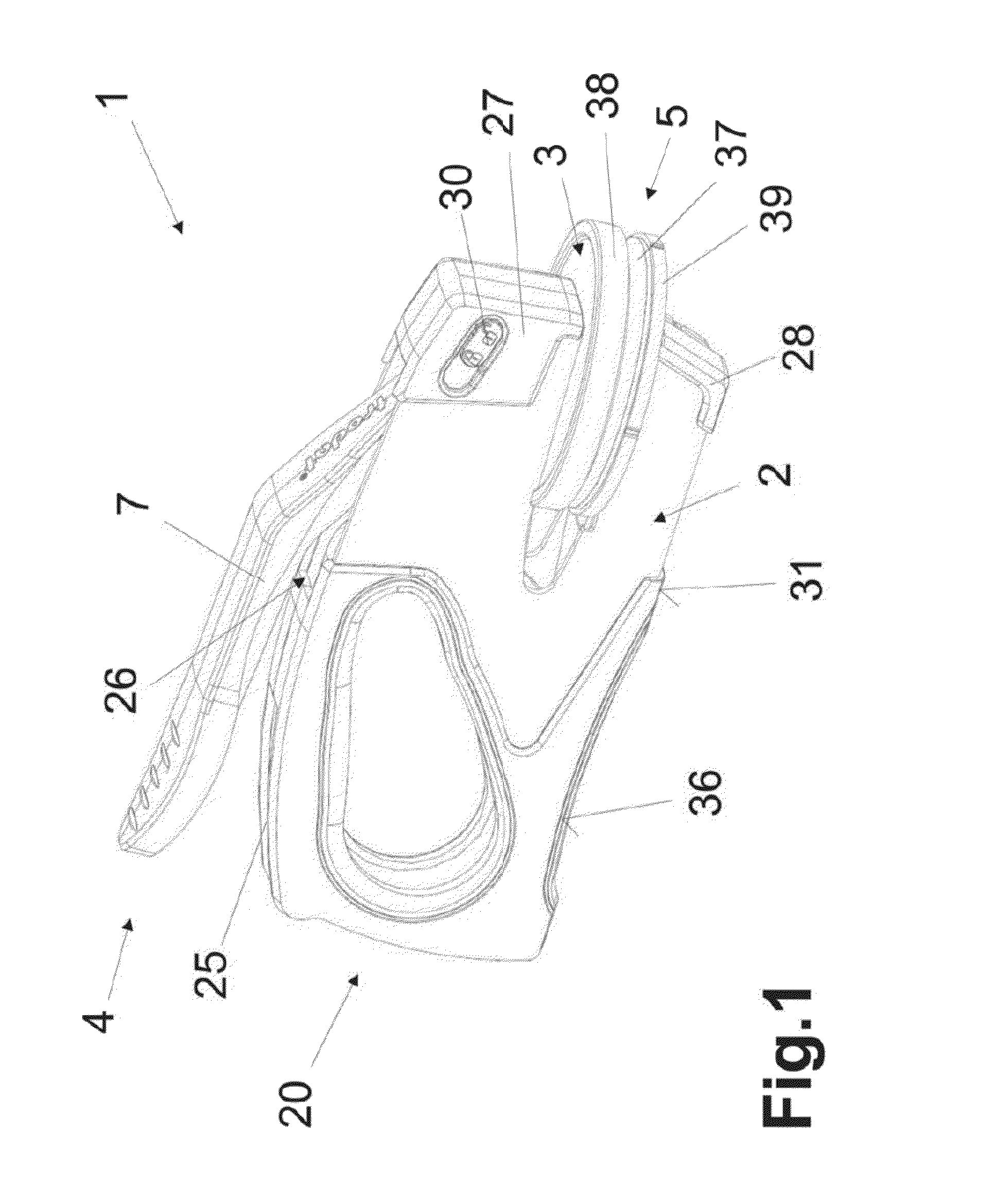

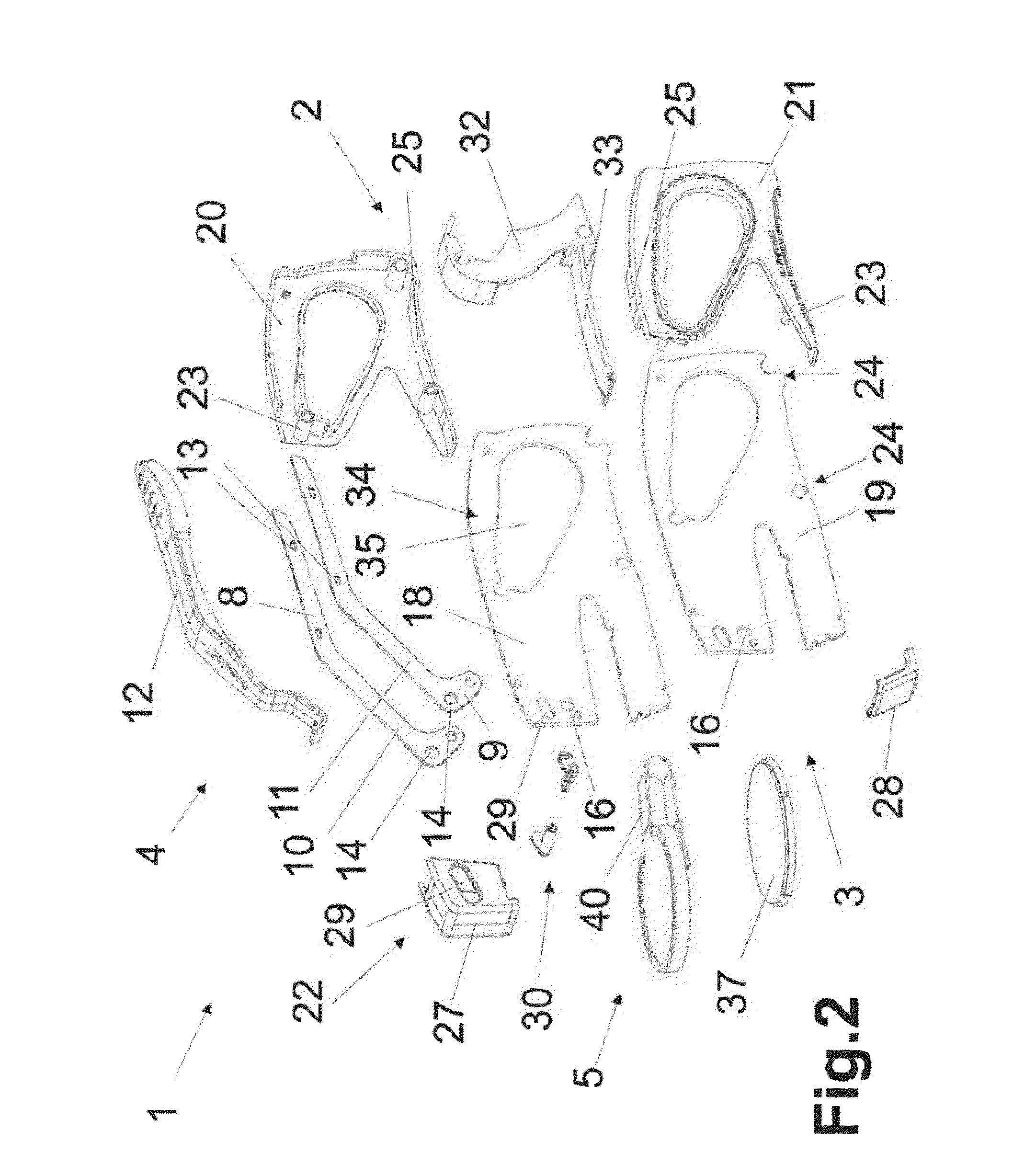

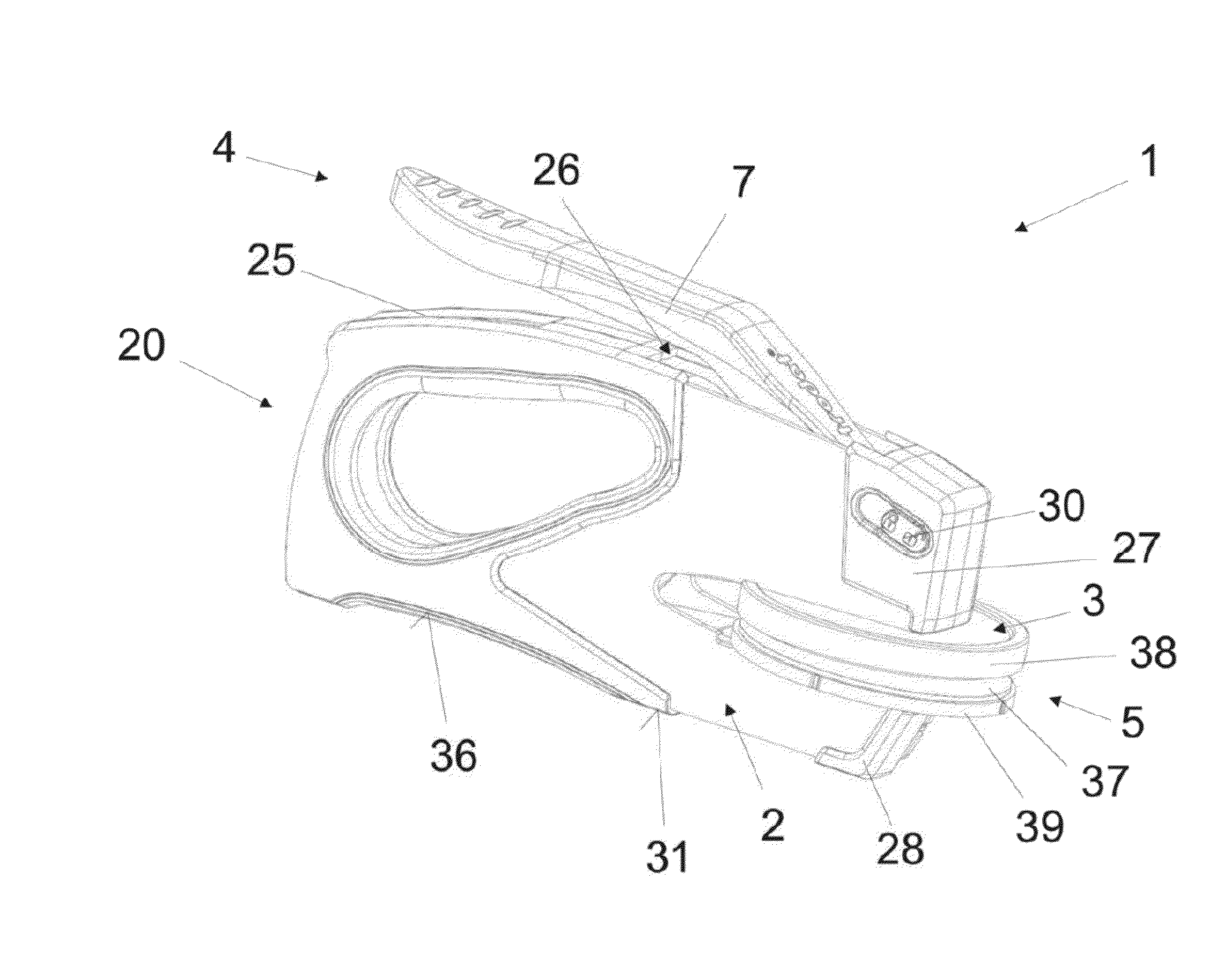

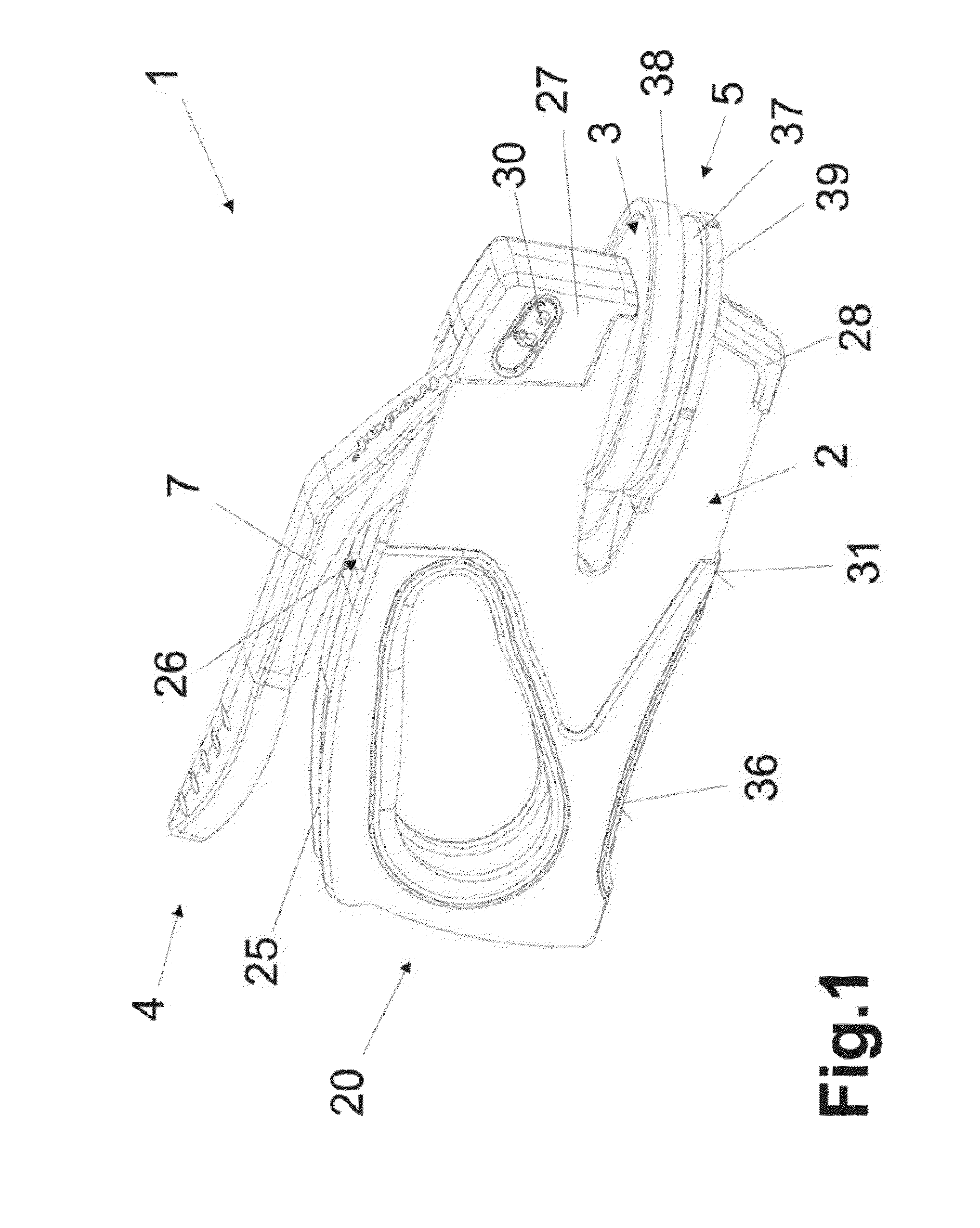

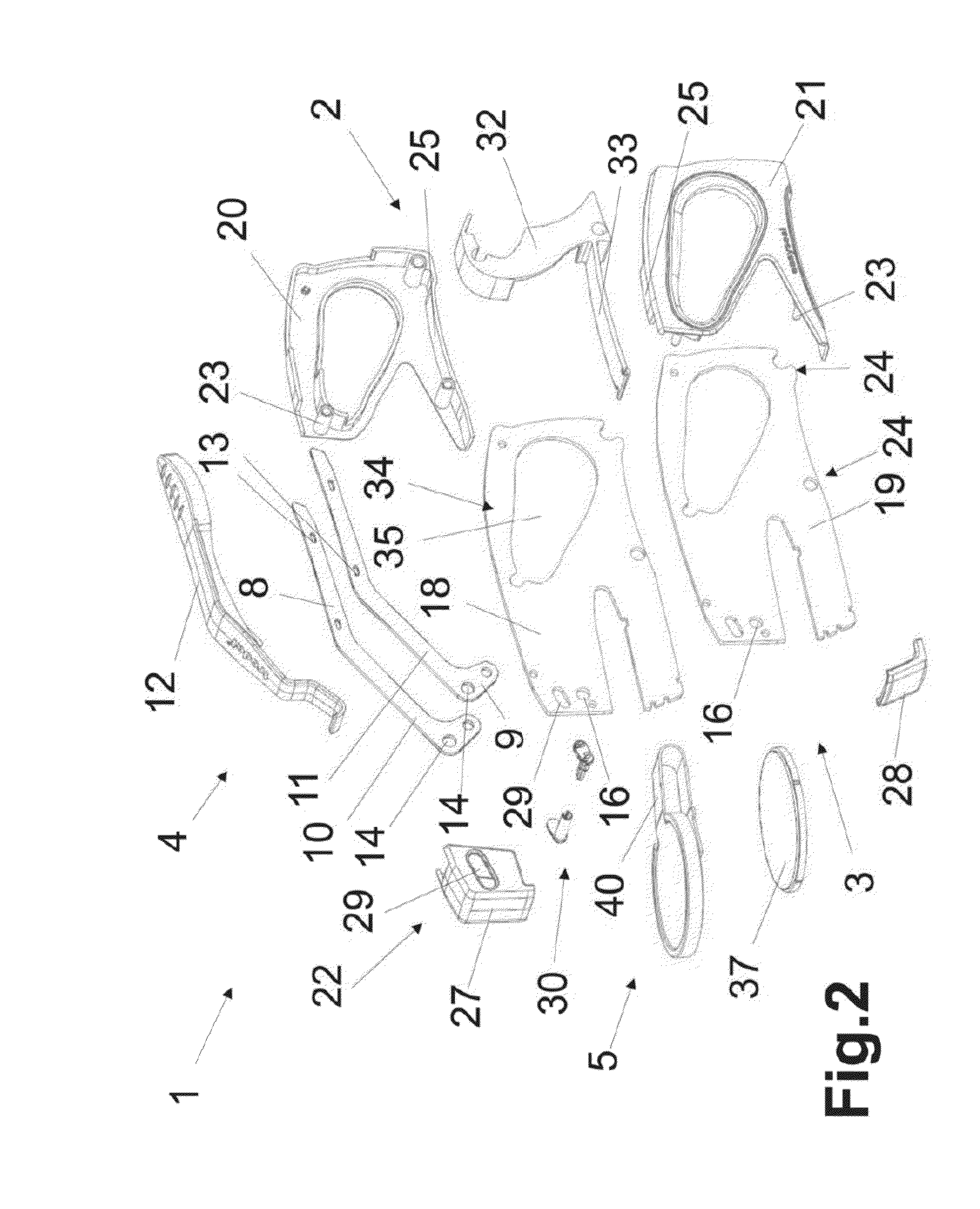

Embossing stamp and die plate holder for the embossing stamp

ActiveUS20140311366A1Compact structureEasily identifiableMechanical working/deformationRotary pressesModular structureBuilding construction

The invention describes an embossing stamp comprising at least a base unit in which a retaining device is disposed on one side to retain a die plate holder and an operating device is disposed on a further side. The operating device is constructed such that it directly or indirectly acts on the retaining device, wherein a pivot of the operating device is disposed in the base unit. The base unit and / or the operating device are modular in construction, wherein the side walls are at least partially formed by panels which are positioned with respect to each other and fastened via half-shells and / or connecting means.

Owner:TRODAT GMBH

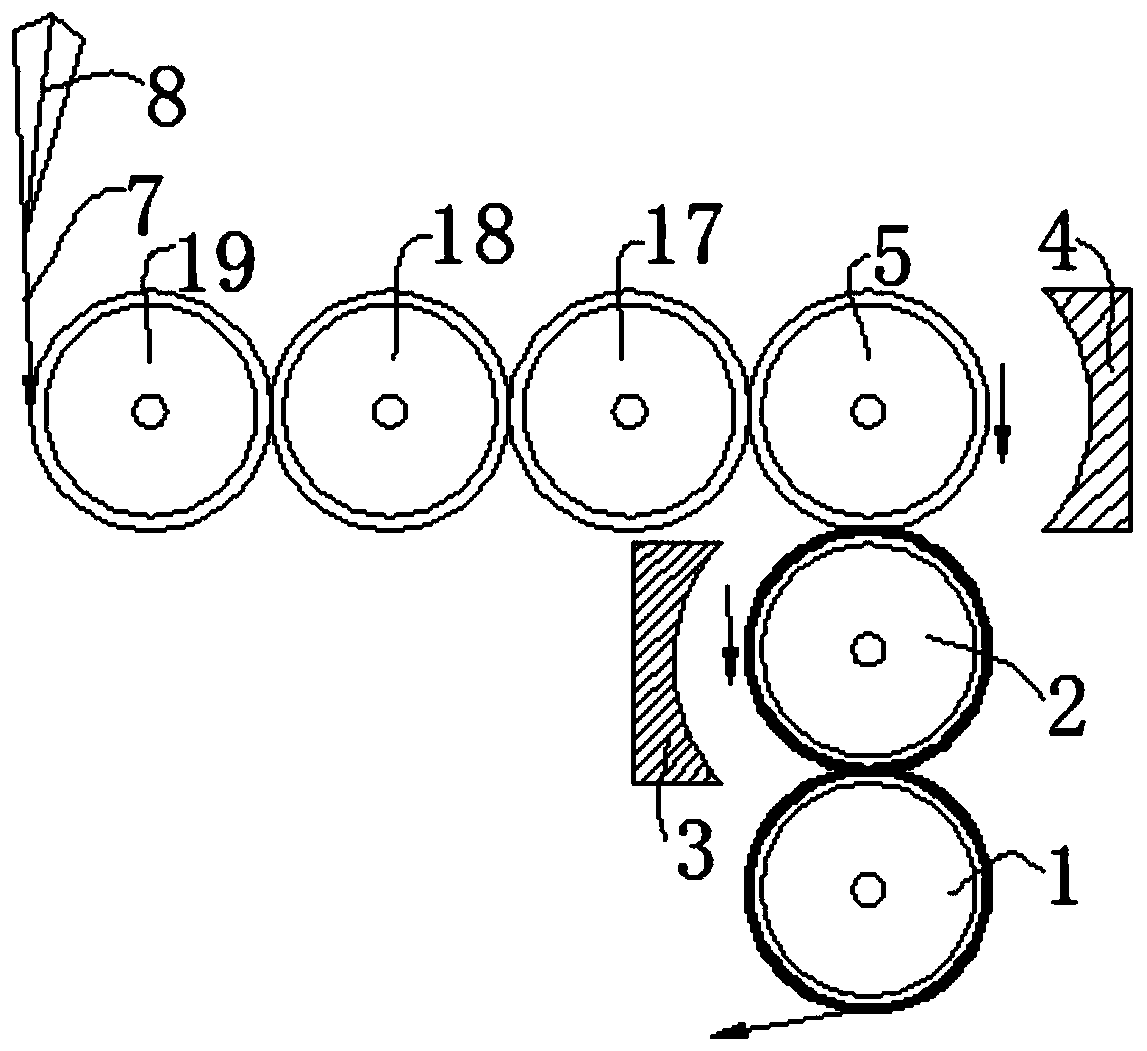

Laminating, combining and embossing integration machine

The invention discloses a laminating, combining and embossing integration machine. The laminating, combining and embossing integration machine comprises a machine frame, a first unwinding roller, a second unwinding roller, a female embossing roller, a male embossing roller, a first cooling roller, a second cooling roller and laminating machine sprayers, the first unwinding roller and the second unwinding roller are arranged at the two ends of the machine frame respectively, the female embossing roller is arranged on the right side of the first unwinding roller, the male embossing roller is arranged on the left side of the second unwinding roller, the laminating sprayers are arranged above the female embossing roller and the male embossing roller, and the first cooling roller and the second cooling roller are arranged below the female embossing roller and the male embossing roller respectively. Thus, the laminating, combining and embossing integration machine has the advantages of being high in reliability, compact in structure, multiple in function, low in power consumption and convenient to use, improving efficiency, saving investment, improving product quality and the like, and meanwhile the laminating, combining and embossing integration machine has a wide market prospect in the thin-film market.

Owner:ALLTEACH SHANGHAI NEW MATERIAL TECH CONSULTING

Embossing device for foam boards

InactiveCN108819202AImprove buffering effectImprove embossing qualityEngineeringMechanical engineering

The invention discloses an embossing device for foam boards. The embossing device comprises an operation platform, a roof plate, an air cylinder 1, a sliding block, fixed plates, pressure rollers, anair cylinder 2 and a bearing stand. The device is characterized in that: the operation platform is arranged on a support, the roof plate is arranged on vertical plates, the air cylinder 1 is arrangedon the roof plate, the sliding block is arranged on a piston rod 1, the fixed plates are disposed on the sliding block, connecting shafts are arranged at both ends of the pressure rollers, the connecting shafts are disposed in fixed rings, the air cylinder 2 is disposed on a vertical plate, and is equipped with a power line and a piston rod 2, the bearing stand is in connection with the piston rod2, the sliding block is disposed above the bearing stand, which connects the sliding block and a sliding rail. Line sleeves on the pressure rollers are set as a replaceable structure, line sleeves with appropriate structures can be selected according to different embossing requirements of foam boards, thus not only improving the embossing quality of foam boards, but also expanding the applicationscope of the embossing device, and lowering the cost of manufacturing multiple sets of embossing devices.

Owner:WUHU QIANKAI MATERIAL TECH CO LTD

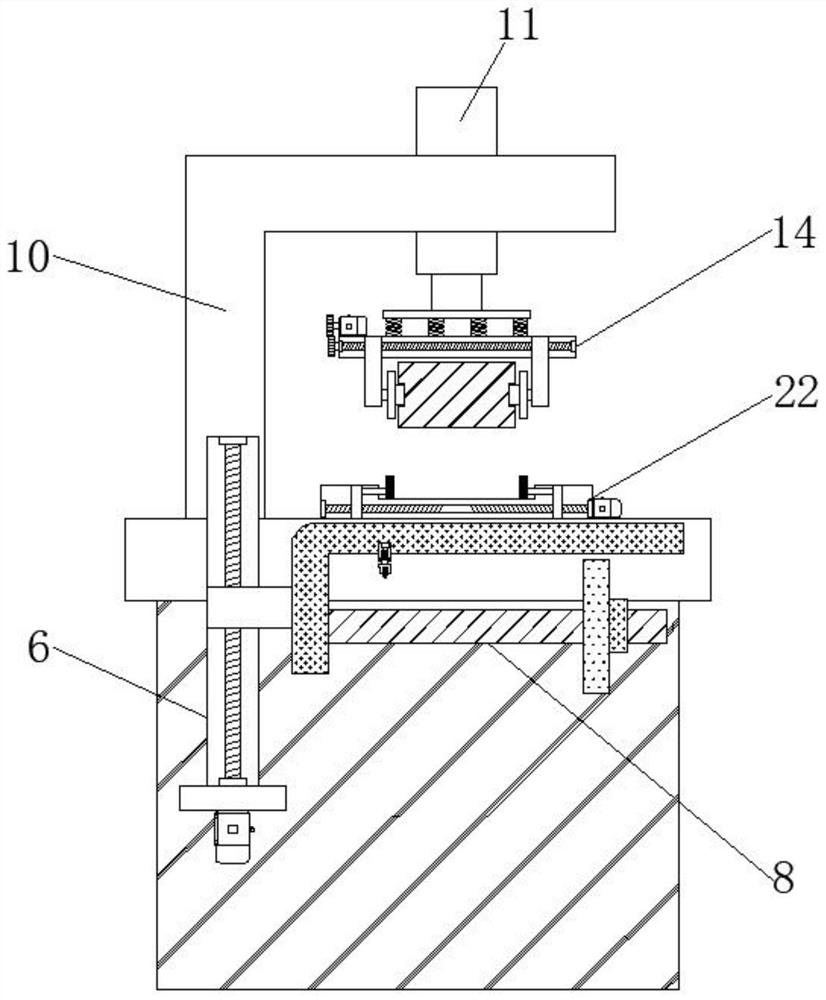

Embossing device for leather production

ActiveCN110129487ARealize synchronized movementAvoid distortionSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringMechanical engineering

The invention discloses an embossing device for leather production. The device comprises a working platform, supporting legs are welded to the four corners of the bottom of the working platform, oblique plates are installed at both front and rear ends of the left and right side walls of the working platform, the inner sides of the two oblique plates which are symmetric at front and back are rotatably connected with the first roller, both front and rear sides of the outer wall of the first roller are in clearance fit with inner rings of two bearings respectively, outer rings of the bearings arefixedly connected with the inner sides of the oblique plates, and an embossing mechanism is installed on the top of the working platform; four circular rods are included in the embossing mechanism, the four round rods are fixed to the four corners of the top of the working platform respectively, and the tops of the round rods are connected with the top plate through screws at the tops of the round rods. The embossing device has the advantages that the synchronous moving of an embossing roller and leather can be achieved to avoid the twisting deformation of leather embossing and improve the embossing quality, embossing on the leather with different thicknesses can be achieved, the practicability is high, and the demand of leather embossing is met to a great extent.

Owner:泰兴市平顺皮革制品有限公司

Embossing device used for non-woven fabric processing and convenient for mold replacement

The invention discloses an embossing device used for non-woven fabric processing and convenient for mold replacement. The embossing device comprises a main body, a limiting mechanism and a second L-shaped fixing part; a control panel is fixed to the front face of the main body; a first motor is fixed to the bottom of a fixing plate; a limiting disc is slidably connected to the outer side of a cross rod; a rotating disc is in threaded connection with the outer side of the fixing disc; and the second L-shaped fixing part is fixedly arranged at the top of the main body, and a hydraulic rod is fixedly arranged at the top of the second L-shaped fixing part. The embossing device used for non-woven fabric processing and convenient for mold replacement is provided with the limiting disc, the fixing disc, the rotating disc, a first spring and an arc-shaped plate, and the rolling width of a non-woven fabric can be limited according to the width of the non-woven fabric through sliding of the limiting disc on the cross rod; and the rotating disc on the outer side of the fixing disc rotates to drive a first trapezoidal block in the fixing disc to abut against a second trapezoidal block, so thatthe arc-shaped plate clamps the cross rod, the limiting disc is conveniently fixed, the phenomenon that the edge is irregular during non-woven fabric winding is prevented, and subsequent processing is facilitated.

Owner:王楠

Free embossing device for fabric

InactiveCN106868766AEffective clamping and flatteningAvoid curling and wrinklingPattern makingSlide plateEngineering

The invention discloses a free embossing device for a fabric. The free embossing device comprises a frame, an embossing mechanism and a fabric conveying mechanism. The embossing mechanism comprises an upper embossing assembly and a lower embossing assembly. The lower embossing assembly comprises a stepping motor, a motor fixing plate, an X axis screw, an X axis guide rail, a sliding plate, a first lower mold and a second low mold. The upper embossing assembly comprises an upper mold and an embossing cylinder. The bottom surface of the upper mold is provided with first incised patterns and first raised patterns. The top surface of the first lower mold is provided with second incised patterns and second raised patterns. The top surface of the second lower mold is provided with third incised patterns. A heating structure is arranged in the upper mold. The fabric conveying mechanism comprises a discharge roller group, a material collection roller and a material collection motor. A cooling mechanism is arranged between the material collection roller and the upper mold. The free embossing device has a compact structure, is easy to use, can emboss different patterns and realizes good embossing quality and efficiency.

Owner:JIAXING WANYUAN FASHION

Metal plate multi-layer texture embossing machining process

InactiveCN113002229AAvoid damageQuality improvementDirt cleaningCleaning using toolsElectric machineEngineering

The invention discloses a metal plate multi-layer texture embossing machining process. An operator feeds a metal plate into an embossing device, a working switch of a feeding mechanism is started, a second linear motor slides leftwards on the surface of a second linear sliding rail, and a positioning frame is driven to be sent out from the left side of a cleaning box. According to the metal plate multi-layer texture embossing machining process, an output shaft of a cleaning motor drives a rotating rod to rotate, a cleaning roller synchronously rotates along with the rotating rod, the surface of the cleaning roller makes contact with the surface of the metal plate, the cleaning roller cleans impurities on the surface of the metal plate, and meanwhile a working switch of a dust collector is started; a dust suction hopper is matched with a dust guide pipe to suck cleaned impurities into a dust suction machine, the cleaning work of the impurities on the surface of the metal plate is completed, the impurities on the surface of the metal plate are cleaned in advance, and meanwhile, the dust suction machine is matched for collecting the impurities, so that the situation that an embossing assembly is damaged by the impurities on the surface of the metal plate is avoided, and the embossing machining quality is improved.

Owner:穆可刚 +1

Embossing stamp and die plate holder for the embossing stamp

ActiveUS9475337B2Easy to operateEasy to manufactureStampingEmbossing decorationsBuilding constructionSurface plate

The invention describes an embossing stamp comprising at least a base unit in which a retaining device is disposed on one side to retain a die plate holder and an operating device is disposed on a further side. The operating device is constructed such that it directly or indirectly acts on the retaining device, wherein a pivot of the operating device is disposed in the base unit. The base unit and / or the operating device are modular in construction, wherein the side walls are at least partially formed by panels which are positioned with respect to each other and fastened via half-shells and / or connecting means.

Owner:TRODAT GMBH

Embossing device for polyvinyl chloride (PVC) tablecloth processing

The invention belongs to the technical field of polyvinyl chloride (PVC) tablecloth processing, in particular to an embossing device for PVC tablecloth processing. Aiming at the problem of a poor embossing effect on a PVC base layer in the prior art, the invention provides the following scheme that the embossing device for PVC tablecloth processing comprises a fixed frame, wherein two embossing rollers are rotatably connected in the middle position between the inner walls of two ends of the fixed frame; two limiting rollers are rotatably connected to the positions, located on two sides of theembossing rollers, between the inner walls of two ends of the fixed frame; inclinedly arranged limiting grooves are formed in the positions, corresponding to the limiting rollers, on the inner walls of two ends of the fixed frame; the top ends of the limiting grooves are inclined toward one sides far away from the embossing rollers; and limiting blocks are slidably connected to the inner walls ofthe limiting grooves. According to the embossing device for PVC tablecloth processing provided by the invention, by utilizing first springs, the shrinkage or elongation of the PVC base layer in the horizontal direction during embossing operation can be reduced; and by utilizing protruding pieces spirally distributed on the outer walls of the limiting rollers, the friction force between the limiting rollers and the PVC base layer in the horizontal direction is improved, so that an embossing error is reduced, and an actual embossing effect of the PVC base layer is improved.

Owner:刘广松

Embossing stamp and die plate holder for the embossing stamp

ActiveUS20150246574A1Easy to operateEasy to manufactureMechanical working/deformationStampingEngineeringModular structure

The invention describes an embossing stamp comprising at least a base unit in which a retaining device is disposed on one side to retain a die plate holder and an operating device is disposed on a further side. The operating device is constructed such that it directly or indirectly acts on the retaining device, wherein a pivot of the operating device is disposed in the base unit. The base unit and / or the operating device are modular in construction, wherein the side walls are at least partially formed by panels which are positioned with respect to each other and fastened via half-shells and / or connecting means.

Owner:TRODAT GMBH

Wood floor embossing device

InactiveCN104290517AUniform depthImprove embossing qualityEmbossing decorationsDrive motorWood grain

The invention discloses a wood floor embossing device. A carrier roller set A is fixed to a rack through a bearing. An upper press roller with wood grains is fixed above the carrier roller set A through a supporting frame A. A carrier roller set B is fixed above the rack through a supporting frame B. A lower press roller with wood grains is fixed below the carrier roller set B through a supporting frame C. A rotary shaft of the upper press roller with the wood grains is provided with a belt pulley A and a belt pulley B. A rotary shaft of the lower press roller with the wood grains is provided with a belt pulley C. The belt pulley A and the belt pulley C are connected through a belt A. A drive motor is arranged below the rack. An output shaft of the drive motor is provided with a belt pulley D. The belt pulley B and the belt pulley D are connected with a belt B. An electric control cabinet is arranged at one end of the rack, and a belt conveyor is arranged at the other end of the rack. The drive motor and the belt conveyor are each electrically connected with the electric control cabinet through a wire. Pressure applied to a wood floor by upper press roller with the wood grains and the lower press roller with the wood grains can be adjusted automatically, so that obtained wood grains are uniform in depth and are more vivid.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

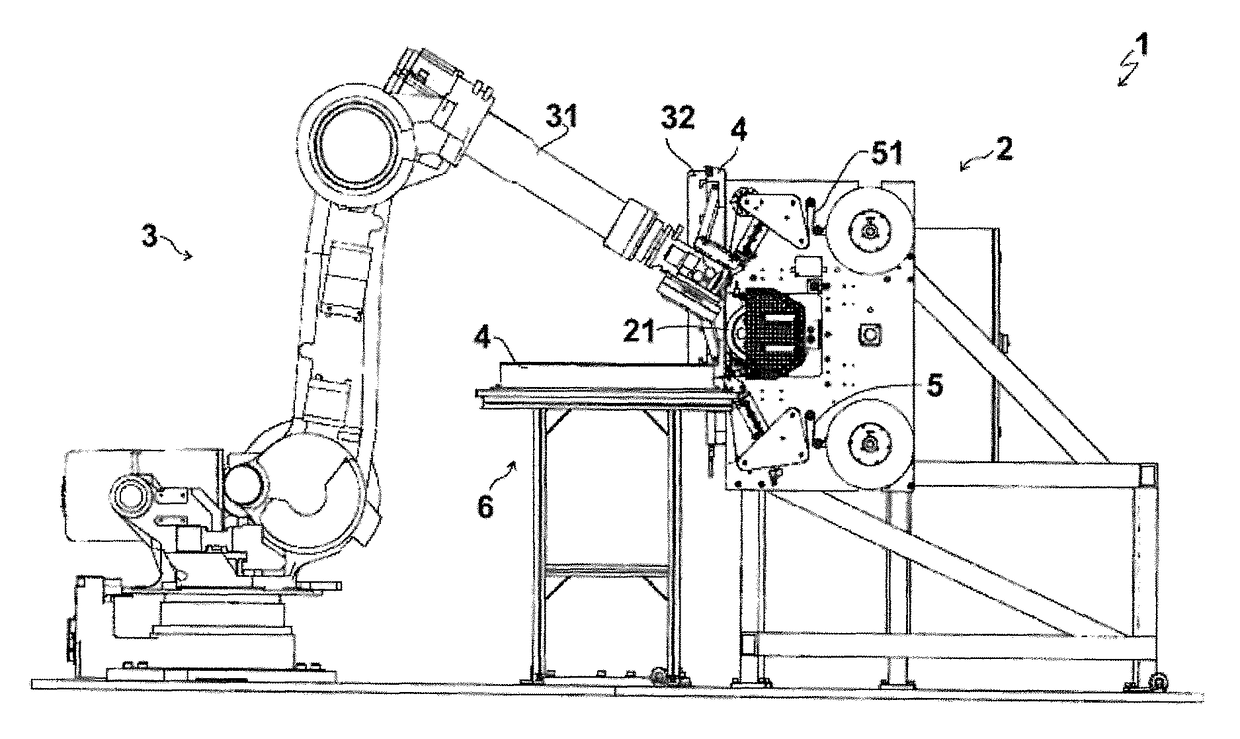

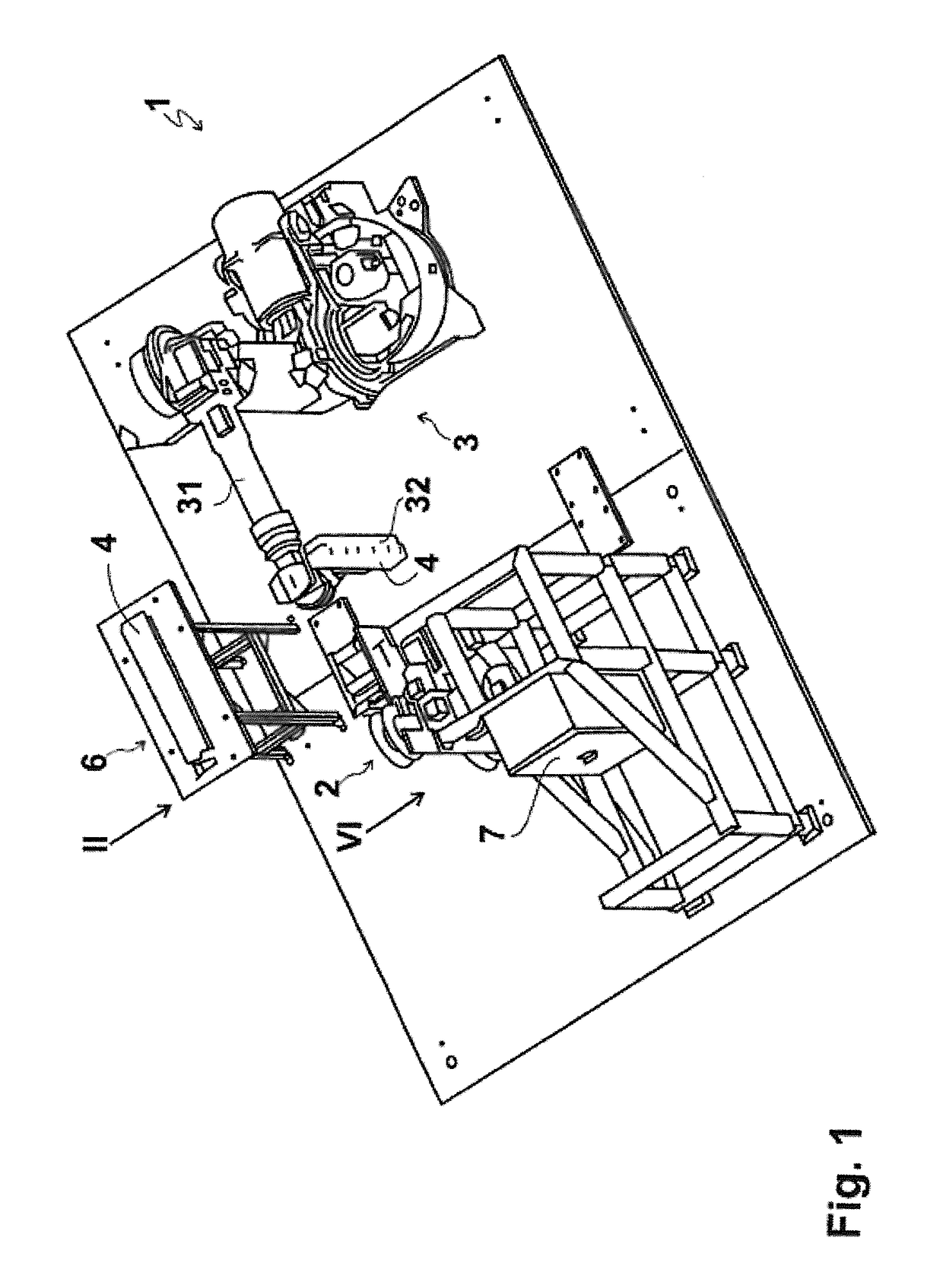

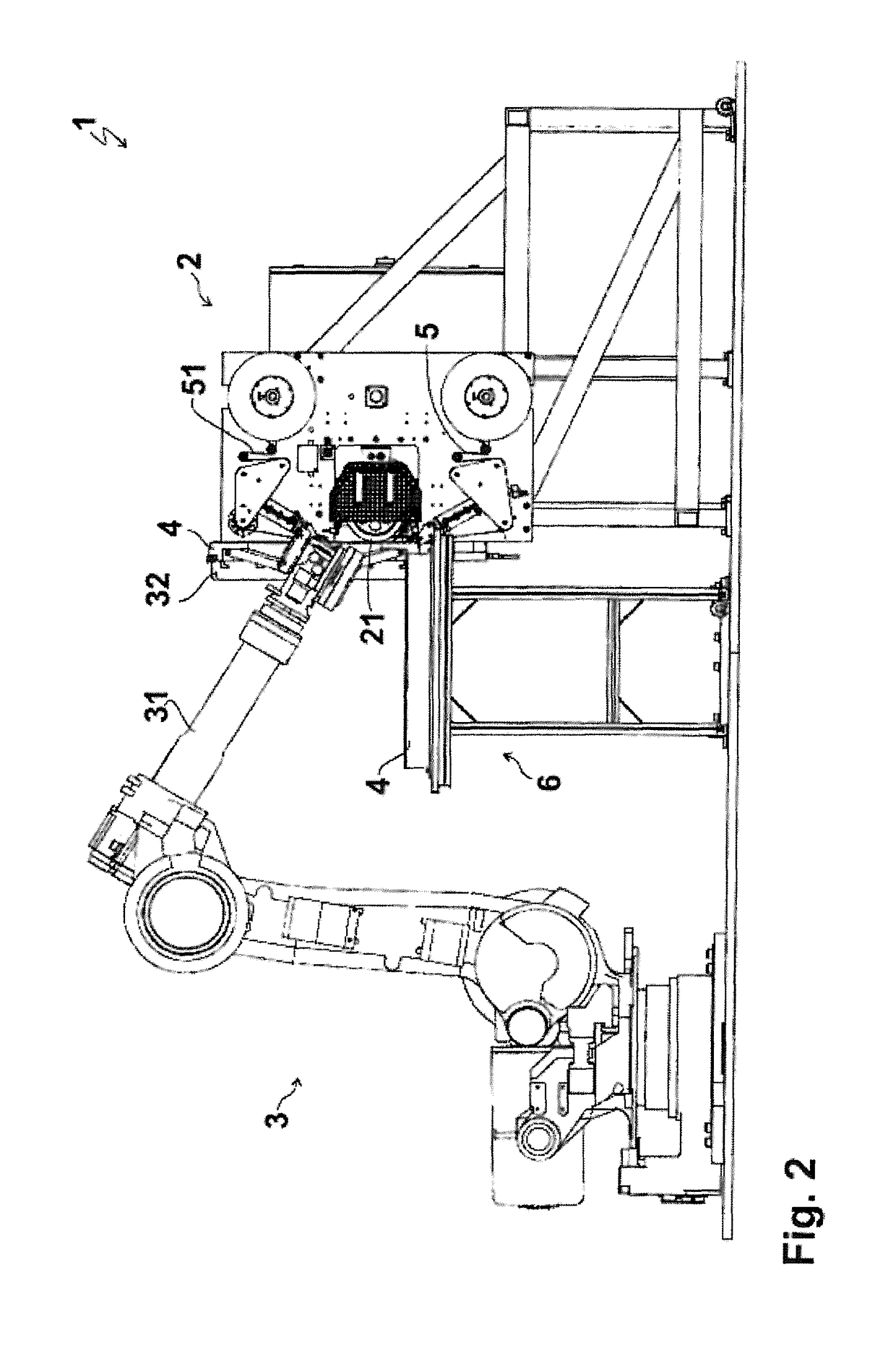

Film-embossing apparatus

ActiveUS9849624B2Improve embossing qualityLamination ancillary operationsLaminationContact pressureEngineering

A film-embossing apparatus with a hot-embossing device which has a heated embossing stamp. With the formation of a contact pressure, a transfer layer, arranged on a carrier film, of a hot-embossing film is transferred to a surface of a workpiece. The hot-embossing device has control inputs and outputs. The film-embossing apparatus has an industrial robot with control inputs and outputs. The control inputs and outputs of the hot-embossing device and of the industrial robot are connected to a control unit. The industrial robot is formed such that it guides the workpiece to the hot-embossing device, positions the workpiece on the embossing stamp, guides the workpiece past the embossing stamp, and guides the embossed workpiece away from the hot-embossing device. The industrial robot can also position the hot-embossing device on the workpiece.

Owner:LEONHARD KURZ STIFTUNG & CO KG

Negative pressure type embossing device capable of rapidly unfolding clothes

InactiveCN112680920AAvoid wrinklesGood for normal embossing operationsPattern makingEngineeringPleat

The invention discloses a negative pressure type embossing device capable of rapidly unfolding clothes. The embossing device comprises an embossing device body, an operation table, a protective door, a support frame, a telescopic mechanism, a support plate, an embossing plate, a control box, a connecting pipe, an exhaust fan, a reset rotating shaft and a fixing screw, wherein the operation table is arranged on the embossing device body; the protective door is arranged on the front side of the operation table; a sliding part is arranged at the lower end of a tensioning structure; the sliding part is connected with a sliding groove in the upper end face of the operation table; meanwhile, a pulling frame is welded to the upper end of a pressing part; and pressing blocks are glued to the inner sides of the front ends of the sliding part and the pressing part. According to the negative pressure type embossing device capable of rapidly unfolding the clothes, by improving an operation table and an embossing plate mounting structure of an existing embossing device, when the clothes are embossed, the area, needing to be embossed, of the clothes can be spread flatly, so that wrinkles of the clothes are avoided, normal embossing operation of the clothes is facilitated, and the embossing quality of the clothes is improved.

Owner:马鞍山鸿儒工业设计有限公司

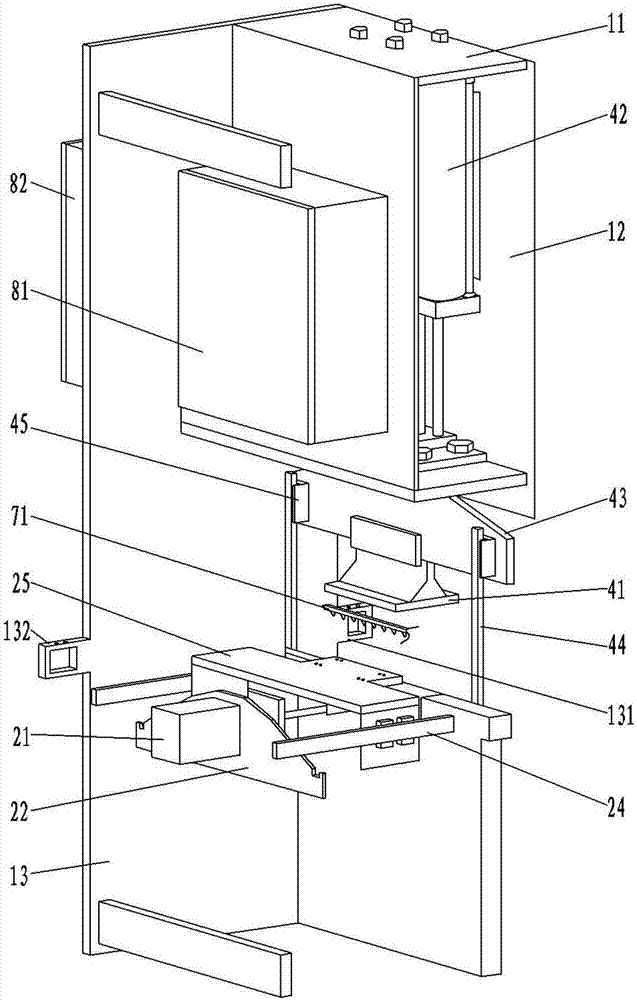

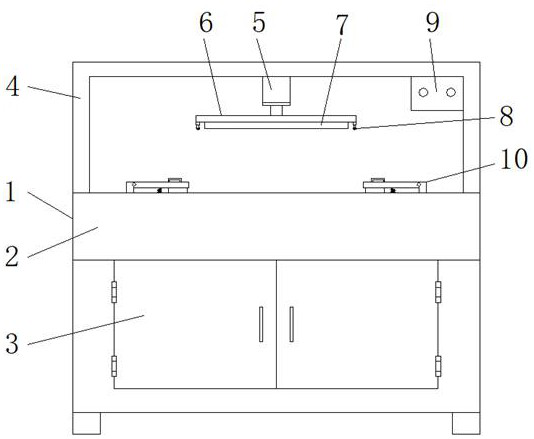

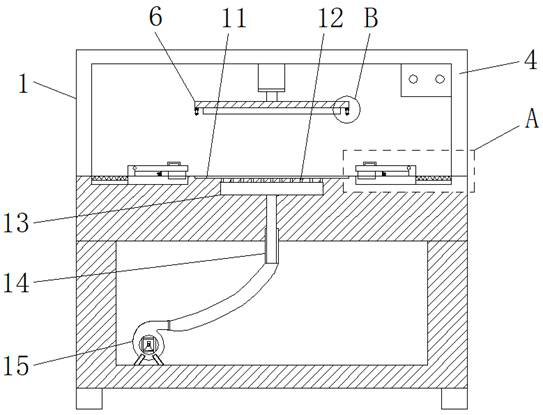

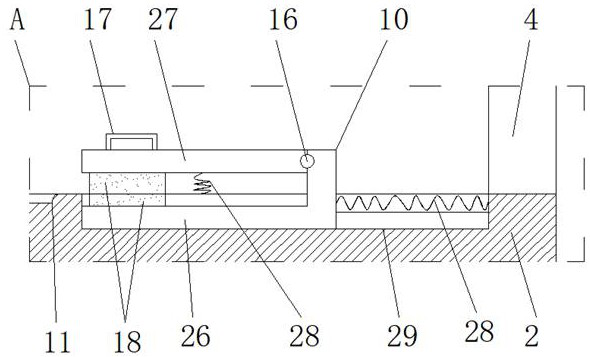

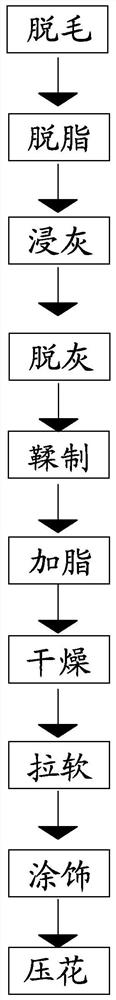

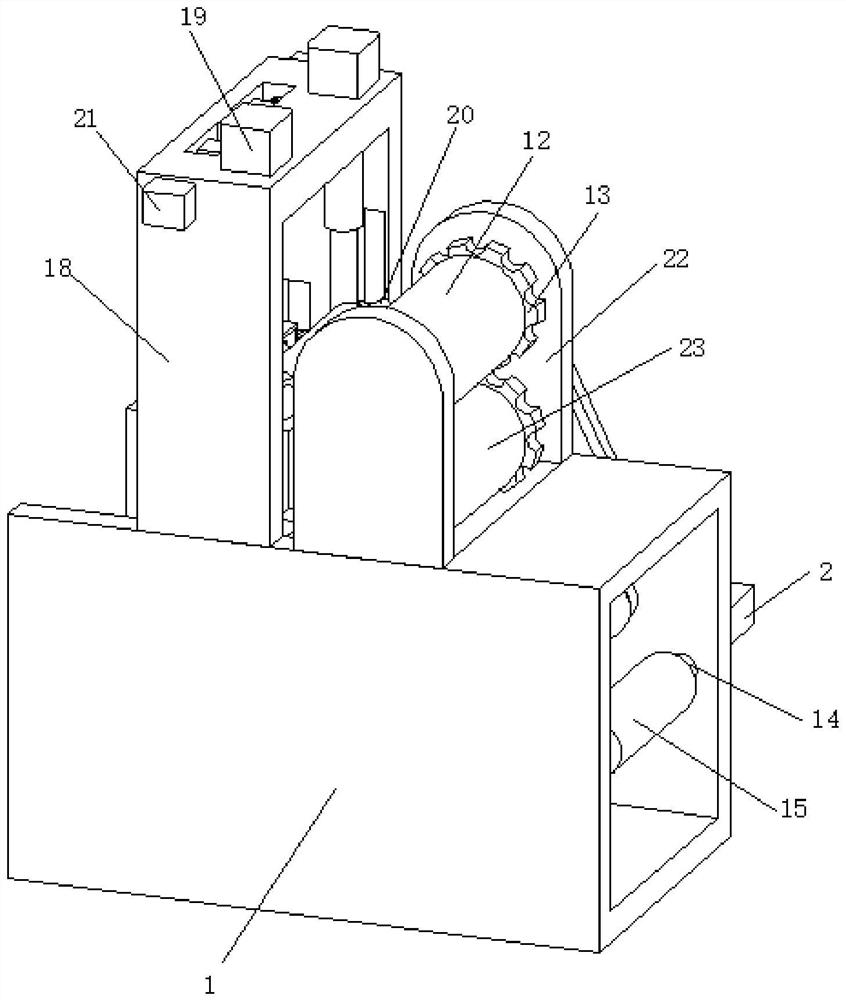

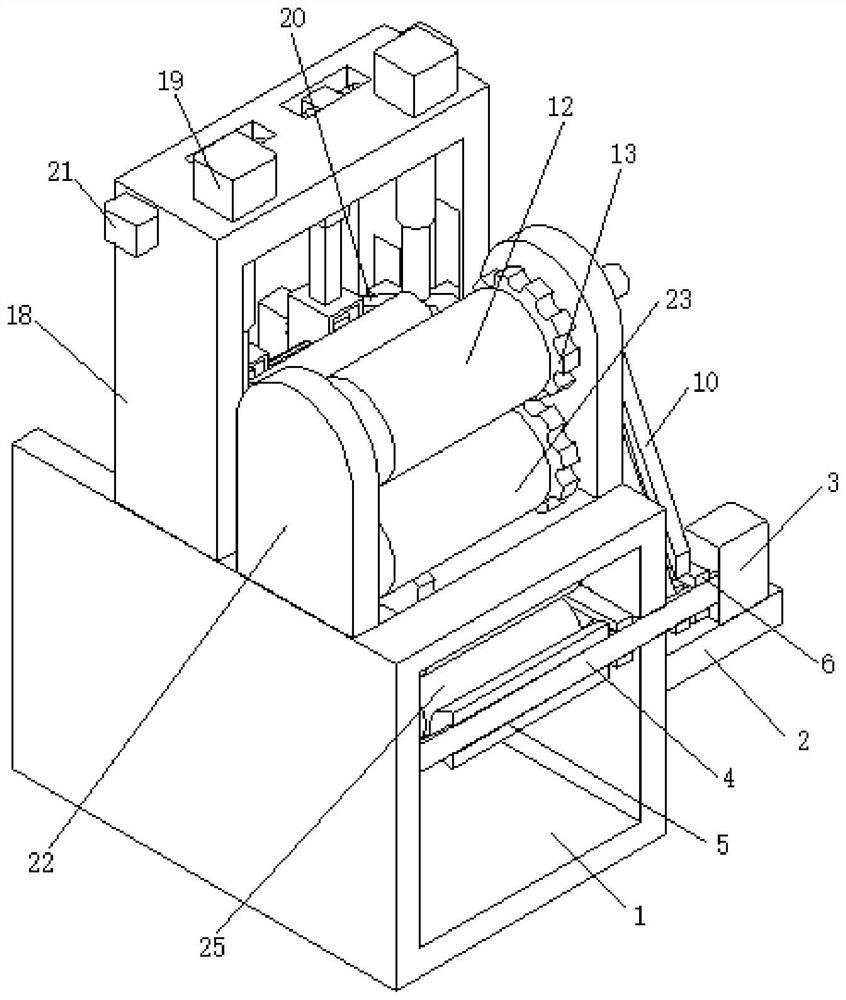

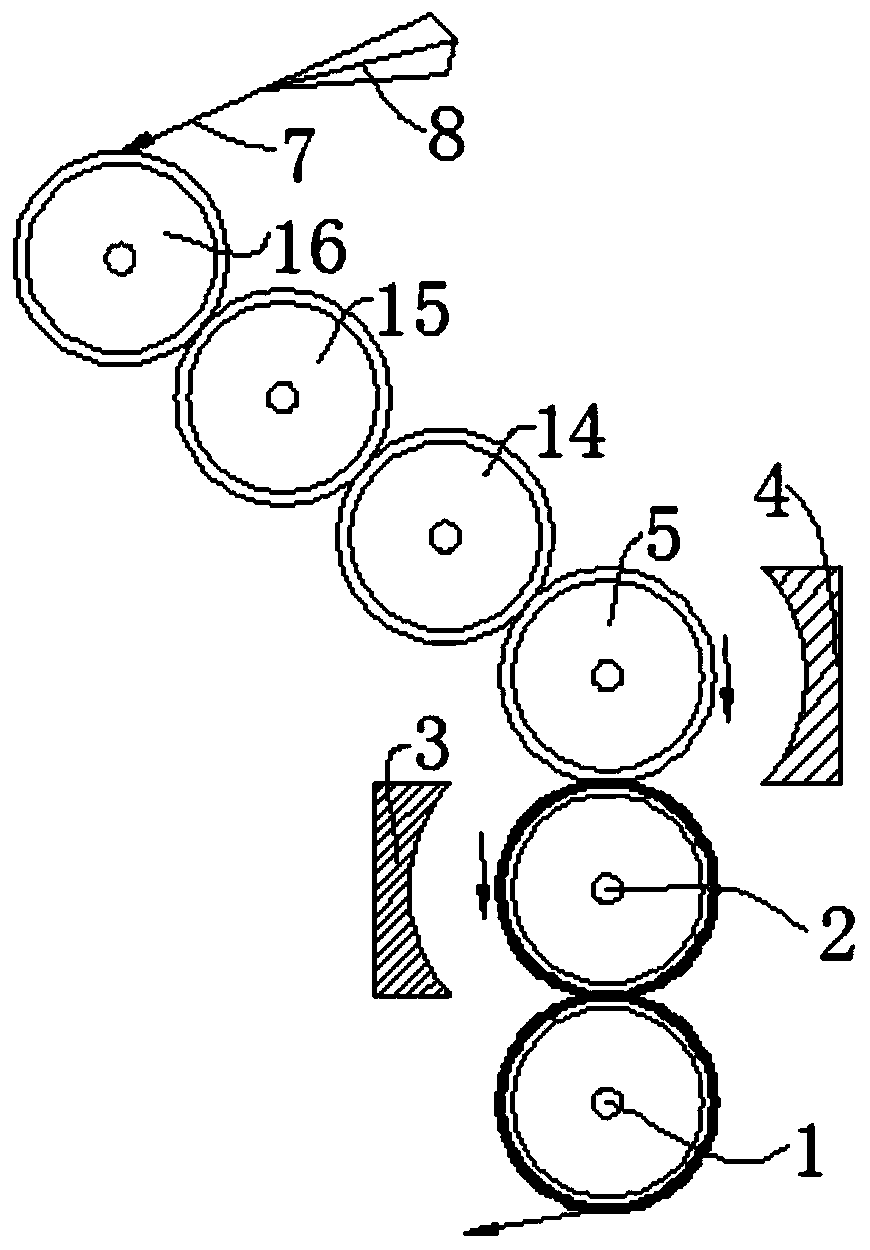

A kind of printed top layer leather and its processing technology

ActiveCN109439808BEmbossing process is smoothImprove embossing qualityTanning treatmentPre-tanning chemical treatmentTextile printerMechanical engineering

The invention discloses a processing technology of embossing top layer leather. The embossing top layer leather is made through the steps of depilating, degreasing, liming, deliming, tanning, fat liquoring, drying, staking, finishing and embossing; in the embossing step, the top layer leather is subjected to printing through an embossing machine; the embossing machine comprises an embossing frame,a flattening device, an embossing device and a cooling roller, and the flattening device, the embossing device and the cooling roller are sequentially arranged on the embossing frame according to theprocessing sequence; the flattening device comprises a heating plate, a flattening piece and a plurality of compressed springs; the multiple compressed springs are vertically and uniformly distributed on the embossing frame, one ends of the compressed springs are connected with the embossing frame, and the other ends of the compressed springs are connected with the lower surfaces of the heating plate; the flattening piece is used for flattening and pushing the top layer leather; the embossing device embosses the top layer leather after flattening; and the embossed top layer leather is cooledthrough the cooling roller. Compared with the prior art, the embossing effect and the embossing efficiency of the processing technology are greatly improved.

Owner:JINJIANG YUANTAI LEATHER

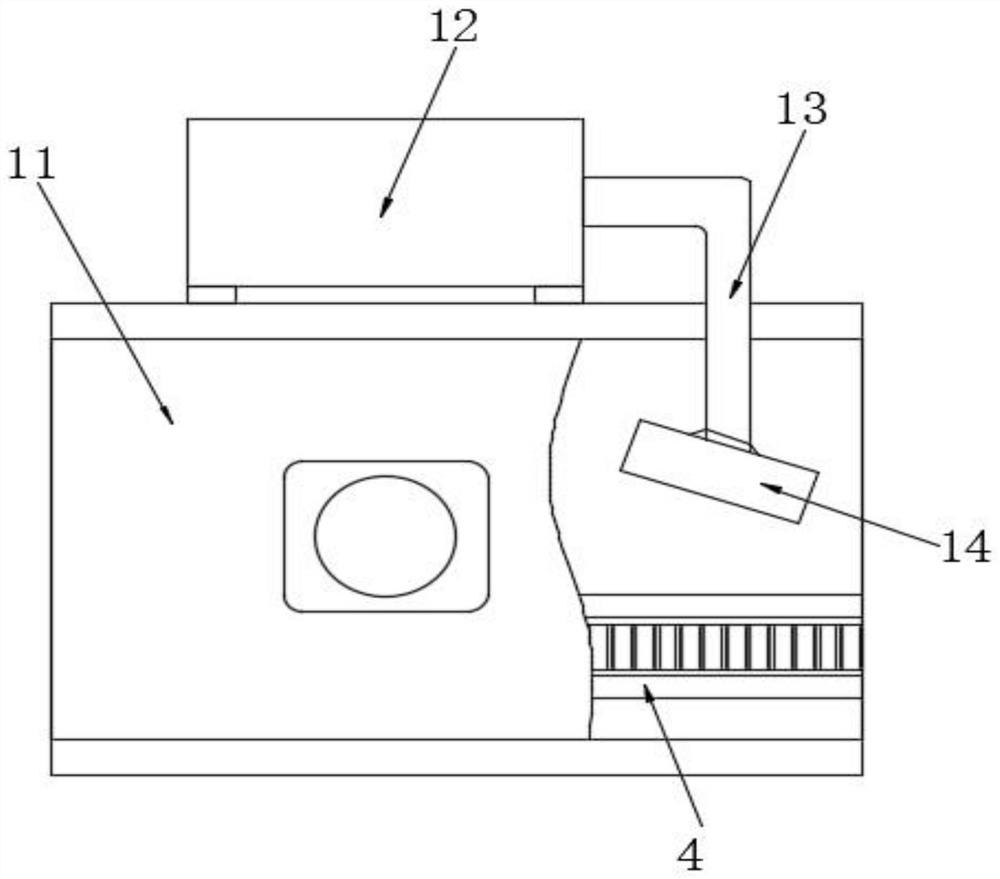

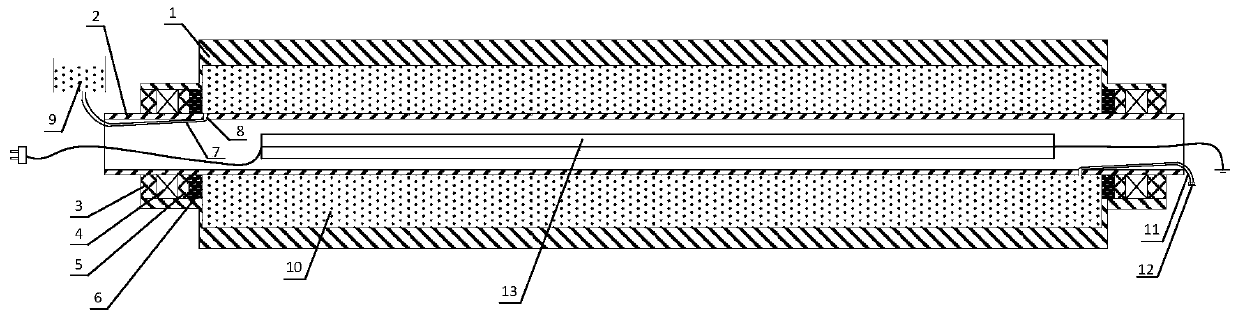

Embossing machine for producing anti-counterfeiting mark type cigarette aluminum-foil paper

PendingCN114834096AReduce consumptionGood energy saving effectMechanical working/deformationMetal working apparatusAluminium foilPaper production

The invention relates to the technical field of aluminum-foil paper embossing equipment, and discloses an embossing machine for anti-counterfeiting mark type cigarette aluminum-foil paper production, the embossing machine comprises a supporting box body, and the right side of the rear end of the supporting box body is fixedly connected with a supporting plate. The embossing cutting structure can move up and down through the lifting structure, then a first embossing roller can make complete contact with aluminum-foil paper, a first embossing rod can drive the first embossing roller to rotate through a second motor, then the first embossing roller conducts secondary embossing work on the aluminum-foil paper, and therefore the aluminum-foil paper can be subjected to secondary embossing. And through cooperative use of a third motor and a first groove rod, the overall stability of the embossing cutting structure can be improved through connection of the first groove rod and a groove plate, and through rotation of the first groove rod, the embossing quality of the equipment is improved. And the cutting disc is used for cutting the aluminum-foil paper, so that the overall functionality of the equipment is improved.

Owner:HEFEI TOBACCO IND & TRADING GENERAL

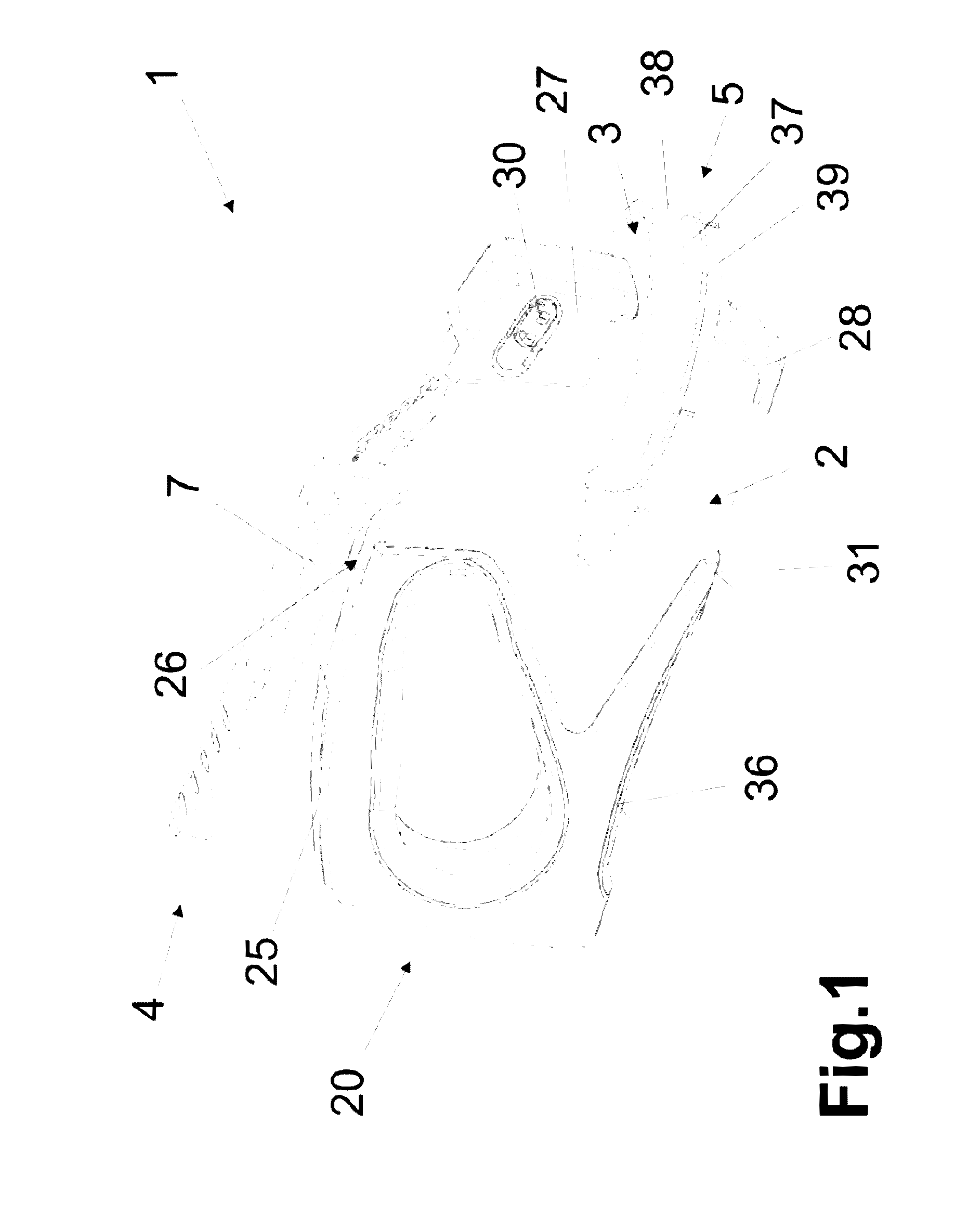

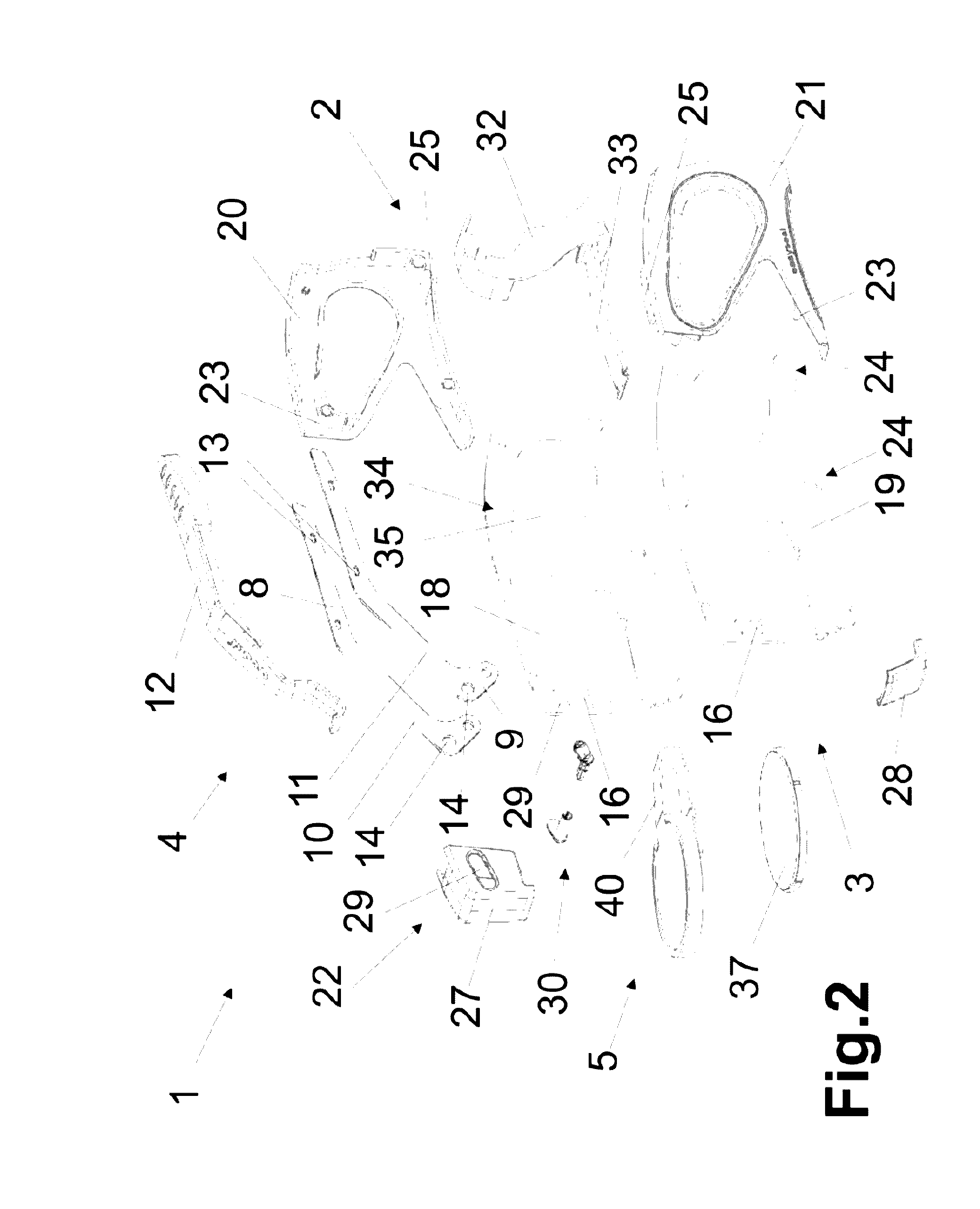

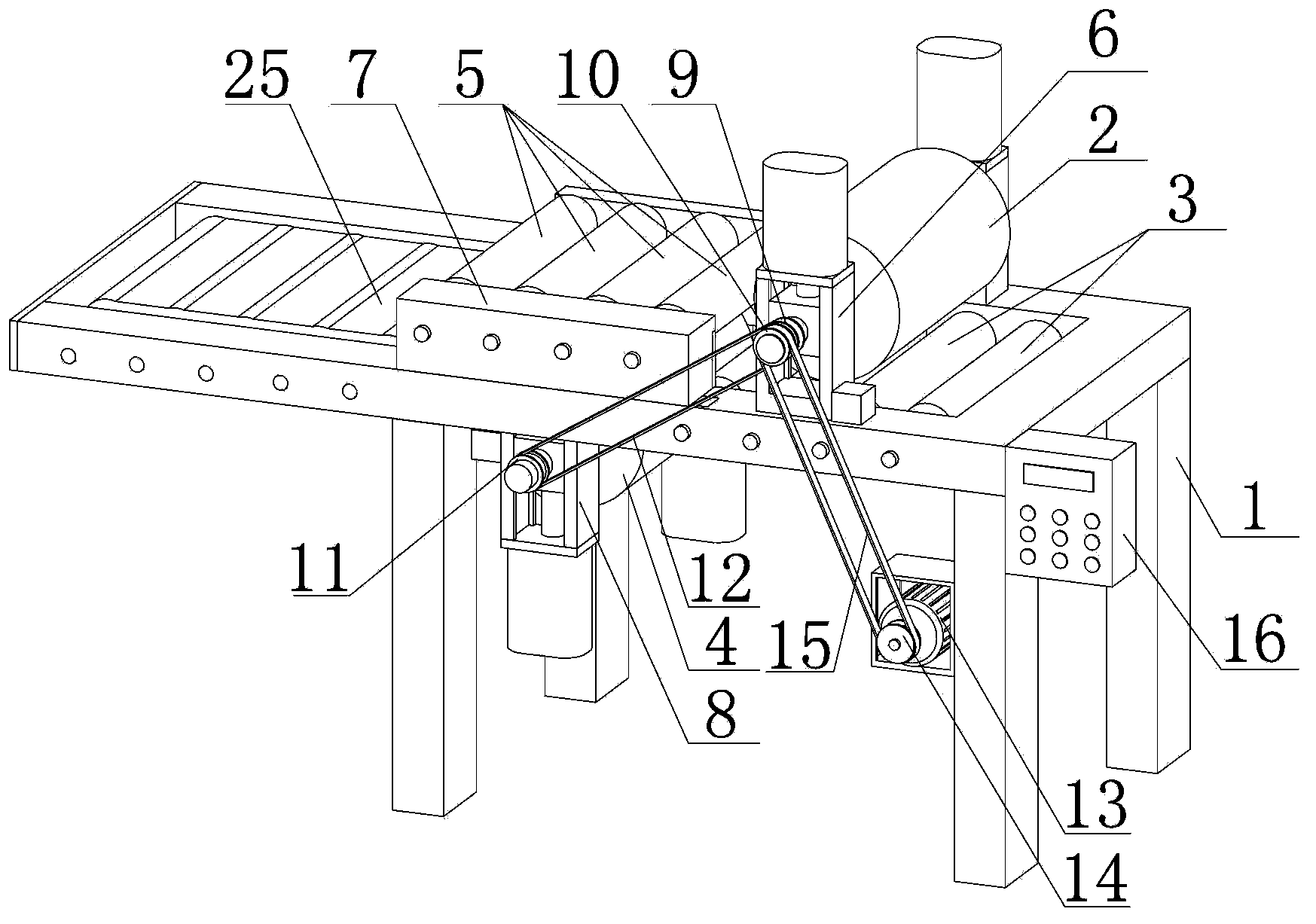

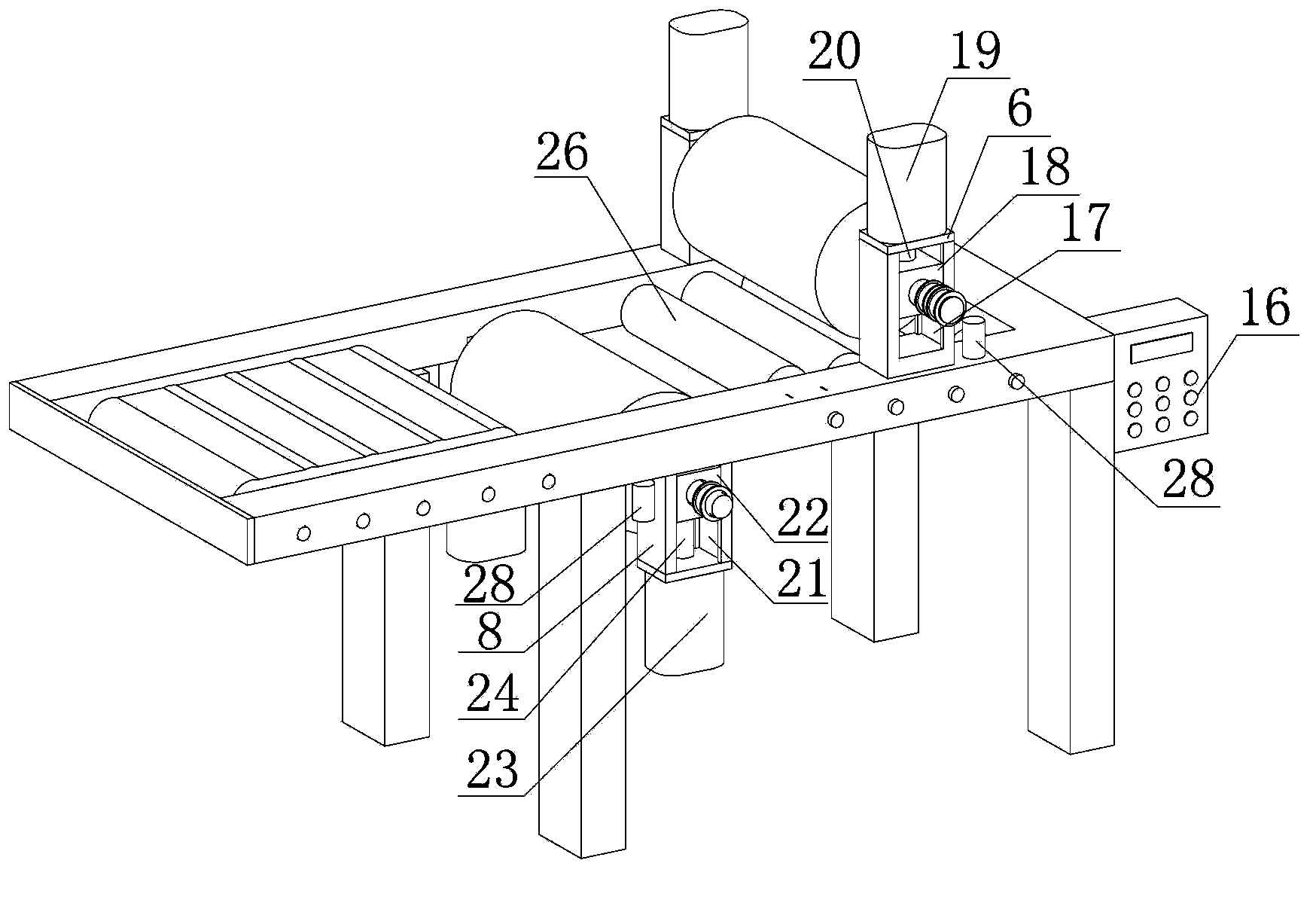

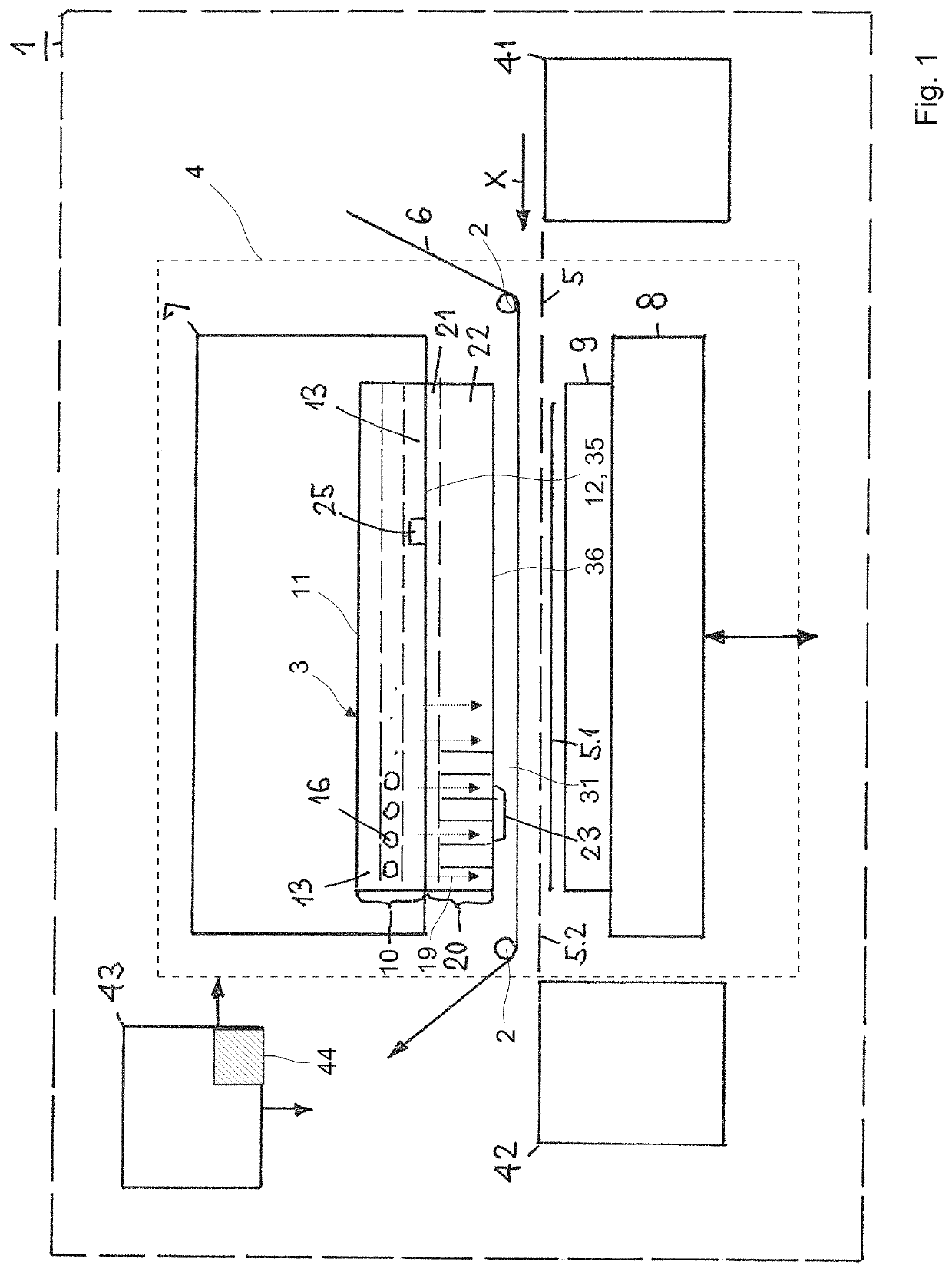

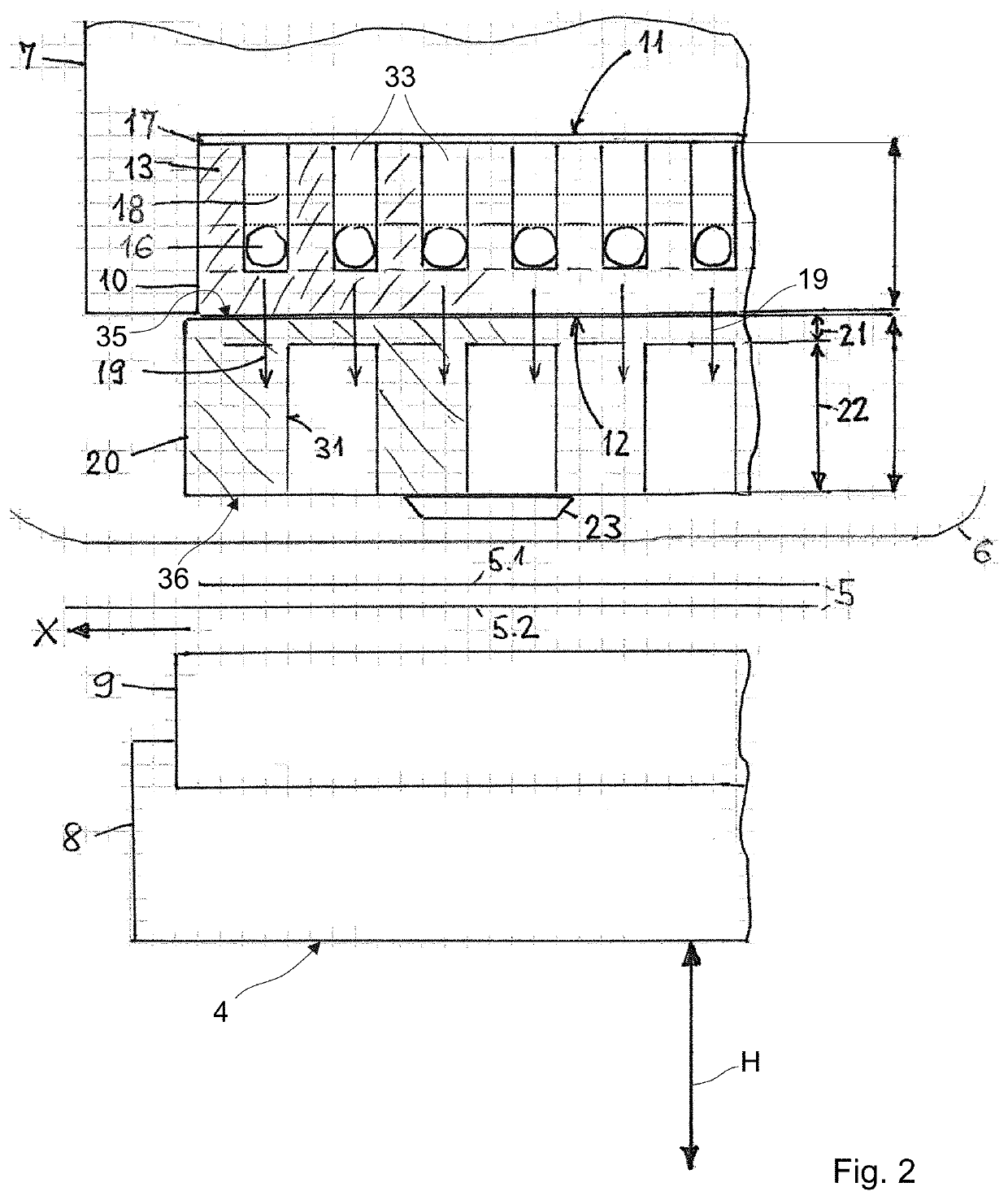

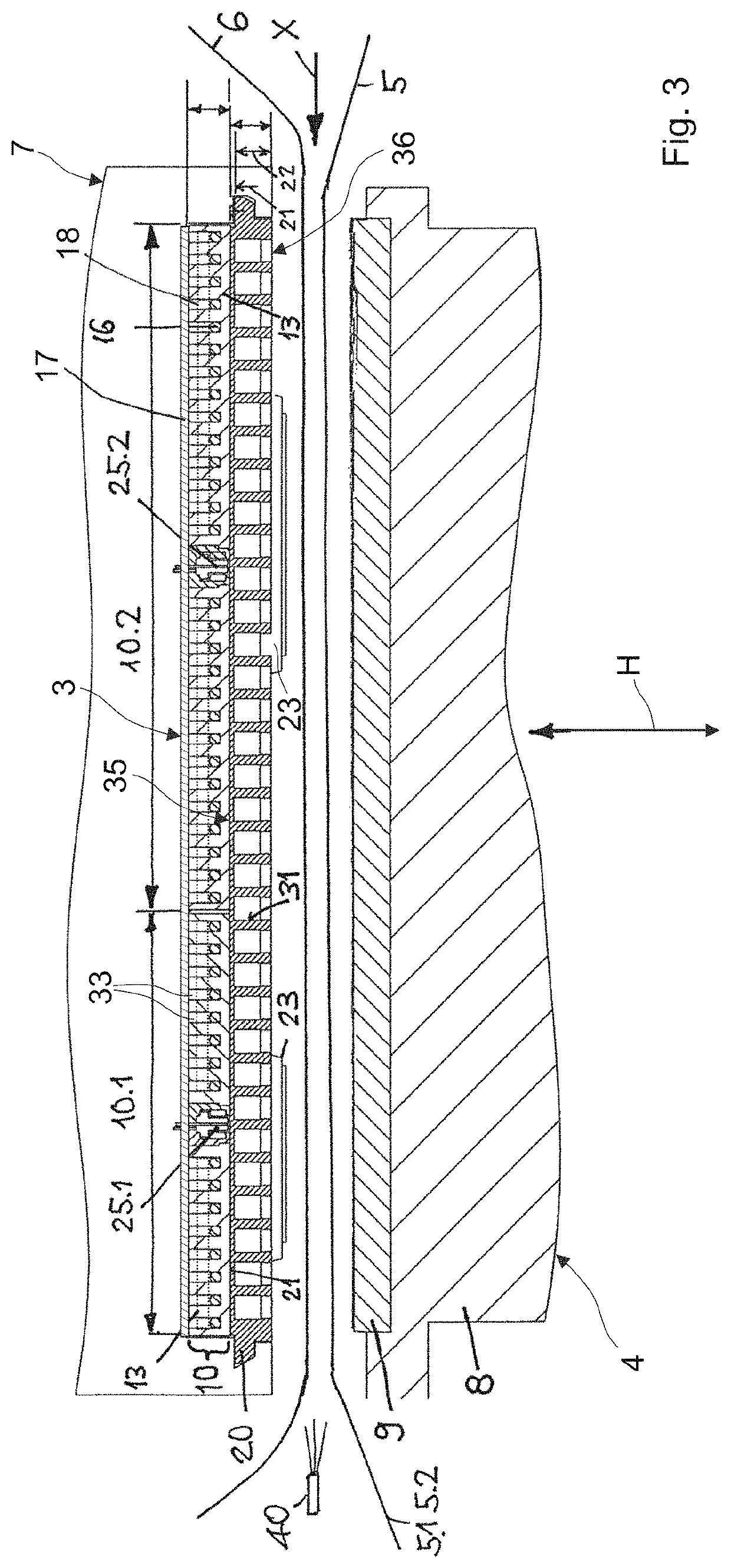

Flatbed embossed-printing machine and embossing plate

ActiveUS11117416B2Reduce settingsReduced reconfiguration timeShaping toolsRotary pressesInductorPrinting press

The invention relates to a flat bed embossing machine (1) comprising a tool plate (20) with a tool side (36) for receiving at least one embossing tool and with a tool plate rear side (35) which lies opposite the tool side (36), further a base plate (10) with a tool plate side (12) which faces the tool plate rear side (35) and with a base plate rear side (11) which is lies opposite the tool plate side (12), for transmitting an embossing force which is exerted upon the tool plate (20), between the tool plate side (12) and the base plate rear side (11), as well as an induction heating appliance (3) for heating the at least one embossing tool (23). The induction heating appliance (3) comprises an inductor (16), the design of which and its arrangement between the tool plate side (12) and the base plate rear side (11) being such that a magnetic alternating field (19) which on the tool plate side (12) reaches beyond the base plate (19) and is for the inductive heating of an inductively heatable tool plate (20) can be produced beyond of the tool plate side (12) and outside the base plate (10).

Owner:GIETZ

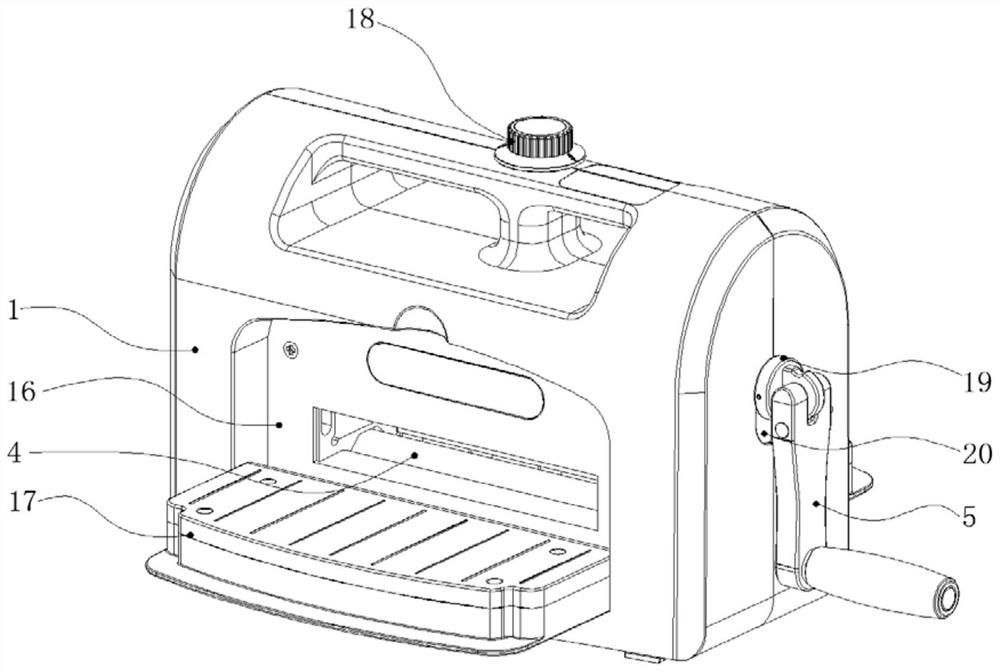

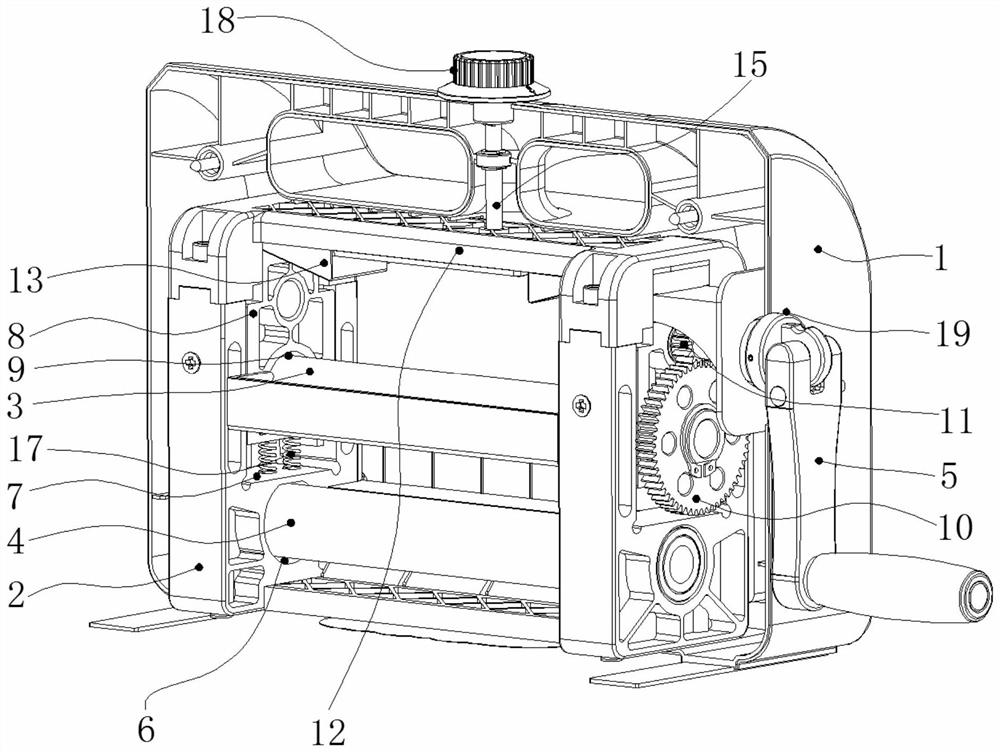

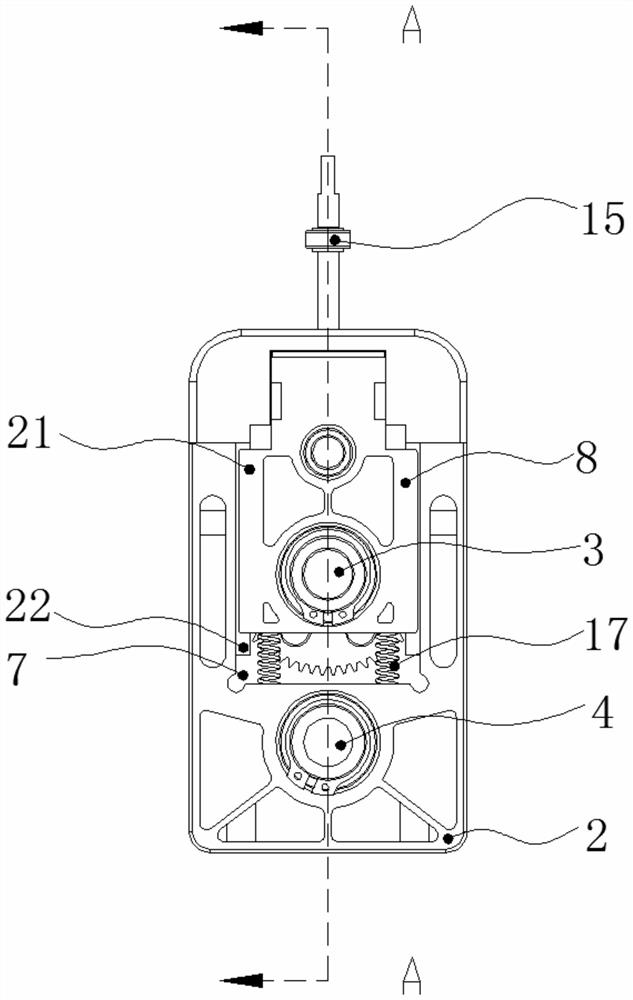

Hand-cranking type multifunctional paper art embossing machine with adjustable roller distance

The invention discloses a hand-cranking type multifunctional paper art embossing machine with an adjustable roller distance. The hand-cranking type multifunctional paper art embossing machine comprises a mechanical shell, a machine core aluminum frame, an upper roller, a lower roller and a handle crank, the handle crank is arranged on the right side of the mechanical shell, the machine core aluminum frame is arranged in the mechanical shell, first round holes allowing the two ends of the lower roller to be inserted therein are formed in the two sides of the bottom of a mechanical aluminum frame. First cavities are formed in the two sides of the middle of the machine core aluminum frame, lifting sliding blocks are arranged in the first cavities correspondingly, second round holes allowing the two ends of the upper roller to be inserted therein are formed in the lifting sliding blocks correspondingly, a first large gear is coaxially arranged at the right end of the upper roller, a sliding groove is formed in the top of the machine core aluminum frame, a pair of racks is arranged in the sliding groove. A second large gear is arranged between the pair of racks, the pair of racks are provided with inclined planes facing the lifting sliding blocks on the same sides, the tops of the lifting sliding blocks on the two sides are also provided with inclined planes facing the racks on the same sides, and a second transmission gear shaft is arranged on the left side of the second large gear.

Owner:荣洋(东莞)文创有限公司

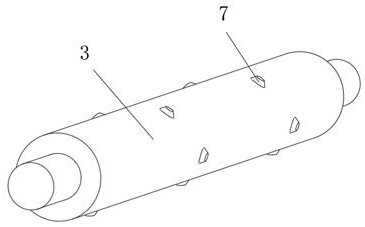

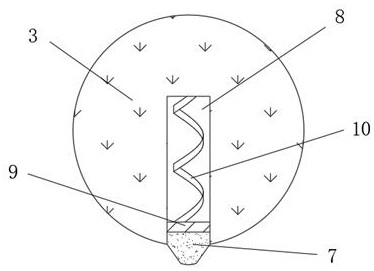

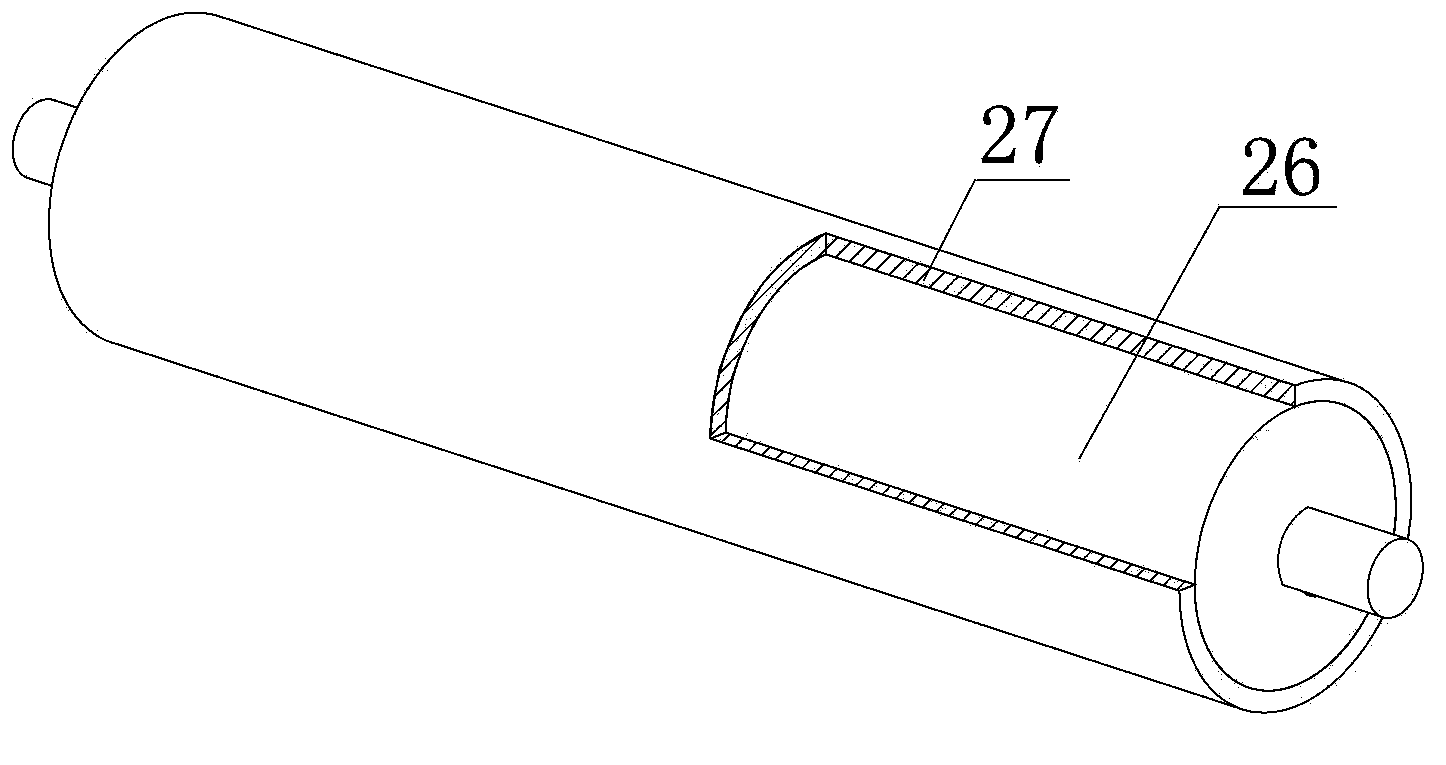

Hot roller, cloth embossing equipment and method

The invention relates to the field of textile processing, and provides a hot roller. The hot roller comprises a shell, a polished shaft and an oil pipe assembly, wherein the polished shaft is coaxially arranged in the shell in a sleeving mode; the polished shaft is a hollow pipe fitting, the two ends of the polished shaft are connected with the inner wall of the shell through bearings respectively, an oil storage cavity capable of storing liquid is formed among the shell, the polished shaft and the bearings, and a through hole capable of communicating the oil storage cavity with the oil pipe assembly is formed in the pipe wall of the polished shaft so that the oil storage cavity can communicate with an external oil tank. The hot roller is used on cloth embossing equipment, and under the working condition of long-time use, oil inlet connection of the hot roller is adjusted and switched. The hot roller is simple in structure, the shell is heated evenly, the hot roller is applied to the cloth embossing equipment, the production efficiency is high, and the embossing quality is high.

Owner:杭州德一润纺织有限公司

A convenient ribbon embossing device

The invention discloses a convenient ribbon embossing device, comprising a fixed base, the left side of the top of the fixed base is fixedly connected with a feeding mechanism, and the center of the top of the fixed base is fixedly connected with an embossing mechanism, and the fixed base is fixedly connected with an embossing mechanism. The left side of the top of the base is fixedly connected with a winding mechanism, and the feeding mechanism includes a fixed block. The number of the fixed blocks is two. The inner cavity of the fixed groove is movably connected with a hexagonal prism block, and the adjacent side of the two hexagonal prism blocks is fixedly connected with a feeding rotating shaft. The present invention achieves the effect of facilitating disassembly and assembly of ribbon rolls through the combined use of fixed blocks, hexagonal prism blocks, clamping blocks, movable blocks, pull rods, springs, clamping slots and fixing slots, thereby greatly facilitating users to replace ribbon rolls. It saves time and labor, thereby improving the working efficiency of the embossing machine, and is suitable for popularization and use.

Owner:惠州南镁丝带制品有限公司

Aluminum plate machining embossing device with cooling device

InactiveCN113580826AEasy to moveEasy embossingEmbossing decorationsWater storage tankMaterials science

The invention discloses an aluminum plate machining embossing device with a cooling device. The aluminum plate machining embossing device with the cooling device comprises a supporting mechanism, a moving mechanism and an embossing mechanism; the supporting mechanism comprises a supporting base, a water storage tank and an extrusion plate, and the extrusion plate is connected to the inner wall of one side of the water storage tank; and the moving mechanism comprises a second electric sliding rail, a second electric sliding block, a spring, a machining supporting plate, a fixing base, a ball and a second electric telescopic rod, and the bottom of the fixing base is connected with the ball. According to the aluminum plate machining embossing device with the cooling device, a liquid pump, an air inlet fan and an exhaust fan are arranged, under the action of the liquid pump, atomizing nozzles can spray water to cool an embossed aluminum plate with waste heat, meanwhile, the exhaust fan and the air inlet fan can accelerate the air circulation speed between a cooling box and the outside, therefore, the aluminum plate with waste heat after water spraying can be conveniently and rapidly dried and cooled, a worker can conveniently collect and store the aluminum plate, and meanwhile, the functionality of the device is conveniently enriched.

Owner:徐州鑫宏铝业有限公司

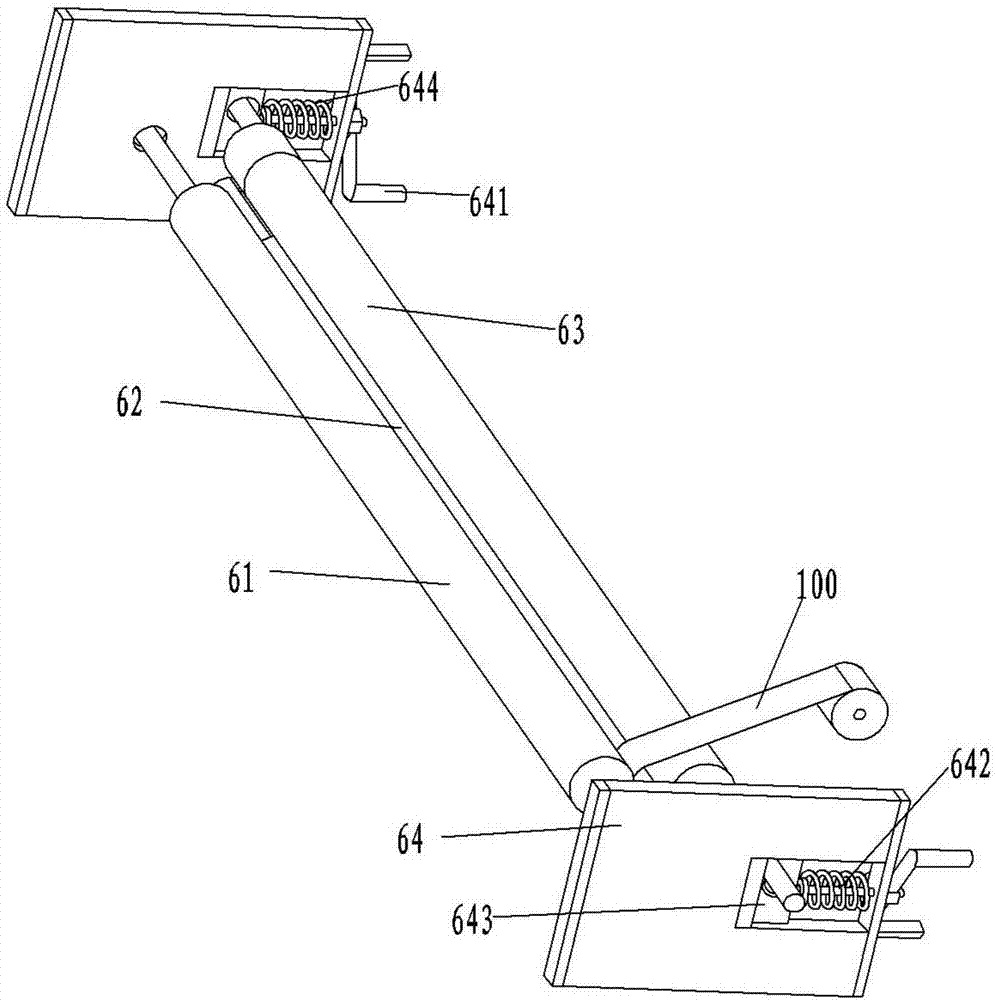

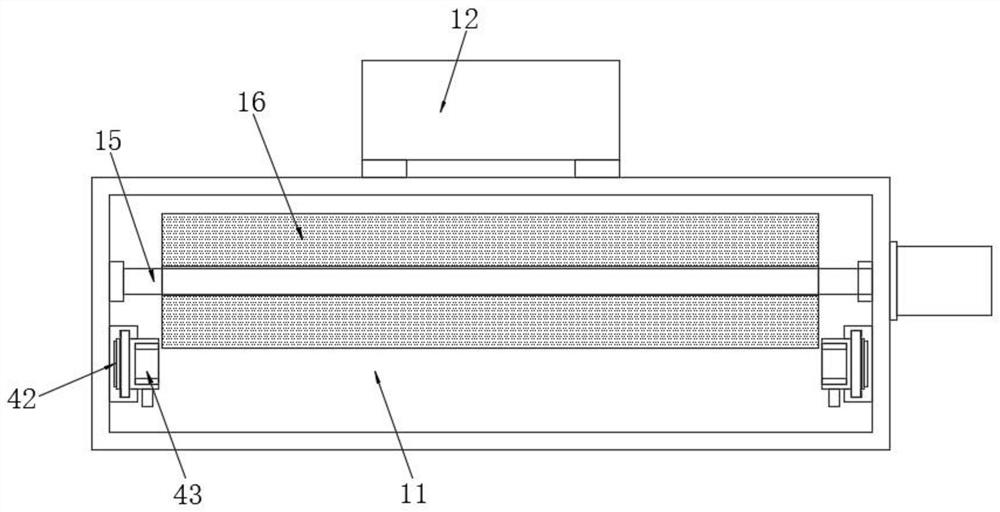

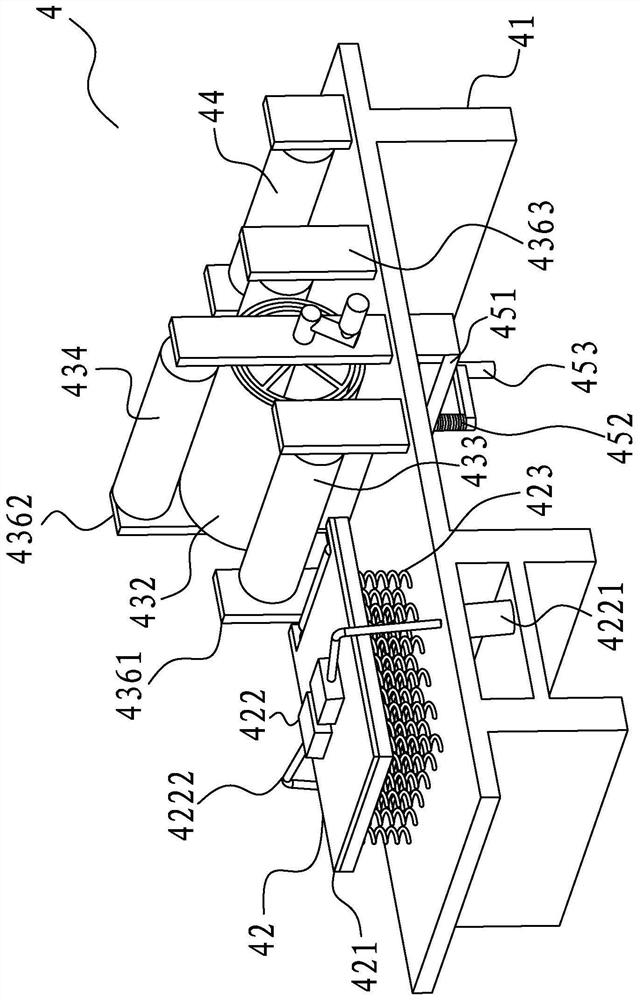

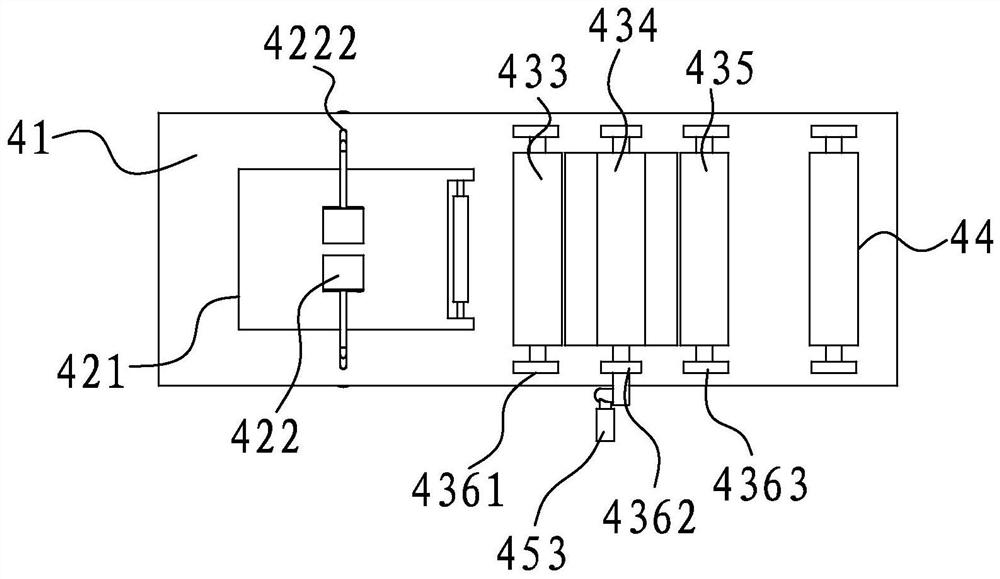

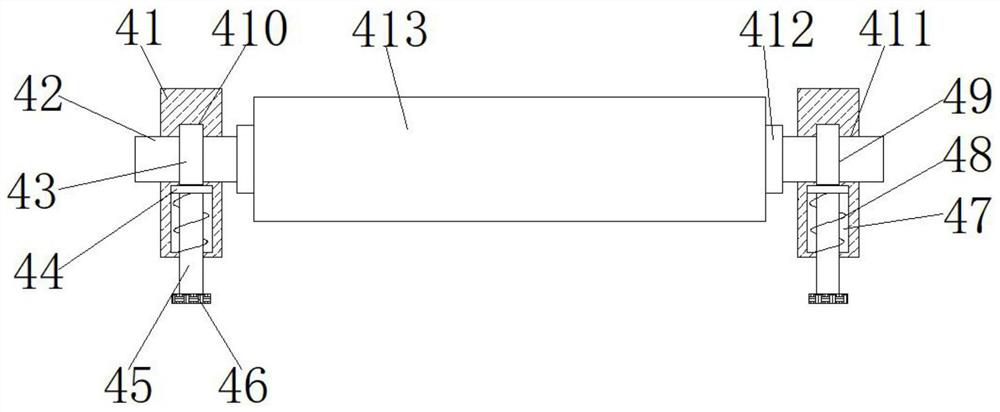

A kind of surface forming embossing equipment of pvb film and its production process

ActiveCN107116782BImprove embossing qualityImprove embossing effectFlat articlesKnurlingMoulding device

The invention discloses surface forming and knurling equipment for a PVB film and a production technology of the surface forming and knurling equipment. The surface forming and knurling equipment comprises a preforming device, a knurling device and heating devices. According to the surface forming and knurling equipment disclosed by the invention, a PVB film is formed into a uniform film piece through the preforming device, two surfaces of the PVB film piece are heated through the heating devices, and finally, the two surfaces of the PVB film piece are knurled through the knurling device so that a PVB knurling finished product is formed; and through the matching of the heating devices and the knurling device, the PVB film can be heated and knurled, so that the knurling quality and knurling effect are improved.

Owner:武汉现代精工机械股份有限公司

A kind of embossing process of pvc leather material for automobile interior decoration

ActiveCN112406085BIntelligent control of the embossing processImprove embossing qualityDomestic articlesEngineeringMechanical engineering

Owner:温州市环球汽车衬垫有限公司

Multi-station garment embossing machine for garment equipment

InactiveCN111850915ALow costNo human intervention requiredPattern makingEngineeringMechanical engineering

The invention discloses a multi-station garment embossing machine for garment equipment, which relates to the technical field of garment processing, in order to solve the problem of low efficiency. The multi-station garment embossing machine for the garment equipment specifically includes a worktable, a conveying mechanism, an embossing mechanism, and an adjustable damping material guiding mechanism; the worktable is fixed to the ground by device legs, and the inner wall of the worktable is provided with a conveying groove, a tensioning groove and a material guiding groove respectively; the conveying mechanism is arranged at a position of the worktable close to the conveying groove; the adjustable damping material guiding mechanism is arranged at a position of the worktable close to the material guiding groove; and the embossing mechanism is arranged on the top outer wall of the worktable. When the multi-station garment embossing machine for the garment equipment is in use, one end ofthe garment is fixed by the adjustable damping material guiding mechanism, and then pulled between a lower mold and an upper mold in a parallel manner, and finally fixed by the conveying mechanism; and the conveying mechanism cooperates with the adjustable damping material guiding mechanism to complete the loading and unloading of garment during the entire work process without manual intervention,which greatly improves the efficiency of embossing, thereby reducing the increase in clothing cost.

Owner:安徽工美服装有限公司

Embossing device for garment fabric

The invention discloses an embossing apparatus for a garment material. The embossing apparatus comprises a feeding mechanism, an embossing mechanism, a material recovering mechanism and a drying mechanism, wherein the feeding mechanism comprises a feeding rack, a feeding roll, a feeding cylinder, a storage bin, a pressing and conveying assembly and a conveying roll; the embossing mechanism comprises an embossing frame, an embossing shaft, an embossing motor, an end plate, a station plate, a first embossing roll, a second embossing roll, a third embossing roll, a fourth embossing roll, a lower embossing roller, a conveying roller, a shell cover and a hot steam nozzle; the lower embossing roller is provided with concave patterns respectively matching with a first convex pattern, a second convex pattern, a third convex pattern and a fourth convex pattern; and the drying mechanism comprises a drying rack, a cold-air drier, a drying roller and an auxiliary roll. The embossing apparatus provided by the invention is simple to operate, high in an automation degree, capable of pressing complex and changeable patterns on fabrics, good in embossing quality and high in embossing efficiency.

Owner:JIAXING WANYUAN FASHION

Embossing device for leather production

ActiveCN110129487BRealize synchronized movementAvoid distortionSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringMechanical engineering

The invention discloses an embossing device for leather production. The device comprises a working platform, supporting legs are welded to the four corners of the bottom of the working platform, oblique plates are installed at both front and rear ends of the left and right side walls of the working platform, the inner sides of the two oblique plates which are symmetric at front and back are rotatably connected with the first roller, both front and rear sides of the outer wall of the first roller are in clearance fit with inner rings of two bearings respectively, outer rings of the bearings arefixedly connected with the inner sides of the oblique plates, and an embossing mechanism is installed on the top of the working platform; four circular rods are included in the embossing mechanism, the four round rods are fixed to the four corners of the top of the working platform respectively, and the tops of the round rods are connected with the top plate through screws at the tops of the round rods. The embossing device has the advantages that the synchronous moving of an embossing roller and leather can be achieved to avoid the twisting deformation of leather embossing and improve the embossing quality, embossing on the leather with different thicknesses can be achieved, the practicability is high, and the demand of leather embossing is met to a great extent.

Owner:泰兴市平顺皮革制品有限公司

Tape surface embossing machine

InactiveCN105171546AStable embossingUniform stylePlane surface grinding machinesHydraulic cylinderMechanical engineering

The invention discloses a tape surface embossing machine which comprises a rack, a die frame, a motor and a hydraulic cylinder. The hydraulic cylinder is fixed to the rack. The die frame is movably connected with the rack. A piston rod of the hydraulic cylinder is connected with the die frame to drive the die frame to move up and down. The rack is provided with a proximity switch. The die frame is provided with a plurality of rotary shafts distributed in a staggered mode. The motor is fixed to the die frame to drive the rotary shafts to rotate. The tail ends of the rotary shafts are sleeved with rubber grinding heads. By means of the structure, the tape surface embossing machine is applicable to surface embossing of tape with different widths. Meanwhile, operation is easy, machining efficiency is greatly improved, and embossment is uniform.

Owner:瑞安市源码科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com