Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Easy embossing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

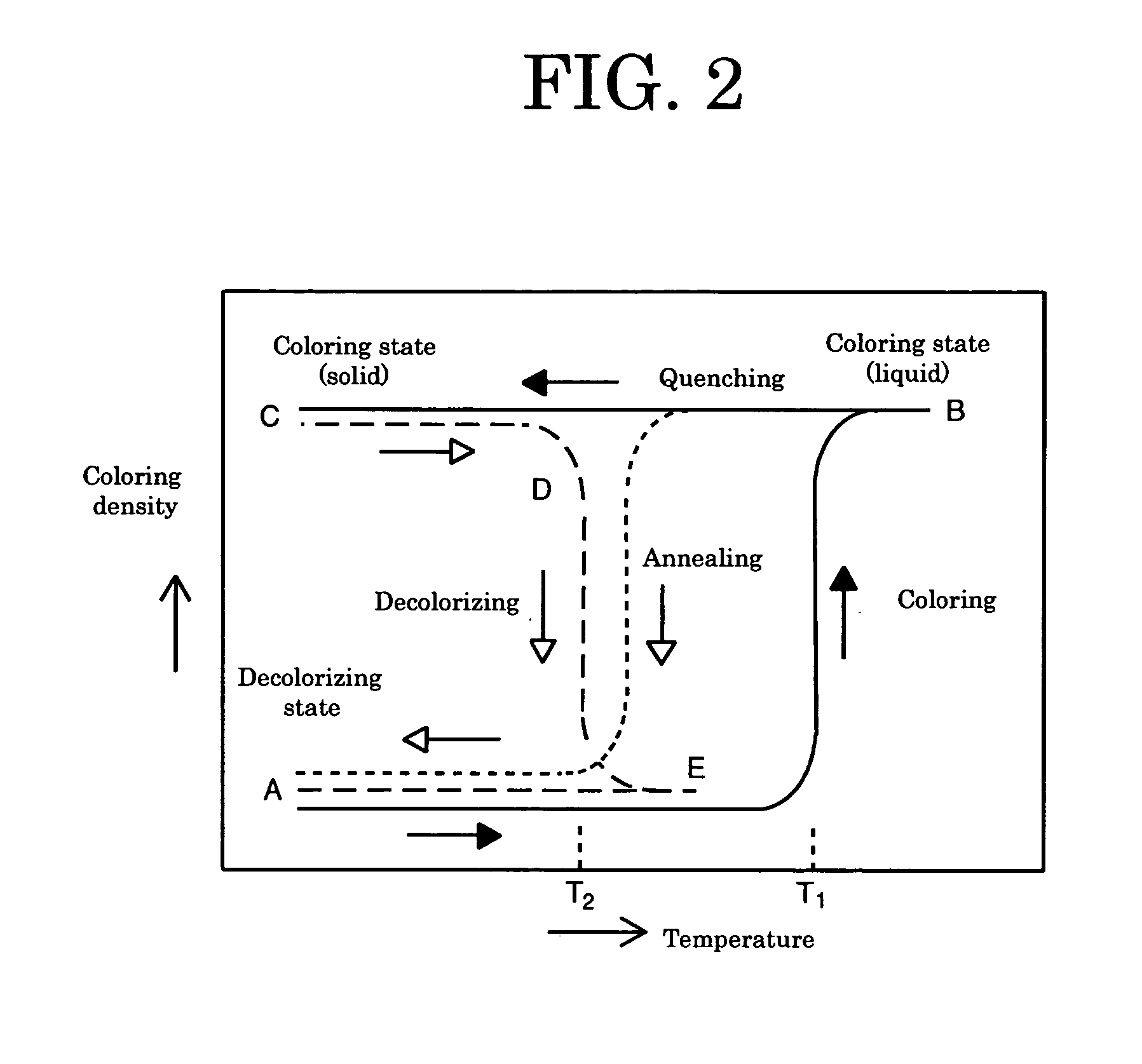

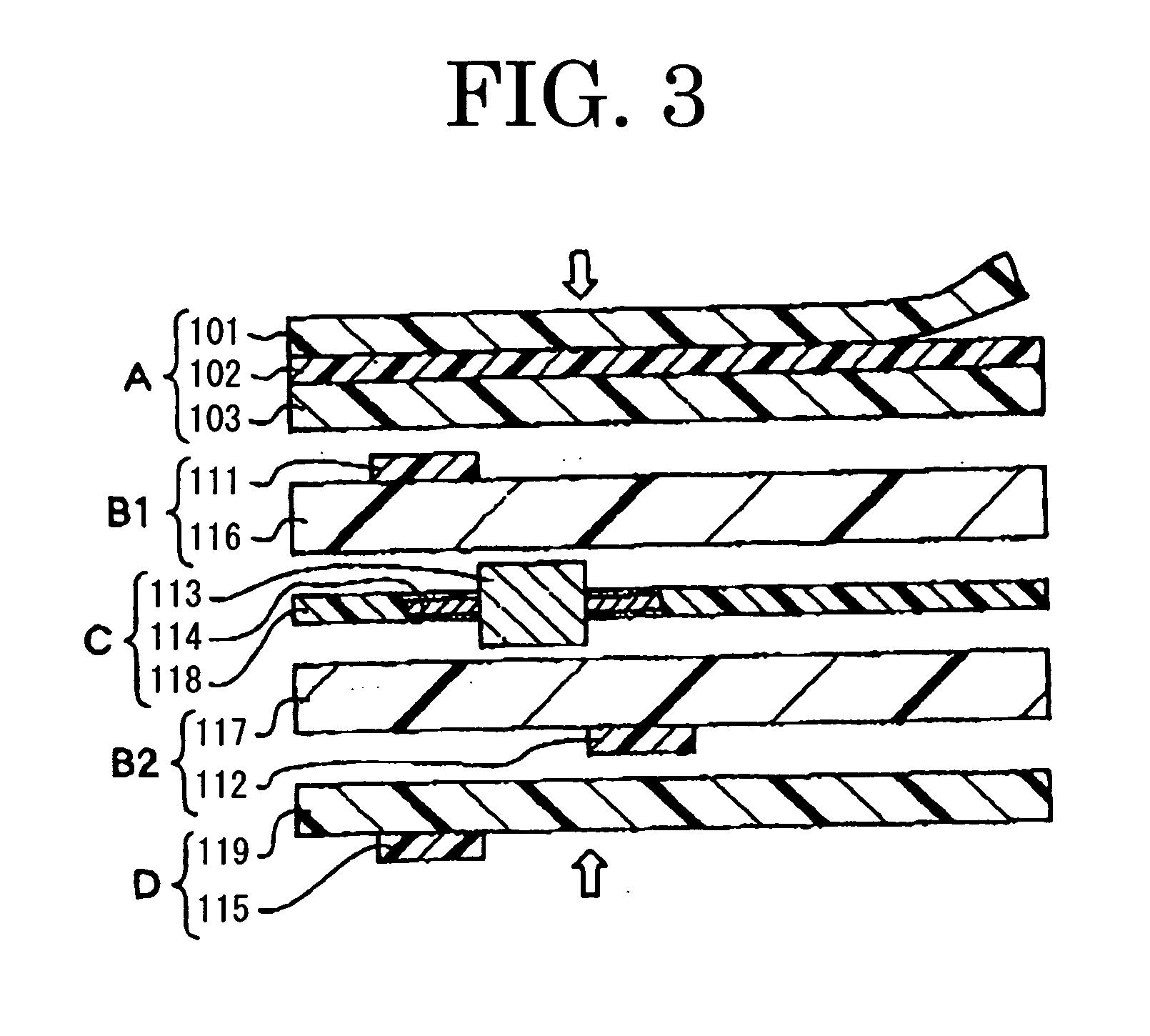

Information recording-displaying card, image processing method using same, and image processor

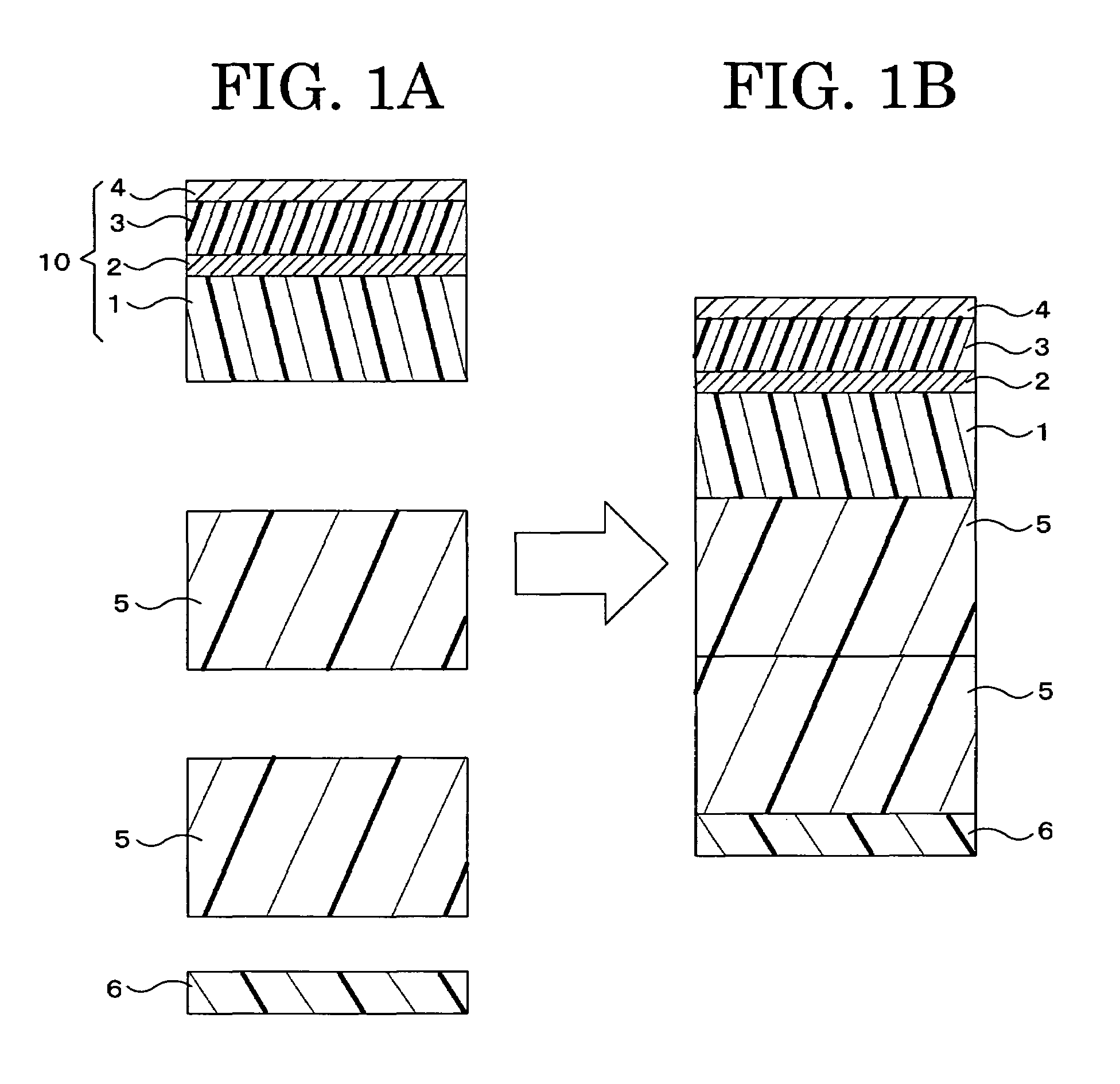

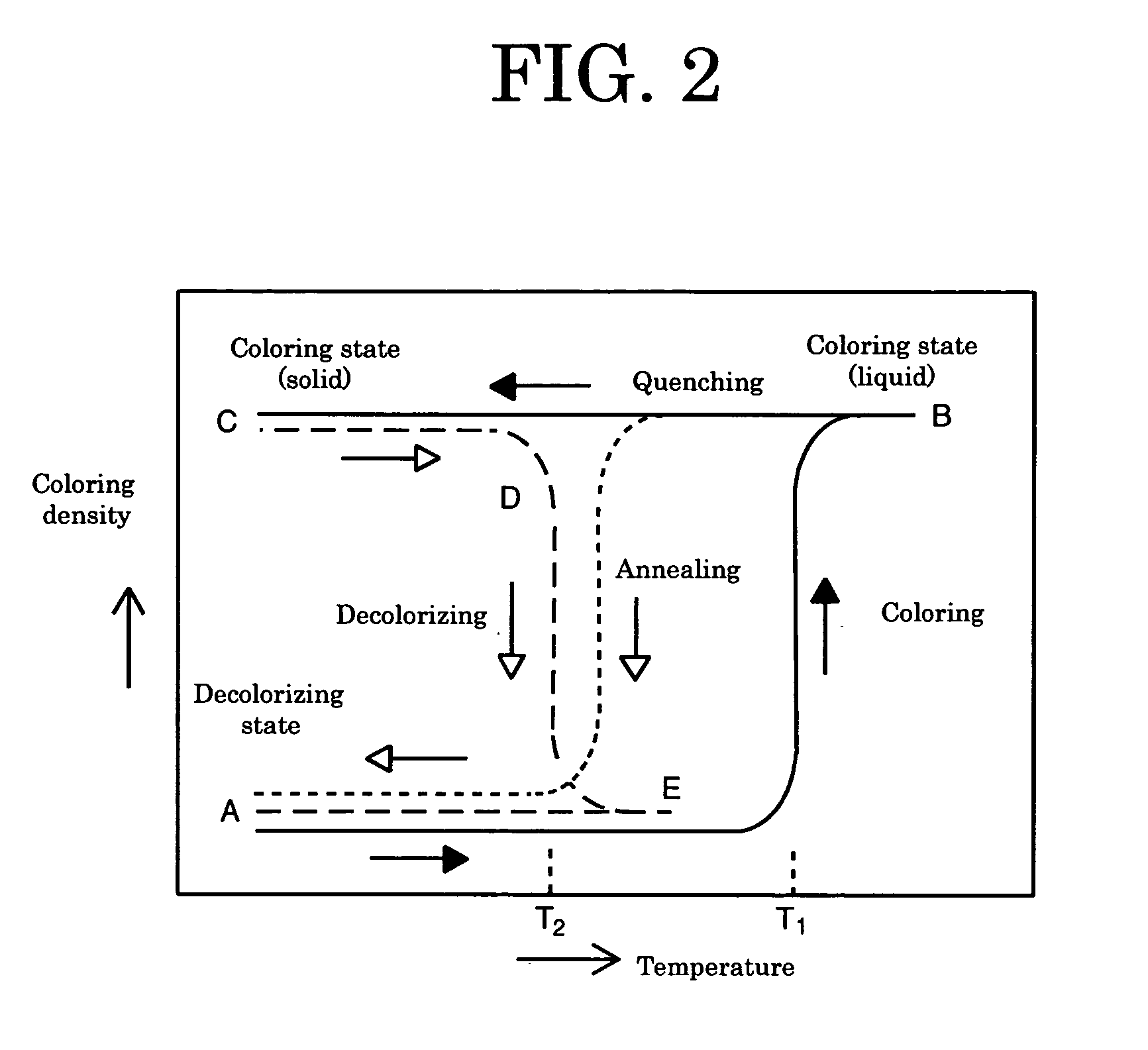

InactiveUS6989349B2Easy embossingIncreased durabilityDecorative surface effectsSynthetic resin layered productsImaging processingPolyester resin

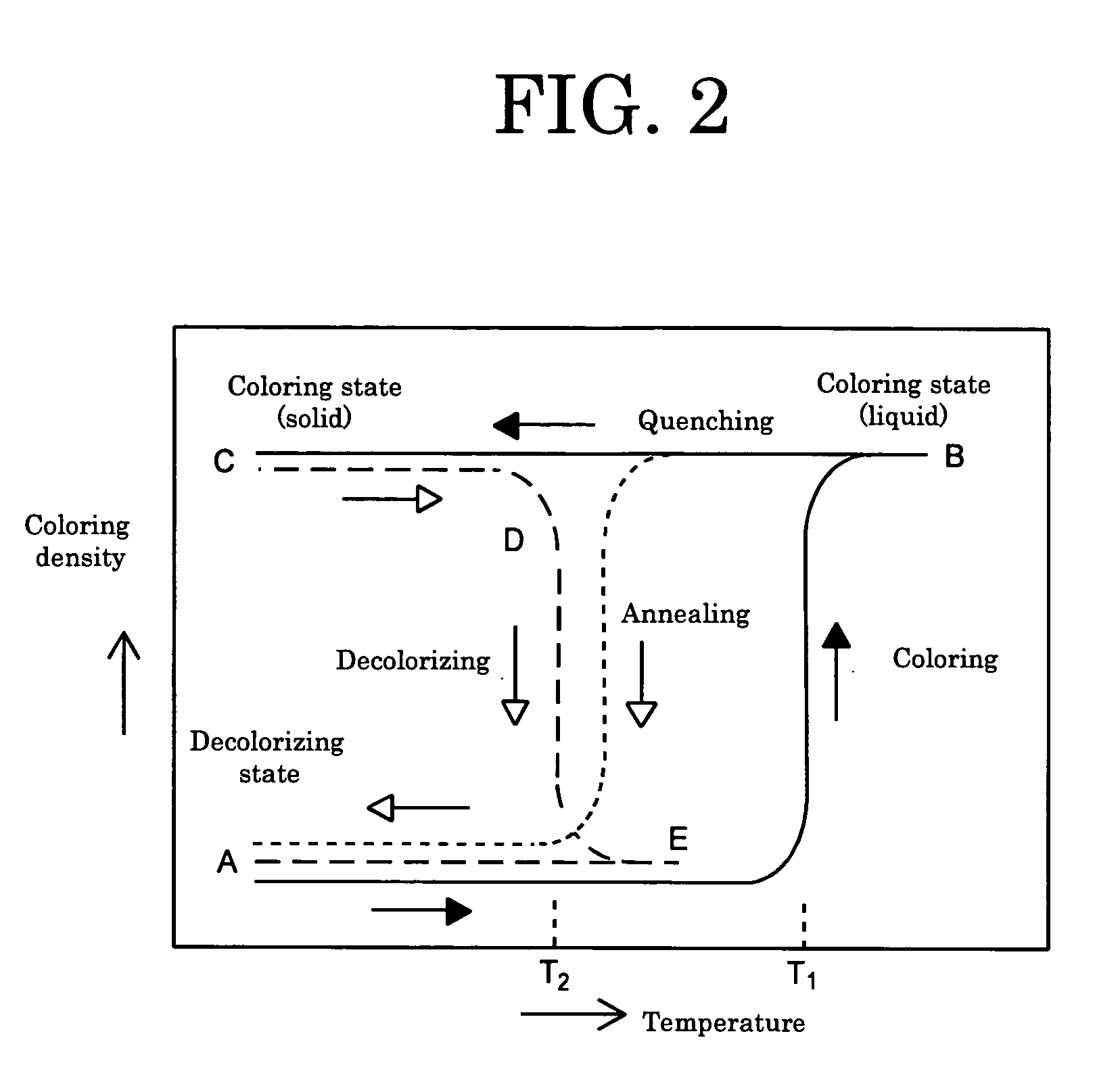

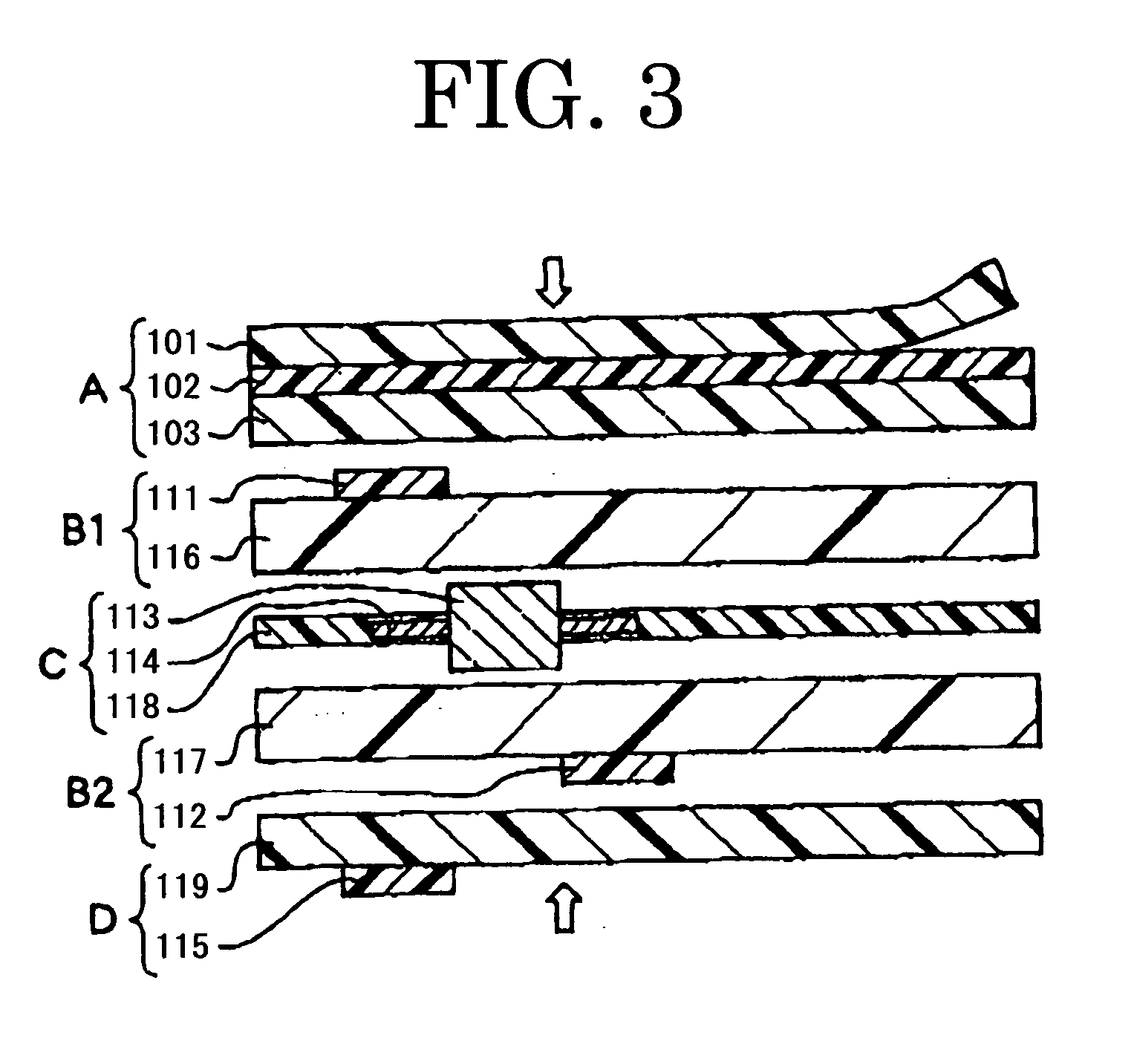

An information recording-displaying card, includes: a core sheet; and an over sheet bonded to the core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer disposed on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of relatively forming a coloring state and a decolorizing state, with a difference in at least one of heating temperature, and cooling rate after heating. The over sheet is embossable in an upper portion thereof, functions as an image displaying section, and meets the following condition (A) and condition (B): (A) (the over sheet's upper limit temperature for erasing −30° C.)≦(temperature of a storage elasticity E′ (1.0 E+08) Pa)≦200° C., and (B) 1.0 E+04 Pa≦(the storage elasticity E′ of the over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

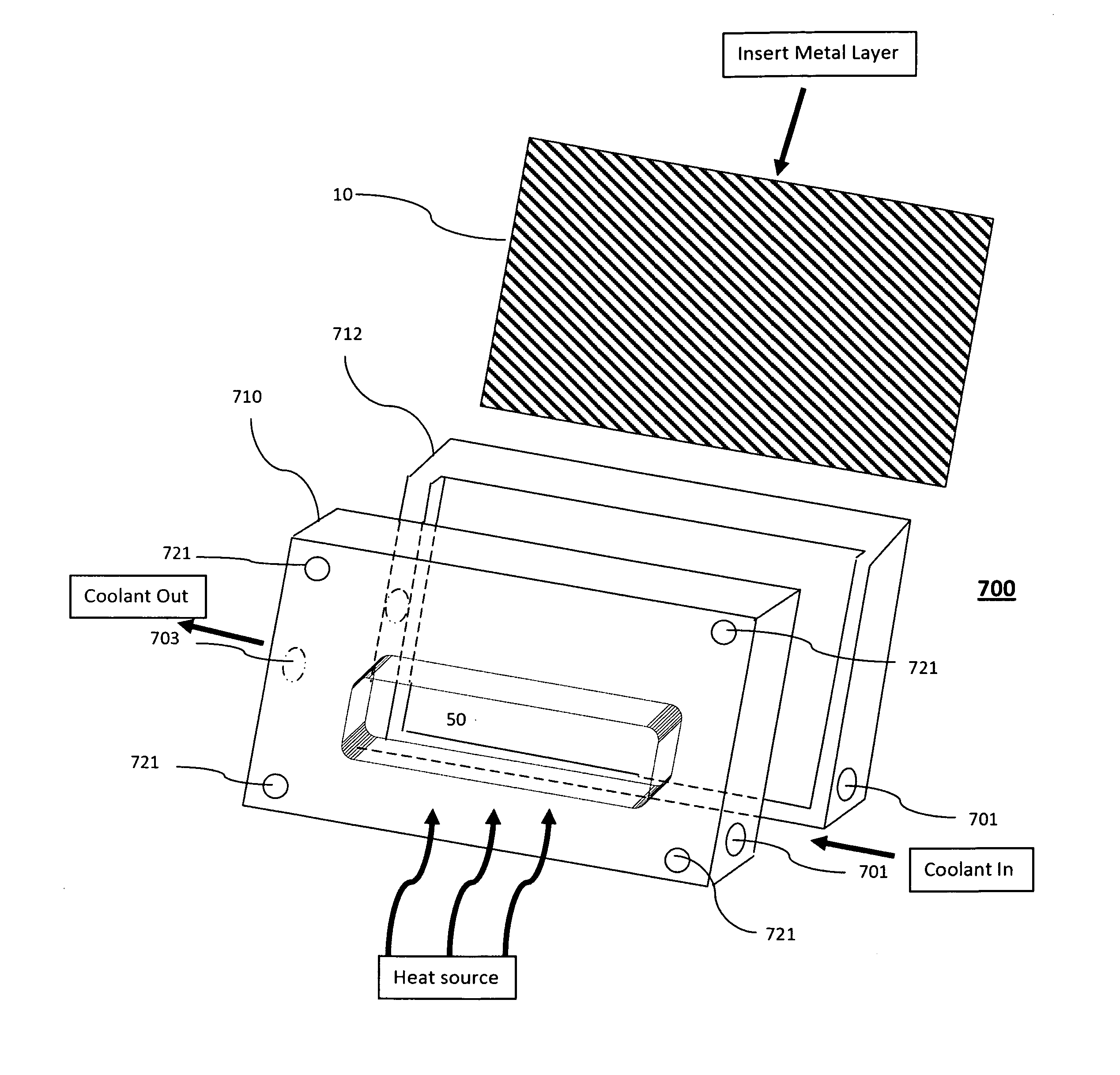

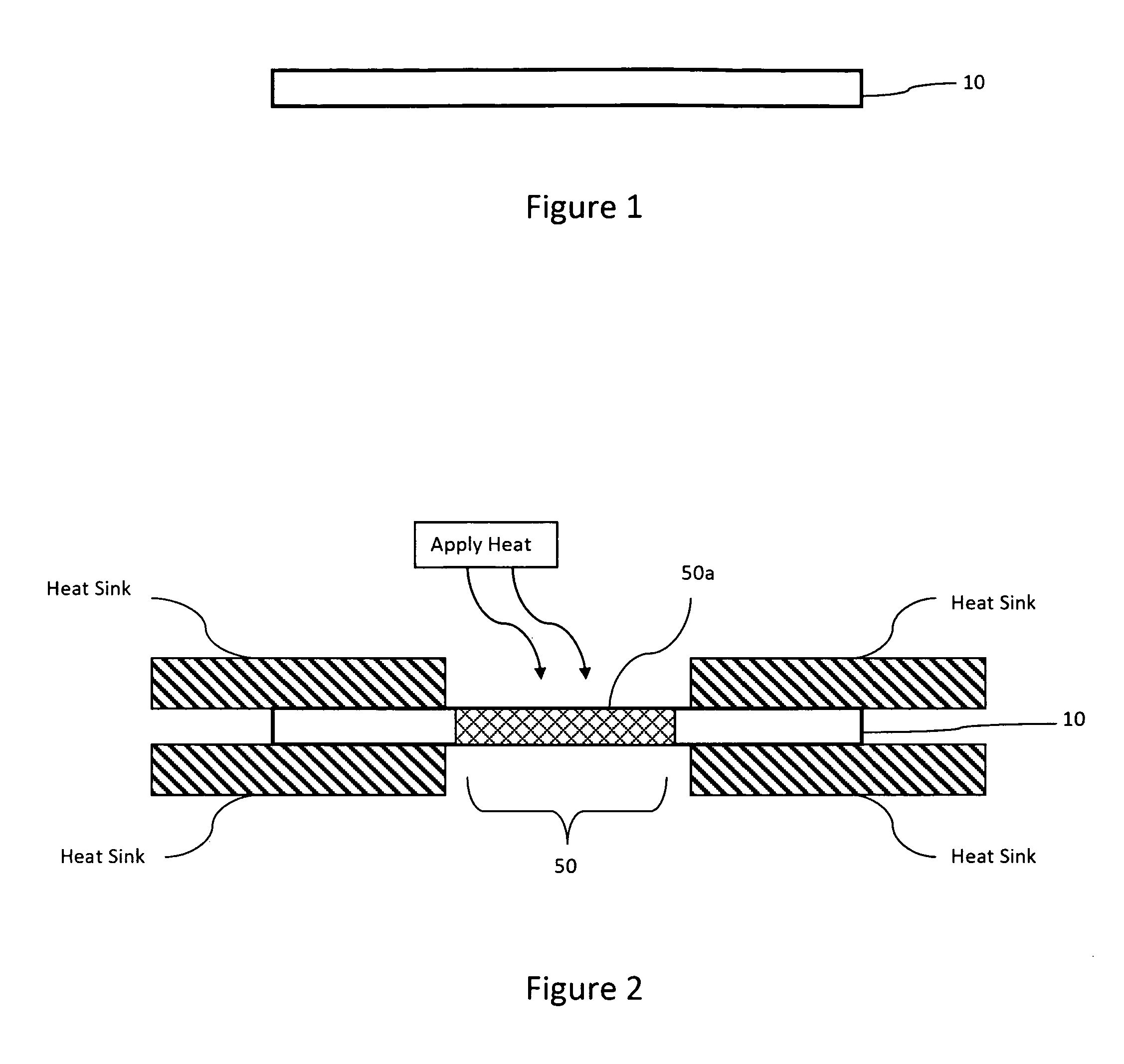

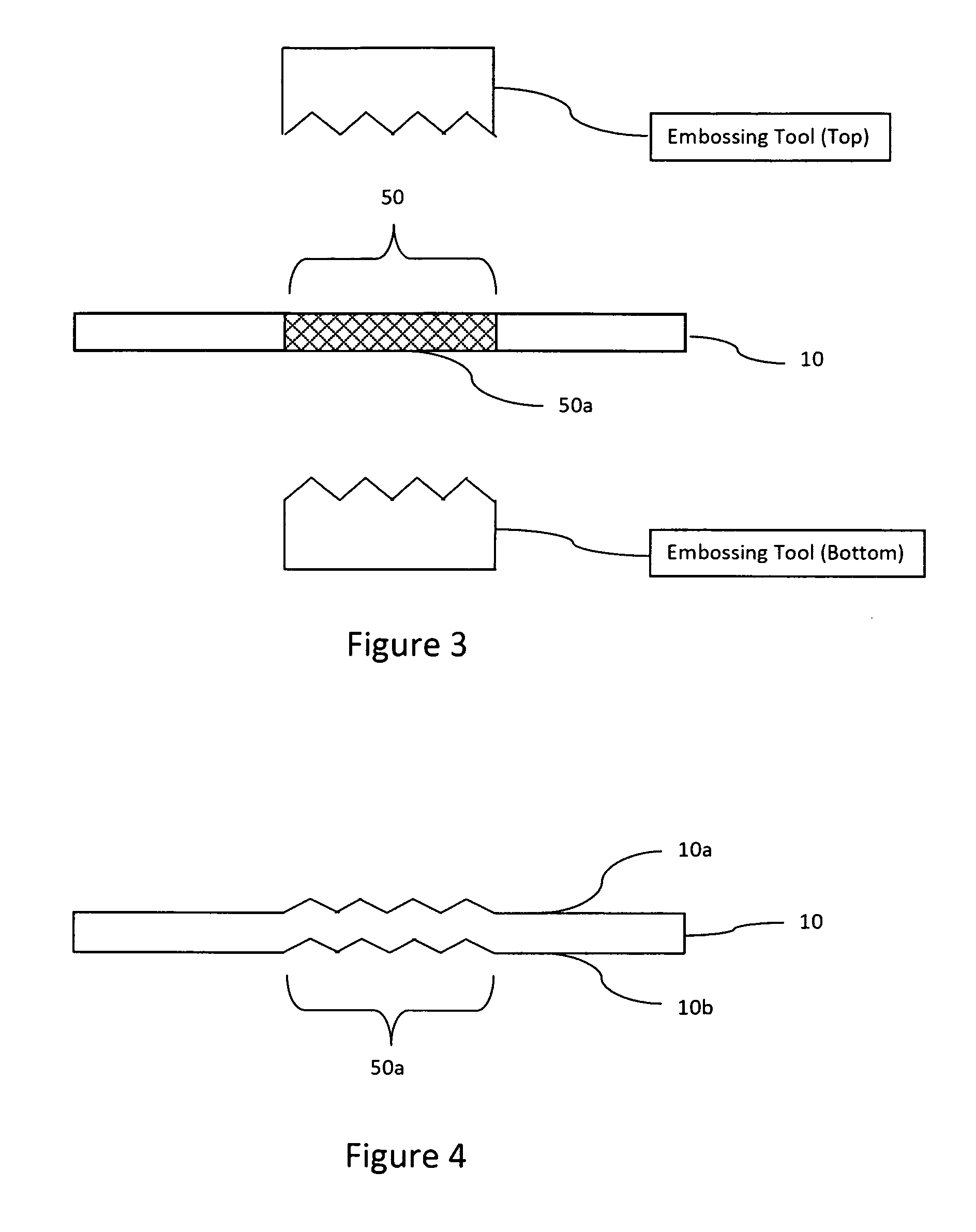

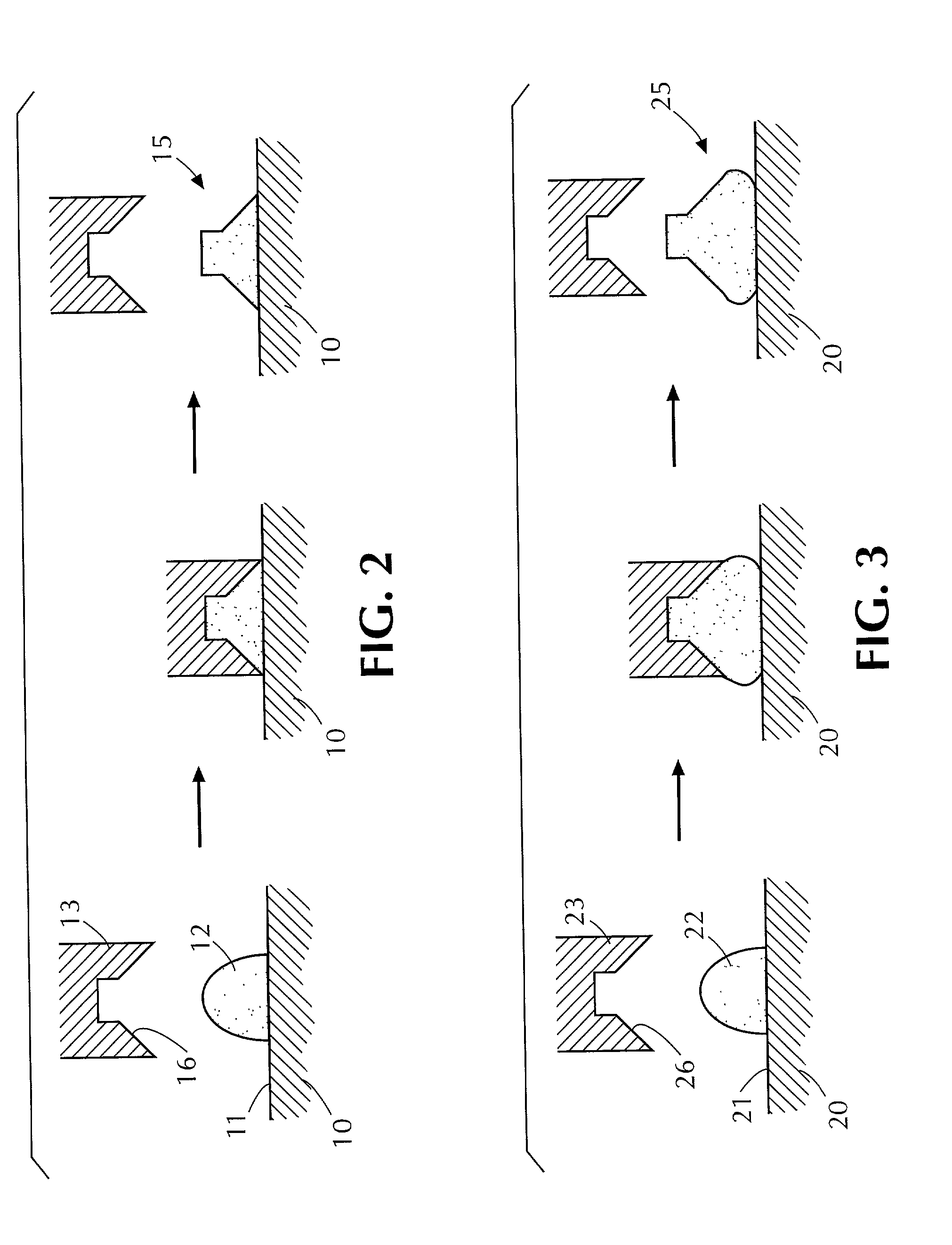

Metal card

ActiveUS8944810B2Easy embossingReduce the amount requiredExothermal chemical reaction heat productionOther heat production devicesMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

Method for providing patterns of functional materials

InactiveUS20140087139A1Reduce wasteEasy to recycleSynthetic resin layered productsPlate printingPolyesterPolyolefin

A method is used to provide a pattern of a functional material for example on a receiving element. To provide this pattern, a laser-engraveable patternable element is imagewise exposed with laser-engraving radiation. This element has a laser-engraveable layer comprising a thermoplastic elastomeric interpolymer alloy. This interpolymer alloy comprises a non-crosslinked halogenated polymer, a partially crosslinked polyolefin, and a polyester. A laser-engraved patterned element is formed that has a relief image in the laser-engraveable layer, and this relief image can be contacted with a suitable functional material that is then transferred to the receiving element to provide the desired pattern.

Owner:MIRACLON CORP

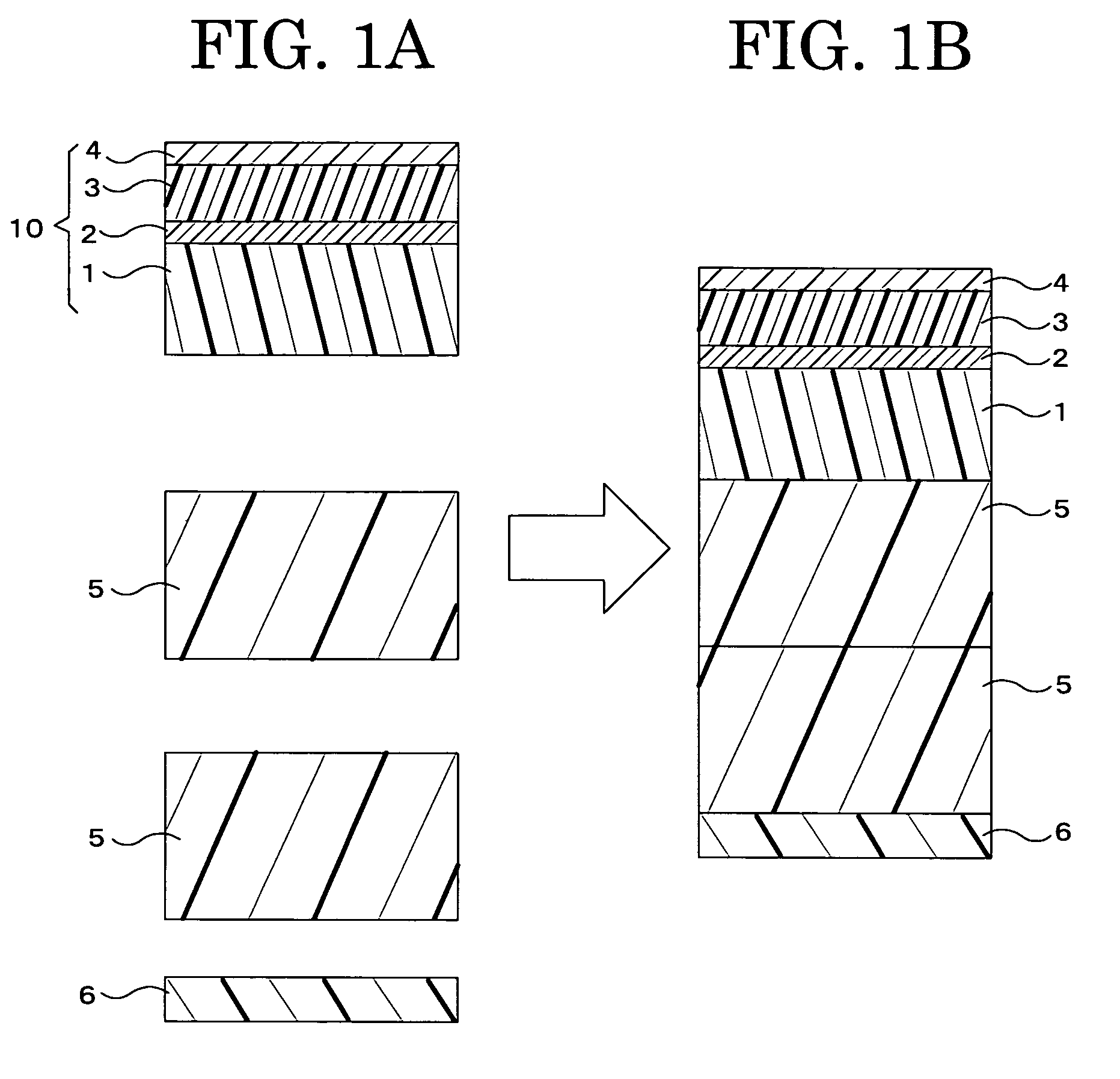

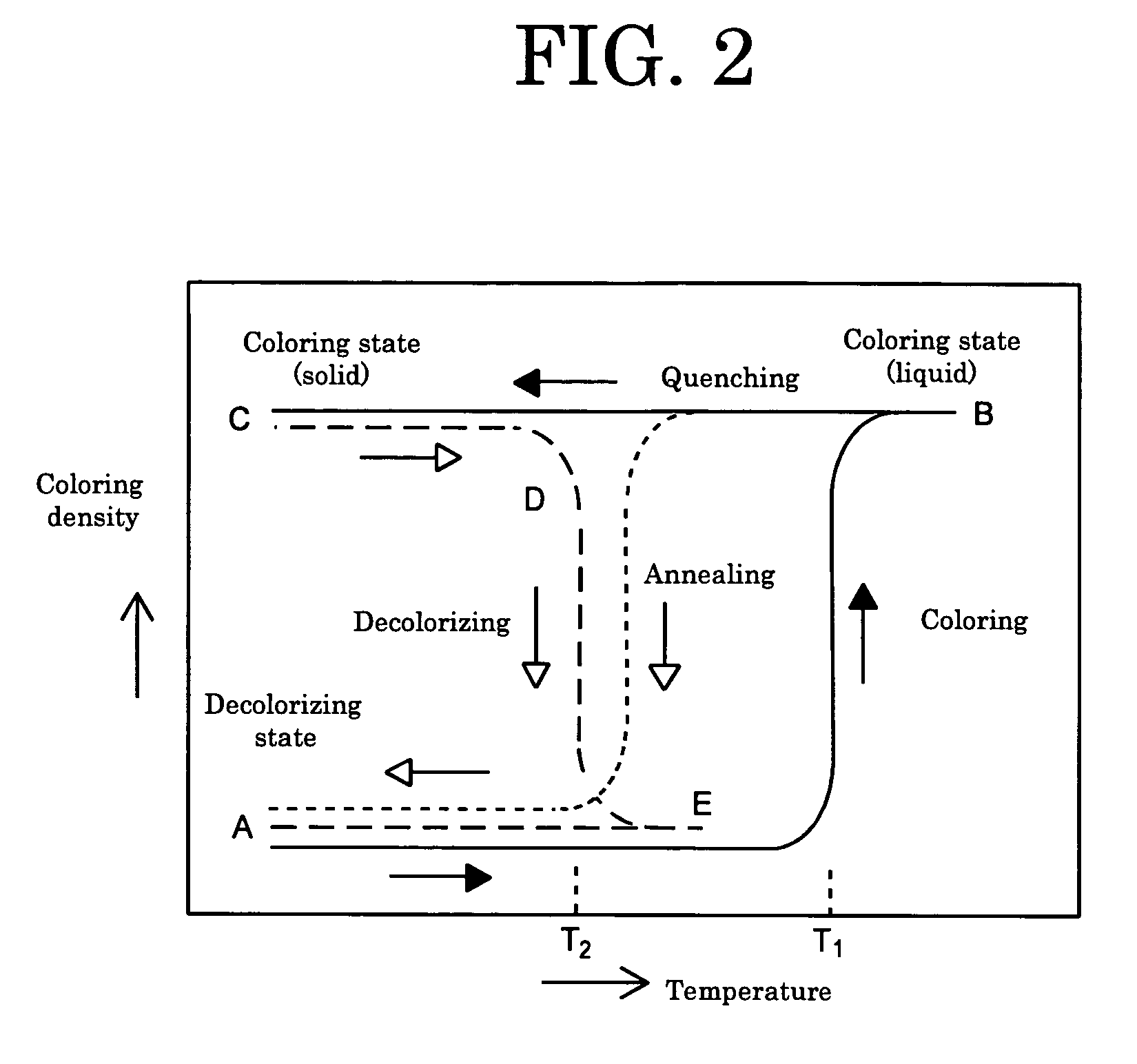

Information recording-displaying card, image processing method using same, and image processor

ActiveUS20050130840A1Excellent in embossability and repetition durabilityEasy to scrap and disposeDecorative surface effectsSynthetic resin layered productsChemistryCooling rates

An information recording-displaying card, includes: a core sheet; and an over sheet bonded to the core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer disposed on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of relatively forming a coloring state and a decolorizing state, with a difference in at least one of: heating temperature, and cooling rate after heating. The over sheet is embossable in an upper portion thereof, functions as an image displaying section, and meets the following condition (A) and condition (B): (A) (the over sheet's upper limit temperature for erasing −30° C.)≦(temperature of a storage elasticity E′ (1.0 E+08)Pa)≦200° C., and (B) 1.0 E+04 Pa≦(the storage elasticity E′ of the over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

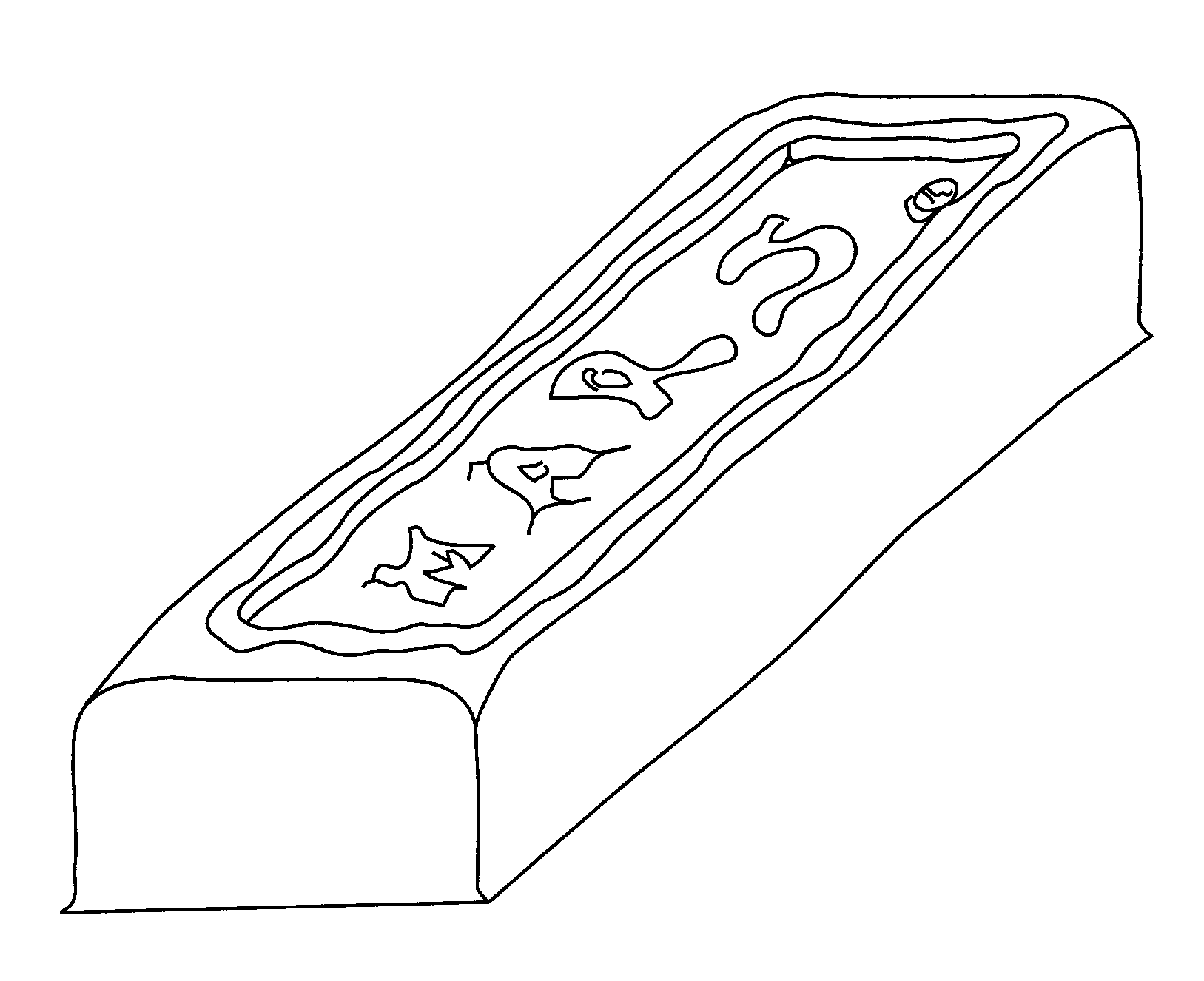

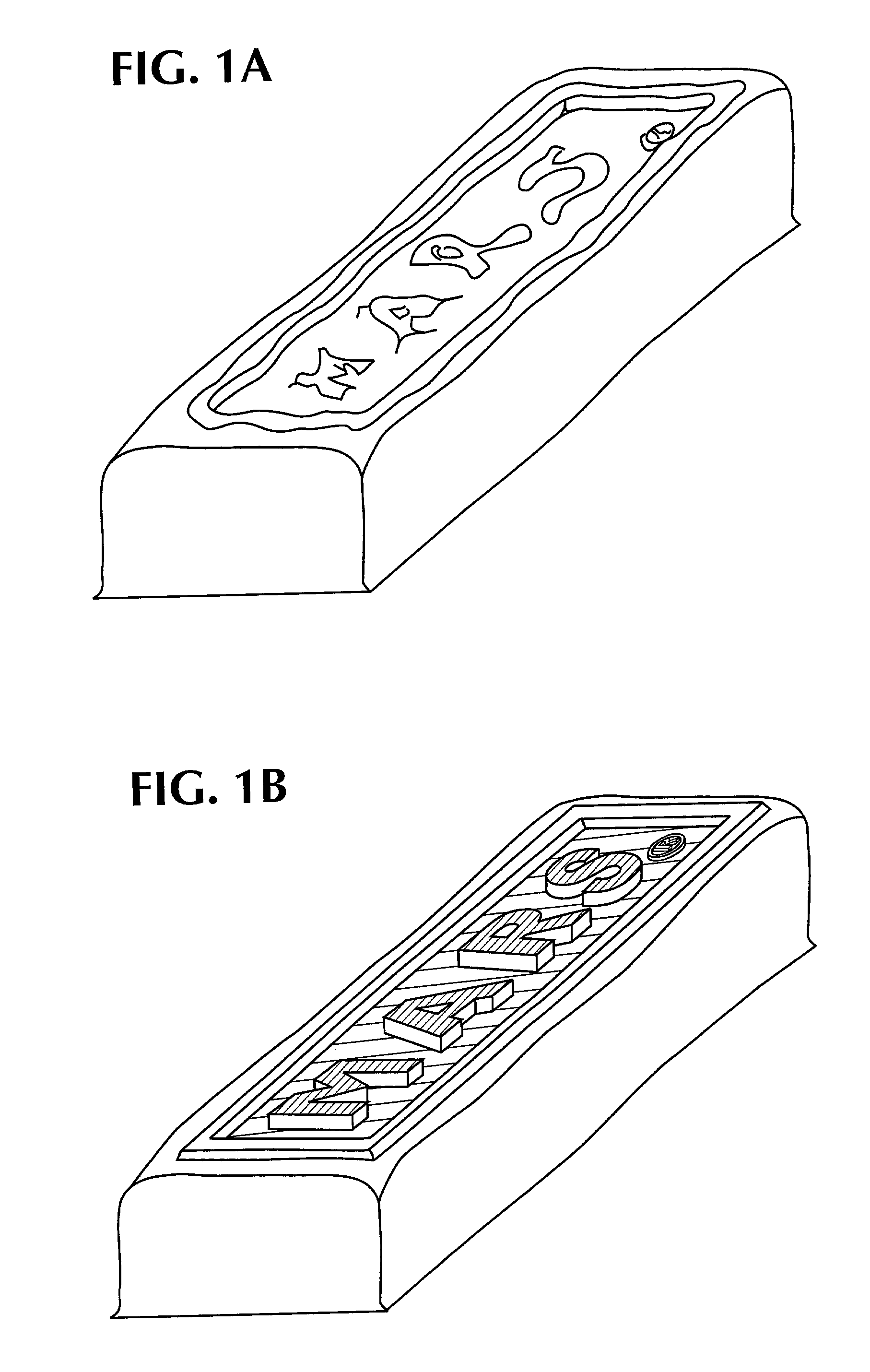

Method of embossing chocolate products

Methods of producing shaped, embossed, or decorated confectionery chocolate products by using chilled forming, shaping, or embossing devices.

Owner:MARS INC

Information recording-displaying card, image processing method using same, and image processor

InactiveUS6969695B2Easy embossingImprove machinabilityDecorative surface effectsSynthetic resin layered productsImaging processingChemical compound

An information recording-displaying card, includes: core sheet; and over sheet bonded to core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of forming coloring state and decolorizing state, with difference in at least one of the following: heating temperature, and cooling rate after heating. The over sheet is embossable in upper portion thereof, functions as image displaying section, and meets the following conditions (A), (B) and (C): (A) (over sheet's upper limit temperature for erasing−30° C.)>(over sheet's temperature of storage elasticity E′ (1.0 E+08) Pa), (B) 10 μm or less of surface waviness WCM, and (C) 1.0 E+02 Pa≦(storage elasticity E′ of reversible thermosensitive over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

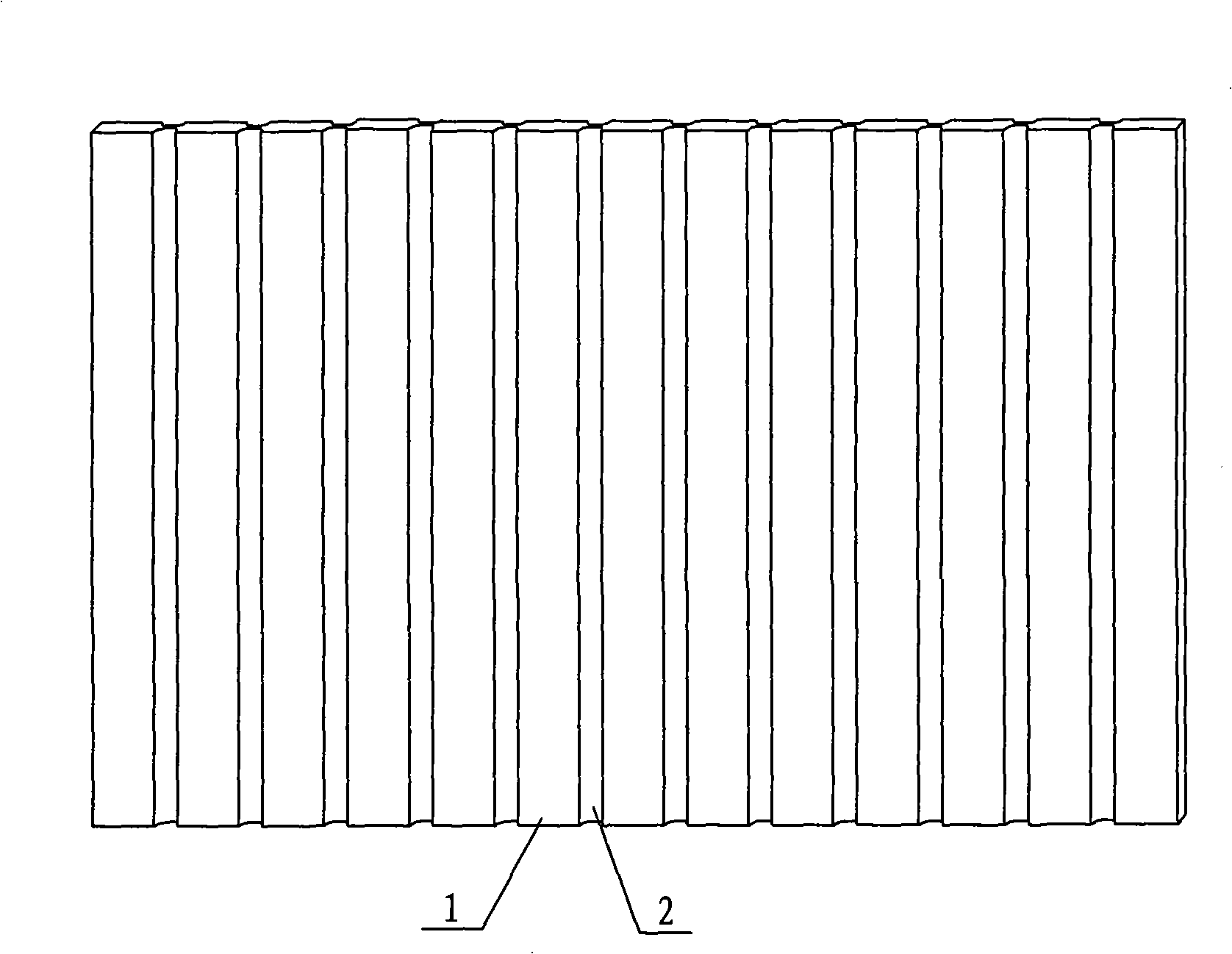

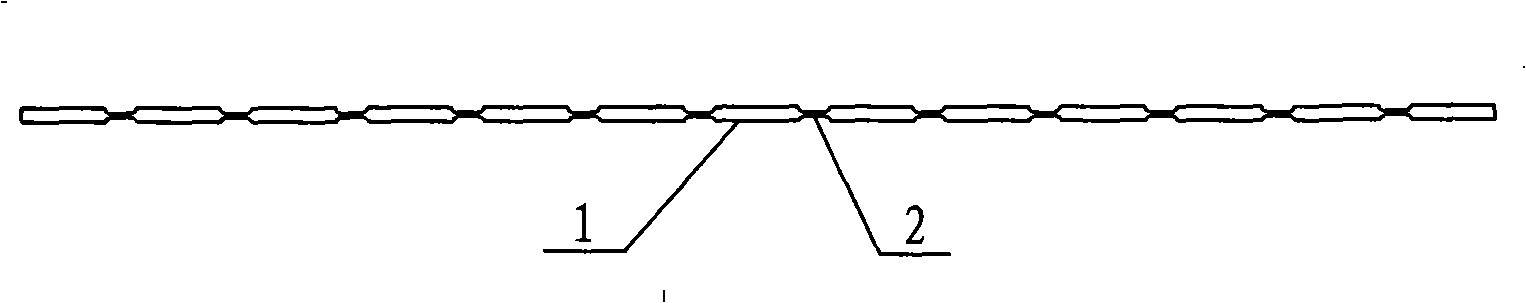

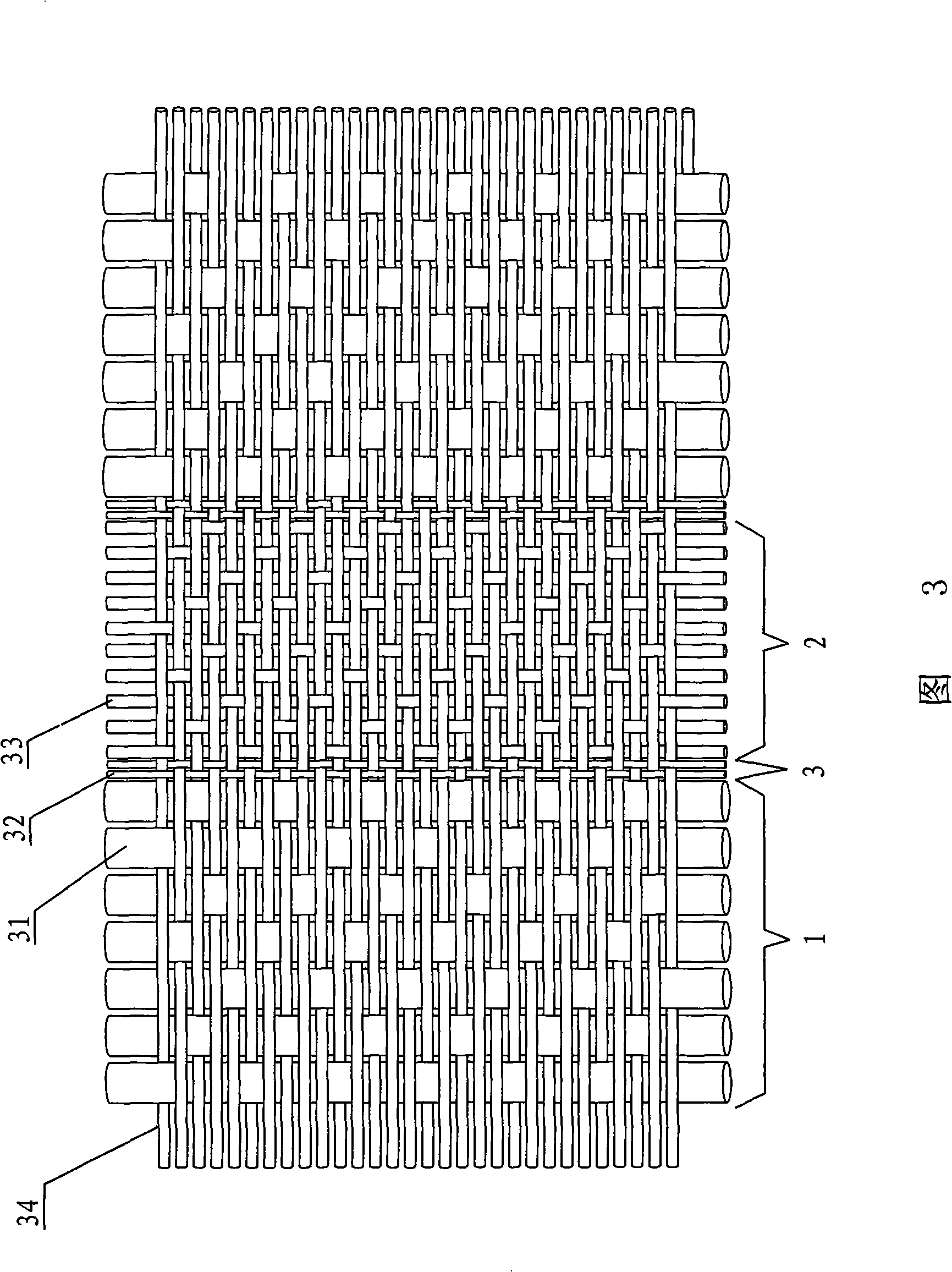

Conveniently folding window curtain

ActiveCN101307671AAvoid patternsAvoid the problem of pattern misalignmentDoor/window protective devicesCurtainsEngineeringLinear density

The invention discloses a curtain which is convenient for folding, comprising a curtain body, wherein, the curtain body is formed by a plurality of thick textile fabric sections and a plurality of thin textile fabric sections which are mutually spaced; a lockstitch structure is arranged on a joint of a thick textile fabric section and a thin textile fabric section which are adjacent to each other; the linear density of warp threads used for weaving the curtain body is less than or equal to 22.2 texes; the linear density of weft threads used for weaving the thick textile fabric sections is between 66 and 333 texes; the linear density of weft threads used for weaving the thin textile fabric sections is less than or equal to 22.2 texes; the density ratio of the thick textile fabric sections to the thin textile fabric sections is 1.5-3 to 1; and each edge lockstitch structure used for weaving the curtain body is woven by 2 to 4 lock lines and warp threads of the curtain body by means of tabby weave. The curtain is convenient to process, has smooth appearance and is convenient for surface treatment.

Owner:游龙

Information recording-displaying card, image processing method using same, and image processor

InactiveUS20050170961A1Excellent in embossabilityEasy scrapingDecorative surface effectsSynthetic resin layered productsRecording layerHeating temperature

An information recording-displaying card, includes: core sheet; and over sheet bonded to core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of forming coloring state and decolorizing state, with difference in at least one of the following: heating temperature, and cooling rate after heating. The over sheet is embossable in upper portion thereof, functions as image displaying section, and meets the following conditions (A), (B) and (C): (A) (over sheet's upper limit temperature for erasing−30° C.)>(over sheet's temperature of storage elasticity E′ (1.0 E+08) Pa), (B) 10 μm or less of surface waviness WCM, and (C) 1.0 E+02 Pa≦(storage elasticity E′ of reversible thermosensitive over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

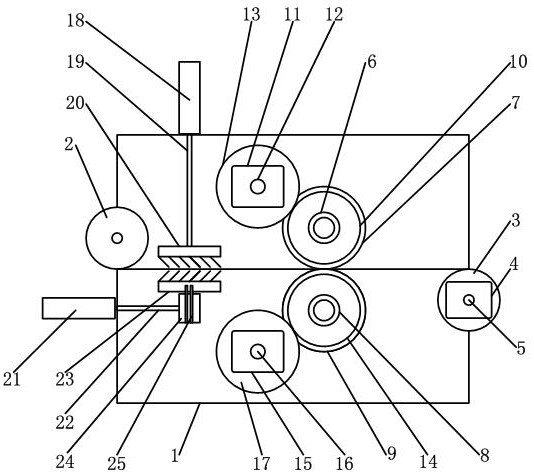

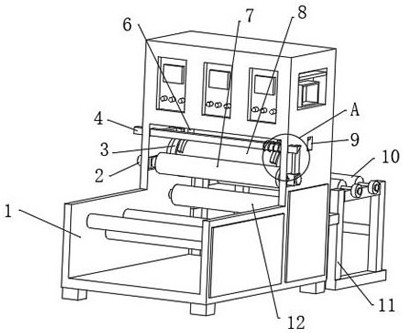

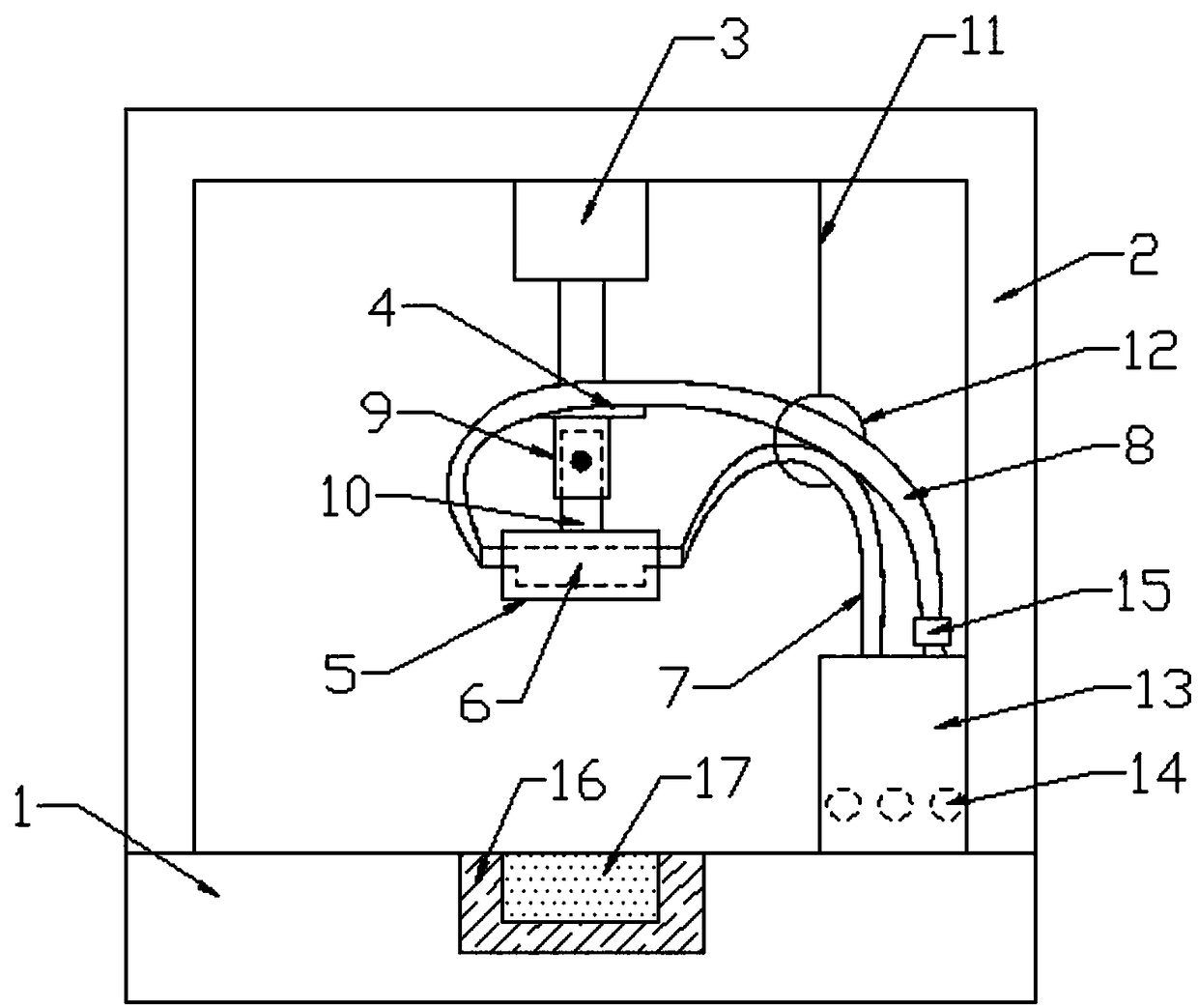

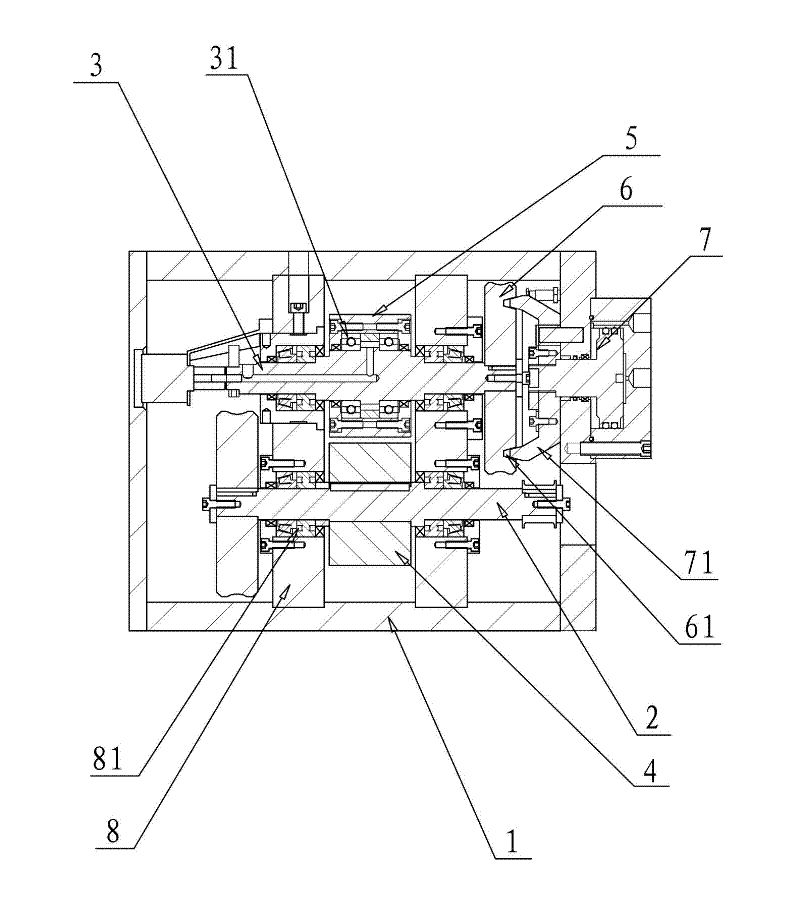

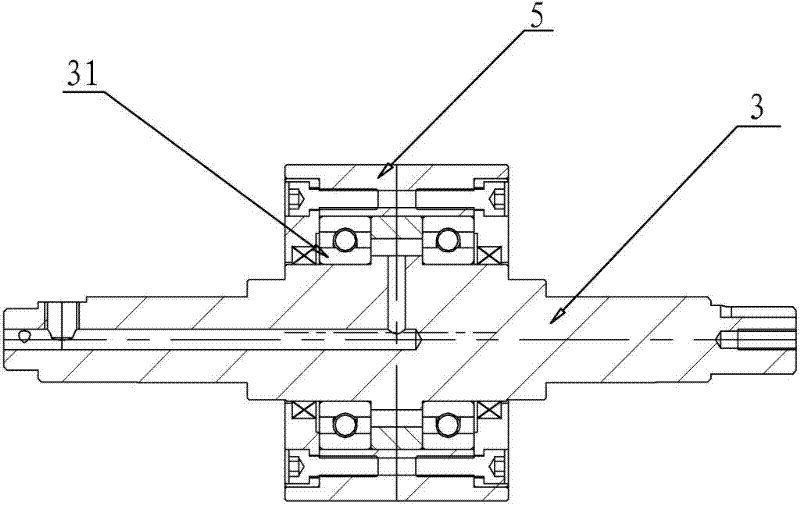

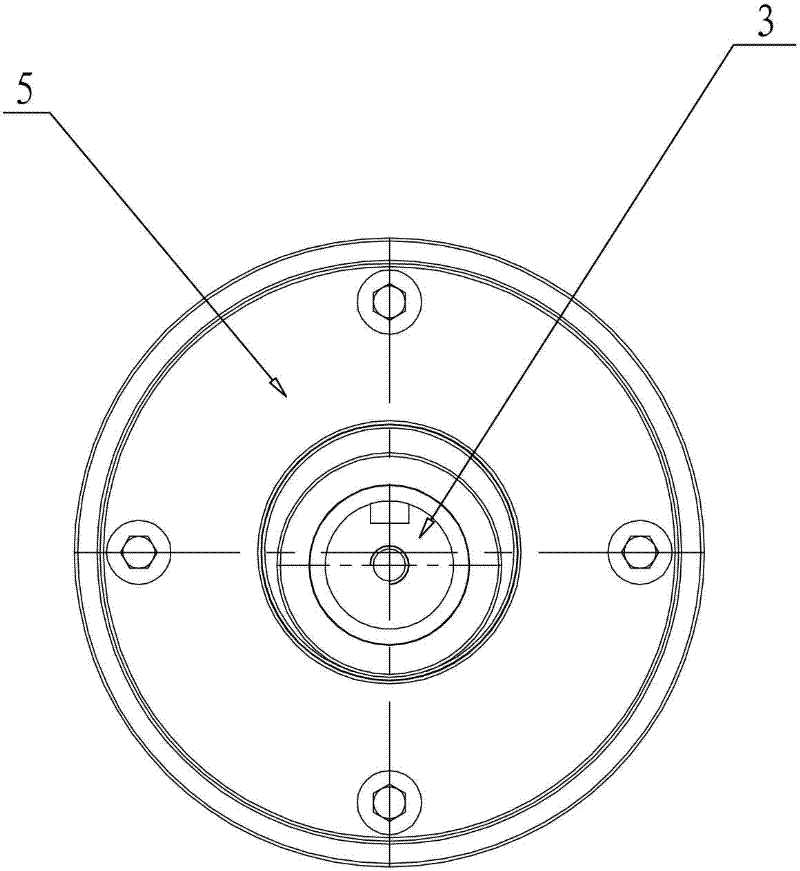

Double-sided embossing device for novel material household decorative plate

InactiveCN111958959AUniform preheatingConstant preheatingDispersed particle separationDirt cleaningEngineeringWorkbench

The invention discloses a double-sided embossing device for a household decorative plate made of a novel material, and relates to the technical field of decorative materials. The double-sided embossing device for the novel material household decorative plate comprises a workbench, a preheating mechanism, an embossing adjusting mechanism, a limiting mechanism, an auxiliary mechanism and a tractionwinding mechanism are arranged on the workbench, two sets of mounting plates are welded to the outer surface of the top of the workbench, and a working box is welded to the outer surface of the top ofthe workbench. According to the double-sided embossing device for the novel material household decorative plate, the embossing depth of the device can be accurately adjusted only by rotating the first crank, so that the device can meet different requirements of PVC soft plates of different specifications on the embossing depth; and meanwhile, the function that embossing treatment is conducted onthe two faces of the PVC soft board at the same time is achieved, practicability and production efficiency are improved, the use scene of the device is widened, and the whole device is easy to operateand understand and convenient to popularize and use.

Owner:湖州新意科技有限公司

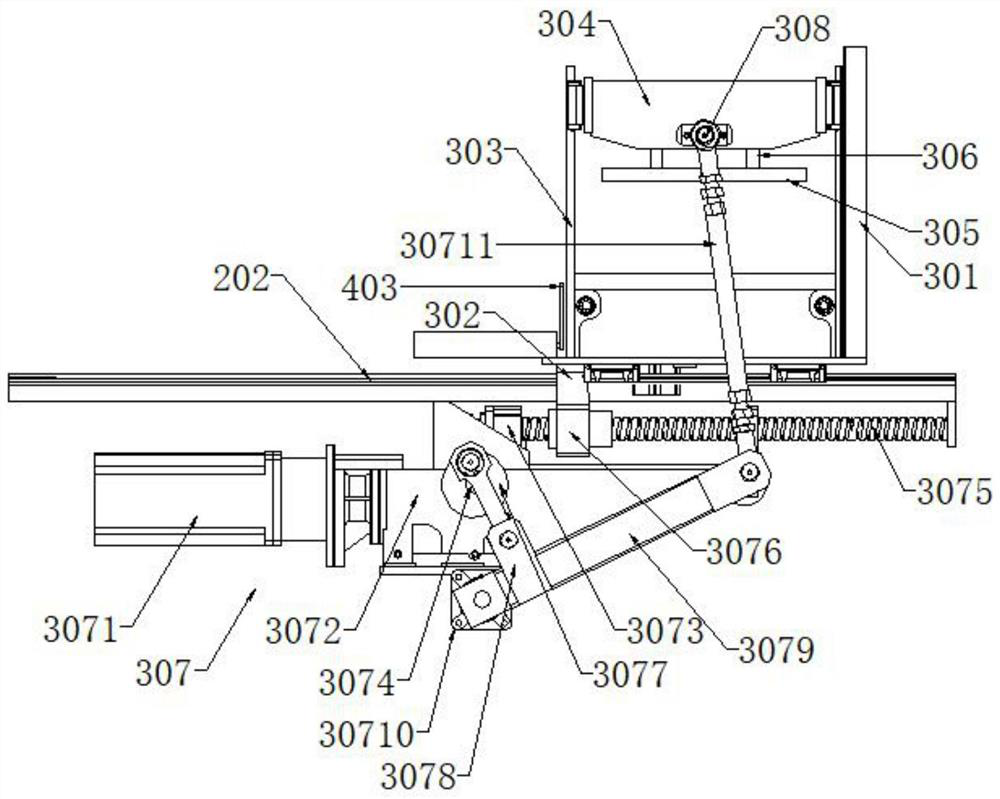

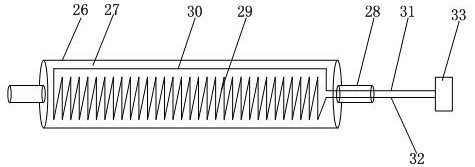

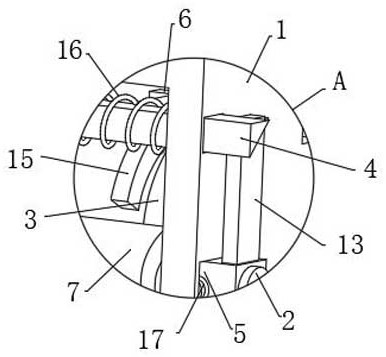

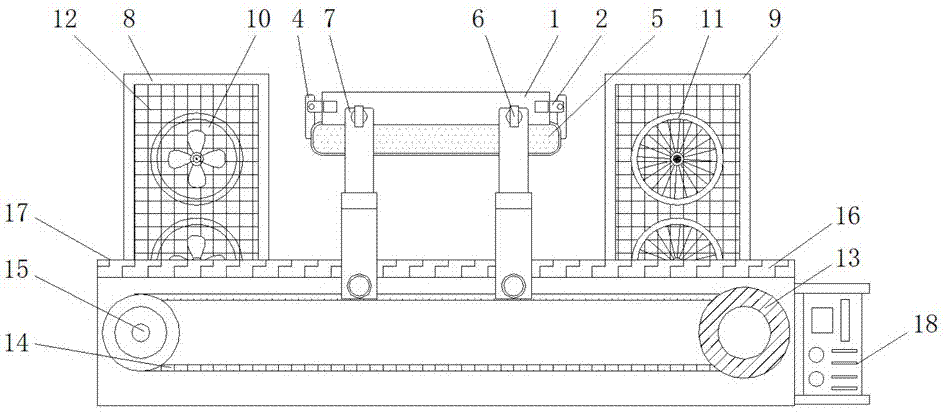

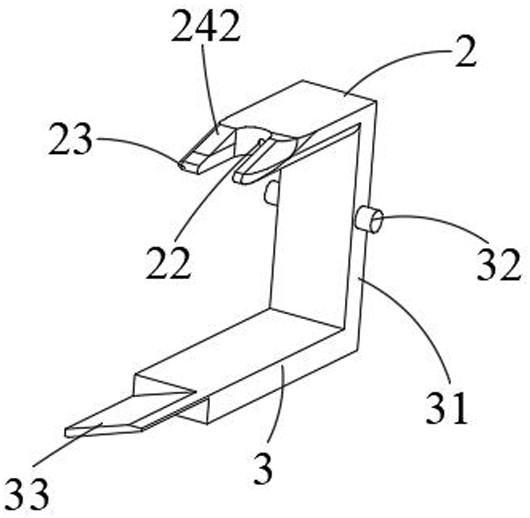

Textile fabric winding mechanism with embossing protection function and working method of textile fabric winding mechanism

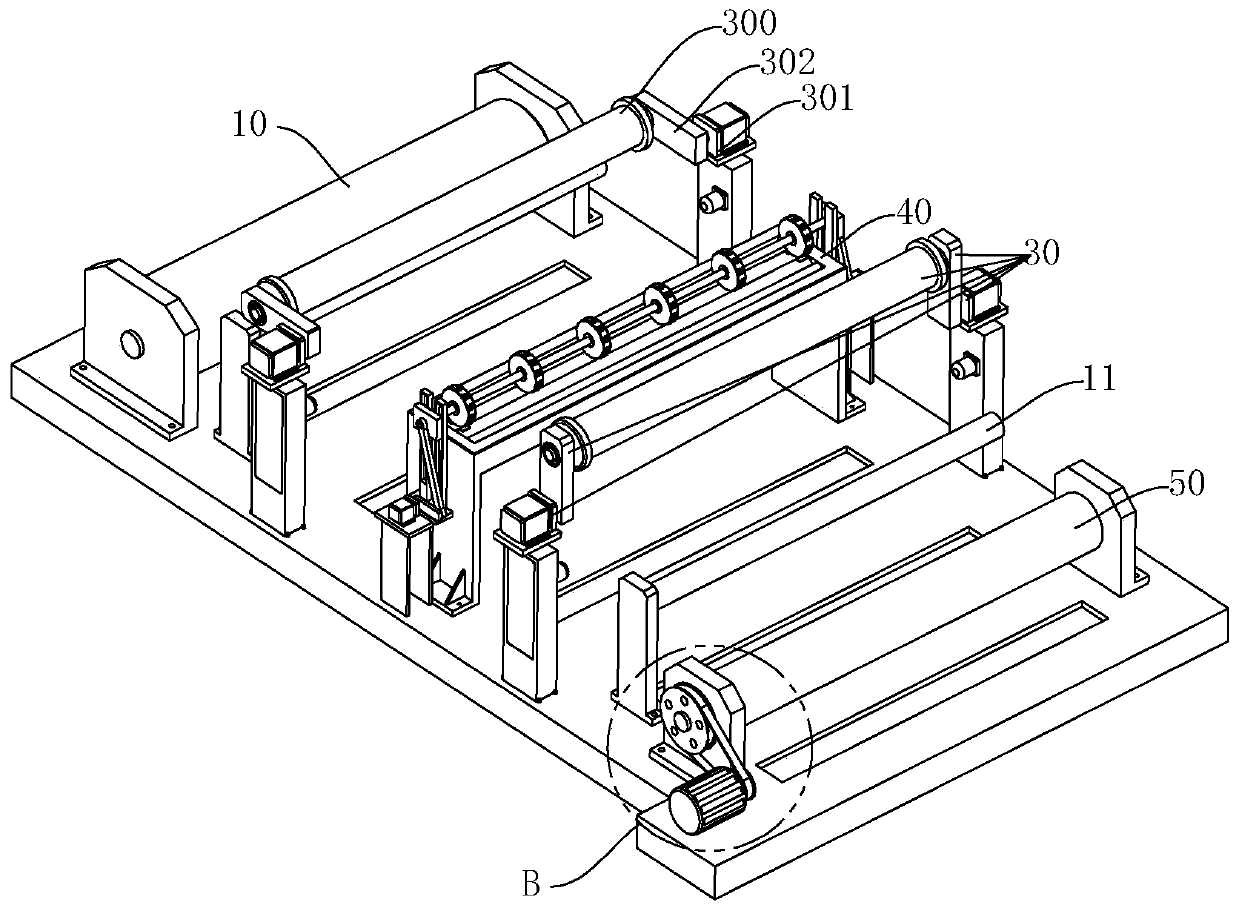

InactiveCN111410068AFor precise adjustmentMeet regulatory needsPattern makingWebs handlingRotational axisManufacturing engineering

The invention relates to the field of textile devices, in particular to a textile fabric winding mechanism with an embossing protection function and a working method of the textile fabric winding mechanism. The mechanism comprises a base and further comprises a controller, a guiding device, a pressure adjusting device and a winding device; the guiding device comprises two guiding roller assemblies; the pressure adjusting device comprises a bearing table, a rotating shaft, two sliding assemblies and a plurality of rollers; the winding device is arranged at the top of the base and used for winding embossed textile fabric, and the winding device comprises a winding roller and a transmission assembly; and the transmission assembly, the two guiding roller assemblies and the two sliding assemblies are electrically connected with the controller. According to the textile fabric winding mechanism with the embossing protection function and the working method of the textile fabric winding mechanism, the embossing force can be accurately controlled, the embossing deformation is prevented, and meanwhile, a buffering structure is designed, so that the situation that the surface of the fabric isscratched or even damaged when the embossing force is large is prevented, the product quality is guaranteed, and benefits of enterprises can be increased.

Owner:朱蕾

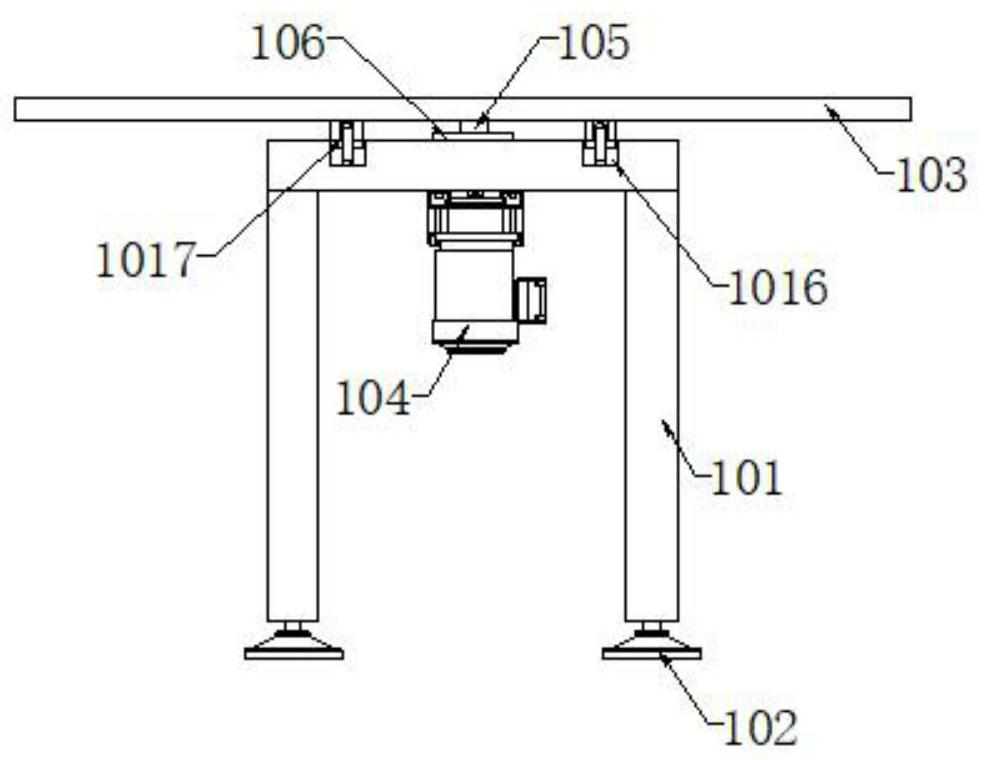

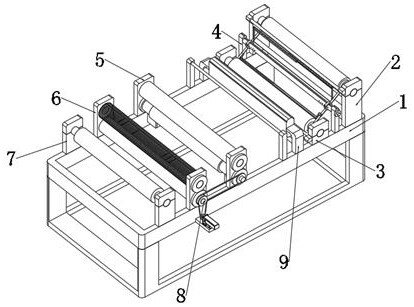

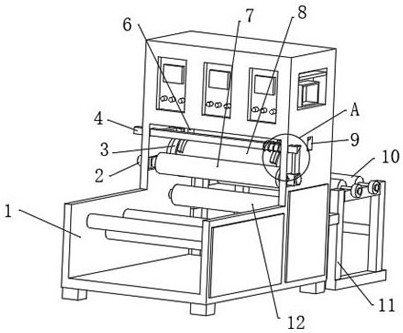

PVC board embossing system and use method thereof

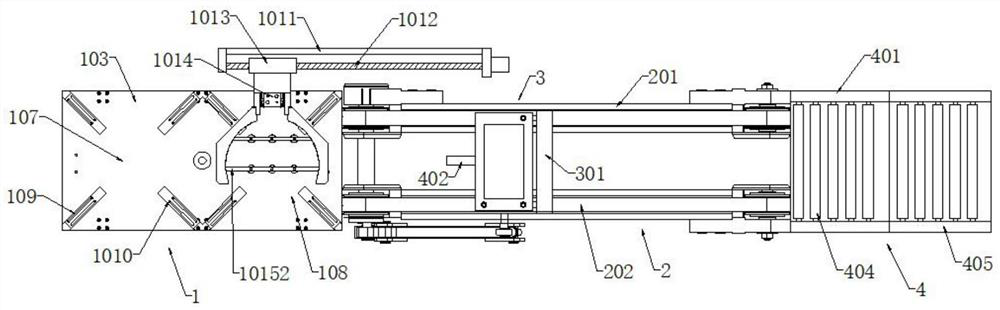

ActiveCN111844709AImprove feeding efficiencyImprove weight capacityFlat articlesProcess engineeringElectric power

The invention discloses a PVC board embossing system and a use method thereof. The embossing system comprises a loading device, a feeding mechanism, an embossing mechanism and a blanking device, wherein the loading device is located at the left end of the feeding mechanism, the loading device and the feeding mechanisms are matched with each other, the loading device adopts vacuum suction cups forloading, two groups of working stations to be loaded are provided with one for loading and one for replenishment to greatly increase the efficiency of loading, the embossing mechanism is located abovethe feeding mechanism and is slidably arranged on the feeding mechanism, the embossing mechanism and the feeding mechanism move synchronously to improve the accuracy of embossing, the blanking deviceis located at the right end of the feeding mechanism, and the blanking device and feeding mechanism are matched with each other. The PVC board embossing system and the use method thereof can realizesynchronous embossing, save electrical equipment, reduce power resource waste, reduce cost, and increase the accuracy of embossing.

Owner:扬州扬铭新材料有限公司

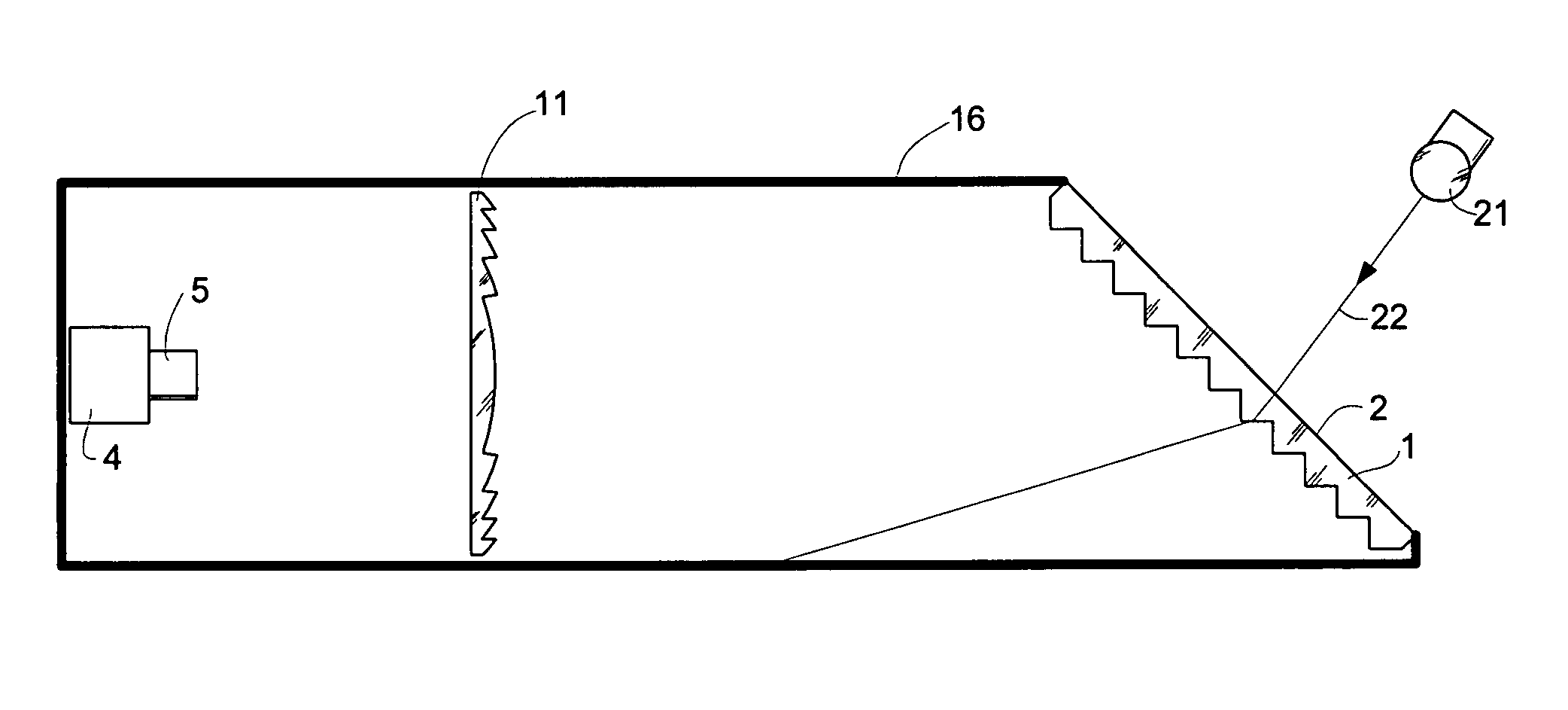

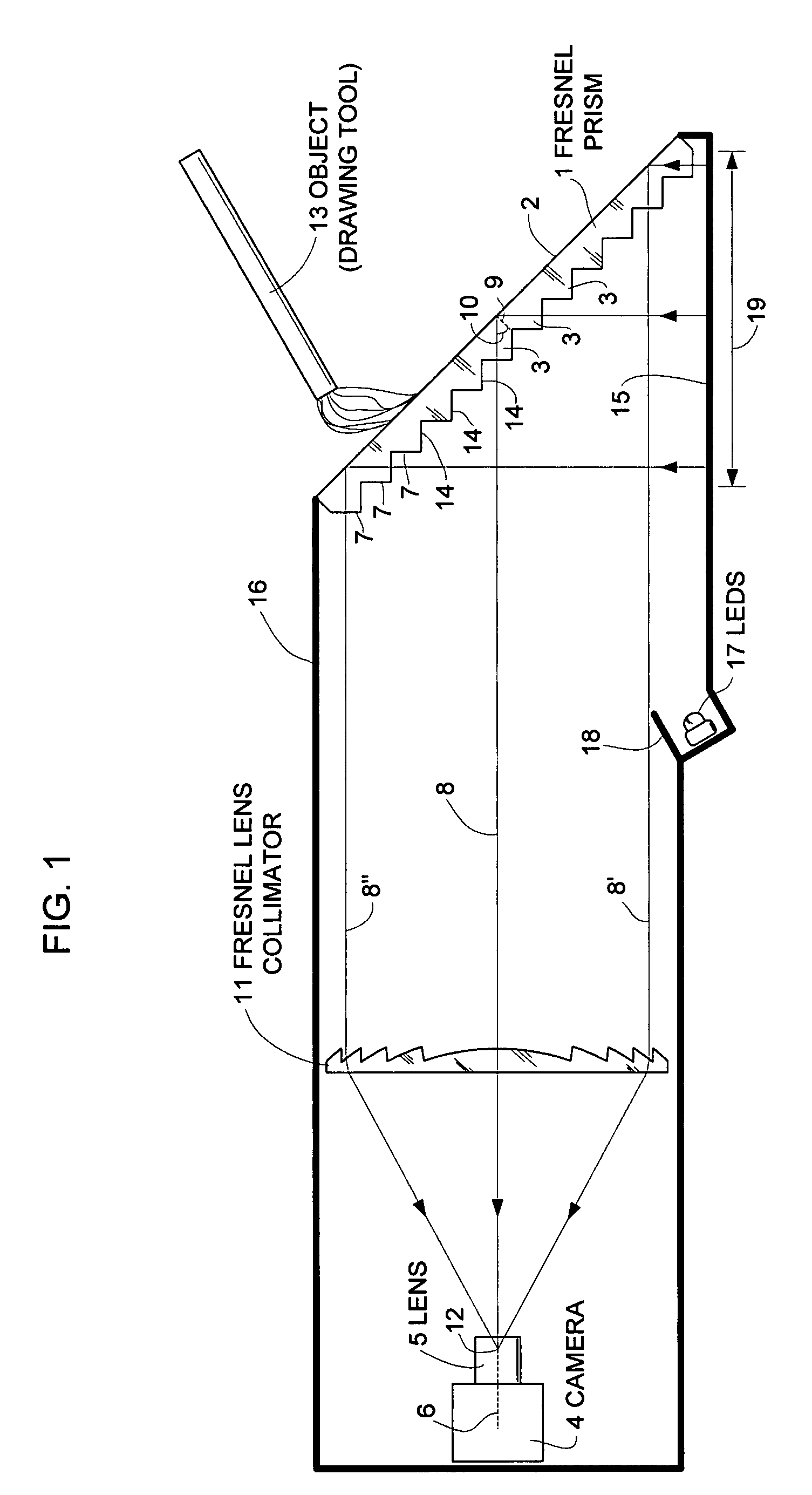

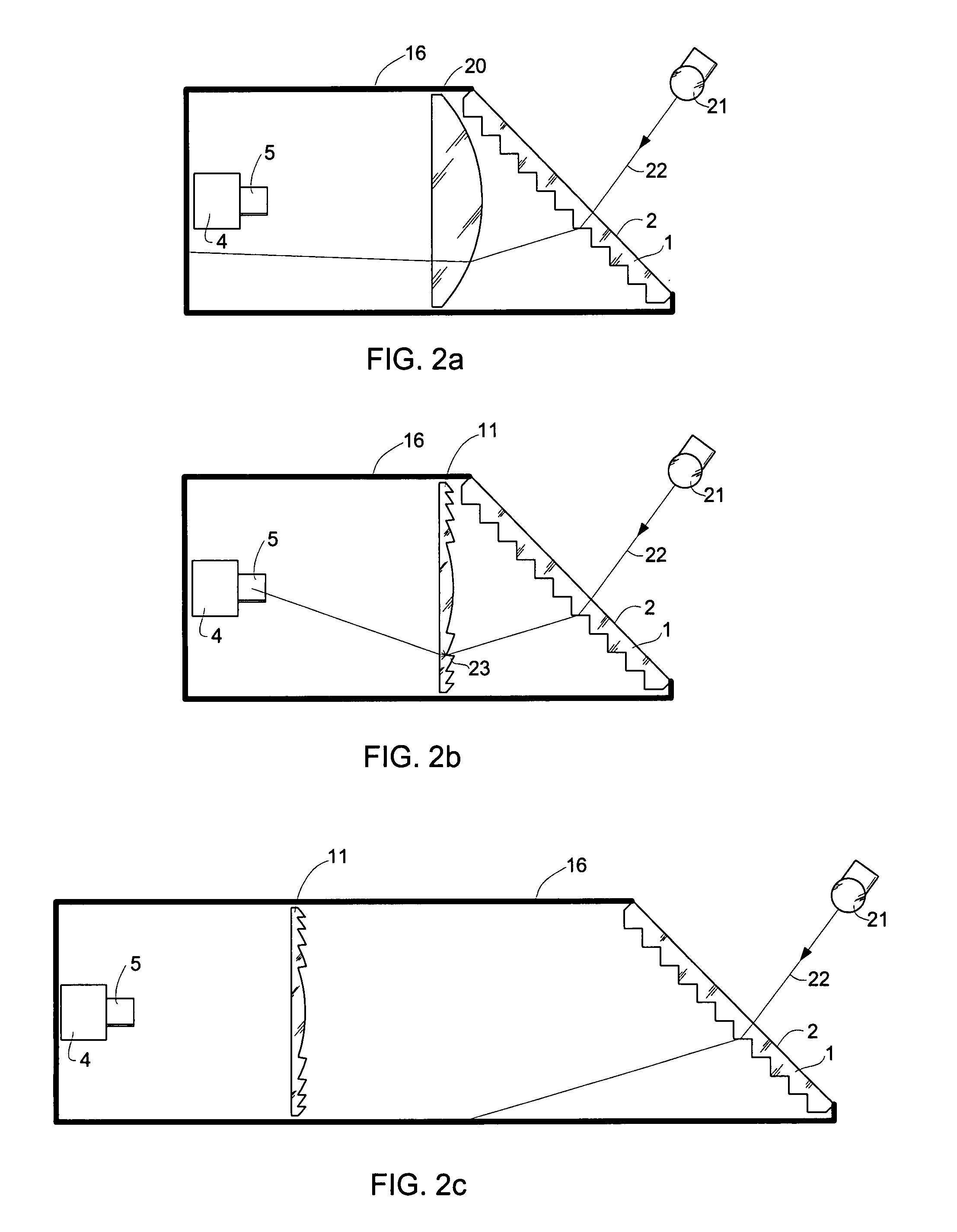

Low-cost graphic input device with uniform sensitivity and no keystone distortion

ActiveUS8022927B1Uniform sensitivityLighter and less-expensive to manufactureTelevision system detailsPicture reproducers using cathode ray tubesGraphicsLens flare

The invention provides a graphic input device which has uniform sensitivity and is free of keystone distortion but which is lighter and less expensive to manufacture than the prior art, particularly for large drawing surfaces. It uses Fresnel optics to reduce the cost, thickness, and weight of the prism or collimator or both. Means are provided to mitigate the effects of lens flare from the Fresnel optics, minimize the thickness of the device, and to correct any remaining distortion in the camera's image using software executing on a standard computer.

Owner:RICHARD GREENE & ROBYN GREENE AS TRUSTEES OF THE ROBYN & RICHARD TRUST DATED SEPTEMBER 09 2016

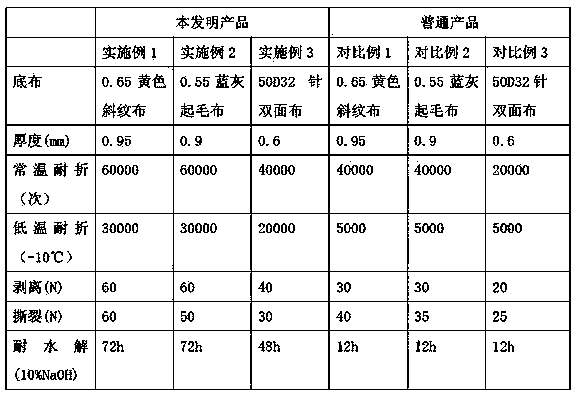

Preparation method and application of low-elasticity polyurethane resin

The invention relates to a preparation method and application of low-elasticity polyurethane resin. The preparation method of the low-elasticity polyurethane resin comprises the following steps: preparing the low-elasticity polyurethane resin; the preparation method comprises the following steps: mixing polyether polyol, polyester polyol, polyolefin polyol, a chain extender I (without carboxyl), achain extender II (with carboxyl) and diphenylmethane diisocyanate according to a certain molar ratio, and processing the mixture according to a preparation process of thermoplastic polyurethane resin, thereby preparing low-elasticity polyurethane resin A when the addition amount of the chain extender II is 0, otherwise, preparing low-elasticity polyurethane resin B. The application includes steps of: the low-elasticity polyurethane resin A and the low-elasticity polyurethane resin B are mixed to prepare a low-elasticity polyurethane resin mixture, and furthermore, the mixture is adopted to prepare the superfine fiber base cloth based on the low-elasticity polyurethane resin. The limitation that high-density embossed products are difficult to obtain from traditional polyurethane superfinefiber base cloth is overcome, and the applicability of the embossing technology to the synthetic leather field with high-density requirements such as rugby leather is improved.

Owner:HUAFON MICROFIBER SHANGHAI

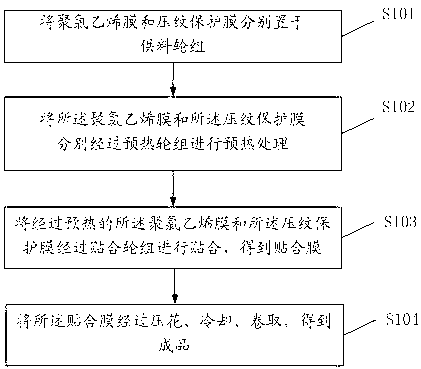

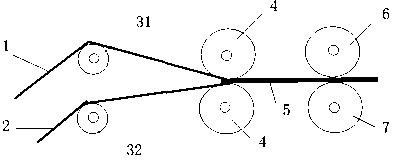

Embossing method for polyvinyl chloride film

The invention discloses an embossing method for a polyvinyl chloride film. The embossing method for a polyvinyl chloride film sequentially comprises the following steps of: placing the polyvinyl chloride film and an embossing protective film in a feeding wheel group respectively; performing preheating treatment on the polyvinyl chloride film and the embossing protective film via a preheating wheel group respectively; bonding the preheated polyvinyl chloride film and embossing protective film via a bonding wheel group, so as to obtain a bonded film; and embossing, cooling and winding the bonded film, so as to obtain the finished product. With the adoption of the embossing method disclosed by the invention, a layer of high-temperature-resistant protective film is added outside the polyvinyl chloride film, so as to obtain an embossed film product with a high-glossiness and high-mirror-finish non-embossed surface.

Owner:GUANGDONG TIANAN NEW MATERIAL

Textile fabric double-roller hot embossing device

PendingCN111778676AFast winding operationEasy embossingPattern makingHeating/cooling textile fabricsDrive shaftElectric machinery

The invention discloses a textile fabric double-roller hot embossing device which comprises an embossing machine frame, an unwinding roller is arranged on one side of the embossing machine frame, a winding roller is arranged on the other side of the embossing machine frame, a driving motor is arranged on the side portion of the other side of the embossing machine frame, a driving shaft is arrangedon the front portion of the driving motor, and the front end of the driving shaft is connected with the end of the winding roller. Upper positioning cylinders are arranged on the two sides of the upper portion of the embossing machine frame, an embossing pattern core roller is arranged between the upper positioning cylinders, lower positioning cylinders are arranged on the two sides of the lowerportion of the embossing machine frame, an embossing pattern cavity roller is arranged between the lower positioning cylinders, the embossing pattern cavity roller and the embossing pattern core roller are arranged in parallel, and the embossing pattern core roller is installed above the embossing pattern cavity roller. By means of the embossing cavity roller and the embossing core roller, the embossing treatment efficiency of the textile fabric is greatly improved; and the hot embossing treatment efficiency is greatly improved.

Owner:新昌县丙辰储能科技有限公司

Highly acoustical, wet-formed substrate

ActiveUS8025769B2High porosityHigh strengthFibreboardConstruction materialWater dispersibleCellulose fiber

This invention is an acoustic fiber-based substrate composed primarily of insulation-type spun fibers or blends of such fibers and wheel spun fibers. The fibers are bound with a water-dispersible latex binder, or an agri-binder such as starch in conjunction with cellulose fiber. The insulation-type spun fibers can be first quality virgin, post-industrial waste-stream or post-consumer waste stream fiber. The substrate is wet-formed from a very dilute aqueous dispersion of ingredients onto a mesh forming screen, as on a Fourdrinier paper machine. By virtue of the insulation-type spun fiber dimensions, morphology and orientation: very low density wet-mats can be formed from a sufficiently dilute suspension. With respect to other wet-formed substrates, the invention is much lower in density and more highly porous, and, thus, the substrate is highly absorbing, exhibiting noise reduction coefficients, NRC values of about 0.80 or greater. Such NRC values have only been achieved with dry-formed, or air-laid processes in which the fiber are bound with formaldehyde emitting reactive resins.

Owner:AWI LICENSING

Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

ActiveCN102787510BNo pollutionObvious cloth seamLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

Owner:浙江昶丰新材料有限公司

Decorative brick and preparation method thereof

InactiveCN101634182AReduce sizeFirmly connectedCovering/liningsCeramic shaping apparatusSurface layerBrick

The invention belongs to a building material and the field of preparation thereof, in particular to a decorative brick and a preparation method thereof. The decorative brick consists of two or three layers. A surface layer is a concave-convex stereoscopic pattern layer which is prepared from cement, fine stone powder, reinforced materials and water, or the cement, the fine stone powder, mica, the reinforced materials and the water as main raw materials, and is hydraulically formed through a mould. A bottom layer is a compound layer which is prepared from river sand, the cement, stones and water, or the cement, the fine stone powder, the reinforced materials and the water as the main raw materials, and is hydraulically formed through the mould. The preparation method comprises the following steps of: taking the raw materials of the bottom layer in proportion, fully mixing the materials, and pouring the mixture onto the bottom layer of the mould; then taking the raw materials of the surface layer in proportion, fully mixing the materials, and pouring the mixture onto the upper layer of the mould; delivering the filled mould onto a hydraulic machine with a stereoscopic pattern top die, and carrying out surface stereoscopic embossing and instant forming and demoulding; and then solidifying the materials at a normal temperature or by heating to obtain a product of which one lateral surface is provided with a stereoscopic pattern. The decorative brick and the method have the advantages of simple process, convenient operation, low cost, beautiful product appearance and rich stereoscopic sensation.

Owner:潘淑兰

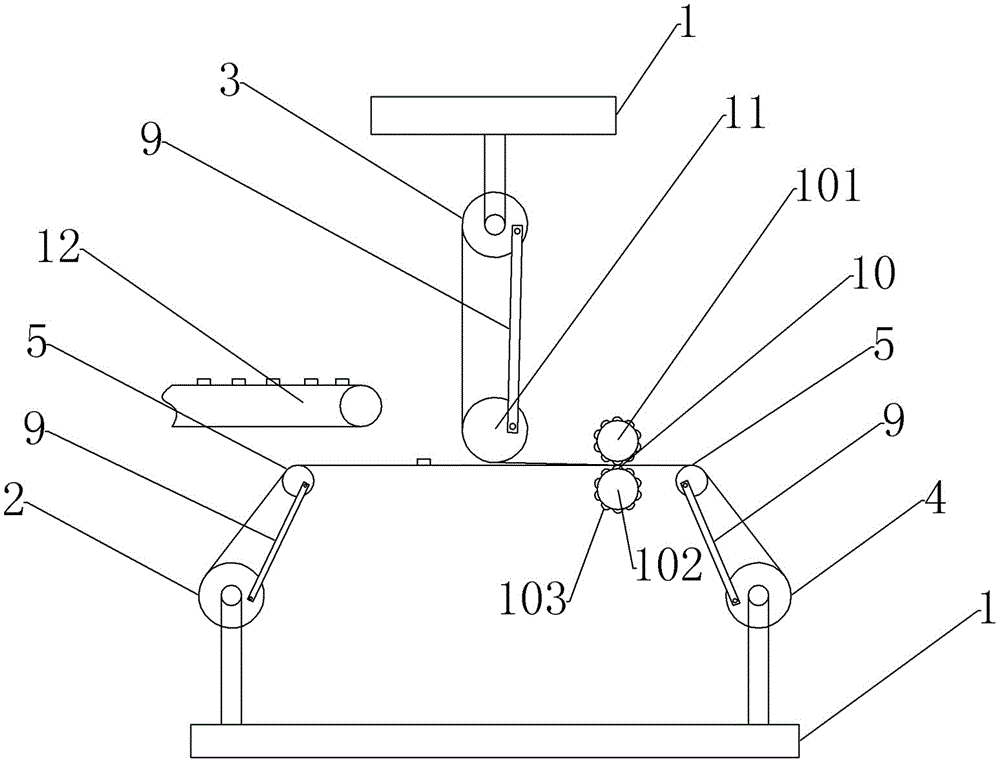

Paper diaper 3D embossing device

ActiveCN113290946ACompound completelyAvoid wastingMechanical working/deformationEngineeringMechanical engineering

The invention discloses a paper diaper 3D embossing device. The paper diaper 3D embossing device comprises a shell, two pressing rollers installed on the shell and two correcting rings, a second embossing roller is arranged between the two pressing rollers, the shell is provided with a first embossing roller used in cooperation with the second embossing roller, the shell is used for supporting the whole paper diaper 3D embossing device, and a rack is installed on the rear side of the shell; and the two correcting rings are symmetrically arranged at the two ends of the second embossing roller, each correcting ring is tightly connected with the shell through a first spring, and a limiting block with the L-shaped cross section is fixedly installed at the top of each correcting ring. A straightening block on an adjusting rod moves and pushes a surface layer at the same time, so that the deviated surface layer is straightened, the subsequent surface layer compounding is more complete, the dislocation phenomenon is avoided, the subsequently produced paper diapers can be normally used, and the resource waste is avoided.

Owner:华昊无纺布(南通)有限公司

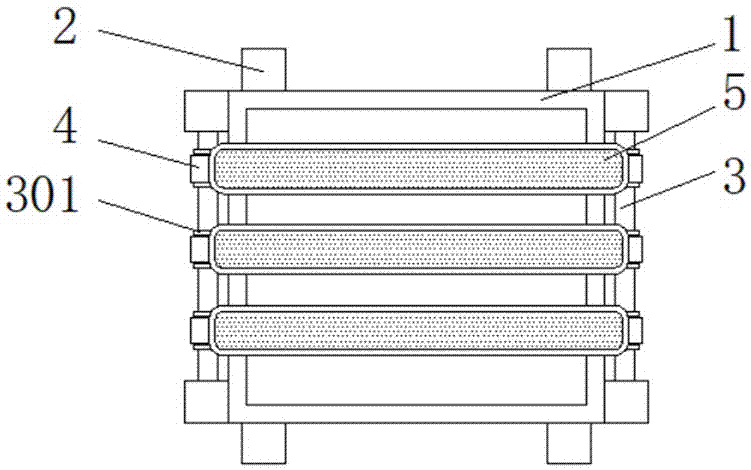

Reflective film continuous processing production device based on base material embossing and processing method thereof

PendingCN112848620AEasy to pressEasy embossingLamination ancillary operationsLaminationEmbossingMachining

The invention relates to a reflective film continuous processing production device based on base material embossing and a processing method thereof. The device comprises a processing table, a first conveying roller is fixedly installed on one side of the top end of the processing table, and a second conveying roller is fixedly installed on the side, close to the first conveying roller, of the top end of the processing table; and a positioning cleaning mechanism is fixedly installed at the position, between the first conveying roller and the second conveying roller, of the top end of the machining table, a pressing assembly is fixedly installed in the middle of the top end of the machining table, and an embossing assembly is fixedly installed on the side, close to the pressing assembly, of the top end of the machining table. Through the positioning cleaning mechanism, a first base material and a second base material which are different in length and size can be positioned, the first base material and the second base material are prevented from deviating in the follow-up pressing operation, the opposite faces of the first base material and the second base material can be effectively cleaned, dust pollution is prevented, then follow-up glue attaching operation is facilitated, and therefore, the processing quality of the light film is improved.

Owner:田学芳

Wooden product embossing device

InactiveCN108944222AAchieve heating effectEasy embossingEmbossing decorationsBiochemical engineeringFuel tank

The invention discloses a wooden product embossing device. The wooden product embossing device comprises a base, a supporting frame, an air cylinder, a fixing plate, an embossing die, an oil storage cavity, an oil outlet pipe, an oil inlet pipe, a connecting pipe, a connecting head, a lifting rope, a lifting ring, a heat conduction oil tank, a heating pipe, a pump, a fixing die and a wooden product. According to the wooden product embossing device, a fixing groove is formed in the base, moreover, the fixing die is placed in the fixing groove, and the fixing dies with different shapes can be placed according to the shapes of the different wooden products so that the wooden products with the different shapes can be embossed by the device; then the oil storage cavity is formed in the embossing die, moreover, the heat conduction oil tank is arranged, the heating pipe is arranged in the heat conduction oil tank so that heat conduction oil in the heat conduction oil tank can be heated through the heating pipe, then the heat conduction oil is guided into the oil storage cavity, then the effect of heating the embossing die can be achieved, and then the wooden product can be conveniently embossed; and then the connecting head is arranged at the top end of the embossing die, and the connecting head can be fixed in the connecting pipe so that different patterns can be conveniently formedon the wooden product through embossing.

Owner:霍邱新阳之光电子商务有限公司

High-elongationstretchability shoe leather base cloth device

The invention discloses a high-elongation shoe leather base cloth equipment, which comprises a steel roller groove, a connecting block, a first fan groove, a second fan groove and a transmission motor. connected, and the cross bar is connected with the embossing roller through the rolling rod, the connecting block is arranged on the steel roller groove, and the connecting block is connected with the electric telescopic rod, and the first fan groove and the second fan groove are respectively arranged on the The two ends of the steel roller trough, and the inside of the first fan trough and the second fan trough are respectively installed with a fan and a warm fan, the drive motor is connected with the drive shaft through a conveyor belt, and a control box is installed on one side of the console . The high-elongation shoe leather base fabric equipment first softens the fabric coated with rubber, then embosses the fabric, and finally cools the fabric and the completed embossing to obtain a shoe leather base with a pattern. Cloth and embossing rollers can be disassembled, which is convenient for manufacturers to replace different embossing rollers according to different patterns.

Owner:HAINING HONGYUAN NON WOVEN FABRIC

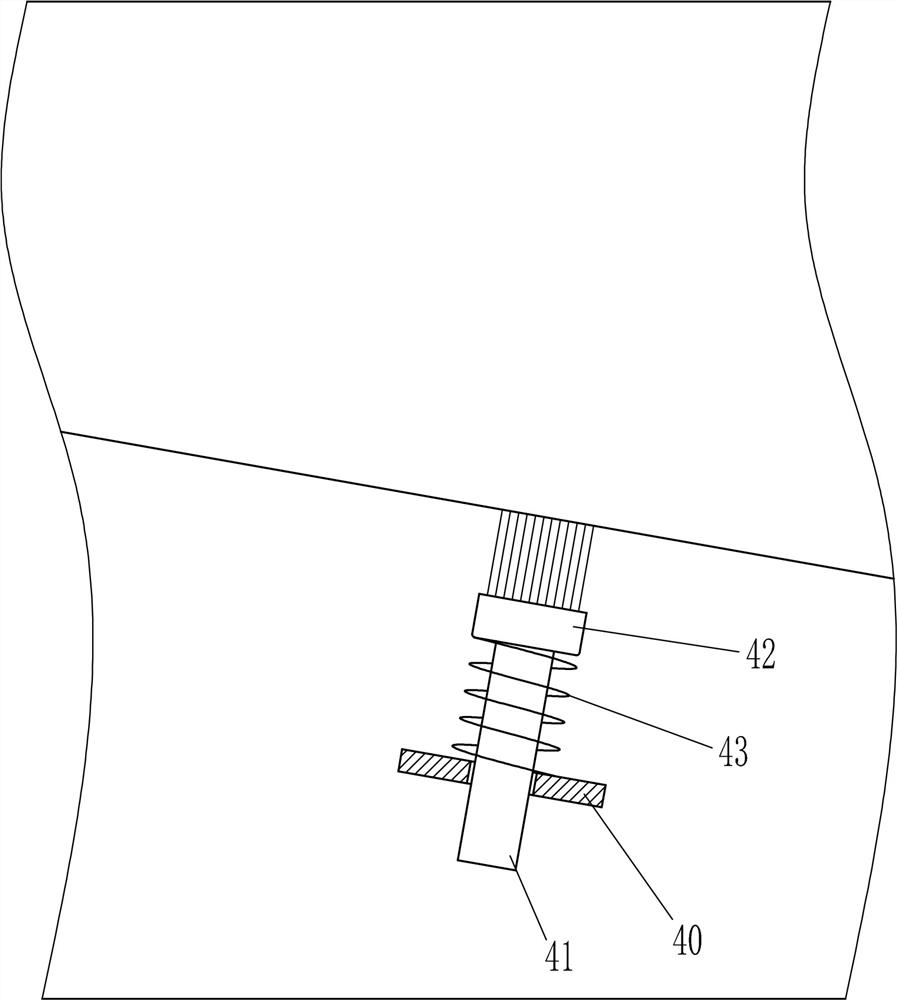

Textile fabric embossing machine

PendingCN111826871AEasy embossingEasy to collectMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The invention relates to an embossing machine, in particular to a textile fabric embossing machine. As a result, according to the technical problem, the textile fabric embossing machine which can reduce the labor intensity and avoid scratches is provided. According to the technical execution scheme, the textile fabric embossing machine comprises a base, a machine frame, first rolling shafts, a first installation plate, a first sector gear, a handle, a guide rod, a first spring and the like. The machine frame is arranged on the rear side of the top of the base, and the two first rolling shaftsare rotationally connected to the lower portion of the front side face of the machine frame. A first through hole is formed in the top of the machine frame, and the first installation plate is fixed to the left side of the upper portion of the machine frame and located on the right side of the first through hole. According to the textile fabric embossing machine, a textile fabric is wound throughthe anticlockwise rotation of a fabric winding shaft device, the textile fabric can be embossed in the mode that an embossing tool downwards moves to cooperate with an embossing die, and therefore embossing operation can be conveniently conducted on the textile fabric, the labor intensity of a user is reduced, and the user can be prevented from being scratched.

Owner:李三妹

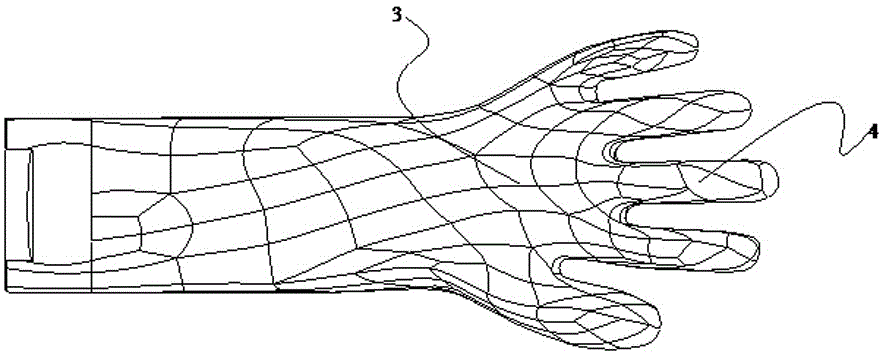

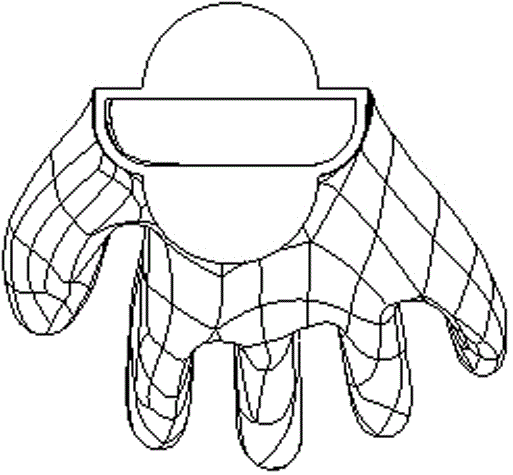

Thermo-sensitive embossing flat-plate hand mold

The invention discloses a thermo-sensitive embossing flat-plate hand mold. The thermo-sensitive embossing flat-plate hand mold comprises a palm, a wrist, a hand back and fingers, wherein the palm and the front surfaces of the fingers are located on the same plane and the back surfaces of the fingers are sharp; drilling holes are formed in two ends of a lug boss of the tail end of the wrist; and pressure on the hand back is generated and patterns on a template are pressed on the palm and the front surfaces of the fingers. The thermo-sensitive embossing flat-plate hand mold has the beneficial effects that the wall thickness of the hand mold is uniform and the temperature of the whole hand mold is uniform. The back surfaces of the fingers are sharp so that the glue immersing depth is conveniently and accurately controlled; and when the hand mold works, the palm and the front surfaces of the fingers form a horizontal plane, and glue immersing and embossing are convenient to realize.

Owner:SHANDONG XINGYU GLOVES

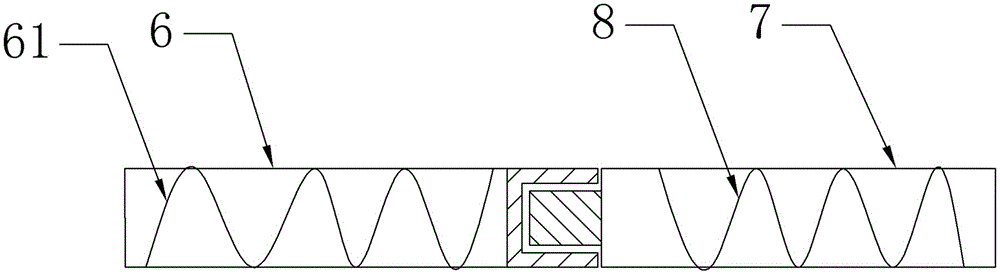

Embossing press for lubrication belt

The invention discloses an embossing press for a lubrication belt. The embossing press comprises a frame, a driving rotating shaft and a driven rotating shaft, wherein the driving rotating shaft and the driven rotating shaft are arranged in the frame and are arranged in parallel mutually; the driving rotating shaft is fixedly provided with a driving wheel; the driven rotating shaft is provided with a driven wheel which can be rotated around the shaft; the rotating shaft center of the driven rotating shaft and the axis of the driven wheel are not in the same straight line; and one side of the driven rotating shaft is provided with a fixing device for fixing the driven rotating shaft. According to the embossing press, the driven wheel which is rotated around the driven rotating shaft is eccentrically arranged, and the axis of the driven wheel and the rotating shaft center of the driven rotating shaft are not in the same straight line, so that the distance between the nearest points on the surfaces of the driving wheel and the driven wheel can be eccentrically adjusted by rotating the driven rotating shaft when the surfaces of brake bars with different thicknesses and specifications are embossed; and the driven rotating shaft is fixed through the fixing device when adjusted to a suitable position, so that the embossing press can more conveniently emboss the brake bars with various thicknesses and specifications. The embossing press is used in the field of the embossing of the brake bars.

Owner:广州钜锋机电设备有限公司

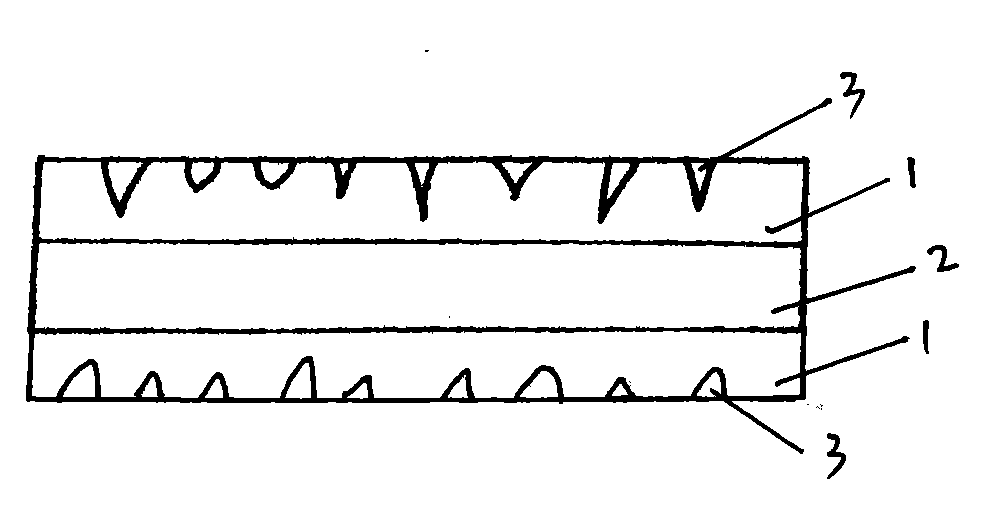

Water-based environment-friendly high-flame-retardant solvent-free embossed grain-absorbed synthetic leather and preparation method thereof

PendingCN114379175ANon-toxicOdorlessLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolyol

The invention relates to water-based environment-friendly high-flame-retardant solvent-free embossed grain-absorbing synthetic leather which comprises a surface layer, a foaming layer and base cloth, the foaming layer comprises a solvent-free component A, a solvent-free component B and a flame retardant, the solvent-free component A comprises polyether polyol, a small-molecule chain extender, a foaming agent, a foam stabilizer and a catalyst, the solvent-free component B comprises an isocyanate prepolymer, and the flame retardant is a flame retardant. The polyether polyol used in the invention is prepared by mixing glycerol-based polyether polyol with the molecular weight of 3000-4000 and propylene glycol-based polyether polyol with the molecular weight of 1000-2000 according to a certain ratio; the glycerol-based polyether polyol with the molecular weight of 3000-4000 forms network crosslinking in the chain extension reaction of the solvent-free component A and the solvent-free component B to provide better toughness and physical properties for a solvent-free layer, and the propylene glycol-based polyether polyol with the molecular weight of 1000-2000 enables the solvent-free component A and the solvent-free component B to be further subjected to chain extension, so that more macromolecular straight chains exist; and during embossing, softening can be achieved more easily through high temperature, and embossing is facilitated.

Owner:浙江昶丰新材料有限公司

A 3D embossing device for diapers

ActiveCN113290946BCompound completelyAvoid wastingMechanical working/deformationEngineeringMechanical engineering

Owner:华昊无纺布(南通)有限公司

Conveyor for lace machine

ActiveCN113981646BEasy embossingMechanical cleaningLiquid surface applicatorsAdhesive glueEngineering

The invention relates to the technical field of lace machines, in particular to a conveyor for lace machines. The invention provides a conveyor for a lace machine, comprising: two pressure plates, a detection plate, a cleaning plate and a torsion spring, a first support point is arranged between the two pressure plates, and the two pressure plates are respectively arranged on the fabric lace On both sides; the cleaning plate is set parallel to the bottom of the detection plate; the torsion spring is set on the end of the detection plate away from the edge plate; the end of the detection plate close to the edge plate is fixed with two parallel detection feet, and the upper ends of the two detection feet are respectively provided with a Extrusion assembly connected to rubber storage bin. The cloth lace is suitable for slidingly conveying between the two edge-holding plates. The detection board is suitable for detecting whether there is a breakpoint on the edge of the fabric lace, and if there is a breakpoint in the fabric lace, the detection board can spray glue to the inside of the breakpoint of the fabric lace to repair the breakpoint. The cleaning plate can clean the other side end face of the fabric lace. The torsion spring is suitable for driving the detection board to be inserted between the breakpoints of the fabric lace.

Owner:常州万腾超声波设备有限公司

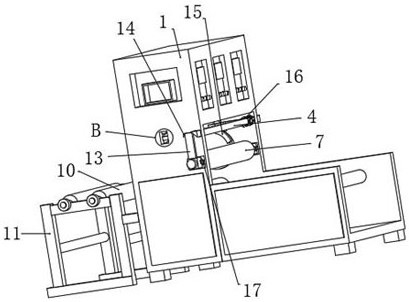

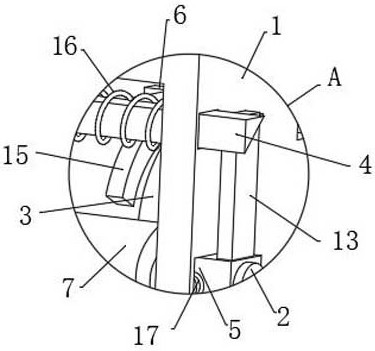

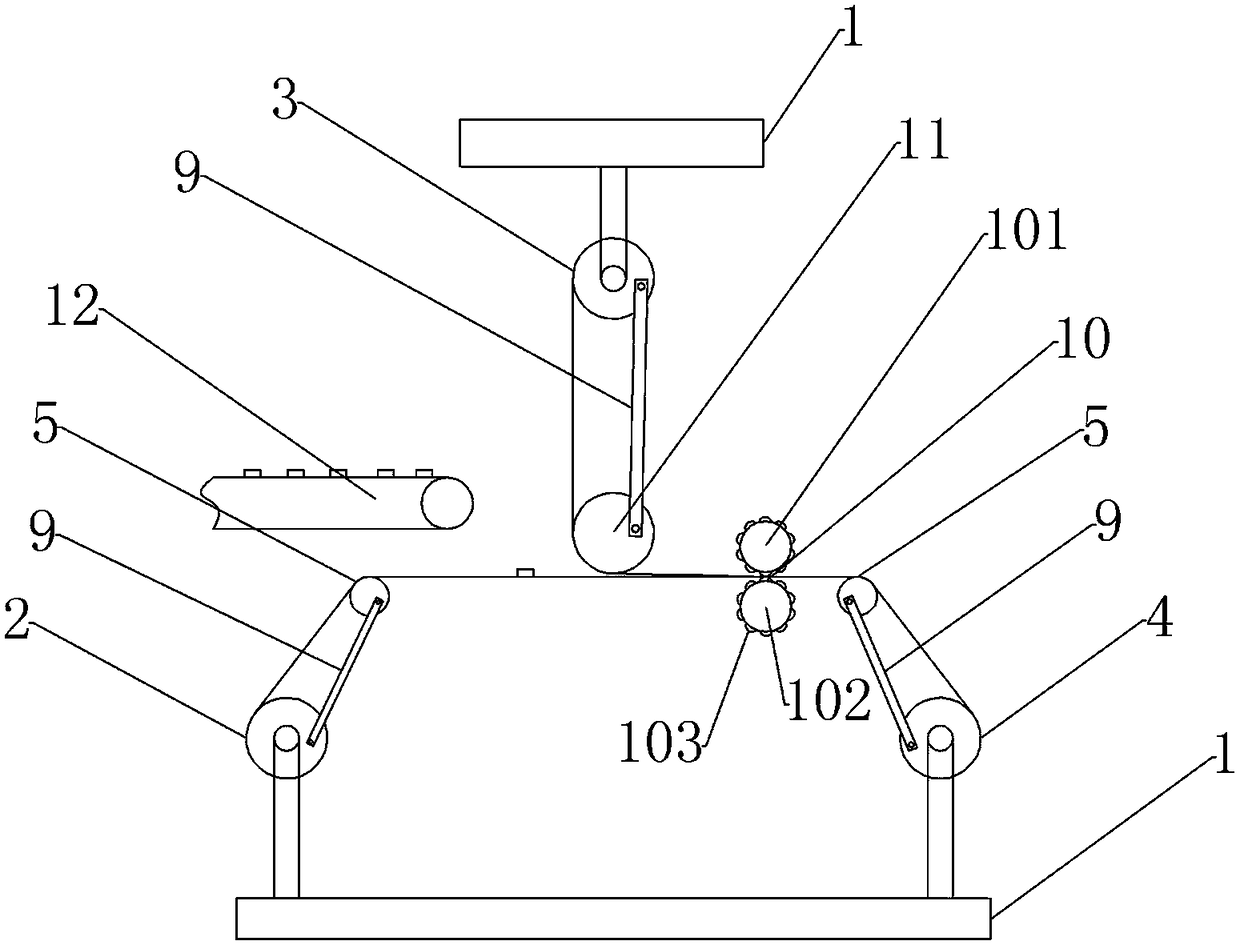

Plants for toilet paper processing

ActiveCN106821106BStable atEasy embossingMechanical working/deformationDomestic applicationsToilet paperPulp and paper industry

The invention relates to the technical field of toilet paper processing, in particular to a device for toilet paper processing. A first paper feeding roll and a paper winding roll are located at the bottom of a rack, the portion over the first paper feeding roll and the portion over the paper winding roll are each provided with a leveling rod, and the leveling rods serve as crease-resistant rods; a second paper feeding roll is located on the top of the rack, a toilet paper embossing device is arranged between the two leveling rods, and the distance between the embossing device and the paper winding roll is smaller than that between the second paper feeding roll and the paper winding roll; a conveyor belt is arranged over the leveling rods in the horizontal direction, and the projection of the output end of the conveyor belt on the plane where the two leveling rods are located is located between the projection of the paper feeding roll on the plane and the leveling rod close to the first paper feeding roll. According to the device, the problems that in the processing process of an existing rewinding machine, due to the fact that creases are likely to be generated on the surface of toilet paper, the surface and the end face of the toilet paper completing rewinding are uneven, and corn leaf strips stretch out of the space between two layers of toilet paper can be solved.

Owner:枣庄市恒宇纸业有限公司

Device for toilet paper processing

ActiveCN106821106AStable atPrevent fallingMechanical working/deformationDomestic applicationsToilet paperPulp and paper industry

The invention relates to the technical field of toilet paper processing, in particular to a device for toilet paper processing. A first paper feeding roll and a paper winding roll are located at the bottom of a rack, the portion over the first paper feeding roll and the portion over the paper winding roll are each provided with a leveling rod, and the leveling rods serve as crease-resistant rods; a second paper feeding roll is located on the top of the rack, a toilet paper embossing device is arranged between the two leveling rods, and the distance between the embossing device and the paper winding roll is smaller than that between the second paper feeding roll and the paper winding roll; a conveyor belt is arranged over the leveling rods in the horizontal direction, and the projection of the output end of the conveyor belt on the plane where the two leveling rods are located is located between the projection of the paper feeding roll on the plane and the leveling rod close to the first paper feeding roll. According to the device, the problems that in the processing process of an existing rewinding machine, due to the fact that creases are likely to be generated on the surface of toilet paper, the surface and the end face of the toilet paper completing rewinding are uneven, and corn leaf strips stretch out of the space between two layers of toilet paper can be solved.

Owner:枣庄市恒宇纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com