Conveyor for lace machine

A conveyor and lace machine technology, applied in mechanical cleaning, textiles and papermaking, coating, etc., can solve the problems affecting the beauty of flannel and affecting the use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

[0056] In this embodiment, the velvet pressure flow is sutured by two velvet cloth, thereby forming a thick velvet cloth, but in the actual production, a partial flaw occurs to cause a breakpoint between the velvet embossed. This embodiment gives a specific solution based on the above background.

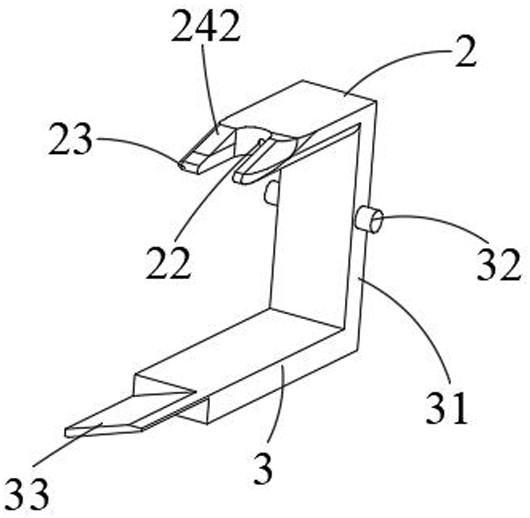

[0057] Such as Figure 1 to 8, The present invention provides a lace machine conveyor, comprising: two bead plates 1, the detection plate 2, the torsion spring 4 and the cleaning plate 3. 1 is adapted to slide between two conveyor velvet embossed bead. Cloth 2 is adapted to detect whether there embossing plate edge detection breakpoint, the breakpoint when the cloth is not present embossing, embossing the cloth can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com