Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299 results about "Machine failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term "machinery failure" or "malfunction" usually implies that the machine has stopped functioning the way in which it was intended or designed. This is referred to as “loss of usefulness” of the machine or component. For instance, if a pump is installed to pump 100 gallons of oil per minute...

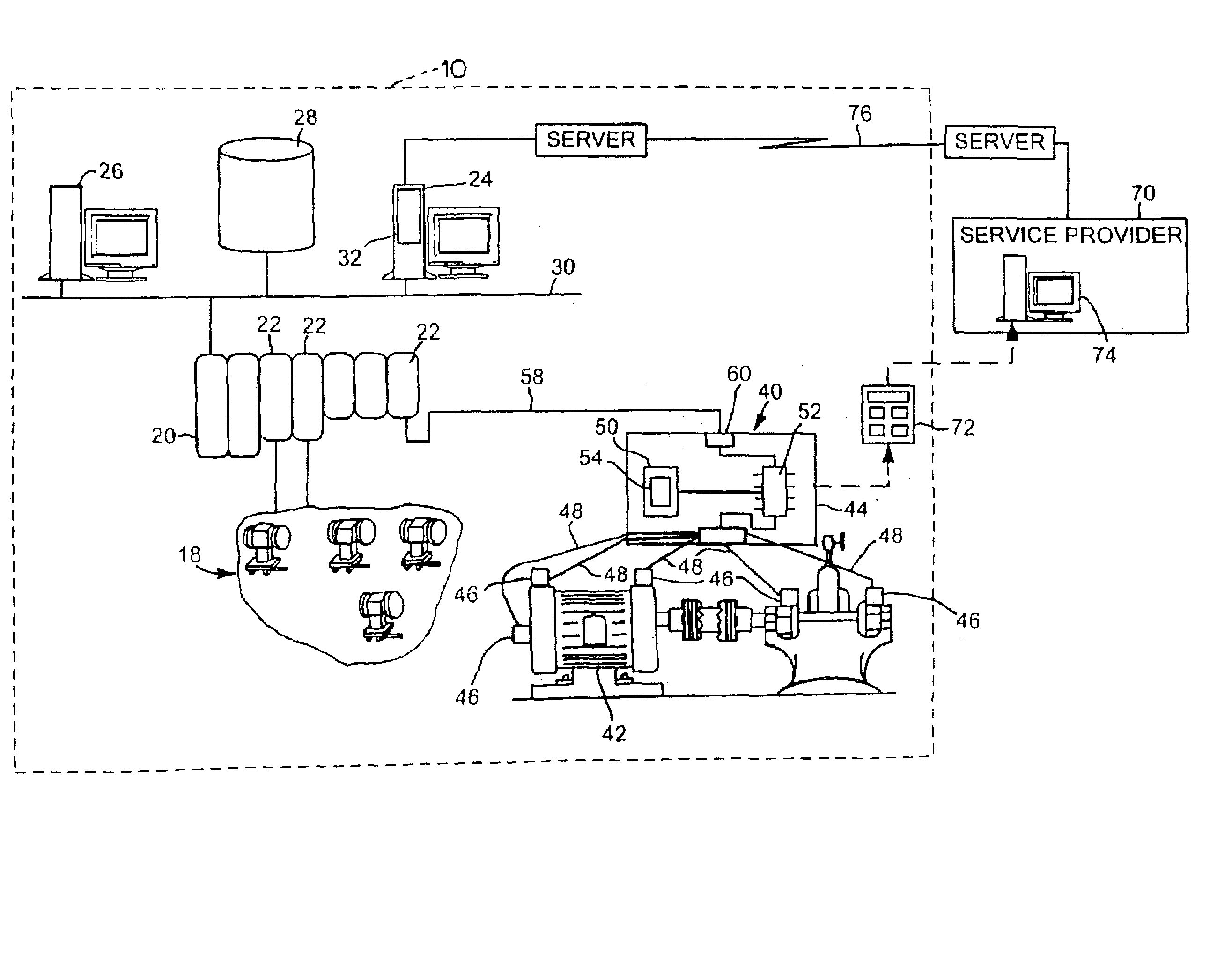

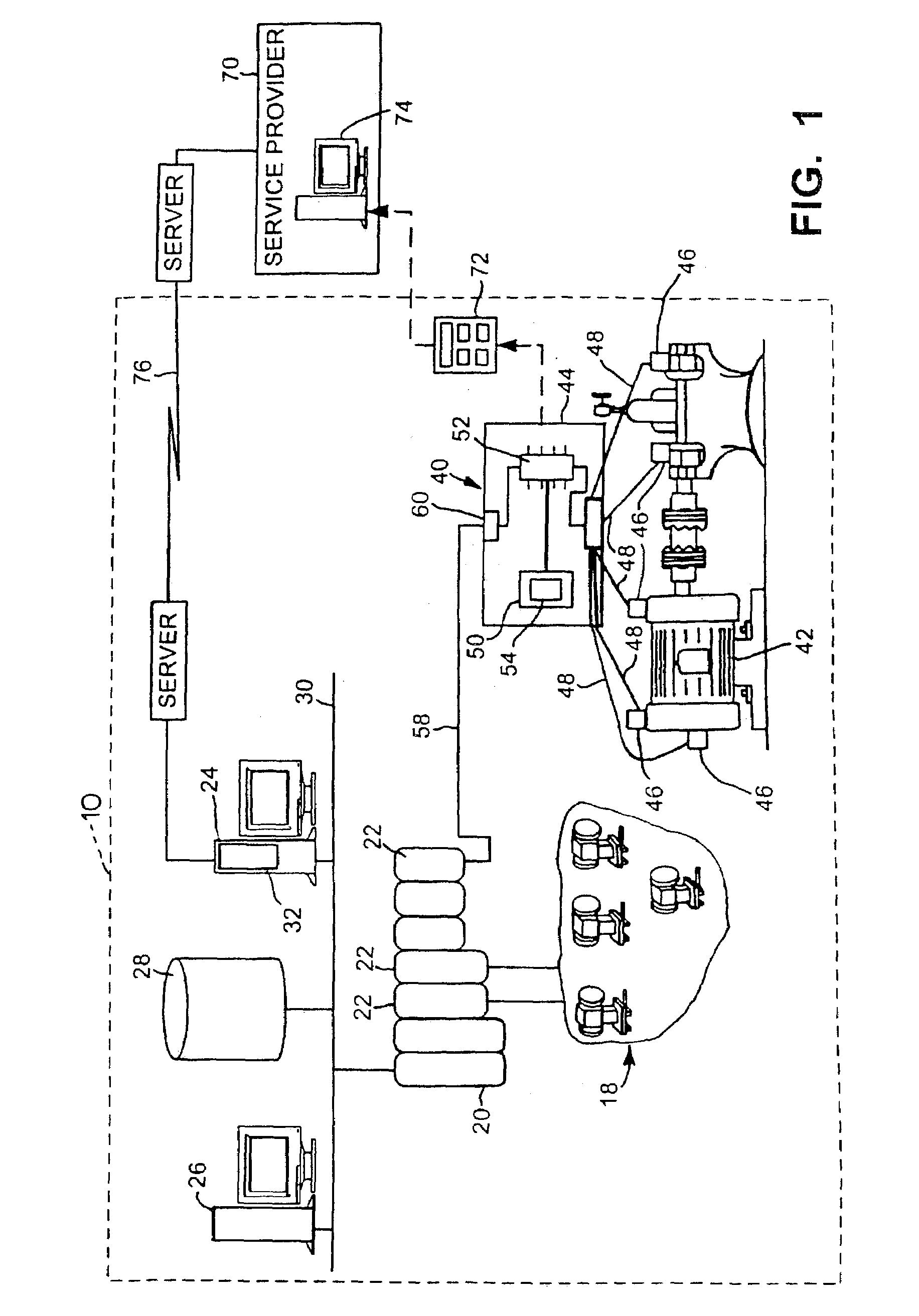

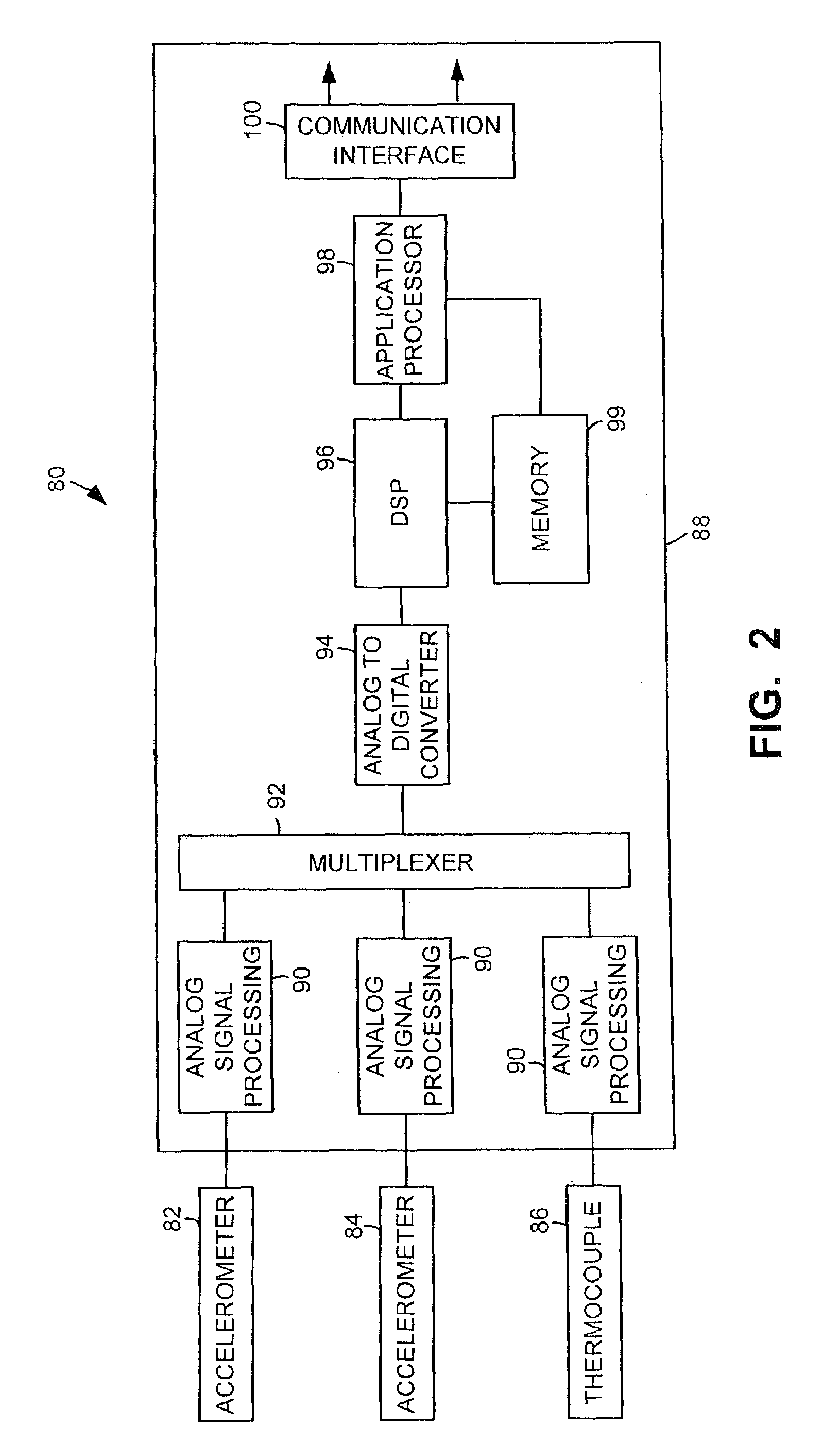

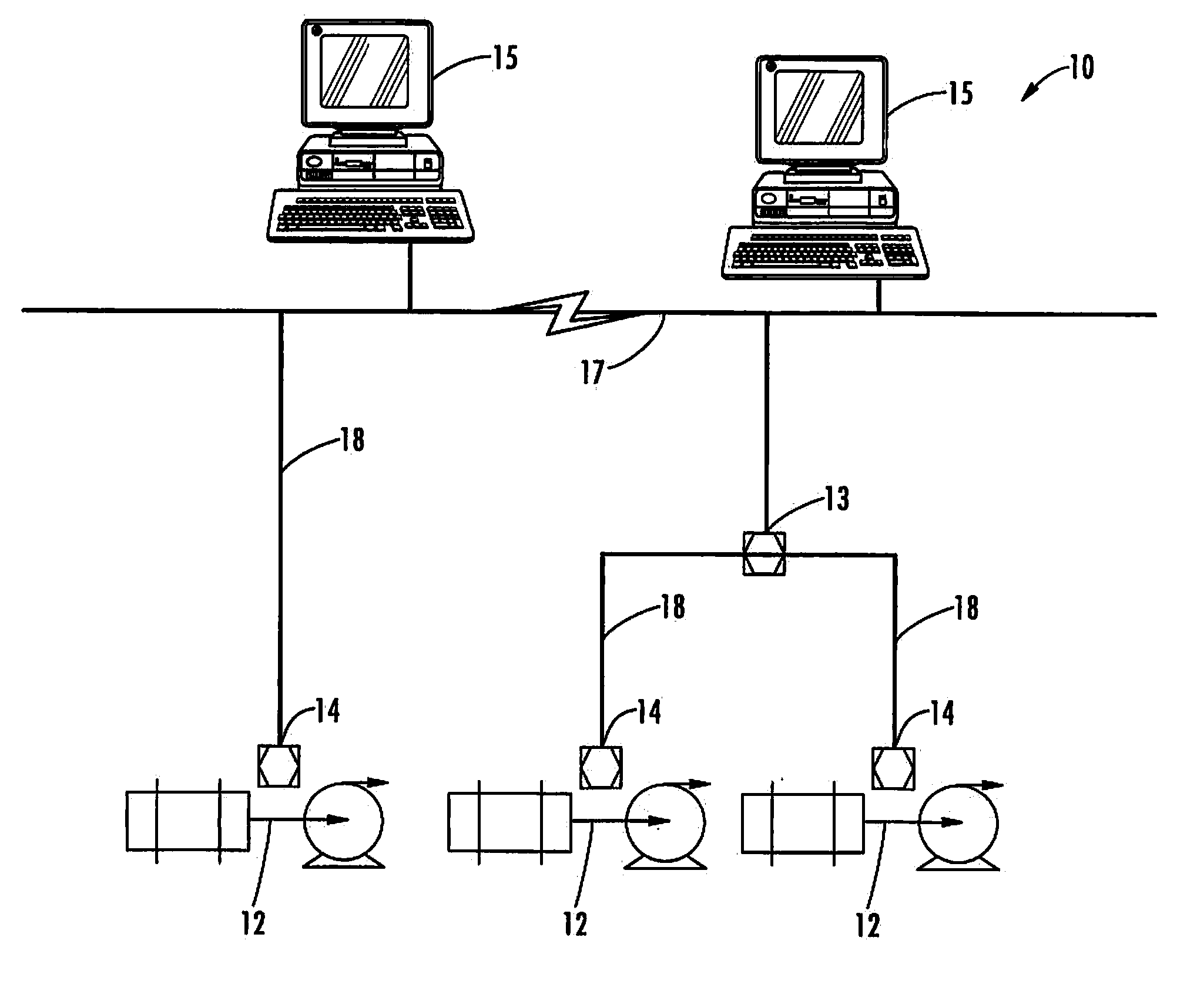

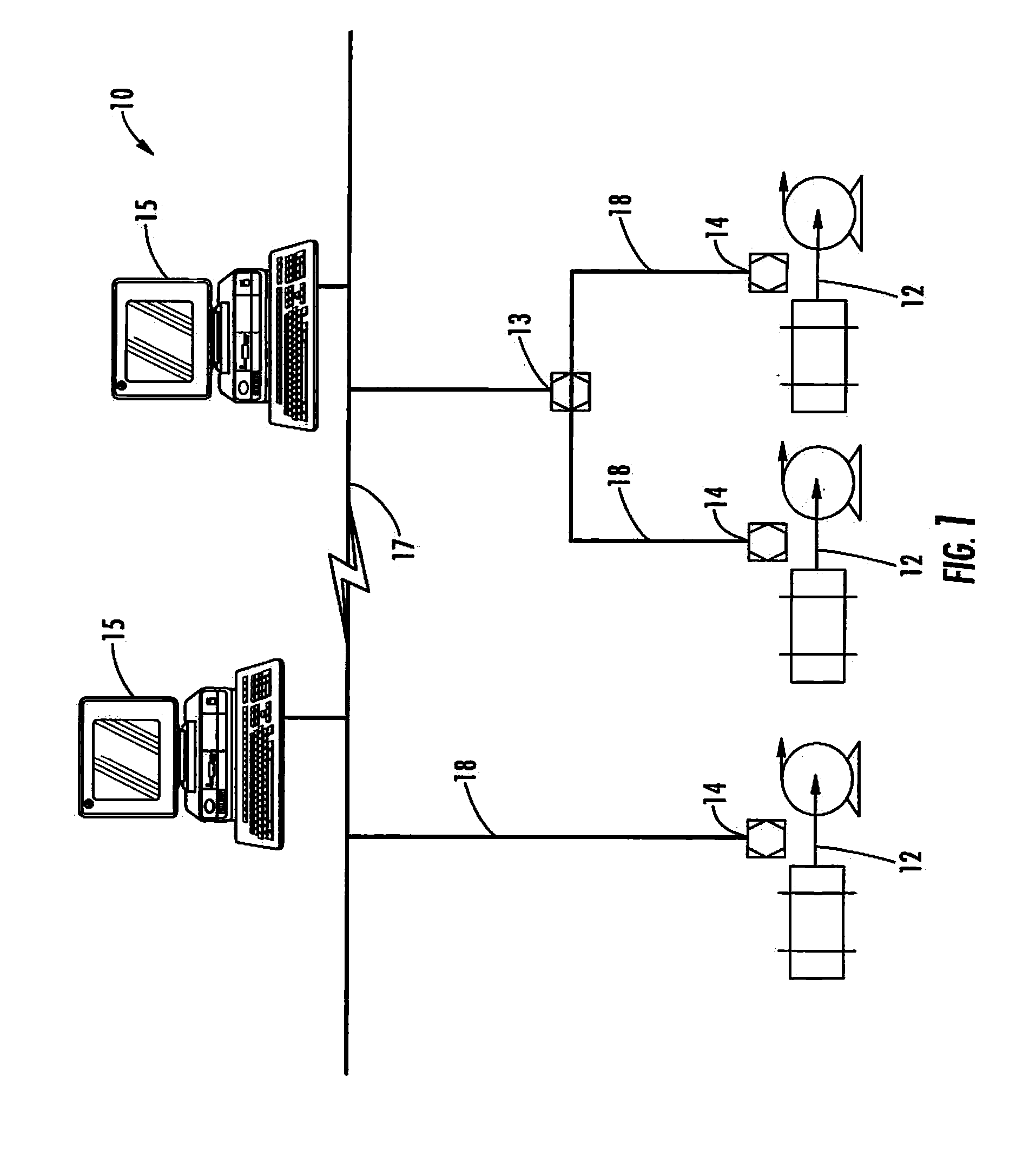

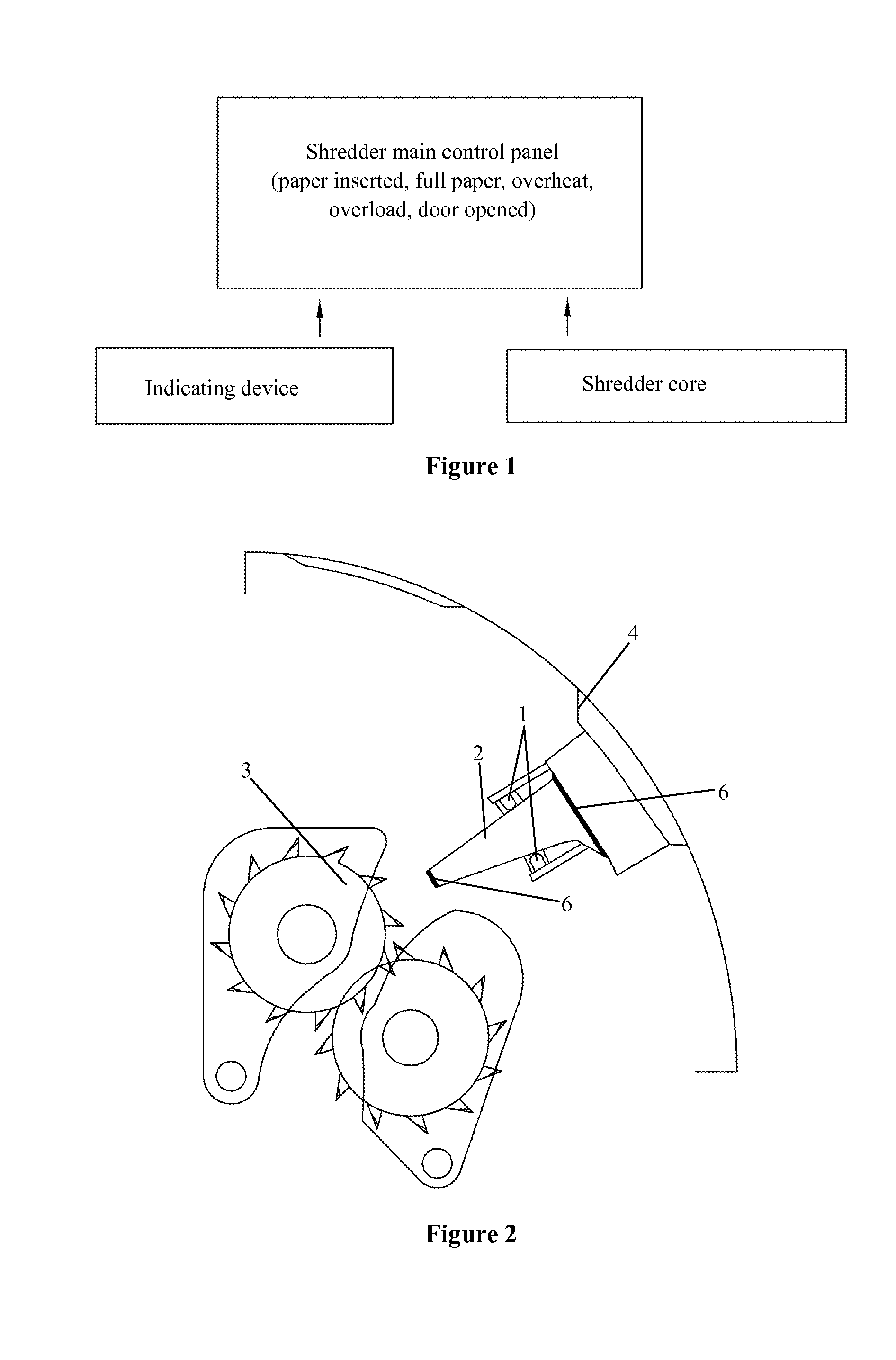

Machine fault information detection and reporting

InactiveUS7142990B2Quick identificationEasy to installAmplifier modifications to reduce noise influenceComputer controlCavitationLogical operations

Sensors detect machine parameters such as vibration, turning speed, and temperature, and a local processor performs logic operations based on the parameters and inference rules to produce fault information that is reported to a system processor, which selectively uses the fault information to control the plant machines. The inference rules include rules for determining faults as to balance, alignment, bearing condition, electrical condition, and cavitation. The inference rules are contained in rules code that is separate from the analysis code that performs the logical operations. Thus, the inference rules may be easily changed without changing other code, such as the analysis code.

Owner:COMPUTATIONAL SYST

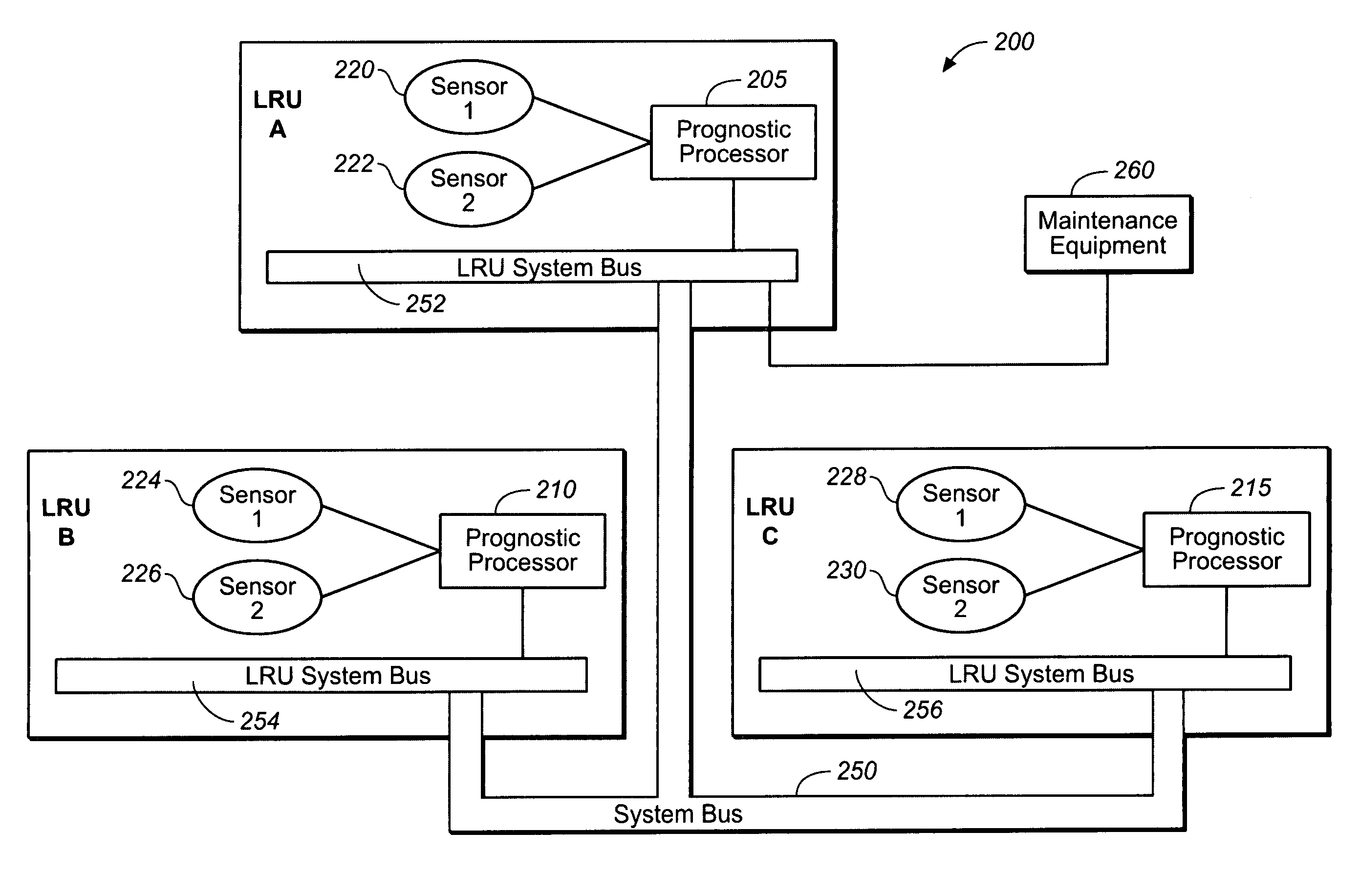

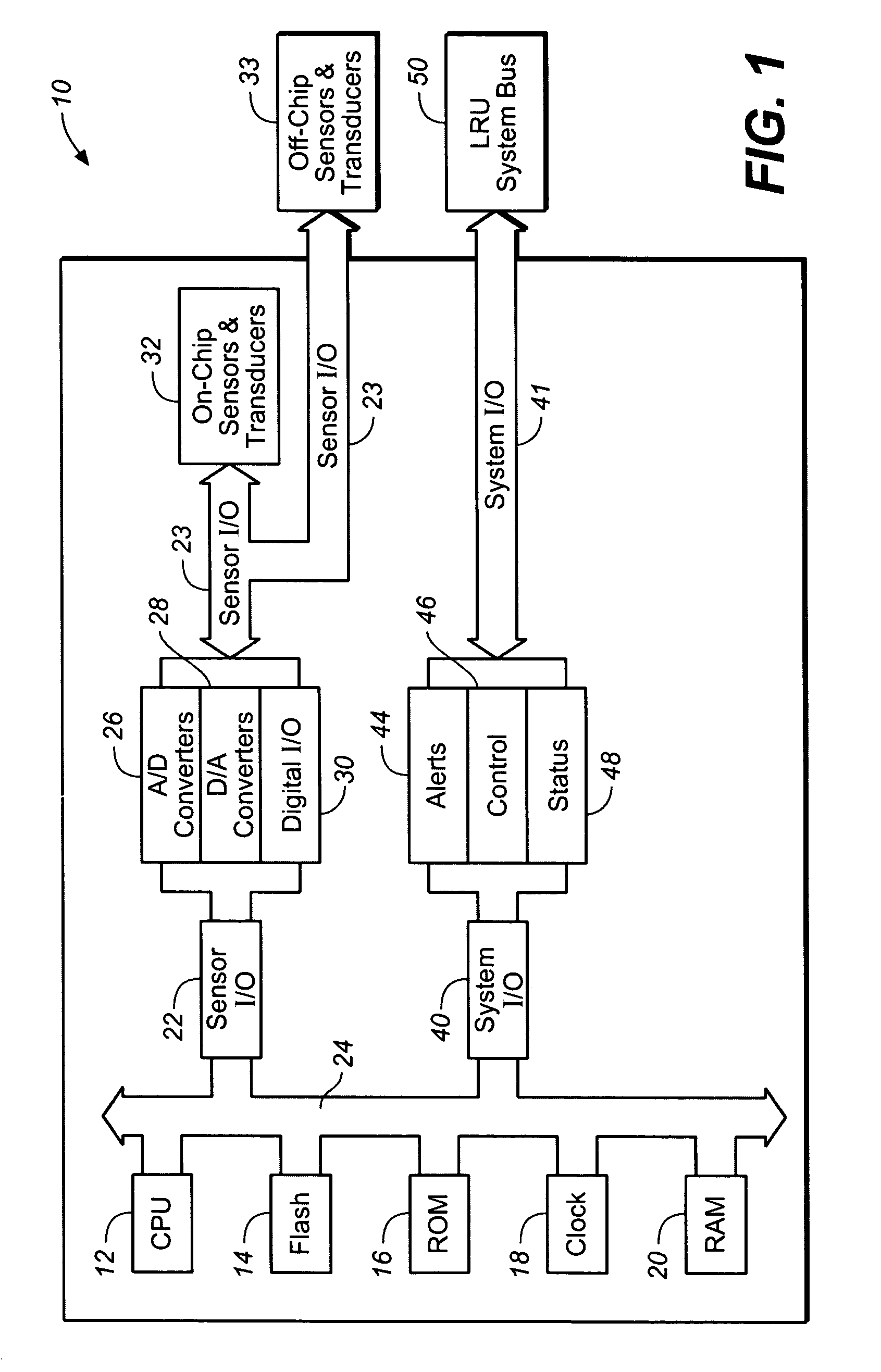

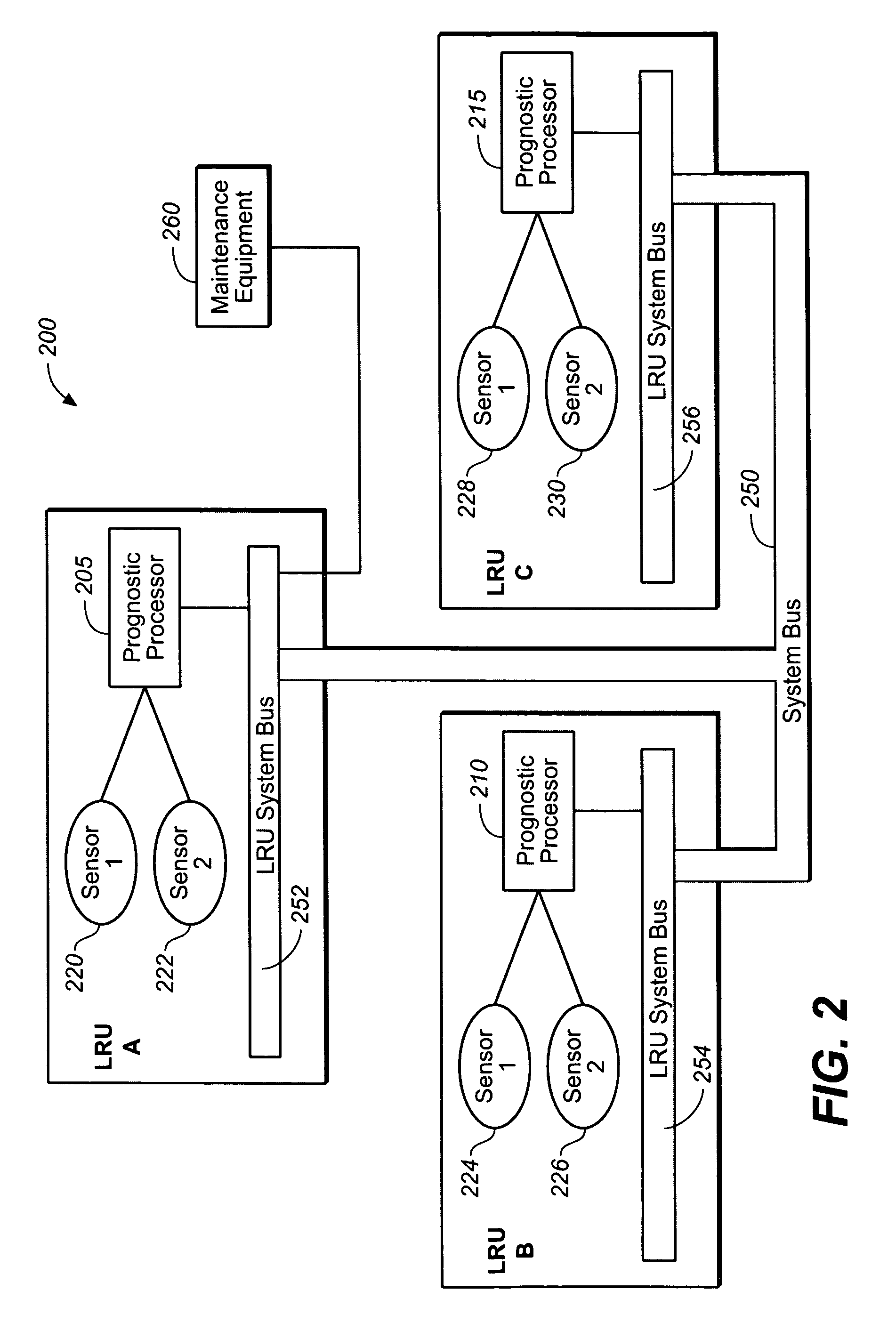

Prognostic processor system for real-time failure analysis of line replaceable units

ActiveUS7509537B1Electronic circuit testingTesting/monitoring control systemsModeling softwarePredictive failure analysis

A prognostic processor for predicting machine failure in avionics electronics comprises prognostic capabilities in a single integrated circuit, with a processor, volatile and non-volatile memory, clock, on-chip and off-chip sensors and transducers, A / D converters, a common I / O interface adapted to be employed in a network of similar prognostic processors, and predictive Failure Analysis (FA) model software, which may be distributed throughout the network. The FA software employs a log file history, with the log file history storing data collected by the prognostic processor, real-time execution of a predictive model, with the ability to update the FA model with data from field failures. The prognostic processor network supports hierarchical processing to work with multiple prognostic processors. The prognostic processor system is applicable to FA monitoring of a wide range of avionics electronic equipment, in particular, Line Replacement Units (LRUs).

Owner:ROCKWELL COLLINS INC

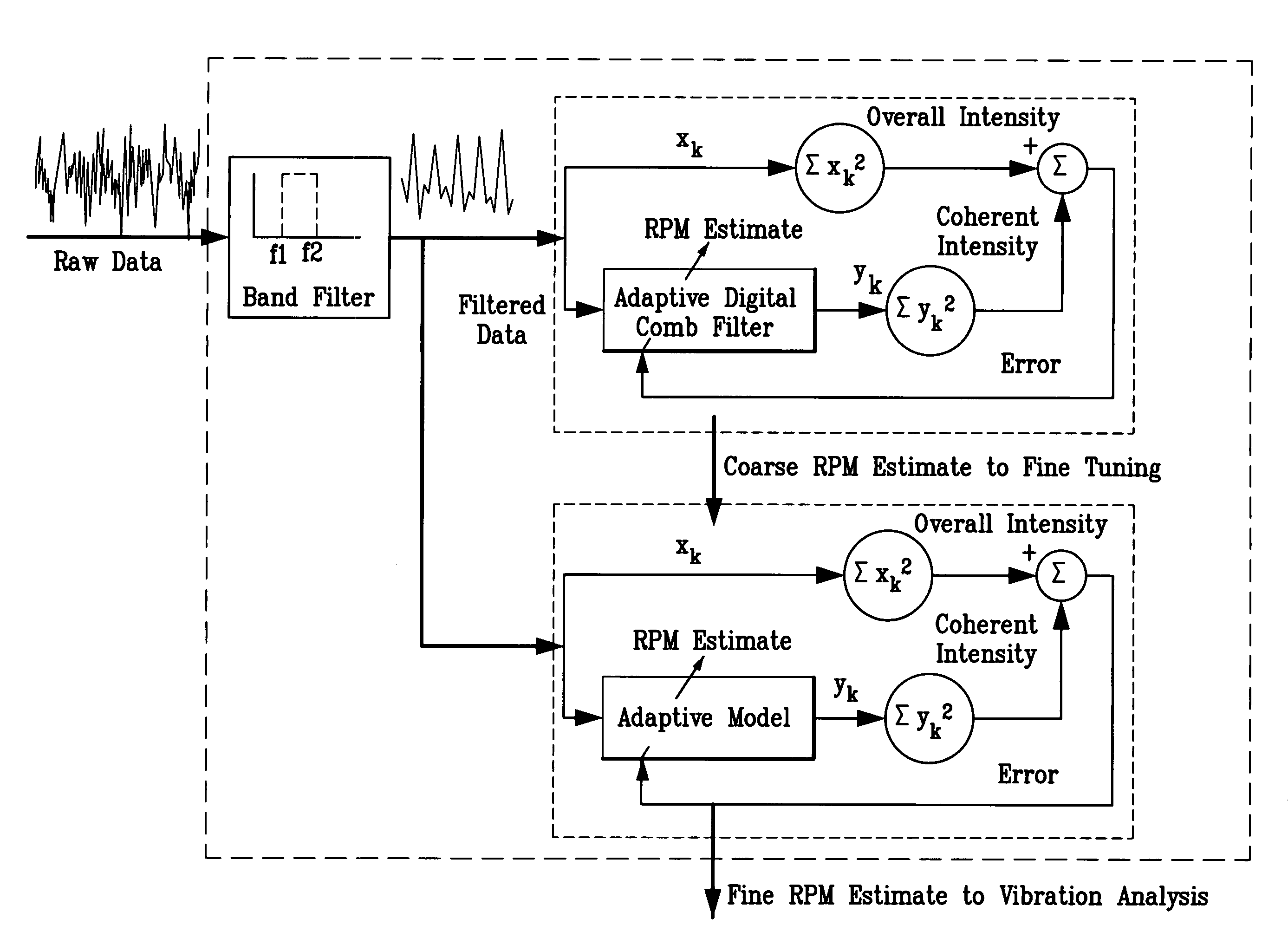

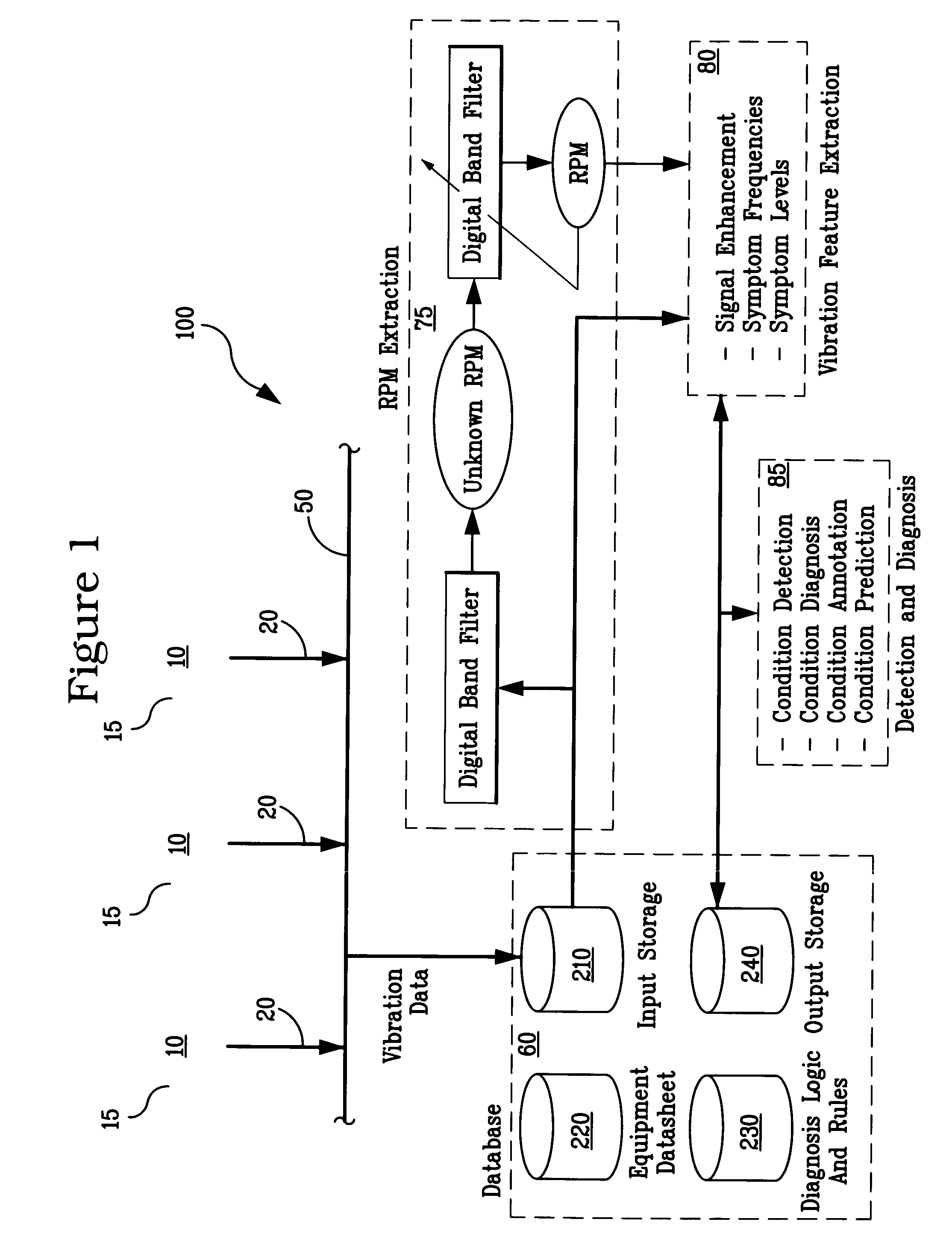

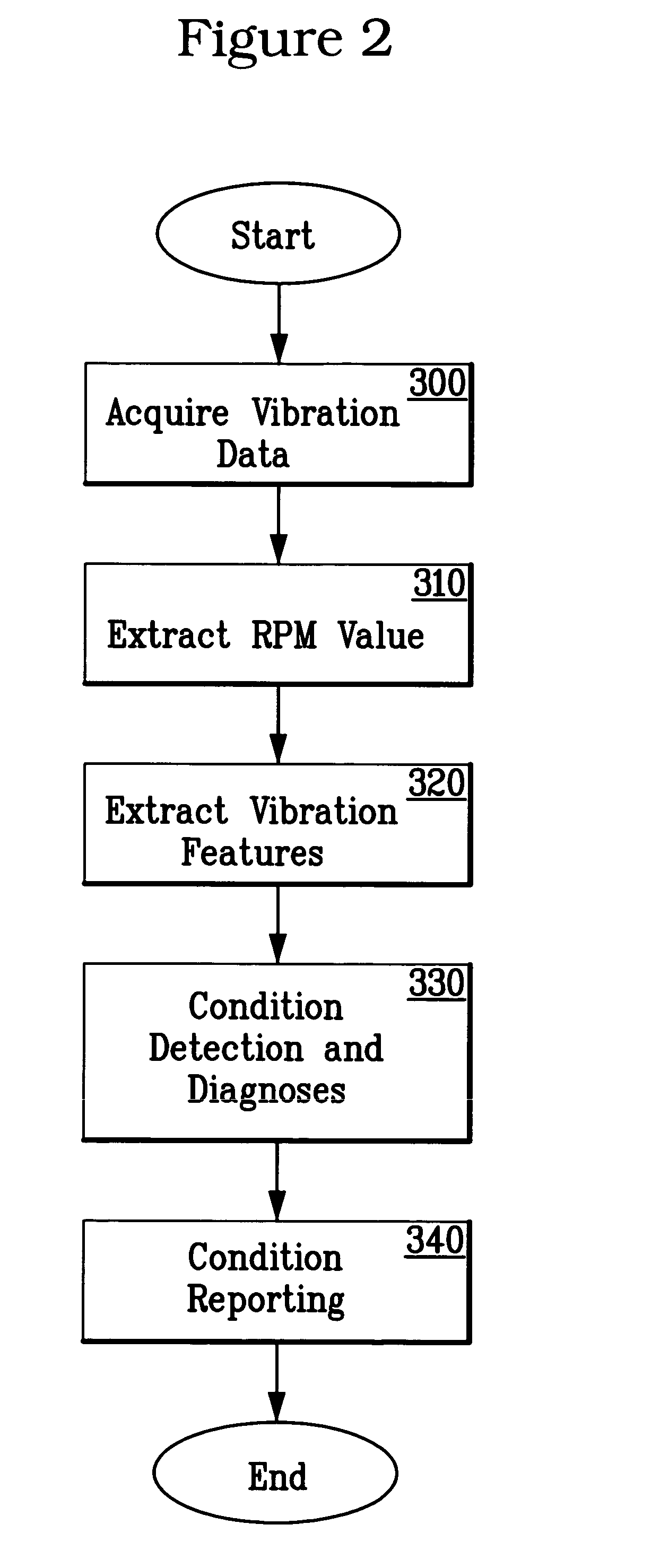

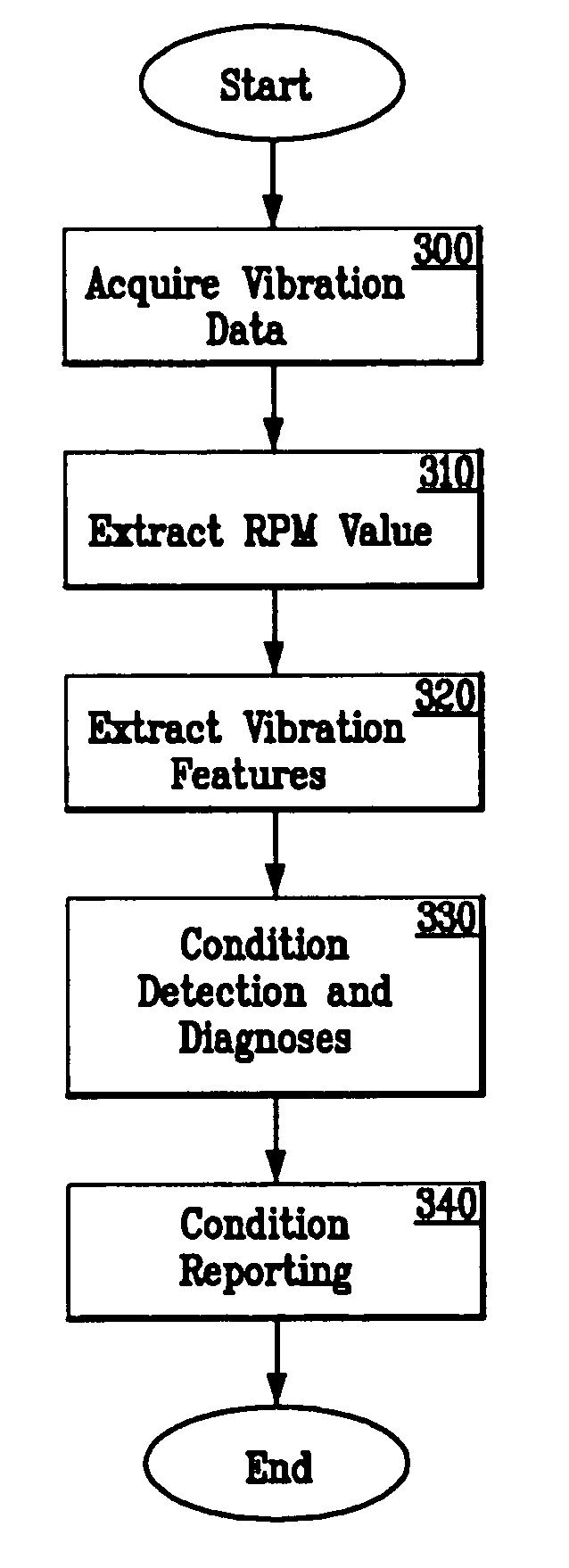

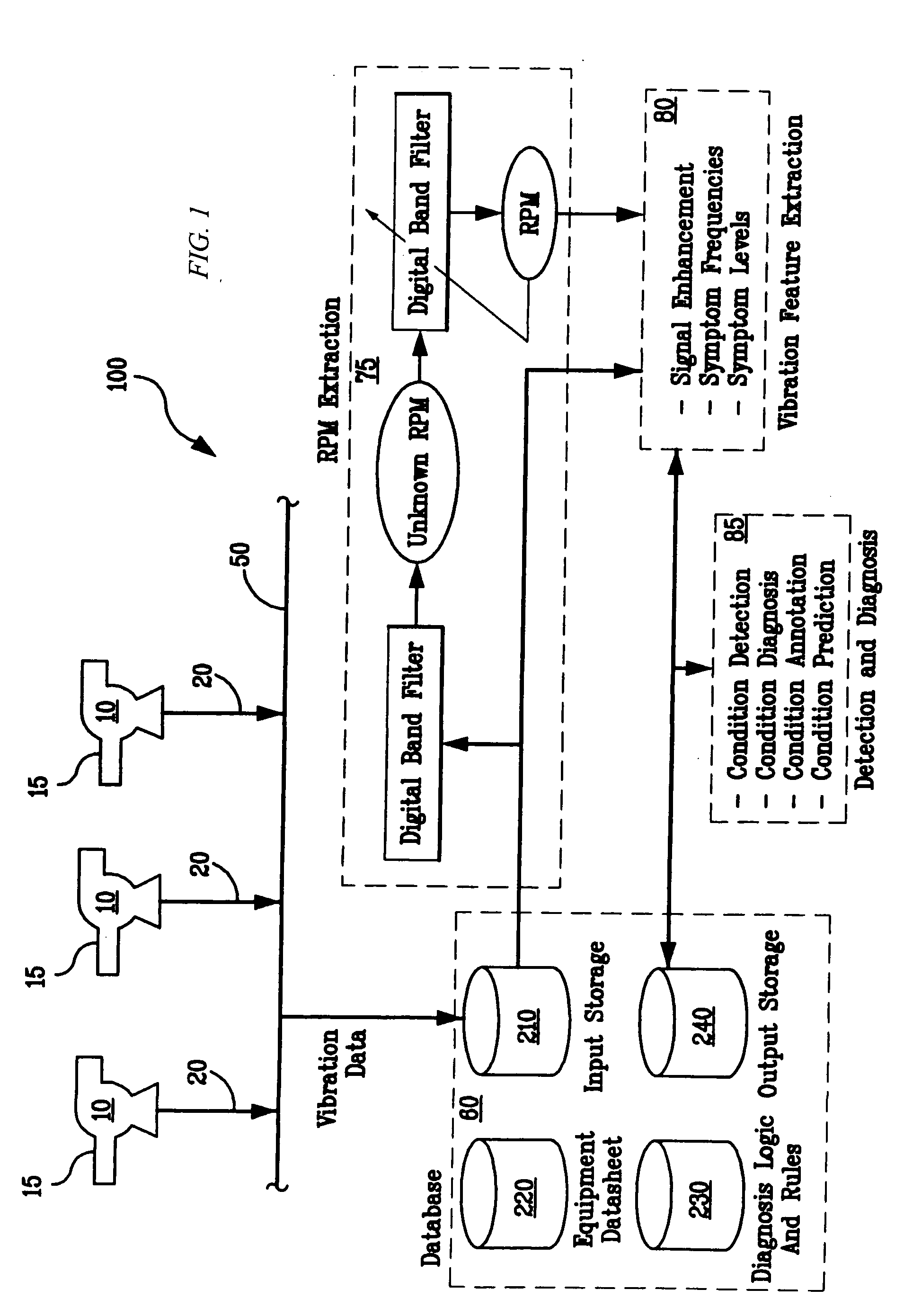

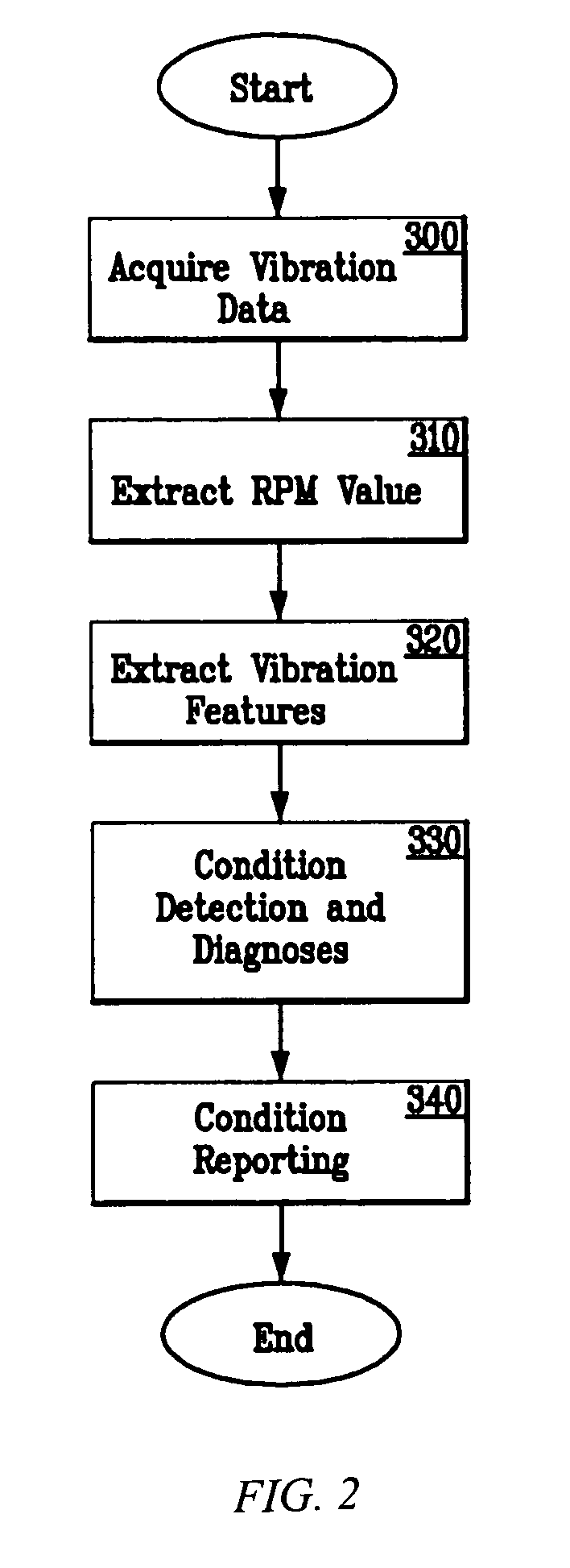

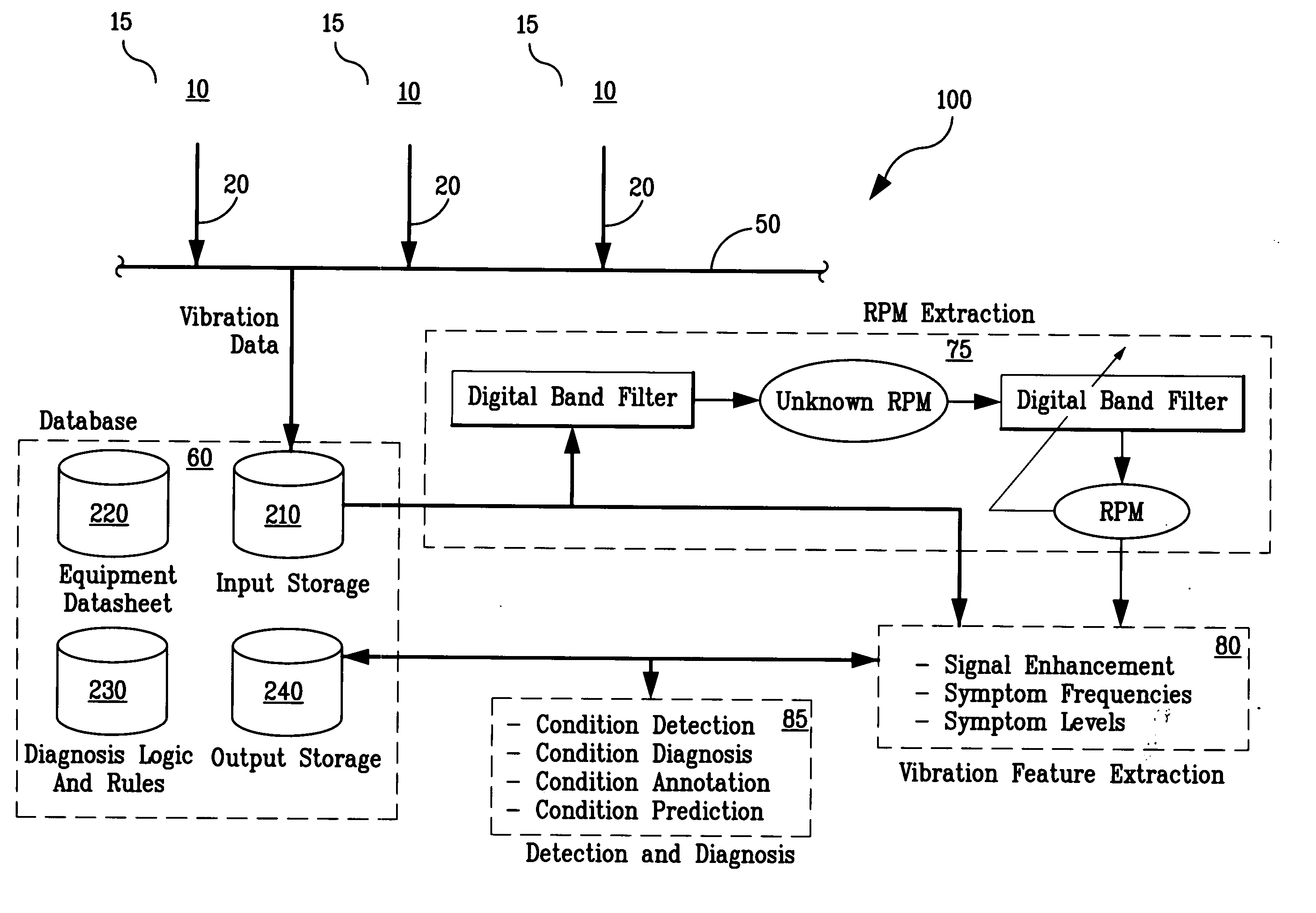

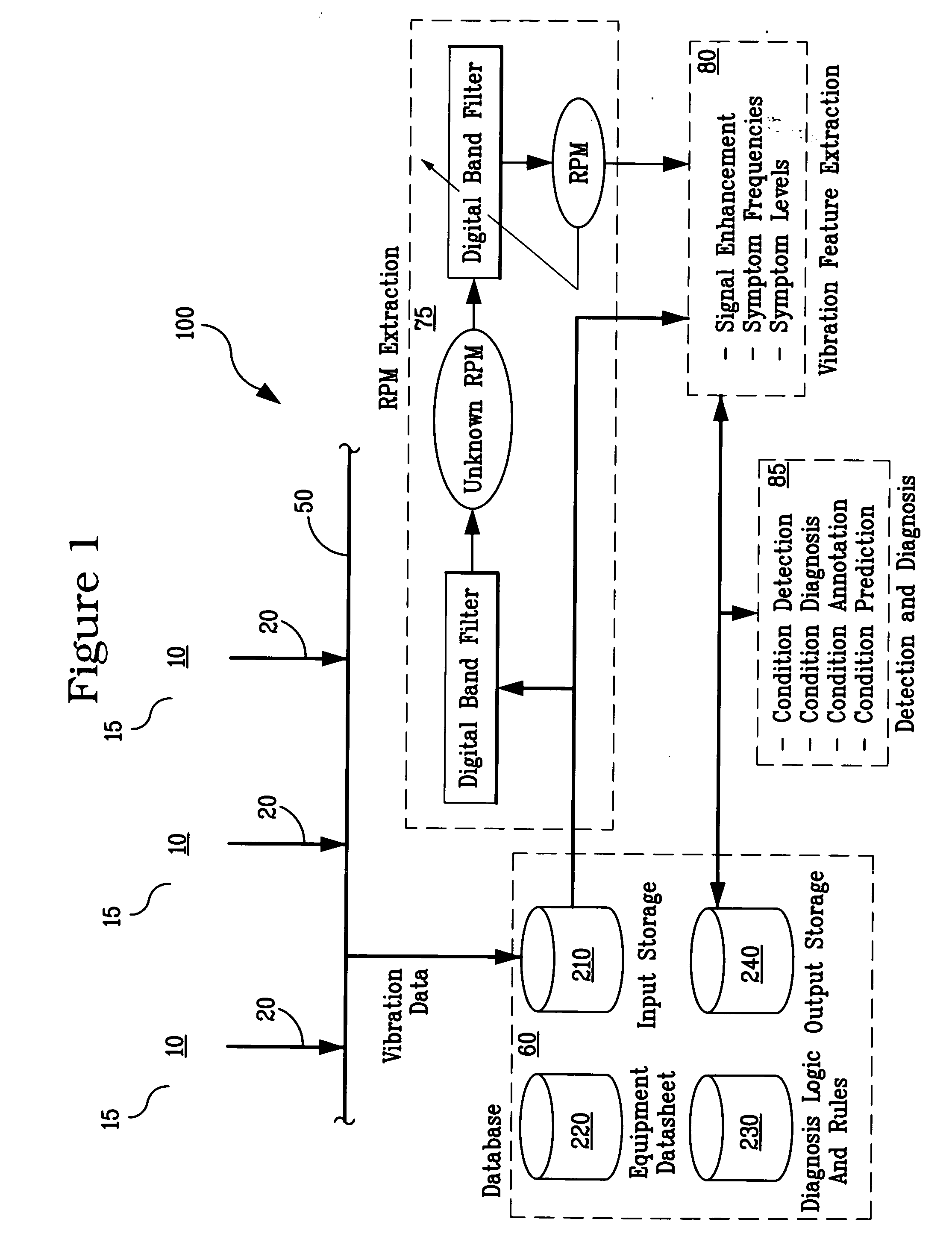

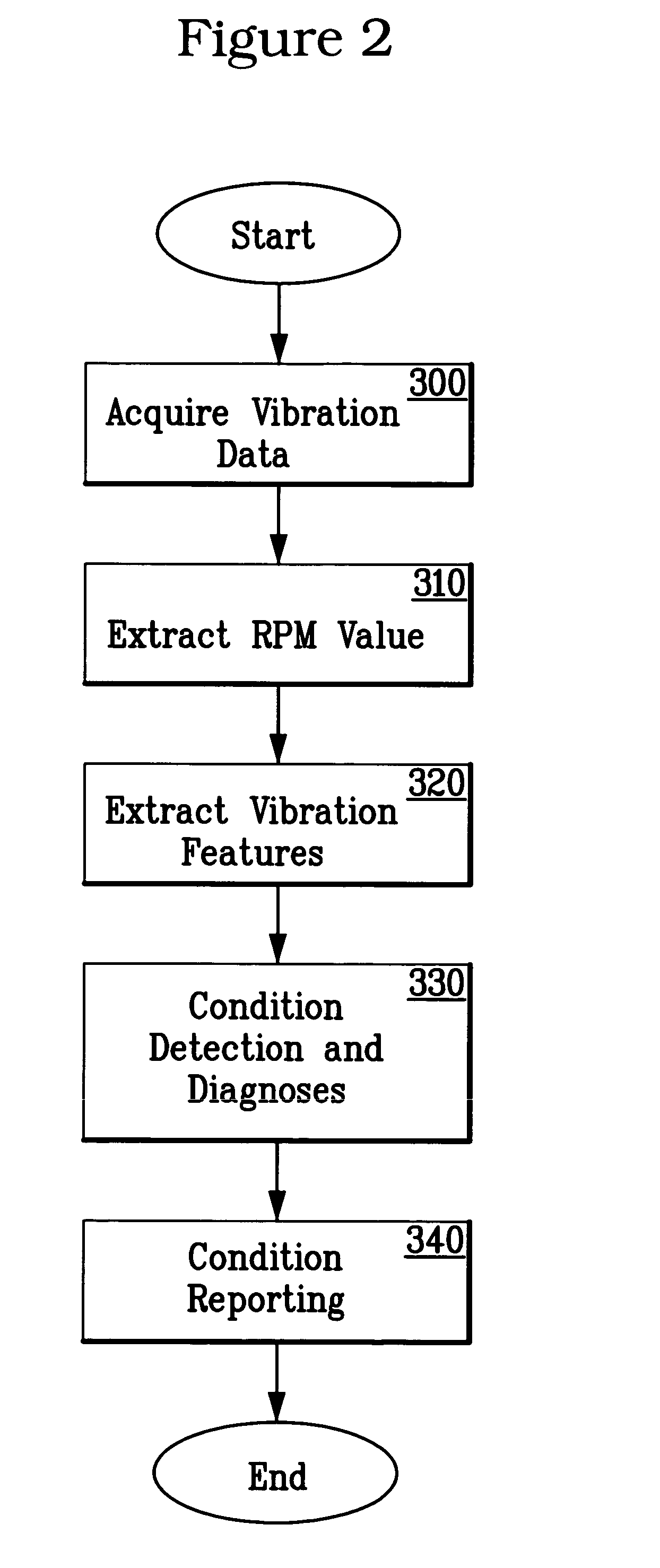

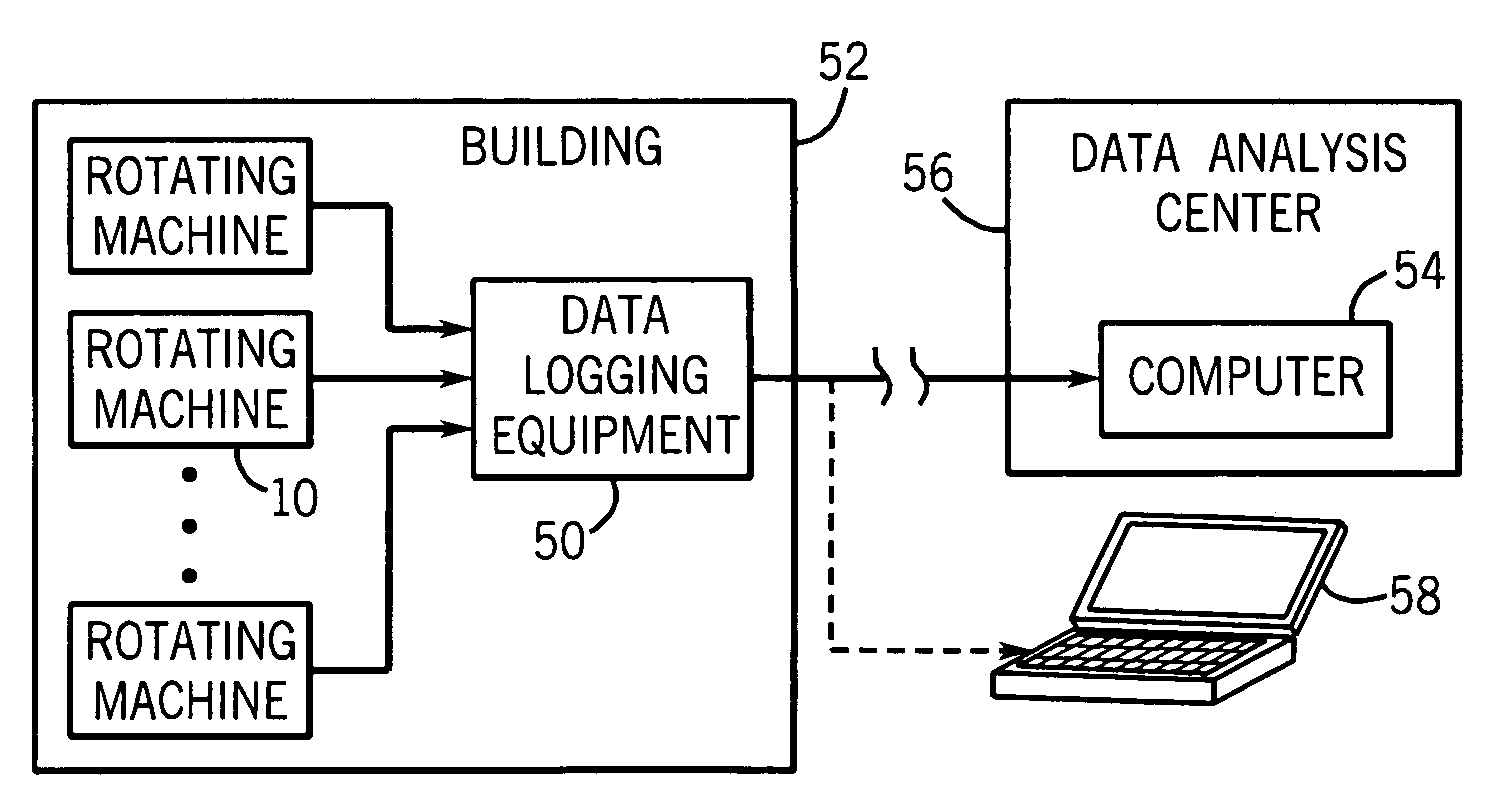

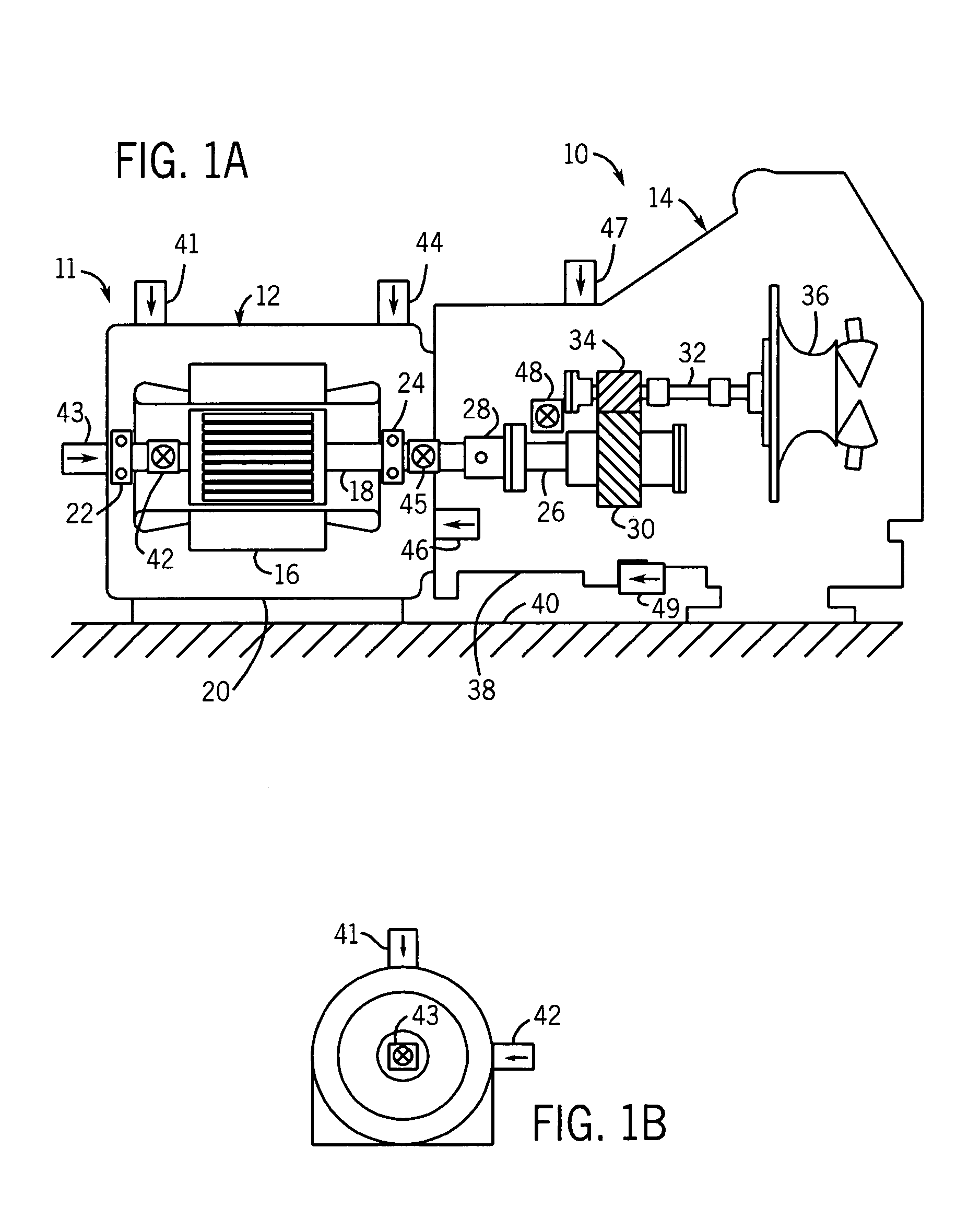

System and methodology for vibration analysis and condition monitoring

InactiveUS7133801B2Accurate speedImplemented quickly and inexpensivelyDigital computer detailsDevices using electric/magnetic meansTransducerSample sequence

A system and methodology for continuous condition monitoring of rotating equipment. Employ adaptive signal processing techniques to determine the RPM of a rotating machine from time-based vibration data. RPM is determined based upon the input of a digitized time-based sample sequence of vibration data acquired directly from a vibration transducer for on-line real-time measurement of the machine RPM. Once RPM is determined, online vibration analysis for a given RPM or set of RPMs may be performed. The present invention extracts characteristic vibration features from vibration data and uses these extracted values to provide condition detection and diagnoses of machine faults.

Owner:EXXON RES & ENG CO

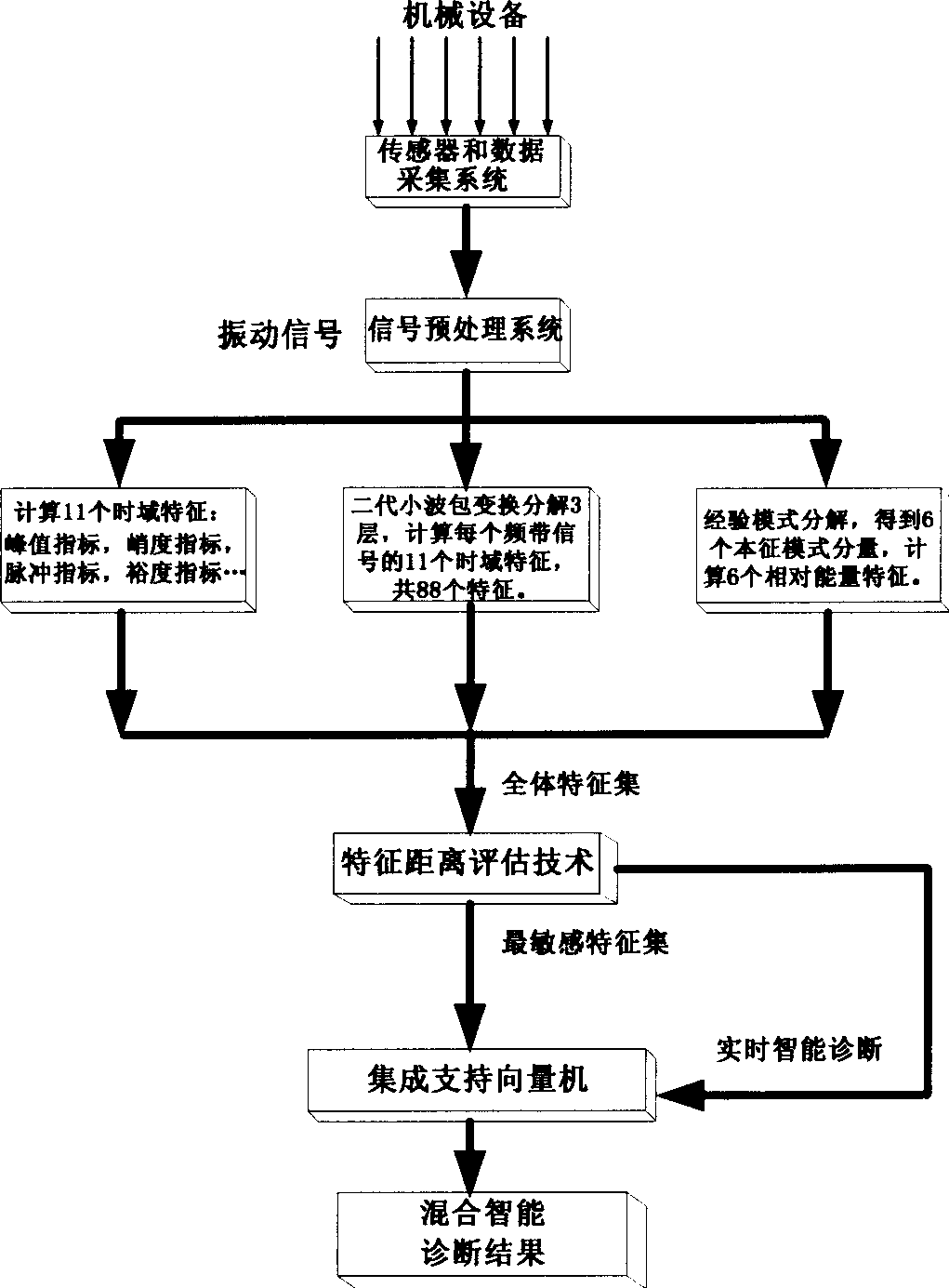

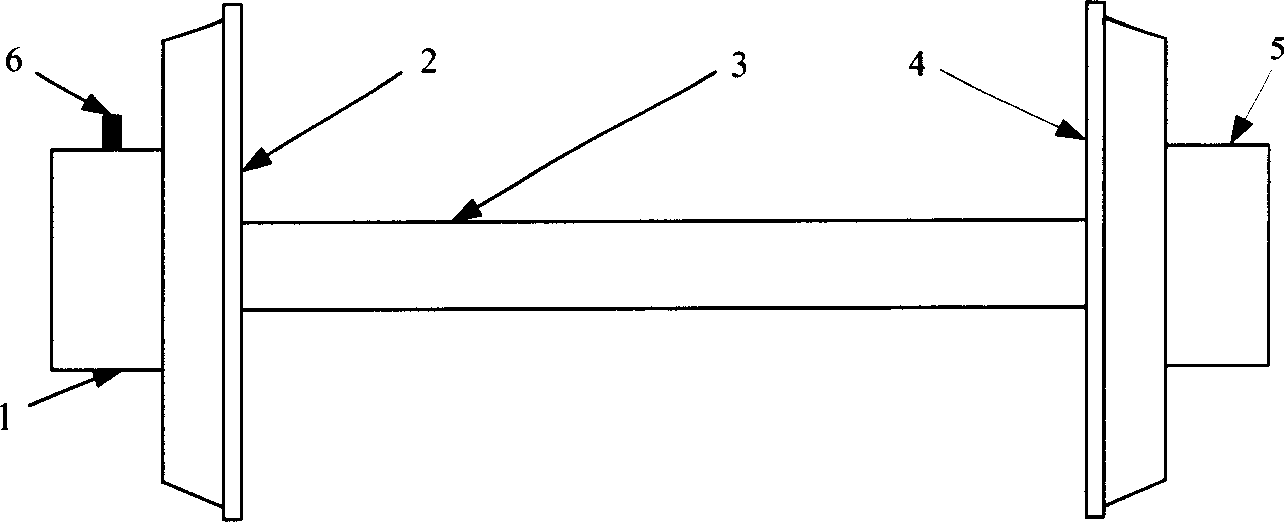

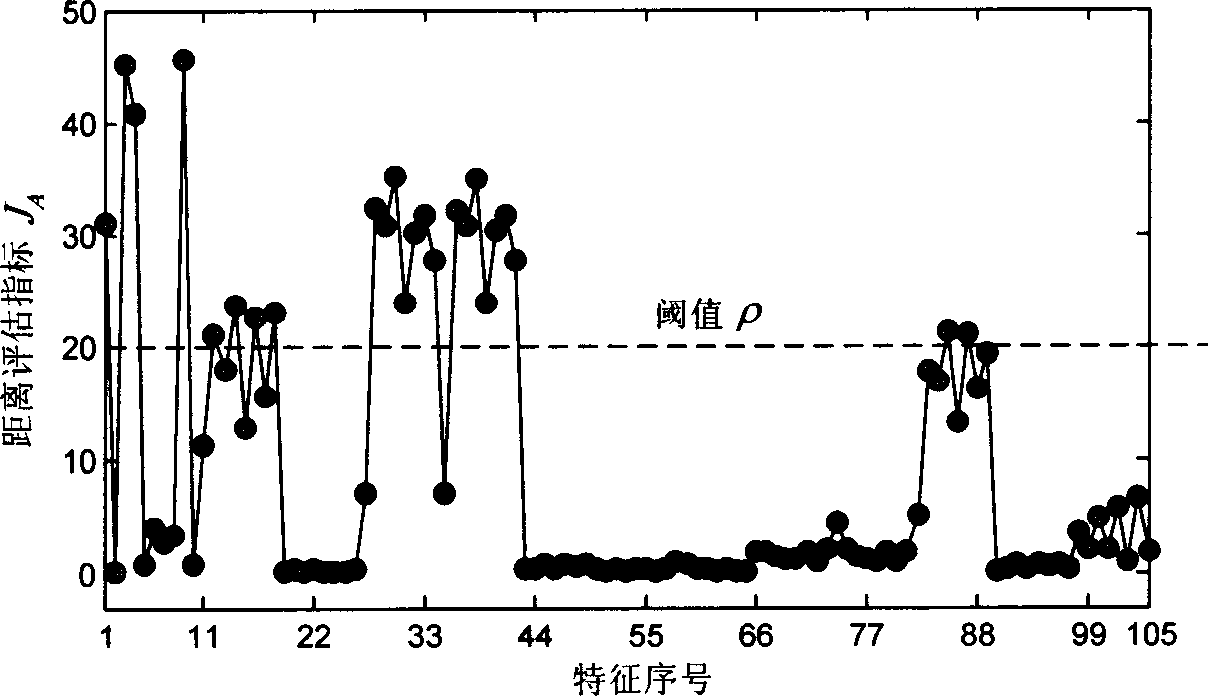

Integrated supporting vector machine mixed intelligent diagnosing method for mechanical fault

InactiveCN1811367ARealize intelligent diagnosisEfficient removalMachine part testingTime domainSupport vector machine

The present invention discloses an integrated support vector machine mixed intelligent diagnosis method of machine failure. Said method includes the following steps: respectively adopting and lifting small wave packet, utilizing frequency band and empirical mode decomposition process to decompose vibration signal according to the eigen mode component and extract time domain statistical character of decomposed signal to form total characteristic set; providing characteristic distance evaluation technique and characteristic evaluation index; utilizing said characteristic evaluation index to select most sensitive characteristic set from the total characteristic set; using said most sensitive characteristic set as diagnosis characteristics and creating integrated support vector machine mixed intelligent diagnosis model so as to implement intelligent diagnosis of machine failure state.

Owner:SHENJI GRP KUNMING MACHINE TOOL

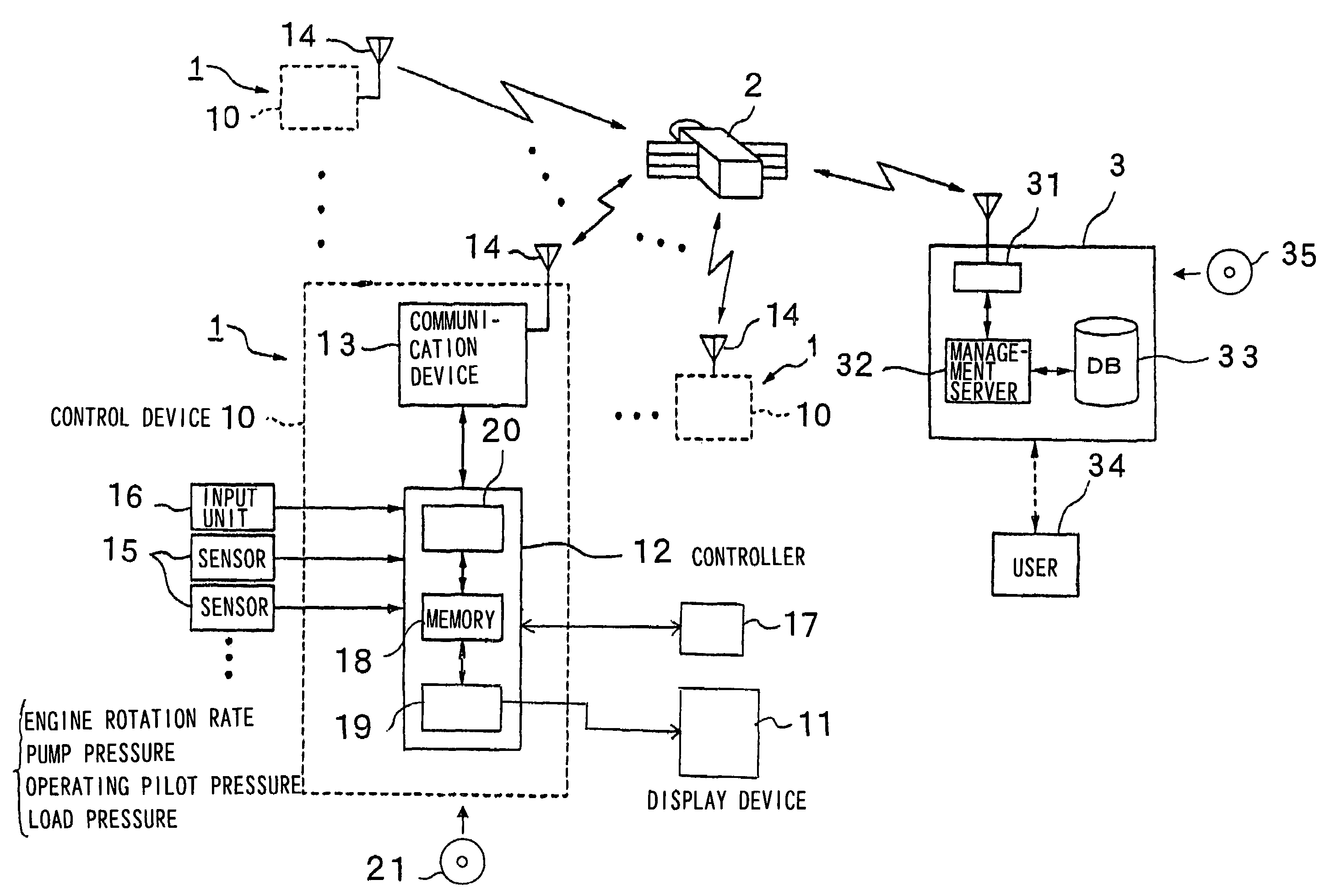

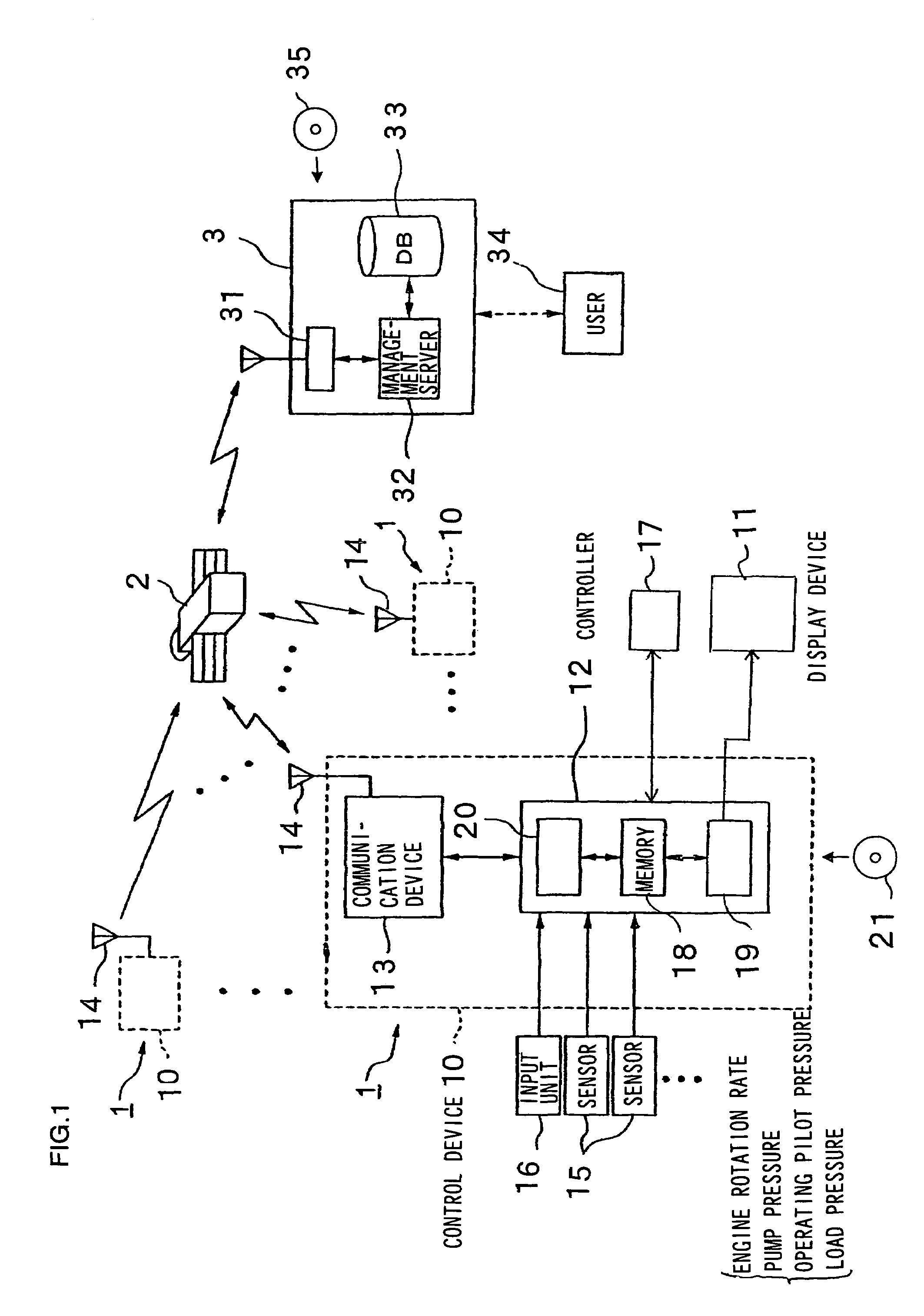

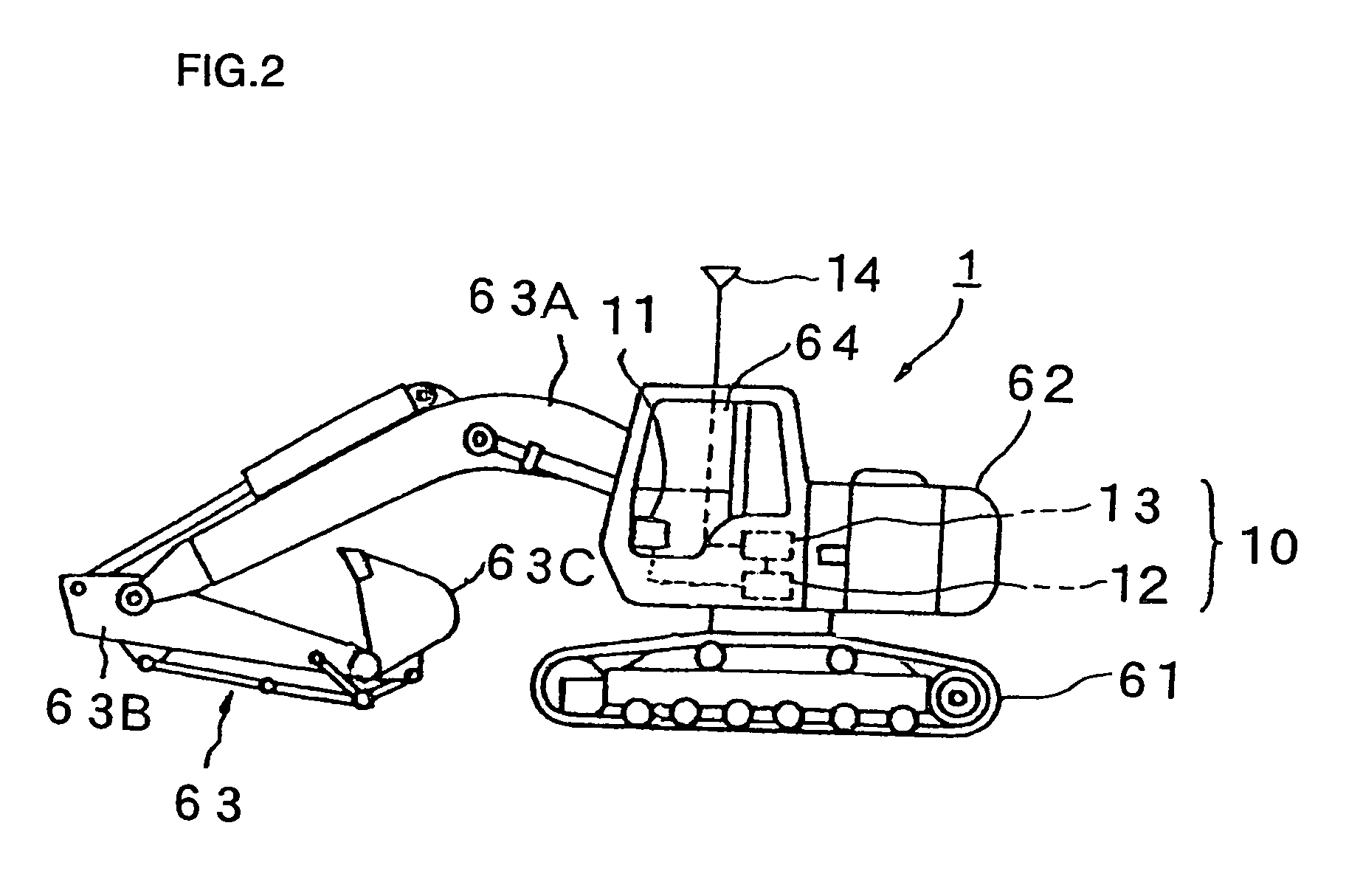

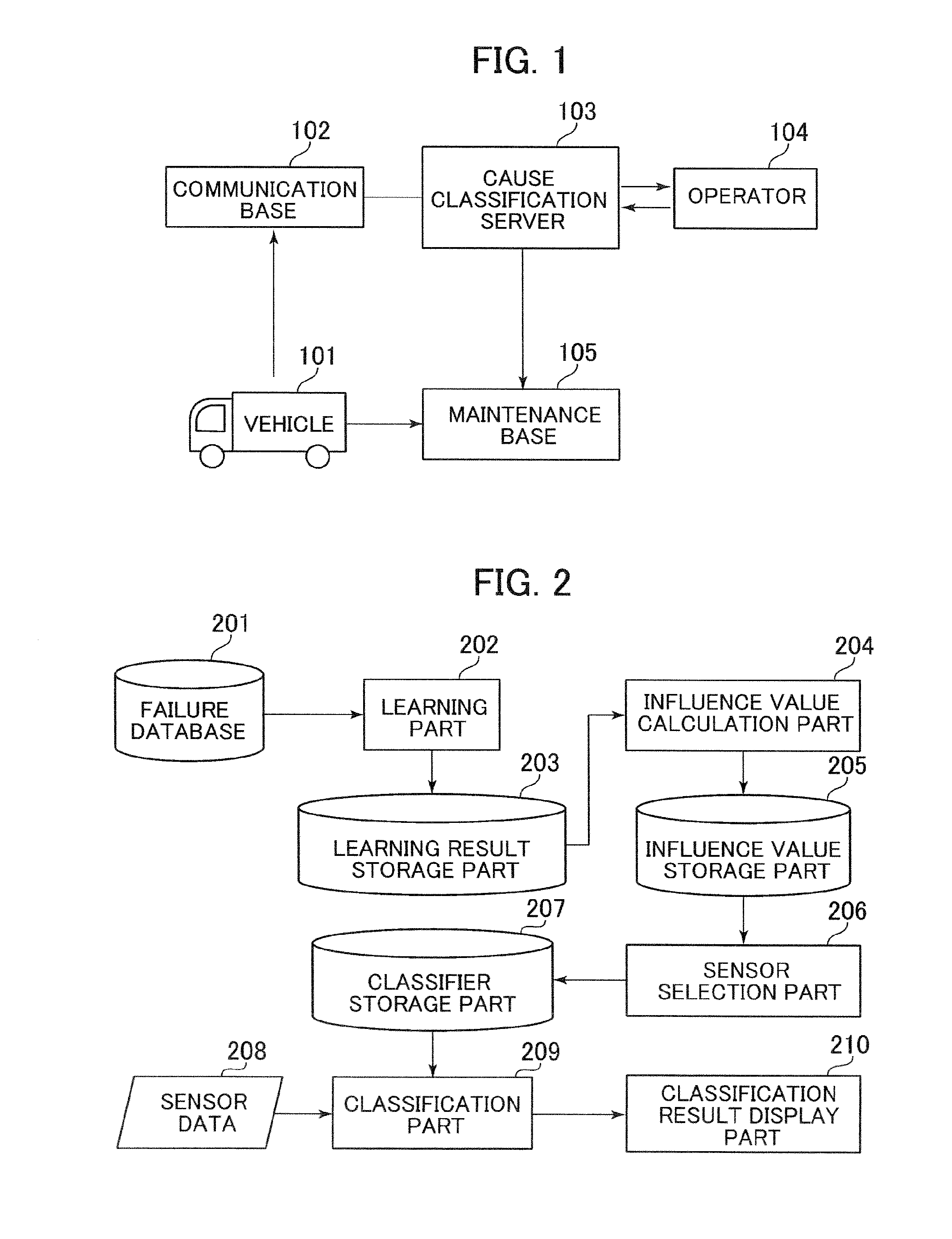

Working machine, trouble diagnosis system of working machine, and maintenance system of working machine

InactiveUS7079982B2Guaranteed to workAnalogue computers for vehiclesAnalogue computers for trafficDiagnosis methodsCommunication device

A working machine failure diagnosis method for performing a failure diagnosis by transmitting and receiving signals through communication devices provided at a working machine and at an information management center, according to the present invention, includes: a first step in which a first signal related to a failure of the working machine is generated at the working machine and the first signal is transmitted to the information management center from the working machine via the communication devices; a second step in which, after the first signal is transmitted, the information management center generates a second signal for identifying a location of the failure based upon the first signal and the second signal is then transmitted from the information management center to the working machine via the communication devices; and a third step in which failure information corresponding to the first signal and the second signal is provided to an operator.

Owner:NIHON KENKI CO LTD

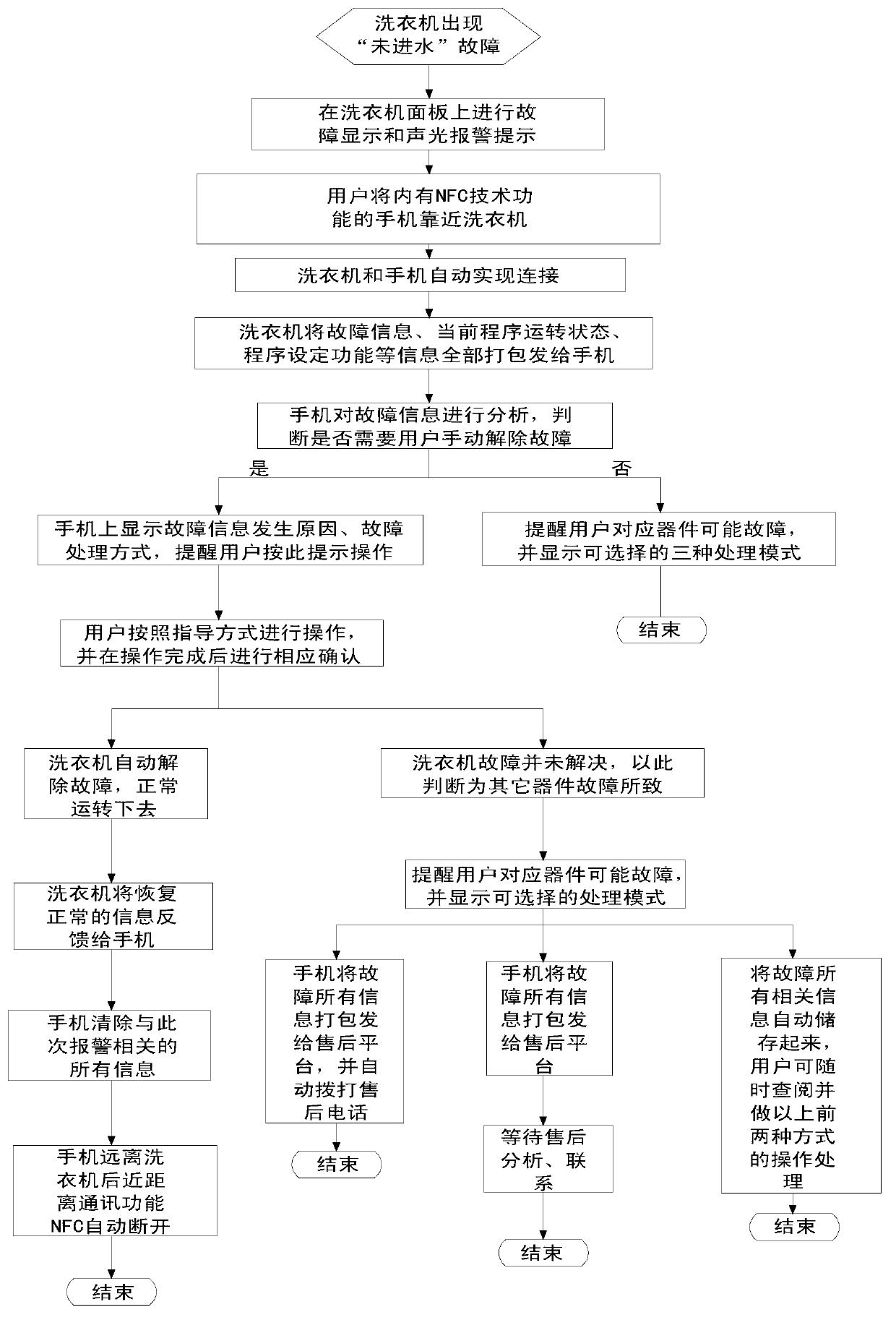

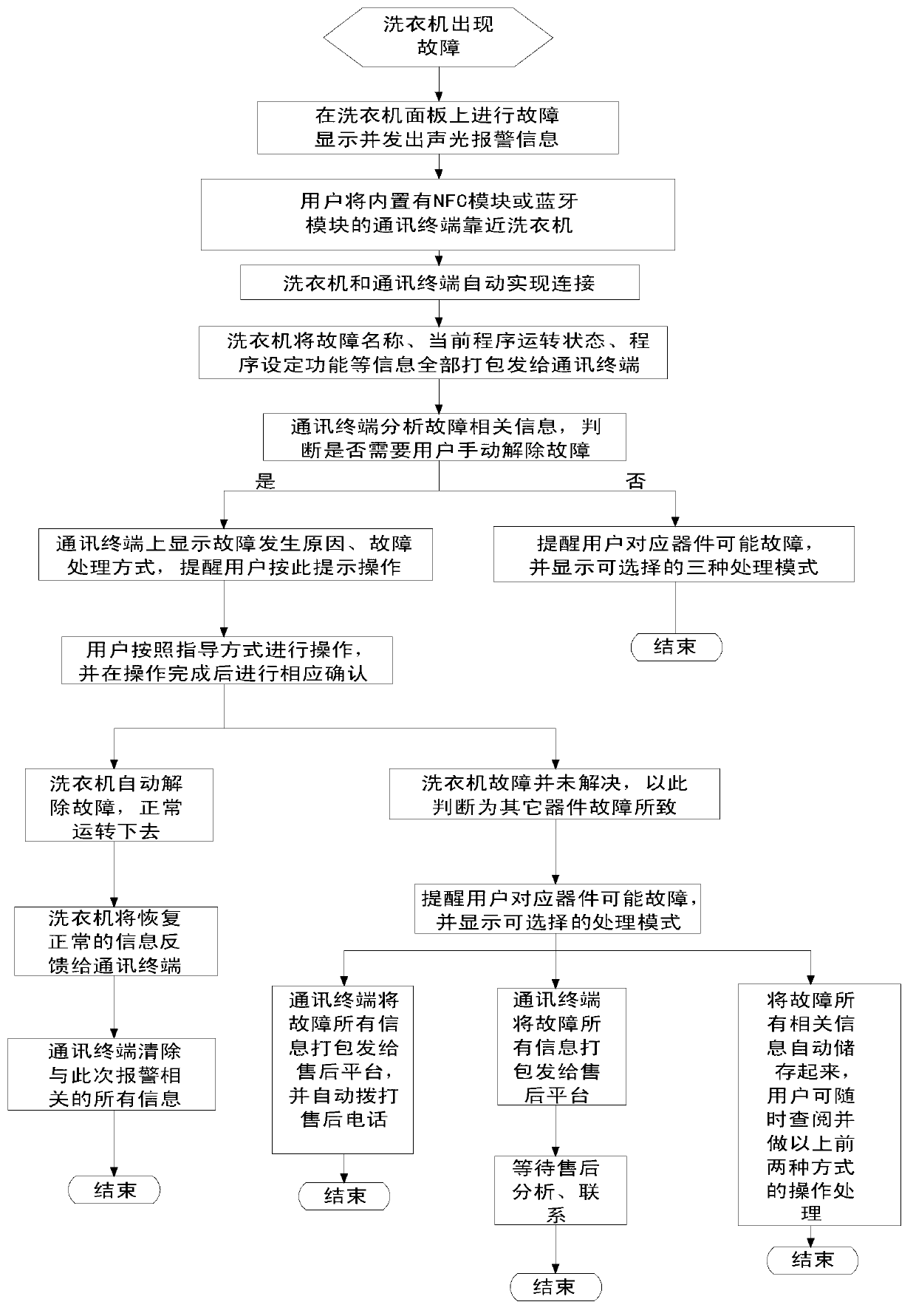

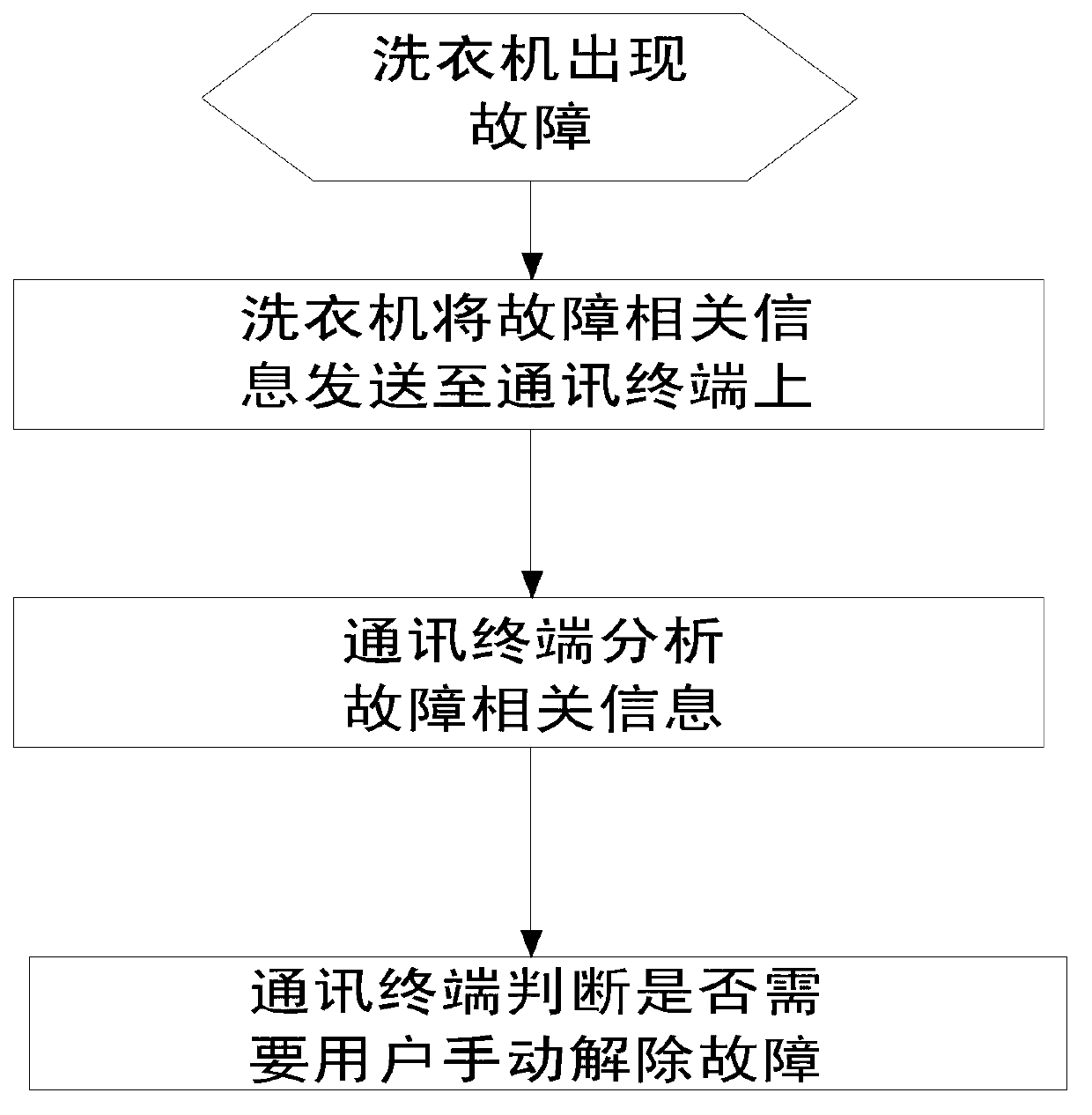

Washing machine malfunction warning and judging method, washing machine and washing machine malfunction warning and judging system

ActiveCN103276557AEasy to useRealize short-distance communication functionOther washing machinesControl devices for washing apparatusRelevant informationMessage passing

The invention discloses a washing machine malfunction warning and judging method, a washing machine and a washing machine malfunction warning and judging system. The washing machine failure warning and judging method includes the steps that when a malfunction occurs, the washing machine sends malfunction relevant information to a specified communication terminal, and the communication terminal analyzes and judges whether the malfunction needs to be eliminated by a user according to the received malfunction relevant information. The washing machine comprises a washing machine body and a communication module, and message passing can be conducted between the communication module and a communication terminal of the user. The washing machine malfunction warning and judging system comprises the communication terminal and the washing machine, and communication models which are mutually matched are arranged in the communication terminal and the washing machine respectively. The washing machine malfunction warning and judging method and the washing machine malfunction warning and judging system can solve an occurred malfunction problem within shortest time, improve user satisfaction degree, feed the malfunction problem back to a design source, and prevent the problem from happening again.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

System and methodology for vibration analysis and conditon monitoring

InactiveUS20070032966A1Implemented quickly and inexpensivelyAccurate speedTesting/monitoring control systemsDigital computer detailsTransducerSample sequence

A system and methodology for continuous condition monitoring of rotating equipment employ adaptive signal processing techniques to determine the RPM of a rotating machine from the time-based vibration data. RPM is determined based upon the input of a digitized time-based sample sequence of vibration data acquired directly from a vibration transducer for on-line real-time measurement of the machine RPM. Once RPM is determined, online vibration analysis for a given RPM or set of RPMs may be performed. The present invention extracts characteristic vibration features from vibration data and uses these extracted values to provide condition detection and diagnoses of machine faults.

Owner:EXXONMOBIL RES & ENG LAW DEPT

System and methodology for vibration analysis and condition monitoring

InactiveUS20050209814A1Accurate speedImplemented quickly and inexpensivelyDigital computer detailsDevices using electric/magnetic meansTransducerSample sequence

A system and methodology for the continuous condition monitoring of rotating equipment. The present invention comprises a method that employs adaptive signal processing techniques to determine the RPM of a rotating machine from the time-based vibration data. According to a preferred embodiment of the present invention, RPM is determined based upon the input of a digitized time-based sample sequence of vibration data acquired directly from a vibration transducer mounted on the machine for on-line real-time measurement of the machine RPM. Alternatively, the input to the “virtual RPM sensor” could come from a database or file where the sample sequences of the vibration signal are stored for off-line measurement of the machine RPM. Once RPM is determined, online vibration analysis for a given RPM or set of RPMs may be performed. The present invention extracts characteristic vibration features from vibration data and uses these extracted values to provide condition detection and diagnoses of machine faults.

Owner:EXXON RES & ENG CO

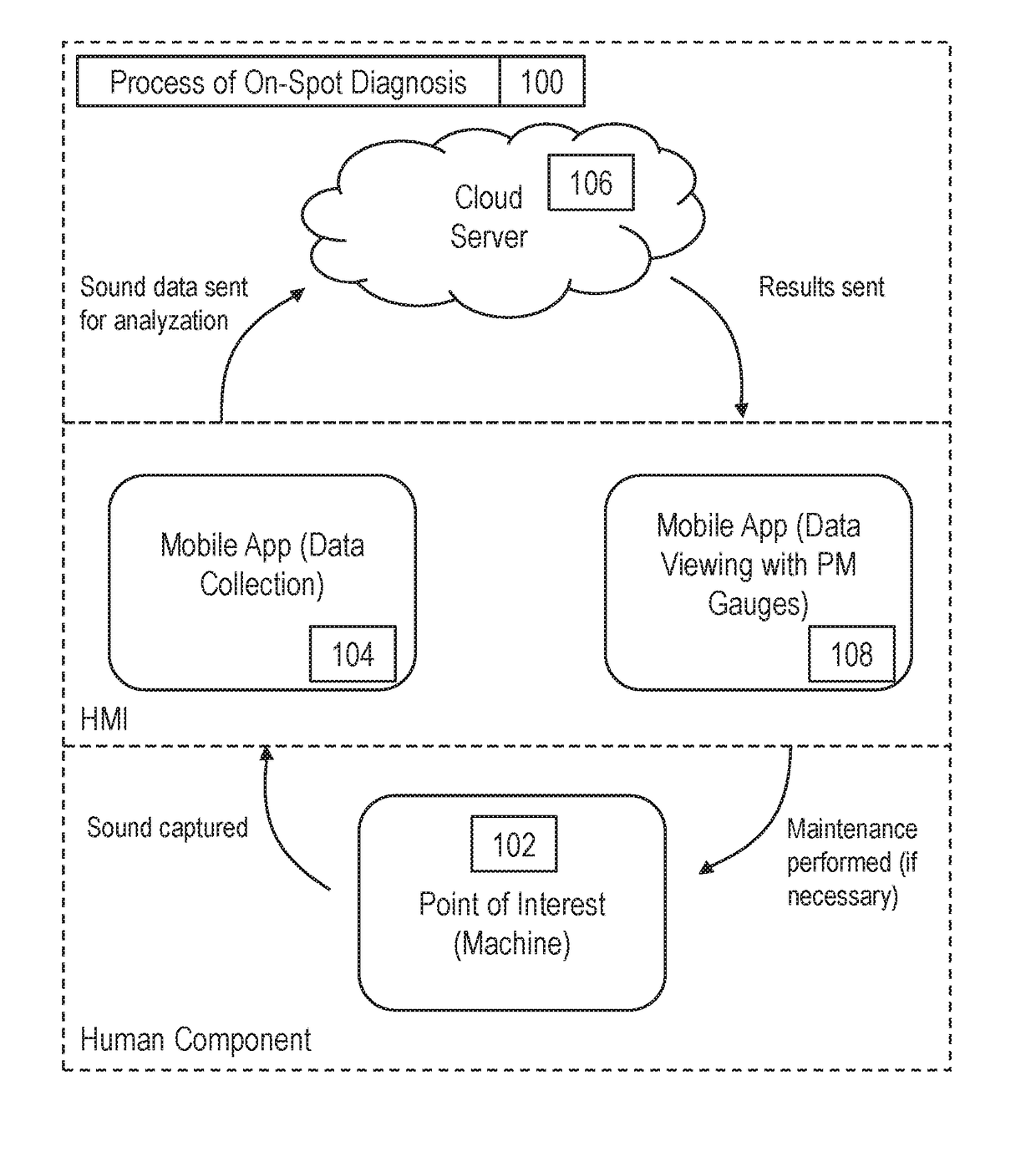

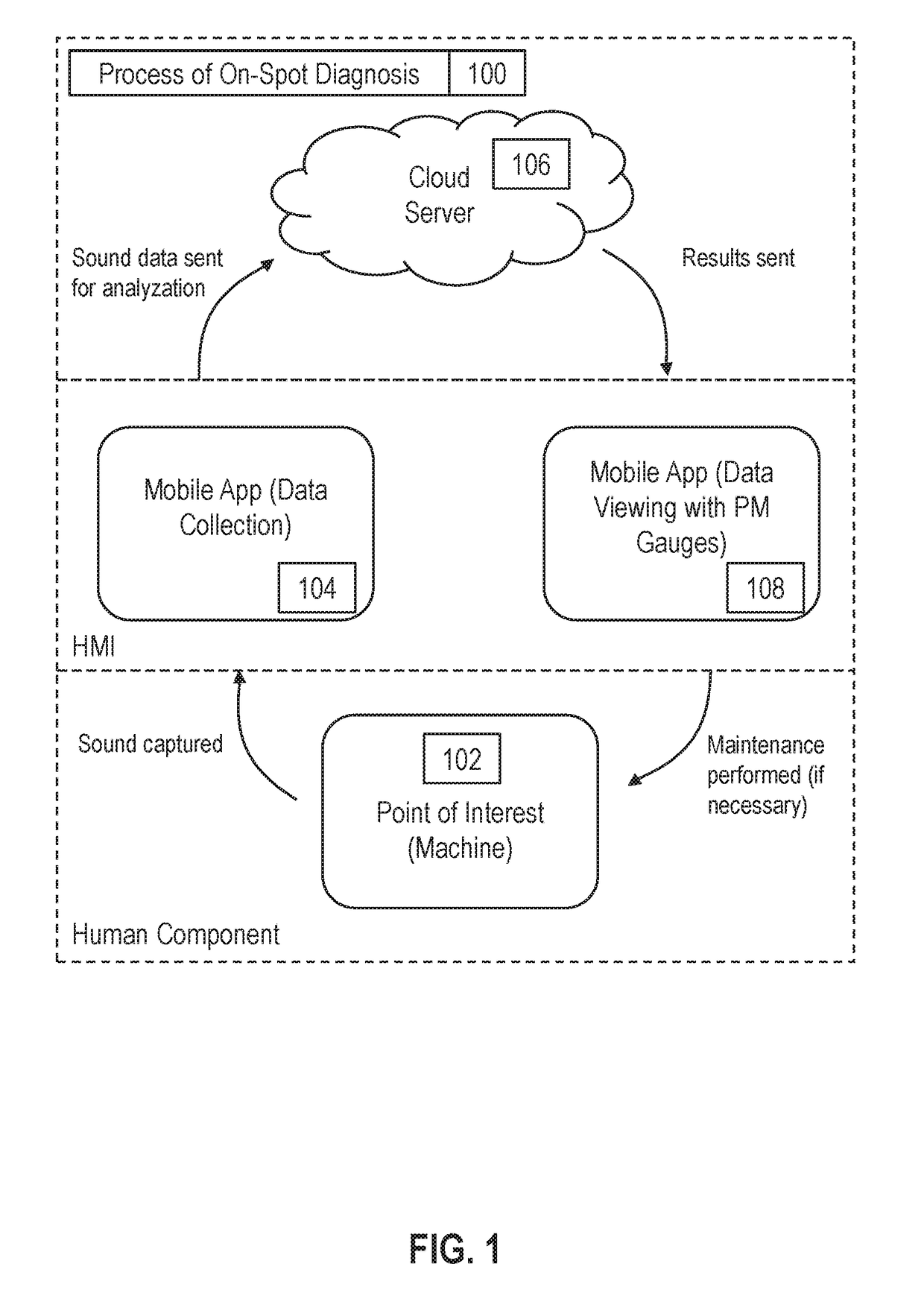

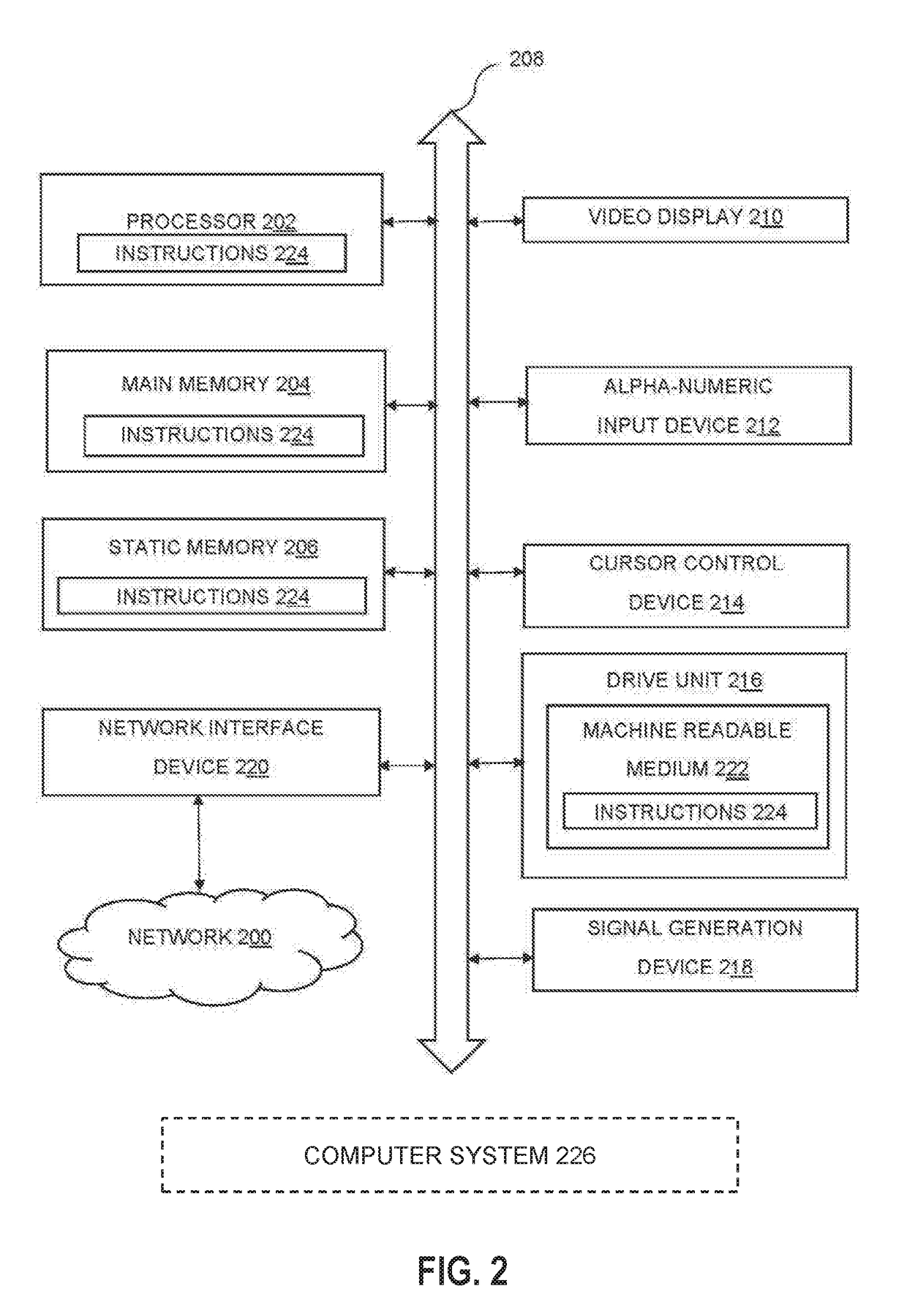

Machine fault detection based on a combination of sound capture and on spot feedback

A method and system of on spot diagnosis of one or more issues associated with a machine includes collecting sound data and image data associated with a machine through a mobile device and transmitting them to a cloud server over a communications network. The on spot diagnosis includes analyzing the sound data and image data in combination with an on spot feedback system through the cloud server. The on spot feedback system is communicatively coupled to a machine-learning engine and a Big Data architecture. The machine issue condition is indicated through a user interface dynamic such a circular gauge. An alarm is set, through a mobile device, for the machine issue.

Owner:MACHINESENSE LLC

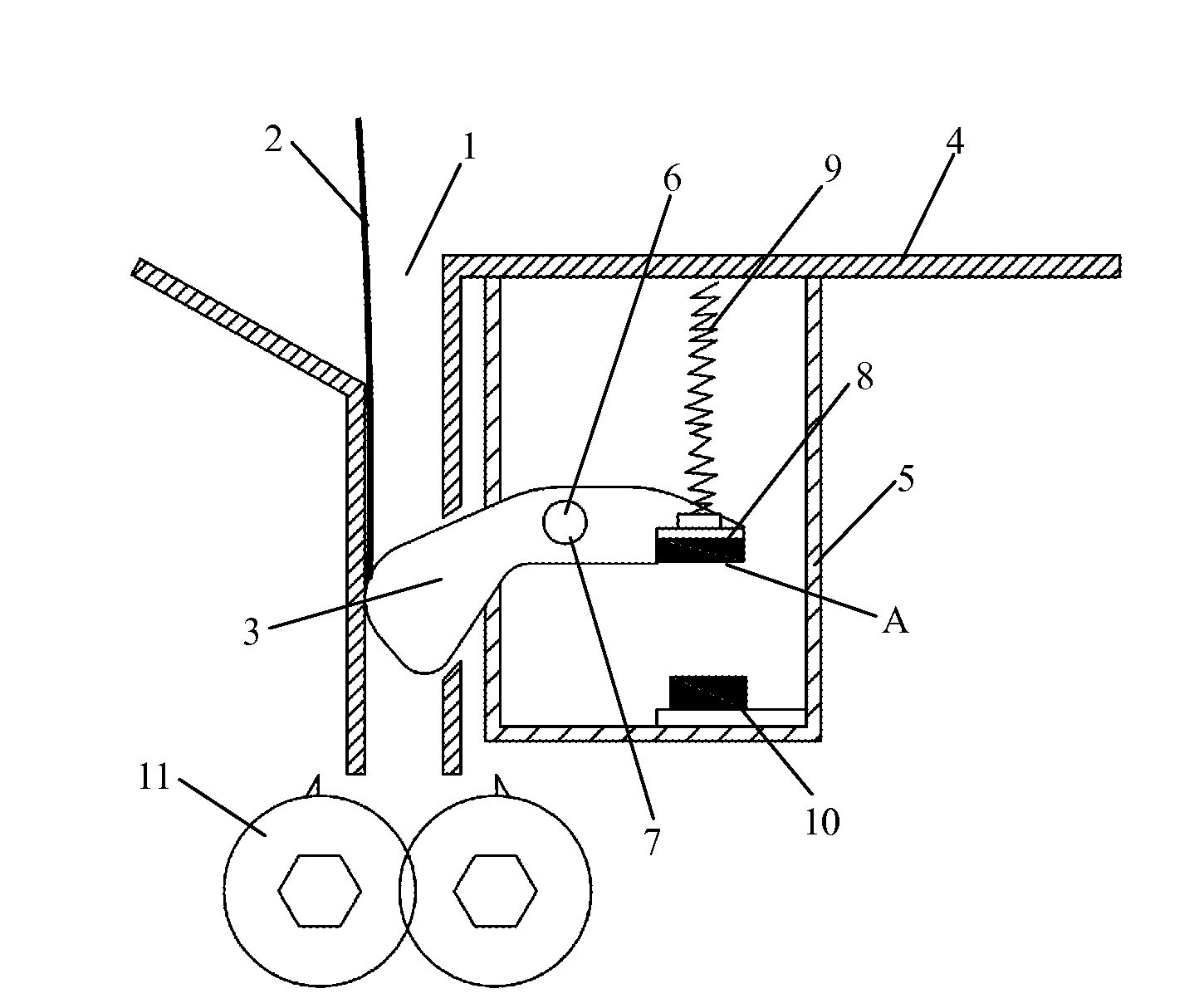

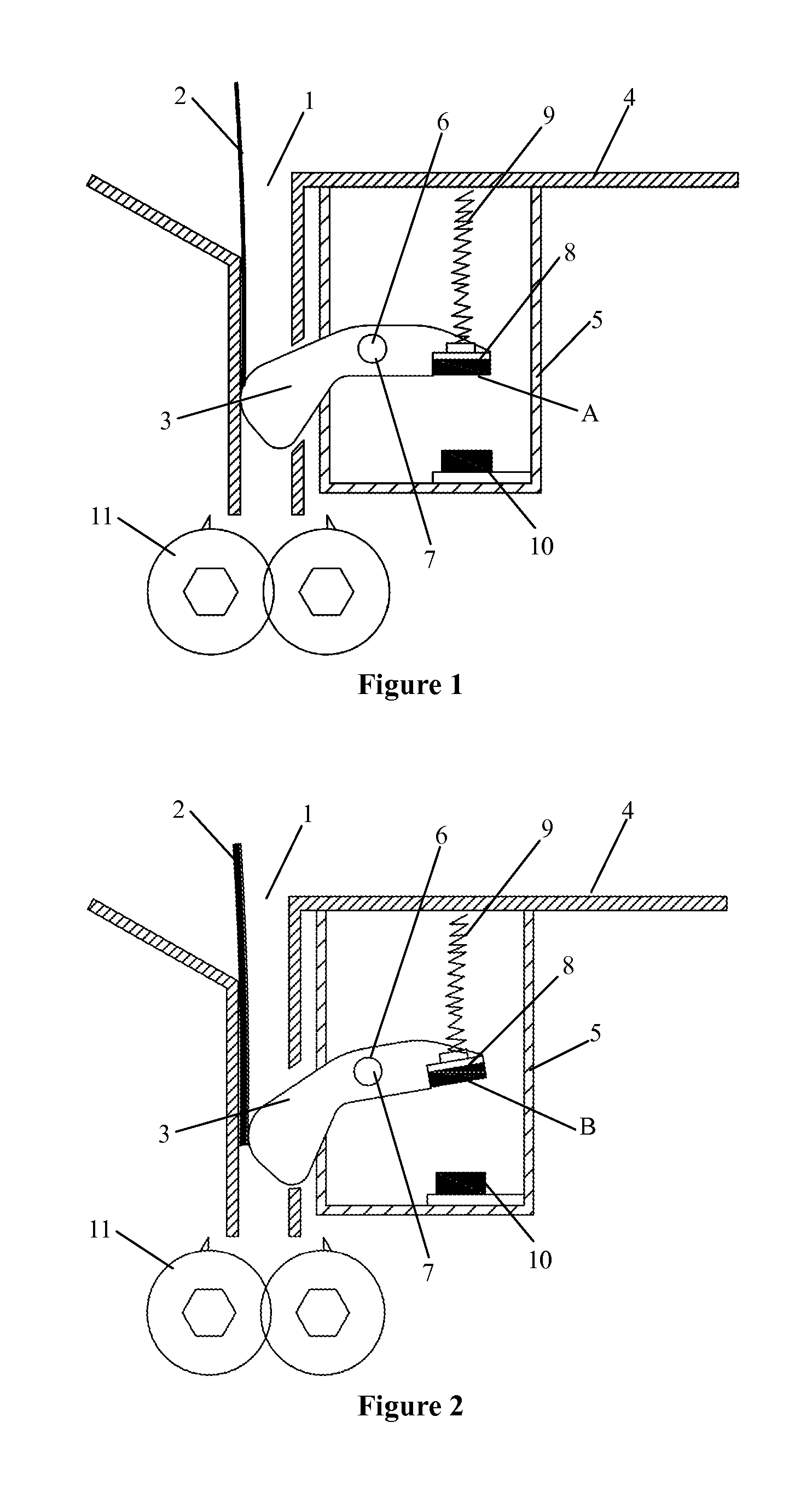

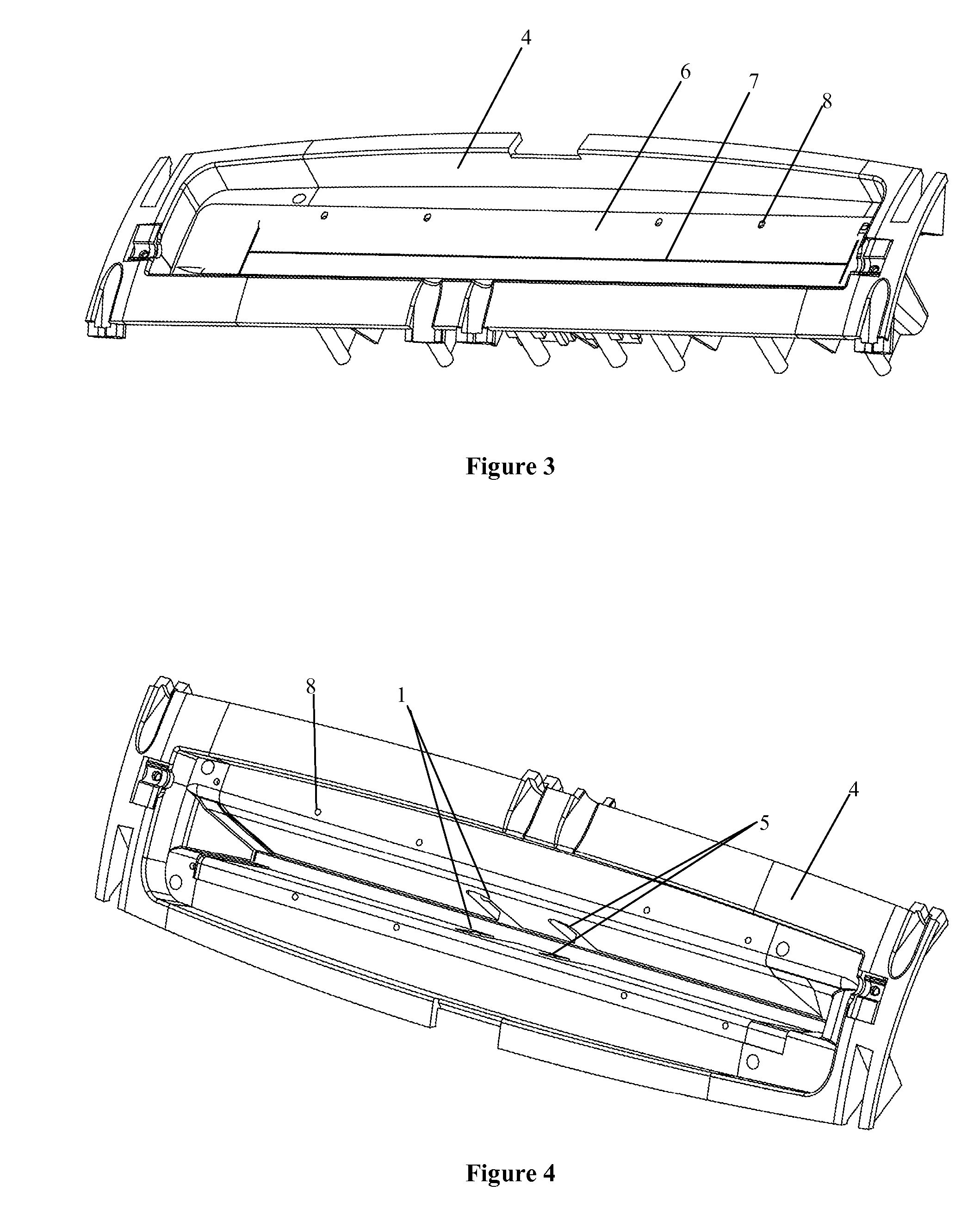

Anti-paper jam protection device for shredders

InactiveUS20100282879A1Shorten maintenance timeEasy to getBalingCocoaPulp and paper industryContact element

The present invention relates to an anti-paper jam protection device for shredders comprising a paper thickness detecting device, an indicating device and a controlling device, wherein the paper thickness detecting device is an electromagnetic induction paper thickness detecting device comprising a contact element, an electromagnetic element and an electromagnetic induction element, the contact element is connected rotatably to the body of the shredder, one end of which is positioned in the paper inserting passage, on the other end of which is mounted the electromagnetic element, the electromagnetic induction element is mounted on the body of the shredder and spaced with the electromagnetic element face to face, and the controlling device is in line connection with the electromagnetic induction element, the present invention controls the thickness of the paper to be shredded during the paper inserting stage, and shreds paper automatically only in a predetermined value range, to avoid abnormalities that result in failure of the machine such as jam and tooth breaking when the shredder is shredding many pieces of paper, so as to reduce maintenance times and cost, extend service life, and make application of shredders safer and more reliable, more convenient and simpler, then to achieve better protection of shredders.

Owner:AURORA OFFICE EQUIP

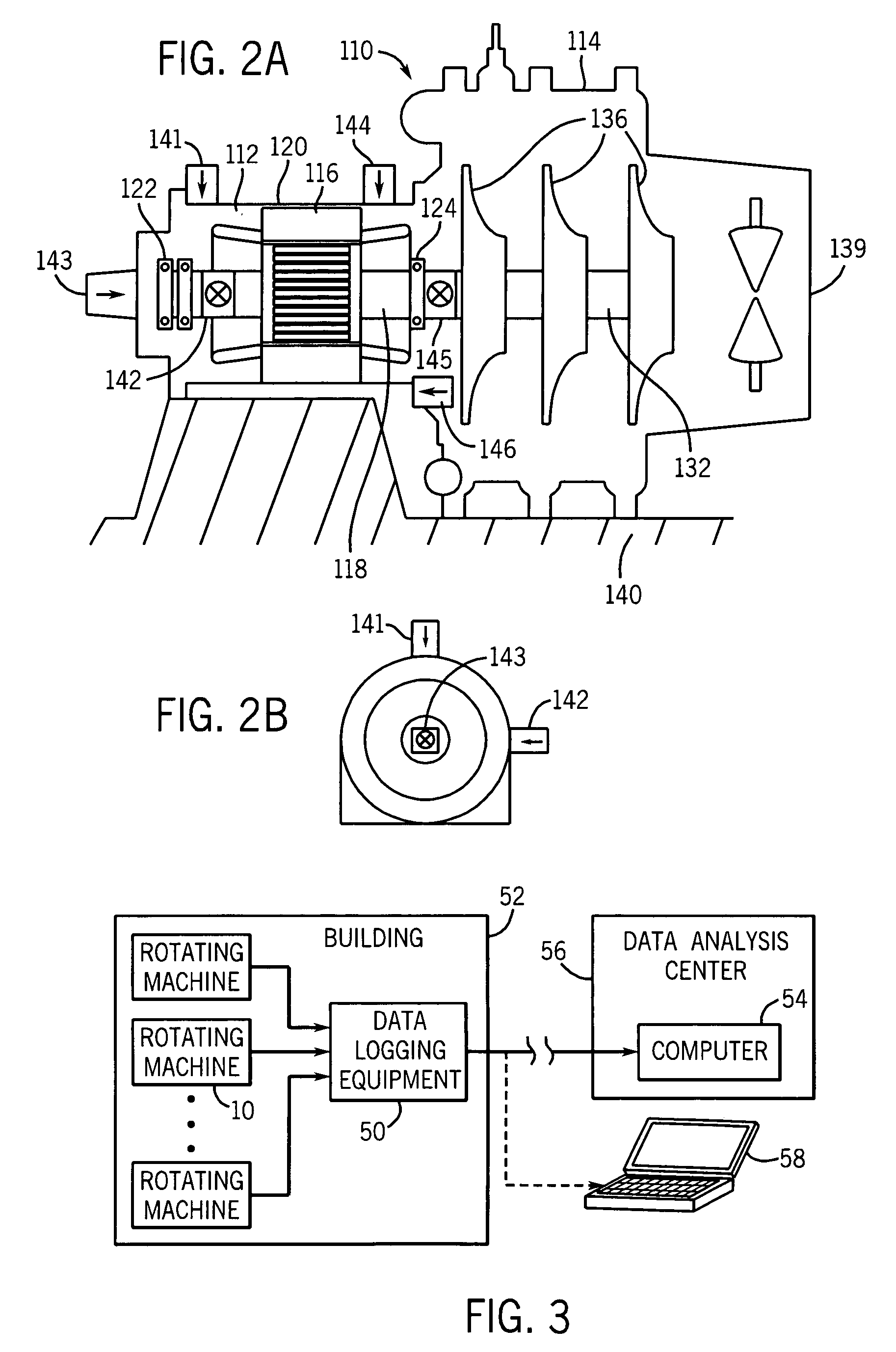

Machine condition indication system

ActiveUS20080106424A1Programme controlTesting/monitoring control systemsState parameterIndustrial communication

A machine condition monitor resides in close proximity to a machine train, such as an AC inductive electric motor coupled to a driven unit such as a centrifugal pump or fan. A plurality of sensing devices are connected to the machine and the machine condition monitor. Machine state and condition parameters sensed by these devices are utilized by the machine condition monitor to derive machine condition values for each component and for the machine train as a whole. These derived condition values are transmitted via an industrial communications network to a control center where they can be trended and monitored. With no particular knowledge of machine analysis techniques or severity of specific machine faults, and no special training, Operators and Production Planners can use the condition values to plan production schedules, adjust process parameters, and request appropriate maintenance action.

Owner:COMPUTATIONAL SYST

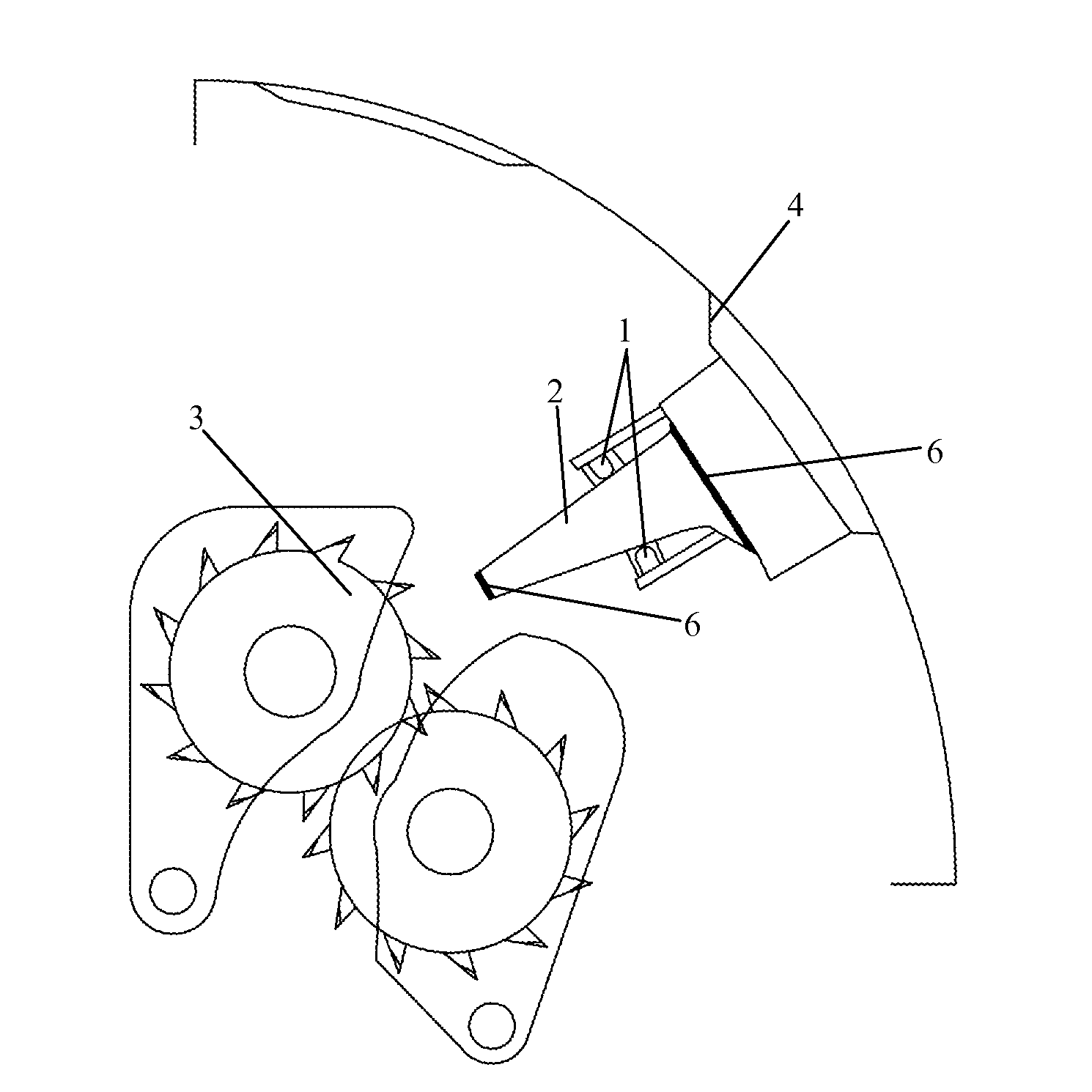

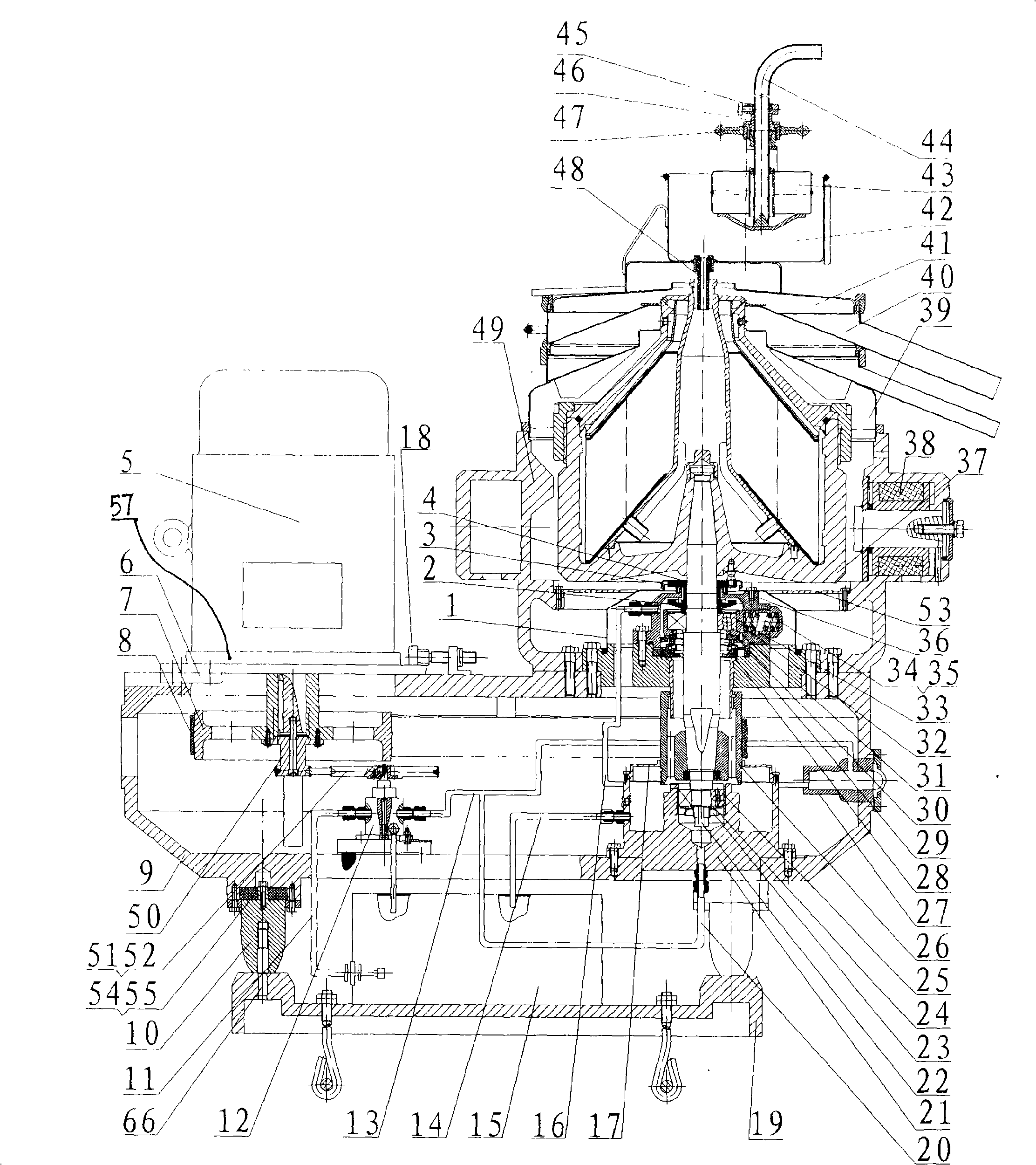

Type protection device for shredders

InactiveUS20100270404A1Easy to useSimple structureCocoaGrain treatmentsPulp and paper industryPaper sheet

The present invention relates to a new type protection device for shredders which comprises a paper number detecting device mounted at the paper inserting passage of the shredder, a warning device mounted on the shredder and a controlling device in line connection with the paper number detecting device and the warning device respectively, mounted in the shredder and in line connection with the driving component of the shredder driving the shredder blades, preferably the protection device further comprises an insert detecting device in line connection with the controlling device and mounted at the paper inserting passage, and at least one opaque shielding component mounted at the paper inserting passage and at the middle of which there is at least one slot along the length direction, the present invention controls the number of the paper to be shredded during the paper inserting stage, and shreds paper automatically only in a predetermined value range, to avoid abnormalities that result in failure of the machine such as jam and tooth breaking when the shredder is shredding many pieces of paper, so as to reduce maintenance times and cost, extend service life, and make application of shredders safer and more reliable, more convenient and simpler, then to achieve better protection of shredders.

Owner:AURORA OFFICE EQUIP

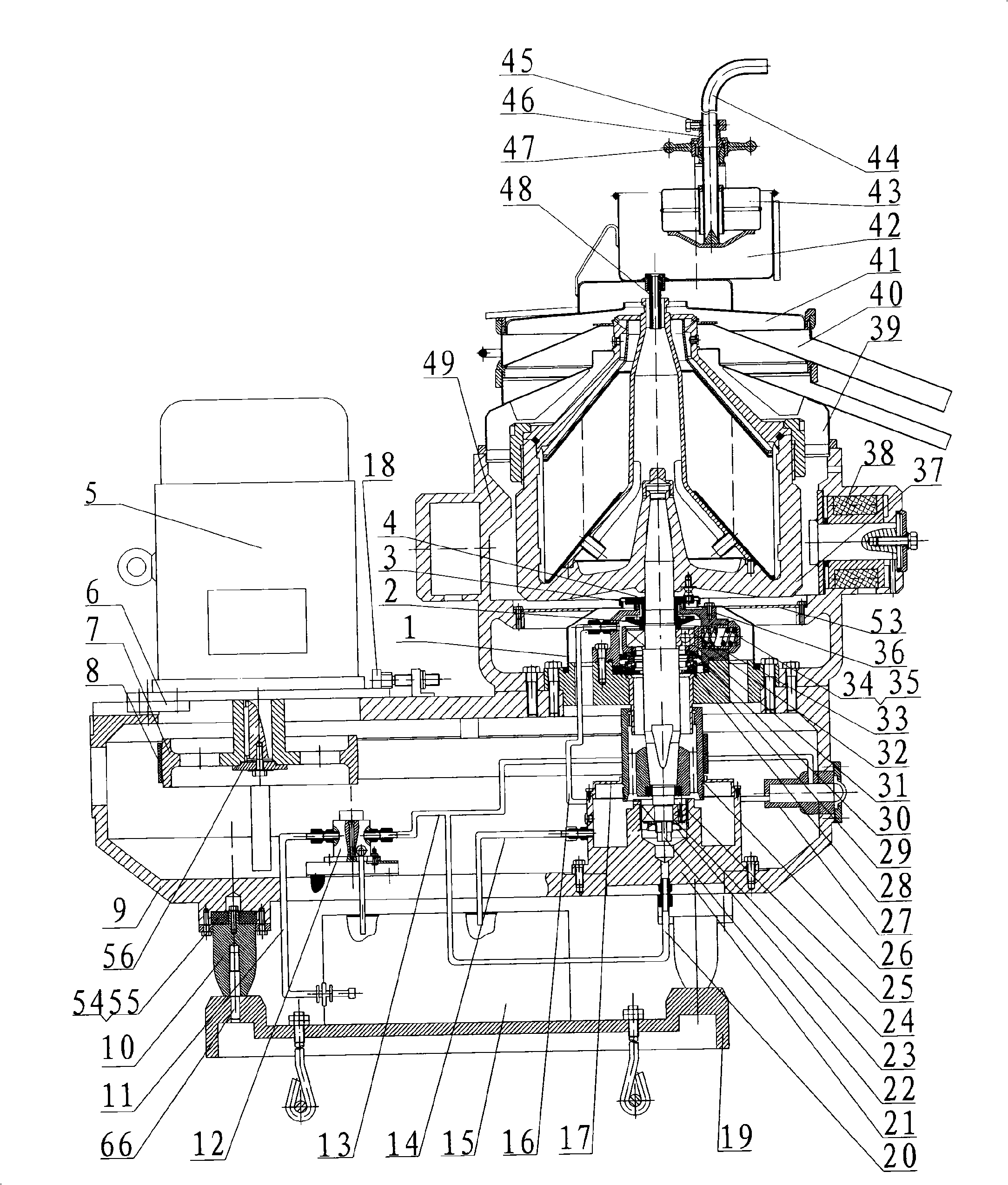

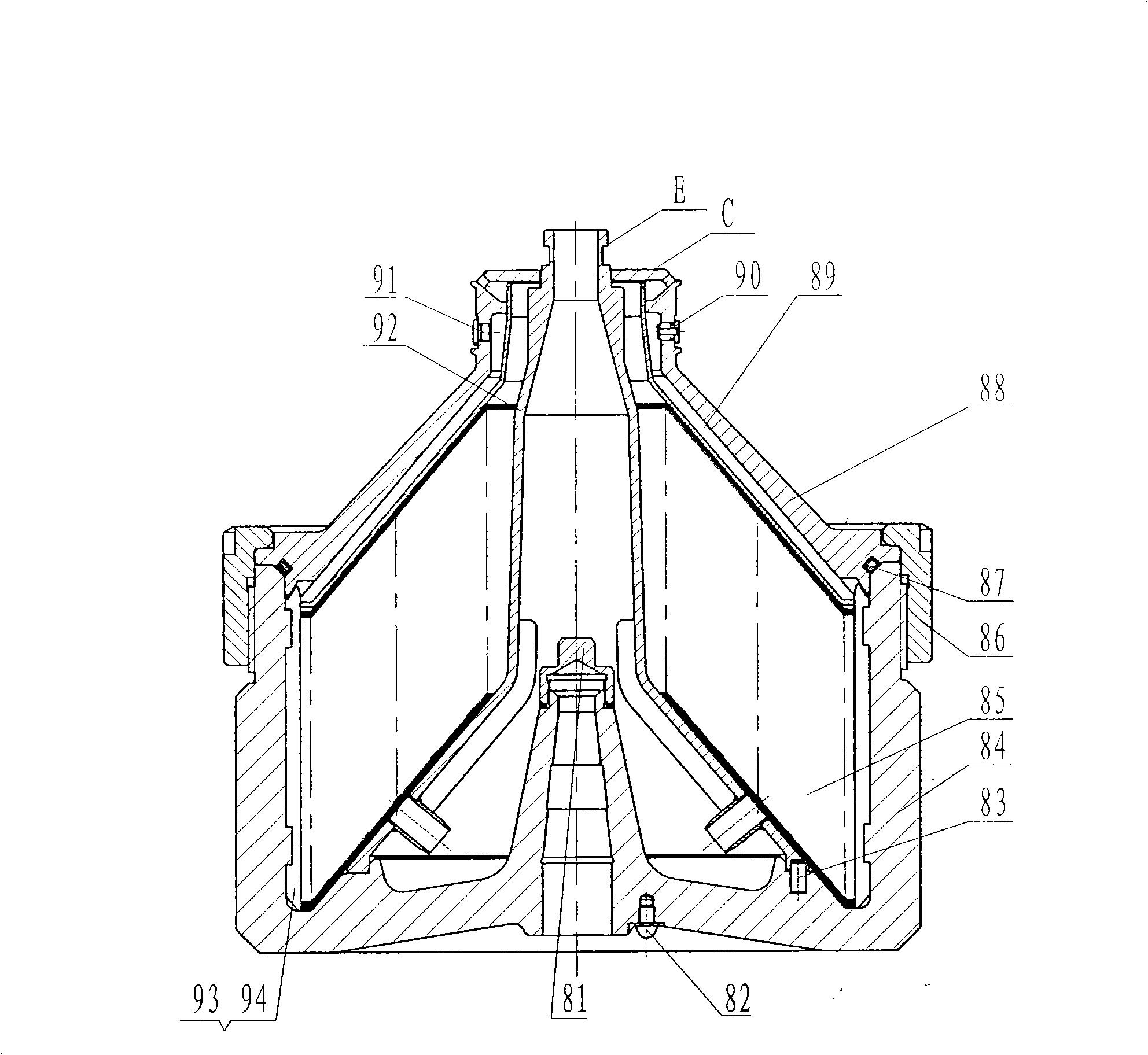

Flat belt driven dish type splitter

The present invention discloses a flat-belt driven disc separator, comprising a power part, a driving part, a lubrication system, a working part, a machine part and a control and assisting part. In addition to that the requirements of the function and performance of the separator is satisfied, the driving system is largely simplified, the driving path is brief, the quantity of driving components is largely reduced and the technical requirement of processing is lowered; regular replacement of expensive copper gear wheel, friction drum and other wearing parts is avoided, and as a result, the structure of the complete machine is simplified, the cost of production and use is reduced, the failure rate of the machine is lowered, and the technical performance of the complete machine is improved. The invention can be directly applied to condensing separation of natural rubber, and the invention can also be applied to separating other emulsions; the rotary-drum structure of the invention can overcome the disadvantages of the prior art; the continuous operation time is prolonged and the rotary-drum heating is alleviated; the strength, safety, reliability and maintenance technique are improved. The driving part and the lower machine body can form the driving of a manual slag-discharge separator, a gushing slag-discharge separator and a ring-valve slag-discharge separator and the lower machine body.

Owner:薛晓宁

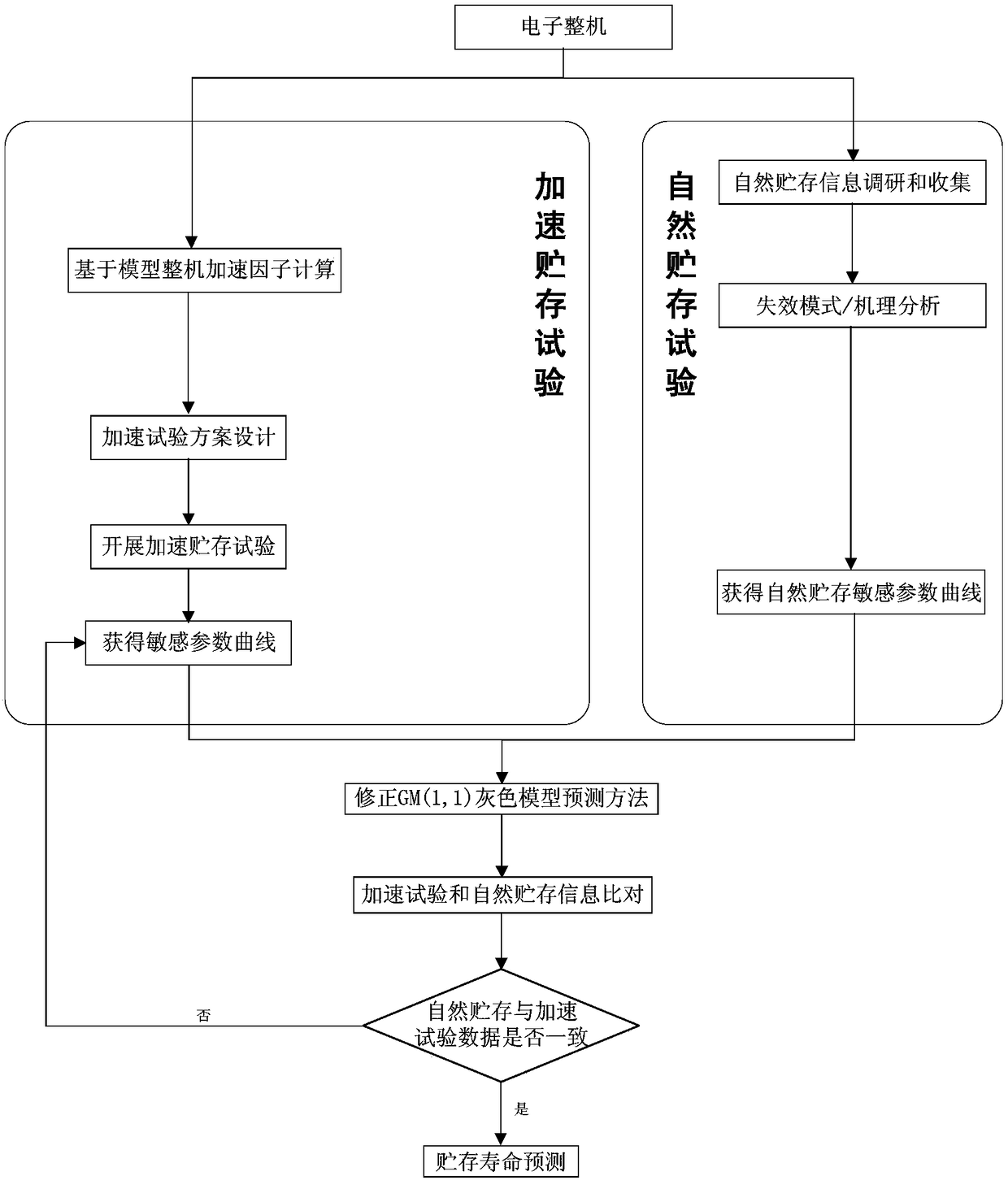

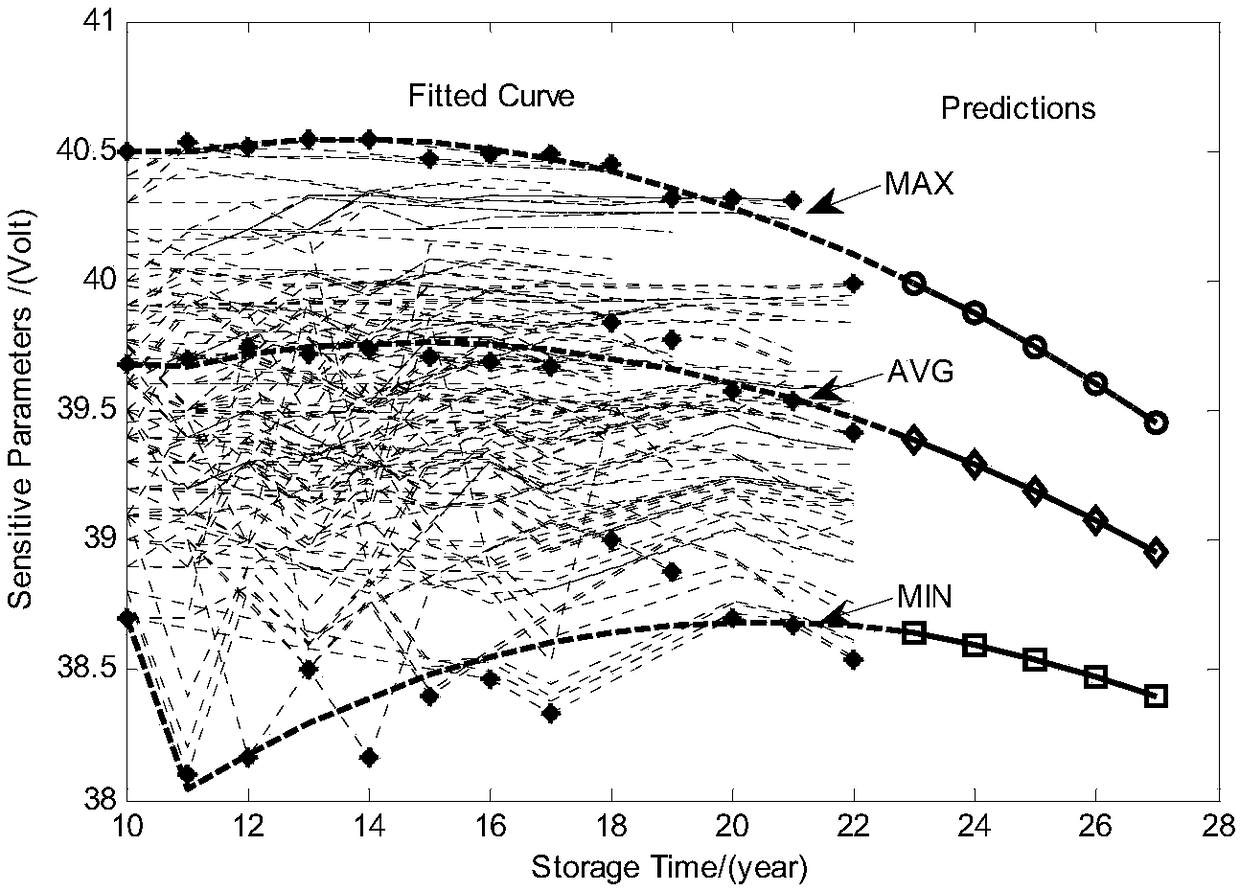

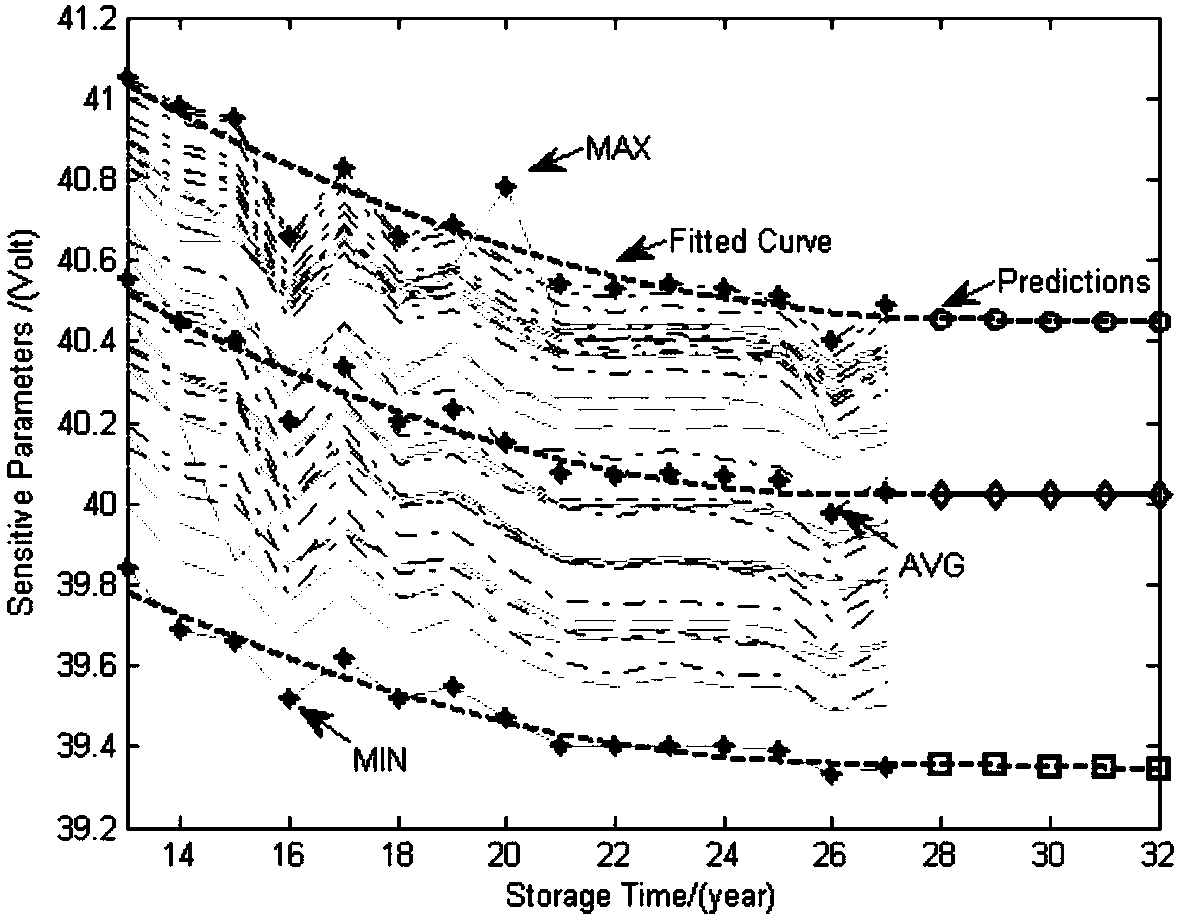

Electronic complete machine storage life assessment and prediction method

ActiveCN108446523APromote engineering applicationSimple calculationGeometric CADSpecial data processing applicationsAcceleration factorPrediction algorithms

The invention relates to an electronic complete machine storage life assessment and prediction method. On the basis of analyzing a typical complete machine failure mechanism, an Arrhenius model-basedcomplete machine level acceleration factor calculation method is proposed; the method can perform electronic complete machine acceleration factor calculation by only three parameters; an accelerationtest is performed according to a calculation result and data is obtained; by utilizing an optimized GM(1,1) grey model-based prediction algorithm, a degradation law of natural storage and accelerationtest data is researched; the consistency of degradation trends of two groups of data is analyzed; closed-loop correction of acceleration factor calculation model parameters is realized by utilizing aconsistency analysis result; and finally electronic complete machine storage life prediction is realized by utilizing a corrected model. The method is simple and easy to understand and relatively high in prediction precision, and is suitable for engineering popularization.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

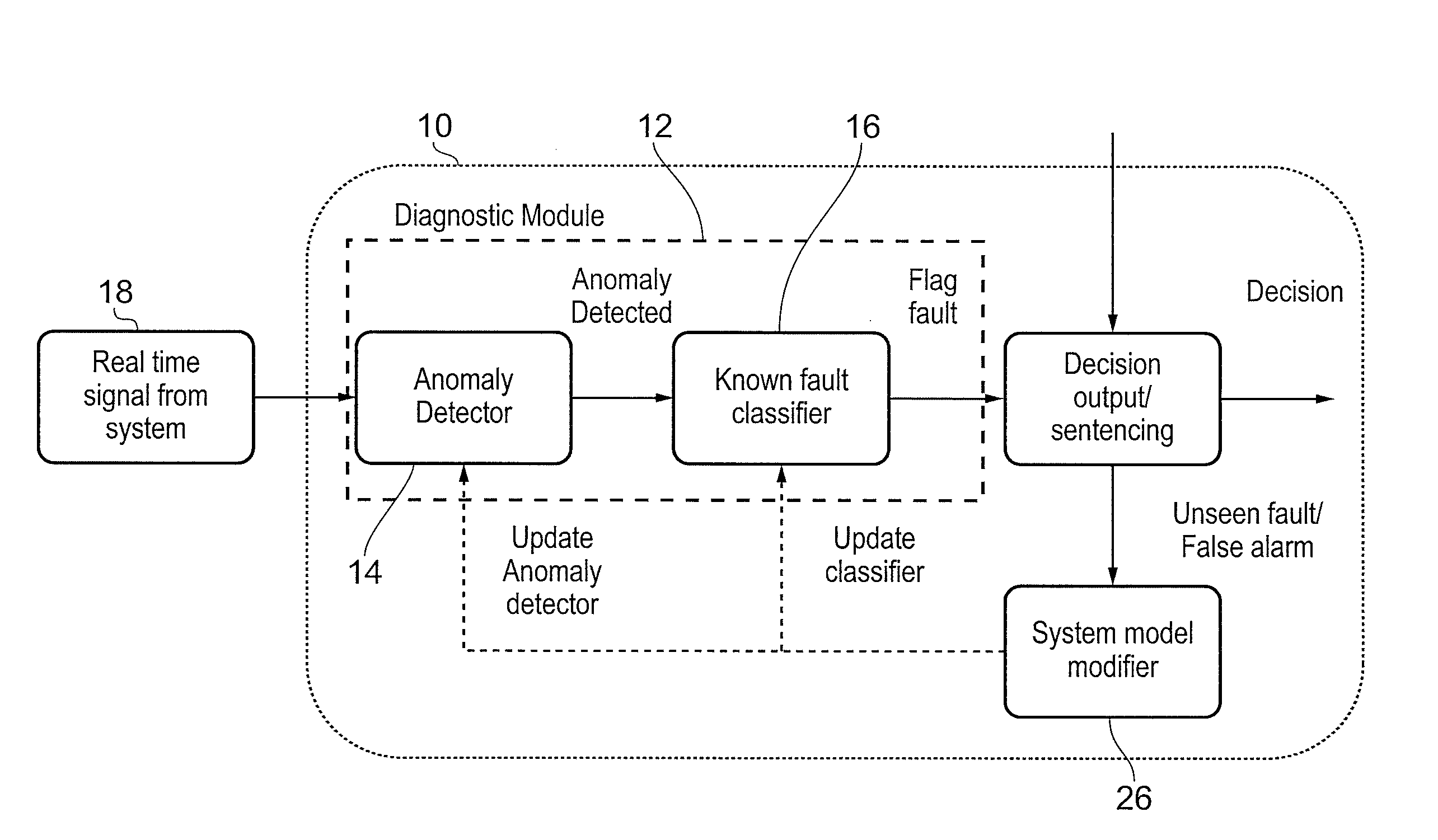

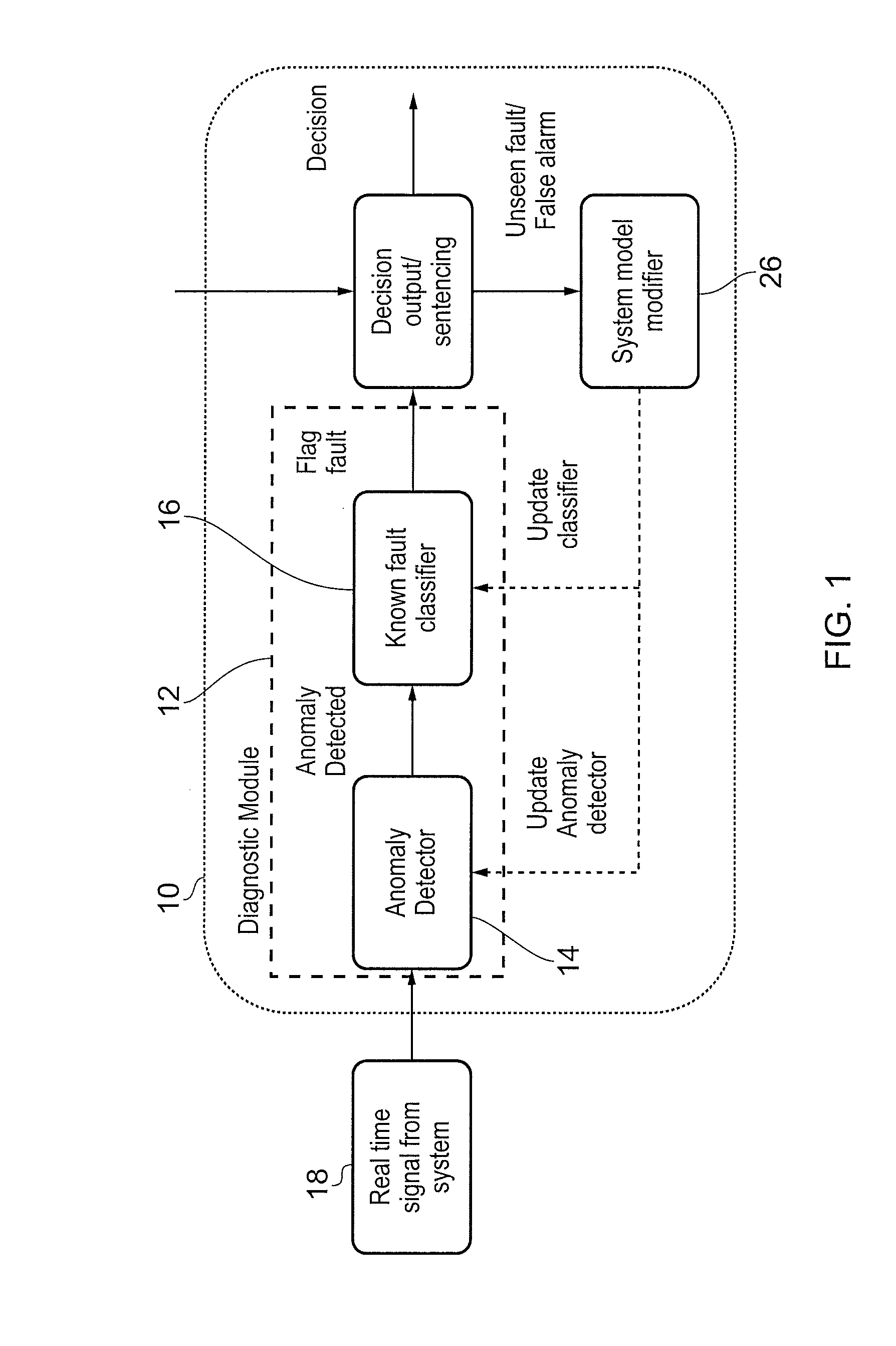

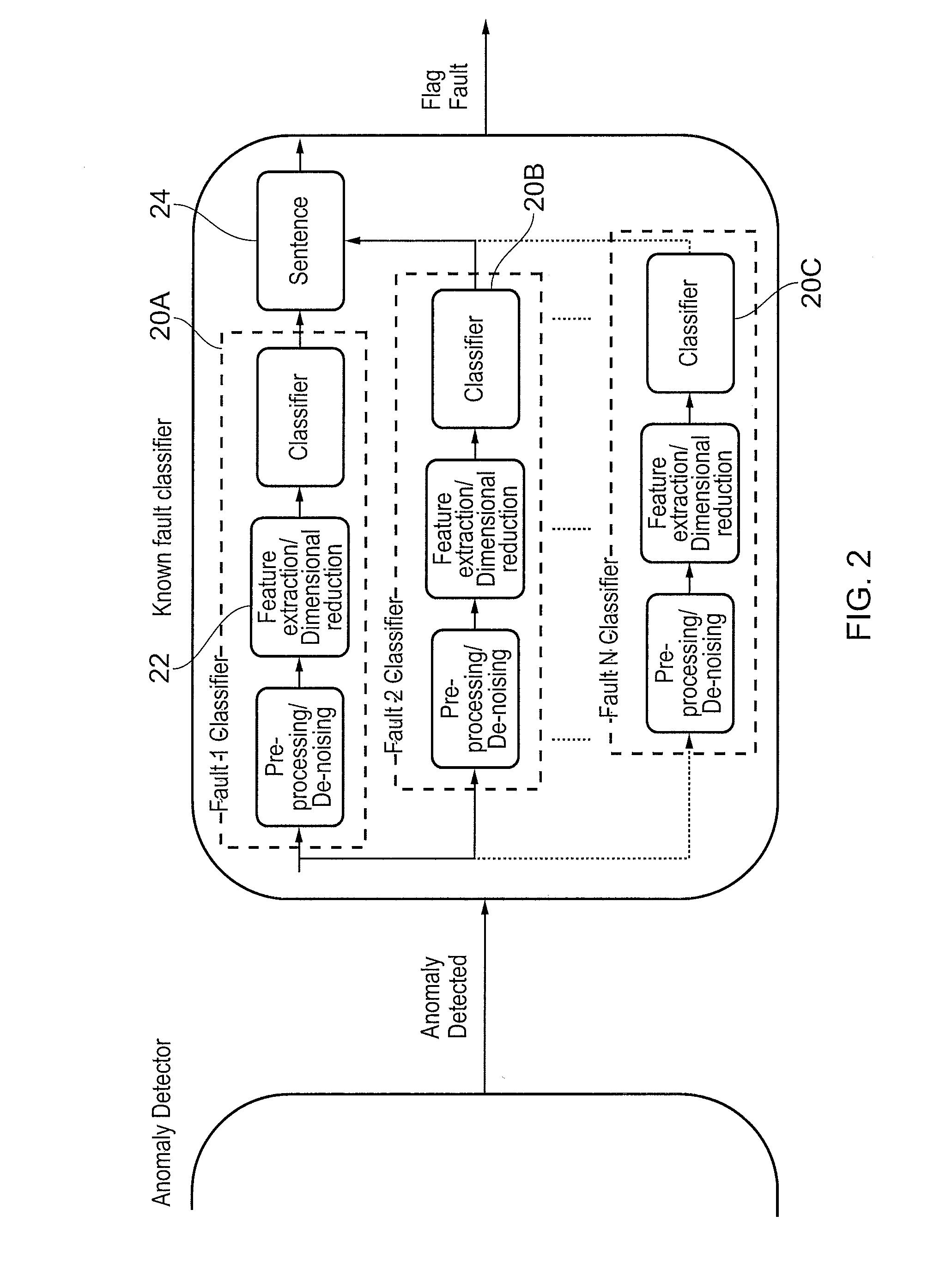

Asset Condition Monitoring

InactiveUS20150346066A1Cancel noiseReduce signalingTesting/monitoring control systemsDigital computer detailsNormal modeOperation mode

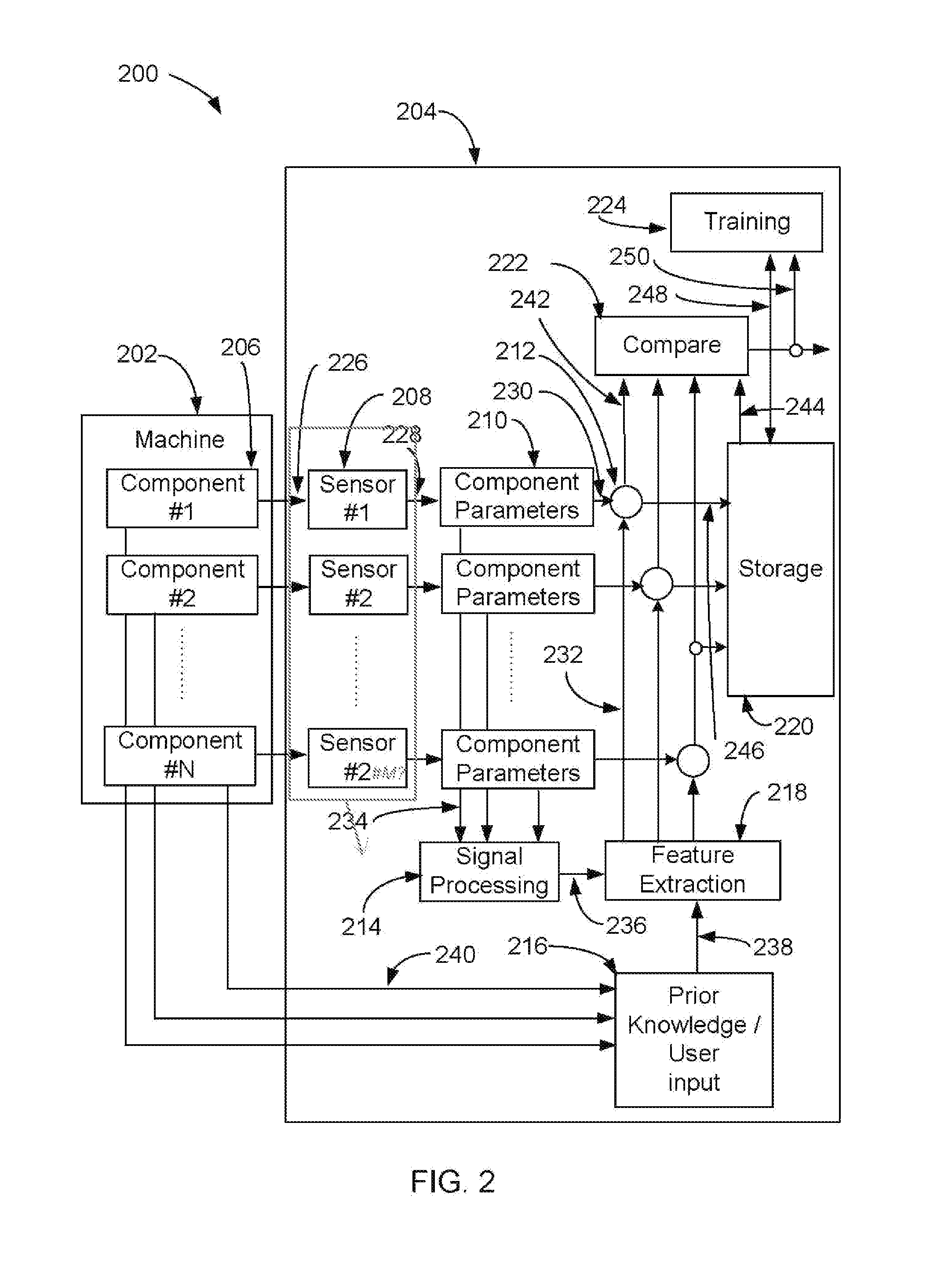

Invention concerns a machine fault diagnostic system. Sensors are provided for sensing an operational parameter of the machine over time in use and outputting corresponding sensor signals. A machine operation diagnosis tool is arranged to receive the sensor signals and has a data store for operational parameter data indicative of a normal mode of machine operation and operational parameter data indicative of one or more known machine faults. The diagnosis tool has one or more processor arranged to compare the received sensor signals with the operational parameter data in the data store in order to determine a match with either the normal mode of operation or the one or more known machine fault, and wherein the processor sentences an unknown fault in the event that said match is not established. The system may record unknown faults and update the diagnosis tool as unknown faults become recognizable faults.

Owner:ROLLS ROYCE PLC

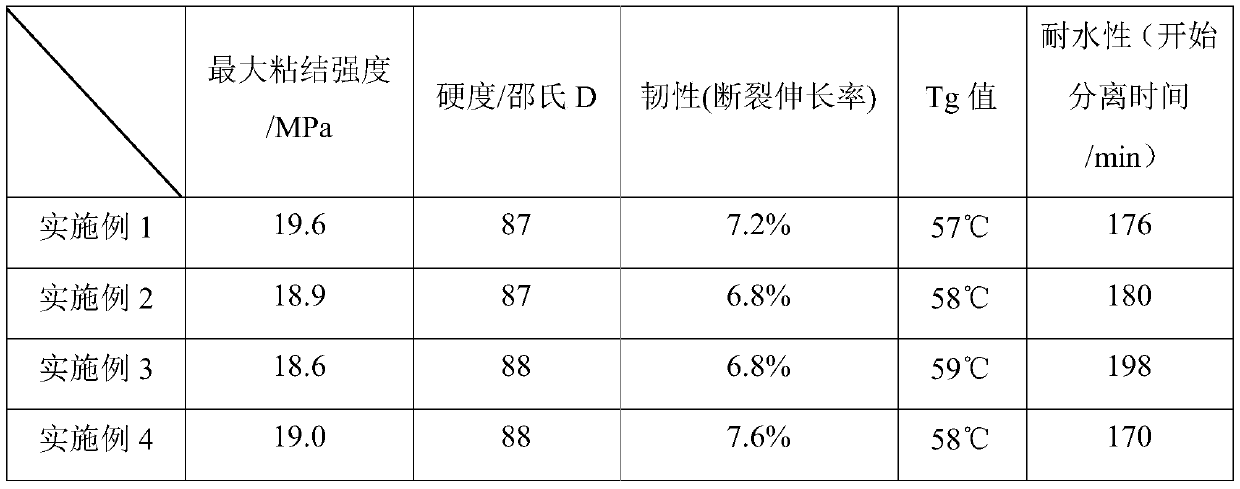

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

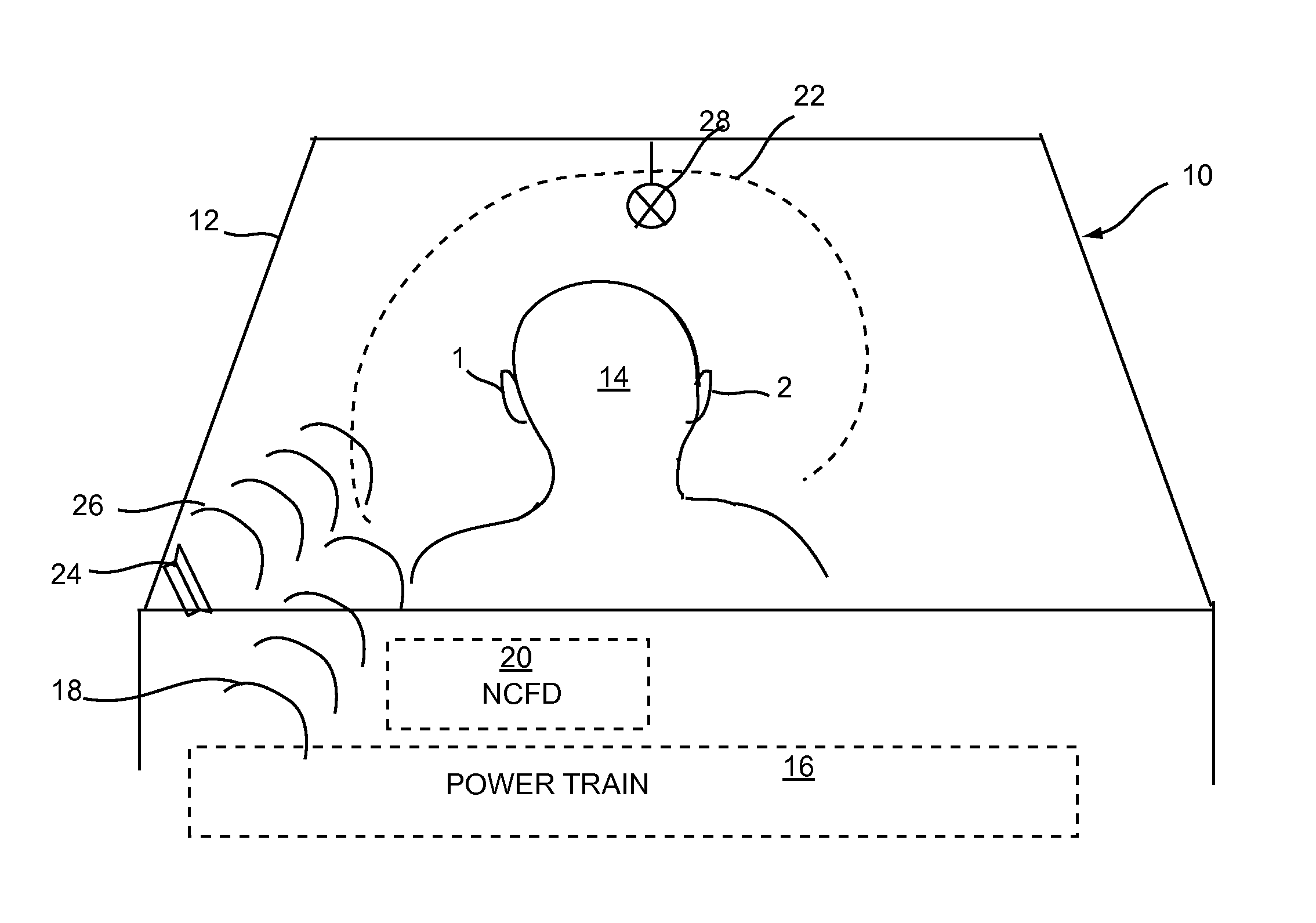

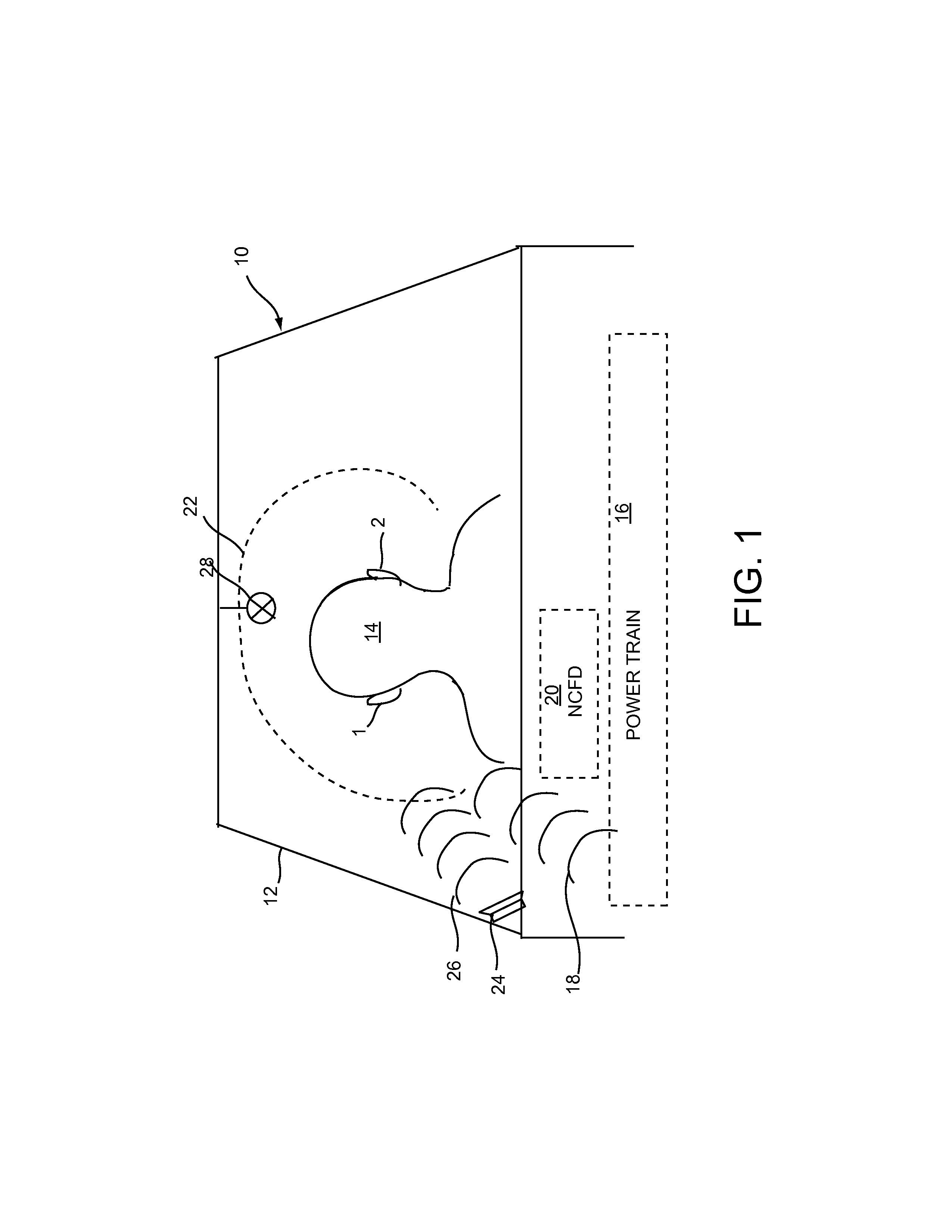

Acoustic fault detection of mechanical systems with active noise cancellation

InactiveUS20130182865A1Suppresses running noiseSuppress noiseEar treatmentNoise generationNoise suppressionFailure detector

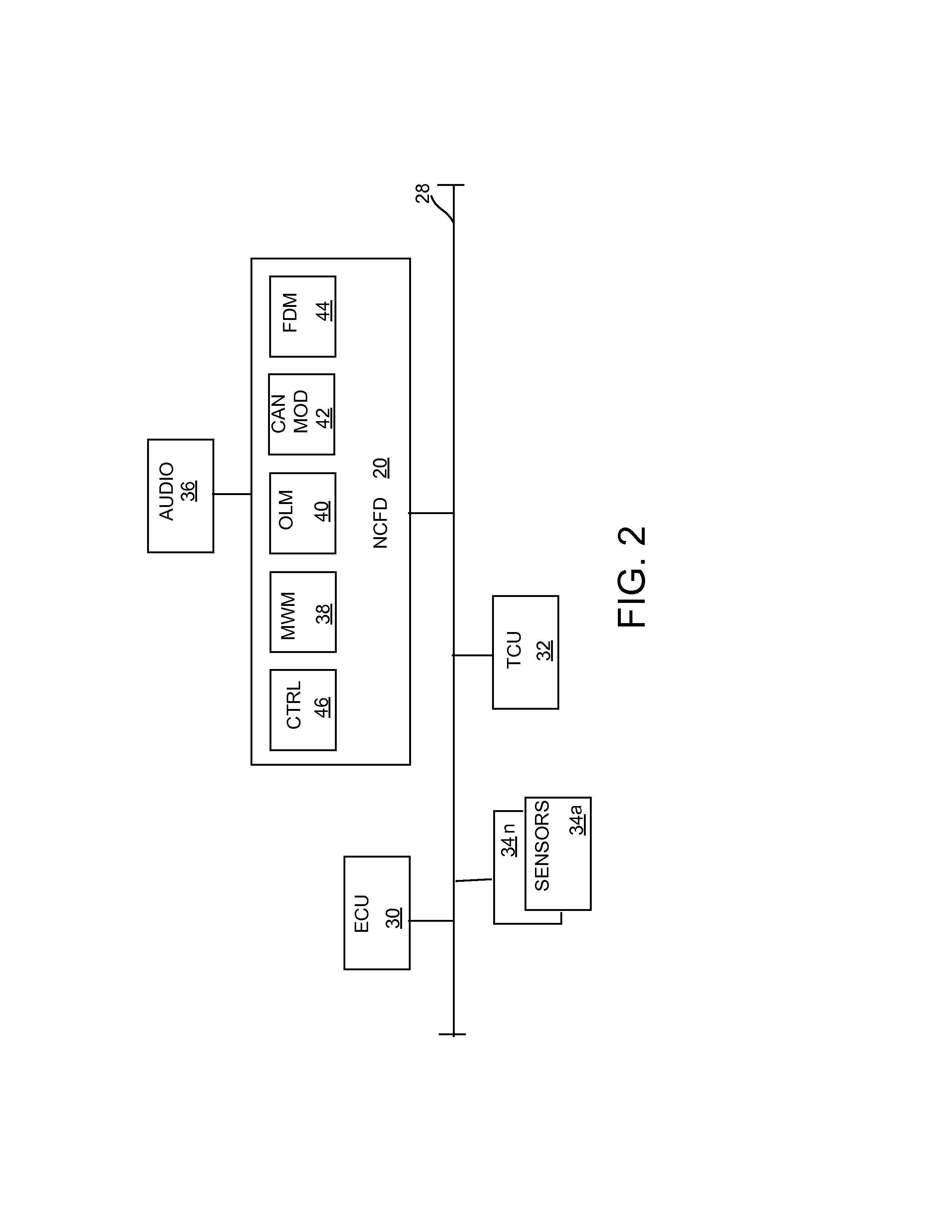

An active noise cancellation fault detector (NCFD) is presented that is configured to cancel normal machine noise in an operator cabin, while allowing noise associated with a machine failure mode to remain so that an operator can hear when a machine component is beginning to fail or is in a failure mode. An NCFD can generate a model waveform of normal noise scaled to machine operating parameters. The model waveform can be inverted and adjusted in gain and phase to provide a cancellation waveform. The invention can be configured to determine operator location within a machine cab so that cancellation signals can be configured with the proper phases to destructively interfere with normal machine noise within a quiet zone or noise suppression envelope around an operator. Noise within the quiet zone can be detected and compared to various fault waveforms to determine whether a machine component is beginning to fail.

Owner:AGCO CORP

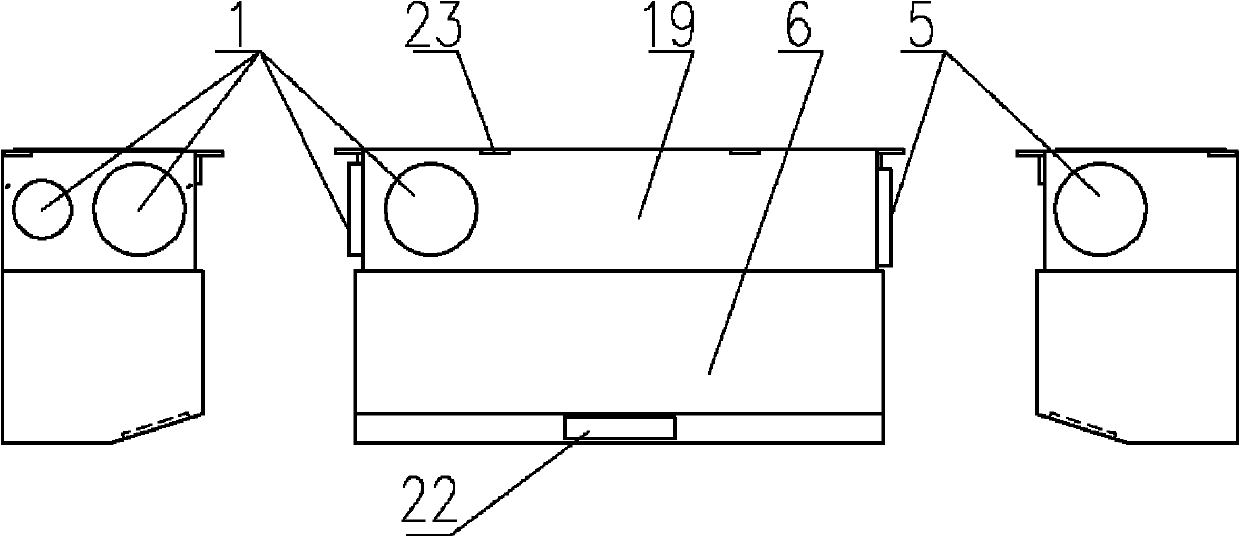

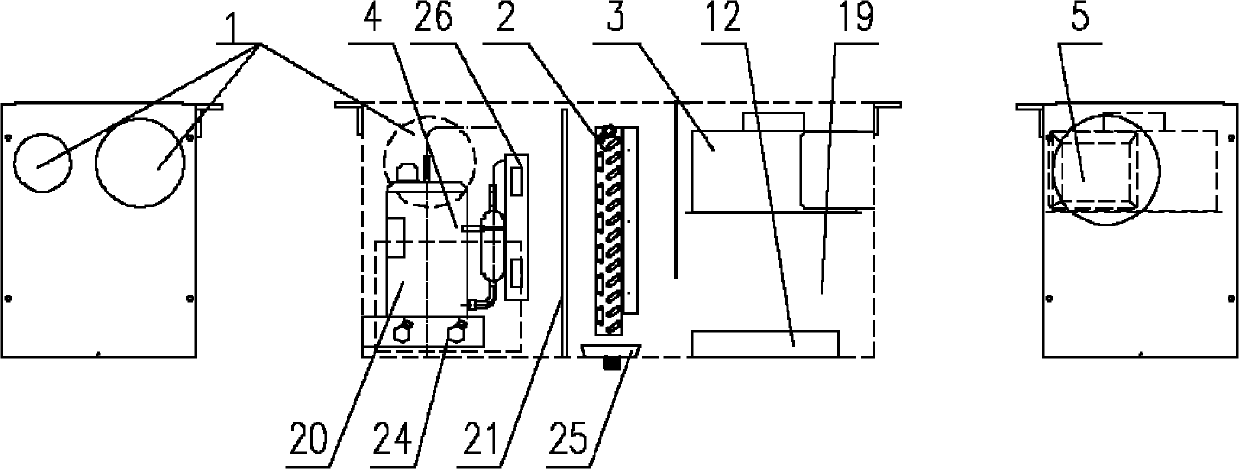

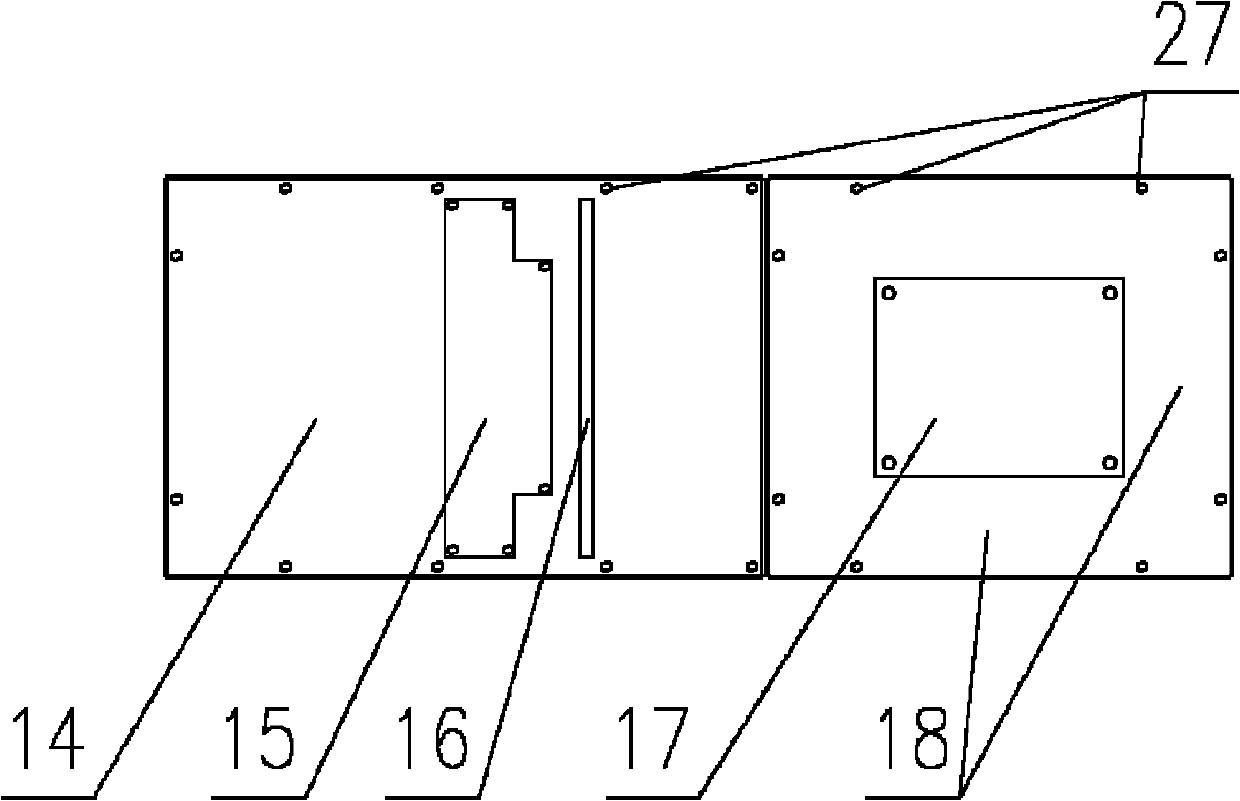

Water heater with semi-concealed assembled air source heat pump

InactiveCN102080875AEasy maintenanceFluid heatersEnergy efficient heating/coolingEngineeringAir exchange

The invention relates to a water heater with a semi-concealed assembled air source heat pump, which particularly changes the original air flowing mode on the basis of the original air source heat pump water heater, achieves an installation mode that the air source heat pump can be arranged in a closed space, also has a base structure for carrying out indoor and outdoor air exchange and belongs tothe field of air source heat recycling and the field of a fresh air system. The water heater with the semi-concealed assembled air source heat pump is characterized in that an airflow channel of theair source heat pump can be concealed on an indoor ceiling; an air source can be from an indoor place or an outdoor place; the air of which the heat is absorbed by the heat pump can be exhausted intoa room or out of the room; and when a machine goes wrong and needs to be maintained or replace parts, the unit does not need to be disassembled integrally or an overhauling opening does not need to be additionally formed for overhauling, and on the premise that the ceiling is not damaged, after a decorative shell (6) is disassembled, a compressor (4), an evaporator (2), a fan (3), an electric heater (26) and a control mainboard (12) are disassembled respectively or in a combination mode from the bottom of the machine for replacement and maintenance.

Owner:张斌

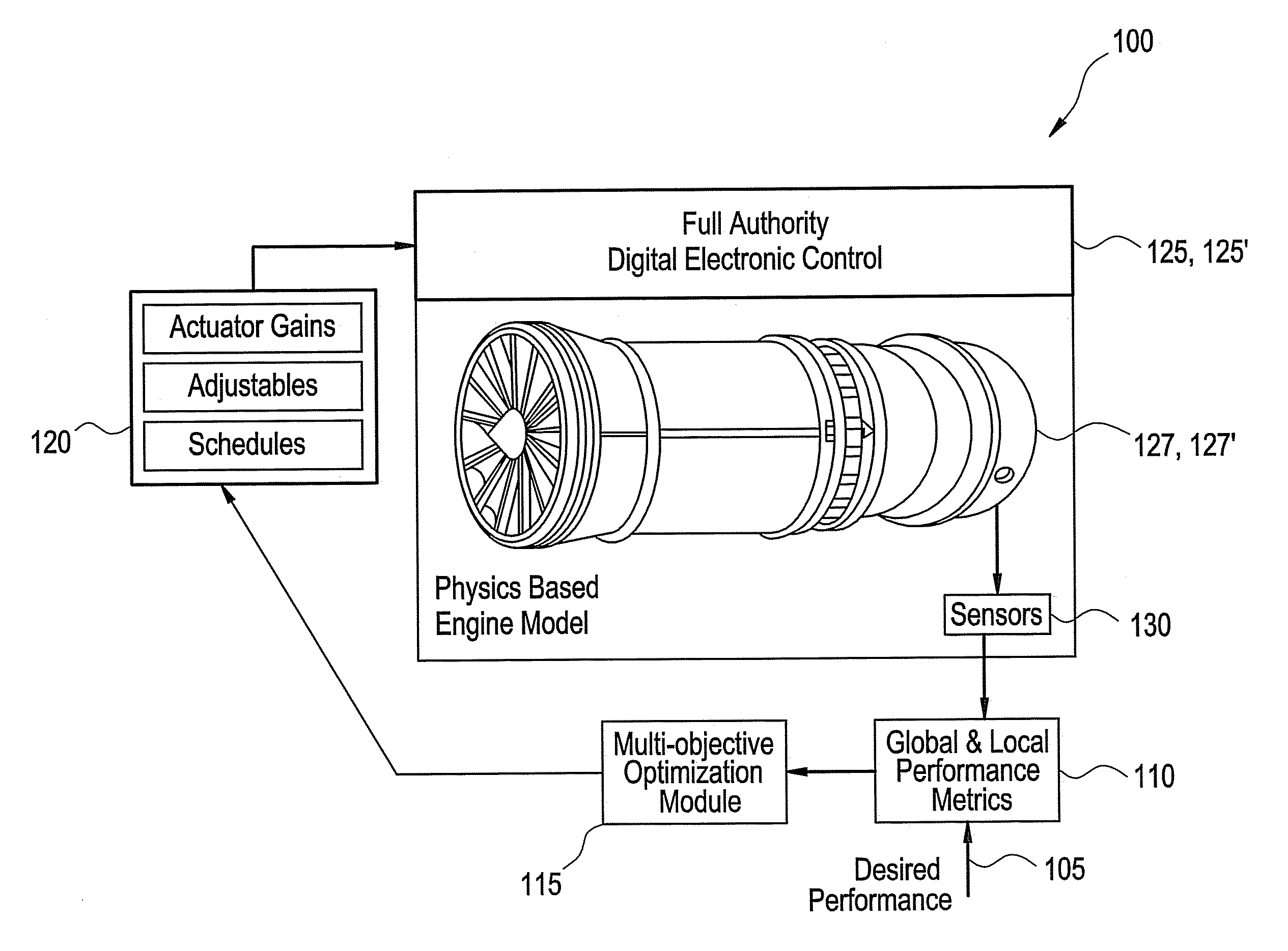

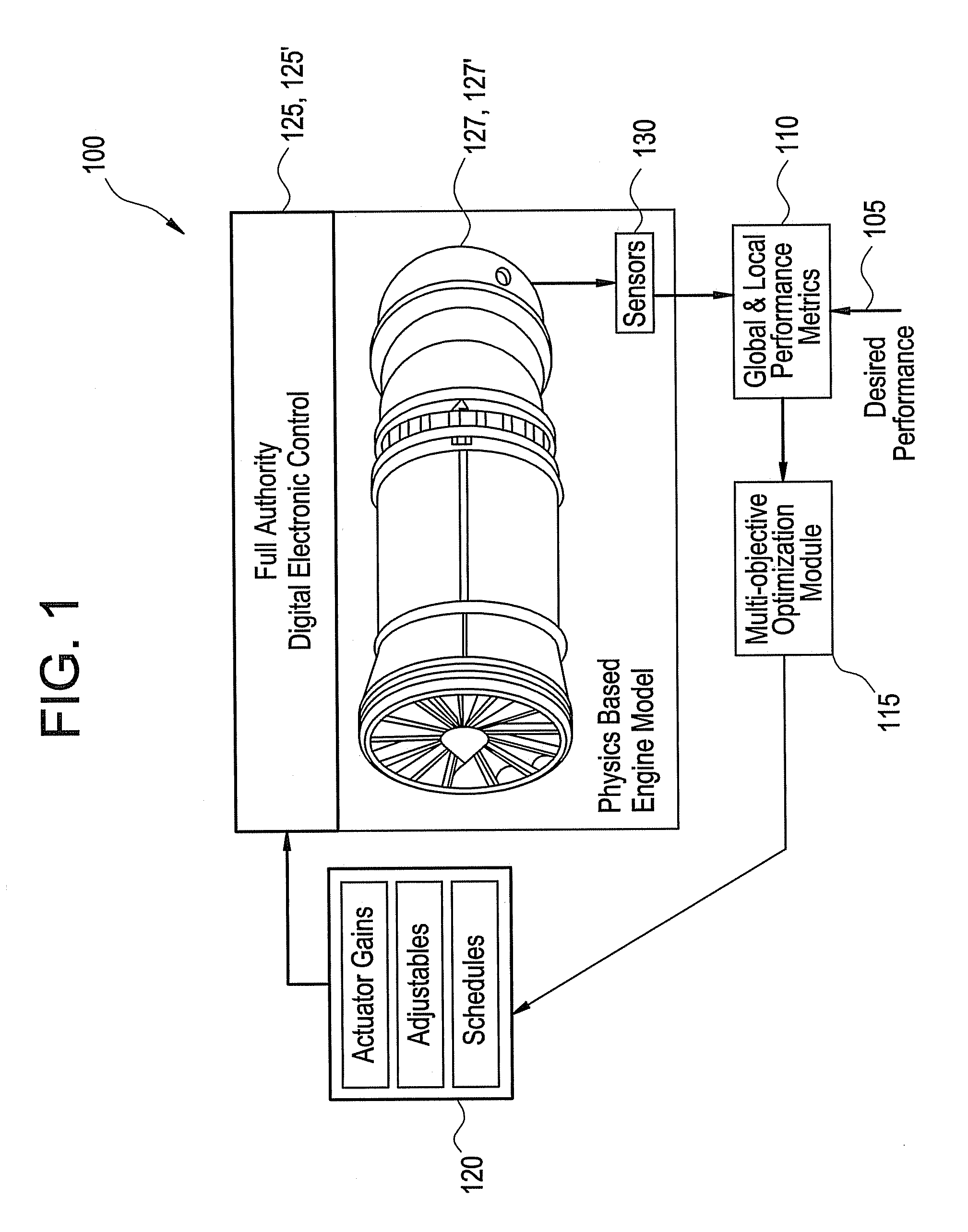

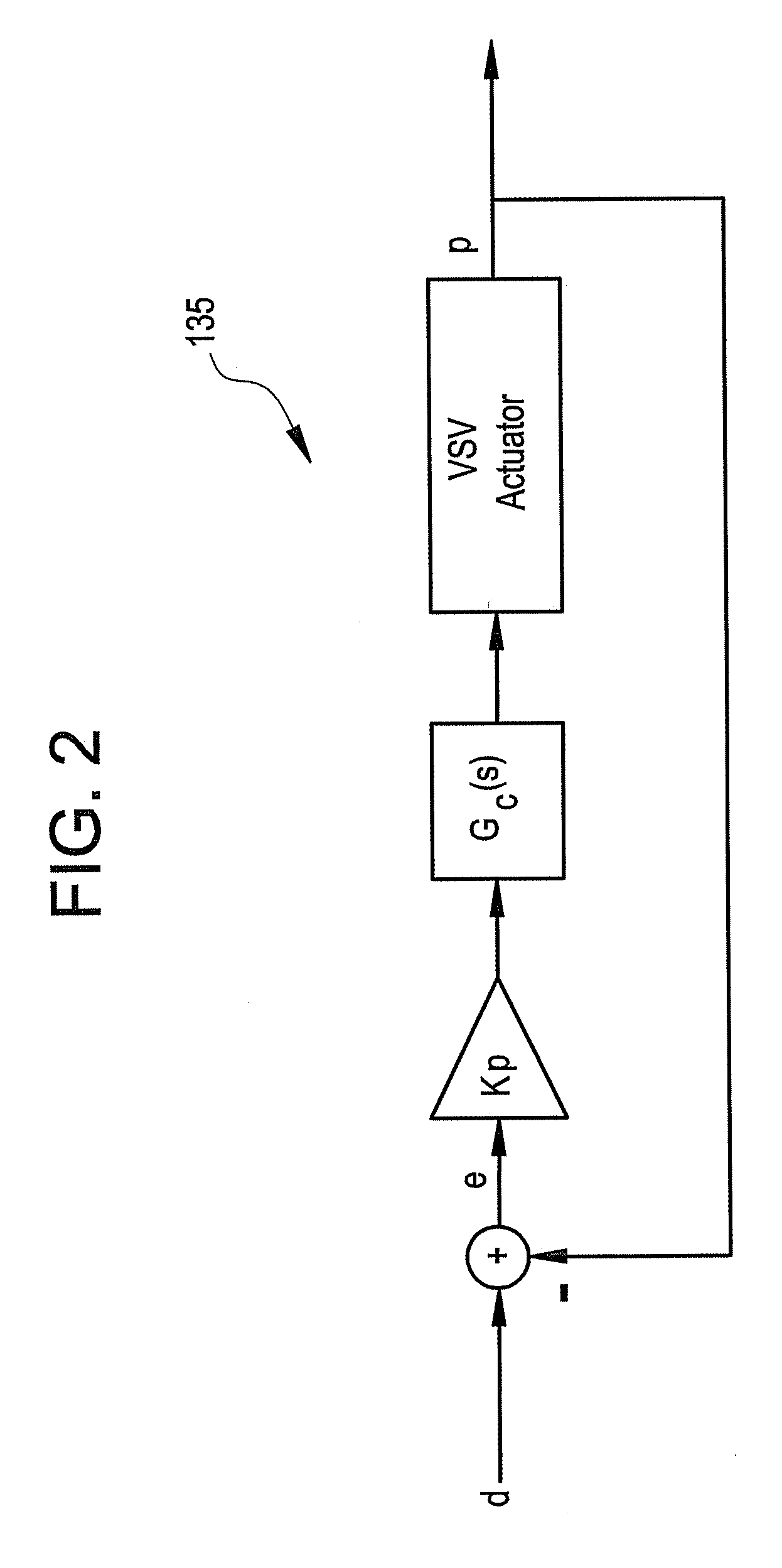

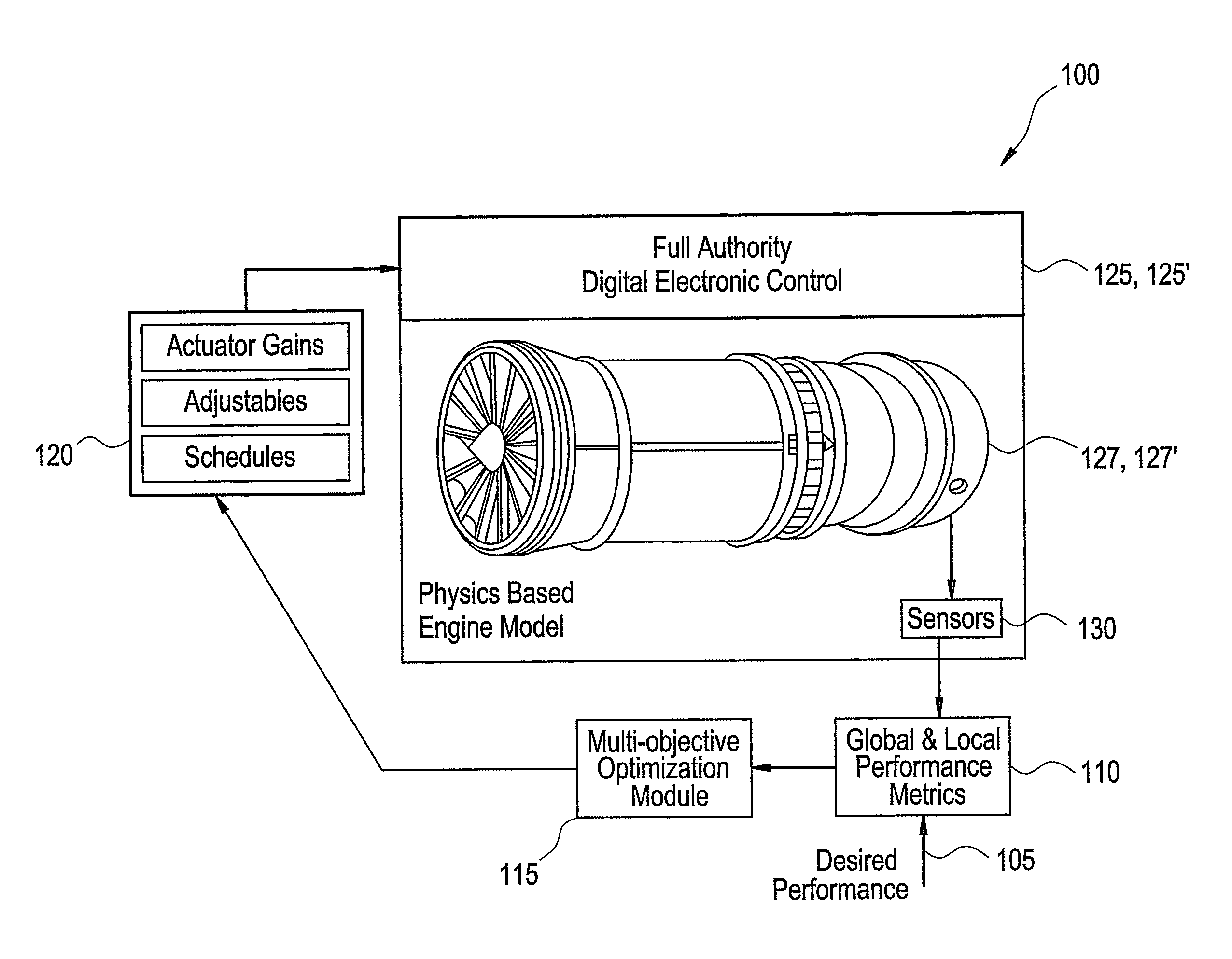

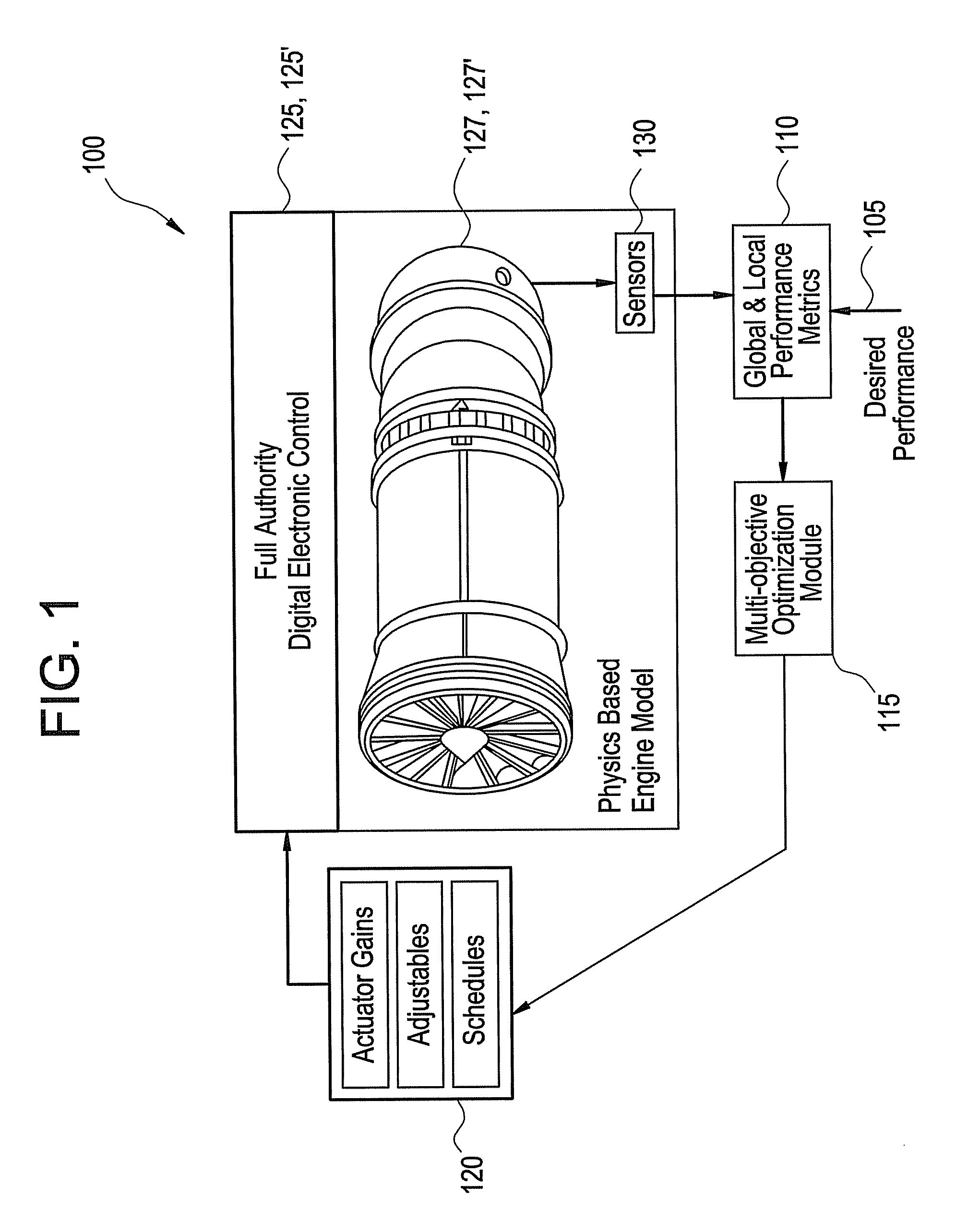

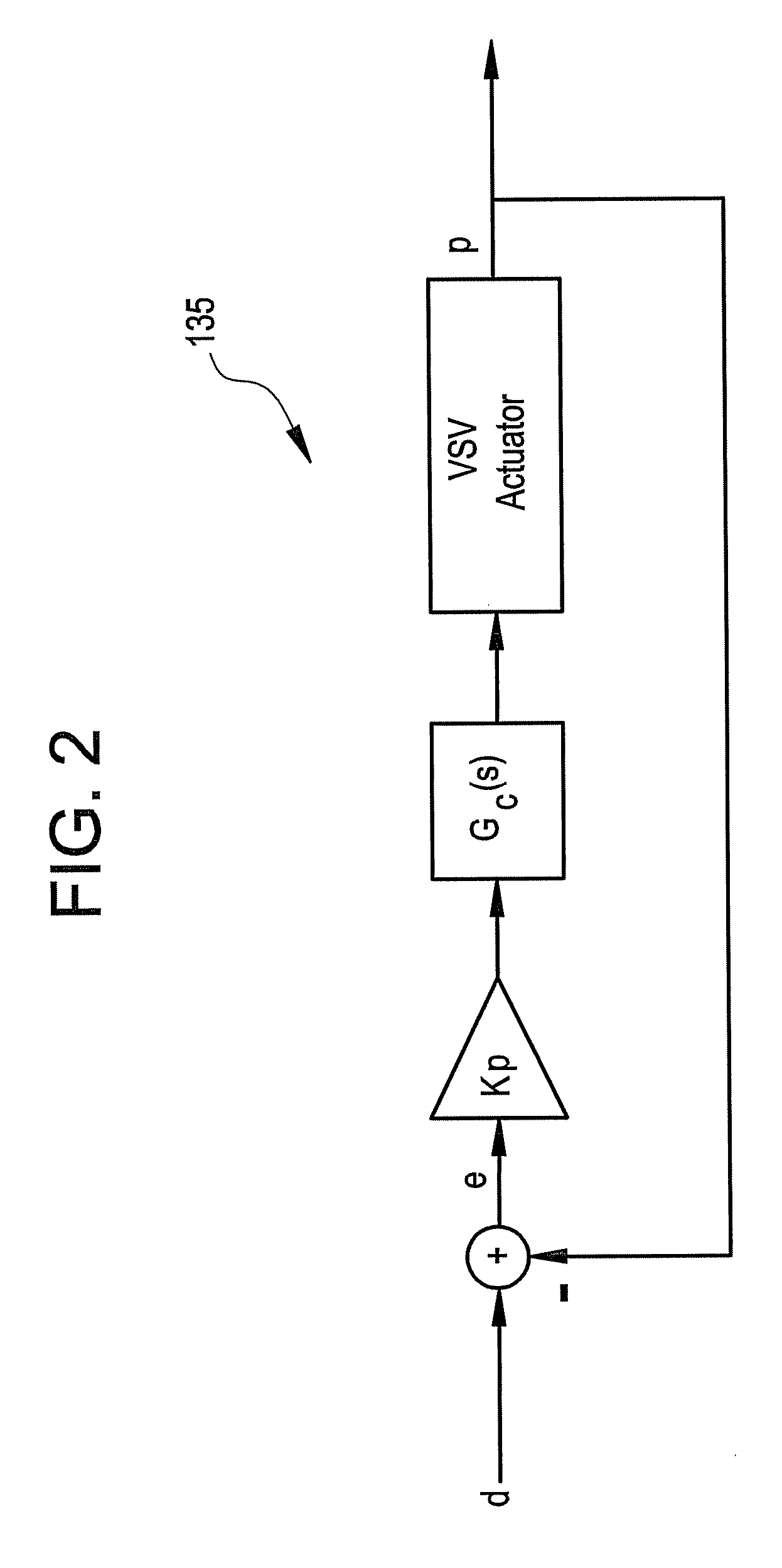

Method and system for fault accommodation of machines

ActiveUS20080229754A1Maximize operational conditionMinimize operational conditionGas turbine plantsEfficient propulsion technologiesMachine controlSimulation

A method for multi-objective fault accommodation using predictive modeling is disclosed. The method includes using a simulated machine that simulates a faulted actual machine, and using a simulated controller that simulates an actual controller. A multi-objective optimization process is performed, based on specified control settings for the simulated controller and specified operational scenarios for the simulated machine controlled by the simulated controller, to generate a Pareto frontier-based solution space relating performance of the simulated machine to settings of the simulated controller, including adjustment to the operational scenarios to represent a fault condition of the simulated machine. Control settings of the actual controller are adjusted, represented by the simulated controller, for controlling the actual machine, represented by the simulated machine, in response to a fault condition of the actual machine, based on the Pareto frontier-based solution space, to maximize desirable operational conditions and minimize undesirable operational conditions while operating the actual machine in a region of the solution space defined by the Pareto frontier.

Owner:GENERAL ELECTRIC CO

Extensions to dynamically configurable process for diagnosing faults in rotating machines

InactiveUS6980910B1Vibration measurement in solidsMachine part testingComputer scienceMachine failure

A method and apparatus for detecting problems in a rotating machine is disclosed. The method and apparatus include creating a definition of the rotating machine using a plurality of templates that specify components and functional characteristics of the components. In addition, the method and apparatus include identifying a plurality of sensors configured to provide operational data related to the rotating machine and defining a plurality of problem rules including logical expressions by which machine faults are deduced from specified portions of the operational data. Further, the method and apparatus include performing an analysis of operation of the rotating machine, the analysis including acquiring actual operational data from the plurality of sensors and applying the problem rules and templates to the operational data to detect faults in the rotating machine and in response thereto generating an indication when a fault is detected.

Owner:JOHNSON CONTROLS TECH CO

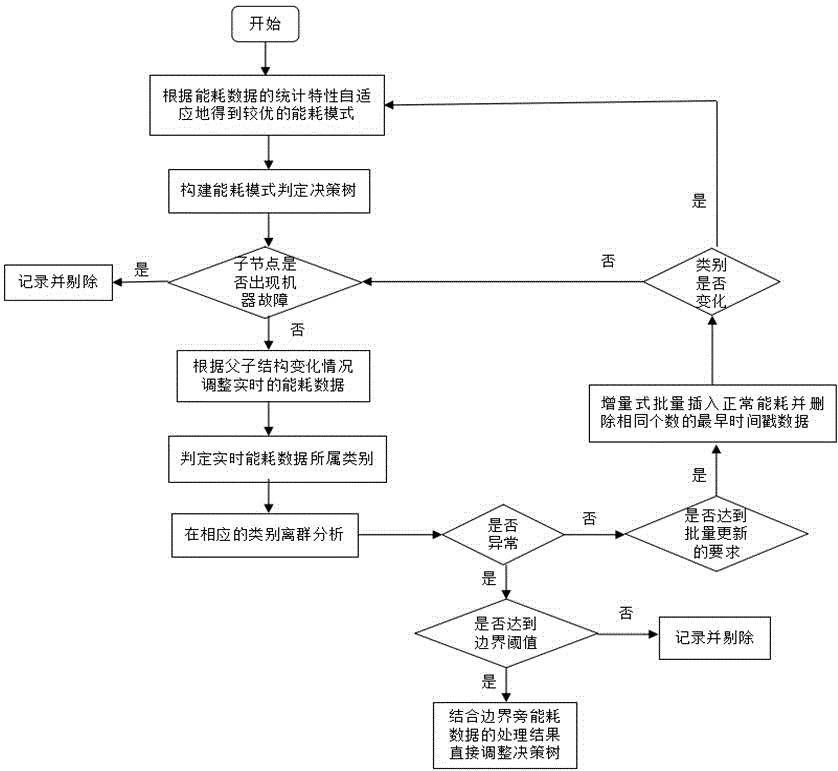

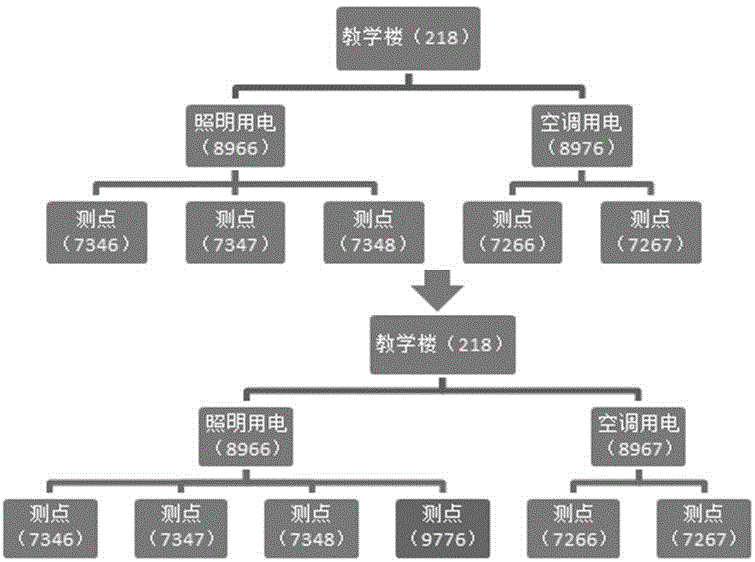

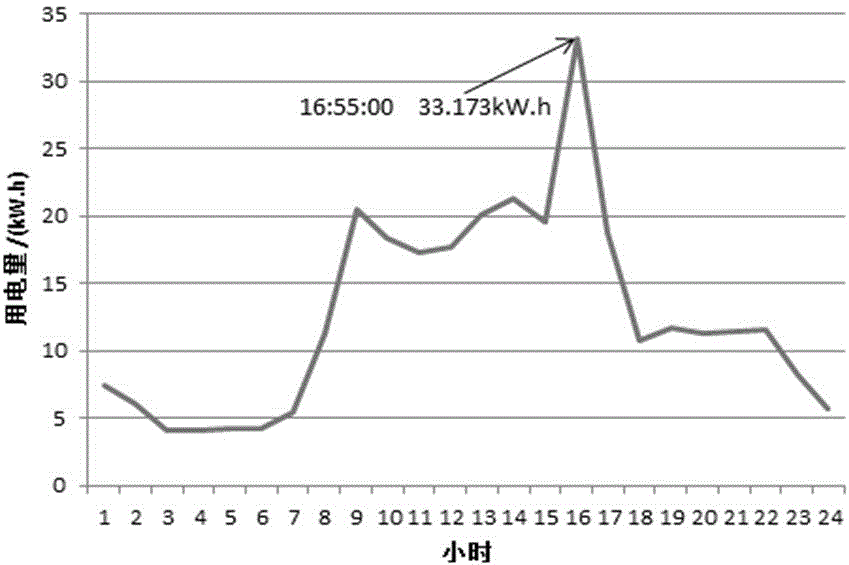

A real-time energy consumption abnormity detection method with college building structure characteristics being combined

ActiveCN106250905AReduce difficultyEfficient identificationCharacter and pattern recognitionAnomaly detectionSimulation

The invention belongs to the technical field of real-time abnormity detection, and specially relates to a real-time energy consumption abnormity detection method with college building structure characteristics being combined. Energy consumption modes of buildings are identified in a self-adaptive manner through a SA-DBSCAN algorithm, and a decision tree of the energy consumption modes is constructed through a C4.5 algorithm; if an acquisition child node has no machine fault, real-time energy consumption is processed first according to change of a parent-child structure of a building node, then, the type of the real-time energy consumption is obtained according to the decision tree, and abnormity is detected through an LOF algorithm; if abnormity is detected, the decision tree is adjusted based on whether a boundary threshold value is reached; and normal energy consumption data increment is updated to the energy consumption modes of the buildings in batch, and an abnormity detection model is adjusted dynamically according to whether the type of energy consumption mode is changed. The method can effectively detect abnormal energy consumption and dynamically adjust the detection model to reduce misjudgment.

Owner:FUDAN UNIV

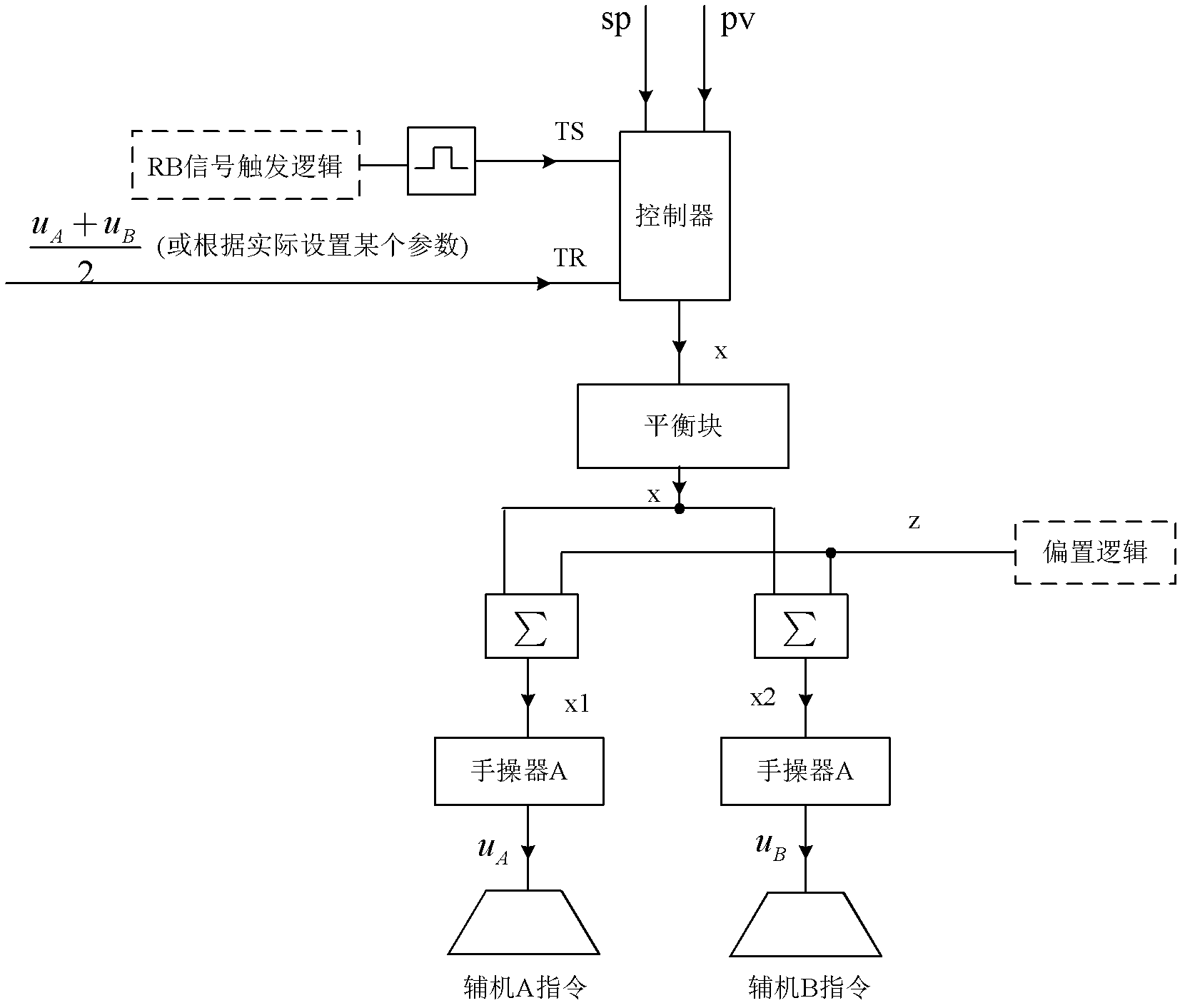

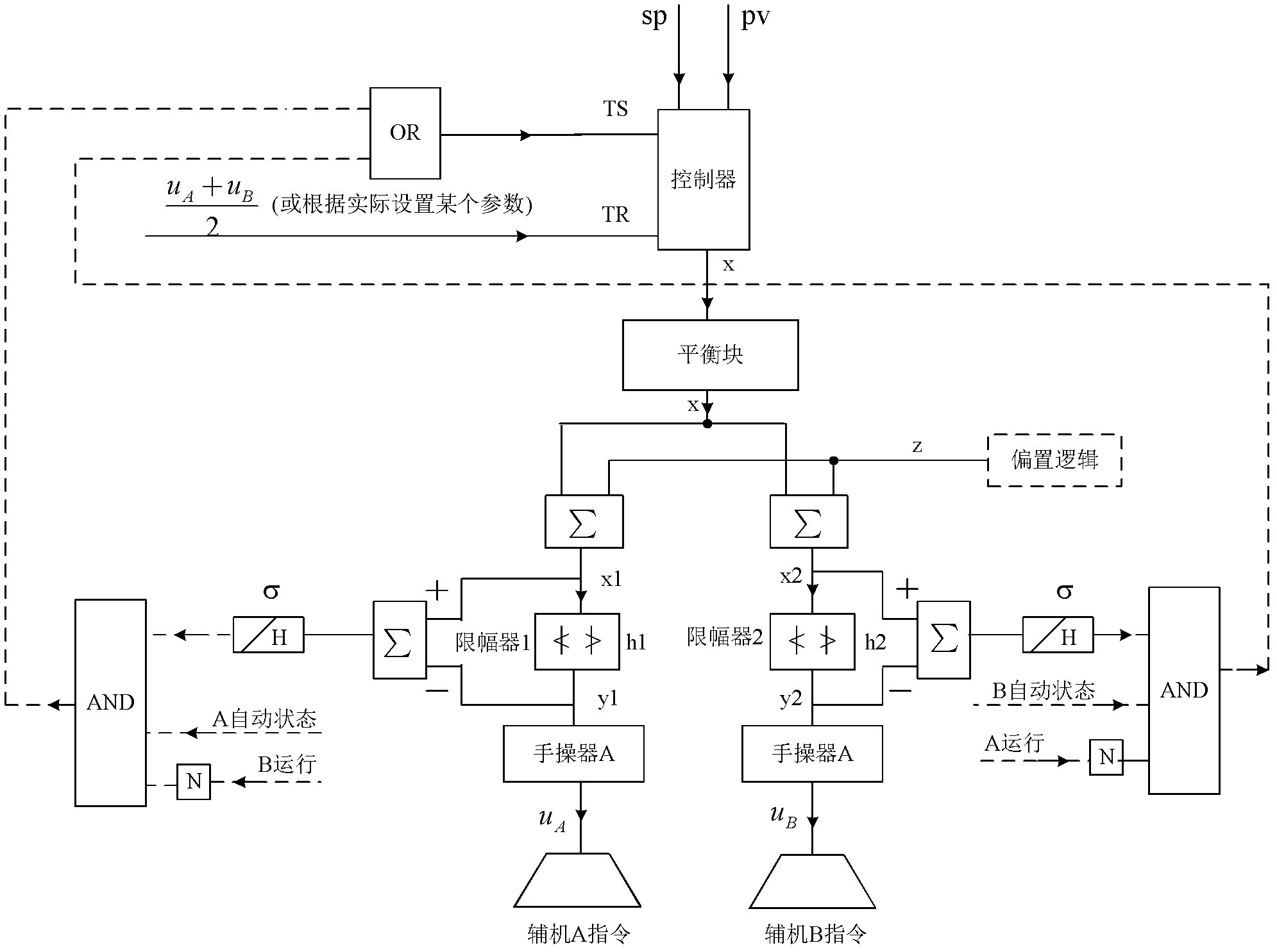

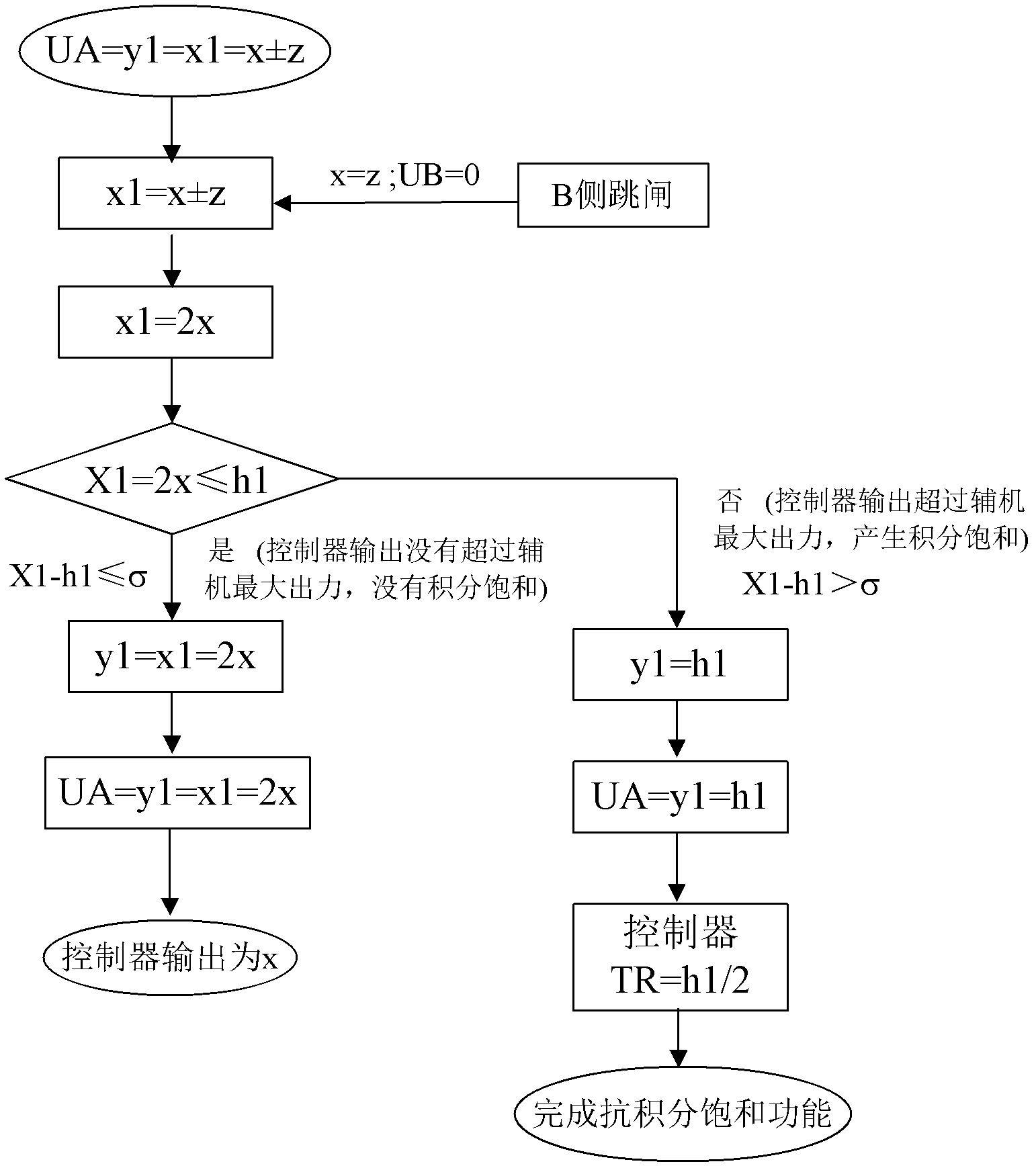

Control method of integral saturation resistance in auxiliary machine failure load reduction process

ActiveCN102591201AMaintain securityReduce loadControllers with particular characteristicsSafe operationPower unit

The invention discloses a control method of integral saturation resistance in the auxiliary machine failure load reduction process, which is characterized in that a RB (Radio Beacon) signal is not adopted to trigger; two amplitude limiters are additionally arranged in front of a hand-operated device; triggering is carried out through comparing a command with the output of an auxiliary machine; when an auxiliary machine at the other side trips or fails, and the auxiliary machine at the side is in an automatic state; the output at the side is suddenly increased; within the scope allowed by the output of the auxiliary machine at the side, the integral saturation resistance action is not generated; and if the output at the side is exceeded, an integral saturation resistance function is generated till the integral saturation is eliminated. The control method has the beneficial effects that when an auxiliary machine of a thermal power unit fails, the load can be quickly and effectively reduced; within a period of time before reset in the RB process, if the auxiliary machine fails or parameters are improperly set, the integral saturation resistance function can also be generated through the design; and when the output of the auxiliary machine is larger and is lower than the maximum output of the auxiliary machine at the single side, the RB signal cannot trigger a controller to track, so that the oscillation of a system is prevented; and the safe operation of the auxiliary machine is favorably maintained.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

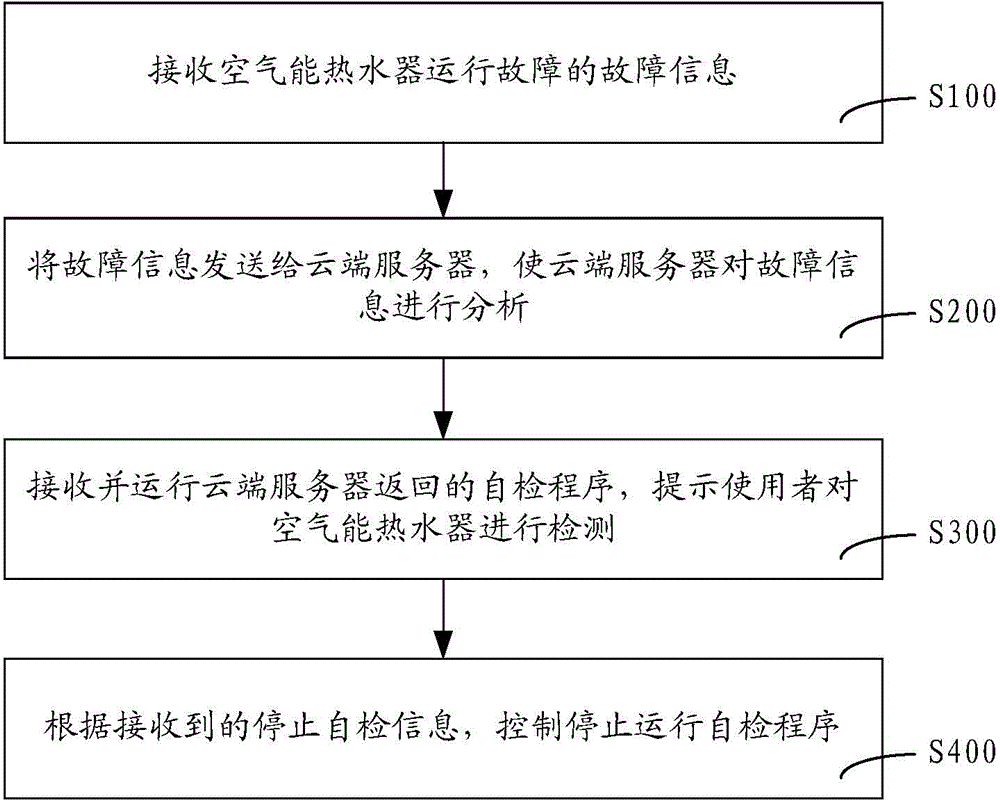

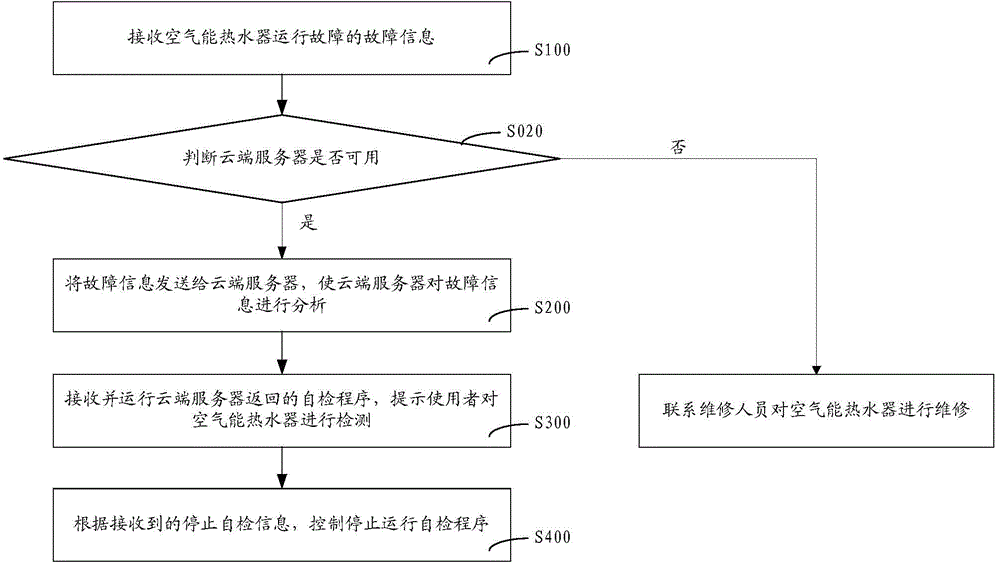

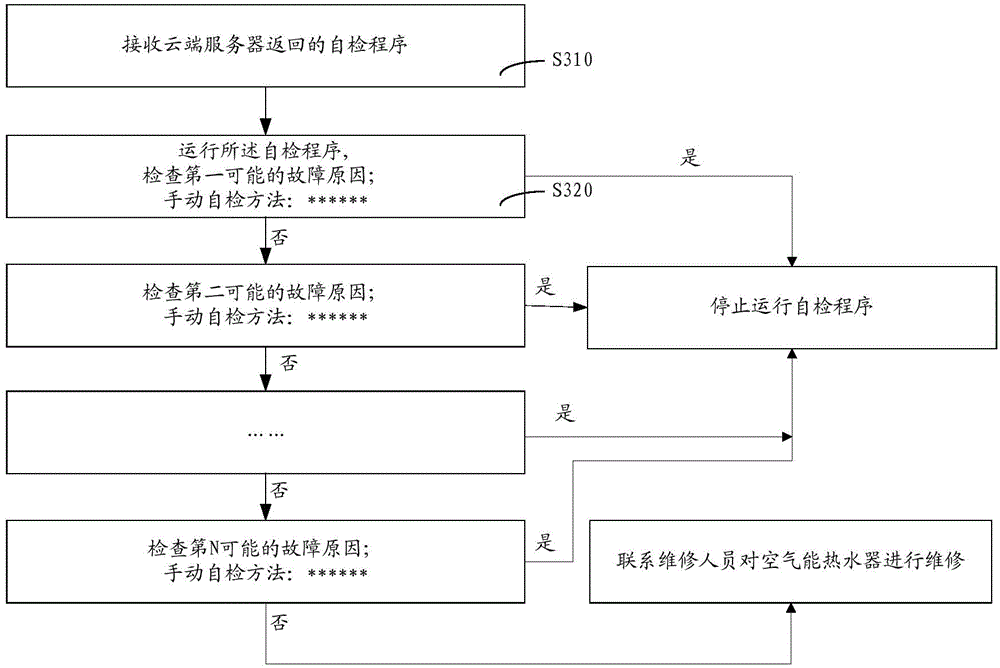

Method, device and system for detecting faults of air energy water heater and air energy water heater

ActiveCN104132463AReduce breakdown repair costsSolve the detection speed is slowFluid heatersEngineeringSelf checking

The invention discloses a method, a device and a system for detecting faults of an energy water heater and the air energy water heater. The method includes the following steps that fault information of the operation faults of the air energy water heater is received; the fault information is sent to a cloud server, and the cloud server is used for analyzing the fault information; a self-check program sent by the cloud server is received and operated, and a user is prompted to detect the air energy water heater; the self-check program is controlled to stop operating according to self-check stopping information; the fault information includes fault codes. According to the method, the user can exclude the simple faults under the guidance of the self-check program, the air energy water heater can rapidly recover to operate normally, and the fault maintaining cost of the device is reduced. For the faults which cannot be excluded by the user, a maintainer can directly conduct maintenance with corresponding tools according to the determined faults, the fault detecting and maintaining speed is improved as well, and the maintaining cost of the air energy water heater is overall reduced.

Owner:GREE ELECTRIC APPLIANCES INC

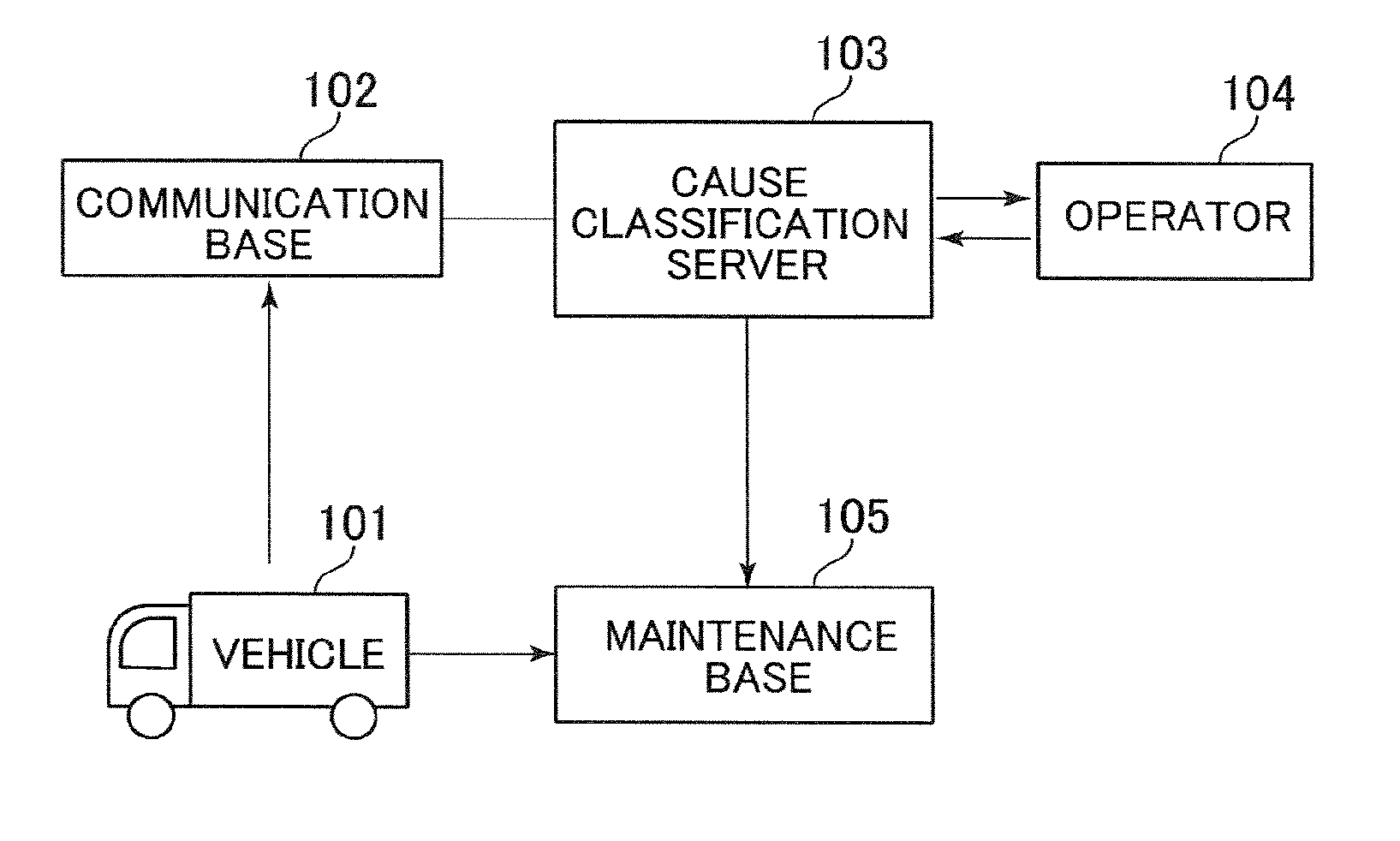

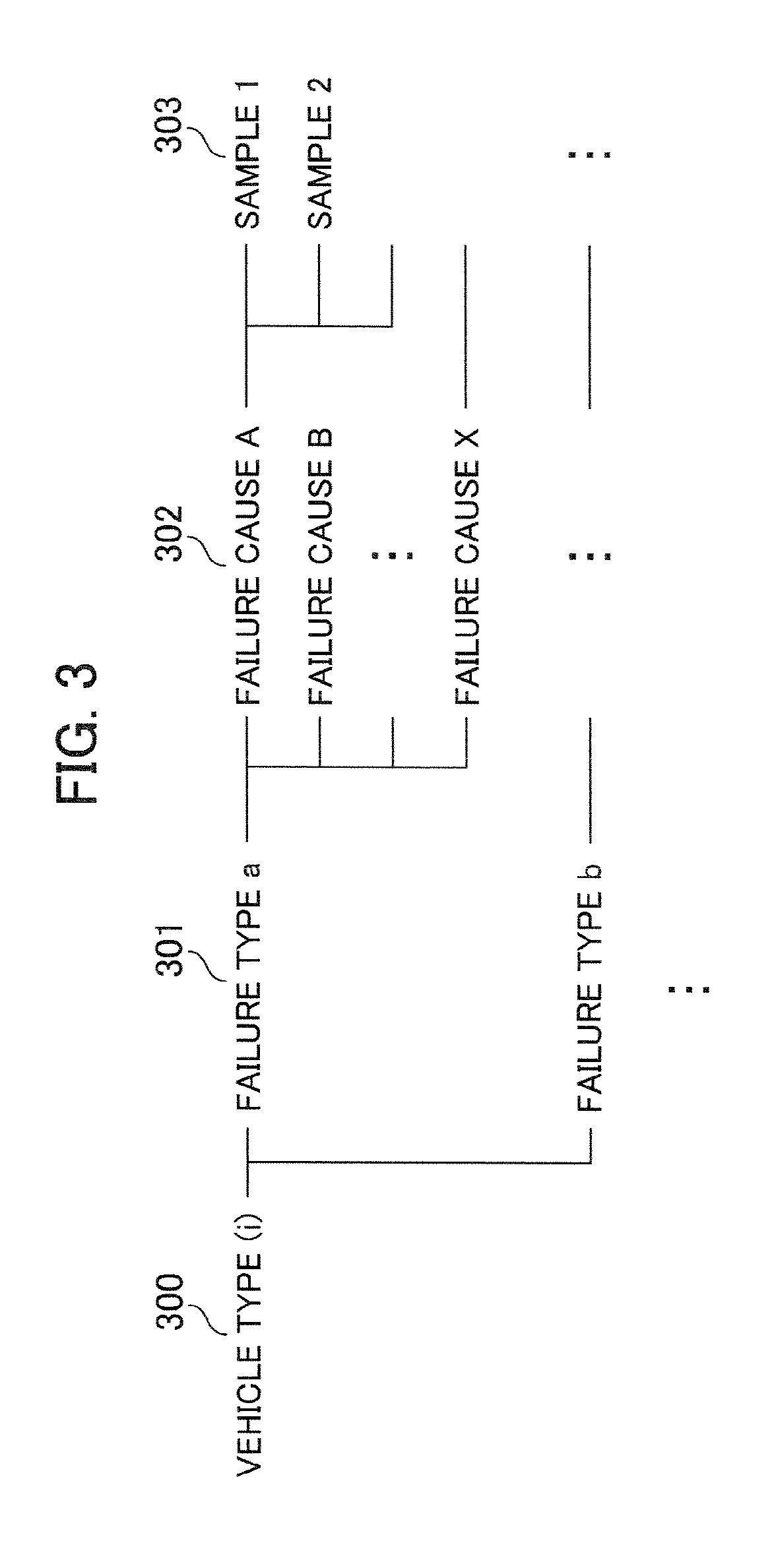

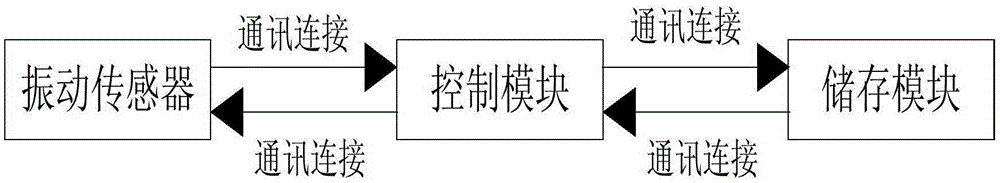

Failure cause classification apparatus

InactiveUS20150279129A1Improve accuracyVehicle testingRegistering/indicating working of vehiclesFailure causesComputer science

Selection of sensors requires the knowledge of individual sensors mounted on a target machine and the knowledge of mechanical features of the machine. In the past, experts having mechanical knowledge selected the sensors. The present invention involves analyzing sensor data at e of machine failure, extracting features from the sensor data regarding each failure cause, and comparing the extracted features so as to clarify the difference between the sensor data about the failure causes and present an operator with the clarified difference thereby to support sensor selection. The invention makes it possible to select more simply than before the sensors considered effective for classifying failure causes. For example, the sensors deemed effective for classifying failure causes without mechanical knowledge can be selected.

Owner:HITACHI HIGH-TECH CORP

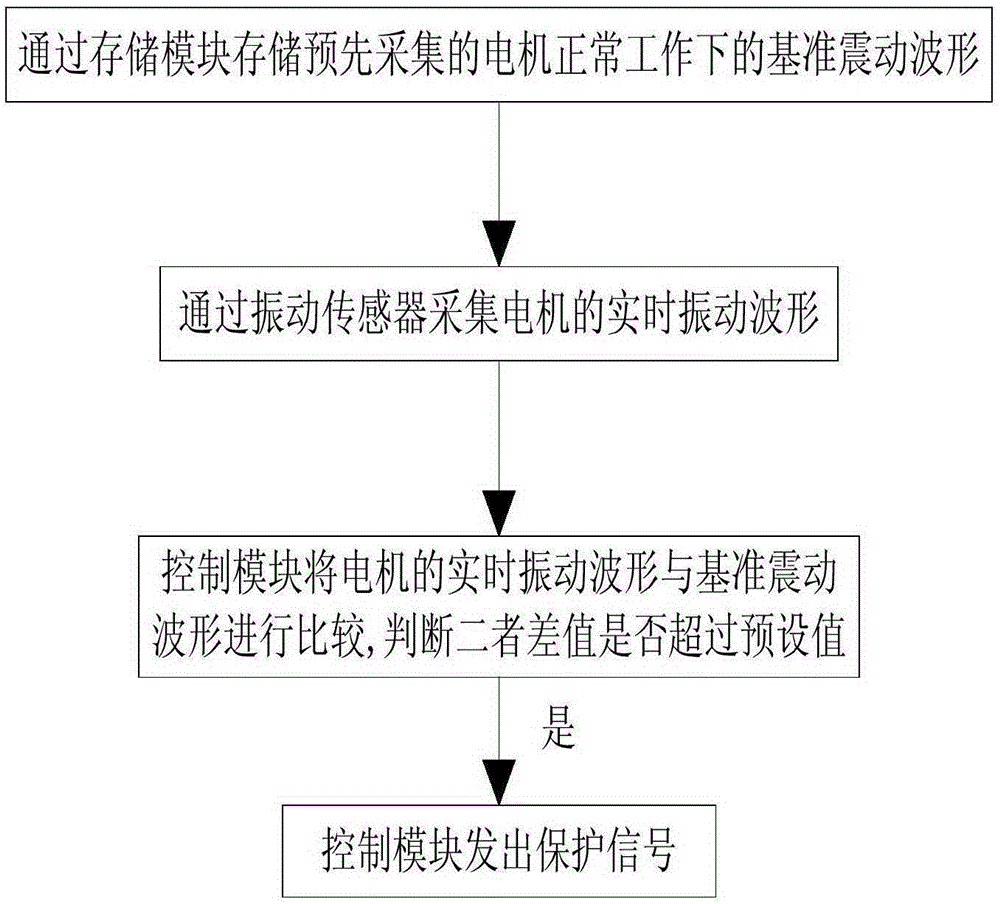

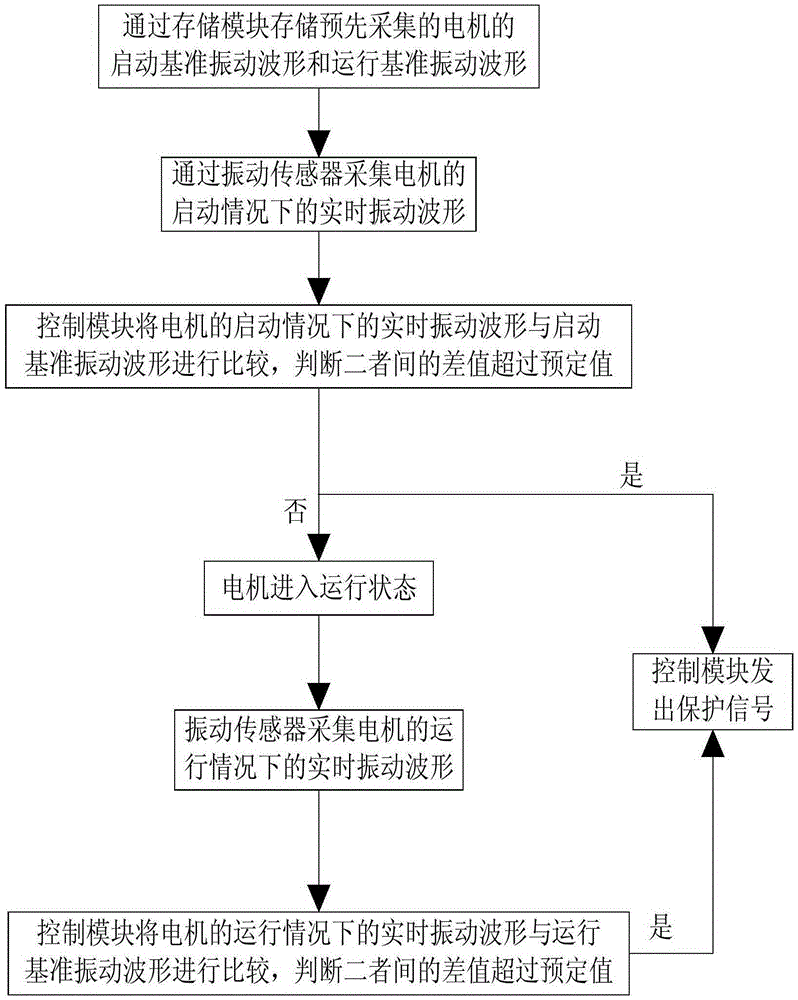

Motor stalling protection method and device

ActiveCN105337259ATimely protectionEasy to controlEmergency protective circuit arrangementsWave shapeMotor control

The invention discloses a motor stalling protection method and device, belonging to the technical field of motor control, and aiming at solving the problems of the existing electric equipment that the equipment does not have a specific stalling protection function, and during operation, hidden dangers of machine failure and motor damage exist. According to the motor stalling protection method disclosed by the invention, a storage module is used for storing a pre-collected standard vibration waveform in normal work of the motor, a vibration sensor is used for collecting a real-time vibration waveform of the motor, a control module is used for comparing the real-time vibration waveform of the motor with the standard vibration waveform in normal work of the motor, and if the difference value between the two excesses a preset value, the control module sends out a protection signal. The response speed is high, the control is accurate, the motor can be timely protected, and failure, vibration, abrasion abnormity and the like caused by mechanical faults of the motor can be prevented. The invention further provides a motor stalling protection device.

Owner:GREE ELECTRIC APPLIANCES INC

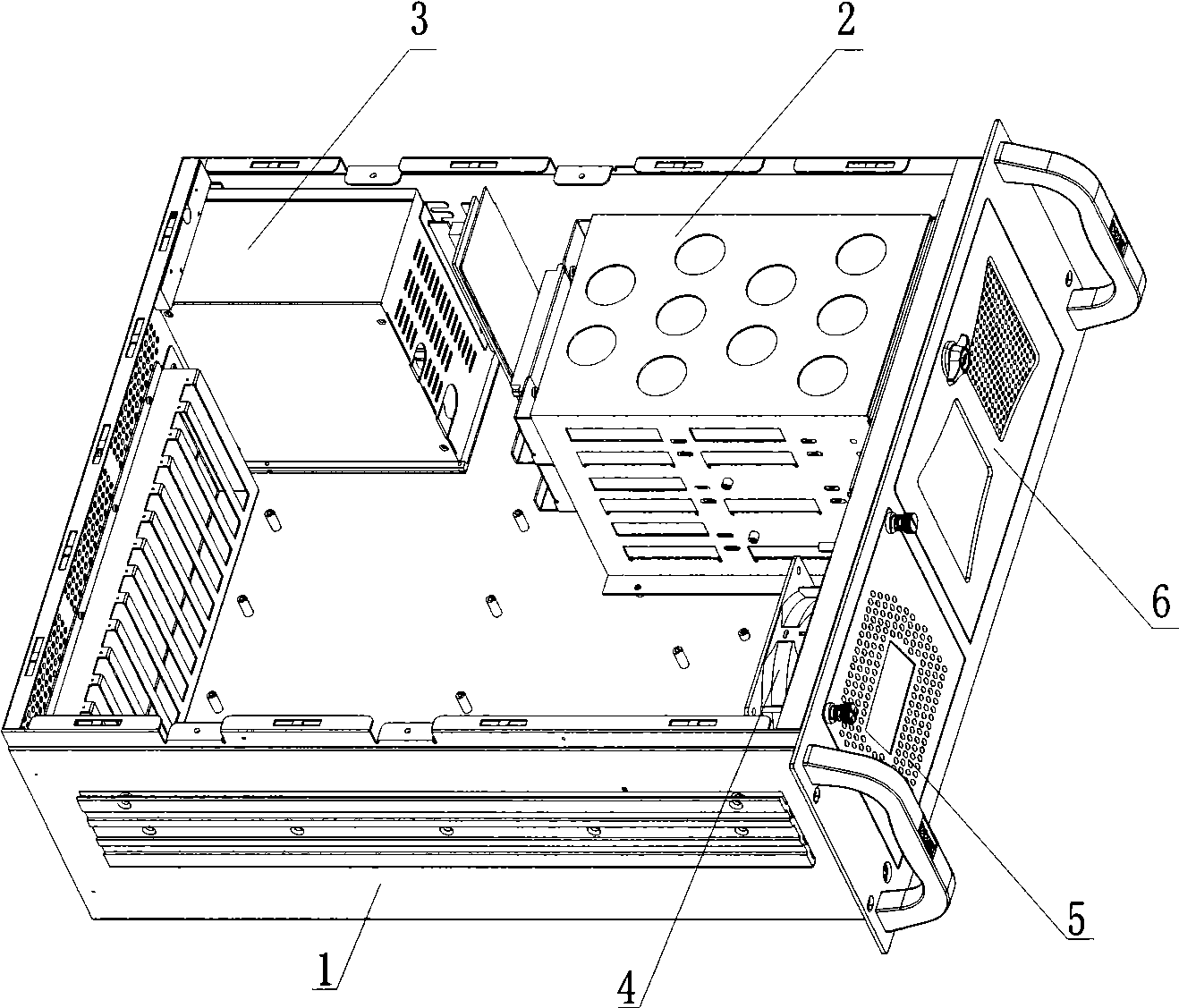

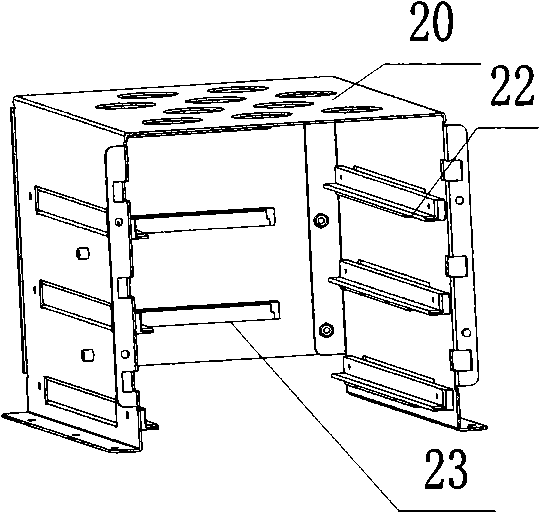

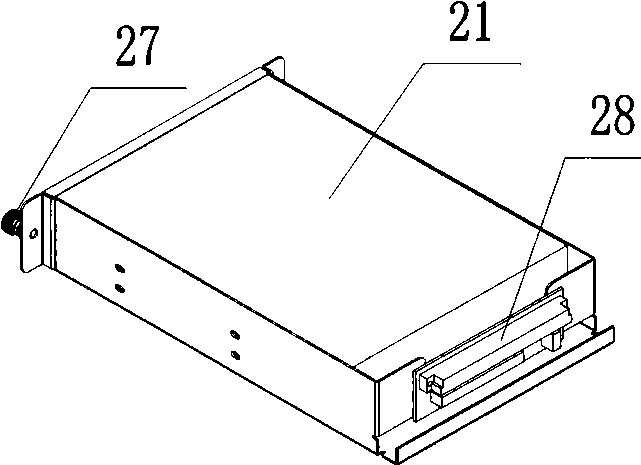

Maintainable special type computer

InactiveCN101546209AImprove seismic performanceDigital processing power distributionEarthquake resistanceModular design

The invention discloses a maintainable special type computer, which comprises a case, wherein the case is provided with a driver module, a power module and a fan module inside; the side of the case is provided with installing ports respectively corresponding to the driver module, the power module and the fan module; the installing port of the fan module is provided with a turnover door, and the fan module is fixed on the turnover door; and the driver module and the power module are drawn off or installed on the respective installing port respectively. The computer carries out modular design on main components, and when in maintenance and replacement, the modules needed to maintain and replace are drawn off from a plurality of installing ports arranged on the side of the case respectively; when the computer has failures, the components are replaced and maintained quickly so as to reduce the maintenance time of machine failures to the utmost extent and improve the efficiency; and the modules are locked on the case through a locking device to improve the earthquake resistance of the computer.

Owner:EVOC INTELLIGENT TECH +1

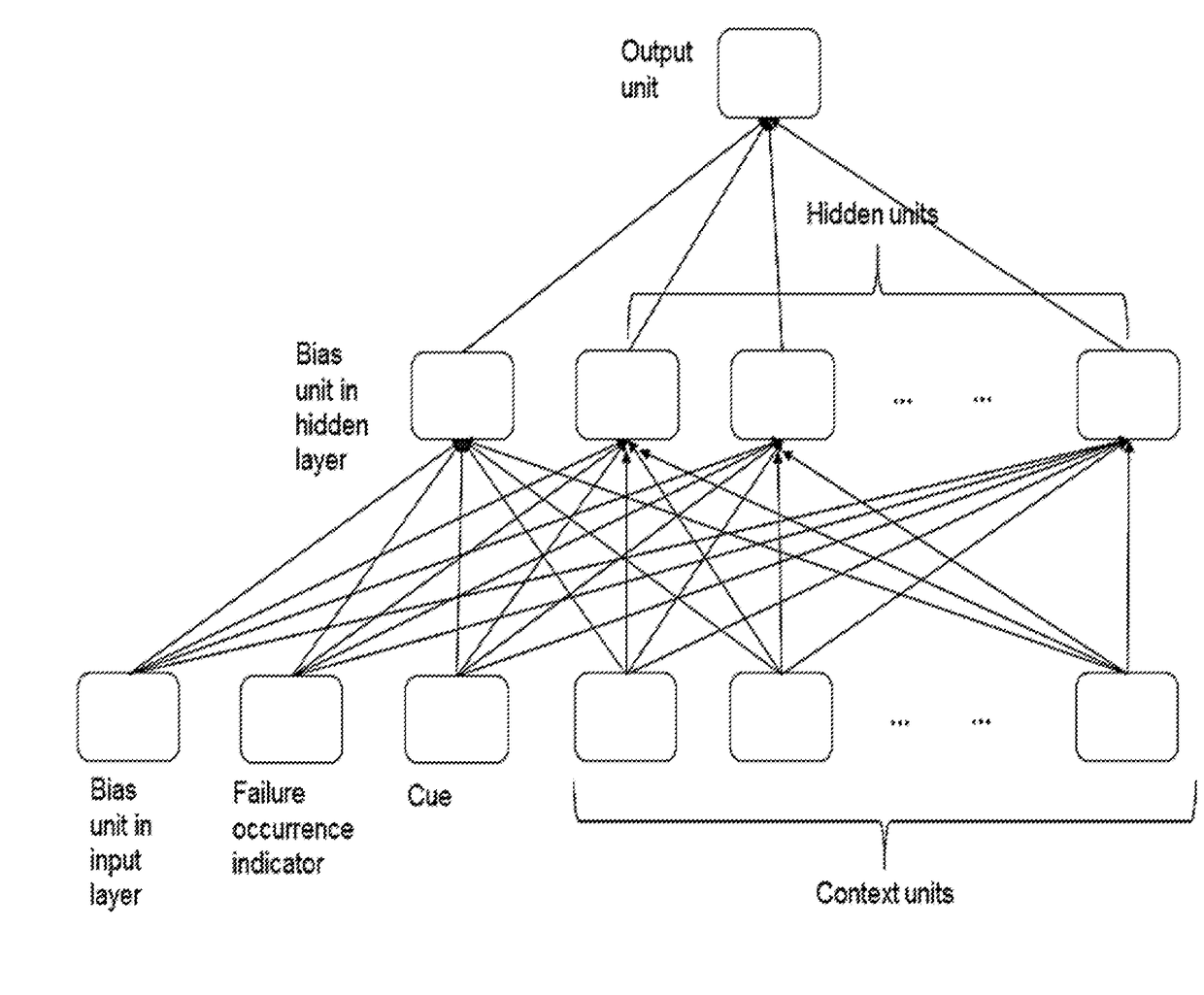

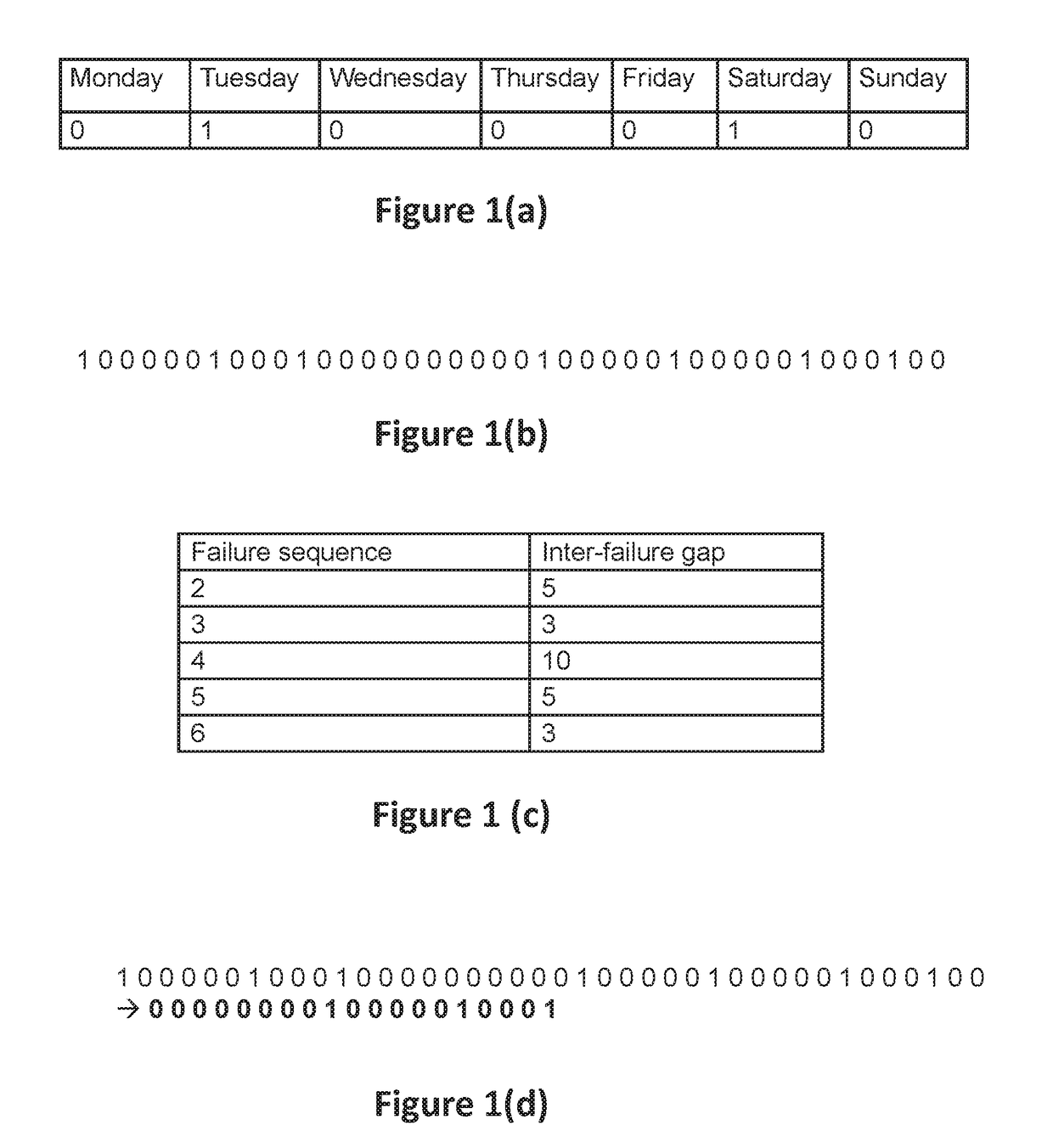

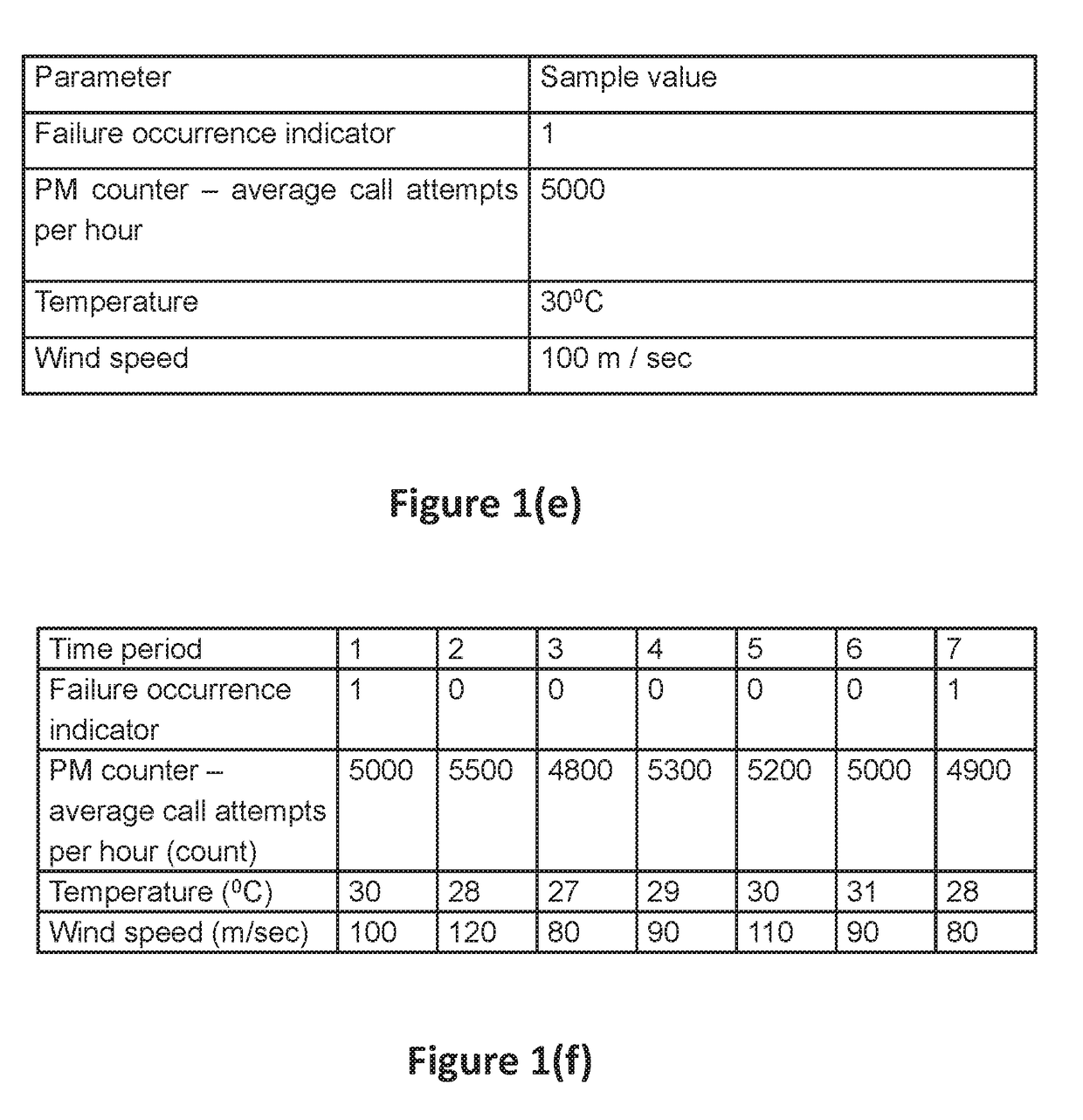

Method and system for machine failure prediction

ActiveUS20180121793A1Problem of failureLong time gapTesting/monitoring control systemsNeural architecturesAlgorithmBack propagation through time

Embodiments of the invention provide a method and system for machine failure prediction. The method comprises: identifying a plurality of basic memory depth values based on a machine failure history; ascertaining a basic weight range for each of the plurality of basic memory depth values according to a pre-stored table including a plurality of mappings each mapping between a basic memory depth value and a basic weight range, or a predetermined formula for calculating the basic weight range based on the corresponding basic memory depth value; ascertaining a composite initial weight range by calculating an average weight range of the ascertained basic weight range for each identified basic memory depth value; generating initial weights based on the composite initial weight range; and predicting a future failure using a Back Propagation Through Time (BPTT) trained Recurrent Neural Network (RNN) based on the generated initial weights.

Owner:AVANSEUS HLDG PTE LTD

Method and system for fault accommodation of machines

ActiveUS7904282B2Maximize operational conditionMinimize operational conditionGas turbine plantsEfficient propulsion technologiesMachine controlPredictive modelling

A method for multi-objective fault accommodation using predictive modeling is disclosed. The method includes using a simulated machine that simulates a faulted actual machine, and using a simulated controller that simulates an actual controller. A multi-objective optimization process is performed, based on specified control settings for the simulated controller and specified operational scenarios for the simulated machine controlled by the simulated controller, to generate a Pareto frontier-based solution space relating performance of the simulated machine to settings of the simulated controller, including adjustment to the operational scenarios to represent a fault condition of the simulated machine. Control settings of the actual controller are adjusted, represented by the simulated controller, for controlling the actual machine, represented by the simulated machine, in response to a fault condition of the actual machine, based on the Pareto frontier-based solution space, to maximize desirable operational conditions and minimize undesirable operational conditions while operating the actual machine in a region of the solution space defined by the Pareto frontier.

Owner:GENERAL ELECTRIC CO

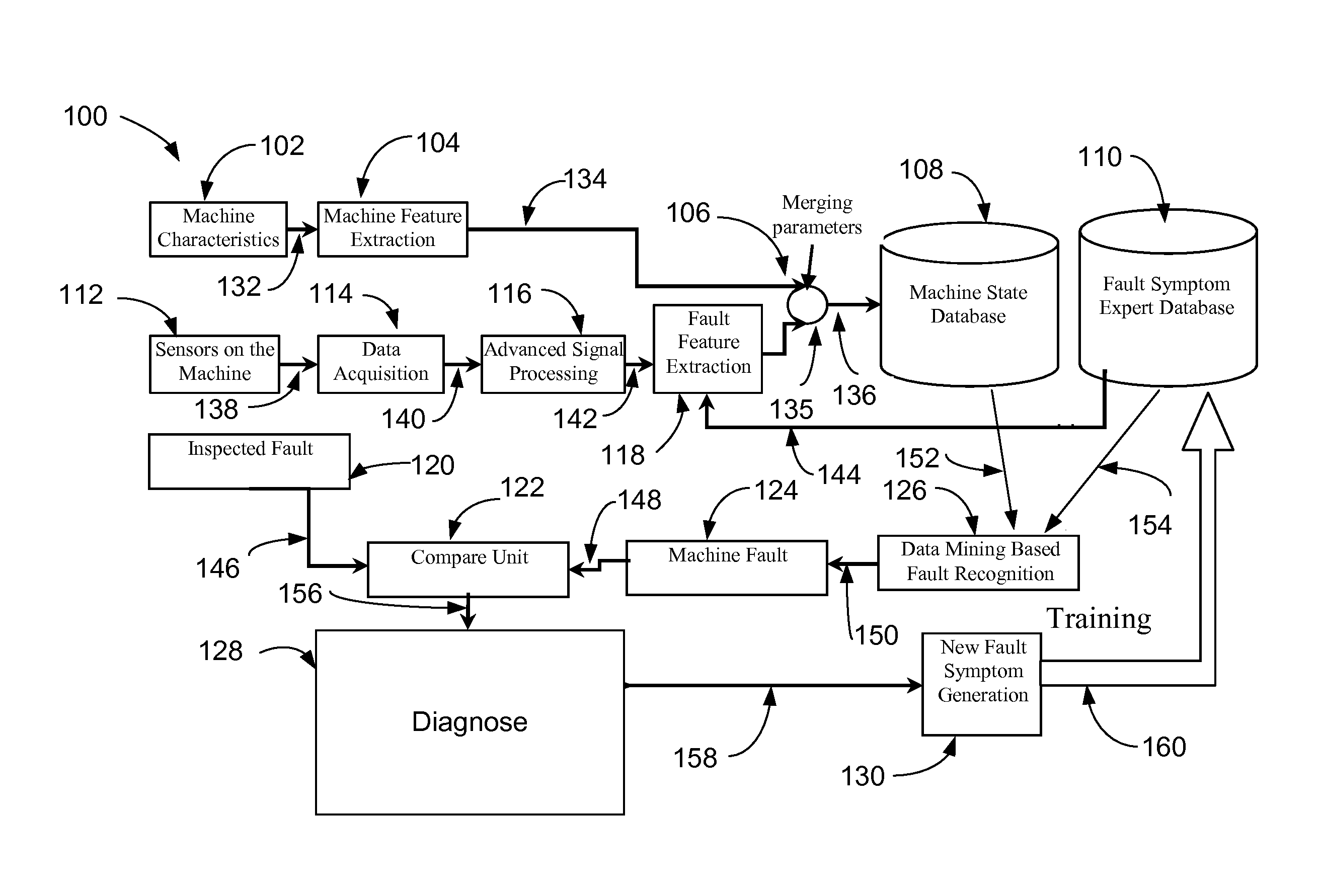

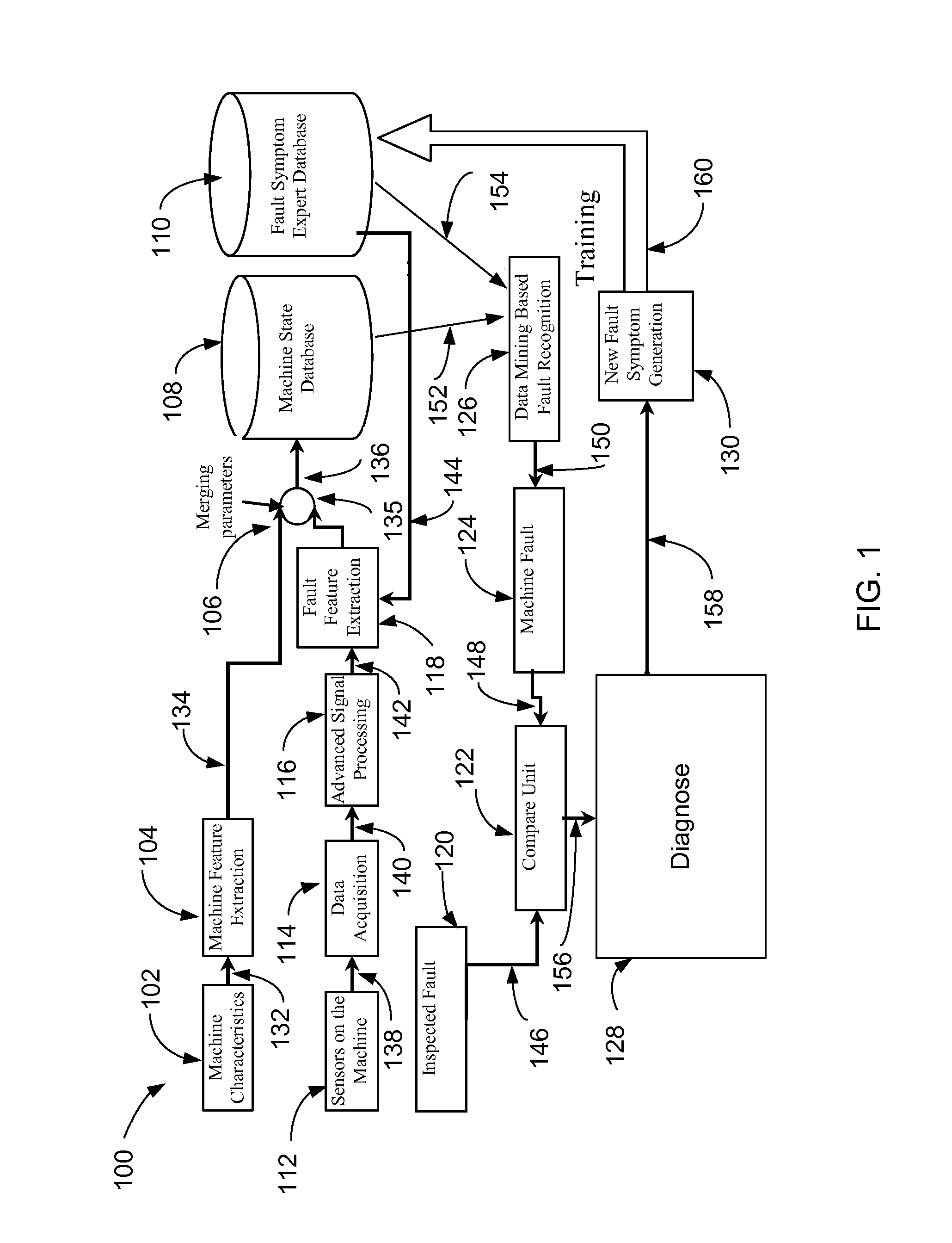

Method and System for Predictive and Conditional Fault Detection

InactiveUS20130297256A1Machine part testingTesting/monitoring control systemsComputer scienceCondition evaluation

A method and system for predictive and conditional fault detection that utilizes a machine's characteristics and sensor detected faults to predict and diagnose future faults. The fault detection method utilizes machine characteristics and fault sensors on the machines to generate extracted vectors. The two types of vectors are combined into an extracted vector. The extracted vector is stored in a machine state database and a fault symptom database. The databases utilize this information for future machine condition evaluation and maintenance suggestions. The information in the databases is mined to provide optimal fault detection suggestions by comparing vectors from the databases. Additional fault inspections, machine fault information, and comparisons between machine vectors and fault vectors further refine the fault vectors for optimal diagnoses. The resultant fault detection generates additional useful fault information, which is added to the database to further refine the fault detection method and system.

Owner:YANG JUN

System and method for vibration analysis and phase analysis of vibration waveforms using dynamic statistical averaging of tachometer data to accurately calculate rotational speed

ActiveCN102087138AVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFrequency spectrumMotor drive

The present invention discloses a system and method for vibration analysis and phase analysis of vibration waveforms using dynamic statistical averaging of tachometer data to accurately calculate rotational speed. Vibration analysis is performed on a machine having a variable frequency drive by using a tachometer to monitor rotational speed of the drive shaft and a logic device to calculate speed parameters associated with the drive shaft using the tachometer data. The speed parameters include a maximum speed, a minimum speed, and an average speed of the drive shaft. By correlating the vibration spectra of the motor drive with the speed parameters, machine faults can be identified based upon the energy distribution in the spectra. Further, vibration waveforms from two or more locations on the machine can be sequentially acquired through synchronous triggering by using a pulse edge of a stable tachometer signal. The waveforms can be compared to determine a phase difference to help in identifying any machine faults that may be present.

Owner:JOHN FLUKE MFG CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com