Paper-aluminum-plastic composite aseptic packaging material

A packaging material, paper-aluminum-plastic technology, applied in the field of packaging materials, can solve problems such as cracking of printed patterns or packaging materials, raising the cost of paper layers, and reducing fiber toughness, so as to reduce the amount of bleaching agent, prevent cracking, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

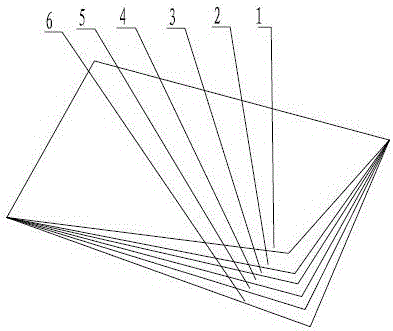

[0025] Such as figure 1 As shown, this embodiment includes an aluminum foil 4, a first adhesive layer 3 is provided on one side of the aluminum foil 4, and a second adhesive layer 5 and a polyethylene heat-sealing layer 6 are sequentially provided on the other side of the aluminum foil 4. The first adhesive layer 3 is made of polyethylene as the main material, and is coated on the surface of the aluminum foil 4 close to the paper layer 2 to provide the adhesion between the aluminum foil 4 and the paper layer 2, and according to the actual mold The difference in the number of heads, the first adhesive layer 3 can be one or more layers of coated polyethylene; Resin, coated on the surface of the aluminum foil 4 away from the paper layer 2, is used to provide the bonding force between the aluminum foil 4 and the polyethylene heat-sealing layer 6; the polyethylene heat-sealing layer 6 is mainly made of polyethylene , coated on the second adhesive layer 5 for heat sealing, the poly...

Embodiment 2

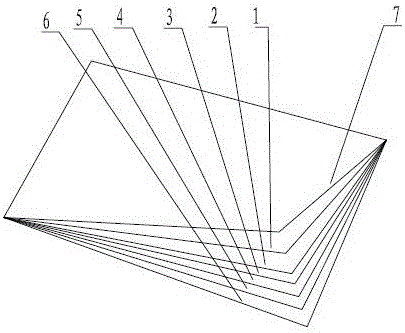

[0028] Such as figure 2 As shown, this embodiment includes an aluminum foil 4, a first adhesive layer 3 is provided on one side of the aluminum foil 4, and a second adhesive layer 5 and a polyethylene heat-sealing layer 6 are sequentially provided on the other side of the aluminum foil 4. The first adhesive layer 3 is made of polyethylene as the main material, and is coated on the surface of the aluminum foil 4 close to the paper layer 2 to provide the adhesion between the aluminum foil 4 and the paper layer 2, and according to the actual mold The difference in the number of heads, the first adhesive layer 3 can be one or more layers of coated polyethylene; Resin, coated on the surface of the aluminum foil 4 away from the paper layer 2, is used to provide the bonding force between the aluminum foil 4 and the polyethylene heat-sealing layer 6; the polyethylene heat-sealing layer 6 is mainly made of polyethylene , coated on the second adhesive layer 5 for heat sealing, the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com