Weather-resisting type single-coating powder paint with metal pattern effect

A powder coating and weather-resistant technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems that the pattern is not easy to emerge, the three-dimensional effect is not strong, etc., to achieve clear pattern effect, strong metal three-dimensional effect, and good coverage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

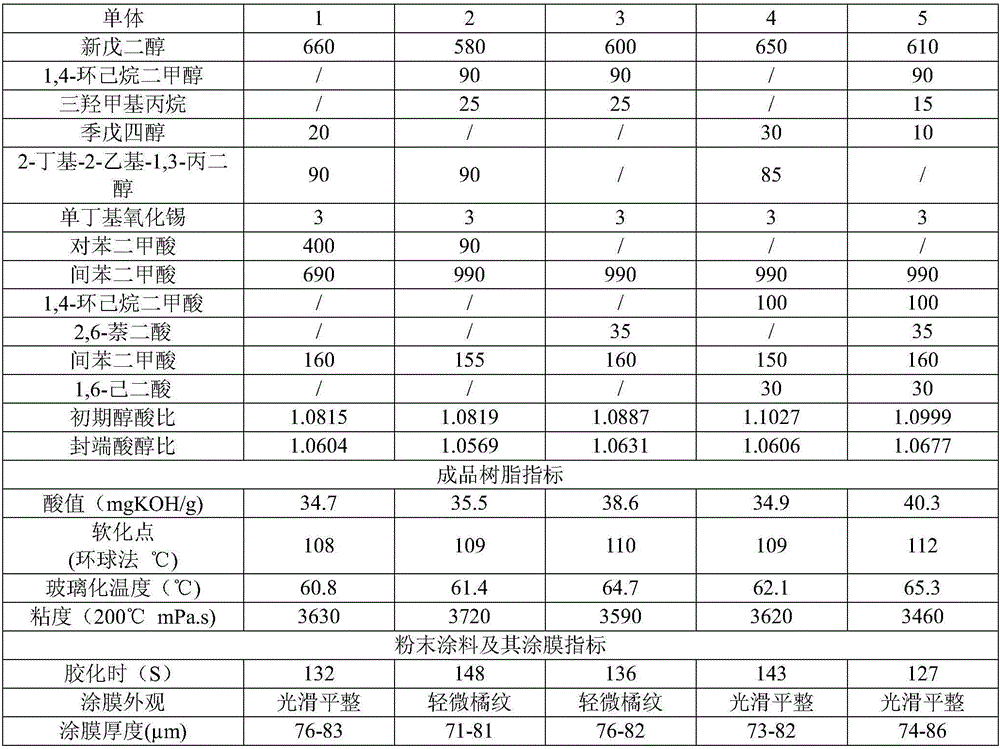

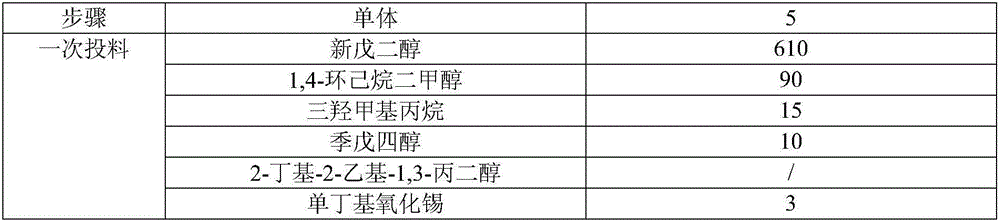

Embodiment 1~ Embodiment 5

[0044] The invention relates to a weather-resistant metal pattern effect single-coat powder coating, the formula of which comprises 90-99.5% of base powder A and 0.5-10% of metal powder B.

[0045] The metal powder B is a composite pearlescent pigment.

[0046] The constituents and percentages by weight of the base powder A are:

[0047] Weather-resistant polyester resin 55-80%; curing agent 4.0-6.2%; modified barium sulfate 0-40%; plasticizer 0.3-1.5%;

[0048] 0.02-2% curing accelerator; 1-5% auxiliary agent; 0-25% pigment; 0.05-0.5% texture agent.

[0049] The above curing agent is TGIC curing agent.

[0050] The above additives are self-made modified embossing agent and CAB cellulose acetate thixotropic additive. The invention adopts self-made modified embossing agent, which is a kind of surfactant, which is made of silicone oil-modified acrylate compound. The auxiliary agent has a very narrow particle size distribution after strict control, and has various particle siz...

Embodiment 1

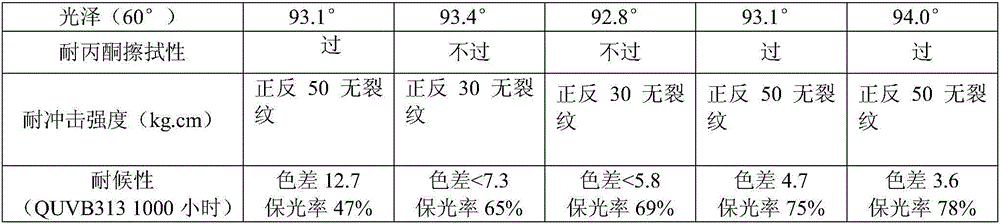

[0059] Example 1 has an exposure rate of 47% after 1000 hours of artificial accelerated aging; Example 2 has an exposure rate of 65%; Example 3 has an exposure rate of 69%. The main change in the formula of polyester resin is to increase the amount of terephthalic acid, showing The weather resistance of isophthalic acid is better than terephthalic acid, so need to adopt isophthalic acid as main acid monomer for the polyester resin of super weather resistance; Embodiment 1 impact performance is 50KG / CM without crack; Embodiment 2 The impact performance is 30KG / CM without cracks; the impact performance of Example 3 is 30KG / CM without cracks, the dosage of isophthalic acid in the formula increases, and the impact performance of the coating film decreases.

Embodiment 4

[0060] The glass transition temperature (TG) of the polyester resin prepared in Example 4 was 62.1°C; the glass transition temperature (TG) of the polyester resin prepared in Example 5 was 65.3°C, indicating that after the naphthalene dioic acid is inserted into the main chain of the polyester resin, Form bigger steric hindrance, can obviously promote the glass transition temperature of polyester resin, improve the storage stability of the powder coating of preparation; The acid value of the polyester resin prepared in embodiment 4 is 34.9mgKOH / g; Polyester resin prepared in embodiment 5 The acid value of the ester resin is 40.3mgKOH / g; the coating film of Example 5 has a high crosslinking density, and the surface of the coating film is dense, and moisture and organic solvents are difficult to enter the inside of the coating film, causing swelling or hydrolysis of the coating film. Therefore, the high crosslinking density The coating film has good weather resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com