Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

363results about How to "Suppress wrinkles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

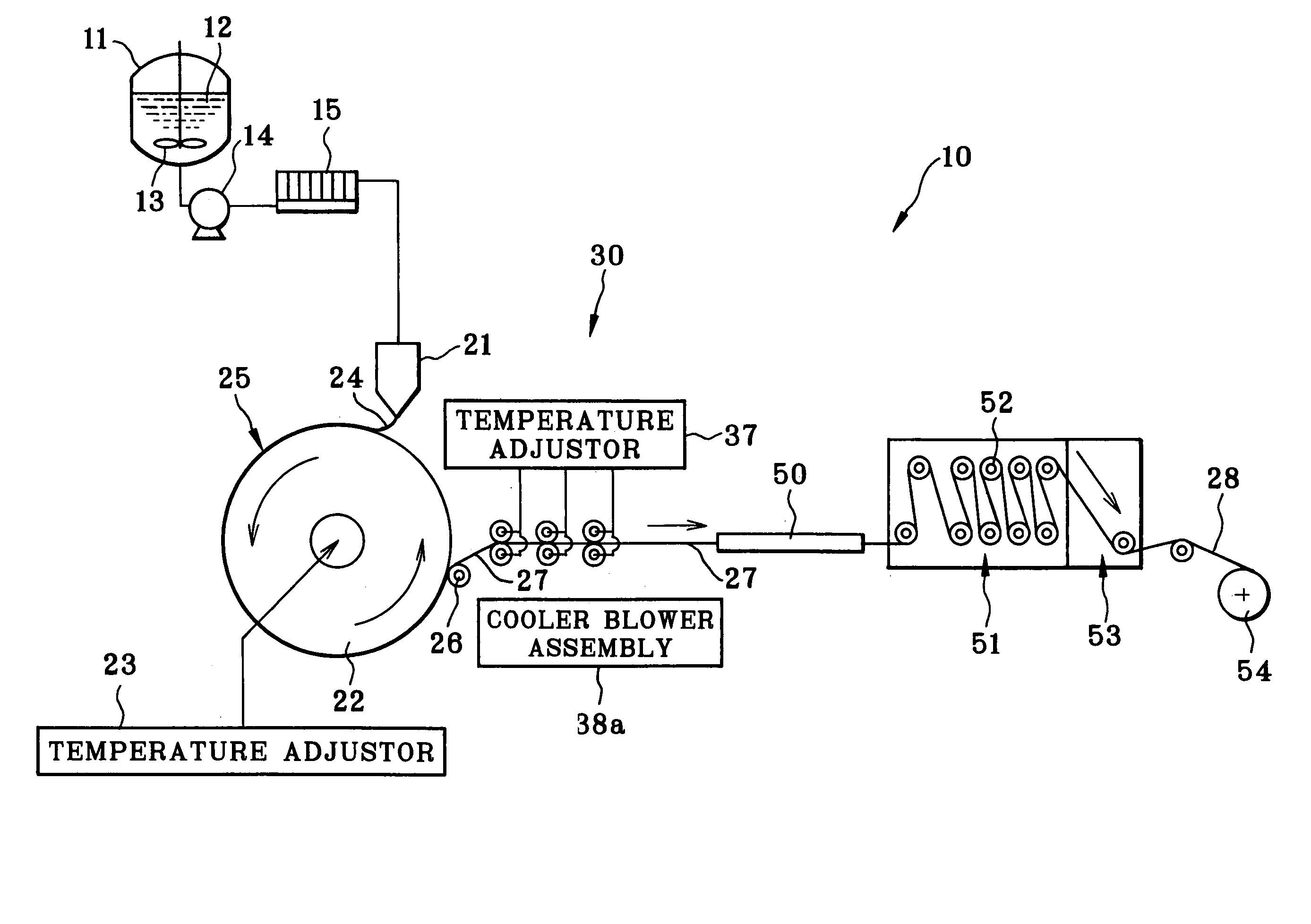

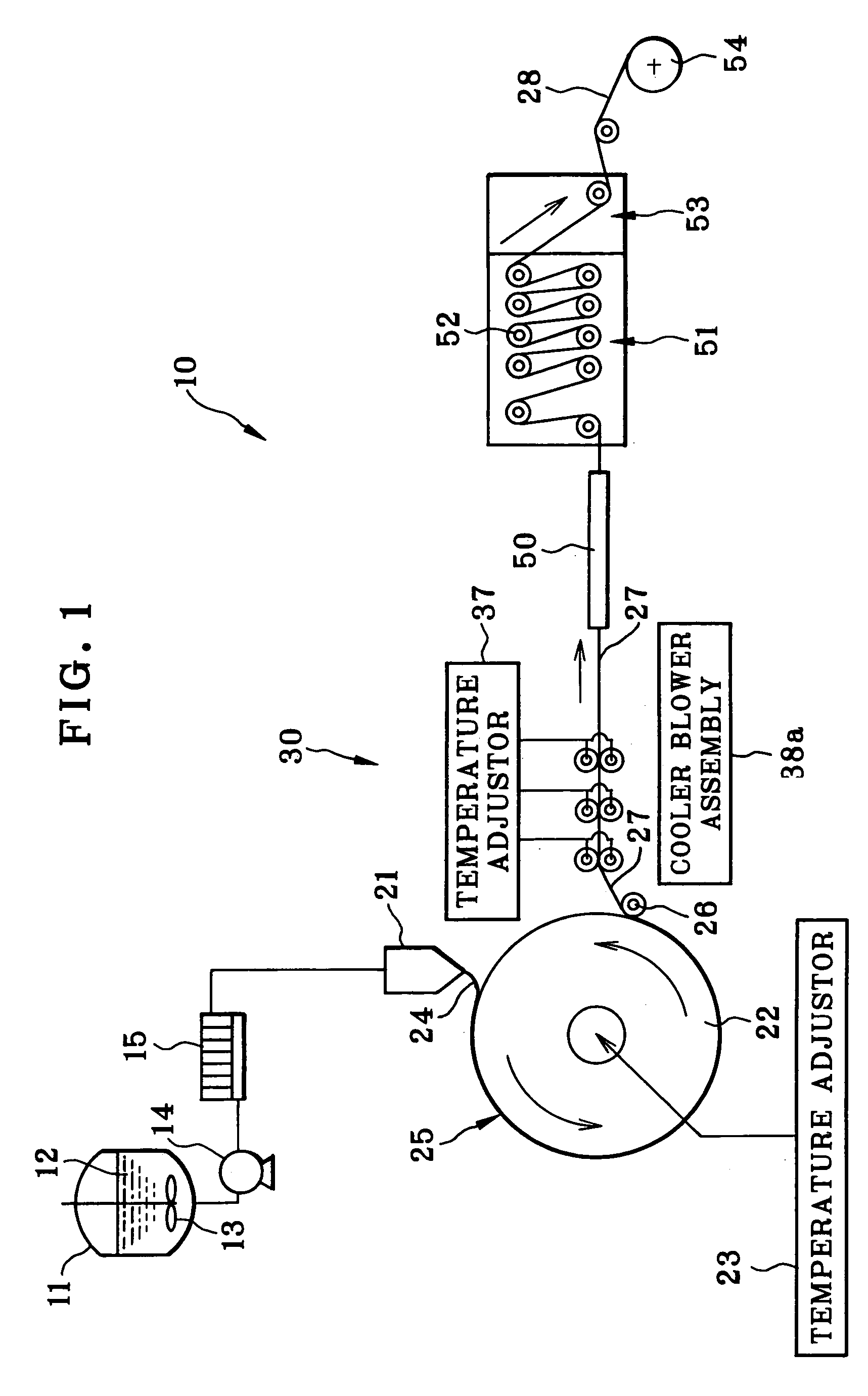

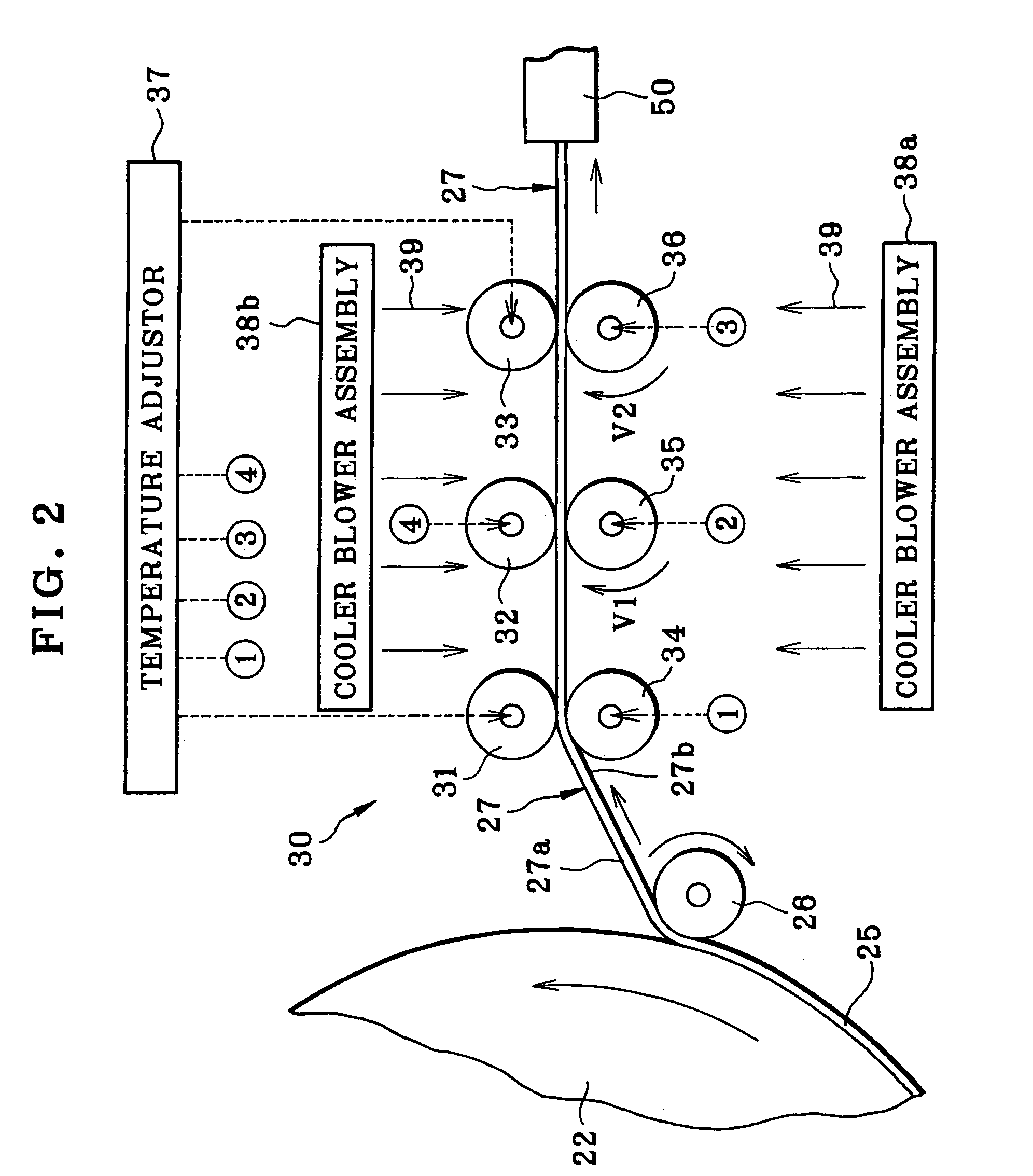

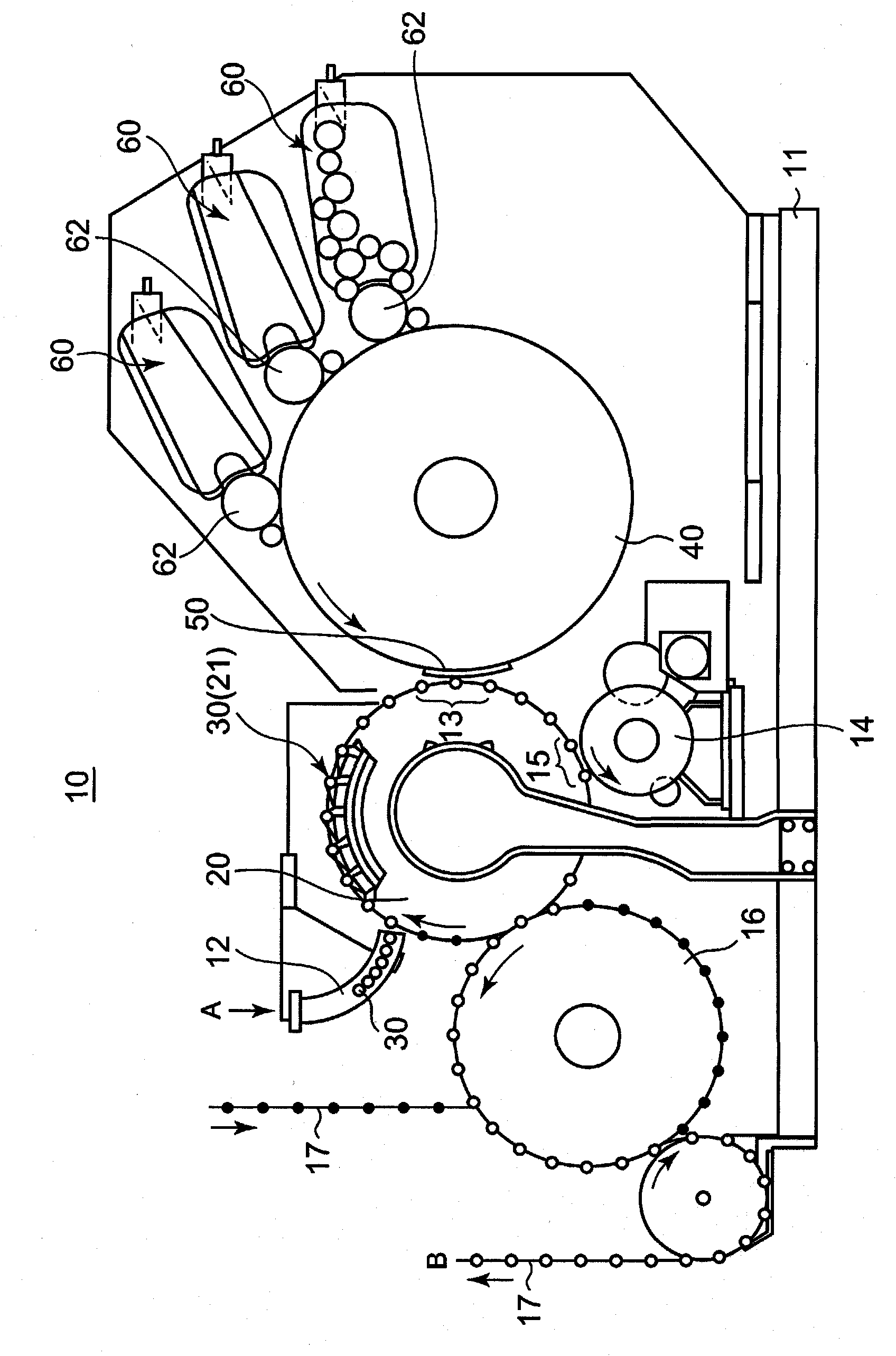

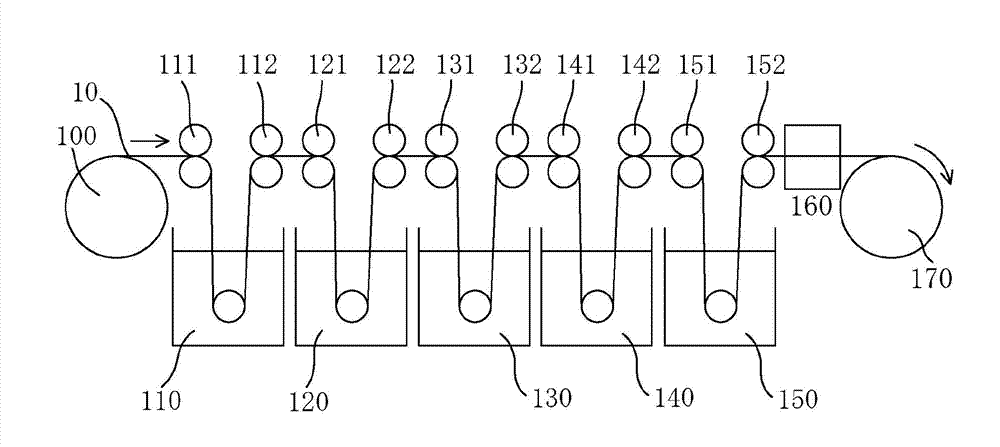

Solution casting process for producing polymer film

InactiveUS7172713B2Suppress wrinklesQuality improvementMovable spraying apparatusLaminationMetallurgyCast films

A solution casting process for producing cellulose triacetate (TAC) film is provided. Bead of dope, which includes cellulose triacetate and solvent, is cast on to a rotating supporting drum, to form self-supporting cast film. The self-supporting cast film is stripped from the supporting drum. The self-supporting cast film is dried while the self-supporting cast film being stripped is fed by feed rollers, to form the cellulose triacetate film. A surface temperature of the feed rollers is set equal to or lower than 0° C. The self-supporting cast film upon being stripped has modulus of longitudinal elasticity equal to or more than 450,000 Pa.

Owner:FUJIFILM HLDG CORP +1

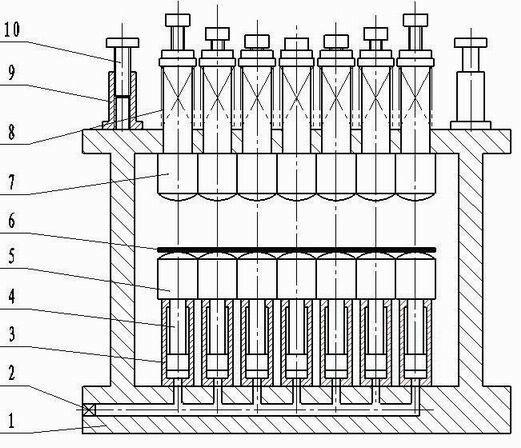

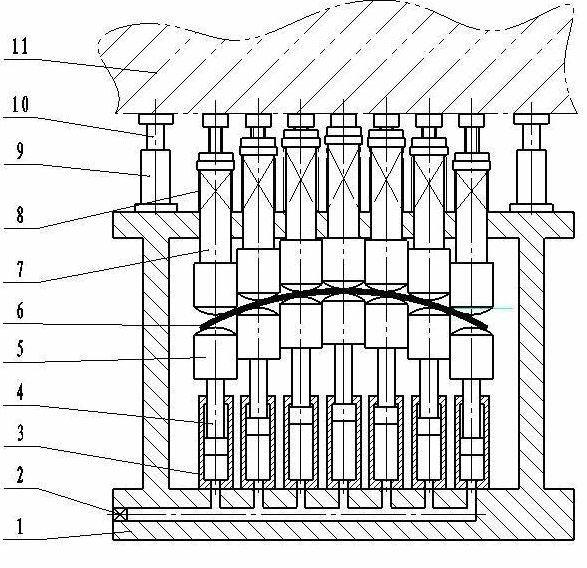

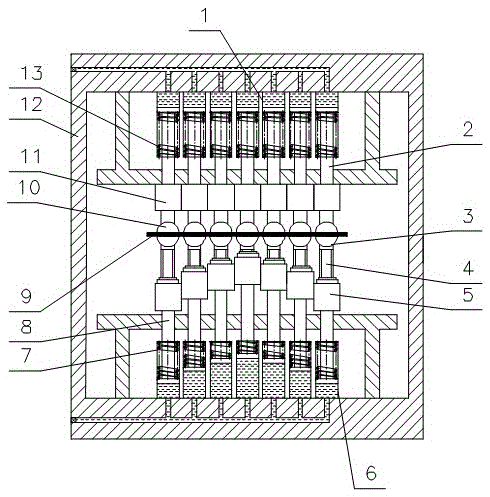

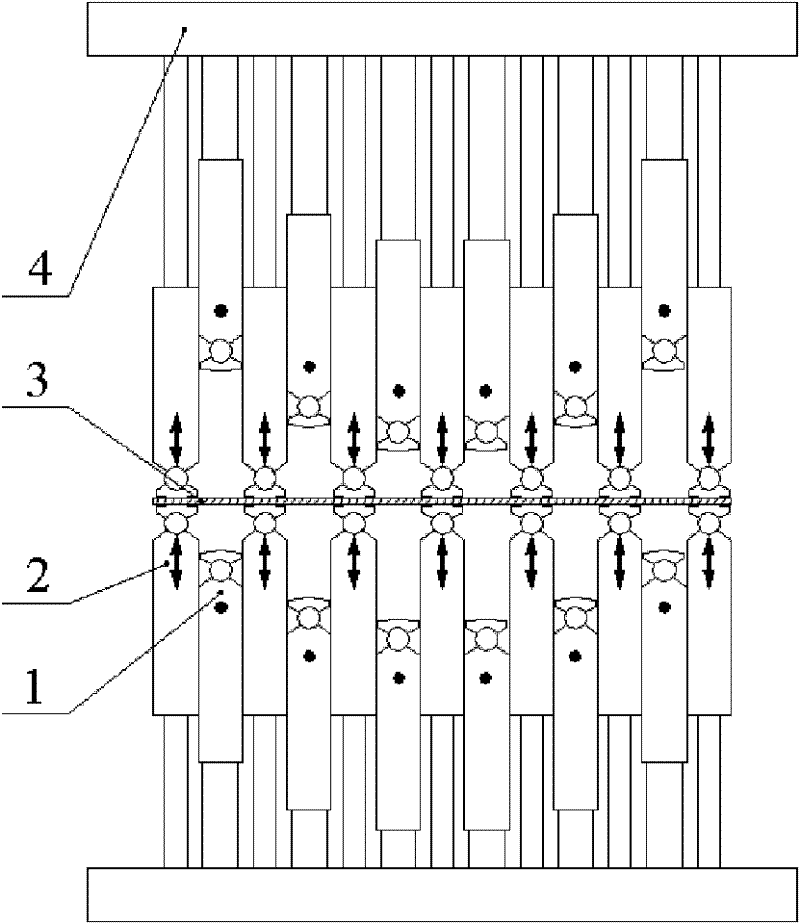

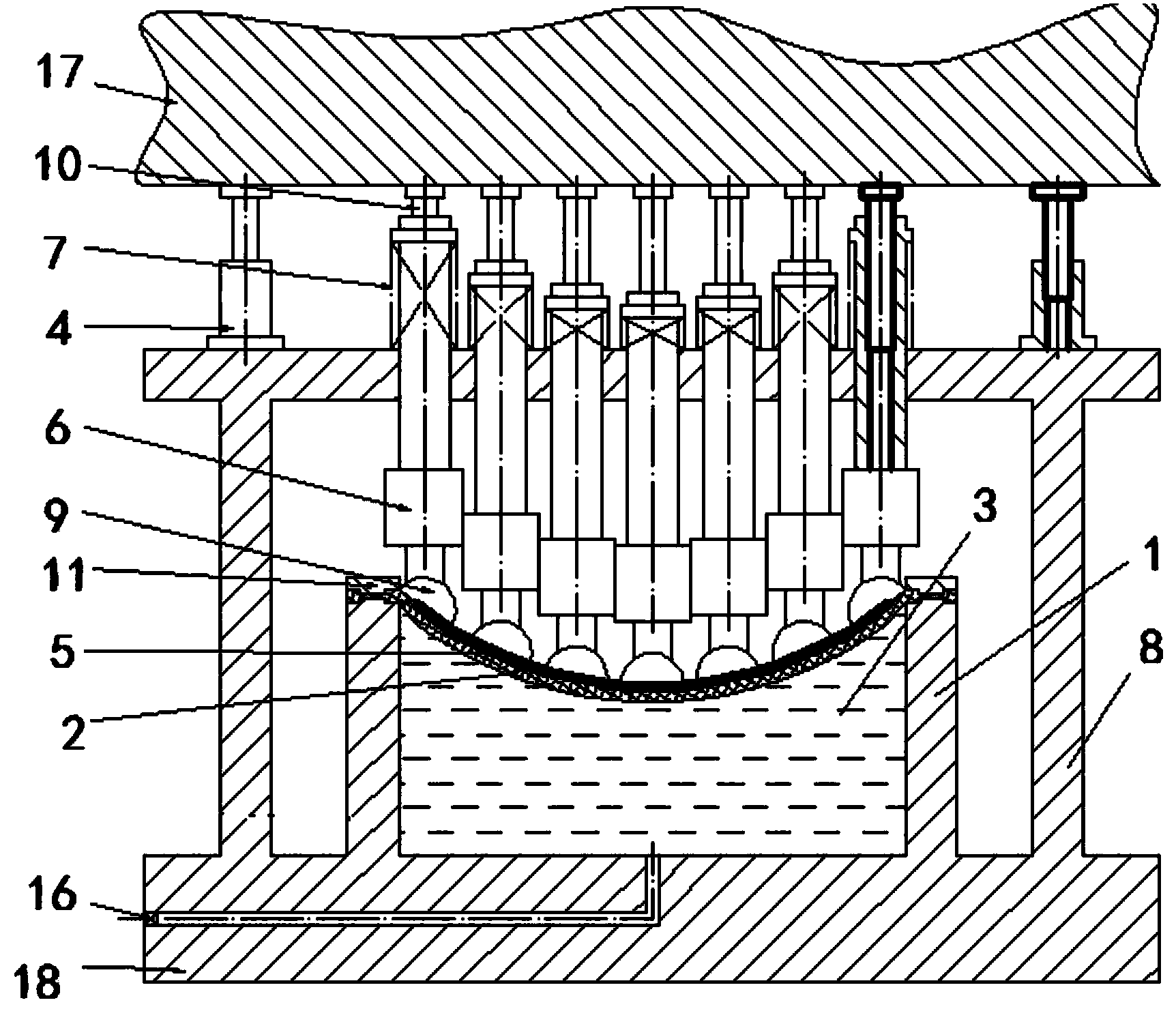

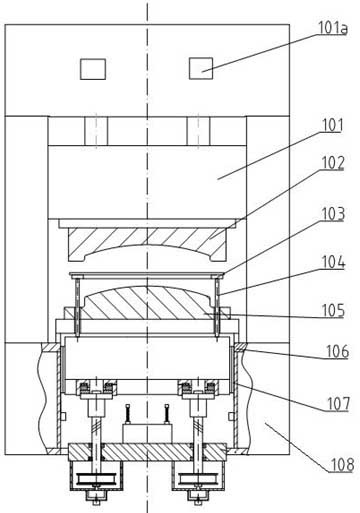

Multi-point forming device for plate

The invention relates to a multi-point forming device for a plate. The device comprises a die carrier, a plurality of upper pressure head pressurizing units and a plurality of lower pressure head supporting units, wherein the plurality of upper pressure head pressurizing units are arranged on an upper flat plate of the die carrier; the plurality of lower pressure head supporting units are arranged on a lower flat plate of the die carrier; each upper pressure head pressurizing unit consists of an upper pressure head, a spring and a travel adjusting component; an upper pressure head is arrangedin a positioning hole on the upper flat plate of the die carrier, and can move up and down along the axis of the hole; the spring is arranged between the upper pressure head and the upper flat plate of the die carrier; each lower pressure head supporting unit consists of a lower pressure head, a plunger and a hydraulic cylinder; the hydraulic cylinder is fixed on the lower flat plate of the die carrier; and the plunger is connected with the lower pressure head. A forming curved surface can be formed optionally and is easy and convenient to adjust. Any element is not required to be adjusted inreal time in a forming process, and stable and uniform normal pressure always acts on the plate, so that effective normal constraint is formed and the plate can be effectively prevented from wrinkling. The device has a reasonable structure, is easy to operate, works reliably, and is an ideal multi-point forming device for the plate.

Owner:HARBIN INST OF TECH AT WEIHAI

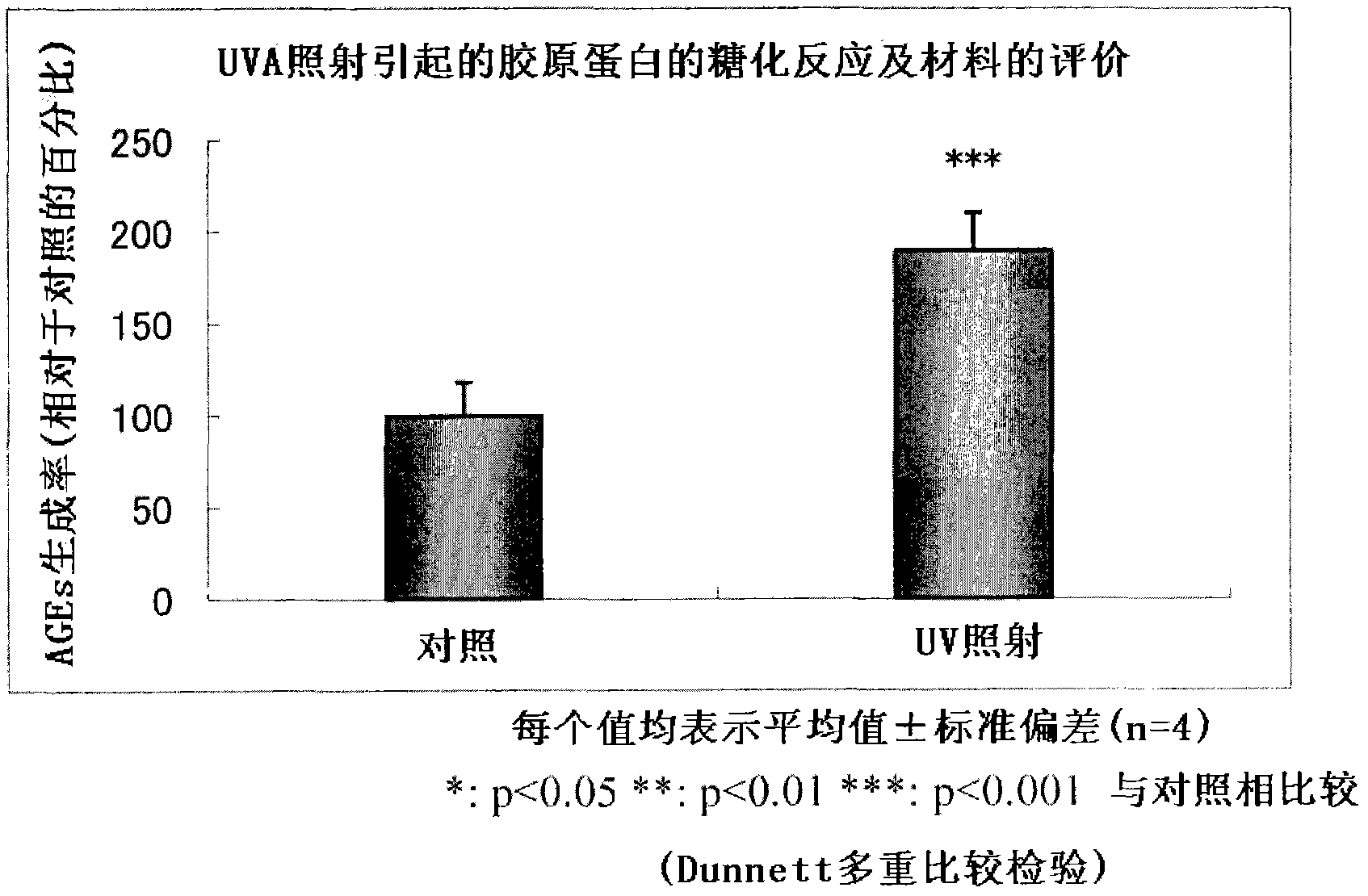

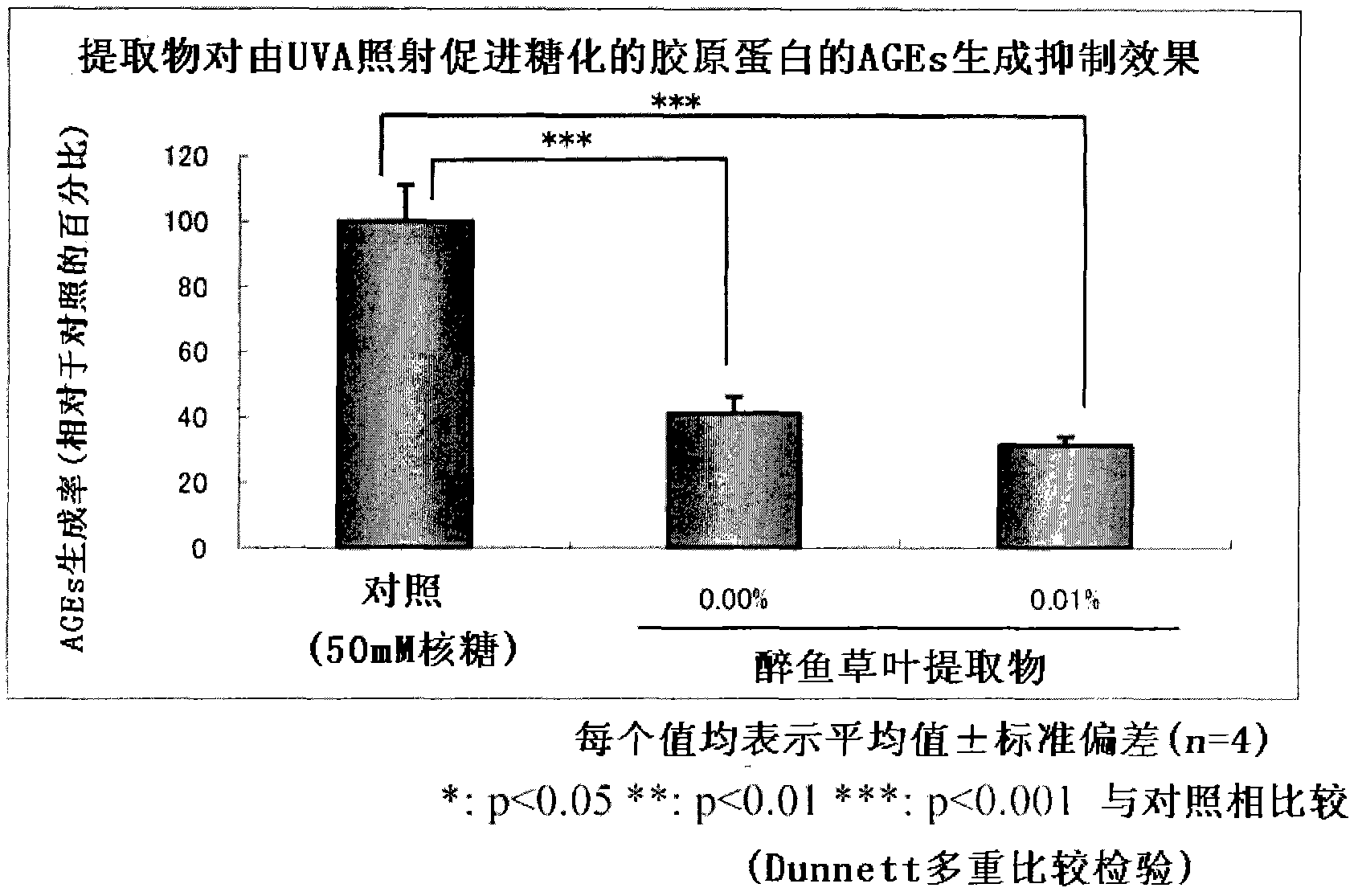

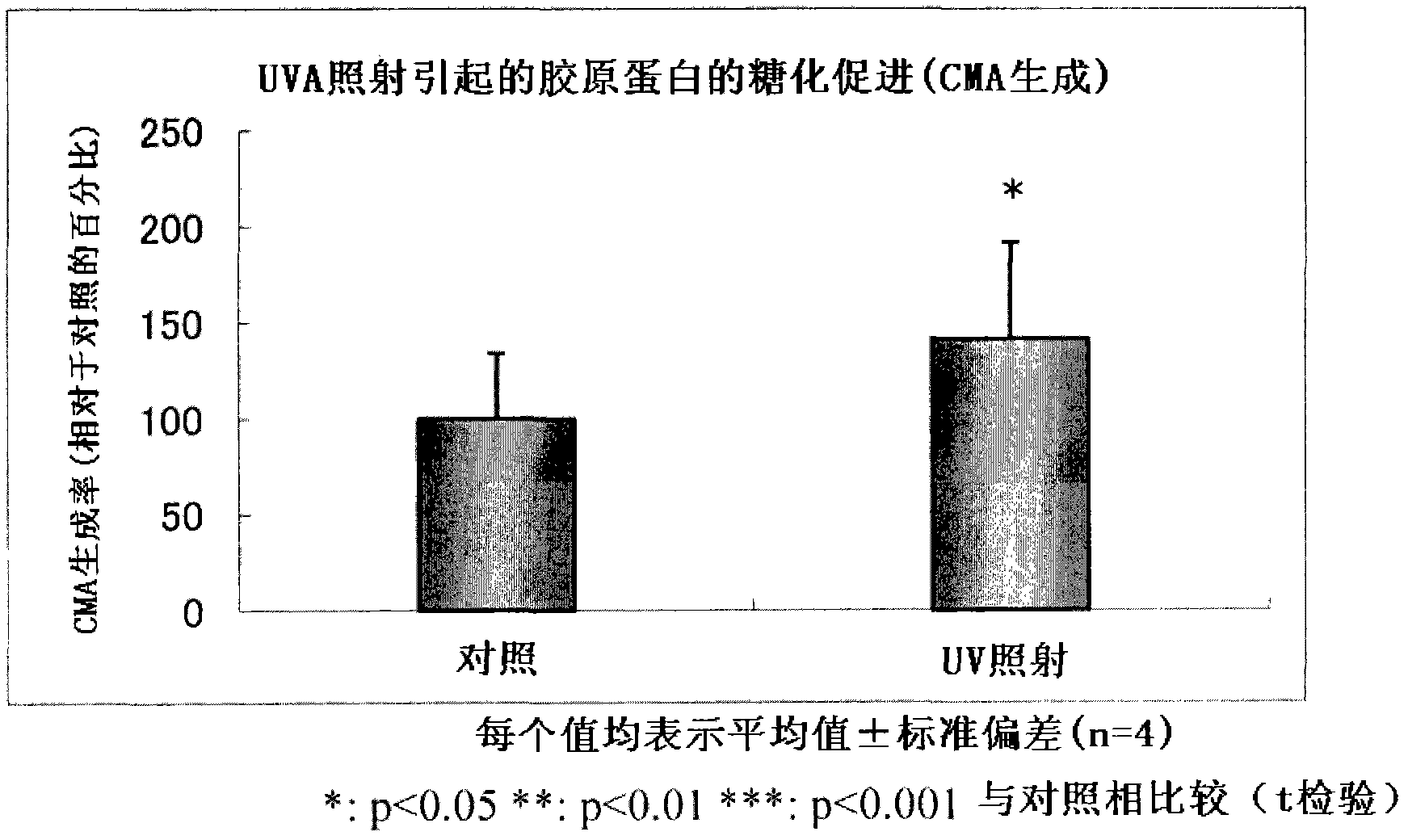

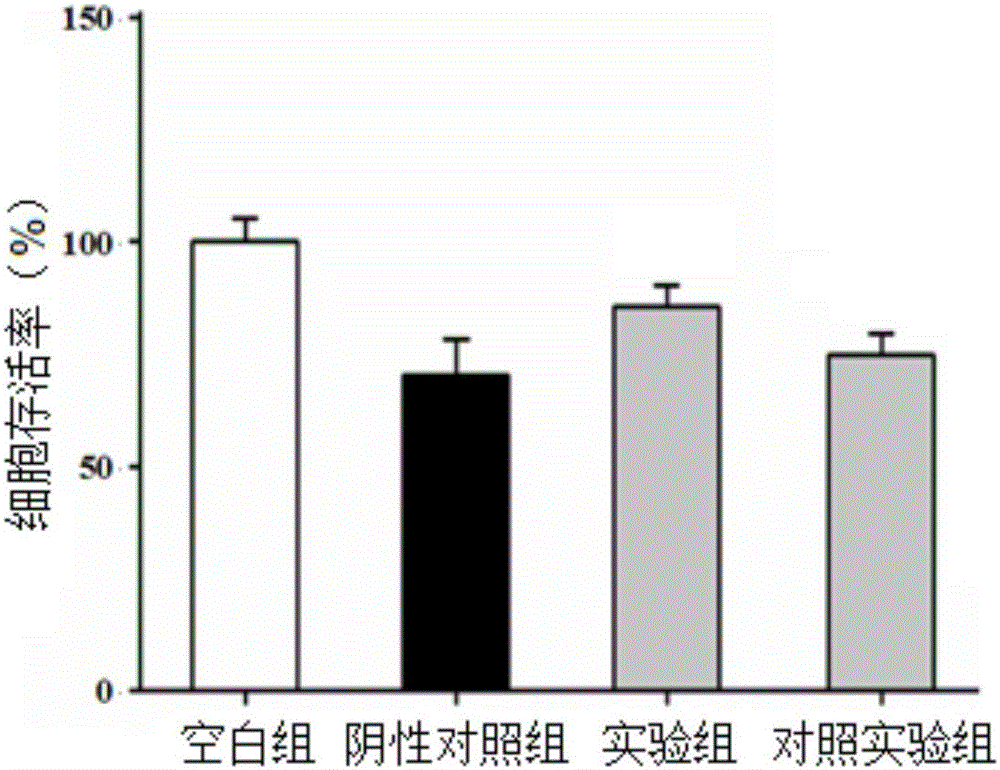

Anti-saccharification agent

InactiveCN102058504AInhibit damagePrevent skin agingCosmetic preparationsToilet preparationsWrinkleSkin wrinkle

The invention provides the application of extracts of buddleja blades, and the extracts of buddleja blades are used to produce anti-saccharification agents, anti-aging agents, skin collagen damage inhibitors, or agents for inhibiting, preventing or improving the decrease in skin firmness or elasticity or skin wrinkles.

Owner:ROHTO PHARM CO LTD

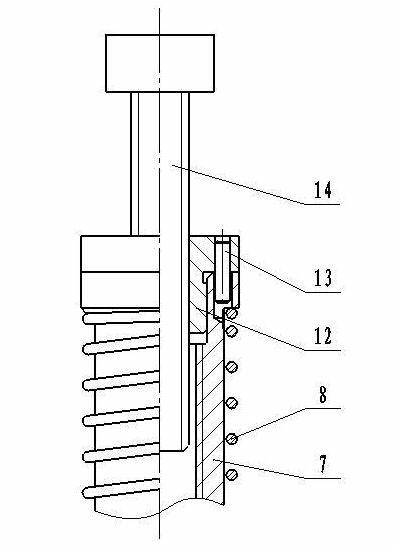

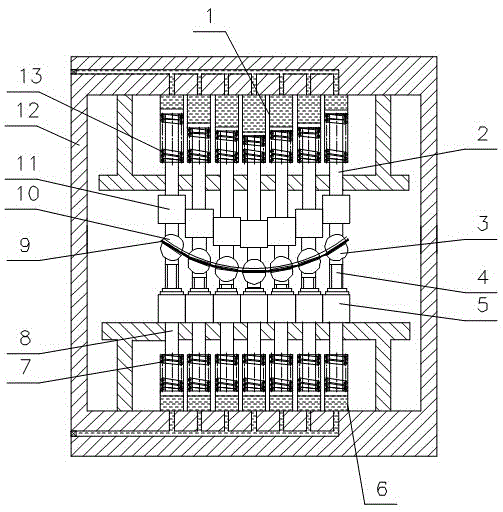

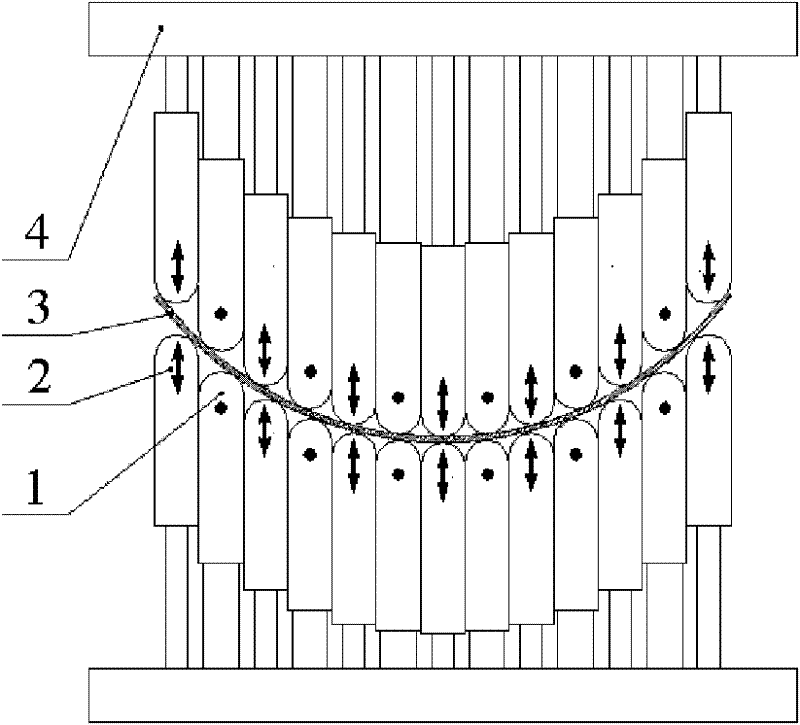

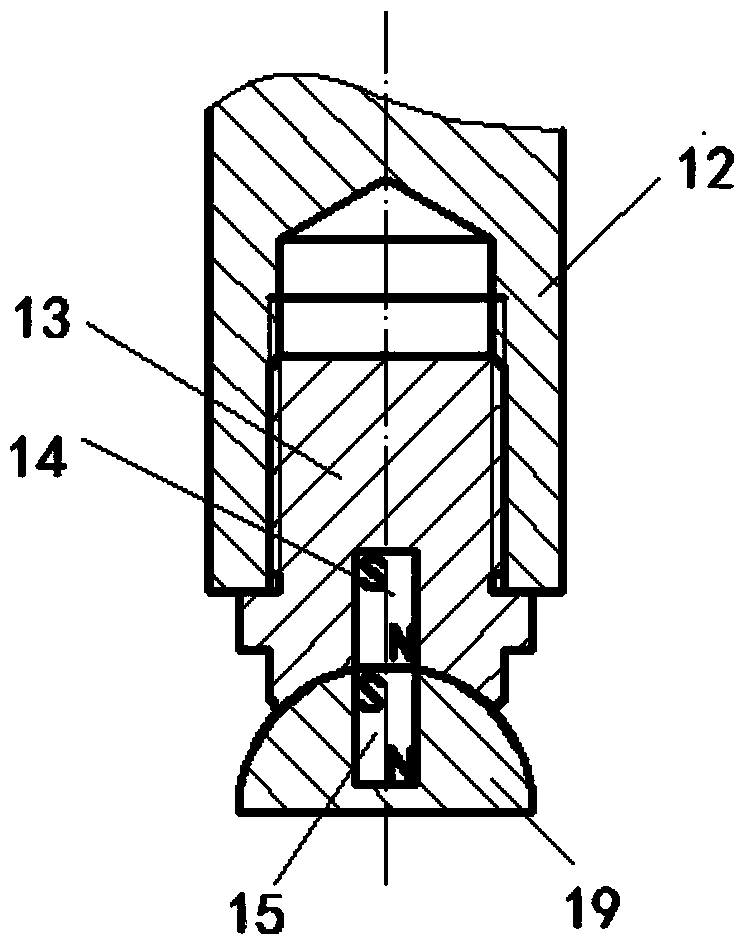

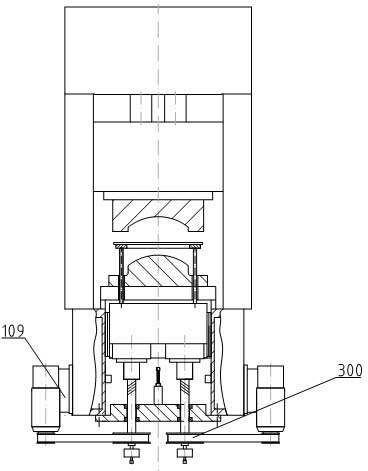

Plate multipoint progressive forming device

ActiveCN105478539AOptimal forming pathRaise the forming limitShaping toolsPress ramPistonEngineering

The invention relates to a plate multipoint progressive forming device which comprises a mould stand, a plurality of driving pressurization units and a plurality of shape adjusting and supporting units, wherein the driving pressurization units are mounted on a top plate of the mould stand; each driving pressurization unit consists of an upper pressing head, a driving basic body, a spring, a piston and a driving hydraulic cylinder; the upper pressing heads are movably mounted at the bottom ends of the driving basic bodies; the driving hydraulic cylinders are fixed to the top plate of the mould stand; the shape adjusting and supporting units are mounted on a bottom plate of the mould stand; each shape adjusting and supporting unit consists of a lower pressing head, a supporting basic body, a spring, an adjusting bolt and a supporting hydraulic cylinder; the lower pressing heads are movably mounted at the top ends of the adjusting bolts; the supporting hydraulic cylinders are fixed to the bottom plate of the mould stand; and under the action of the driving hydraulic cylinders and the supporting hydraulic cylinders, multipoint progressive forming of a plate between the upper pressing heads and the lower pressing heads is realized. The plate multipoint progressive forming device is reasonable in structure; by controlling the pressure difference between the two sides of the plate, the optimal forming effect is realized; the forming precision of the plate is high; and the surface quality of the plate is good.

Owner:HARBIN INST OF TECH AT WEIHAI

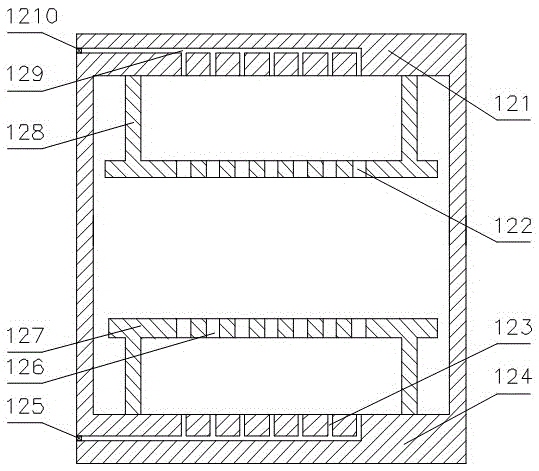

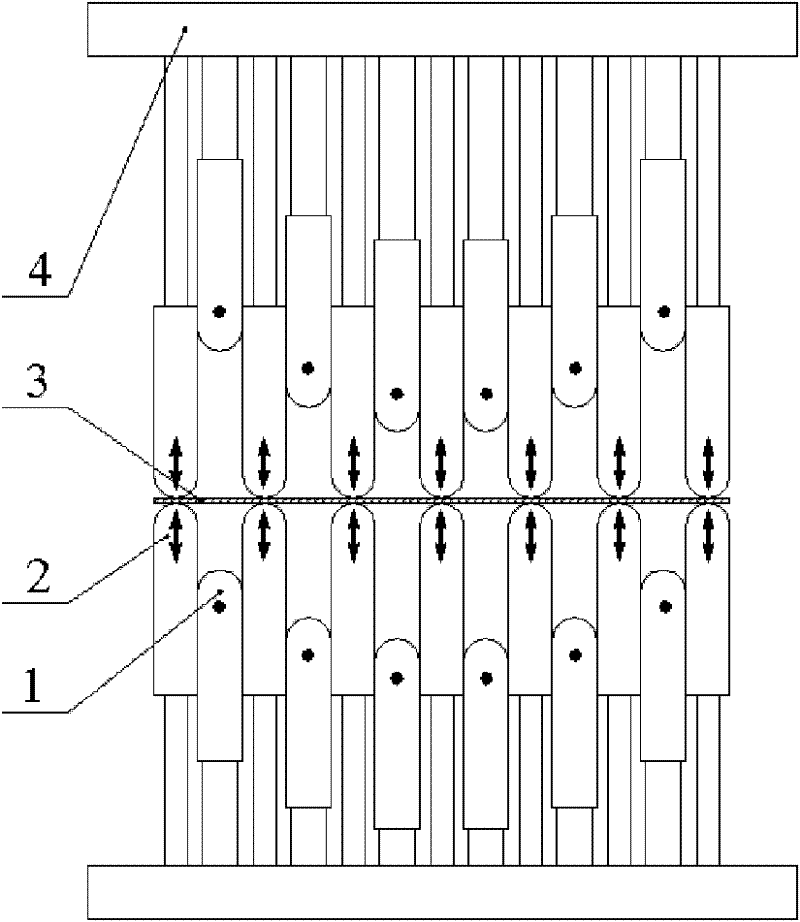

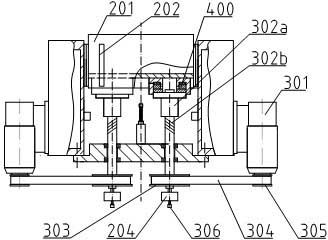

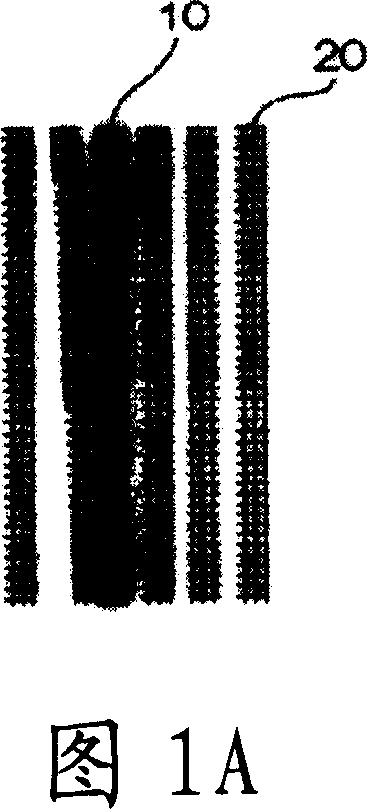

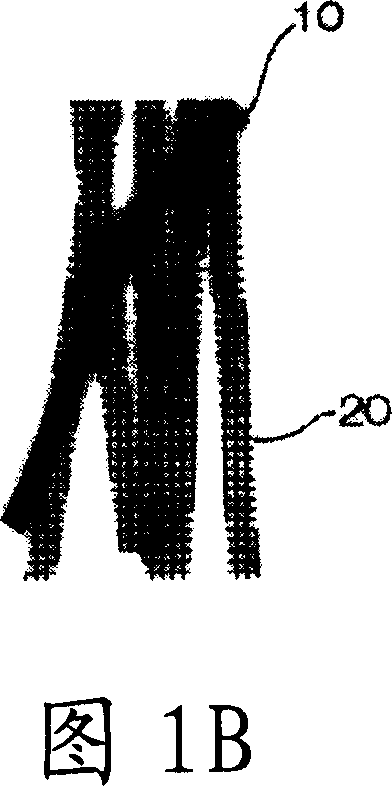

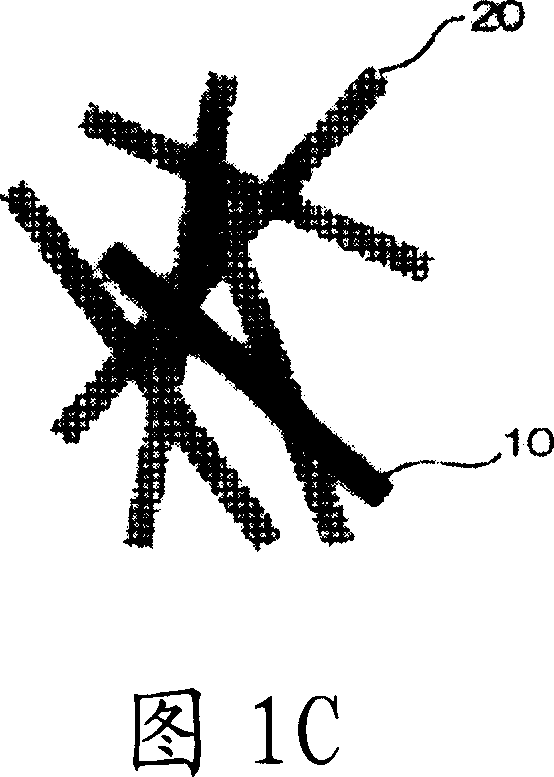

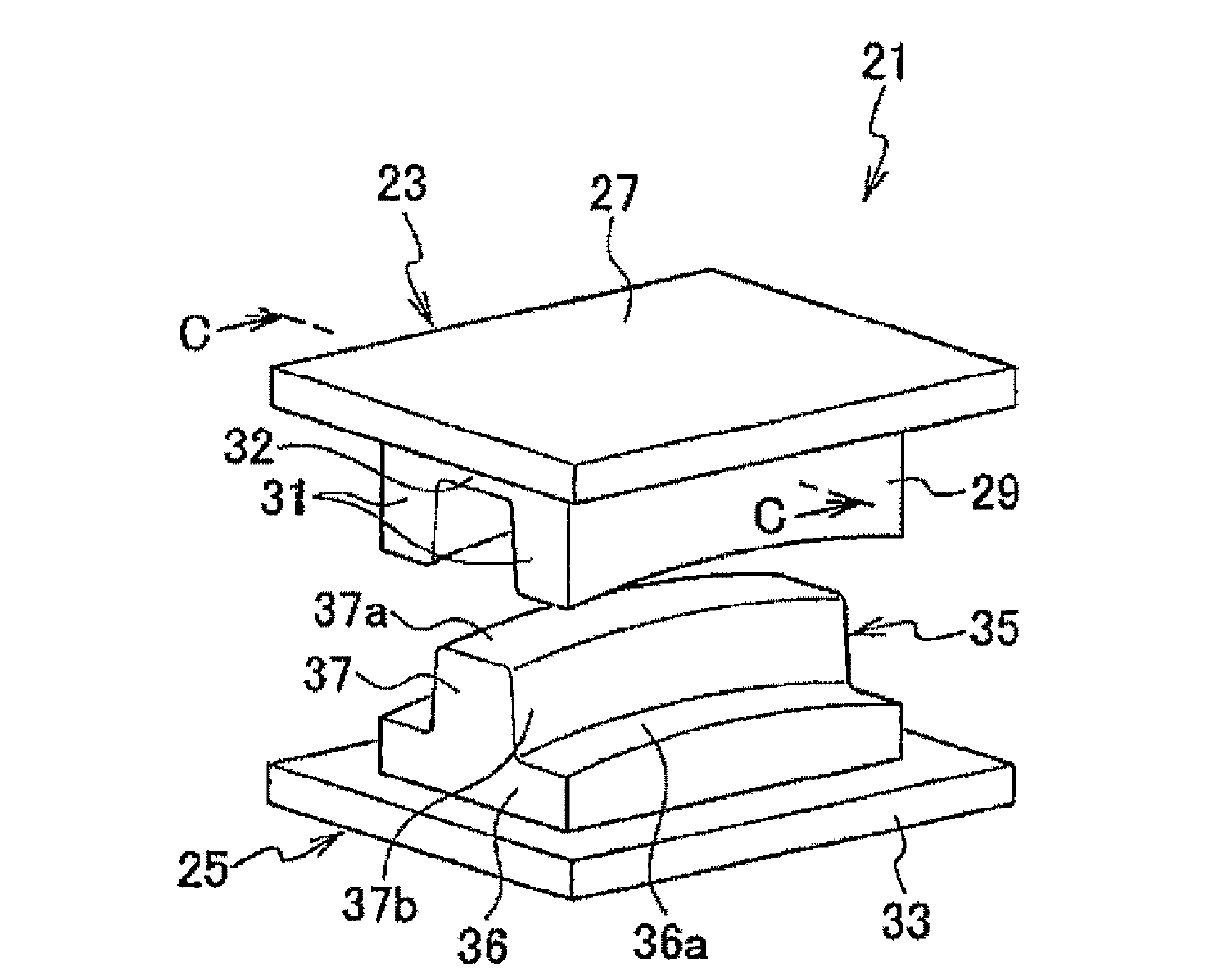

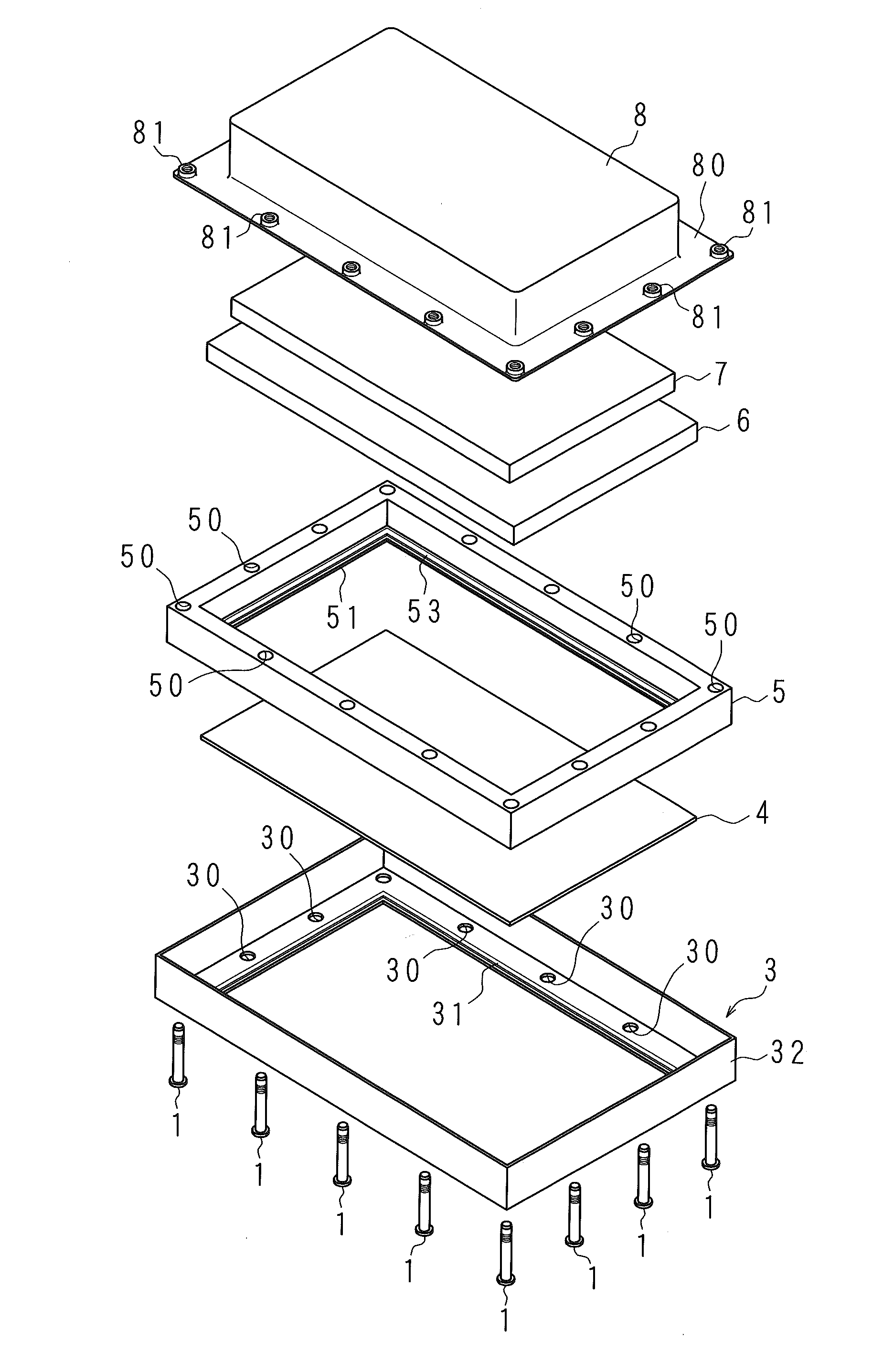

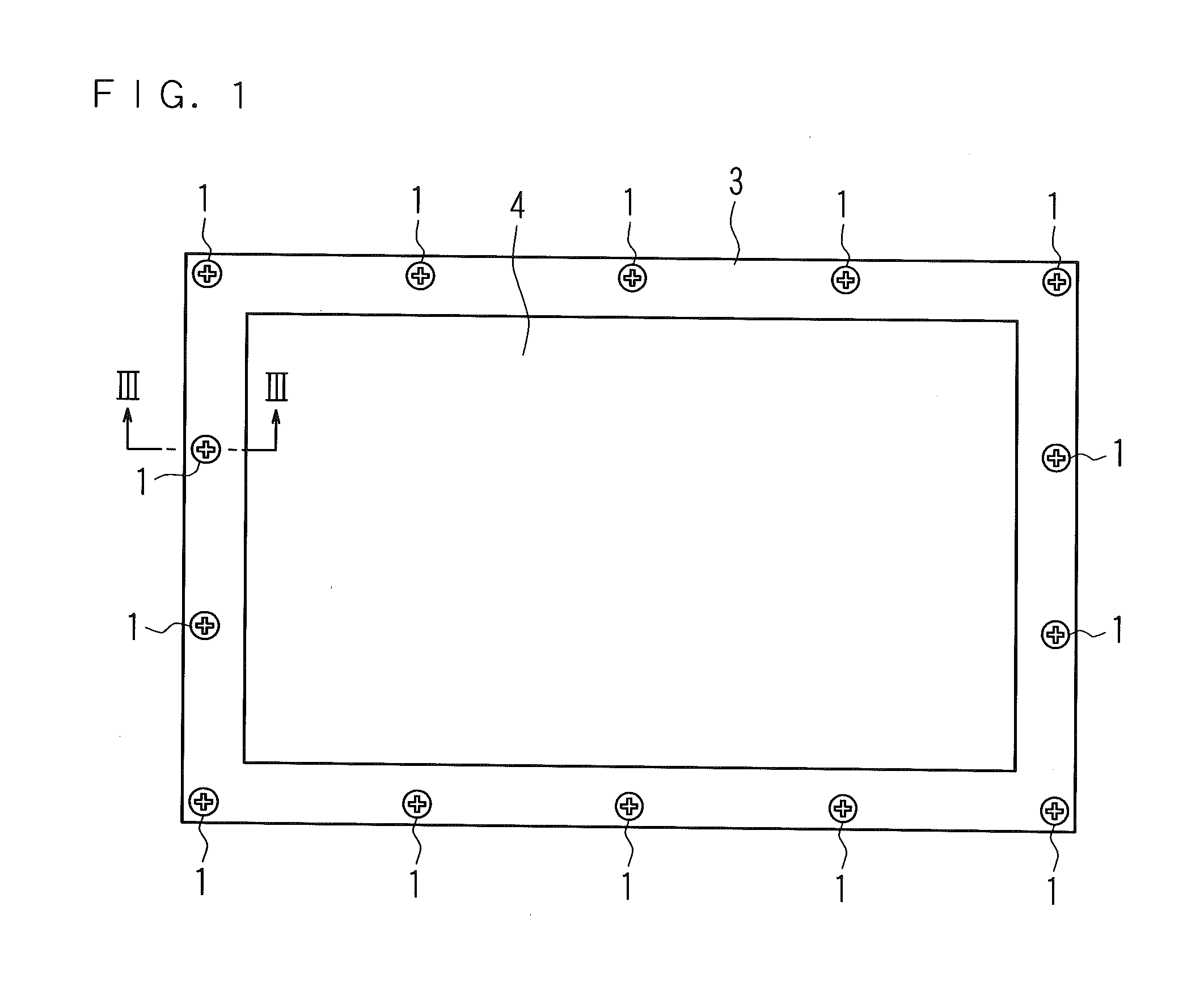

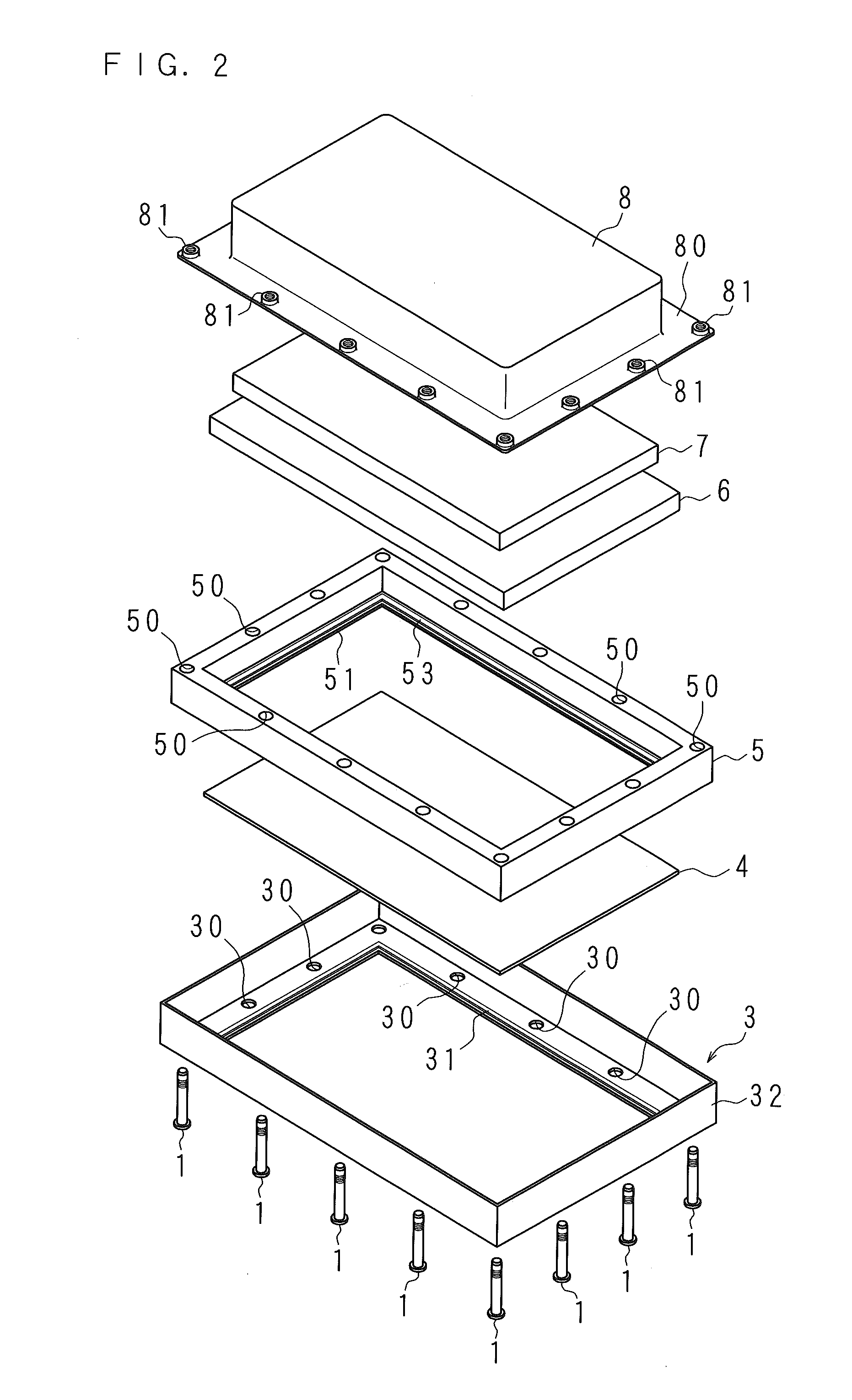

Plate multipoint forming device with crease resistant functions

ActiveCN102248053AReduce designAchieve moldless formingShaping toolsBiomedical engineeringEquipment use

The invention discloses a plate multipoint forming device with crease resistant functions, relating to plastic processing equipment used for plate curved surface forming and belonging to the field of mechanical engineering. The device mainly comprises shape-adjusting units (1), clamping units (2), a unit fixing plate (4) and a loading mechanism and is characterized in that the shape-adjusting units (1) and the clamping units (2) are arranged in a staggering manner; enveloping surface shapes of the plurality of shape-adjusting units (1) with adjustable heights can be changed through a shape-adjusting mechanism; the traditional entity die is replaced; and the plurality of clamping units (2) which are shifted passively are used for clamping a plate through back pressure effects to replace a side-pressing mechanism. The device can be used for inhibiting creases and rebound when the plate is formed and used for forming complex outline curved surface members with different sizes, therefore, the step of cutting sides after forming is omitted, and the utilization rate of the plate is improved.

Owner:JILIN UNIV

Flexible multi-point forming device for plates

Owner:HARBIN INST OF TECH AT WEIHAI

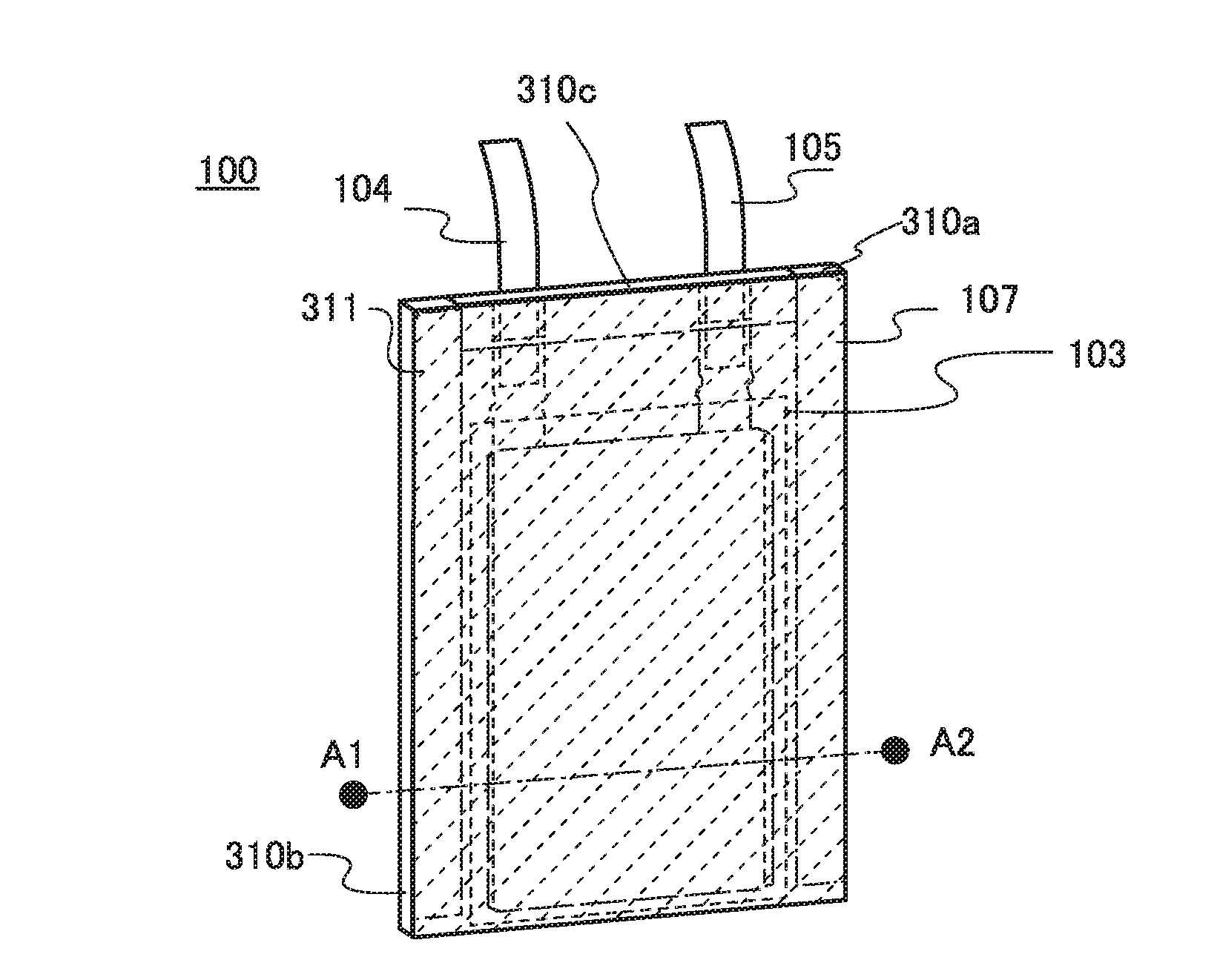

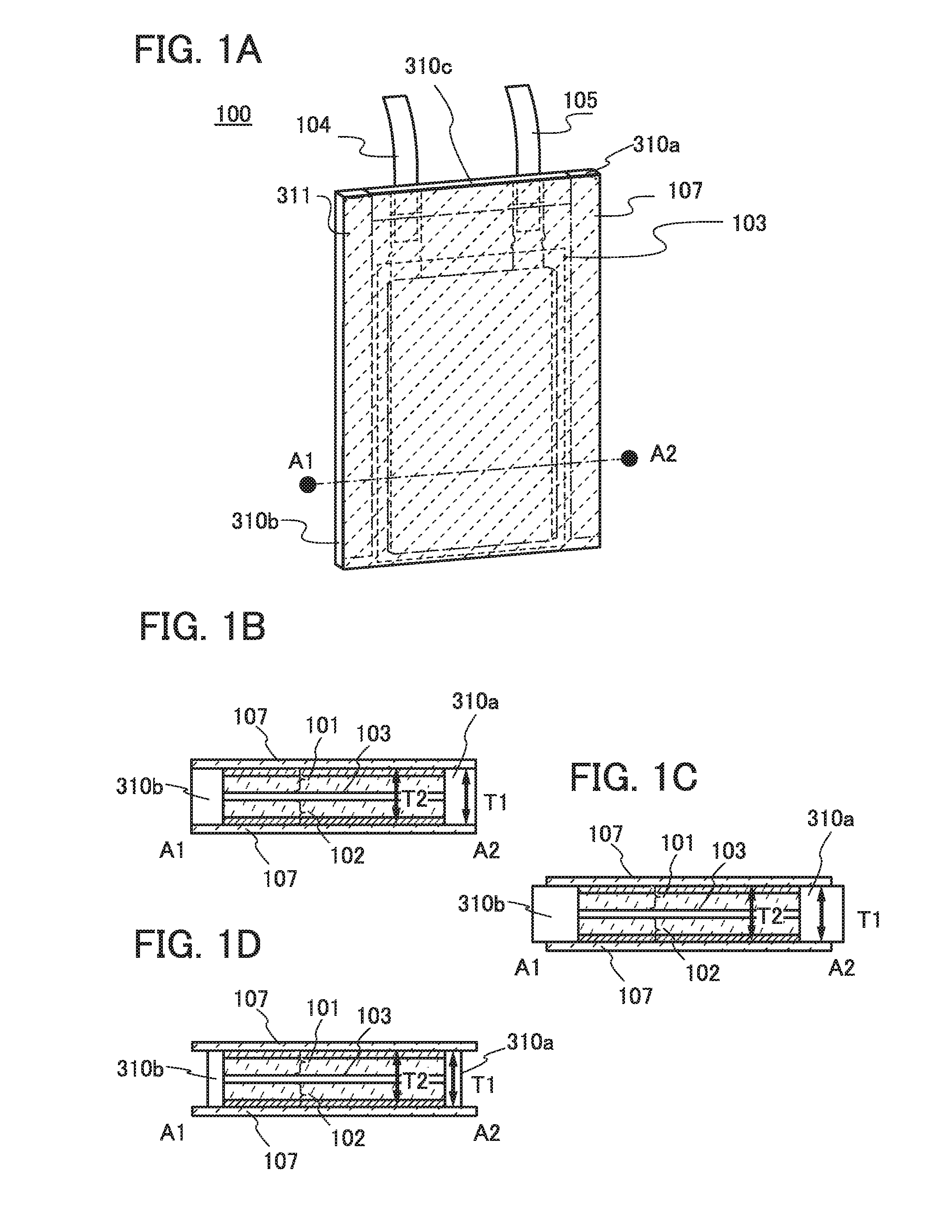

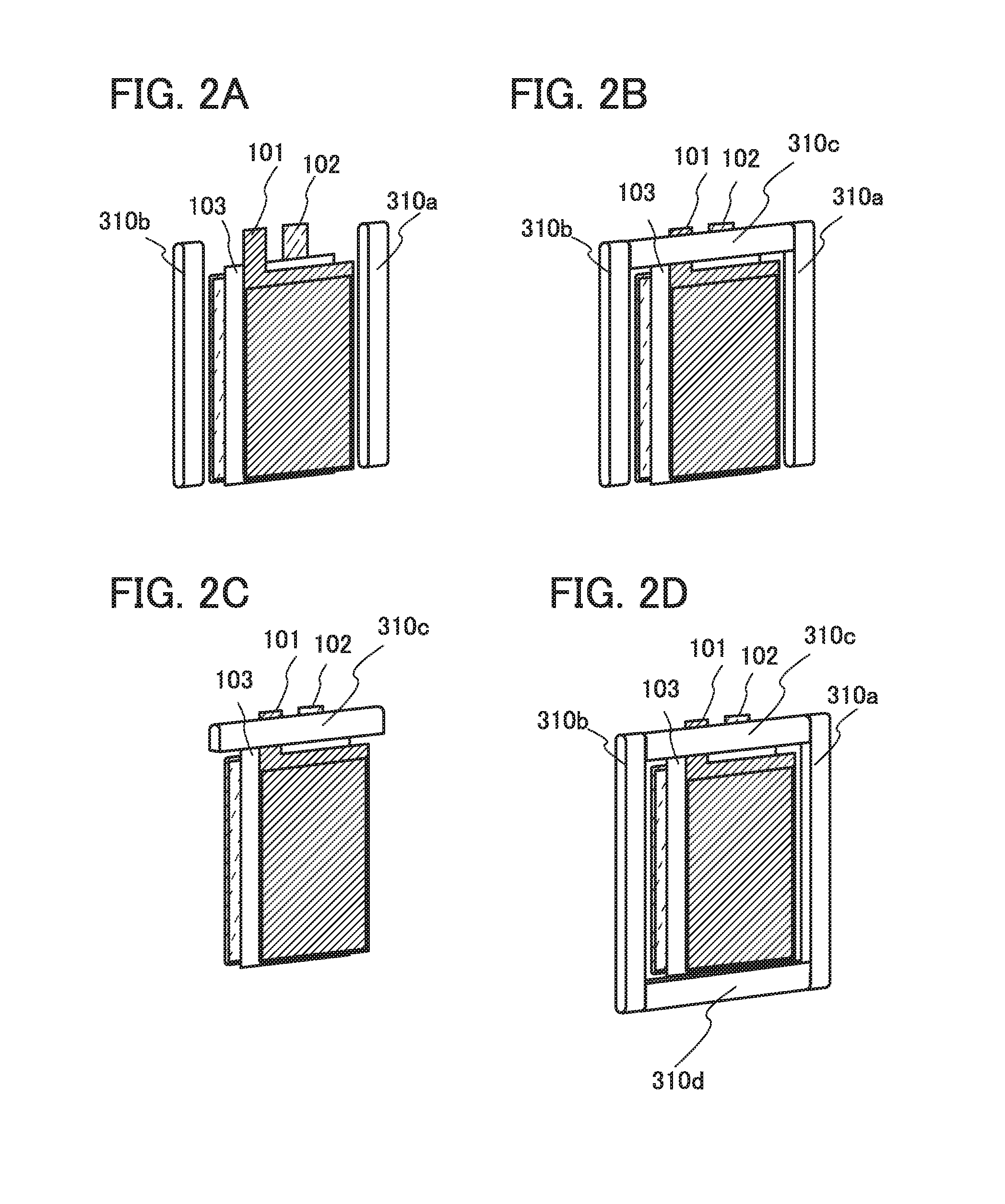

Secondary battery and electronic device

ActiveUS20160218327A1Suppress sharp bendingReduce stress concentrationSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsCushioningElectrical battery

In the case where a film having lower strength than a metal can is used as an exterior body of a secondary battery, a current collector provided in a region surrounded by the exterior body, an active material layer provided on a surface of the current collector, or the like might be damaged when force is externally applied to the secondary battery. A secondary battery resistant to external force is provided. A cushioning material is provided in a region sandwiched by an exterior body of the secondary battery. Specifically, the cushioning material is provided on the periphery of an electrode group including a positive electrode current collector, a positive electrode active material layer formed on at least one surface of the positive electrode current collector, a separator, a negative electrode current collector, and a negative electrode active material layer formed on at least one surface of the negative electrode current collector.

Owner:SEMICON ENERGY LAB CO LTD

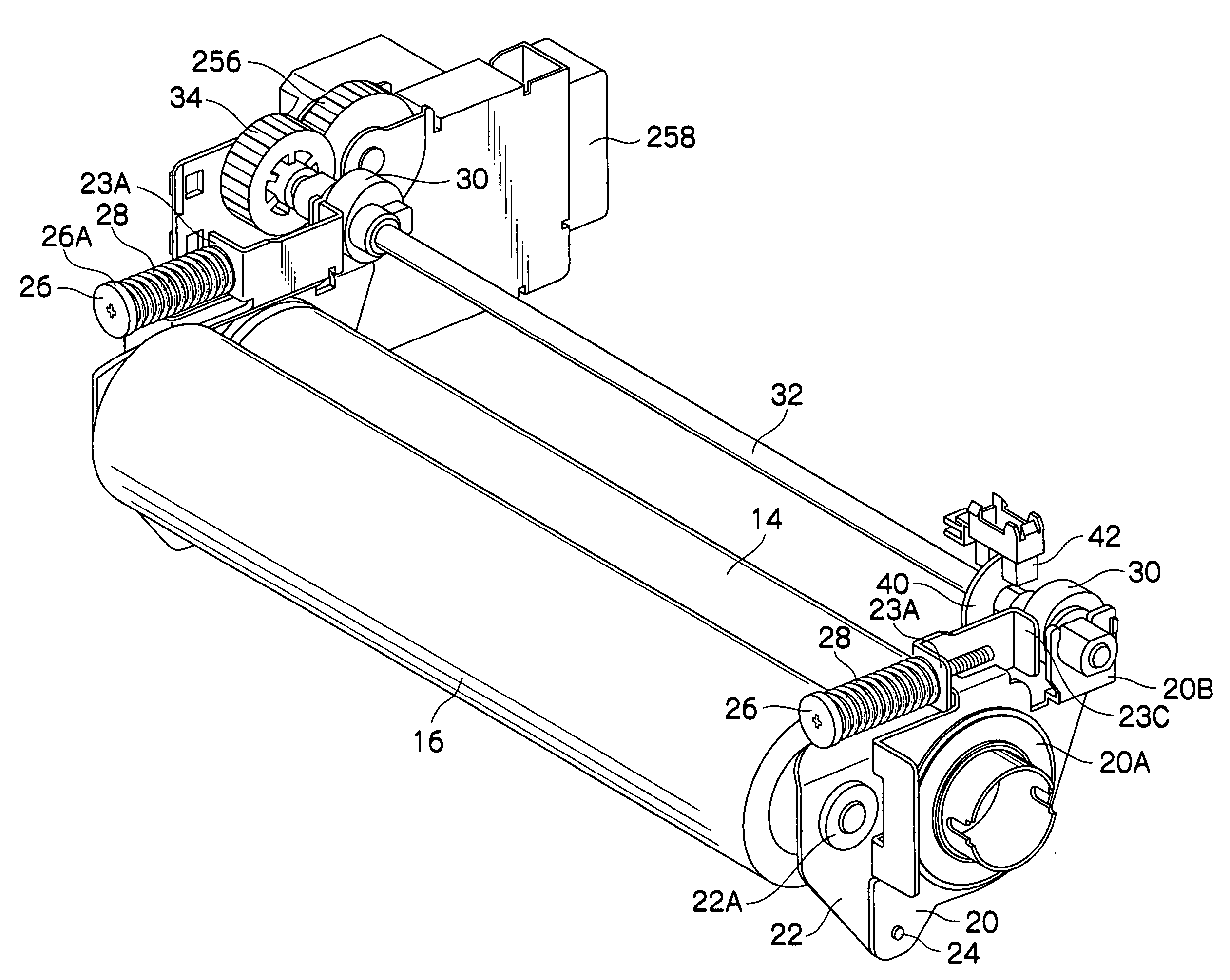

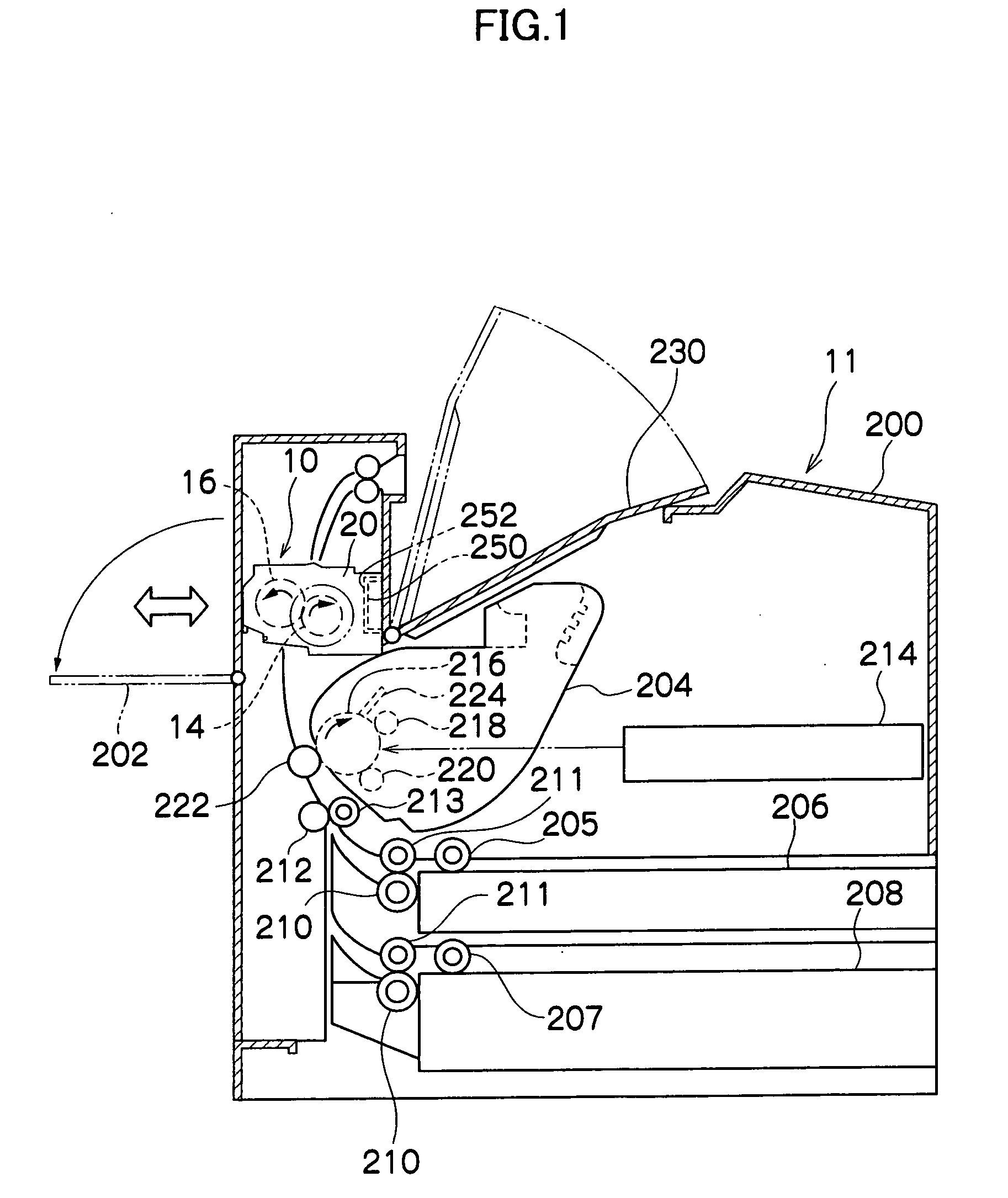

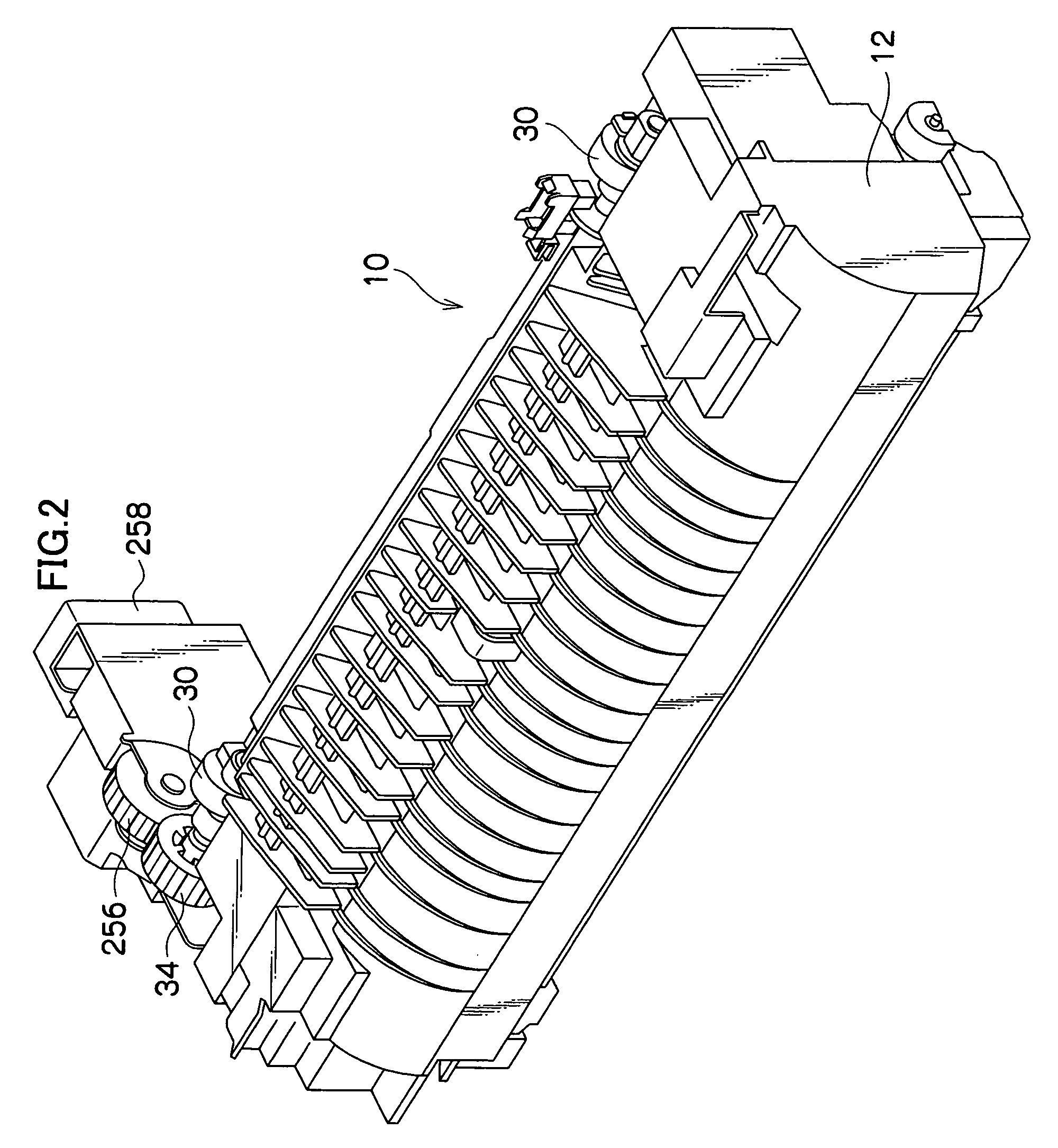

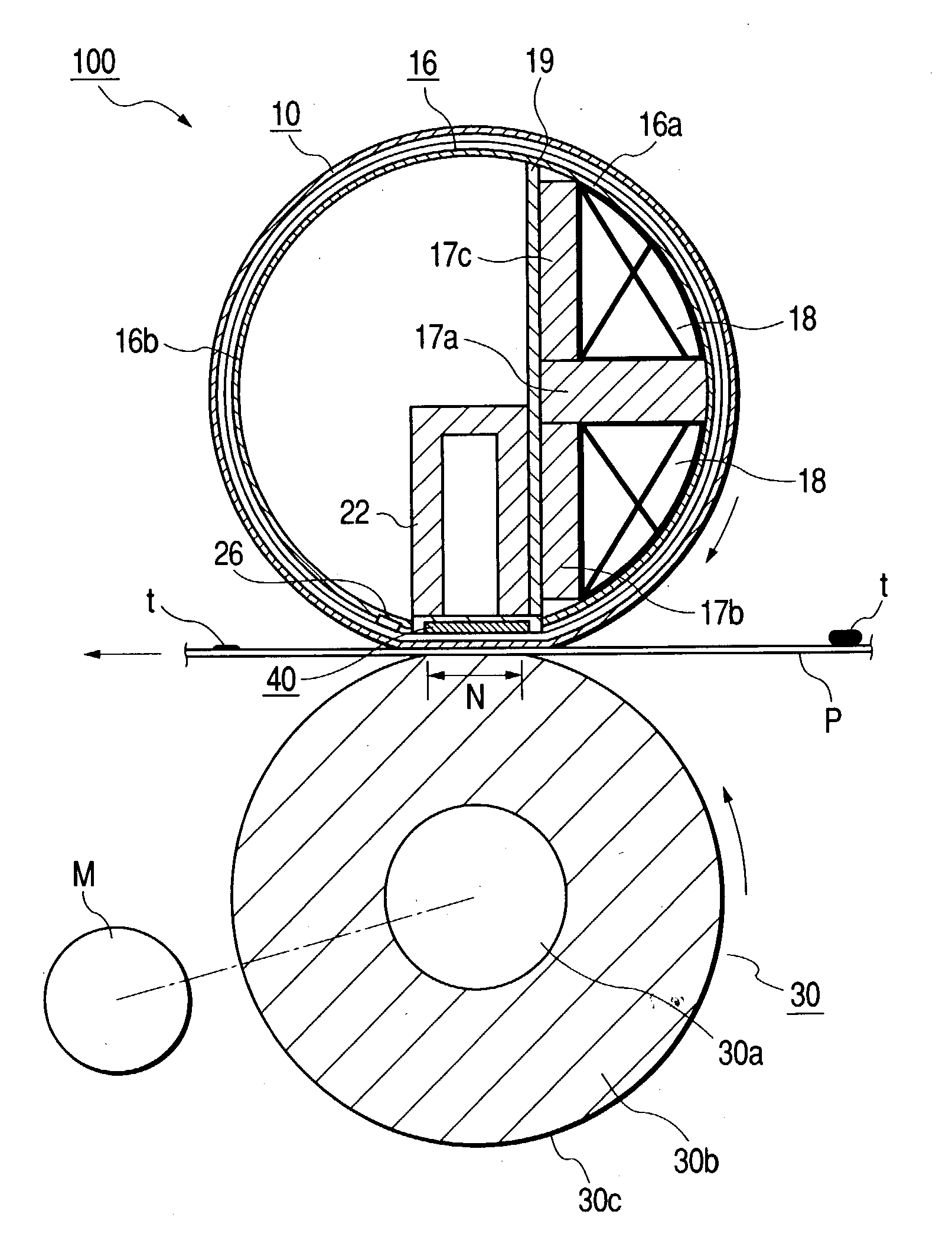

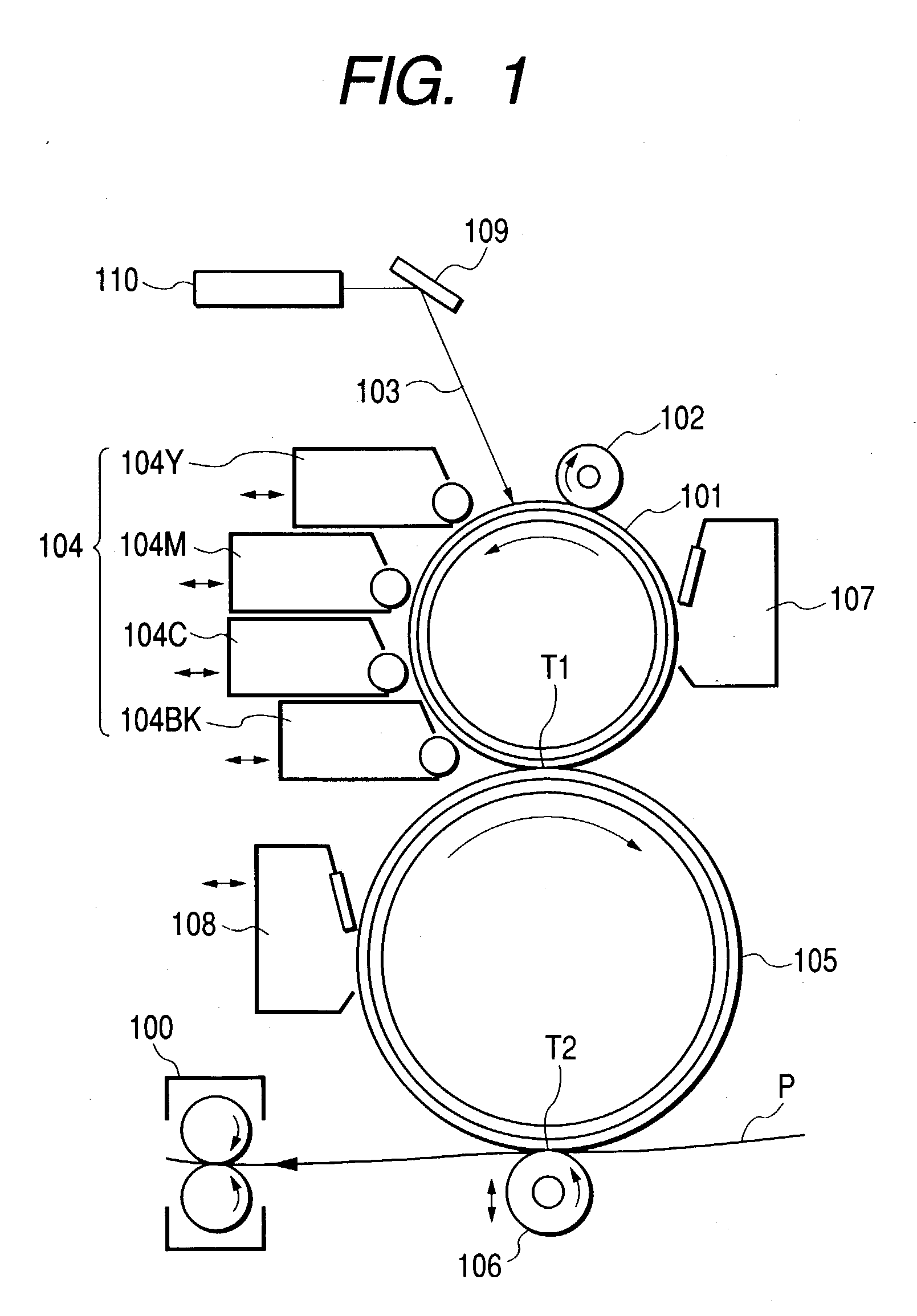

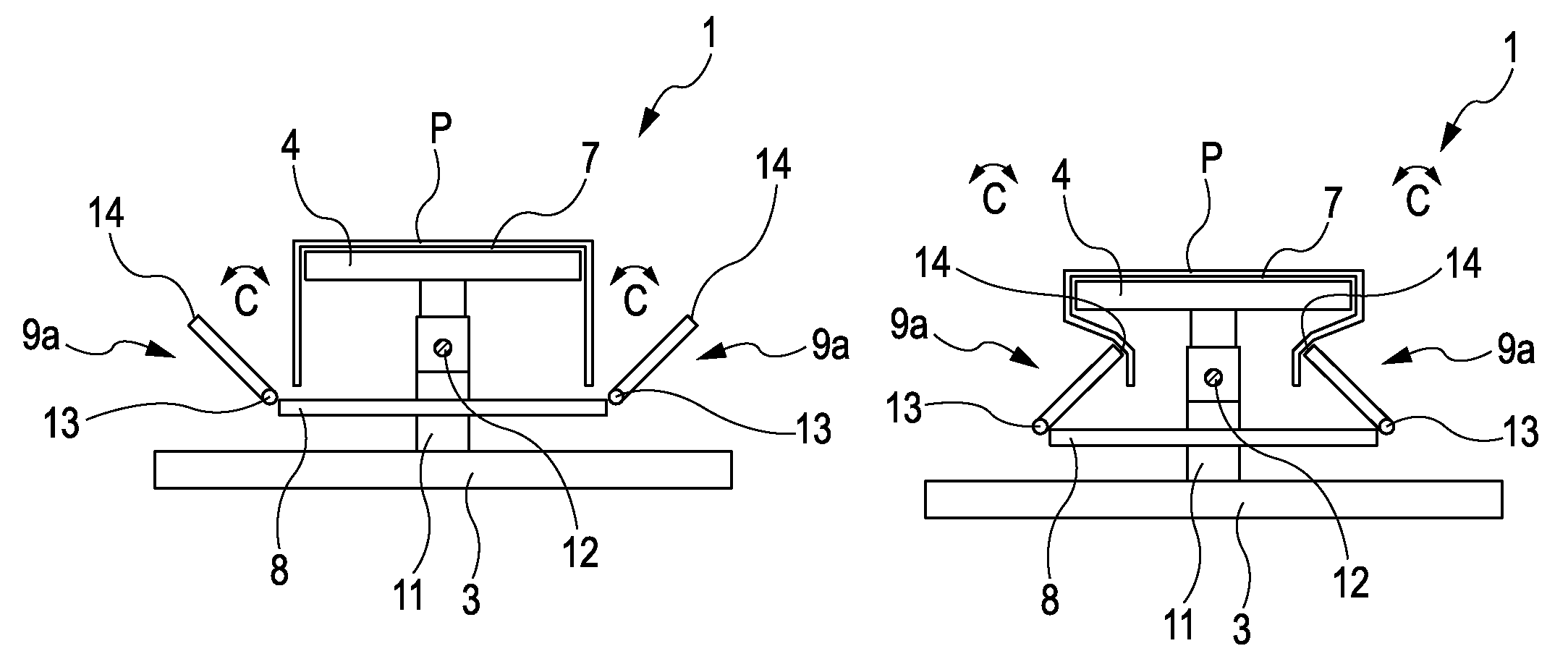

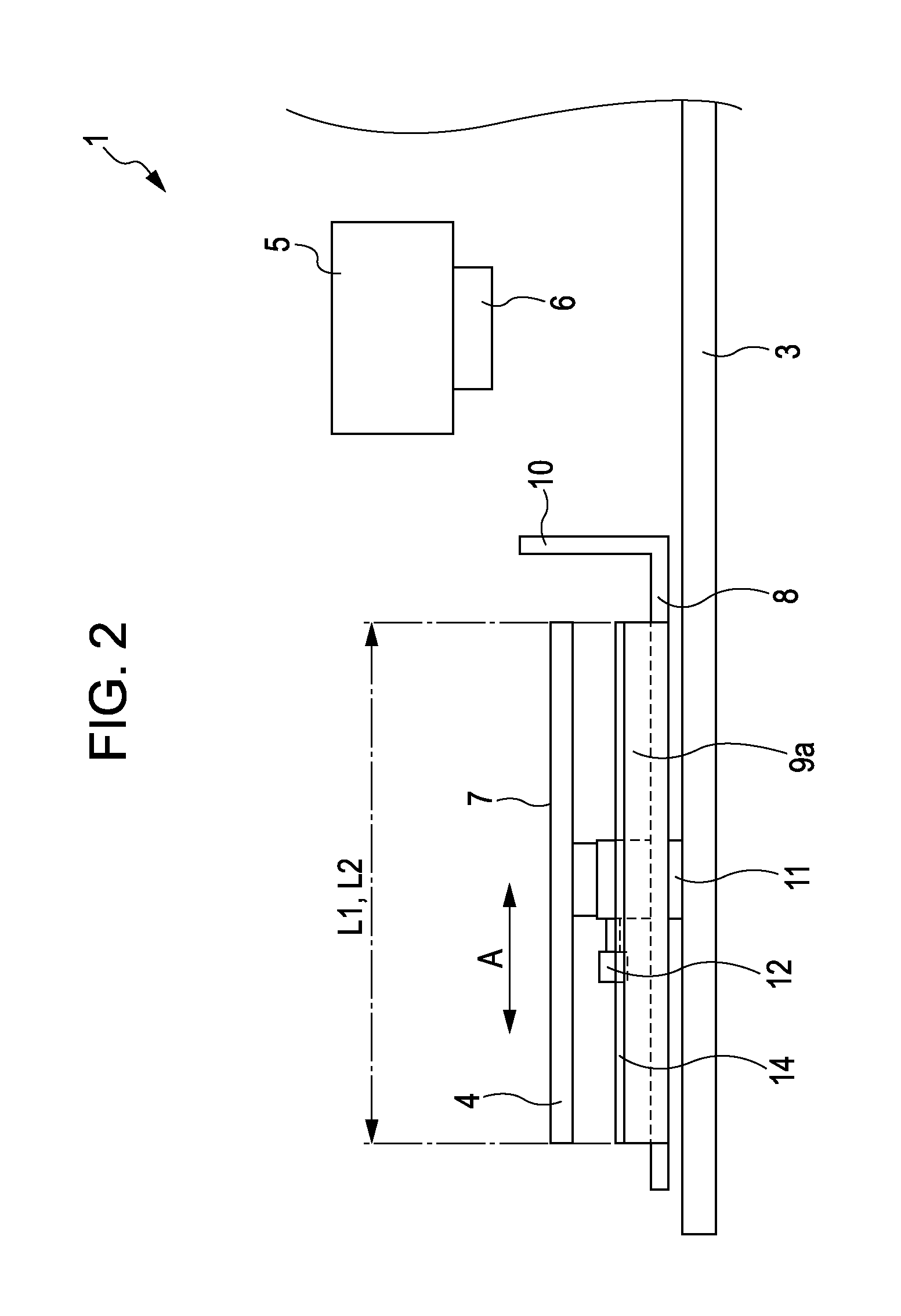

Fixing device and image forming apparatus

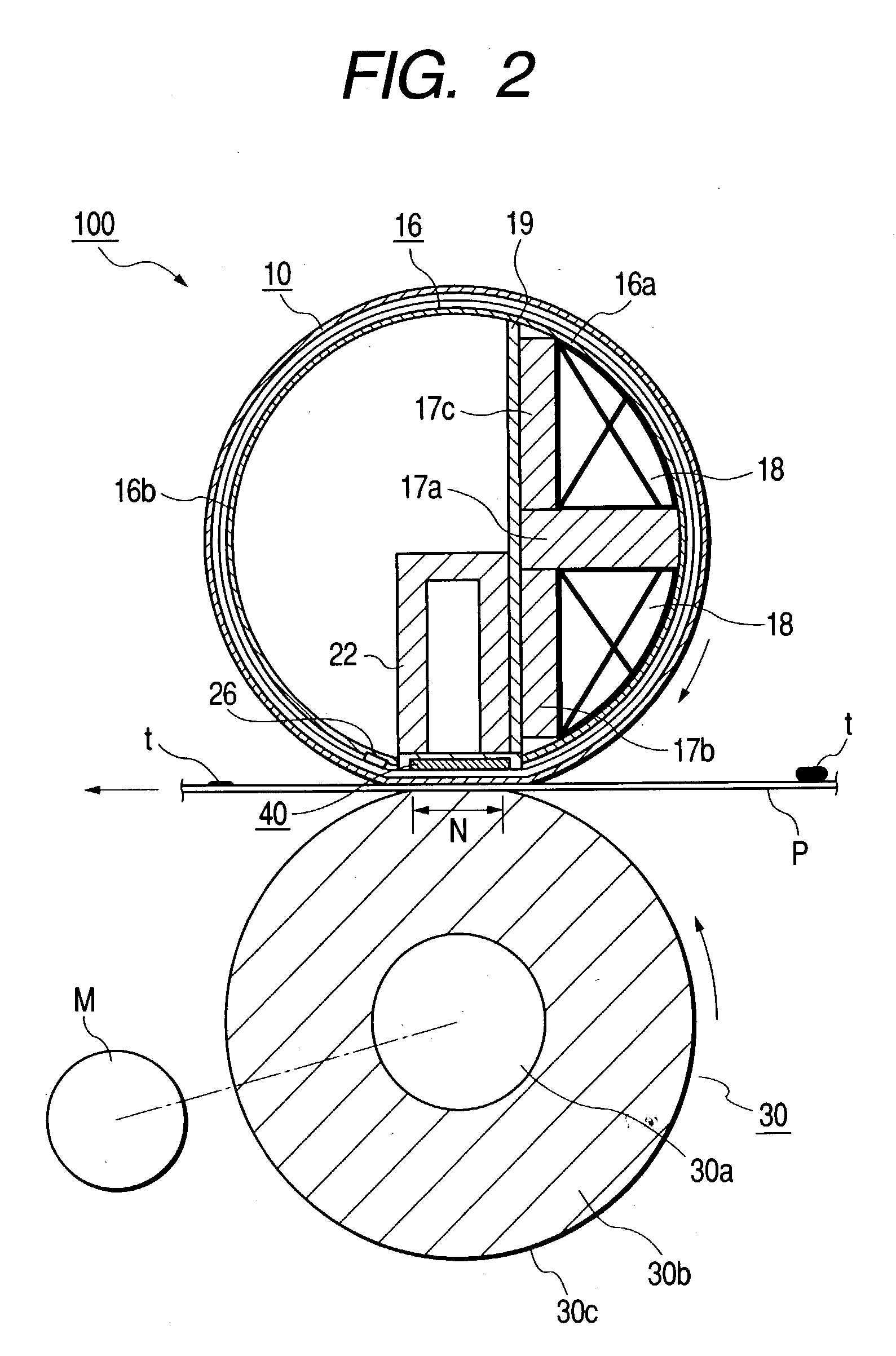

ActiveUS20070019977A1Suppress wrinklesHigh precision stabilityElectrographic process apparatusImage formationEngineering

A fixing device includes a heating member disposed with an internal heating source and a pressuring member that presses against the heating member. The fixing device is configured to be attachable to and detachable from an image forming apparatus body, and includes: brackets that retain the heating member; pressuring levers that retain the pressuring member and are movably supported in the brackets; urging means that push the pressuring levers in a direction where the pressuring member presses against the heating member; and cams that are rotatably supported in the brackets, contact the pressuring levers, and adjust the pressuring force of the pressuring member.

Owner:FUJIFILM BUSINESS INNOVATION CORP

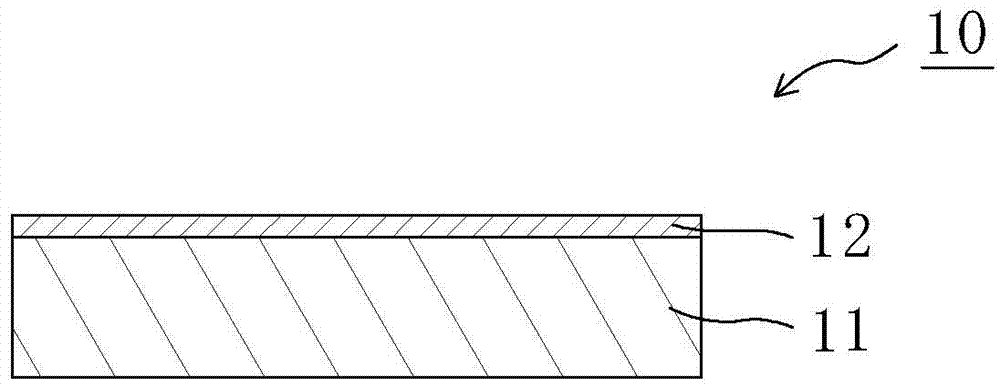

Preparation method of low stress state composite substrate for GaN growth

ActiveCN105514224AReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

The invention discloses a preparation method of a low stress state composite substrate for GaN growth. The preparation method comprises that a GaN monocrystal epitaxial layer is prepared on a sapphire substrate; a stress compensation layer is deposited at the back side of a thermally and electrically conductive transfer substrate of high welding point; bonding dielectric layers of high welding point are prepared at the surfaces of a GaN epitaxial wafer and the transfer substrate respectively; the GaN epitaxial wafer is bonded to the thermally and electrically conductive substrate by the high-temperature diffusion bonding technology; and the composite substrate with high temperature stability and low stress state for GaN growth is obtained. According to the composite substrate of the invention, homoepitaxy can be realized and a vertical structural device can be directly prepared as a traditional composite substrate, the low stress state and high-temperature stability can be also realized, and the quality of subsequent GaN epitaxial growth and chip preparation can be effectively improved.

Owner:SINO NITRIDE SEMICON

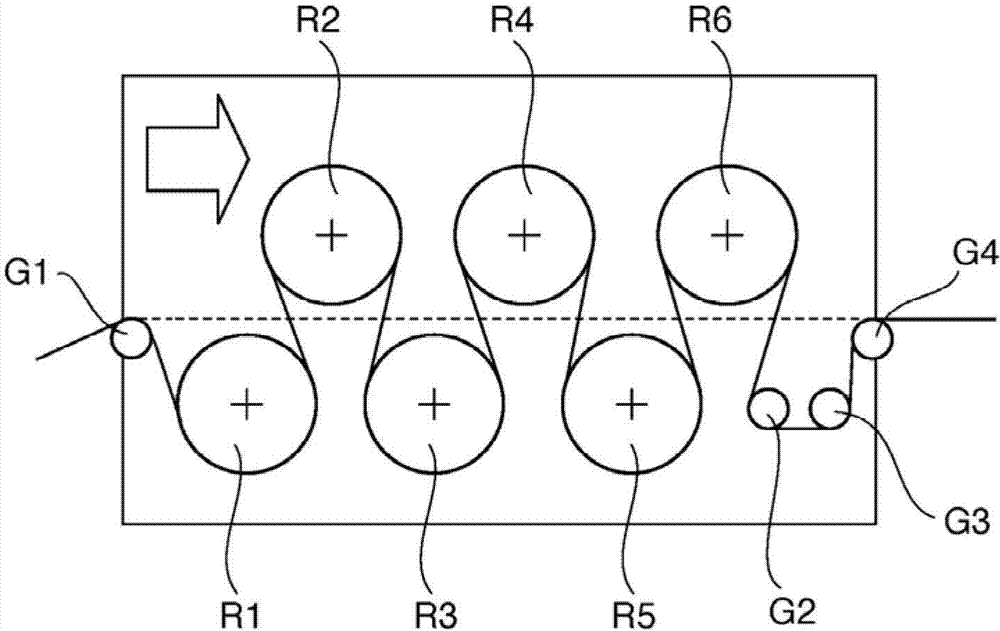

Image heating apparatus

InactiveUS20030156866A1Reduce wrinklesSuppress wrinklesShaft and bearingsOhmic-resistance heatingEngineeringImaging equipment

An image forming apparatus includes a sliding member, and a pressure member which, together with the sliding member, forms a nip part, wherein a sliding surface of the nip part of the sliding member is crown shaped along a longitudinal direction of the sliding member, and the pressure roller is an inverse crown shape along the longitudinal direction. In accordance therewith, wrinkles in a recording material and springing-up of a conveying direction of the recording material can be suppressed.

Owner:CANON KK

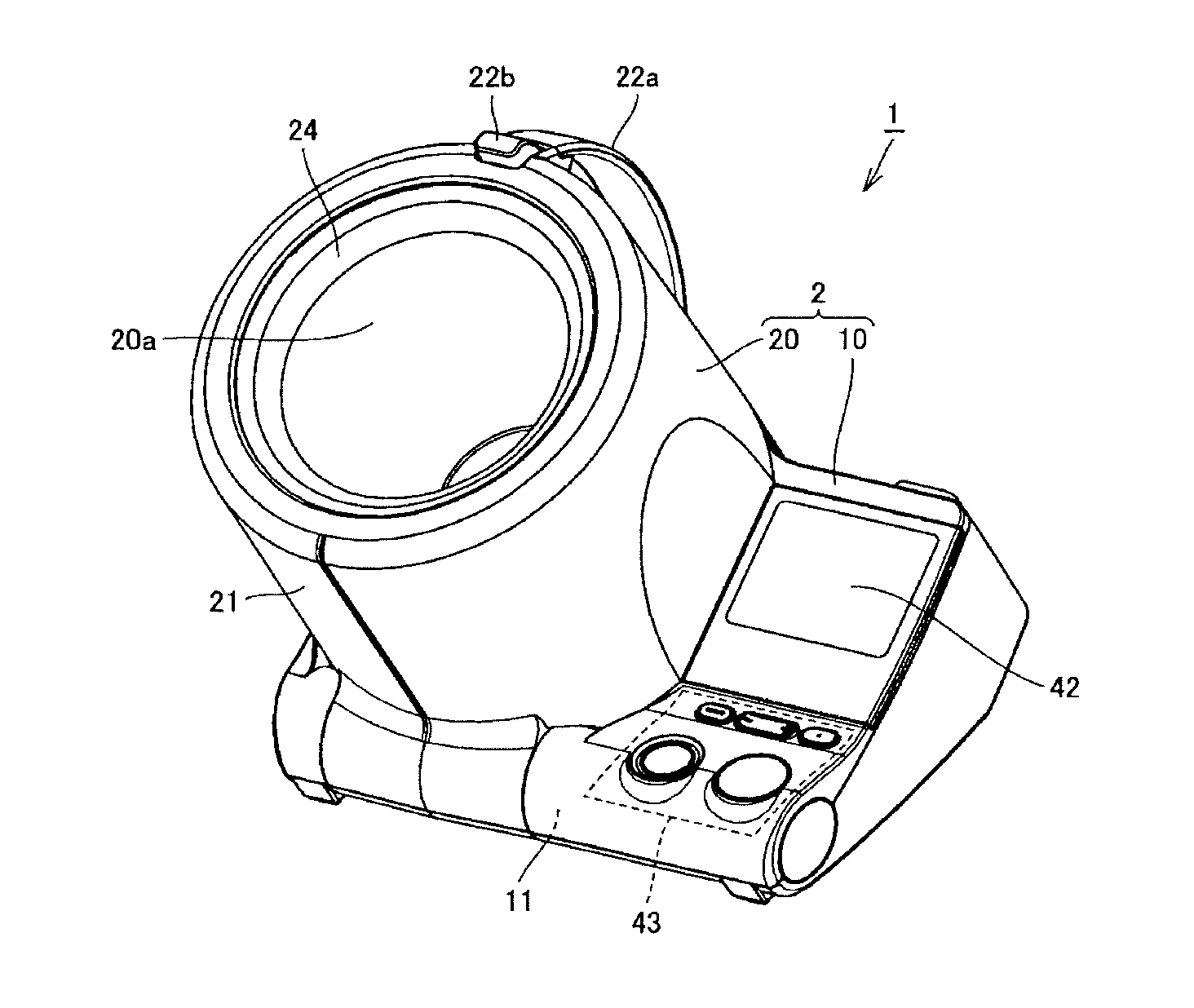

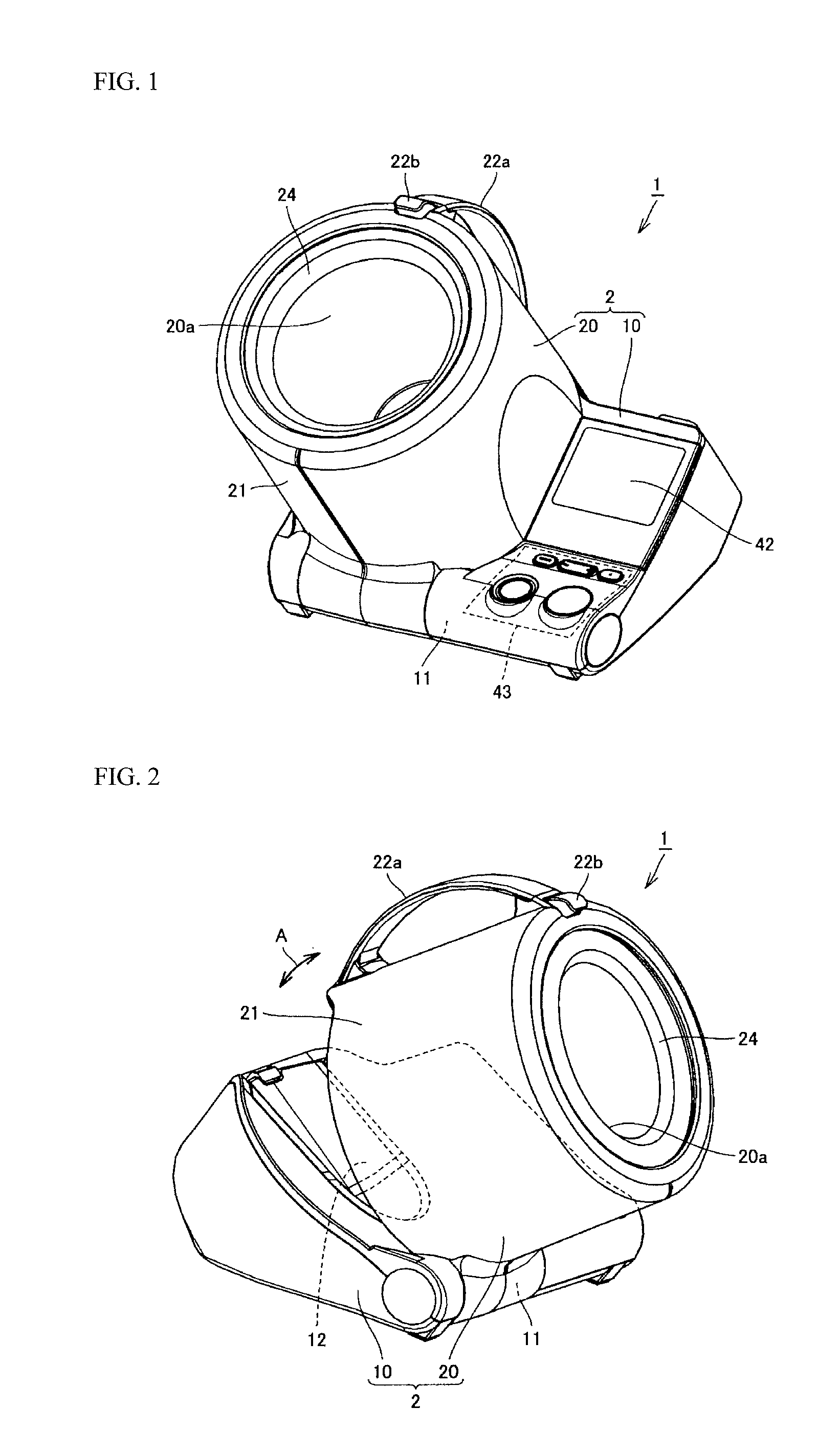

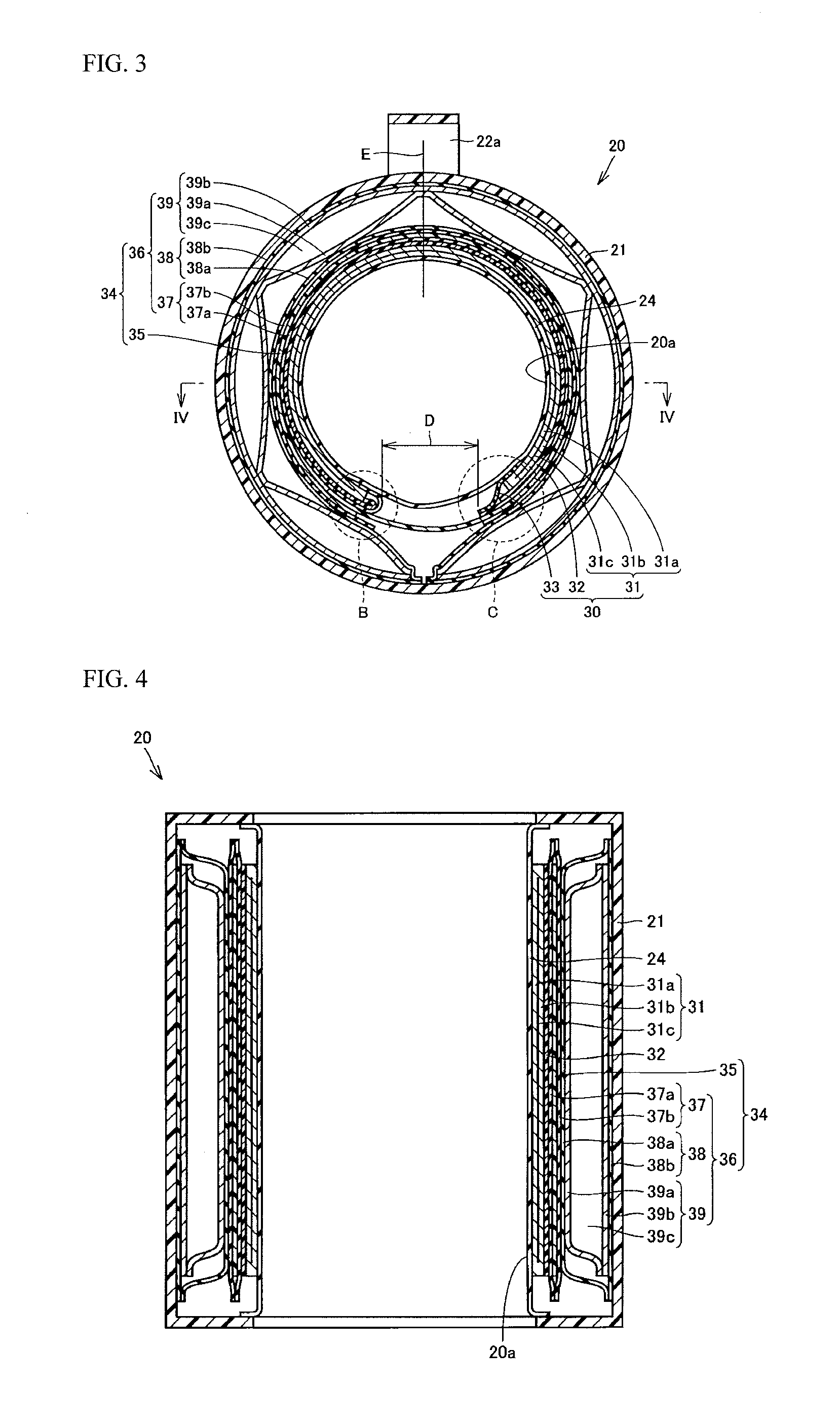

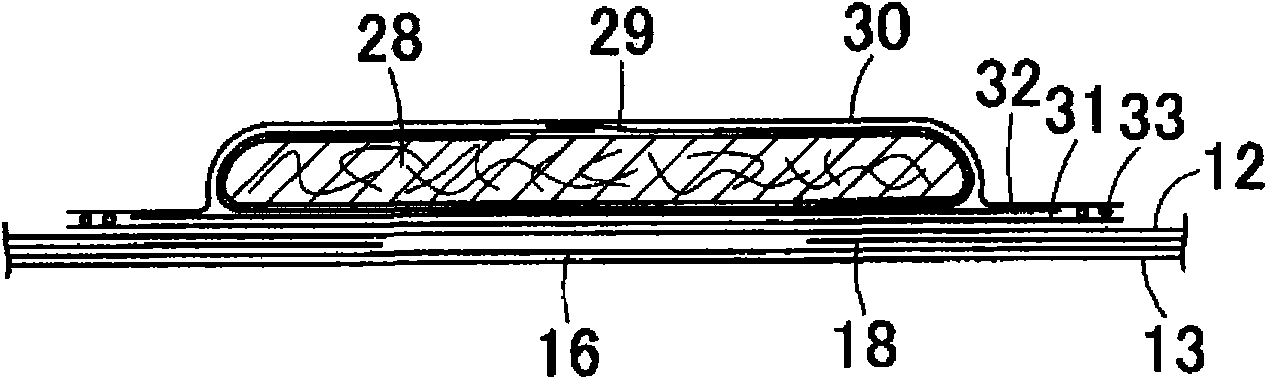

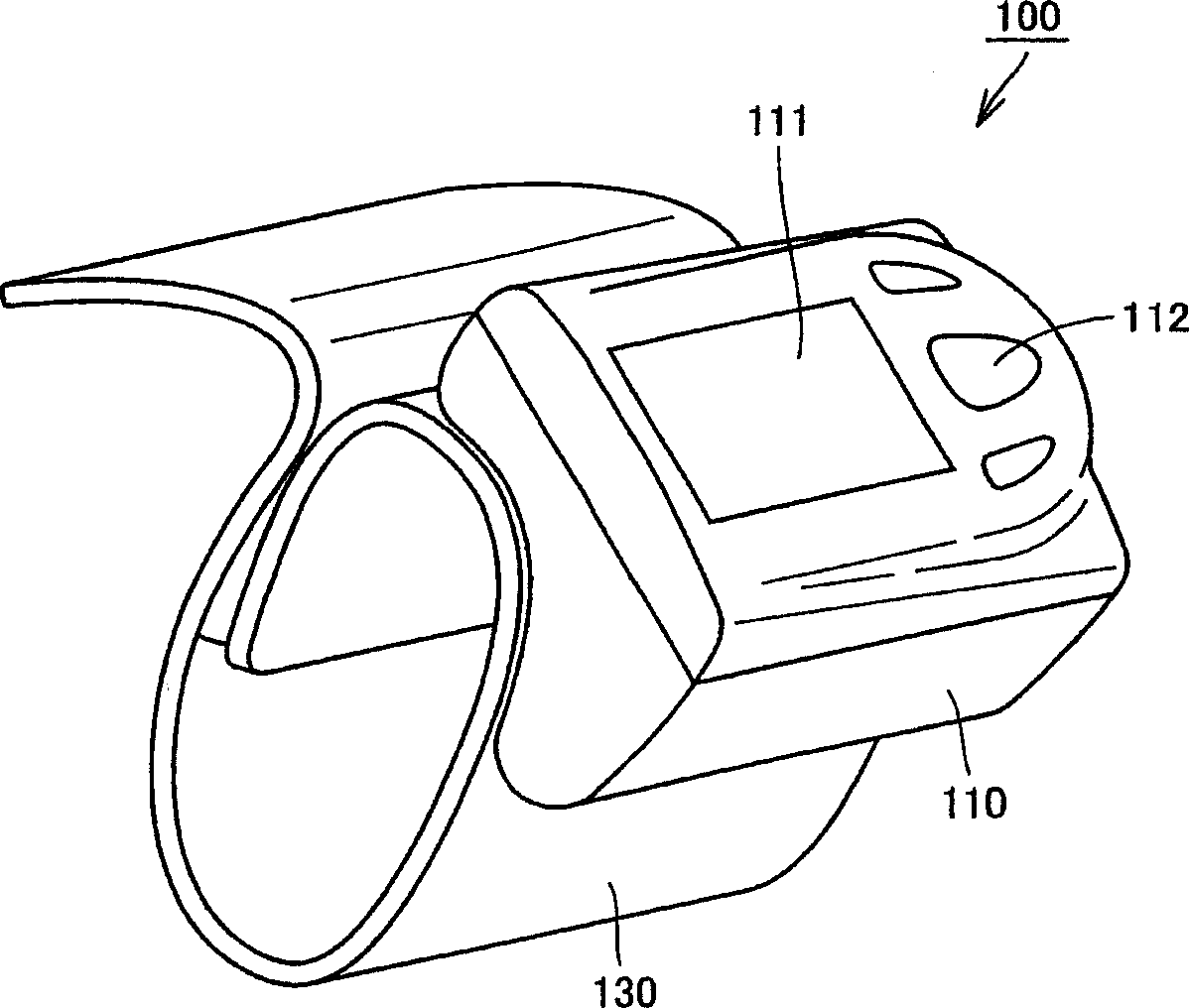

Method of Producing Cuff of Sphygmomanometer Having Automatic Cuff Winding Mechanism

ActiveUS20120240377A1Good blood pressureHigh precision measurementAngiographyMetal working apparatusSphygmomanometerBand shape

In a method of producing a cuff of a sphygmomanometer having an automatic cuff winding mechanism, the cuff includes a band-shaped fluid bladder forming a cavity for inserting a user's arm therein, a shape maintenance member wound on the band-shaped fluid bladder, a band-shaped bag wound on the shape maintenance member, and a cylindrical elastic plate housed in the band-shaped bag. The method includes winding the band-shaped fluid bladder on an outer circumferential surface of a cylindrical jig having approximately the same outer diameter as the cavity of the band-shaped fluid bladder, winding the shape maintenance member on an outer circumferential surface of the band-shaped fluid bladder, winding the band-shaped bag on an outer circumferential surface of the shape maintenance member, removing the cylindrical jig from the band-shaped fluid bladder, and housing the cylindrical elastic plate inside the band-shaped bag.

Owner:OMRON HEALTHCARE CO LTD

Electro-servo stretching pad

The invention provides an electro-servo stretching pad, comprising an apical cap, wherein the apical cap is connected with a servo motor driving mechanism, the servo motor driving mechanism comprises a servo motor arranged on a support base and a screw rod shaft connected on a support, a driving shaft and the screw rod shaft of the servo motor are connected with belt wheels, synchronous belts are connected among the belt wheels, and a nut connected on the apical cap is arranged on the screw rod shaft; and the servo motor is electrically connected with a servo driver, an energy feedback storing device and a servo controller. The electro-servo stretching pad has the beneficial effects that any edge press force required for the tensile deformation of a workpiece can be realized in combination with a slide block of a press machine, the mechanical energy can be converted into electric energy during stretching, so that a mass of electric energy can be saved, and particularly the automobile parts which are high in precision and hard to form required for manufacturing an automobile body such as the high-strength steel, the composite forming material, the aluminum alloy, the material hard to form and the like can be formed in a stretching way.

Owner:JIER MACHINE TOOL GROUP

Coated sheet for rotary offset printing

InactiveUS20060005933A1Reduce wrinklesSuppress wrinklesNatural cellulose pulp/paperSpecial paperSurface layerEngineering

A coated sheet for web offset printing comprising a base paper with a pigment coating layer formed on it, and a surface layer—preferably containing surface-sizing agents and plastic pigments—formed on the pigment coating layer; wherein the air permeability of the sheet before printing is less than 80,000 seconds and the air permeability in a non-image area after printing decreases by 8,000 seconds or more from the level before printing. The coated sheet for web offset printing obtained by the present invention suppresses wrinkling during web offset printing or in the subsequent drying process and also offers excellent blister resistance and other properties.

Owner:NIPPON PAPER IND CO LTD

Seamless can, printing plate, cylindrical printer for seamless can, printing method for seamless can, and method for producing seamless can

InactiveCN102143846AReduce layer thicknessReduce height differencePlate printingRotary pressesWrinkle skinUltimate tensile strength

Occurrence of wrinkles due to neck-in processing is reduced and drop in coating strength of an overlap portion is prevented by reducing the level difference between the overlap portion and an ink layer at a part continuous to the overlap portion. A seamless can is produced by transferring an ink layer onto the can body by cylindrical printing in such a manner that the transferred ink layer has an overlap portion where the ink layer is overlapped at the front and rear ends of the can body in the circumferential direction, and the ink area ratio of the ink layer at at least one of the front or rear end is smaller than that of the ink layer at a part continuous to the overlap portion excluding the overlap portion.

Owner:TOYO SEIKAN KAISHA LTD

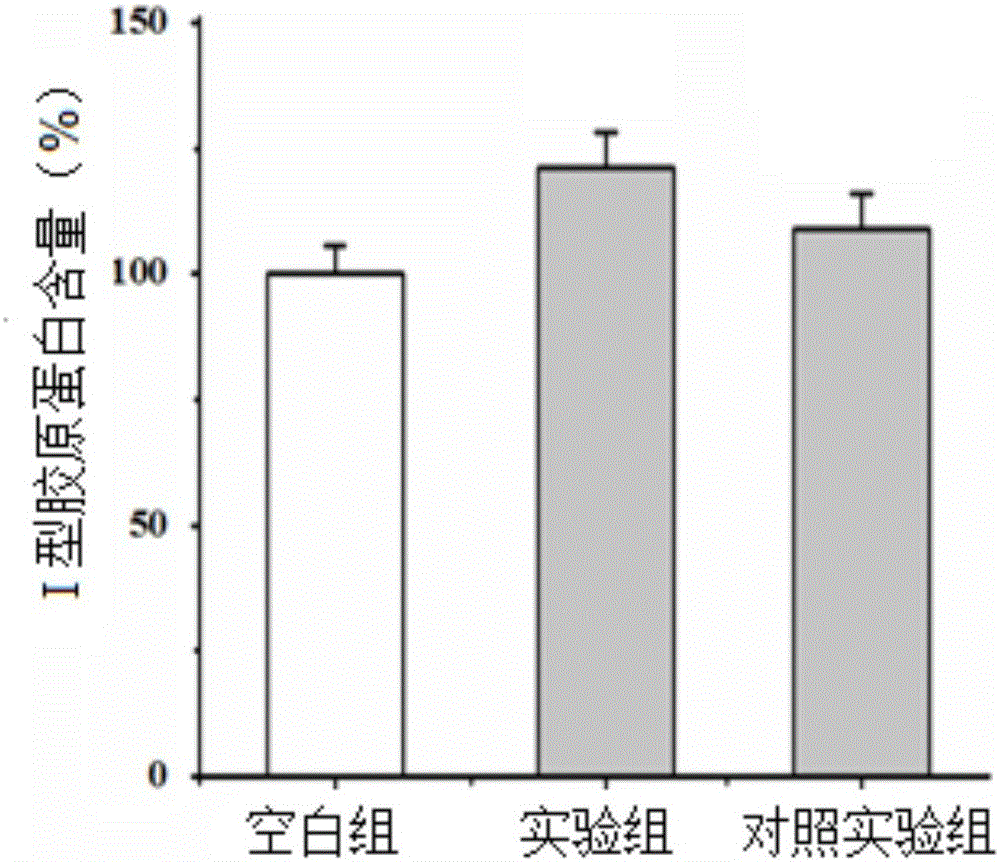

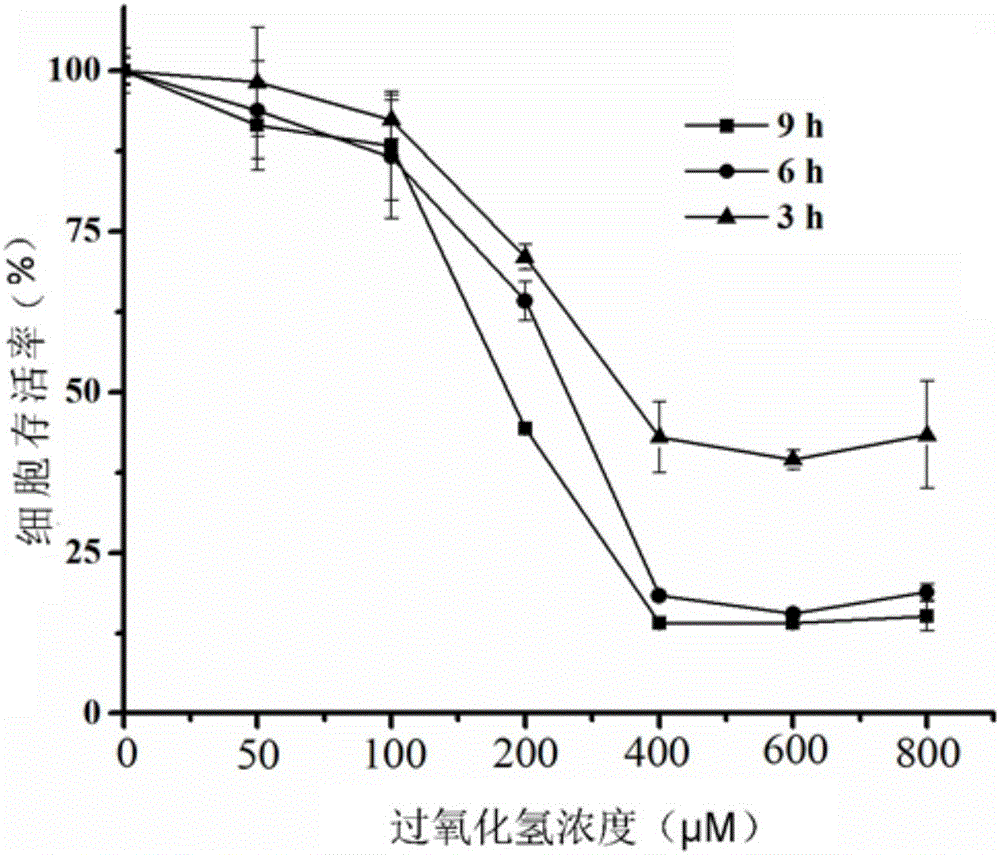

Olive leaf extract and cosmetics containing same

ActiveCN105997703AImprove anti-aging effectStay flexibleCosmetic preparationsToilet preparationsHydroxytyrosolWrinkle skin

The invention provides an olive leaf extract which comprises any one or a combination of 5%-50% by mass of hydroxytyrosol, Oleuropein and Verbascoside. The invention further provides a preparation method of the olive leaf extract and application in cosmetics. The olive leaf extract has a high anti-aging effect because the olive leaf extract can greatly increase the content of collagen in a corium layer of a human body, so that the elasticity of the skin of the human body is maintained, and wrinkles are inhibited fundamentally. In addition, the olive leaf extract can obviously inhibit generation of free radicals (DPPH) and can serve as a product or an additive to be applied to foods, medicines and skin care products and / or the cosmetics, and the double effects of resisting oxidation and aging are played.

Owner:SHANGHAI INOHERB COSMETIC +1

Recording paper

ActiveCN101054782ASuppress wrinklesCoatings with pigmentsMaterials with cobaltFiber orientationWave velocity

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

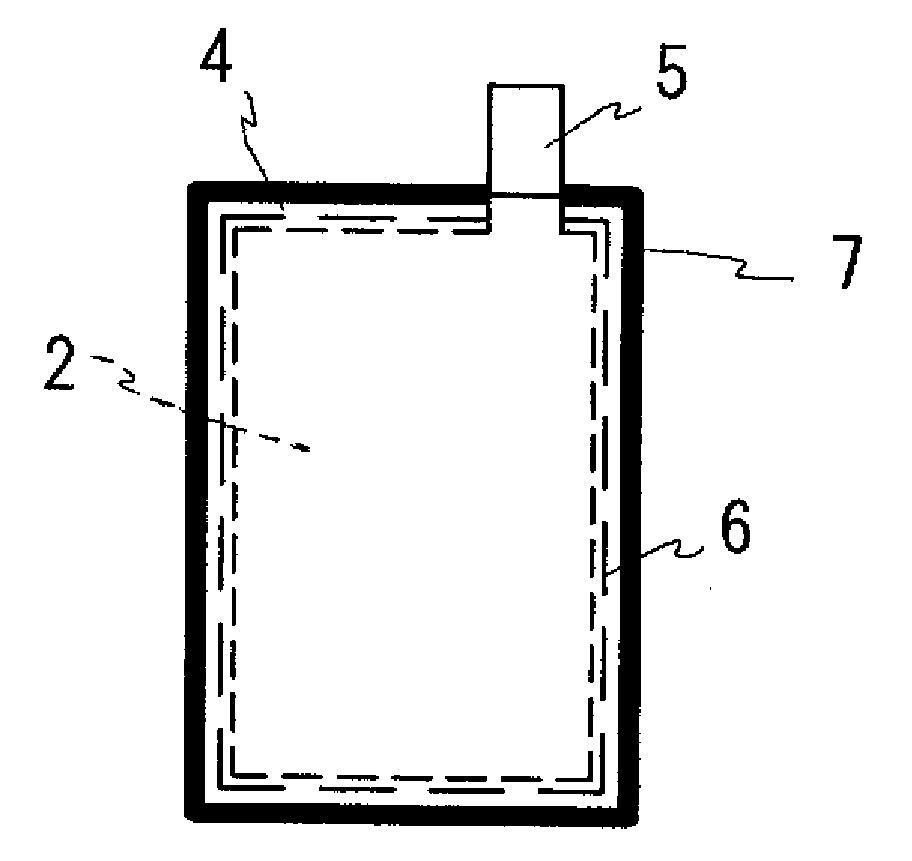

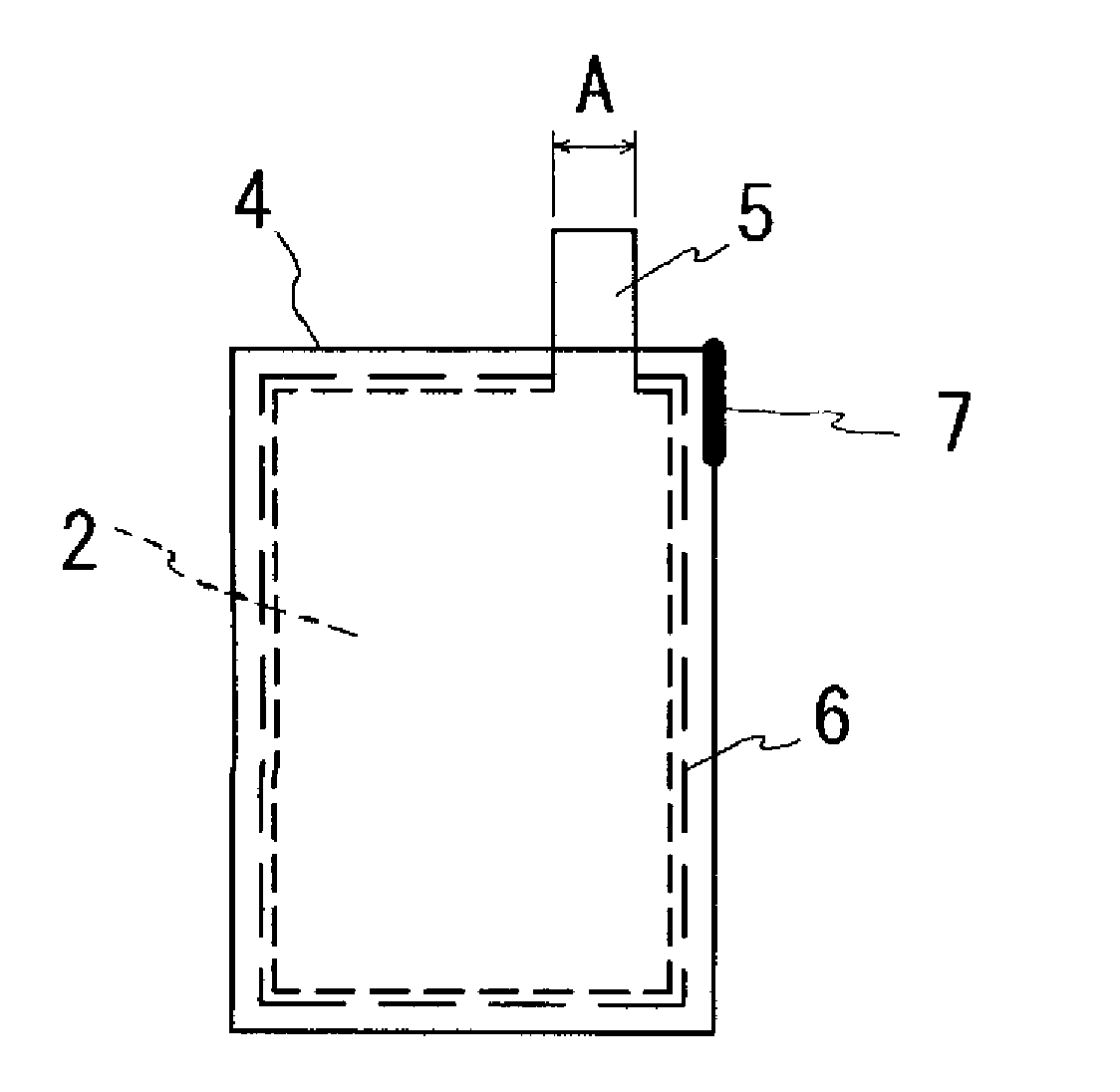

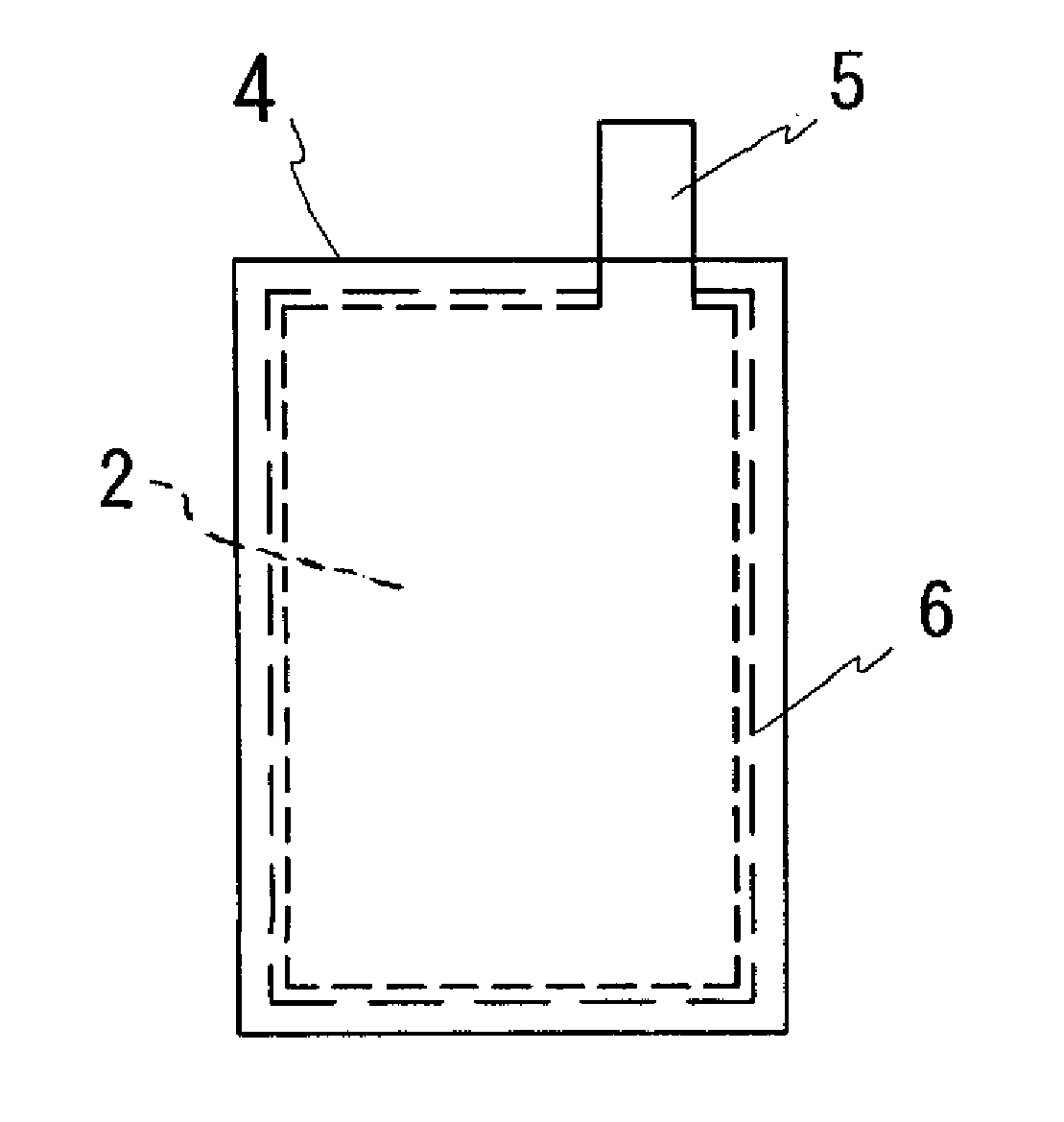

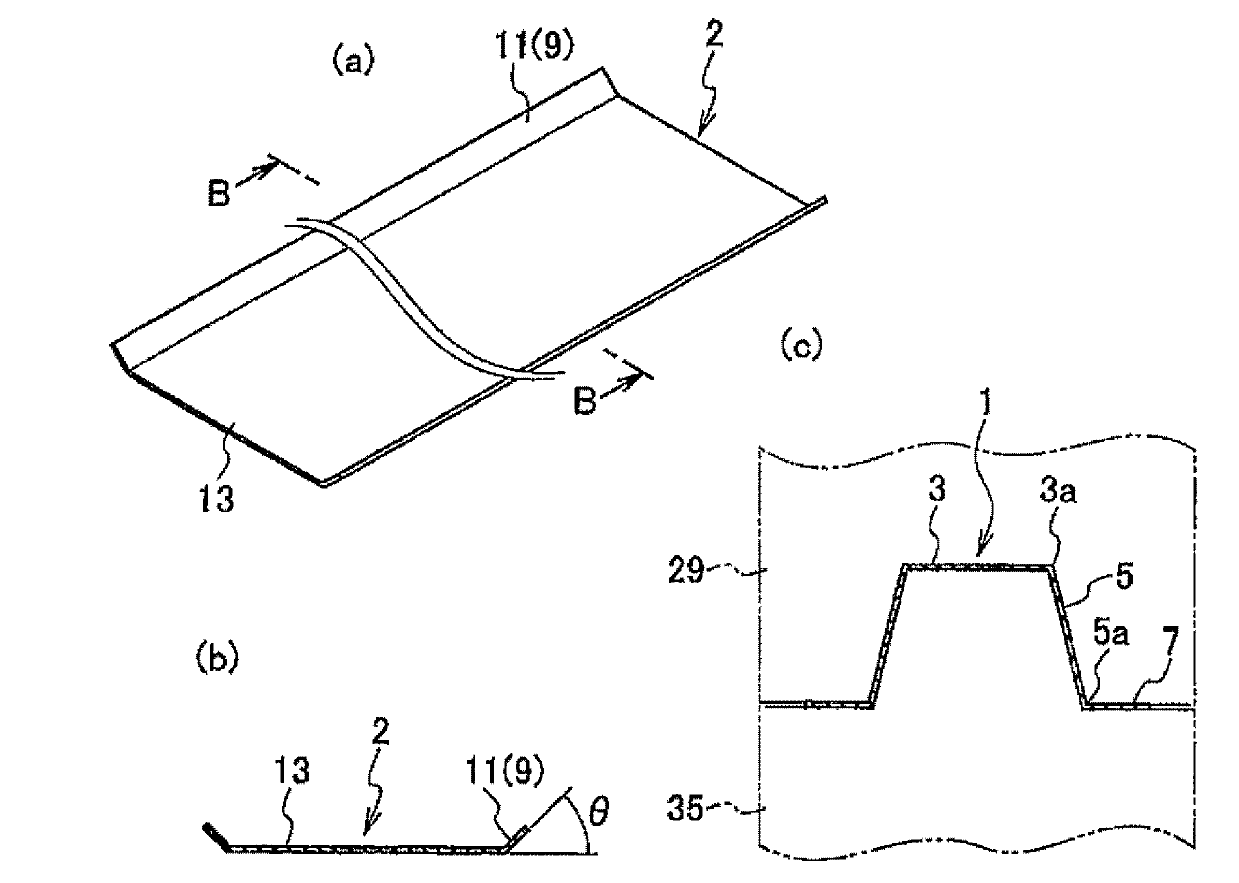

Stacked secondary battery

ActiveCN102742060ASuppress wrinklesSuppression of stack dislocationLarge-sized flat cells/batteriesFinal product manufactureElectrical and Electronics engineeringElectrode

Provided is a stacked secondary battery preventing the occurrence of the wrinkles of a separator and having no electrode-to-electrode and separator-to-separator stacking shifts. The stacked secondary battery has a plurality of flat positive electrodes (2) and negative electrodes (3) stacked alternately and has a plurality of pairs of separators (4'), intermittent bonding portions (6), and an outer circumferential bonding portion (7). The pairs of separators (4') sandwich and cover both the respective positive electrodes (2) and the respective negative electrodes (3) or sandwich and cover either the respective positive electrodes (2) or the respective negative electrodes (3). The intermittent bonding portions (6) are portions where the pairs of separators (4') are bonded and are disposed at intervals along the outer circumference of the positive electrodes (2) or negative electrodes (3). The outer circumferential bonding portion (7) is a portion where outer circumferential parts of the pairs of separators (4') are bonded to each other and are more hardened than any other portions.

Owner:ENVISION AESC ENERGY DEVICES LTD

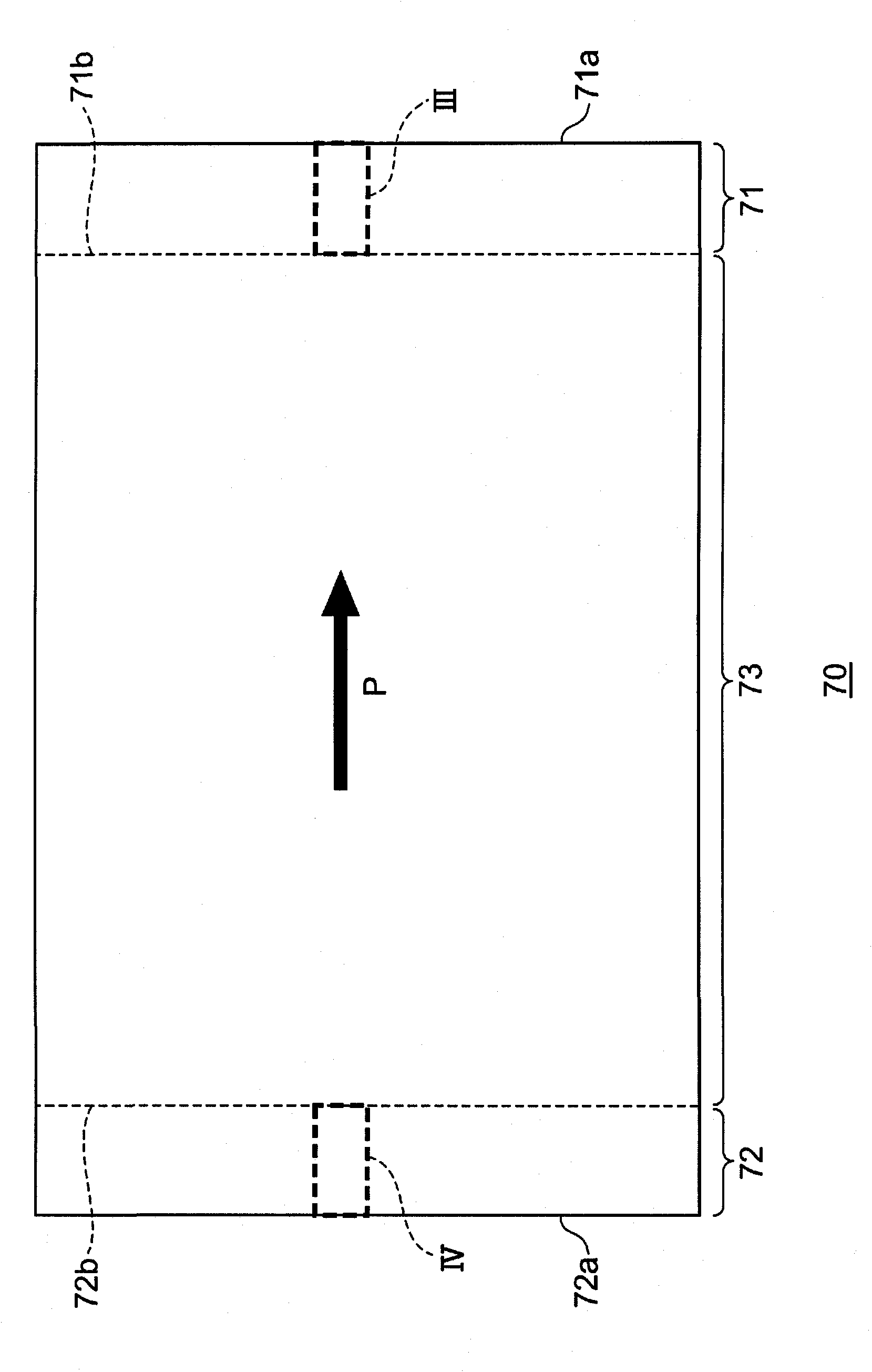

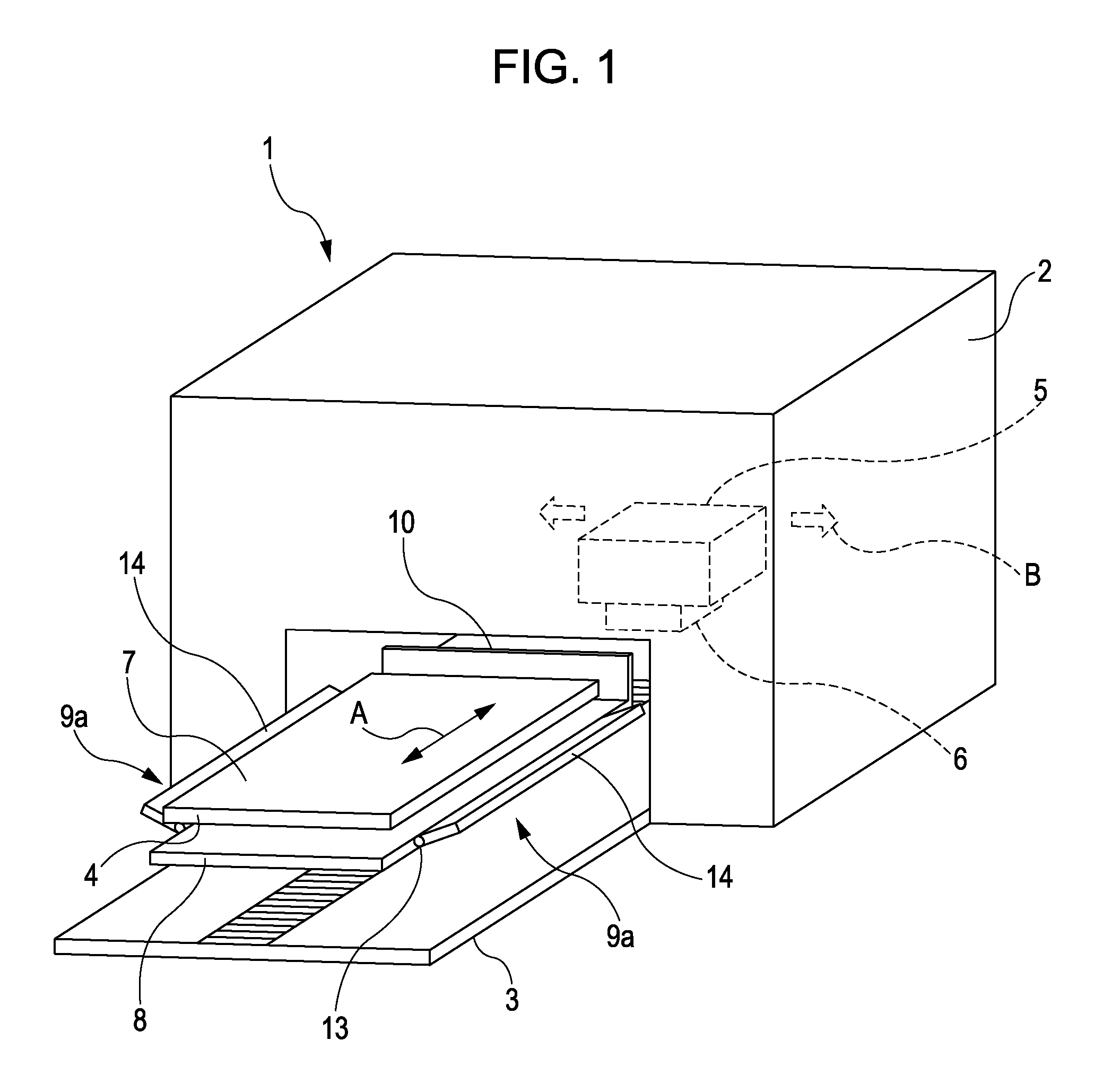

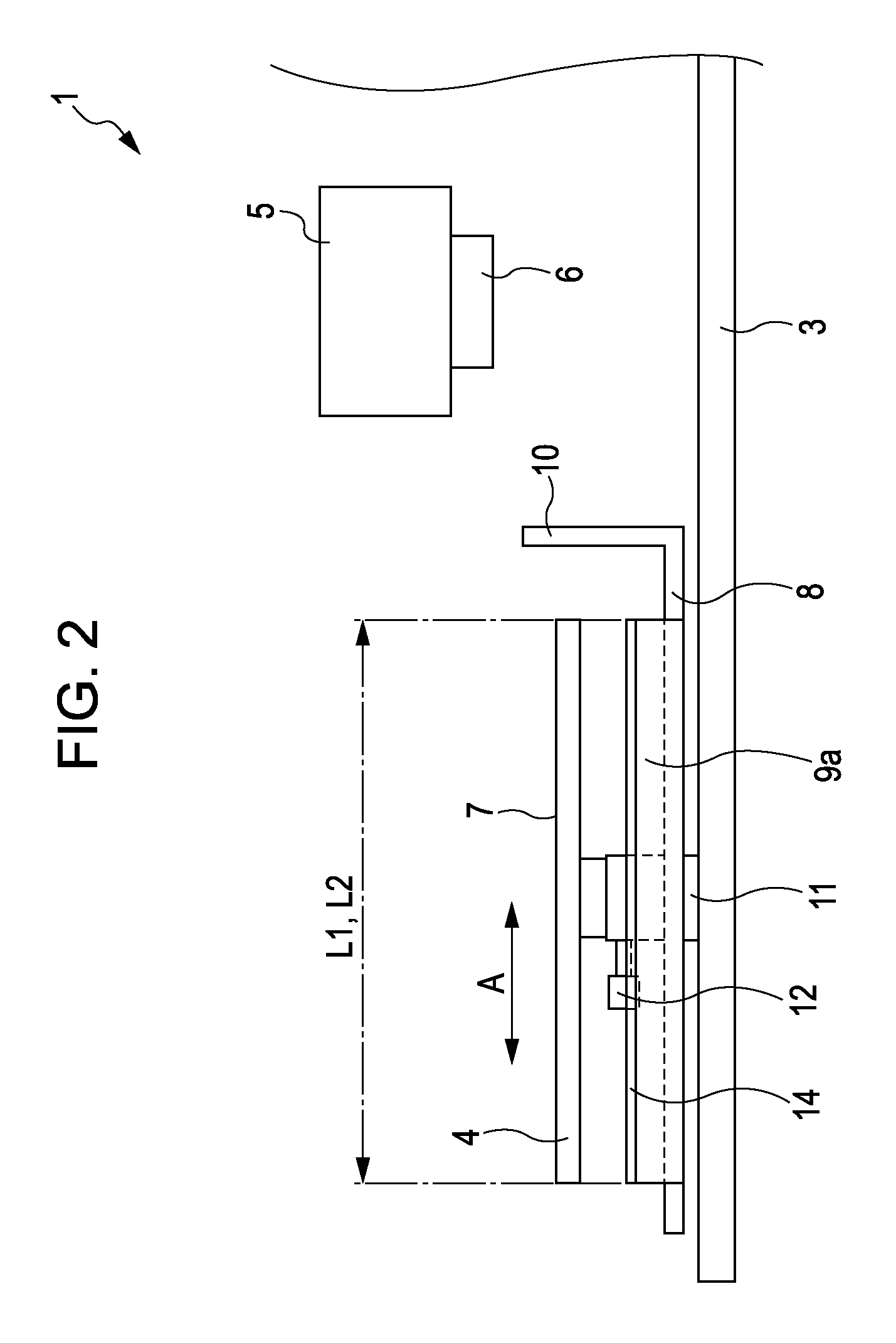

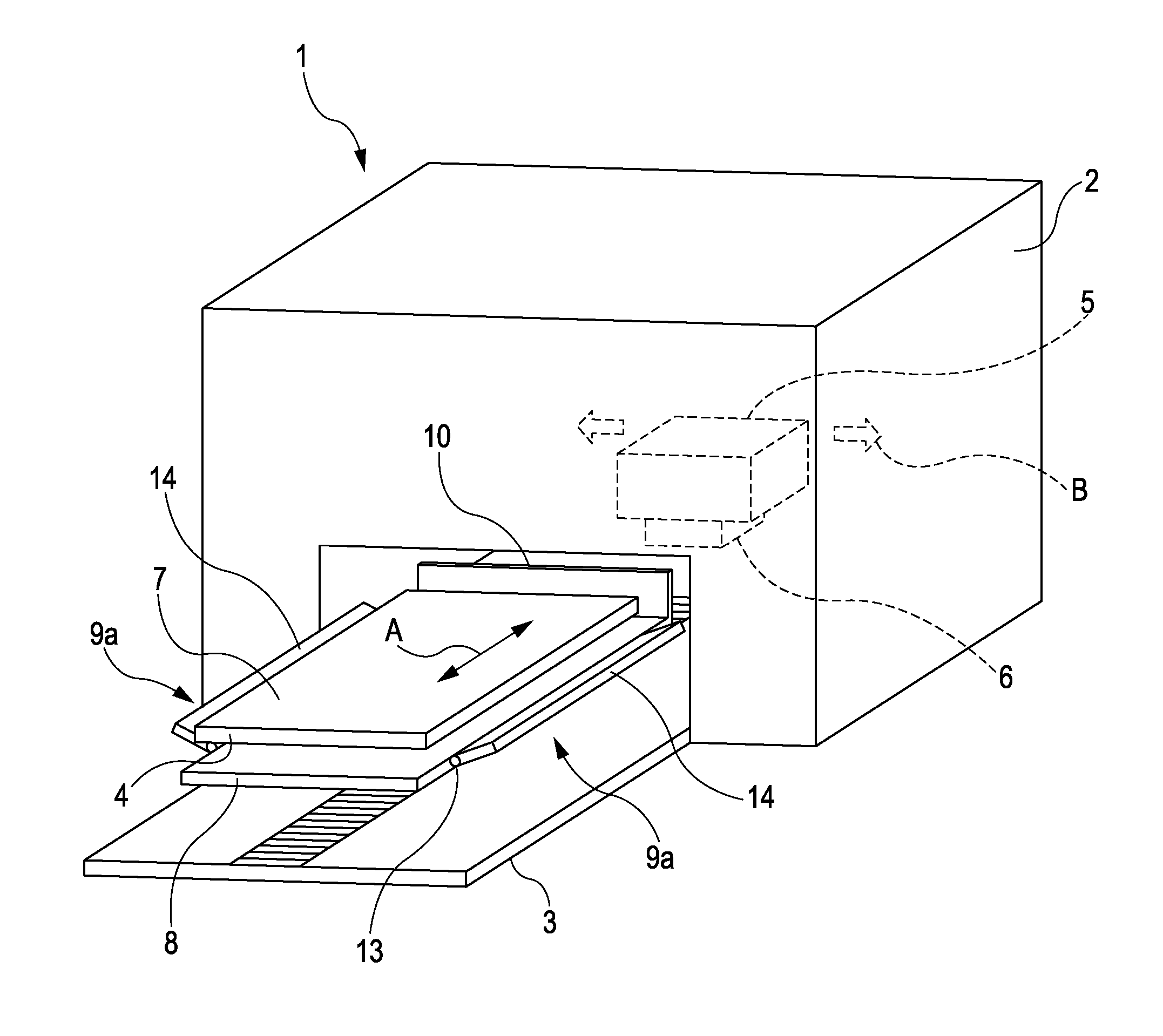

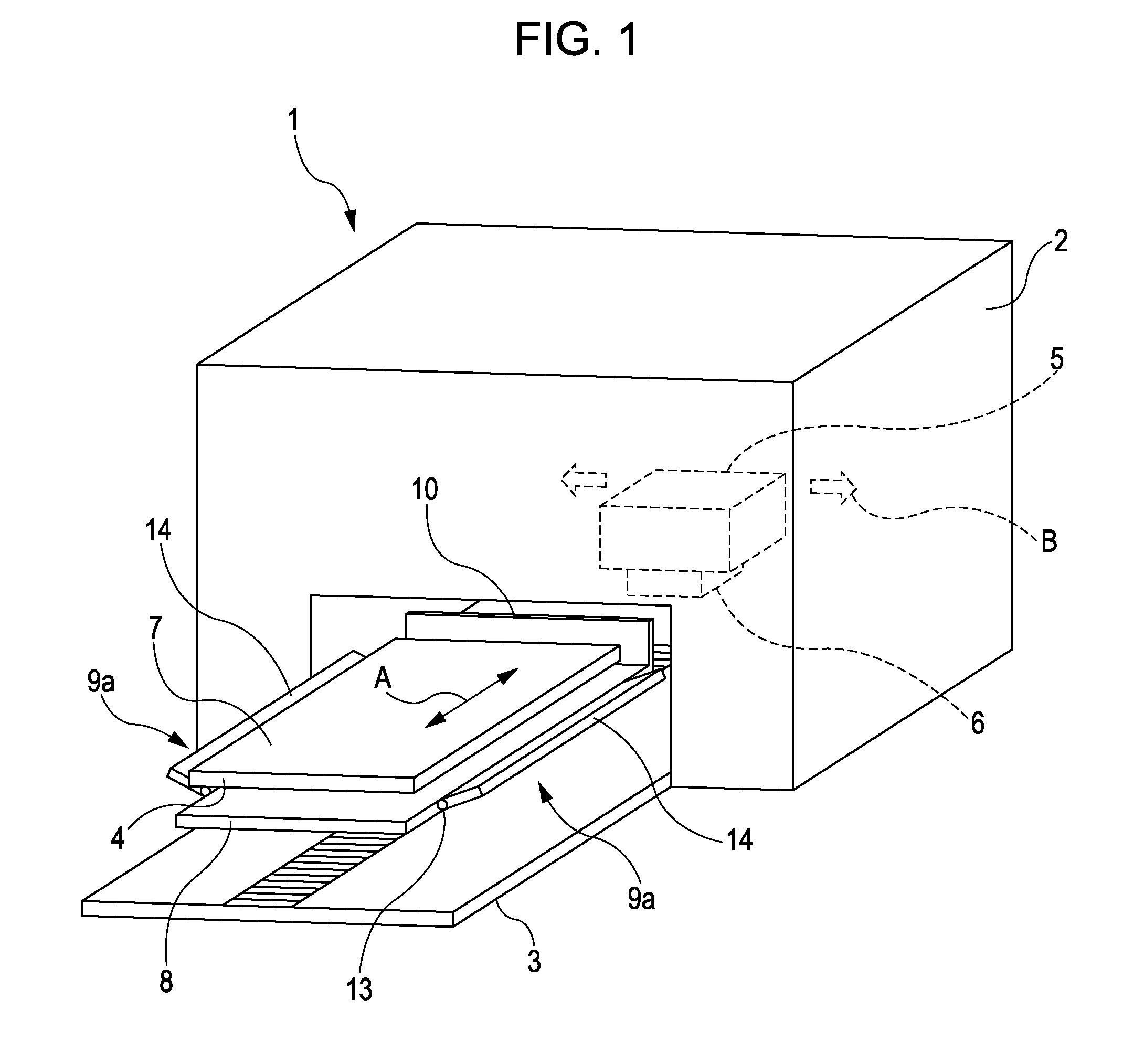

Recording apparatus and method of manufacturing recorded matter

InactiveUS9073369B2Wrinkles of the recording medium are easily suppressedImprove wrinklesTransfer printingPlaten pressesComputer scienceRecording media

Owner:SEIKO EPSON CORP

Recording apparatus and method of manufacturing recorded matter

InactiveUS20130336702A1Wrinkles of the recording medium are easily suppressedImprove wrinklesTypewritersOther printing apparatusComputer scienceRecording media

Owner:SEIKO EPSON CORP

Wearing article

ActiveCN101795653AAvoid exposurePrevent hangingAbsorbent padsBaby linensEngineeringMechanical engineering

A wearing article in which non-contractible regions on which contracting force of elastic members does not act are formed in front and rear waist belts and in which the elastic members do not protrude from the non-contractible regions and are not caught by the non-contractible regions. The front and rear waist members (5, 6) have mounted thereto the waist elastic members (18) extending in the vertical direction (Y). The waist elastic members (18) form the non-contractible regions (35), on which contracting force of the waist elastic members (18) does no act, without being superposed on portions where graphics of heat-bonded sheets (16, 17) are formed. The non-contractible regions (35) are formed in center portions in the lateral direction (X) of the front and rear waist belt members (5, 6) by cutting the waist elastic members (18) mounted in a stretched state without applying an adhesive agent between inner and outer surface sheets (12, 13)(14, 15). On the crotch-side edges (21, 22) of the non-contractible regions (35) are formed joined sections (36) where the inner and outer surface sheets (12, 13)(14, 15) are joined together by heat sealing.

Owner:UNI CHARM CORP

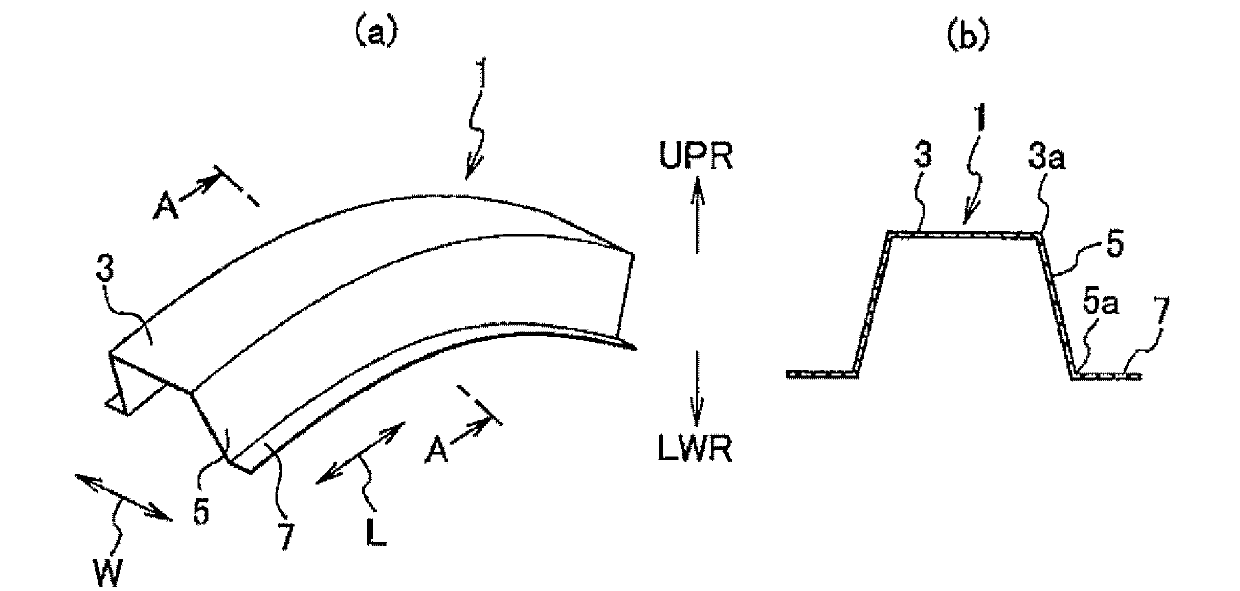

Press product forming method

Provided is a press product forming method which, even under the circumstance of press-forming a curved press product, can inhibit occurring of poor forming such as wrinkles or wrinkle overlap on flange portions. The curved press product is formed into a hat-like cross-section including an upper surface portion, side wall portions, and flange portions. The press product forming method includes: a pre-forming step of forming, at a widthwise end portion of a flat plate-like blank, at least one bending portion extending along a longitudinal direction; and a main forming step of forming the upper surface portion and the side wall portions under a state in which the bending portion is left.

Owner:TOPRE

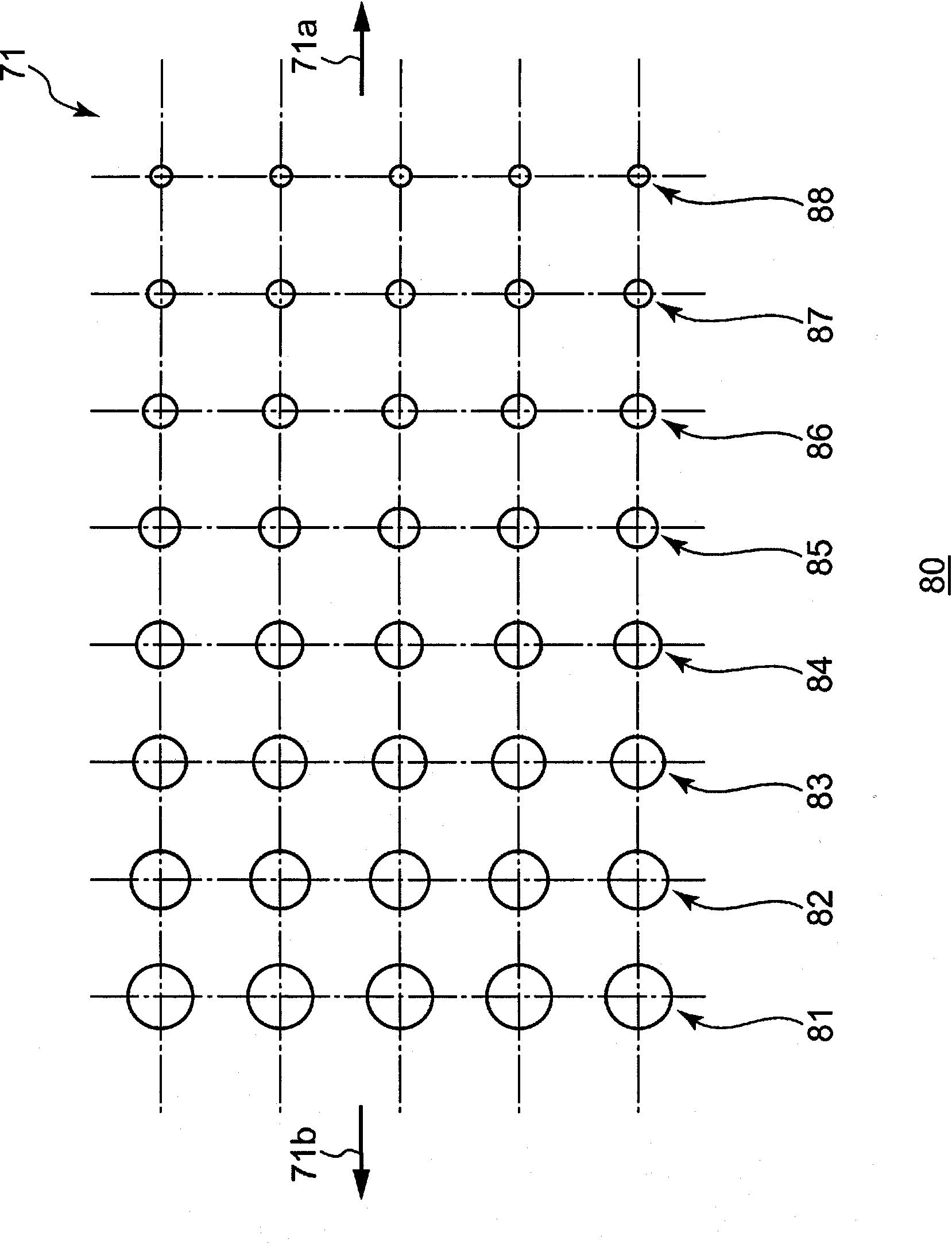

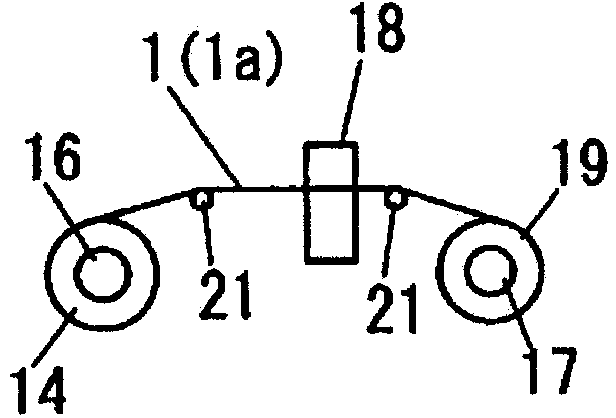

Carrying Device, Recording Device, and Carrying Method

InactiveUS20080128545A1Suppress wrinkleEasy to complyFilament handlingRotary pressesRecording headEngineering

A carrying device includes: a supply portion (16) for supplying a recording sheet (3) from a supply roll (11) wound with the recording sheet (3); a platen (18), which is opposed to a recording head (7) for performing recording on the recording sheet (3) supplied from the supply portion (16), for supporting the recording sheet (3); a take-up portion (20) in which the recording sheet (3) on which recording has been performed by the recording head (7) is taken up by a take-up roll (12); and a suction fan (52) for sucking the recording sheet (3) supported on the platen (18). The platen (18) is provided with, in a position corresponding to an area in which recording is performed by the recording head (7), a plurality of recessed portions (48), which are formed from an upstream side to a downstream side of the platen (18) in a carrying direction of the recording sheet (3) and are surrounded by projected walls (49), aligned in a width direction of the recording sheet (3). In bottom surfaces in the recessed portions (48), there are provided a plurality of suction holes (51) for sucking the recording sheet (3) by the suction fan (52). As a result, quality of recording by the recording head is increased by suppressing occurrence of wrinkles on a recording material which is carried.

Owner:SEIKO I INFOTECH

Method of manufacturing polarizing film

ActiveCN103163583APromote crystallizationHigh crystallinityPolarising elementsThin material handlingPolymer sciencePolyvinyl alcohol

A method of manufacturing a polarizing film according to an embodiment of the present invention includes forming a polyvinyl alcohol-based resin layer on a thermoplastic resin substrate having a crystallinity of 7% or less to produce a laminate and subjecting the laminate to a wet treatment followed by a drying treatment with a heat roll.

Owner:NITTO DENKO CORP

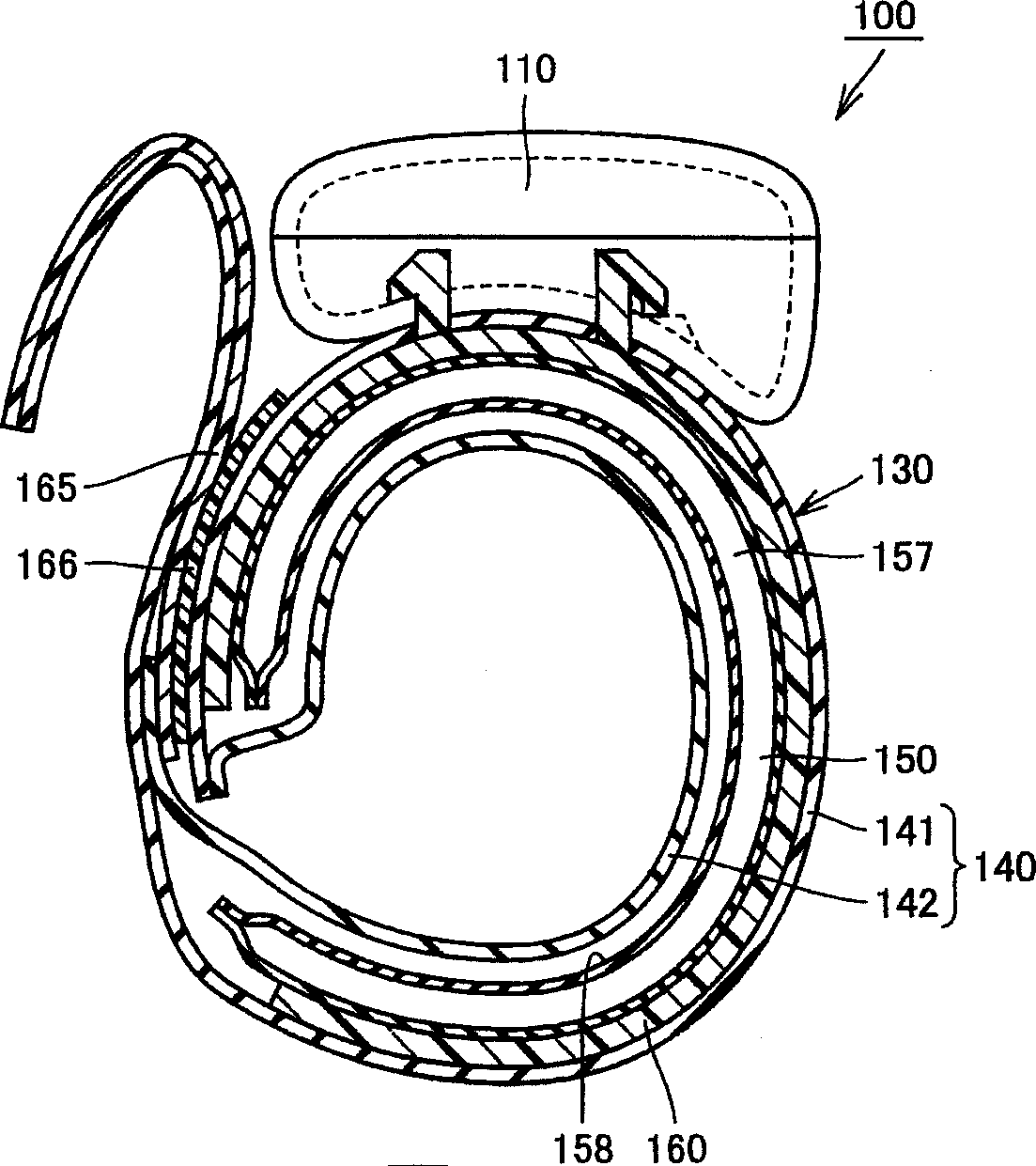

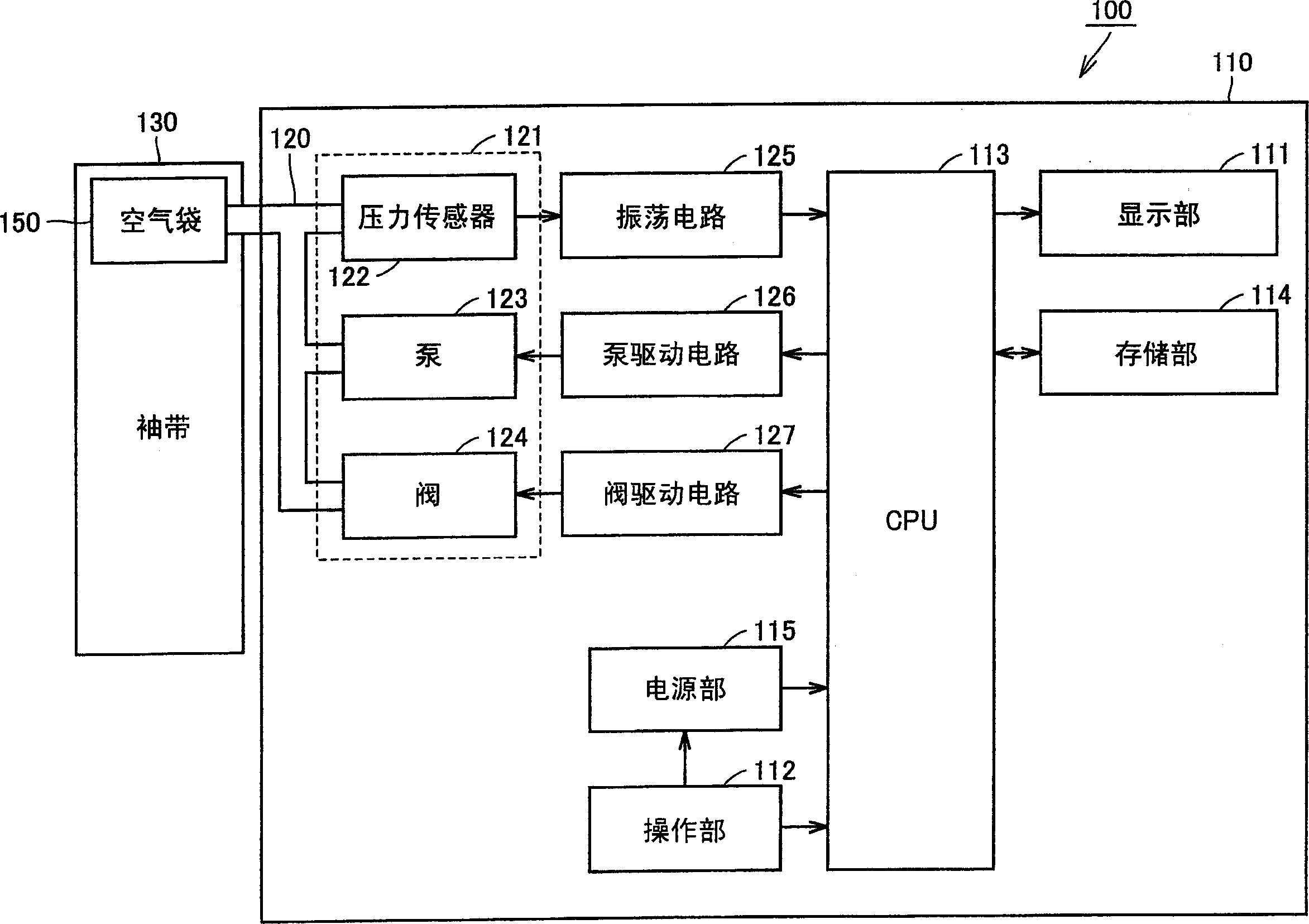

Blood pressure monitor and corresponding cuff

InactiveCN1820702APrecise compressionStability determinationBristleEvaluation of blood vesselsBlood Pressure DeterminationsBlood pressure monitors

An air bag (150) being inflated and deflated as air comes in and out is included. The air bag (150) is formed of a flexible sheet material. The air bag (150) has at least an inner circumferential sheet (162) positioned inside when a blood pressure monitor cuff is wrapped around a living body, and an outer circumferential sheet (161) positioned on the outer circumferential side of the inner circumferential sheet (162). The sheet material forming the air bag (150) has a thickness of 0.15 mm or less. Therefore, big deep wrinkles appearing on the inner surface of the fluid bag fitted on a living body can be reduced, which may otherwise give an adverse effect on blood pressure measurement.

Owner:OMRON HEALTHCARE CO LTD

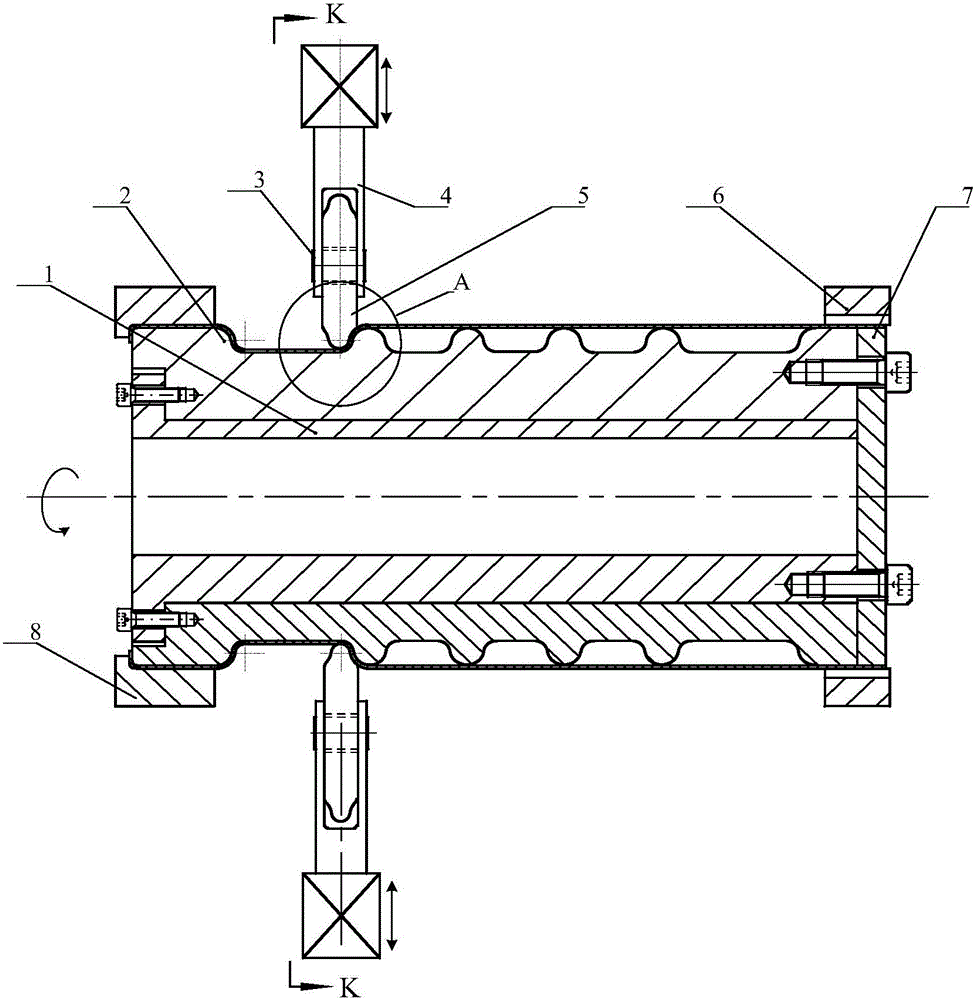

Large-diameter corrugated pipe vibration forming device and method

ActiveCN106040811AReduce deformation resistanceInhibits pipe wrinkling and crackingEngineeringHigh frequency vibration

The invention discloses a large-diameter corrugated pipe vibration forming device and a method. The forming device mainly consists of a mandrel, a corrugated core mold, a connecting disc, forming wheels, a support frame and a vibrating device. The corrugated core mold coats the mandrel, and is connected with a flange at the bottom of the mandrel and the connecting disc at the end part to form an integral mold. A pipe blank coats the outer surface of the corrugated core mold; left and right end clamping jaws are arranged at the two end parts of the pipe blank; and the forming wheels are distributed on the outer side of the pipe blank. After the clamping jaws clamp the pipe blank, the pipe blank rotates around the axis, the vibration excitation is applied to the forming wheels, and the forming wheels radially and axially feed the pipe blank. All traditional forming processes are synthesized; the friction force between the metal pipe blank and the forming mold is effectively reduced by a vibration exciting device; and when high-frequency vibration excitation is applied, the deformation resistance of the metal pipe blank can be reduced, the corrugation and breakage generation and development of the pipe blank are inhibited, the size precision of large-wave high corrugated pipes is guaranteed, and the surface smoothness of formed workpieces is increased.

Owner:YANSHAN UNIV

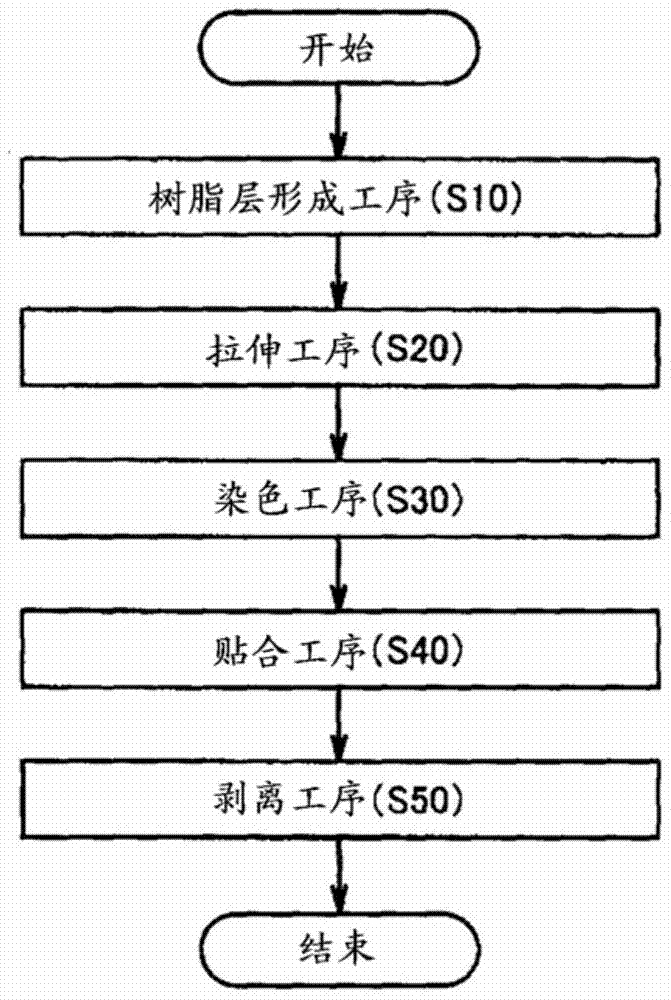

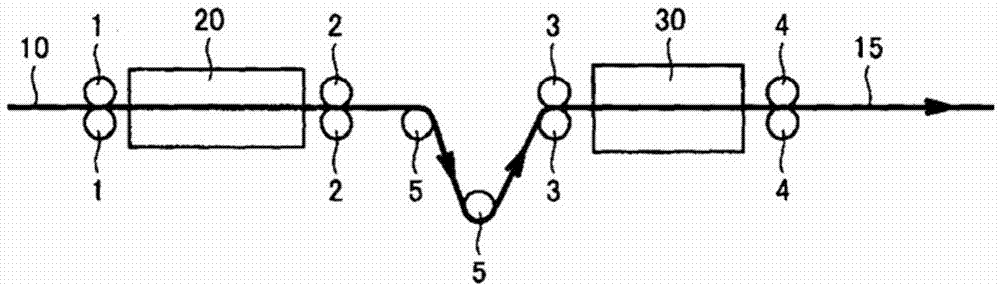

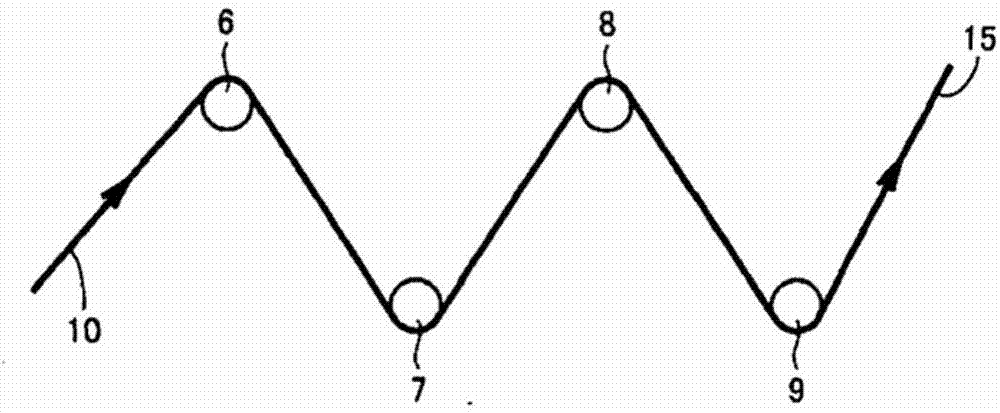

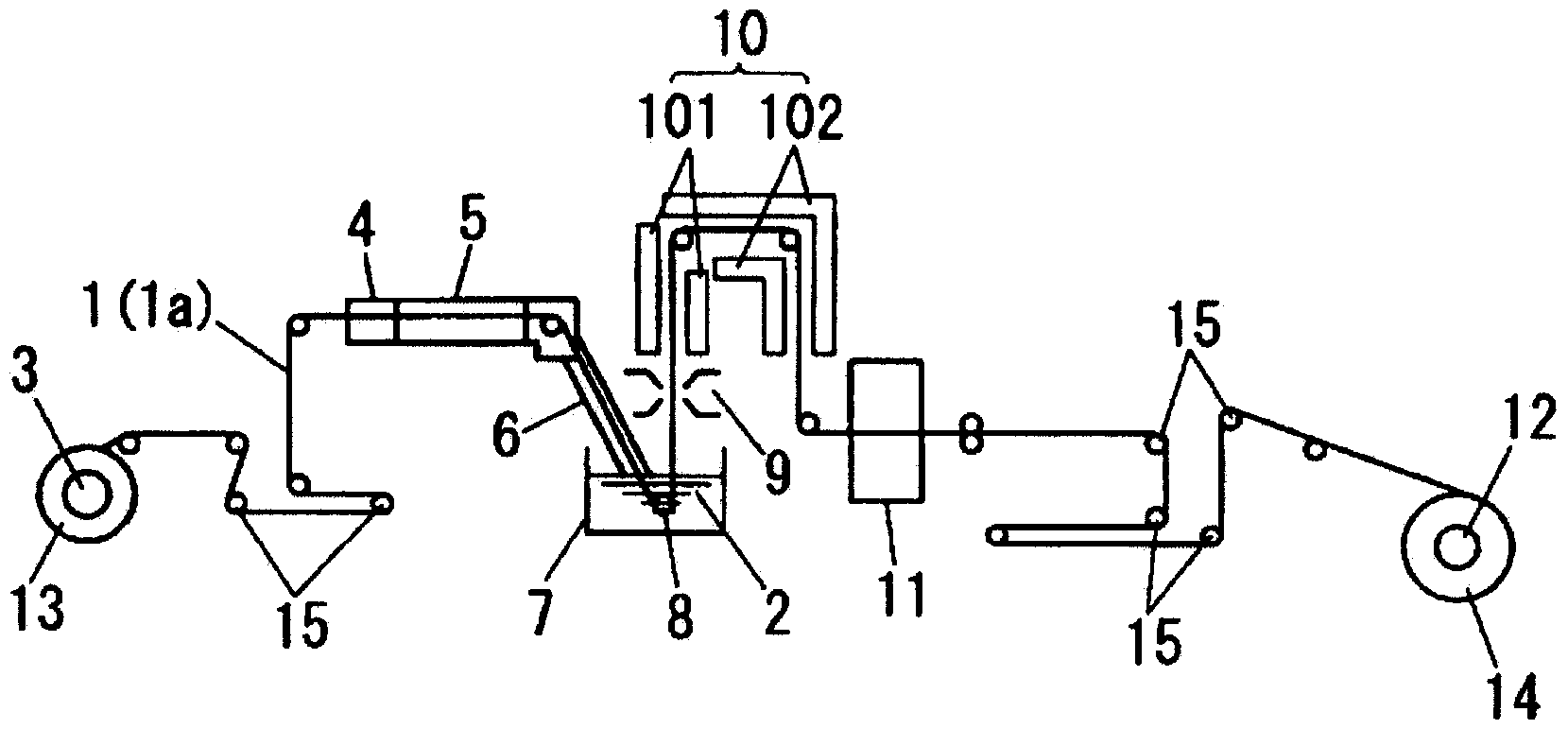

Method for manufacturing polarized laminated film and method for manufacturing polarizing plate

InactiveCN104737042AEfficient preparationGood manufacturing appearanceSynthetic resin layered productsPolarising elementsPolyvinyl alcoholDichroic dye

A method for manufacturing a polarized laminated film provided with a resin-layer-forming step for obtaining a laminated film by coating a substrate film with a coating liquid containing a polyvinyl alcohol resin, a drawing step for obtaining a drawn film by longitudinal uniaxial drawing of the laminated film, and a dyeing step for dyeing the polyvinyl alcohol resin layer of the drawn film with a dichroic dye to form a polarizer layer; and a method for manufacturing a polarizing plate using the polarized laminated film obtained by said method. The drawing step includes two or more drawing process steps, the draw ratio used in the first drawing process step is at least 50% of the draw ratio used in the second drawing process step and the total draw ratio of the polarizer layer is greater than 500%.

Owner:SUMITOMO CHEM CO LTD

Surface-treated hot-dipped steel material

ActiveCN103748253ASuppress wrinklesInhibit saggingHot-dipping/immersion processesSuperimposed coating processTitaniumZirconium

A surface-treated hot-dipped steel material comprises a steel material and a coating material formed on the surface of the steel material, wherein the coating material comprises a plating layer and a coating film formed on the surface of the plating layer and comprising an organic resin in this order when observed from the steel material side, the plating layer contains Al, Zn, Si and Mg as constituent elements, the Al content and the Mg content in the plating layer are 25 to 75 mass% and 0.1 to 10 mass%, respectively, the plating layer contains 0.2 to 15 vol% of an Si-Mg phase, the ratio of the content of Mg in the Si-Mg phase to the total content of Mg in the plating layer is 3 to 100% inclusive by mass, and the organic resin is crosslinked with at least one component selected from a silane coupling agent, a crosslinkable zirconium compound, a crosslinkable titanium compound, an epoxy compound and an amino resin.

Owner:NIPPON STEEL CORP

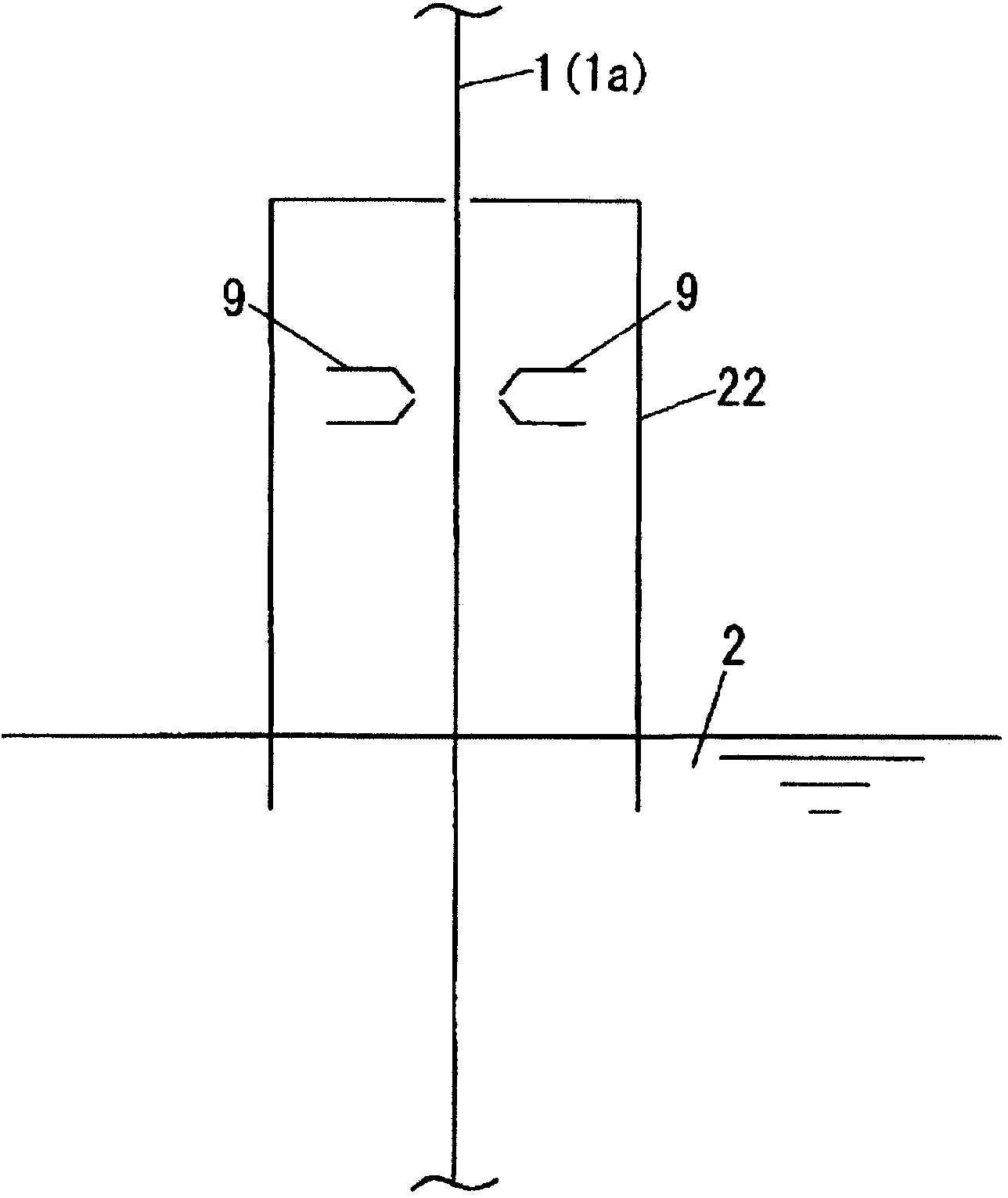

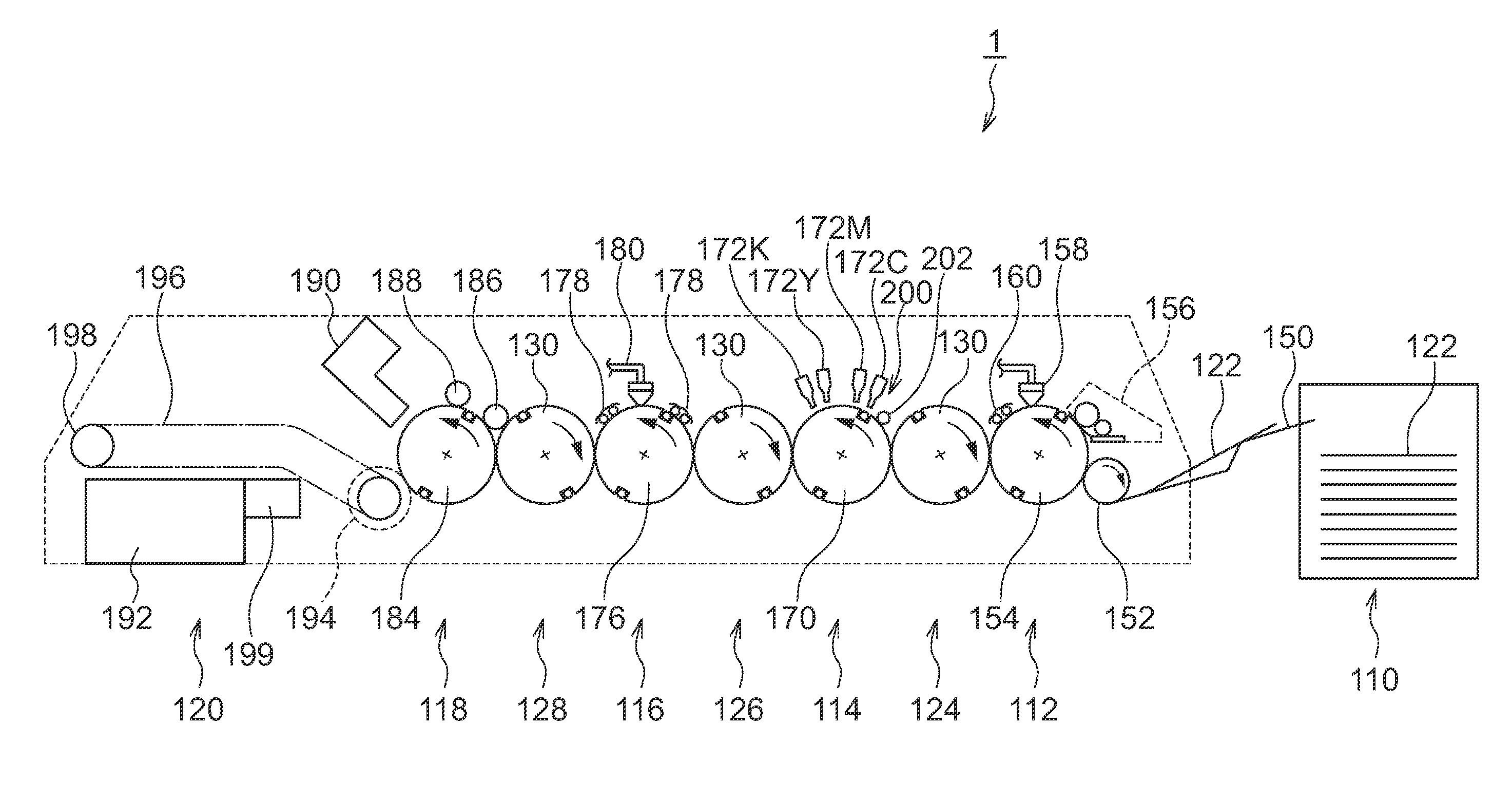

Light source device and display apparatus

InactiveUS20160195770A1Inhibit deteriorationSuppress wrinklesDiffusing elementsLighting heating/cooling arrangementsWrinkle skinComputational physics

Provided are a light source device capable of suppressing the occurrence of wrinkles on an optical sheet even if the optical sheet expands due to heat generated at the time of light emission, and a display apparatus including the light source device. In the light source device, an optical sheet is disposed with one surface facing the light source unit, while the light source unit and the optical sheet are supported by a support member. A contact portion being in contact with the peripheral edge part of the other surface of the optical sheet is pressed to the optical sheet by a connecting member, and the optical sheet is held between the contact portion and the support member. The contact portion and the support member holding the optical sheet are connected with each other by the connecting member. The connecting member is configured to have a weakened force of pressing the contact portion if a surrounding temperature reaches a predetermined temperature or higher.

Owner:SAKAI DISPLAY PROD

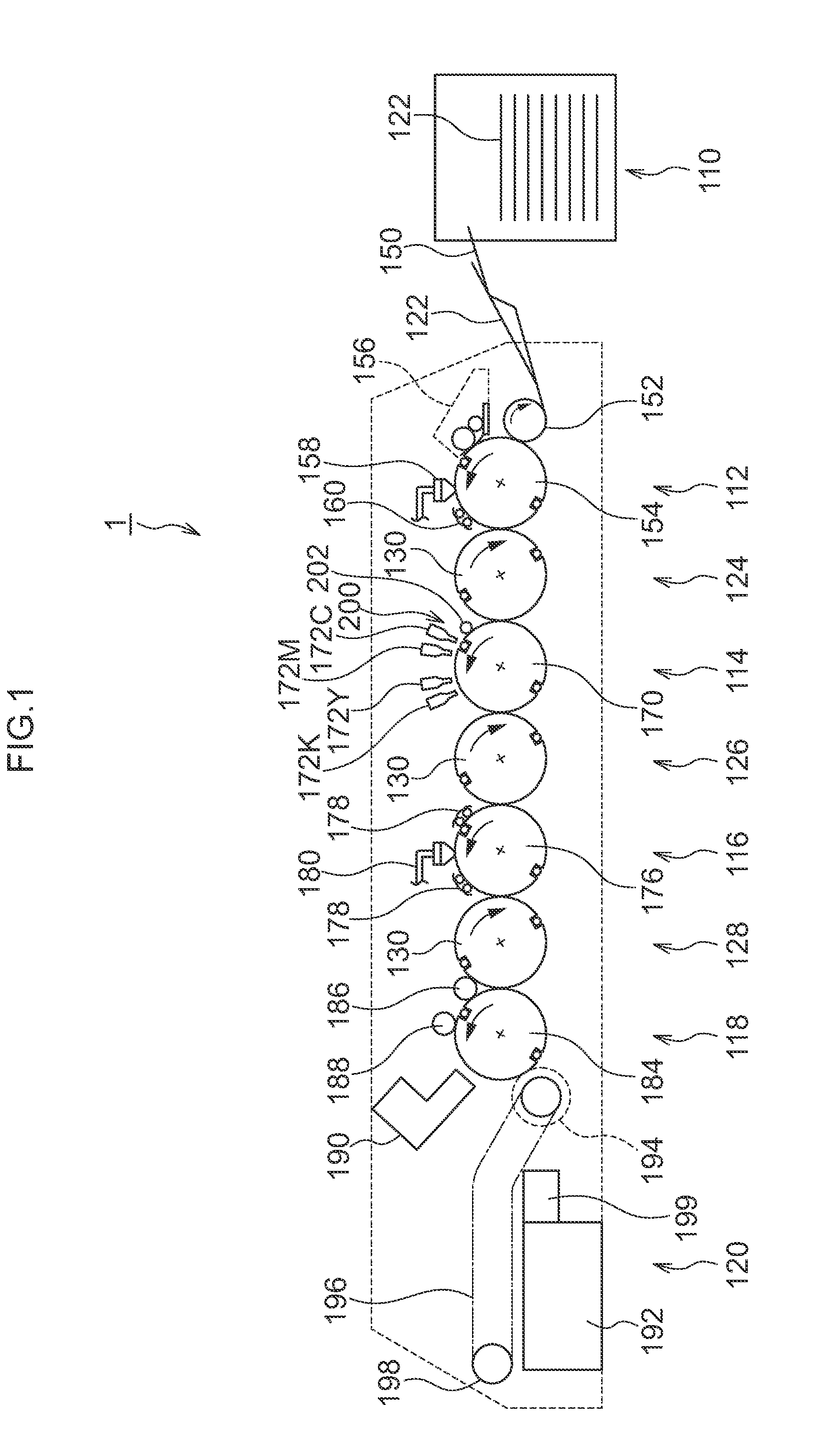

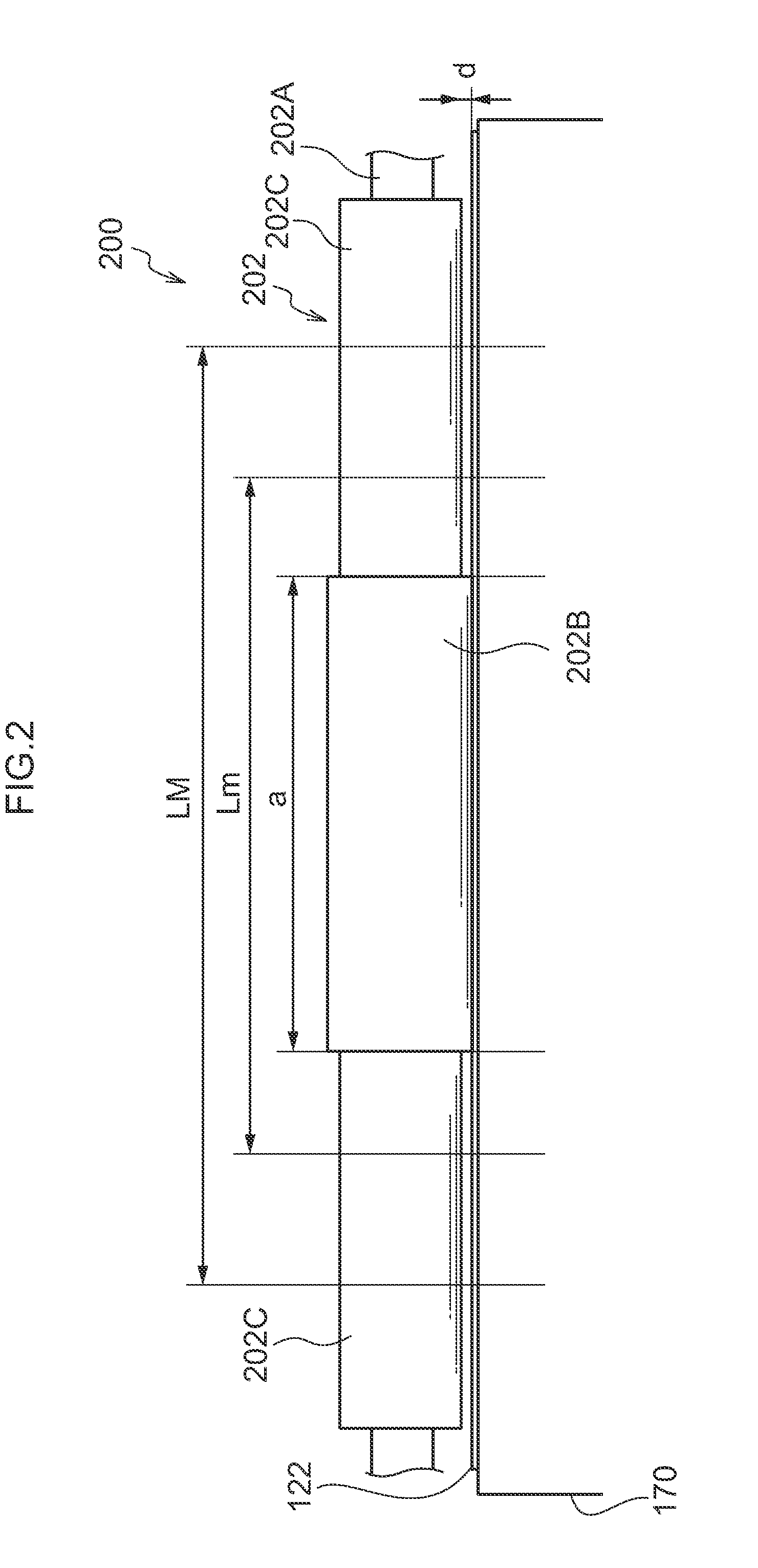

Conveying device and image forming apparatus

InactiveUS20120188318A1Suppress wrinklesSuppressing of creaseOther printing apparatusImage formationEngineering

A conveying device comprising a conveying body that conveys a recording medium; and a press roller comprising a large diameter portion that is formed at an axial direction central portion of the press roller and makes contact with the conveying body, and small diameter portions formed at both axial direction sides of the large diameter portion with a smaller diameter than the large diameter portion. Only a width direction central portion of the recording medium is pressed against the conveying body by the large diameter portion.

Owner:FUJIFILM CORP

Process for producing a polarizing film

ActiveCN101852879ANo color deviationNo scratchesPolarising elementsNon-linear opticsForeign matterPolyvinyl alcohol

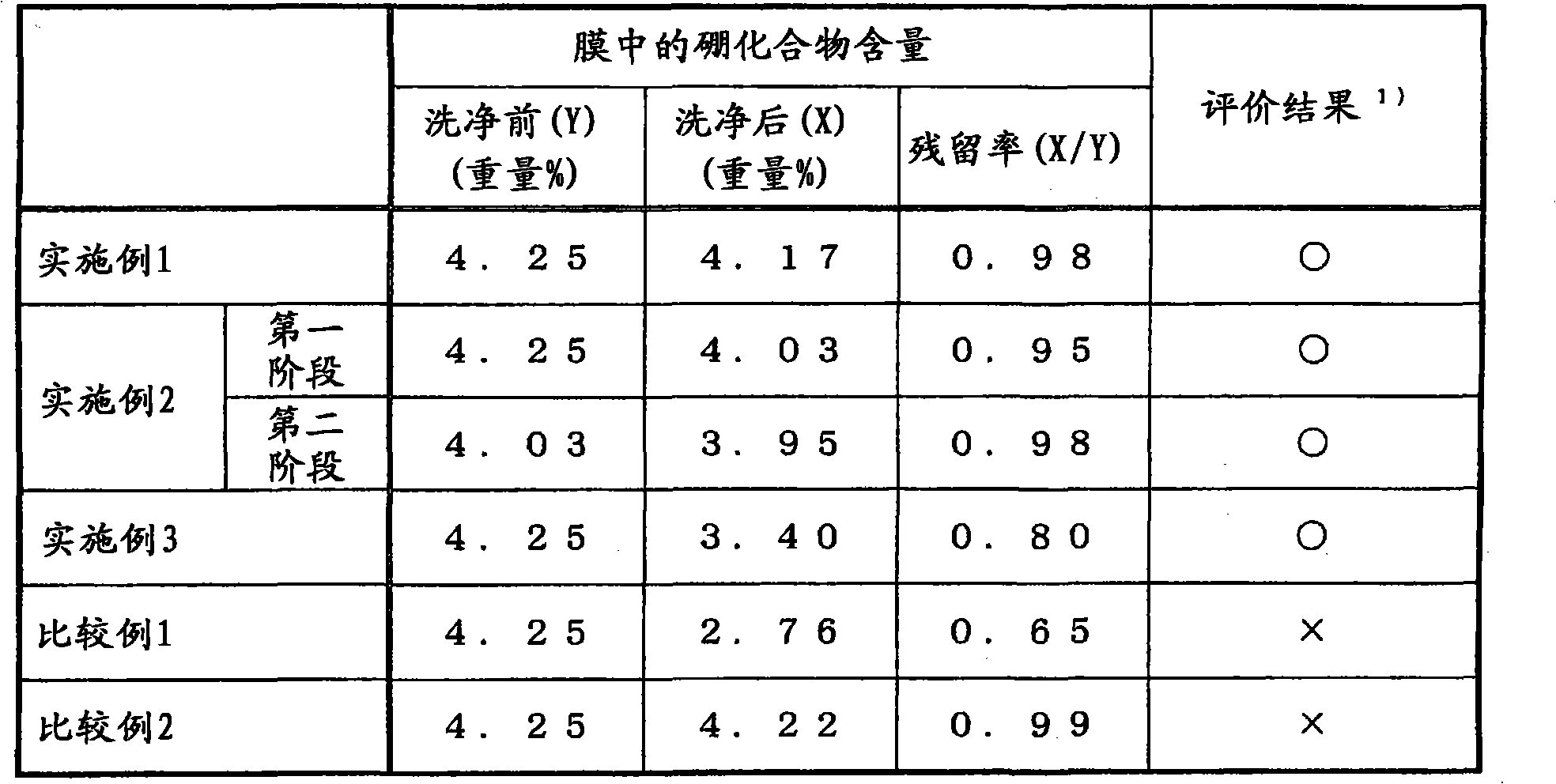

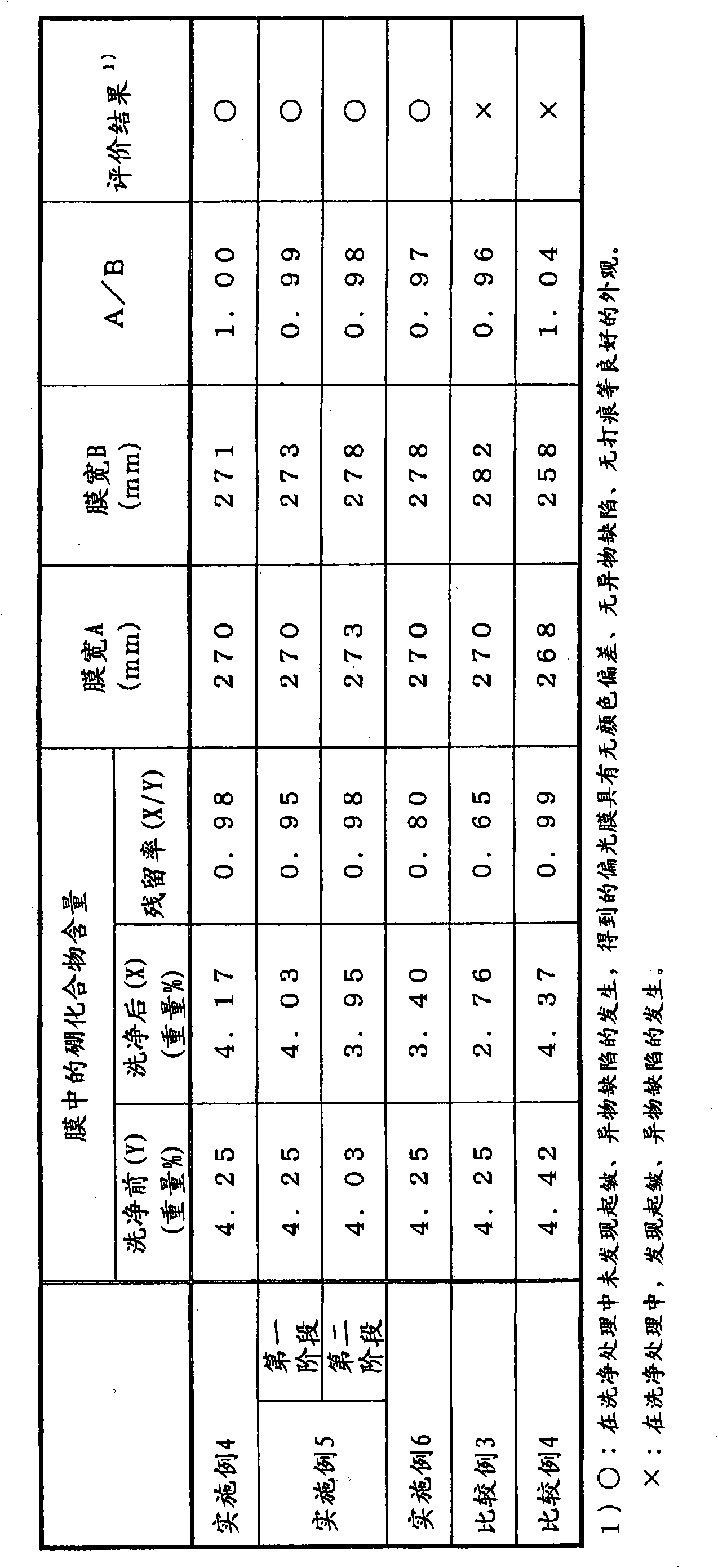

The invention provides a process for producing a polarizing film, performing swelling treatment, dyeing treatment, boric acid treatment washing treatment for polyvinyl alcohol films and performing single axle stretching before treatment and / or in treatment, wherein when the boron compound content in the film before washing is Y and the boron compound content in the film after washing is X, the residual rate of the boron compound content before and after washing treatment at one time is 0.7-0.98; or when the film width before washing treatment is A and the film width after washing treatment is B, A / B before and after washing treatment at one time is 0.97-1.03. The invention provides the process for producing the polarizing film having a good appearance without color deviation, foreign matter defects nor dints.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com