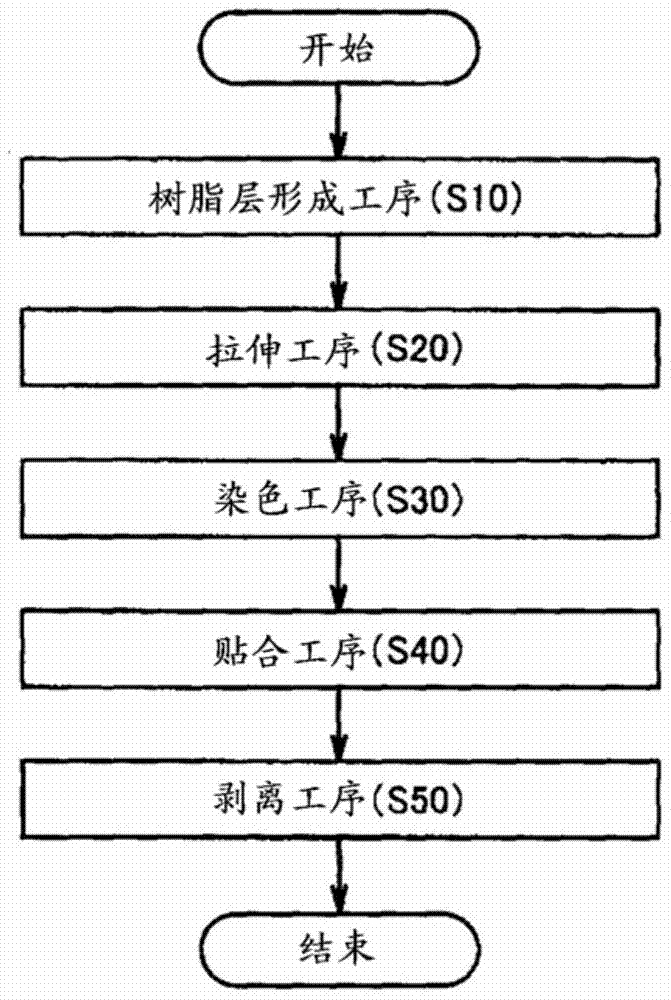

Method for manufacturing polarized laminated film and method for manufacturing polarizing plate

A manufacturing method, a technology for laminating films, applied in polarizing elements, chemical instruments and methods, coatings, etc., can solve problems such as difficulty and film breakage, and achieve the effect of suppressing wrinkles and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

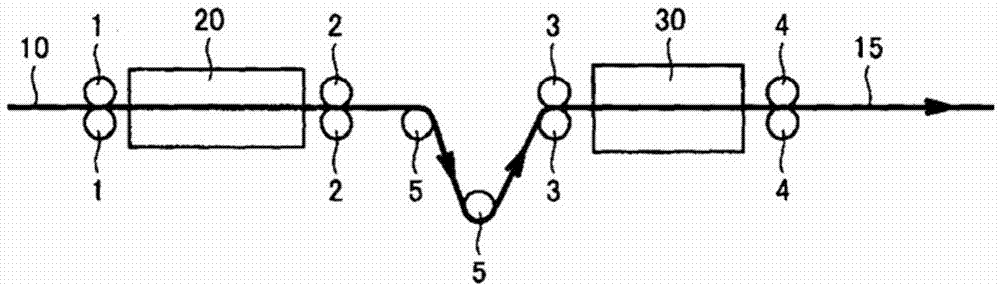

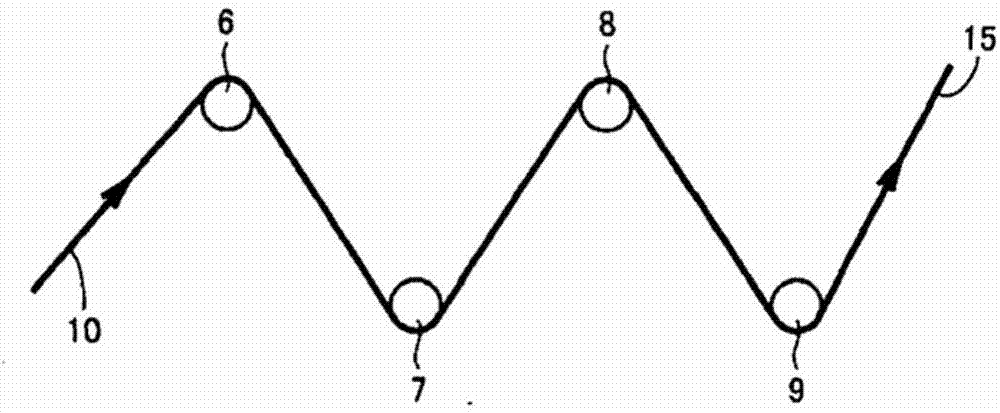

Method used

Image

Examples

Embodiment 1

[0187] (1) Production of substrate film

[0188]By co-extrusion molding using a multilayer extrusion molding machine, a random copolymer of propylene / ethylene containing about 5% by weight of ethylene units ("Sumitomo Noblen W151" manufactured by Sumitomo Chemical Co., Ltd., melting point Tm = 138°C) on both sides of a resin layer consisting of a propylene homopolymer ("Sumitomo Noblen FLX80E4" manufactured by Sumitomo Chemical Co., Ltd., melting point Tm = 163°C) is a long substrate with a three-layer structure. material film. The total thickness of the base film was 100 μm, and the thickness ratio (FLX80E4 / W151 / FLX80E4) of each layer was 3 / 4 / 3.

[0189] (2) Production of laminated film (resin layer formation process)

[0190] Polyvinyl alcohol powder (“Z-200” manufactured by Nippon Synthetic Chemical Industry Co., Ltd., average degree of polymerization 1100, average degree of saponification 99.5 mol%) was dissolved in hot water at 95°C to prepare polyethylene with a concen...

Embodiment 2

[0204] A polarizing plate was produced in the same manner as in Example 1, except that the draw ratios of the first-stage and second-stage stretch treatments were 2.50 times and 2.32 times (total draw ratio 5.80 times), respectively. The thickness of the polyvinyl alcohol-type resin layer in a stretched film was 4.8 micrometers on one side, and 5.0 micrometers on the other side. Wrinkles were not observed in the stretched film, and the thickness difference in the film width direction was 2 μm, and the stretching was performed uniformly. The bonding step and the peeling step were also carried out without any problem, and a polarizing plate on which a protective film was laminated could be obtained.

Embodiment 3

[0206] A polarizing plate was produced in the same manner as in Example 1, except that the draw ratios in the first-stage and second-stage stretch treatments were 2.80 times and 2.07 times (total draw ratio 5.80 times), respectively. The thickness of the polyvinyl alcohol-type resin layer in a stretched film was 5.2 micrometers on one side, and 5.4 micrometers on the other side. Wrinkles were not observed in the stretched film, and the thickness difference in the width direction of the film was 2 μm, and the stretching was performed uniformly. The bonding step and the peeling step were also carried out without any problem, and a polarizing plate on which a protective film was laminated could be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com