Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Efficiently manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fan

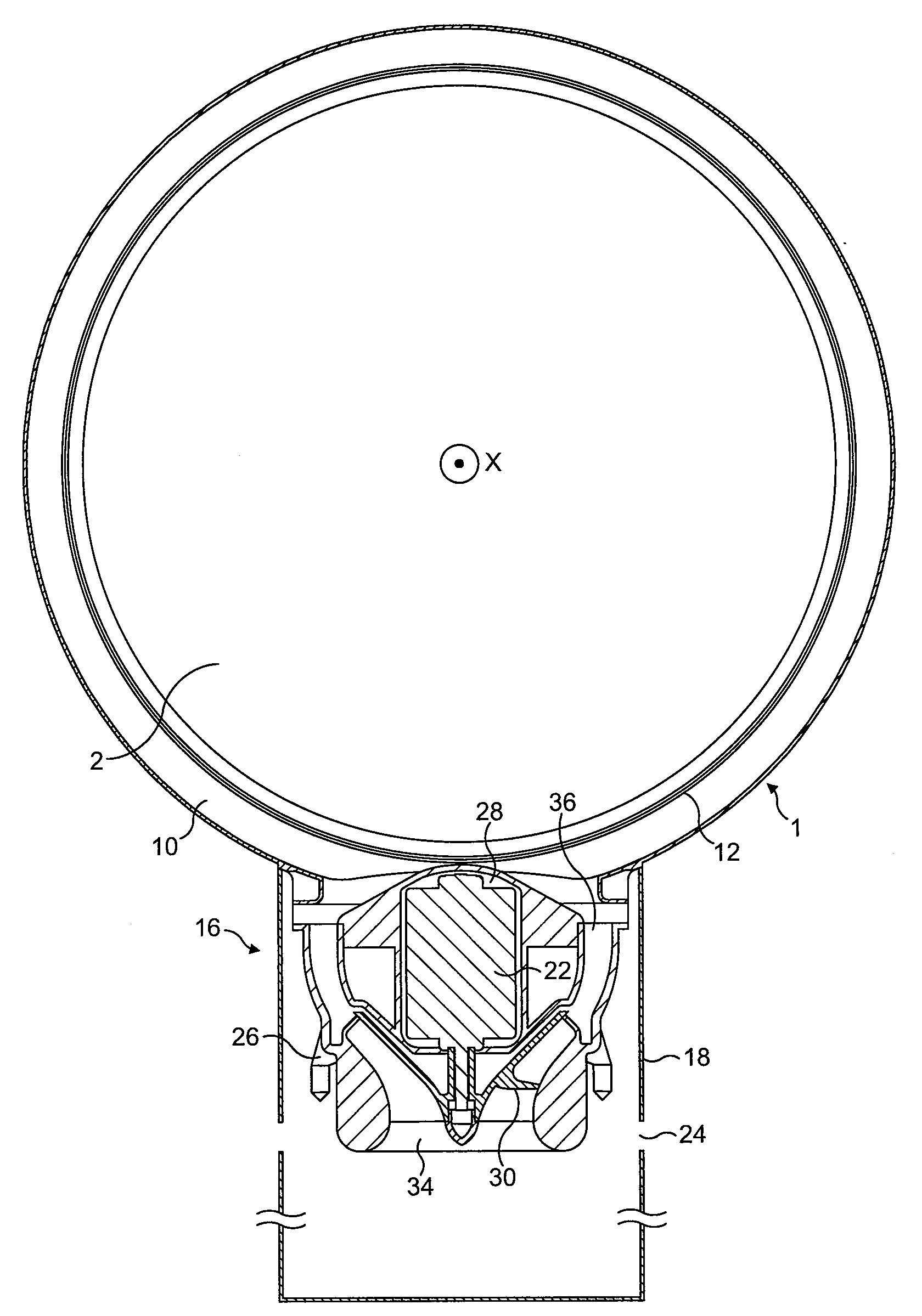

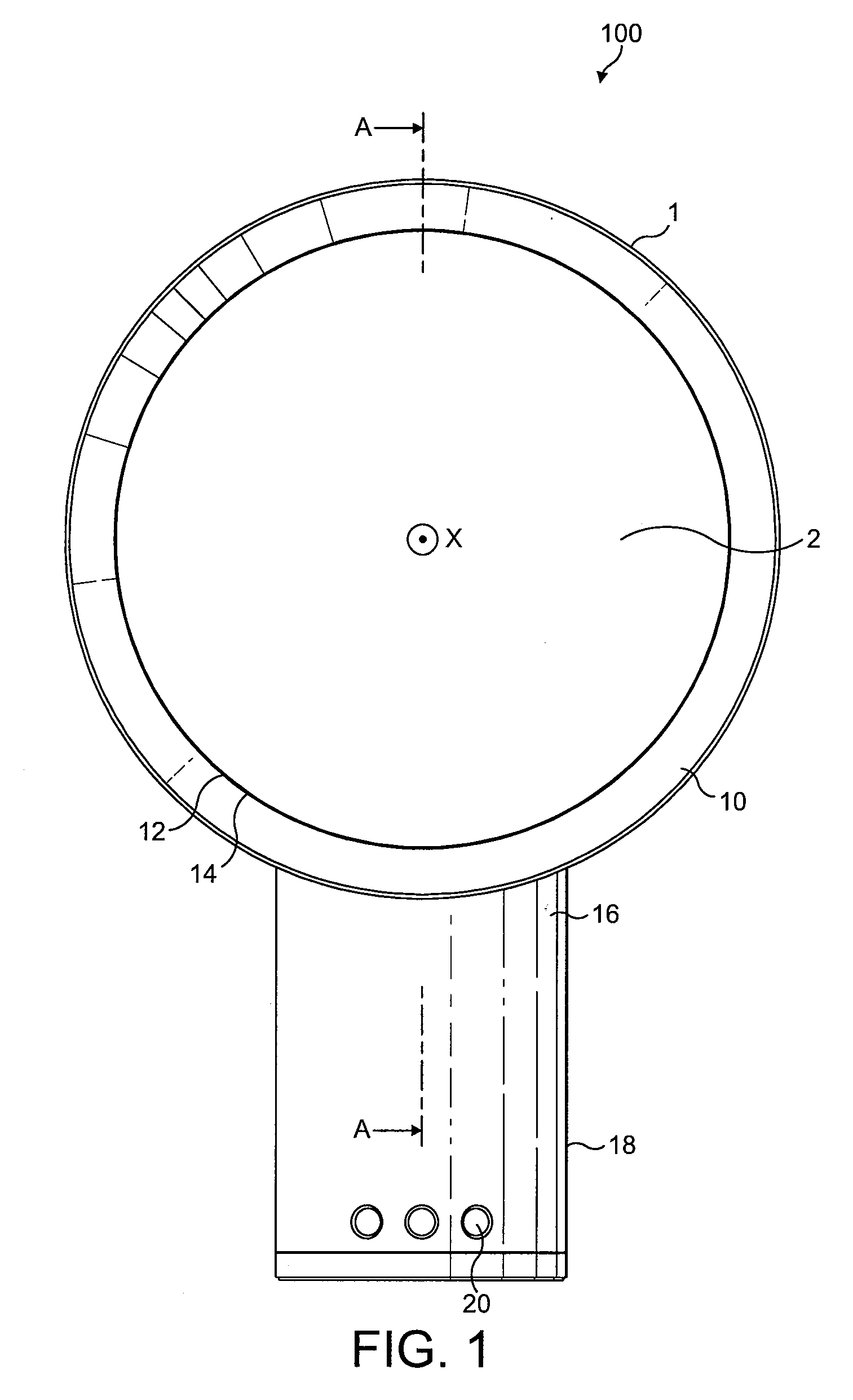

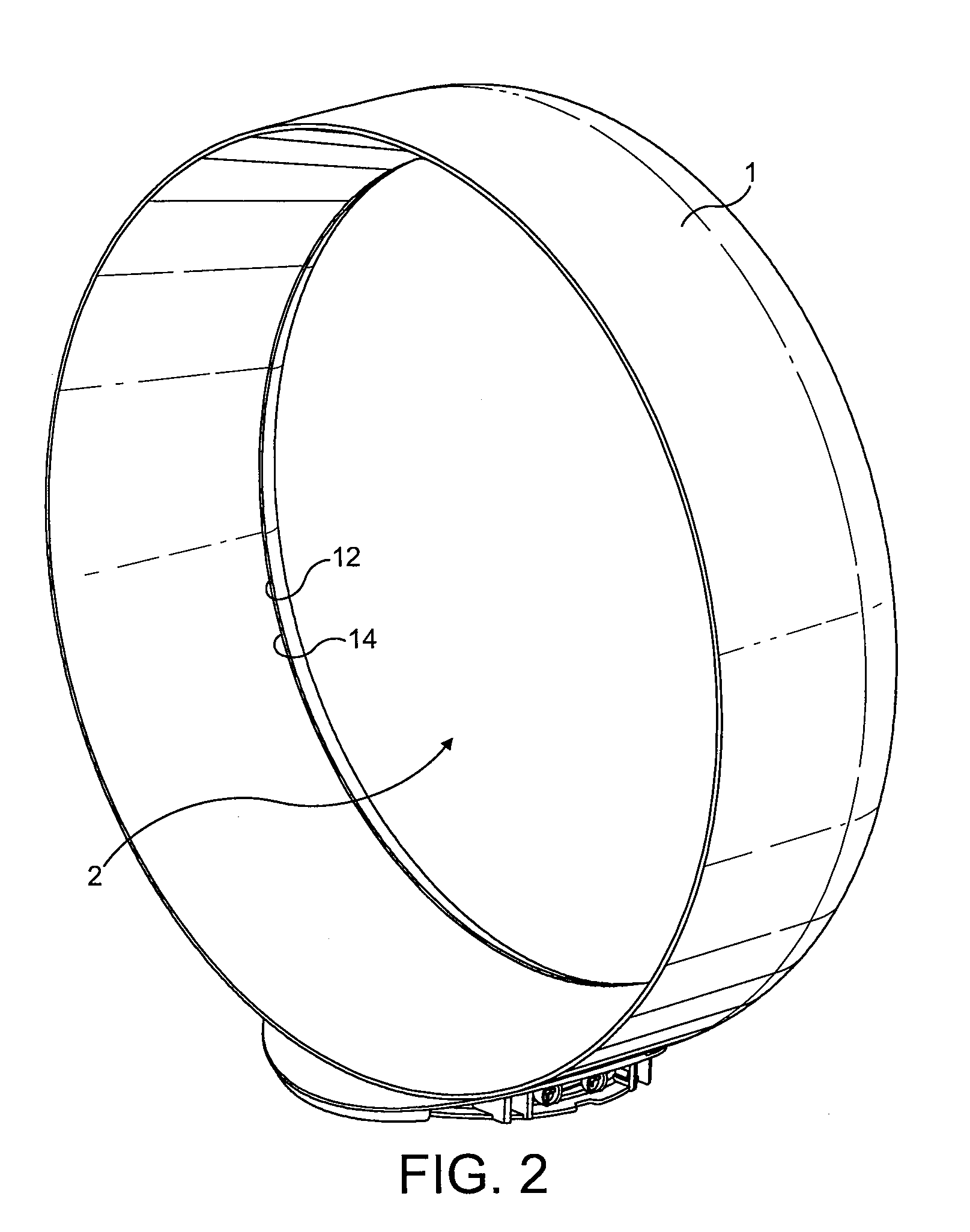

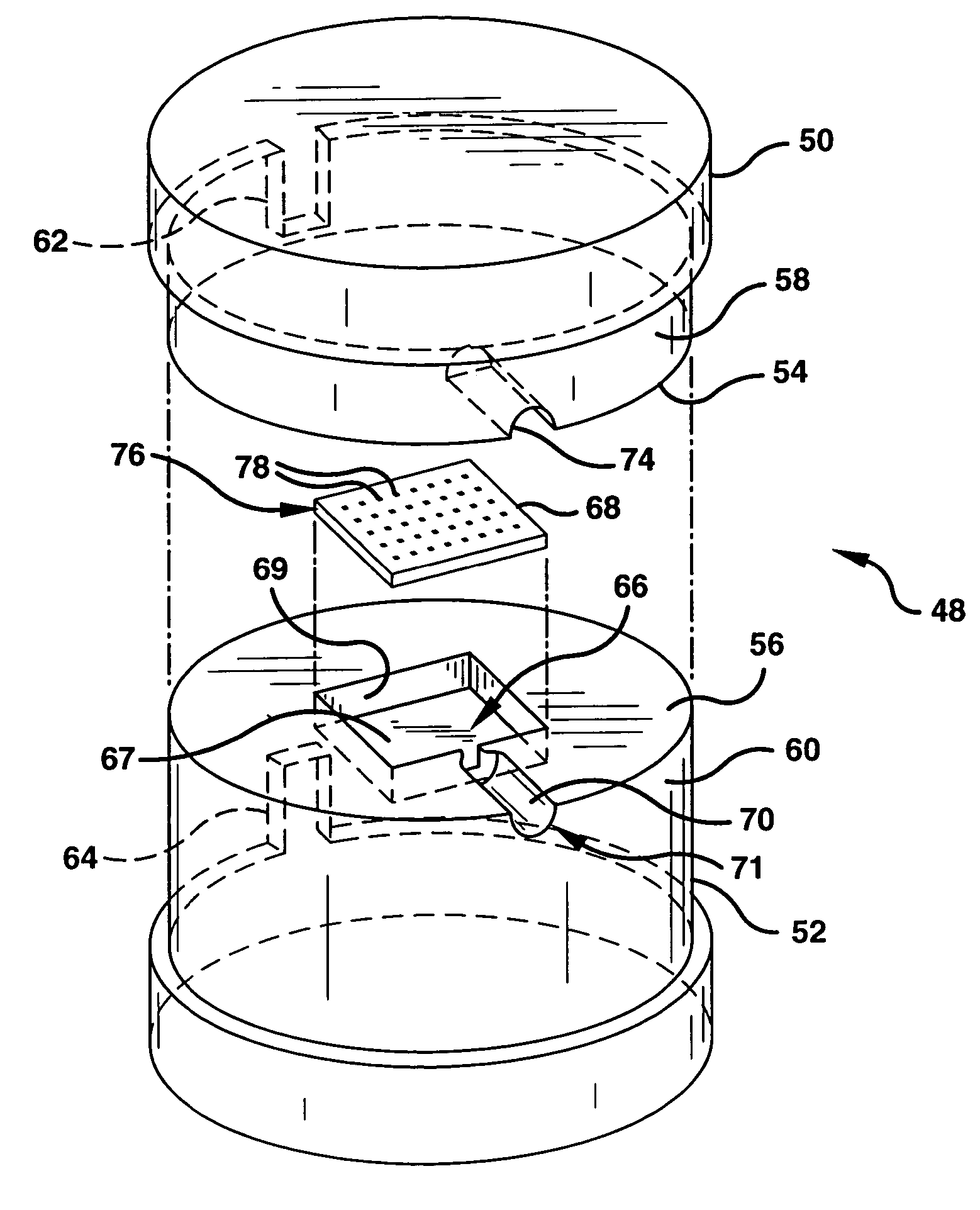

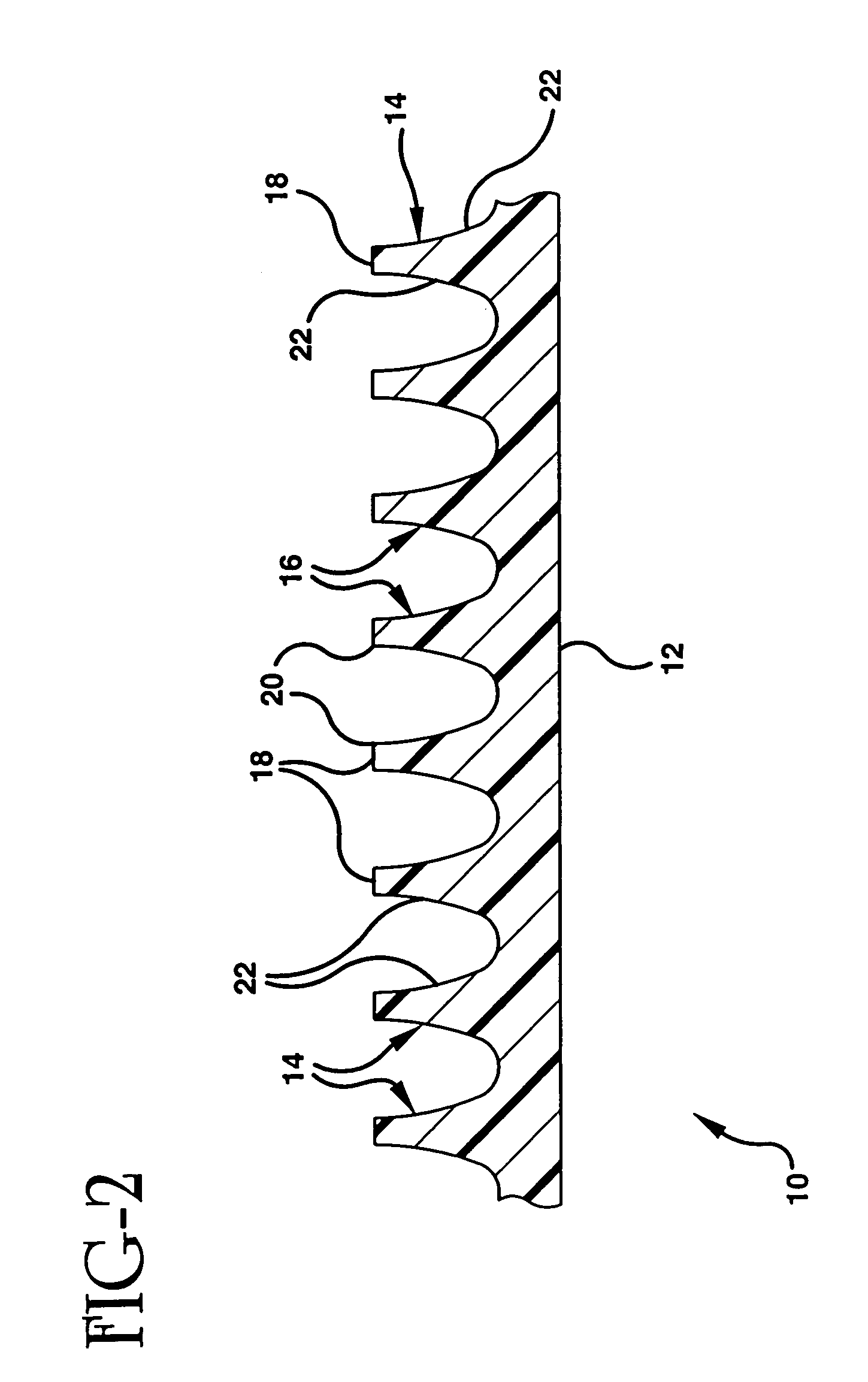

ActiveUS20090060710A1Facilitate manufacturingEfficiently manufacturePump componentsJet pumpsAirflowEngineering

A fan assembly for creating an air current includes a bladeless fan assembly including a nozzle and a device for creating an air flow through the nozzle. The nozzle includes an interior passage and a mouth receiving the air flow from the interior passage. A Coanda surface located adjacent the mouth and over which the mouth is arranged to direct the air flow. The fan provides an arrangement producing an air current and a flow of cooling air created without requiring a bladed fan, that is, the air flow is created by a bladeless fan.

Owner:DYSON TECH LTD

Method and apparatus for manufacturing a device

InactiveUS7052268B2Efficiently manufactureEfficient preparationConfectionerySweetmeatsDrug deliveryPolymer

A device, preferably a micro-device, is molded from a plastic material by injection molding, compression molding or embossing. A microabrader can be molded having microneedles for abrading the stratum corneum of the skin to form an abraded site in the tissue for enhancing drug delivery. The micro-device is molded using a mold assembly having a silicon molding surface. The silicon molding surface can include a recess corresponding to the desired shape and length of the microneedles. The silicon molding surface enables micron and submicron size features to be molded from polymeric materials without the polymeric material adhering to the mold surface. Micro-devices having molded features having micron and submicron dimensions can be rapidly produced without the use of a release agent.

Owner:BECTON DICKINSON & CO

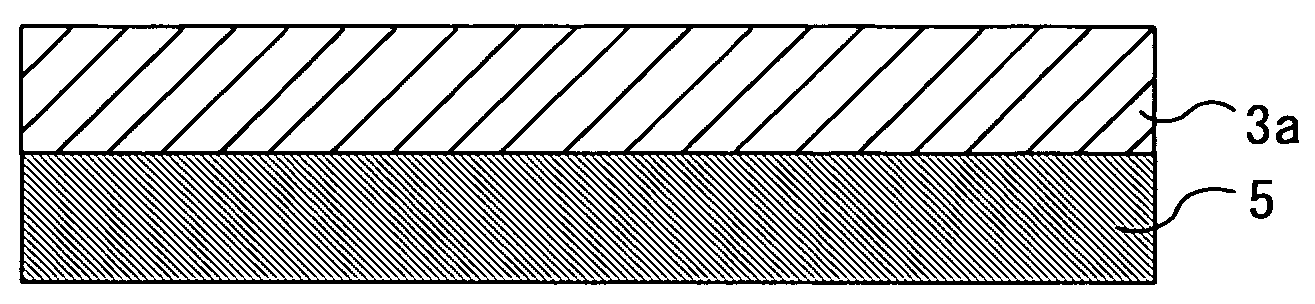

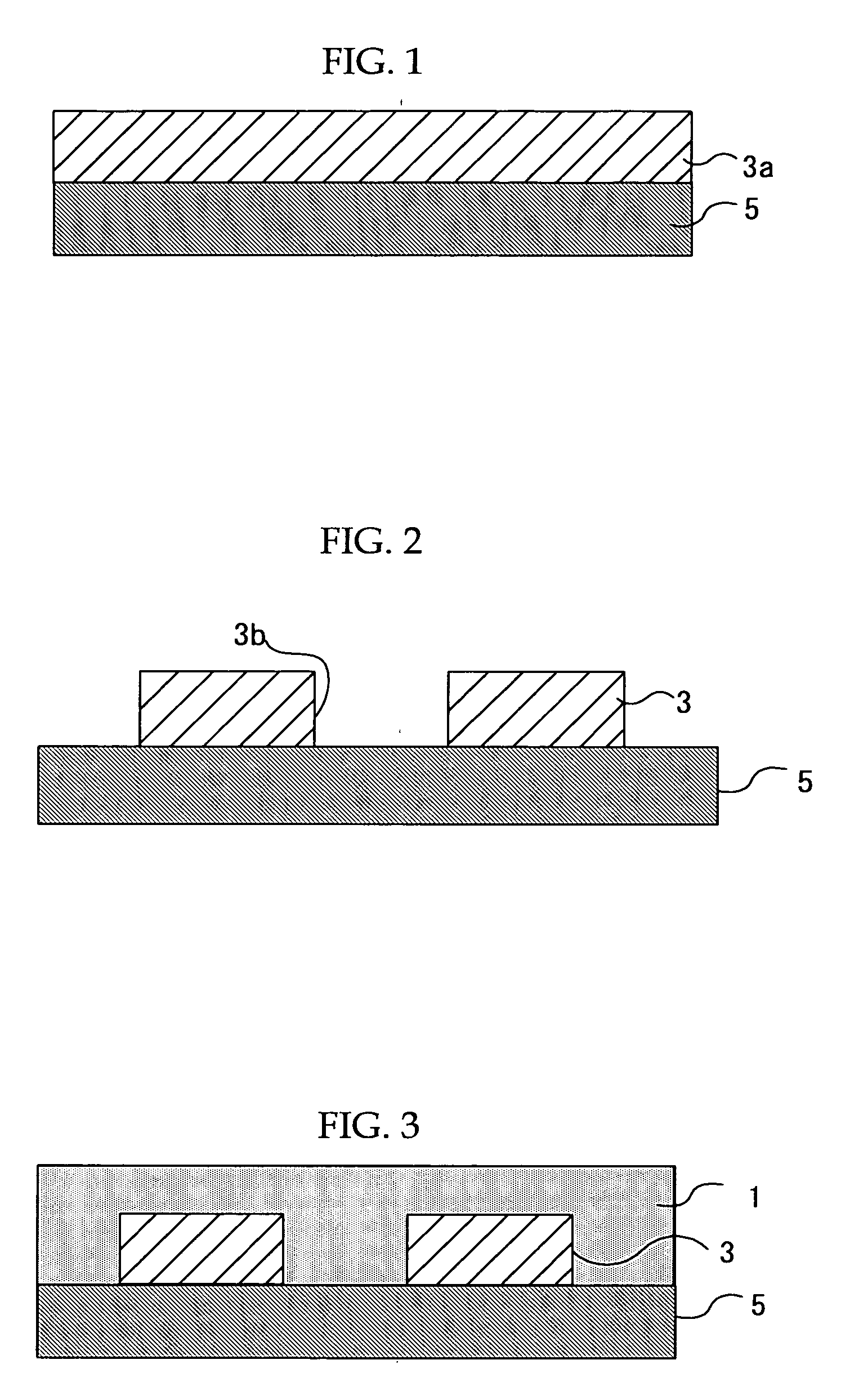

Process for forming resist pattern, semiconductor device and manufacturing method for the same

InactiveUS20080044770A1High precisionEfficiently manufactureSemiconductor/solid-state device manufacturingPhotosensitive material processingResistLight source

To provide a process for forming a resist pattern, which the process can adopt even ArF excimer laser light as exposure light in a patterning step, can thicken a resist pattern (e.g., a hole pattern) regardless of its size, and can reduce the size of a resist space pattern with high precision while preventing changes in the resist pattern shape, to thereby make this process easy, inexpensive and efficient while exceeding the exposure (resolution) limits of light sources of exposure devices. The process of the present invention for forming a resist pattern includes: forming a resist pattern; applying over a surface of the resist pattern a resist pattern thickening material; heating the resist pattern thickening material to thicken the resist pattern followed by development; and heating the resist pattern which has been thickened.

Owner:FUJITSU LTD

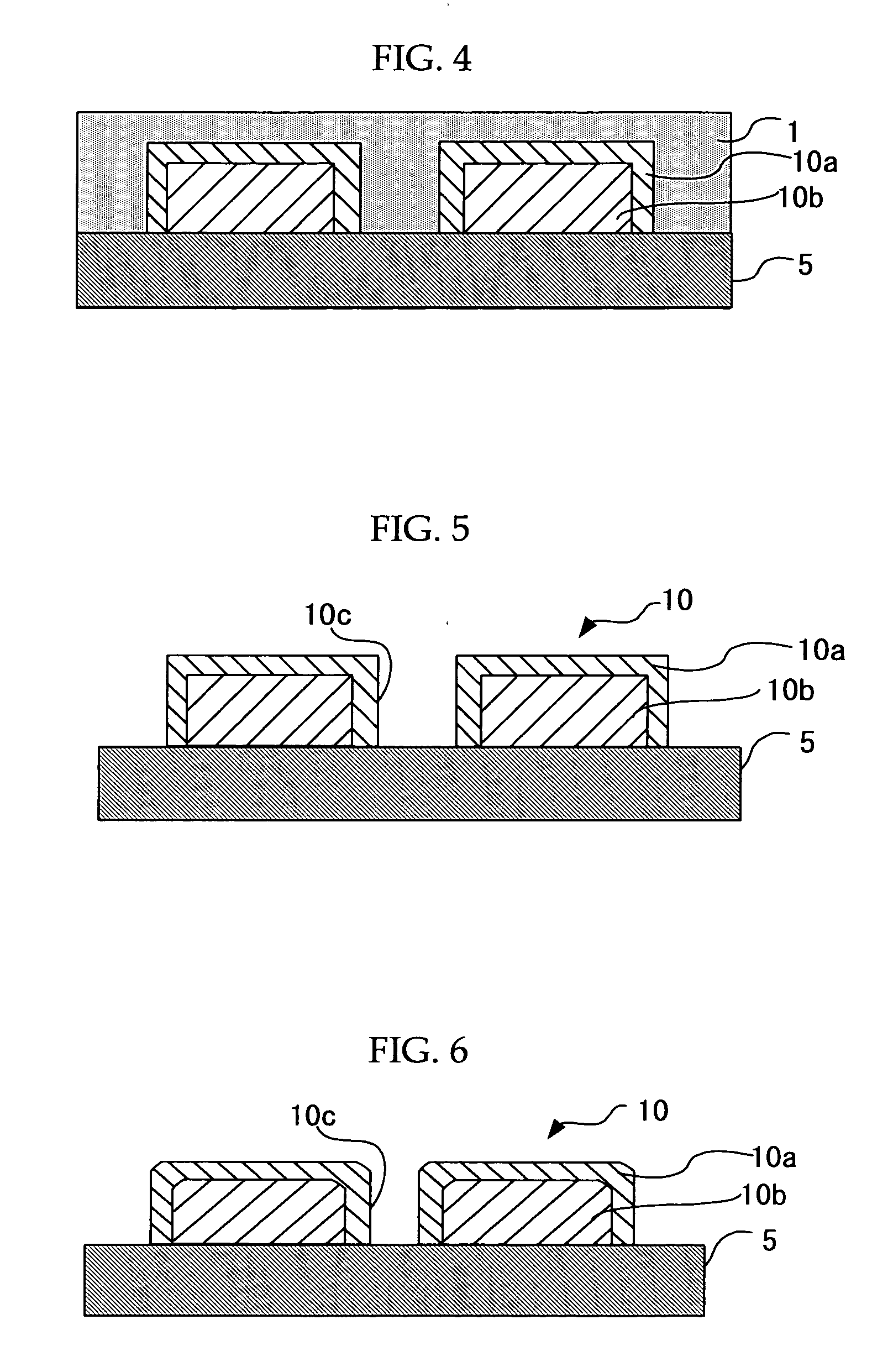

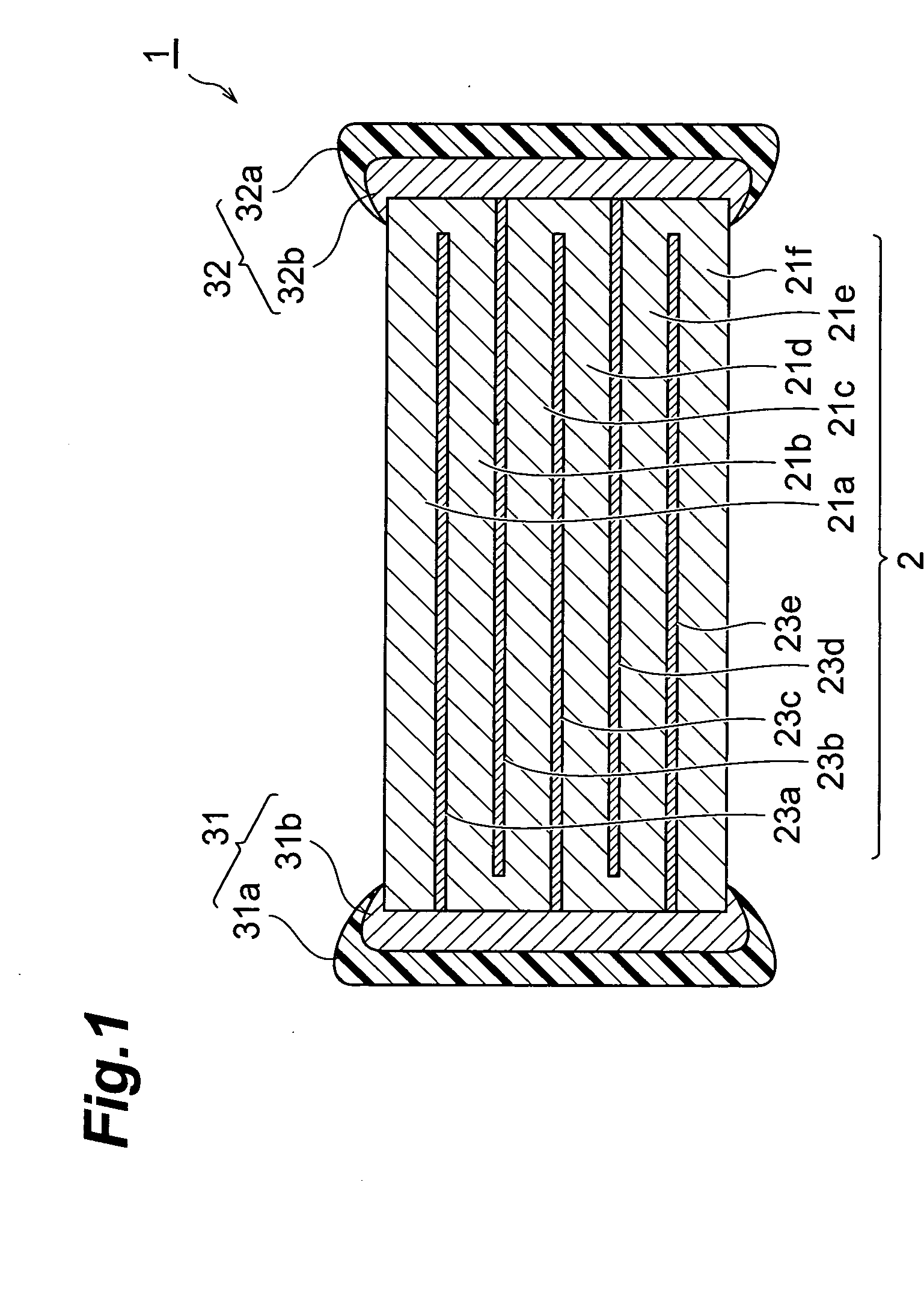

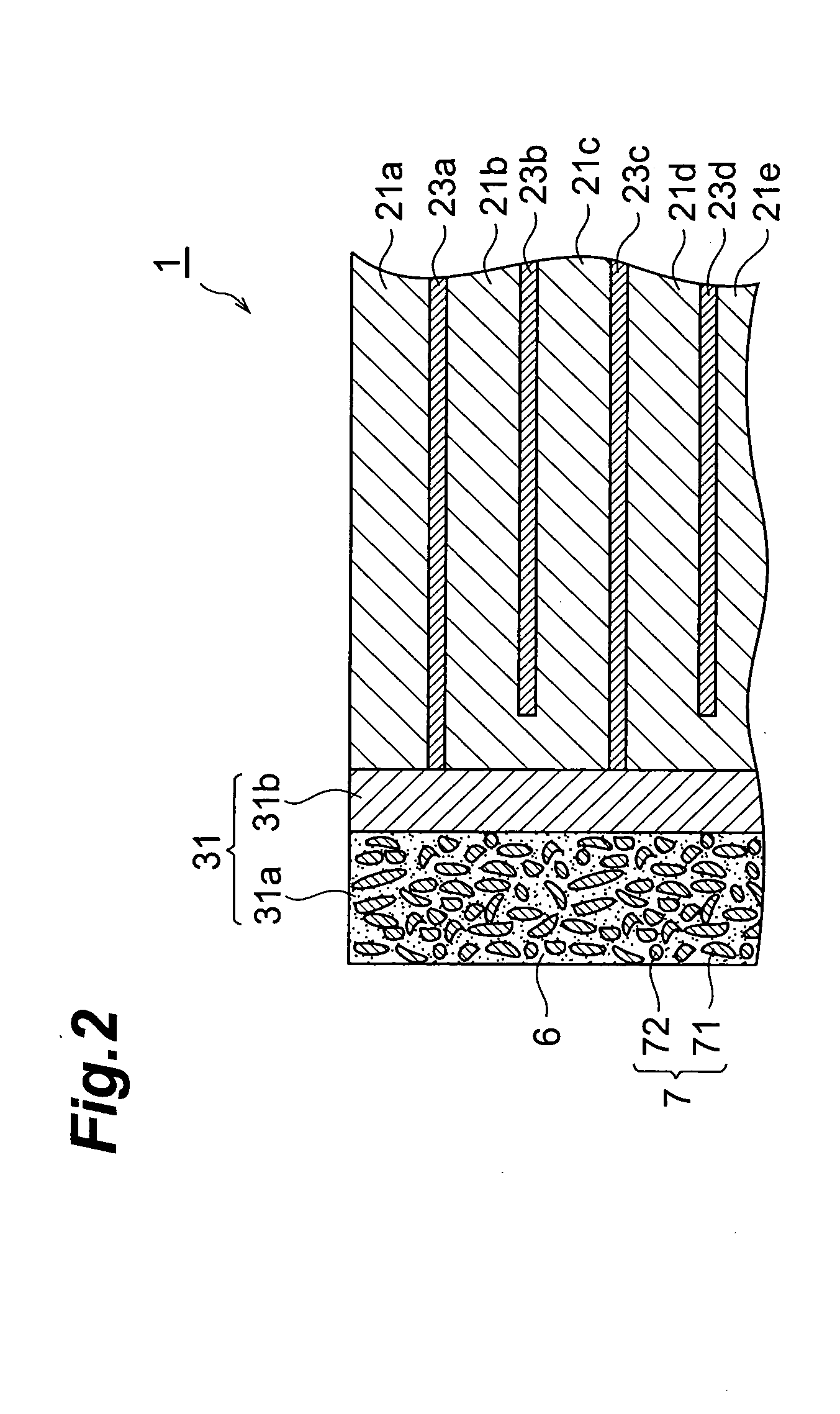

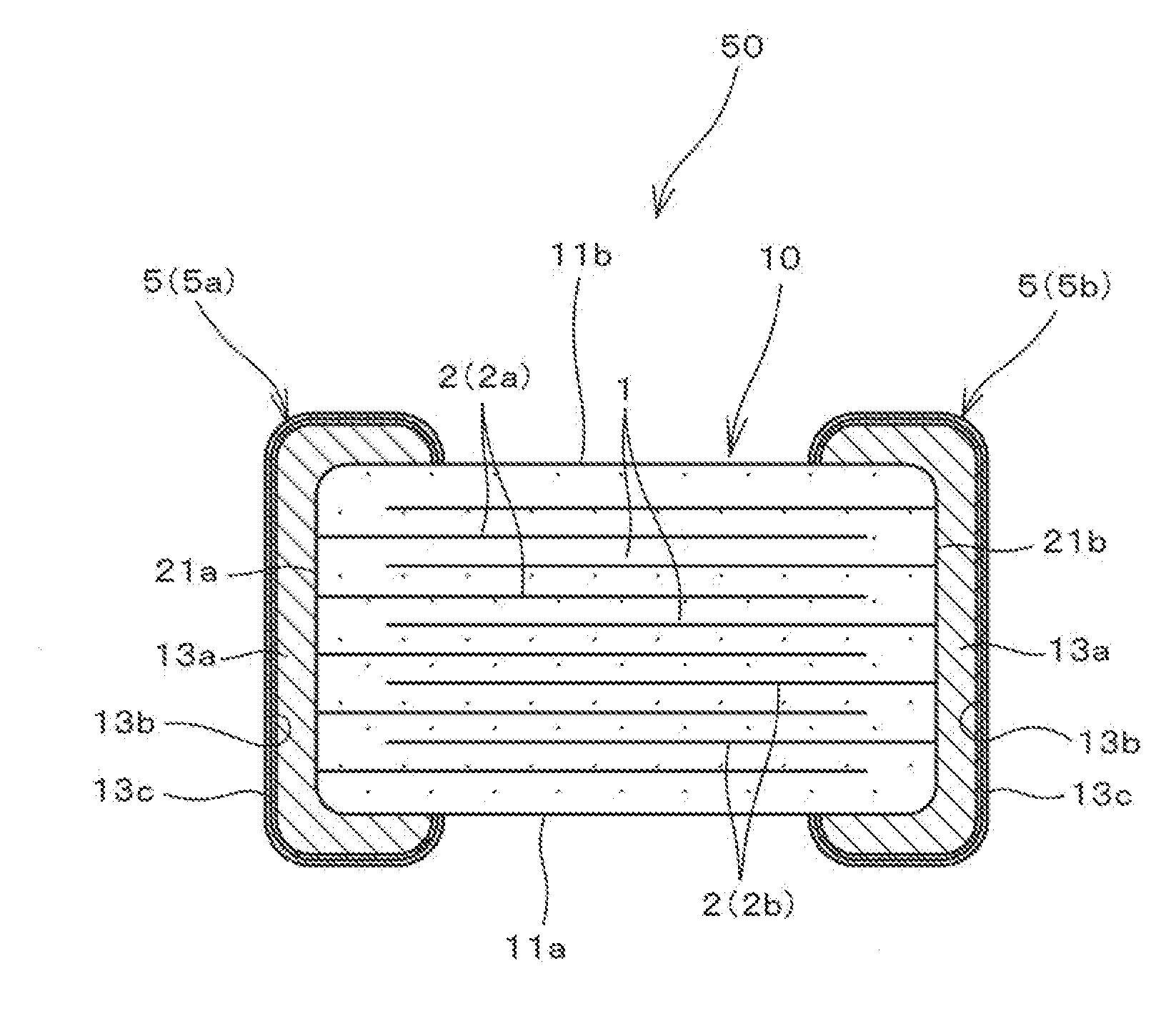

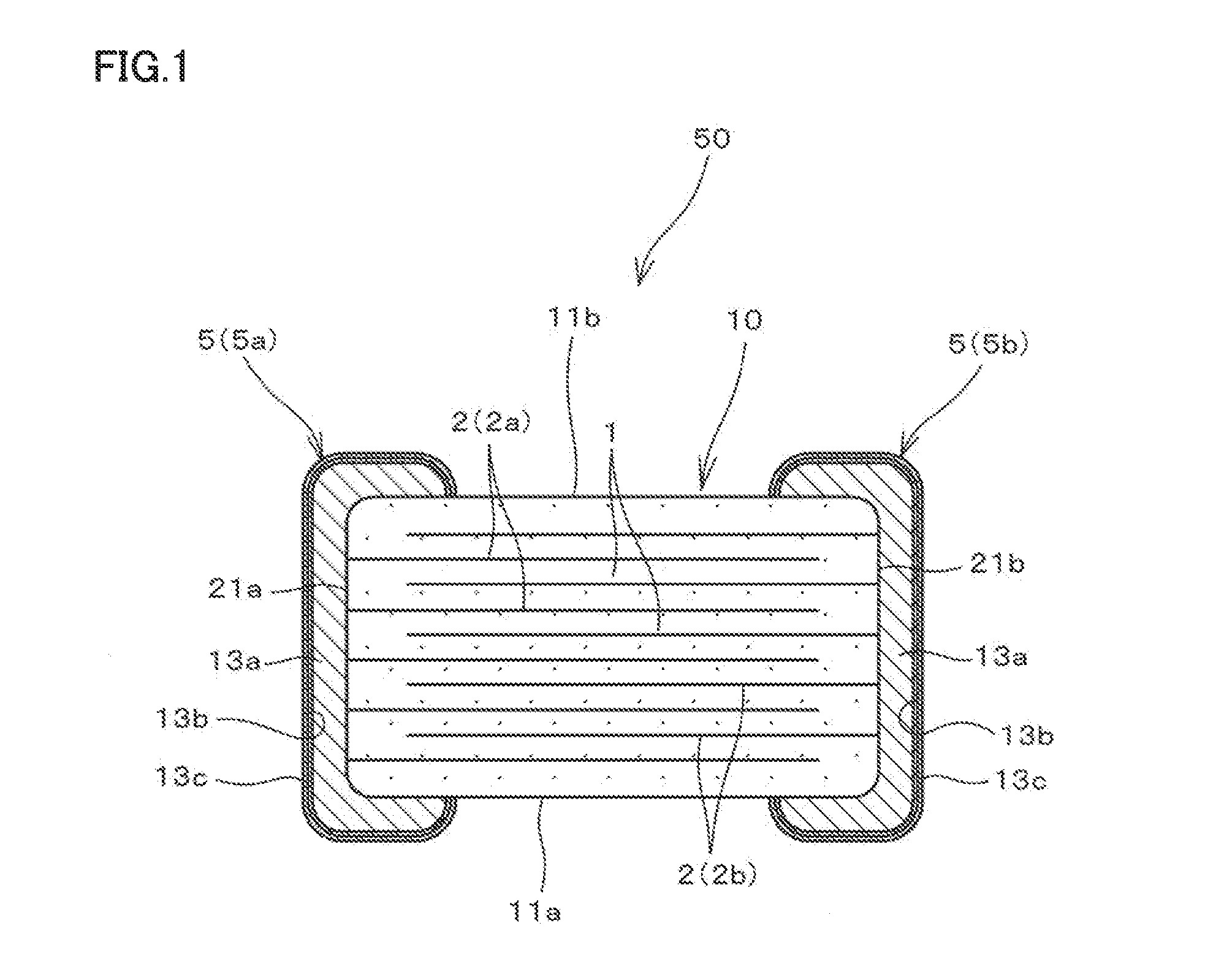

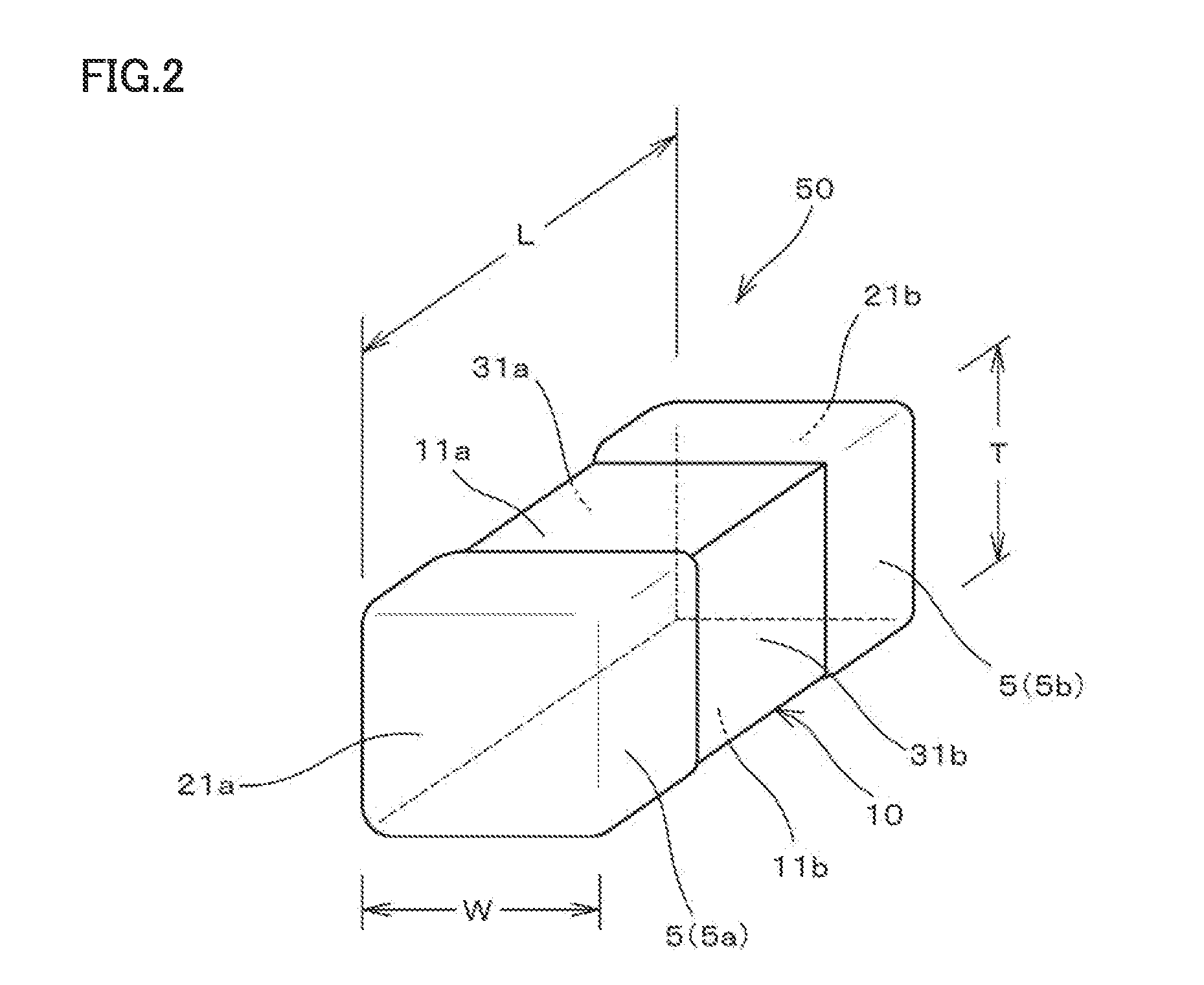

Laminate type electronic component

InactiveUS20050083637A1Sufficiently be lowEfficiently manufactureSubstation/switching arrangement detailsFixed capacitor dielectricAspect ratioDielectric

A laminate type electronic component 1 comprises, at least, a dielectric part 2 containing a dielectric as a constituent material, and a pair of a first external electrode 31 and a second external electrode 32, each disposed in close contact with the dielectric part 2, opposing each other by way of the dielectric part 2. The dielectric part 2 comprises laminated dielectric layers 21a to 21f; and at least two internal electrodes 23a to 23e disposed one by one between layers adjacent each other in the dielectric layers 21a to 21f, while each being electrically connected to one of the first external electrode 31 and second external electrode 32. At least one of the internal electrodes 23a to 23e is electrically connected to the first external electrode 31, and at least one of the internal electrodes 23a to 23e is electrically connected to the second external electrode 32. The first external electrode 31 and second external electrode 32 comprise resin electrode layers 31a and 32a, each made of a conductive resin mainly composed of a thermosetting resin and a conductive particle; a metal electrode layer 31b disposed between the resin electrode layer 31a and the dielectric part 2; and a metal electrode layer 32b disposed between the resin electrode layer 32a and the dielectric part 2. The conductive particle content in the conductive resin is 70 to 75 mass %, whereas the conductive particle contains, as a main ingredient, acicular particles 71 having an average longitudinal length of 30 to 70 μm and an aspect ratio of 1.5 to 3.3.

Owner:TDK CORPARATION

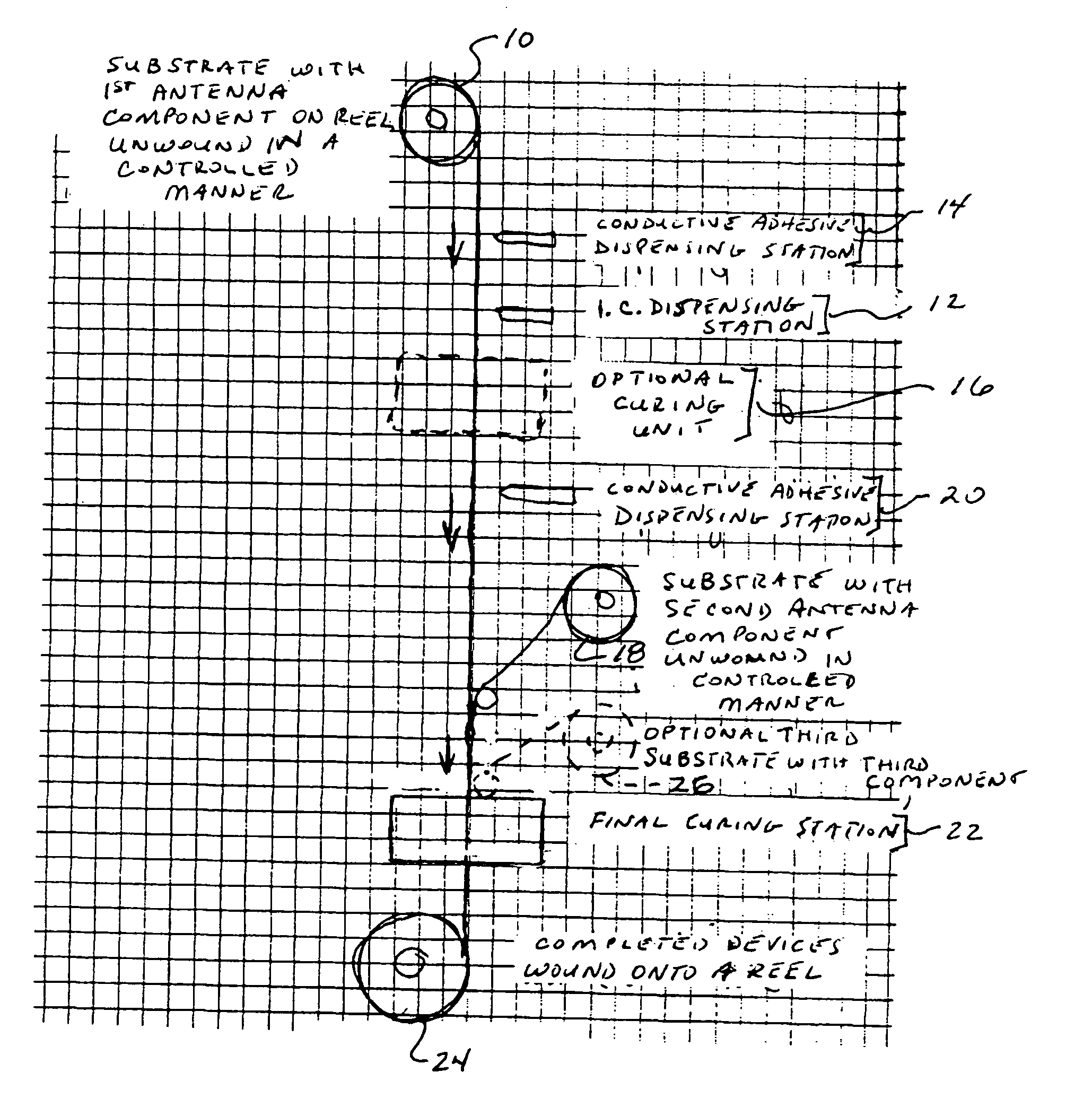

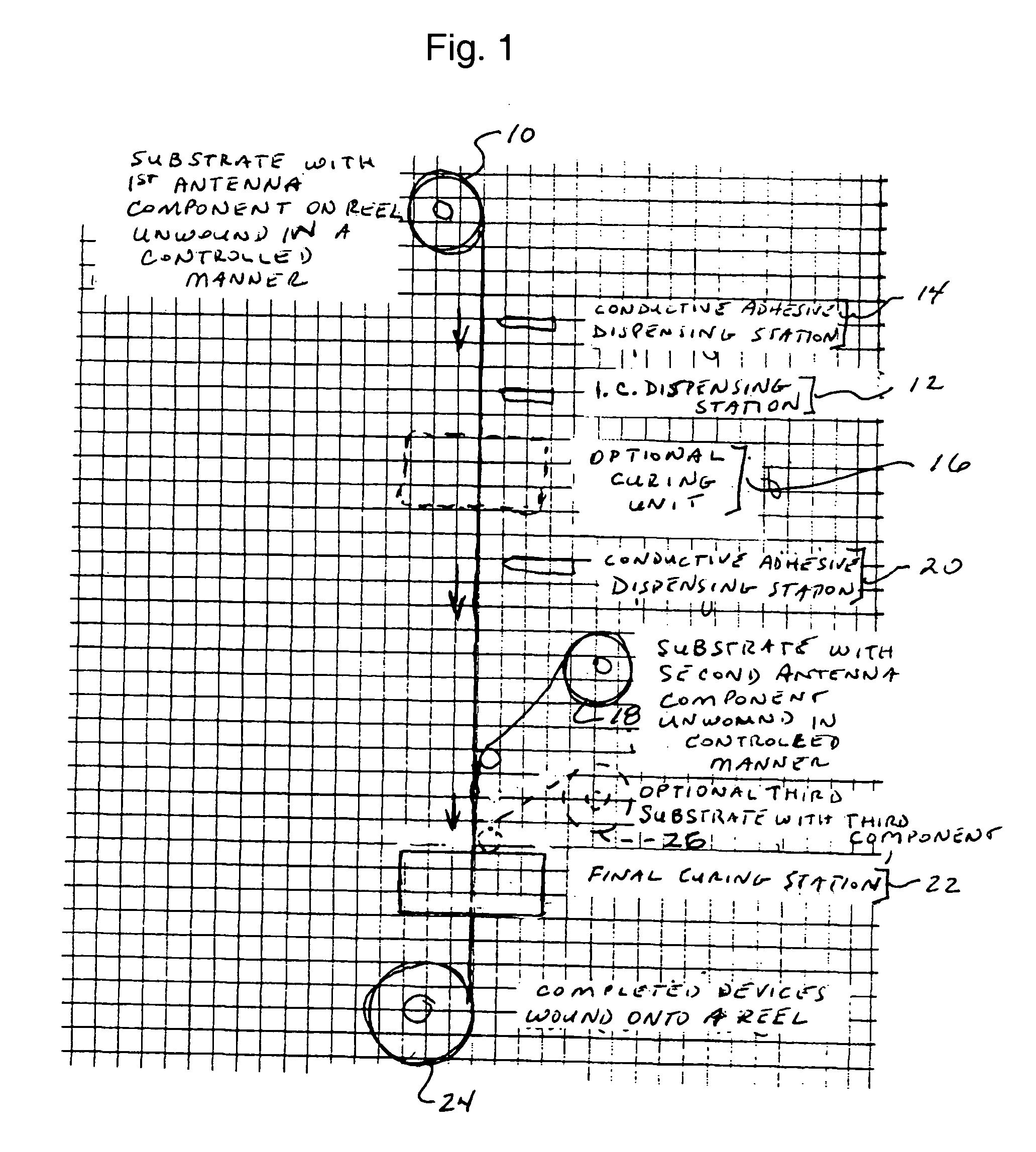

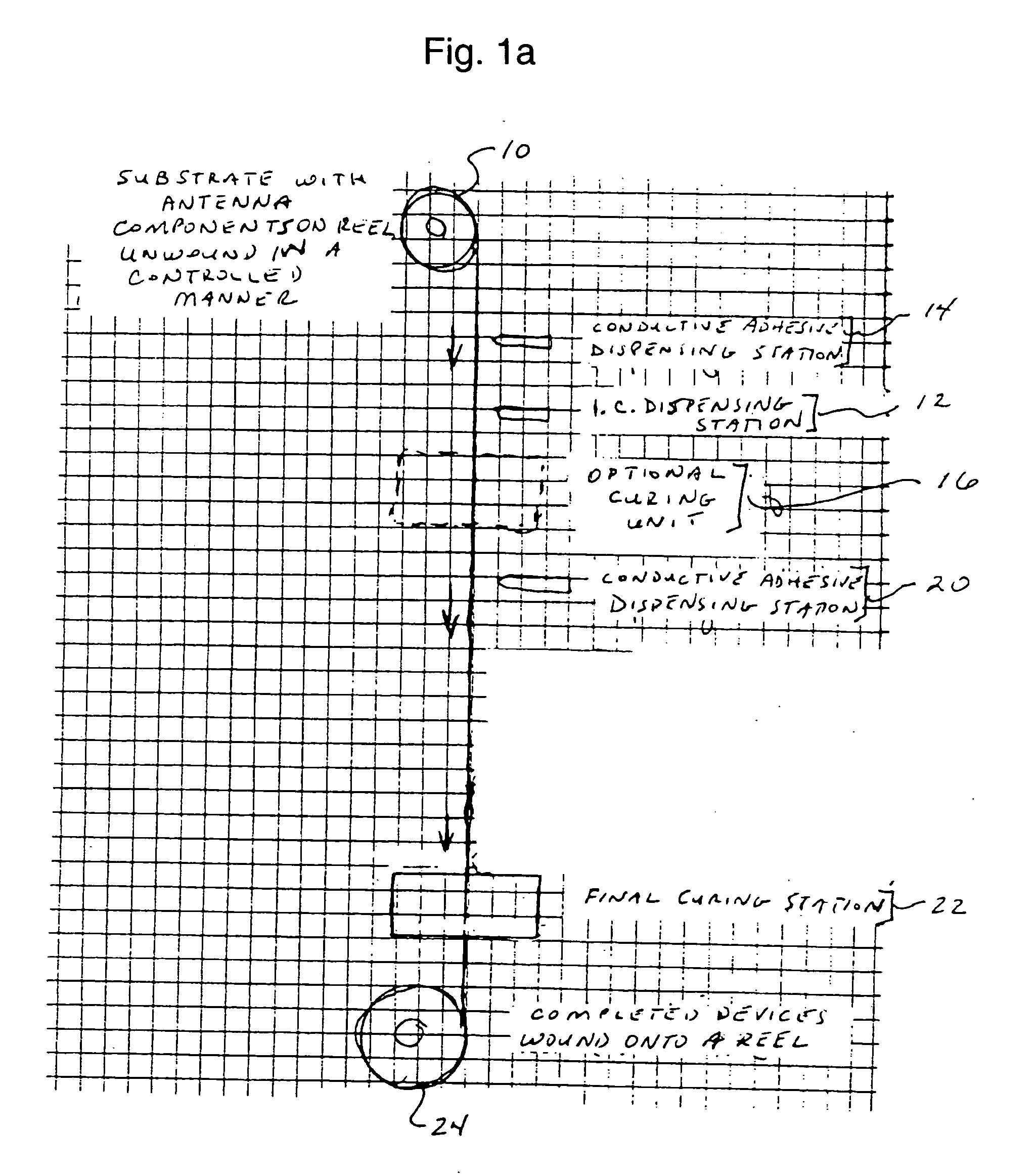

Method of forming circuit assembly

InactiveUS20050231371A1Efficiently manufactureEfficient preparationSemiconductor/solid-state device manufacturingProtective material radiating elementsElectricityRadio-frequency identification

The present invention is directed to a method of forming a circuit assembly, such as including a radio frequency identification device (RFID), wherein first and second portions of an antenna of the circuit assembly are provided on respective first and second substrates, with the associated electrical circuit, having first and second electrical contacts on respective opposite sides thereof, positioned between the first and second substrates. Alternatively, first and second portions of an antenna of the circuit assembly are provided on a substrate, with the associated electrical circuit, having first and second electrical contacts on respective opposite sides thereof, electrically joined to the respective antenna portions. Highly efficient manufacture is thus promoted.

Owner:CREDIT SUISSE SYDNEY BRANCH

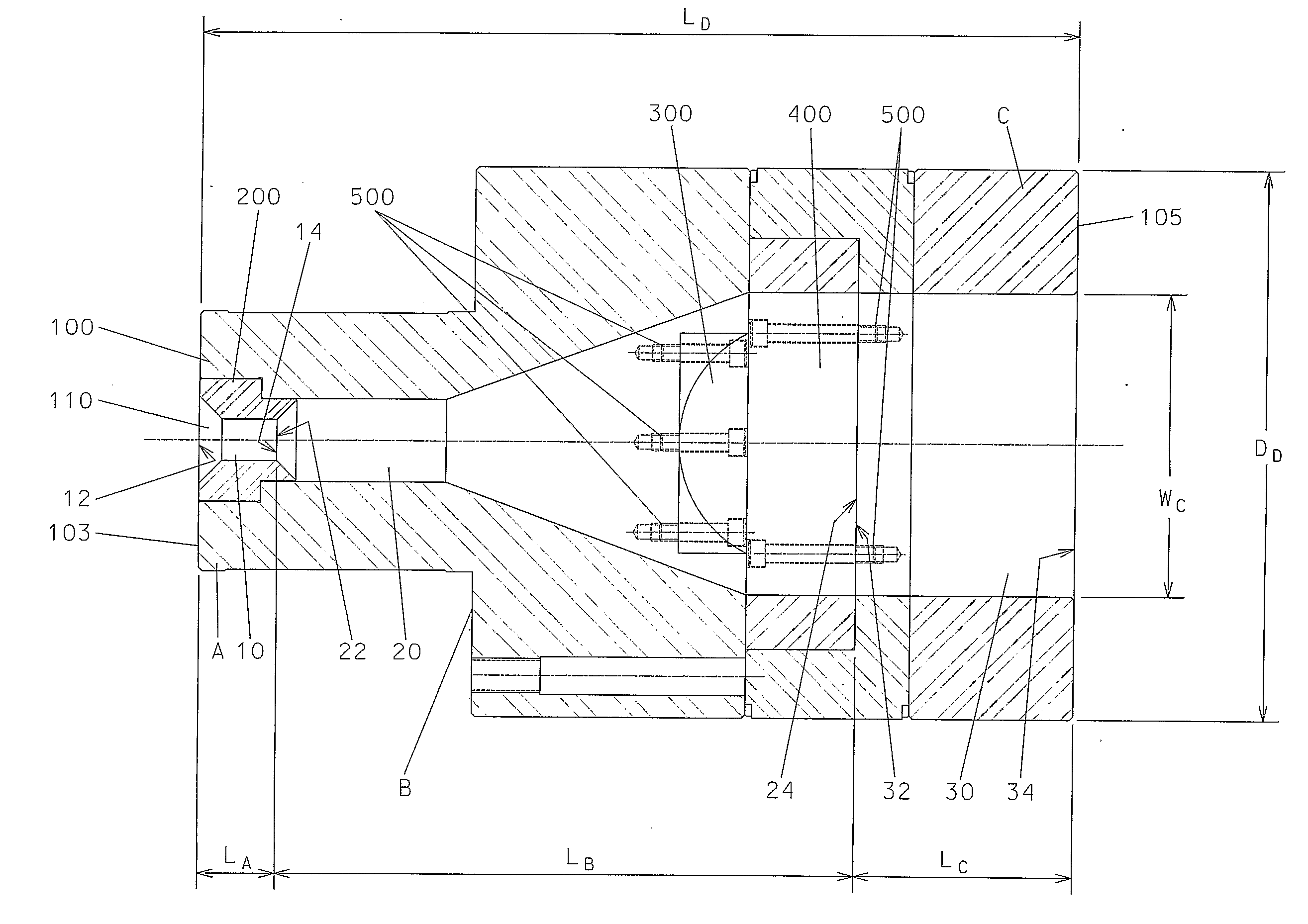

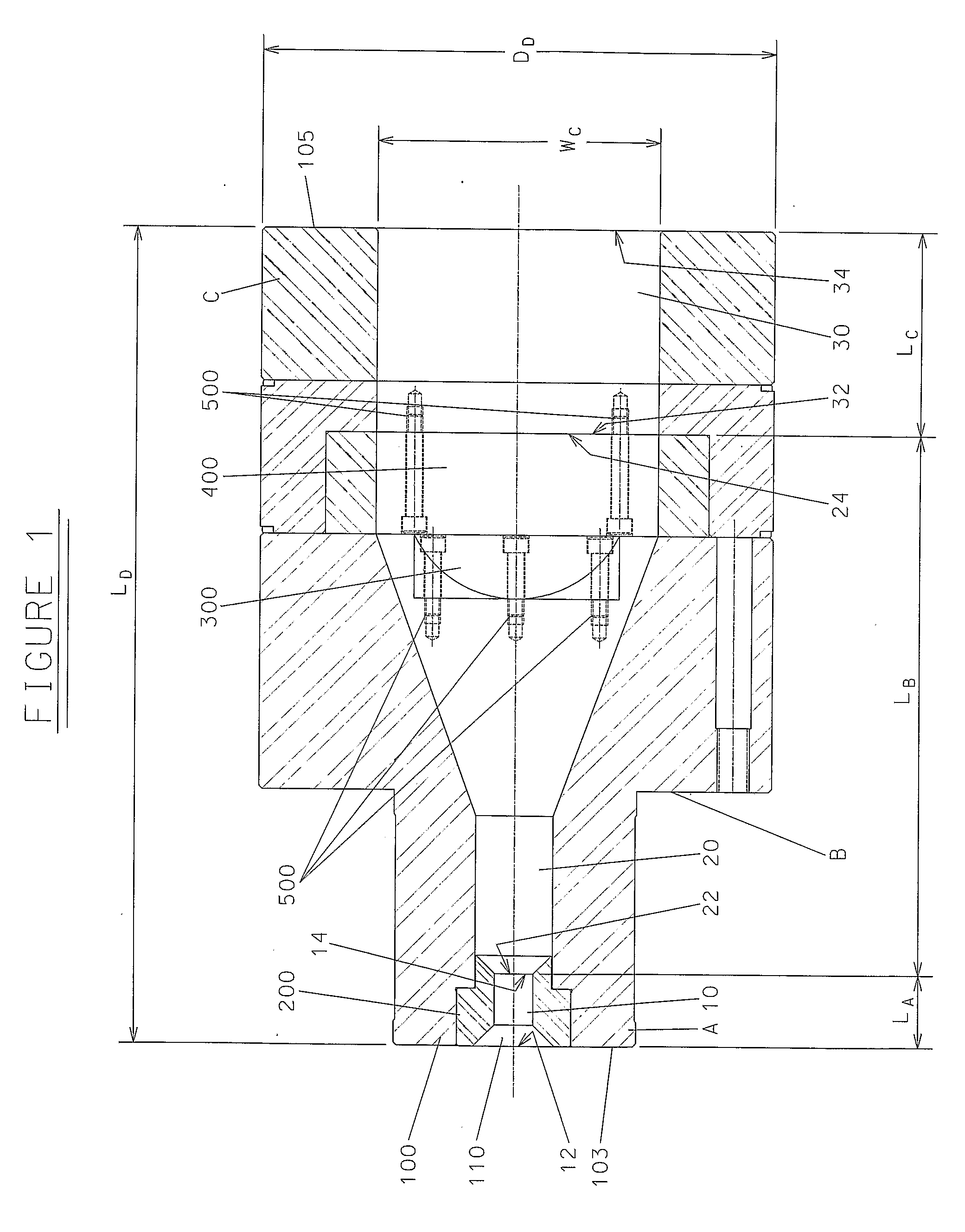

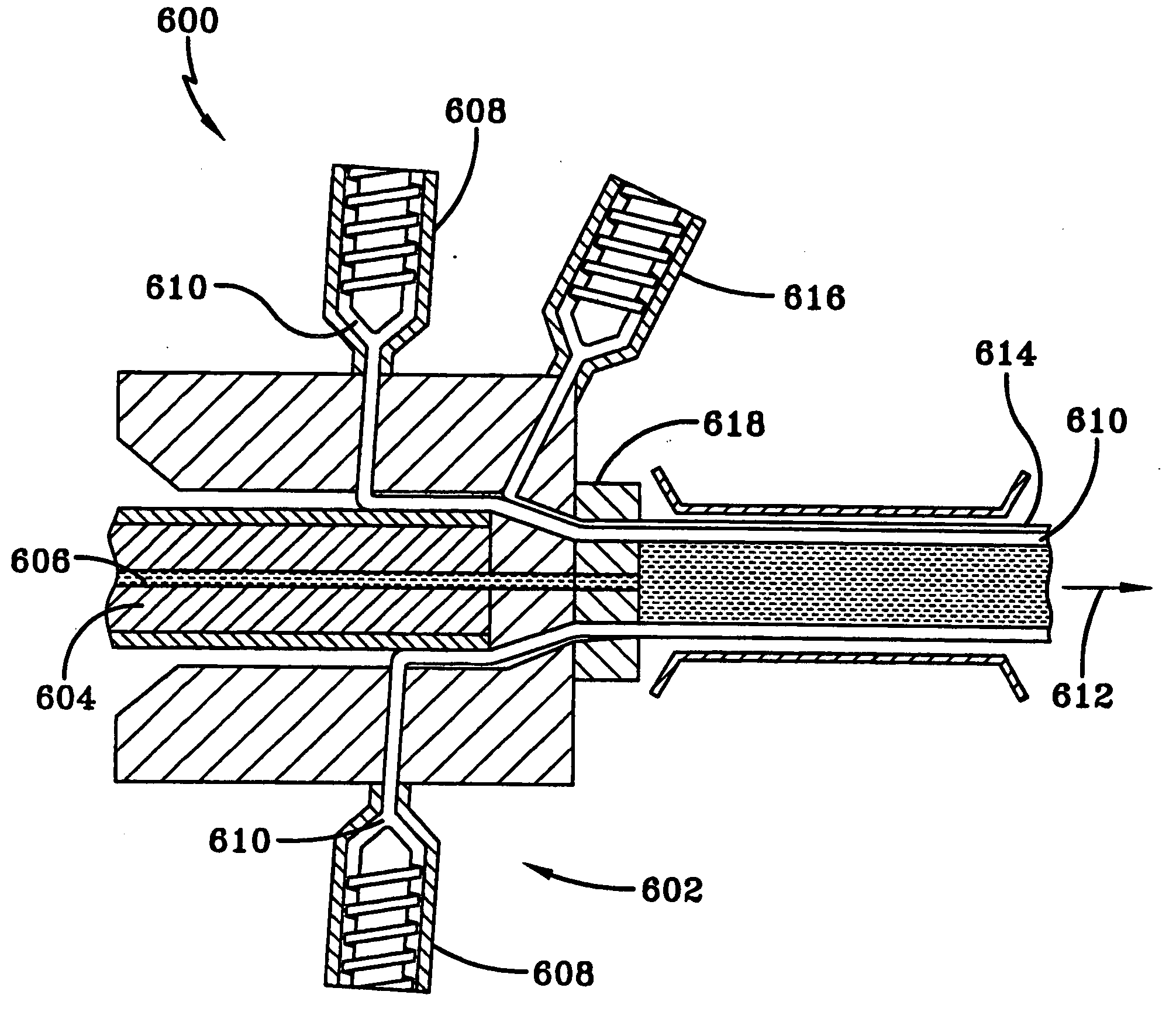

Extrusion Die and Process for Producing an Extruded Filled Polymer Composition

InactiveUS20090146339A1Efficiently manufactureTailstocks/centresConfectioneryPolymer meltLanding zone

Prepare an extruded filled polymer composite having a highly disperse and uniformly distributed filler by extruding a filled polymer composite through a die with a Flow Restriction Zone, a Flow Redistribution Zone and a Land Zone. The Flow Restriction Zone is proximate to the extruder and increases polymer melt backpressure in the extruder sufficient to induce high dispersion of the filler but not enough to cause undesirable degradation of the polymer melt components.

Owner:MALONE BRUCE A +1

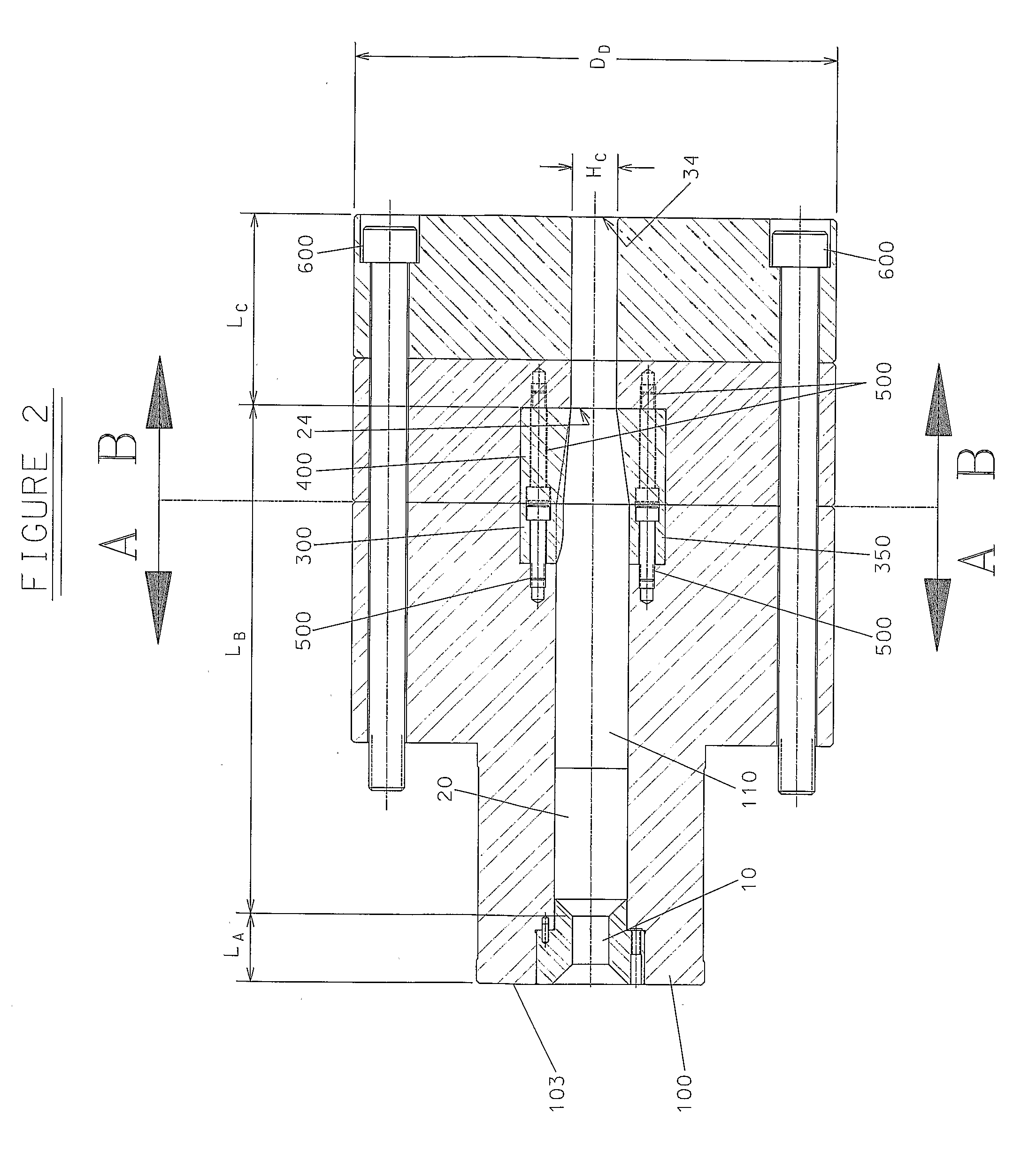

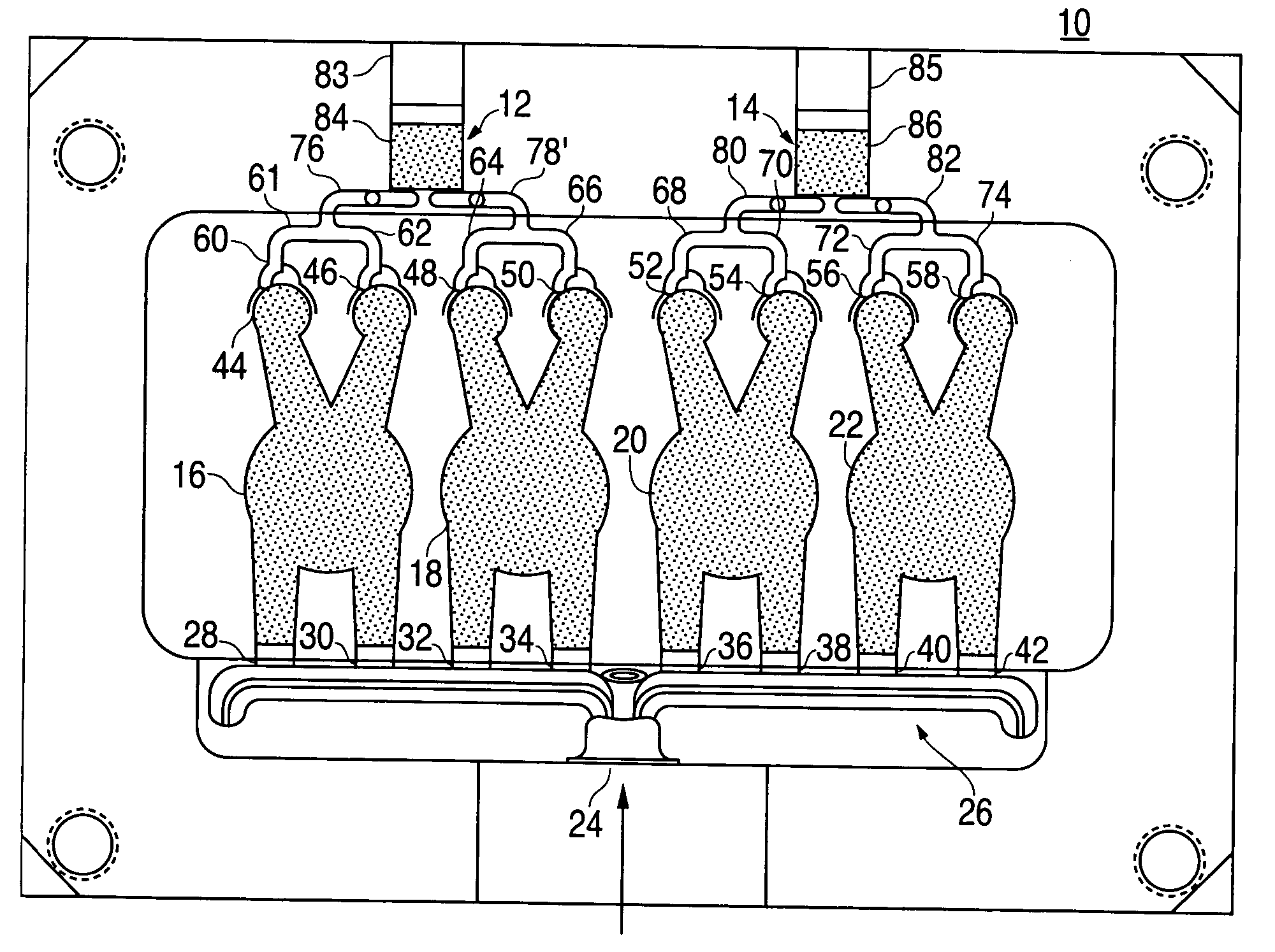

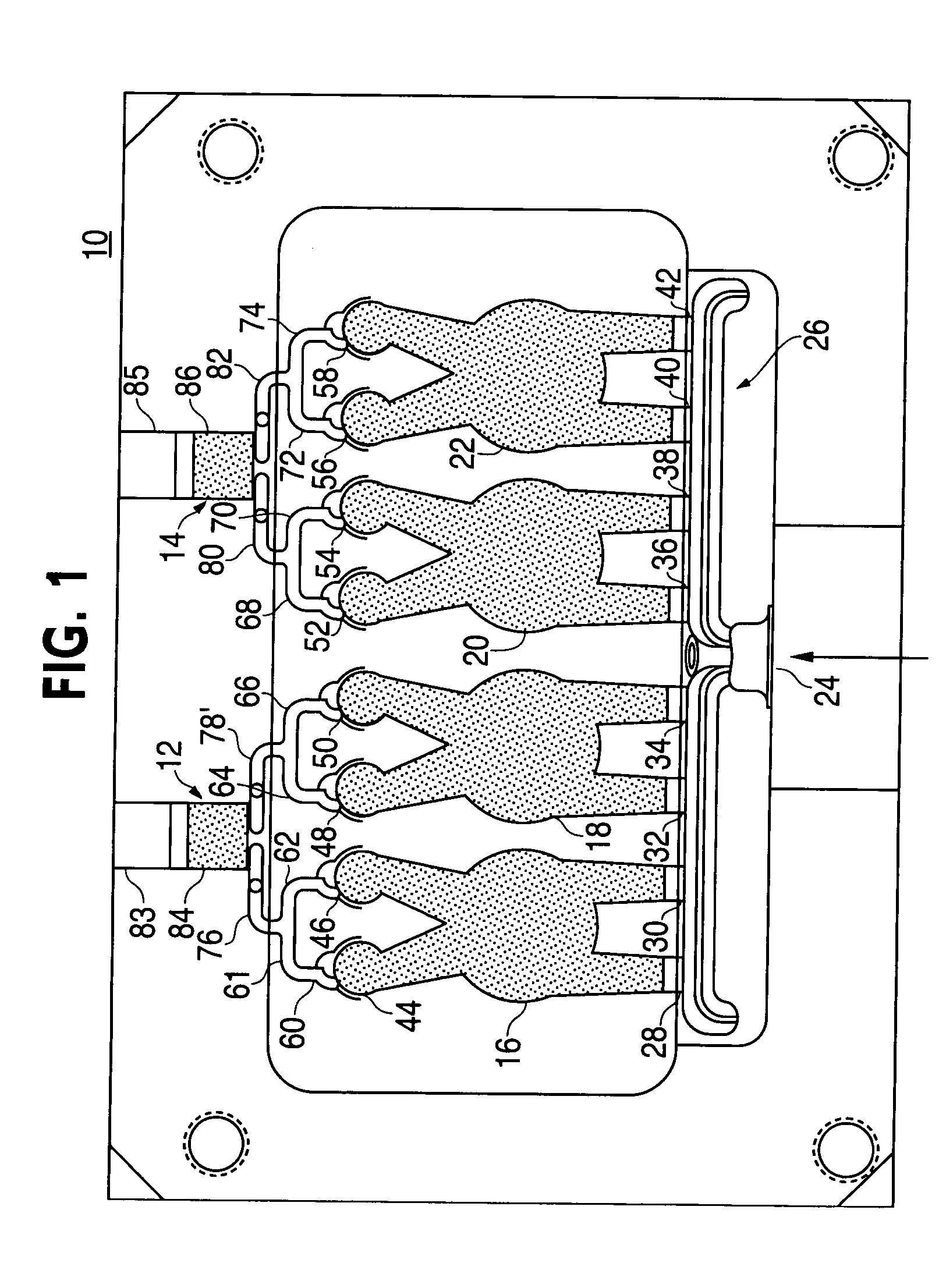

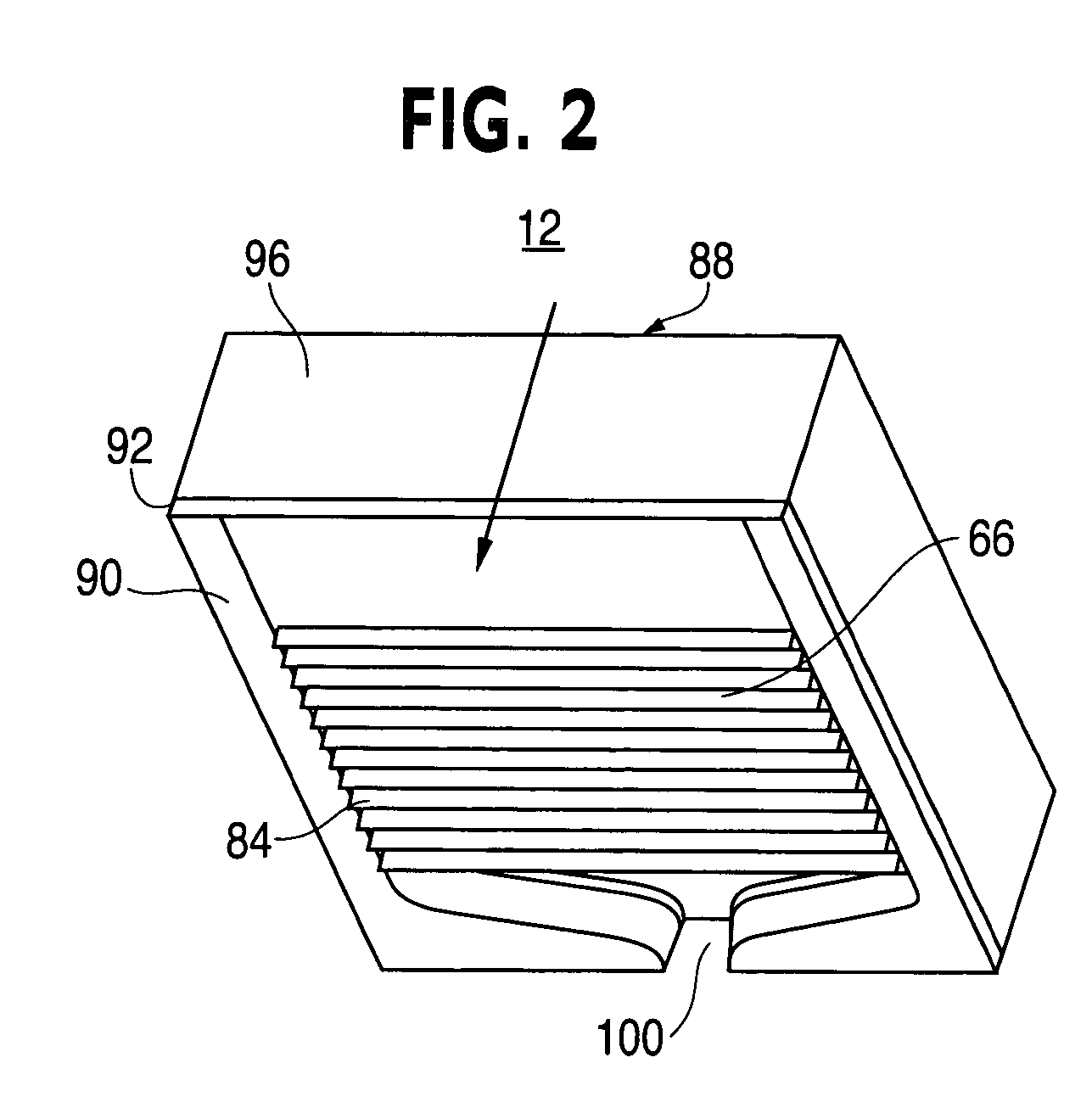

System and method for directing a fluid through a die

InactiveUS20060012066A1Fast production timeEfficiently manufactureDomestic articlesBiomedical engineeringCooling fluid

A system and method for directing a fluid through a die. A transfer device for a fluid (e.g., a cooling fluid or a material) may extend through an interior of the die. The transfer device may be situated such that undesired heat transfer with other portions of the die is limited.

Owner:CRANE BUILDING PRODS

Multilayer ceramic capacitor and method for manufacturing the same

ActiveUS20160268046A1Efficiently manufactureImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricDiffusion layerMetallurgy

A multilayer ceramic capacitor contains Ni in internal electrodes, and includes a sintered metal layer containing Cu in external electrodes. At a joined portion between each internal electrode and each external electrode, mutual diffusion layers of Cu and Ni extend across the internal and external electrodes. On each internal electrode, a mutual diffusion layer is present with a thickness t1, which is defined by a dimension from a first end surface or a second end surface to an interior end in a longitudinal direction, not smaller than about 0.5 μm and not greater than about 5 μm. On each external electrode, a mutual diffusion layer is present with a thickness t2, which is defined by a dimension from the first end surface or the second end surface to an exterior end in the longitudinal direction, not smaller than about 2.5% and not greater than about 33.3% of a thickness t0 of a sintered metal layer.

Owner:MURATA MFG CO LTD

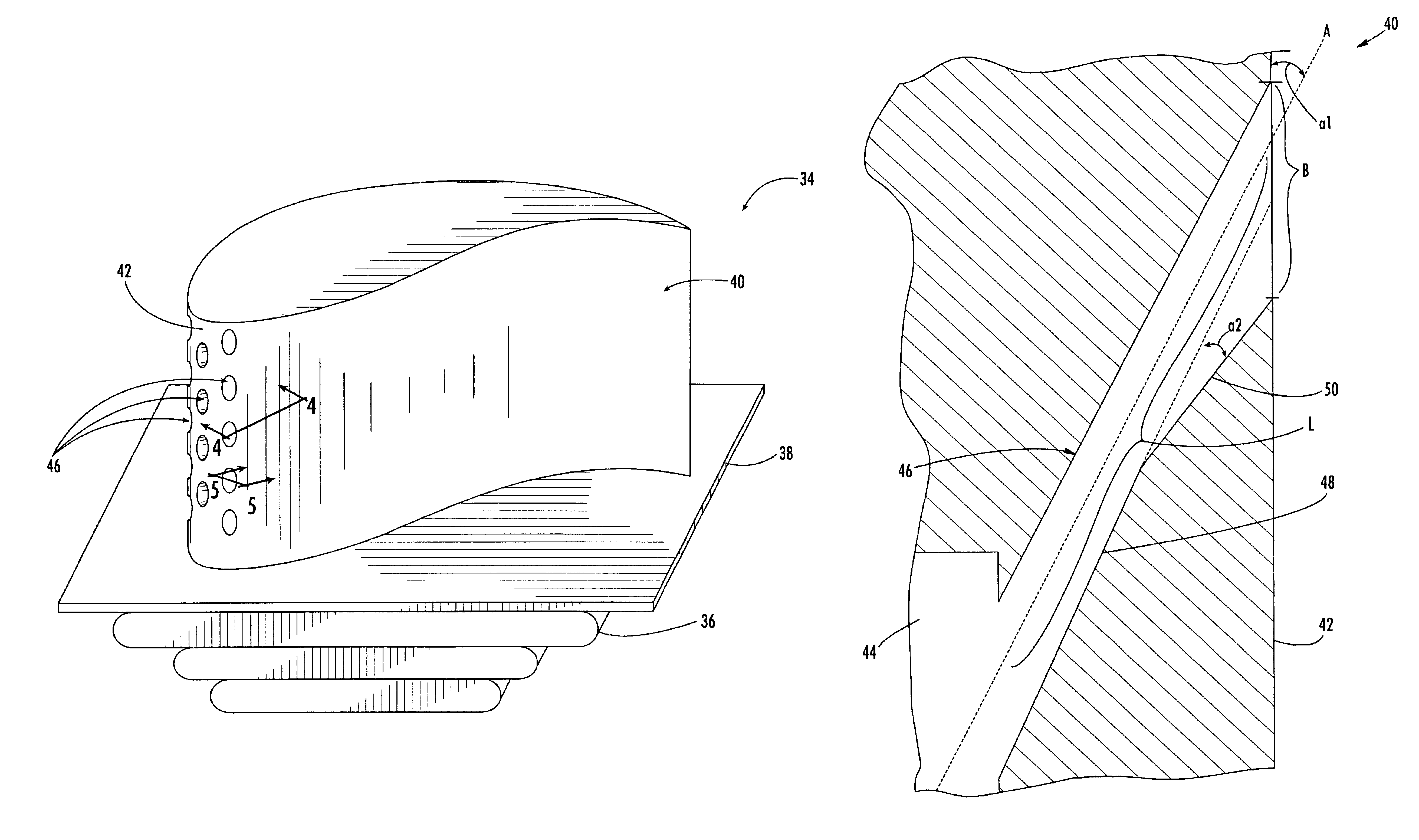

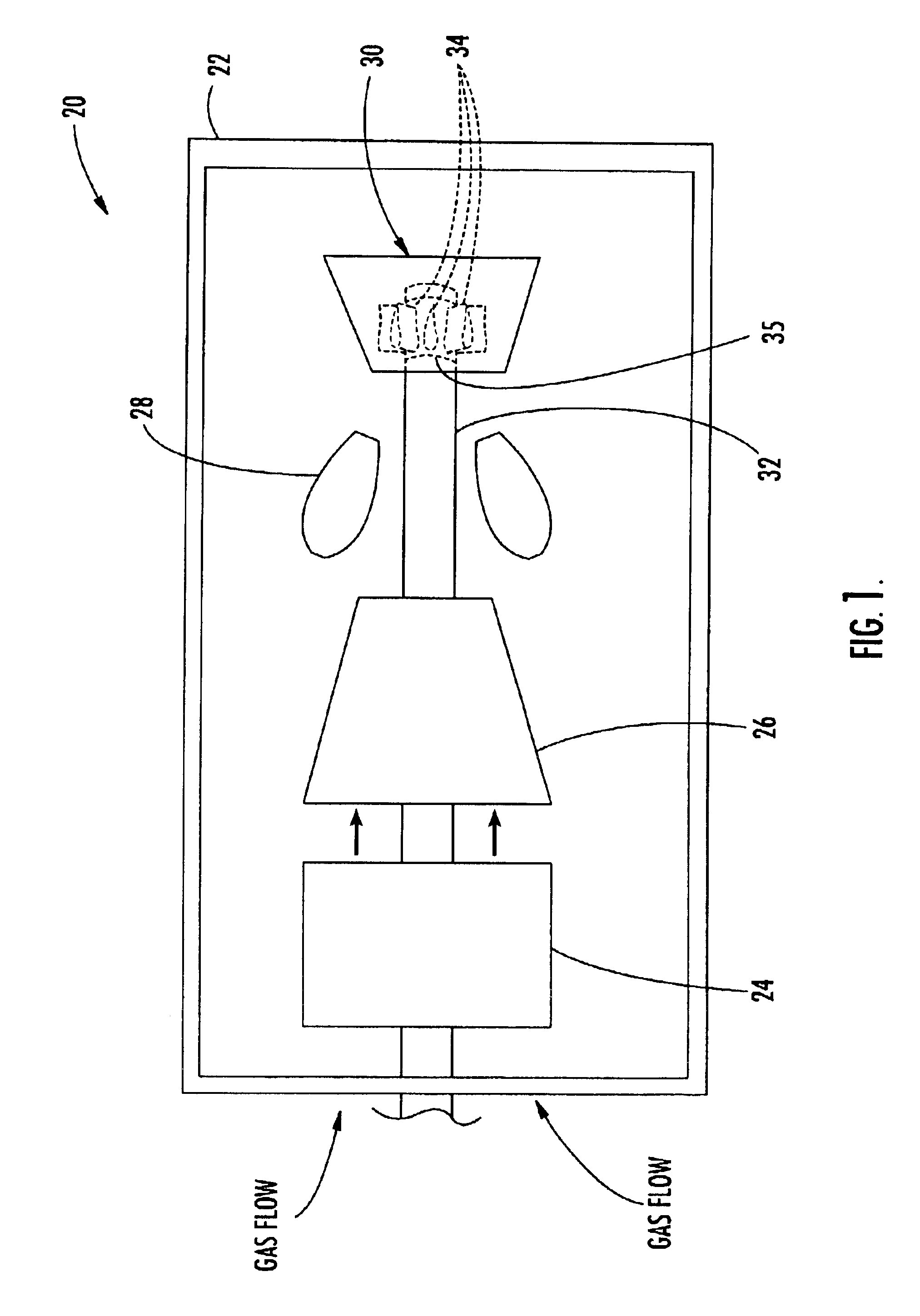

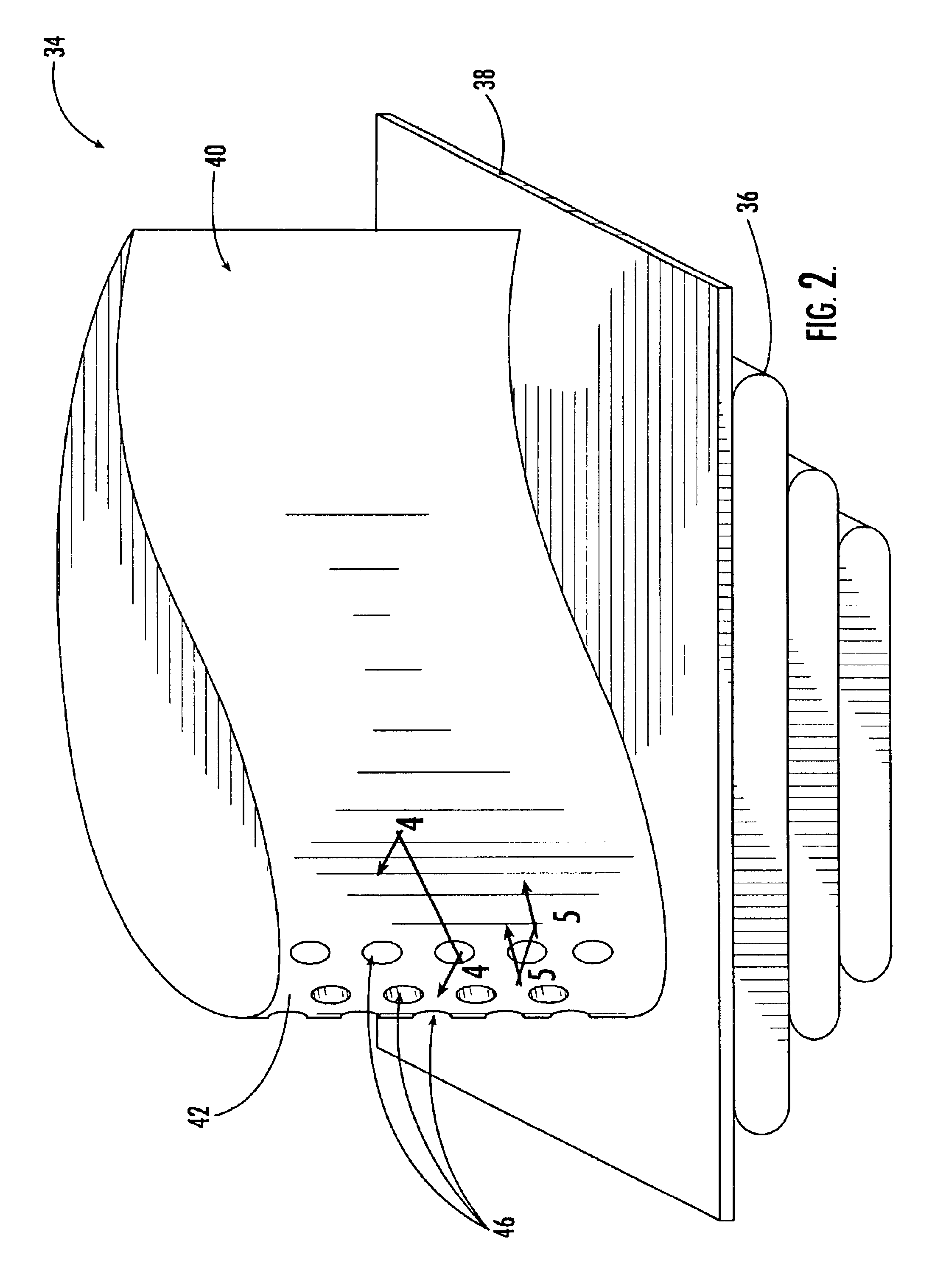

Combustion turbine with airfoil having enhanced leading edge diffusion holes and related methods

InactiveUS6869268B2Easily manufactureEfficiently manufacturePump componentsEngine fuctionsGas turbinesCombustion

A combustion turbine 20 includes a housing 22 and a plurality of airfoils 40 within the housing. Each airfoil 40 has a leading edge surface 42 and at least one interior cooling passageway 44. A plurality of diffusion holes 46 extend from the at least one interior cooling passageway 44 to the leading edge surface 42. Each diffusion hole 46 includes a proximal section 48 having a generally constant cross-sectional shape and a distal tapered section 50 that extends outwardly from the proximal section, tapering in a radially inward direction.

Owner:SIEMENS ENERGY INC

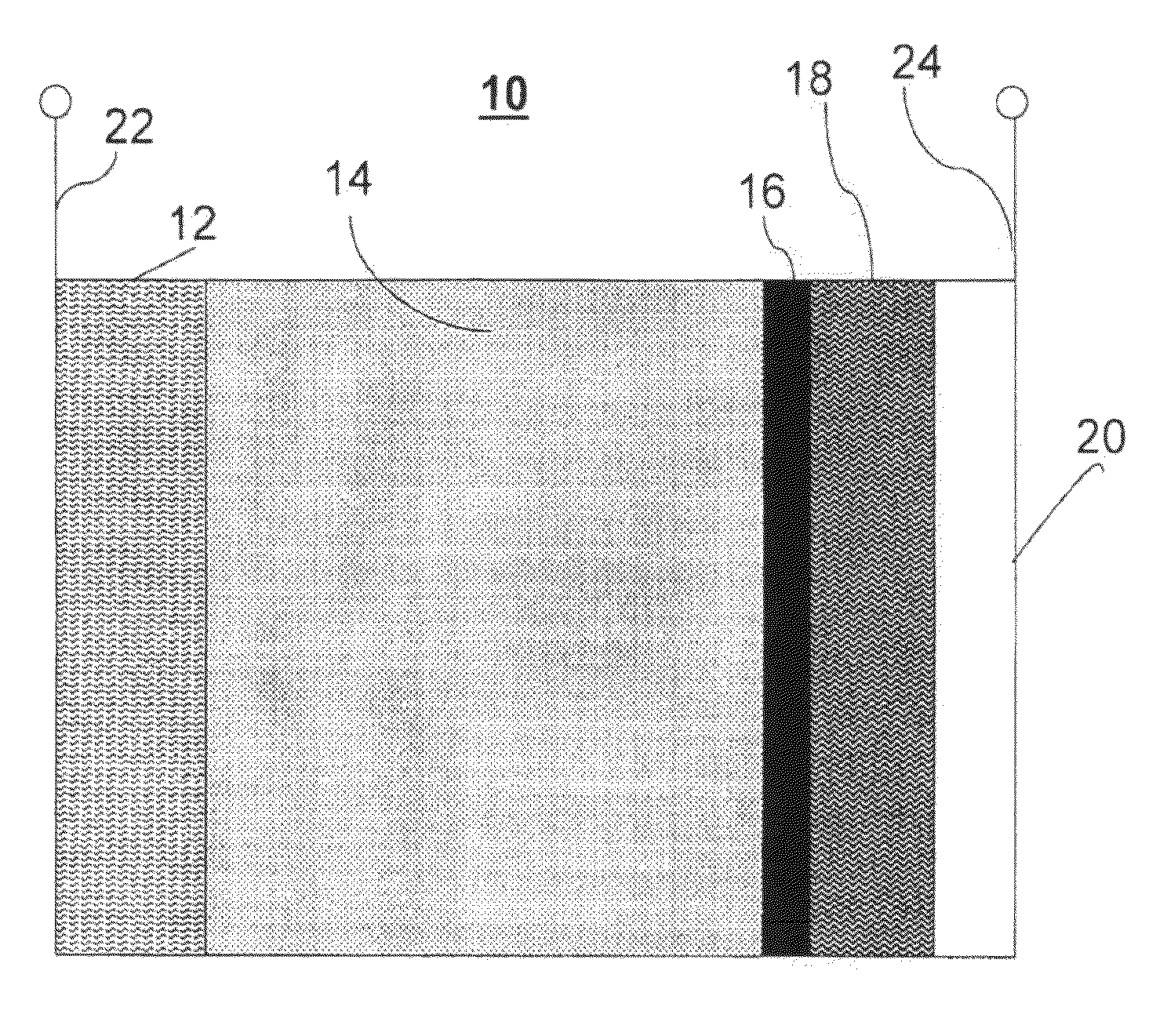

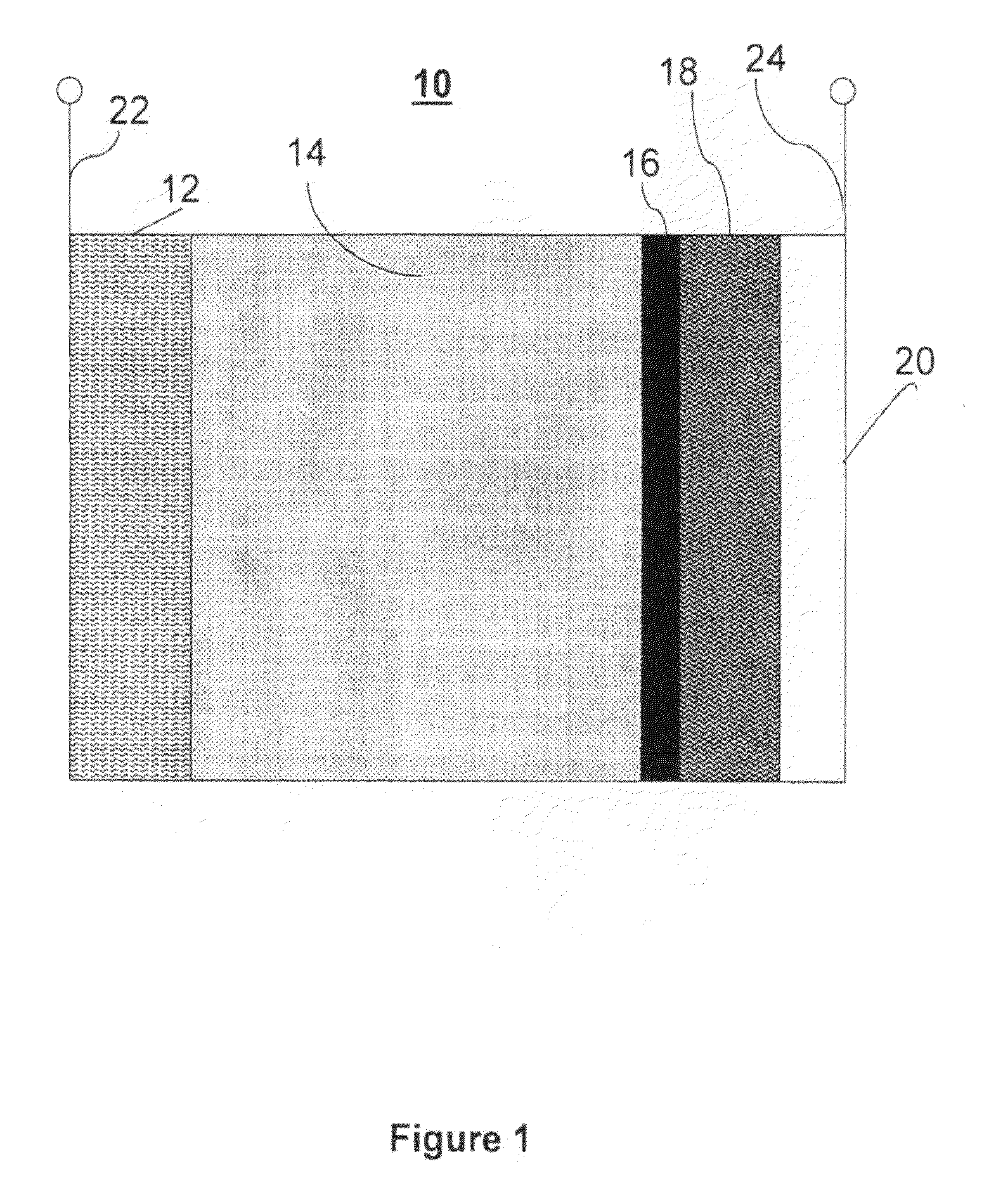

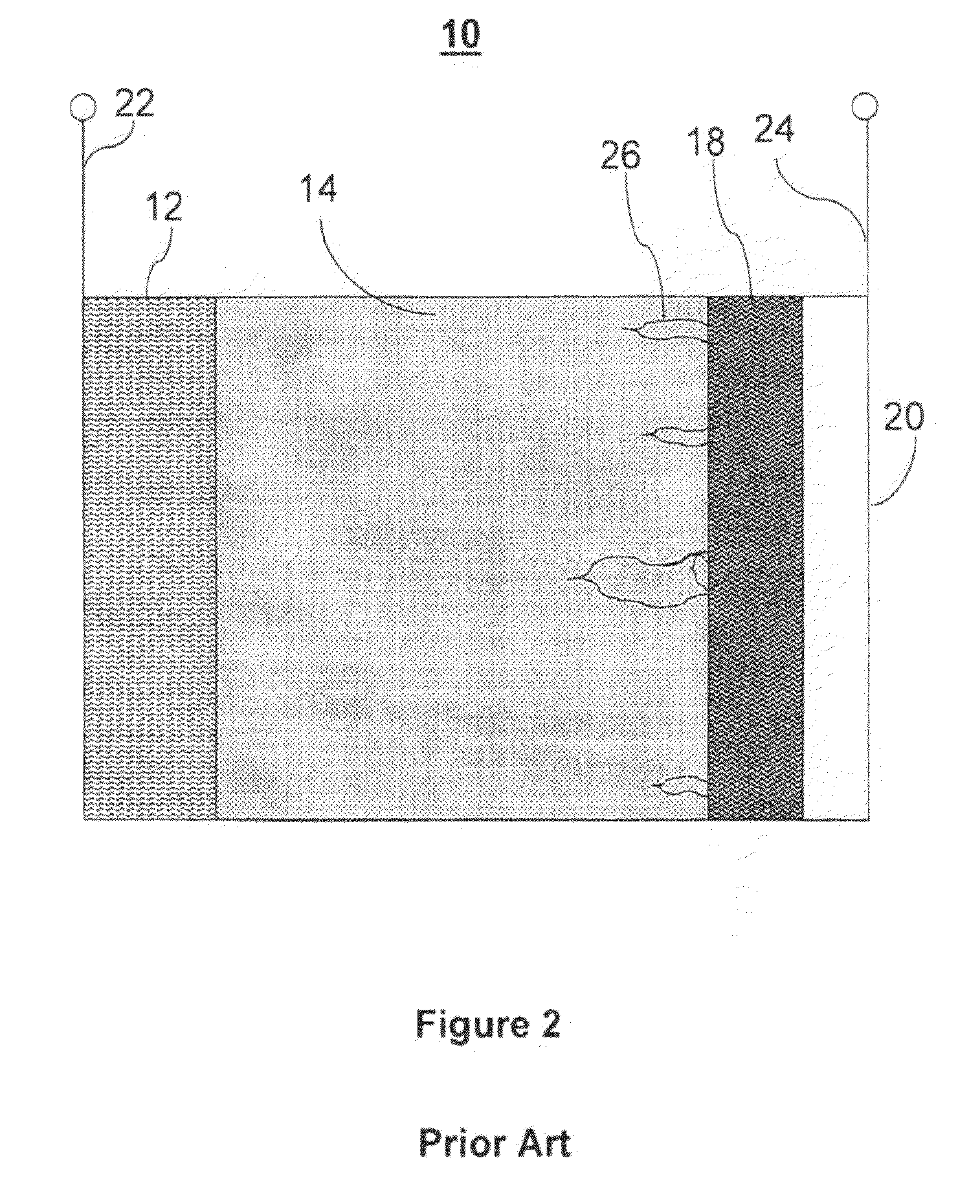

Anodic Dendritic Growth Suppression System for Secondary Lithium Batteries

InactiveUS20100143769A1Efficiently manufactureEfficient preparationBatteries circuit arrangementsLamination ancillary operationsGrowth suppressionMaterials science

Provided herein are methods for manufacturing lithium-metal anode [18] assemblies for thin-film, thick-film and hulk secondary batteries that use liquid or gel-type electrolytes [14], and lithium-metal anode [18] assemblies for thick-film and bulk secondary batteries that use solid electrolytes [18]. These methods involve electrolytic formation of a lithium metal anode [18] between a protecting lithium-stable, solid electrolyte [18] material and an eieethcaiiy-Gonductive substance [20]. Secondary lithium_ batteries made by these methods aw also provided.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

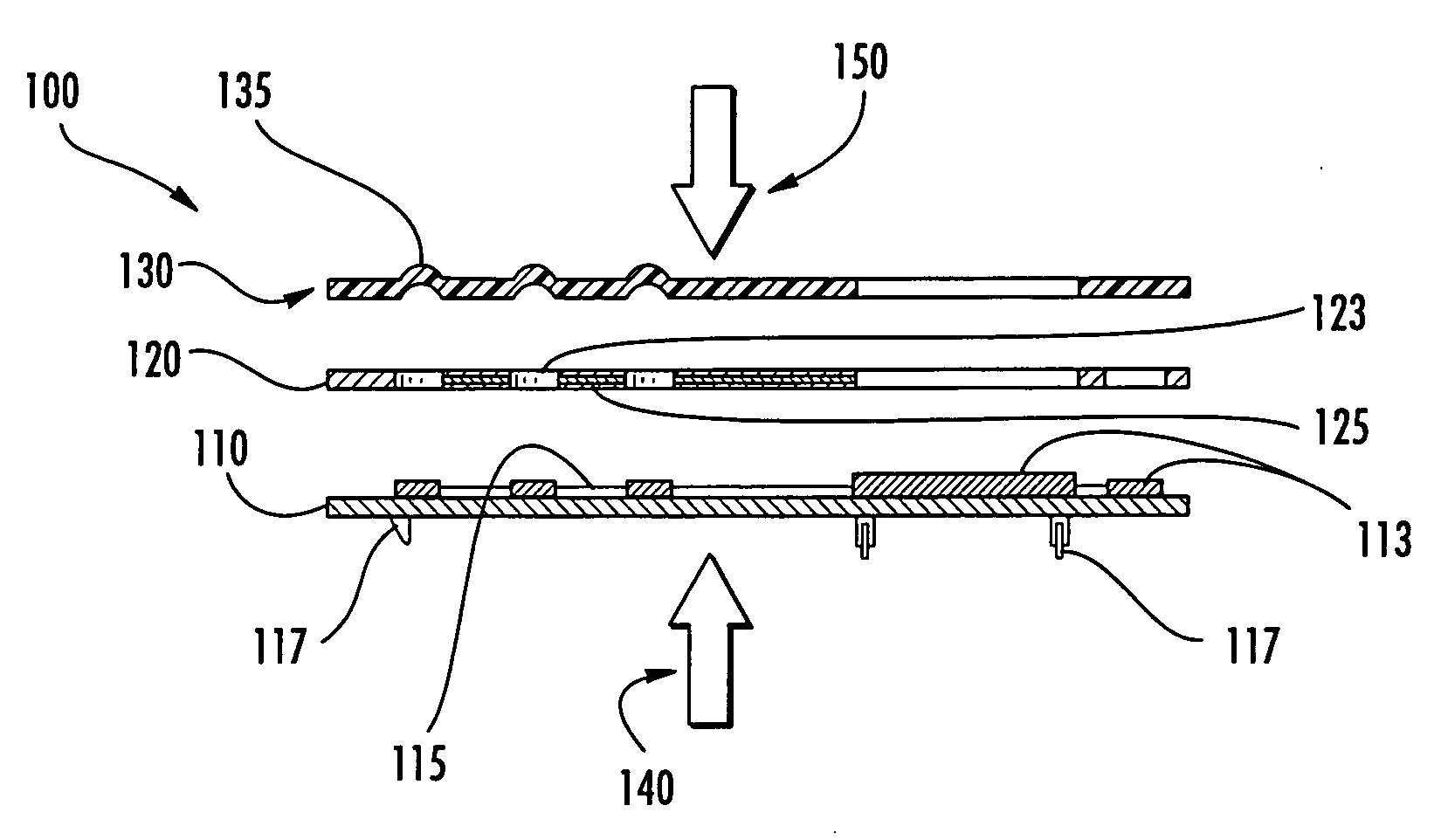

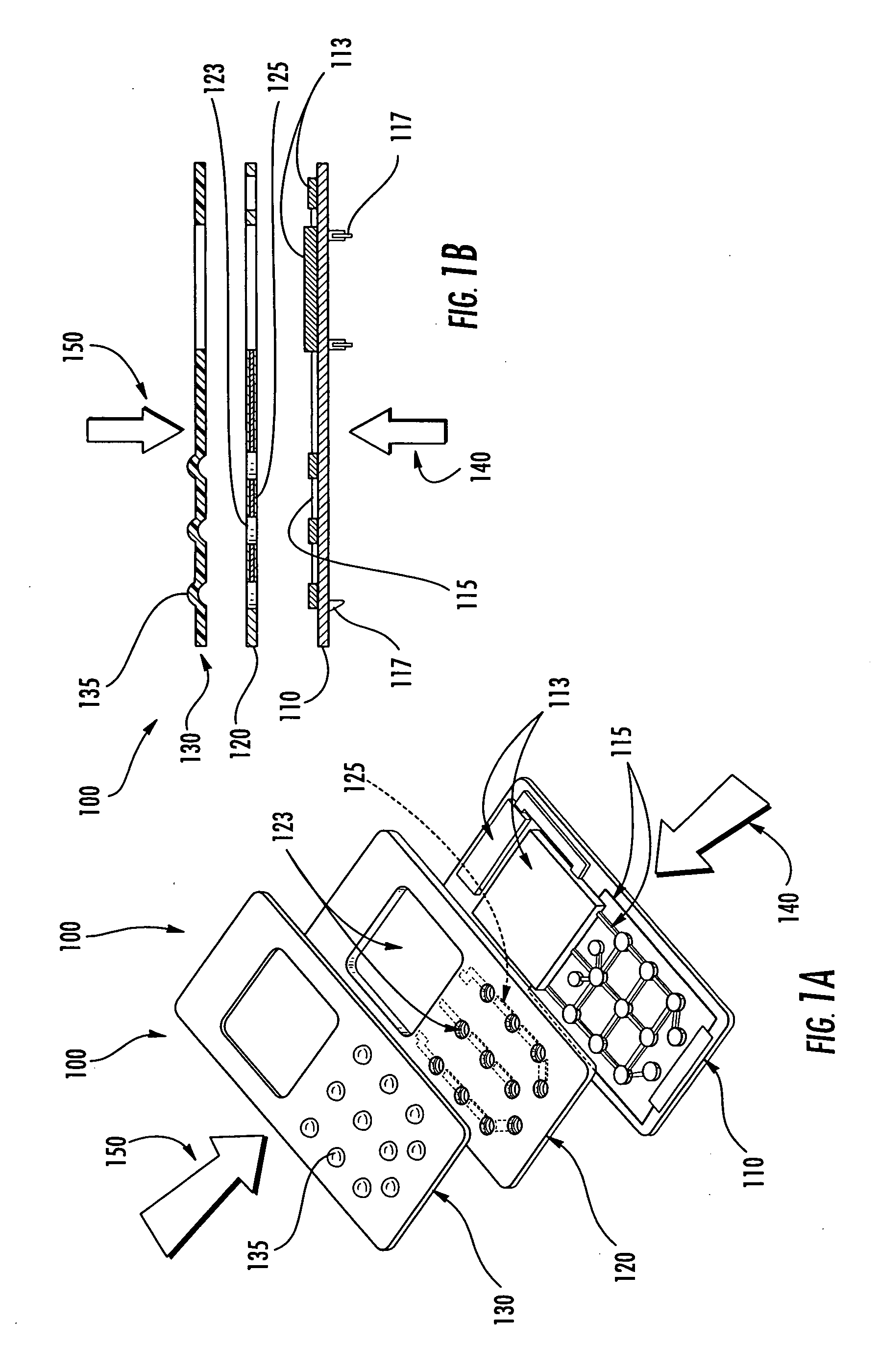

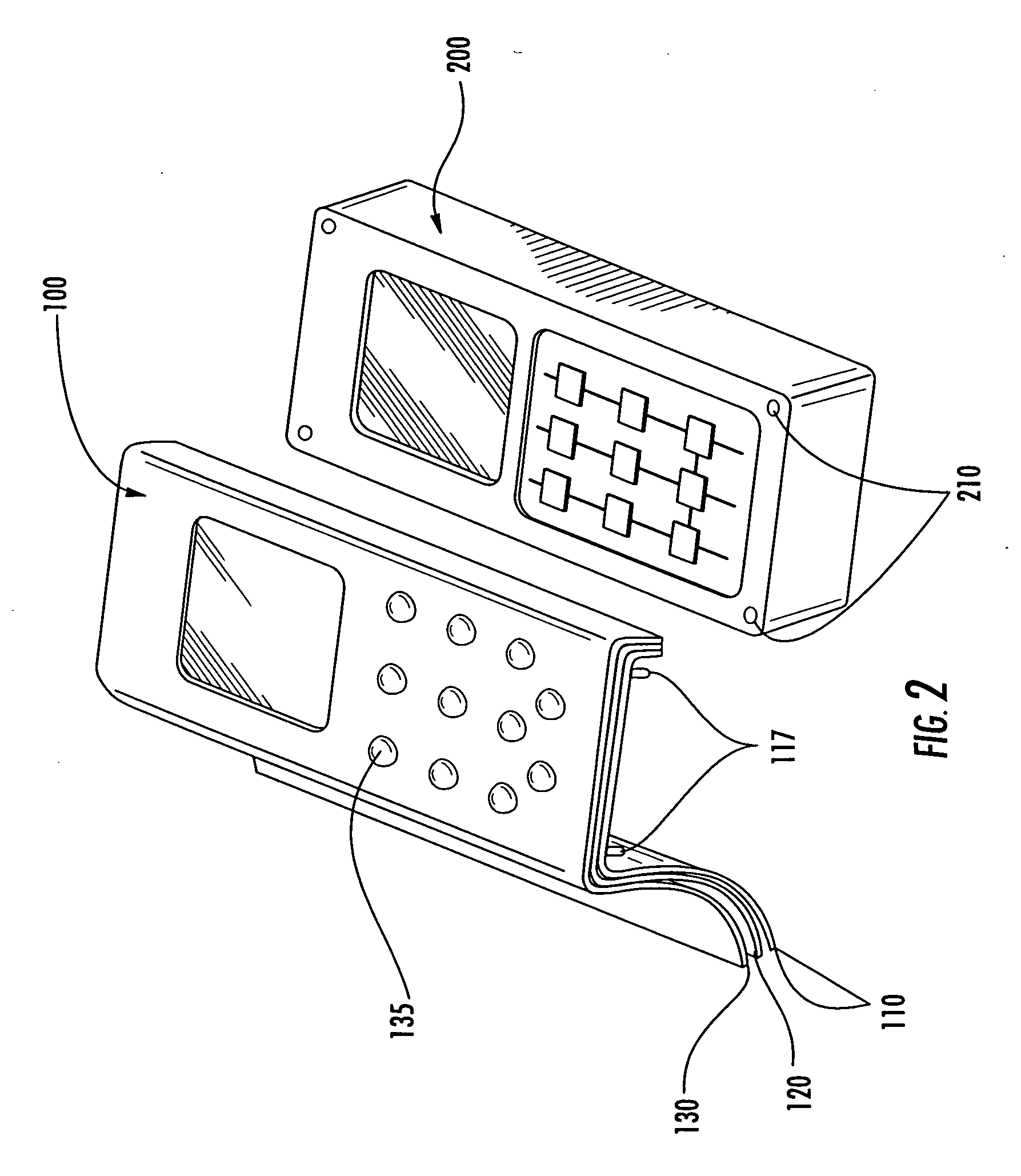

Method for manufacturing a laminate cover, laminate protective layer, and laminate electronic device having a reduced cost, manufacturing time, weight, and thickness

InactiveUS20060248713A1Efficiently manufactureReduce overall weight and thicknessPrinted circuit assemblingEmergency actuatorsEngineeringStructural component

A method is provided for manufacturing an electronically functional structural component adapted to integrate a plurality of electronic functions into a laminate cover, layer, and / or laminate component, for protecting, supporting, and / or forming a complete electronic device (such as a multimedia device). The method includes laminating a plurality of structural and / or protective layers interspersed with electronically functional layers or electronic components in communication with the multimedia device to form a supportive and electronically functional layer, cover, protective layer, and / or electronic device. Thus, the manufacturing methods provided allow for the cost-effective addition of thin and lightweight functional, protective, and / or decorative layers to a multimedia device or other electronic device at a sales location or other customization location.

Owner:NOKIA CORP

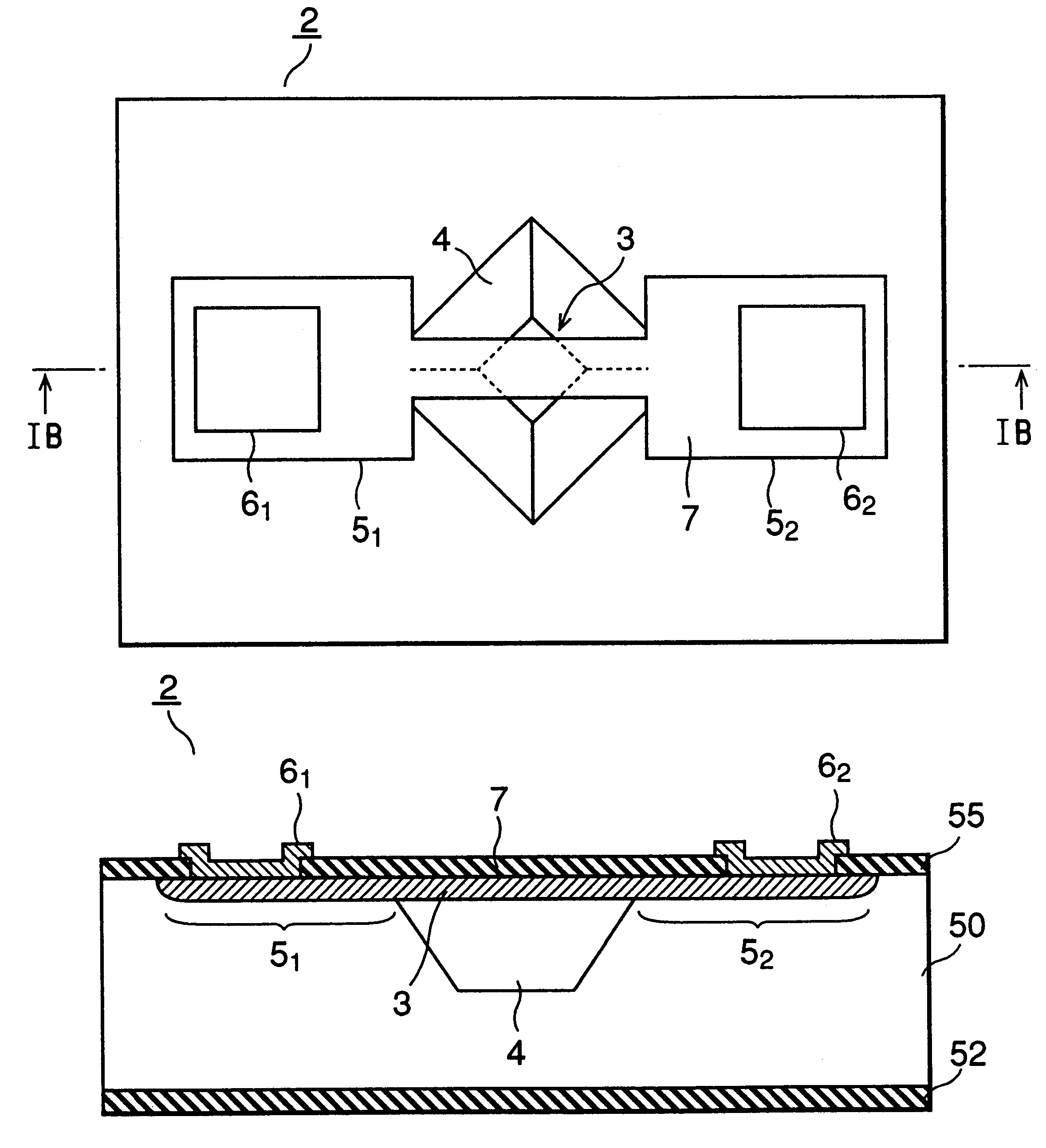

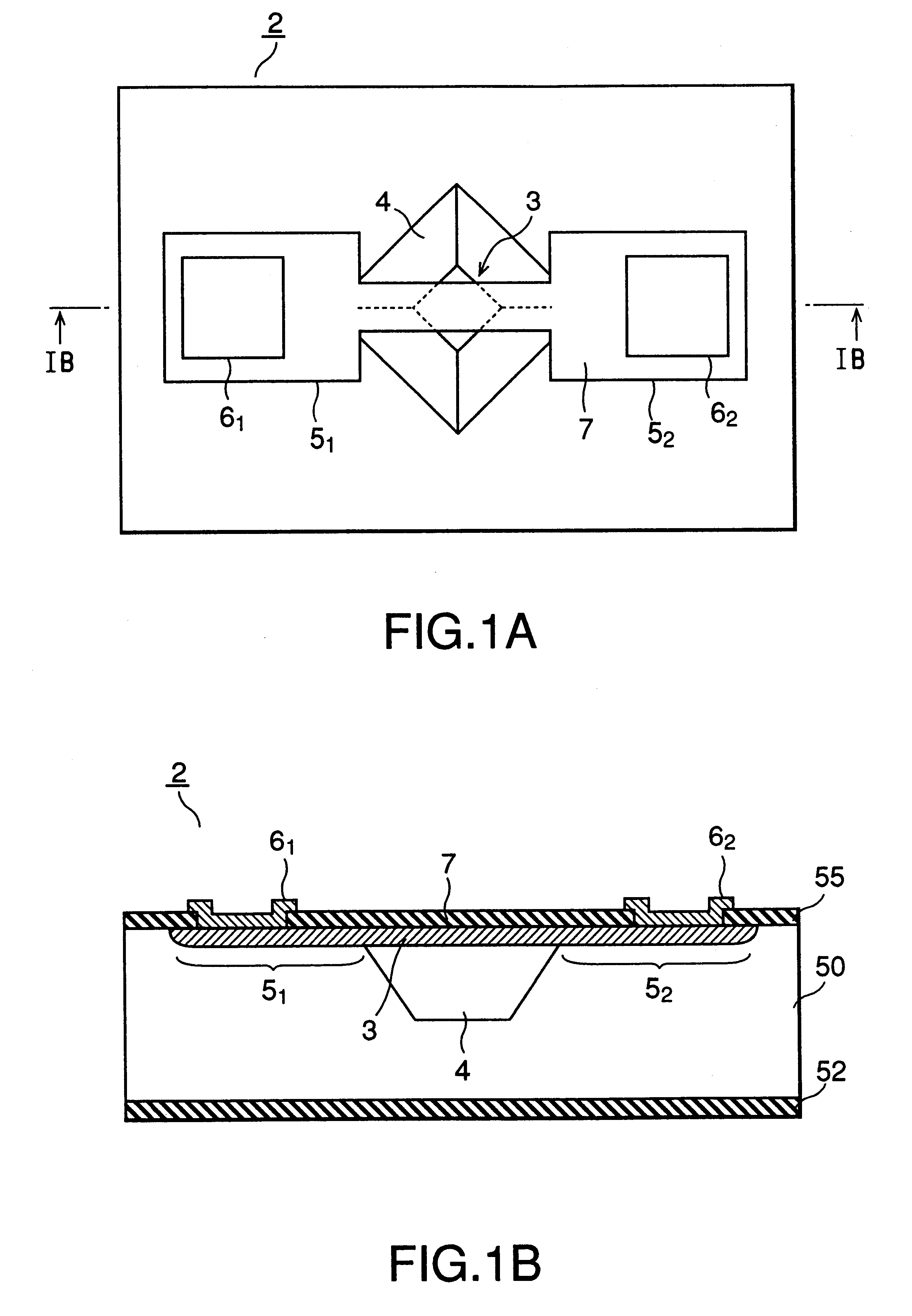

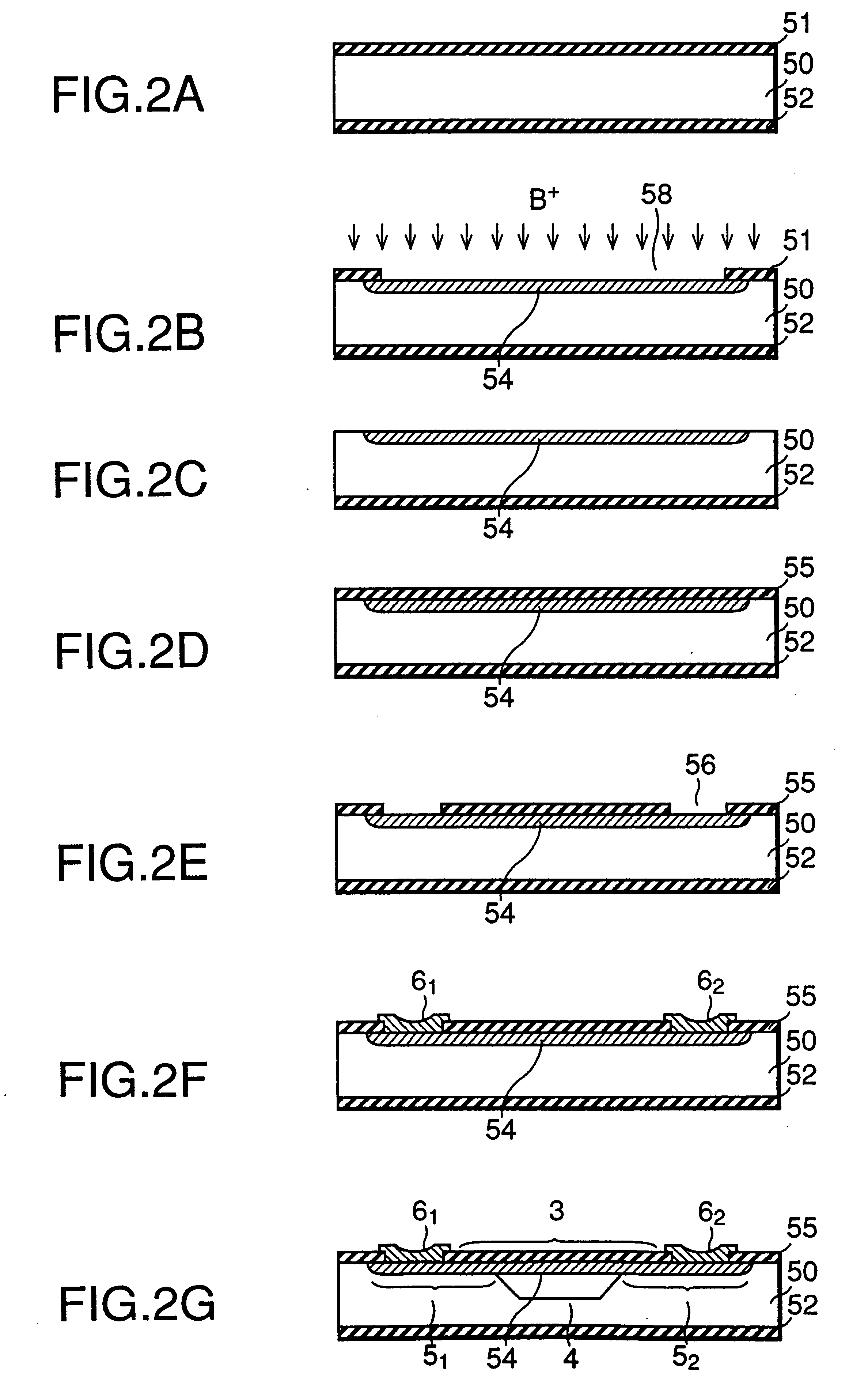

Process for producing infrared emitting device and infrared emitting device produced by the process

InactiveUS6204083B1Efficiently manufactureHigh mass productivityRadiation pyrometrySemiconductor/solid-state device manufacturingPeak valueNitrogen gas

In order, to manufacture a high-performance infrared-emitting element having high-speed thermal response characteristics and a high infrared emissivity, a bridge (heat-generating) portion having a separation space is formed on a silicon element substrate. The bridge portion is formed to have a thickness of 5 mum or less by doping boron as an impurity by ion implantation with a concentration distribution peak value of 1.5x1019 atoms / cm3 or more, and performing annealing under predetermined conditions for activating the impurity layer. In the infrared-emitting element manufactured in this manner, even if the bridge portion is made thin to improve the thermal response characteristics, the infrared emissivity does not decrease because of a high impurity concentration, and a large temperature modulation width can be obtained. In doping boron as the impurity by ion implantation, the dose is preferably set to 3.0x1014 ions / cm2 or more. To activate the impurity layer upon doping boron, the annealing is performed in the nitrogen gas atmosphere at a temperature of 1,100° C. to 1,200° C. for 5 min to 40 min and further in the wet oxygen atmosphere for about 25 min to 40 min. As a result, the doping concentration of boron by ion implantation and the activation of the impurity layer can be stably increased and enhanced.

Owner:ANRITSU CORP

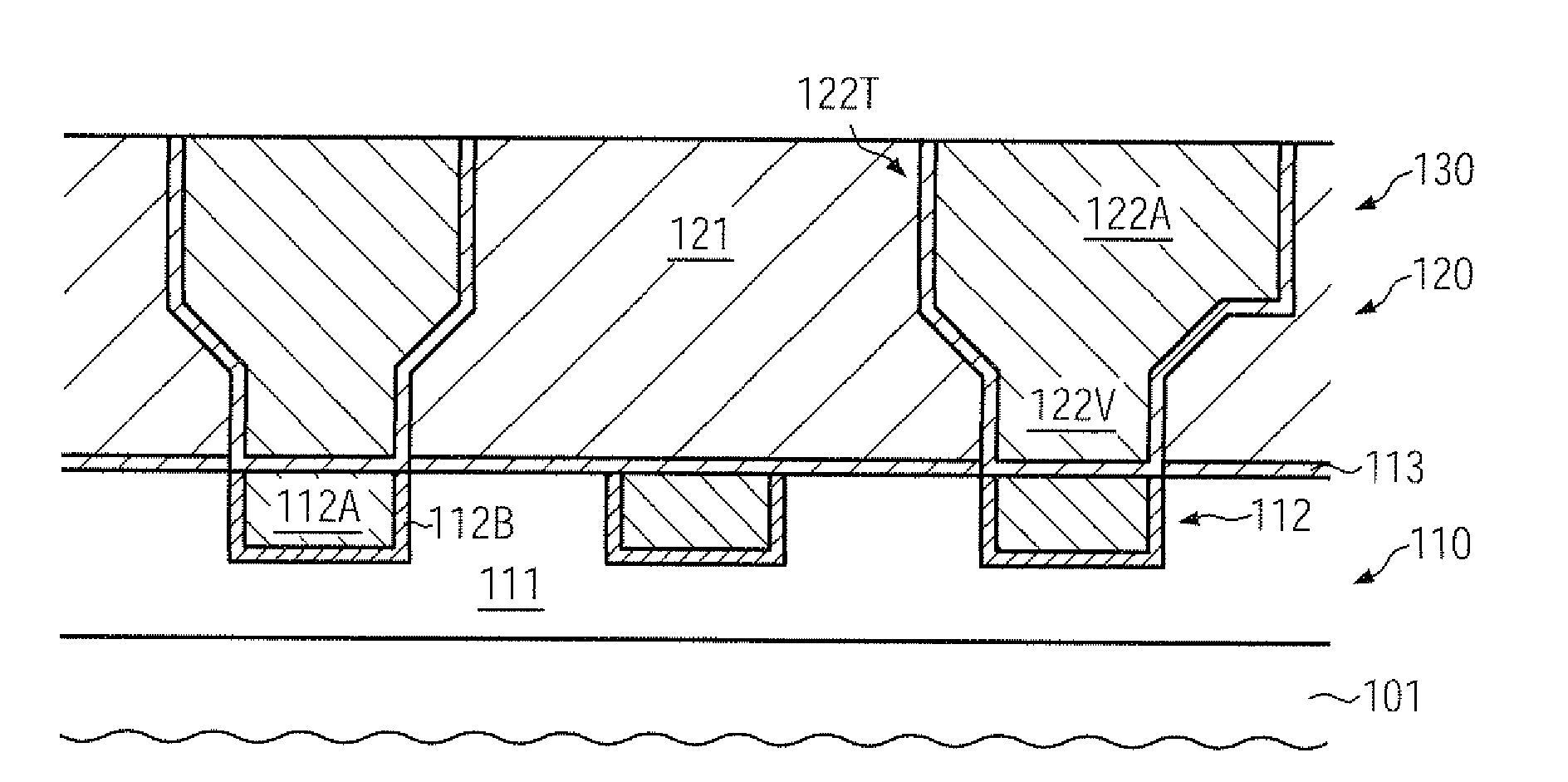

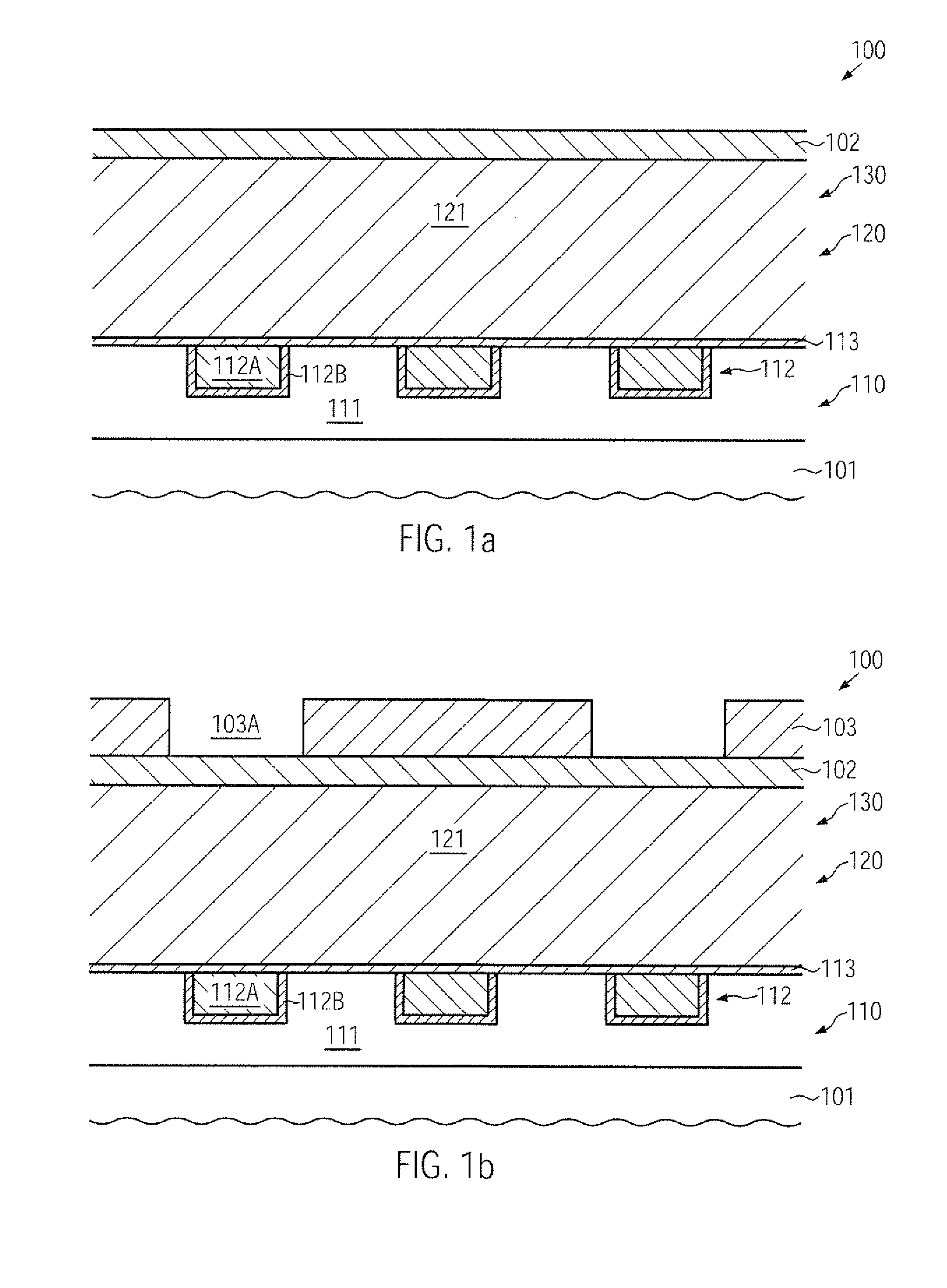

Method of forming a metallization system of a semiconductor device by using a hard mask for defining the via size

InactiveUS20100197133A1Efficiently manufactureReduce complexitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

In a “via first / trench last” approach for forming metal lines and vias in a metallization system of a semiconductor device, a combination of two hard masks may be used, wherein the desired lateral size of the via openings may be defined on the basis of spacer elements, thereby resulting in significantly less demanding lithography conditions compared to conventional approaches.

Owner:ALSEPHINA INNOVATIONS INC

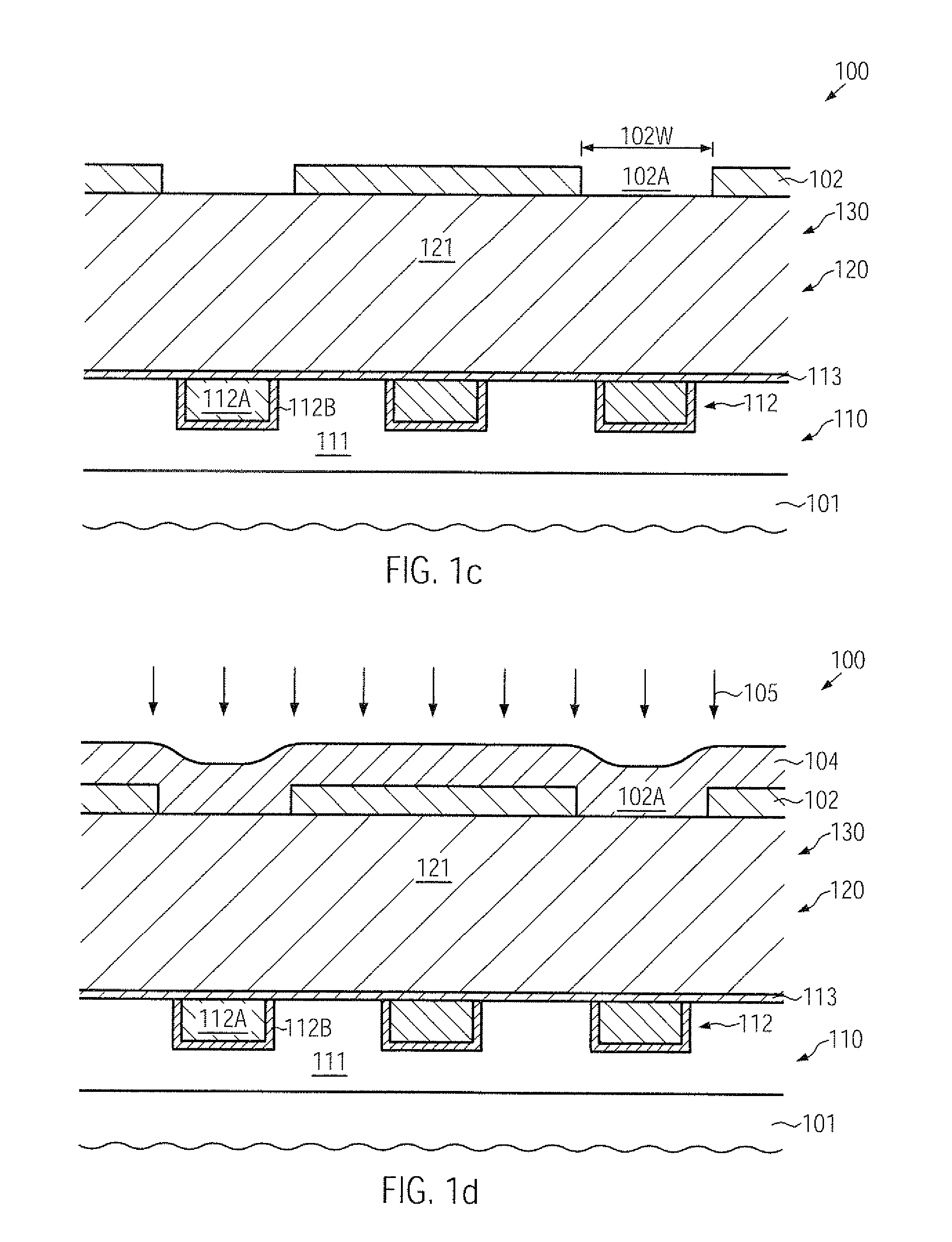

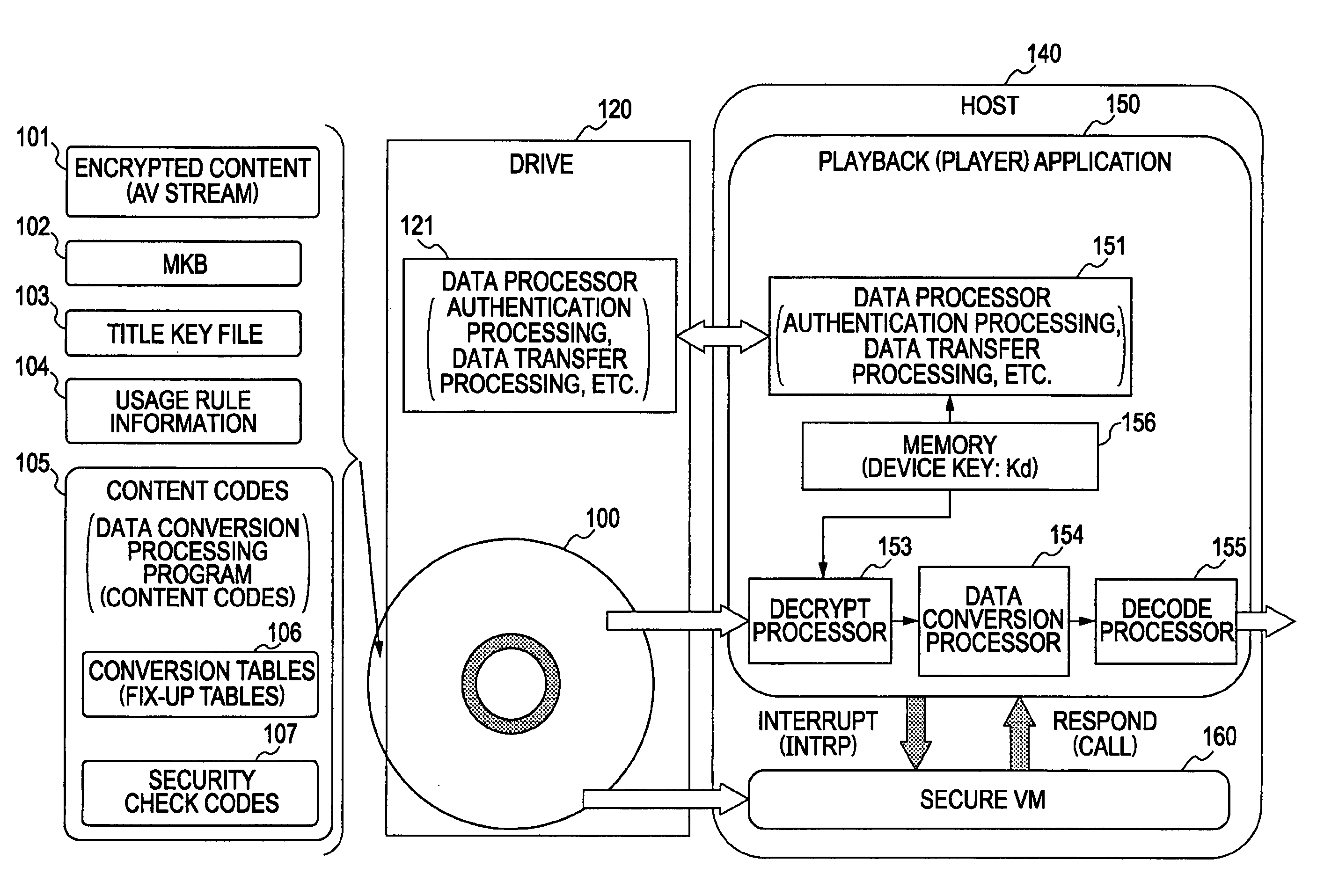

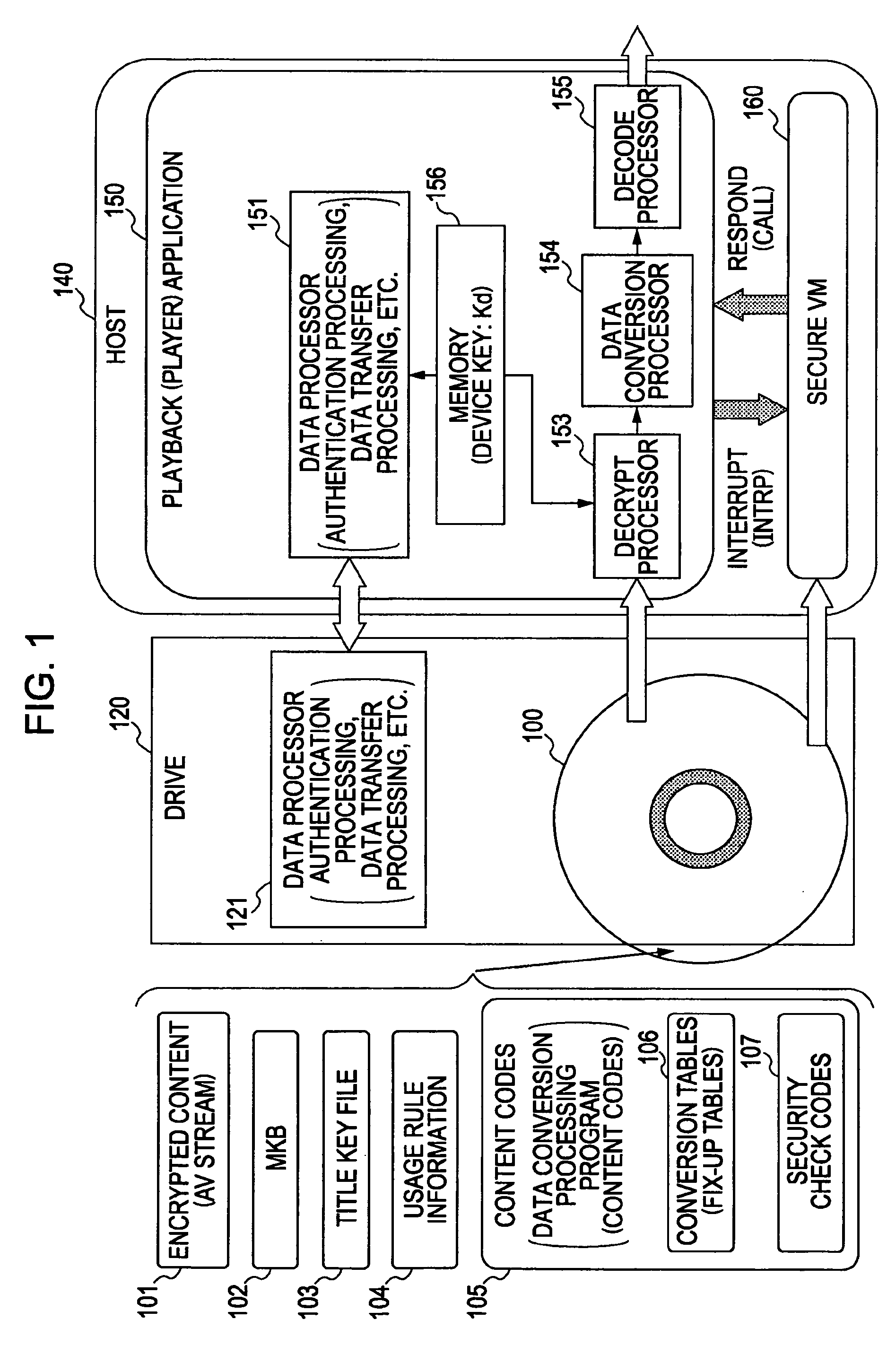

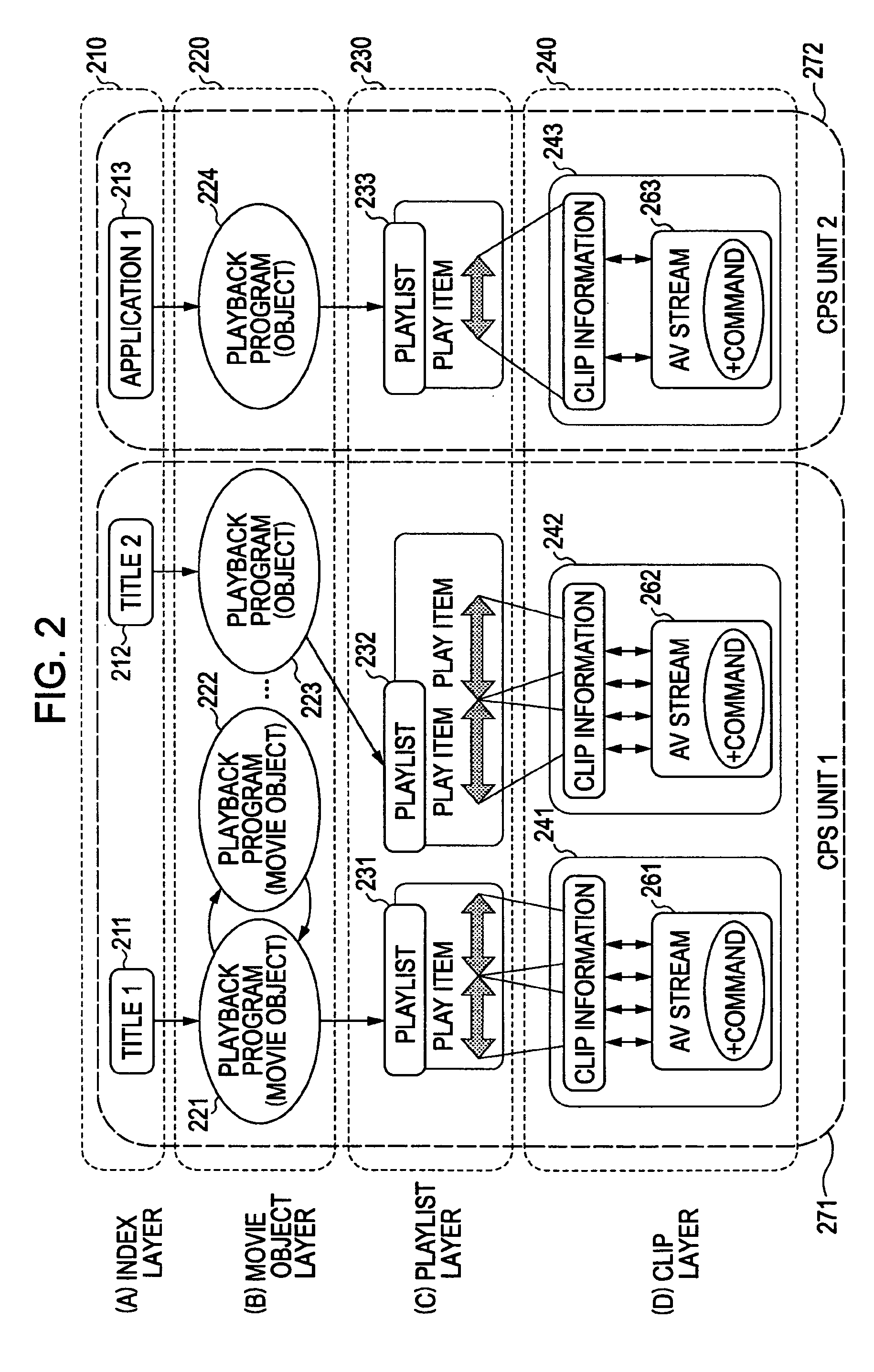

Information processing apparatus and method, information recording medium manufacturing apparatus and method, and information recording medium

InactiveUS20070116280A1Unauthorized useEfficiently manufactureDigital data processing detailsAnalogue secracy/subscription systemsData fileSecurity check

An information processing apparatus includes a data processor that obtains a security check code included in content codes recorded on an information recording medium when using content and that conducts security check for the information processing apparatus in accordance with the obtained security check code. The data processor obtains information based on at least one of identification information and configuration information corresponding to the information processing apparatus or a content usage application, and among security check codes classified into a plurality of data files, the data processor selects a security check code corresponding to the obtained information to conduct security check on the basis of the selected security check code.

Owner:SONY CORP

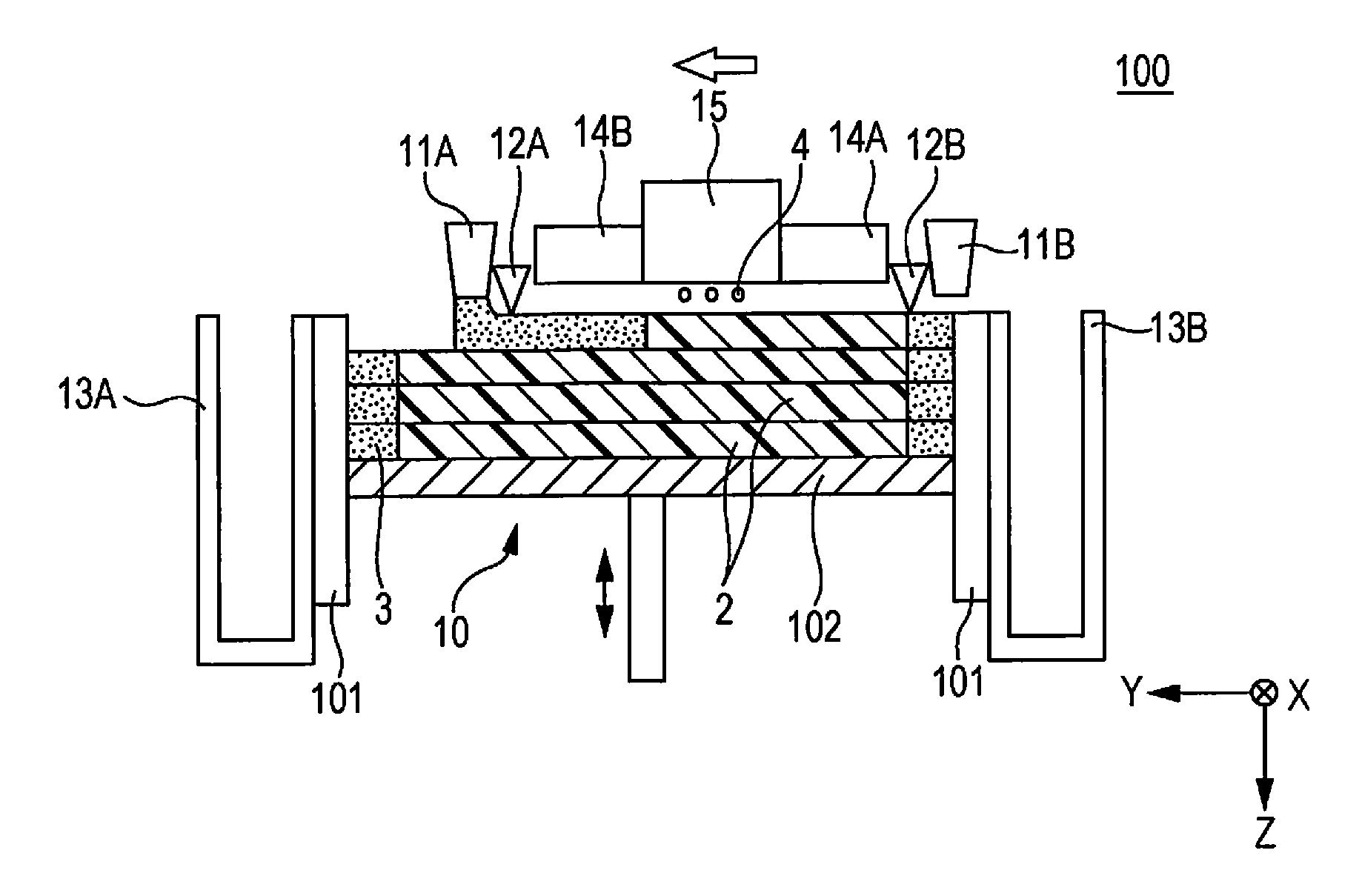

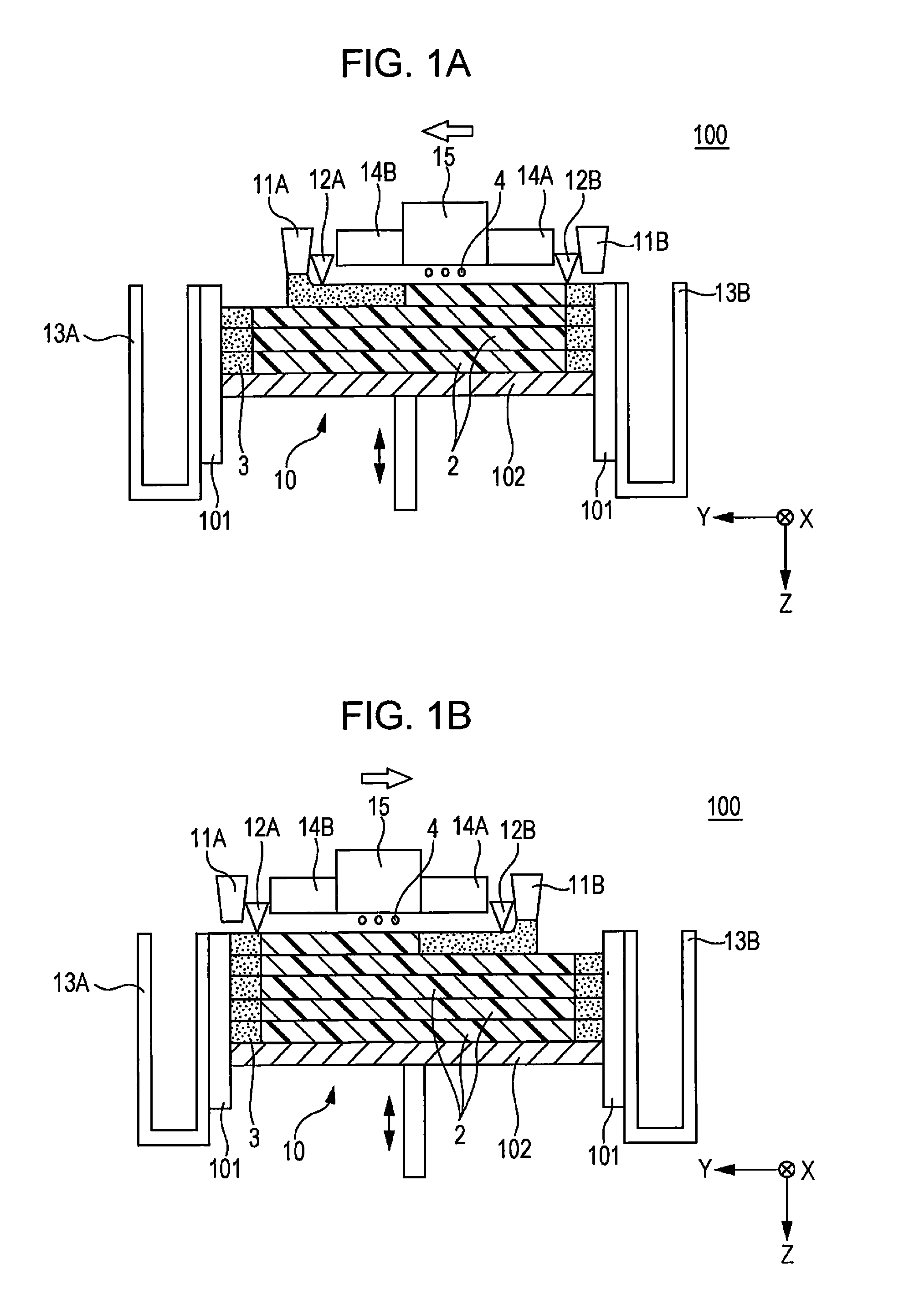

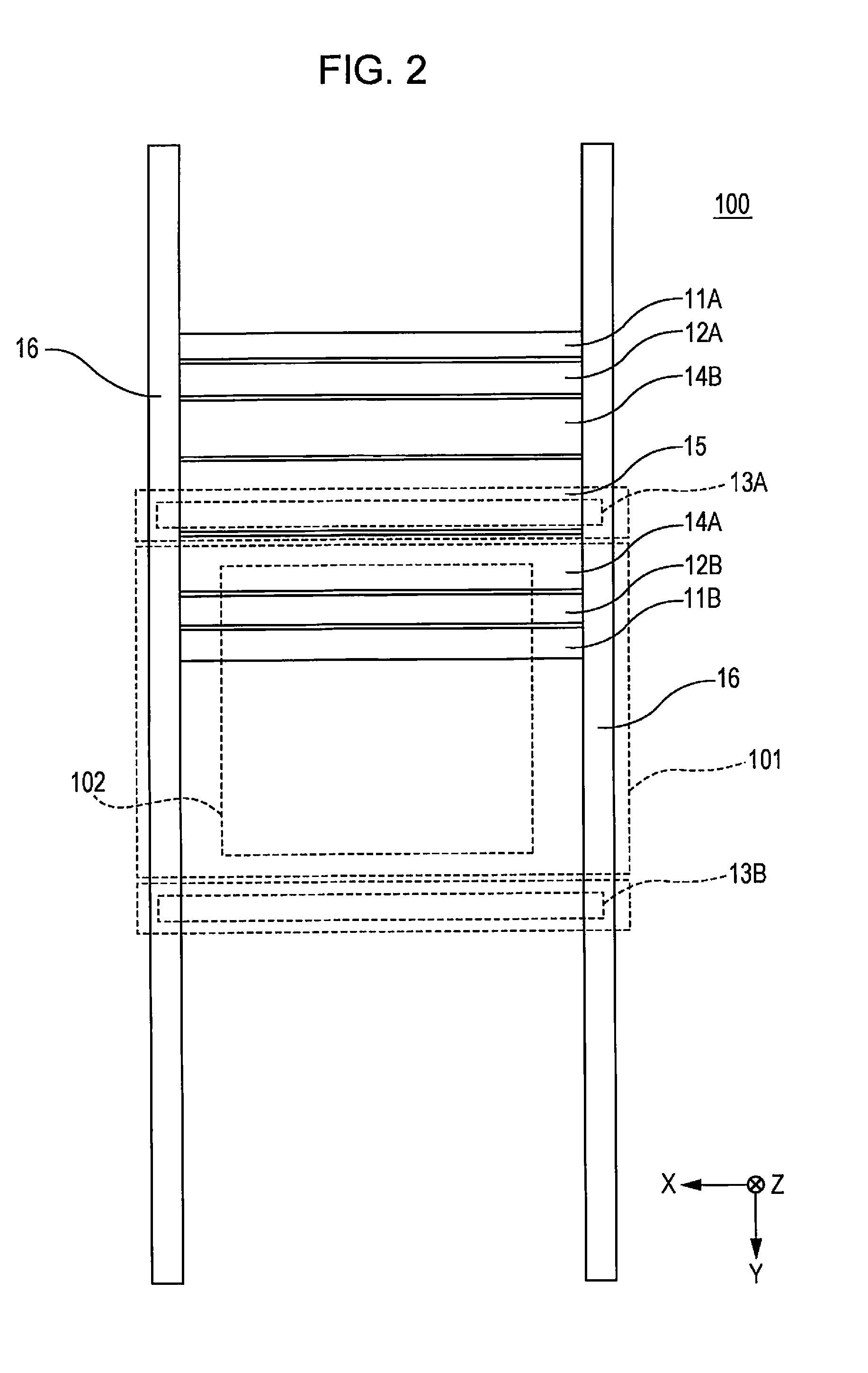

Three-dimensional structure manufacturing apparatus, manufacturing method of three-dimensional structure, and three-dimensional structure

ActiveUS20150258733A1Efficiently manufacturePrevent manufactureAdditive manufacturing apparatusConfectioneryEngineeringElectrical and Electronics engineering

Provided is a three-dimensional structure manufacturing apparatus which manufactures a three-dimensional structure by laminating layers formed using three-dimensional formation compositions containing three-dimensional formation powders, the apparatus including: a formation unit in which the three-dimensional structure is formed; a first supply unit and a second supply unit which supply the three-dimensional formation compositions to the formation unit; a first squeegee and a second squeegee which form the layers configured with the three-dimensional formation compositions on the formation unit; and a discharge unit which discharges a binding solution for binding the three-dimensional formation compositions to the layer, in which the first supply unit, the first squeegee, the discharge unit, the second squeegee, and the second supply unit are arranged in this order, along a movement direction of the discharge unit.

Owner:SEIKO EPSON CORP

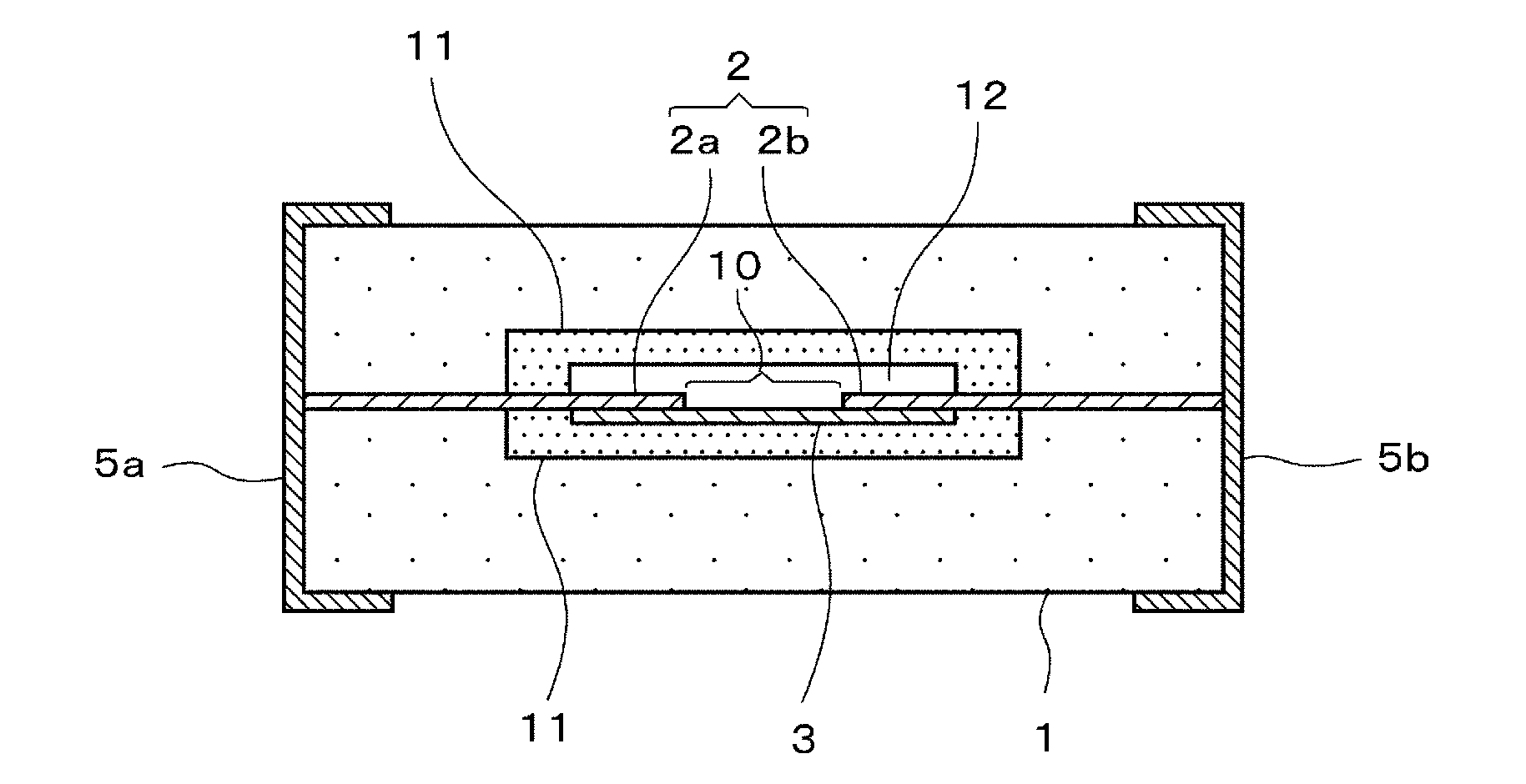

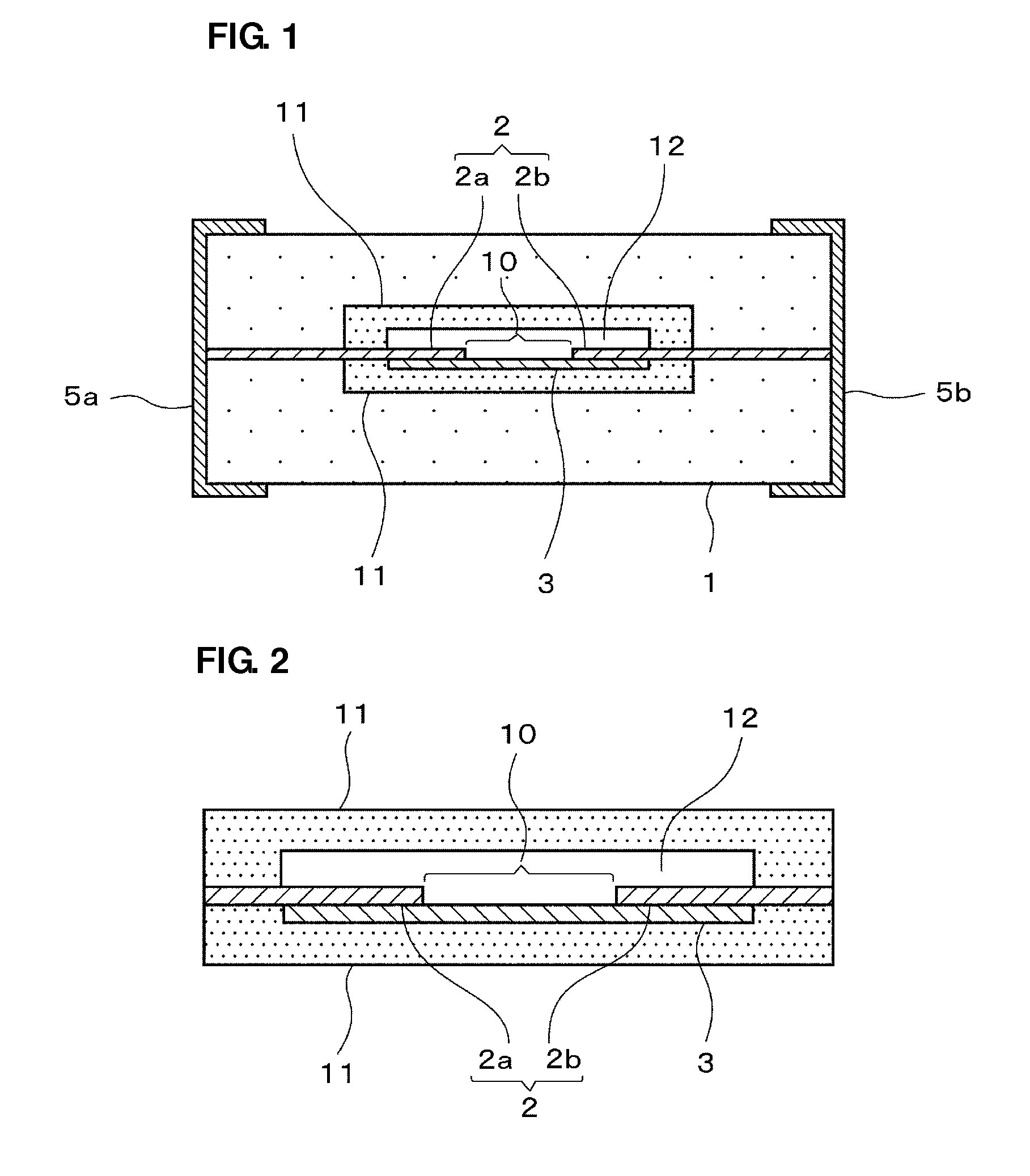

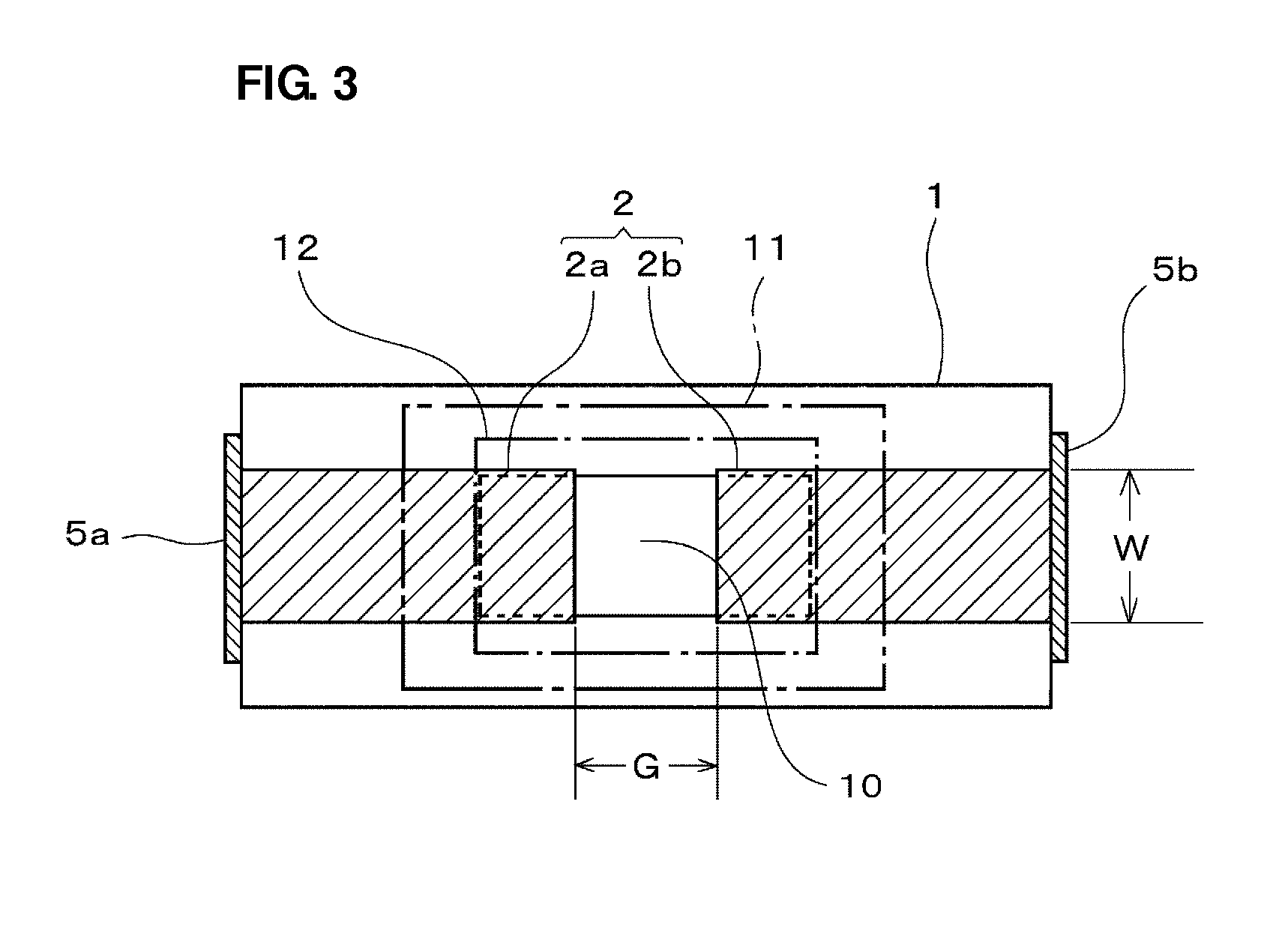

ESD protection device and manufacturing method therefor

ActiveUS20120169452A1Efficiently manufactureReduce peak voltageSparking plugsSpark gap detailsAuxiliary electrodeMetallurgy

An ESD protection device includes opposed electrodes in a ceramic base material and a discharge auxiliary electrode in contact with each of the opposed electrodes which is arranged so as to provide a bridge from the opposed electrode on one side to the opposed electrode on the other side, the discharge auxiliary electrode includes metallic particles, semiconductor particles, and a vitreous material, and bonding is provided through the vitreous material between the metallic particles, between the semiconductor particles, and between the metallic particles and the semiconductor particles. The metallic particles have an average particle diameter X of about 1.0 μm or more, and the relationship between the thickness Y of the discharge auxiliary electrode and the average particle diameter X of the metallic particles satisfies about 0.5≦Y / X≦ about 3.

Owner:MURATA MFG CO LTD

Adhesive-carrying porous film for battery separator and use thereof

InactiveUS20070184340A1Efficiently manufactureReduce or preventCell seperators/membranes/diaphragms/spacersFilm/foil adhesivesIsocyanate compoundAdhesive

The invention provides an adhesive-carrying porous film for use as a battery separator, which comprises: a substrate porous film such that when a probe of a probe penetrating thermomechanical analyzer, said probe having a diameter of 1 mm, is placed on the porous film under a load of 70 g to measure a thickness thereof while heating the porous film from room temperature at a rate of 2° C. / minute, a temperature at which the thickness of the porous film decreases to a half of the thickness of the porous film when the probe was initially placed thereon is 200° C. or more; and a partially crosslinked adhesive carried on the substrate porous film, the partially crosslinked adhesive being prepared by reacting a reactive polymer having a functional group capable of reacting with an isocyanate group therein with a polyfunctional isocyanate so that the reactive polymer is partially crosslinked. Such a porous film (a separator) is temporarily bonded to an electrode to provide an electrode / separator laminate. In manufacturing a battery, the use of the laminate makes it possible to manufacture a battery efficiently with no mutual slip movement between the electrode and the separator, and is addition, the porous film (the separator) itself, after manufacturing a battery, functions as a separator which does not melt or break, and has a small heat shrinkage under high temperatures

Owner:NITTO DENKO CORP

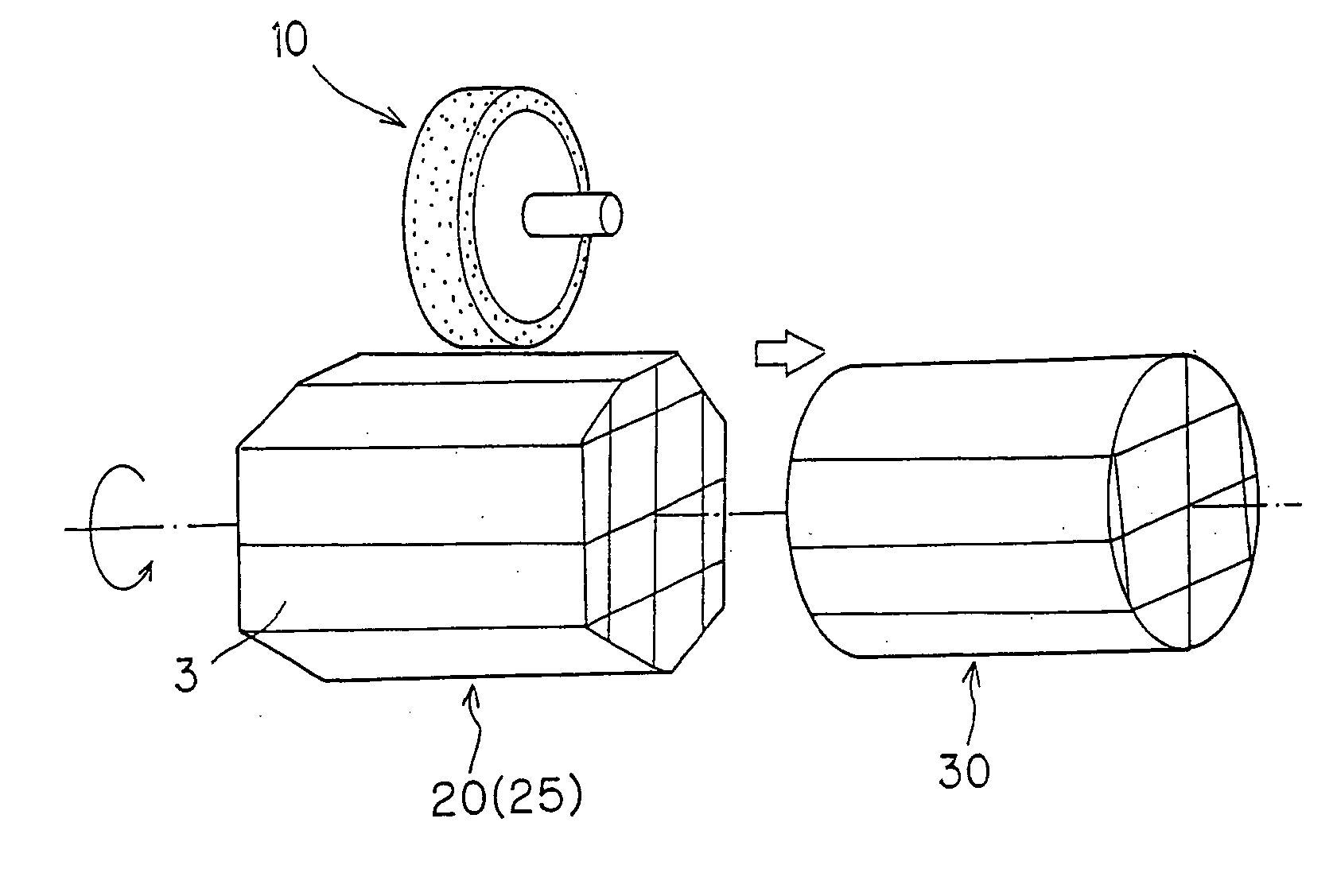

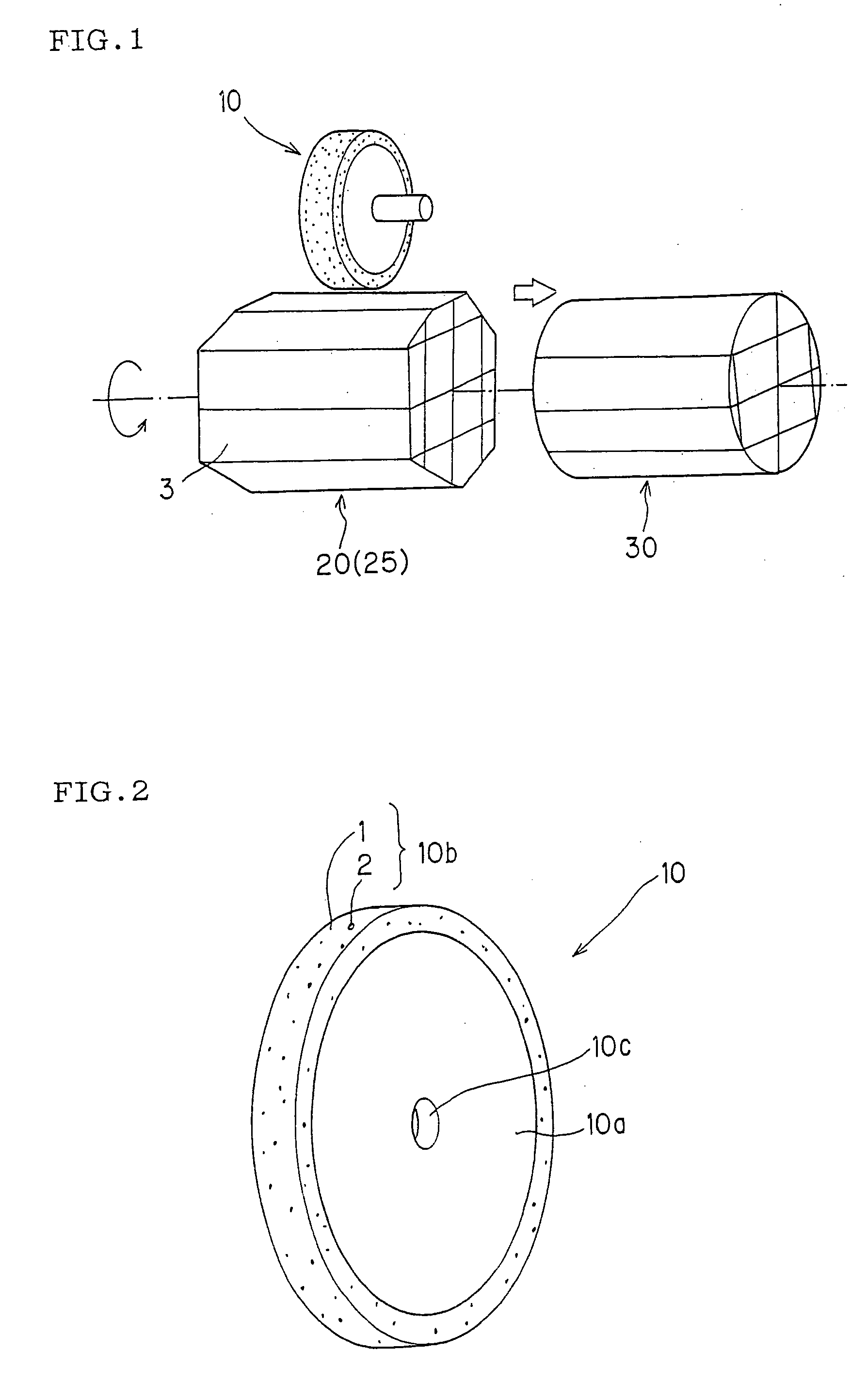

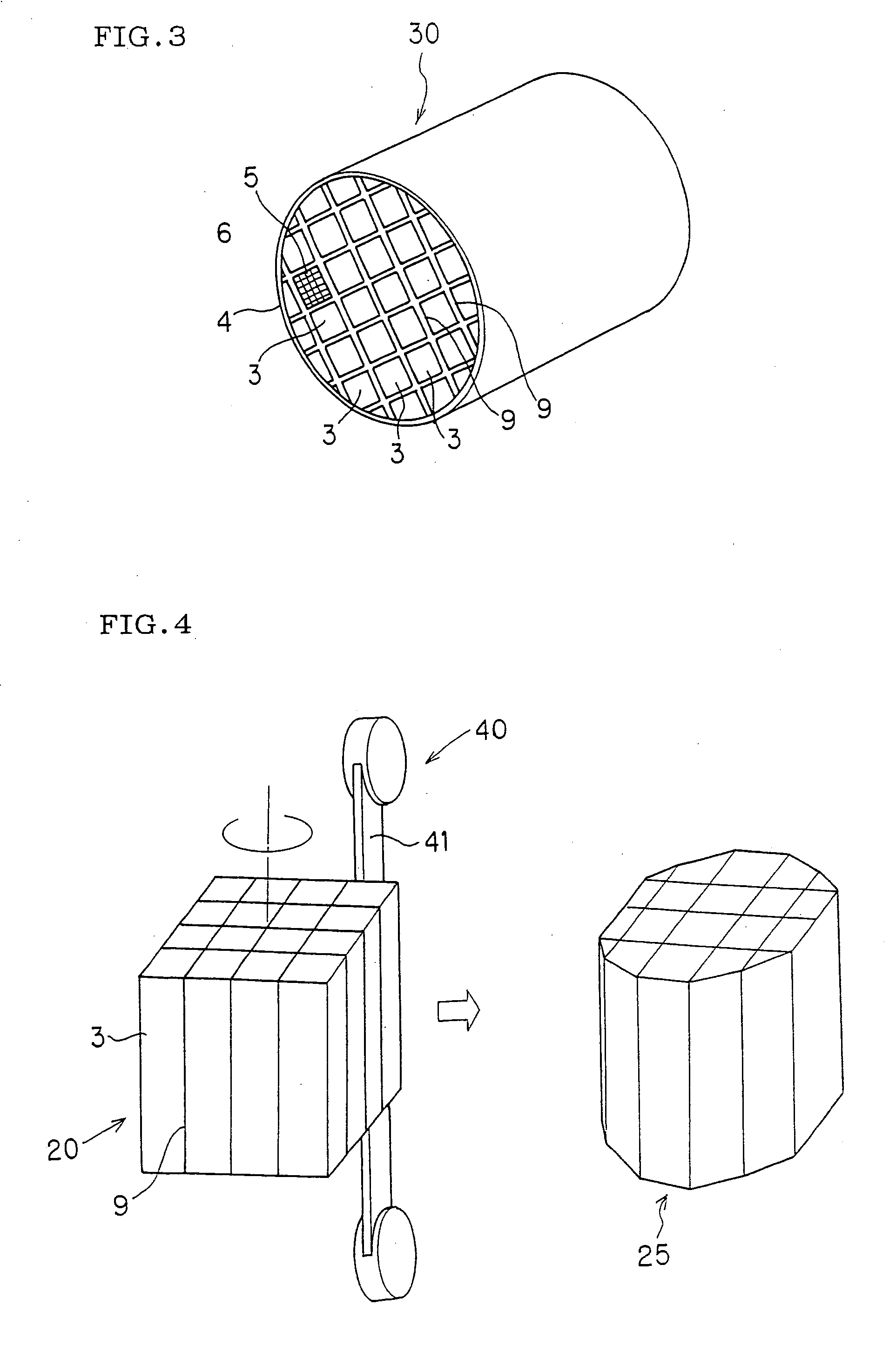

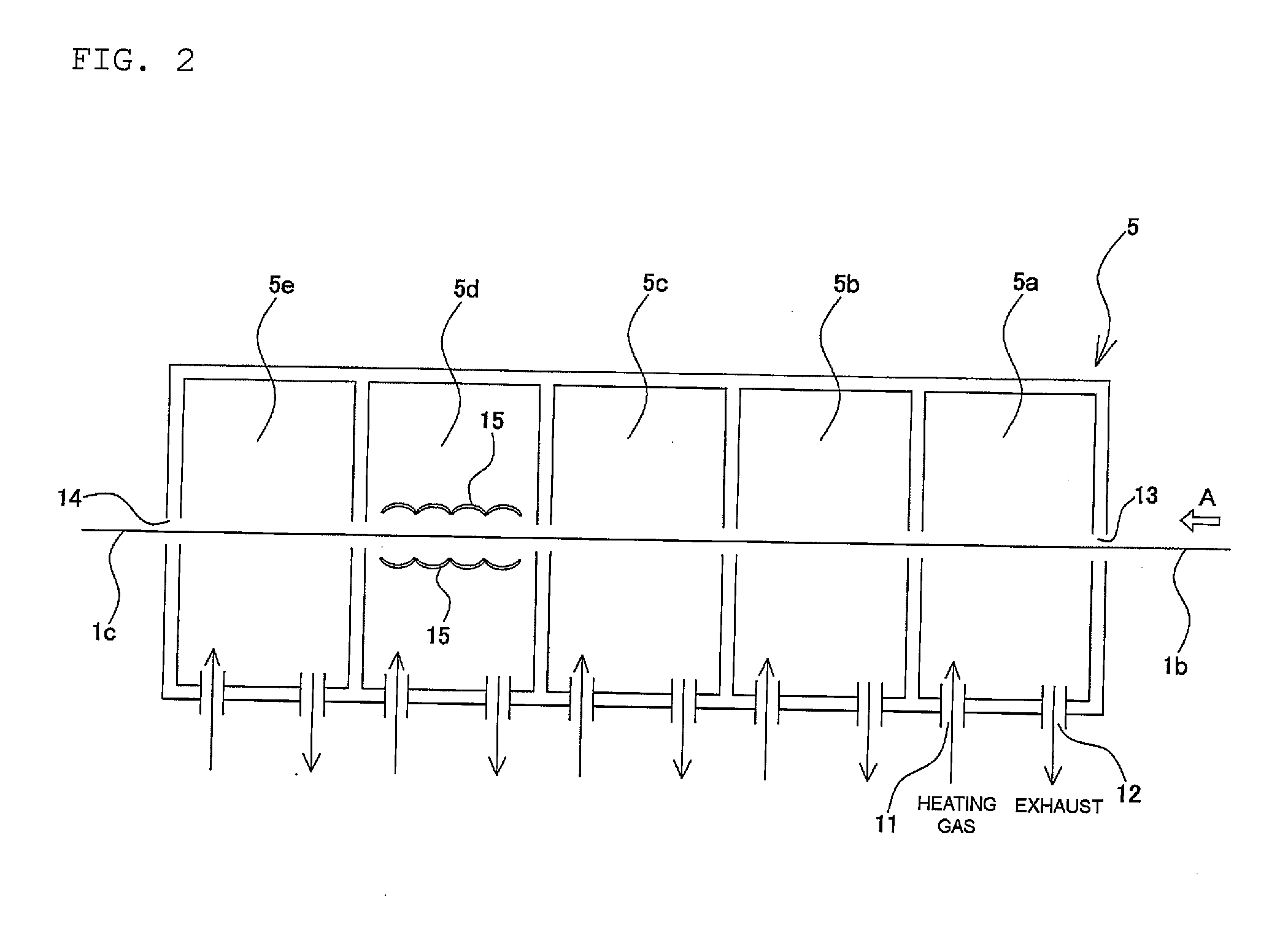

Method of manufacturing honeycomb structure

InactiveUS20060289501A1Efficiently manufactureSatisfactory performanceEdge grinding machinesAbrasion apparatusExhaust gasHoneycomb structure

There is disclosed a honeycomb structure manufacturing method which is capable of efficiently and inexpensively manufacturing a honeycomb structure for preferable use in a filter for trapping particulates in an exhaust gas or the like by use of a long-life grinding member whose satisfactory grinding performance is retained for a long time. The method includes the step of: working an outer periphery of a coarsely shaped honeycomb structure 20 made of a porous ceramic by use of a grinding member 10 to obtain a honeycomb structure 30 having a predetermined shape, wherein diamond abrasive grains of the grinding member 10 have a grain size of 40 to 150 mesh (JIS B 4130 standard) and a concentration degree of 80 or more, and the surfaces of the diamond abrasive grains are coated with at least one selected from the group consisting of Ti, Ni, and Cr.

Owner:NGK INSULATORS LTD

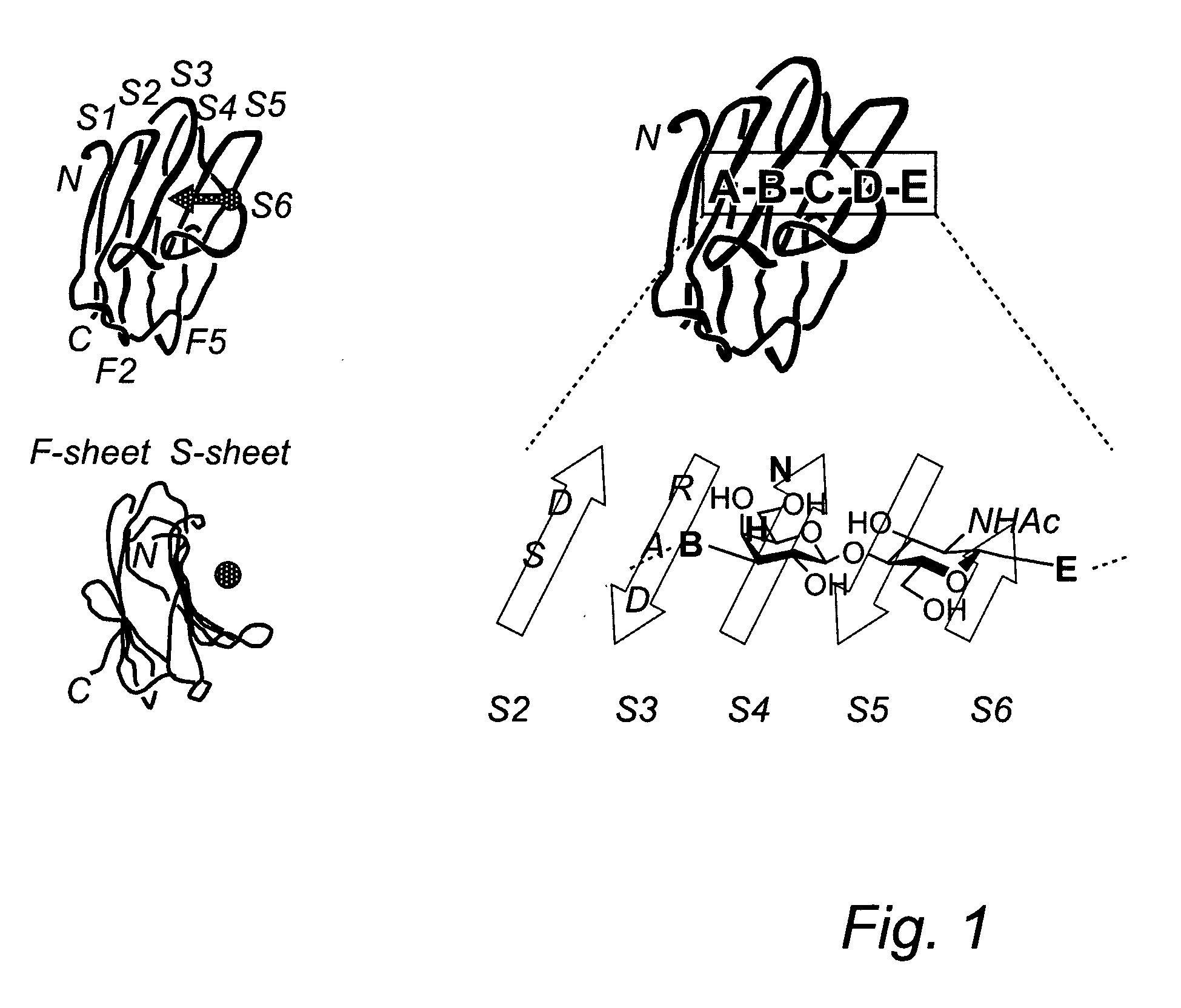

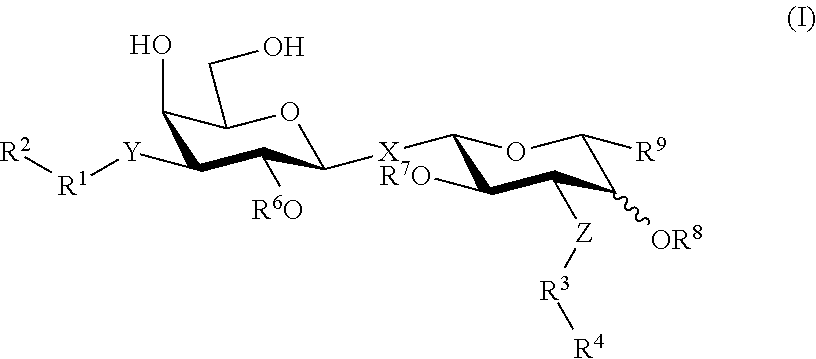

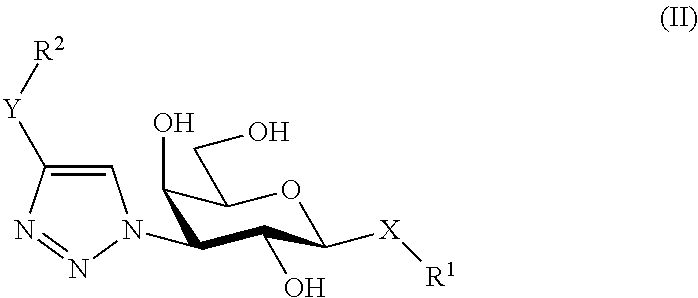

Novel synthesis of galactoside inhibitors

ActiveUS20110130553A1Efficiently manufactureEfficient preparationEsterified saccharide compoundsSugar derivativesAzideThio-

Novel synthesis routes for preparation of thiodigalactosides and intermediates are presented. The method includes the use of a 3-azido-galactosyl thiouronium salt derivative, which is activated to the corresponding thiol in situ, which in turn is directly reacted with a 3-azido-galactosyl bromide resulting in the 3,3′-di-azido-thio-di-galactoside before the thiol has a chance to reduce the azido 10 group. Hence, in situ formation of the 3-azido-galactosyl thiol from the thiouronium salt is essential in the synthesis procedure, because any other method that generate the thiol separately results in extensive unwanted azide reduction.

Owner:GALECTO BIOTECH

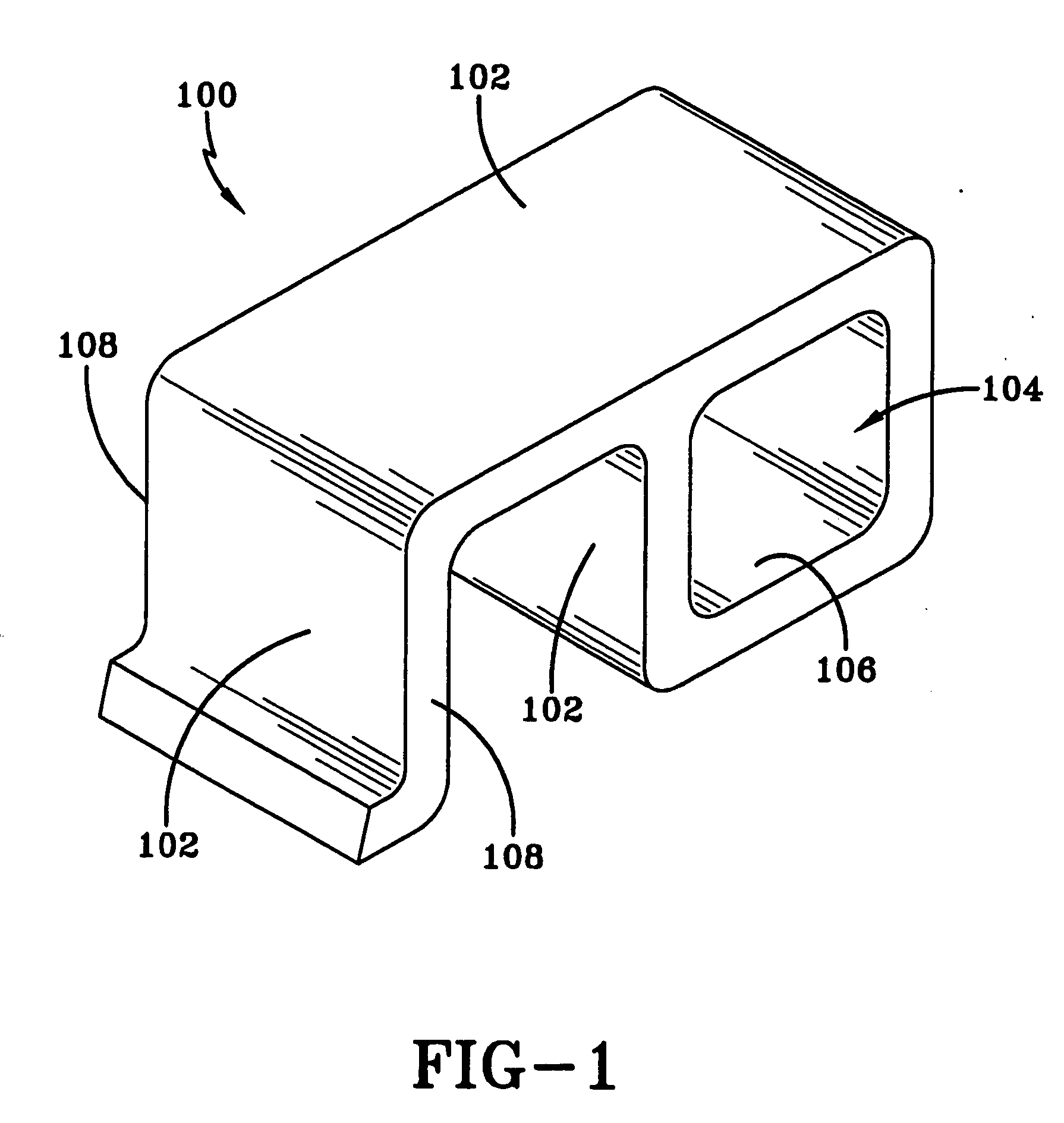

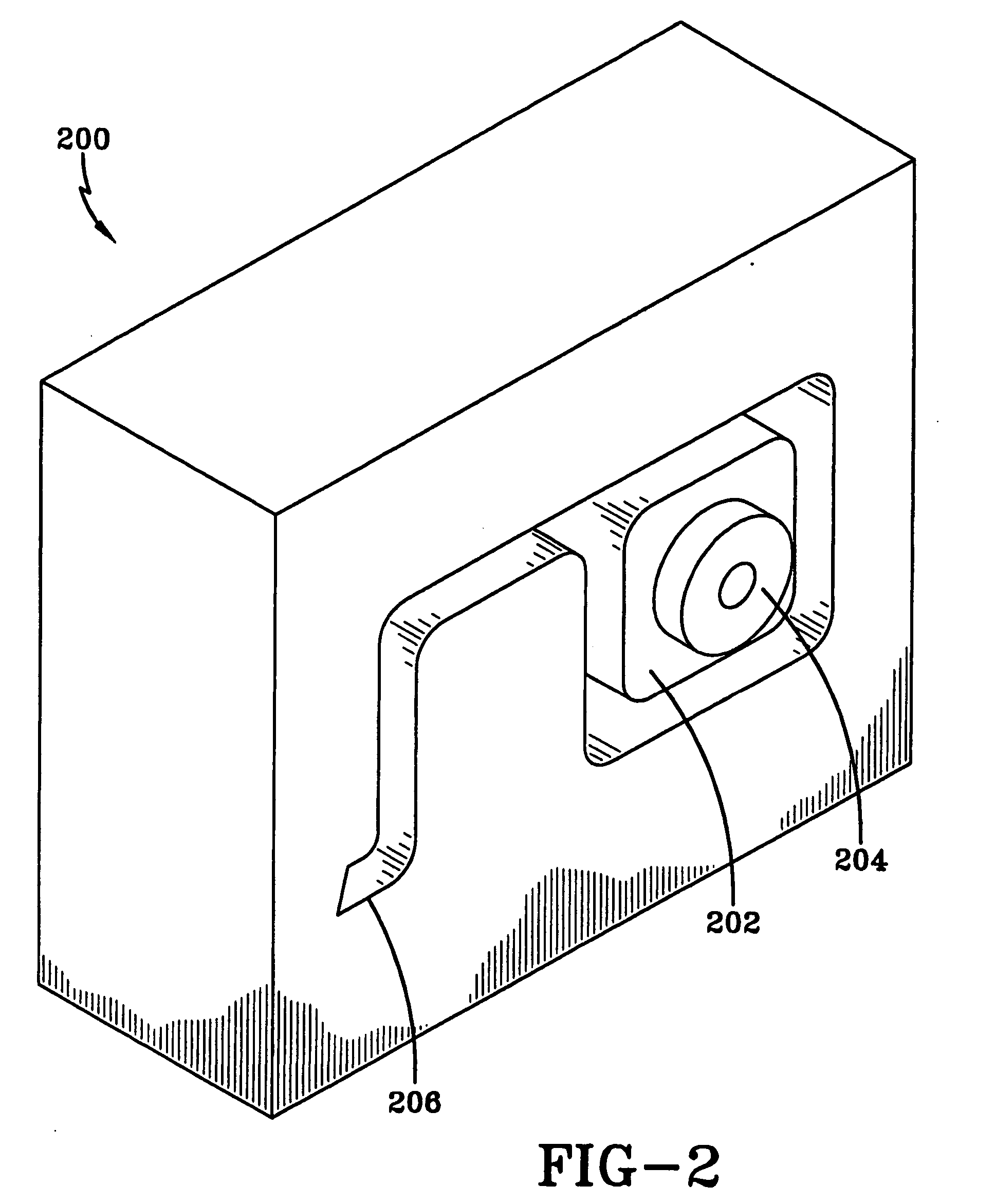

Chill blocks and methods for manufacturing chill blocks

A chill block made from copper bonded to tool steel is disclosed. A tool steel layer of the chill block of less than about 0.5 inches thick is present on the parting surface of the chill block or chill block face. A tool steel layer may also be present on a portion of the sides of the chill blocks and / or the bottom of the chill block. Chill blocks in accordance with the present invention allow molten metal to solidify in the passageway formed by a pair of chill blocks, and provide for efficient manufacturing of objects by die casting methods.

Owner:SPX CORP

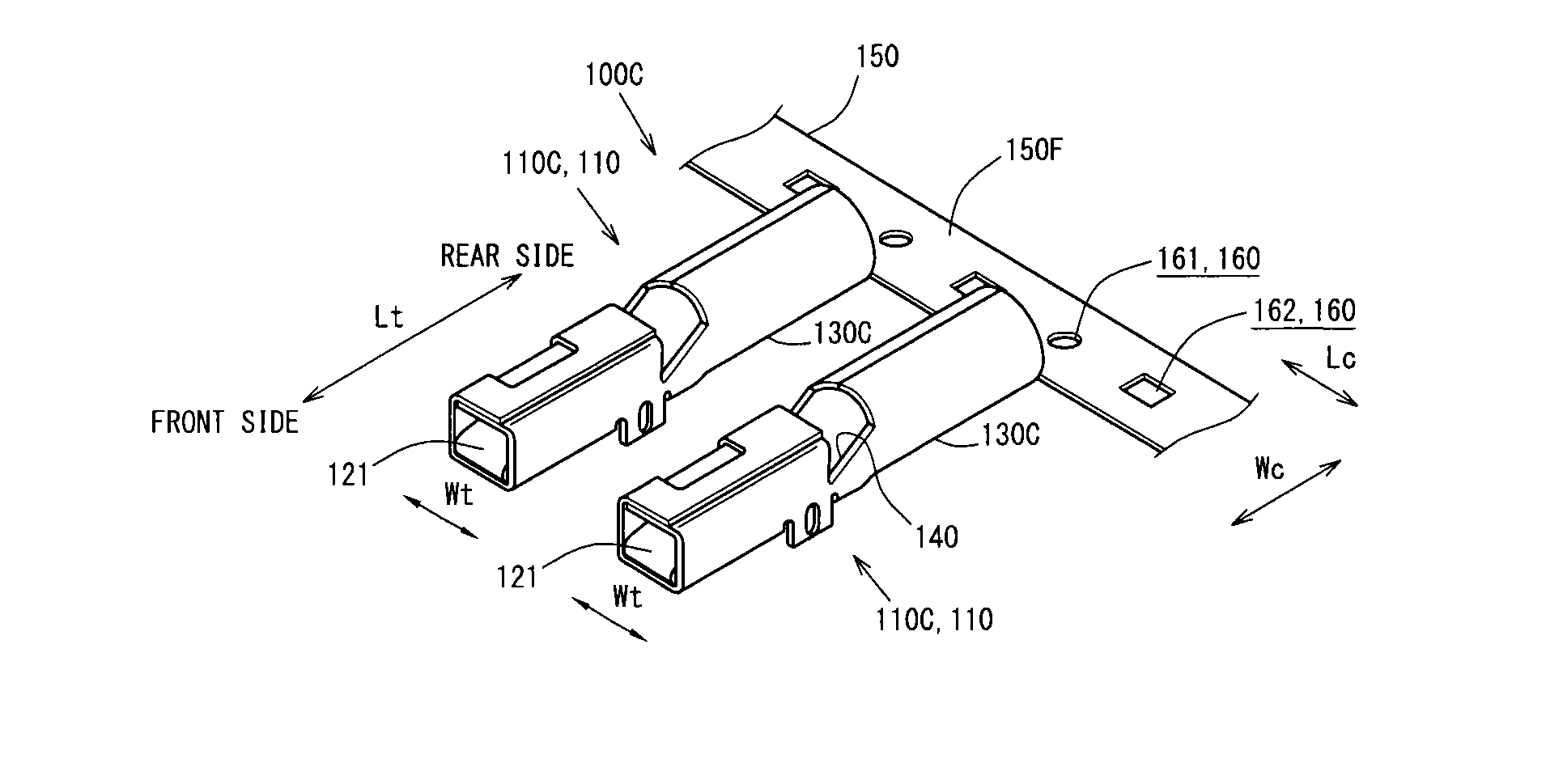

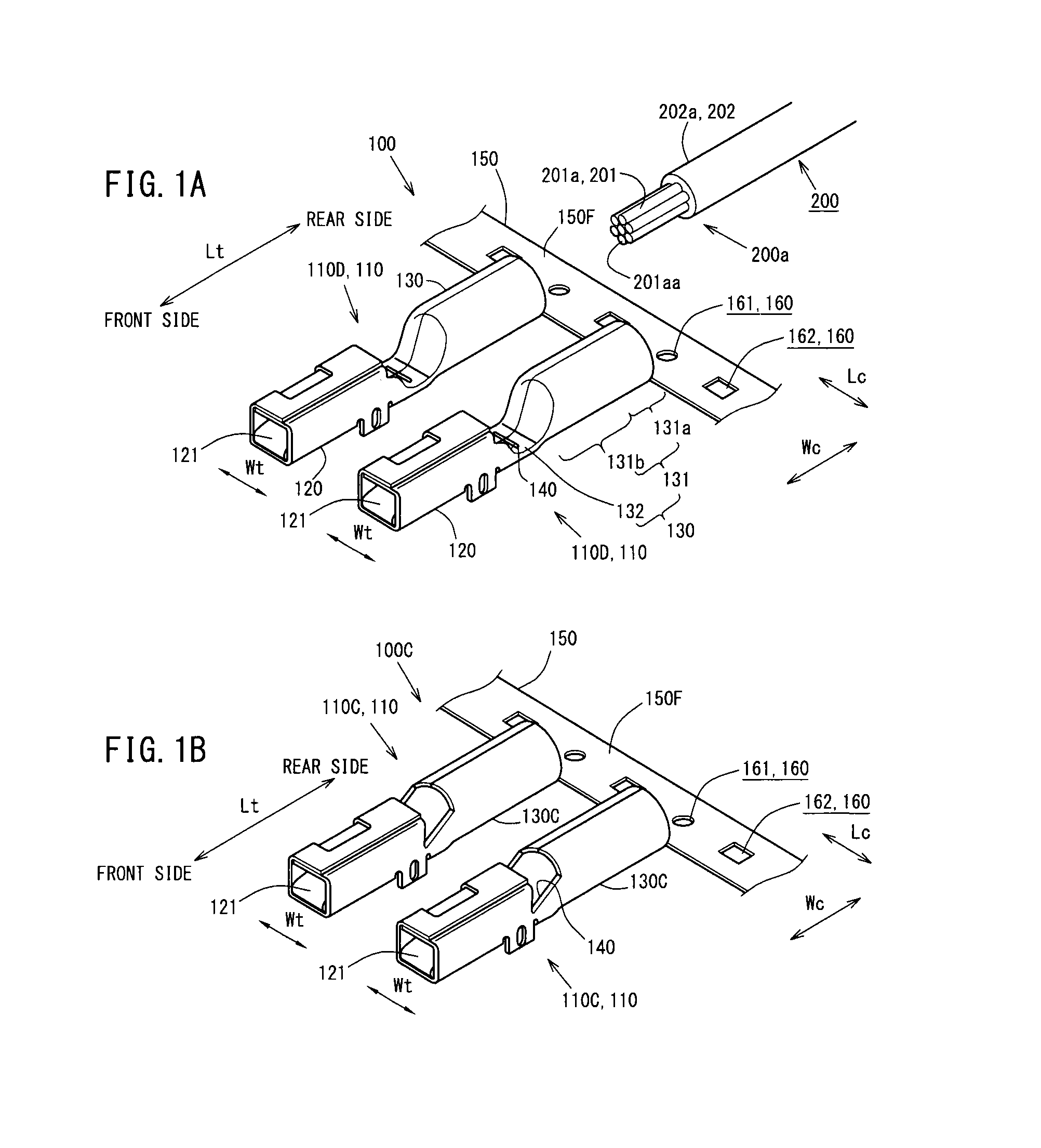

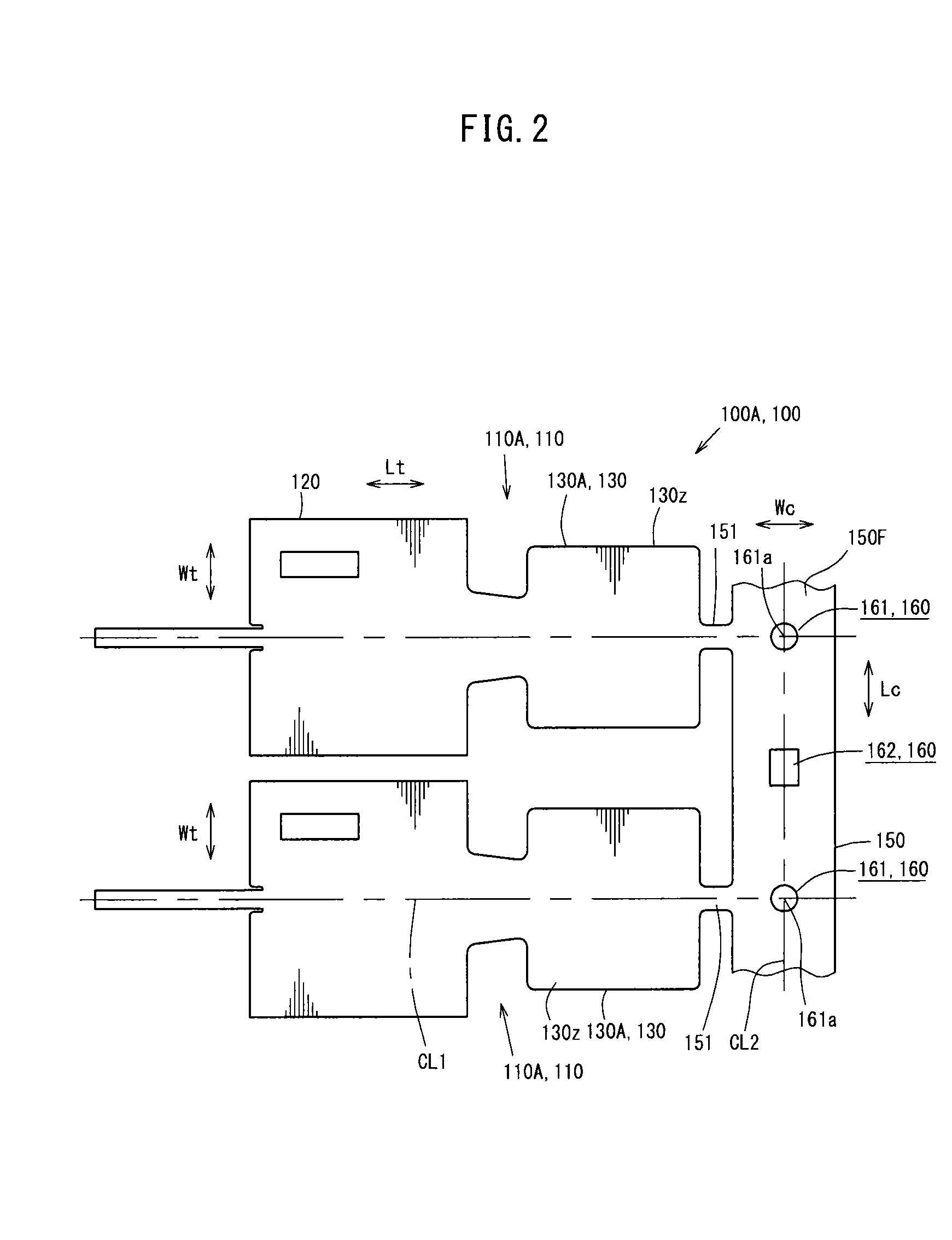

Terminal connection strip, method of manufacturing crimp terminal, wire crimping device, and method of crimping wire

ActiveUS20150364838A1Efficiently manufactureHigh qualityContact member manufacturingConnections effected by permanent deformationEngineeringElectrical conductor

The terminal connection strip includes: a carrier formed in a strip shape; and a plurality of terminal fitting which project from at least one edge side of the carrier in a width direction. The terminal fitting includes a crimping section which connects by crimping at least a conductor tip of an insulated wire provided with the conductor tip where a conductor is covered with an insulating cover and the conductor is exposed by peeling off the insulating cover on a distal end side of the insulated wire to the terminal fitting. The crimping section is formed into a hollow shape which allows the insertion of at least the conductor tip from a proximal end side of the crimping section and allows the crimping section to surround the conductor tip.

Owner:FURUKAWA ELECTRIC CO LTD +1

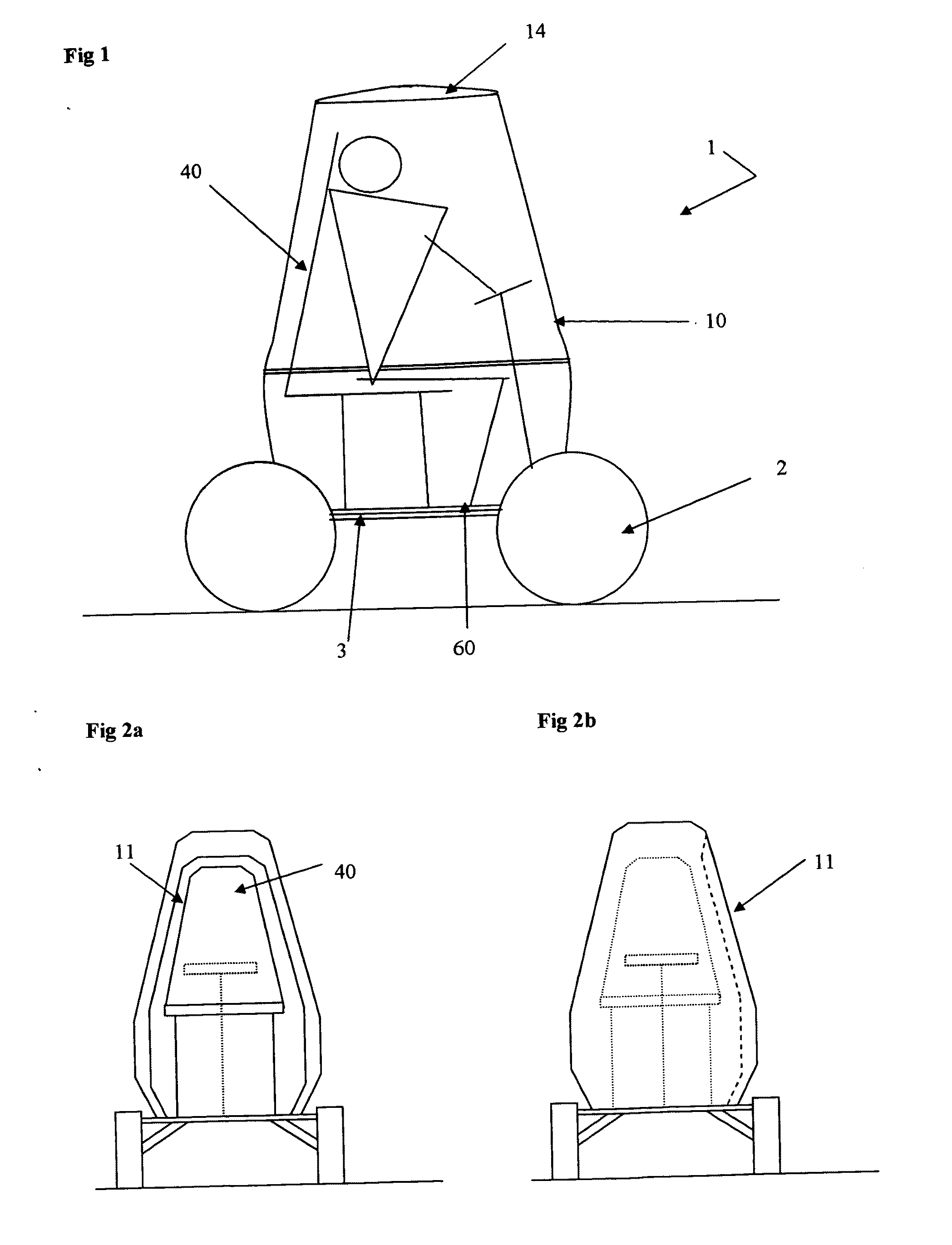

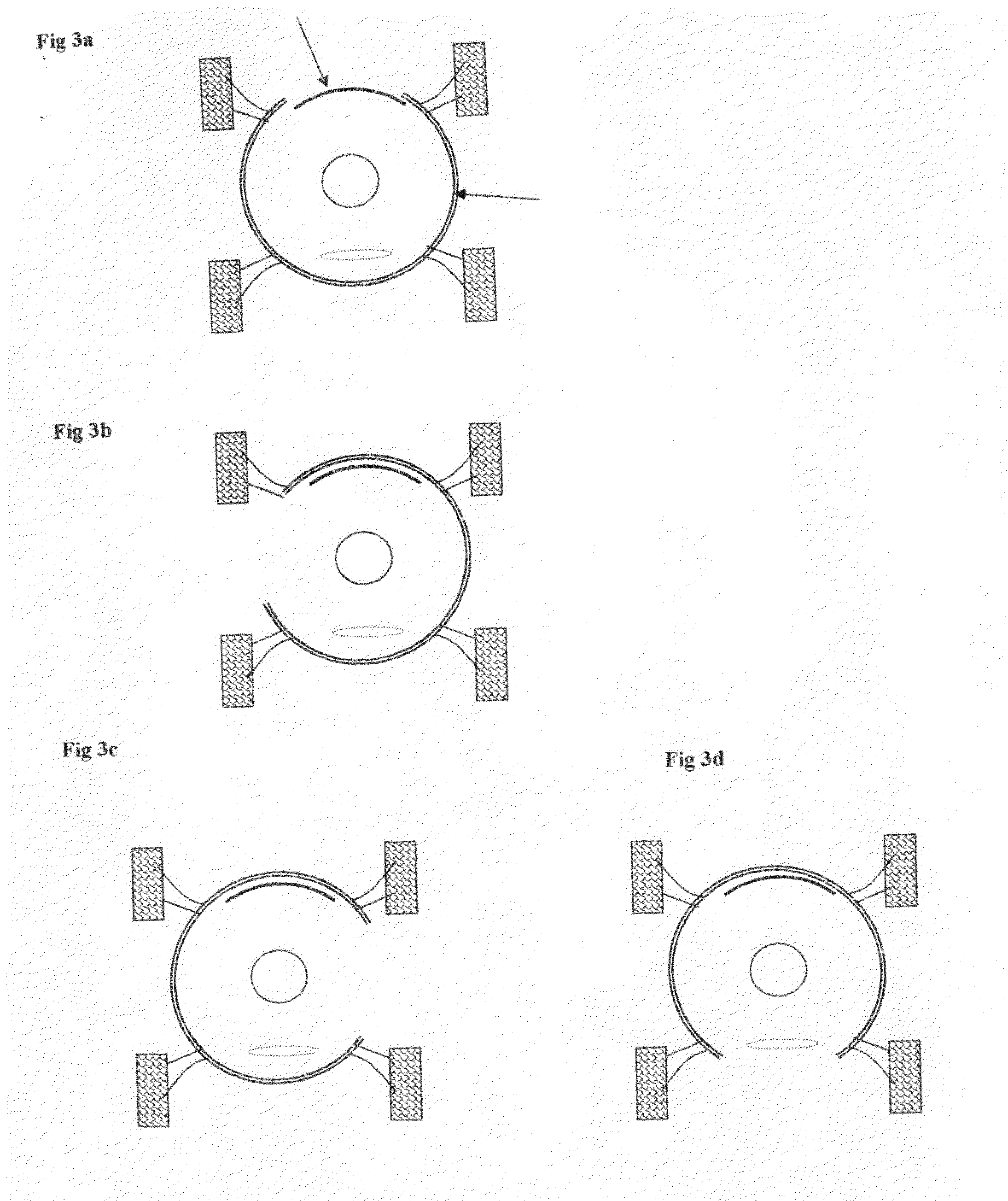

Cockpit of Vehicle with Adaptable Opening

InactiveUS20090256395A1Maximum visibilityEfficiently manufactureVehicle seatsSuperstructure subunitsCockpitChassis

Owner:NAUD FREDERIC +1

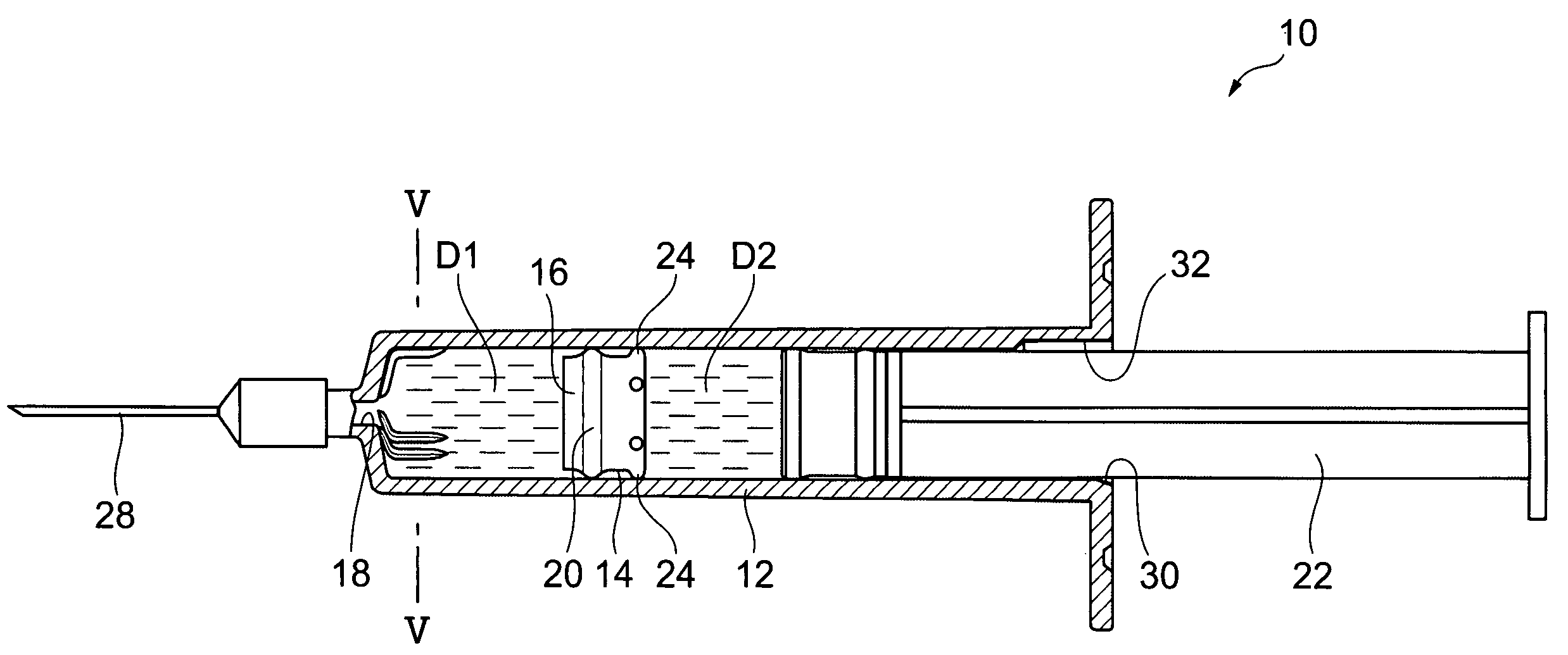

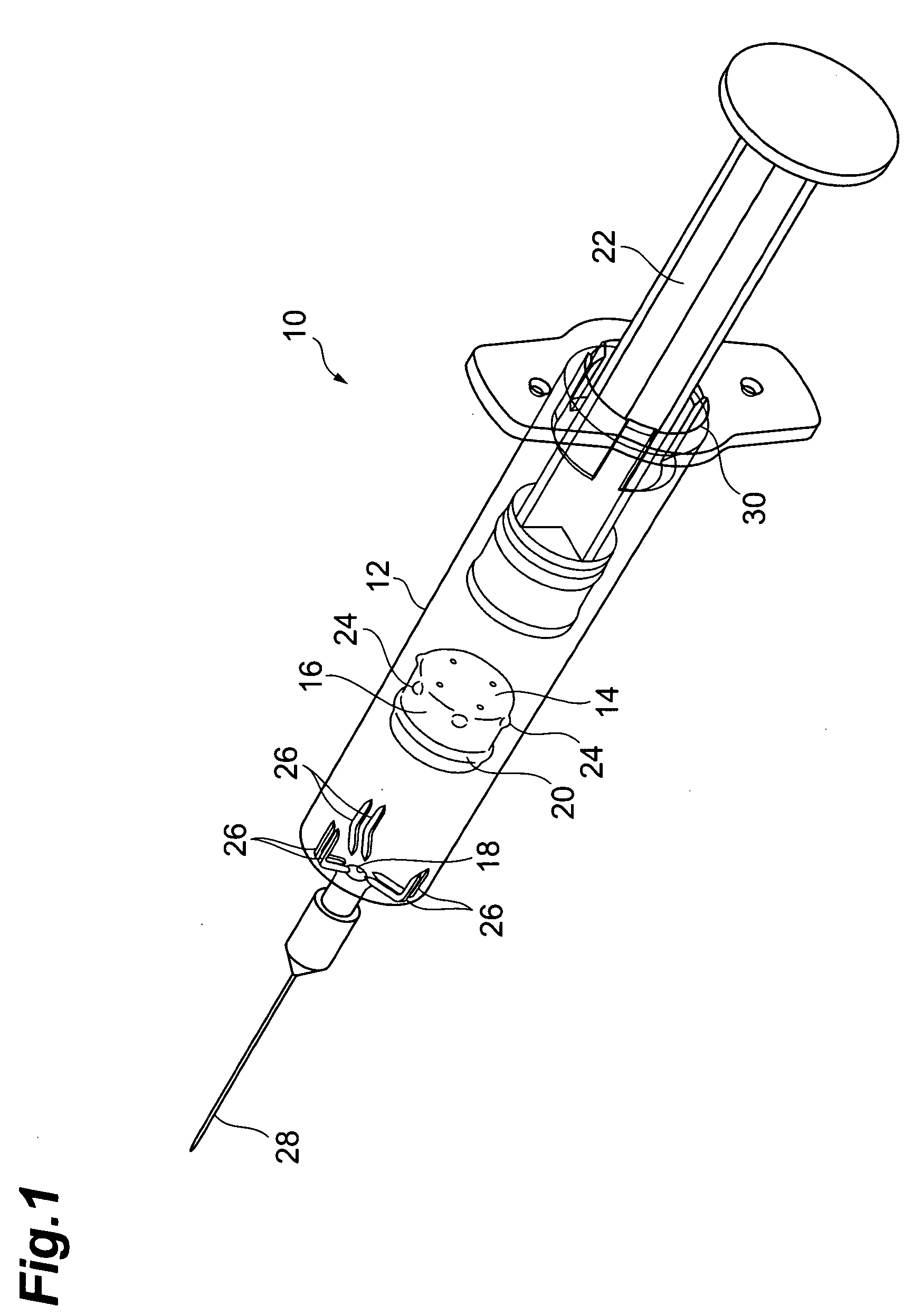

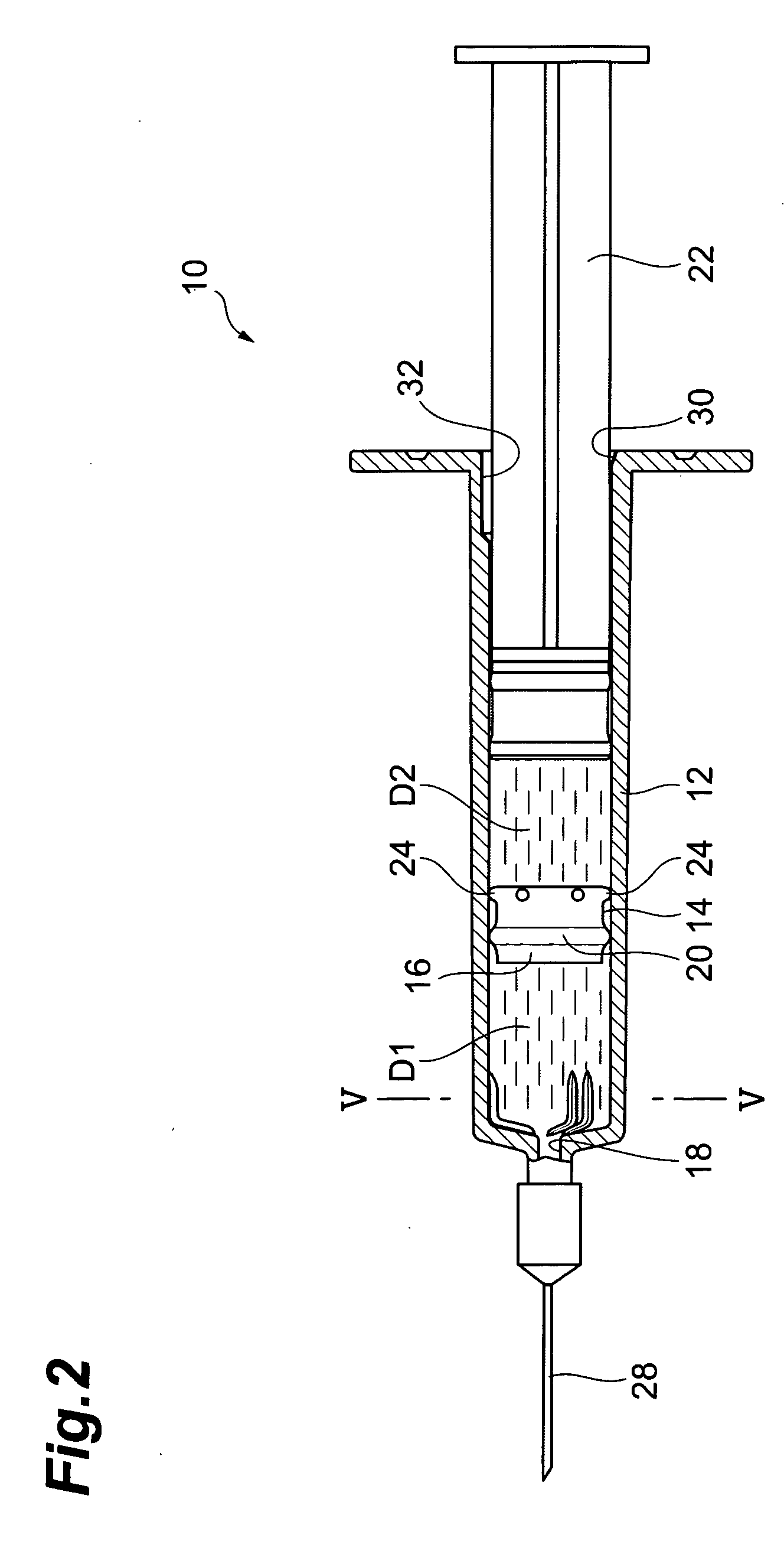

Syringe Cylinder

InactiveUS20090105660A1Efficiently manufactureEasy and reliableInfusion syringesMedical devicesSyringeBiomedical engineering

A syringe cylinder 12 includes a groove 32 formed in an inner peripheral surface thereof and extending over a predetermined length from an opening end 30 thereof. Even with the intermediate sliding stopper 14 located at a position where the groove 32 is formed, the pressure inside the syringe cylinder 12 can be reduced. Thus, during vacuum tapping, the intermediate sliding stopper 14 can be held in the vicinity of the opening end 30 of the syringe cylinder 12. Consequently, the intermediate sliding stopper 14 can be inserted into the syringe cylinder 12 in a correct posture and reliably moved to a predetermined position in the syringe cylinder 12.

Owner:HISAMITSU PHARM CO INC

Upper Body Exercise Apparatus, Method and System

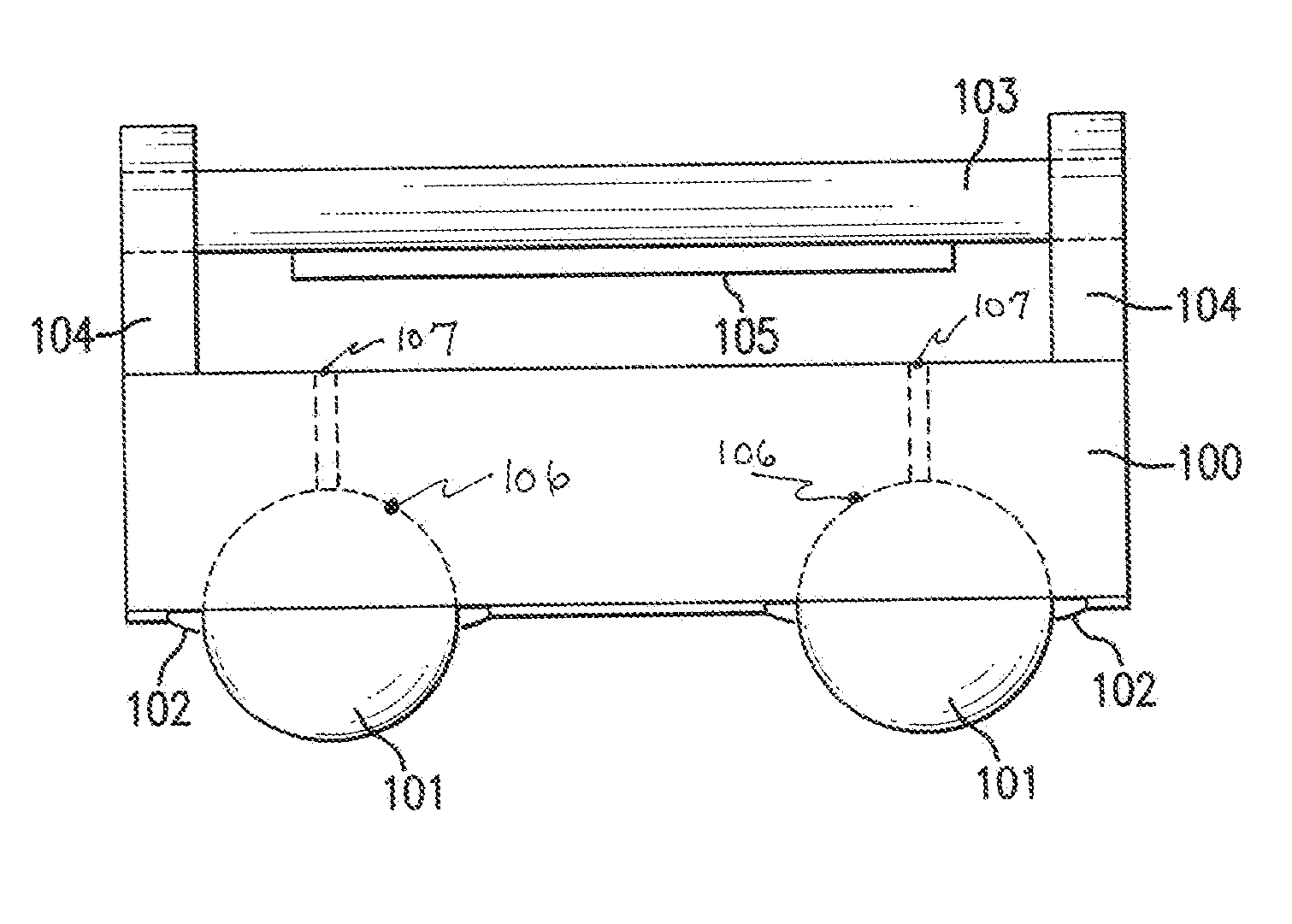

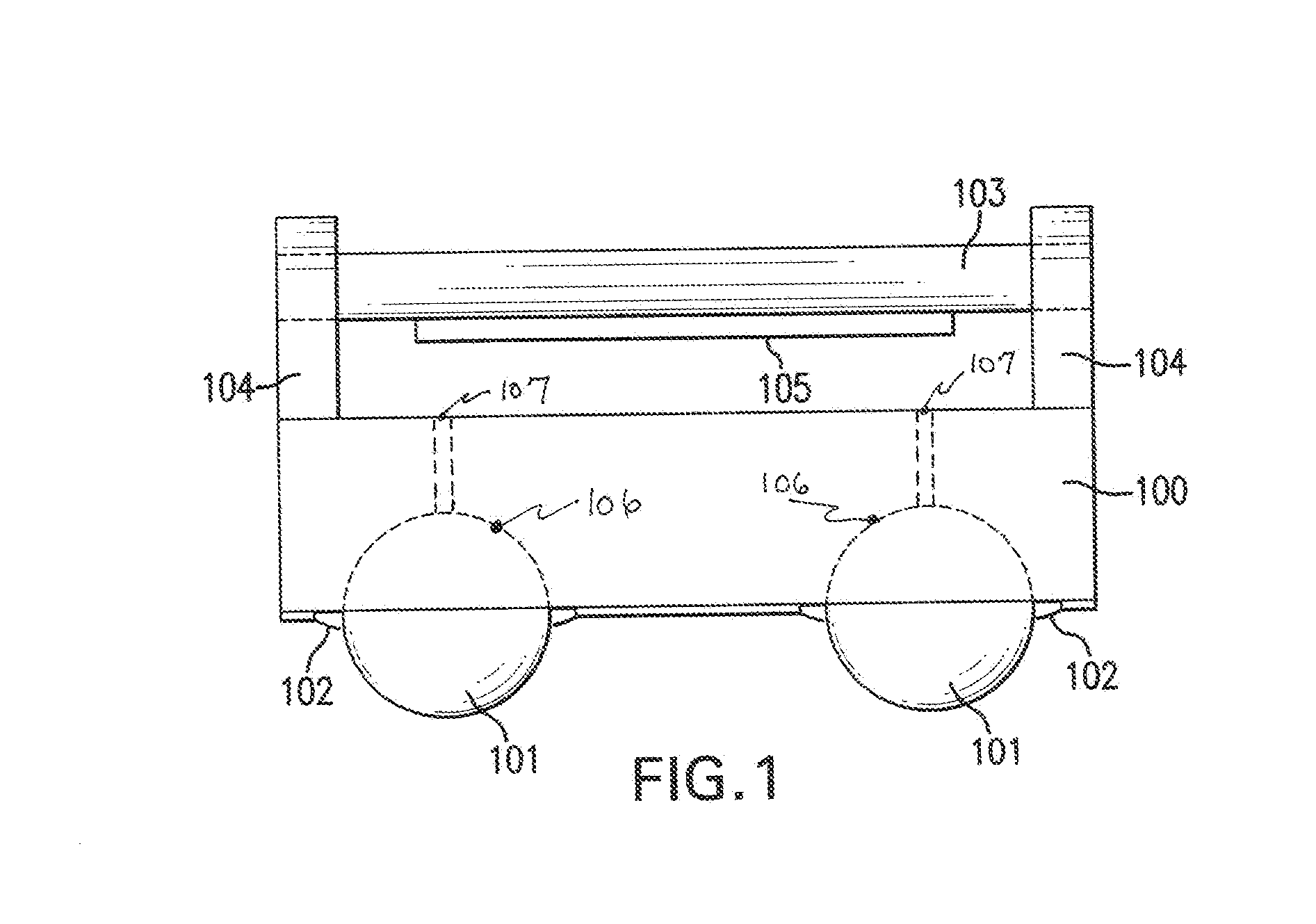

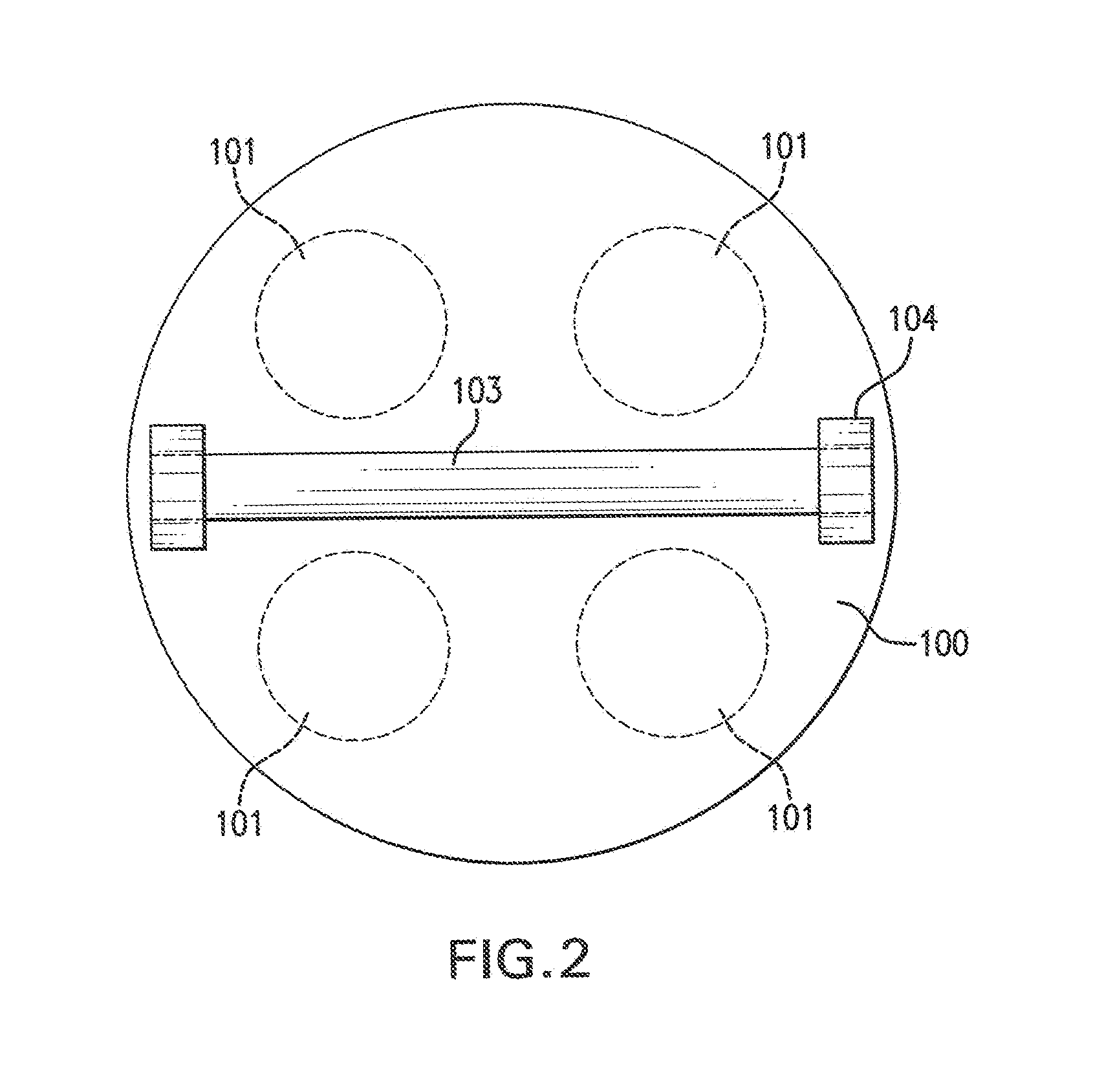

ActiveUS20120238420A1Easily and more efficiently manufacture and marketEfficiently manufactureFrictional force resistorsMovement coordination devicesTransverse planeEngineering

The present invention relates to an apparatus, method and system for a human individual to exercise his body in a novel manner wherein the user, when he is in the prone position, is able to move his arms, while holding the instant apparatus placed on a relatively flat surface, in all three planes of human motion simultaneously; i.e. saggital, frontal and transverse planes.

Owner:MEANT 2 MOVE

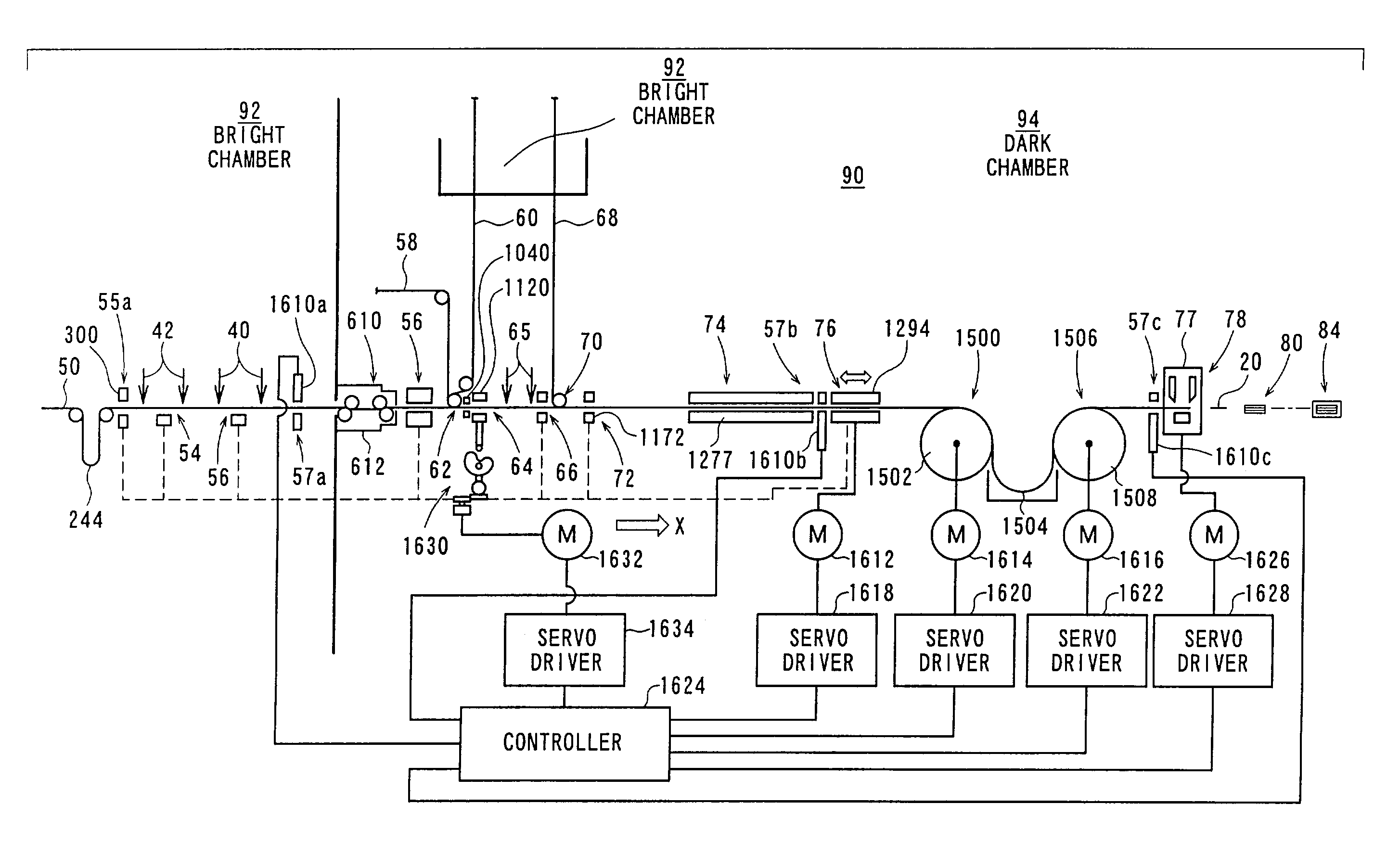

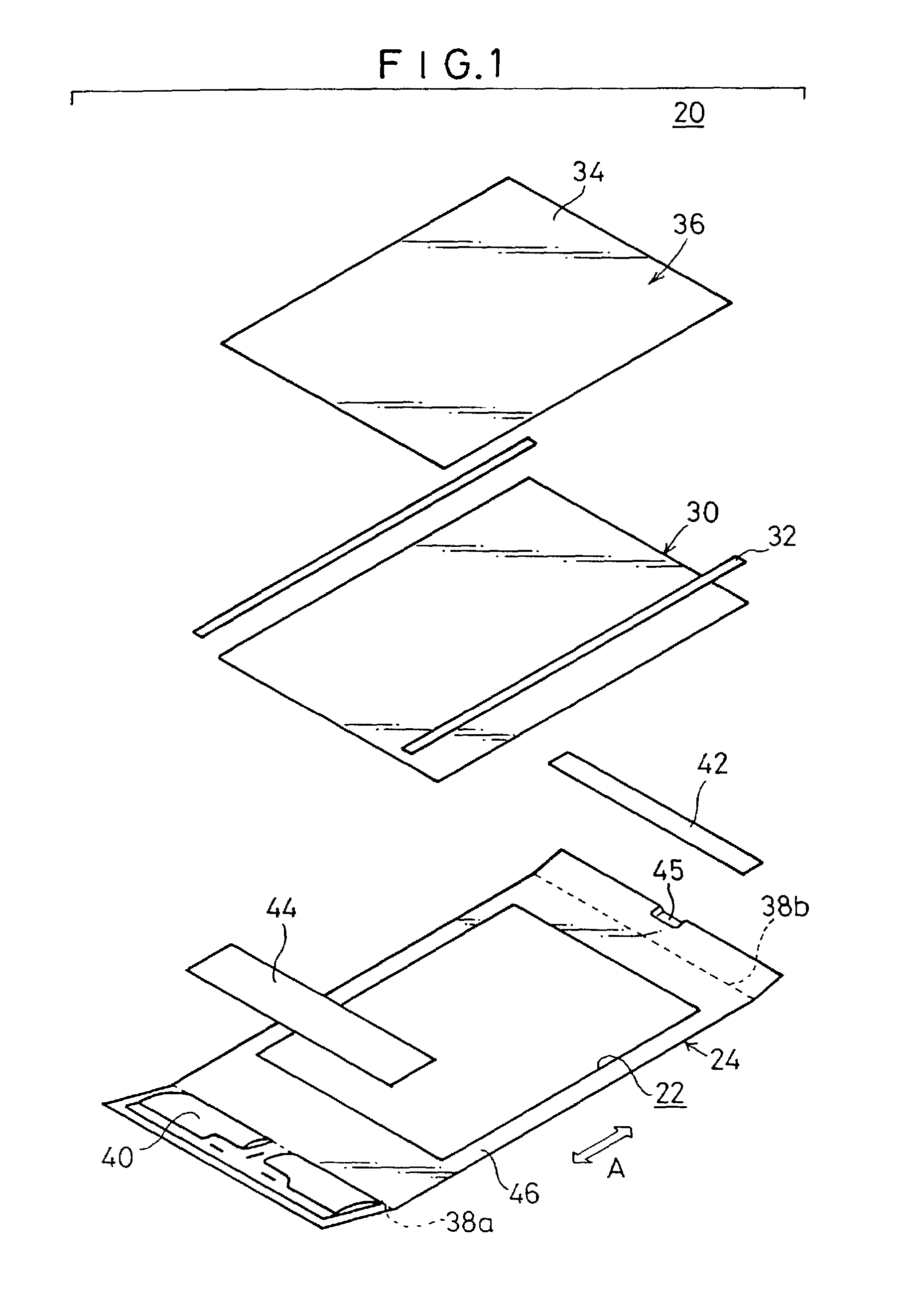

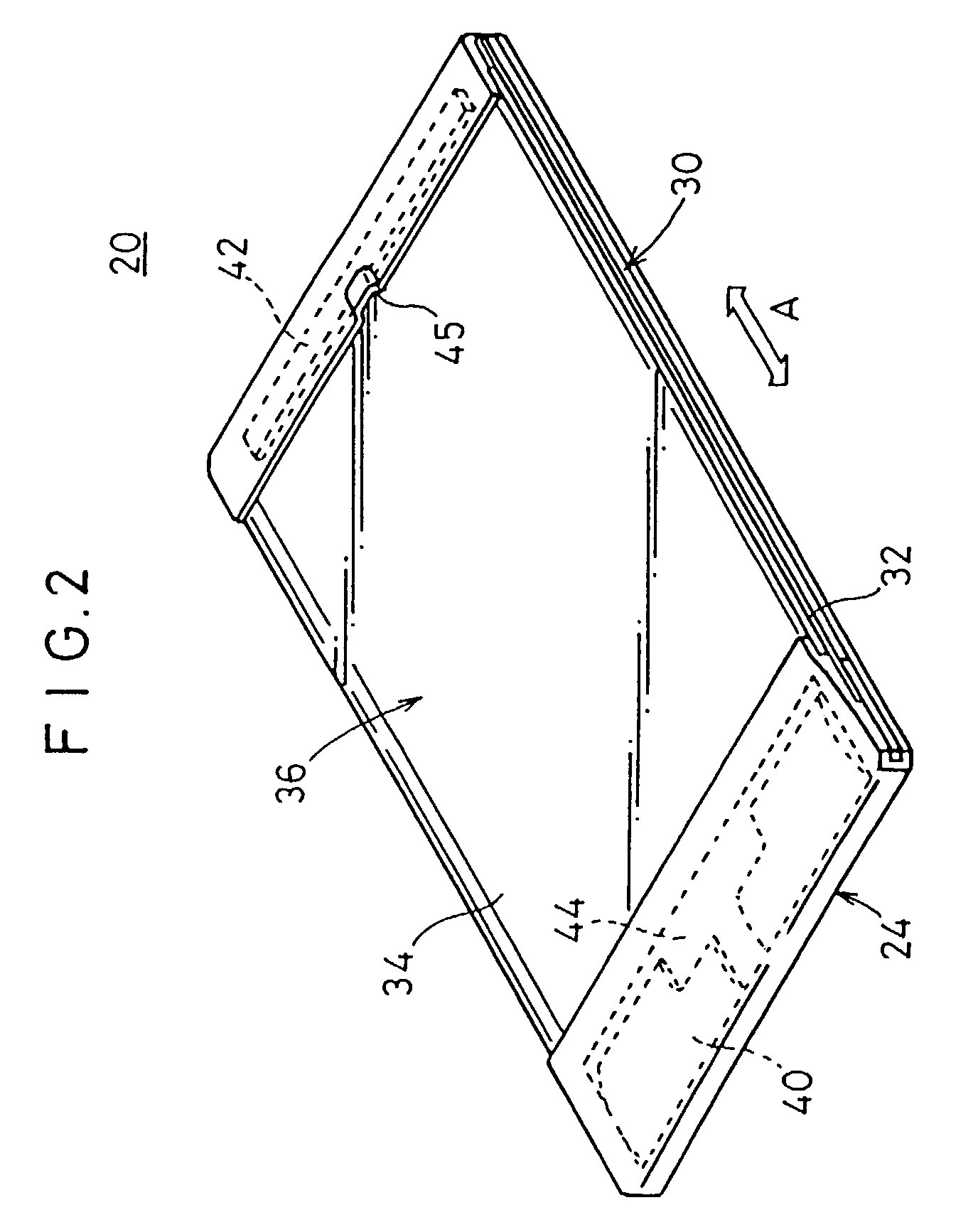

Method of and apparatus for manufacturing instant photographic film units

InactiveUS7267150B2Efficiently manufactureSimple stepsAdhesivesConnectionsFilm (photographic)Electrical and Electronics engineering

An instant photographic film unit includes a mask sheet having an image frame and two sheets, one of which has a photosensitive layer, laminated and bonded together, and a developing liquid container disposed in a predetermined position for supplying a developing liquid between the two sheets to produce an image. The mask sheer and the two sheets are bonded together in a predetermined laminated state, with at least one of the mask sheet and the two sheets being in the form of a continuous web. The continuous web is cut off into self-developed instant photographic film units of a predetermined length. A predetermined number of instant photographic film units are automatically stacked and placed in a film pack.

Owner:FUJIFILM CORP

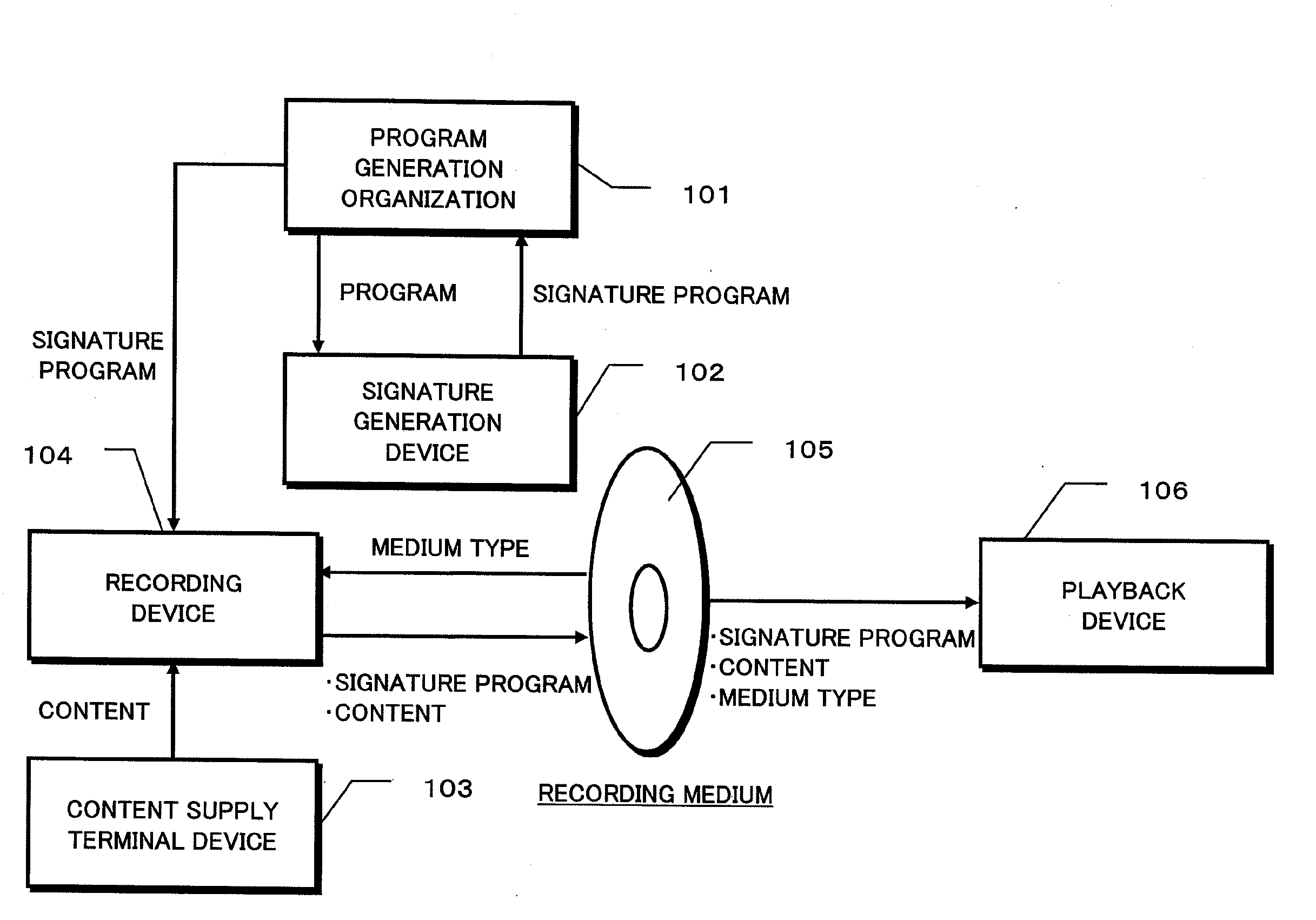

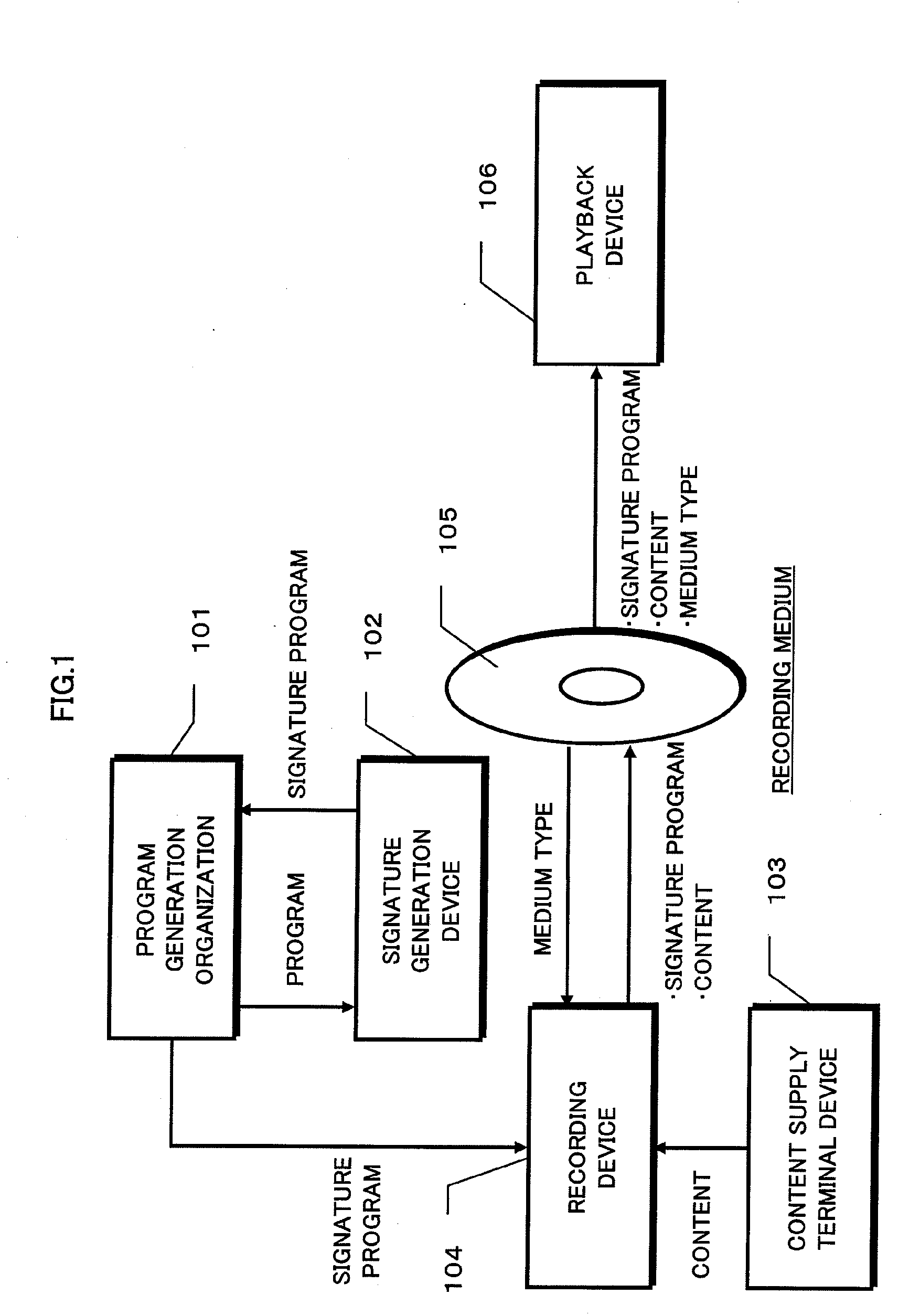

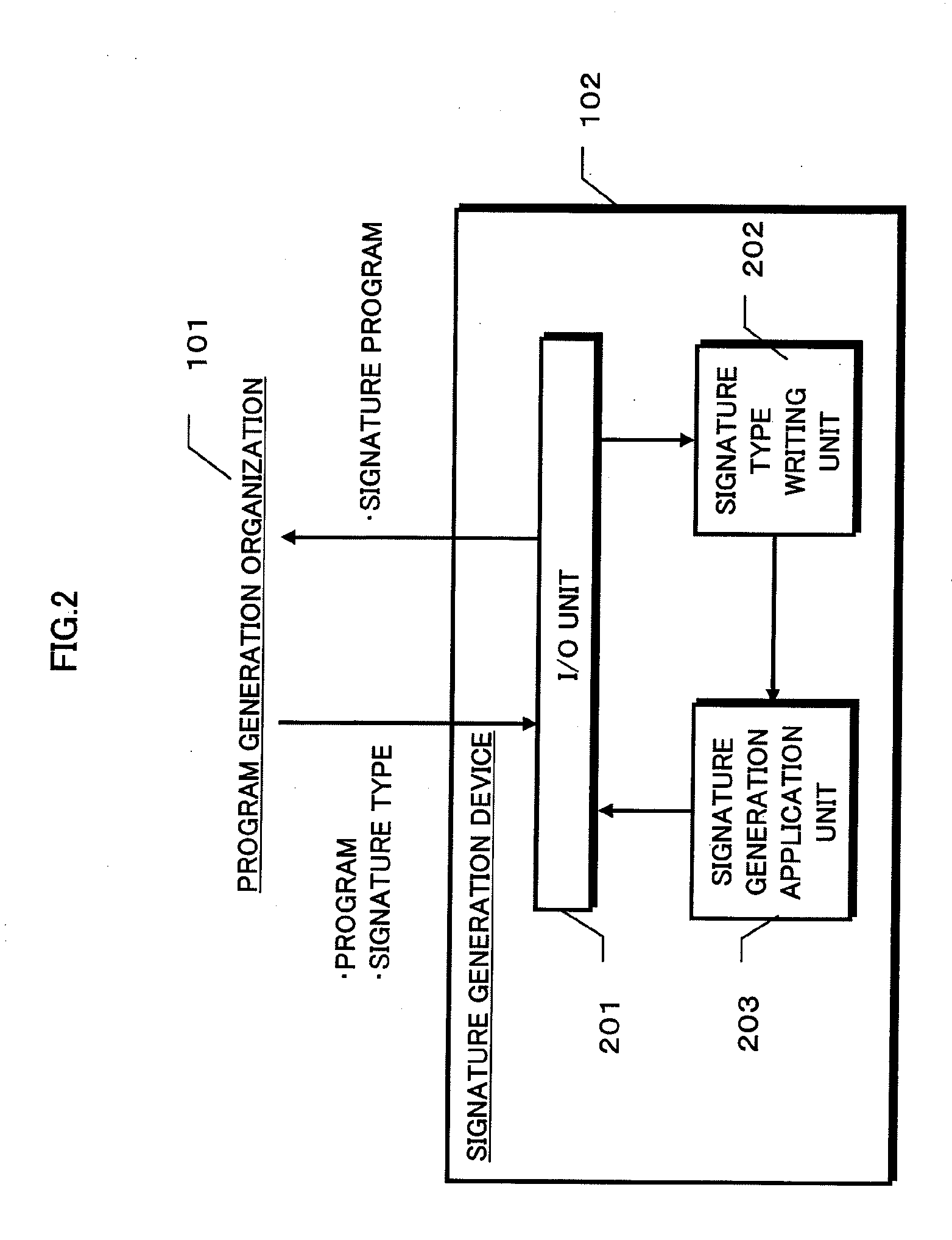

Copyright protection data processing system and reproduction device

ActiveUS20100100969A1Efficiently manufactureEfficient preparationTelevision system detailsAccessories for auxillary signalsData processingReproduction

If playback devices are prohibited from playing back contents recorded in R media, there occurs a problem that it takes more time to manufacture commercial ROM media. Conversely, if playback devices are permitted to play back contents recorded in R media, there occurs a problem that copyrights might be infringed. In view of these, the aim of the present invention is to provide a content protection data processing system and a playback device capable of determining whether to permit playback of a content recorded in a recording medium, based on a medium type of the recording medium and a signature type of a signature attached to a program, and switching a procedure relating to a digital signature for each signature type of the digital signature. This enables both the protection of the copyright of the content and the efficient manufacturing of commercial ROM media.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Soft capsule

InactiveUS20070042035A1High qualityEfficiently manufacturePretreated surfacesPharmaceutical non-active ingredientsBiomedical engineeringWater activity

It is an object of the present invention to provide a capsule anti-sticking agent which can provide excellent anti-sticking effect on a soft capsule without impairing various properties such as water activity, disintegration property and safety, a coated soft capsule of high quality which is coated with the capsule anti-sticking agent and excels in anti-sticking effect, and an efficient method for manufacturing the coated soft capsule. The present invention includes a capsule anti-sticking agent containing an enzymatically decomposed lecithin, a coated soft capsule wherein a surface is coated with the capsule anti-sticking agent, and a method for manufacturing the coated soft capsule in which a surface of a soft capsule is coated with the capsule anti-sticking agent.

Owner:EISIA R&D MANAGEMENT CO LTD

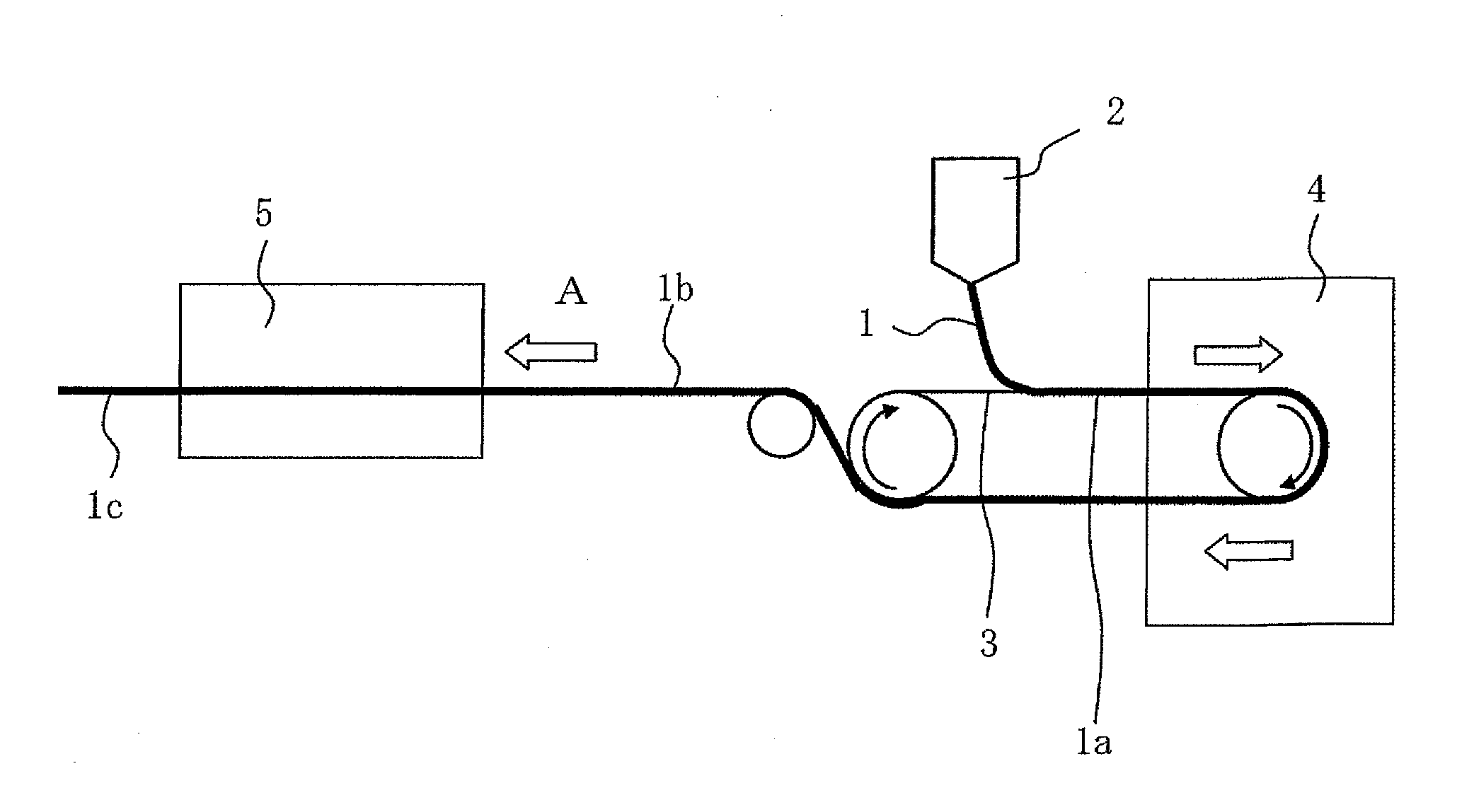

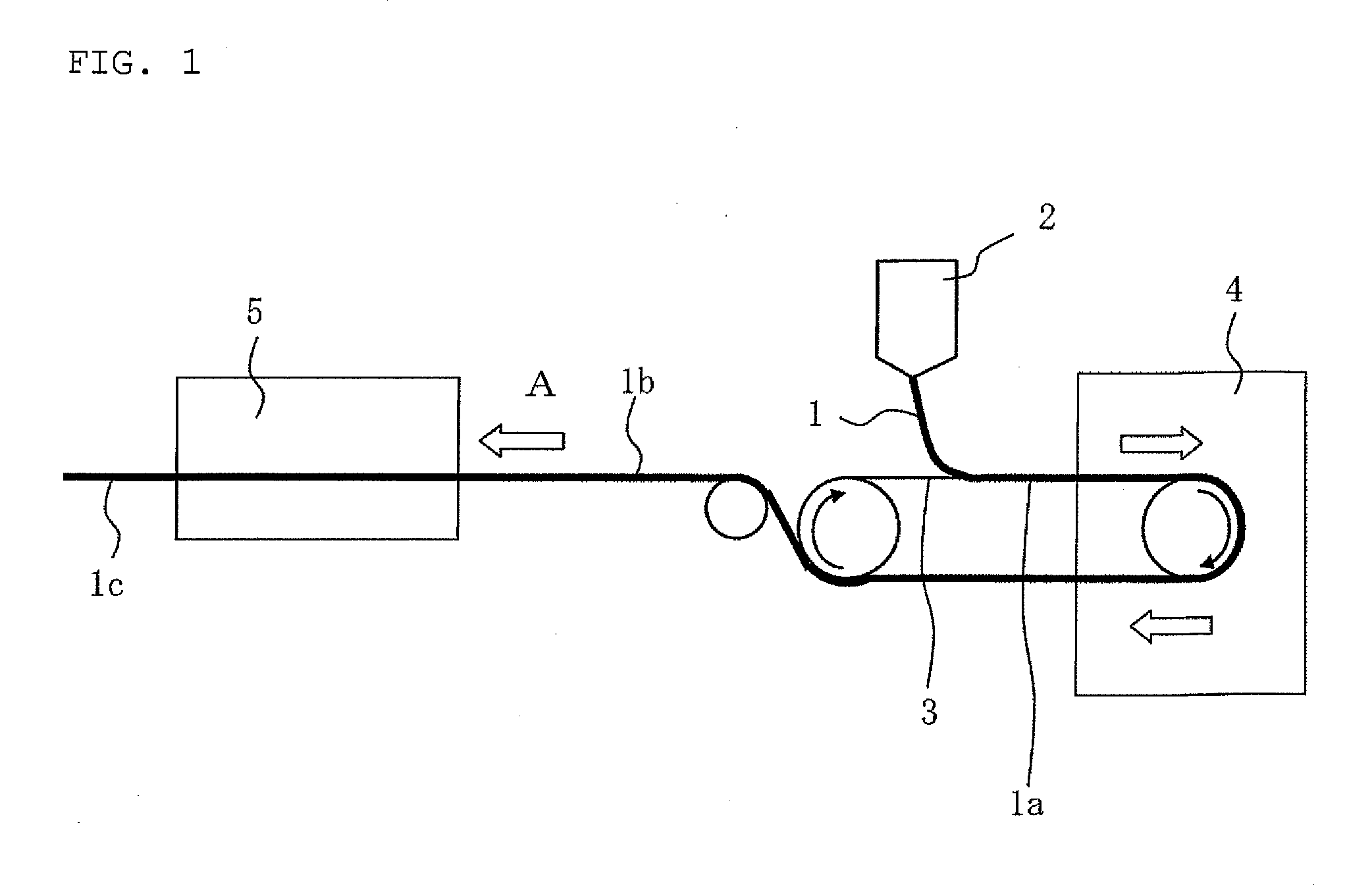

Polyimide film production method, polyimide film production apparatus, and polyimide film

ActiveUS20140058060A1Efficiently removeEfficiently manufactureConfectionerySweetmeatsPolyimide membraneMetallurgy

Owner:UBE IND LTD

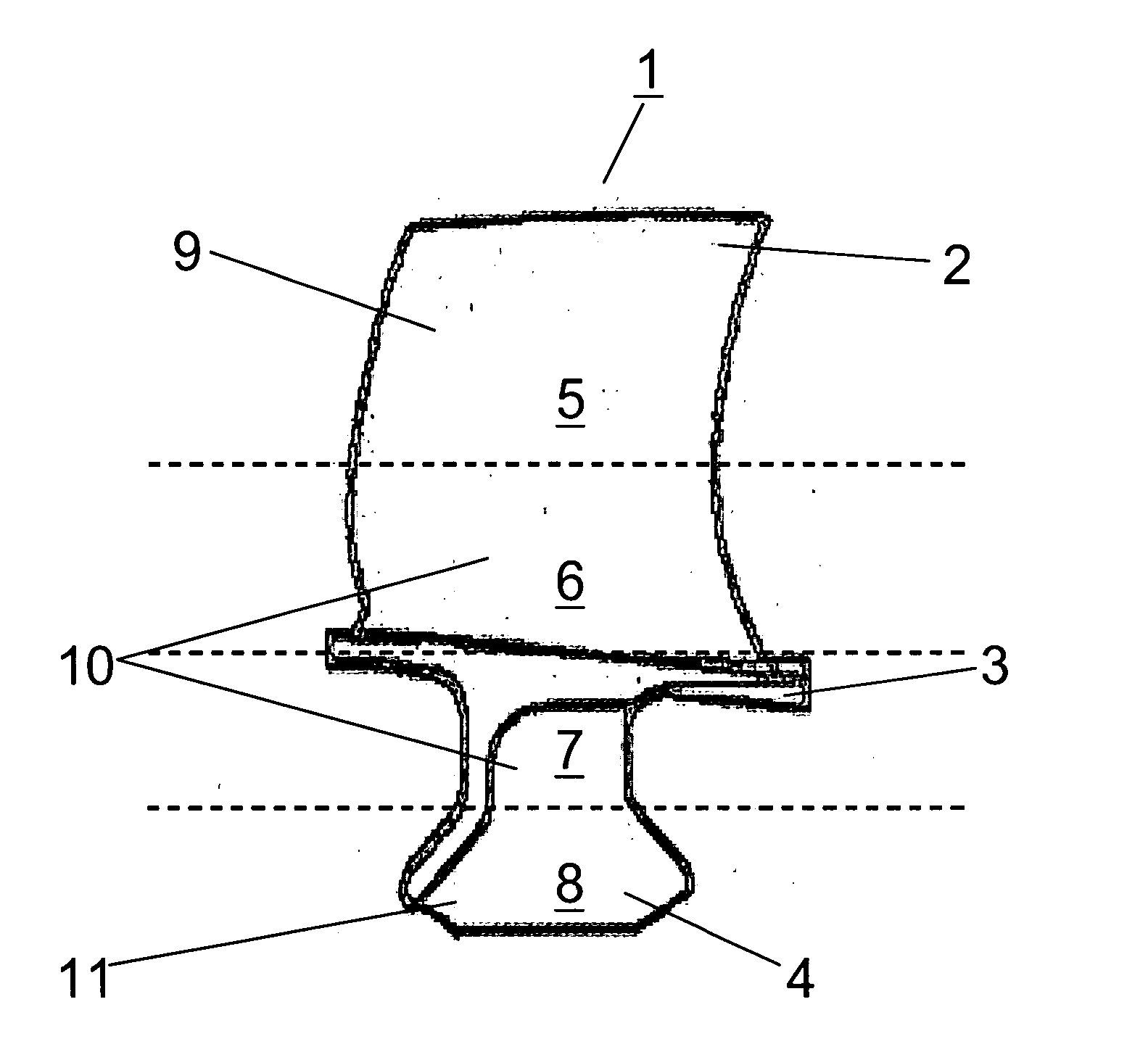

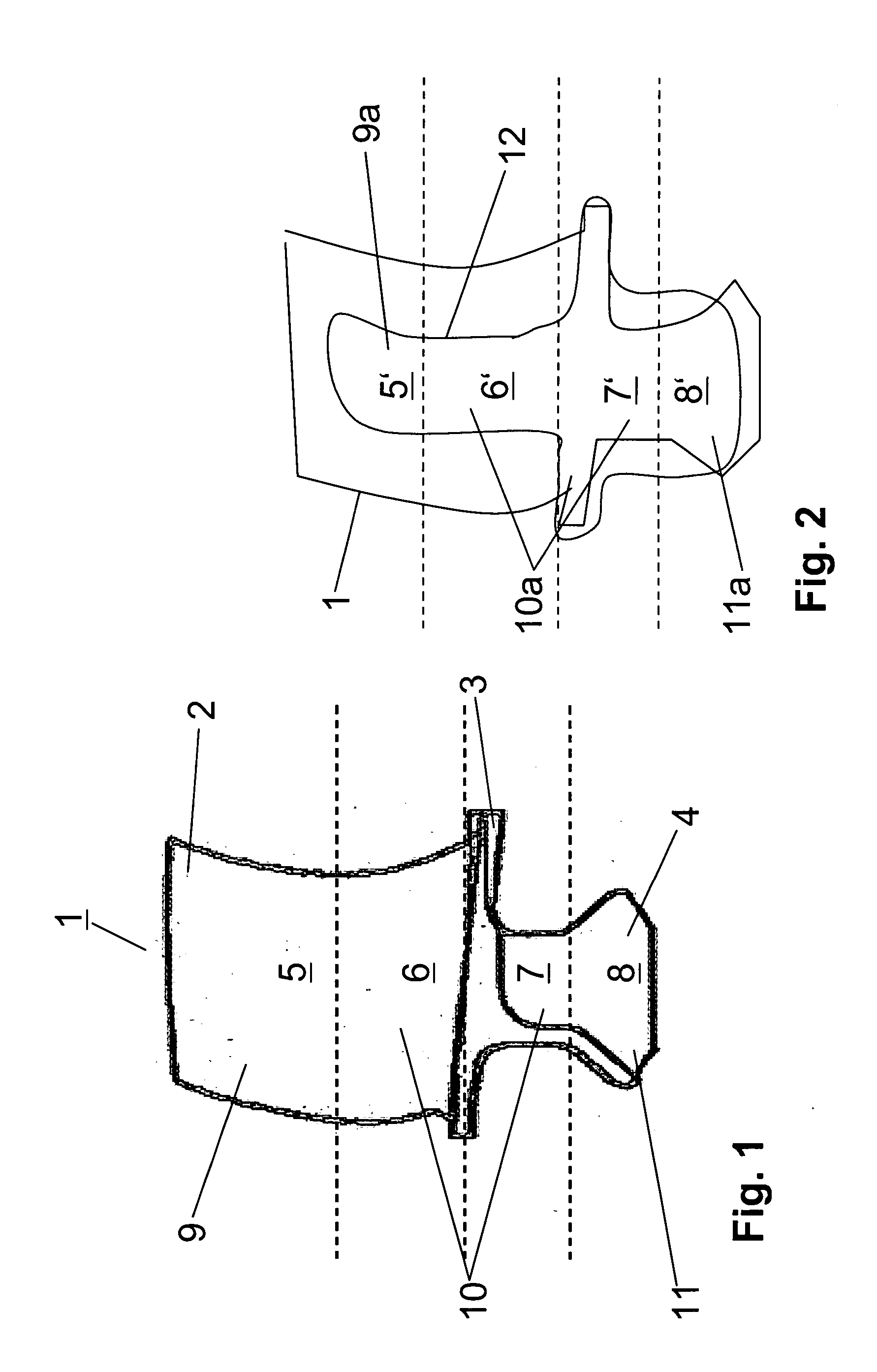

Method for the manufacture of highly loadable components by precision forging

ActiveUS20060130553A1Efficiently manufactureLow costMetal rolling stand detailsEngine componentsCritical stressCompressor blade

A method for the manufacture of highly loadable components by precision forging, e.g., of gas turbine compressor blades with different stress zones, initially provides for the production of a preform in a one-step forming operation, e.g., casting or sintering, with further deformable volume zones with a certain volume concentration in the highly loaded areas. The preform is subsequently finish-forged at a deformation rate which is limited by the respective volumes and is merely directed to the load and strength-specific recrystallization and structural requirements in the critical stress zones of the component.

Owner:ROLLS ROYCE DEUT LTD & CO KG

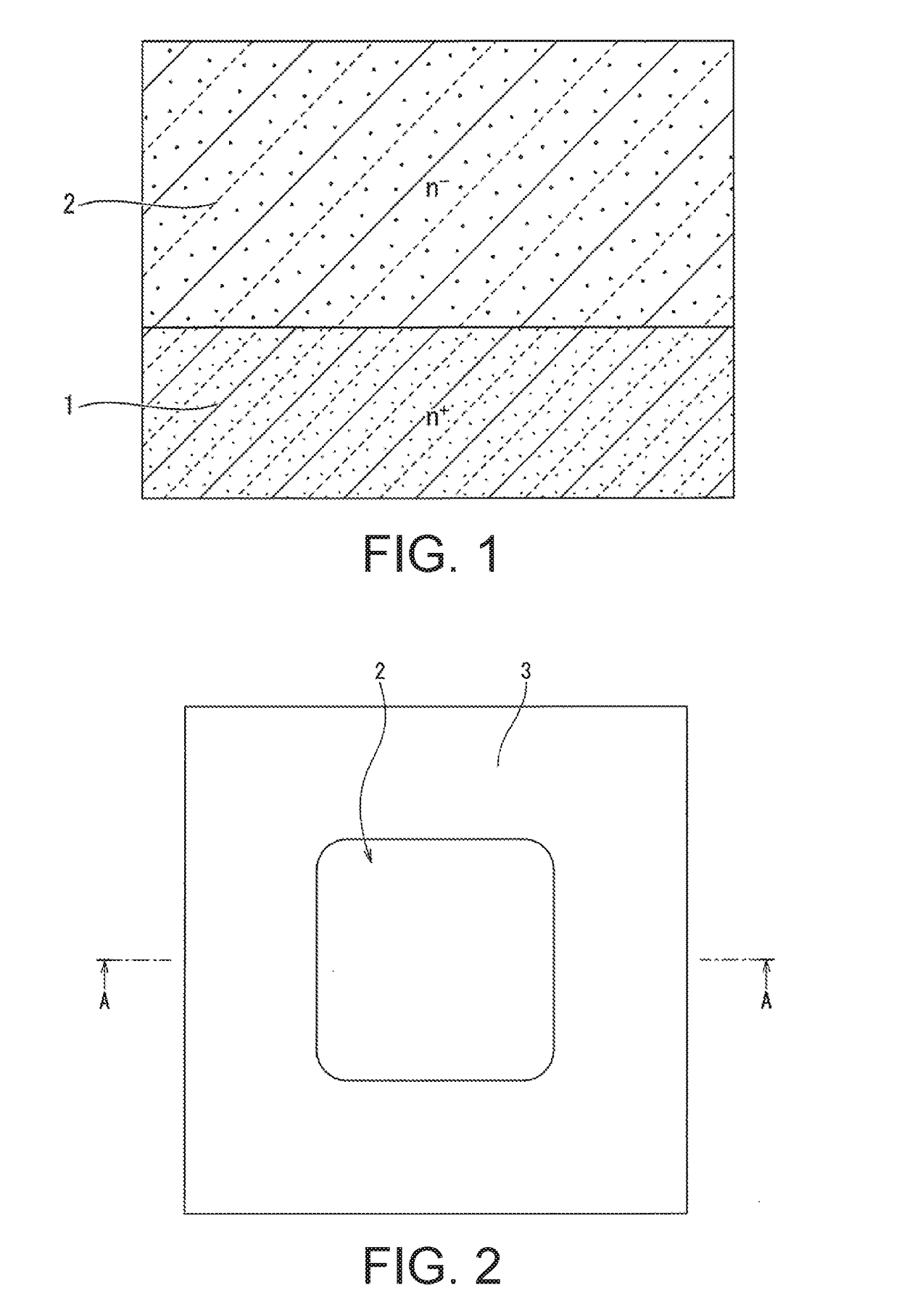

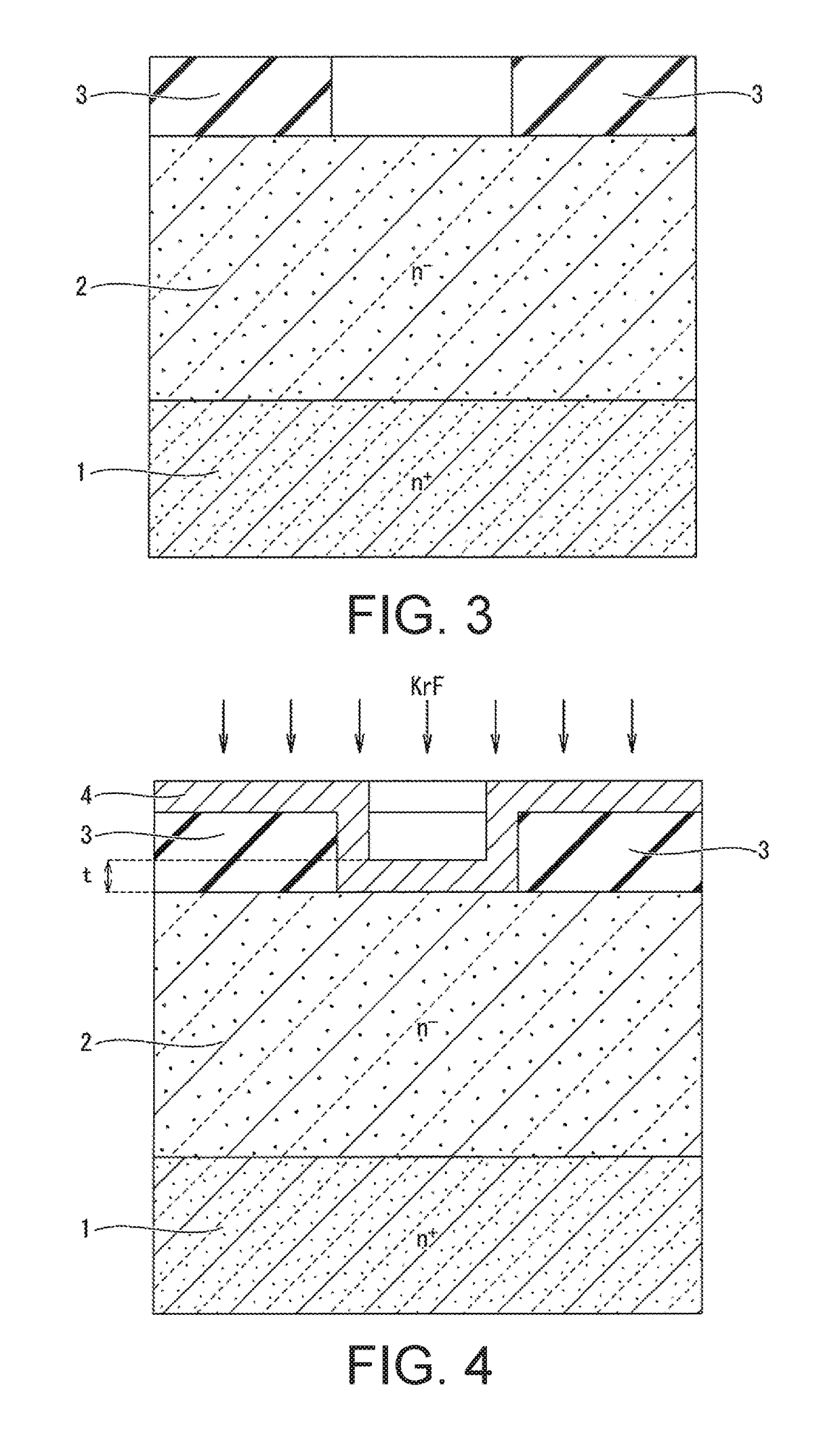

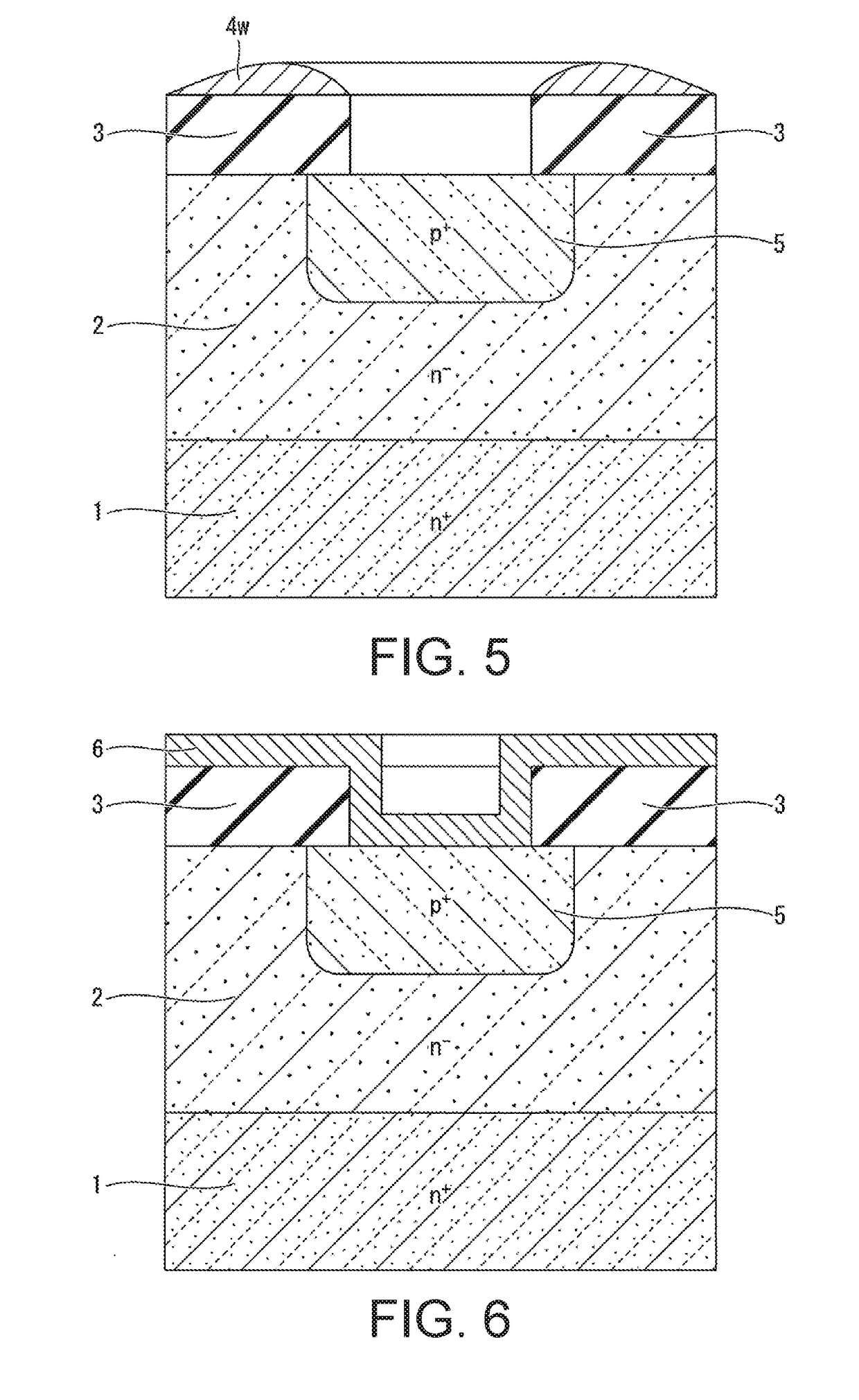

Method of manufacturing semiconductor device

ActiveUS20190019679A1Efficiently manufactureEfficient preparationSemiconductor/solid-state device manufacturingSemiconductor devicesLaser lightAluminium

A method of manufacturing a semiconductor device includes: forming, on a surface of an n-type semiconductor layer, an impurity source film containing both aluminum and beryllium; and forming a p-type impurity-doped layer in the n-type semiconductor layer by irradiating the impurity source film with first laser light to simultaneously introduce the aluminum and the beryllium into the n-type semiconductor layer.

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com