Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Reduce layer thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

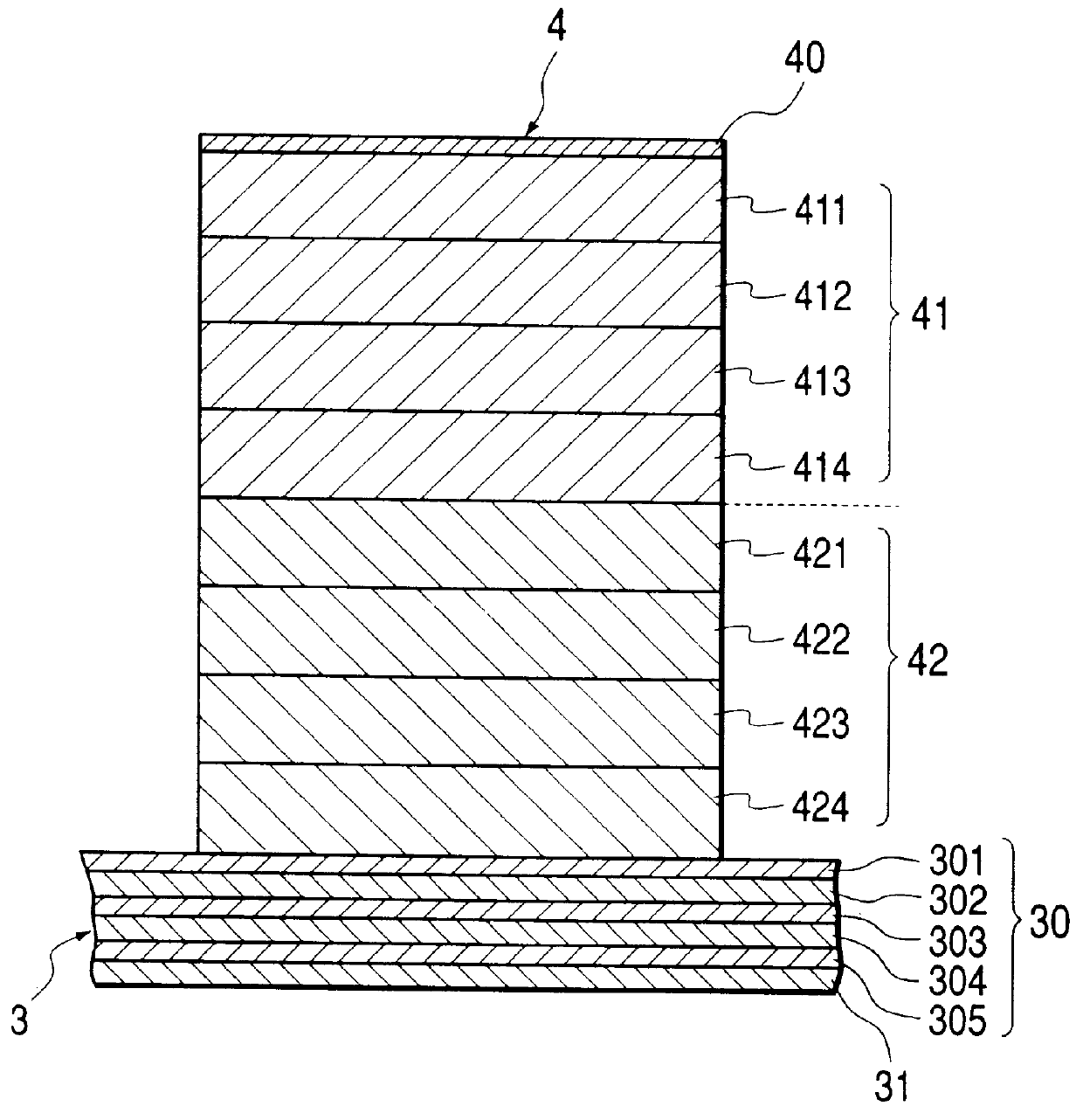

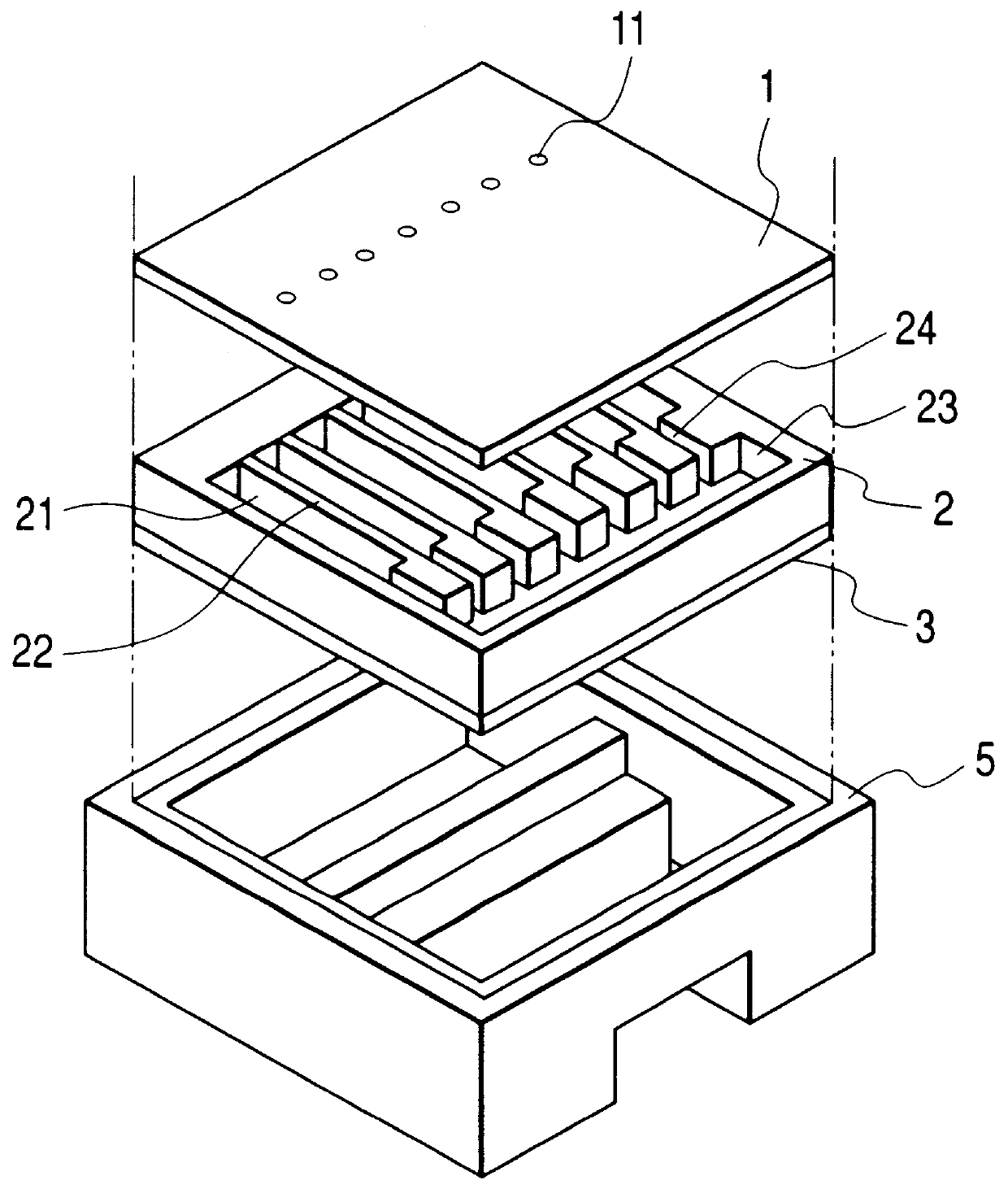

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

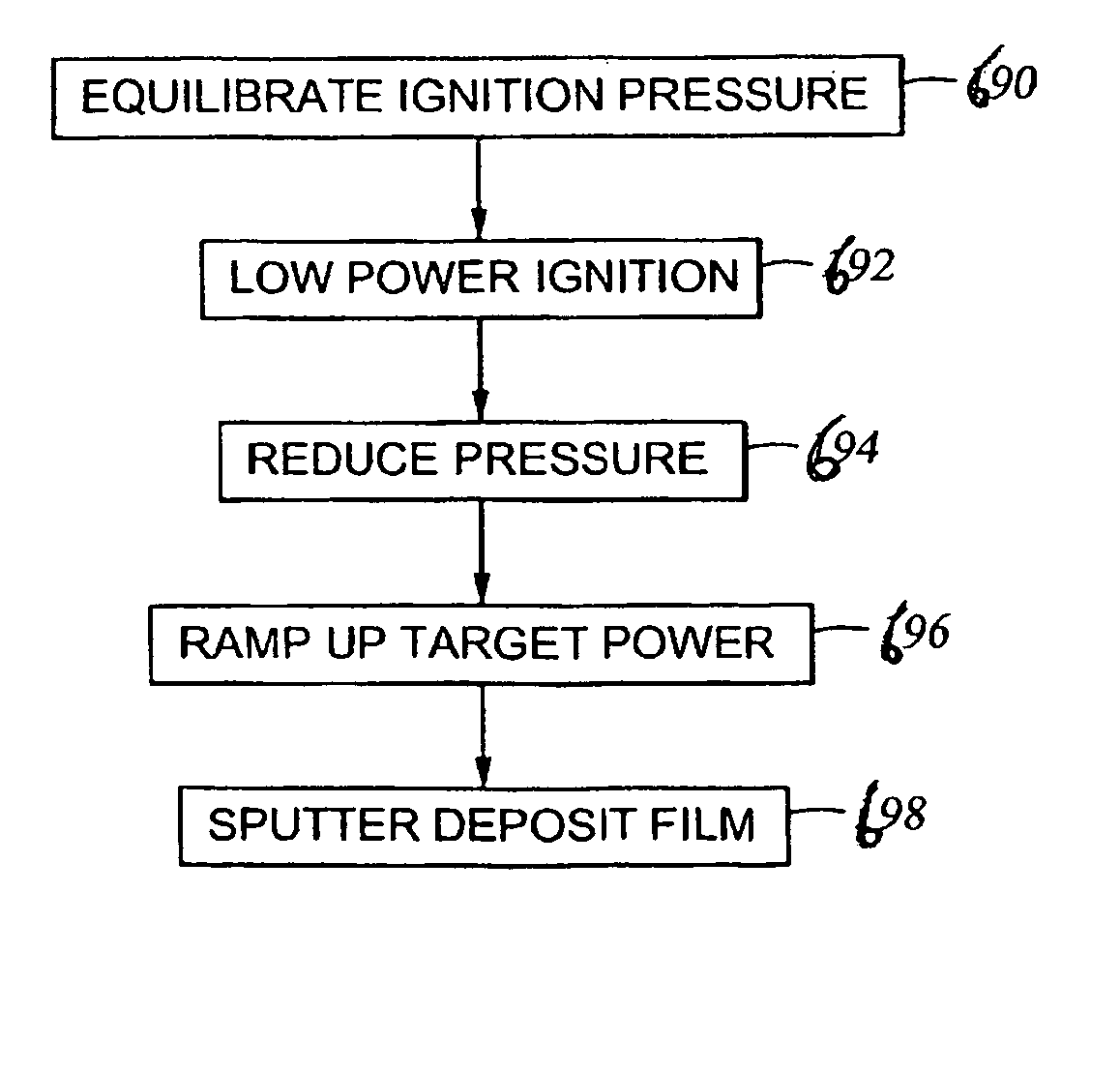

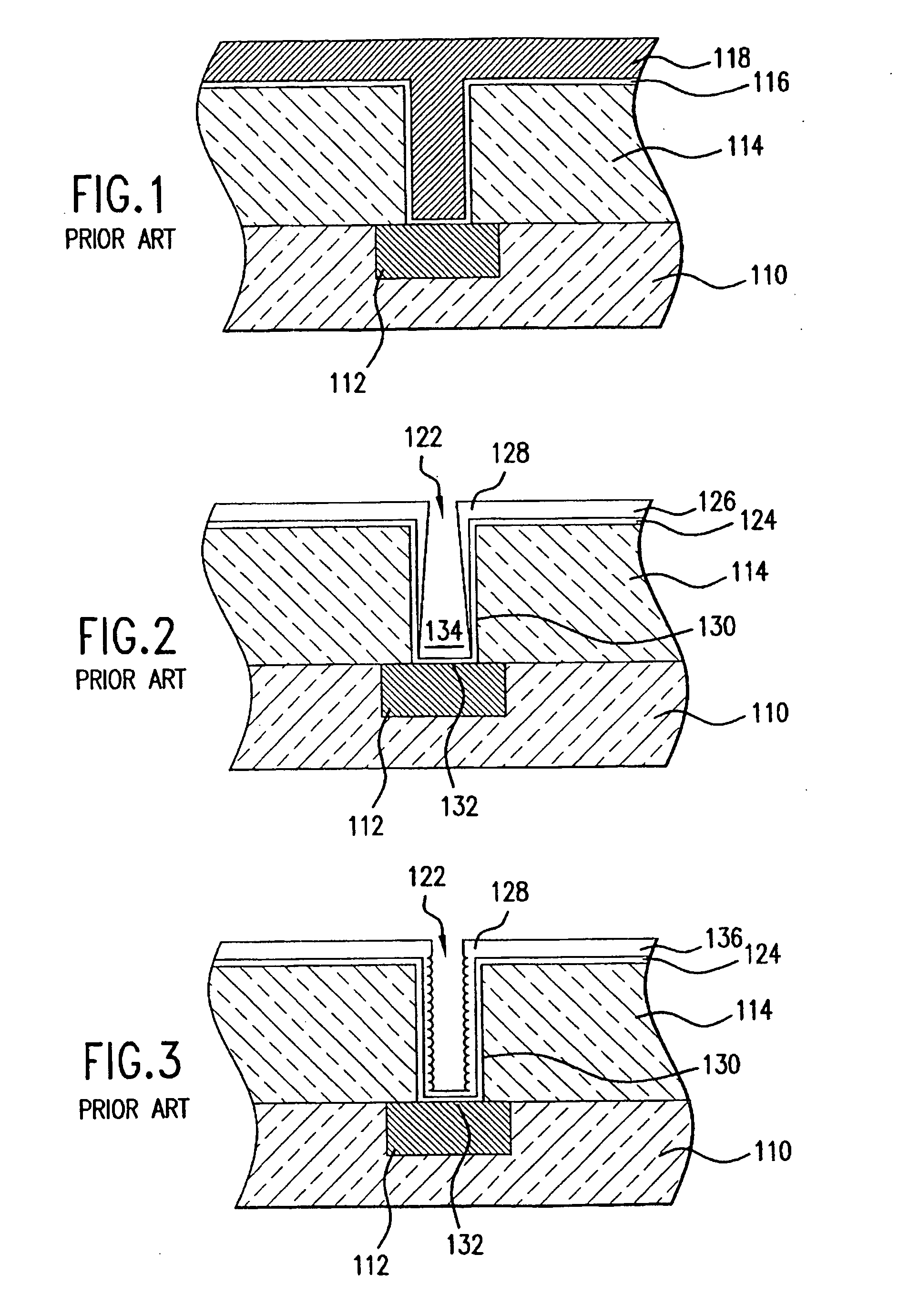

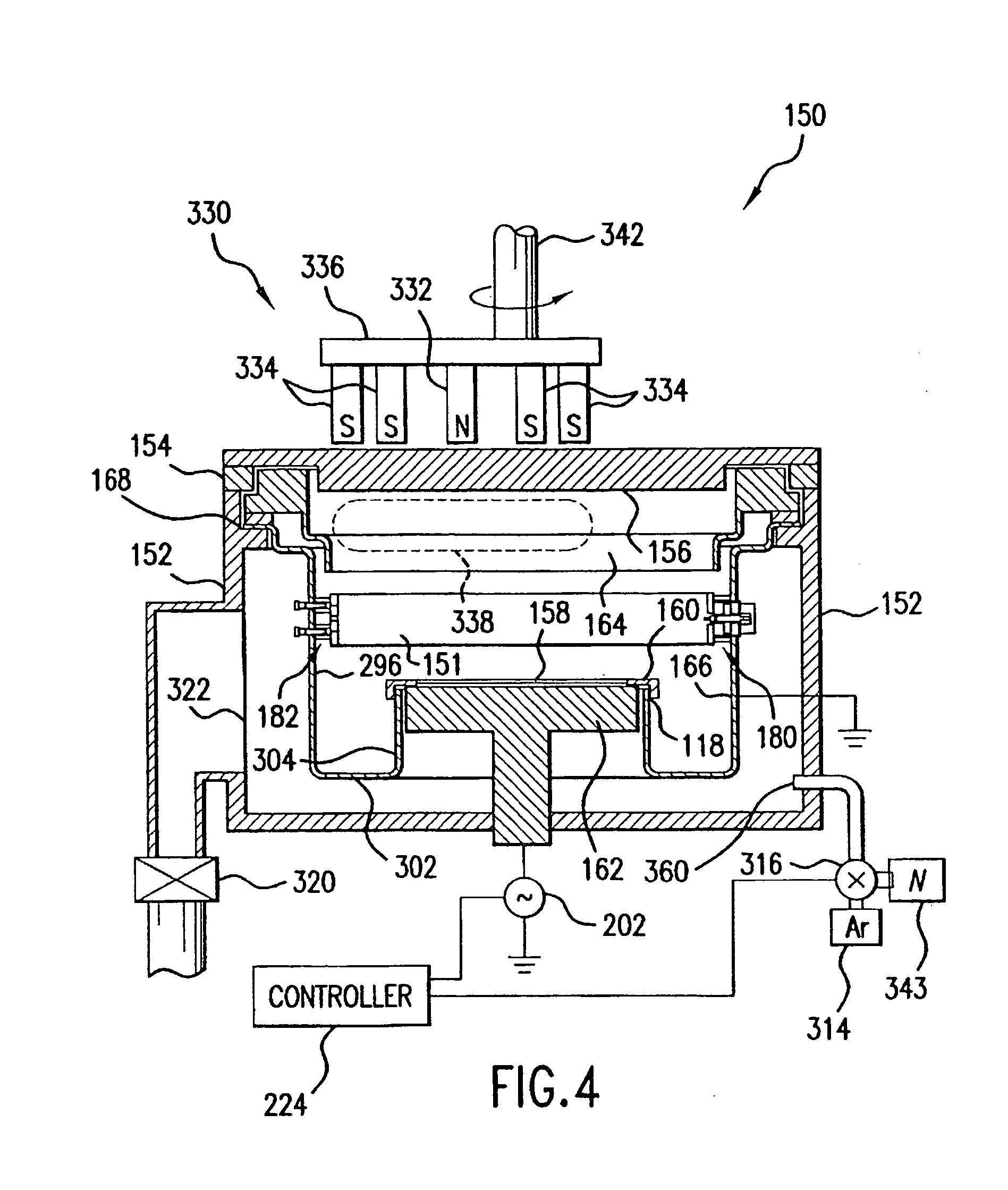

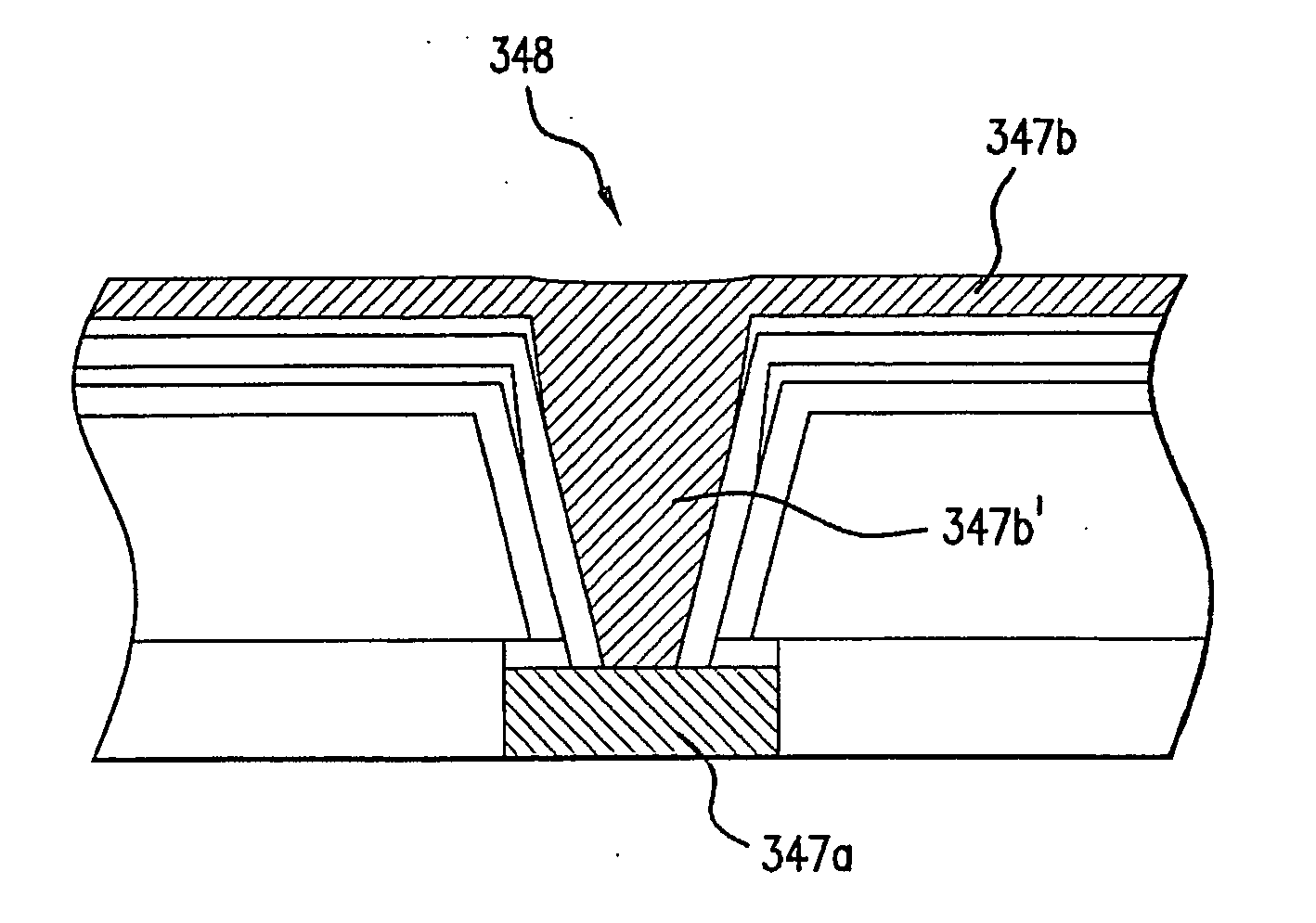

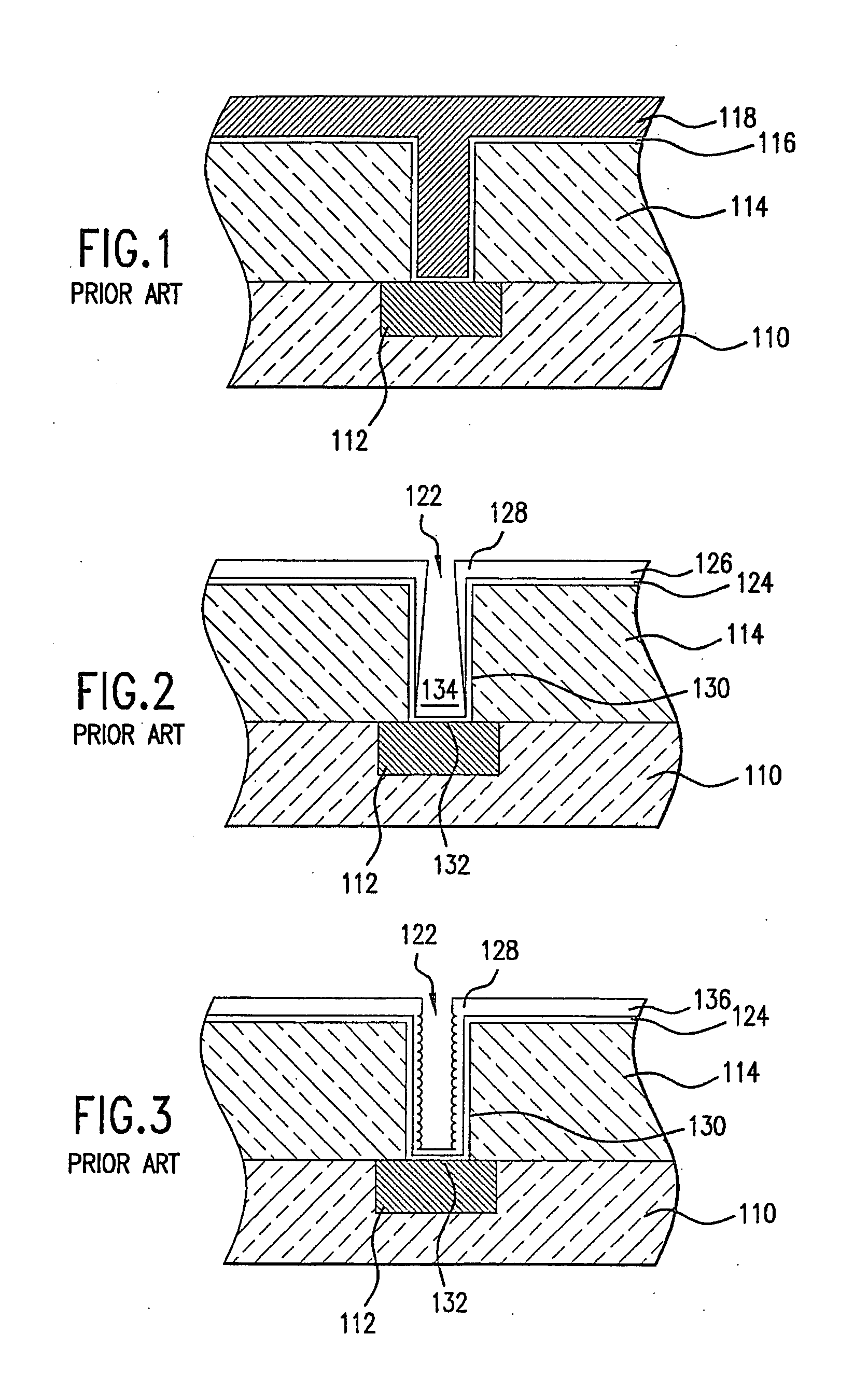

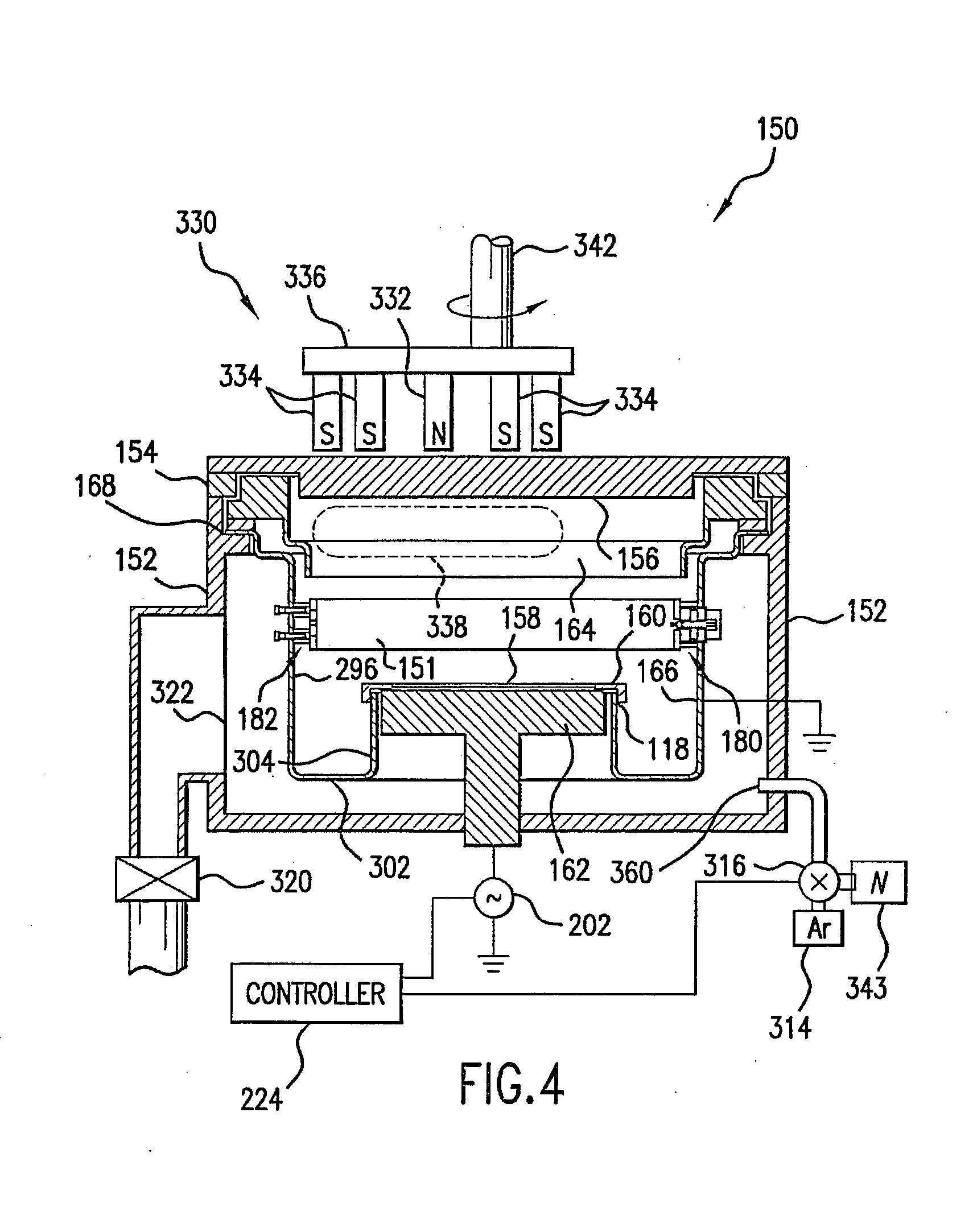

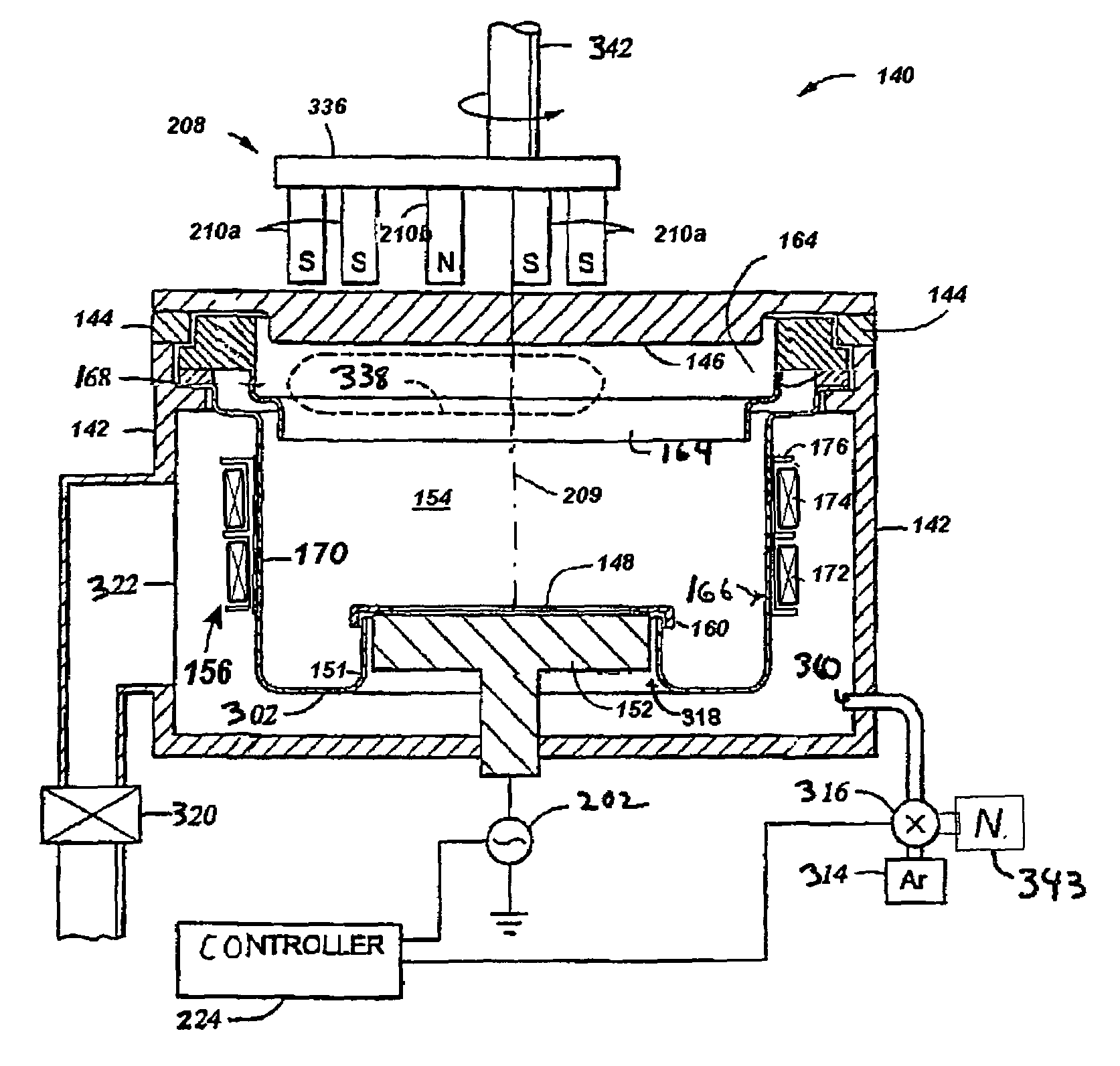

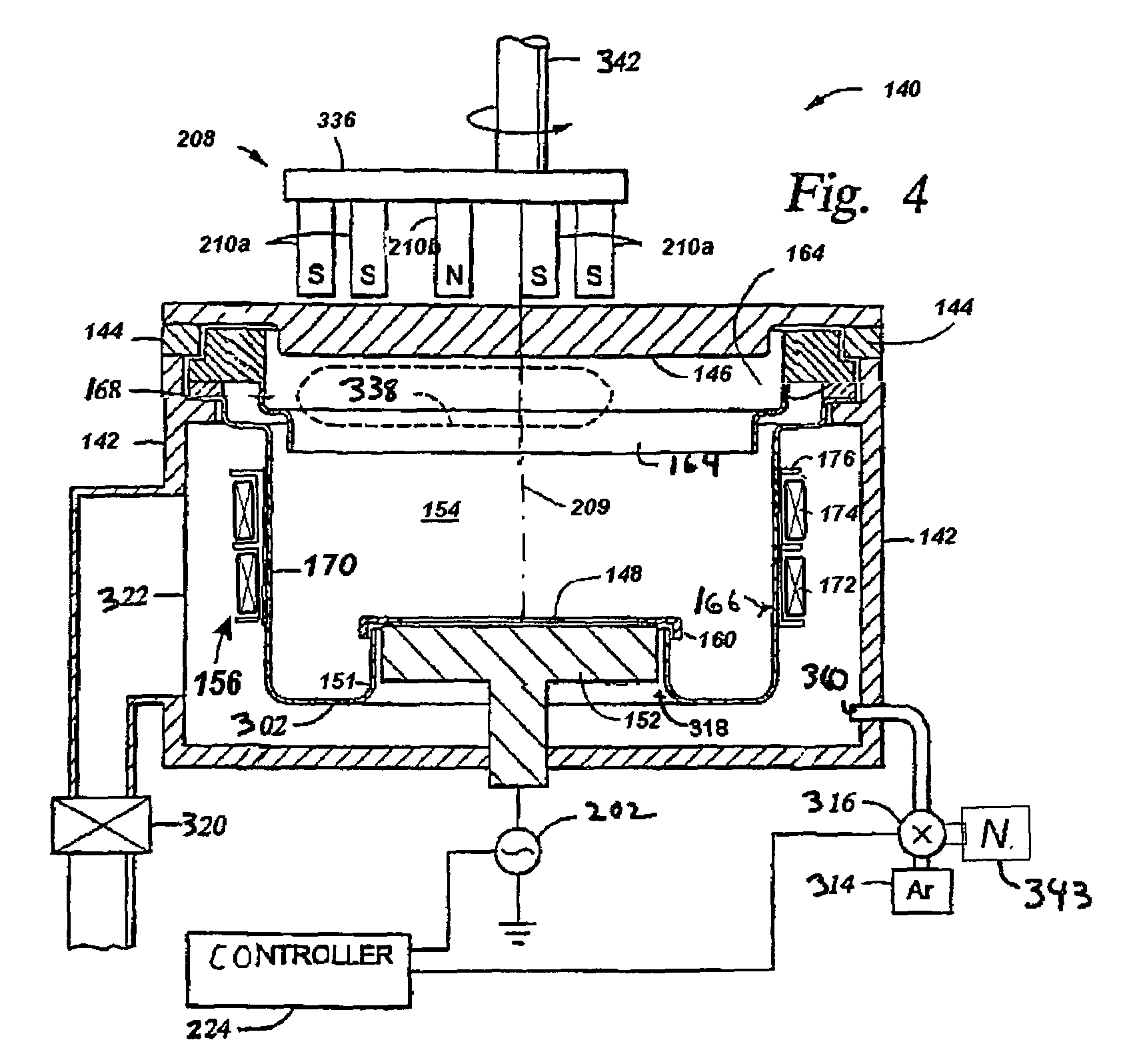

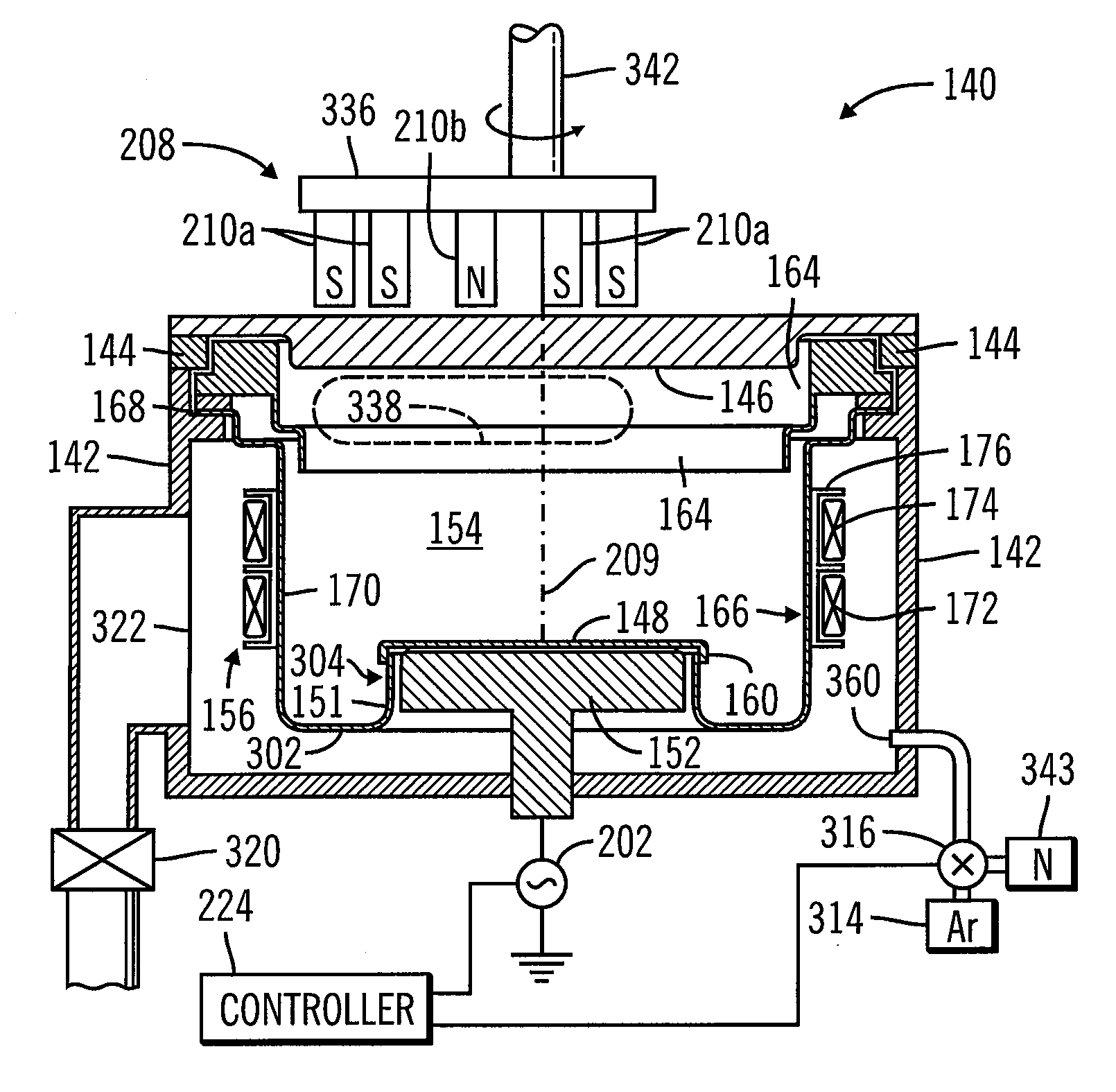

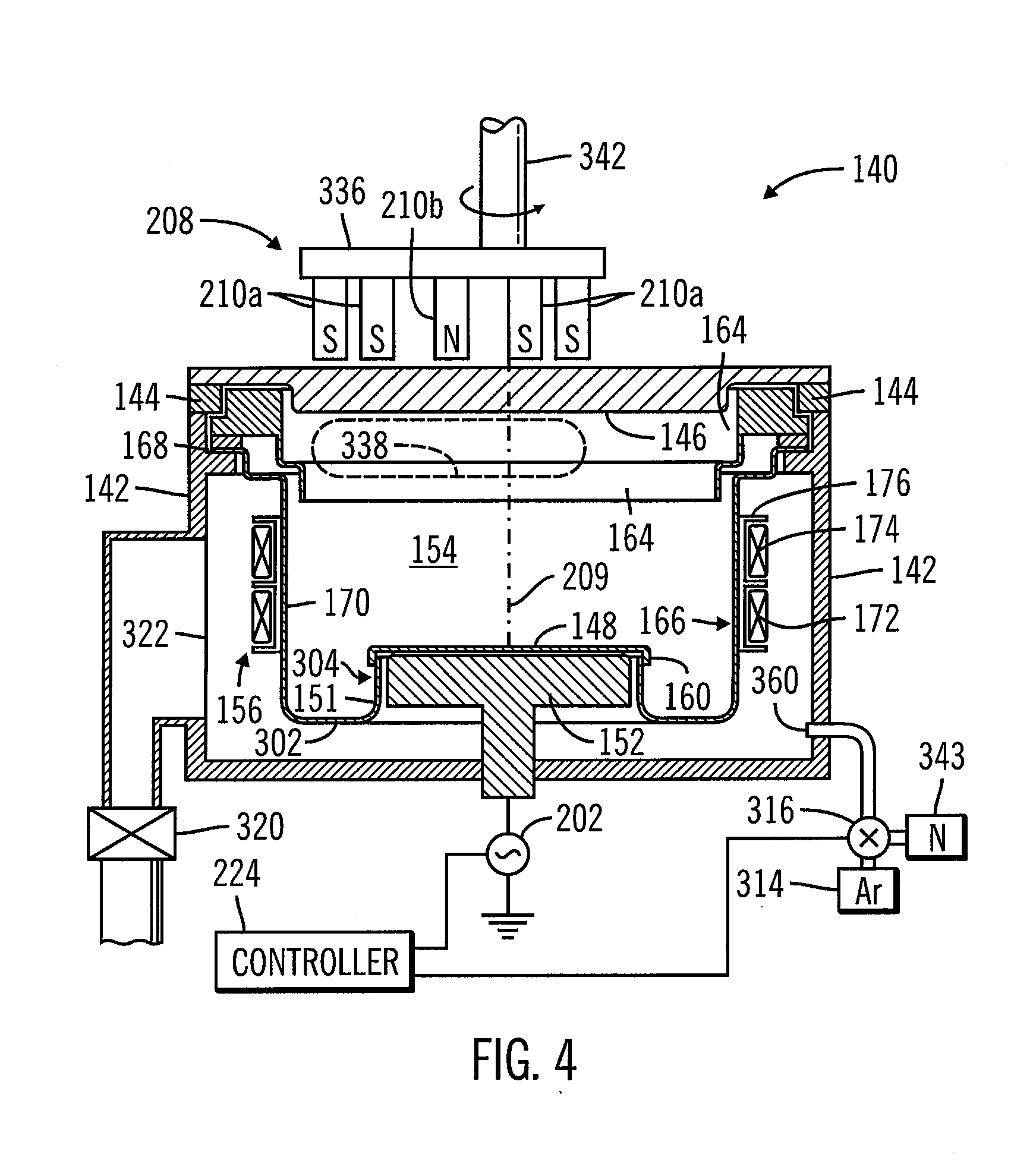

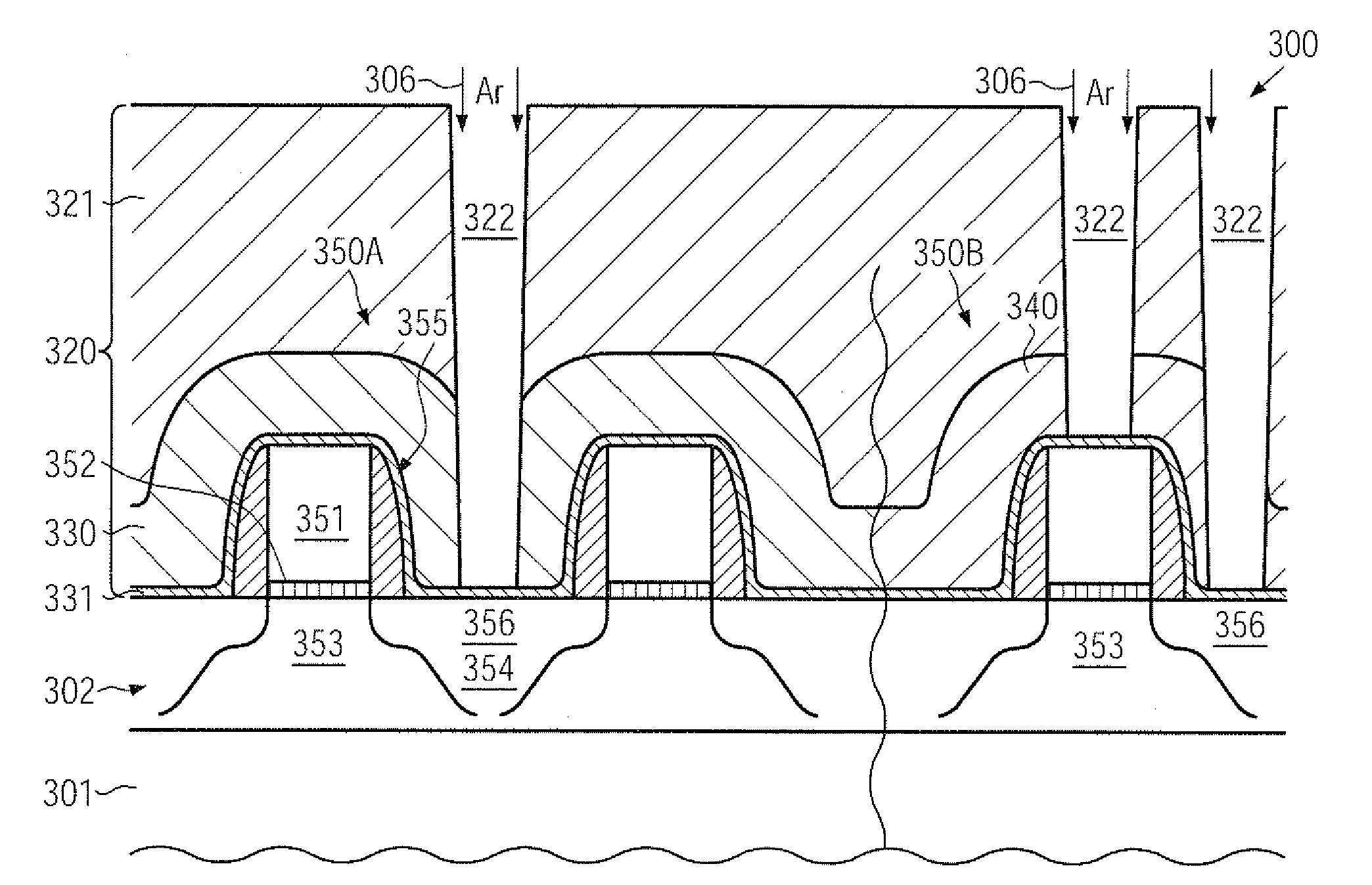

Self-ionized and inductively-coupled plasma for sputtering and resputtering

InactiveUS20050006222A1Raise the ratioReduce layer thicknessCellsElectric discharge tubesSputteringInductively coupled plasma

A magnetron sputter reactor (410) and its method of use, in which SIP sputtering and ICP sputtering are promoted is disclosed. In another chamber (412) an array of auxiliary magnets positioned along sidewalls (414) of a magnetron sputter reactor on a side towards the wafer from the target is disclosed. The magnetron (436) preferably is a small one having a stronger outer pole (442) of a first polarity surrounding a weaker inner pole (440) of a second polarity all on a yoke (444) and rotates about the axis (438) of the chamber using rotation means (446, 448, 450). The auxiliary magnets (462) preferably have the first polarity to draw the unbalanced magnetic field (460) towards the wafer (424), which is on a pedestal (422) supplied with power (454). Argon (426) is supplied through a valve (428). The target (416) is supplied with power (434).

Owner:APPLIED MATERIALS INC

Self-ionized and inductively-coupled plasma for sputtering and resputtering

InactiveUS20050255691A1Raise the ratioReduce layer thicknessElectric discharge tubesSolid-state devicesRadio frequency energyMagnetic poles

Owner:APPLIED MATERIALS INC

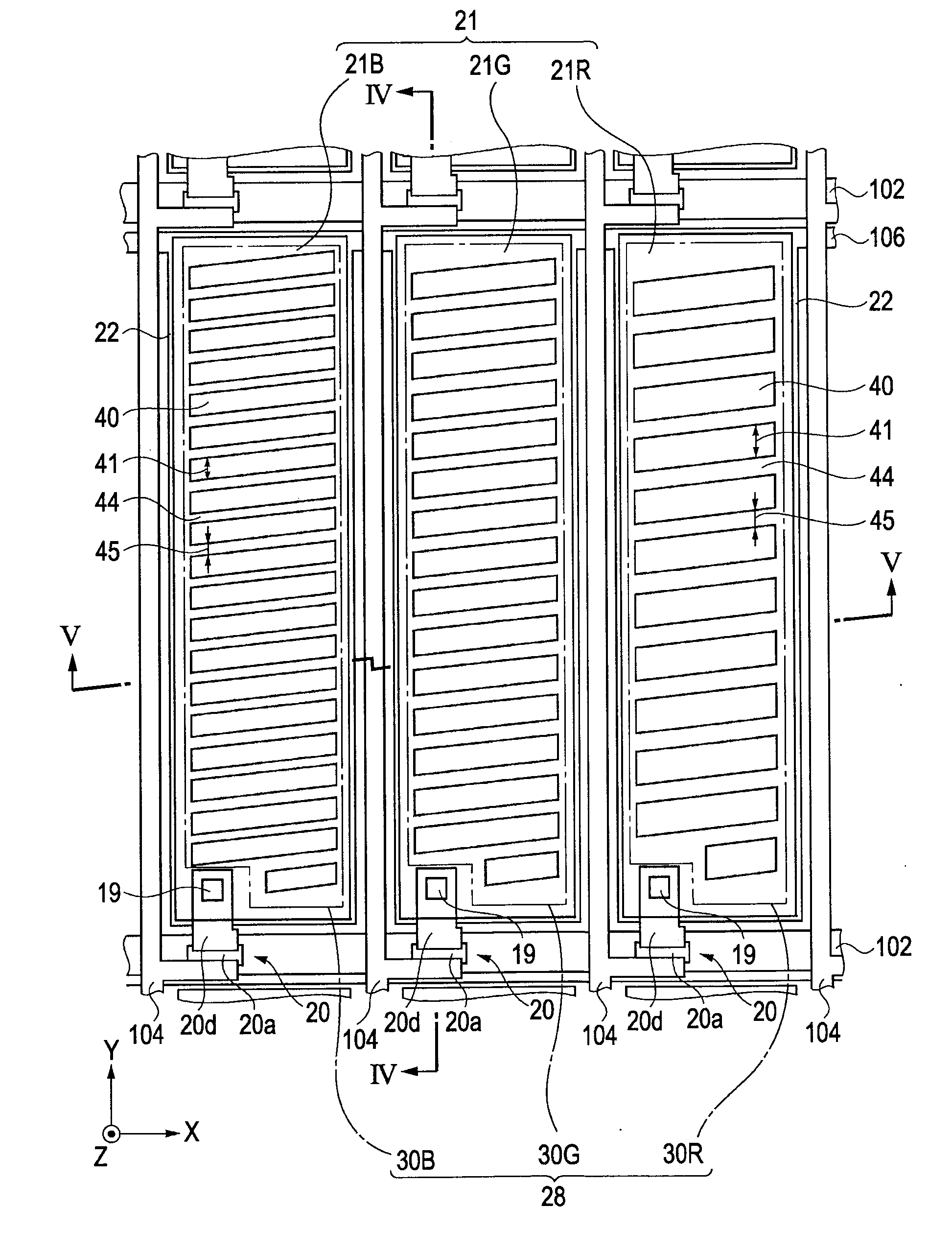

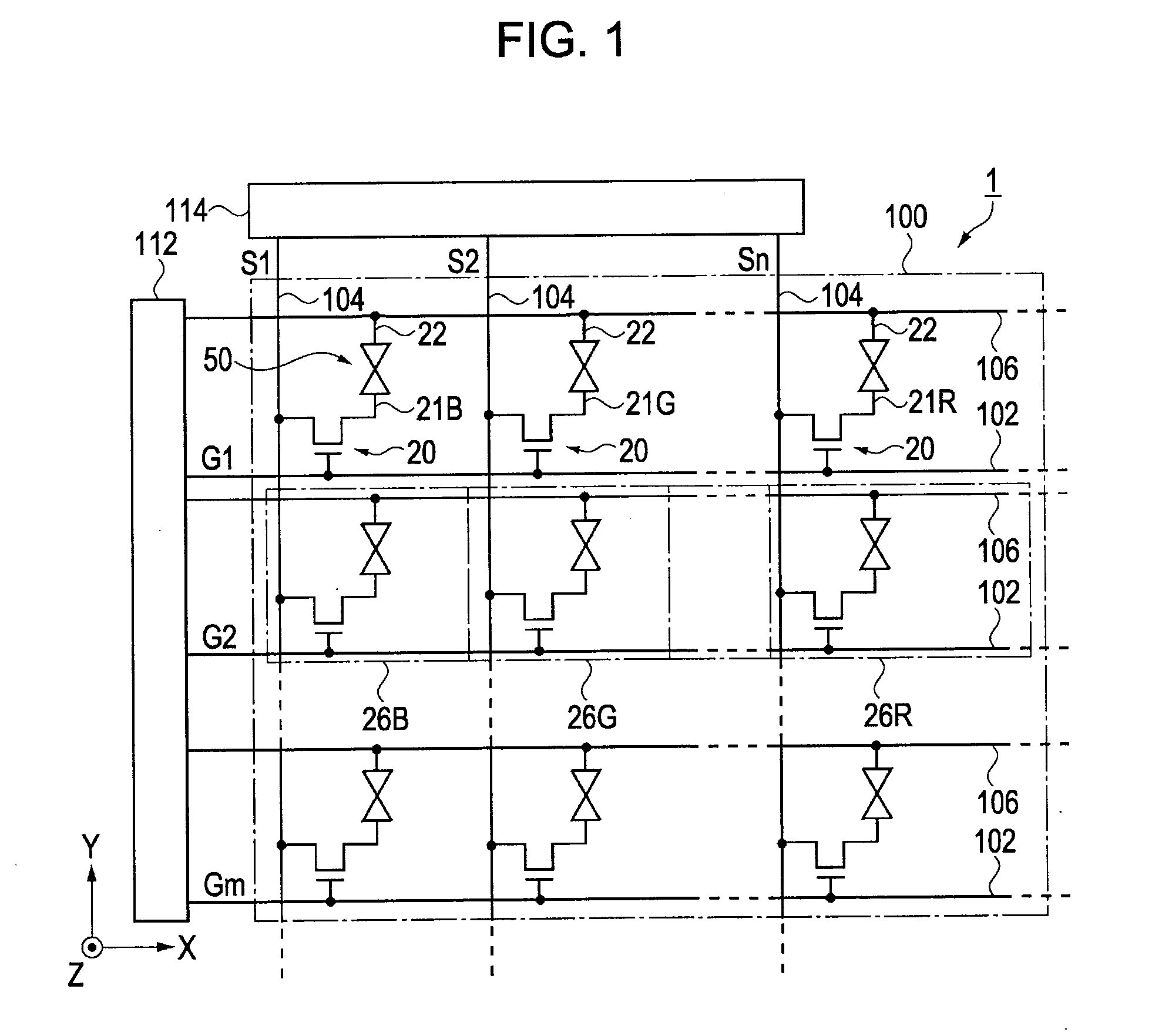

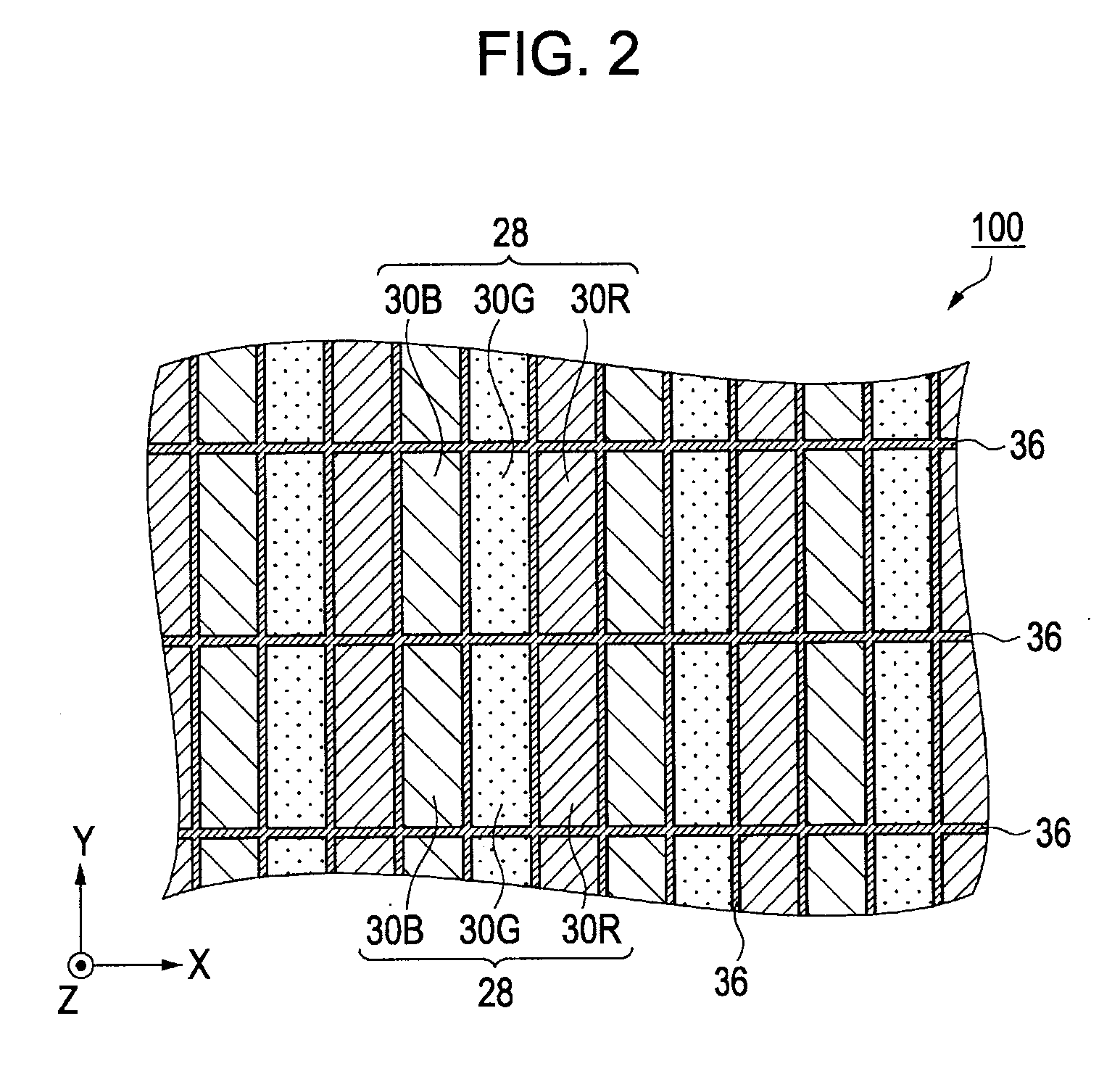

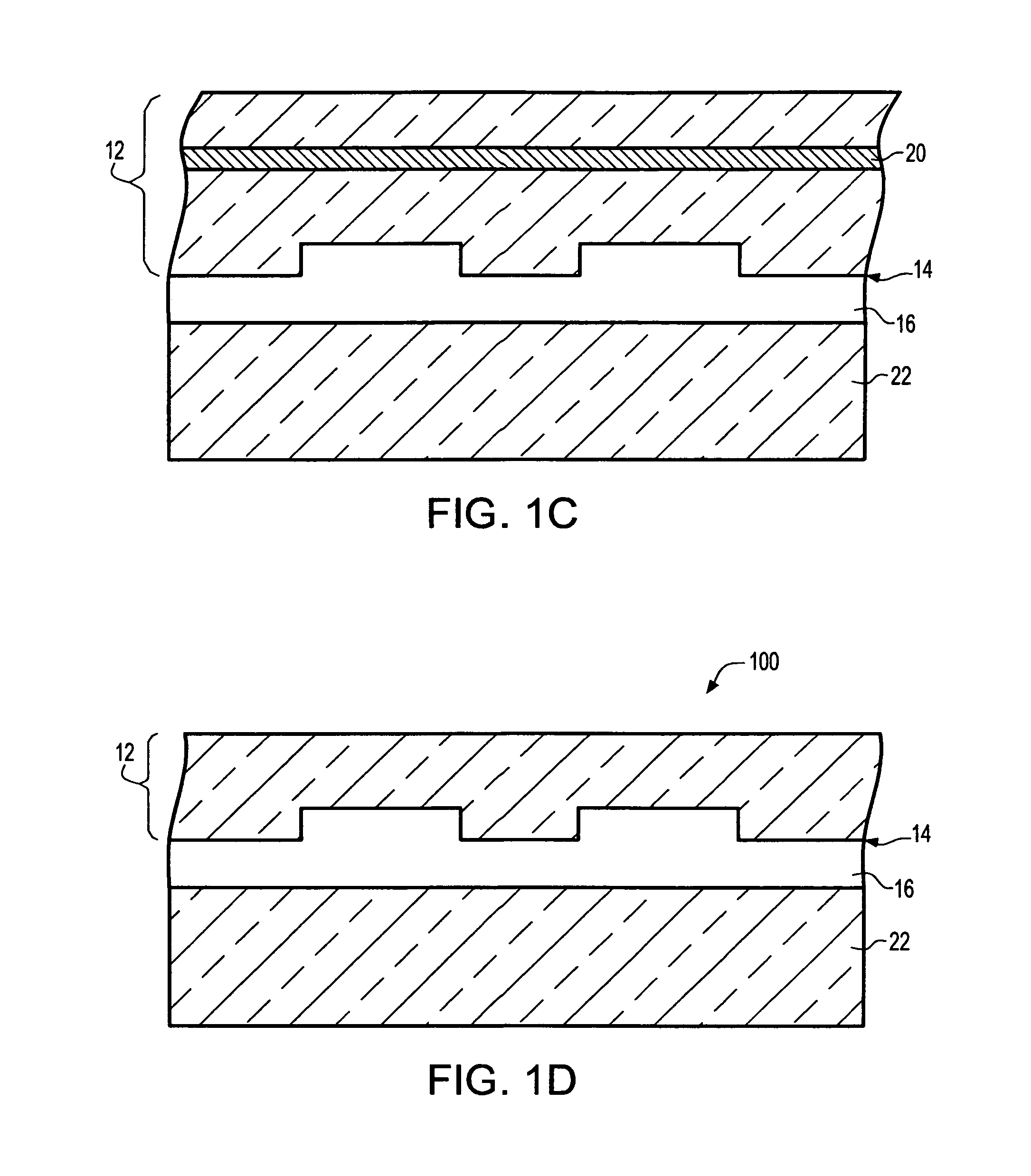

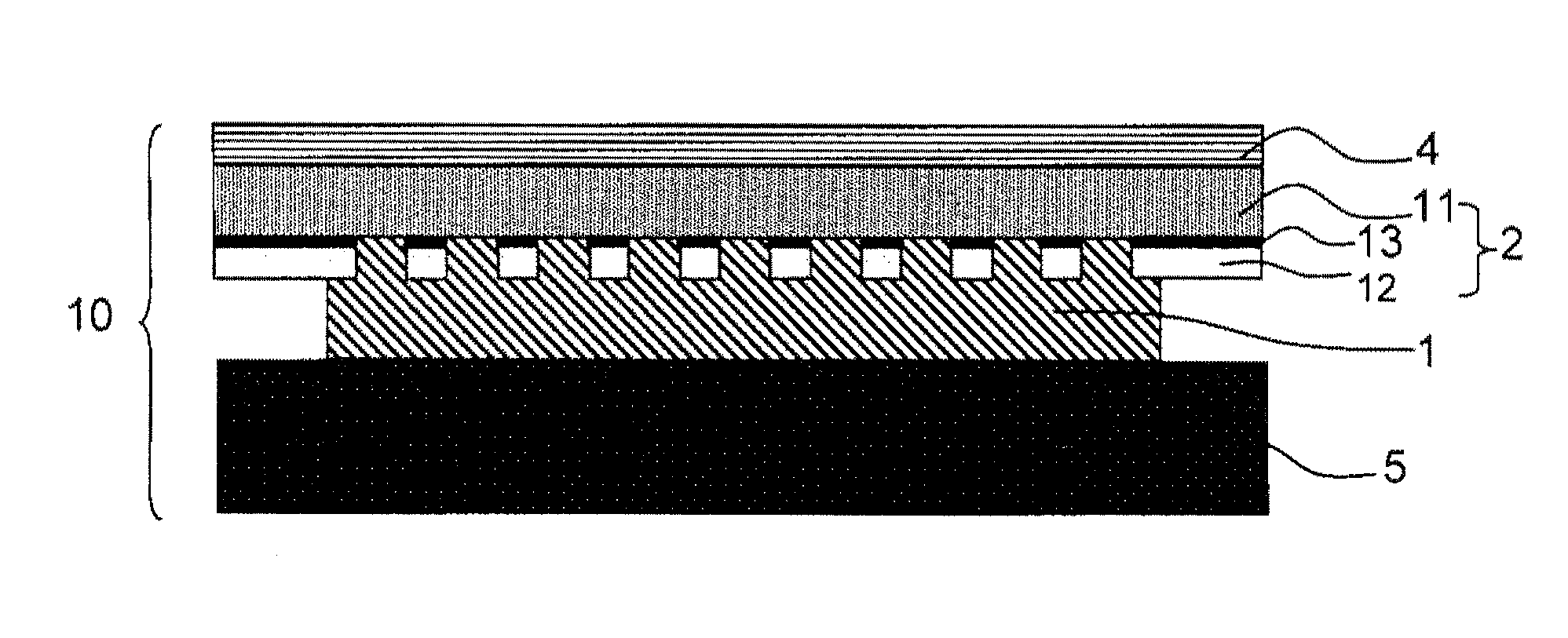

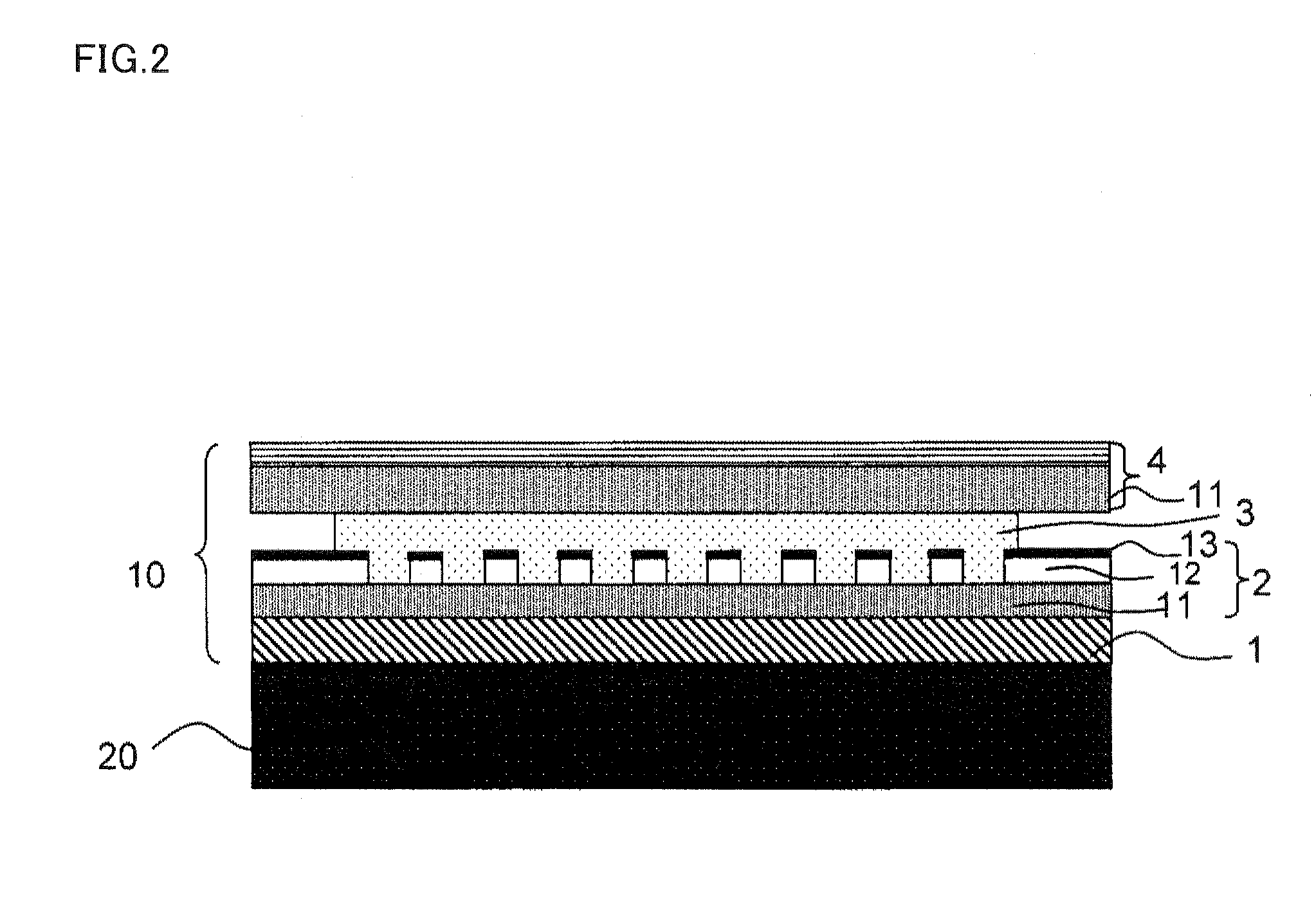

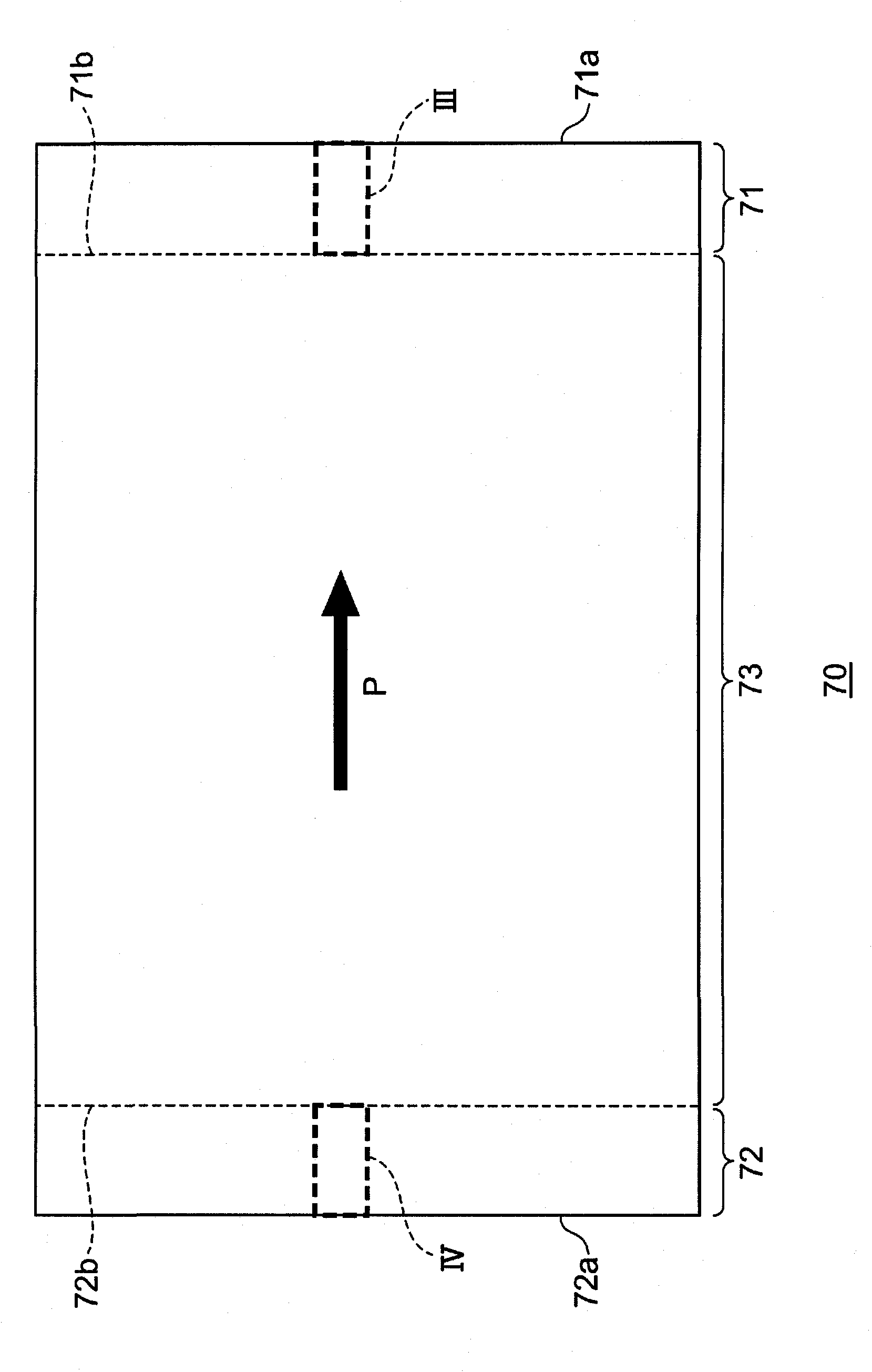

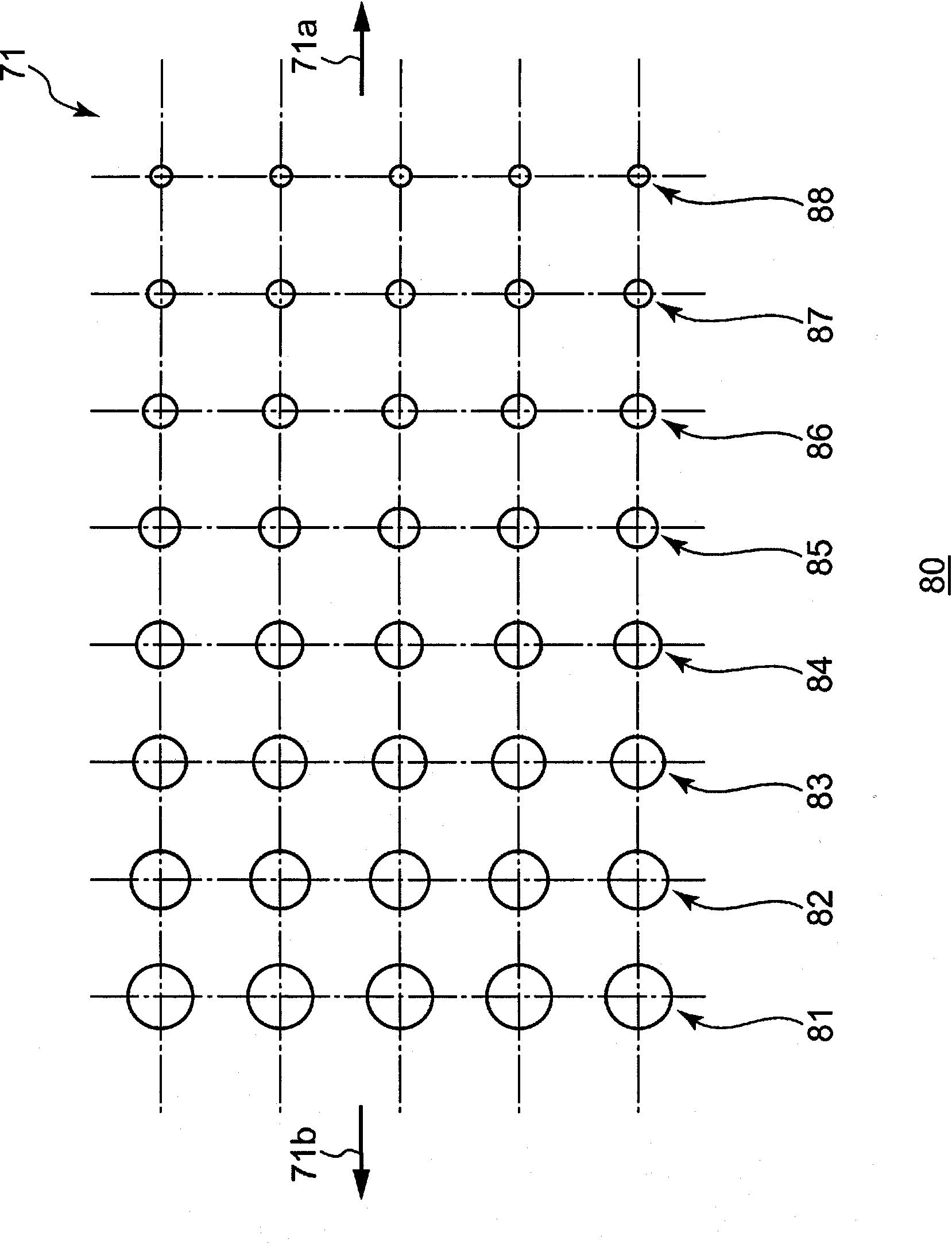

Liquid crystal device and electronic apparatus

ActiveUS20100066952A1Suppress difference in V-T characteristicSuppress deterioration in transmittanceNon-linear opticsLiquid-crystal displayBand shape

A liquid crystal device includes: a liquid crystal layer which is sandwiched between a pair of substrates; a color filter layer has a first coloration layer for transmitting a first light and a second coloration layer for transmitting a second light; first electrodes has a first pixel electrode disposed on a first sub-pixel region corresponding to a planar region of the first coloration layer and a second pixel electrode disposed on a second sub-pixel region corresponding to a planar region of the second coloration layer; and second electrodes each of which faces each first electrode. Any one electrode of each first electrode and each second electrode has a plurality of band-like portions which are arranged at predetermined intervals. A layer thickness of the liquid crystal layer, a width of each band-like portion, and the predetermined intervals within the first sub-pixel region are smaller than they within the second sub-pixel region.

Owner:138 EAST LCD ADVANCEMENTS LTD

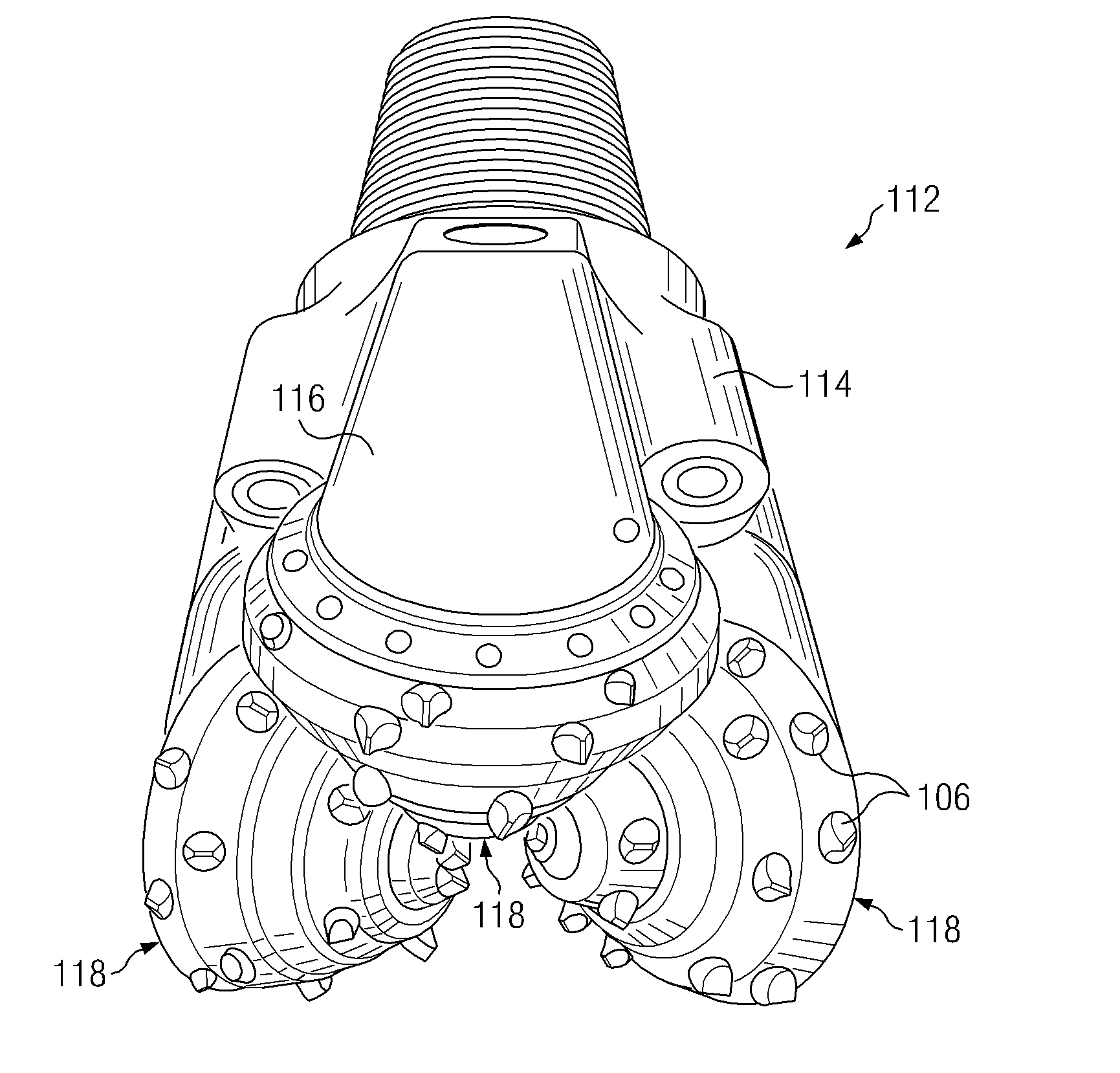

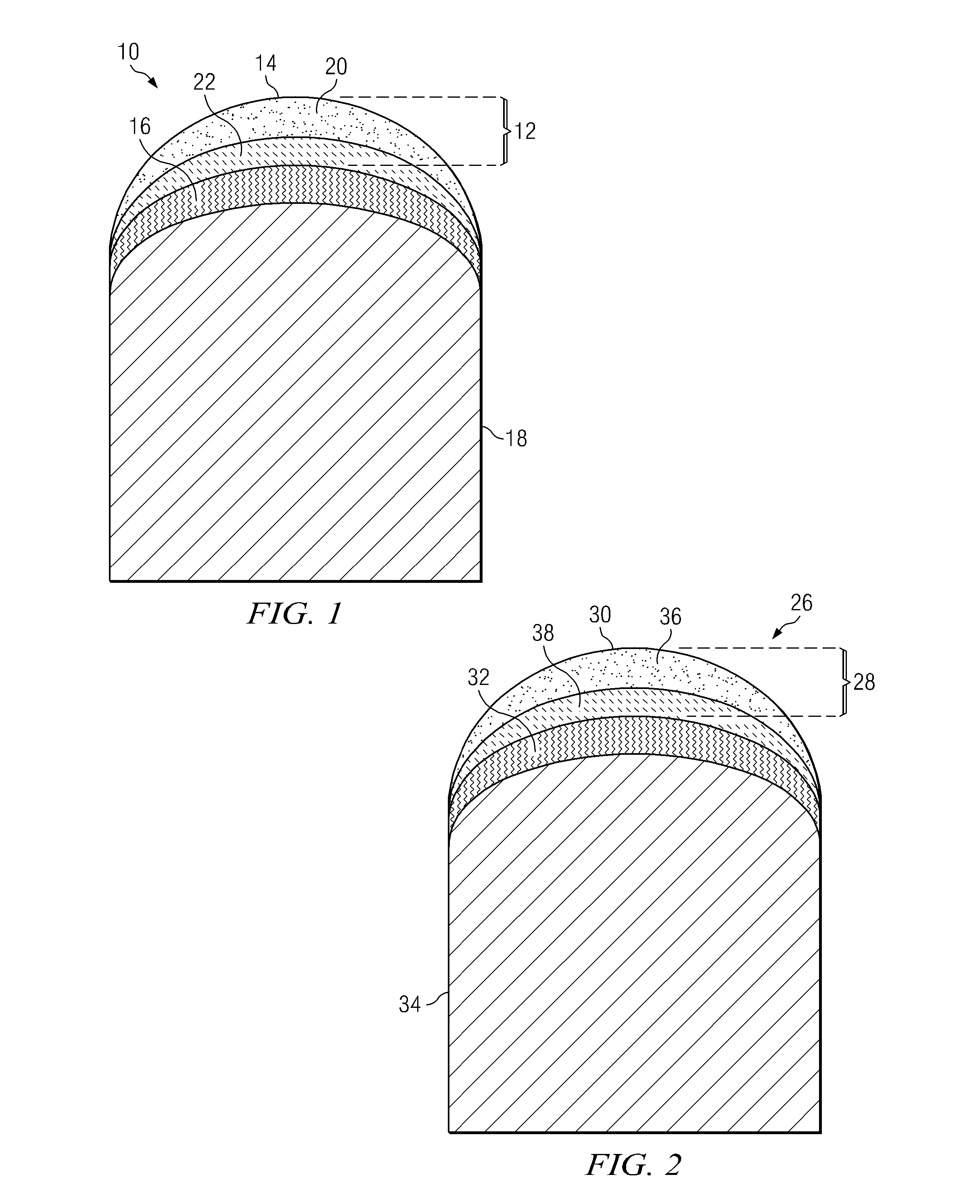

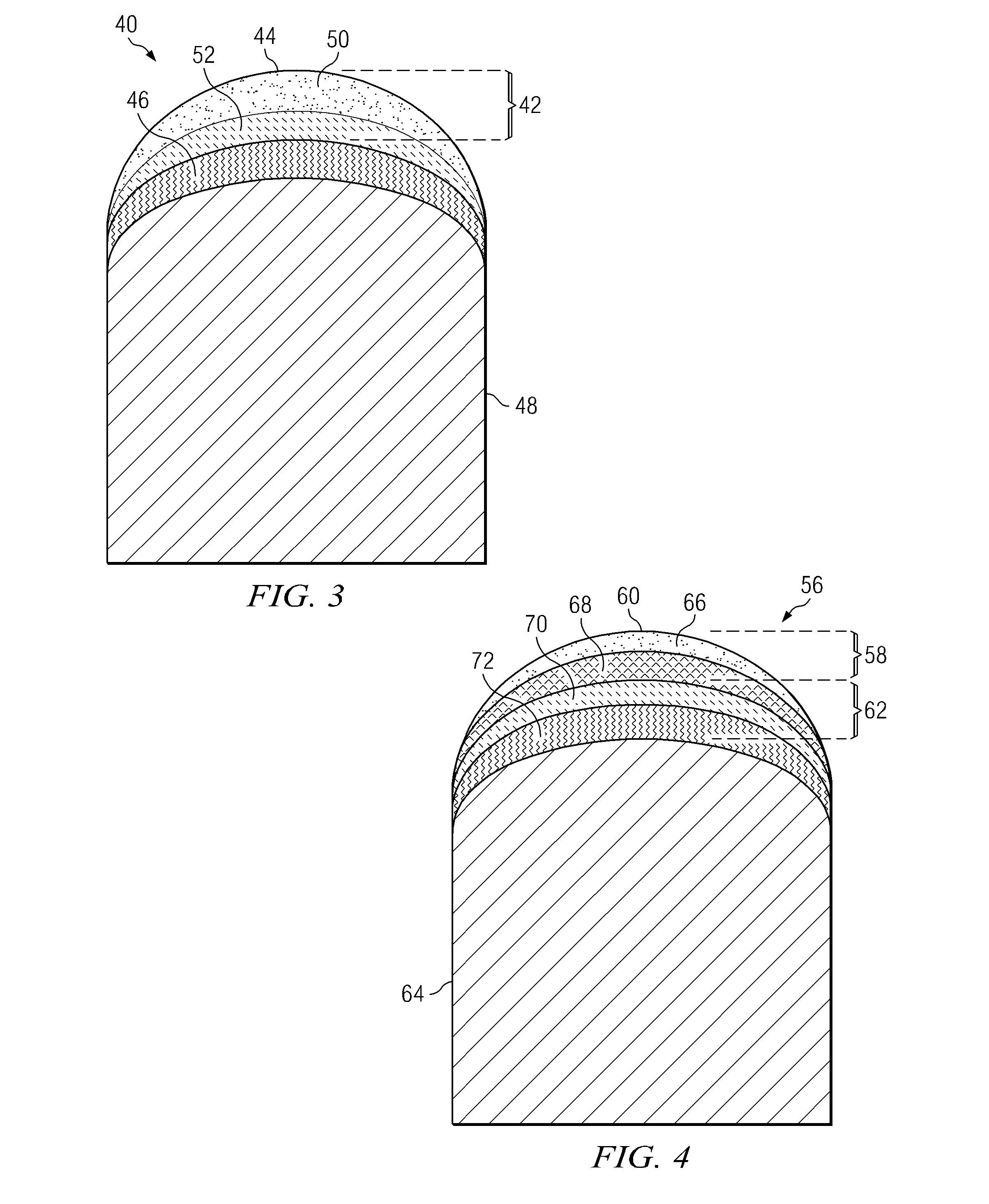

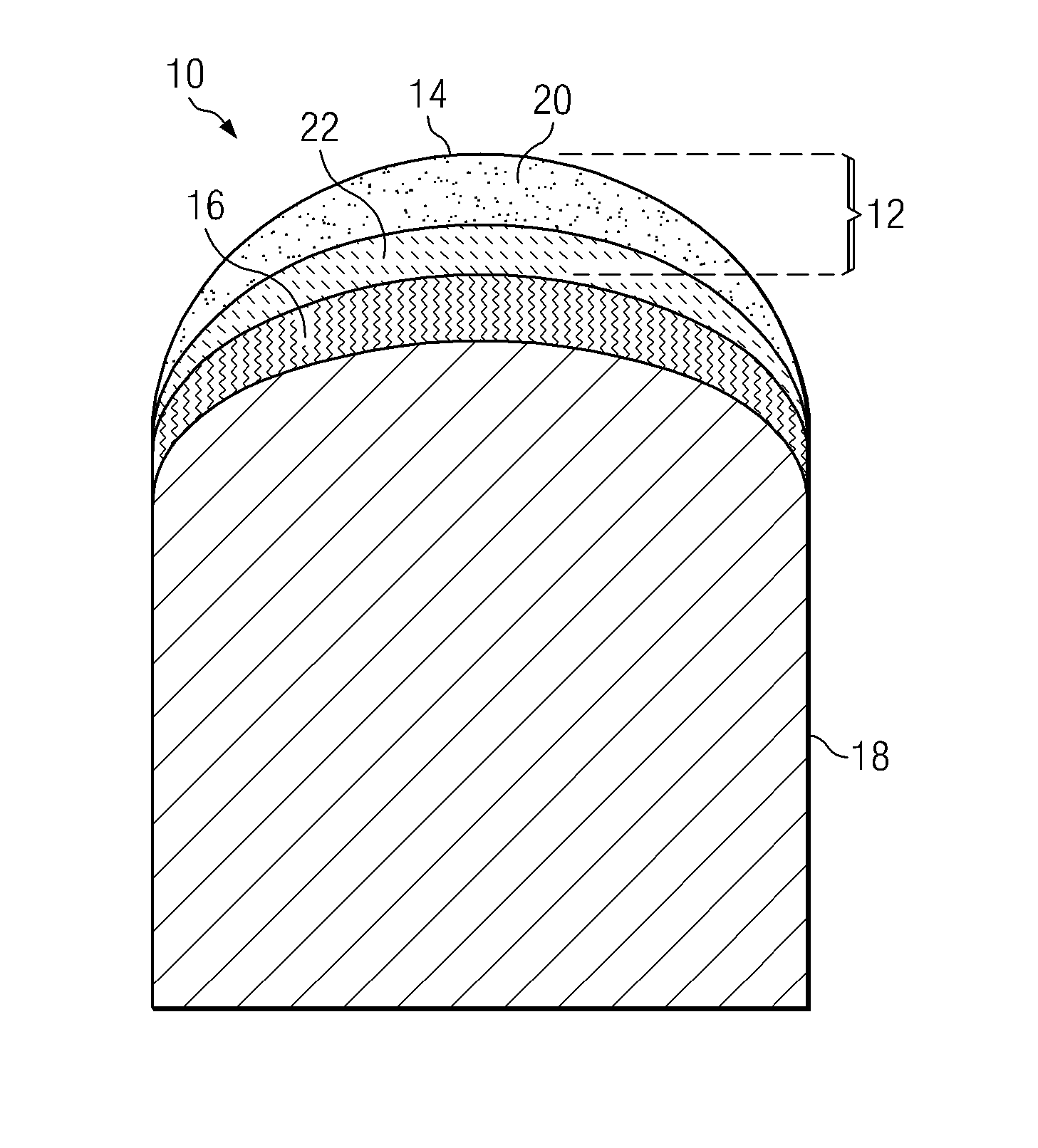

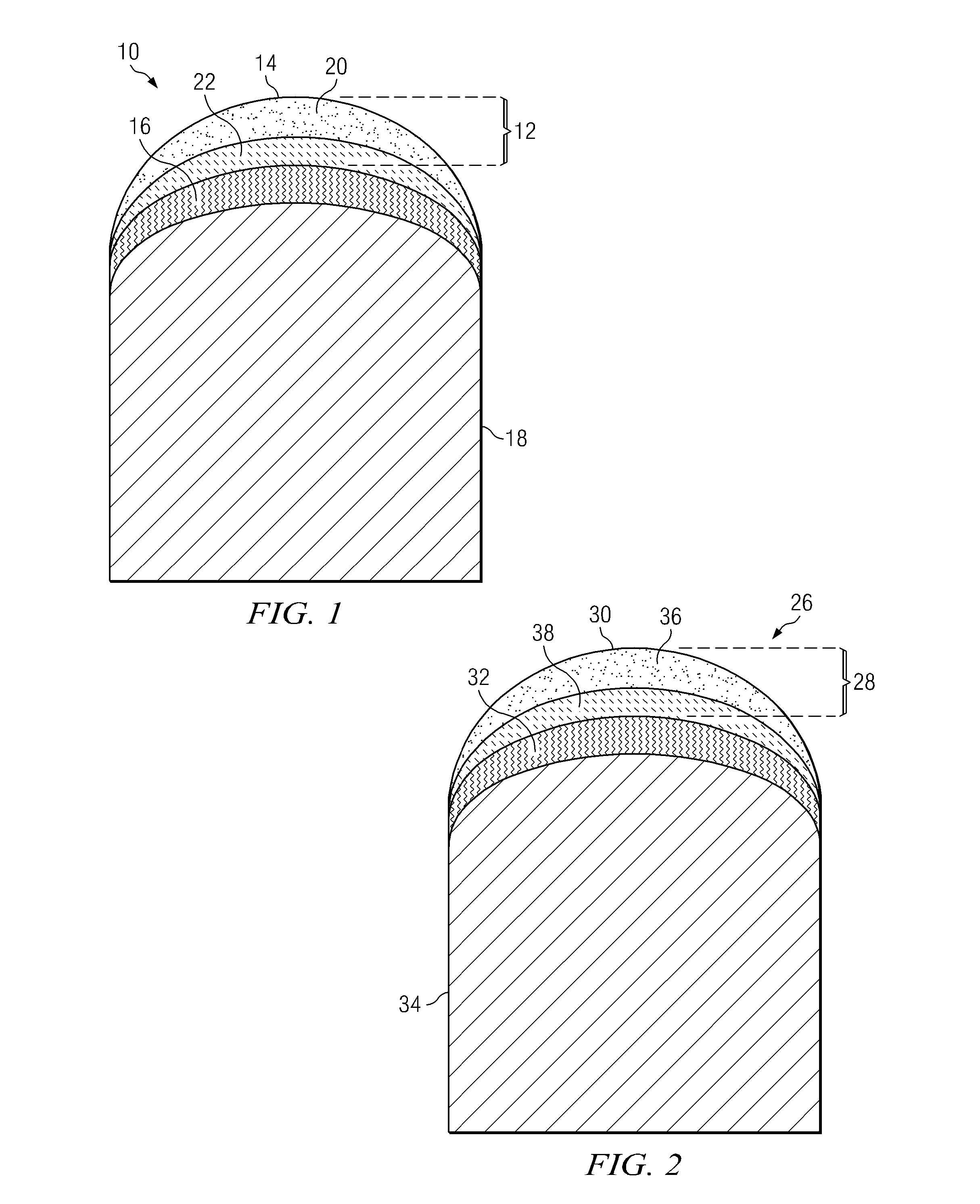

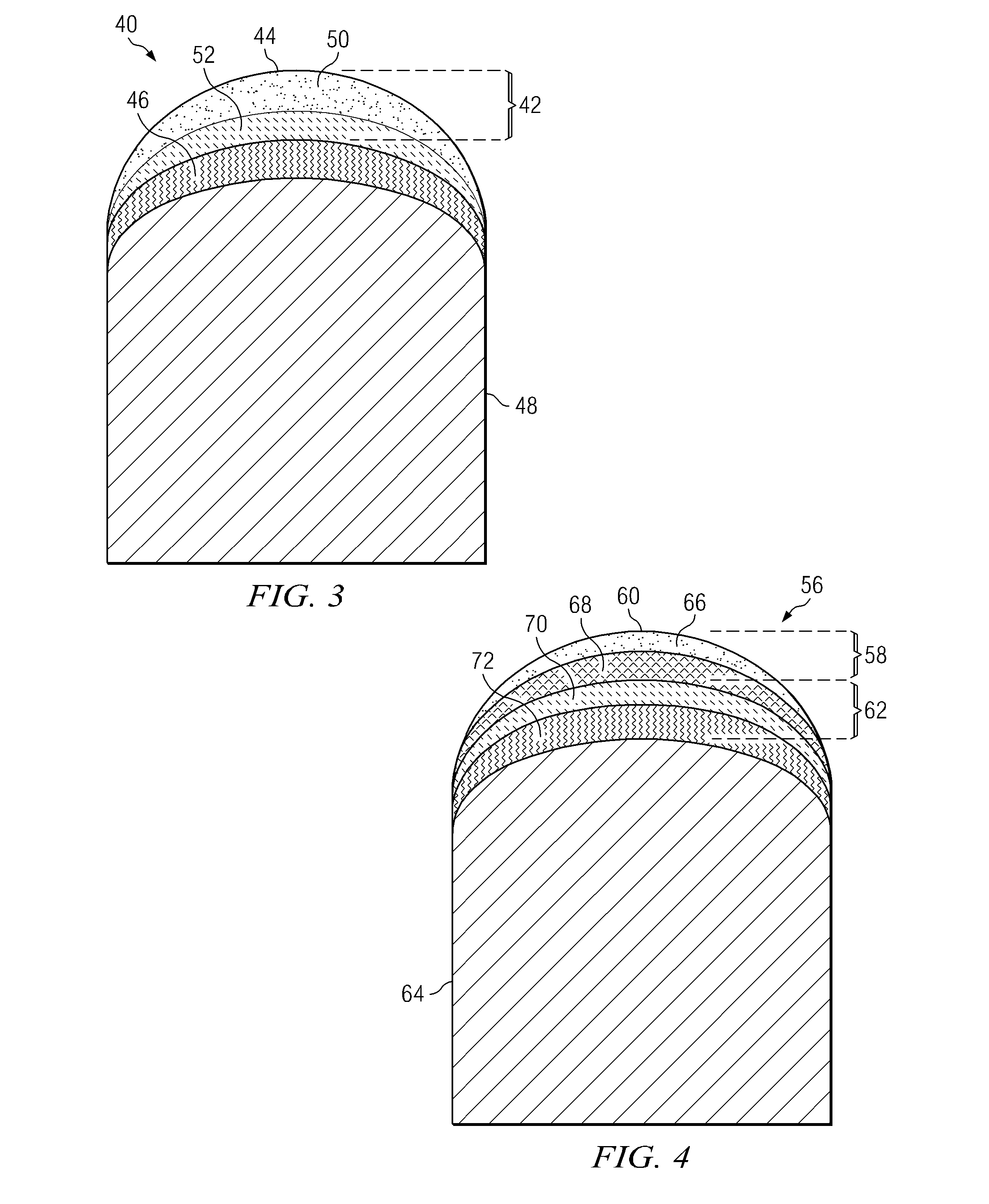

Functionally graded polycrystalline diamond insert

ActiveUS20110042147A1Improve thermal stabilityEffectively extending service lifePigmenting treatmentDrill bitsCarbidePolycrystalline diamond

PCD inserts comprise a PCD body having multiple FG-PCD regions with decreasing diamond content moving from a body outer surface to a metallic substrate. The diamond content changes in gradient fashion by changing metal binder content. A region adjacent the outer surface comprises 5 to 20 percent by weight metal binder, and a region remote from the surface comprises 15 to 40 percent by weight metal binder. One or more transition regions are interposed between the PCD body and substrate. The transition region comprises PCD, binder metal, and a carbide, comprises a metal binder content less than that present in the PCD body region positioned next to it.

Owner:SMITH INT INC

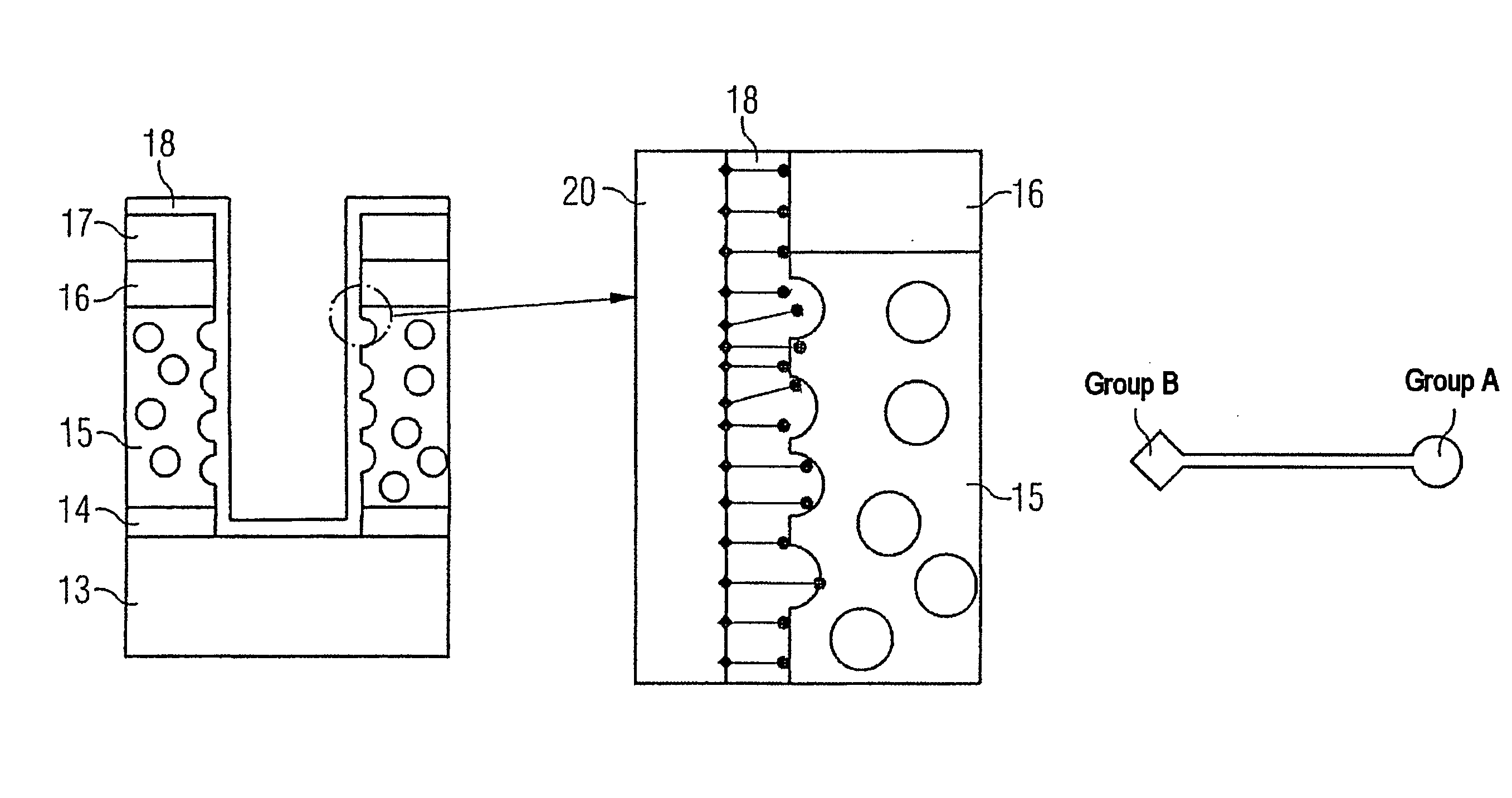

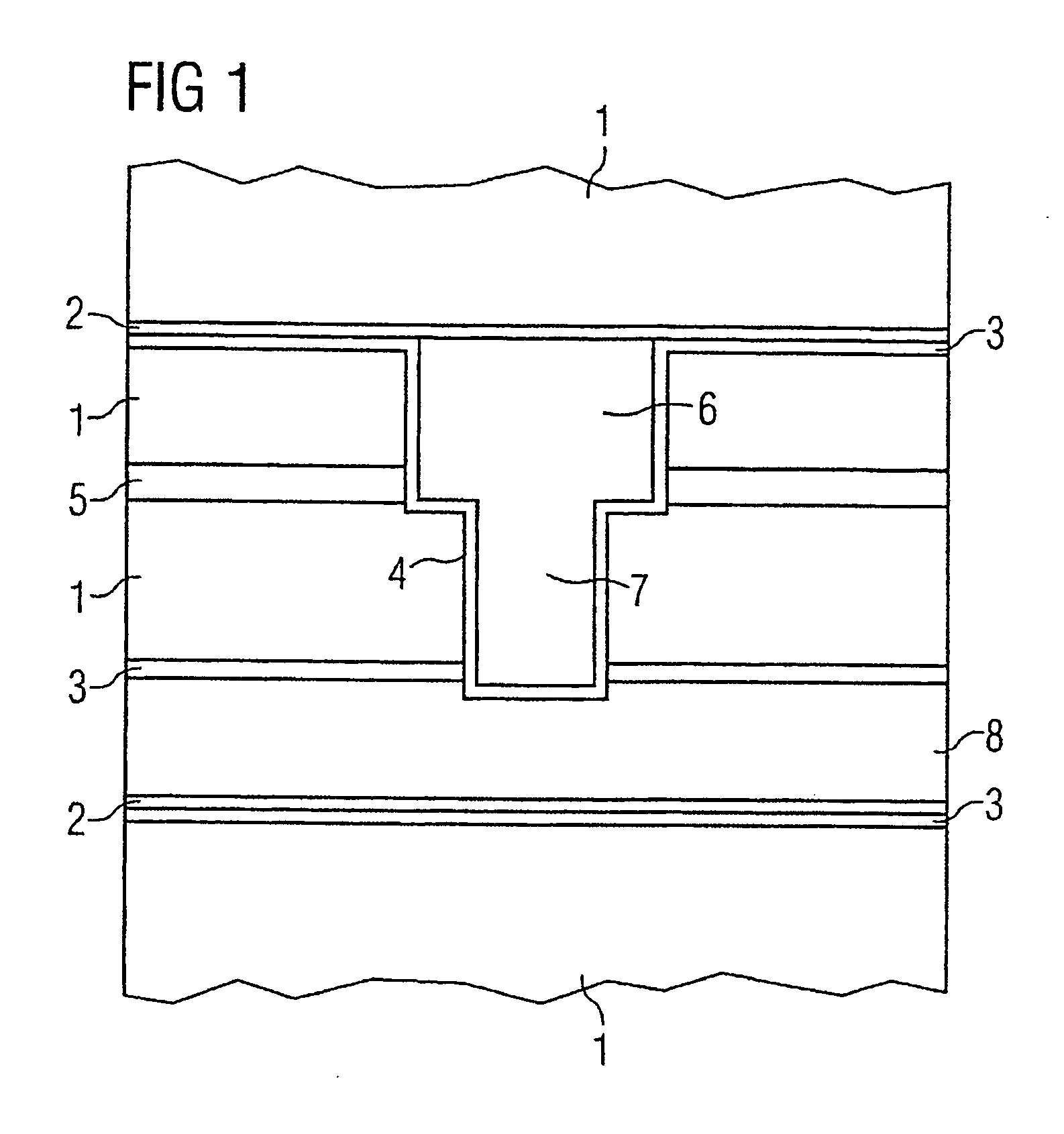

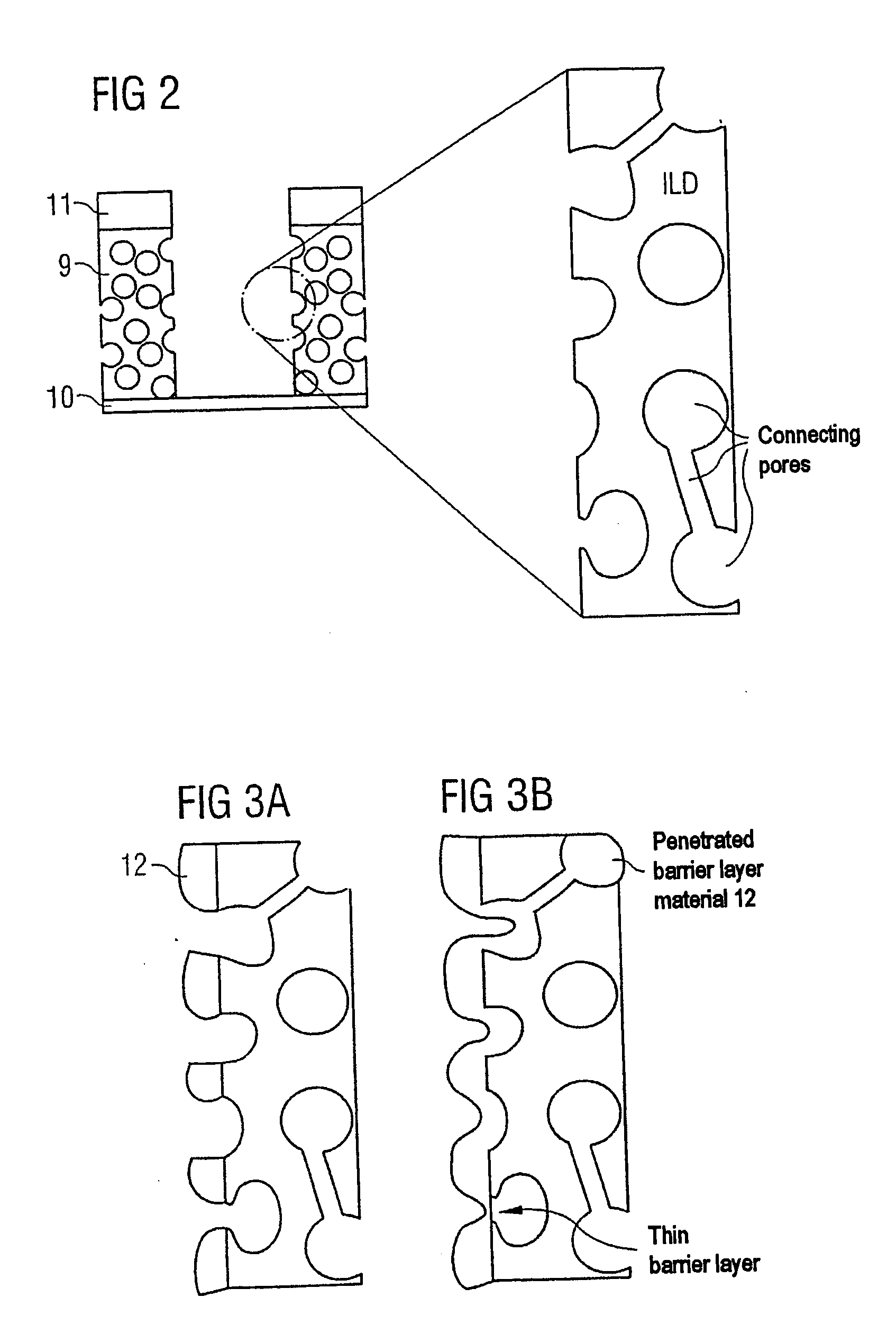

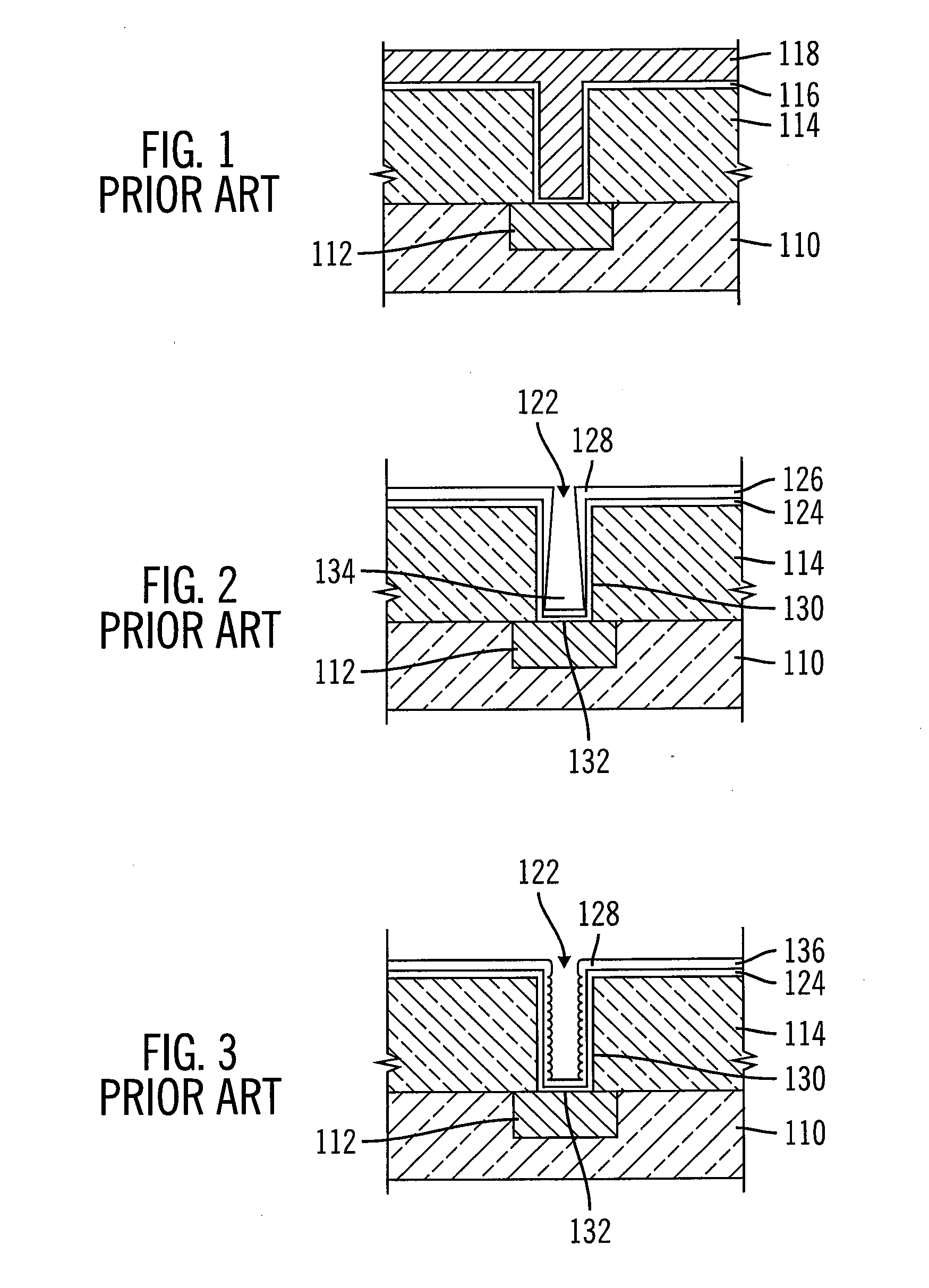

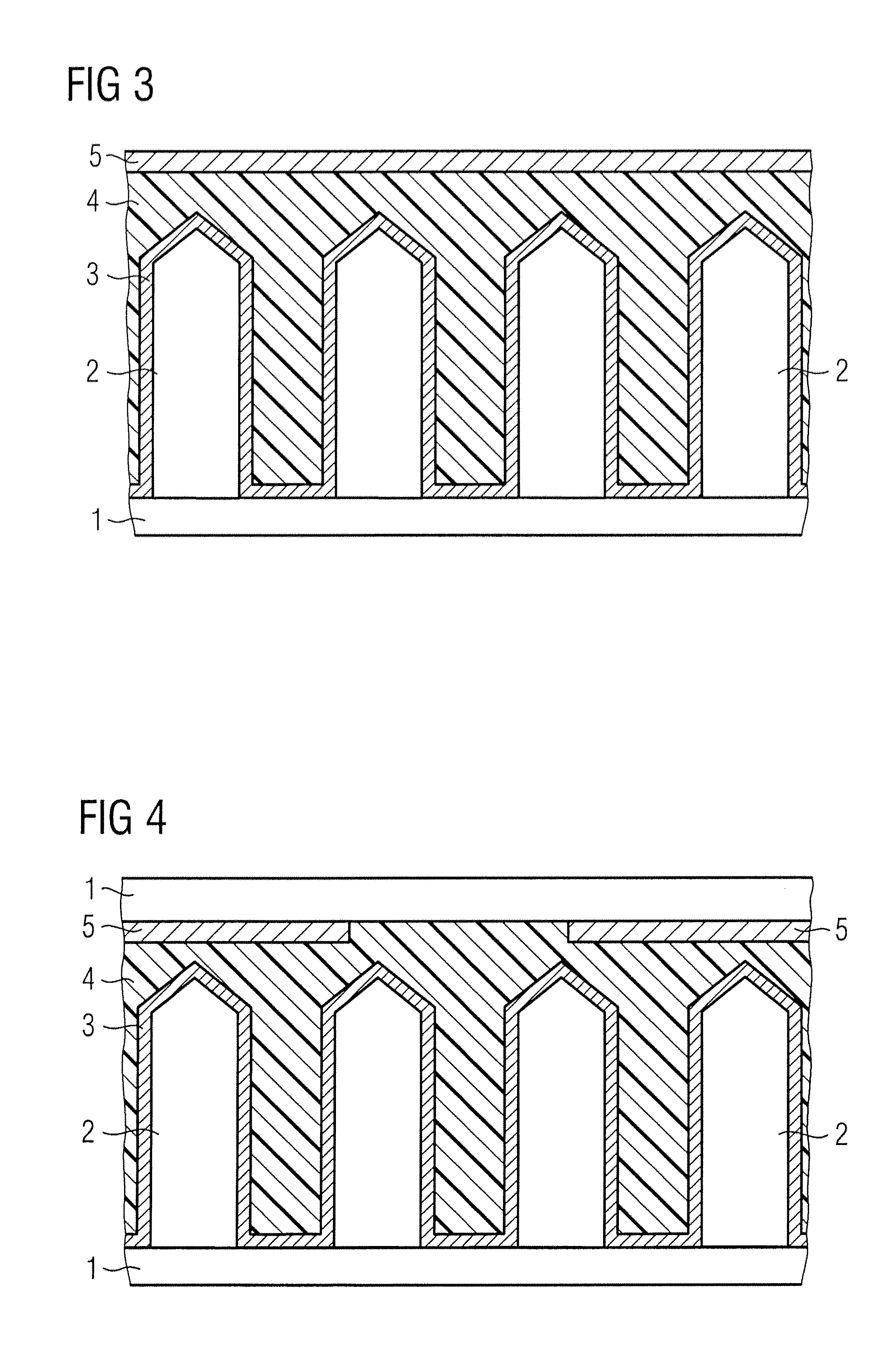

Method for sealing porous materials during chip production and compounds therefor

ActiveUS20050148202A1Reduced dimensionEliminate excessOther chemical processesSemiconductor/solid-state device detailsChemical compoundSemiconductor

A compound and method for sealing or protecting porous materials used in semiconductor fabrication, and in particular for protecting the inner walls of trenches or recesses or vias which are present in such materials. Specifically, compounds and the method of use of the compounds in which polymer compounds comprising functional groups A and B are used to seal surface-exposed pores in porous materials used in chip production.

Owner:INFINEON TECH AG

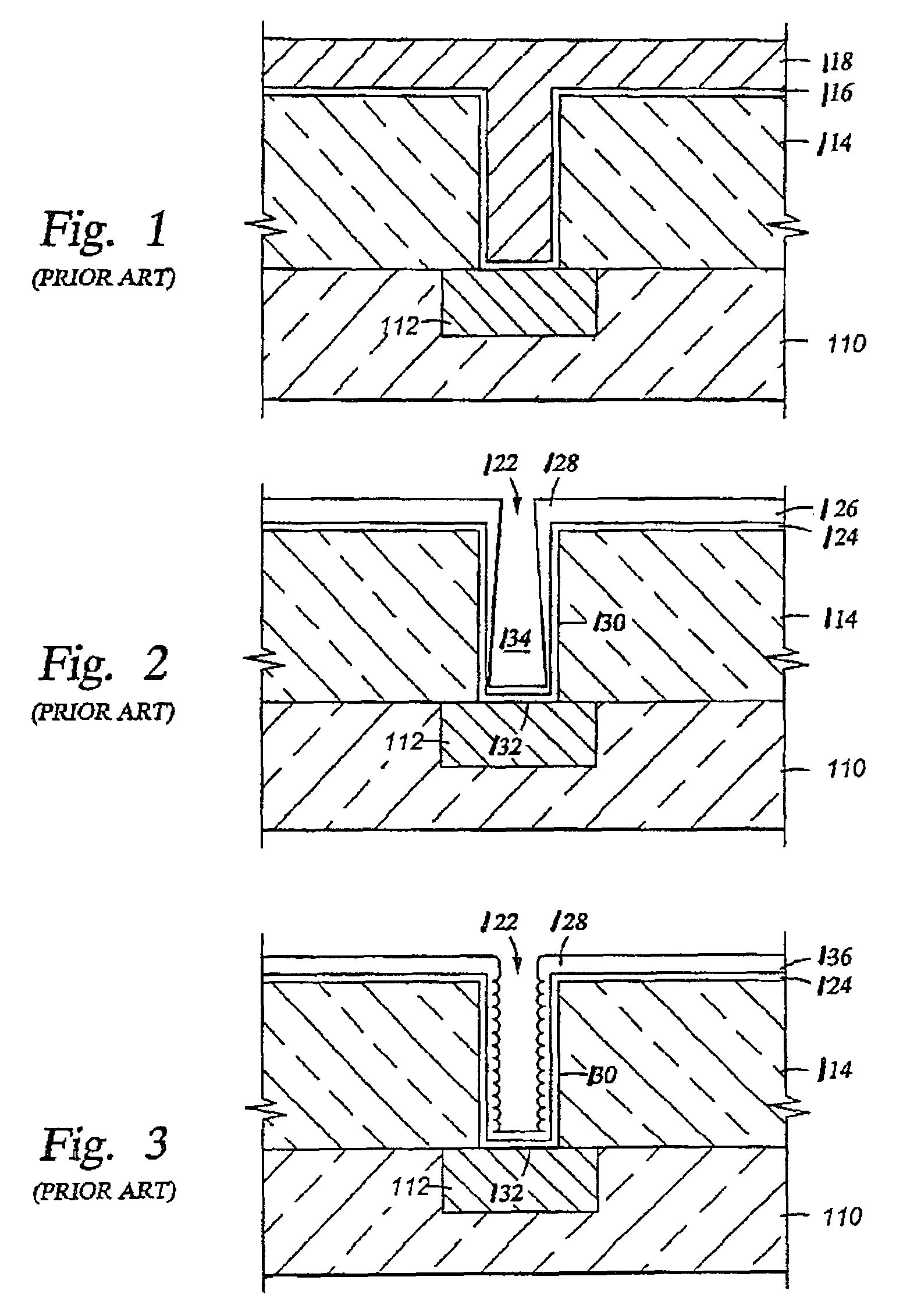

Self-ionized and capacitively-coupled plasma for sputtering and resputtering

InactiveUS7504006B2Raise the ratioIncrease plasma densityCellsElectric discharge tubesCapacitanceTantalum nitride

A DC magnetron sputter reactor for sputtering deposition materials such as tantalum and tantalum nitride, for example, and its method of use, in which self-ionized plasma (SIP) sputtering and capacitively coupled plasma (CCP) sputtering are promoted, either together or alternately, in the same chamber. Also, bottom coverage may be thinned or eliminated by inductively-coupled plasma (ICP) resputtering. SIP is promoted by a small magnetron having poles of unequal magnetic strength and a high power applied to the target during sputtering. CCP is provided by a pedestal electrode which capacitively couples RF energy into a plasma. The CCP plasma is preferably enhanced by a magnetic field generated by electromagnetic coils surrounding the pedestal which act to confine the CCP plasma and increase its density.

Owner:APPLIED MATERIALS INC

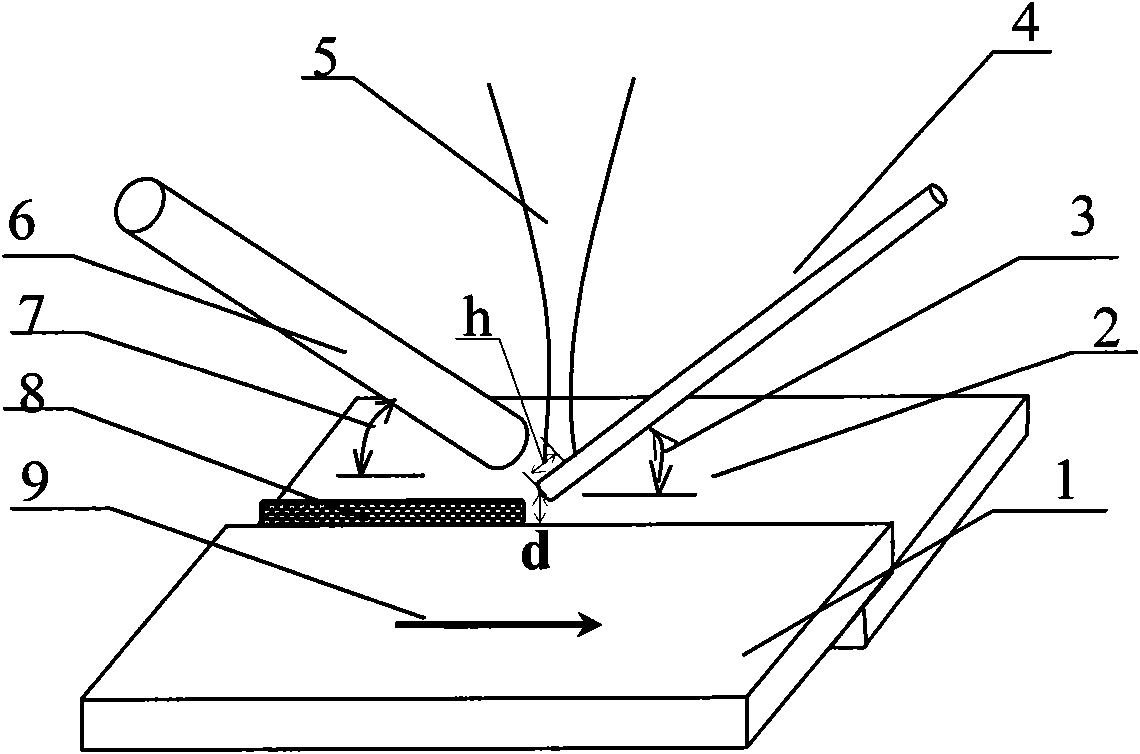

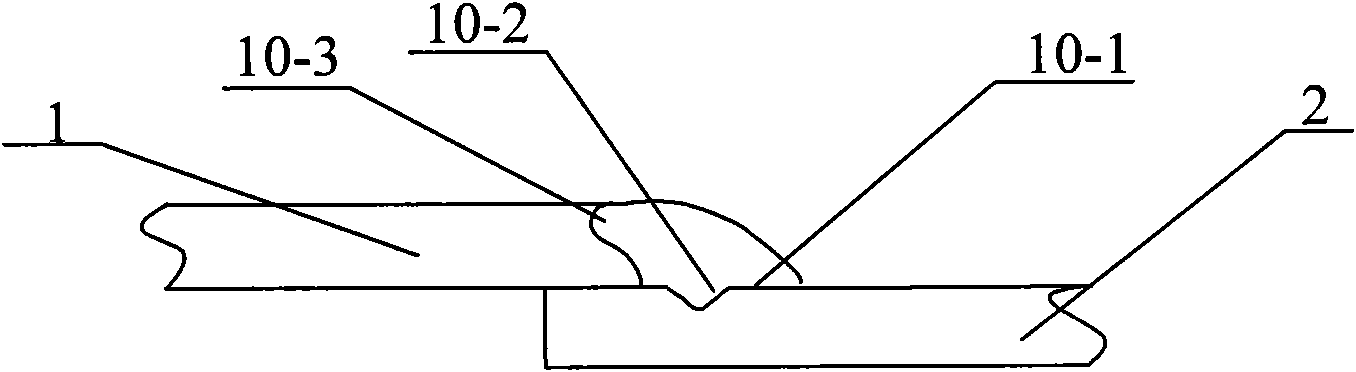

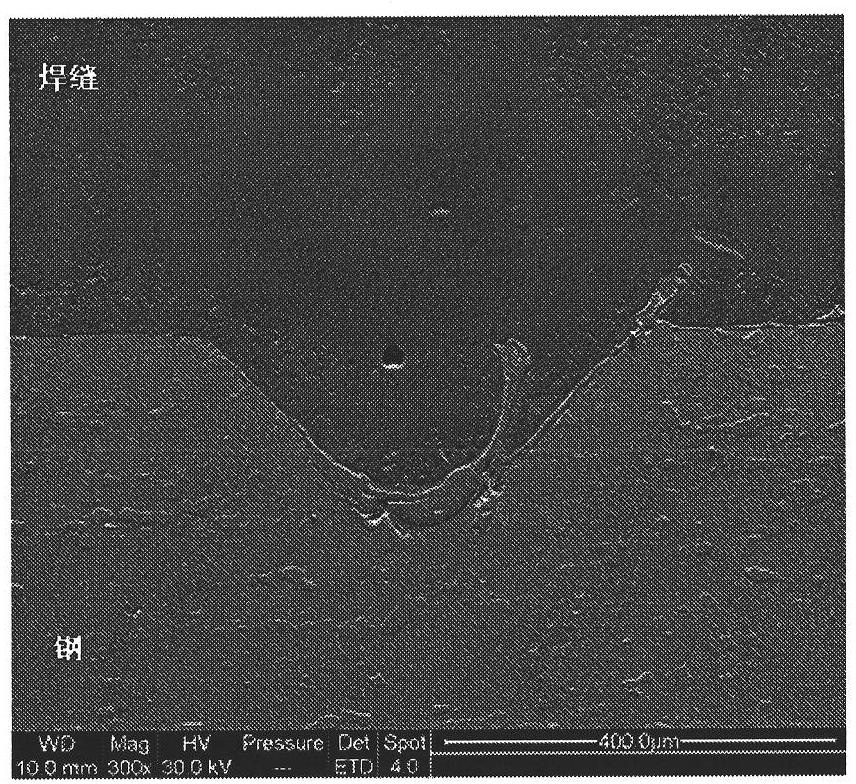

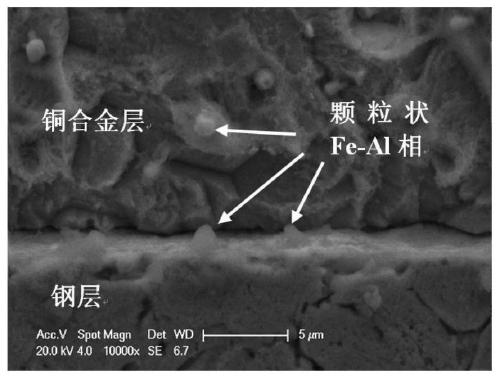

Method for connecting aluminum alloy and steel by laser filler wire

InactiveCN101941119AAchieve fusion-braze connectionPrecise control of heat inputLaser beam welding apparatusLap jointLaser beams

The invention relates to a method for connecting an aluminum alloy and steel by a laser filler wire, which is suitable for the field of dissimilar material connection and particularly suitable for the connection between dissimilar materials of which fusion points and thermal physical properties differ from each other greatly. The method comprises the following steps of: assembling a lap joint in which an aluminum plate is arranged on a steel plate, wherein a laser beam, a wire feeding nozzle and a protective gas nozzle are fixed in the same plane, the laser beam is vertically incident, and a laser focus, a wire dropping point of a welding wire and a protective gas feeding point are guaranteed to be consistent during welding; and melting the fed aluminum welding wire by using the laser to ensure that the molten aluminum welding wire is in fusion connection with the aluminum plate, simultaneously a micro fusion layer is formed on one side of the steel plate and then a fusion-braze welding connection is formed, thus the lap joint between dissimilar metals such as the aluminum alloy and the steel is realized. The method improves the connection efficiency between the dissimilar metals such as the aluminum alloy and the steel, and the tensile strength of the joint is over 149.6N / mm. The method solves the problems of long preparation time, low automation degree and poor reproducibility of welding results in the process of connecting pre-coated layers of the dissimilar materials such as welded-aluminum and the steel.

Owner:BEIJING UNIV OF TECH

Self-ionized and capacitively-coupled plasma for sputtering and resputtering

ActiveUS20080142359A1Raise the ratioIncrease plasma densityCellsElectric discharge tubesIonizationSputter deposition

A DC magnetron sputter reactor for sputtering deposition materials such as tantalum and tantalum nitride, for example, and its method of use, in which self-ionized plasma (SIP) sputtering and capacitively coupled plasma (CCP) sputtering are promoted, either together or alternately, in the same chamber. Also, bottom coverage may be thinned or eliminated by inductively-coupled plasma (ICP) resputtering. SIP is promoted by a small magnetron having poles of unequal magnetic strength and a high power applied to the target during sputtering. CCP is provided by a pedestal electrode which capacitively couples RF energy into a plasma. The CCP plasma is preferably enhanced by a magnetic field generated by electromagnetic coils surrounding the pedestal which act to confine the CCP plasma and increase its density.

Owner:APPLIED MATERIALS INC

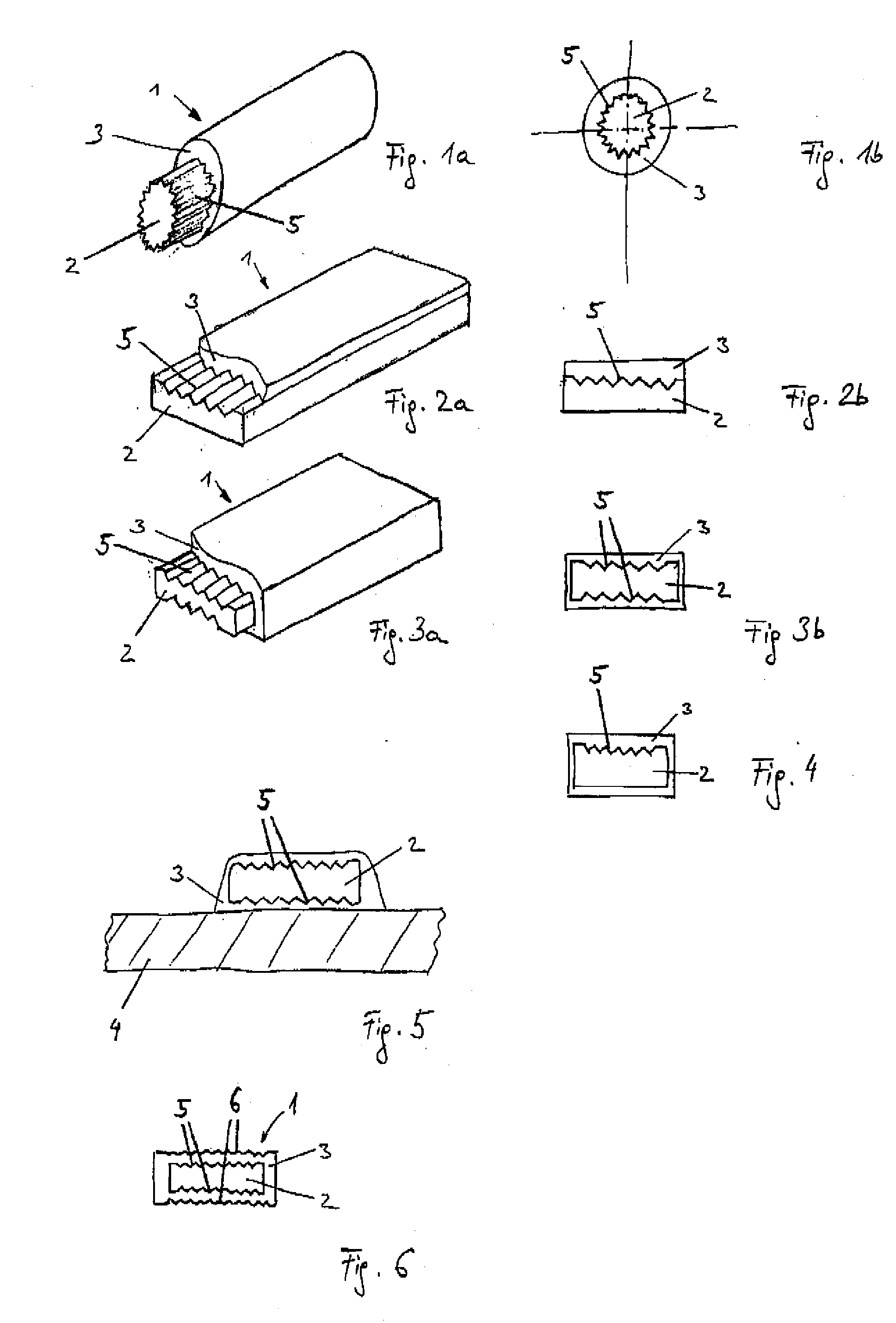

Electric connection element

InactiveUS20060272844A1Improve relationshipReduce layer thicknessSoldered/welded conductive connectionsPrinted circuit aspectsElectricityRough surface

An electric connection element includes an electric conductor having a surface configured, at least in regions thereof, with a structuring and / or rough surface, and an electrically conductive coating. As a result, the connection element can easily be handled and requires only little coating thickness.

Owner:OUTOKUMPU COPPER NEUMAYER

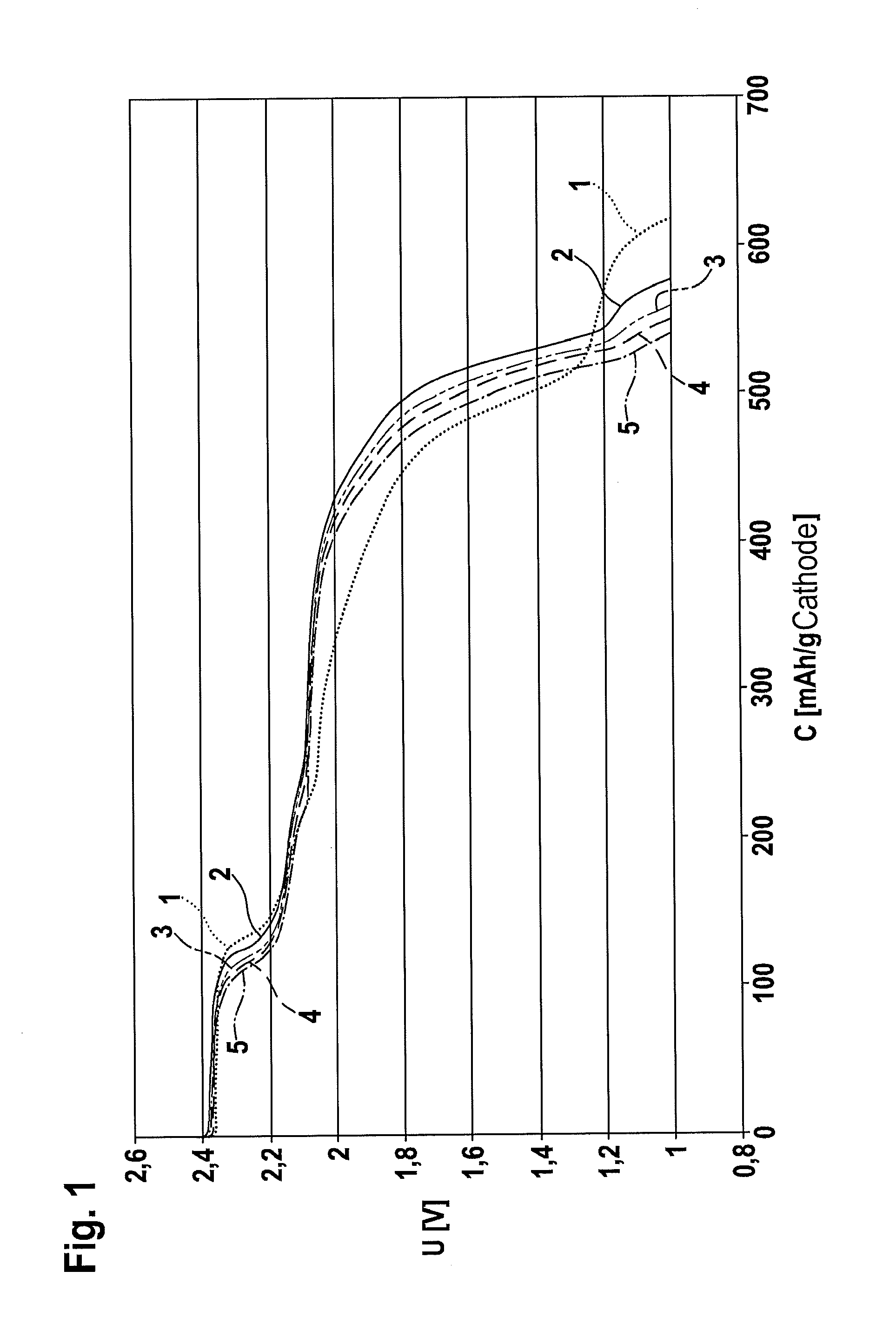

Cathode material for a lithium-sulfur battery

InactiveUS20130292613A1Increase contactImprove distributionElectrode melt handlingConductive materialSulfurGalvanic cell

A method for producing a cathode material for a cathode of a galvanic cell, such as a lithium or natrium sulfur cell. In order to improve the electric and ionic conductivity, the sulfur accessibility and utilization, elemental sulfur, at least one electrically conductive component and a solvent or a solvent mixture are mixed in method step a), the elemental sulfur being completely dissolved in the solvent or in the solvent mixture, and the solvent or solvent mixture is removed in a method step b).

Owner:ROBERT BOSCH GMBH

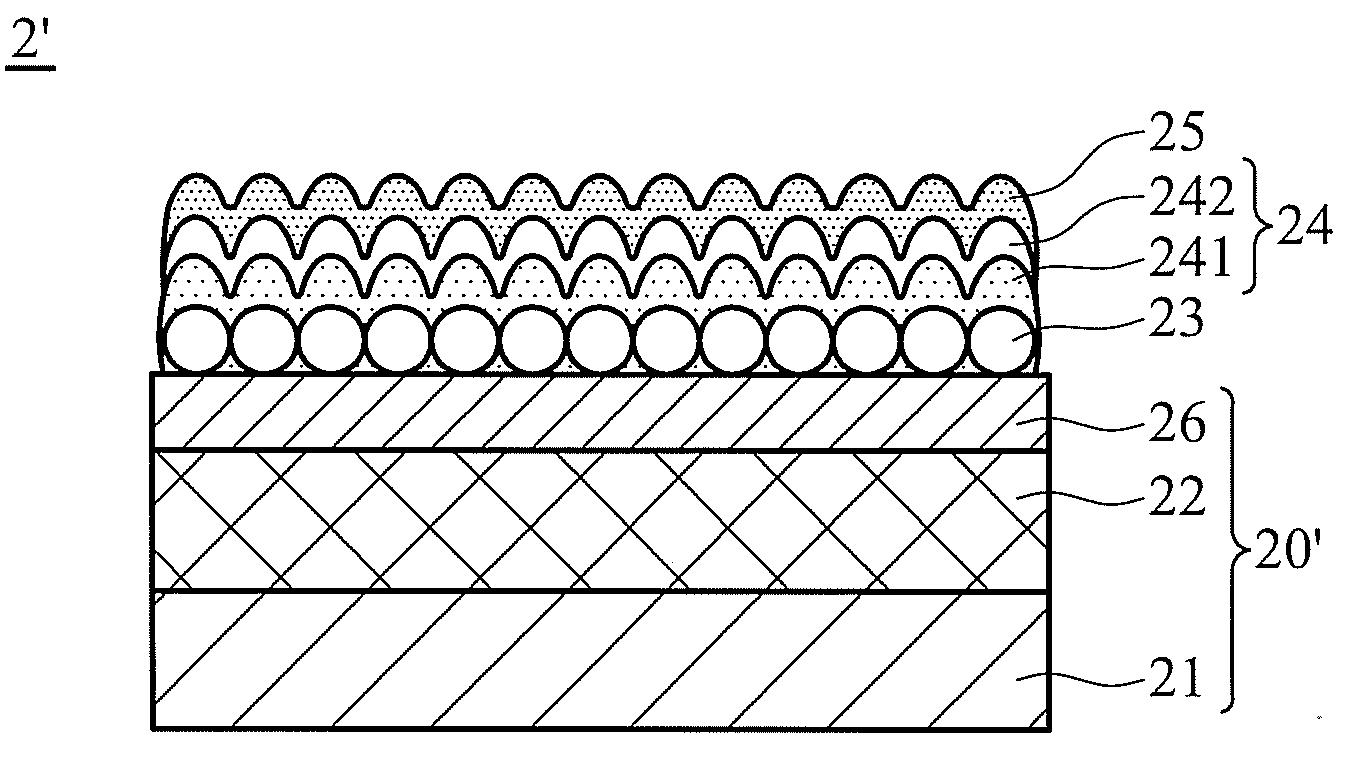

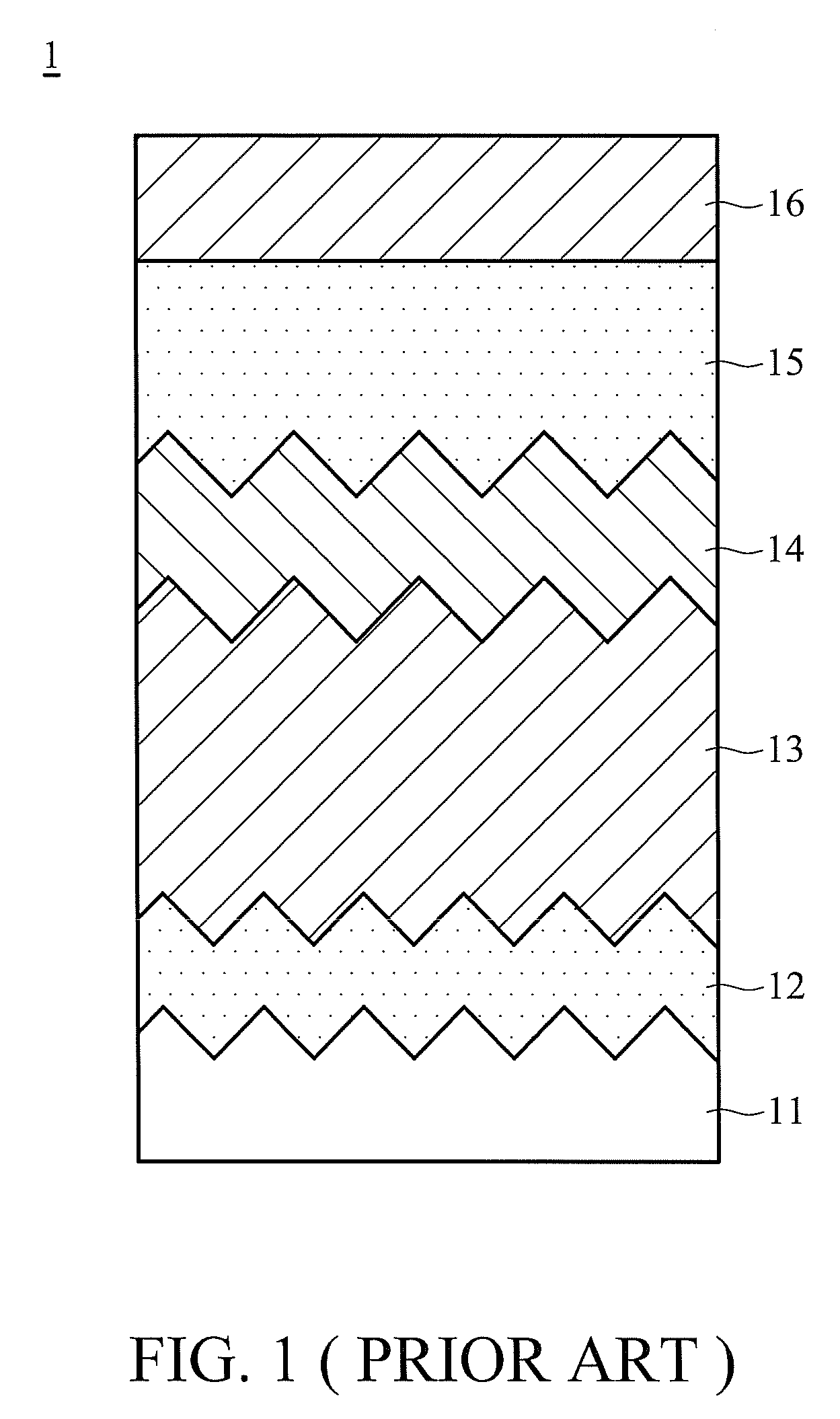

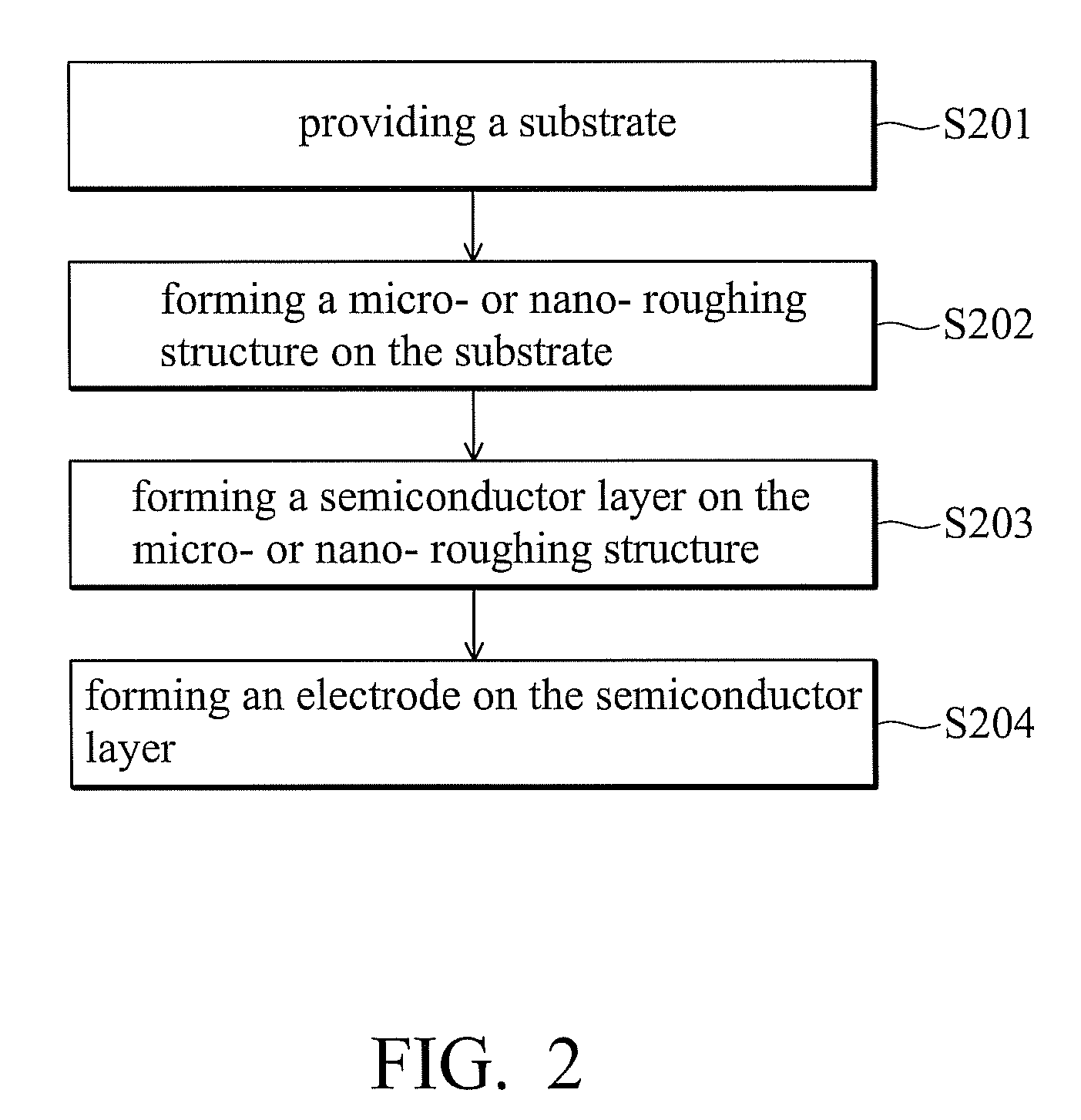

Solar cell and manufacturing method thereof

InactiveUS20090139571A1Reduce layer thicknessLight absorption efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringSolar cell

A solar cell and a manufacturing method thereof are provided herein. The solar cell includes a substrate with a first transparent conductive layer, a micro- or nano-roughing structure formed on the first transparent conductive layer, and a semiconductor active layer formed on the micro- or nano-roughing structure and covering the micro- or nano-roughing structure.

Owner:DELTA ELECTRONICS INC +1

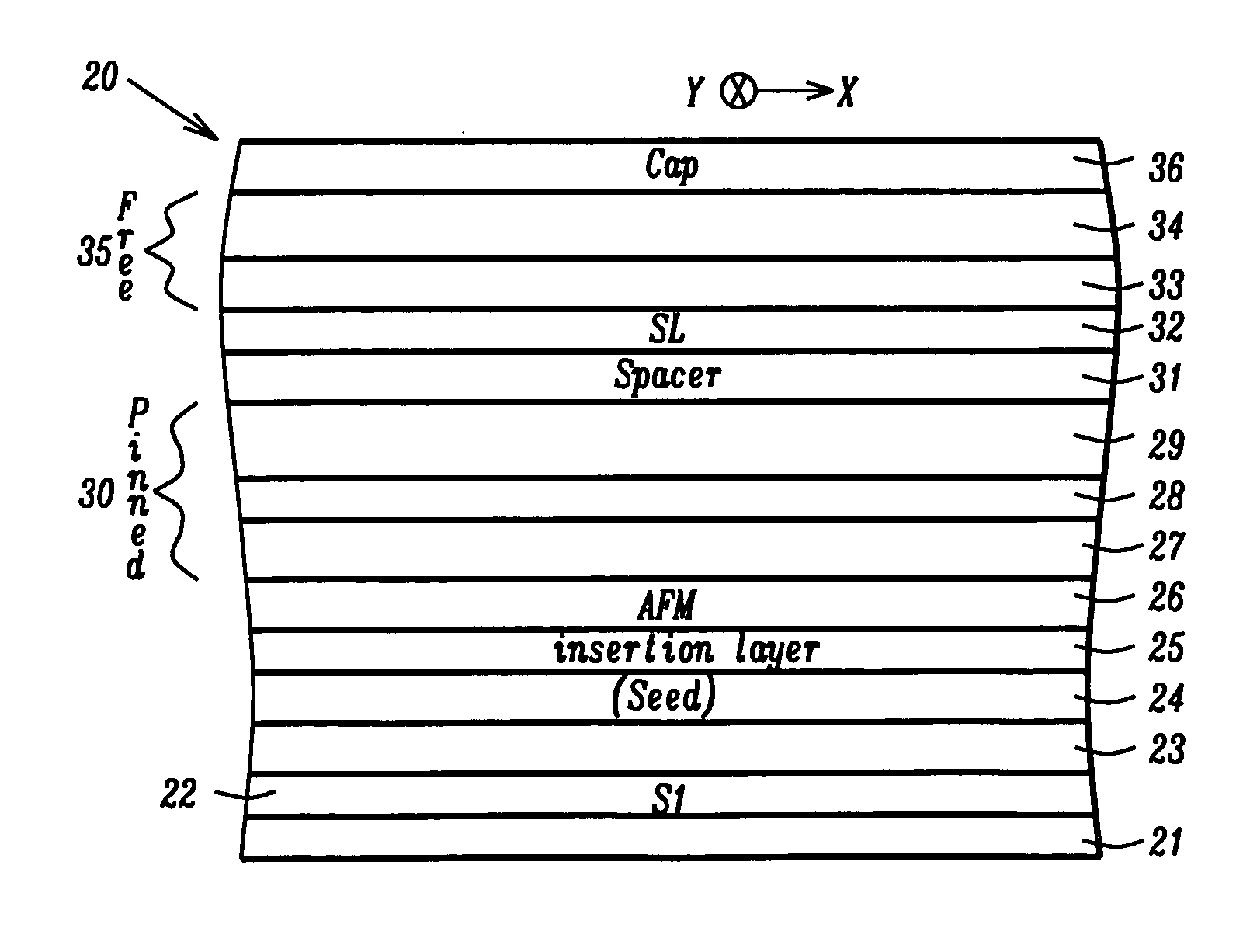

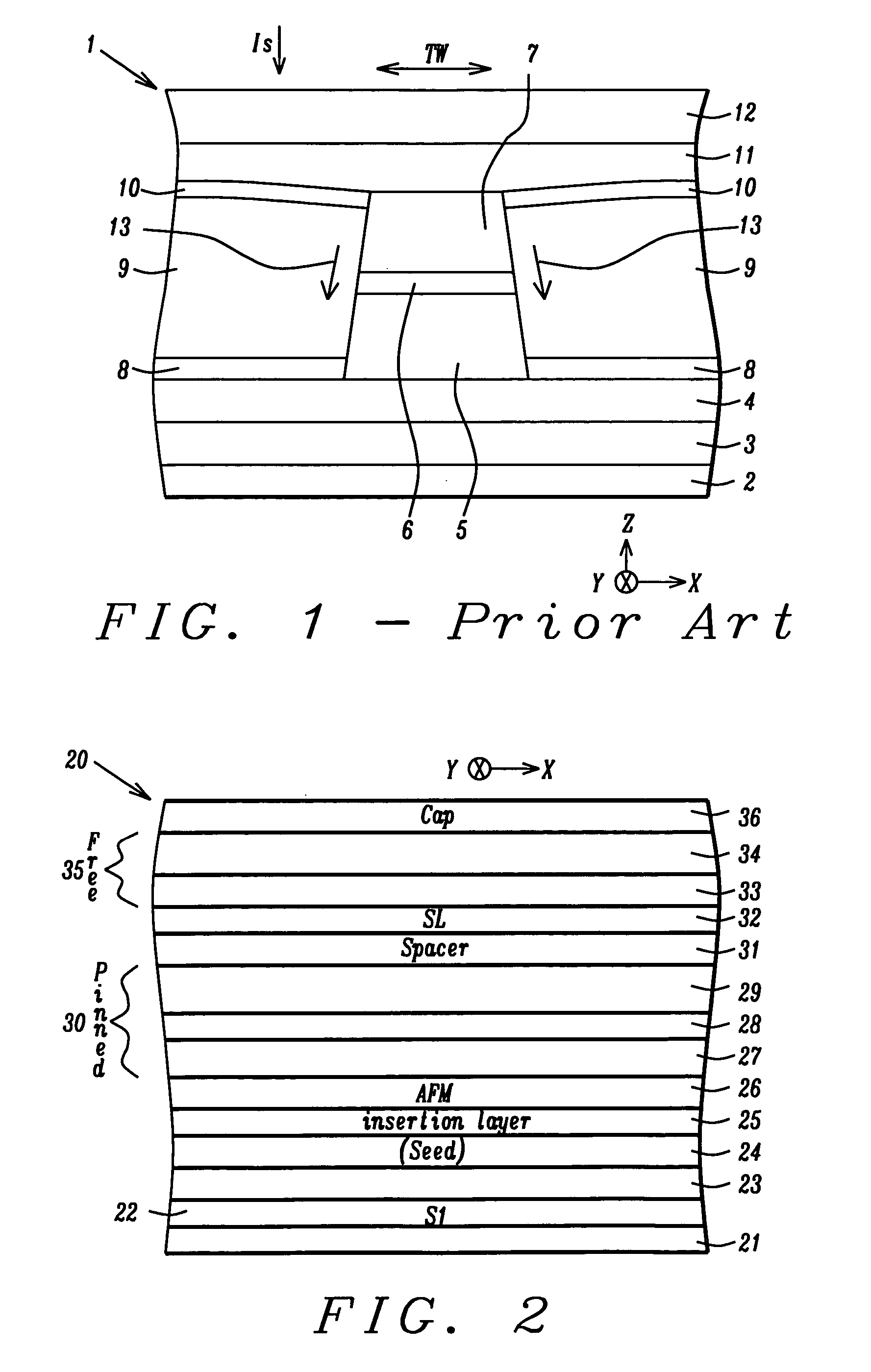

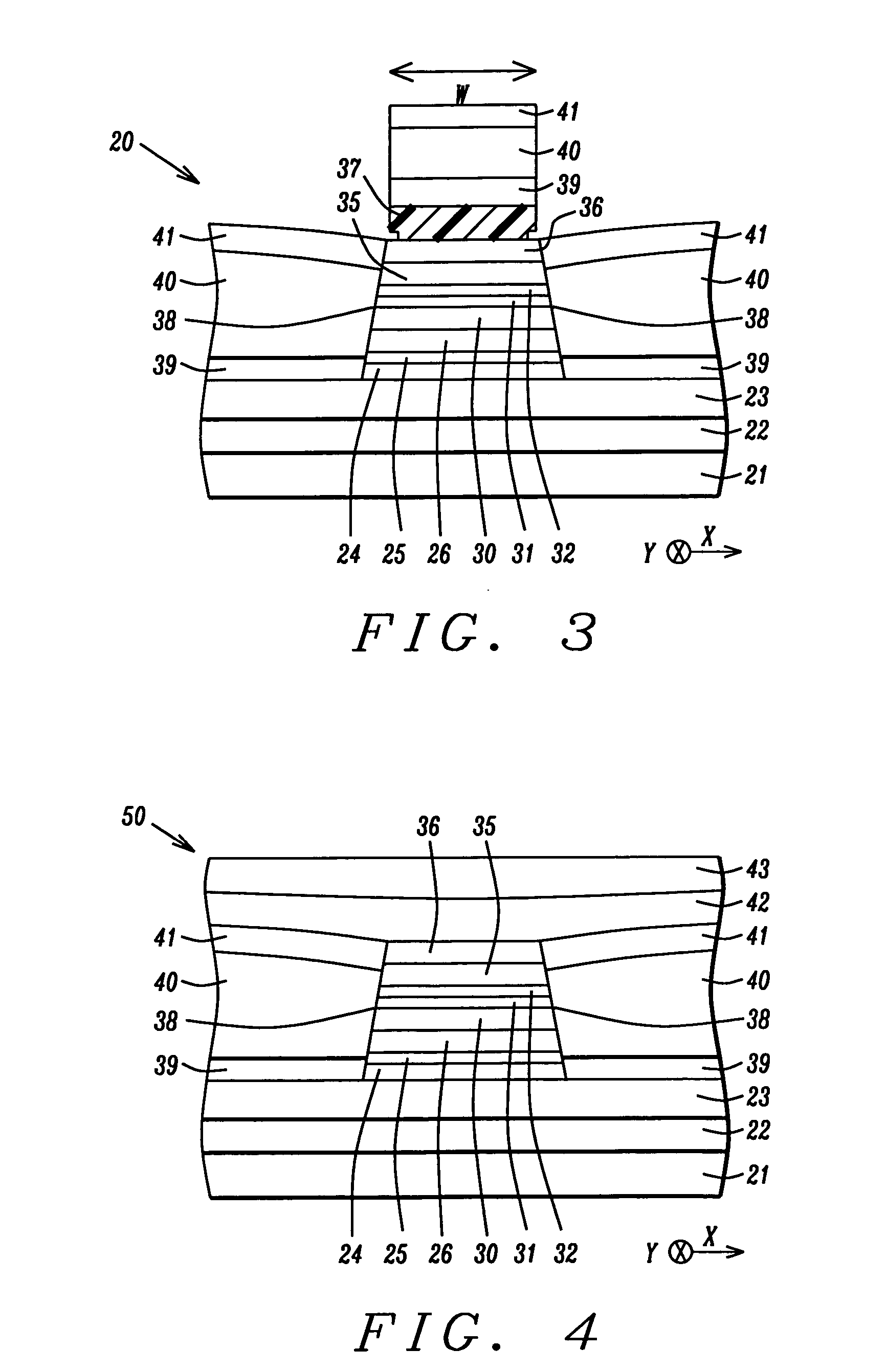

CoFe insertion for exchange bias and sensor improvement

ActiveUS20060061915A1Improved GMR ratioReduce couplingNanomagnetismMagnetic measurementsSputter depositionExchange bias

A GMR spin value structure with improved performance and a method for making the same is disclosed. A key feature is the incorporation of a thin ferromagnetic insertion layer such as a 5 Angstrom thick CoFe layer between a NiCr seed layer and an IrMn AFM layer. Lowering the Ar flow rate to 10 sccm for the NiCr sputter deposition and raising the Ar flow rate to 100 sccm for the IrMn deposition enables the seed layer to be thinned to 25 Angstroms and the AFM layer to about 40 Angstroms. As a result, HEX between the AFM and pinned layers increases by up to 200 Oe while the Tb is maintained at or above 250° C. When the seed / CoFe / AFM configuration is used in a read head sensor, a higher GMR ratio is observed in addition to smaller free layer coercivity (HCF), interlayer coupling (HE), and HK values.

Owner:HEADWAY TECH INC

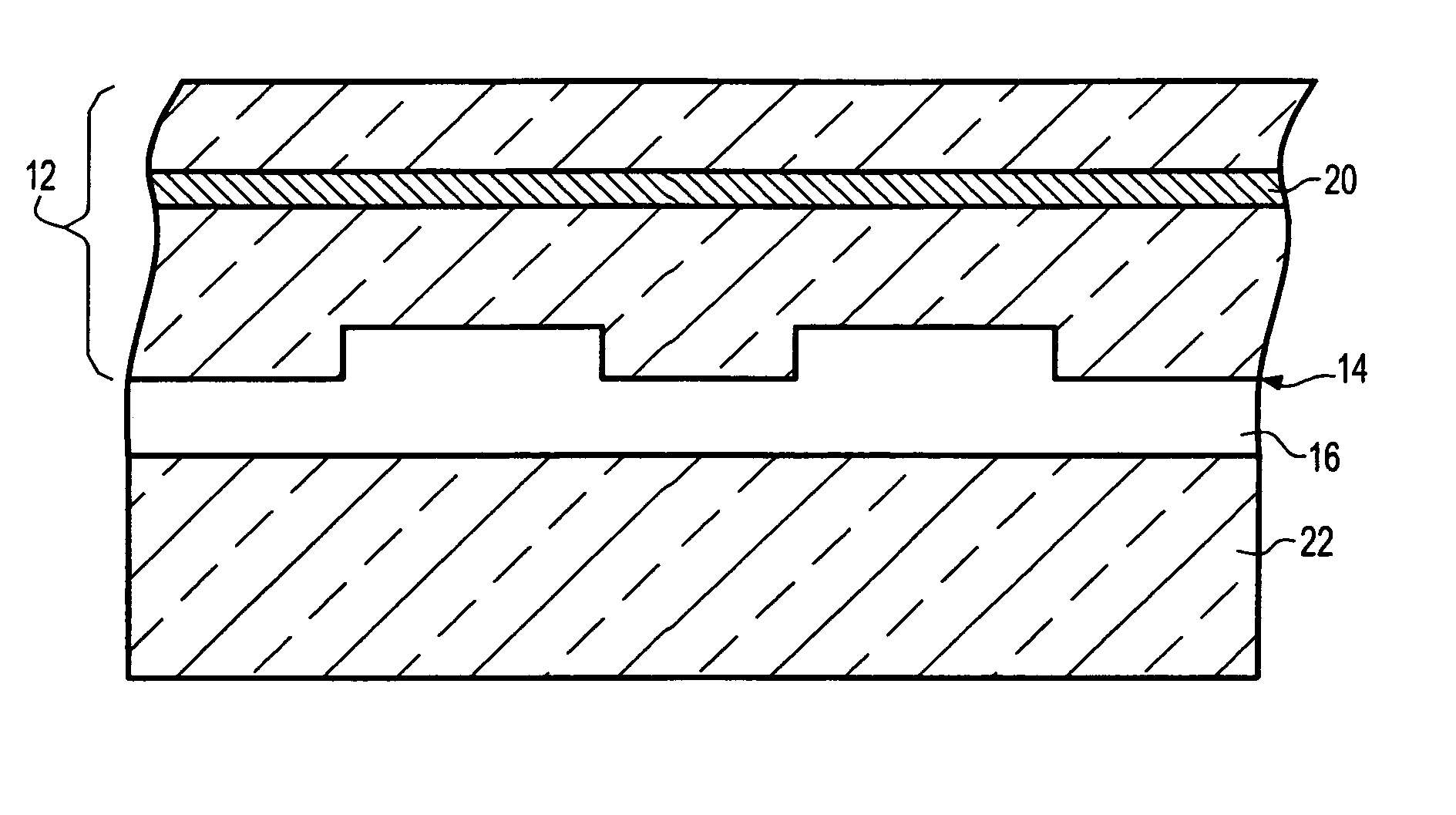

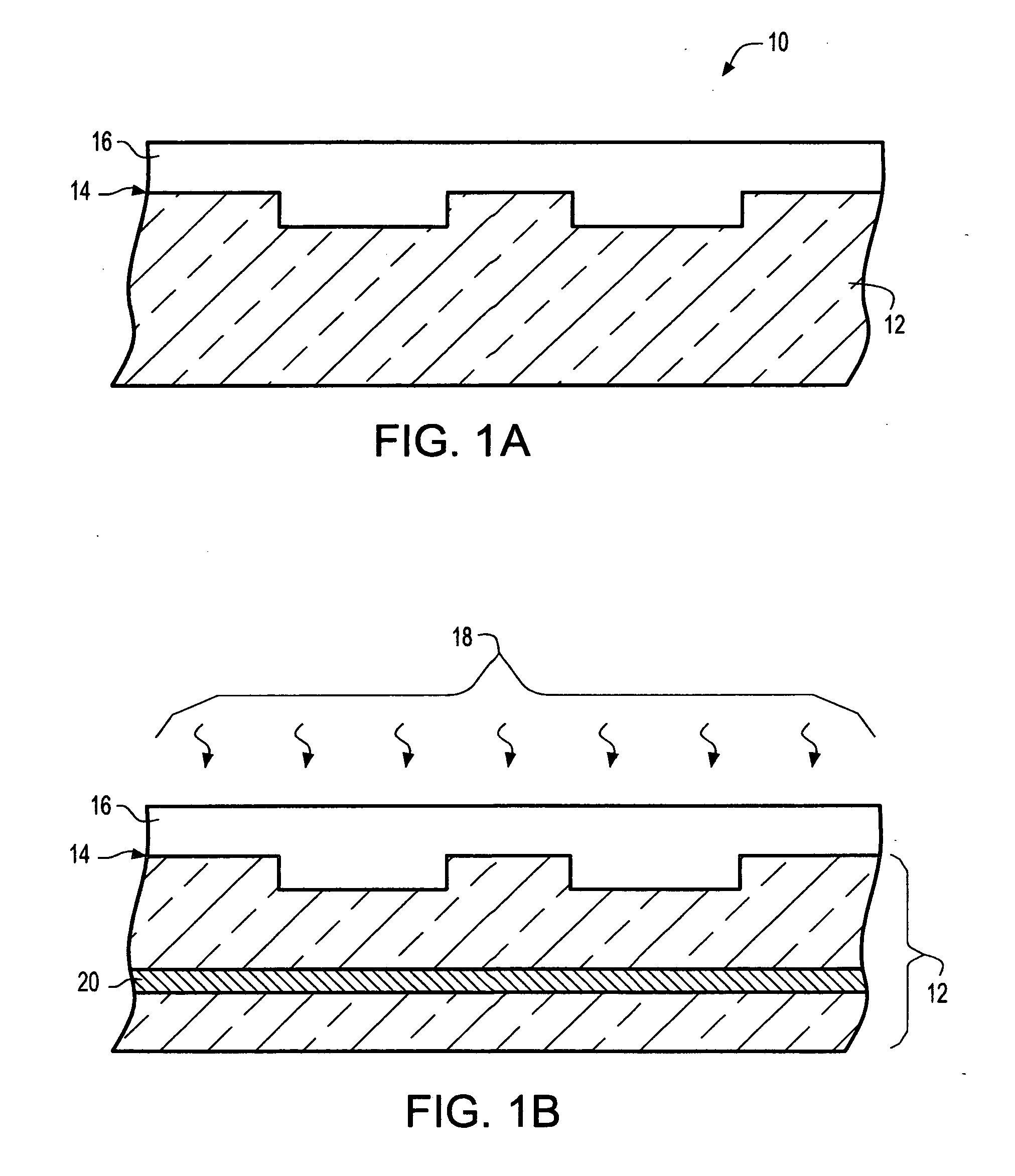

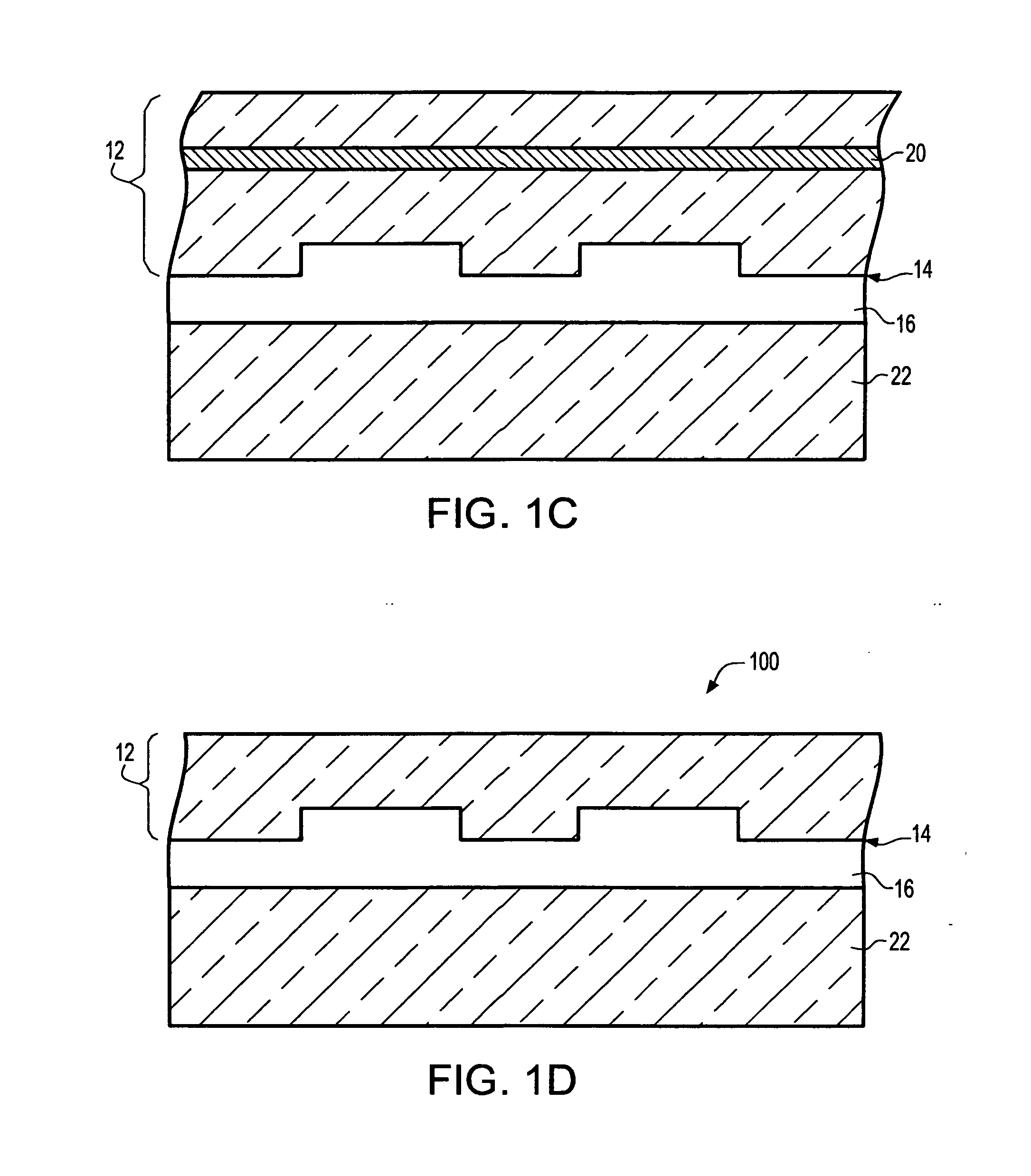

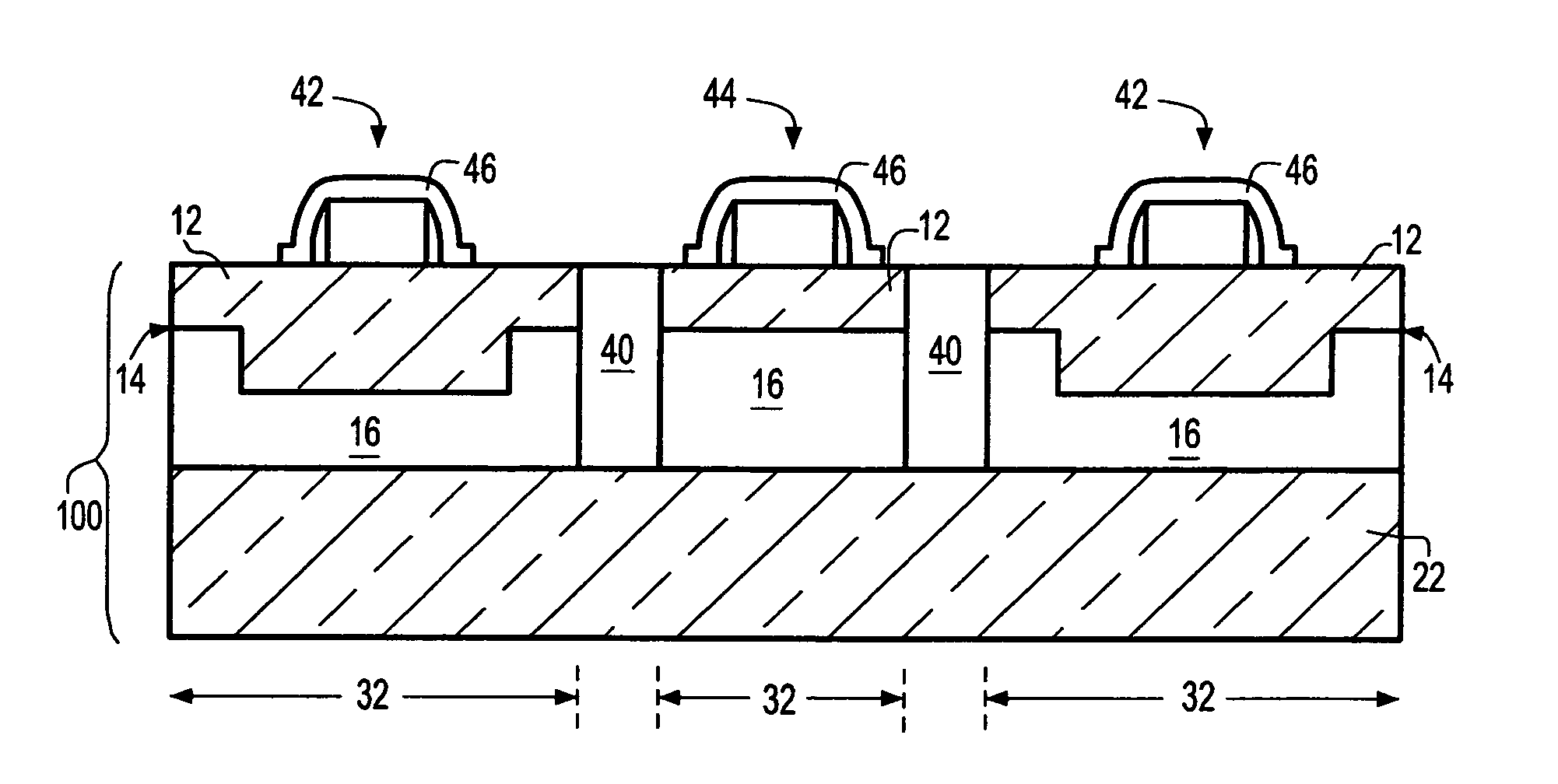

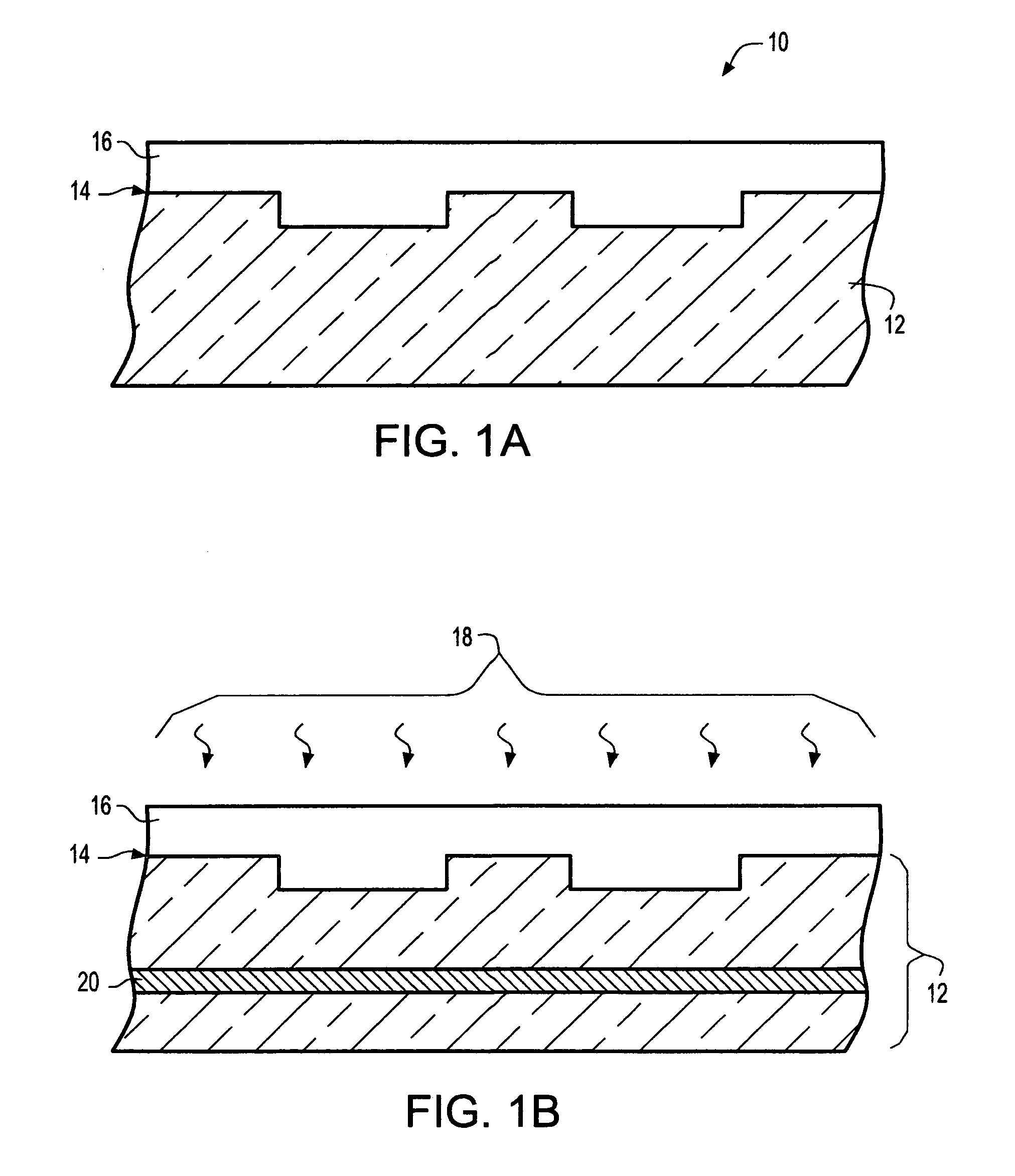

High performance field effect transistors on SOI substrate with stress-inducing material as buried insulator and methods

InactiveUS20060214225A1Enhance performanceHigh stressSemiconductor/solid-state device detailsSolid-state devicesStress inducedPerformance enhancement

The present invention provides a semiconductor structure that includes a high performance field effect transistor (FET) on a semiconductor-on-insulator (SOI) in which the insulator thereof is a stress-inducing material of a preselected geometry. Such a structure achieves performance enhancement from uniaxial stress, and the stress in the channel is not dependent on the layout design of the local contacts. In broad terms, the present invention relates to a semiconductor structure that comprises an upper semiconductor layer and a bottom semiconductor layer, wherein said upper semiconductor layer is separated from said bottom semiconductor layer in at least one region by a stress-inducing insulator having a preselected geometric shape, said stress-inducing insulator exerting a strain on the upper semiconductor layer.

Owner:GLOBALFOUNDRIES INC

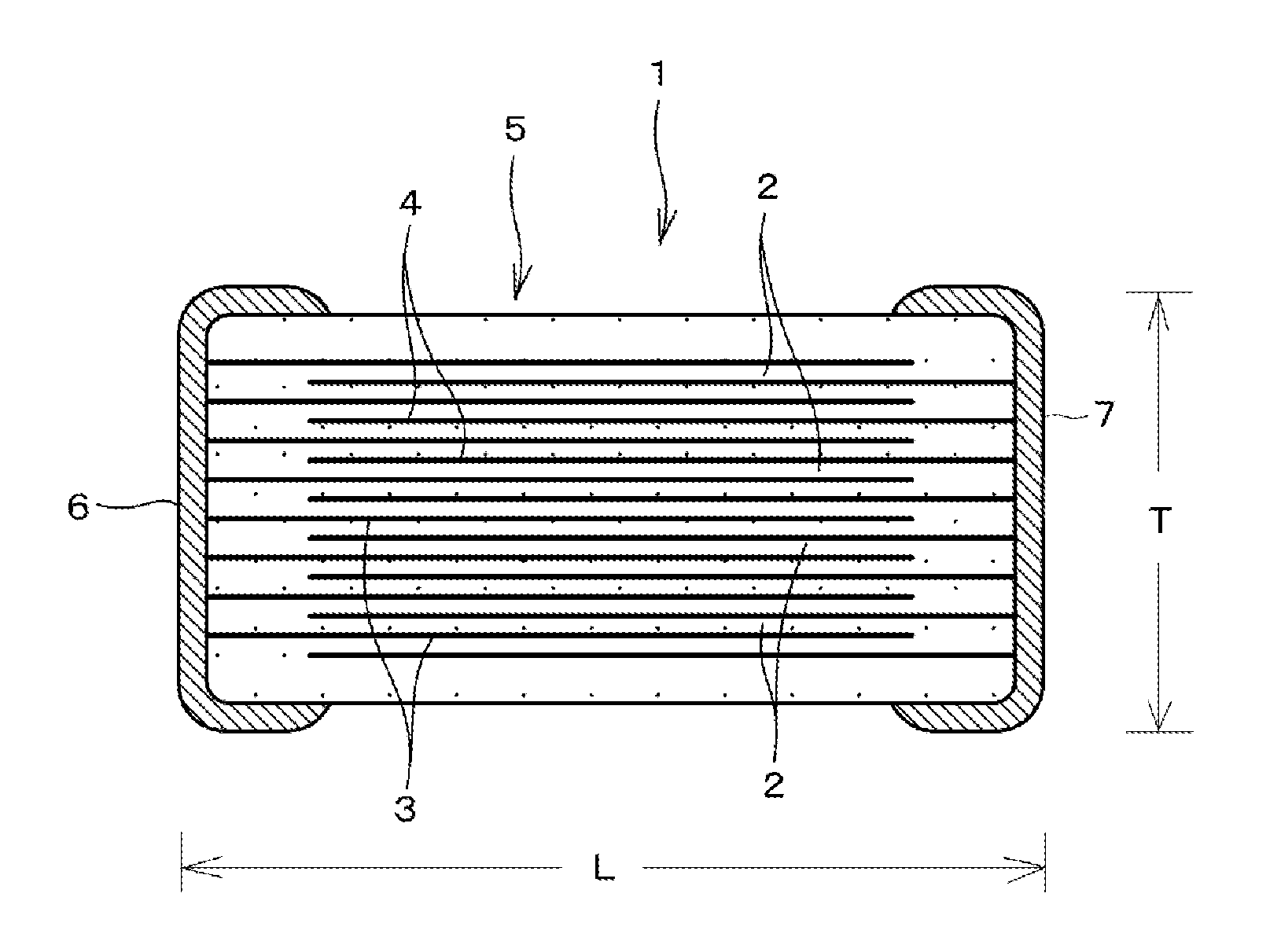

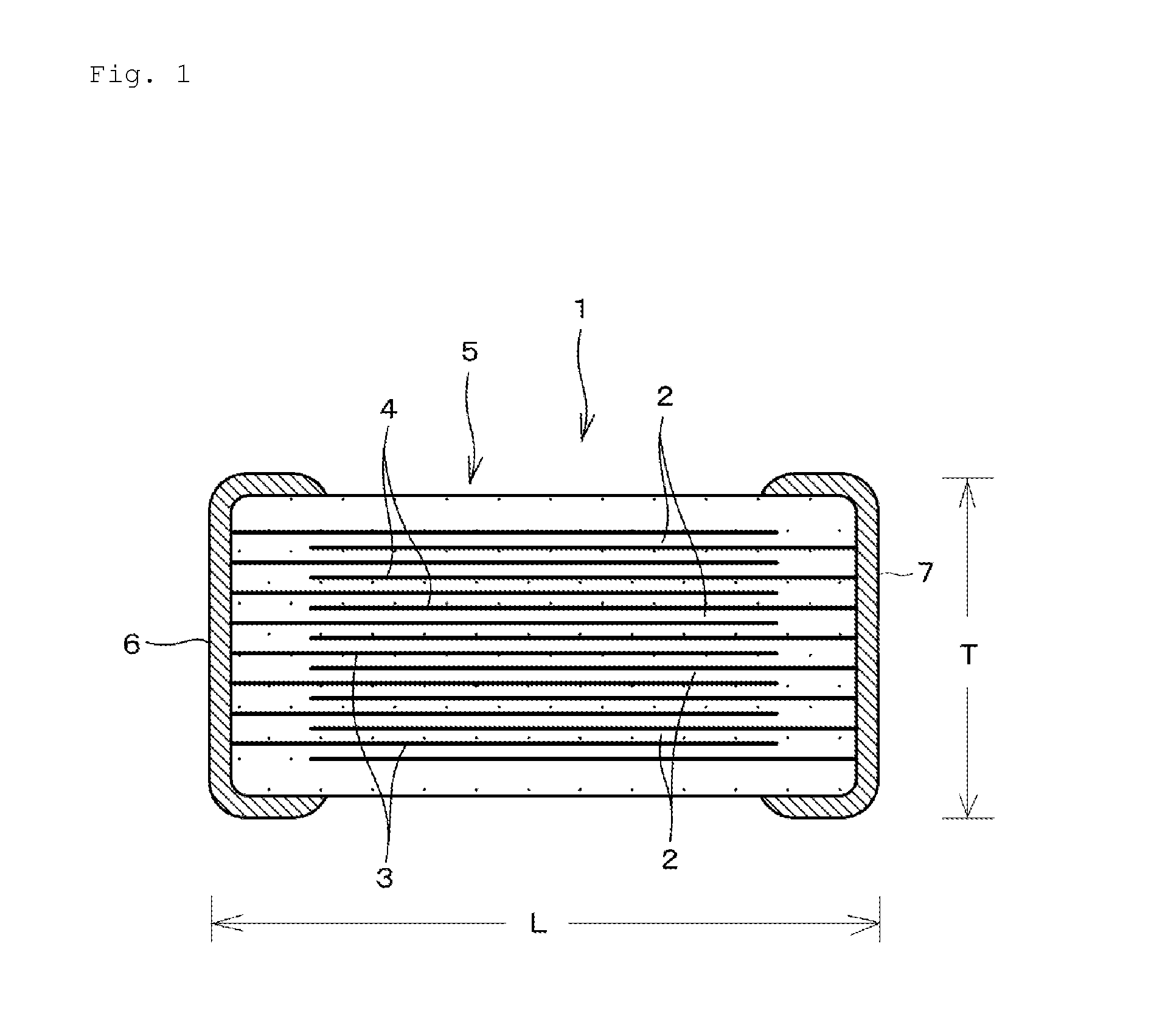

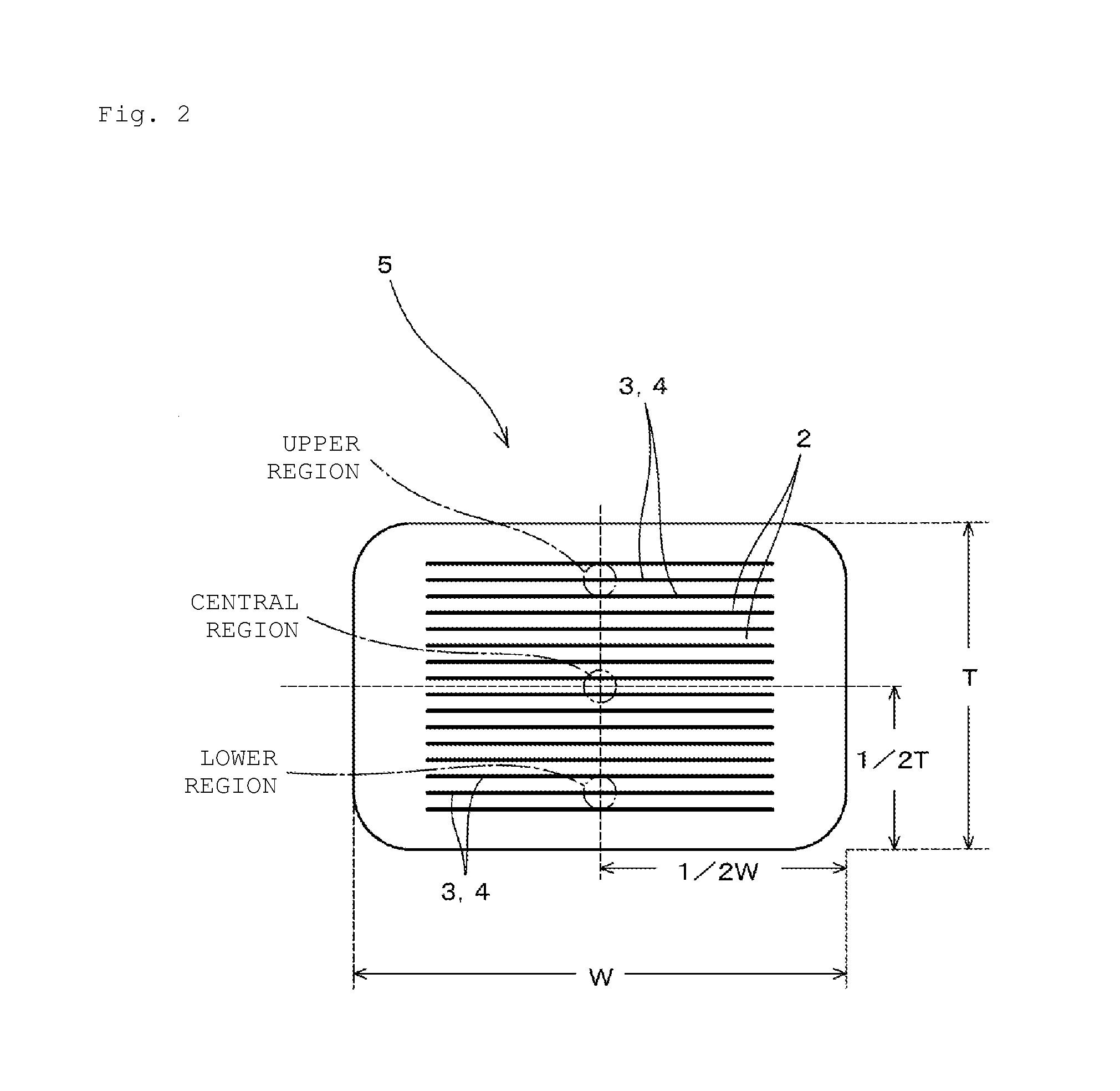

Laminated ceramic capacitor and method for manufacturing laminated ceramic capacitor

ActiveUS20150155098A1Improve reliabilityExcellent in high-temperature load lifeFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

A laminated ceramic capacitor that includes a ceramic laminated body having a stacked plurality of ceramic dielectric layers and a plurality of internal electrodes opposed to each other with the ceramic dielectric layers interposed therebetween, and external electrodes on the outer surface of the ceramic laminated body and electrically connected to the internal electrodes. The internal electrodes contain Ni and Sn, a proportion of the Sn / (Ni+Sn) ratio is 0.001 or more in molar ratio is 75% or more in a region of the internal electrode at a depth of 20 nm from a surface opposed to the ceramic dielectric layer, and the proportion of the Sn / (Ni+Sn) ratio is 0.001 or more in molar ratio is less than 40% in a central region in a thickness direction of the internal electrode.

Owner:MURATA MFG CO LTD

High performance field effect transistors on SOI substrate with stress-inducing material as buried insulator and methods

InactiveUS7388278B2Reduce parasitic capacitanceFast switching timeSemiconductor/solid-state device detailsSolid-state devicesStress inducedPerformance enhancement

The present invention provides a semiconductor structure that includes a high performance field effect transistor (FET) on a semiconductor-on-insulator (SOI) in which the insulator thereof is a stress-inducing material of a preselected geometry. Such a structure achieves performance enhancement from uniaxial stress, and the stress in the channel is not dependent on the layout design of the local contacts. In broad terms, the present invention relates to a semiconductor structure that comprises an upper semiconductor layer and a bottom semiconductor layer, wherein said upper semiconductor layer is separated from said bottom semiconductor layer in at least one region by a stress-inducing insulator having a preselected geometric shape, said stress-inducing insulator exerting a strain on the upper semiconductor layer.

Owner:GLOBALFOUNDRIES INC

Adhesive composition for optical filter, optical filter and display device

InactiveUS20090279168A1Prevent discolorationReduce manufacturing costNon-macromolecular adhesive additivesMirrorsVitrificationHigh humidity

The object of the invention is to provide an adhesive composition attaining, in a single layer, both adhesiveness capable of direct attachment to a glass plate disposed on the front face of a display device and desired optical filter functions and hardly undergoing the change in spectral characteristics attributable to deterioration in a light absorbing agent, even during long-time use, particularly at high temperature under high humidity, as well as an optical filter using this adhesive composition. The object is solved by an optical filter comprising an adhesive layer having optical filter functions, comprising a block copolymer (I) having at least a specific triblock structure in its molecule and having a weight average molecular weight of 50,000 or more and a molecular weight distribution (Mw / Mn) of less than 1.5, a resin (IV) having the glass transition temperature of 60° C. or more and one or more light absorbing agents (III) each having light absorption in a predetermined wavelength region.

Owner:DAI NIPPON PRINTING CO LTD

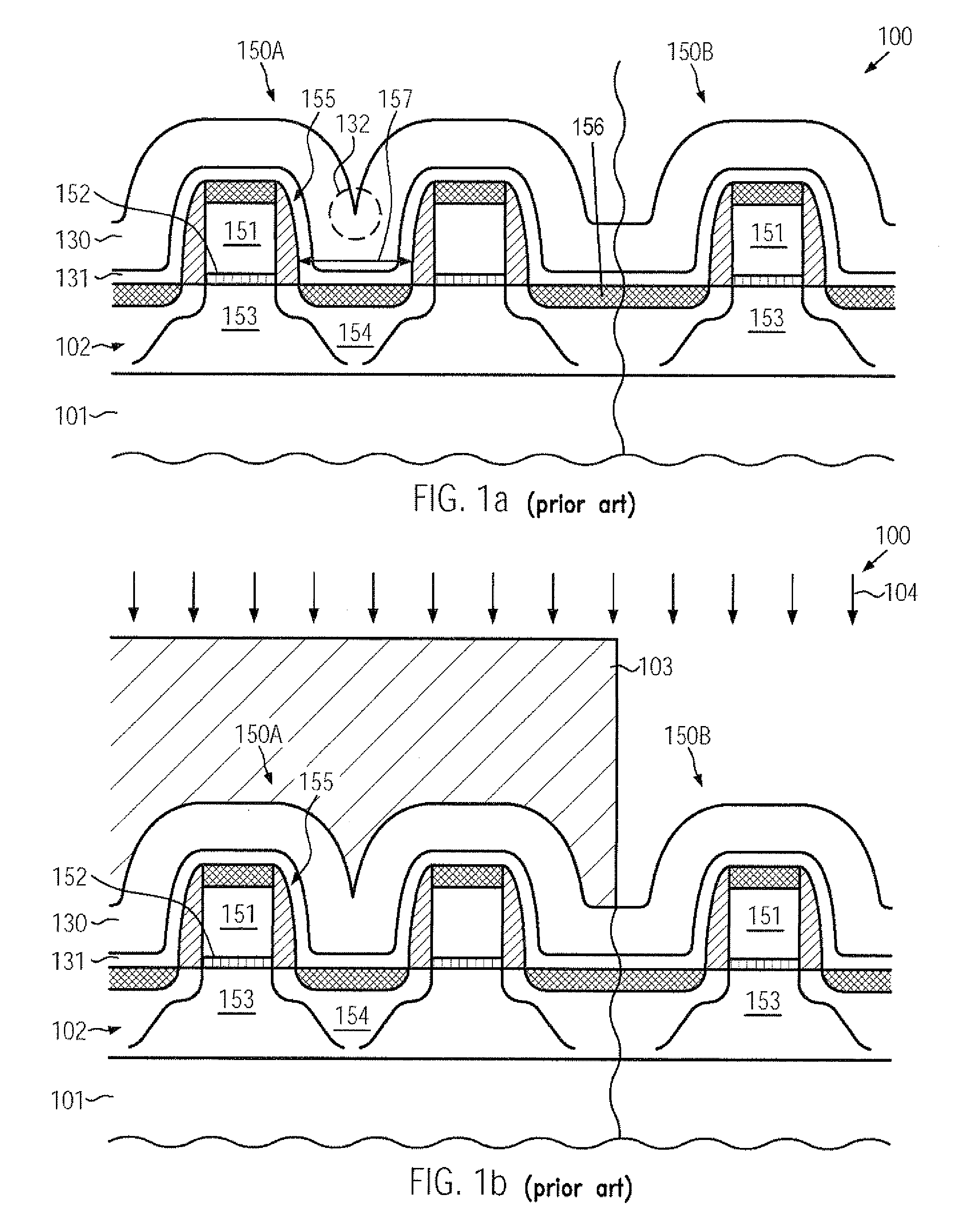

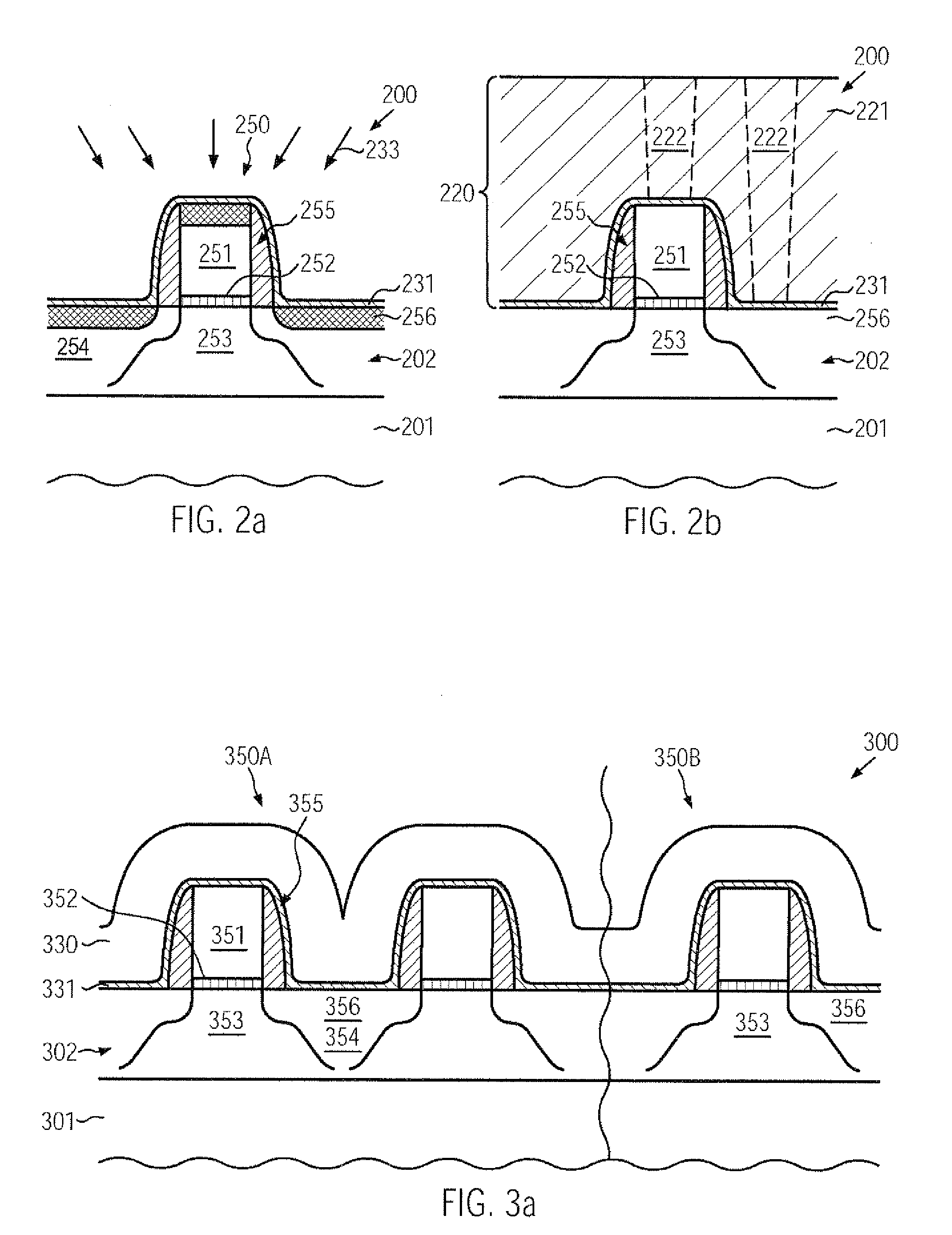

High-k etch stop layer of reduced thickness for patterning a dielectric material during fabrication of transistors

InactiveUS20100090321A1Reduce thicknessIncrease volumeSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceTransistor

By providing a high-k dielectric etch stop material as an etch stop layer for patterning an interlayer dielectric material, enhanced performance and higher flexibility may be achieved since, for instance, an increased amount of highly stressed dielectric material may be positioned more closely to the respective transistors due to the reduced thickness of the high-k dielectric etch stop material.

Owner:ADVANCED MICRO DEVICES INC

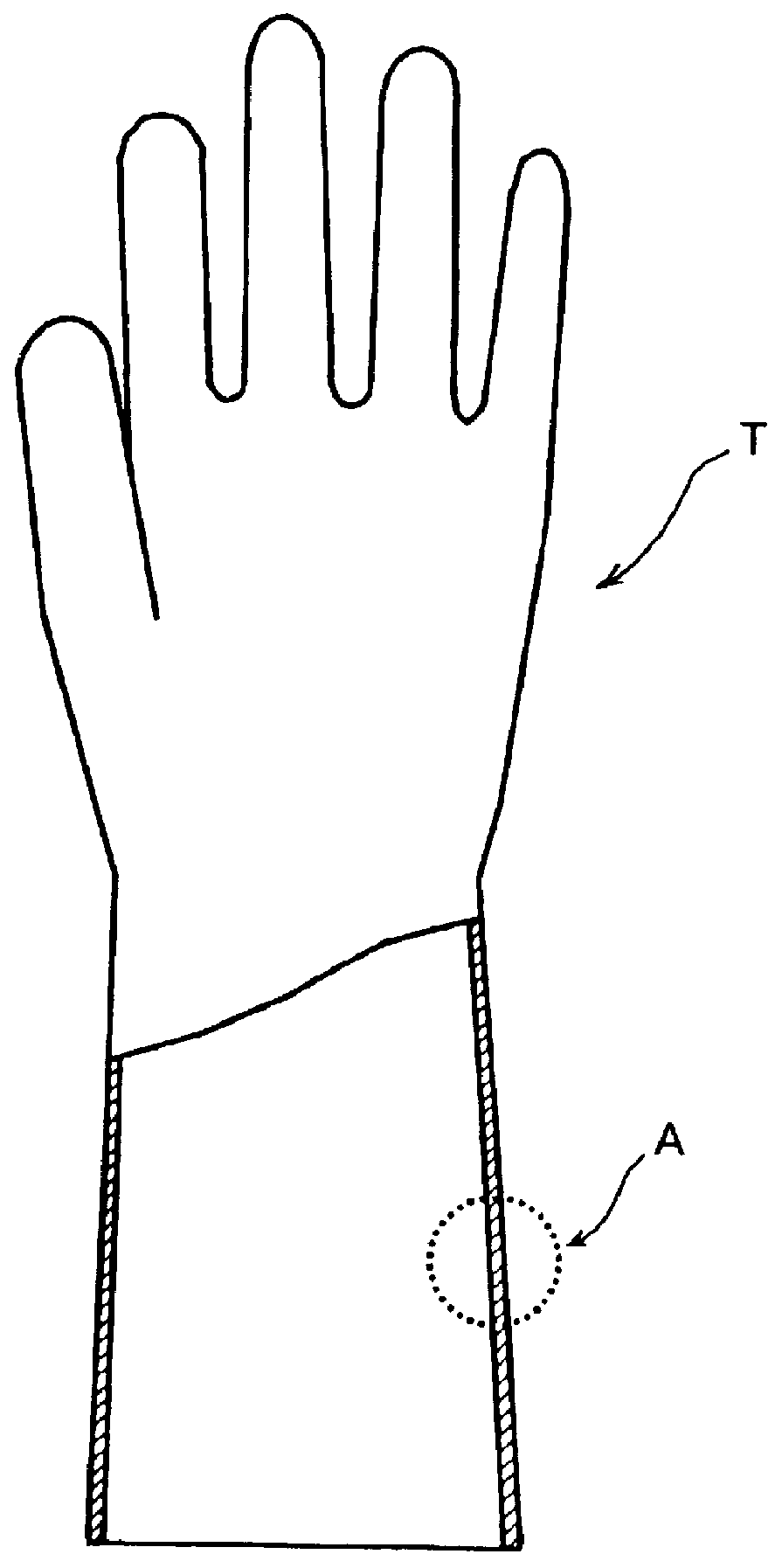

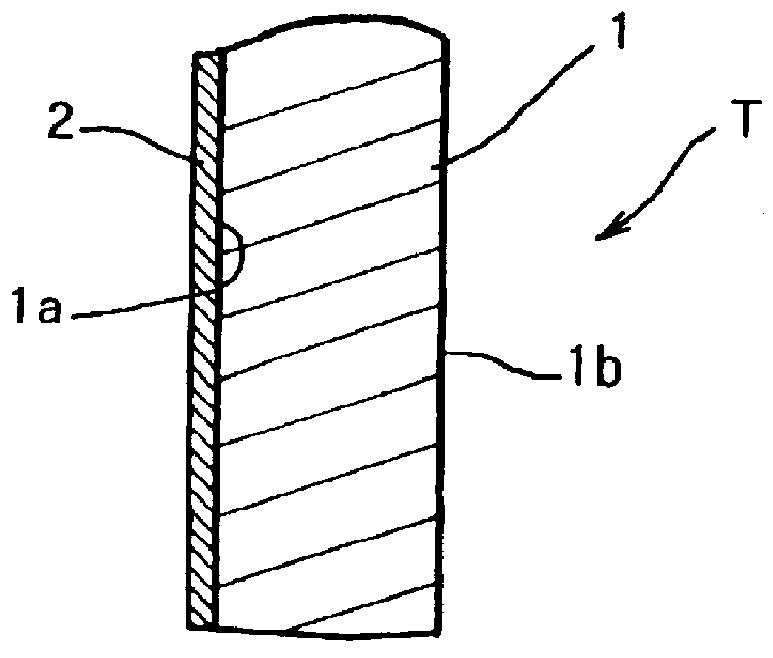

Glove made of polyvinyl chloride resin

InactiveUS6012169AReduce layeringReduce layer thicknessGarment special featuresAntifouling/underwater paintsCost competitivenessAntimicrobial

Owner:SHOWA CORP

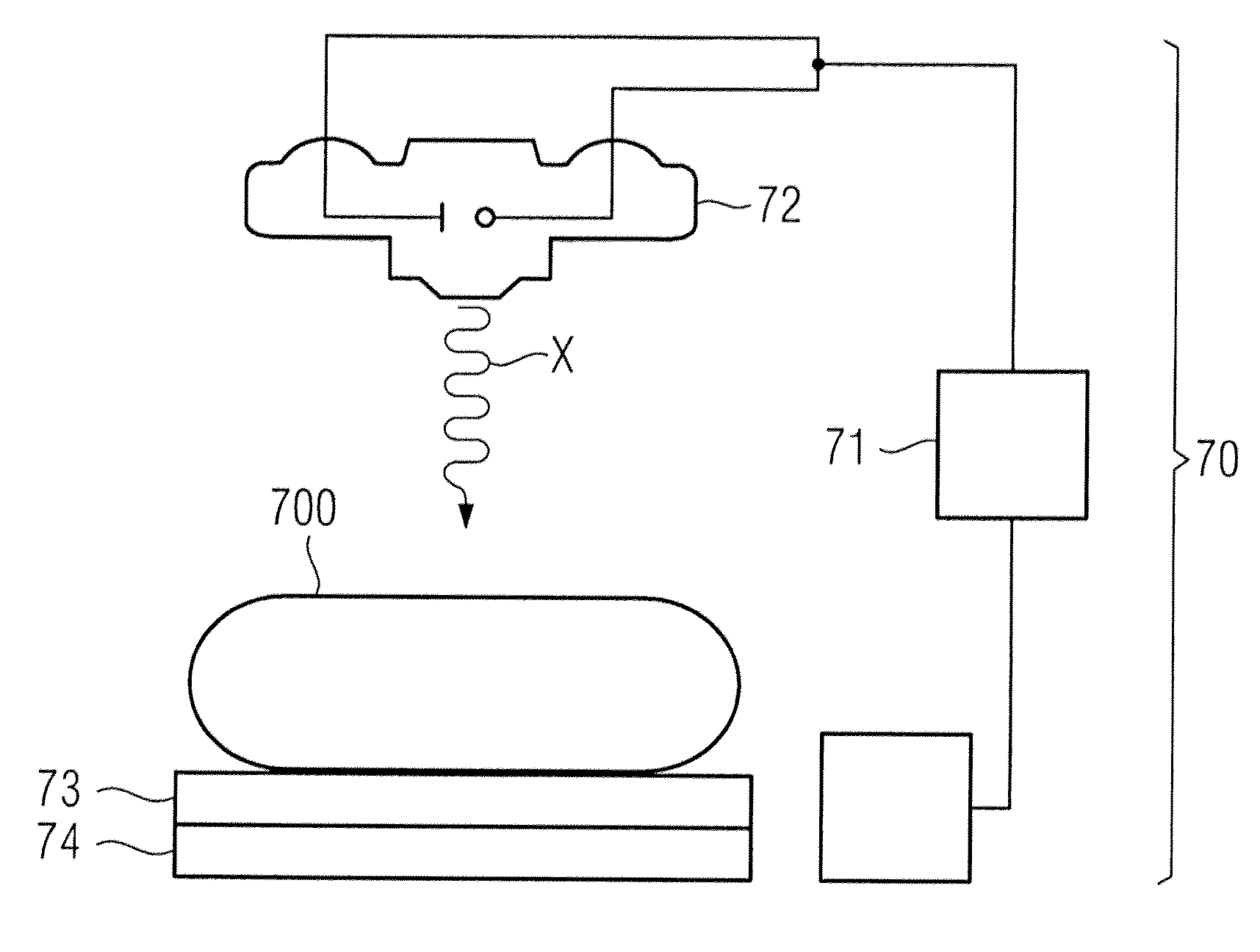

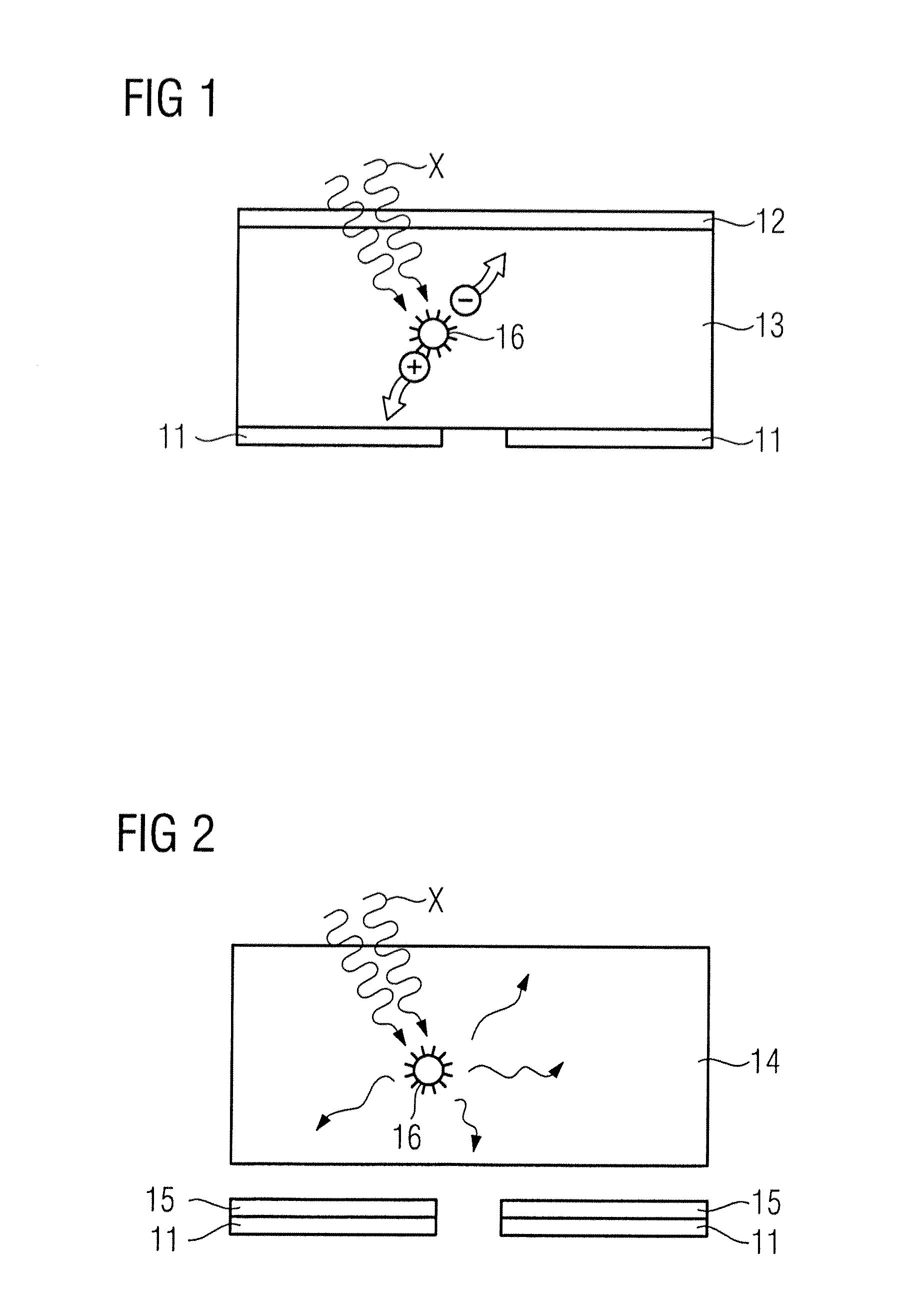

Hybrid organic photodiode

InactiveUS20120121067A1Reduce layer thicknessReduce absorptionDosimetersMaterial analysis by optical meansPhysicsElectron hole

An x-ray detector that is suitable for both imaging and dose rate measurement has a hybrid photoactive layer arranged between an electrode and a substrate. The hybrid photoactive layer includes a number of scintillators as well as a bulk heterojunction and is designed to produce indirect x-ray conversion. The bulk heterojunction absorbs the scintillator radiation to form electron-hole pairs that are detected electrically. The production takes place by a spraying process, in particular a co-spraying process of bulk heterojunction solution and scintillator particle suspension.

Owner:SIEMENS HEALTHCARE GMBH

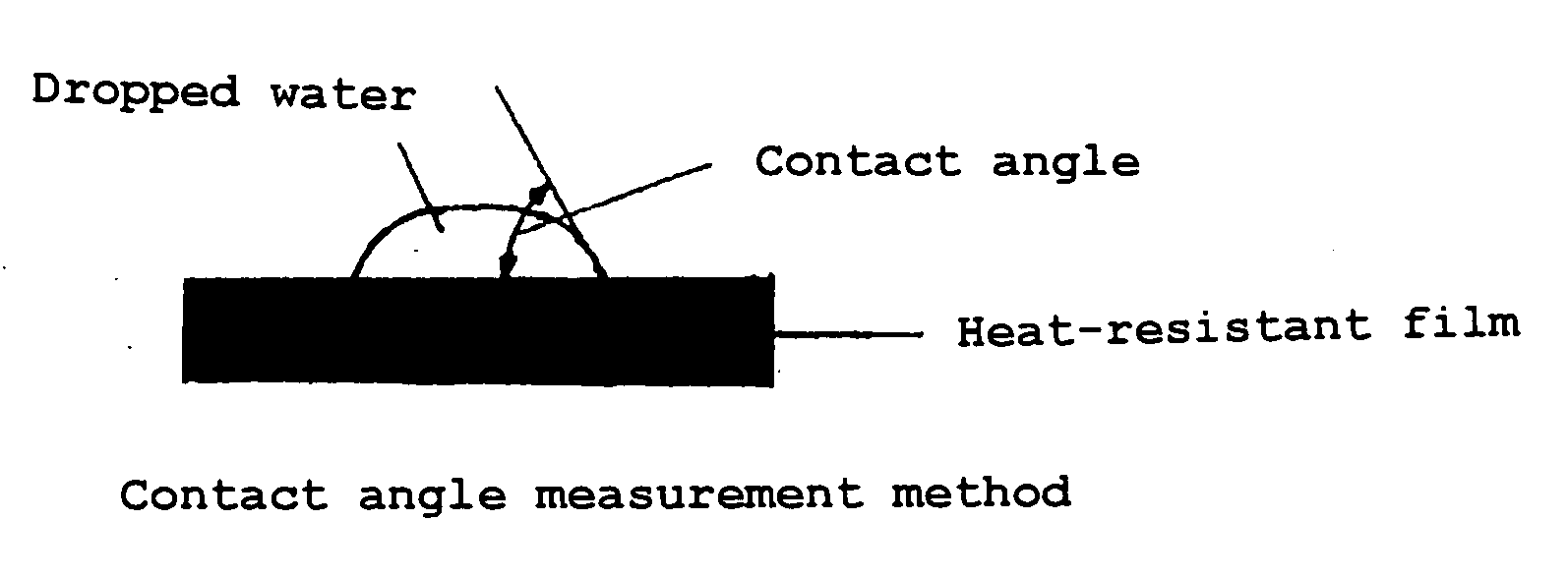

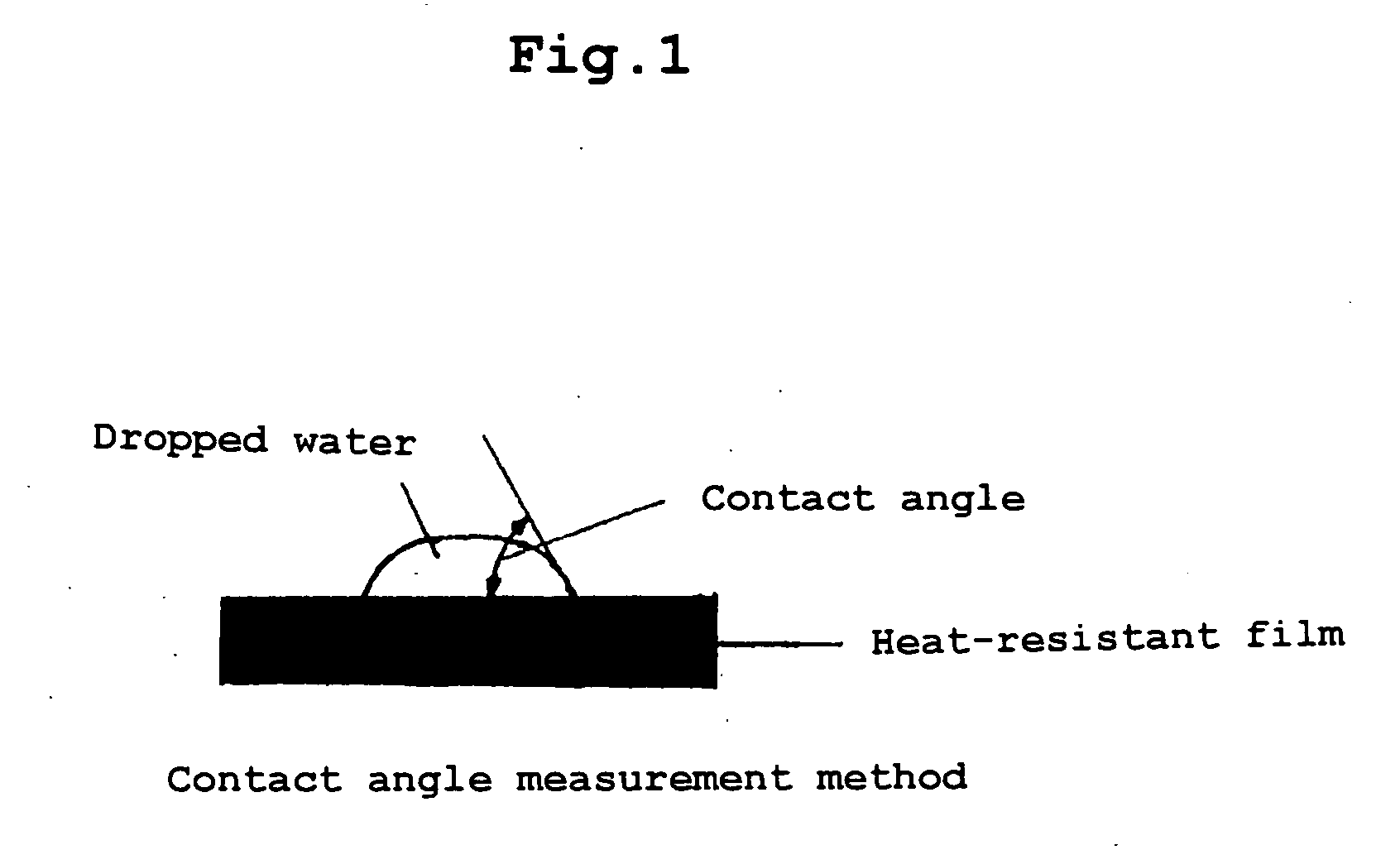

Heat-resistant film base-material-inserted B-staged resin composition sheet excellent in adhesion to resin, multilayer board using the sheet and manufacturing process of the multilayer board

InactiveUS20040091688A1Improve heat resistanceImprove reliabilityLamination ancillary operationsSynthetic resin layered productsHeat resistanceFilm base

A heat-resistant film base-material-inserted B-staged resin composition sheet obtainable by adhering a layer of a B-staged resin composition to a heat-resistant film base material, wherein the heat-resistant film base material is plasma-treated before adhering the B-staged resin composition layer, a multilayer board using the above heat-resistant film base-material-inserted B-staged resin composition sheet in a buildup layer and / or a bonding layer, and a manufacturing process of the multilayer board.

Owner:MITSUBISHI GAS CHEM CO INC

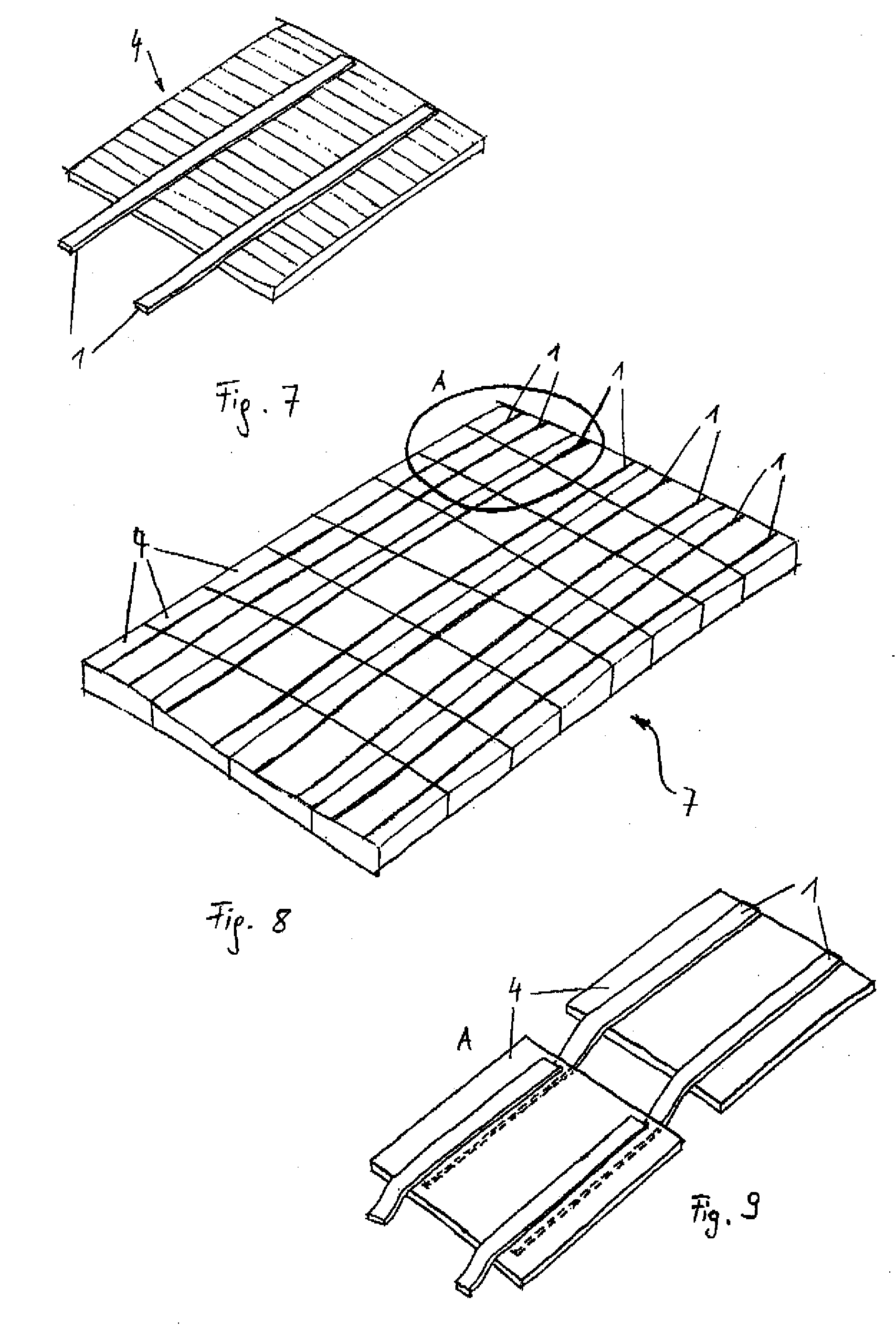

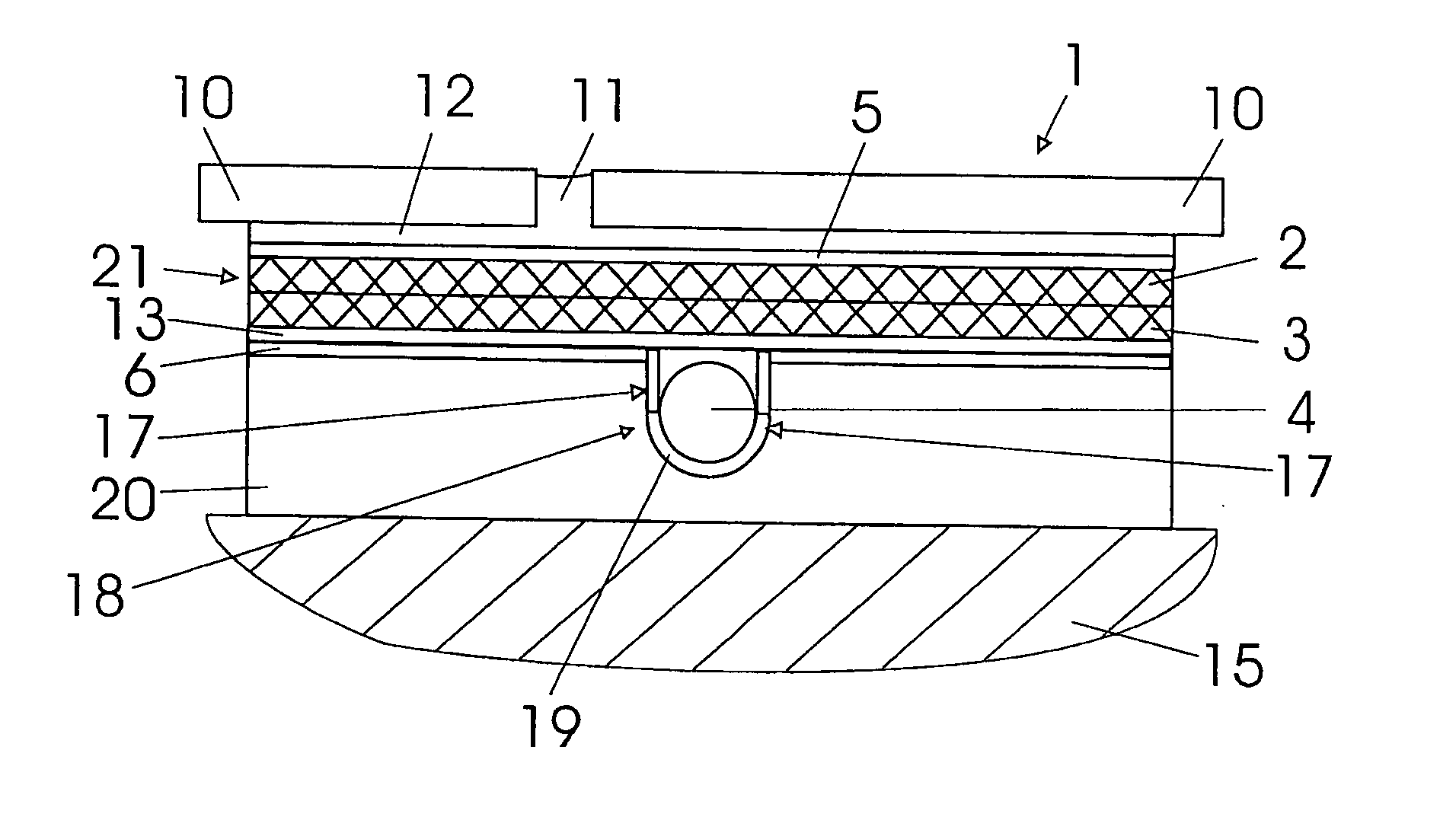

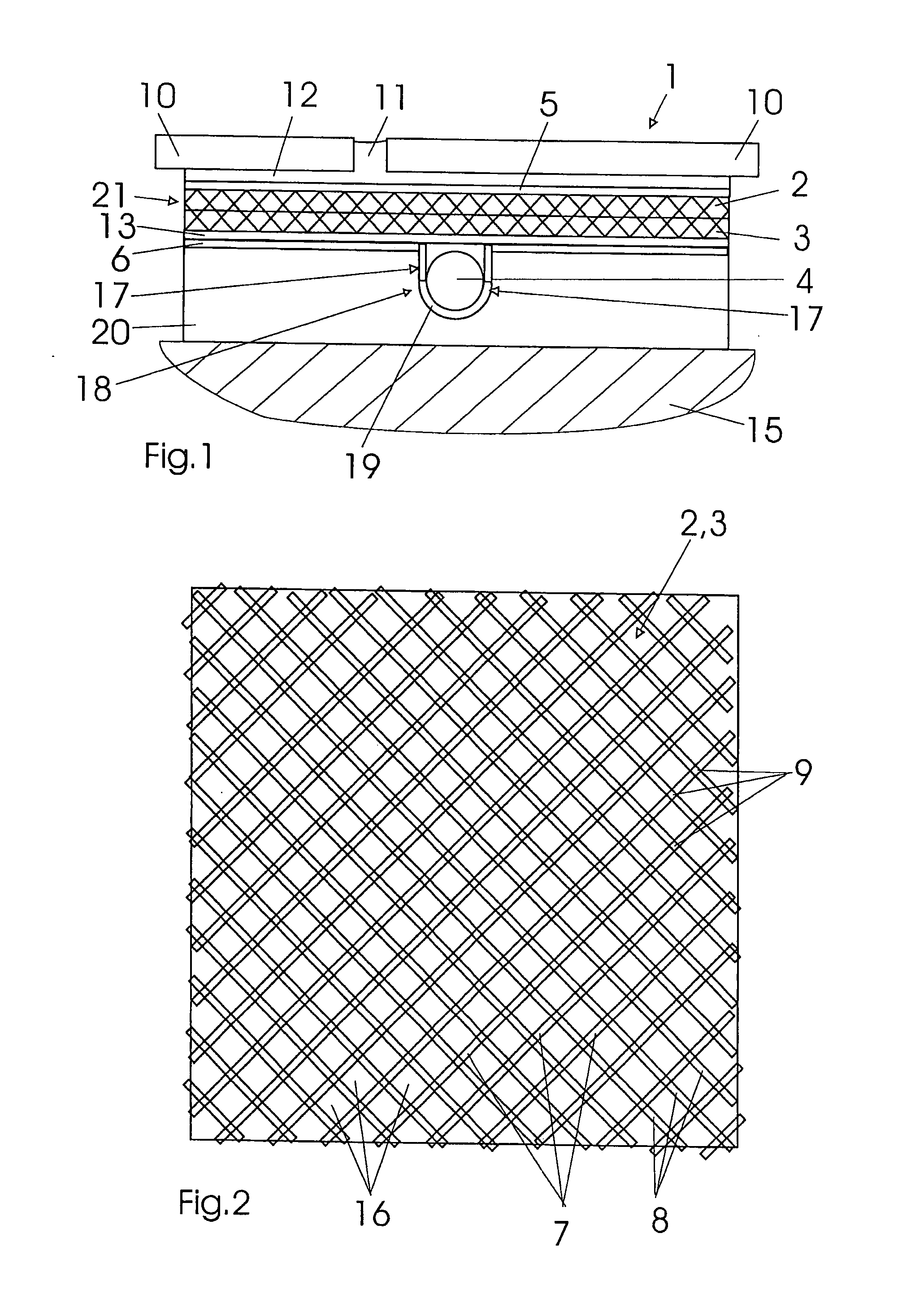

Multi-layer build-up system for floor coverings when using floor heating systems

InactiveUS20080083833A1Improve relationshipEasy to embedFluid heatersHot-air central heatingEngineeringStructuring element

A multi-layer build-up system for floor coverings when using floor heating systems, particularly for laying ceramic floor coverings using the thin-bed method, has, on the underside, an essentially plate-shaped component for planar laying and for the accommodation of pipelines of a floor heating system. Component accommodation spaces for the pipelines are formed in the plate-shaped component and an uncoupling mat is disposed on the surface of the plate-shaped component. The uncoupling mat has an uncoupling layer on top of which an anchoring layer is disposed. The anchoring layer forms a structure element for a filler mass to be introduced in the top of the build-up system. The mass is plastic during processing and hardens afterwards. A reinforcement layer is disposed on top of and rigidly connected with the anchoring layer, at least in sections.

Owner:BLANKE

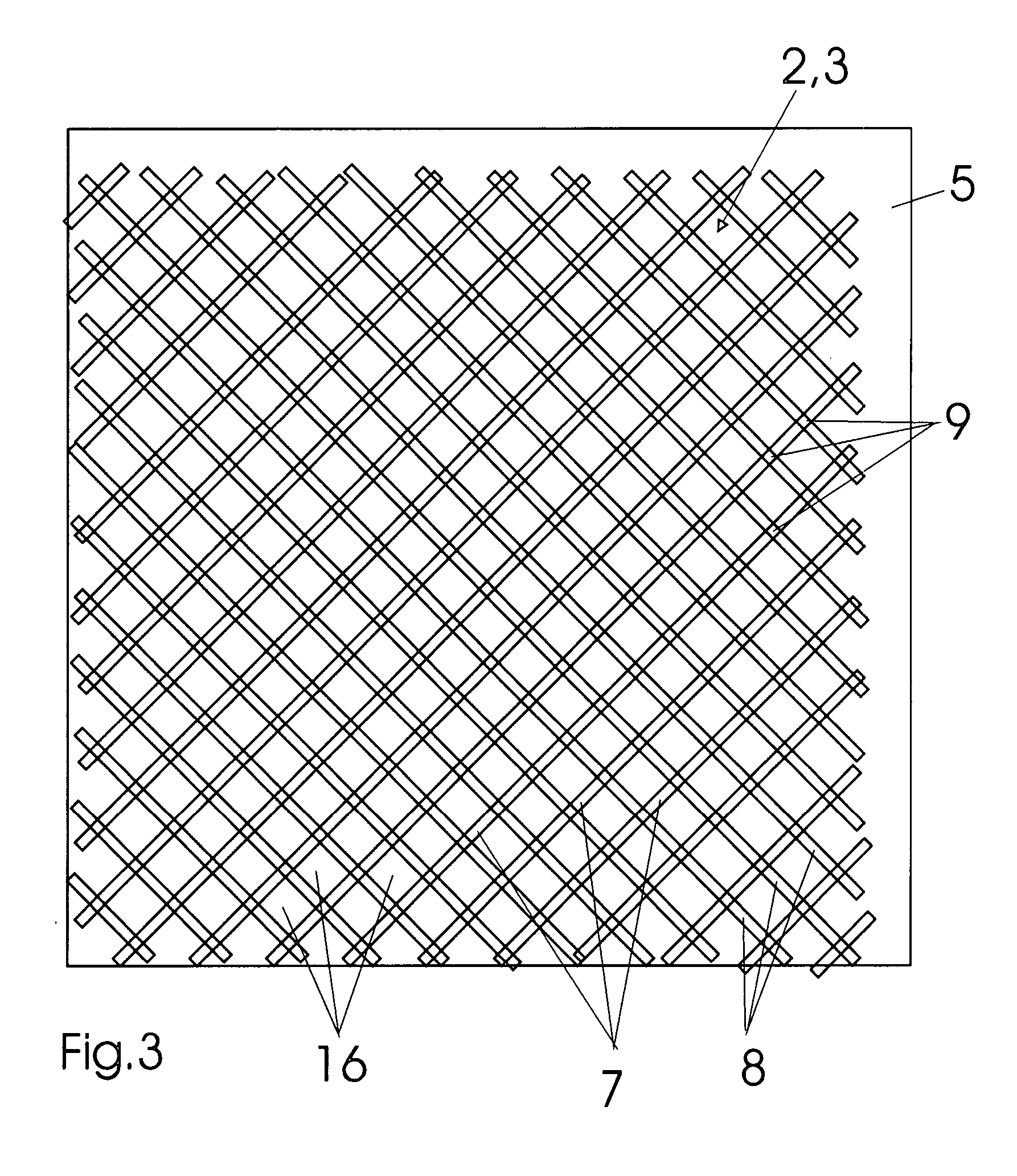

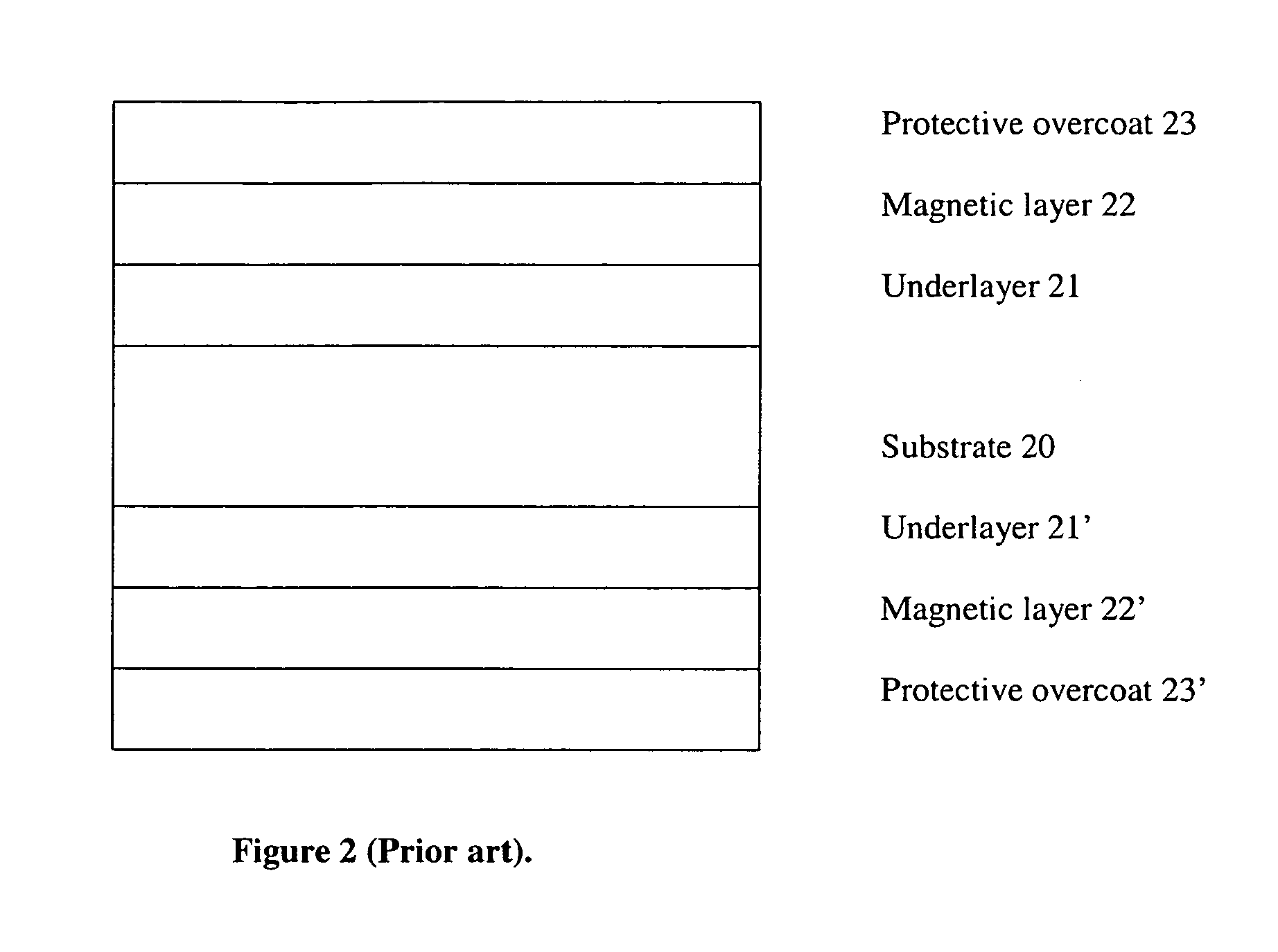

Magnetic media with high Ms magnetic layer

InactiveUS7314675B1Reduced total magnetic layer thicknessEnhanced signalRecord information storageCoating part of support with magnetic layerMagnetic anisotropyMagnetic media

Magnetic recording media having a magnetic layer, wherein the magnetic layer comprises a continuous matrix material and a separate portion that is different from the matrix is disclosed. The matrix comprises a non-ferromagnetic material that is non-ferromagnetic in a bulk state. The separate portion comprises a ferromagnetic material and comprises substantially none of at least one component of the non-ferromagnetic material. One embodiment is a dual magnetic layer recording media including a lower magnetization (Ms), exchange decoupled magnetic bottom layer; and a high Ms, high magnetic anisotropy (Ku), magnetic top layer having exchange decoupled grains. This media enables reduced total magnetic layer thickness and higher signal, while maintaining high Ku and low media noise.

Owner:SEAGATE TECH LLC

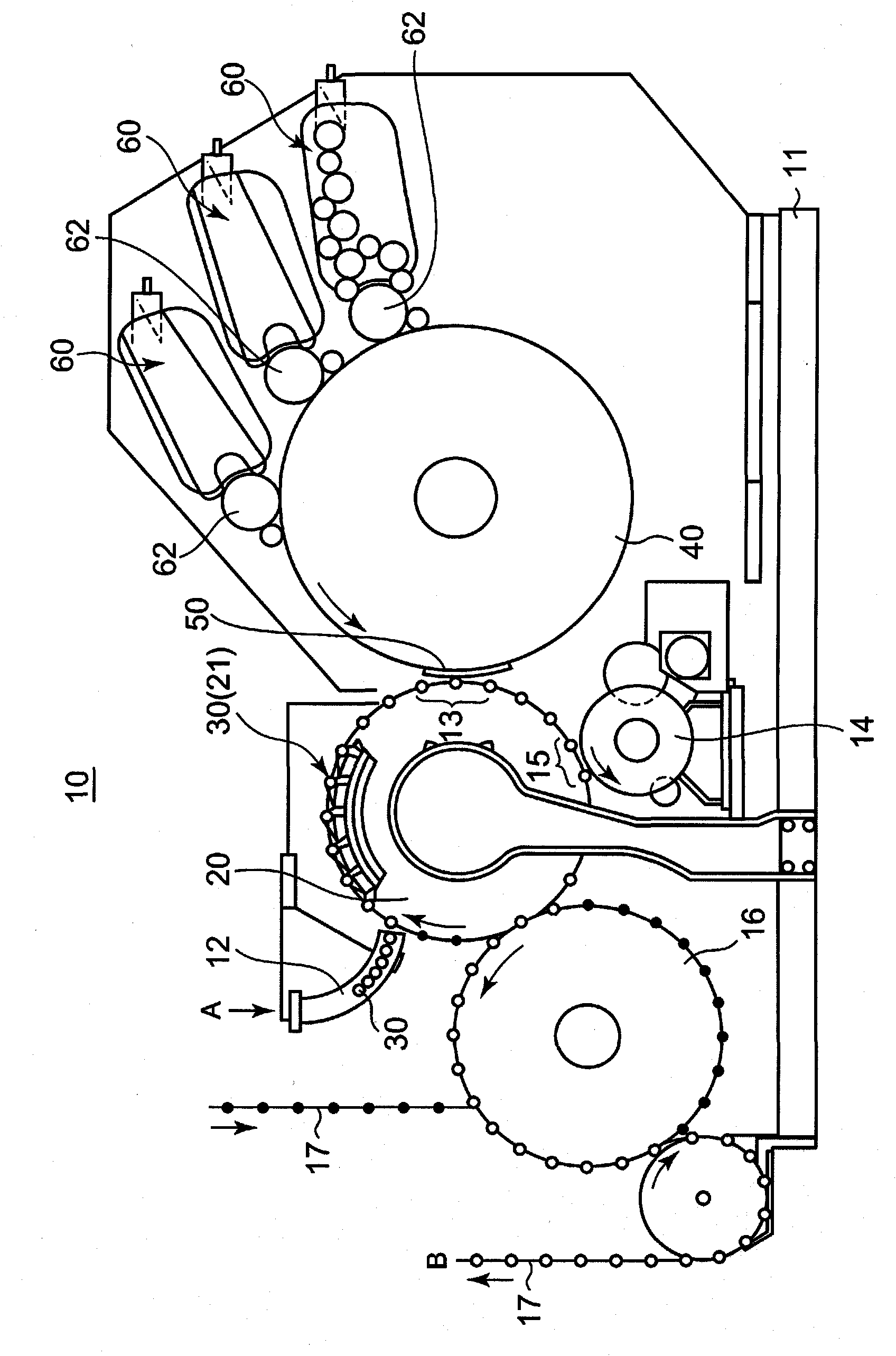

Seamless can, printing plate, cylindrical printer for seamless can, printing method for seamless can, and method for producing seamless can

InactiveCN102143846AReduce layer thicknessReduce height differencePlate printingRotary pressesWrinkle skinUltimate tensile strength

Occurrence of wrinkles due to neck-in processing is reduced and drop in coating strength of an overlap portion is prevented by reducing the level difference between the overlap portion and an ink layer at a part continuous to the overlap portion. A seamless can is produced by transferring an ink layer onto the can body by cylindrical printing in such a manner that the transferred ink layer has an overlap portion where the ink layer is overlapped at the front and rear ends of the can body in the circumferential direction, and the ink area ratio of the ink layer at at least one of the front or rear end is smaller than that of the ink layer at a part continuous to the overlap portion excluding the overlap portion.

Owner:TOYO SEIKAN KAISHA LTD

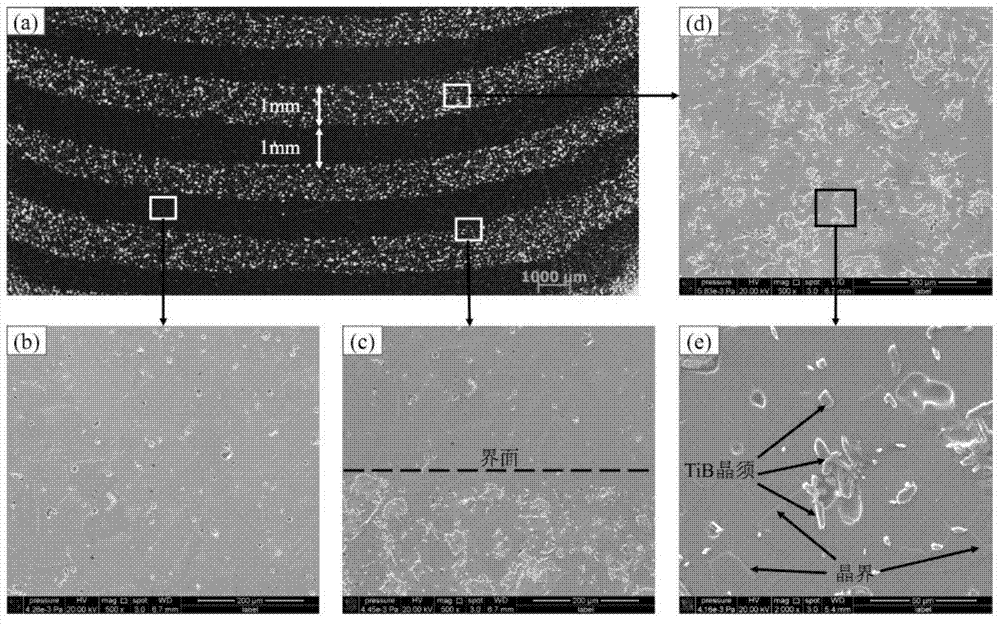

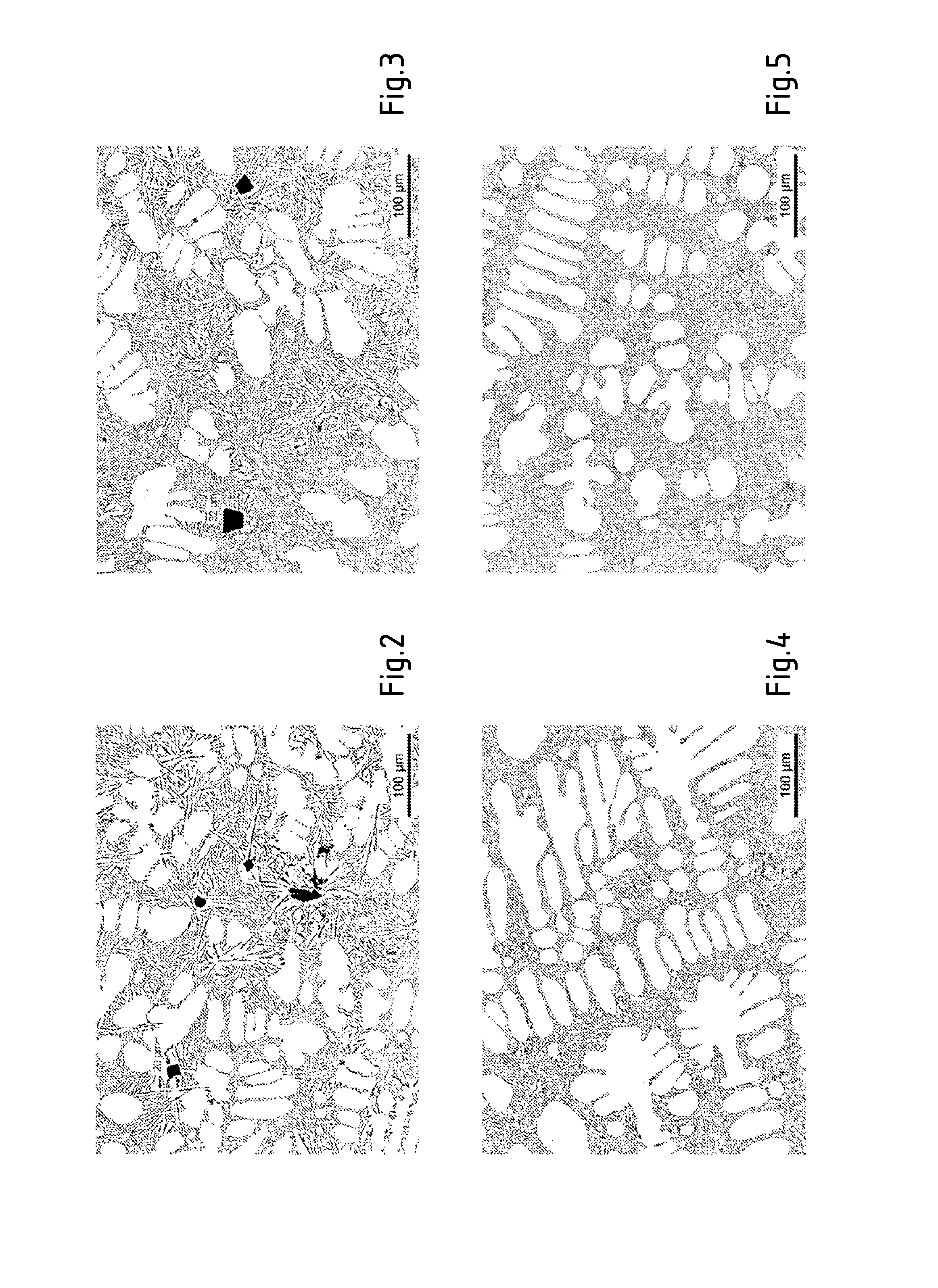

Method for preparing laminated-structured Ti-(TiB+La2O3)/Ti composite material

The invention provides a method for preparing a laminated-structured Ti-(TiB+La2O3) / Ti composite material. The method comprises the following steps of calculating the mass of Ti powder and LaB6 powder needed for preparing reinforcement material according to the volume fraction of the reinforcement material, and weighing the Ti powder and the LaB6 powder; ball-milling the Ti powder and the LaB6 powder, and mixing uniformly to obtain mixed powder; taking Ti powder additionally, laying the Ti powder and the mixed powder in a mould alternately in layers, and performing cold pressing and forming to obtain a laminated-structured prefabricate; performing high-temperature densification sintering on the laminated-structured prefabricate in vacuum, furnace-cooling and taking the prefabricate out to obtain the laminated-structured Ti-(TiB+La2O3) / Ti composite material. The relative density of the laminated-structured Ti-(TiB+La2O3) / Ti composite material is further improved by adopting multi-channel high-temperature hot rolling, grains are refined, the distribution of the reinforcement material is improved, and layer thickness is obviously reduced.

Owner:SHANGHAI JIAO TONG UNIV

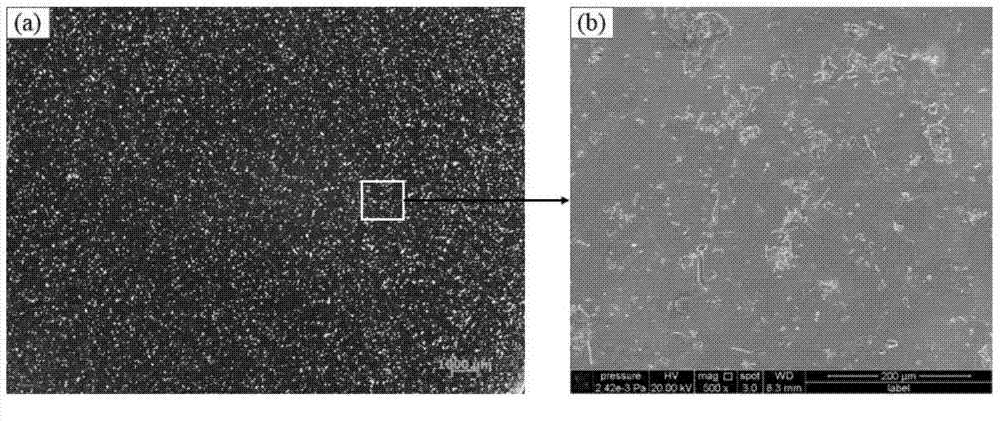

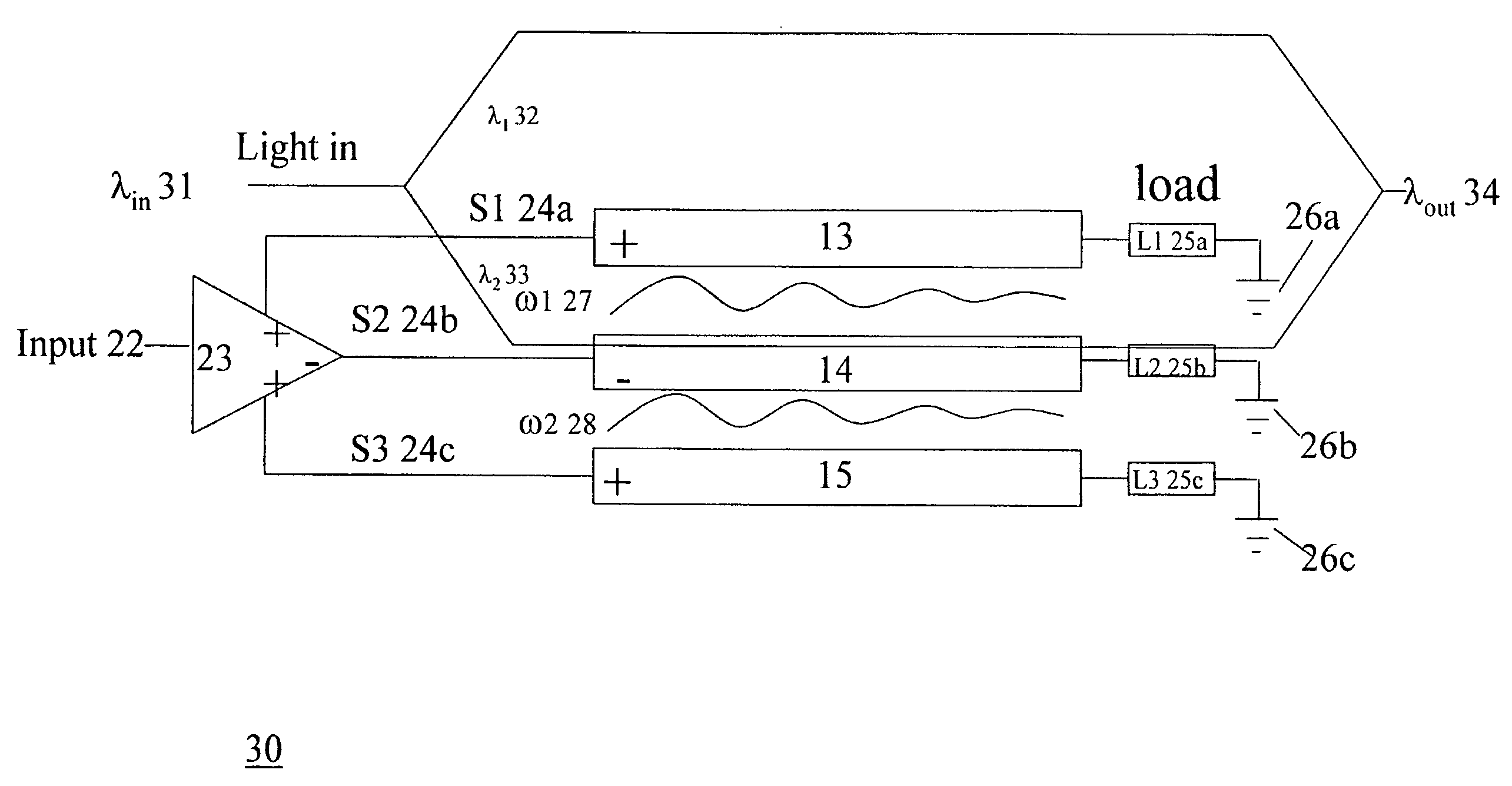

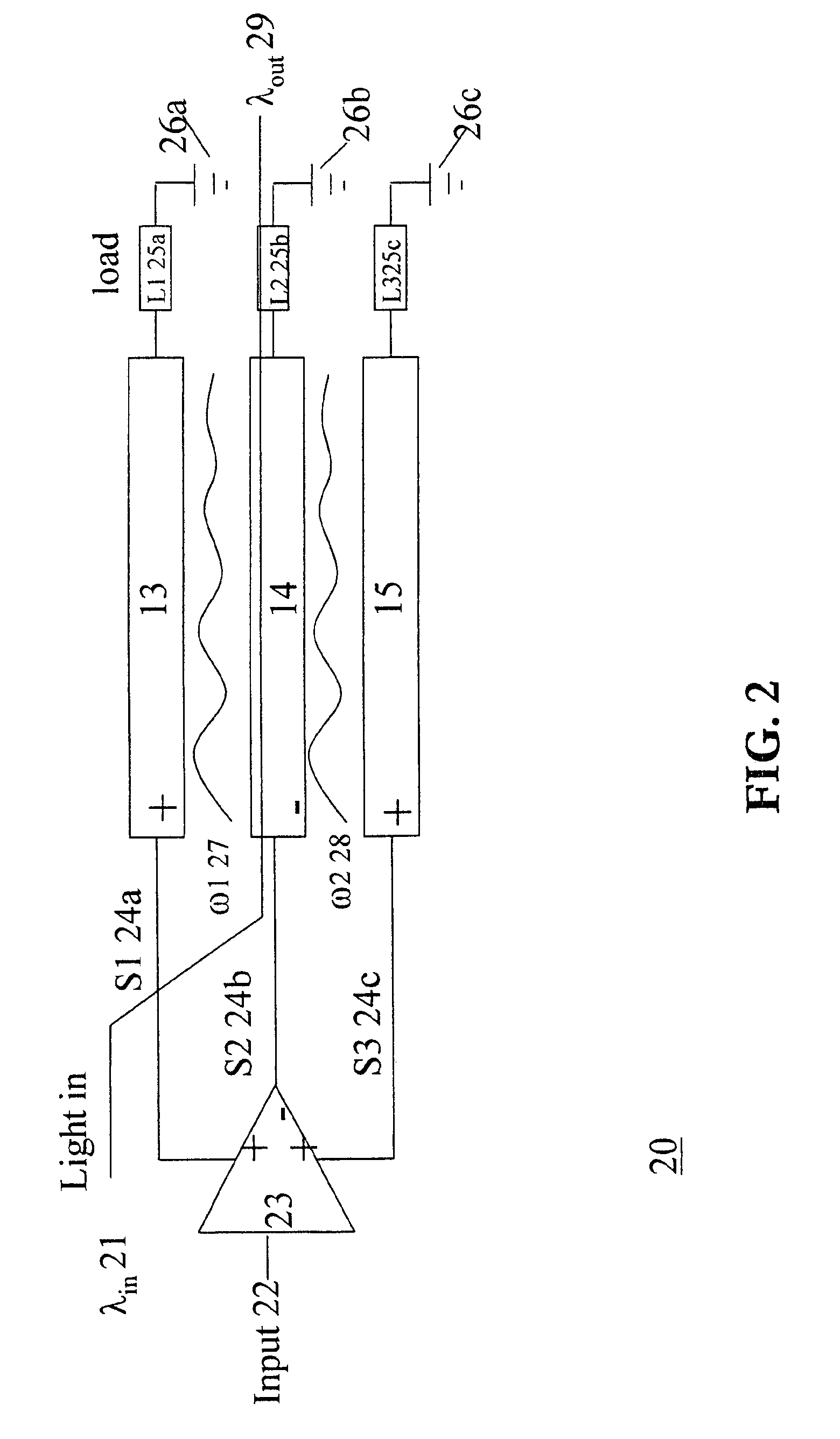

Dual-electrode traveling wave optical phase shifters and methods

The invention discloses phase-shifters, modulators, and method that produces a smaller π by means of a field excitation using multiple electrodes. A negative signal is introduced that travels with the positive signal, which enhances the electric field significantly. The field enhancement is provided by the superposition of the fields accumulated from each electrode. A base or substrate material can be made from any compound having linear electro-optic properties, such as lithium niobate, lithium tantalite, potassium lithium niobate, potassium titanyl phosphate or gallium-arsenide. For lithium niobate, there are two possible orientations of electric field, z-cut orientation or x-cut orientation.

Owner:II VI DELAWARE INC

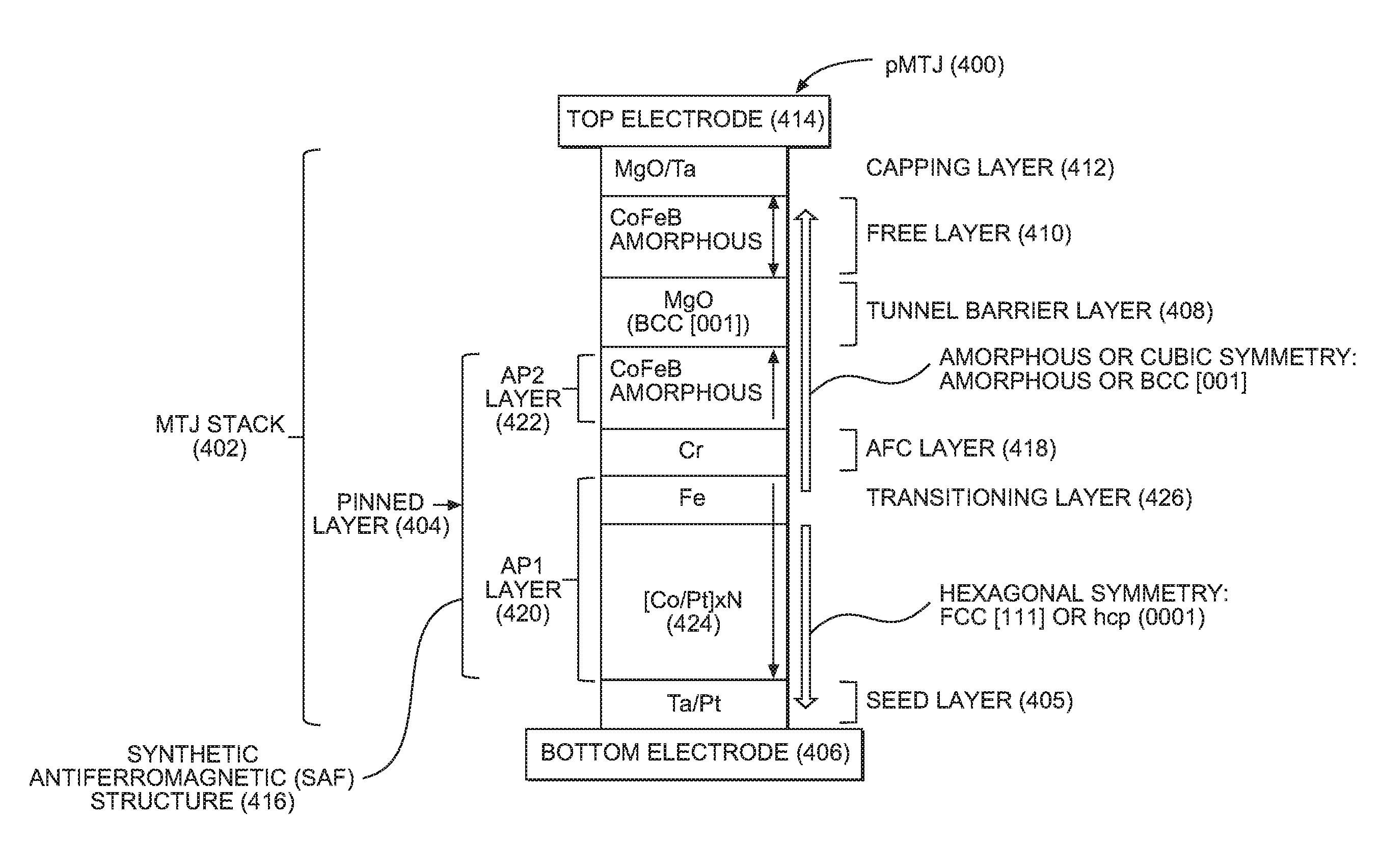

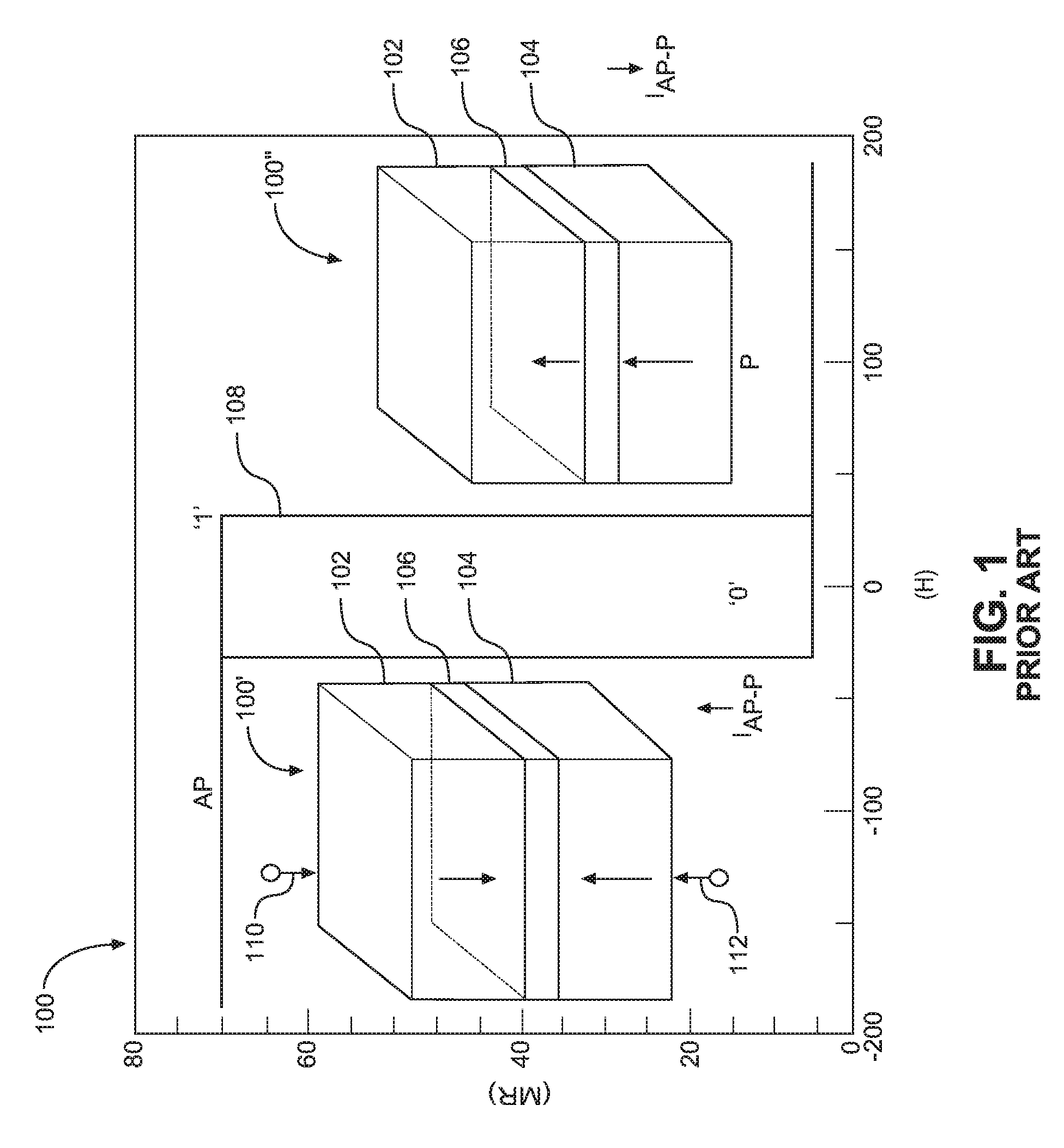

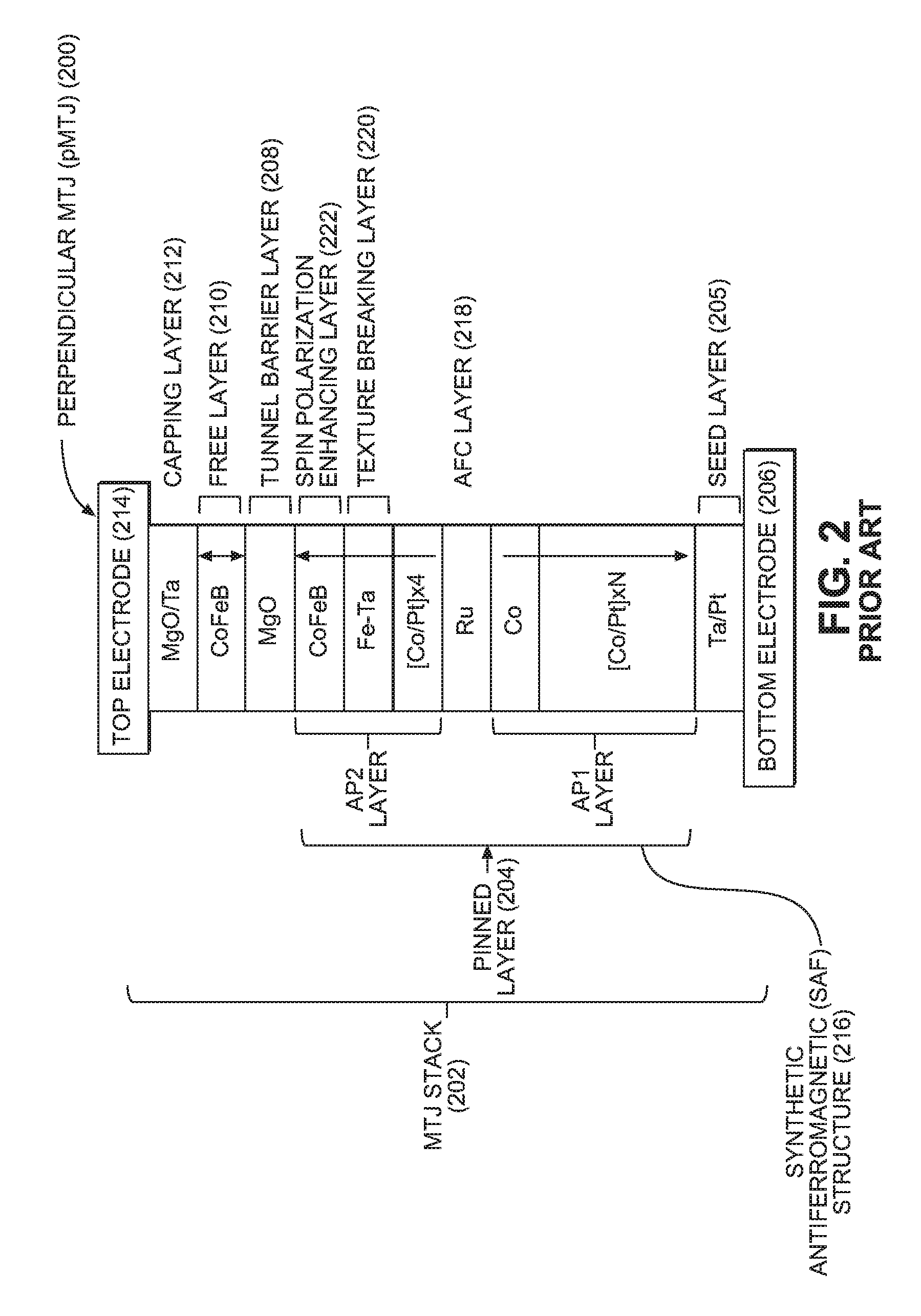

Perpendicular magnetic tunnel junction (pMTJ) devices employing a thin pinned layer stack and providing a transitioning start to a body-centered cubic (BCC) crystalline / amorphous structure below an upper anti-parallel (AP) layer

ActiveUS9590010B1High tunneling magnetoresistance ratio (TMR)Reduced pinned layer thicknessMagnetic-field-controlled resistorsSolid-state devicesCrystal structureLayer thickness

Perpendicular magnetic tunnel junction (pMTJ) devices employing a pinned layer stack with a thin top anti-parallel (AP2) layer and having a transitioning layer providing a transitioning start to a body-centered cubic (BCC) crystalline / amorphous structure below the top anti-parallel (AP2) layer, to promote a high tunnel magnetoresistance ratio (TMR) with reduced pinned layer thickness are disclosed. A first anti-parallel (AP) ferromagnetic (AP1) layer in a pinned layer has a face-centered cubic (FCC) or hexagonal closed packed (HCP) crystalline structure. A transitioning material (e.g., Iron (Fe)) is provided in a transitioning layer between the AP1 layer and an AFC layer (e.g., Chromium (Cr)) that starts a transition from a FCC or HCP crystalline structure, to a BCC crystalline / amorphous structure. In this manner, a second AP ferromagnetic (AP2) layer disposed on the AFC layer can be provided in a reduced thickness BCC crystalline or amorphous structure to provide a high TMR with a reduced pinned layer thickness.

Owner:QUALCOMM INC

Functionally graded polycrystalline diamond insert

ActiveUS8695733B2Reduce layer thicknessImprove thermal stabilityDrill bitsConstructionsCarbidePolycrystalline diamond

Owner:SMITH INT INC

Copper steel composite material, arc additive preparing method and application of copper steel composite material and tin bronze alloy

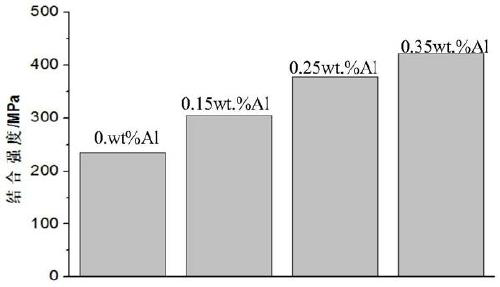

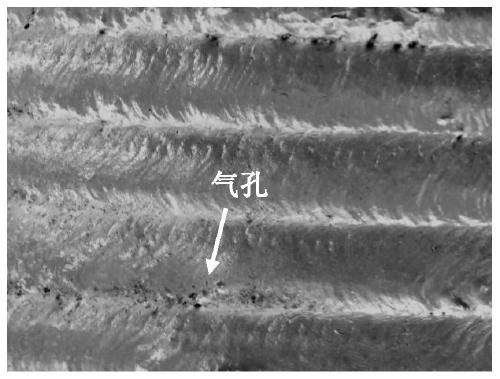

ActiveCN110039154AHigh bonding strengthImprove wear resistanceAdditive manufacturing apparatusArc welding apparatusSheet steelUltimate tensile strength

The invention discloses a copper steel composite material, an arc additive preparing method and application of the copper steel composite material and a tin bronze alloy. The composite material is composed of a copper alloy layer and a steel layer. The copper alloy layer is novel tin bronze and comprises the following components including, by weight percent, 5%-10% of Sn, 0.15%-0.35% of Al, 0.05%-0.2% of Si, smaller than 0.01% of Pb, smaller than 0.01% of Ni and the balance Cu. A preparing technology of the composite material includes the steps that firstly, casting of a novel tin bronze alloybar is conducted; secondly, the alloy bar is subjected to extruding and drawing technologies, and a wire with the diameter being 0.8 mm to 1.6 mm is prepared; and thirdly, the wire is arranged on thesurface of a steel plate in an arc additive manner, and the copper / steel composite material is obtained. The copper steel composite material is high in combination strength and has dendrite tissue which is compact, uniform and fine, and the wear reducing and resisting performance and the bearing performance are high.

Owner:SOUTHEAST UNIV

Aluminium alloy free from si primary particles

InactiveUS20130302643A1Simple structureGood welding performanceWelding/cutting media/materialsThin material handlingIngotSoldering process

The invention relates to an aluminium alloy, and aluminium alloy product consisting at least in part of an aluminium alloy, an ingot formed from an aluminium alloy, and also a method for producing an aluminium alloy. An improved soldering process is achieved by an AlSi aluminium alloy that has the following proportions of alloy components in percentage by weight:4.5%≦Si ≦12%,P≦10 ppm,B≦10 ppm,30 ppm≦Ti≦240 ppm, Fe ≦0.8%,Cu ≦0.3%,Mn≦0.10%,Mg ≦2.0%,Zn≦0.20%,Cr≦0.05%,the remainder being Al and unavoidable impurities, individually at most 0.05% by weight and in total at most 0.15% by weight, wherein the aluminium alloy is free from Si primary particles with a size of more than 10 μm.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com