Method for connecting aluminum alloy and steel by laser filler wire

A technology of laser wire filling and aluminum alloy, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high quality and efficient connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

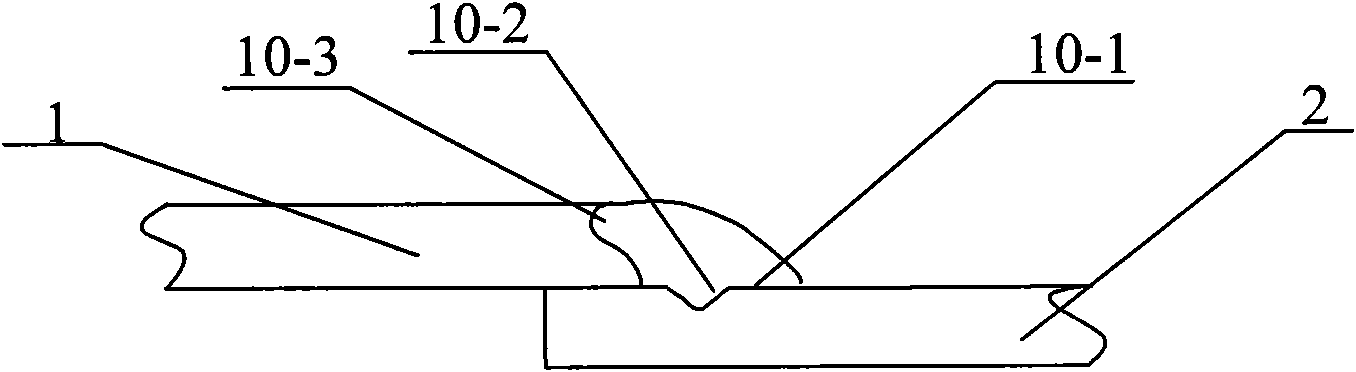

[0028] Other welding conditions are identical with embodiment 1, do not go into details here, the cross-sectional view of two kinds of metal melting-brazing connection is as follows Figure 4 shown.

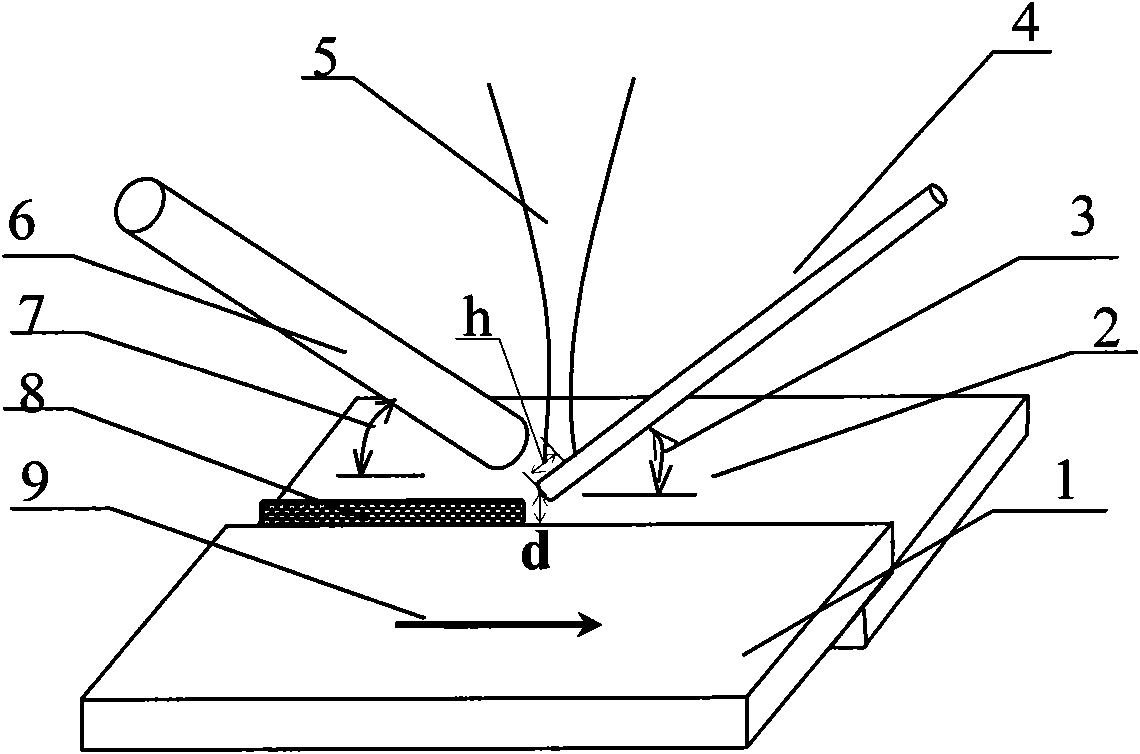

[0029] Laser power P = 3000W, welding speed 3m / min, wire feeding speed 9m / min, defocus + 5mm, laser spot diameter 0.38mm on the welding wire, filling welding wire is AlSi5 welding wire with a diameter of 1.2mm, falling wire The position of the point is that the distance d between the center of the welding wire and the side of the aluminum plate on the upper part of the welding joint is 1.0mm, the length h between the center of the laser spot and the front end of the aluminum alloy welding wire is 1.0mm, the shielding gas is He, and the flow rate is 25L / min , wire feed angle 56°

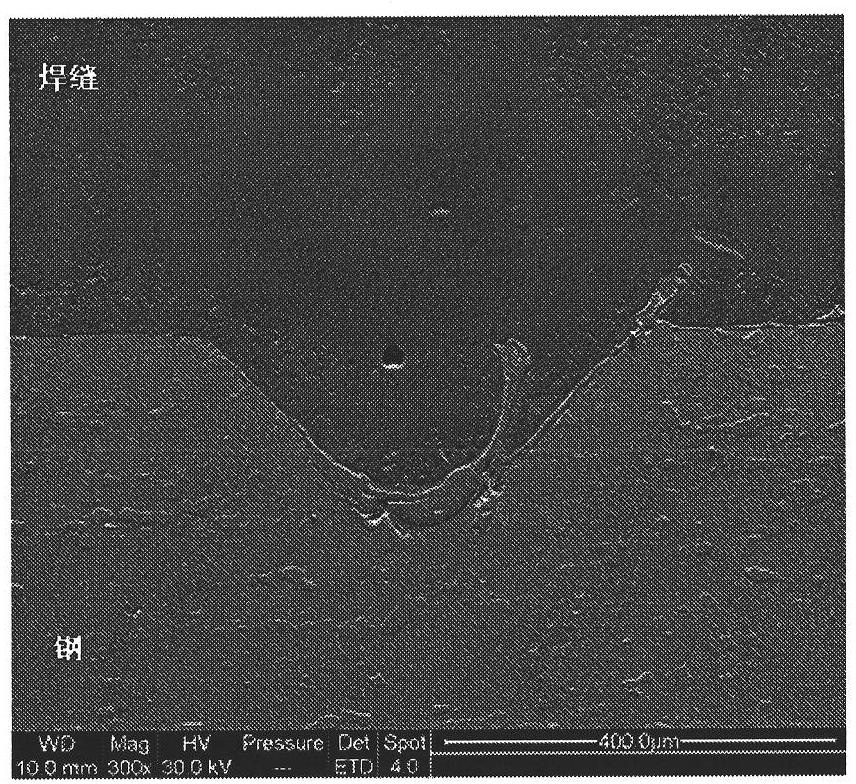

[0030] The tensile-shear test results of the connection joints obtained by the above method show that the damage position of the sample mainly occurs in the heat-affected zone of the aluminum alloy plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com