Laser Welding Process of Molybdenum Group Glass and Kovar Alloy

A technology of laser welding and process method, which is applied in the field of welding, can solve the problems of limited application, poor impact toughness, and low precision, and achieve the effects of avoiding cracking and fusing, reducing post-weld stress, and being suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

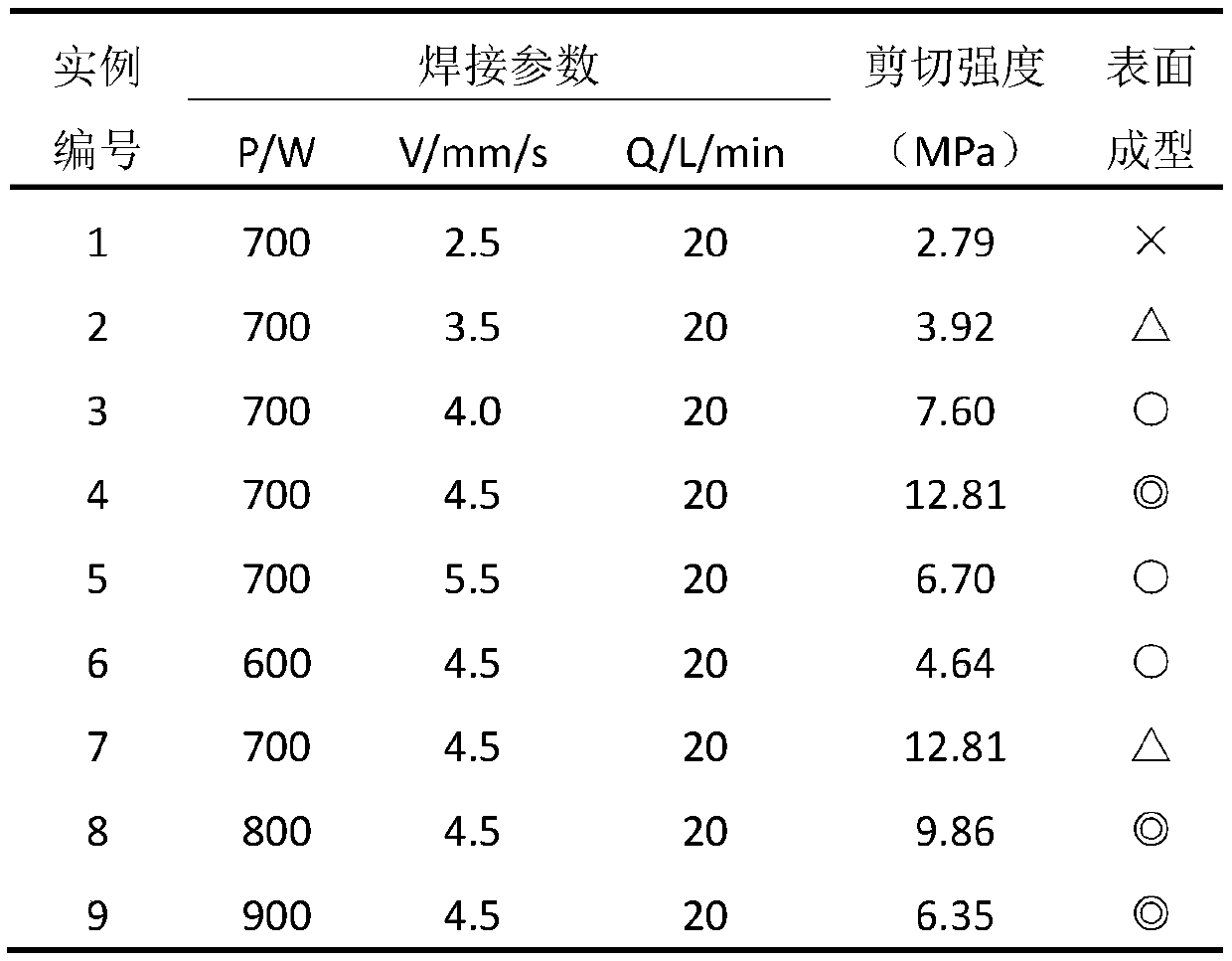

Examples

Embodiment 1

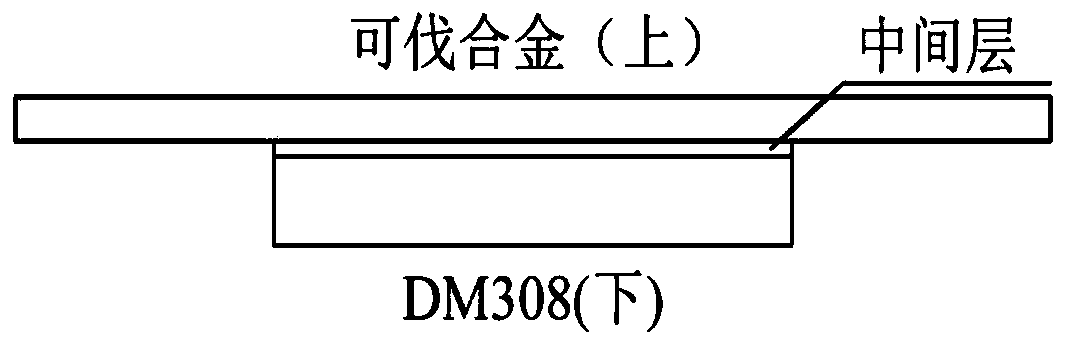

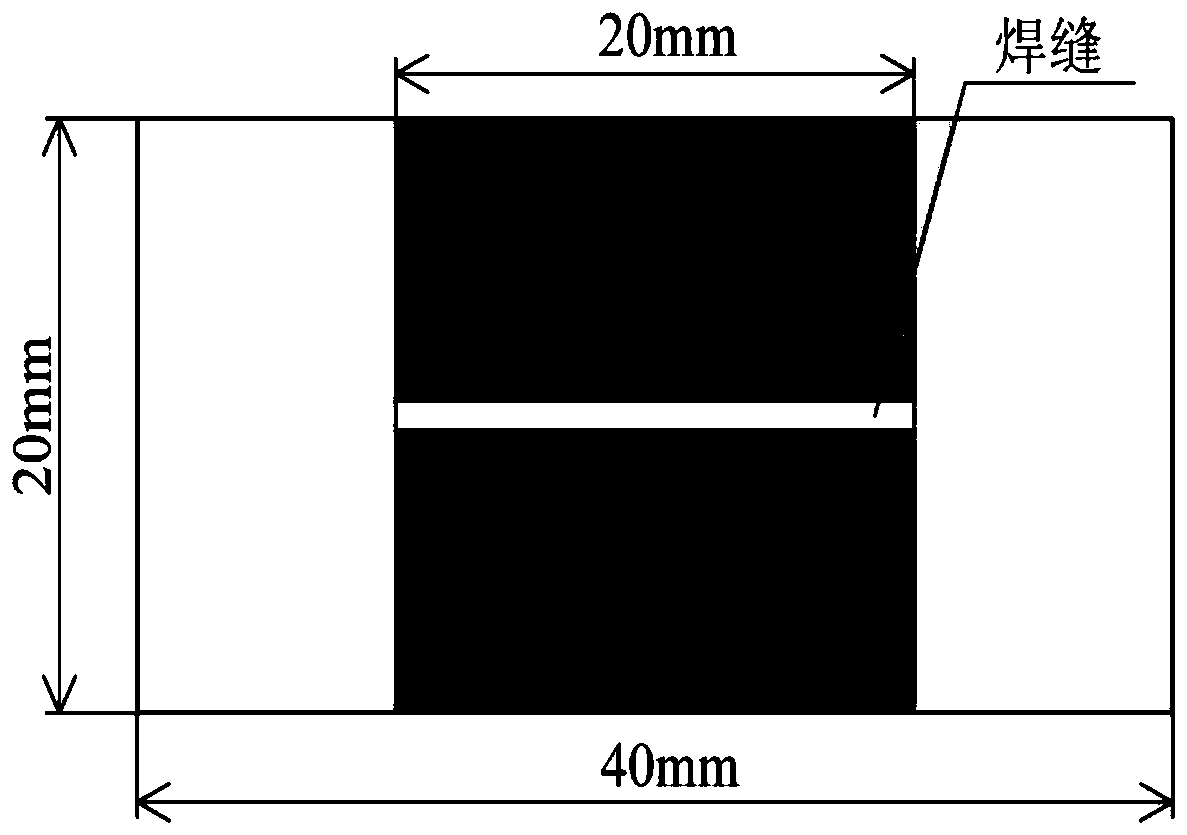

[0026] (1) Grind the surface of Kovar alloy from 400 mesh to 1200 mesh with sandpaper, smooth the molybdenum group glass with metallographic sandpaper, and clean the surface with acetone and ethanol respectively for 5 minutes. The glass is dried in the furnace;

[0027] (2) The size of the Kovar alloy sample is 40×20×1.1mm, and the vacuum degree is 10 -1 Treat in MPa environment for 5 minutes, and then oxidize in a furnace at a temperature of 650°C for 10 minutes;

[0028] (3) Ni 2 o 3 -MnO 2 -B 2 o 3 Metal oxide powder (the oxide powder mass percentage is composed of: Ni 2 o 3 35%, MnO 2 10%, B 2 o 3 19%, Al 2 o 3 5%, SiO 2 31%) and alcohol mixed evenly, the ratio is 150g / 100ml, the coating solution is coated on the surface of step (2) Kovar alloy, and the thickness of the coating layer is 120 μm; then the Kovar alloy is prepared by sintering in the furnace (4) Put the oxidized Kovar alloy sample on the molybdenum group glass sample (20×15×3mm), and install ...

Embodiment 2

[0034] (1) Grind the surface of the Kovar alloy from 400 mesh to 1200 mesh with sandpaper, smooth the molybdenum group glass with metallographic sandpaper, and clean the surface with acetone and ethanol respectively for 5 minutes. drying in the oven;

[0035] (2) The size of the metal sample is 40×20×1.1mm, and the vacuum degree is 10 -1 Treat in MPa environment for 5 minutes, and then oxidize in a furnace at a temperature of 650°C for 10 minutes;

[0036] (3) Ni 2 o 3 -MnO 2 -B 2 o 3 Metal oxide powder (the oxide powder mass percentage is composed of: Ni 2 o 3 35%, MnO 2 10%, B 2 o 3 19%, Al 2 o 3 5%, SiO 231%) and alcohol mixed evenly, the ratio is 150g / 100ml, the coating solution is coated on the surface of step (2) Kovar alloy, and the thickness of the coating layer is 120 μm; then the Kovar alloy is prepared by sintering in the furnace layer, the temperature is 800°C, and the time is 10min;

[0037] (4) Place the oxidized metal sample on the molybdenum g...

Embodiment 3

[0043] (1) Grind the surface of the Kovar alloy from 400 mesh to 1200 mesh with sandpaper, smooth the molybdenum group glass with metallographic sandpaper, and clean the surface with acetone and ethanol respectively for 5 minutes. drying in the oven;

[0044] (2) The size of the metal sample is 40×20×1.1mm, and the vacuum degree is 10 -1 Treat in MPa environment for 5 minutes, and then oxidize in a furnace at a temperature of 650°C for 10 minutes;

[0045] (3) Ni 2 o 3 -MnO 2 -B 2 o 3 Metal oxide powder (the oxide powder mass percentage is composed of: Ni 2 o 3 35%, MnO 2 10%, B 2 o 3 19%, Al 2 o 3 5%, SiO 2 31%) and alcohol mixed evenly, the ratio is 150g / 100ml, the coating solution is coated on the surface of step (2) Kovar alloy, and the thickness of the coating layer is 130 μm; then the Kovar alloy is prepared by sintering in the furnace layer, the temperature is 800°C, and the time is 10min;

[0046] (4) Place the oxidized metal sample on the molybdenum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com