A plugging welding process

A welding process and hole plugging technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as plugging bolt holes, and achieve the effects of reducing post-weld stress, good control, and easy arc ignition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

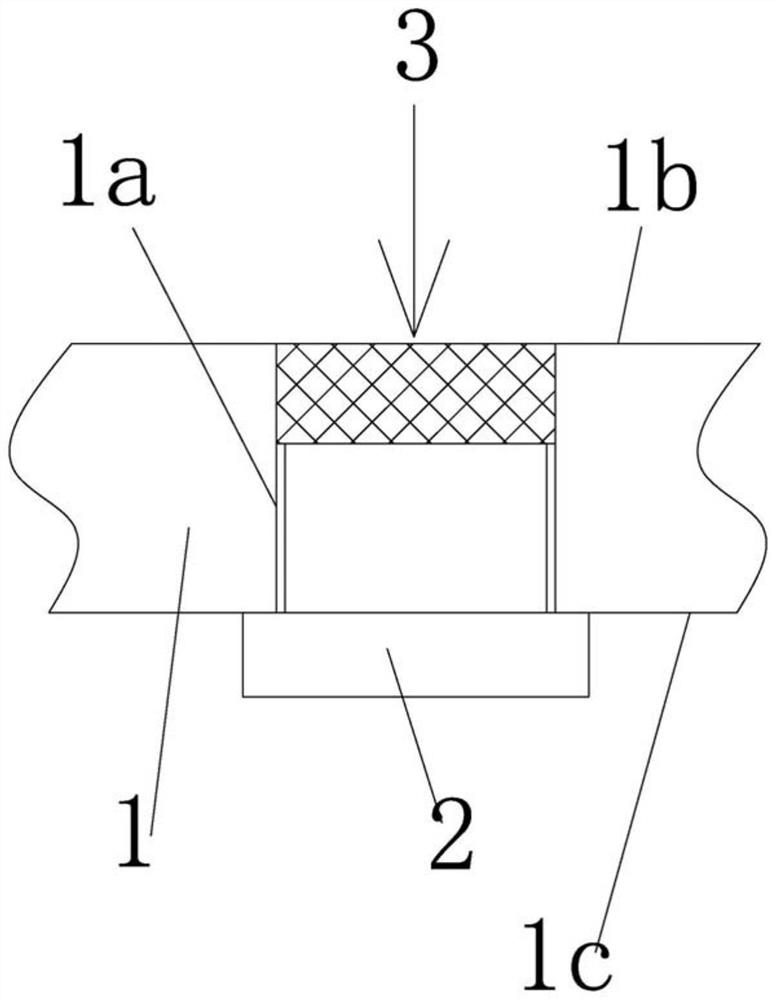

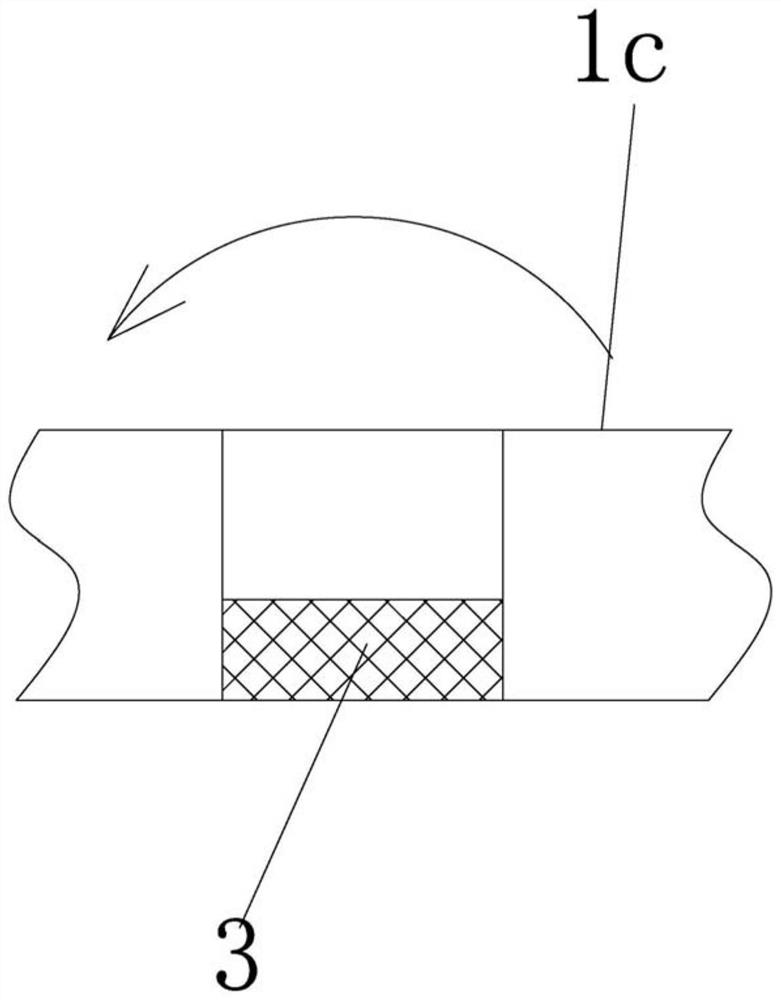

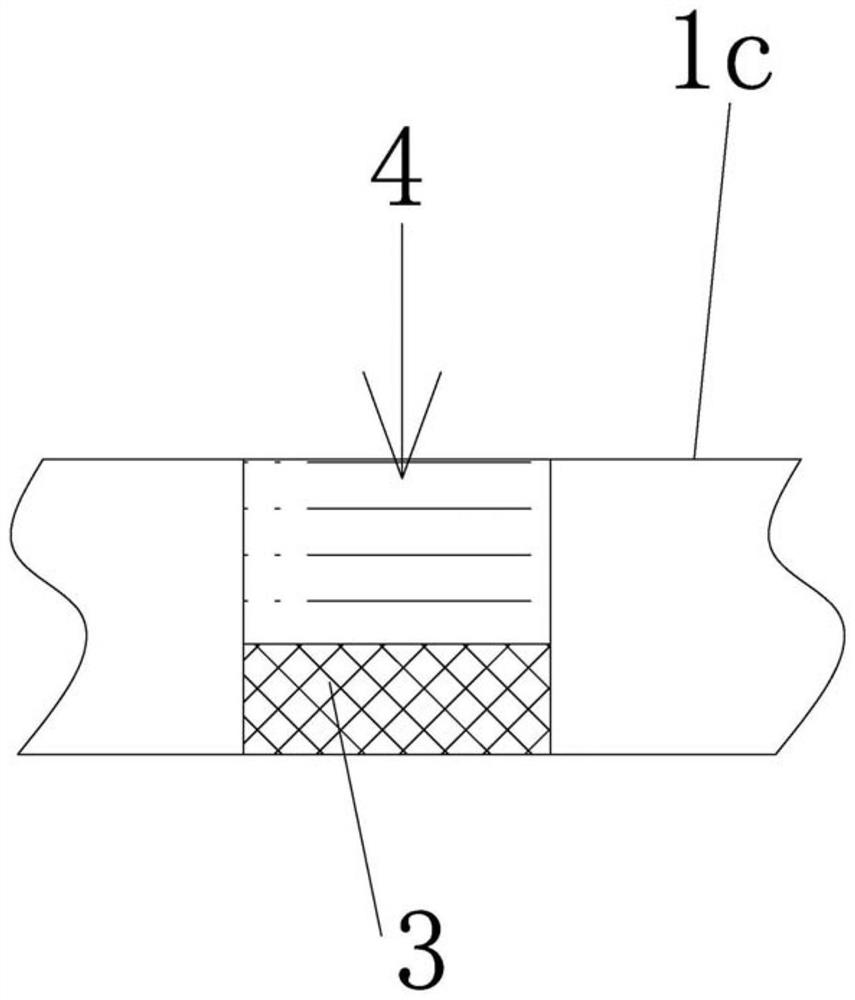

[0029] Attached below Figure 1-3 The present invention is further illustrated with specific examples.

[0030] like figure 1 As shown, a hole plugging welding process includes the following steps:

[0031] S1. Referring to the diameter of the bolt hole 1a at the staggered position, process the tooling block 2 made of conductive metal, so that the diameter of the cylindrical part of the tooling block 2 inserted into the bolt hole 1a is smaller than the diameter of the bolt hole 1a 1-2mm, And make the tooling block 2 have a limit flange;

[0032] S2. Grind the bolt holes 1a to a smooth level, clean the two surfaces of the steel plate 1 at the same time, and define the two surfaces of the steel plate 1 as the first surface 1b and the second surface 1c;

[0033] S3. Preheat the steel plate 1, and the preheating temperature is 100°C-150°C;

[0034] S4. Leveling the steel plate 1 so that the flatness of the steel plate 1 meets the requirements of surfacing welding;

[0035] S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com