Surface-treated hot-dipped steel material

A surface treatment and hot-dip plating technology, applied in hot-dip plating process, superimposed layer plating, metal material coating process, etc. Deterioration and other problems, to achieve the effect of suppressing the occurrence of wrinkles and sagging, good stain resistance, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0255] The present invention will be further described below by using an example of using a hot-dipped steel plate as a hot-dipped steel material. However, the present invention is not limited to the following examples.

[0256] (1) Hot dipped steel plate (hot dipped steel)

[0257] First, a method for producing a hot-dip-coated steel sheet, an evaluation test method for the hot-dip-coated steel sheet obtained thereby, and test results will be described.

[0258] [1.1. Manufacturing method of hot-dip coated steel sheet]

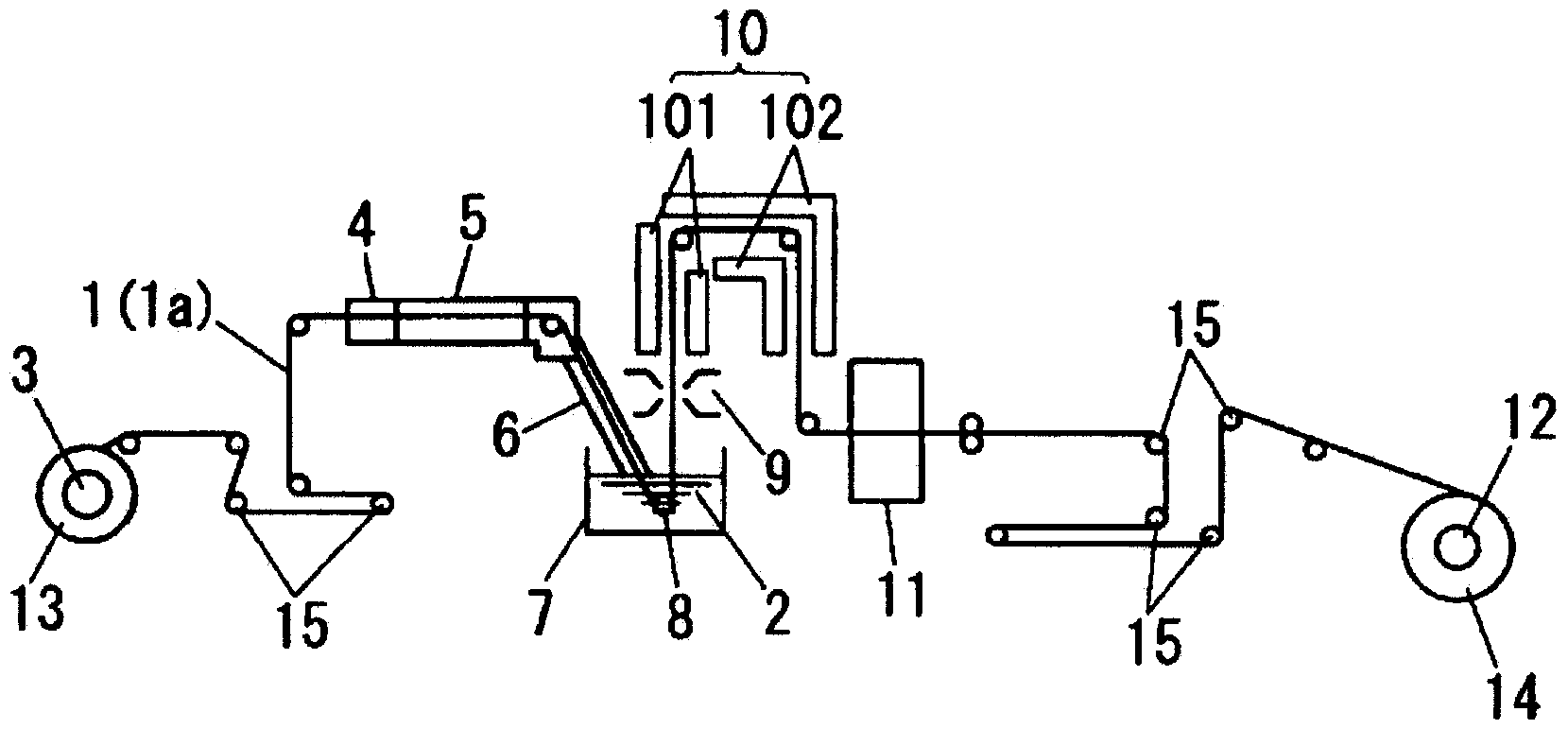

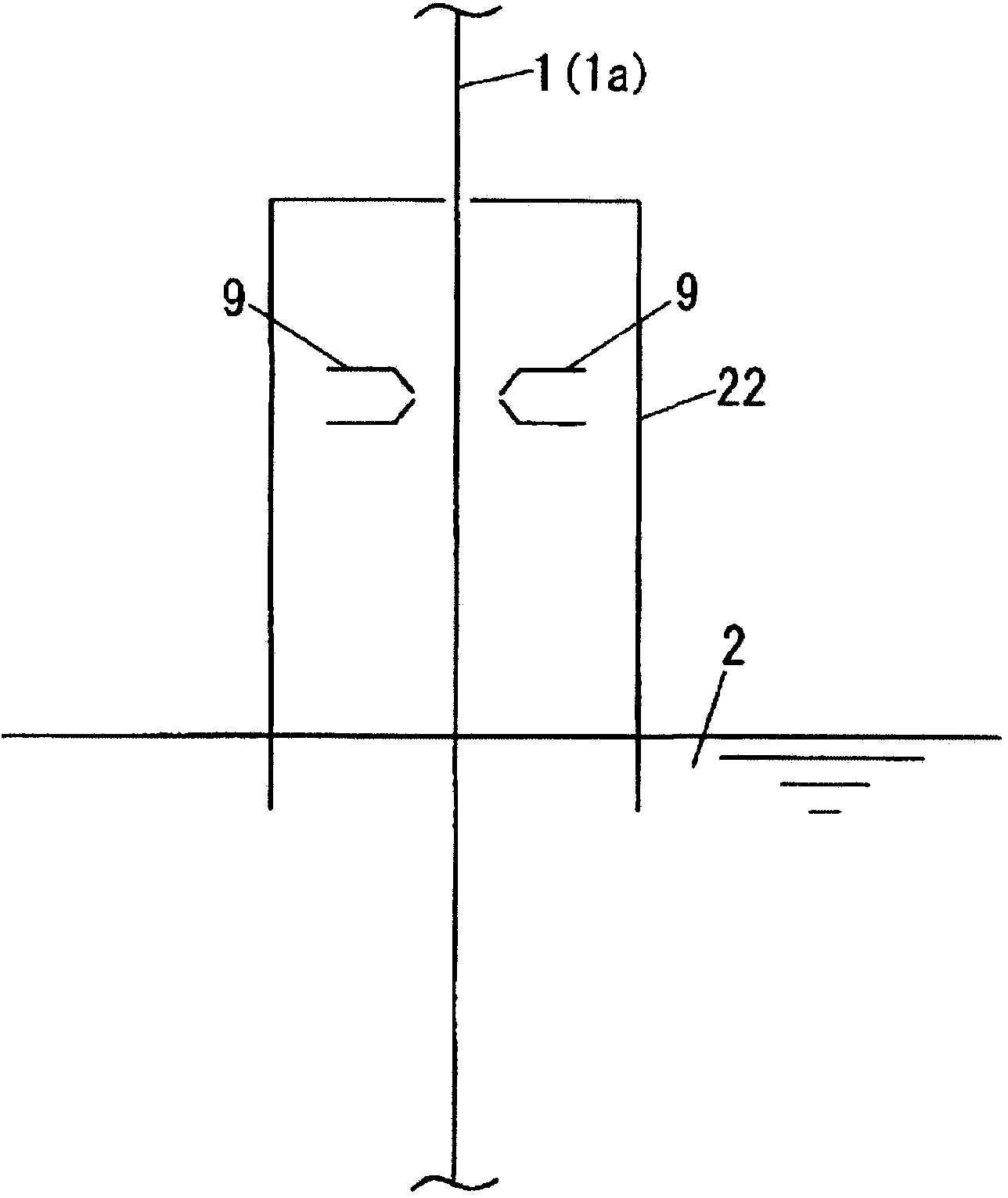

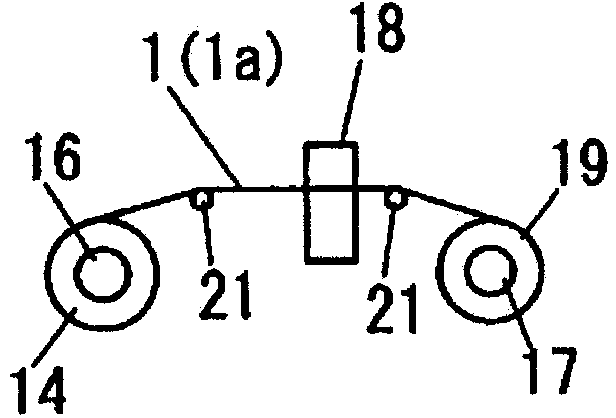

[0259] As the steel material 1 , a long steel plate 1 a (made of low-carbon aluminum-killed steel) having a thickness of 0.80 mm and a width of 1000 mm was used. For this plate 1a, use figure 1 The shown hot-dipping treatment apparatus performs hot-dipping treatment. The processing conditions are shown in Table 1-Table 3. The solidification initiation temperature shown in Tables 1 to 3 is a value derived from the liquid phase curve of the state diagram o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com