Hall ion source actuated magnetron sputtering enhancing type multi-arc ion plating film method

A magnetron sputtering, multi-arc ion technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of thin film loose, quality reduction, magnetron sputtering deposition rate film-base bonding strength Low and other problems, to achieve the effect of significant strengthening effect and improving ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: prepare TiN hard thin film

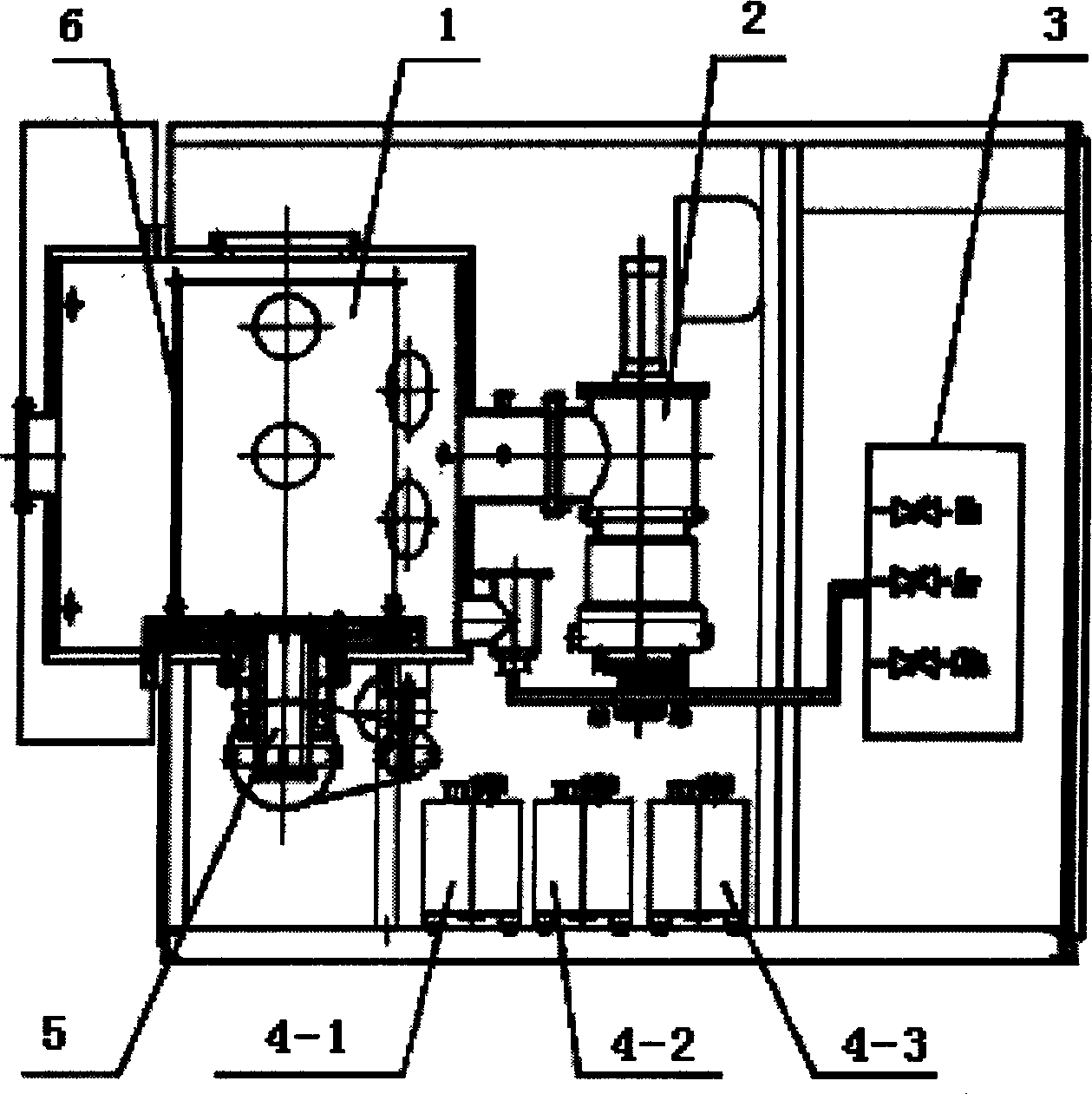

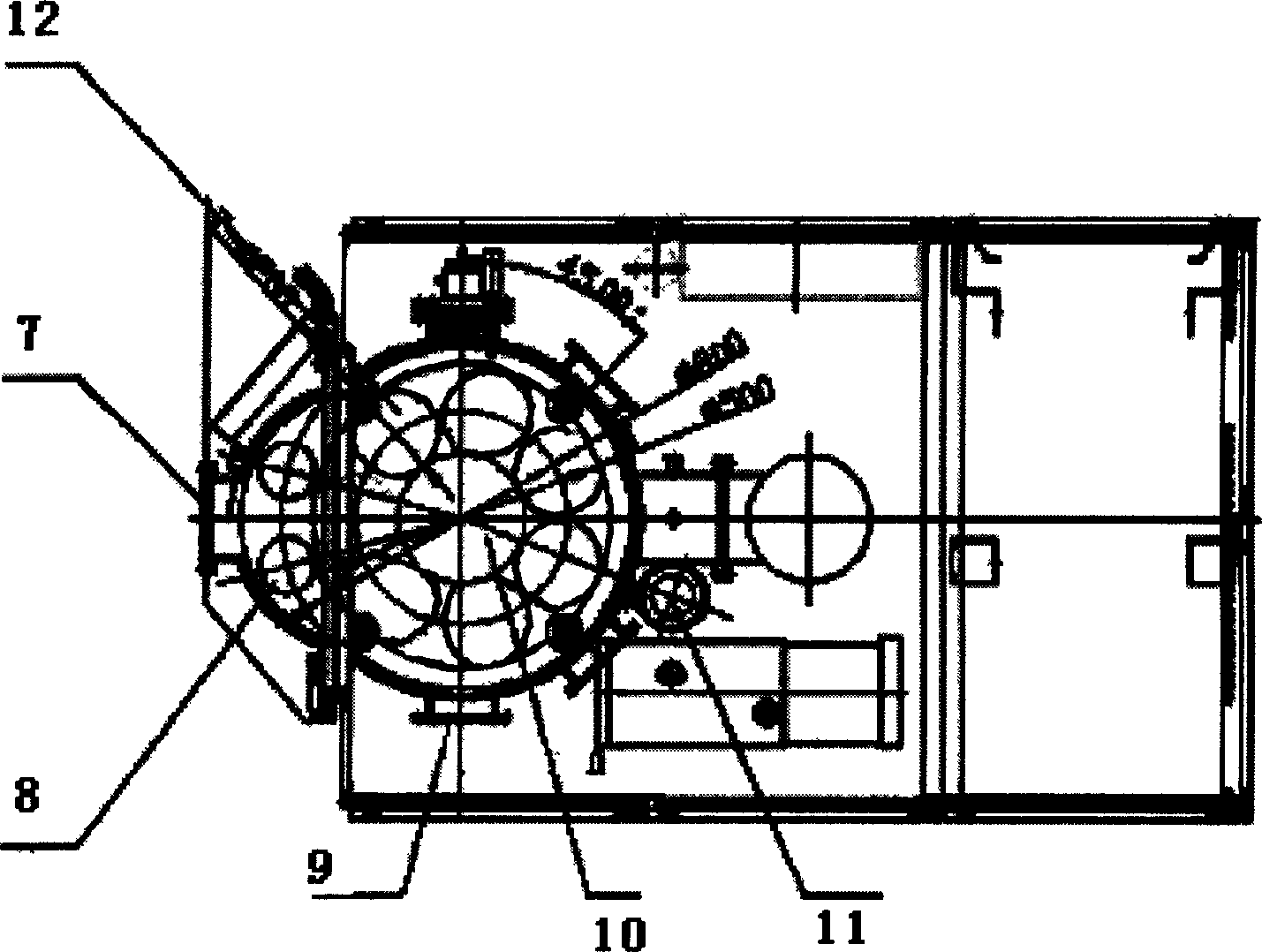

[0022] Put the workpiece 12 to be processed into the reaction chamber 1 of the furnace body, turn on the vacuum system 2 to evacuate the furnace body to 5×10 -4 During Pa, start to open the Ar in the gas supply system 3, keep the Ar flow rate as 100ml / min, bombard the workpiece 12 surface for 10 minutes by means of the high-energy ions in the plasma field generated by the bias power supply system 4-3, to reach the workpiece surface The effect of cleaning treatment; then turn on the heating system 6 to heat the workpiece to 300°C-350°C for 15 minutes, then at 1-2×10 -1 Under the pressure condition of Pa, pass the working gas Ar and N 2, keep the flow rate at 500ml / min, and provide discharge voltages of 25V and 200V for the multi-arc target 9 and the sputtering target 8 respectively by the multi-arc DC power supply 4-1 and the magnetron sputtering intermediate frequency AC power supply 4-2, and the discharge voltage is provided by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com