Supersonic wave reinforcement sludge anaerobic digestion gas production method

An anaerobic digestion and ultrasonic technology, applied in biological sludge treatment, waste fuel and other directions, to achieve the effect of low energy consumption, promoting the utilization of sludge resources and increasing the total amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

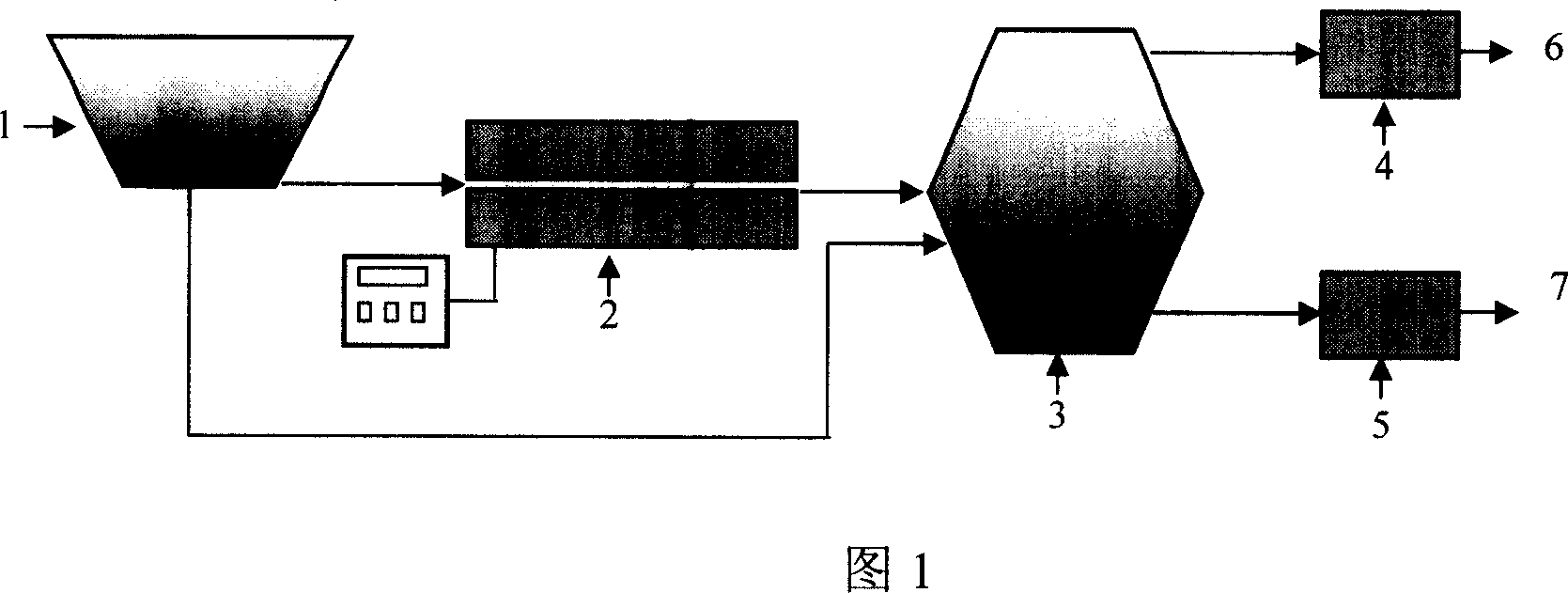

Image

Examples

Embodiment 1

[0025] An urban sewage treatment plant in Shenzhen adopts the activated sludge method for treatment, and the properties of the concentrated sludge are as follows:

[0026]

[0027] After all the sludge entering the anaerobic digestion tank is treated with 80kHz, 0.075W / ml ultrasonic waves, the final gas production of the sludge is as follows:

[0028] time / s

[0029] Through the large-scale application of the sewage treatment plant, the ultrasonic wave can significantly promote the gas production of the anaerobic digestion of the sludge, and it can also control the foam effect of the sludge very well, which has the prospect of large-scale application.

Embodiment 2

[0031] An urban sewage treatment plant in Harbin adopts the activated sludge method for treatment, and the properties of the concentrated sludge are as follows:

[0032]

Moisture content (%)

pH value

(mg / L)

(mg / L)

dissolved organic matter

(mg / L)

96.97

6.72

5206

4117

1840

[0033] 80% of the sludge entering the anaerobic digestion tank is subjected to 40kHz, 1.000W / ml ultrasonic treatment, and then mixed with the remaining sludge for anaerobic digestion. The final gas production is as follows:

[0034] time / s

Embodiment 3

[0036] An urban sewage treatment plant in Beijing adopts the activated sludge method for treatment, and the properties of the concentrated sludge are as follows:

[0037]

Moisture content (%)

pH value

(mg / L)

(mg / L)

dissolved organic matter

(mg / L)

97.03

6.69

5074

4001

1769

[0038] 50% of the sludge entering the anaerobic digestion tank is mixed with the remaining sludge for anaerobic digestion after applying 25kHz, 1.500W / ml ultrasonic treatment, and the final gas production is as follows:

[0039] time / s

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com