Phosphorus containing free-cutting silicon brass alloy and preparation method thereof

A silicon brass, free-cutting technology, which is applied in the field of phosphorus-containing free-cut silicon brass alloy and its preparation, can solve the problems of poor welding performance, tool wear, high content of alloy Bi, etc., and achieve excellent dezincification resistance and improved corrosion resistance. The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

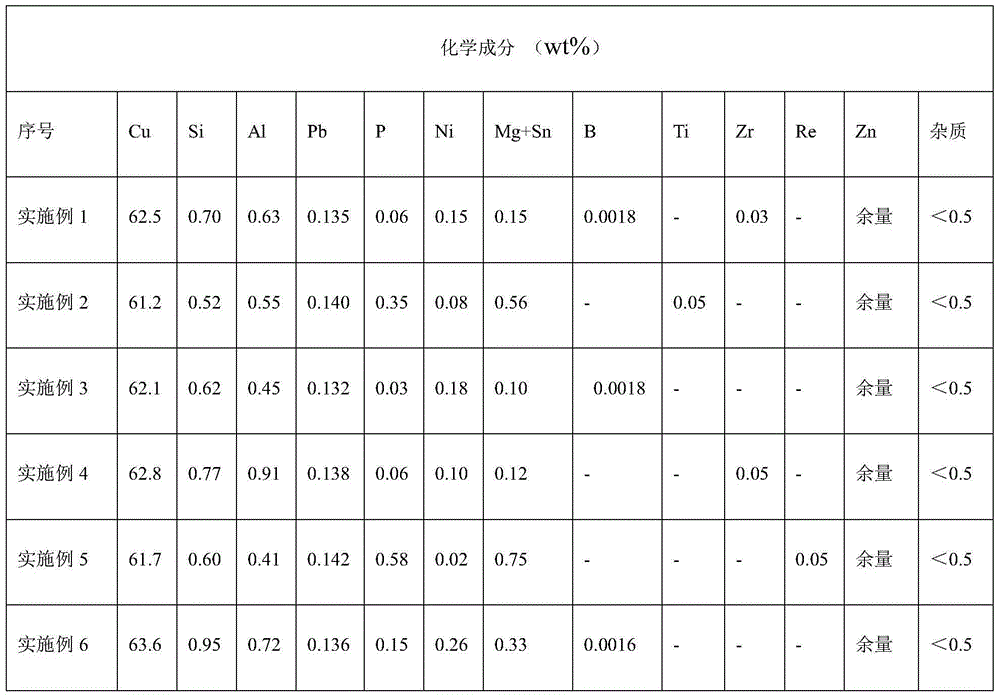

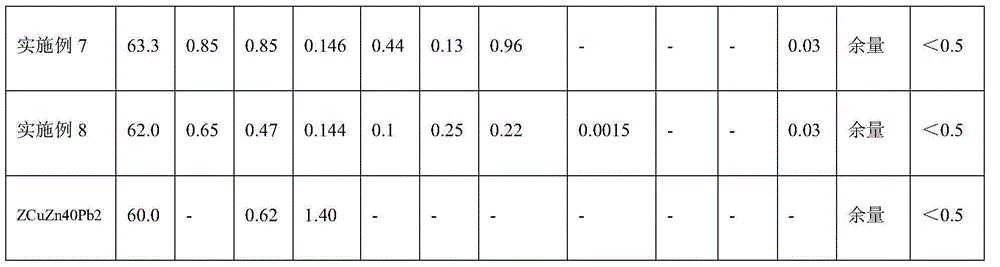

[0028]A phosphorus-containing free-cutting silicon brass alloy is composed of the following components: 61-64wt% Cu, 0.5-1.0wt% Si, 0.4-1.0wt% Al, 0.01-0.6wt% P, 0.1-0.15wt% Pb , 0.01-0.3wt% Ni, 0.1wt%

[0029] The method for preparing the above phosphorus-containing free-cutting silicon brass alloy is as follows: put metal silicon and electrolytic copper on the bottom of the induction furnace, add slag cleaning agent and cover with charcoal, heat up to 1050-1150°C until the materials are completely melted, filter out Scum and impurities to improve the purity; reduce the temperature to 1030-1080°C, add 0# zinc and quickly press it into the bottom of the furnace, stir fully after melting, add aluminum ingots, tin ingots, lead ingots and pure nickel, and fully stir to ensure The composition of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com