Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

946results about How to "Easy to oxidize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

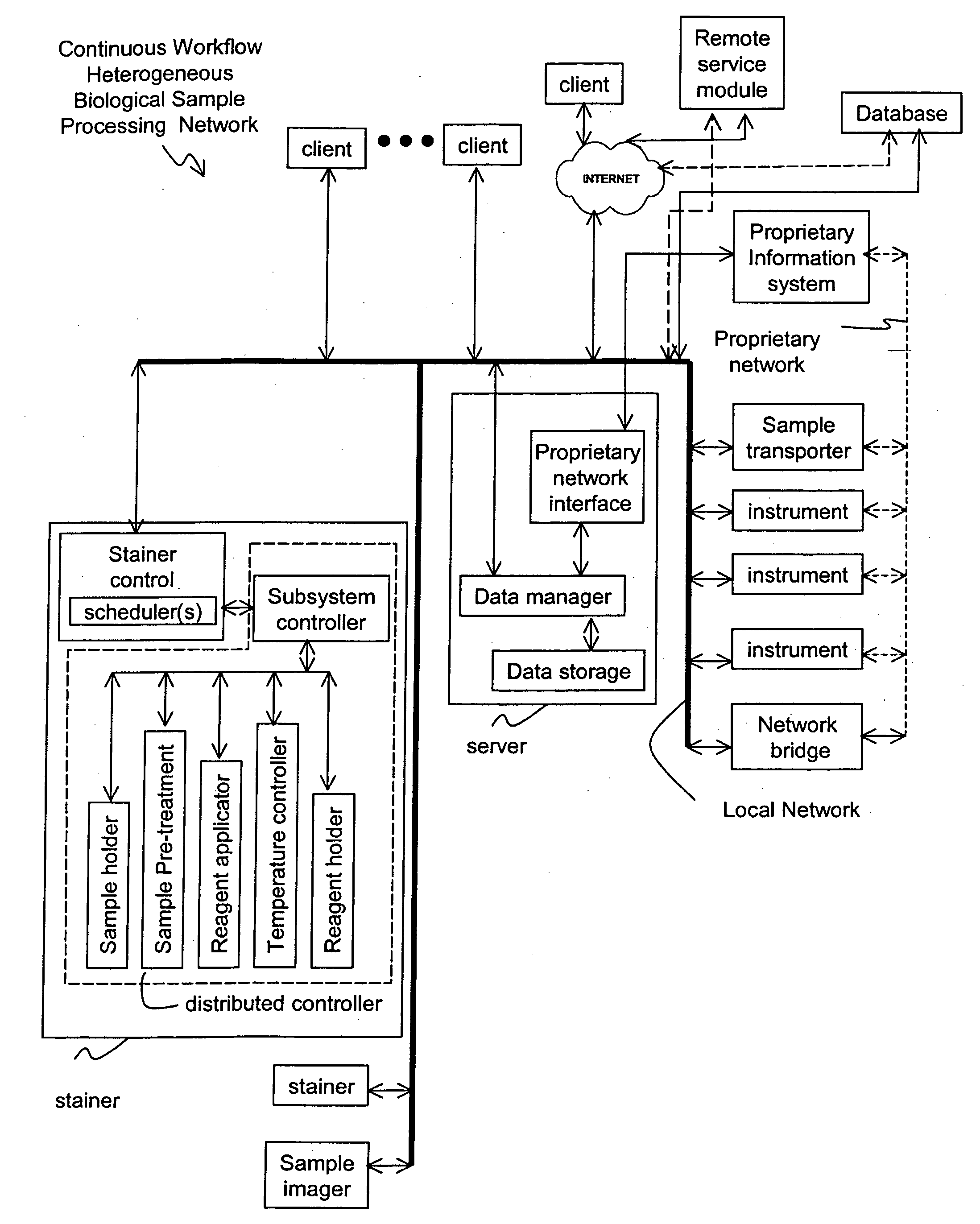

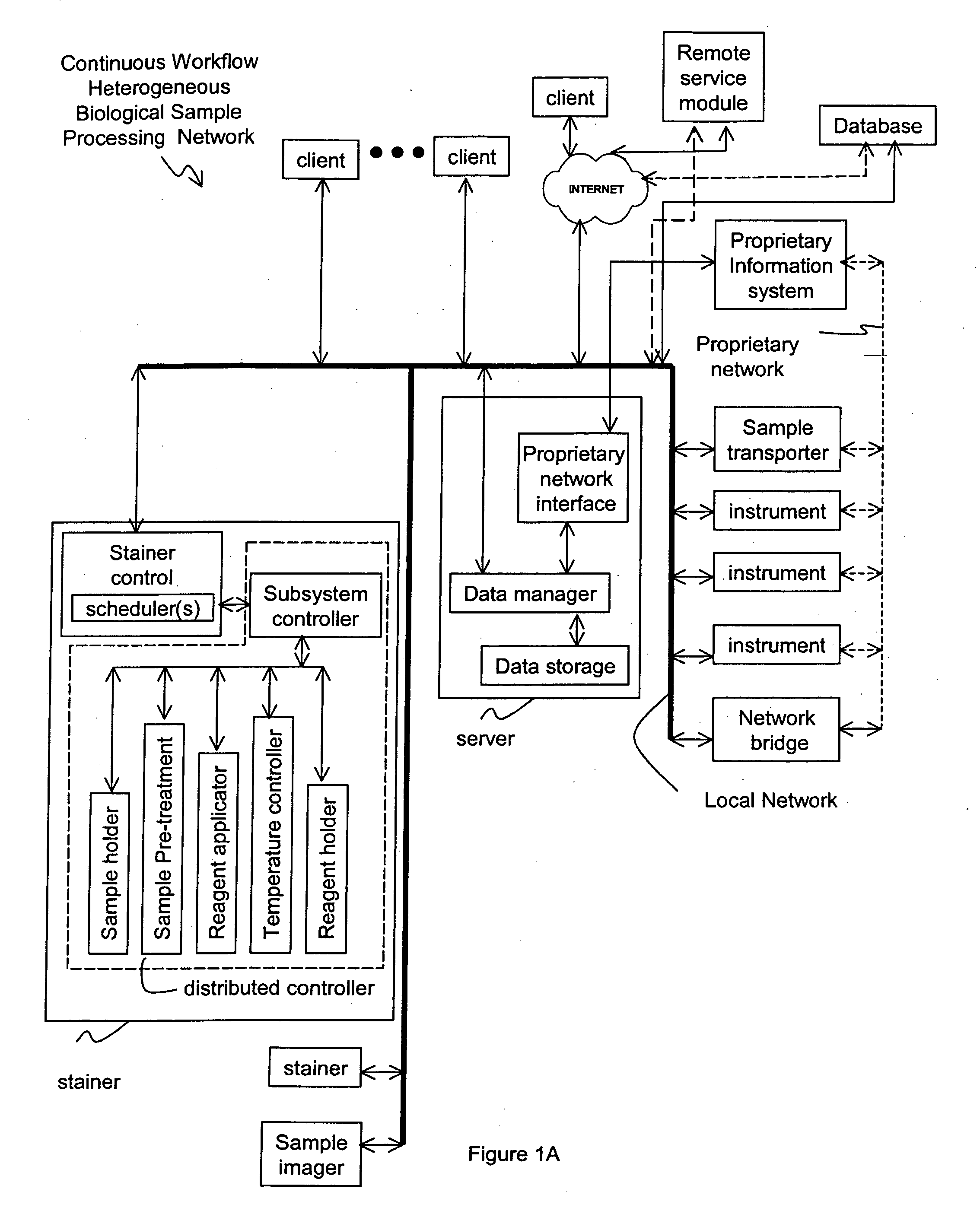

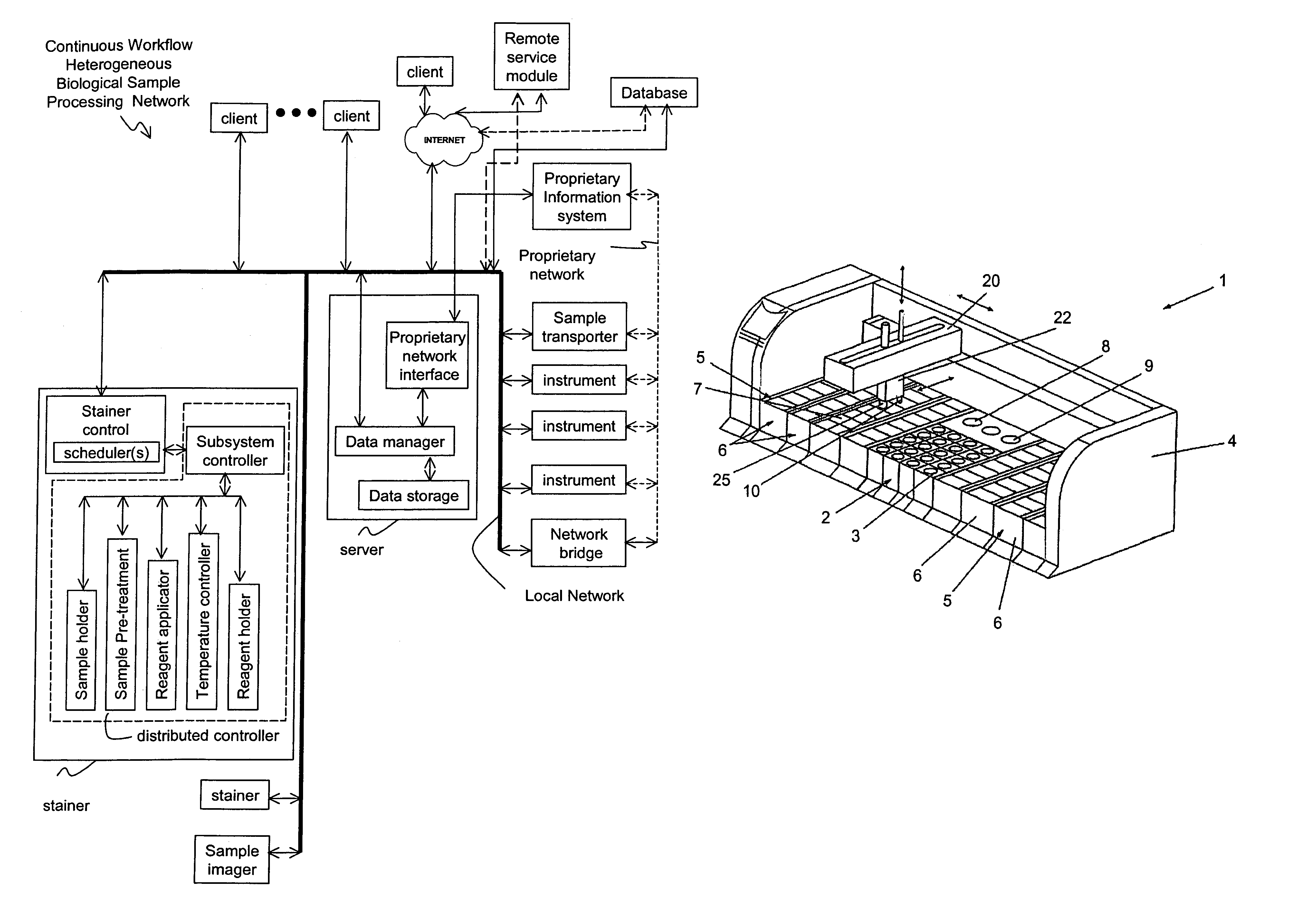

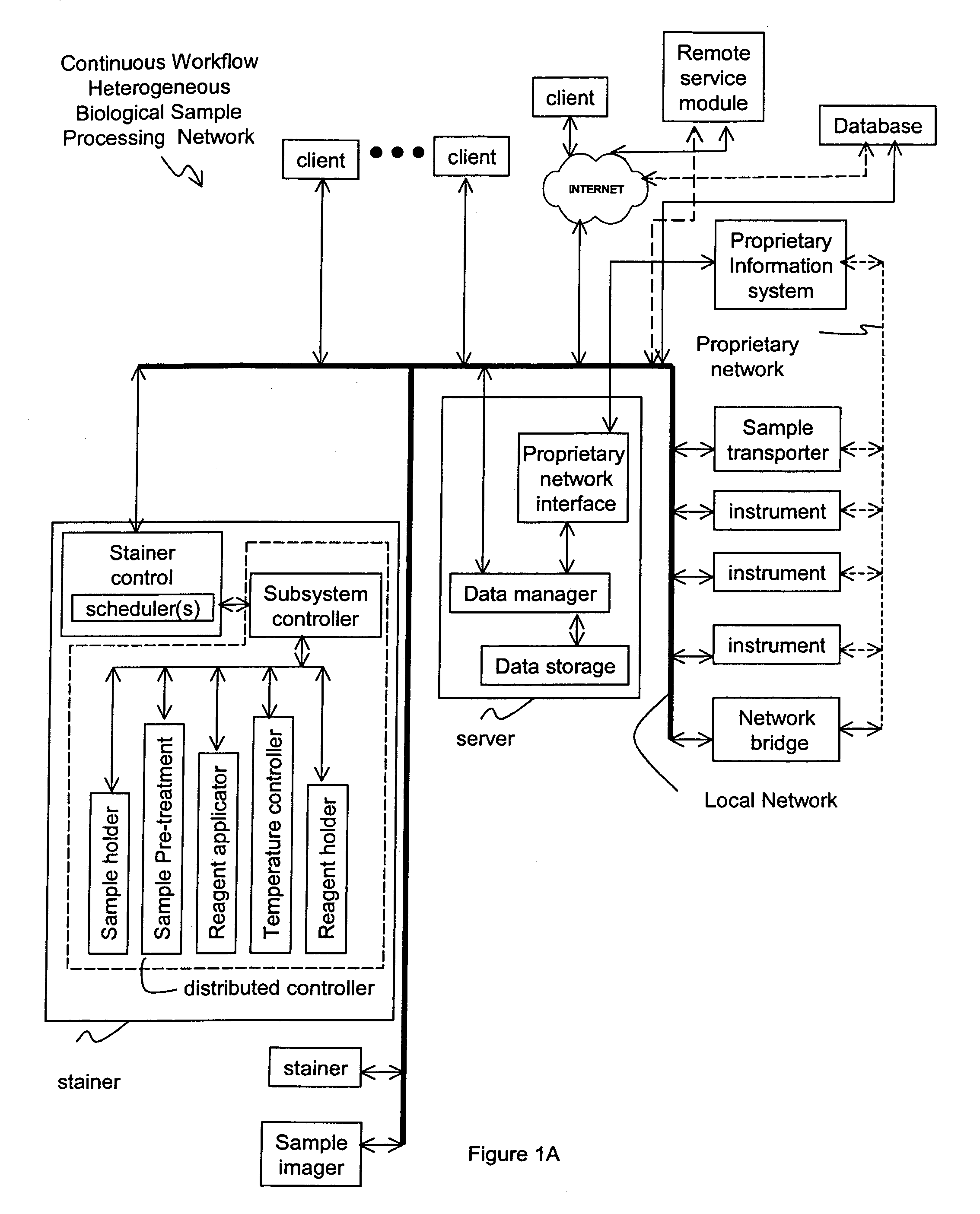

Method and apparatus for automated pre-treatment and processing of biological samples

ActiveUS20060148063A1Maximize throughputImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPre treatmentComputer science

A method and apparatus for continuous workflow processing of biological samples. In one embodiment, the appratus includes a probe for dispensing one or more reagents from one or more reagent containers onto one or more biological sample carriers. The method and apparatus includes processing each biological sample according to a respective sequence of protocol steps which may be ordered by a scheduler protocol. The method and apparatus also includes network capability for connectivity with additional equipment for receiving or transmitting pertinent data via the network.

Owner:AGILENT TECH INC

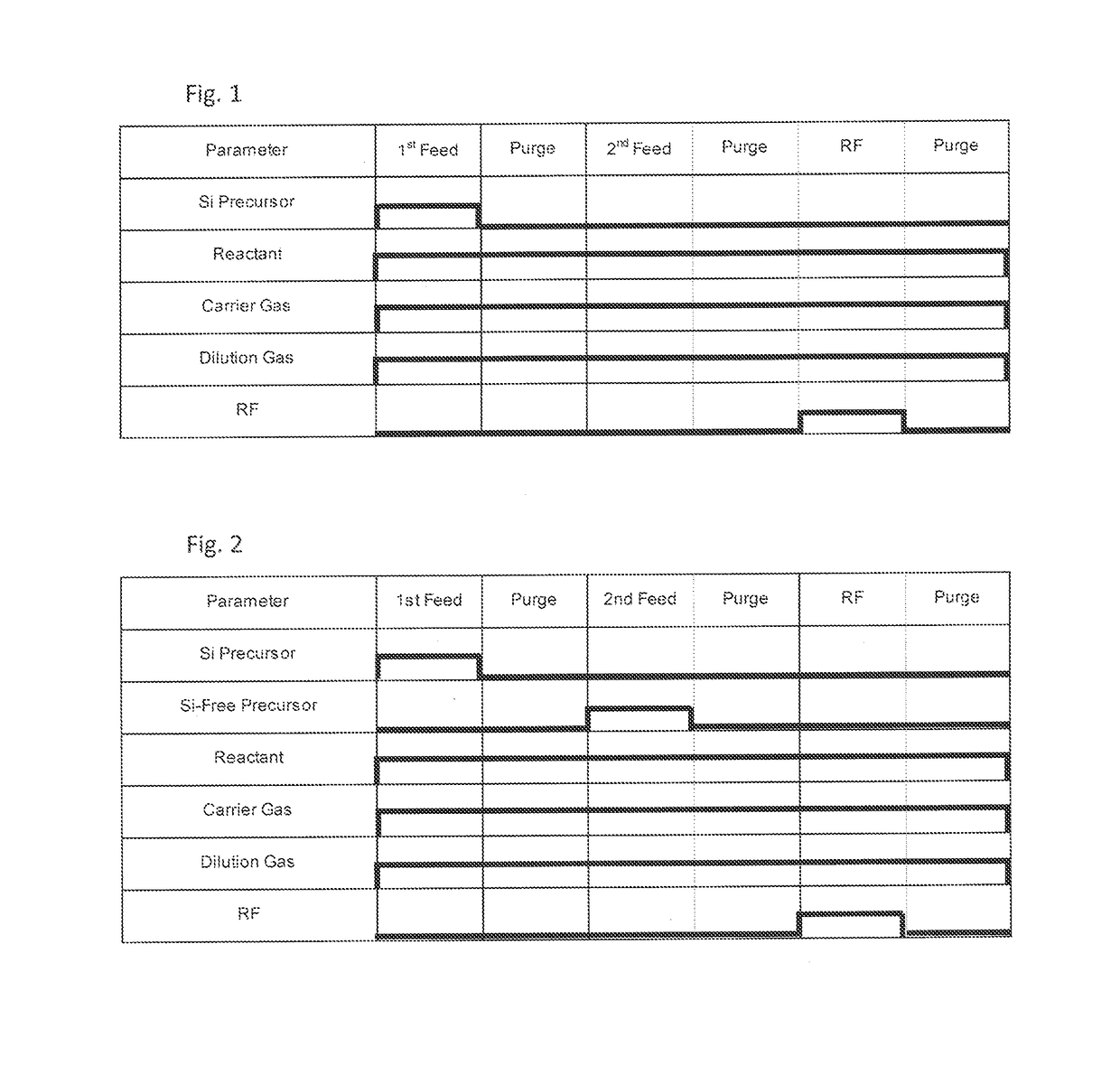

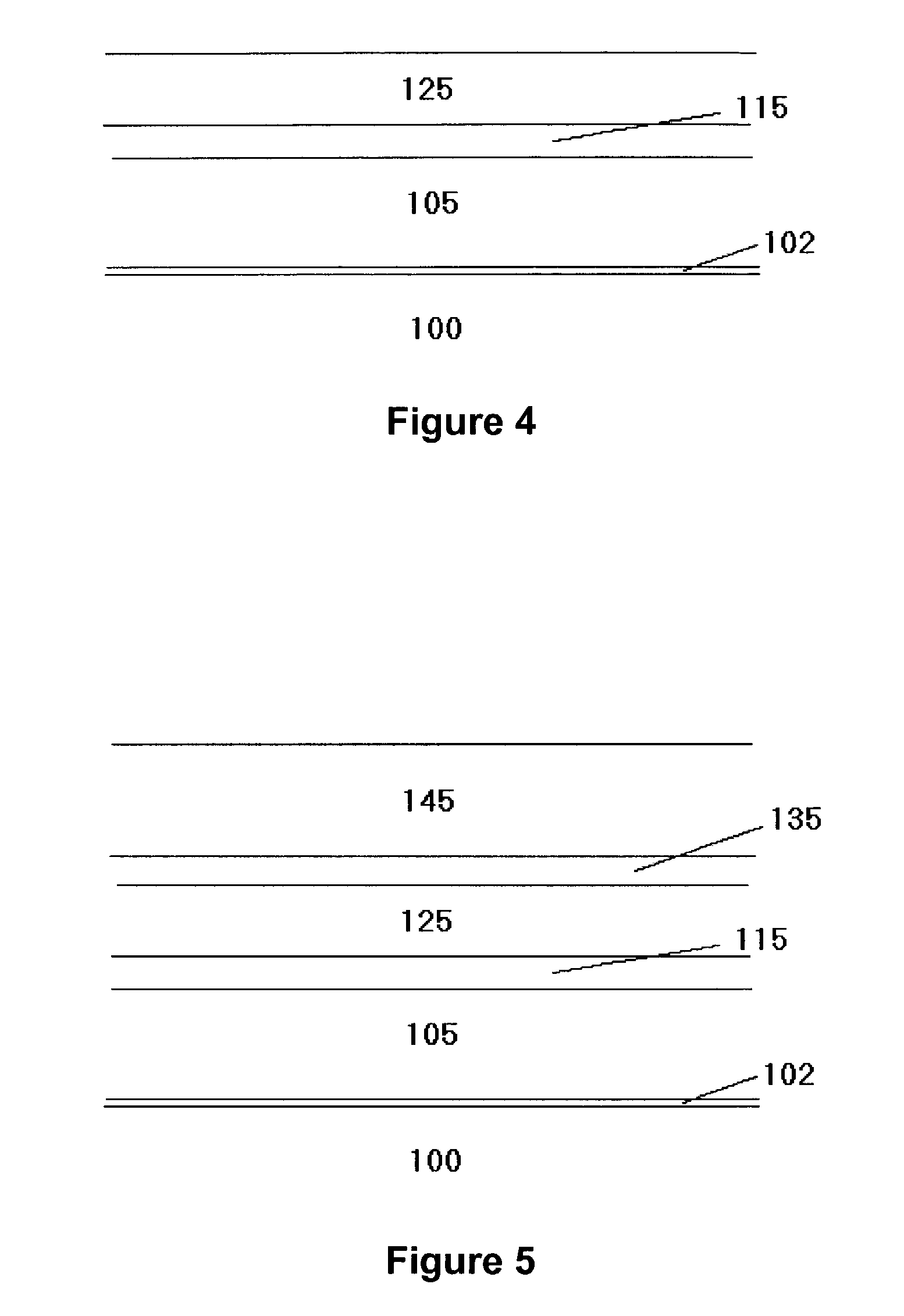

Method for forming conformal nitrided, oxidized, or carbonized dielectric film by atomic layer deposition

ActiveUS10179947B2Easy to oxidizeEasily and nitridedChemical vapor deposition coatingPlasma techniqueDielectric membraneThin membrane

A method for forming a film on a patterned surface of a substrate by atomic layer deposition (ALD) processing includes: adsorbing onto a patterned surface a first precursor containing silicon or metal in its molecule; adsorbing onto the first-precursor-adsorbed surface a second precursor containing no silicon or metal in its molecule; exposing the second-precursor-adsorbed surface to an excited reactant to oxidize, nitride, or carbonize the precursors adsorbed on the surface of the substrate; and repeating the above cycle to form a film on the patterned surface of the substrate.

Owner:ASM IP HLDG BV

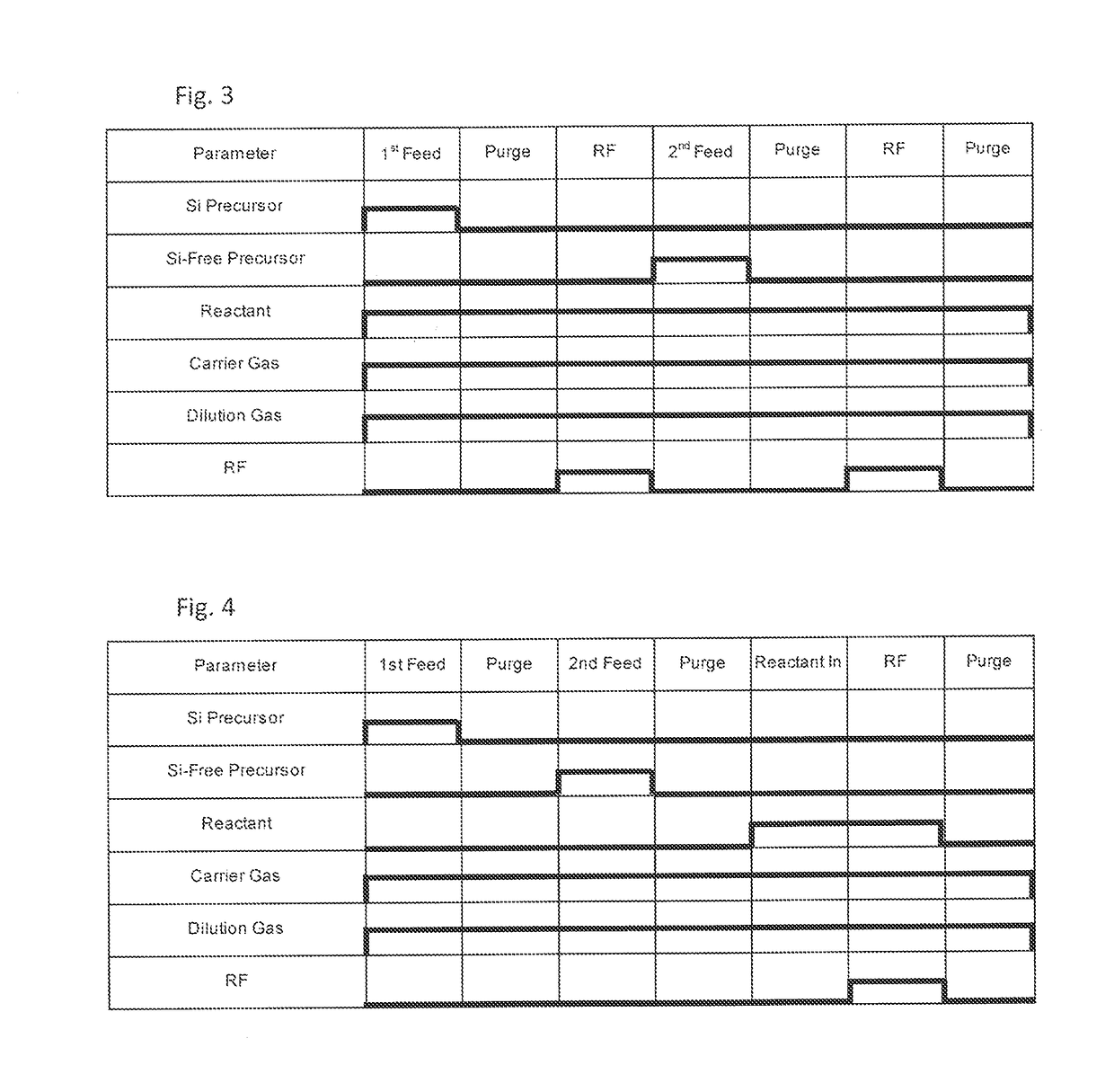

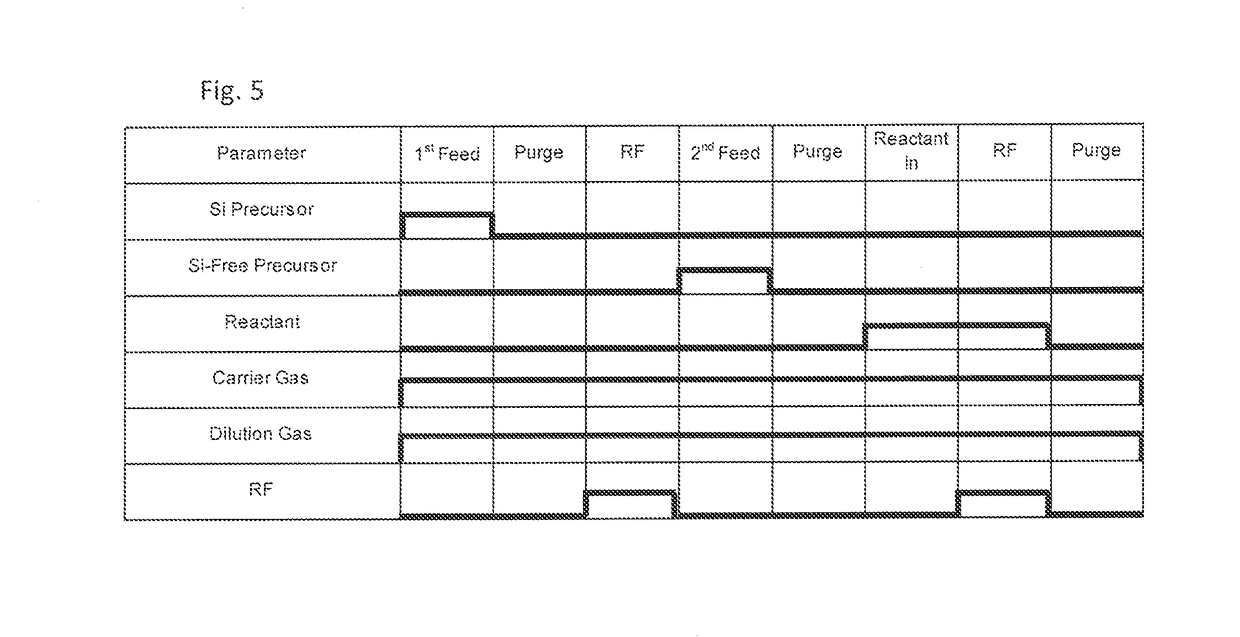

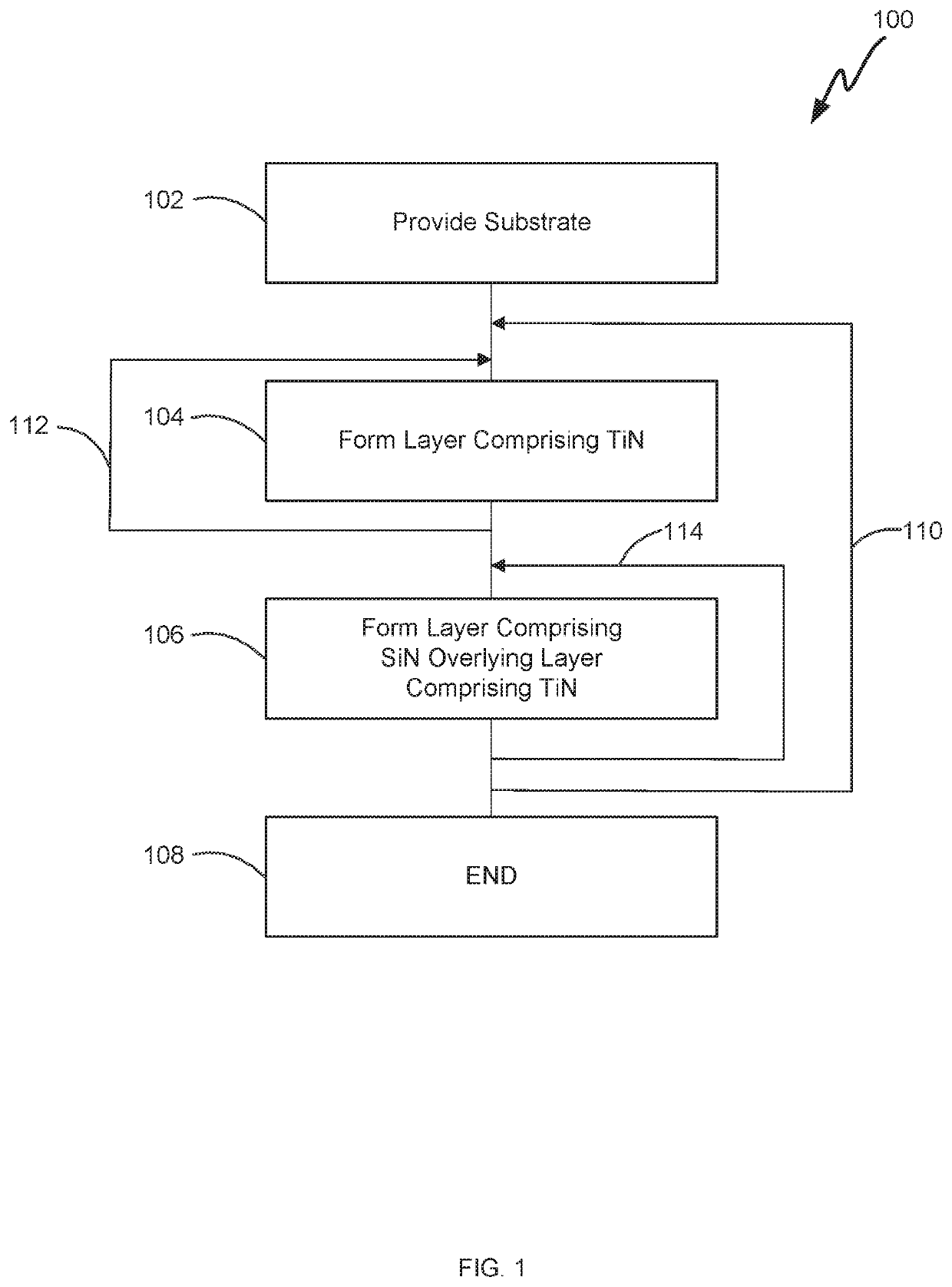

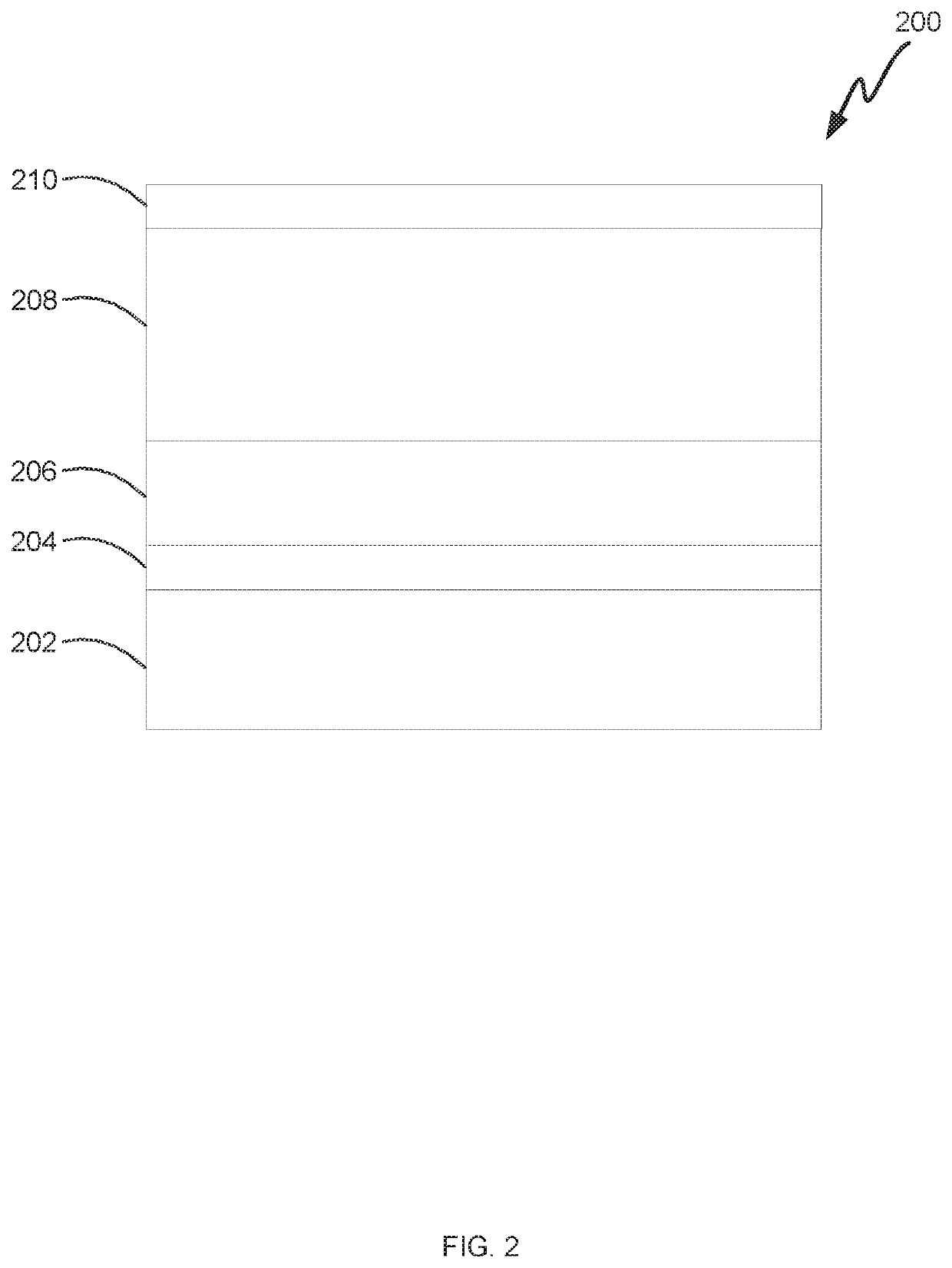

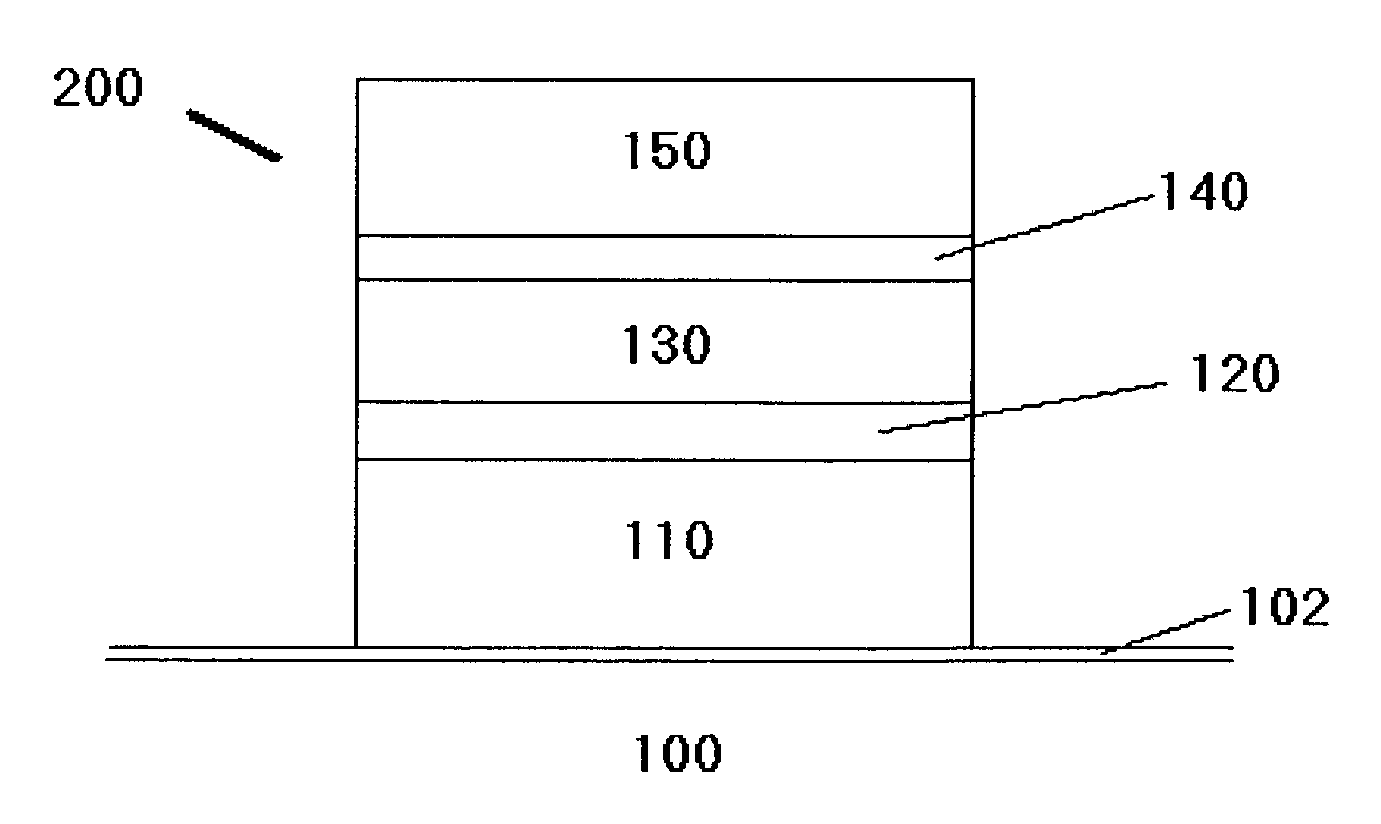

Method of forming a structure including silicon nitride on titanium nitride and structure formed using the method

PendingUS20200181770A1Reduce oxidationEasy to oxidizeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyTitanium nitride

A method of forming a structure including a silicon nitride overlying a titanium nitride layer is disclosed. The method includes forming the titanium nitride layer and the silicon nitride layer in the same reaction chamber—e.g., without a vacuum break—to mitigate oxidation of the titanium nitride layer that might otherwise occur.

Owner:ASM IP HLDG BV

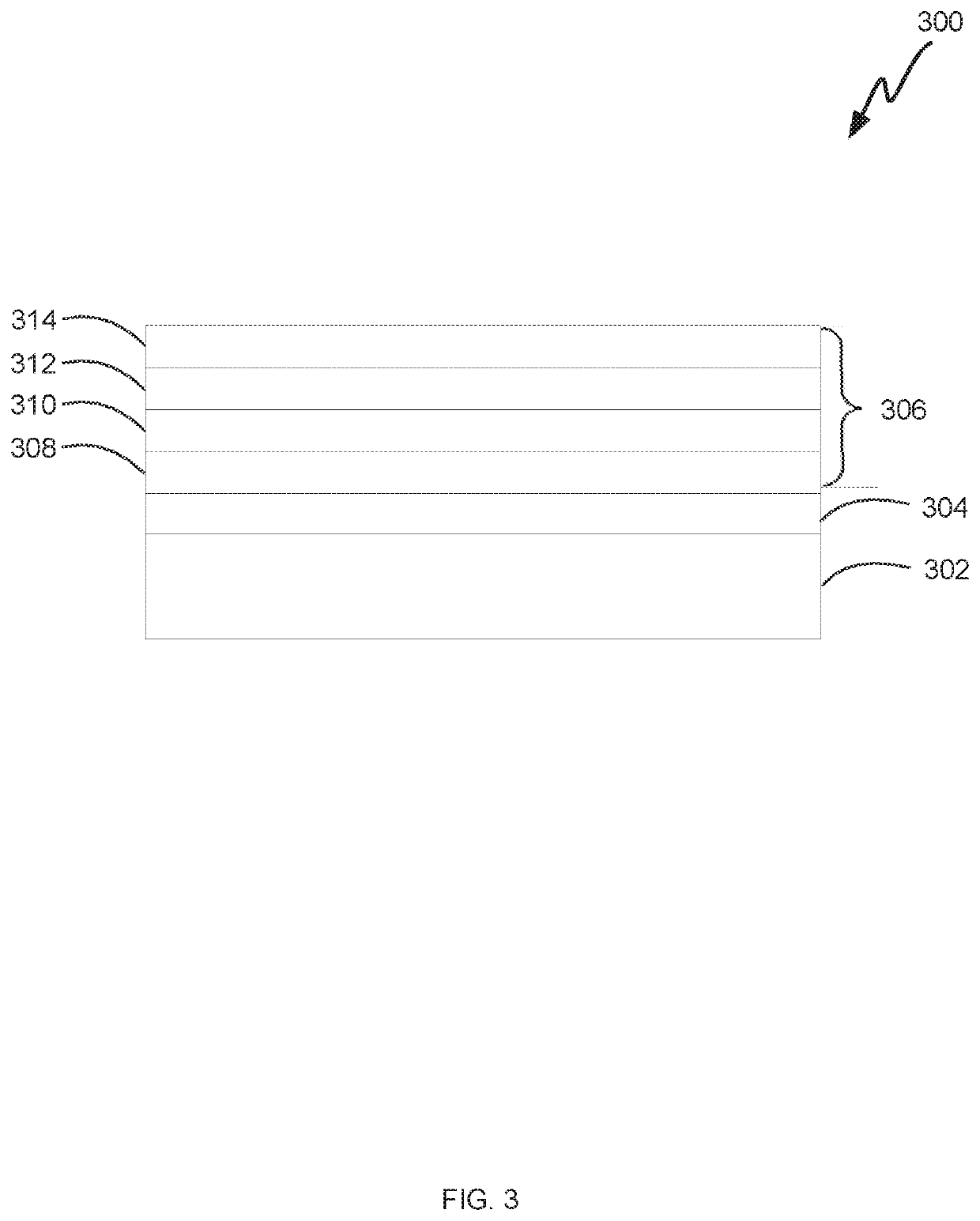

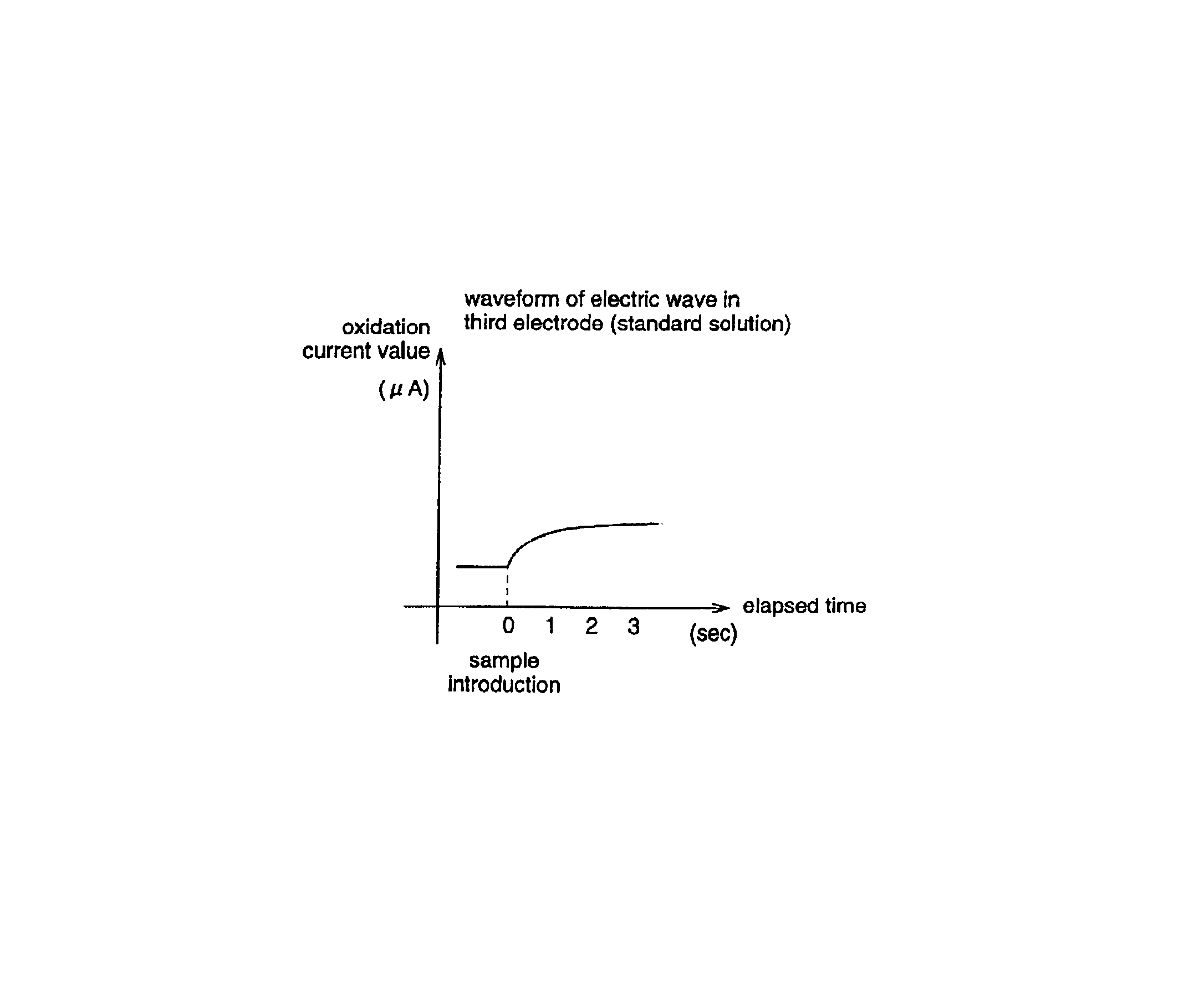

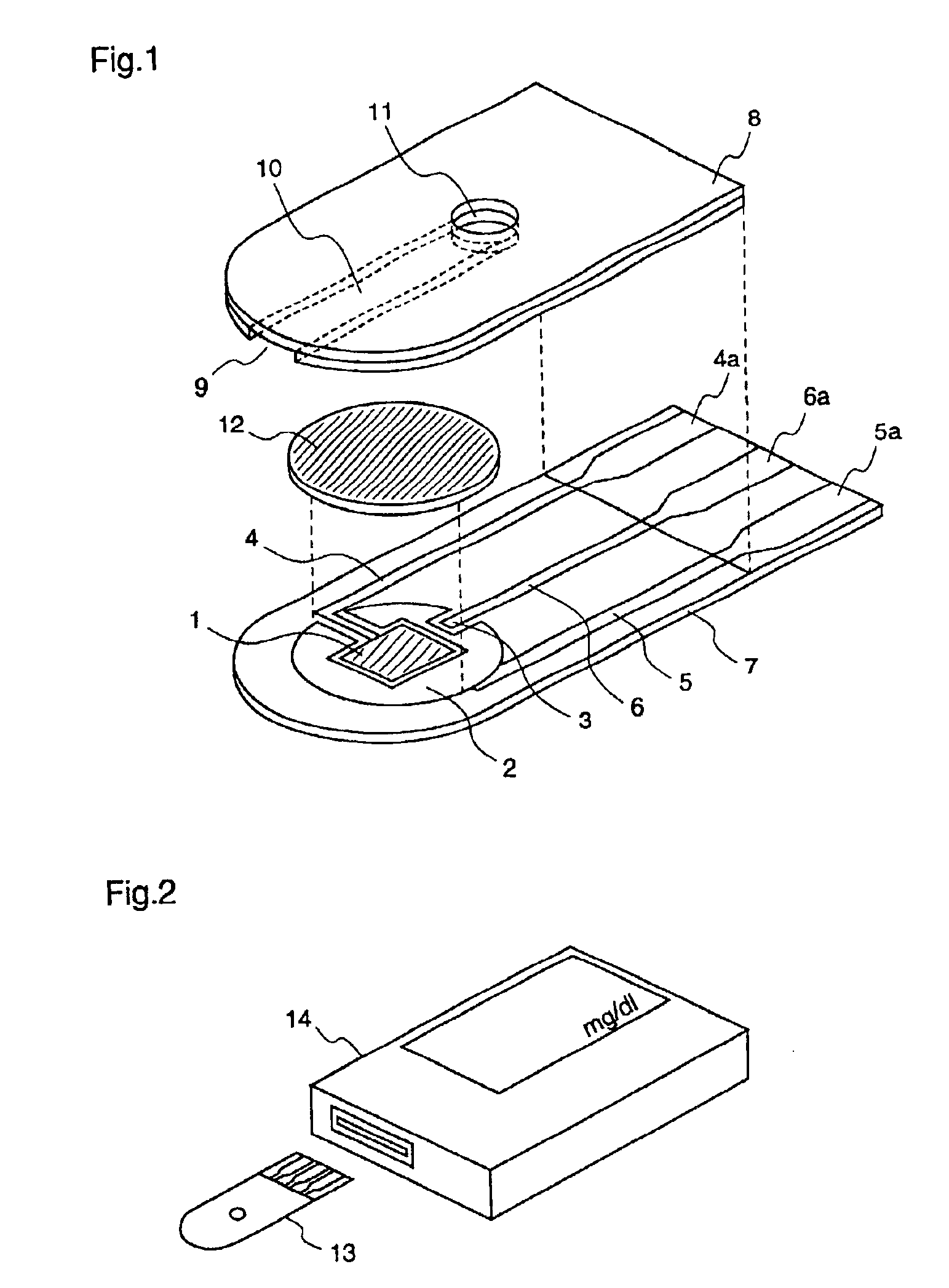

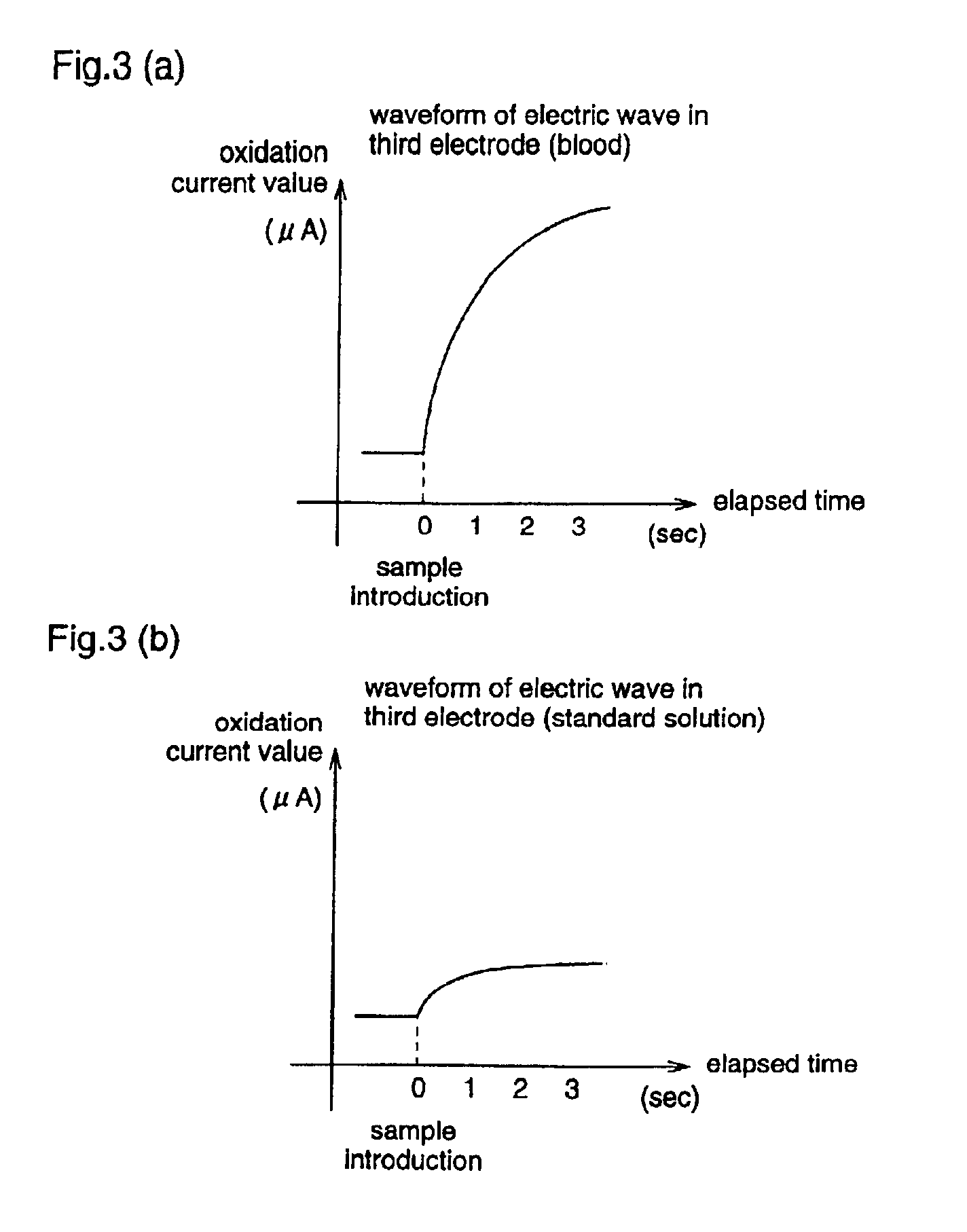

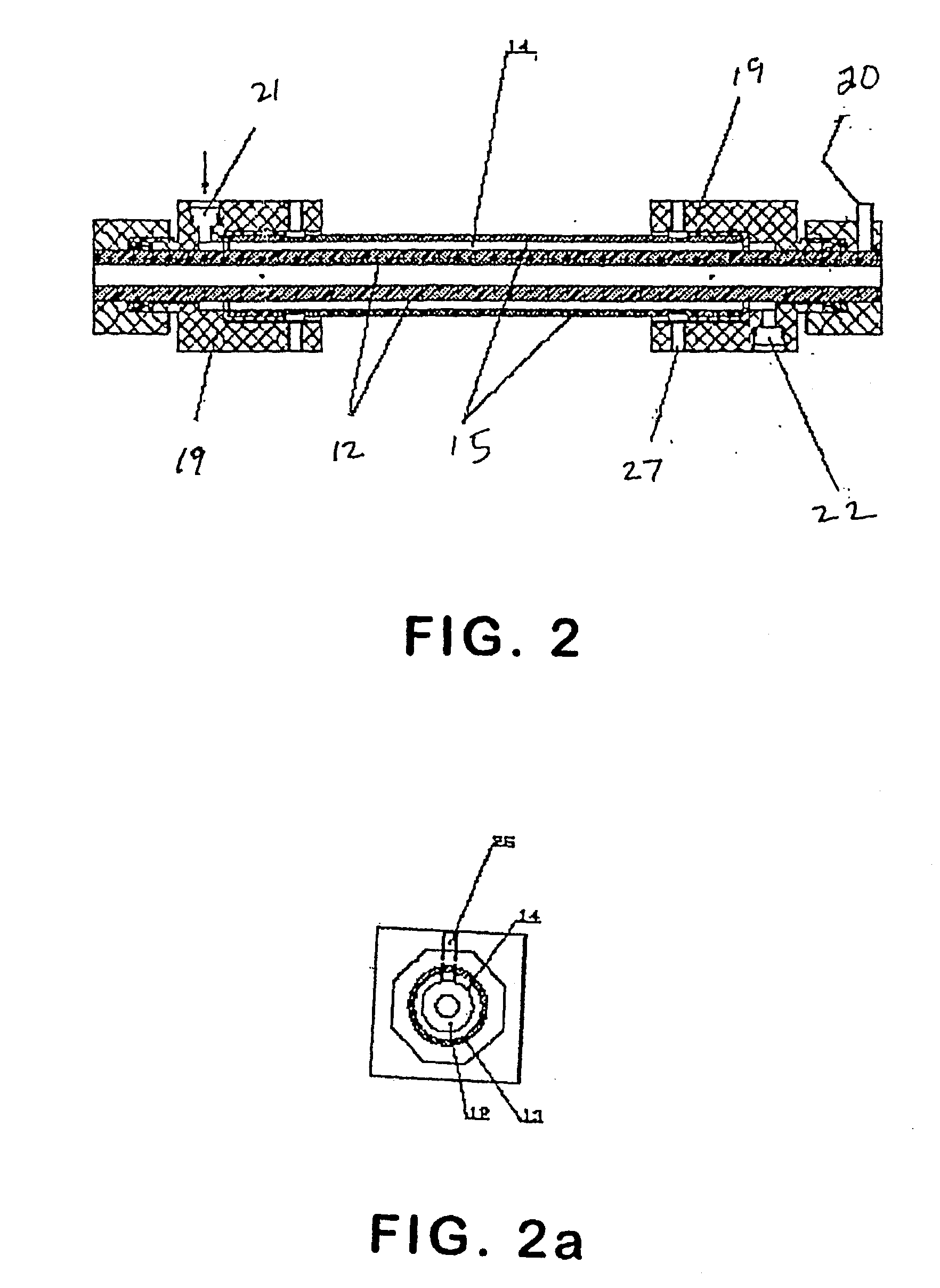

Measuring device using biosensor and biosenor used for it, and dedicated standard liquid

InactiveUS6881322B2Easy to oxidizeImmobilised enzymesBioreactor/fermenter combinationsReaction layerMeasurement device

A reaction layer 12 which reacts with a substance to be measured in a sample solution is provided on a working electrode 1, a counter electrode 2, and a third electrode 3 which are provided on an insulating substrate 7 so as to bridge the respective electrodes, the content of the substance to be measured is measured from a current value which reaction is obtained between the working electrode 1 and the counter electrode 2, and the types of sample solution is judged by a difference between oxidation current values or between oxidation current waveforms, which are obtained between the third electrode 3 and the counter electrode 2 or between the third electrode 3 and the working electrode 1, thereby automatically judging the types of sample solution.

Owner:PHC HLDG CORP

Method for cleaning a gate stack

InactiveUS7396773B1Easy to oxidizeNon-surface-active detergent compositionsDetergent mixture composition preparationSemiconductor structureGate stack

A method of making a semiconductor structure, comprises cleaning a gate stack with a cleaning solution. The gate stack comprises a gate layer, a metallic layer on the gate layer, and a etch-stop layer on the metallic layer. The gate layer is on a semiconductor substrate, the cleaning solution is a non-oxidizing cleaning solution, and the metallic layer comprises an easily oxidized metal.

Owner:CYPRESS SEMICON CORP

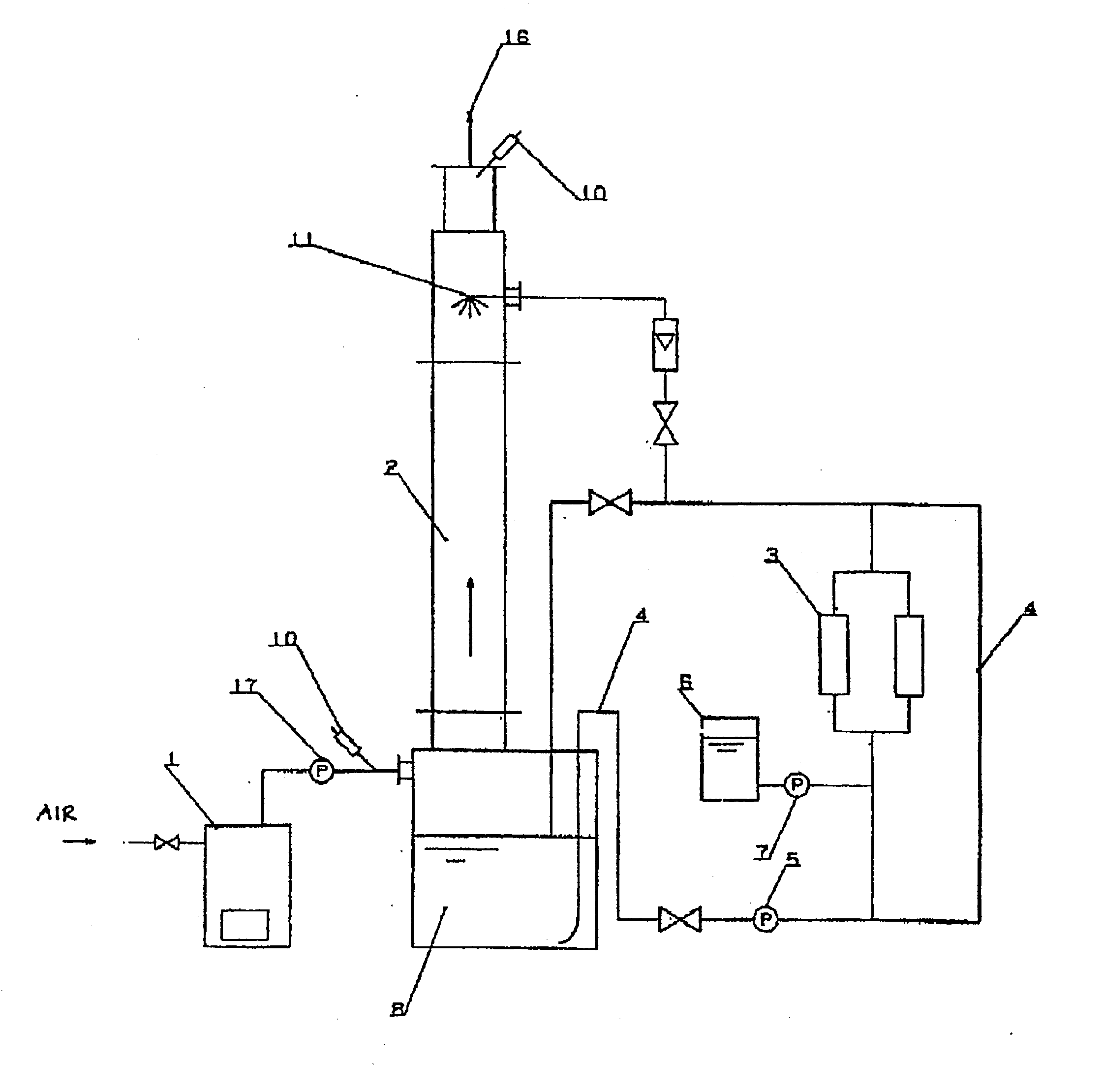

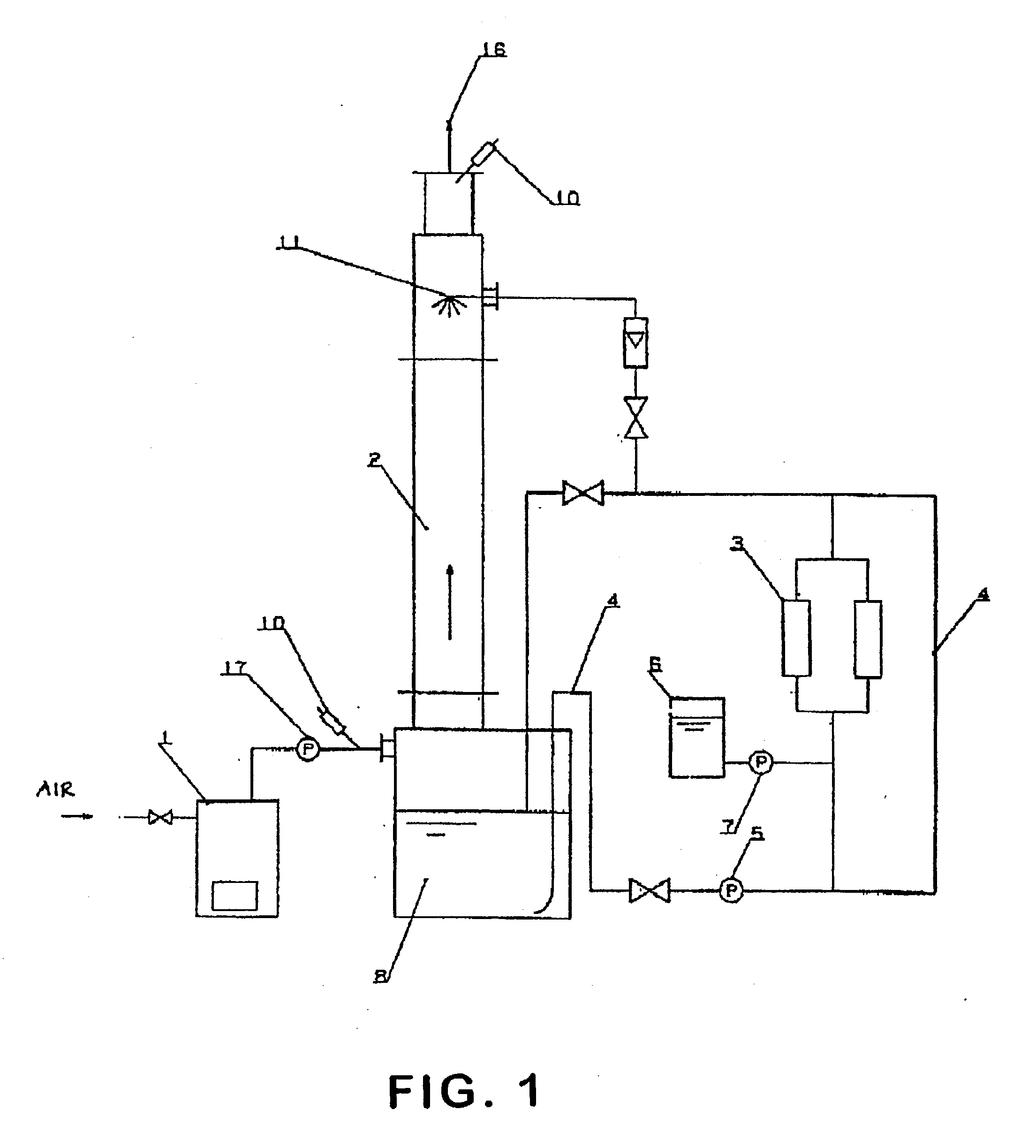

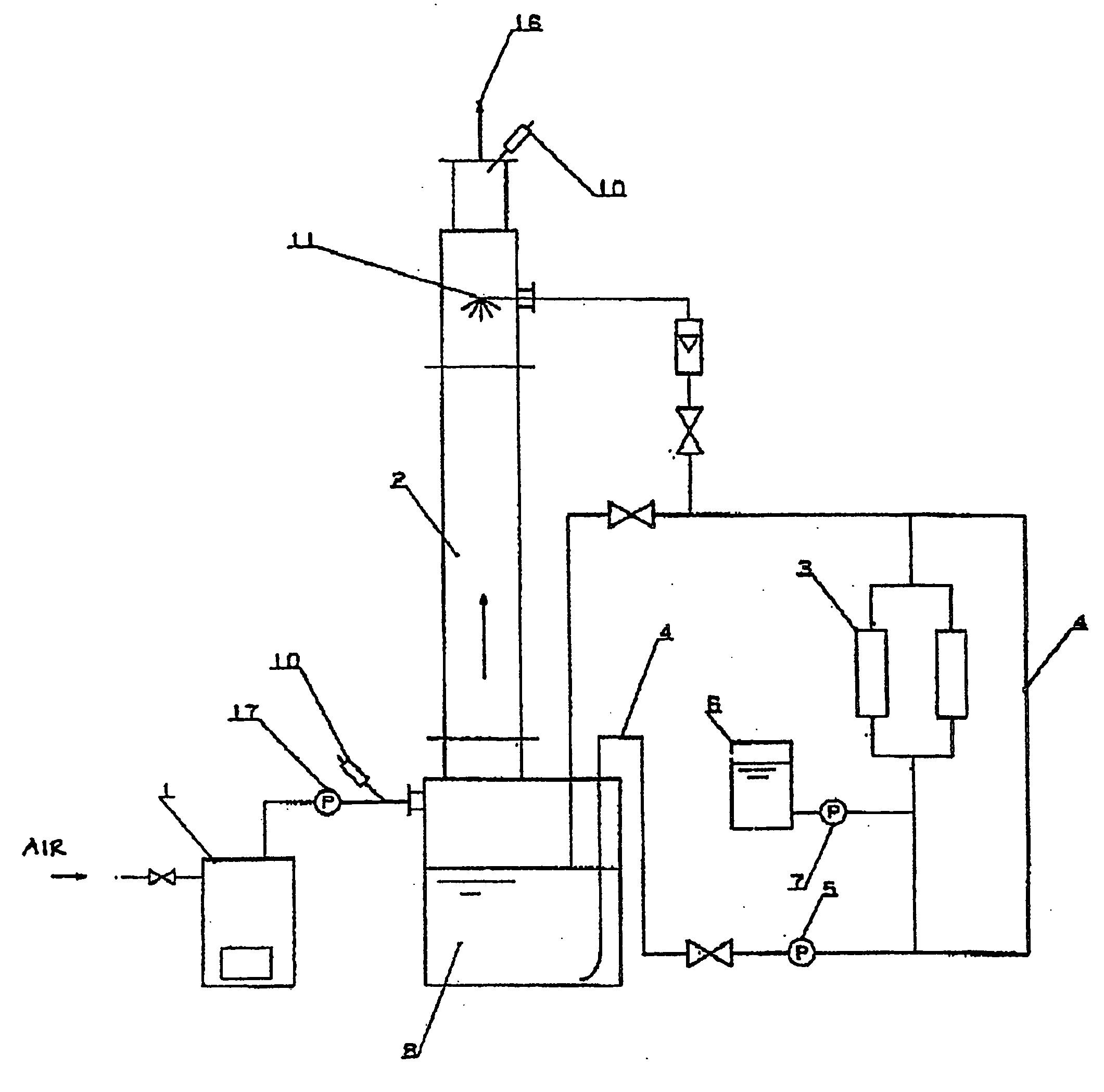

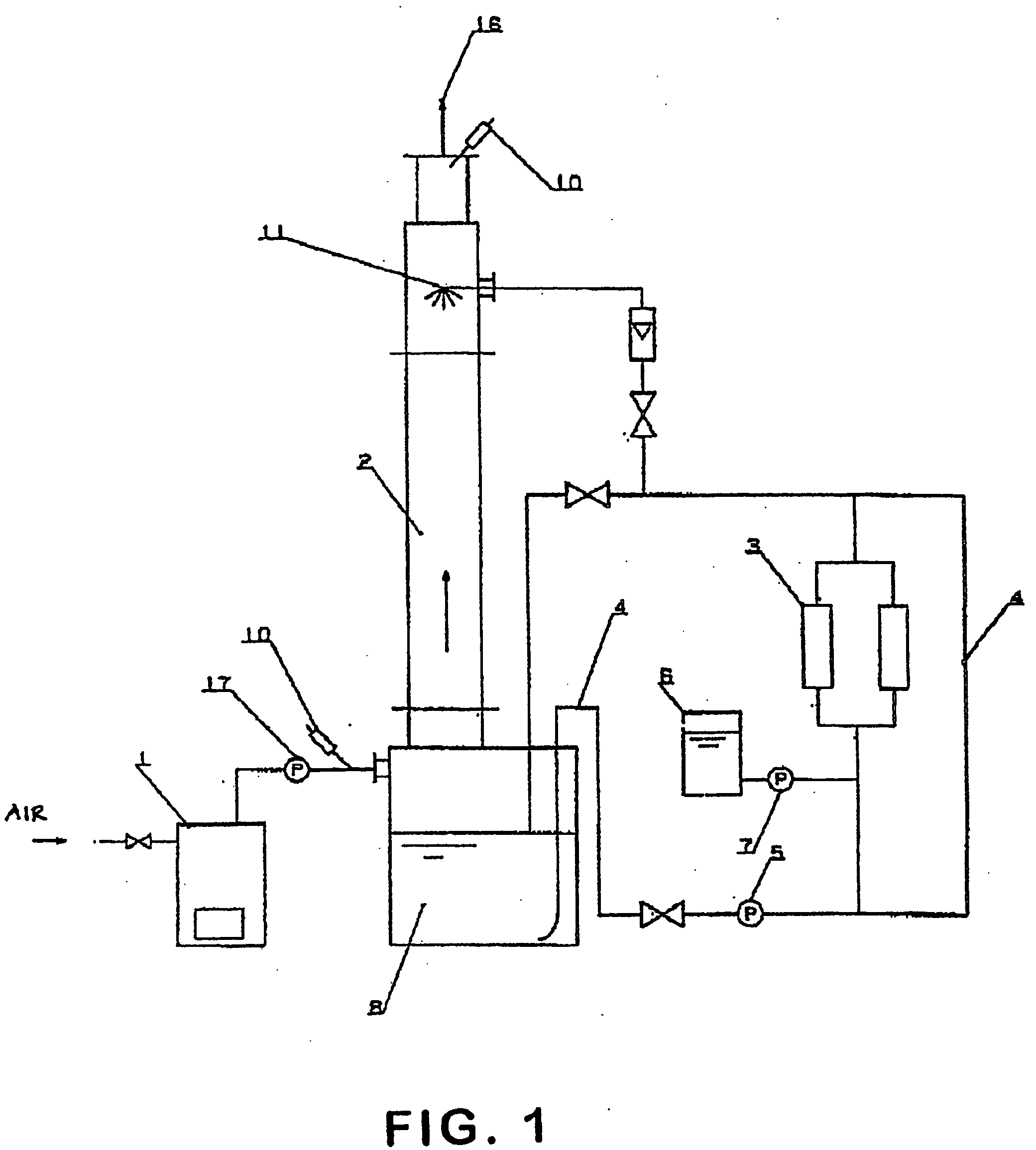

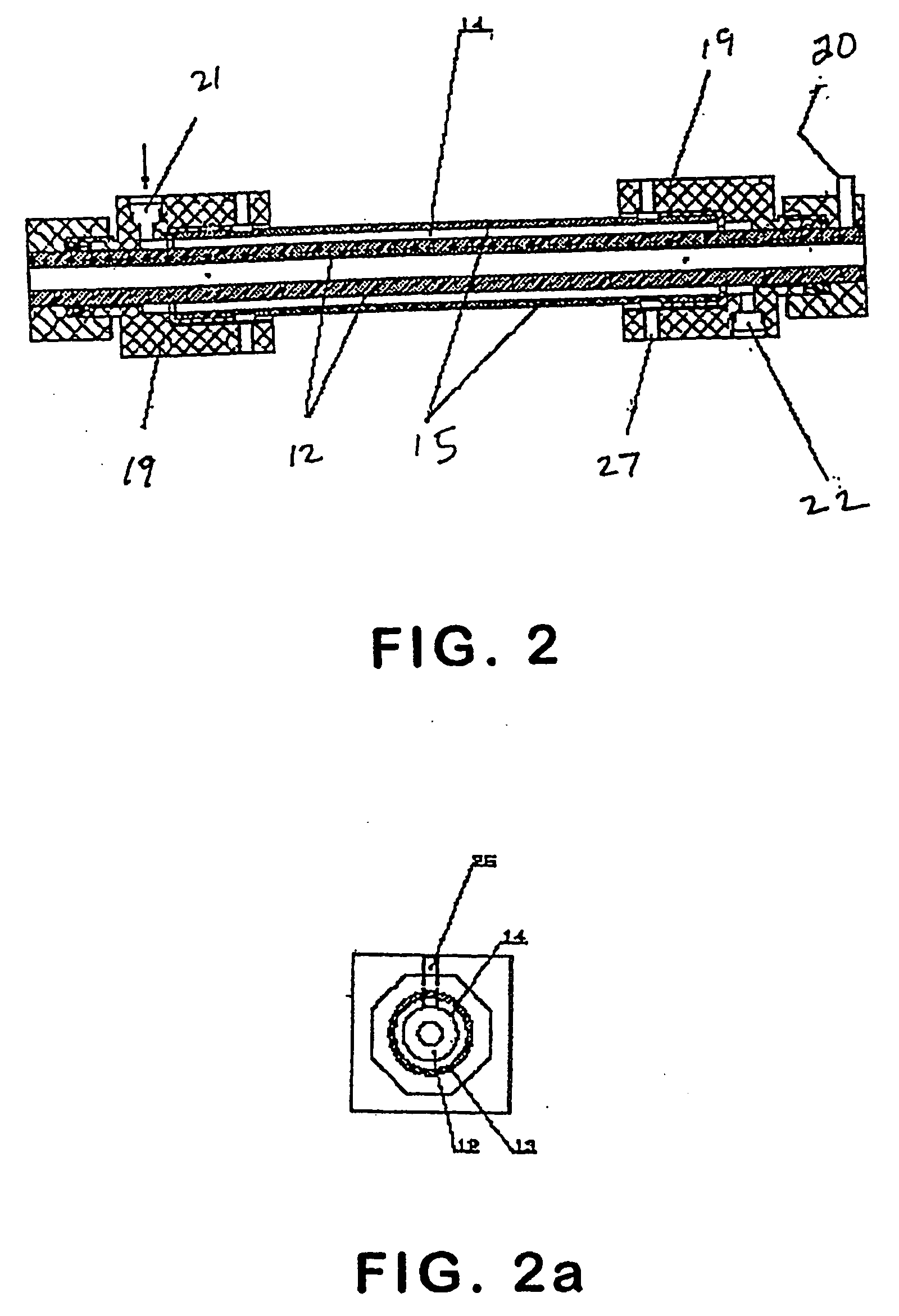

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

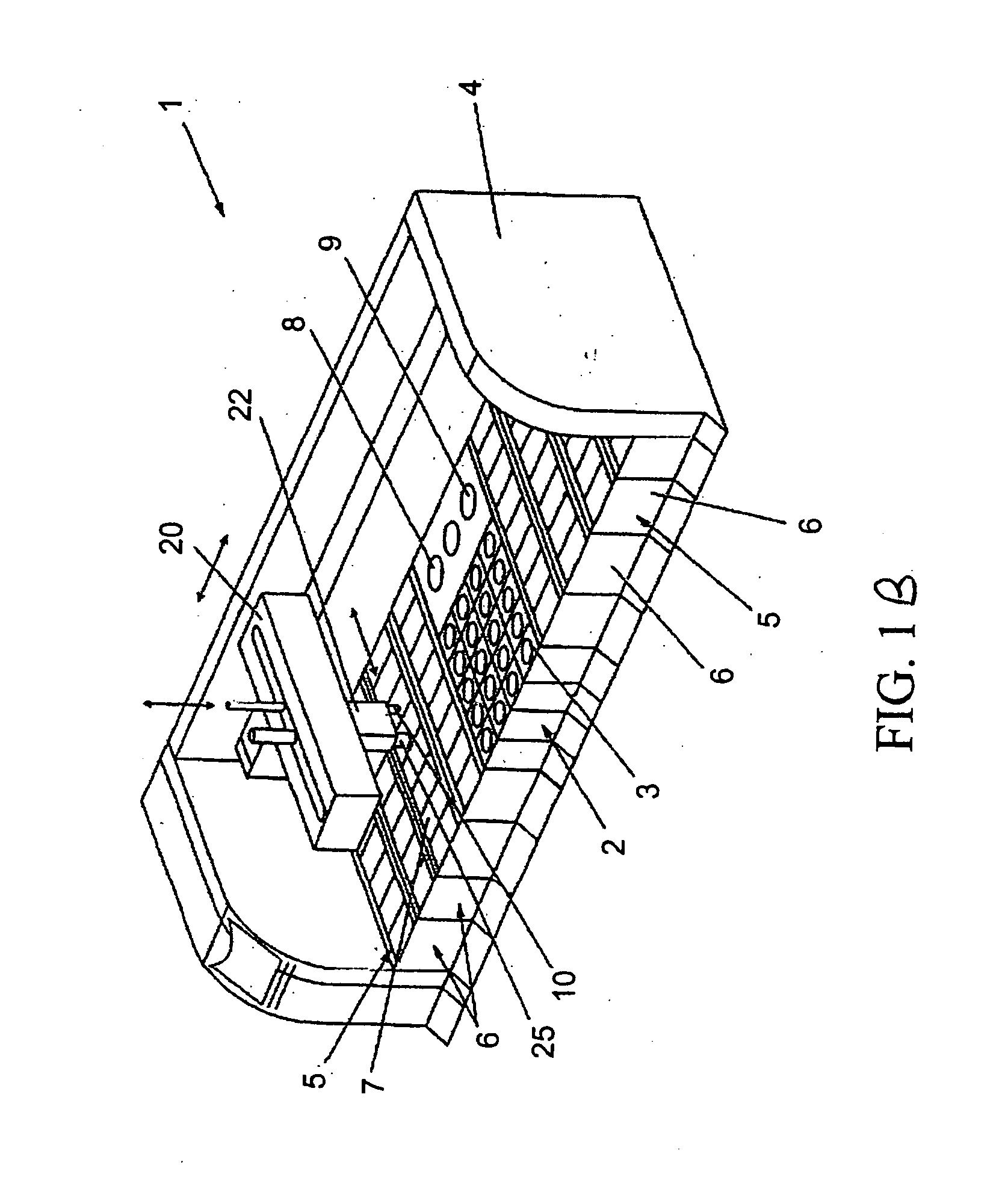

Method and apparatus for automated pre-treatment and processing of biological samples

ActiveUS7850912B2Unstable over timeShort timeBioreactor/fermenter combinationsBiological substance pretreatmentsSequence processingWork flow

A method and apparatus for continuous workflow processing of biological samples. In one embodiment, the apparatus includes a probe for dispensing one or more reagents from one or more reagent containers onto one or more biological sample carriers. The method and apparatus includes processing each biological sample according to a respective sequence of protocol steps which may be ordered by a scheduler protocol. The method and apparatus also includes network capability for connectivity with additional equipment for receiving or transmitting pertinent data via the network.

Owner:AGILENT TECH INC

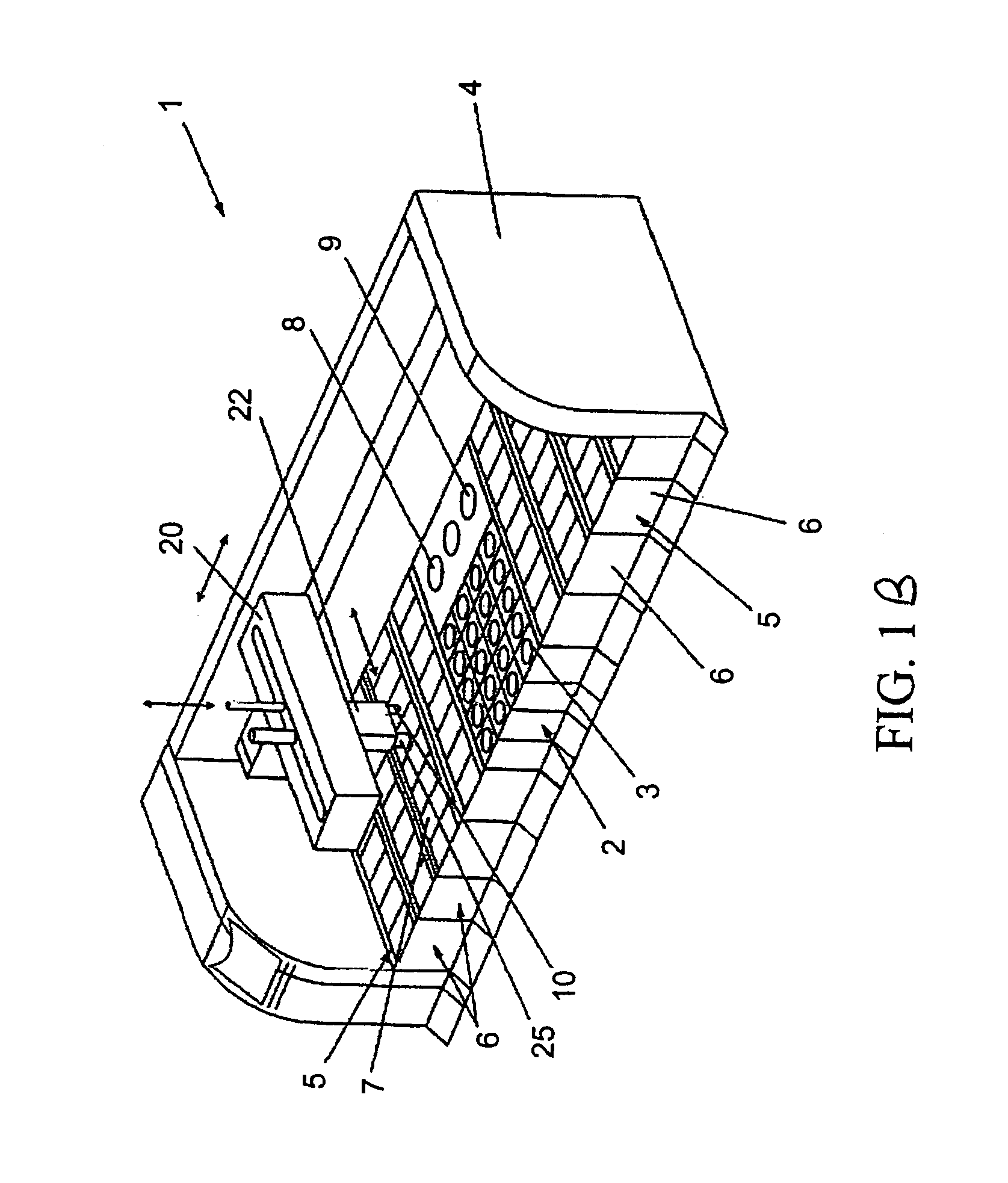

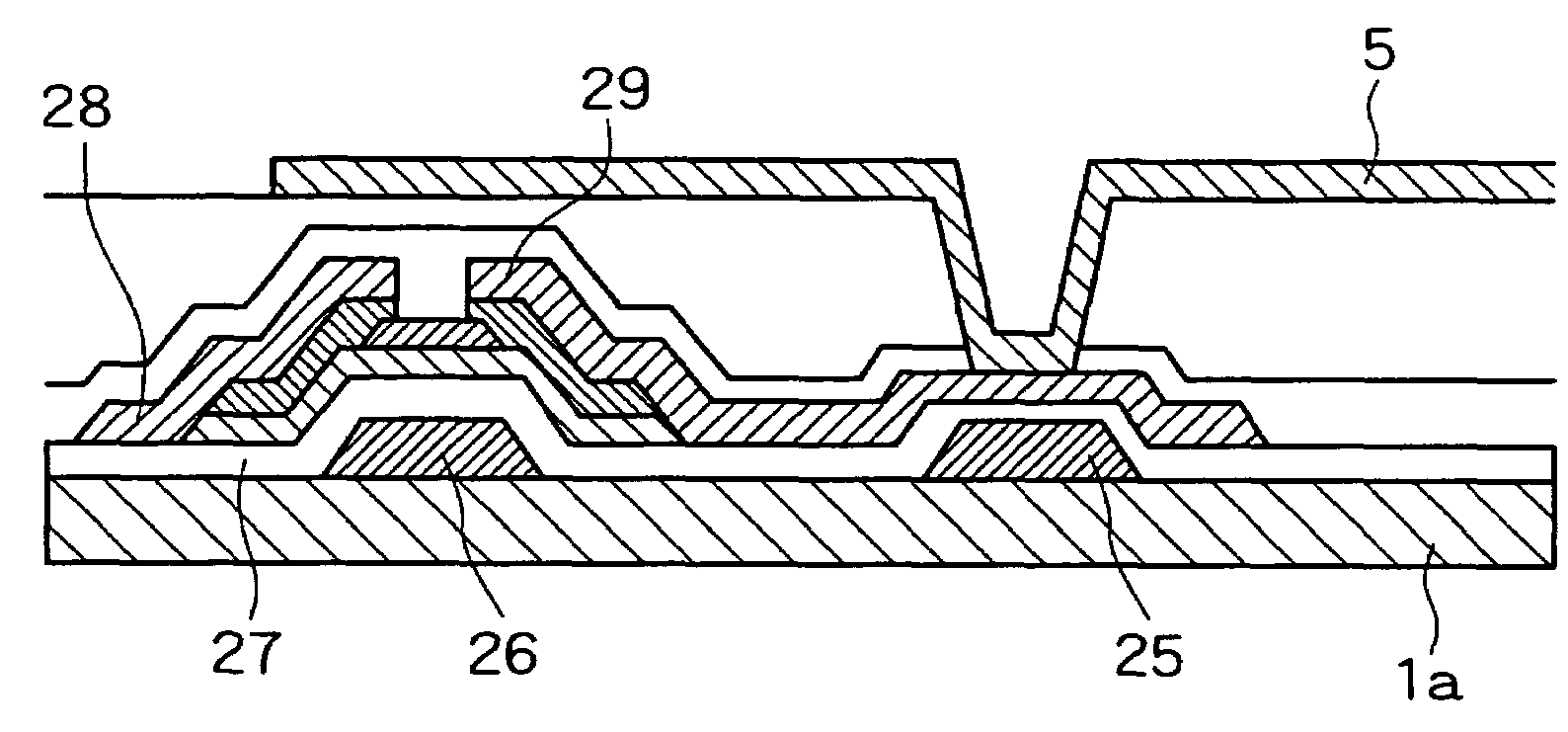

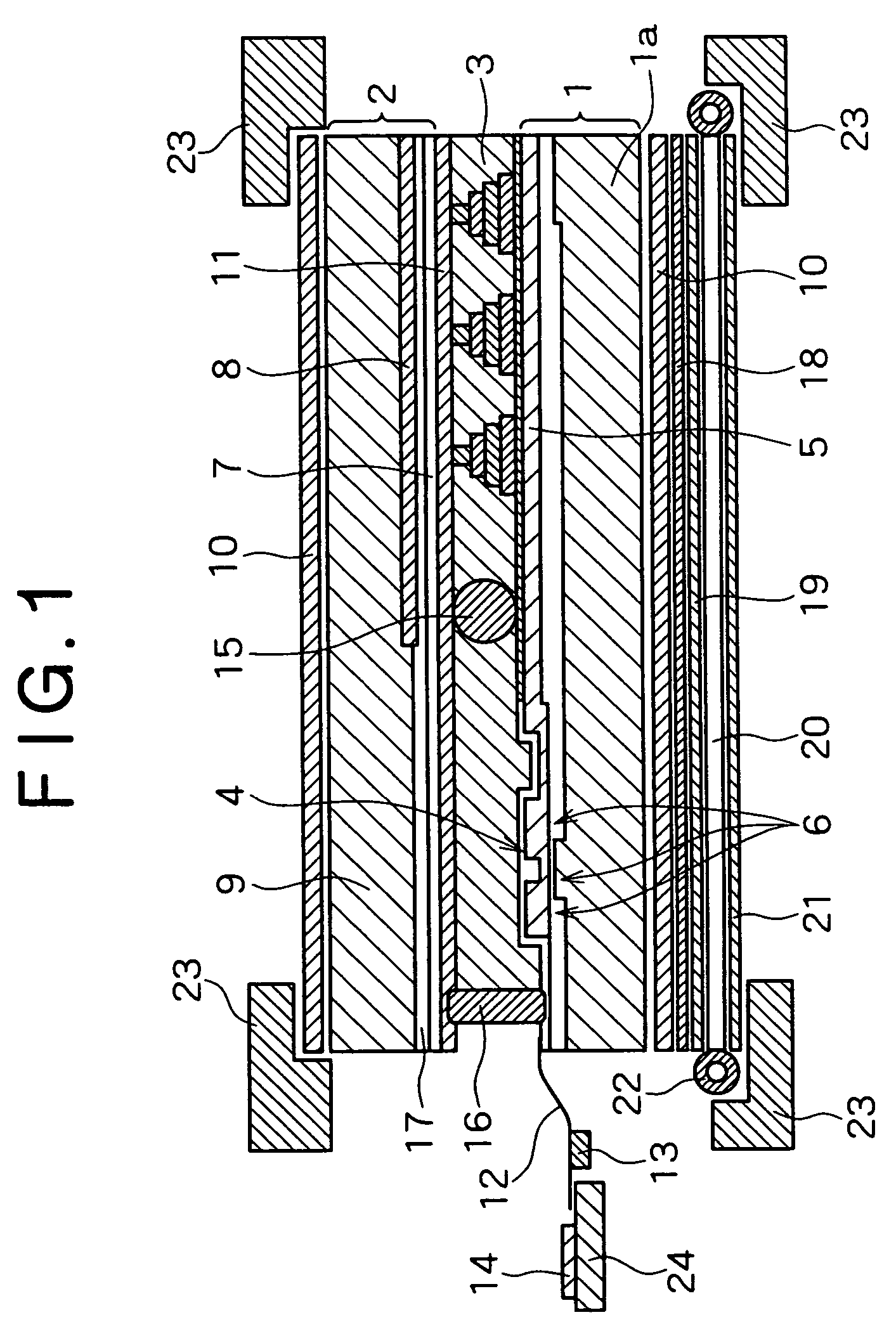

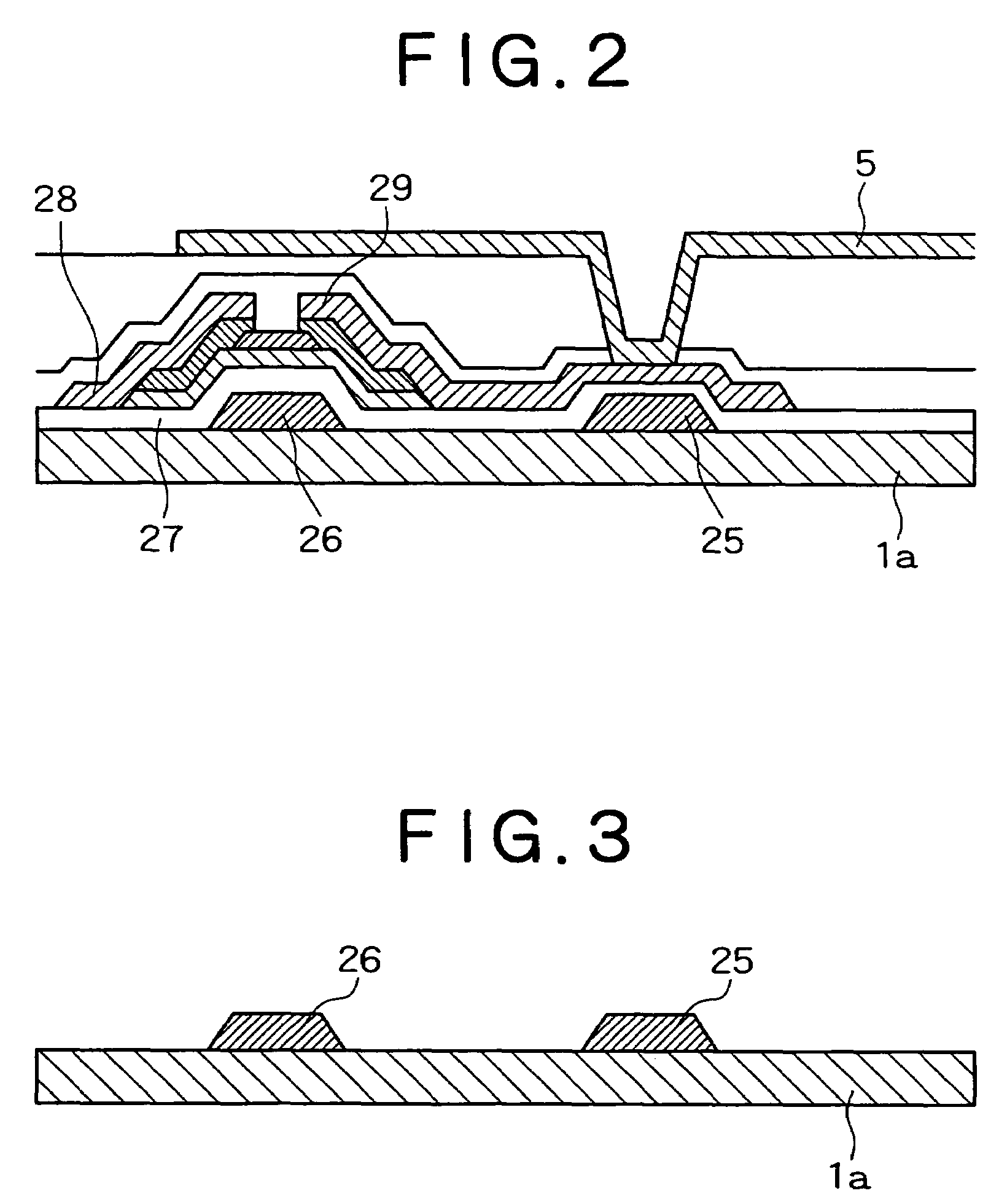

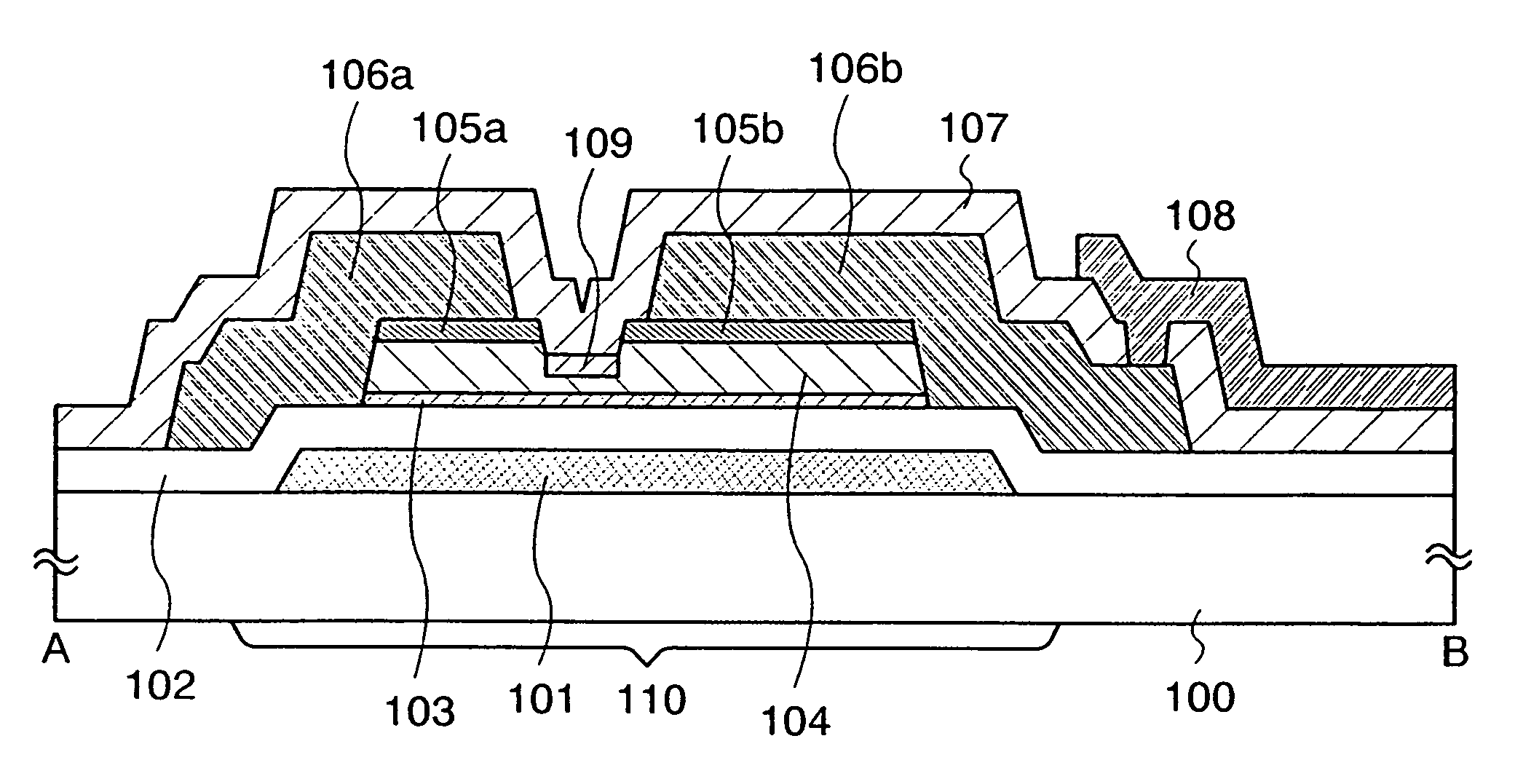

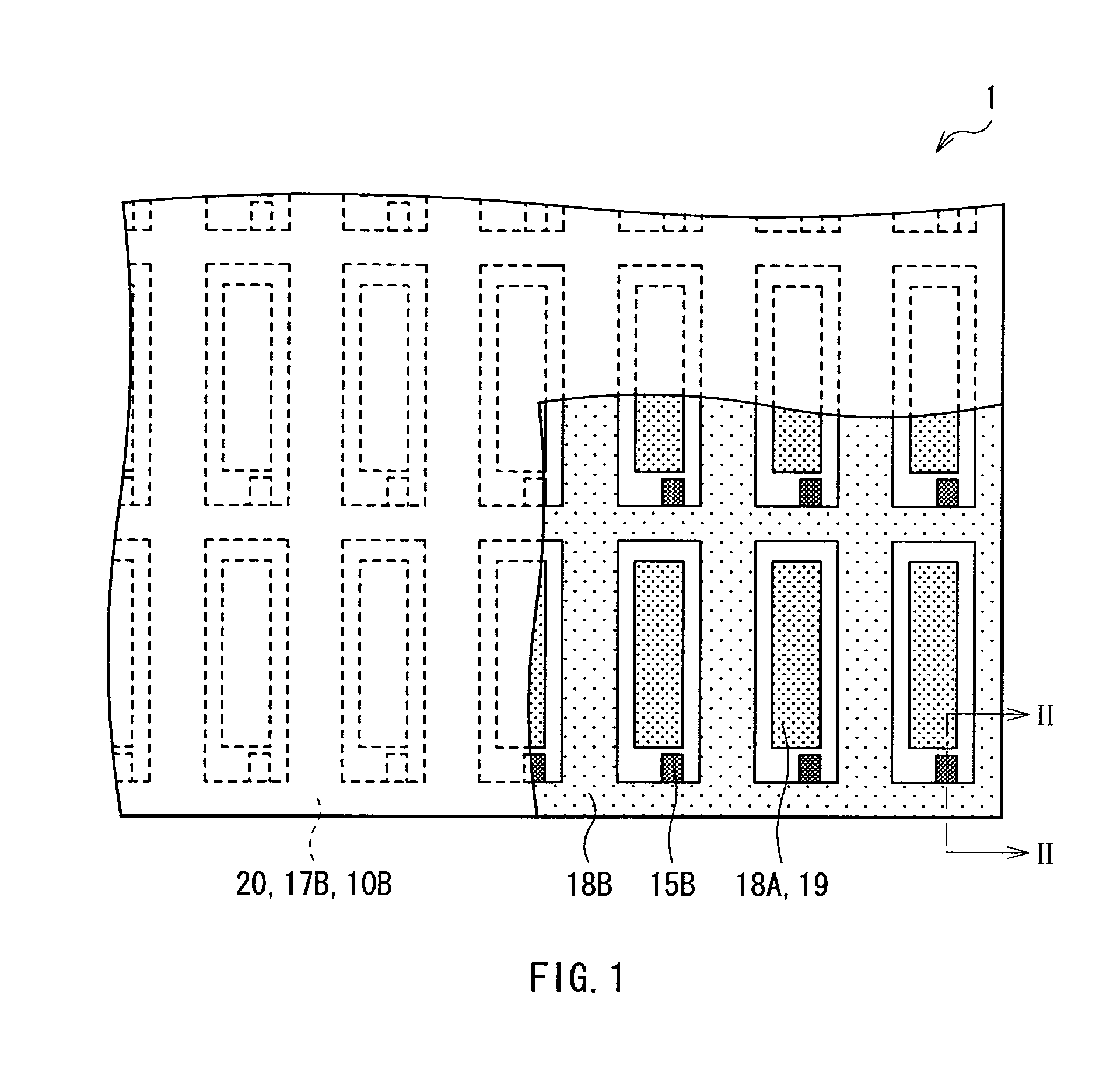

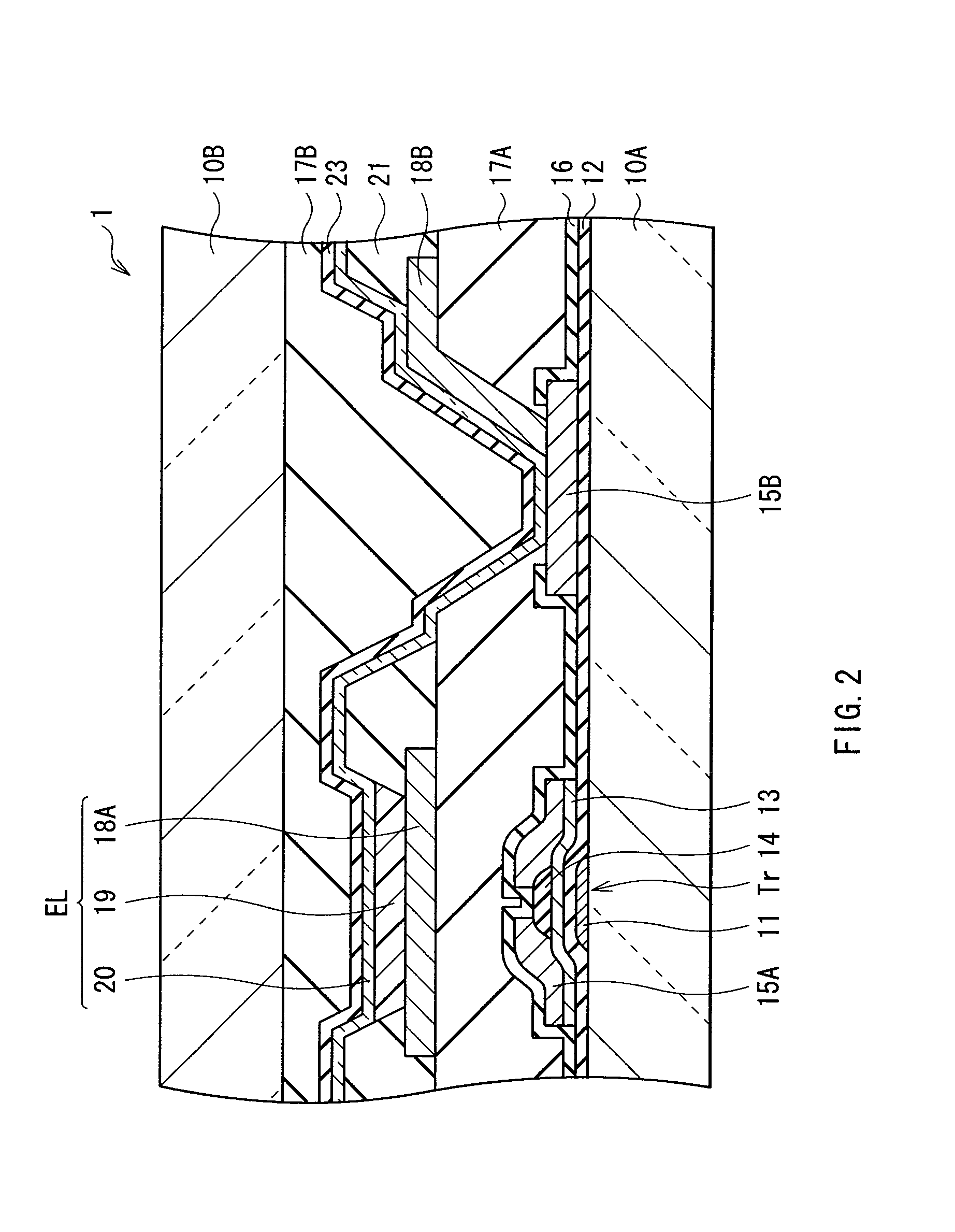

Display device and method for production thereof

ActiveUS7365810B2Increase resistanceQuality improvementStatic indicating devicesNon-linear opticsDisplay deviceTransparent conducting film

A display device and a method for production thereof. The display device comprises a substrate, thin film transistors and a transparent conductive film which are formed on the substrate, and an aluminum alloy film which electrically connects the thin film transistors to the transparent conductive film, such that there exists an oxide film of said aluminum alloy at the interface between said aluminum alloy film and said transparent conductive film, said oxide film having a thickness of 1 to 10 nm and containing oxygen in an amount no more than 44 atom %. The display device has the aluminum alloy film and the transparent conducive film in direct contact with each other, obviating the necessity of barrier metal between them.

Owner:KOBE STEEL LTD

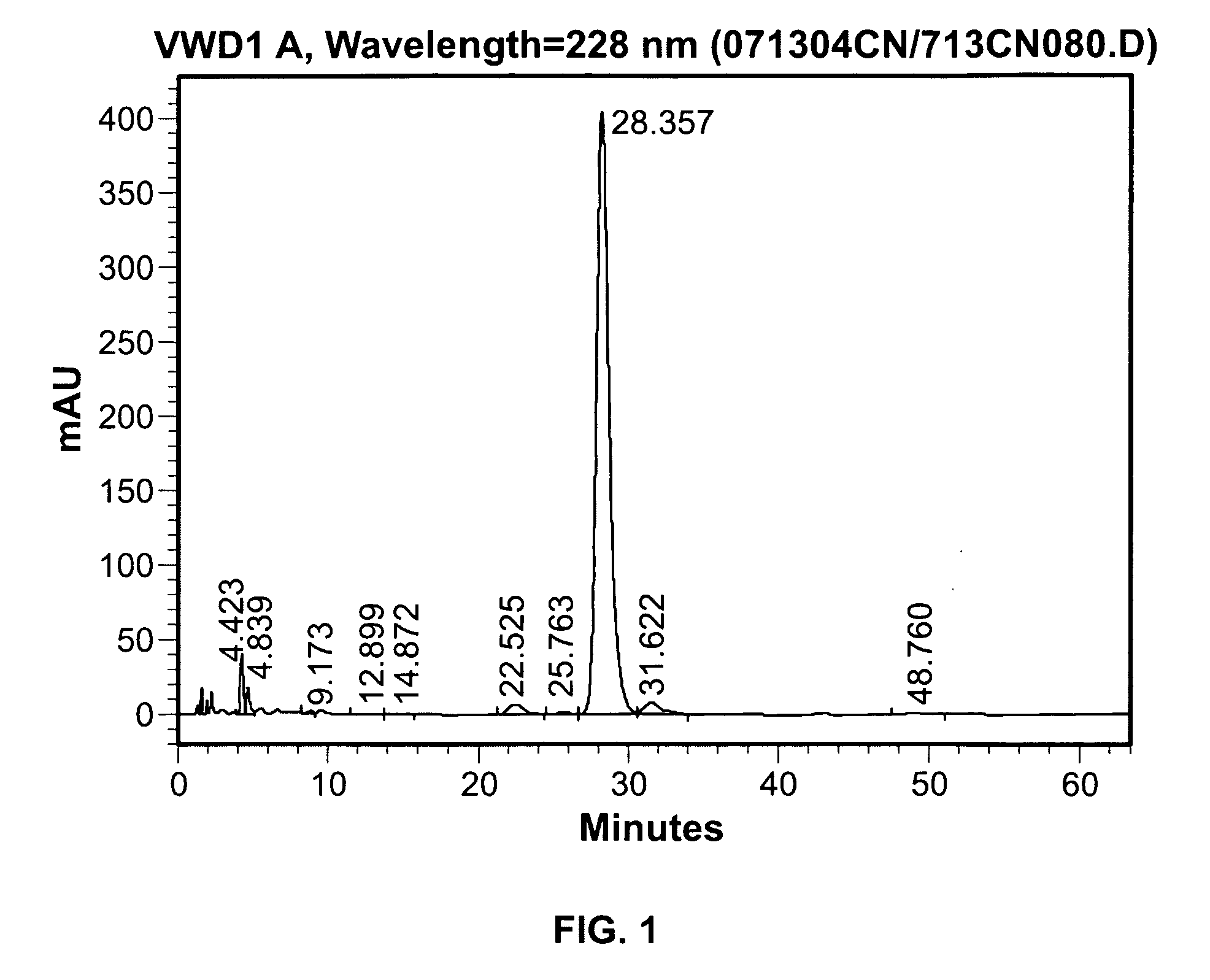

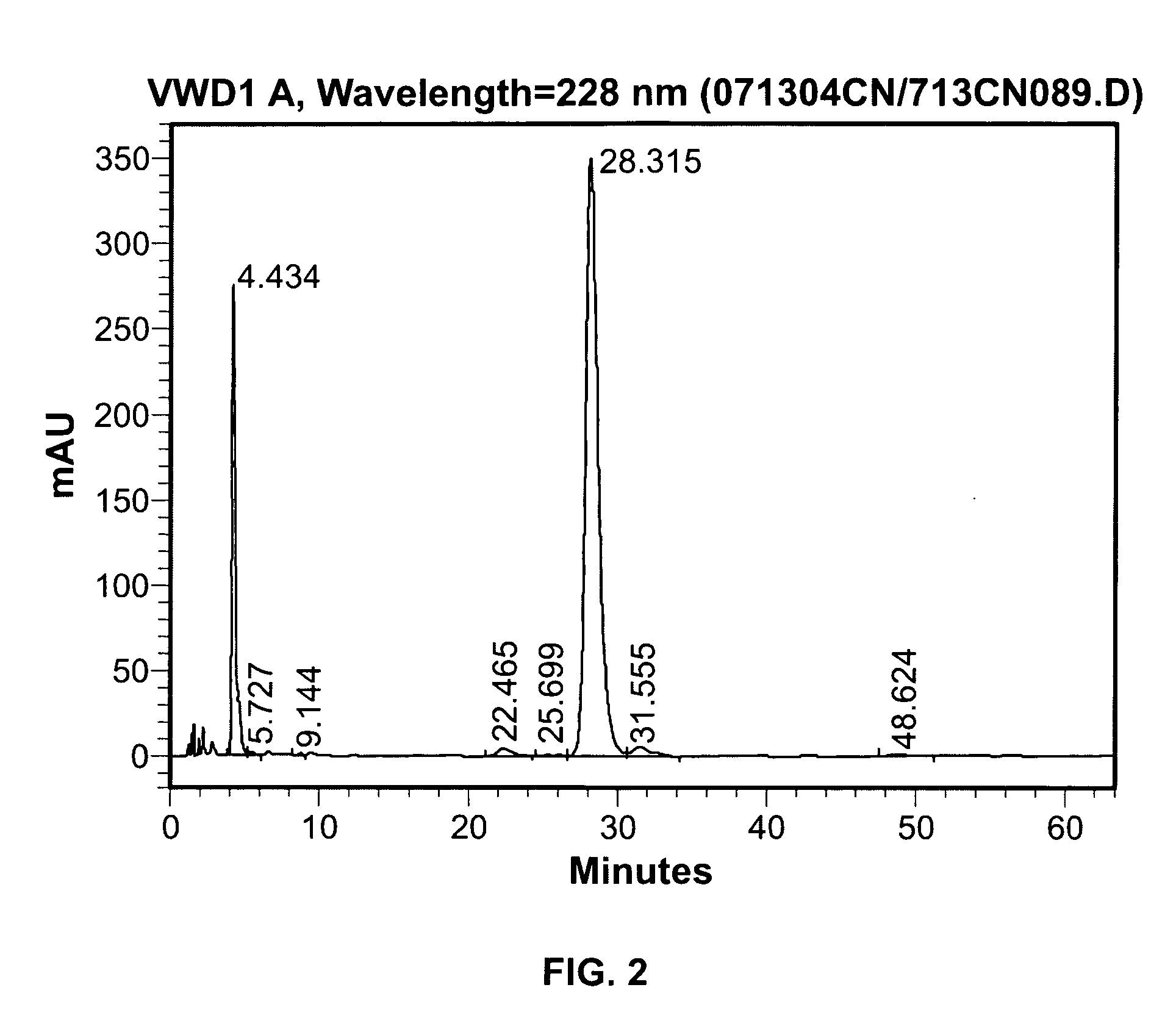

Room-temperature stable dronabinol formulations

ActiveUS20060160888A1Improve stabilityLow oxygen permeabilityBiocideDigestive systemDronabinolMedicine

A room temperature stable cannabinoid formulation is disclosed. In preferred embodiments, the cannabinoid formulation is dronabinol in an oil-based carrier contained within a hard gelatin capsule.

Owner:BENUVIA OPERATIONS LLC

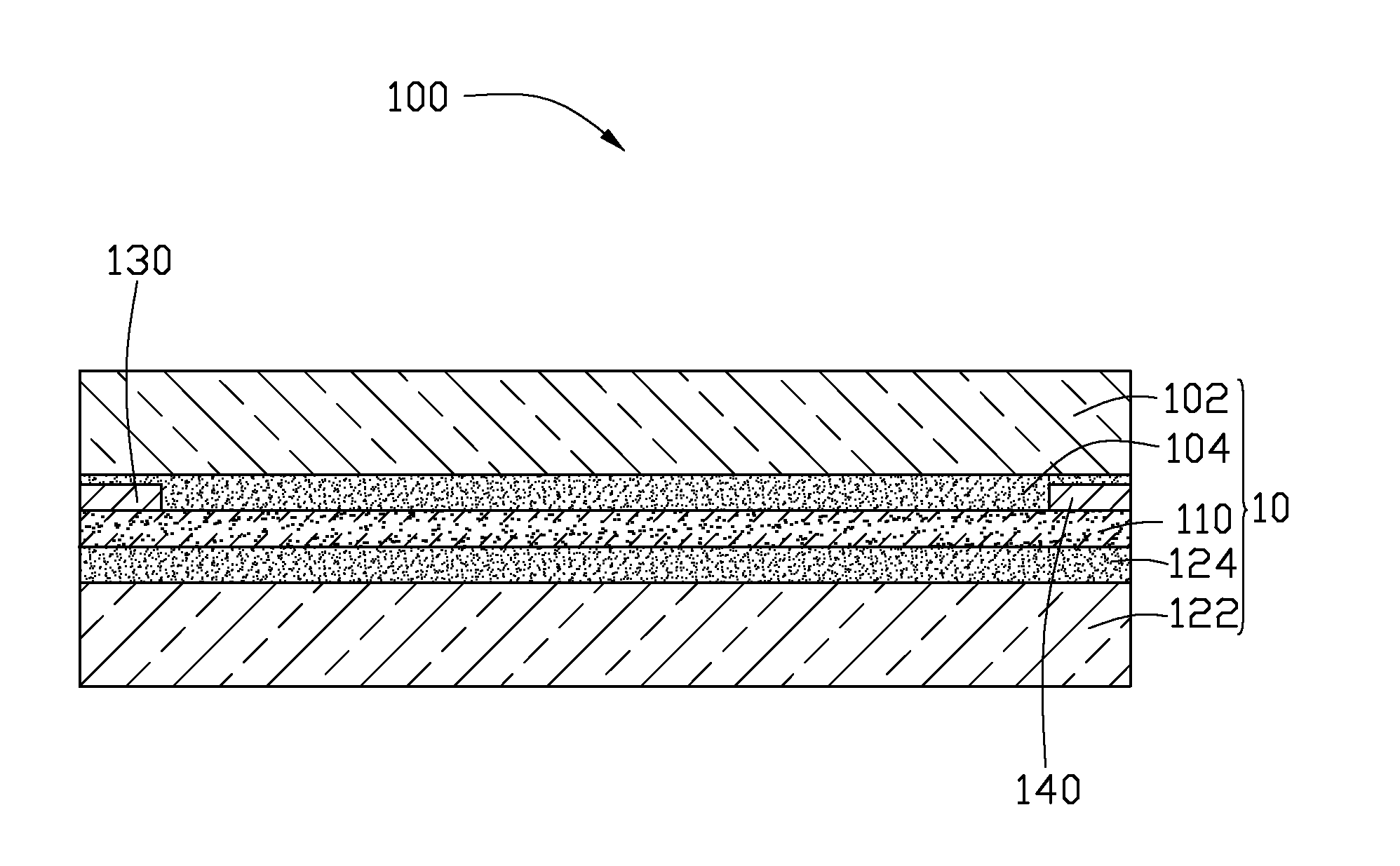

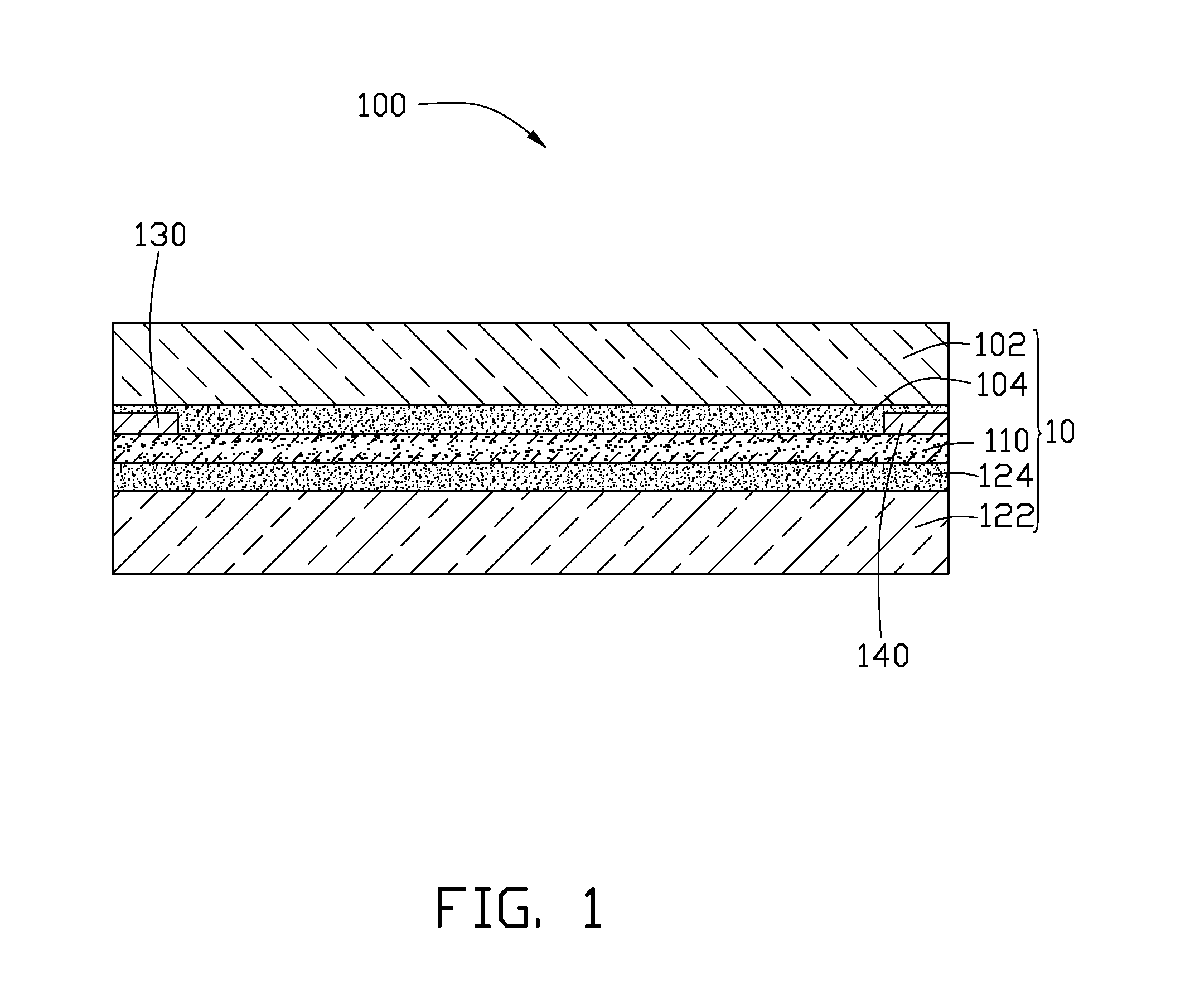

Heater and method for making the same

InactiveUS20110108545A1Improve conductivityGenerate lot of heatEnvelope/housing resistor manufactureHeater elementsCarbon nanotubeHeating element

A heater includes a first electrode, a second electrode, and a heating element. The second electrode is spaced from the first electrode. The heating element includes a first substrate, a second substrate, a first adhesive layer, a second adhesive layer and a carbon nanotube structure. The carbon nanotube structure is located between the first substrate and the second substrate, and combined with the first substrate by the first adhesive layer, and combined with the second substrate by the second adhesive layer. The carbon nanotube structure is electrically connected to the first electrode and the second electrode. A method for making the heater is also provided.

Owner:TSINGHUA UNIV +1

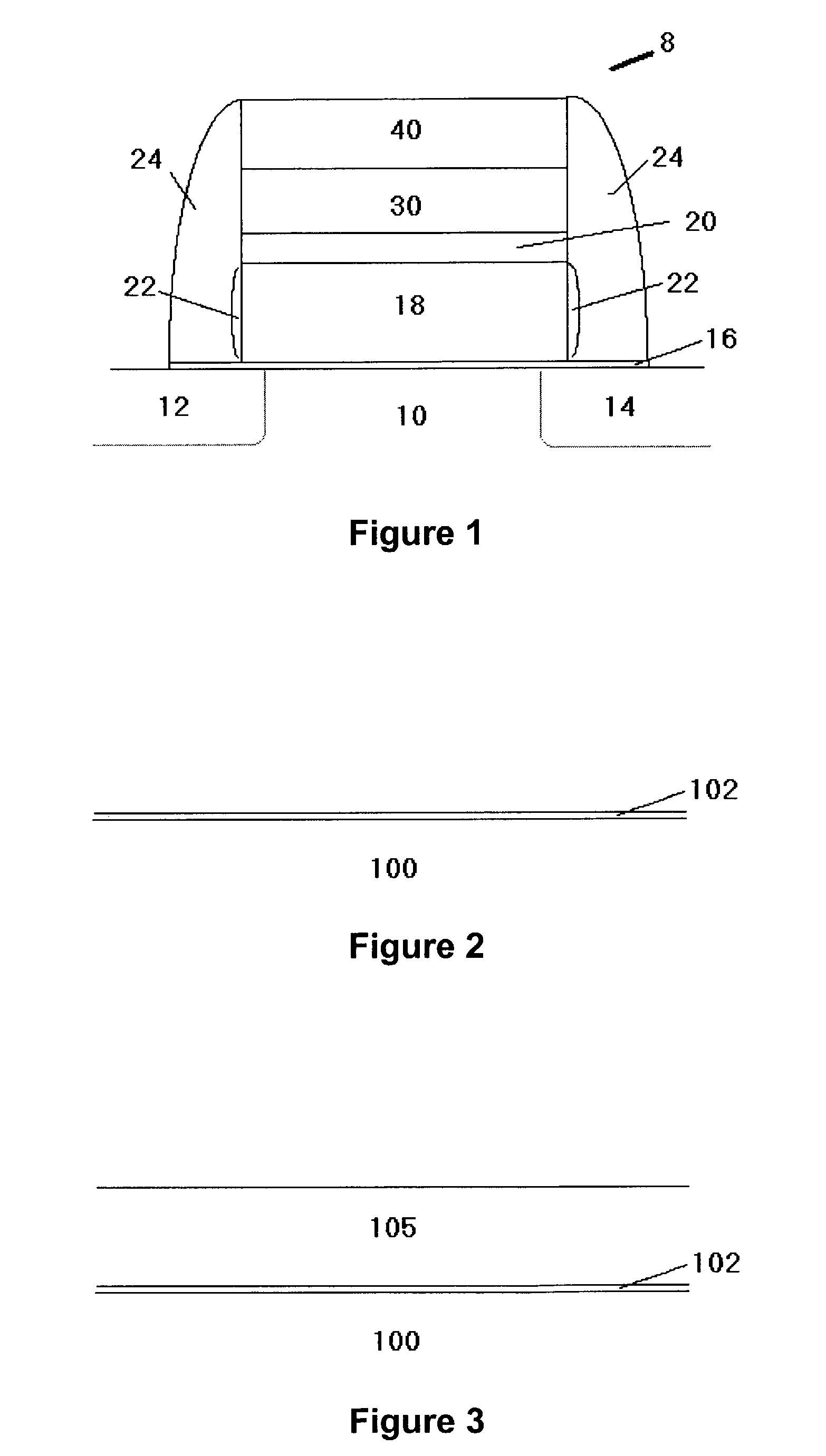

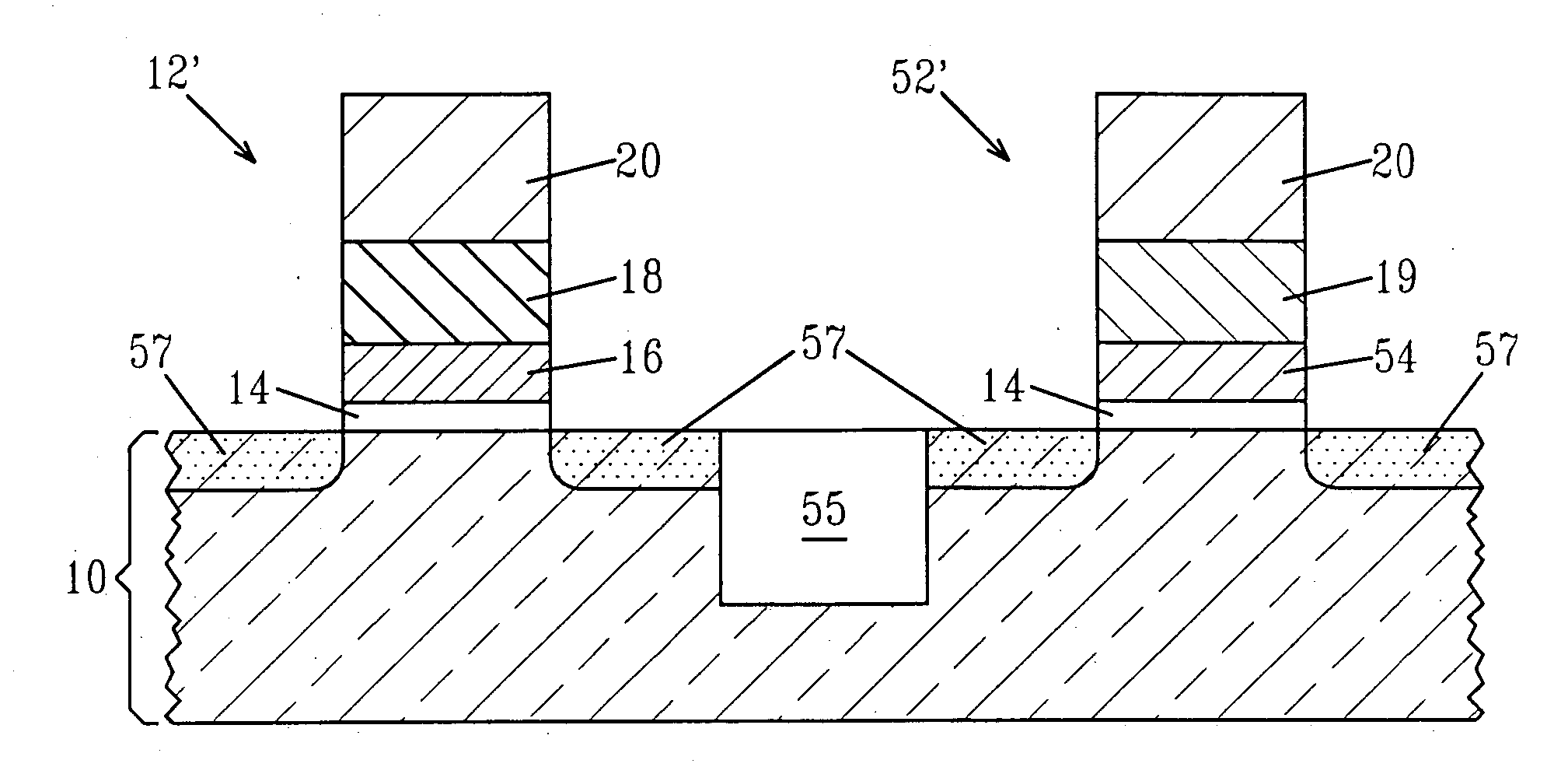

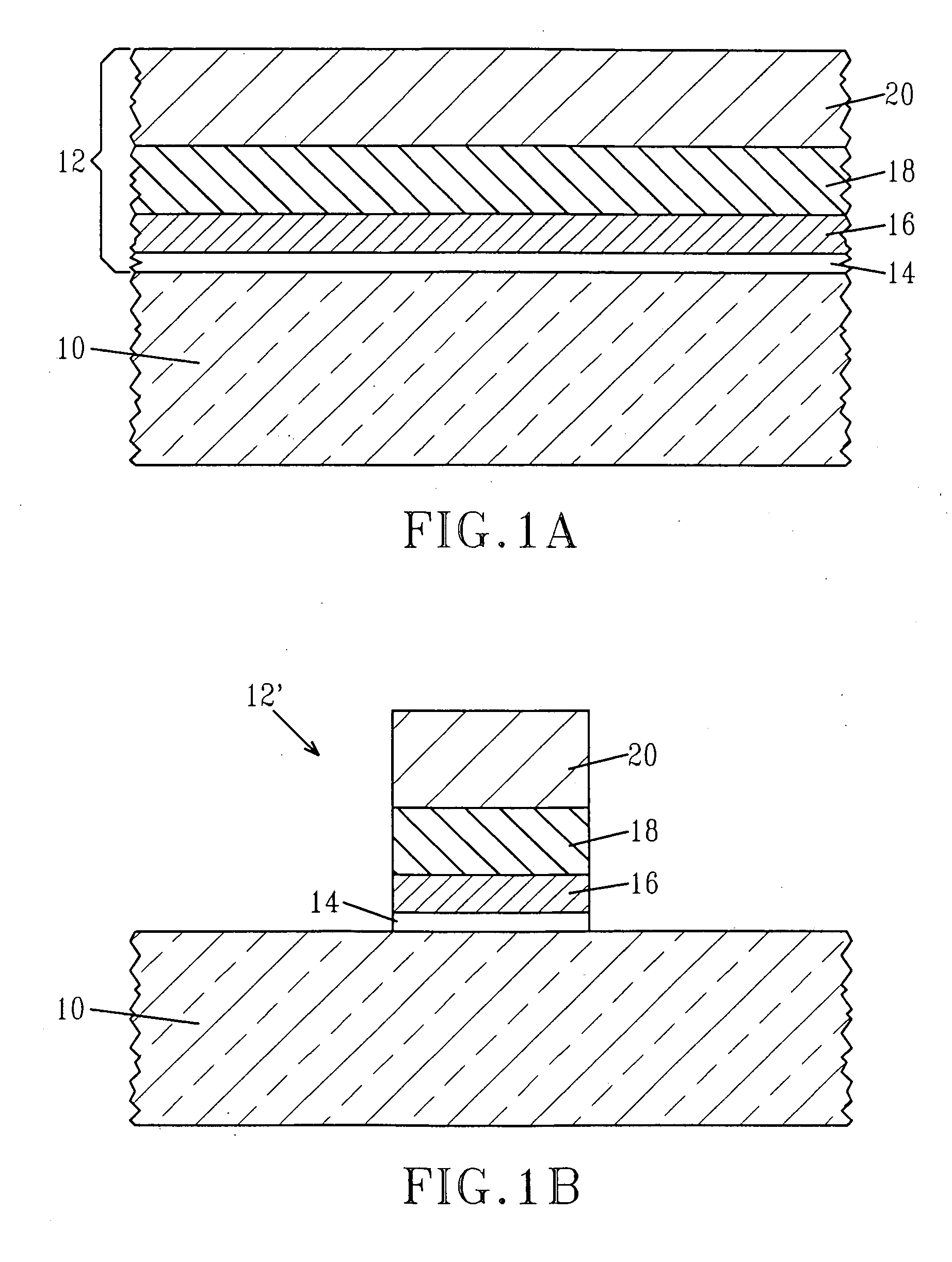

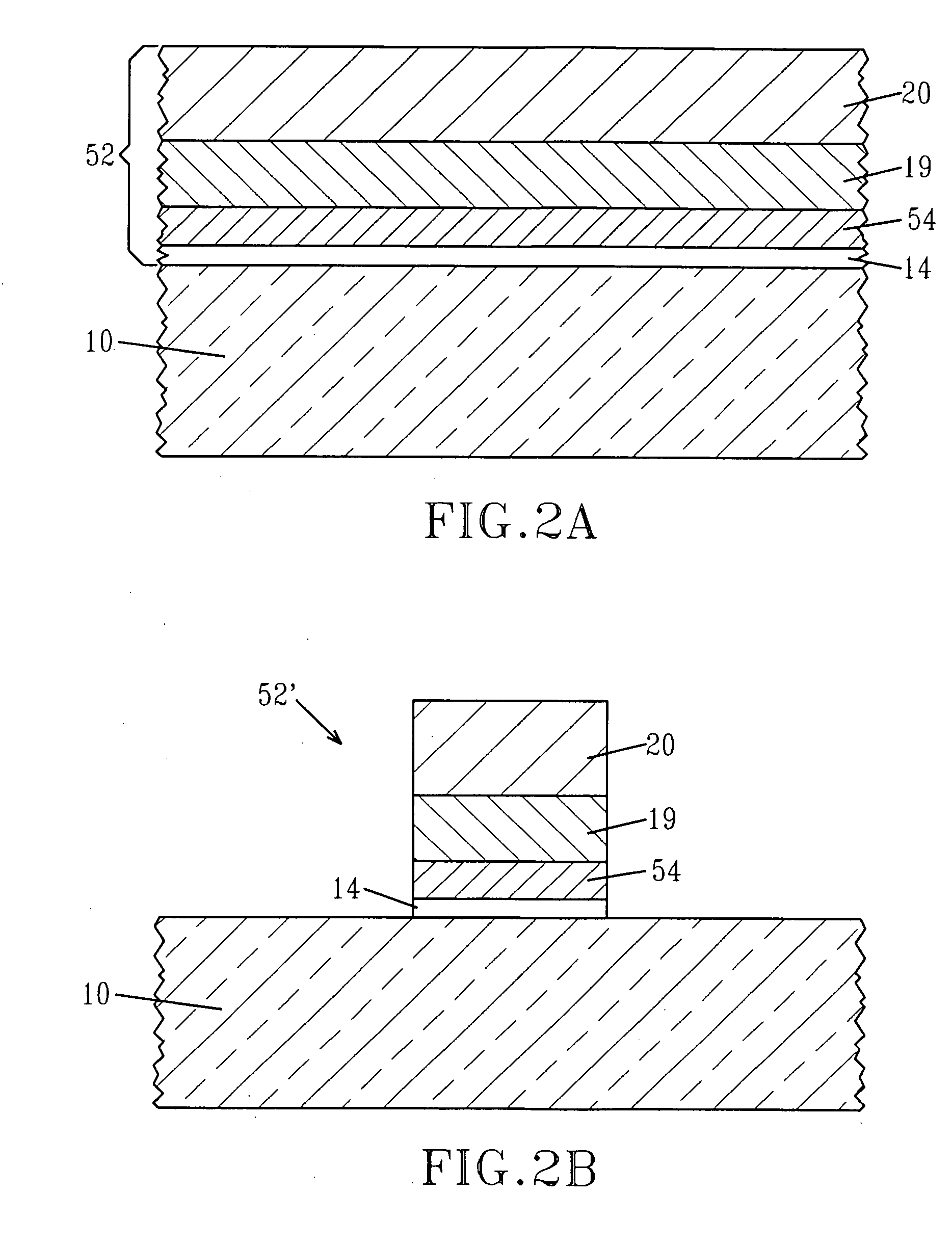

Using metal/metal nitride bilayers as gate electrodes in self-aligned aggressively scaled CMOS devices

ActiveUS20060237796A1Improve work functionIncreasing the thicknessTransistorSolid-state devicesCMOSGate dielectric

The present invention is directed to CMOS structures that include at least one nMOS device located on one region of a semiconductor substrate; and at least one pMOS device located on another region of the semiconductor substrate. In accordance with the present invention, the at least one nMOS device includes a gate stack comprising a gate dielectric, a low workfunction elemental metal having a worfunction of less than 4.2 eV, an in-situ metallic capping layer, and a polysilicon encapsulation layer and the at least one pMOS includes a gate stack comprising a gate dielectric, a high workfunction elemental metal having a workfunction of greater than 4.9 eV, a metallic capping layer, and a polysilicon encapsulation layer. The present invention also provides methods of fabricating such a CMOS structure.

Owner:TAIWAN SEMICON MFG CO LTD

Bonding Material for Semiconductor Devices

ActiveUS20130134591A1Improve reliabilityFew voidPorous dielectricsLayered productsMetallurgyInternal bond

A semiconductor device is provided which has internal bonds which do not melt at the time of mounting on a substrate. A bonding material is used for internal bonding of the semiconductor device. The bonding material is obtained by filling the pores of a porous metal body having a mesh-like structure and covering the surface thereof with Sn or an Sn-based solder alloy.

Owner:SENJU METAL IND CO LTD

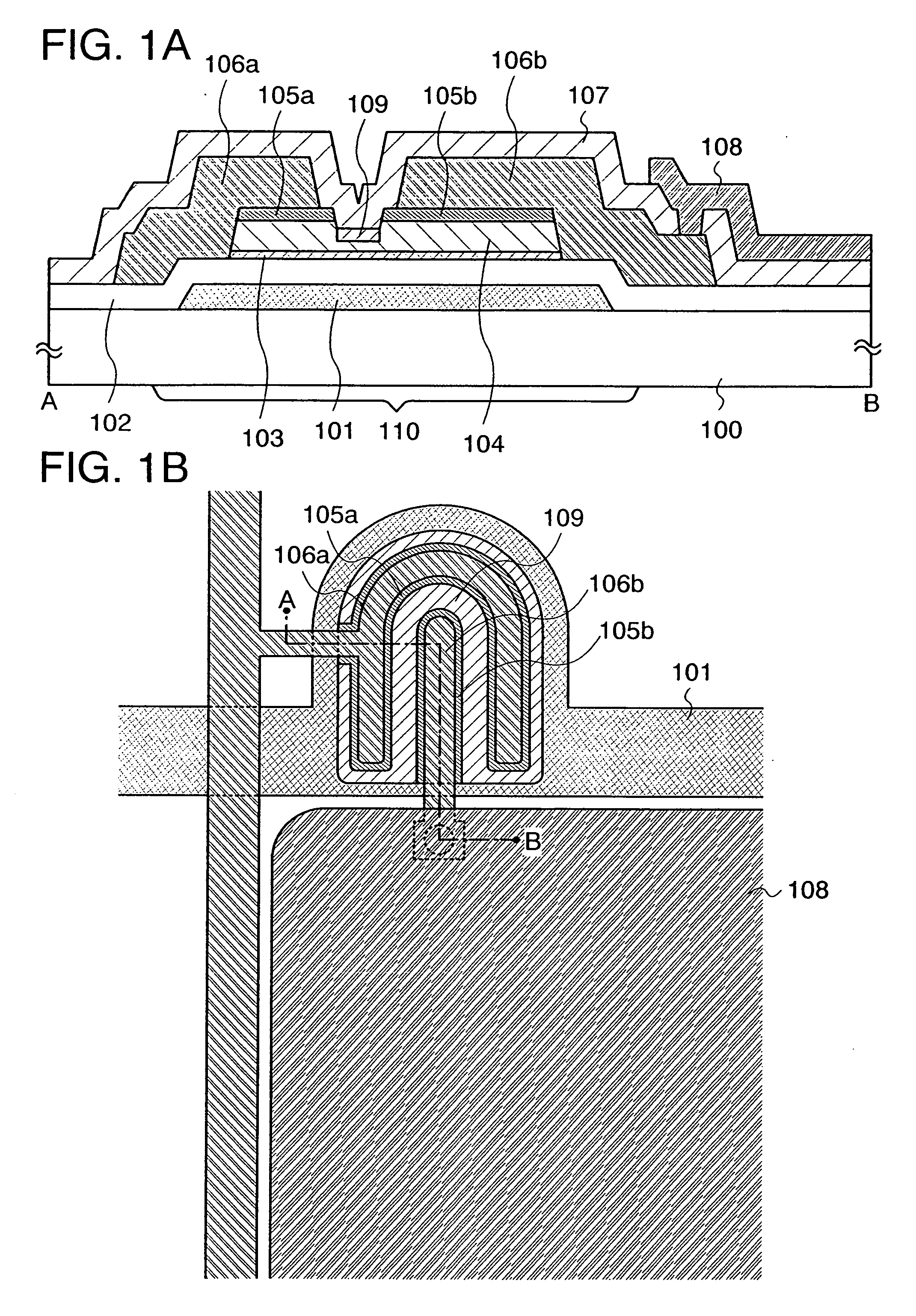

Display device and manufacturing method thereof

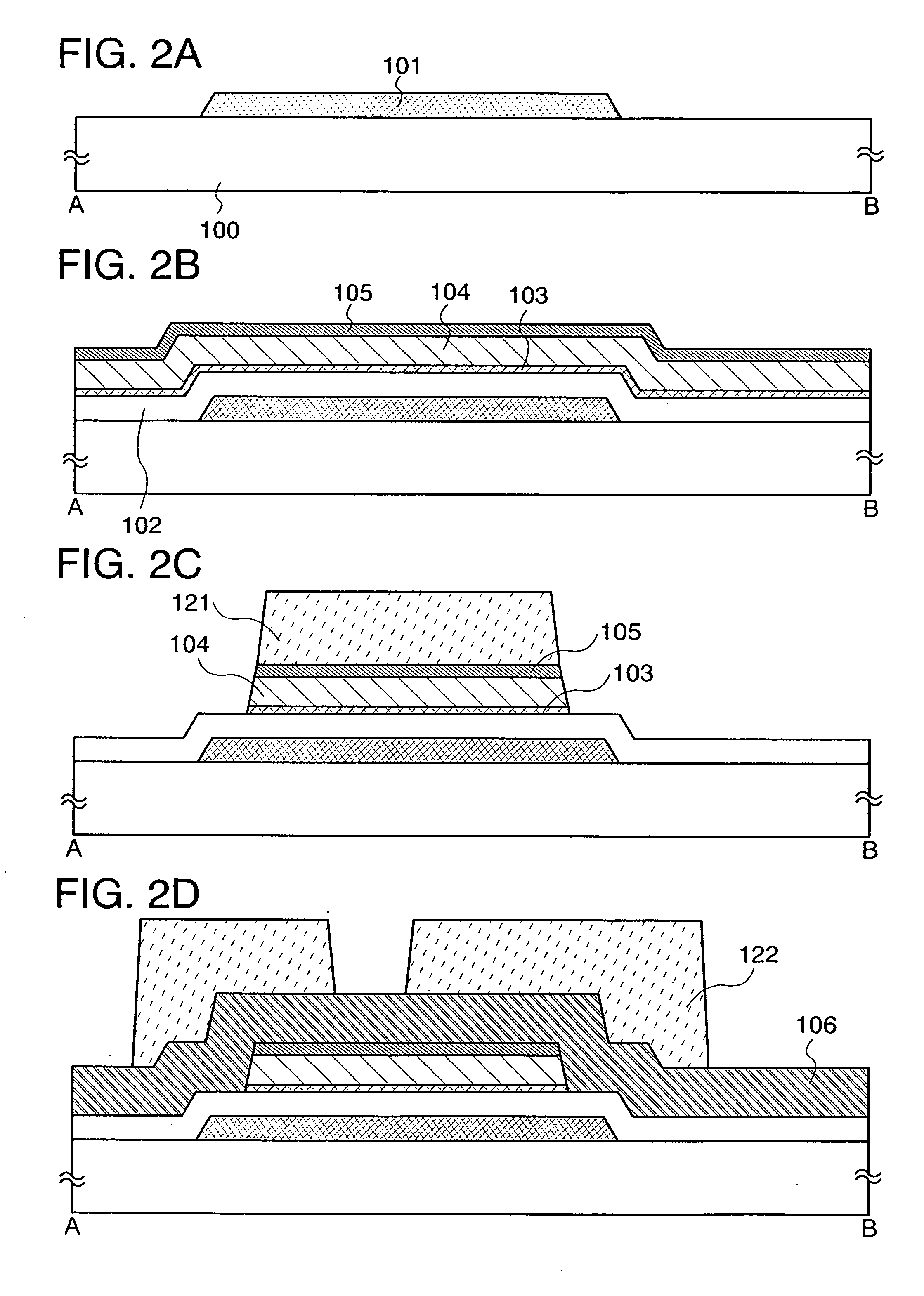

InactiveUS20090039351A1Excellent characteristicsDisplay device be improvedSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorDisplay device

To provide a display device having a thin film transistor with high electric characteristics and excellent reliability and a manufacturing method thereof. A gate electrode, a gate insulating film provided over the gate electrode, a first semiconductor layer provided over the gate insulating film and having a microcrystalline semiconductor, a second semiconductor layer provided over the first semiconductor layer and having an amorphous semiconductor, and a source region and a drain region provided over the second semiconductor layer are provided. The first semiconductor layer has high crystallinity than the second semiconductor layer. The second semiconductor layer includes an impurity region having a conductivity type different from a conductivity type of the source region and the drain region between the source region and the drain region.

Owner:SEMICON ENERGY LAB CO LTD

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS20010043896A1Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

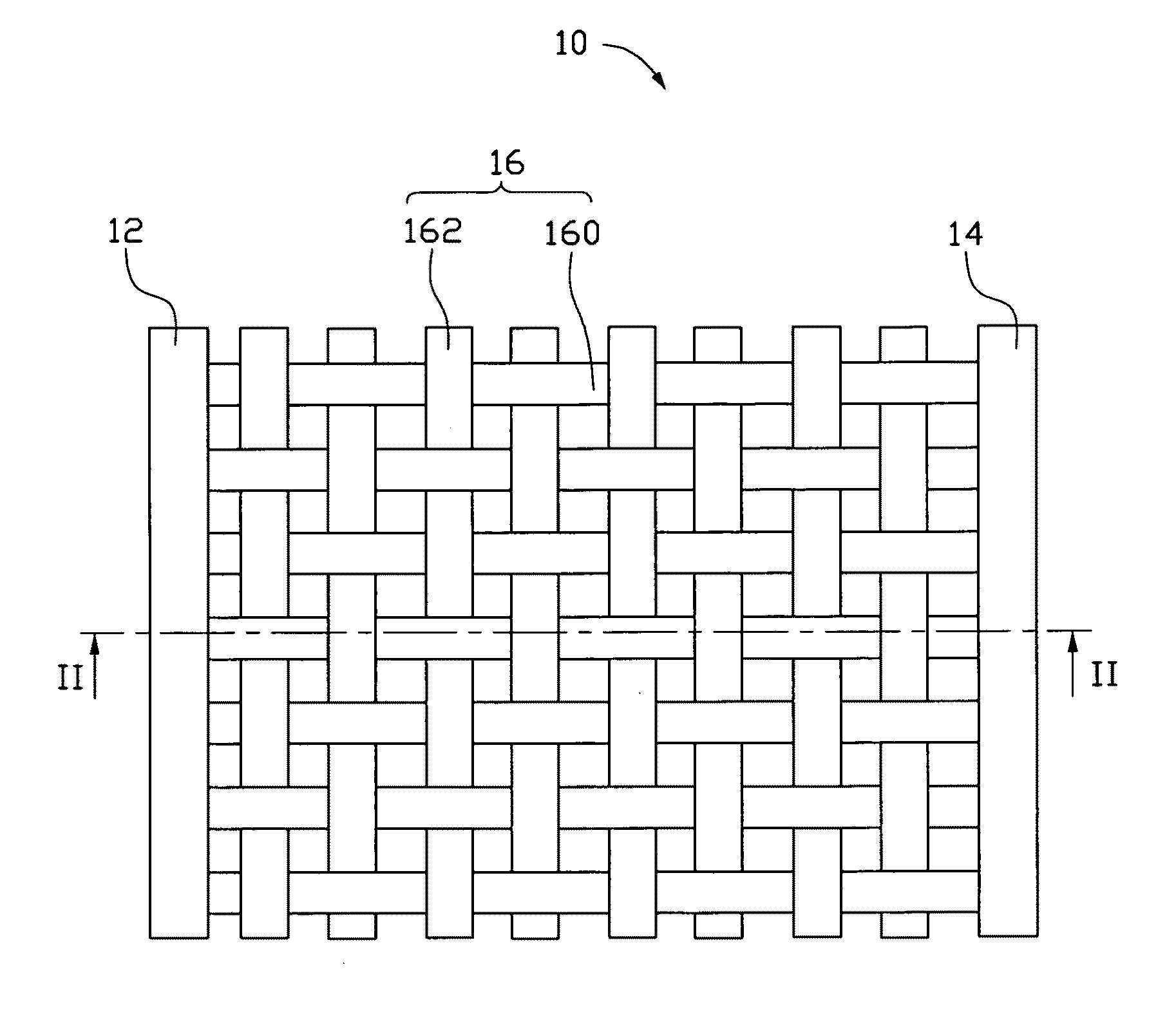

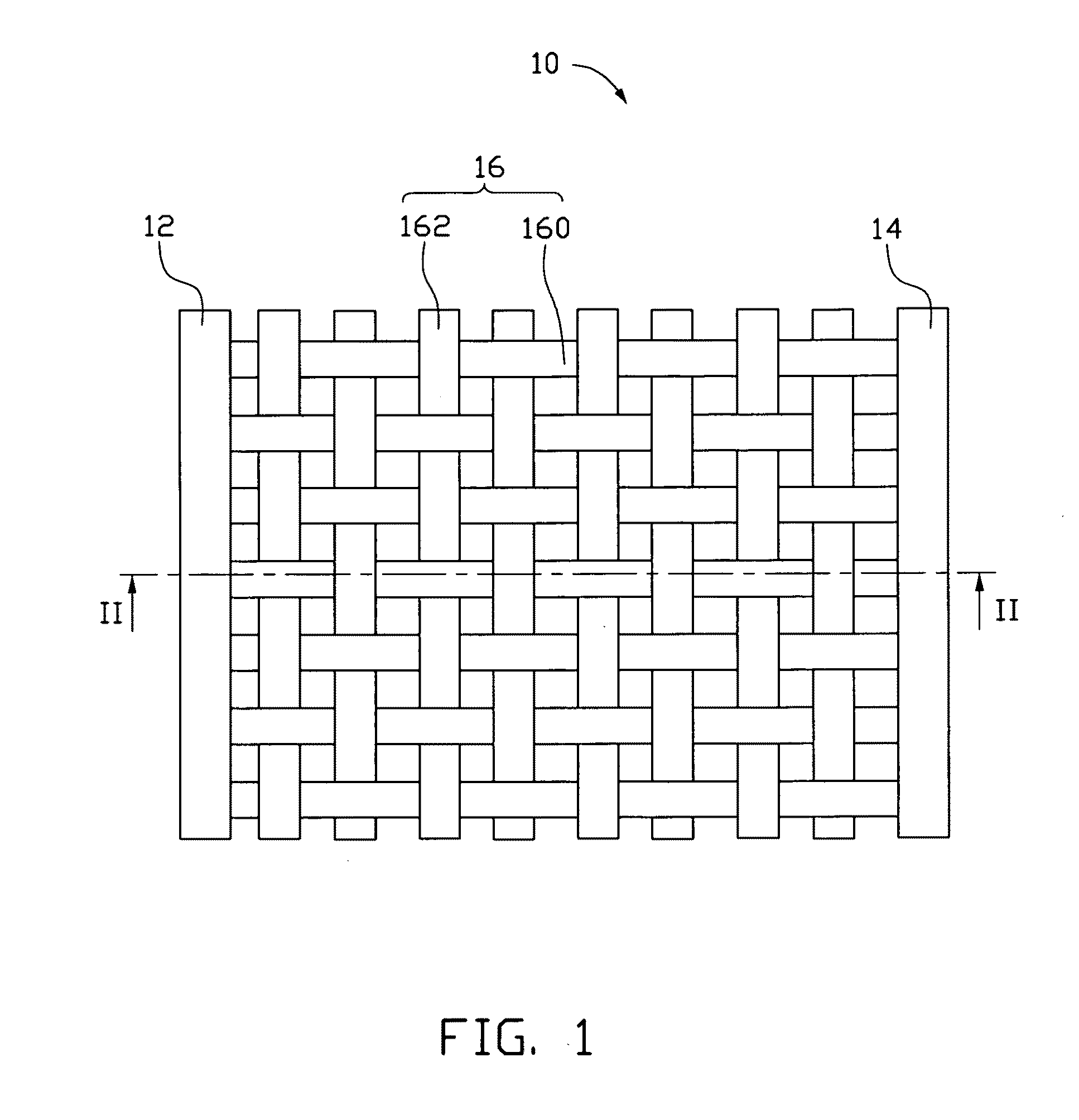

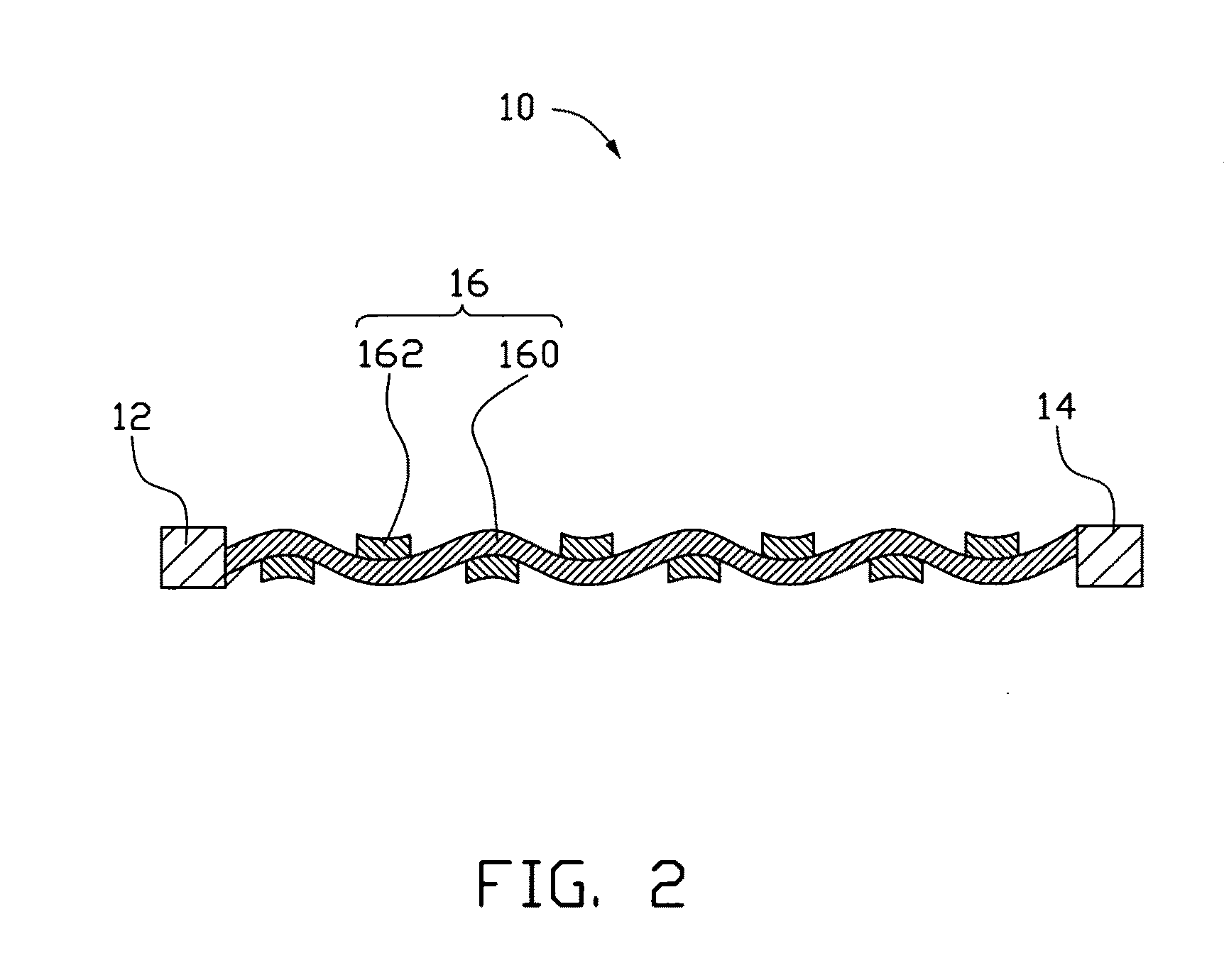

Carbon nanotube fabric and heater adopting the same

ActiveUS20110036828A1Improve conductivityGenerate lot of heatHeating element shapesHeating element materialsCarbon nanotubeElectrode

A carbon nanotube fabric includes a heating element and at least two electrodes. The heating element includes a plurality of carbon nanotubes joined end to end. The at least two electrodes are separately located and electrically connected to the carbon nanotubes of the heating element.

Owner:TSINGHUA UNIV +1

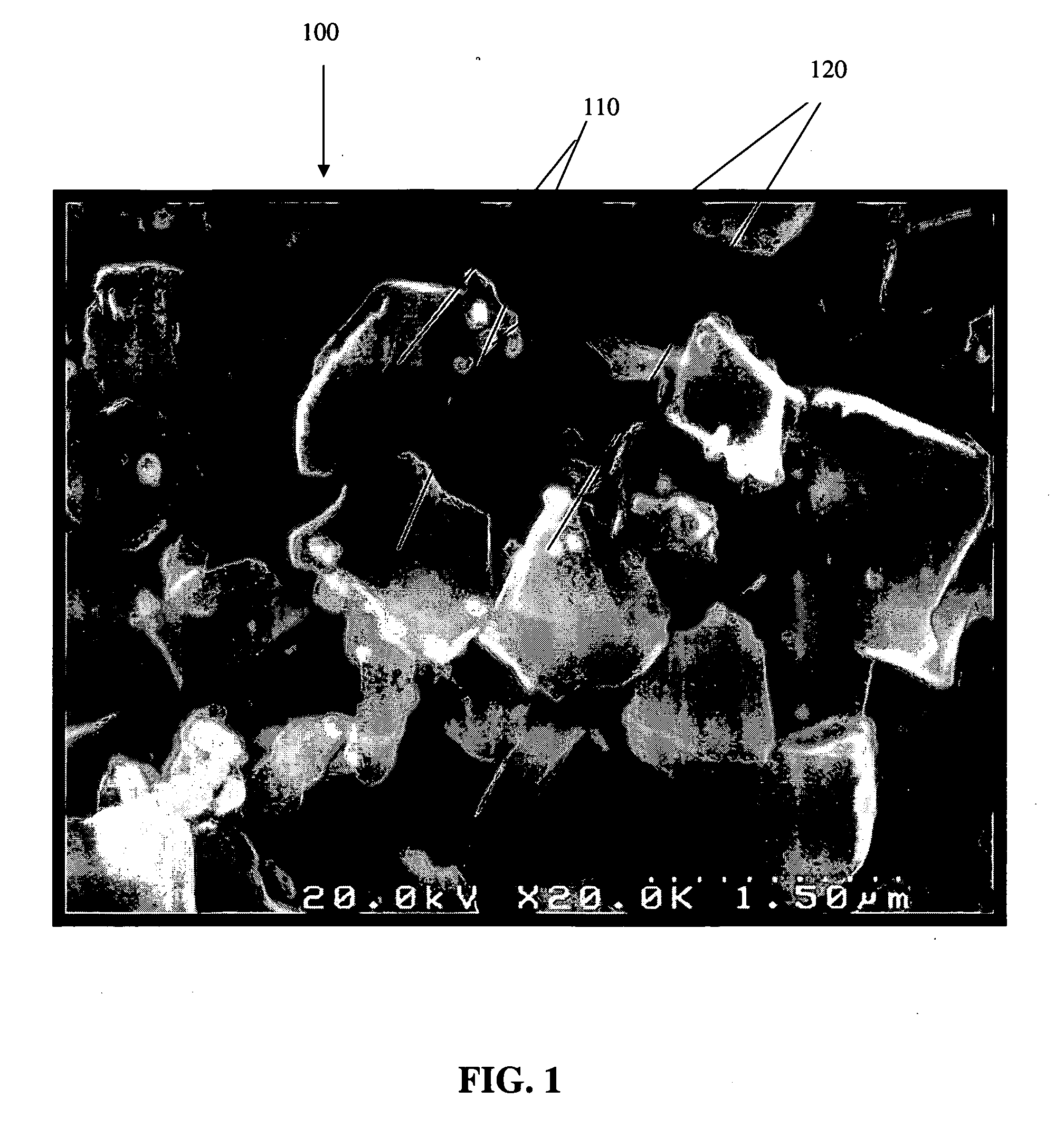

Polycrystalline diamond material with extremely fine microstructures

ActiveUS20090178345A1High melting pointHigh purityPigmenting treatmentOther chemical processesPolycrystalline diamondHigh pressure

A sintered polycrystalline diamond material (PCD) of extremely fine grain size is manufactured by sintering under high pressure / high temperature (HP / HT) processing, a diamond powder which is blended with a pre-milled source catalyst metal compound. The PCD material has an average sintered diamond grain structure of less than about 1.0 μm.

Owner:DIAMOND INNOVATIONS INC

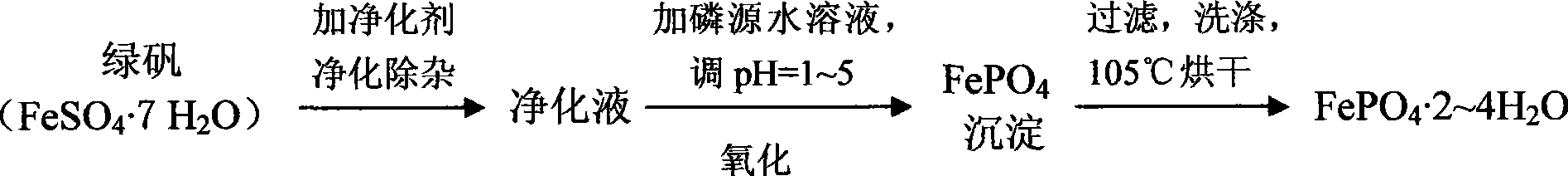

Method for preparing high purity ferric phosphate using ferrous sulfate as by-product of white titanium pigment

InactiveCN101531355AEasy to oxidizeSolve the use problemPhosphorus compoundsLithium iron phosphateGlaze

The invention relates to a preparation method of pure ferric phosphate, characterized in that: iron vitriol, phosphorus source as by-product of white titanium pigment are used as reactant and purificant and oxidant are added into the reactant and the reaction temperature is controlled at 25-100 DEG C and the reaction time is 0.5-10 hours, thus white ferric phosphate powder (FePO[4]2-4H[2]O) with 2-4 crystal water is obtained. The technological process has features of simple process, low production cost, high product purity, increased added value of ferrous sulfate as by-product of white titanium pigment and the product can be used as ceramic metal glaze-color glaze material and raw material for producing lithium iron phosphate as lithium ionization cell anode material.

Owner:GUANGXI UNIV +1

Catalyst for purifying the exhaust gases of diesel engines, and process for the preparation thereof

InactiveUS6685900B2Increase lytic activityLow ignition temperatureNitrogen compoundsInternal combustion piston enginesIridiumAluminum silicate

A catalyst for purifying the exhaust gases of diesel engines, which catalyst contains at least one zeolite and, additionally, at least one of the support oxides aluminum oxide, silicon dioxide, titanium dioxide and aluminum silicate and at least one of the noble metals platinum, palladium, rhodium and iridium. In this catalyst the atoms of the noble metals have a mean oxidation number of less than +2.5, on average more than 3 metal ligands and less than 3 oxygen ligands and are present on the zeolites and support oxides in the form of crystallites having a mean particle size of from 1 to 6 nm.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC +1

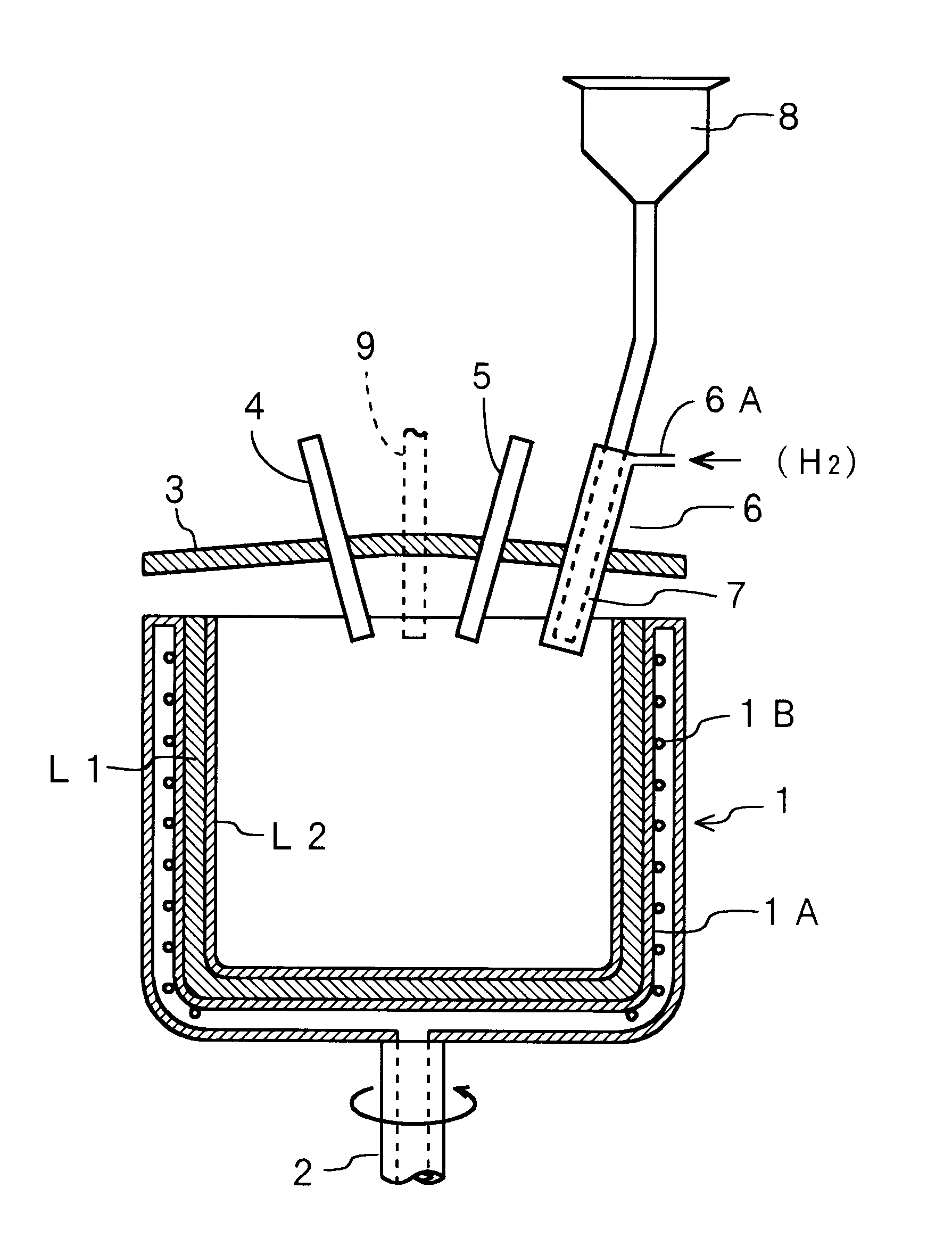

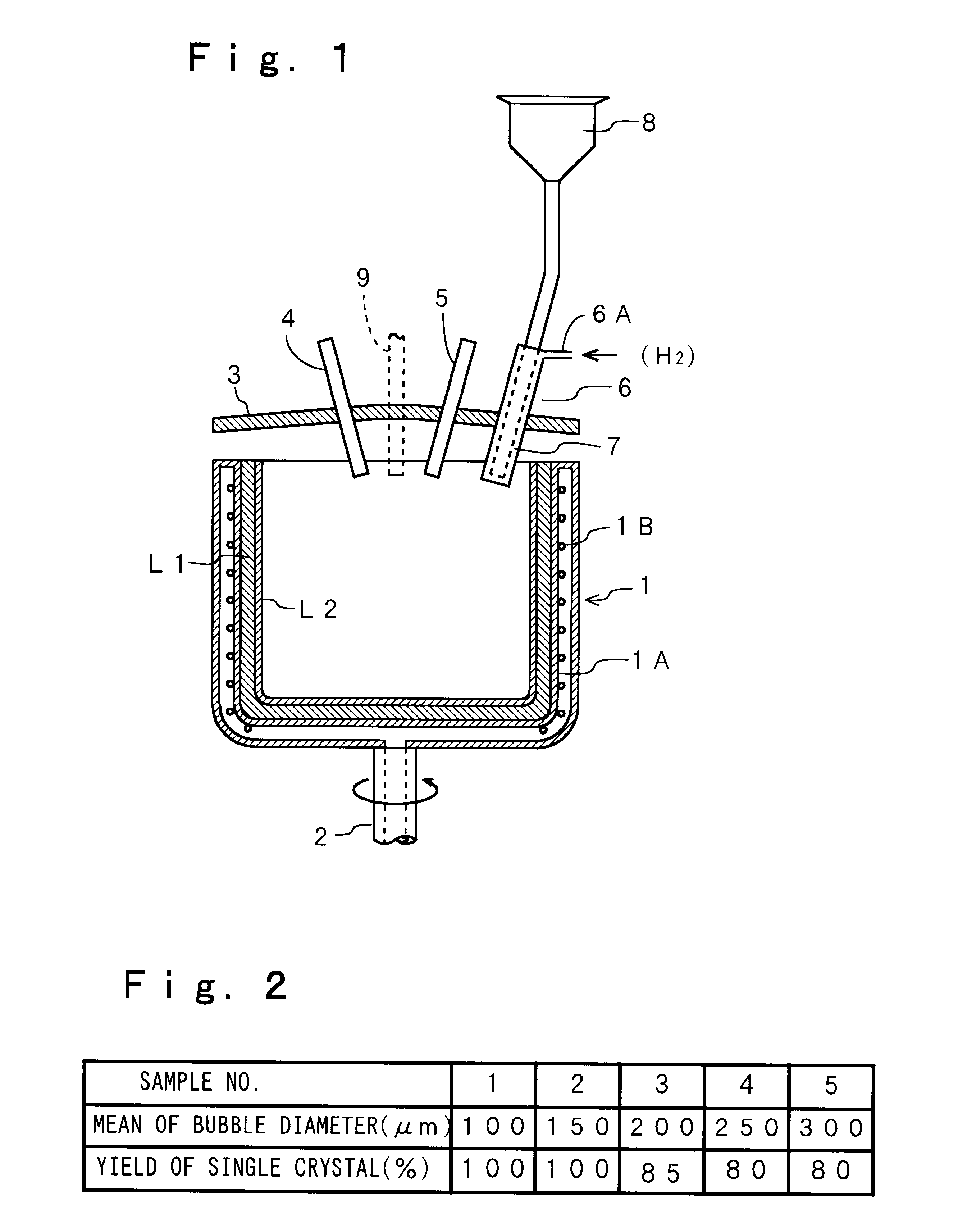

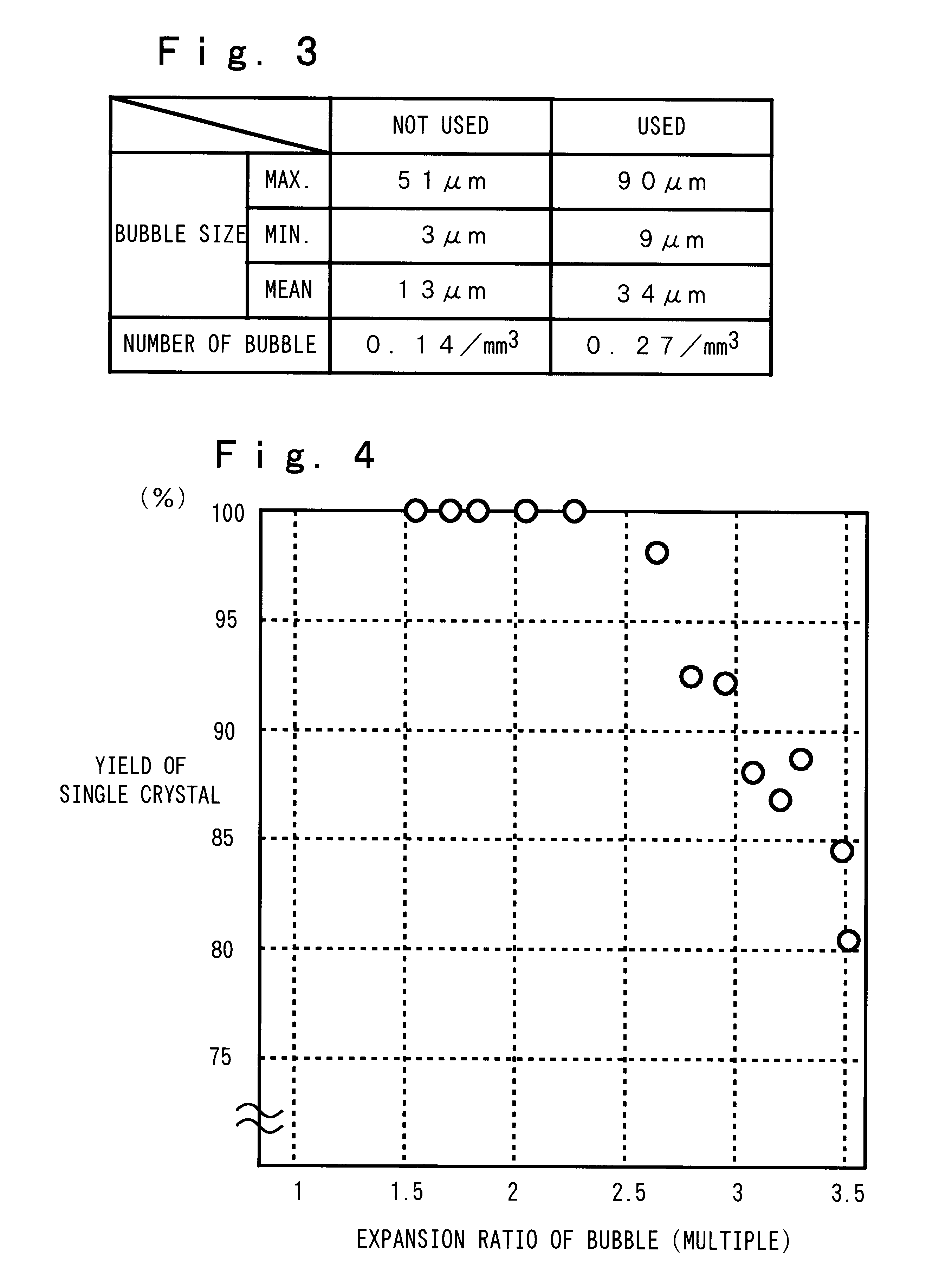

Method for manufacturing quartz glass crucible

InactiveUS6553787B1Increase productionReduce the temperatureAfter-treatment apparatusGlass furnace apparatusTemperature loadGraphite

Present invention suppresses undesirable effects of the bubbles trapped in a silica glass crucible on single crystallization during the pulling process under a high-temperature load. When raw material powder is melted in a mold 1, graphite components of electrodes and impurities contained in the raw material are removed by introducing hydrogen gas and / or oxygen gas immediately after the start of arc discharge. Graphite and impurities are prevented from entering the product crucible, thereby suppressing the volume increase rate of the bubbles and reducing the inner pressure of the bubbles. Gases remaining in voids of an accumulated layer of silica powder formed inside the mold 1 can be replaced with helium gas, by supplying helium gas to the accumulated layer from the mold 1.

Owner:NANWA QUARTZ

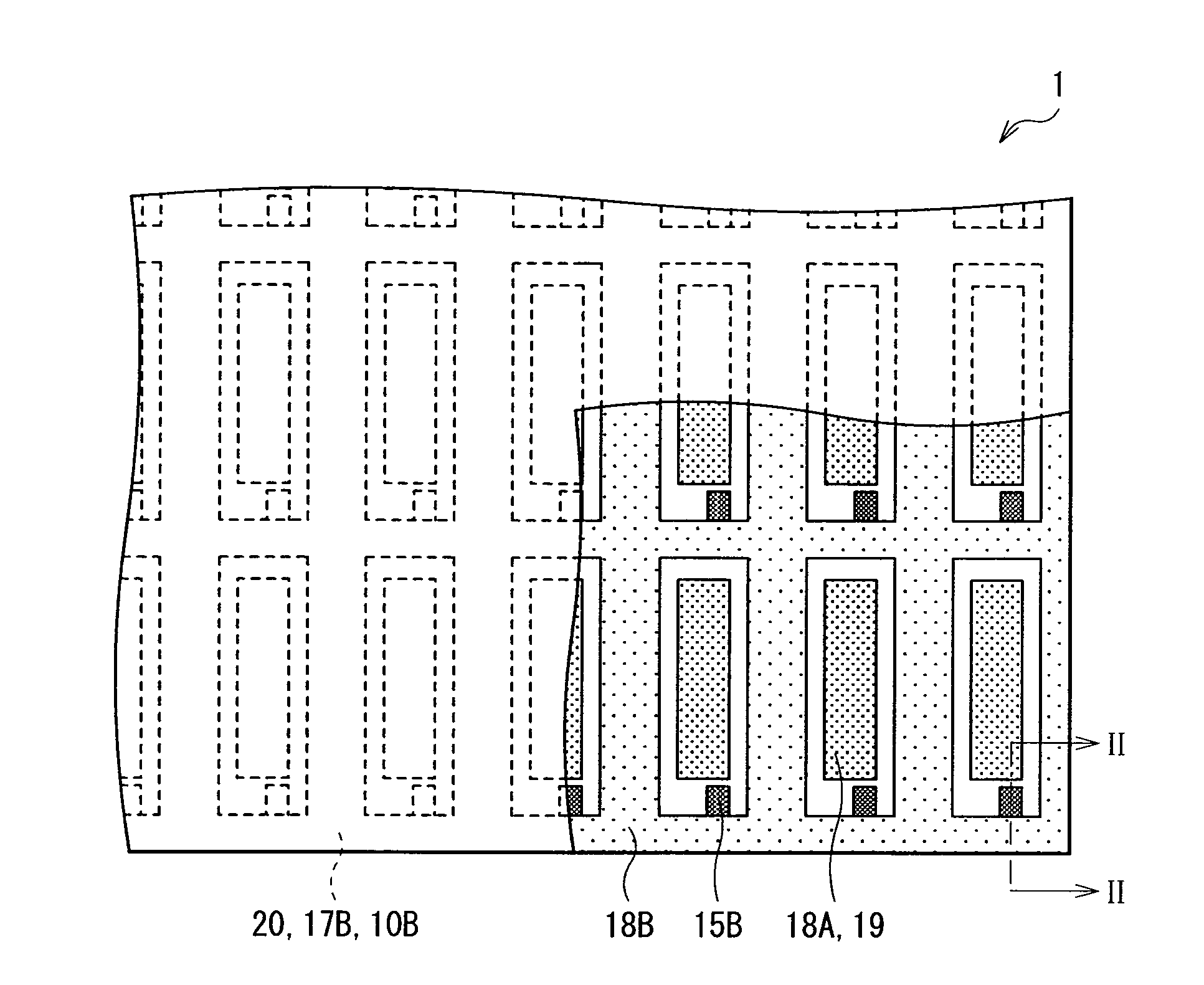

Light-emitting display and method of manufacturing the same

ActiveUS20100244664A1Increase connection resistanceReduce power consumptionDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

A light-emitting display capable of maintaining low power consumption and improving display quality irrespective of the configuration of an auxiliary wiring is provided. A second electrode 20 and an auxiliary wiring 18B are electrically connected to each other through a conductive contact section 15B. Moreover, only a part of the auxiliary wiring 18B is connected to the contact section 15B. Even if the surface of the auxiliary wiring 18B is oxidized, an increase in connection resistance is prevented. Moreover, a restriction on layout is not imposed at the time of forming the contact section 15B.

Owner:JOLED INC

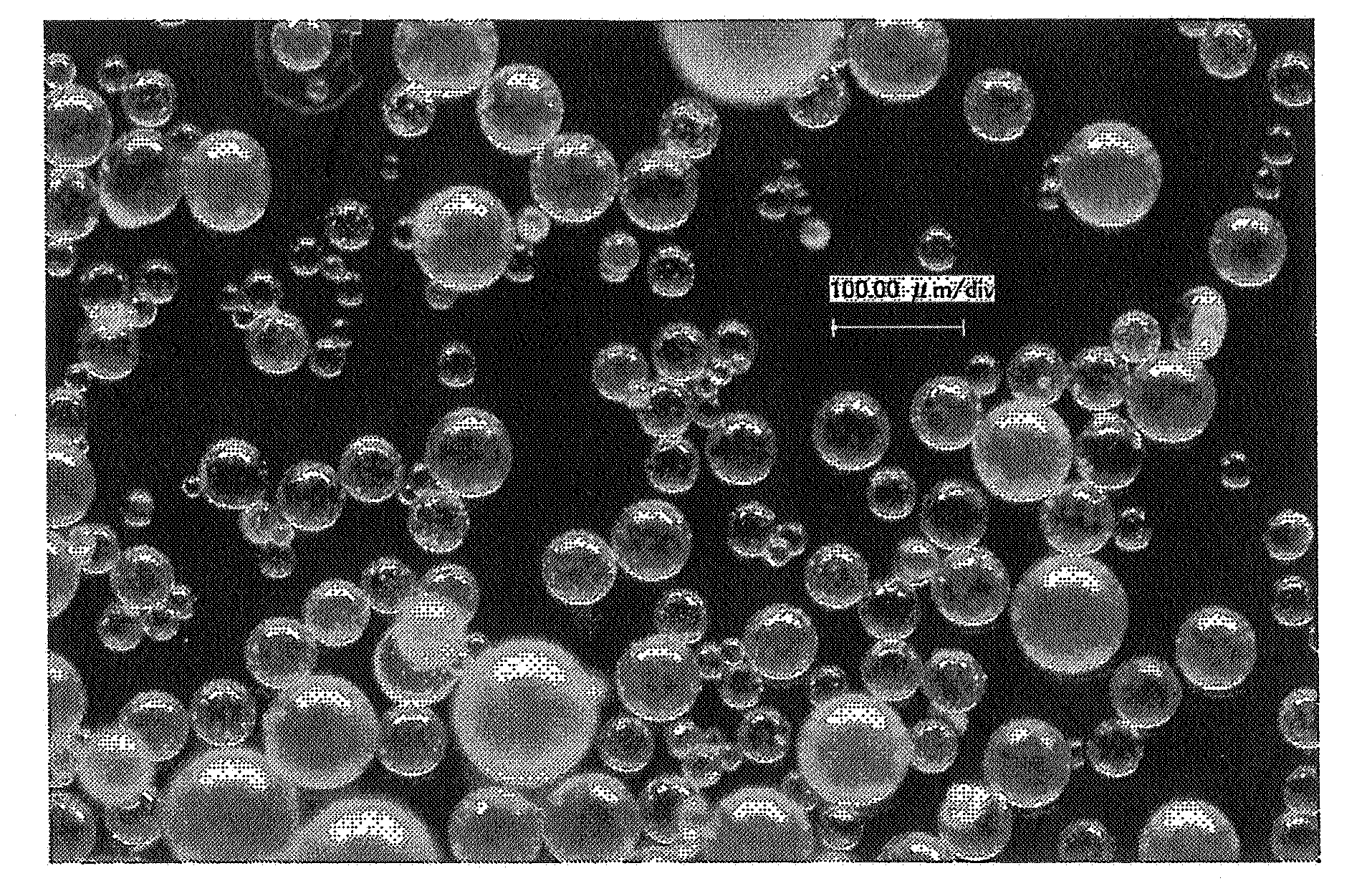

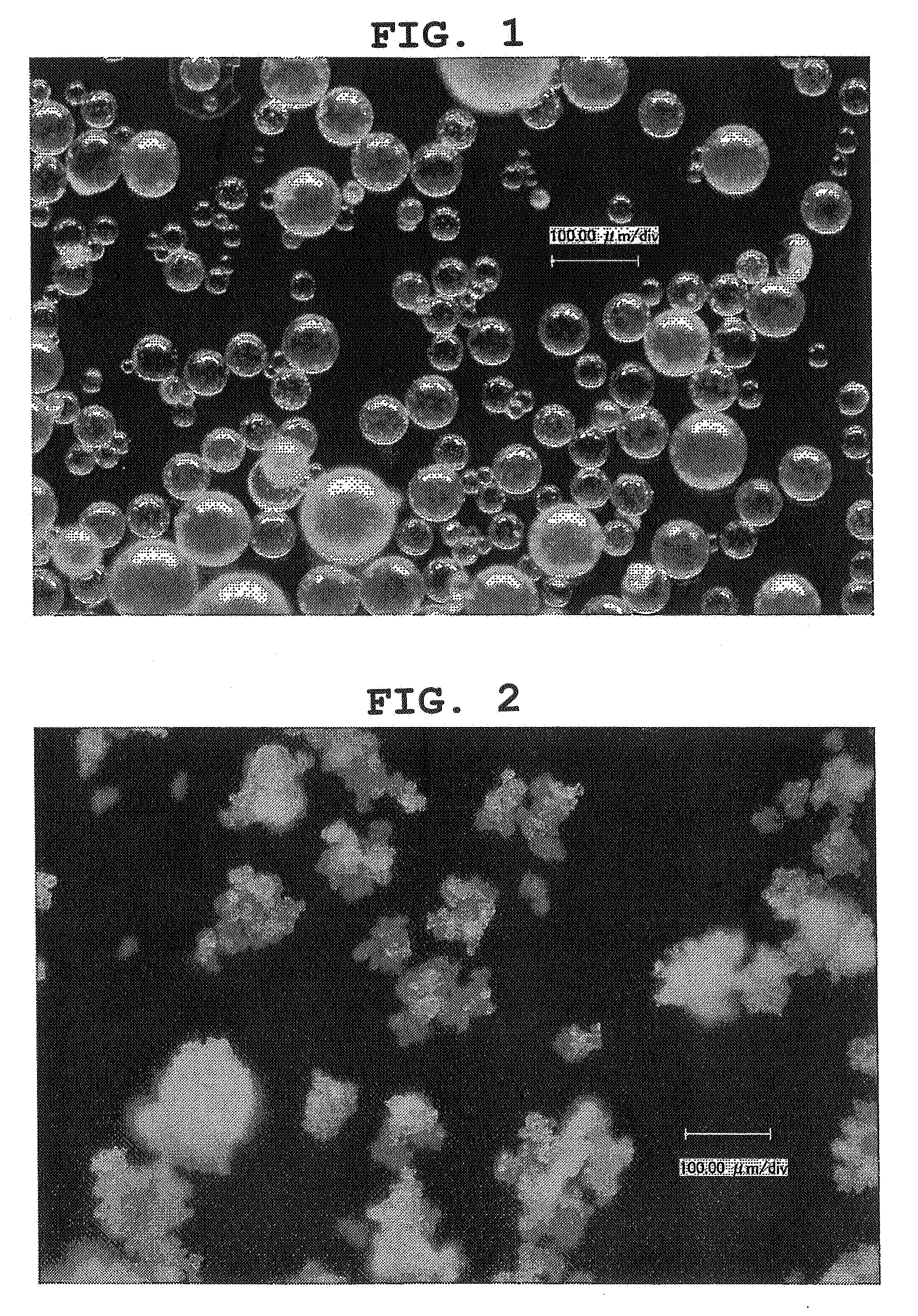

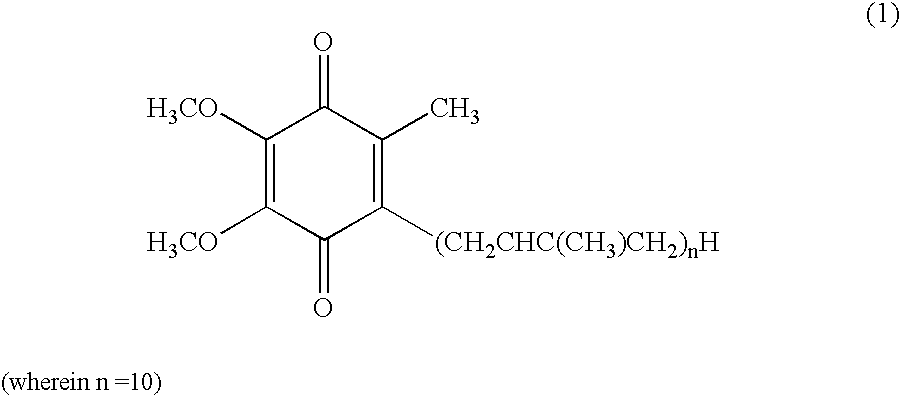

Particulate composition comprising bioactive substance and method of producing the same

InactiveUS20080102131A1High recovery rateAmeliorating issue of low recovery rateBiocidePowder deliverySolubilityParticulates

The present invention provides a particulate composition wherein an oil component (A) comprising a water-insoluble bioactive substance is poly-dispersed while forming a domain in a matrix comprising of a water-soluble excipient based on a water-soluble polymer, and wherein the sphericity of the particulate composition is not less than 0.9 and a method of producing the same. The particulate composition simultaneously has excellent water solubility, workability, tabletability and heat-resistance. It also provides a food, food with nutrient function claims, food for specified health uses, nutritional supplement, nutritional product, animal drug, drink, feed, pet food, cosmetic, pharmaceutical product, therapeutic drug, prophylactic drug and the like, which contain the particulate composition.

Owner:KANEKA CORP

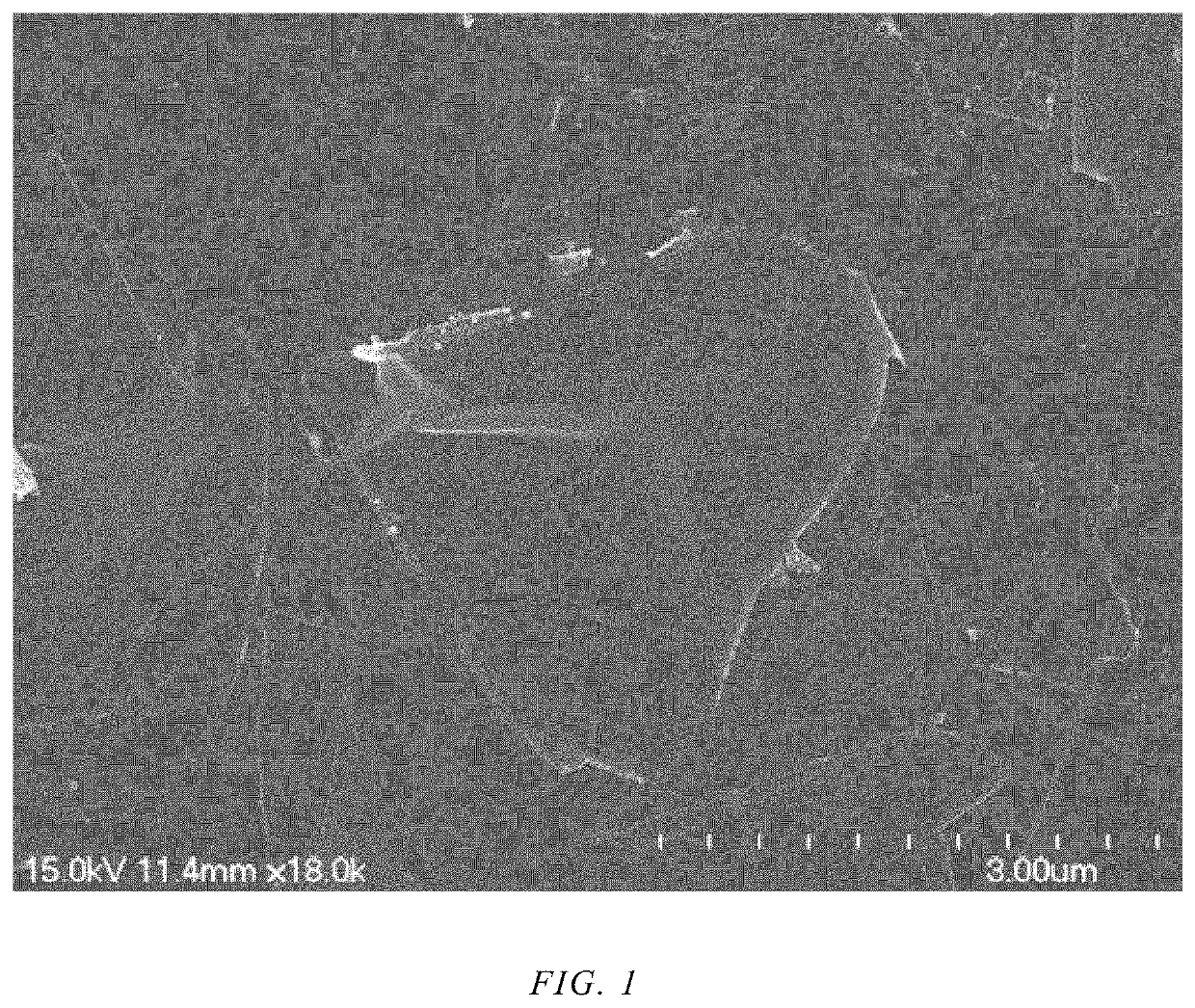

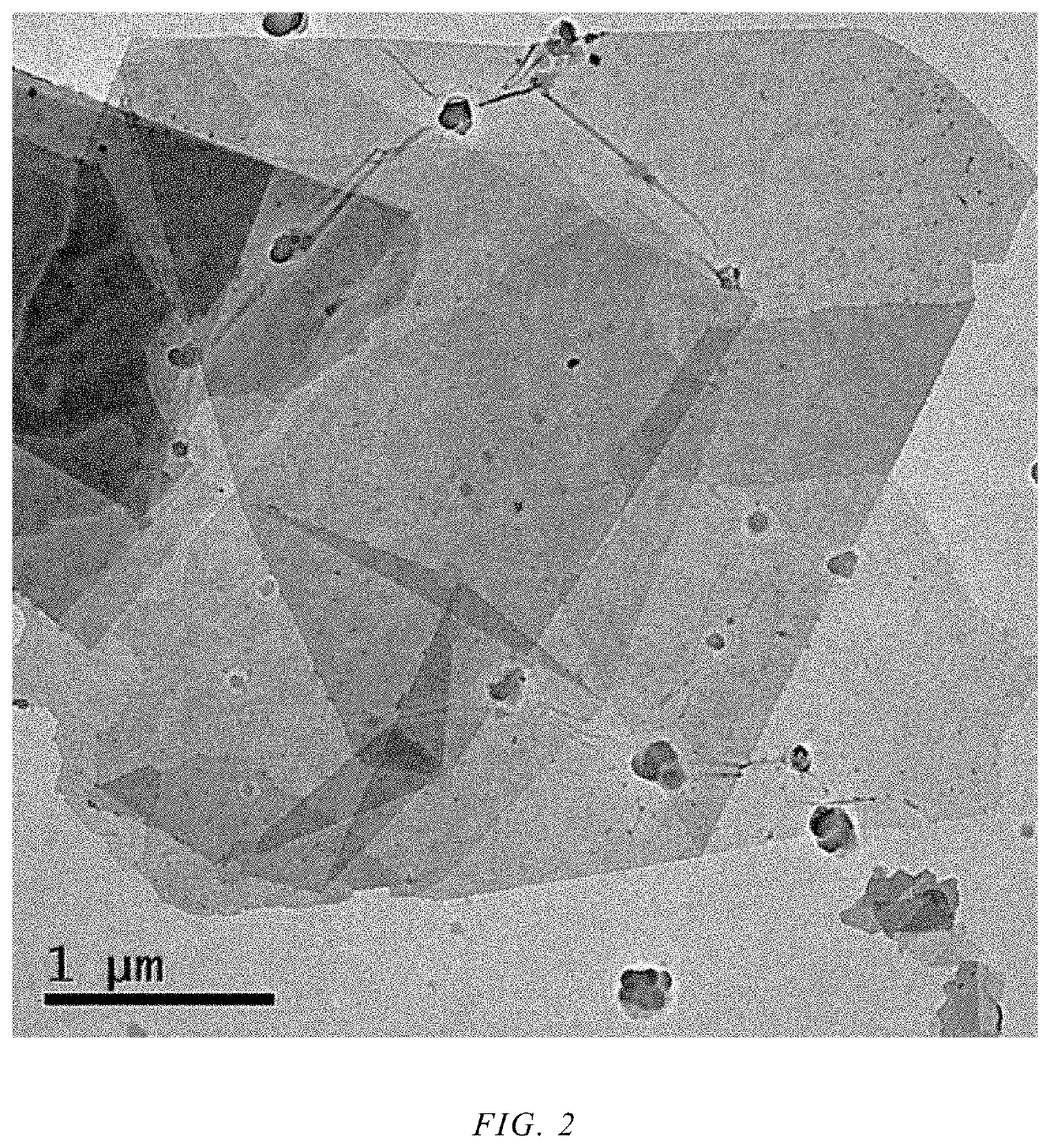

Two-dimensional nitrogen-doped carbon-based titanium dioxide composite material, and preparation method and application thereof for degrading and removing organic pollutants in water

ActiveUS20200122130A1Good repeatabilitySmall sizeWater/sewage treatment by irradiationWater treatment compoundsTransition metal carbidesCarbide

A preparation method of a two-dimensional nitrogen-doped carbon-based titanium dioxide composite material includes: (1) etching Ti3AlC2 with LiF / HCl to prepare two-dimensional transition metal carbide nanosheet; (2) preparing a nanosheet aggregate by electrostatic self-assembly of a two-dimensional transition metal carbide nanosheet and a positively charged nitrogen-containing cationic compound; (3) calcining the nanosheet aggregates to prepare a two-dimensional nitrogen-doped carbon-based titanium dioxide composite material. A method for degrading and removing organic pollutants in water includes (1) etching Ti3AlC2 with LiF / HCl to prepare two-dimensional transition metal carbide nanosheet; (2) preparing a nanosheet aggregate by electrostatic self-assembly of a two-dimensional transition metal carbide nanosheet and a positively charged nitrogen-containing cationic compound; (3) calcining the nanosheet aggregates to prepare a two-dimensional nitrogen-doped carbon-based titanium dioxide composite material; (4) placing the two-dimensional nitrogen-doped carbon-based titanium dioxide composite material into water containing organic pollutants to degrade and remove organic pollutants in water.

Owner:SUZHOU UNIV

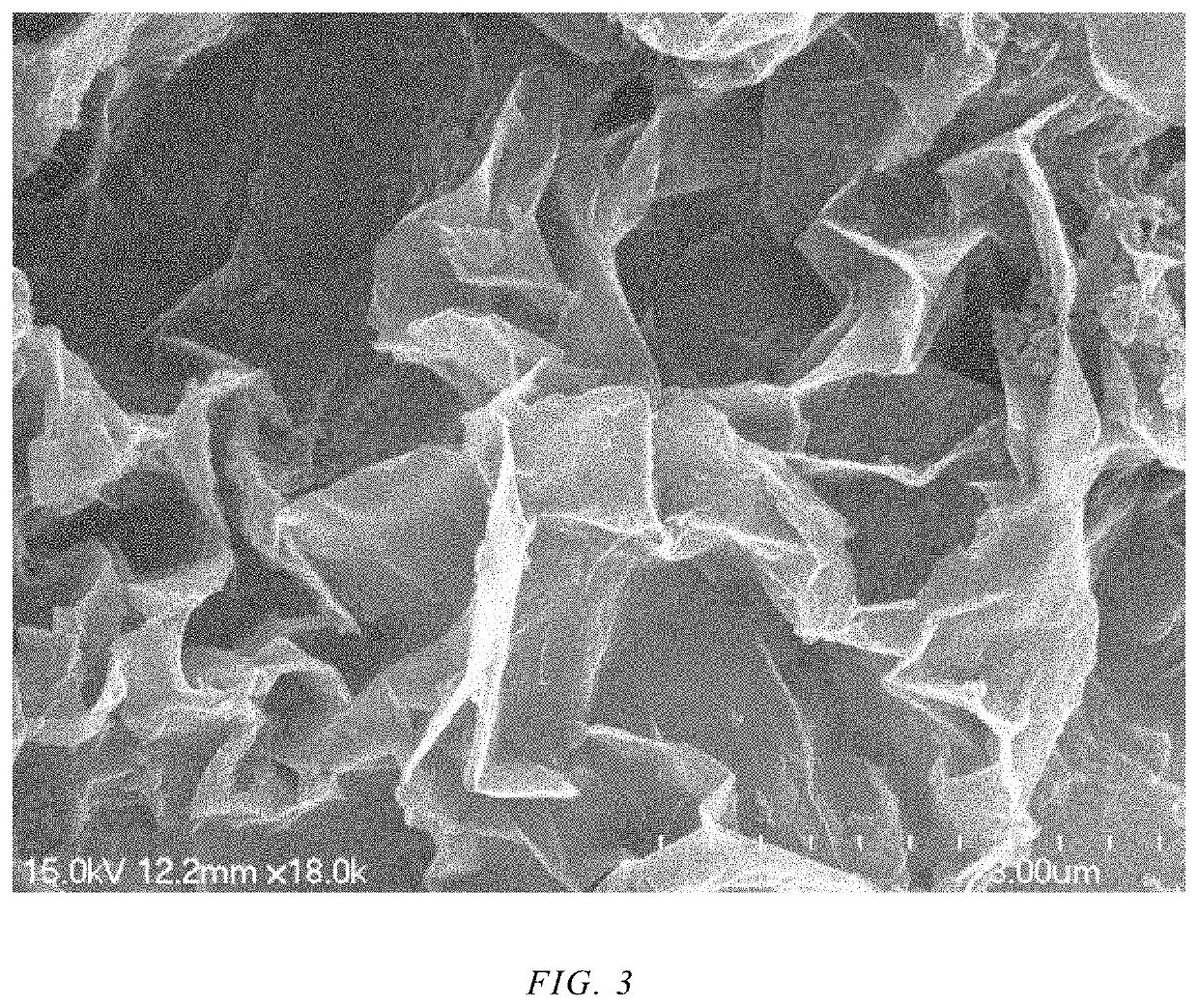

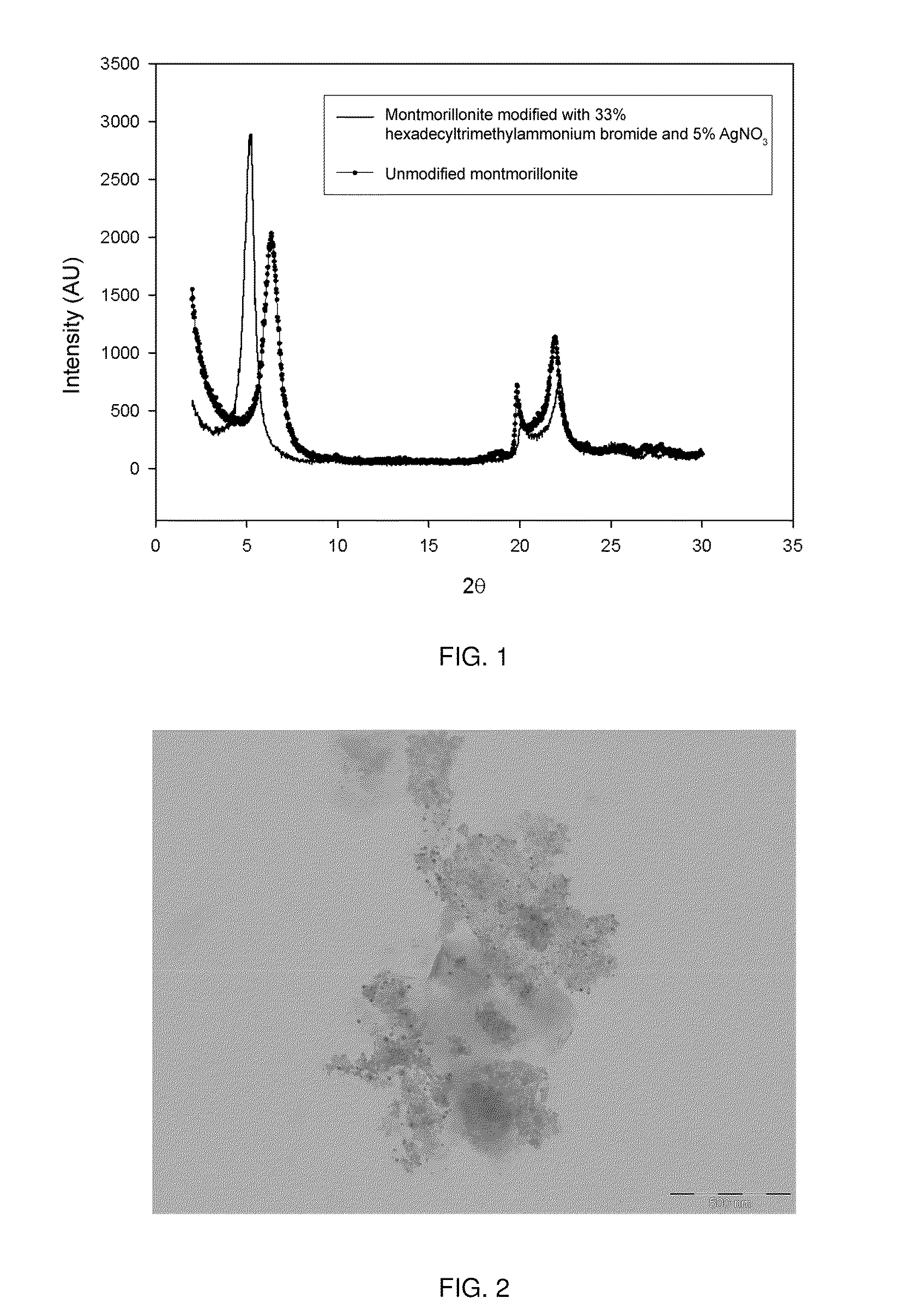

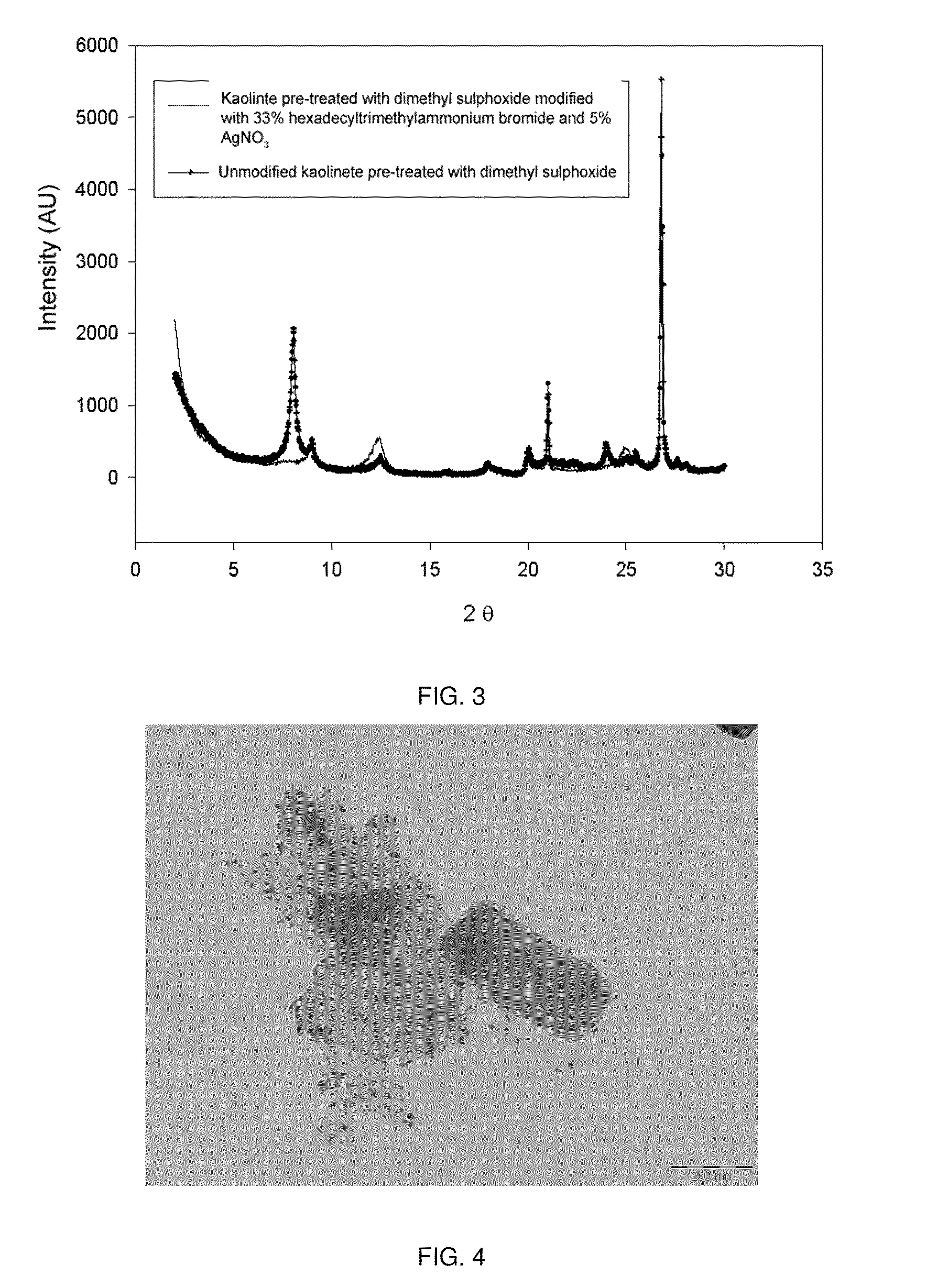

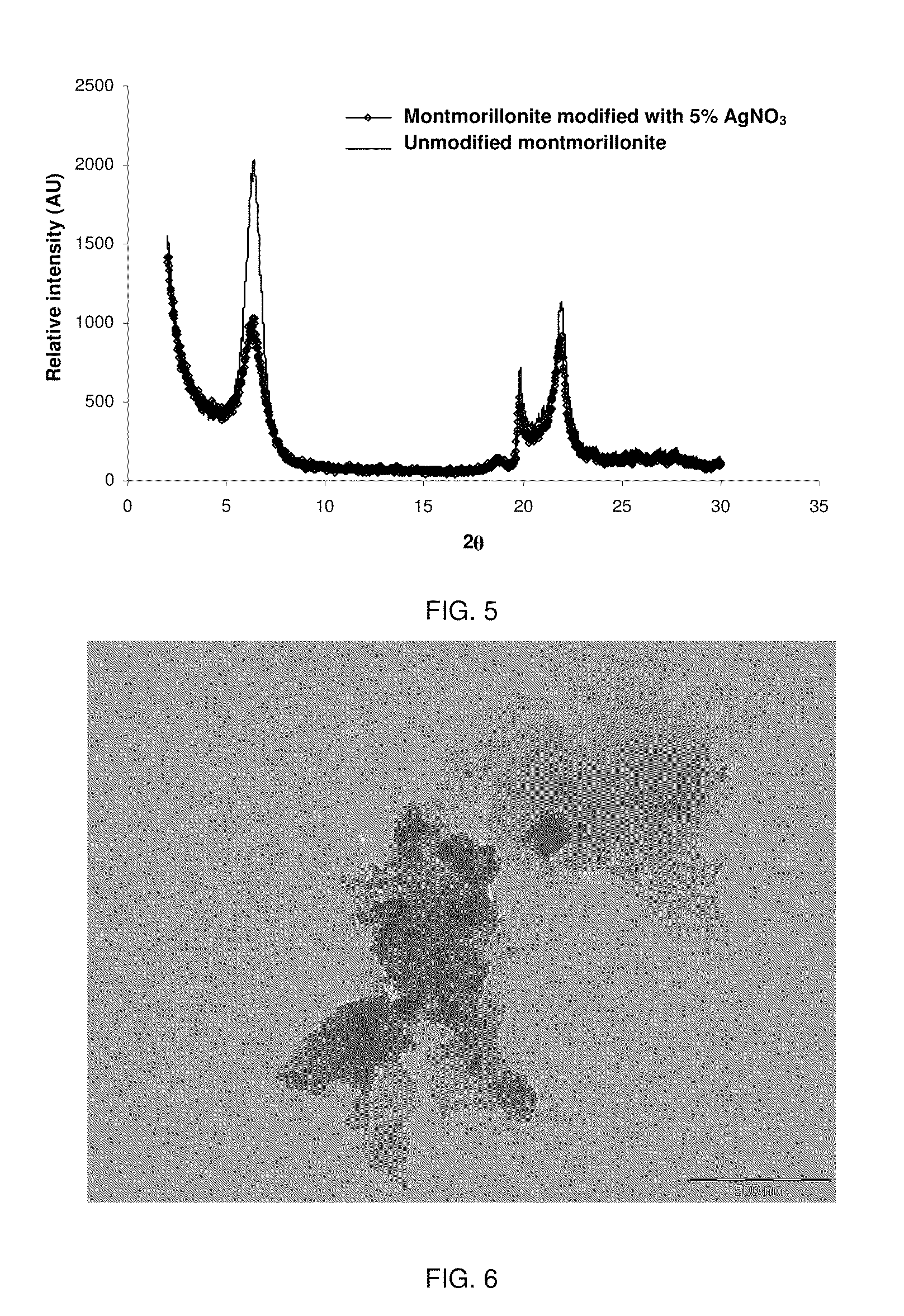

Active nanocomposite materials and production method thereof

ActiveUS20110142899A1Easy to oxidizeImprove efficiencyPigmenting treatmentMaterial nanotechnologyMaterials scienceIndustry sector

SUMMARY The present invention refers to new active nanocomposite materials, comprising a matrix and additives. The present invention also describes a process for obtaining these nanocomposite materials and their use in various industry sectors.

Owner:LAB ARGENOL

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20060124444A1Reduce needRemove films of protein oil and fatsLighting and heating apparatusExhaust apparatusElectrolysisHazardous substance

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogenous acid compounds such as sodium hypochlorite, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:NAKAMURA SHINICHI +2

Solder alloy, solder paste, and electronic circuit board

ActiveUS9221132B2Low costEasy to oxidizePrinted circuit assemblingComponent plug-in assemblagesIndiumTin-silver-copper

A solder alloy is a tin-silver-copper solder alloy containing tin, silver, copper, nickel, antimony, bismuth, and indium, and substantially does not contain germanium, wherein relative to the total amount of the solder alloy, the silver content is more than 0.05 mass % and less than 0.2 mass %, and the antimony content is 0.01 mass % or more and less than 2.5 mass %.

Owner:HARIMA CHEM INC

Method for reducing NOx during combustion of coal in a burner

InactiveUS20060228282A1Reduce outputEasy to oxidizeNitrogen compoundsTobacco treatmentNano catalystSulfonyl halide

An organically complexed nanocatalyst composition is applied to or mixed with coal prior to or upon introducing the coal into a coal burner in order to catalyze the removal of coal nitrogen from the coal and its conversion into nitrogen gas prior to combustion of the coal. This leads to reduced NOx production during coal combustion. The nanocatalyst compositions include a nanoparticle catalyst that is made using a dispersing agent. The dispersing agent includes at least one functional group such as a hydroxyl, a carboxyl, a carbonyl, an amine, an amide, a nitrile, a nitrogen having a free lone pair of electrons, an amino acid, a thiol, a sulfonic acid, a sulfonyl halide, and an. acyl halide. The dispersing agent forms stable, dispersed, nano-sized catalyst particles. The catalyst composition can be formed as a stable suspension to facilitate storage, transportation and application of the catalyst nanoparticles to a coal material. The catalyst composition can be applied before or after pulverizing the coal material or it may be injected directly into the coal burner together with pulverized coal.

Owner:HEADWATERS TECH INNOVATION GRP

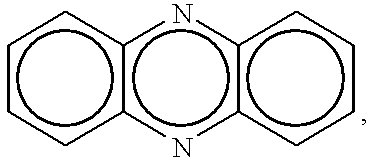

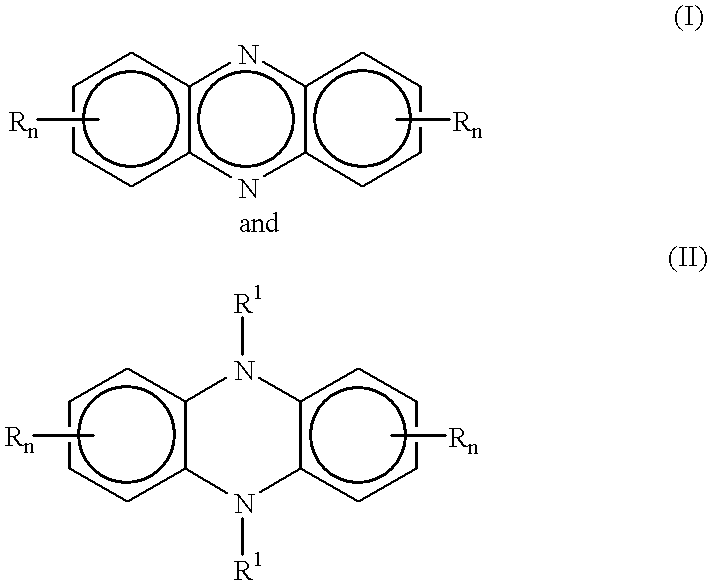

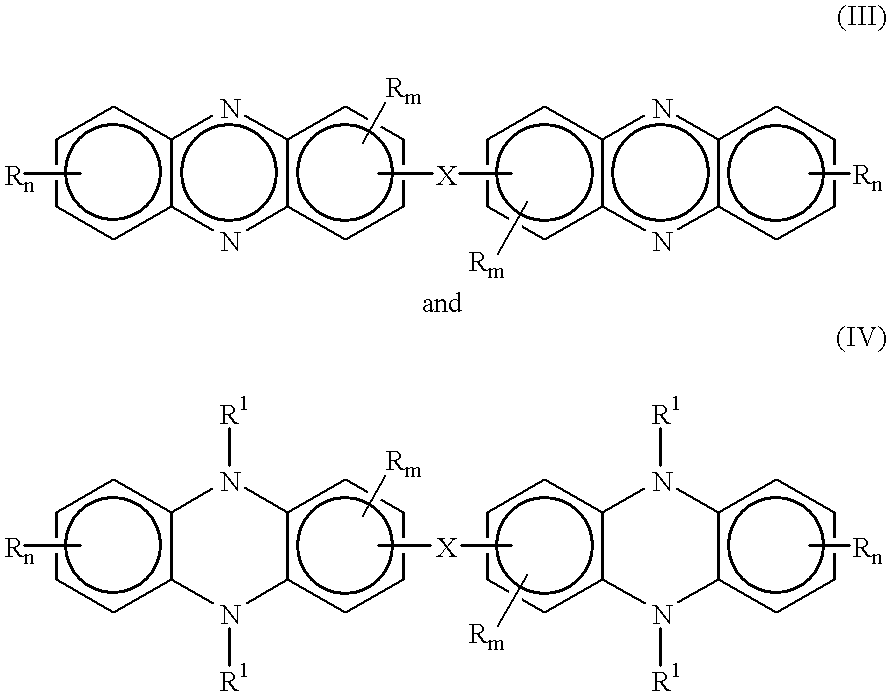

One pot synthesis of 5,10-dihydrophenazine compounds and 5,10-substituted dihydrophenazines

Dihydrophenazines and bis(dihydrophenazines) are prepared in high yield under commercially viable reaction conditions by reacting a catechol with a 1,2-diaminoaryl compound, wherein either the catechol or the 1,2-diaminoaryl compound is provided in at least 50% molar stoichiometric excess. The product may be oxidized to the corresponding phenazine, but is preferably derivatized at one or both of the 5,10-positions to form a monosubstituted or disubstituted dihydrophenazine or bis(dihydrophenazine). Most preferably, 5,10-dialkyl-5,10-dihydrophenazines are prepared starting from catechol and 1,2-diaminoaryl compound in a one pot synthesis. The products are useful as dyes, and in particular as chromophores in electrochromic systems.

Owner:GENTEX CORP

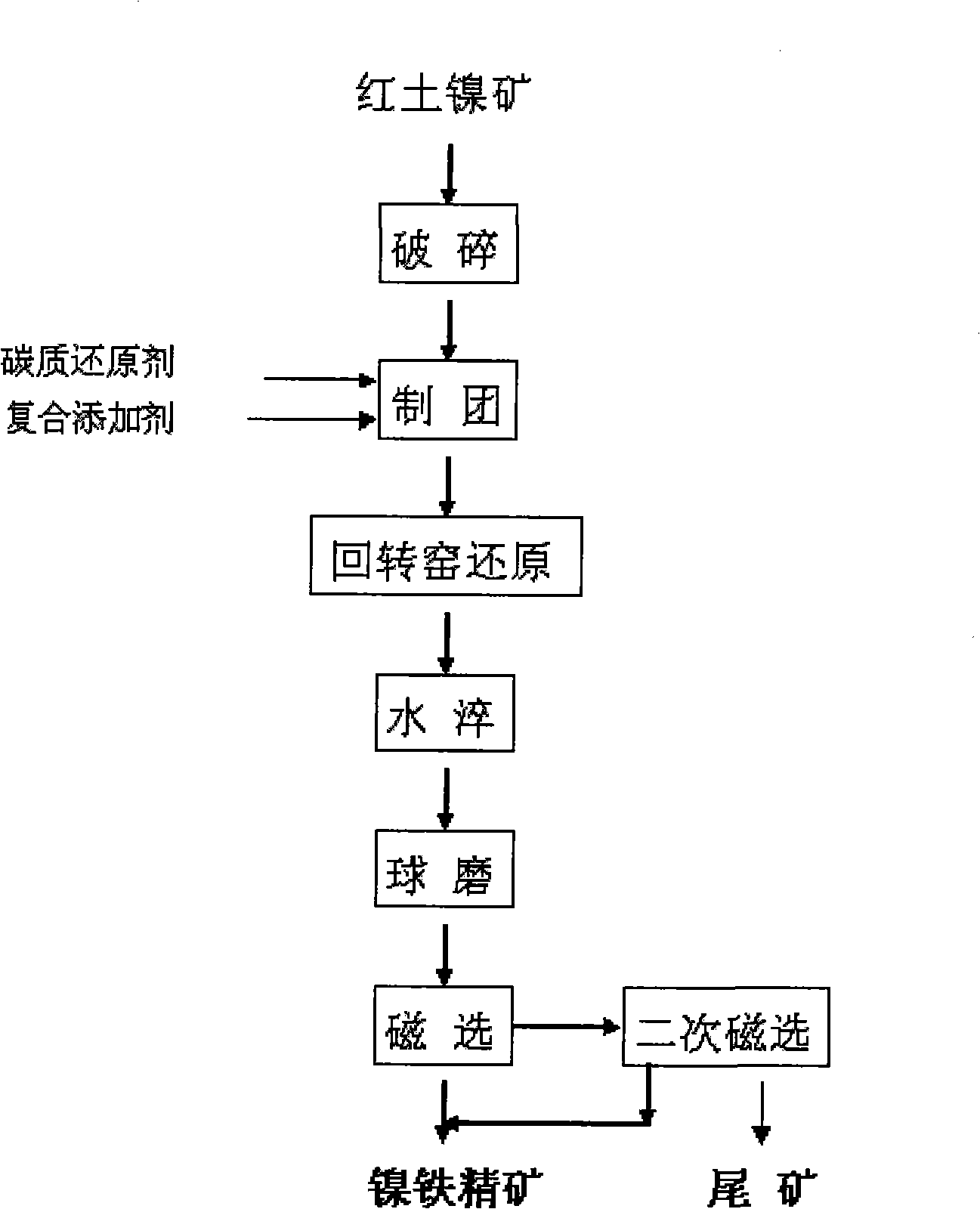

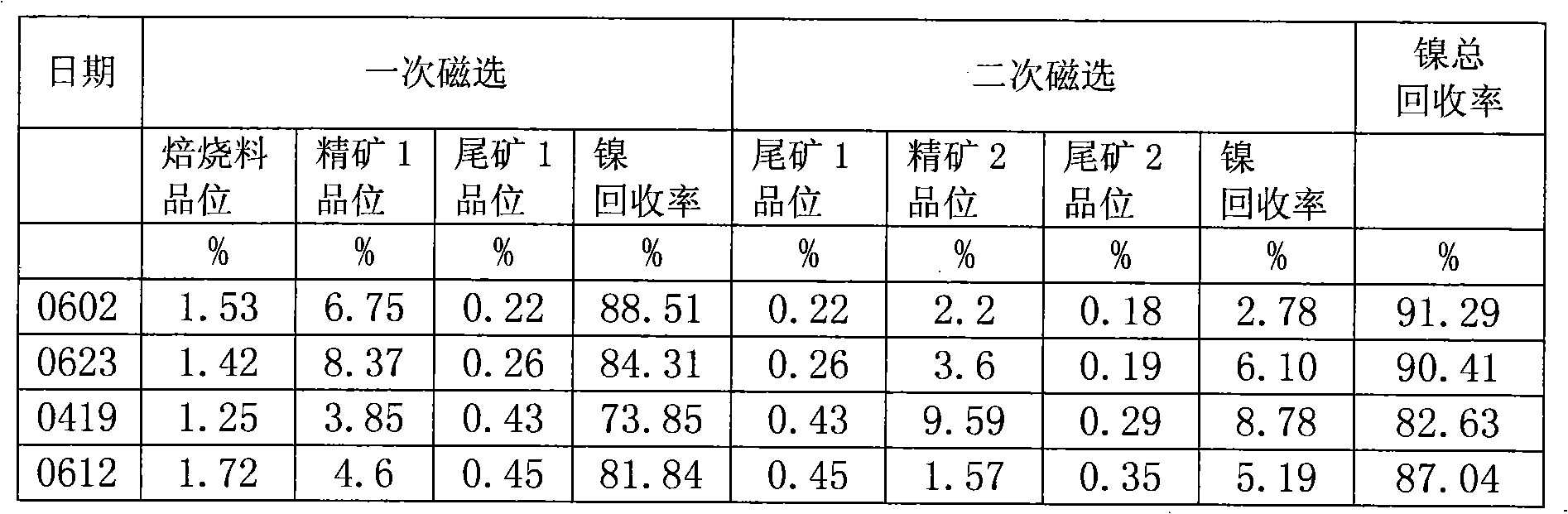

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

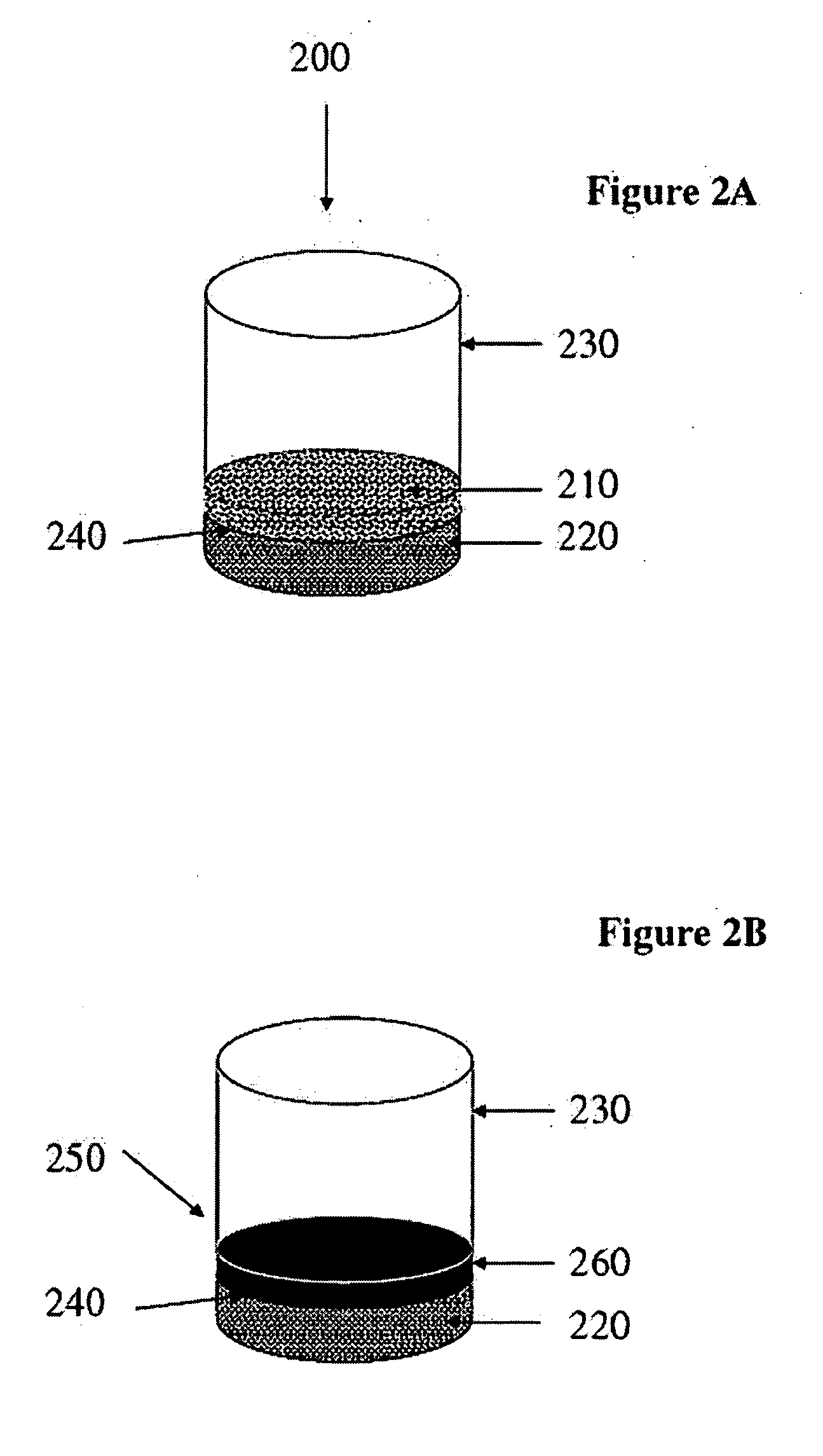

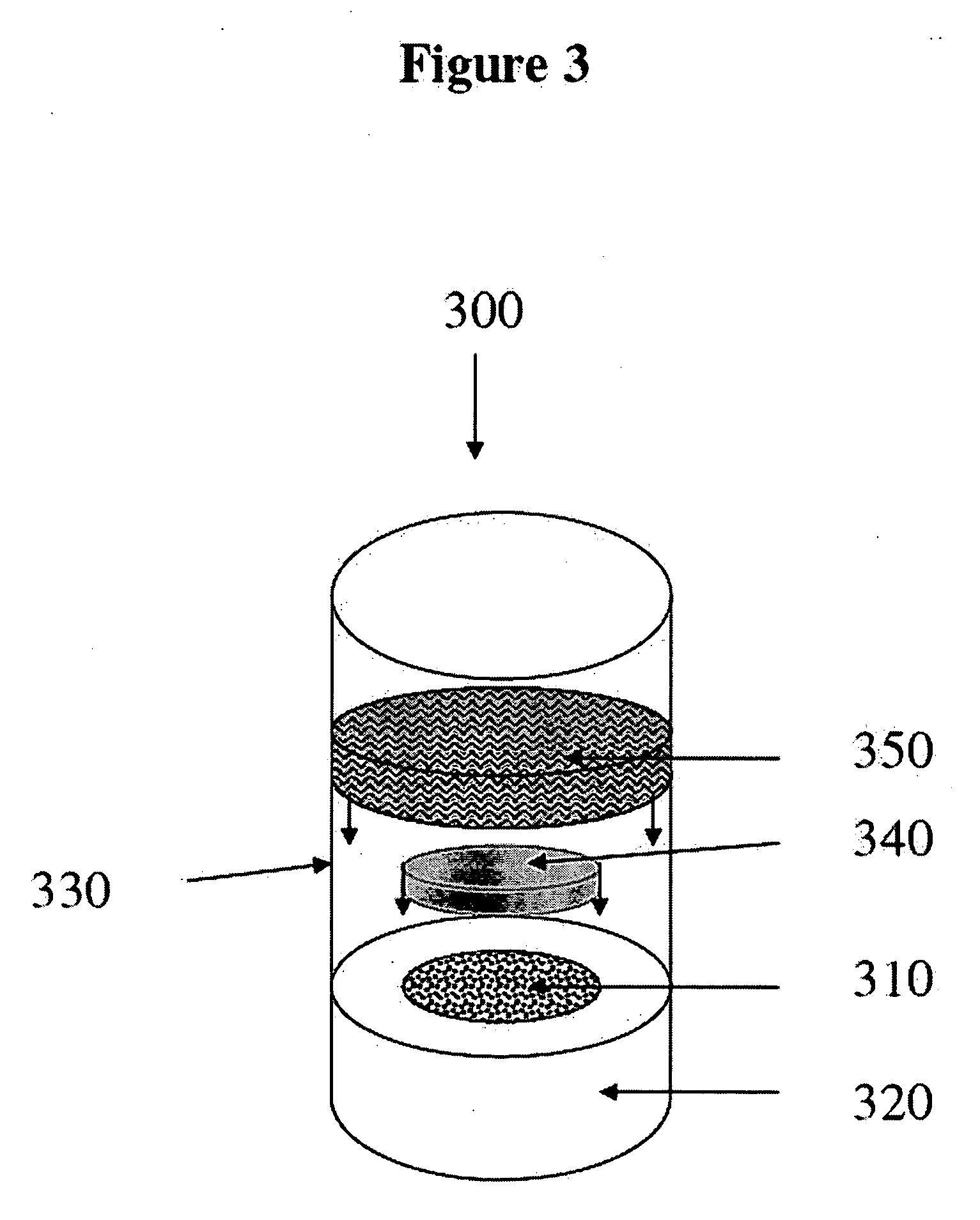

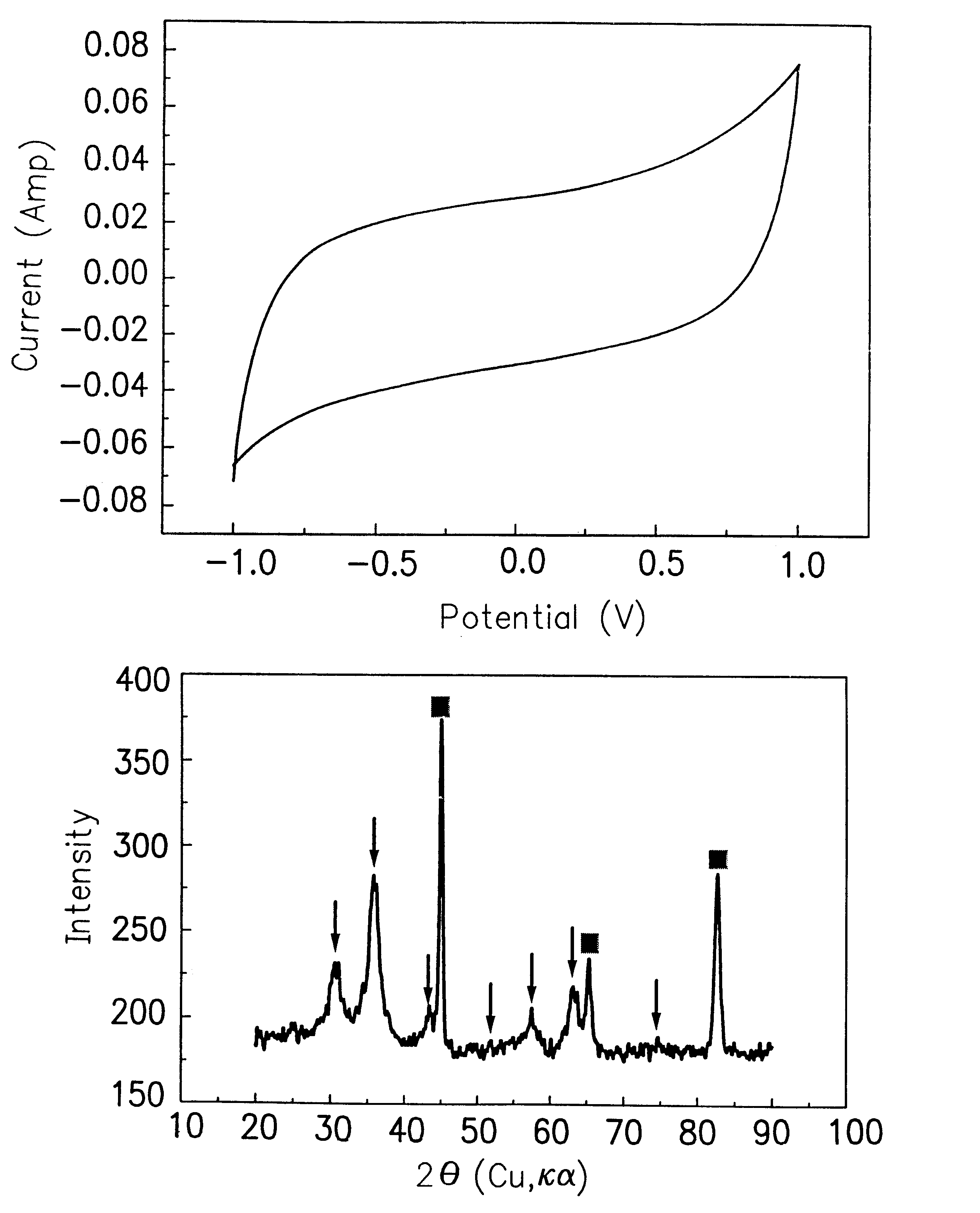

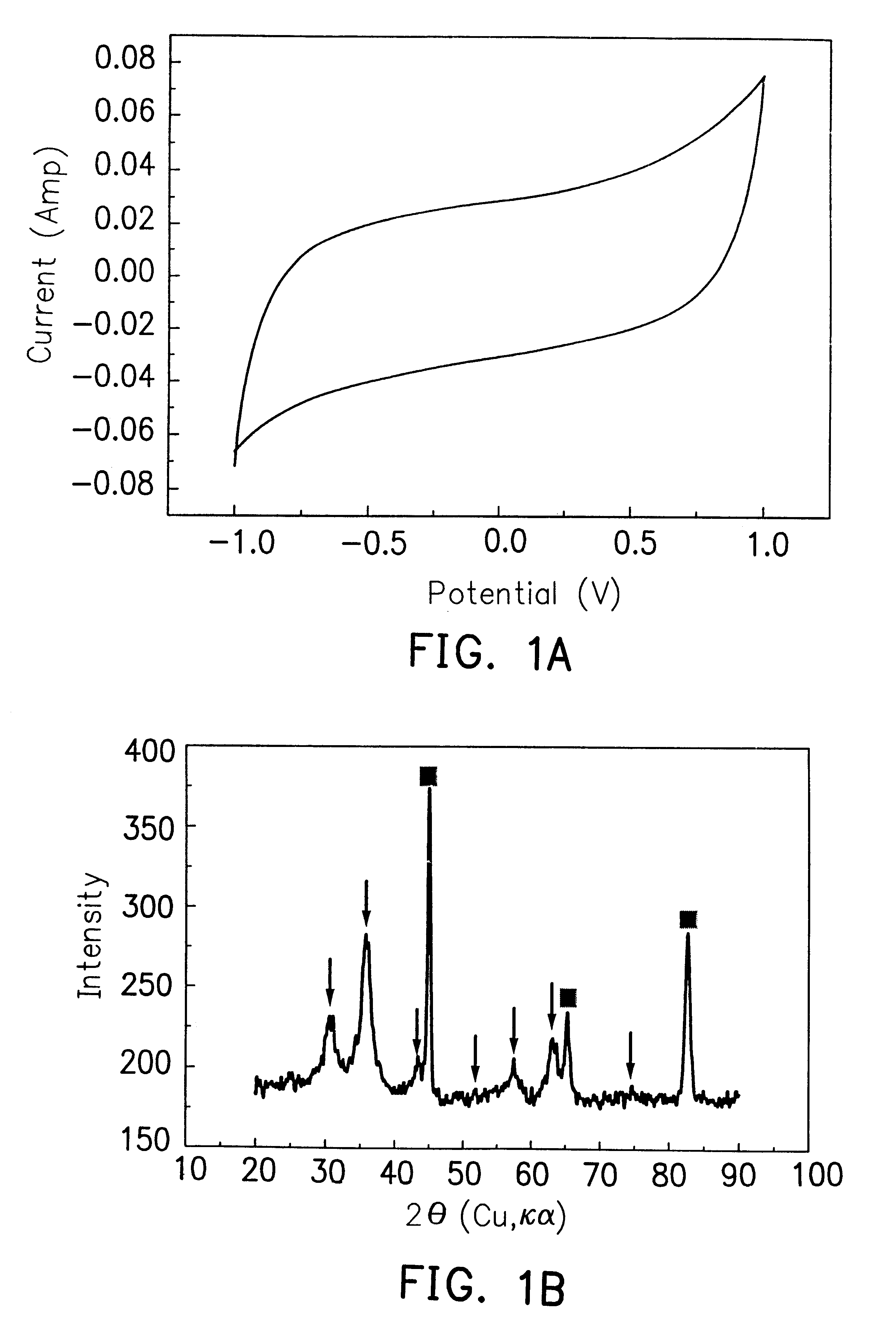

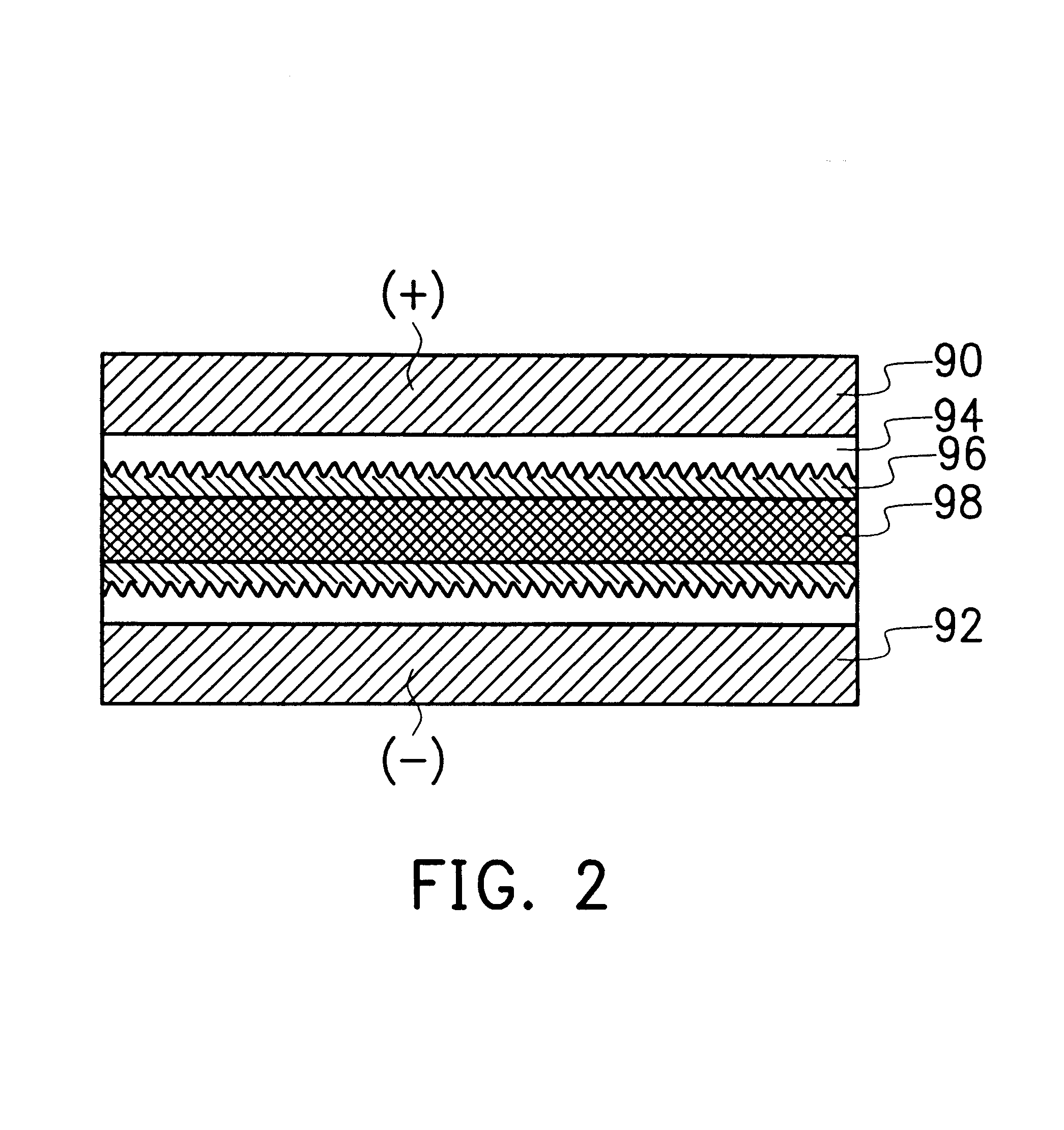

Supercapacitors and method for fabricating the same

InactiveUS6512667B2Long usage timeReduce battery usageMaterial nanotechnologyLiquid electrolytic capacitorsBrown iron oxideCurrent collector

Using thin-films of iron oxide as the active material of electrodes, supercapacitors are fabricated on various substrates in different shapes. By chemical oxidation the iron-oxide film is formed directly and conformably on the substrates in a short period of cooking. The iron oxide has a chemical composition of Fe.sub.x O.sub.y H.sub.z, where 1.0.ltoreq.x.ltoreq.3.0, 0.0.ltoreq.y.ltoreq.4.0, and 0.0.ltoreq.z.ltoreq.1.0. Substrates, as the current collector, tested includes Al, Ti, Fe, Cu and Ni. Measurements by cyclic voltammetry indicates that the iron-oxide electrodes in a selected electrolyte can store charges as high as 0.5 F / cm.sup.2 or 417 F / g of the electrode materials. Supercapacitors as prepared are economical and can be used as enclosure housings for portable electronics, power tools, and batteries. The supercapacitors can also be integrated with the frames and chassis of electric vehicles.

Owner:LUXON ENERGY DEVICES CORP

Microalgal feeds containing arachidonic acid and their production and use

InactiveUS20060024404A1Improve stabilityEasy to oxidizeClimate change adaptationAnimal feeding stuffAnimal feedLong chain fatty acid

An animal feed with a high level of arachidonic acid is produced from microalgae, and fed to aquatic animals grown in aquaculture. The arachidonic acid-rich microalgae are fed directly to the aquatic animals, or processed to produce an oil that can be used as a human nutritive supplement. The arachidonic acid-rich microalgae can be combined with long chain omega-3 fatty acids to provide a source of nutrition for humans and animals. The animal feed and nutritional supplements are free of animal byproducts.

Owner:INTERVET INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com