Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Few void" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

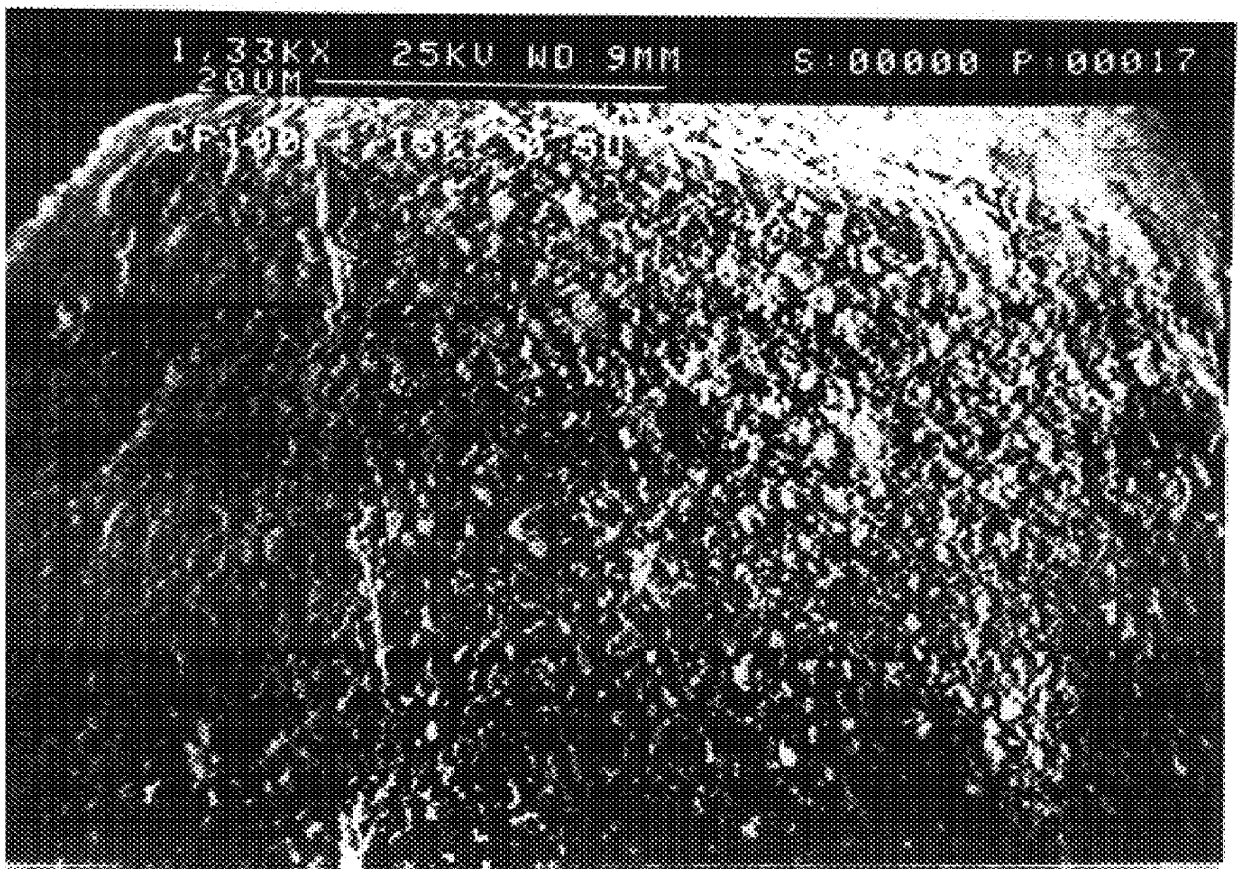

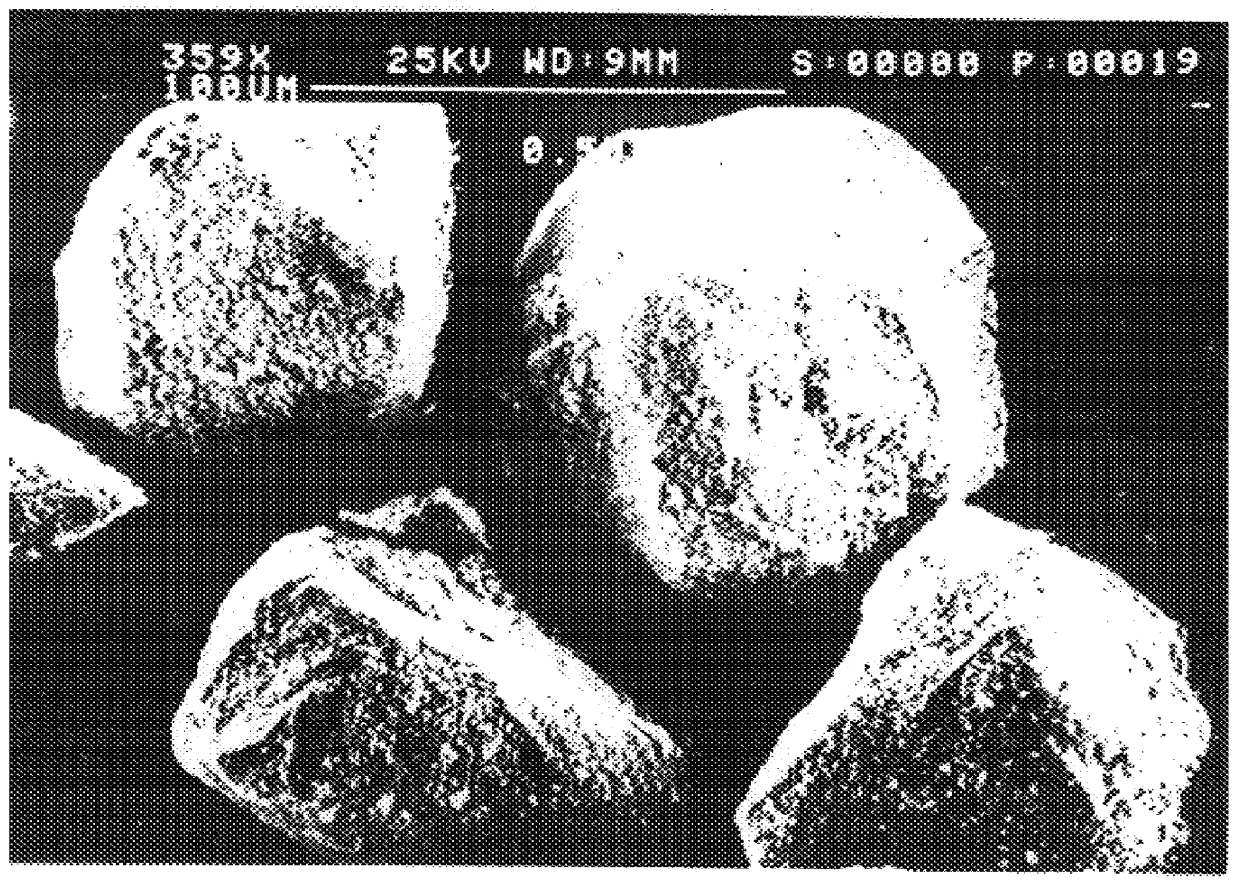

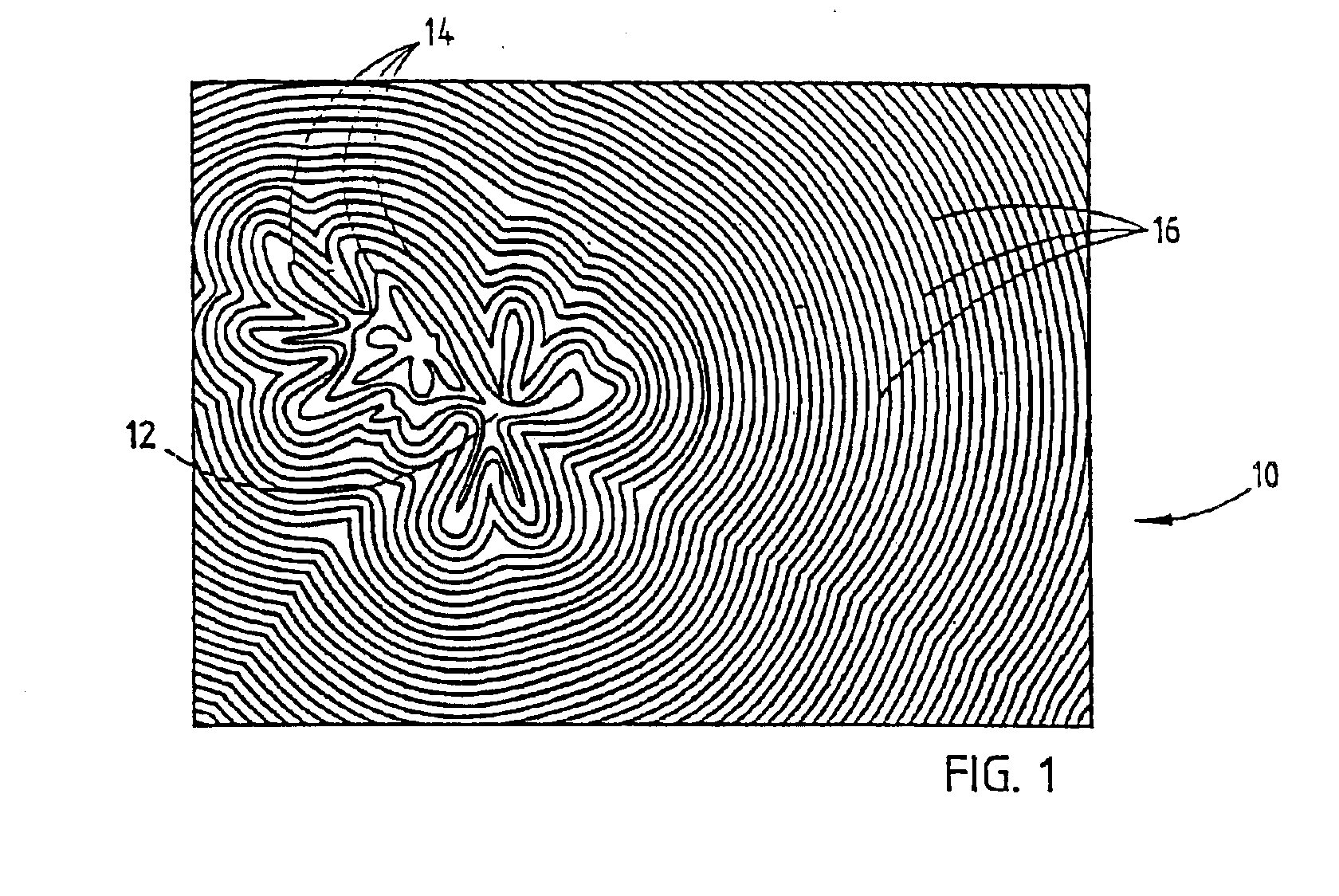

Method for producing abrasive compact with improved properties

InactiveUS6132675AImproved abrasionImprove stabilityUltra-high pressure processesCeramic shaping apparatusPolycrystalline diamondCarbide

Metal carbide supported polycrystalline diamond (PCD) compacts having improved abrasion / impact resistance properties and a method for making the same under high temperature / high pressure (HT / HP) processing conditions. The PCD compact is characterized as having a mixture of submicron sized diamond particles and large sized diamond particles.

Owner:DIAMOND INNOVATIONS INC

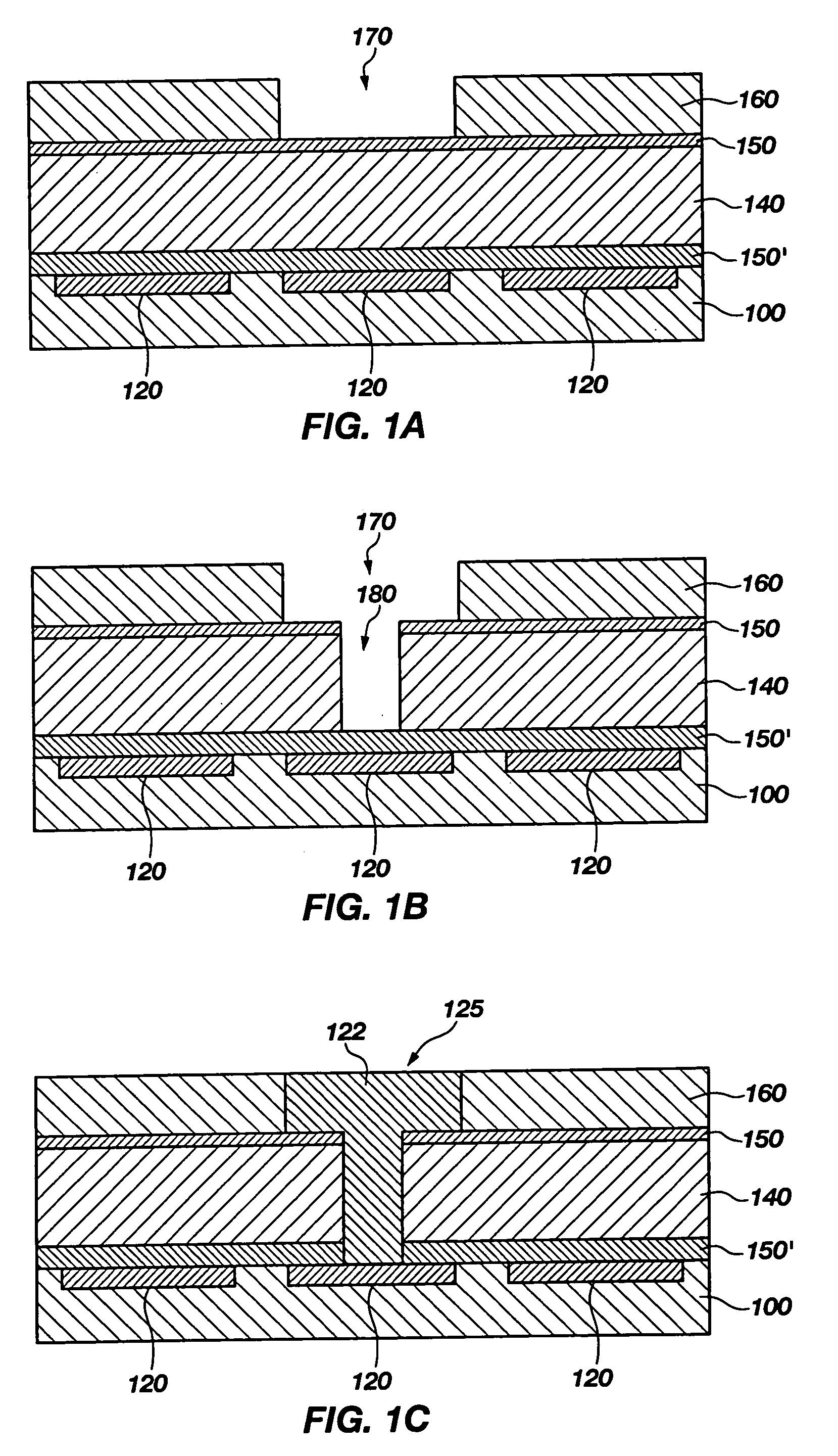

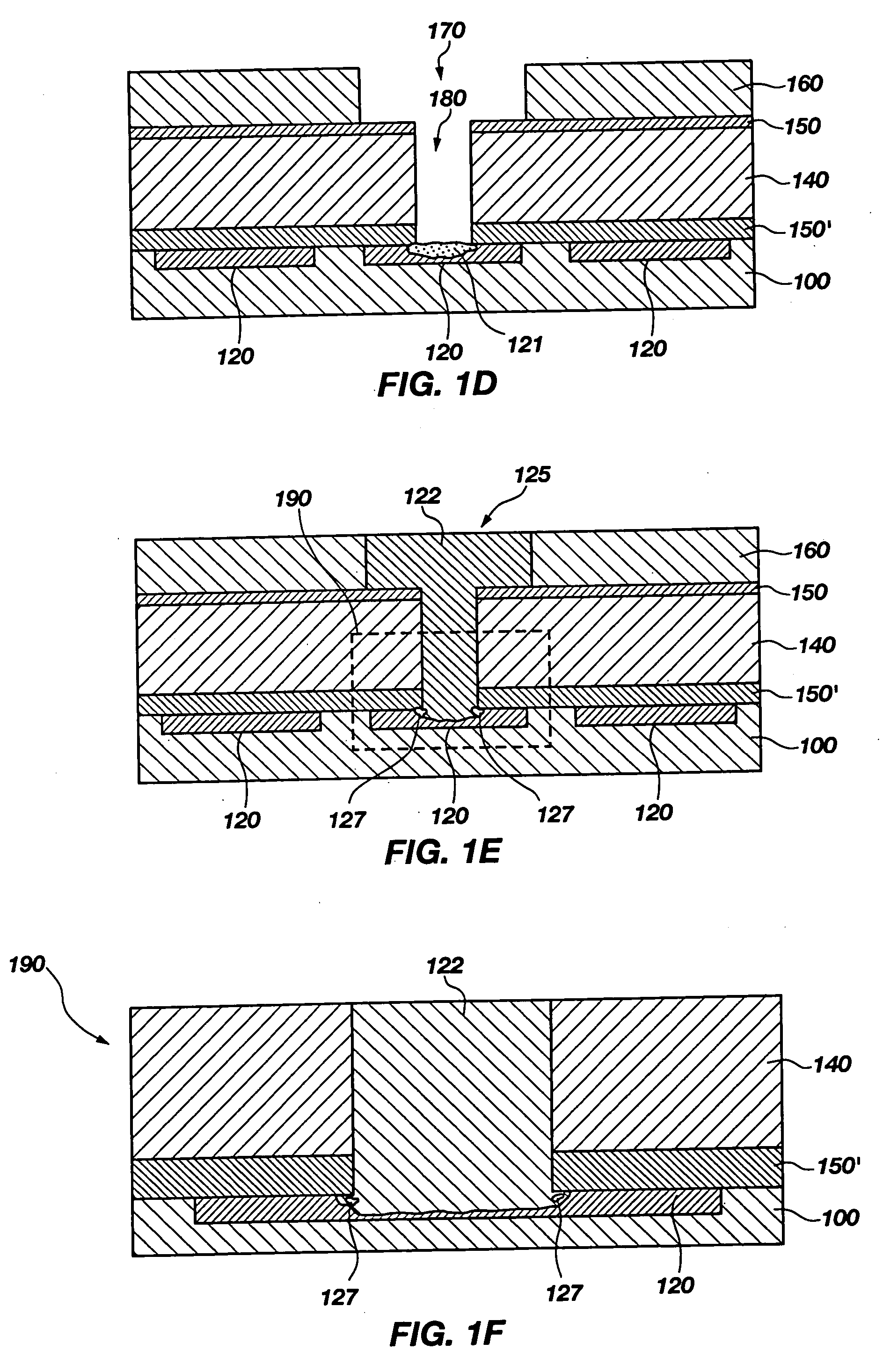

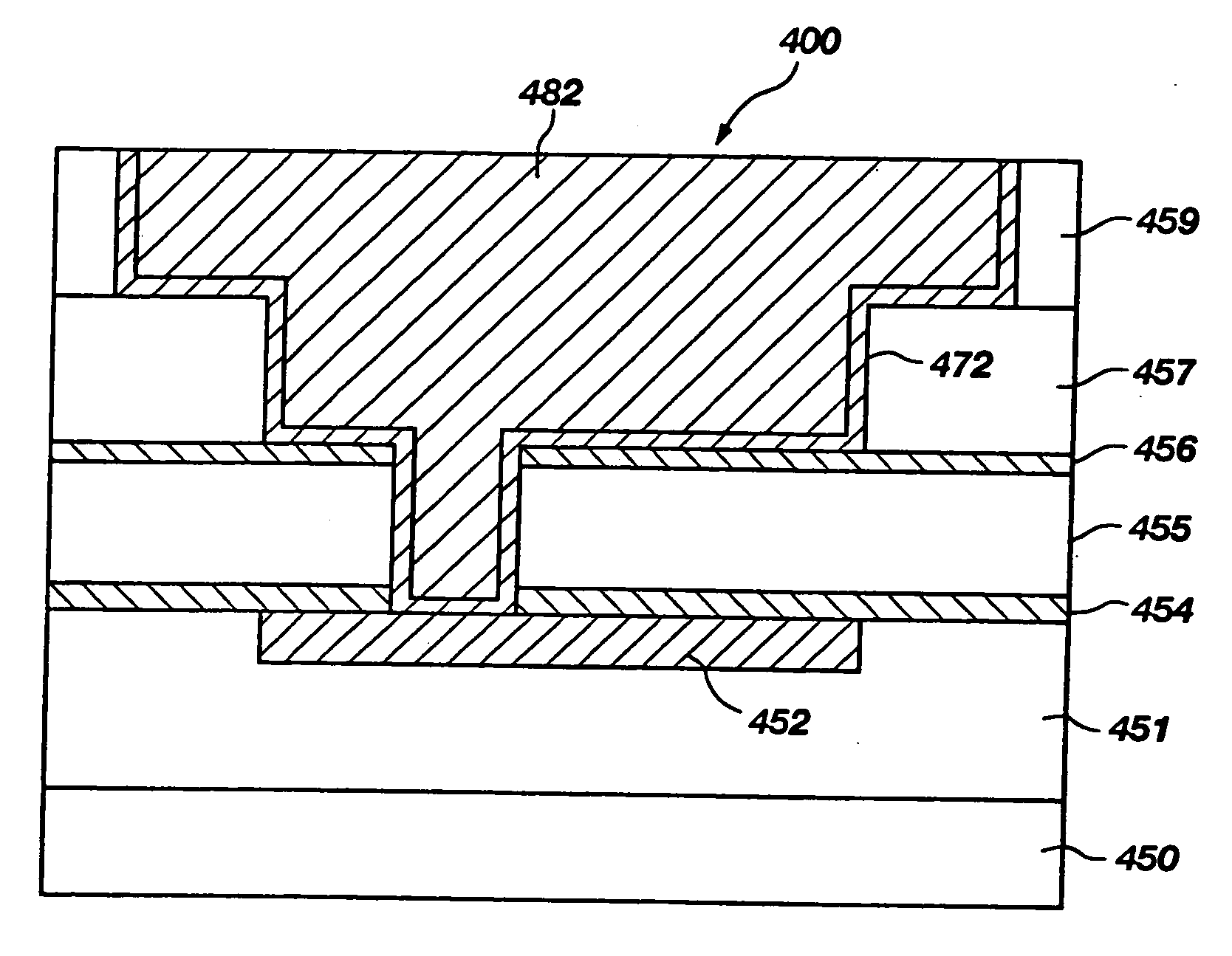

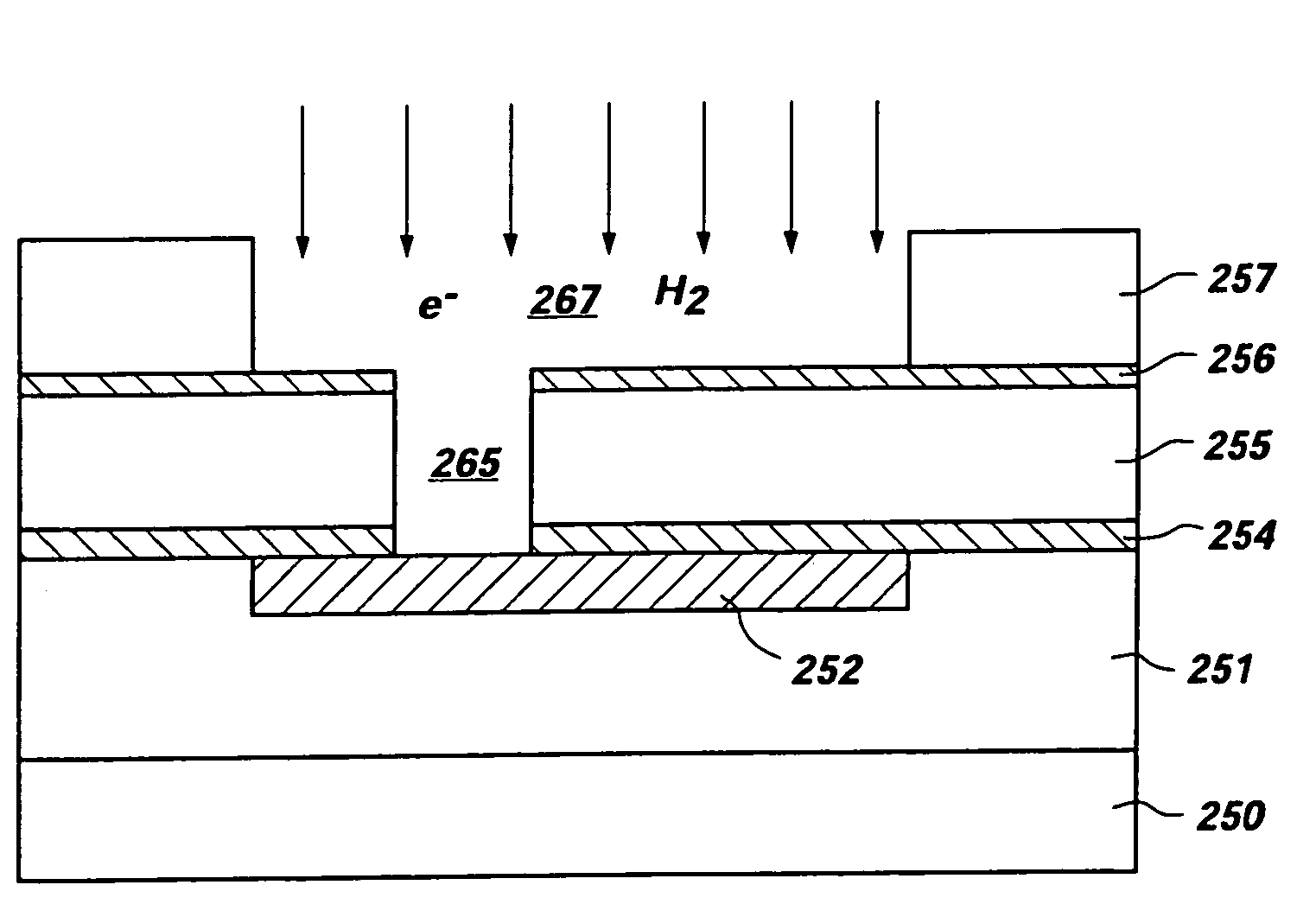

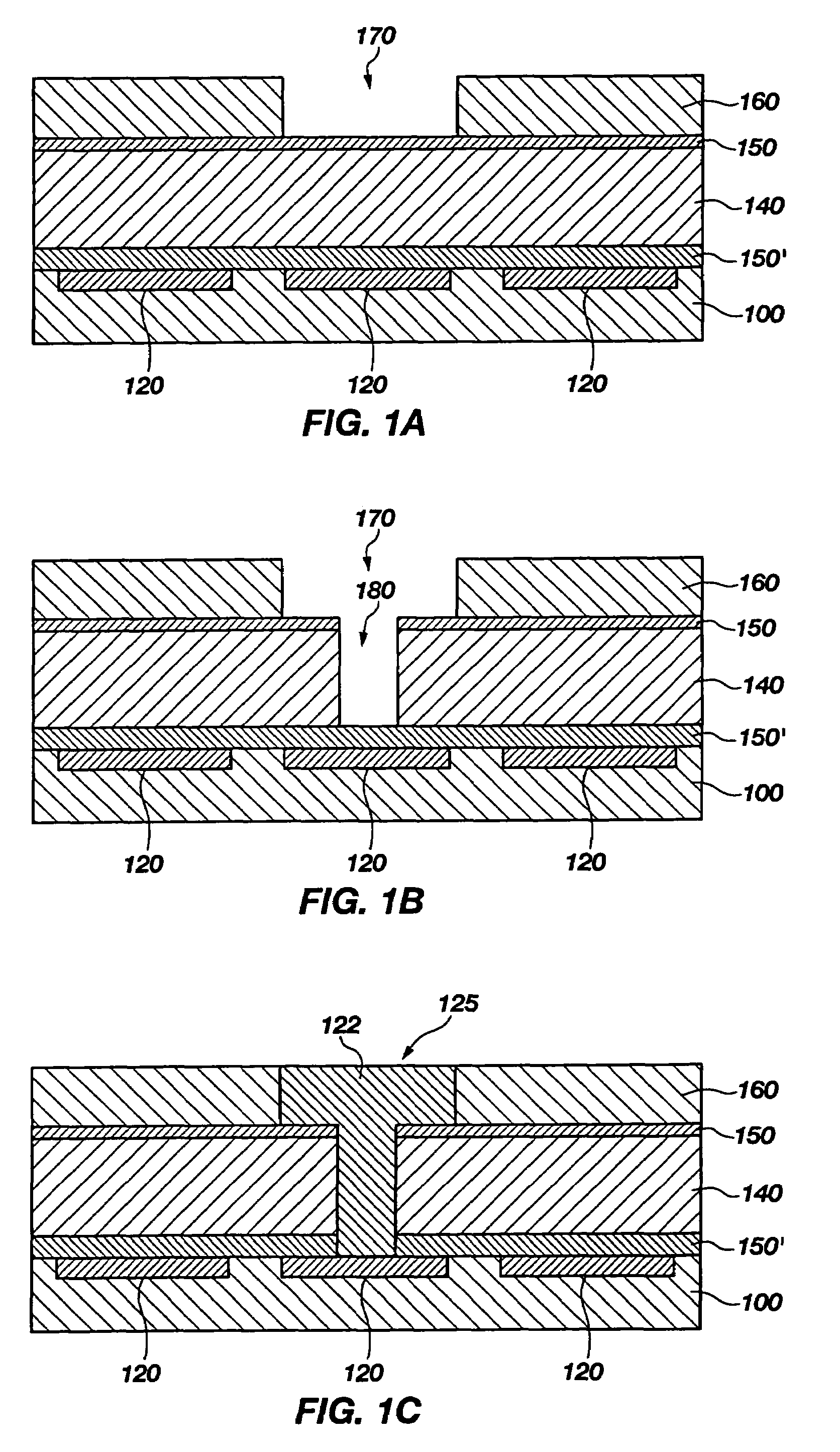

Methods for improving metal-to-metal contact in a via, devices made according to the methods, and systems including the same

ActiveUS20050170642A1Compromise reliabilityMinimize exposureSemiconductor/solid-state device manufacturingState of artProcess integration

In damascene process integration, a reducing plasma is applied after the etch stop or barrier layer is opened over a copper layer. Currently known methods for opening barrier layers suffer from the disadvantage that they cause at least some of the underlying copper to oxidize to copper oxide.. Because copper oxide is selectively removed by subsequent wet cleaning, voids can form where damaged copper (e.g., copper oxide) is removed, thus compromising the reliability of metal-to-metal contact in vias. The present invention advantageously overcomes this and other disadvantages of the prior art through the use of a hydrogen plasma following the barrier layer opening step, which repairs damaged copper (e.g., reduces copper oxide to copper), thus preventing and / or diminishing defects in metal-to-metal contacts in vias and concomitantly improving the reliability of the same.

Owner:MICRON TECH INC

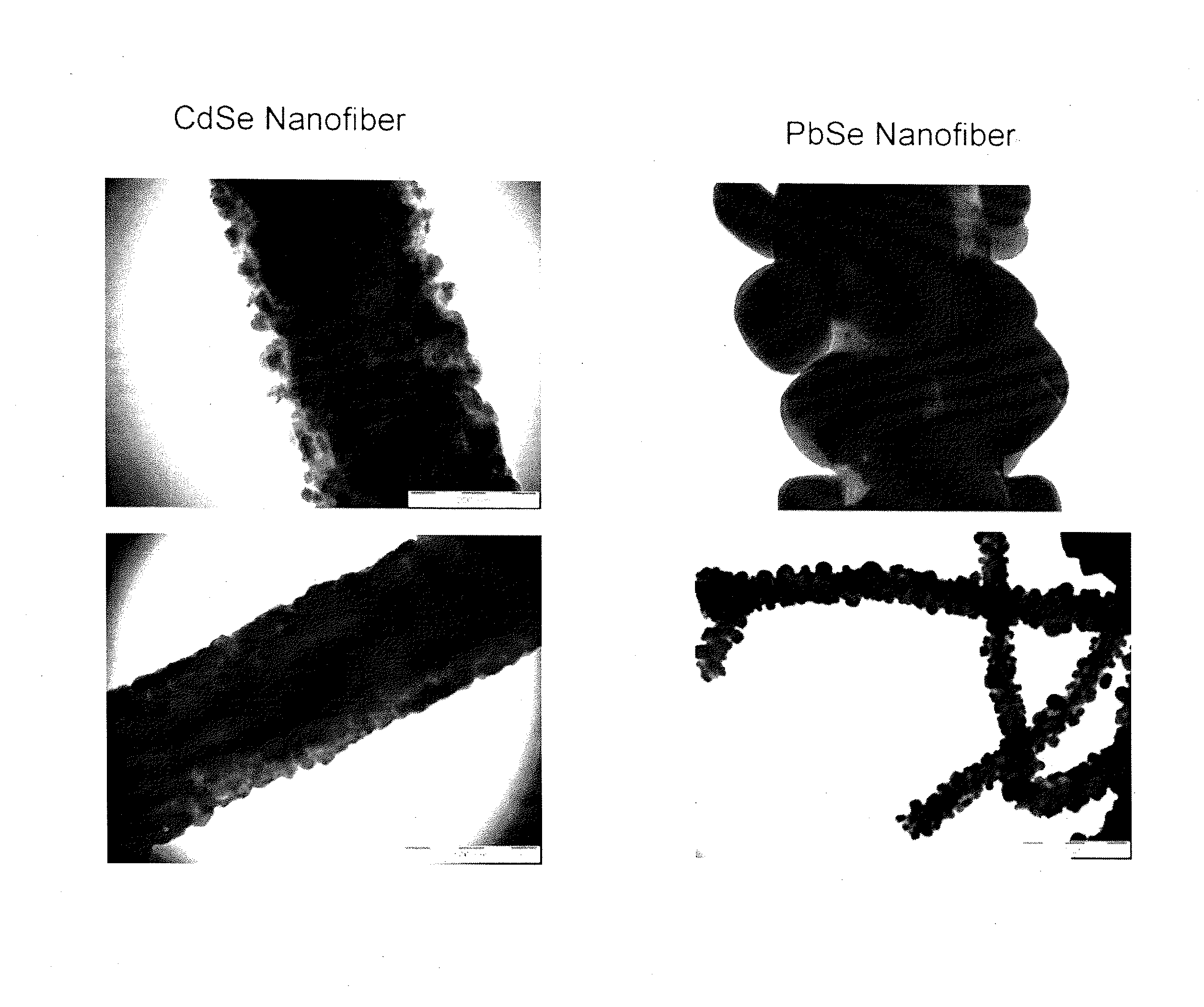

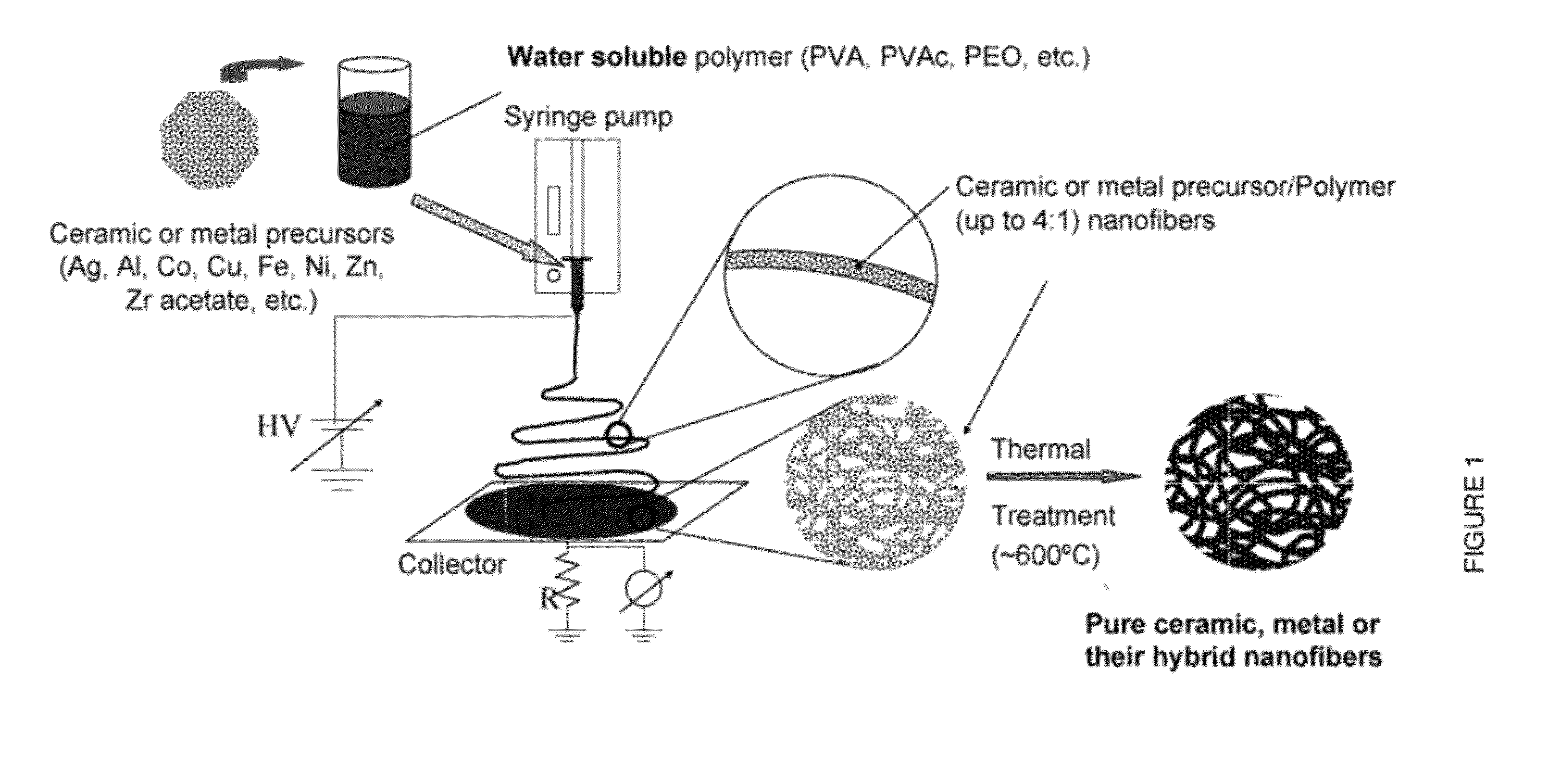

Metal and ceramic nanofibers

ActiveUS20120282484A1Few voidFew defectInorganic material artificial filamentsCell electrodesPolymer scienceElectrospinning

Provided herein are nanofibers and processes of preparing nanofibers. In some instances, the nanofibers are metal and / or ceramic nanofibers. In some embodiments, the nanofibers are high quality, high performance nanofibers, highly coherent nanofibers, highly continuous nanofibers, or the like. In some embodiments, the nanofibers have increased coherence, increased length, few voids and / or defects, and / or other advantageous characteristics. In some instances, the nanofibers are produced by electrospinning a fluid stock having a high loading of nanofiber precursor in the fluid stock. In some instances, the fluid stock comprises well mixed and / or uniformly distributed precursor in the fluid stock. In some instances, the fluid stock is converted into a nanofiber comprising few voids, few defects, long or tunable length, and the like.

Owner:CORNELL UNIVERSITY

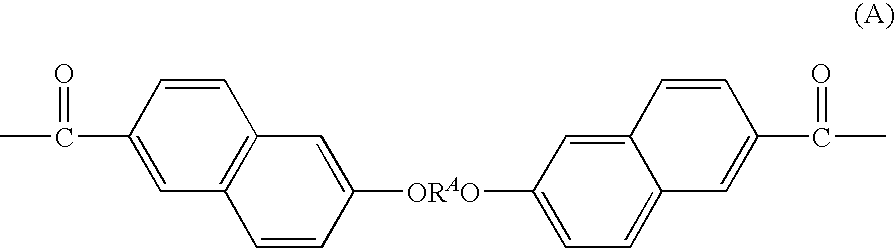

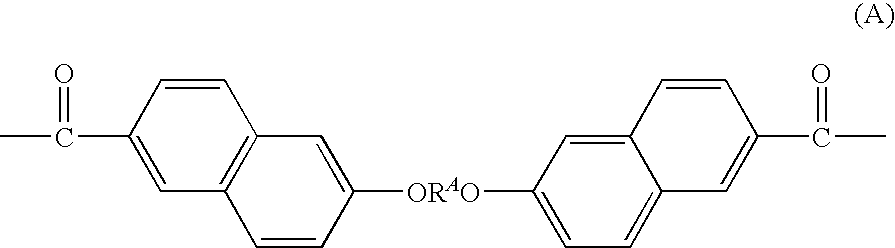

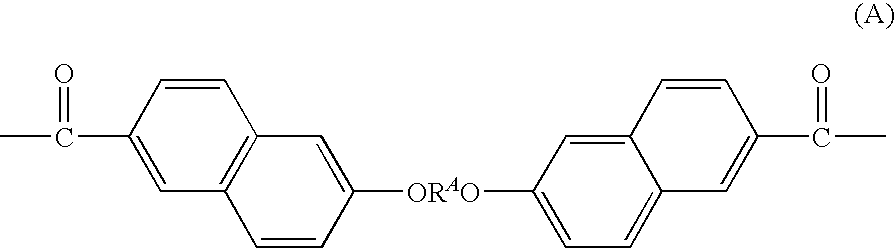

Biaxially oriented laminated film

ActiveUS20100190037A1Good dimensional stabilityFew voidMagnetic materials for record carriersBase layers for recording layersBoPETSurface roughness

It is an object of the present invention to provide a biaxially oriented laminated polyester film which has excellent dimensional stability to environmental changes such as temperature and humidity variations and excellent flatness and windability.The present invention is a biaxially oriented laminated polyester film comprising a film layer B on one side of a film layer A and having a surface roughness (RaB) on the film layer B side which is 1.0 nm or more larger than the surface roughness (RaA) on the film layer A side, whereinat least one of the film layers comprises an aromatic polyester (I) composed of a glycol component and a dicarboxylic acid component containing 5 mol % or more and less than 80 mol % of a recurring unit represented by the following formula (A):wherein RA is an alkylene group having 1 to 10 carbon atoms.

Owner:TEIJIN LTD

Methods for forming conductive vias in a substrate and electronic devices and systems including an at least partially reversed oxidation injury at an interface between a conductive via and a conductive interconnect structure

InactiveUS20070007657A1Compromise reliabilityMinimize exposureSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsConductive materials

Owner:HINEMAN MAX F +1

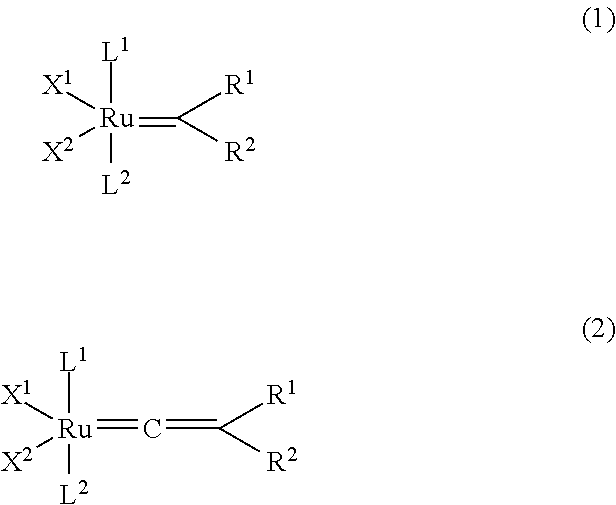

Polymerizable composition, cross-linkable shaped article, cross-linked shaped article, and cross-linked shaped article composite

ActiveUS20110237718A1High mechanical strengthSuitable for useImpression capsCarbon fibresFiberCross-link

A polymerizable composition which contains a cycloolefin monomer, metathesis polymerization catalyst, cross-linking agent, and carbon fiber which is brought into contact in advance with a sizing agent which includes a compound having an unsaturated terminal group and a polar group, a cross-linkable shaped article obtained by polymerizing the polymerizable composition, a cross-linked shaped article obtained by cross-linking the cross-linkable shaped article, and a cross-linked shaped article composite which contains the cross-linked shaped article and other members.

Owner:ZEON CORP

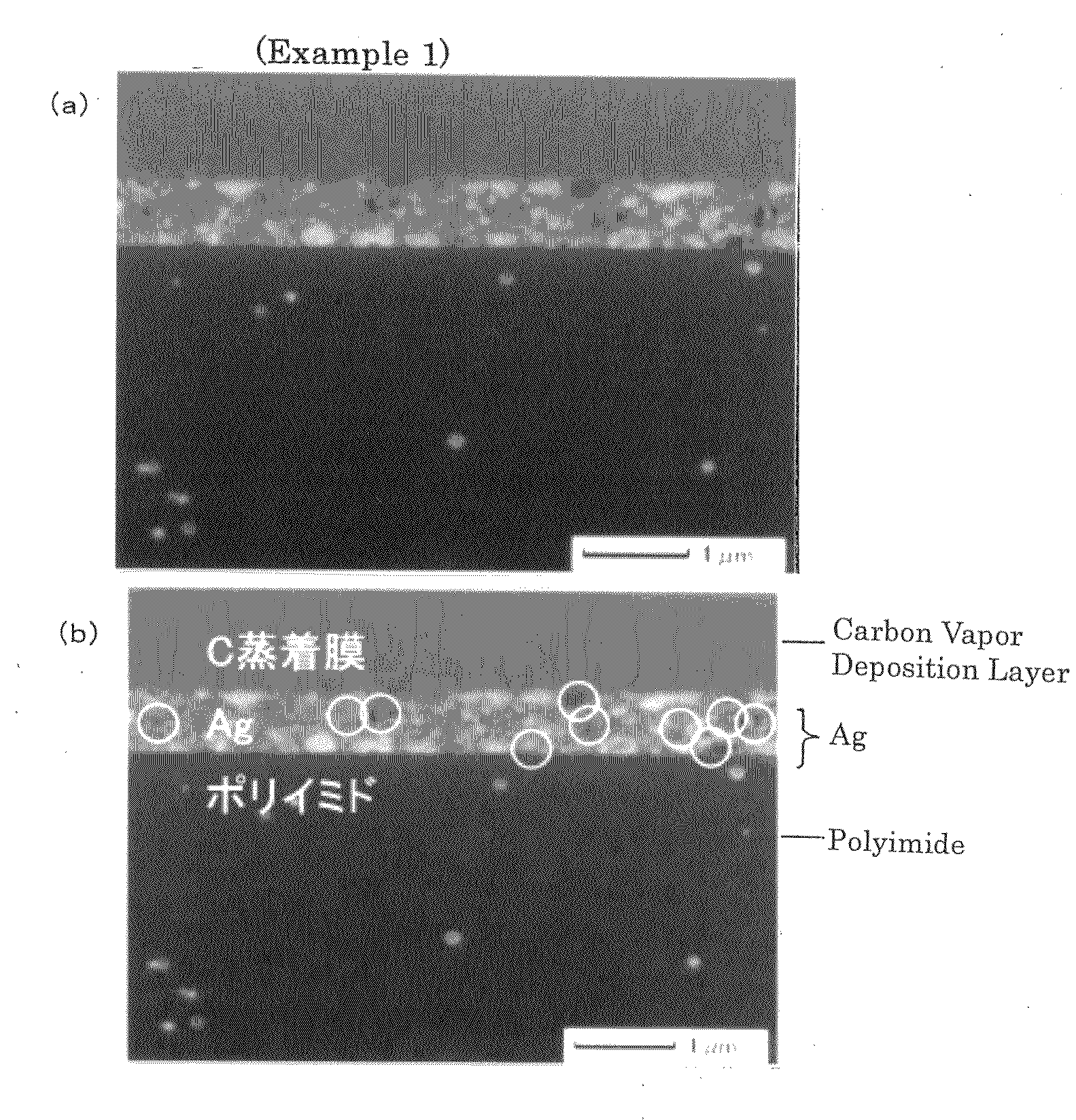

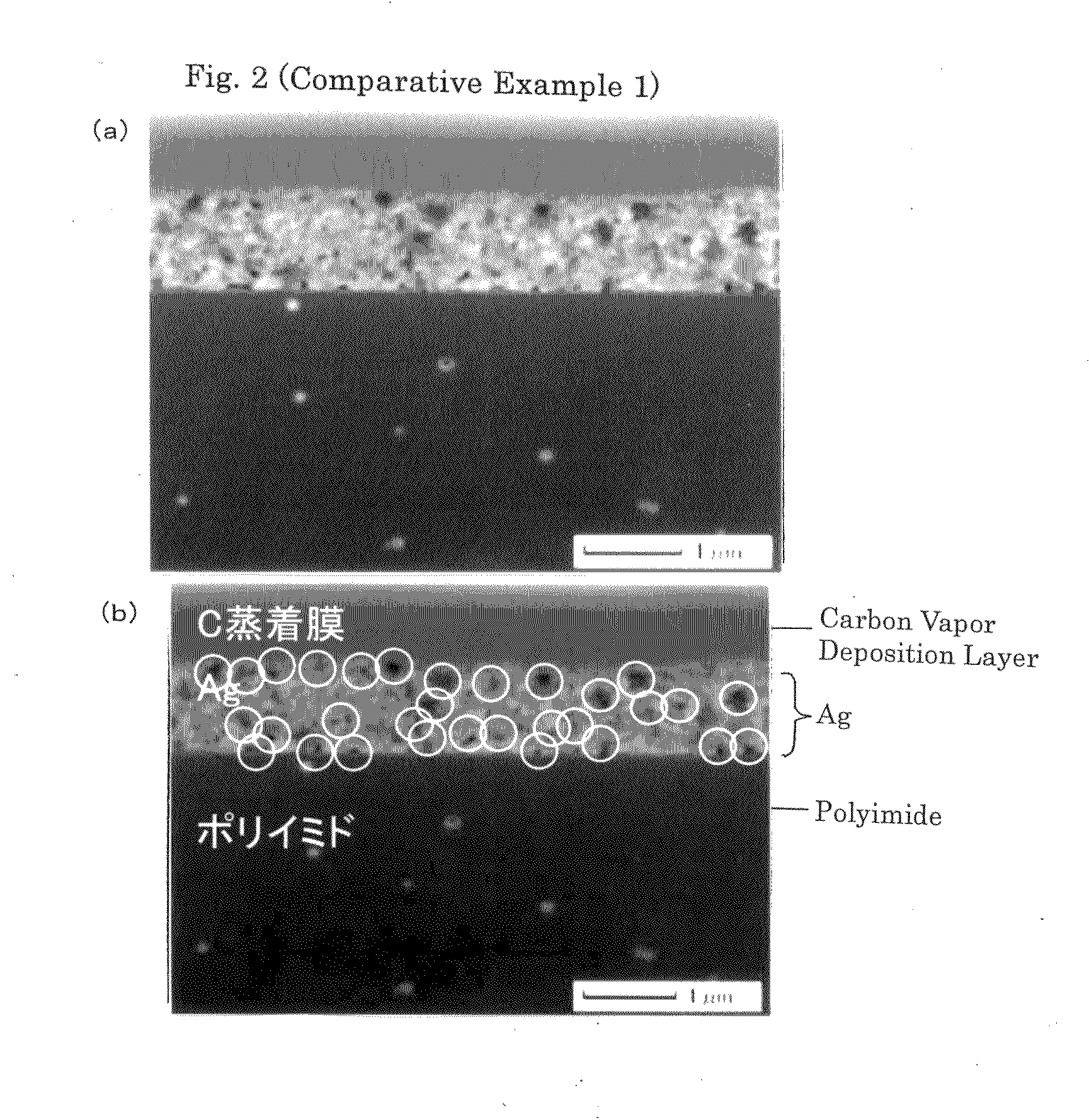

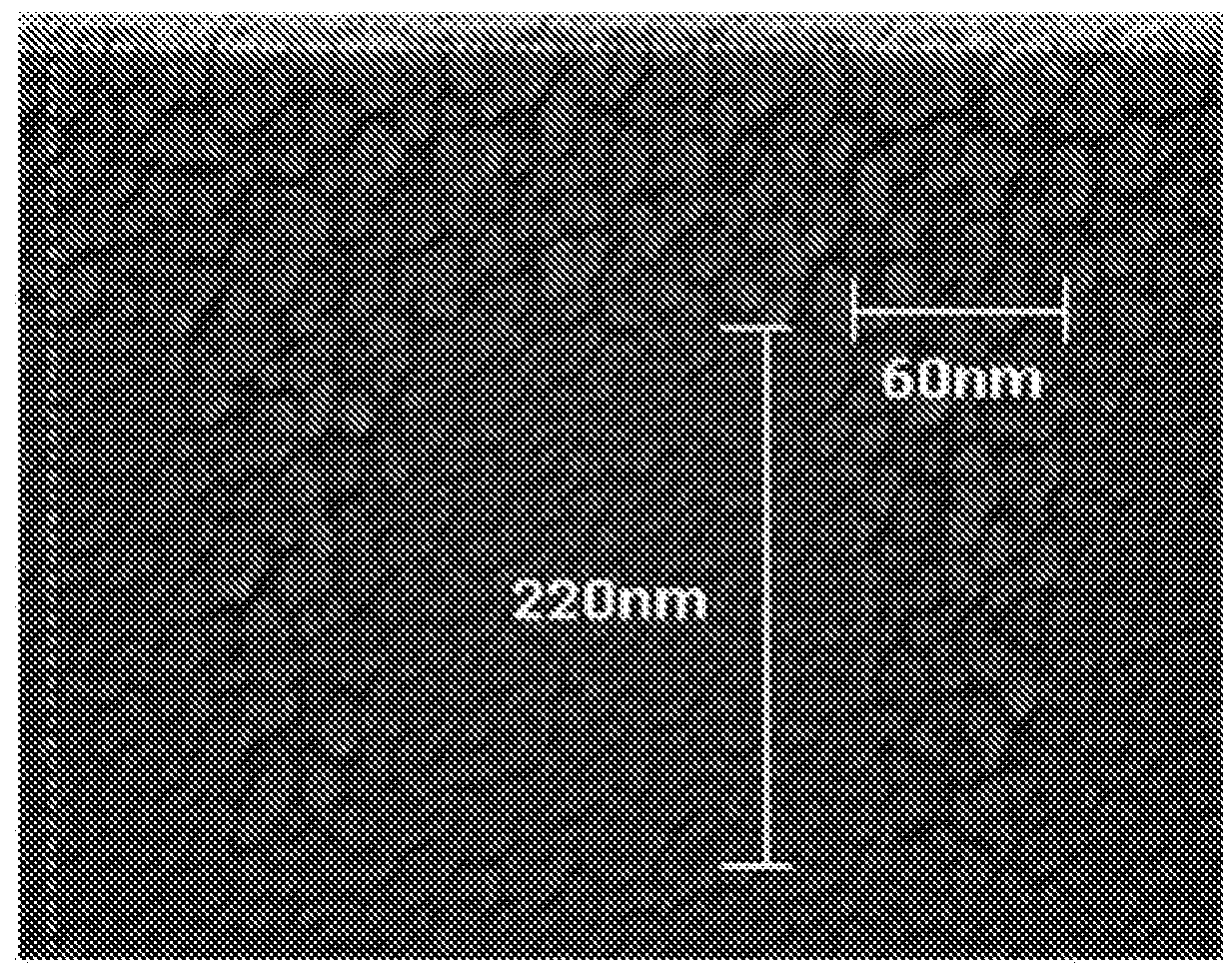

Silver Conductive Film and Production Method Thereof

InactiveUS20090053469A1Lower resistanceFew voidConductive layers on insulating-supportsLayered productsBoiling pointSurface roughness

Provided is a silver conductive film, a thin film of silver comprising a sintered layer of silver particles having a mean particle size DTEM of at most 100 nm. Its specific resistance is at most 5 μΩ·cm, the ratio of the voids in the sintered layer is at most 3 / μm2, and the film has a texture structure with a surface roughness Ra of from 10 to 100 nm. The silver conductive film having such a texture structure may be produced according to a production process comprising a step of applying a silver particle dispersion of silver particles having a mean particle size DTEM of at most 100 nm dispersed in a non-polar or poorly-polar liquid organic medium having a boiling point of from 60 to 300° C., onto a substrate to form a coating film thereon, and thereafter baking the coating film.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

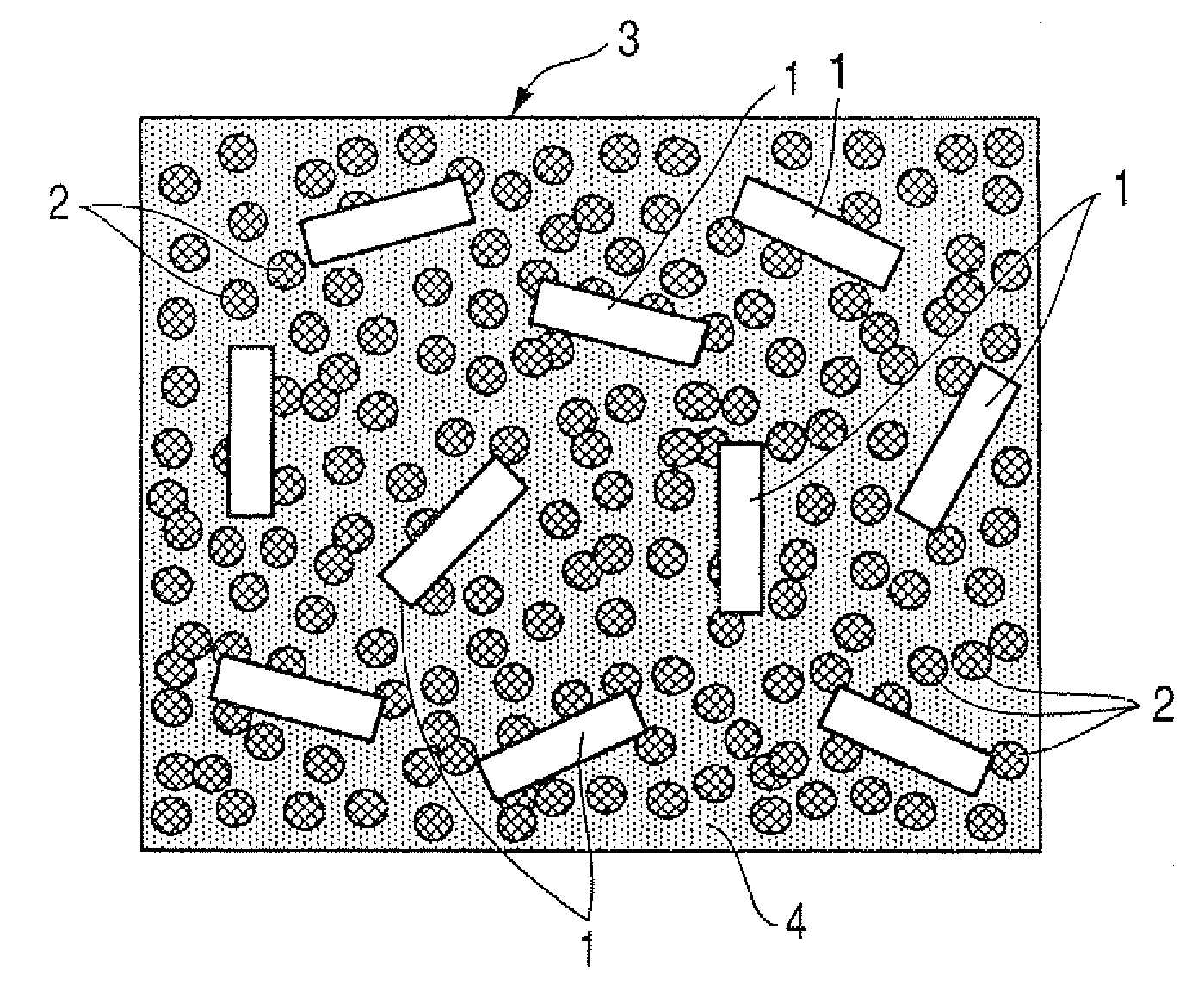

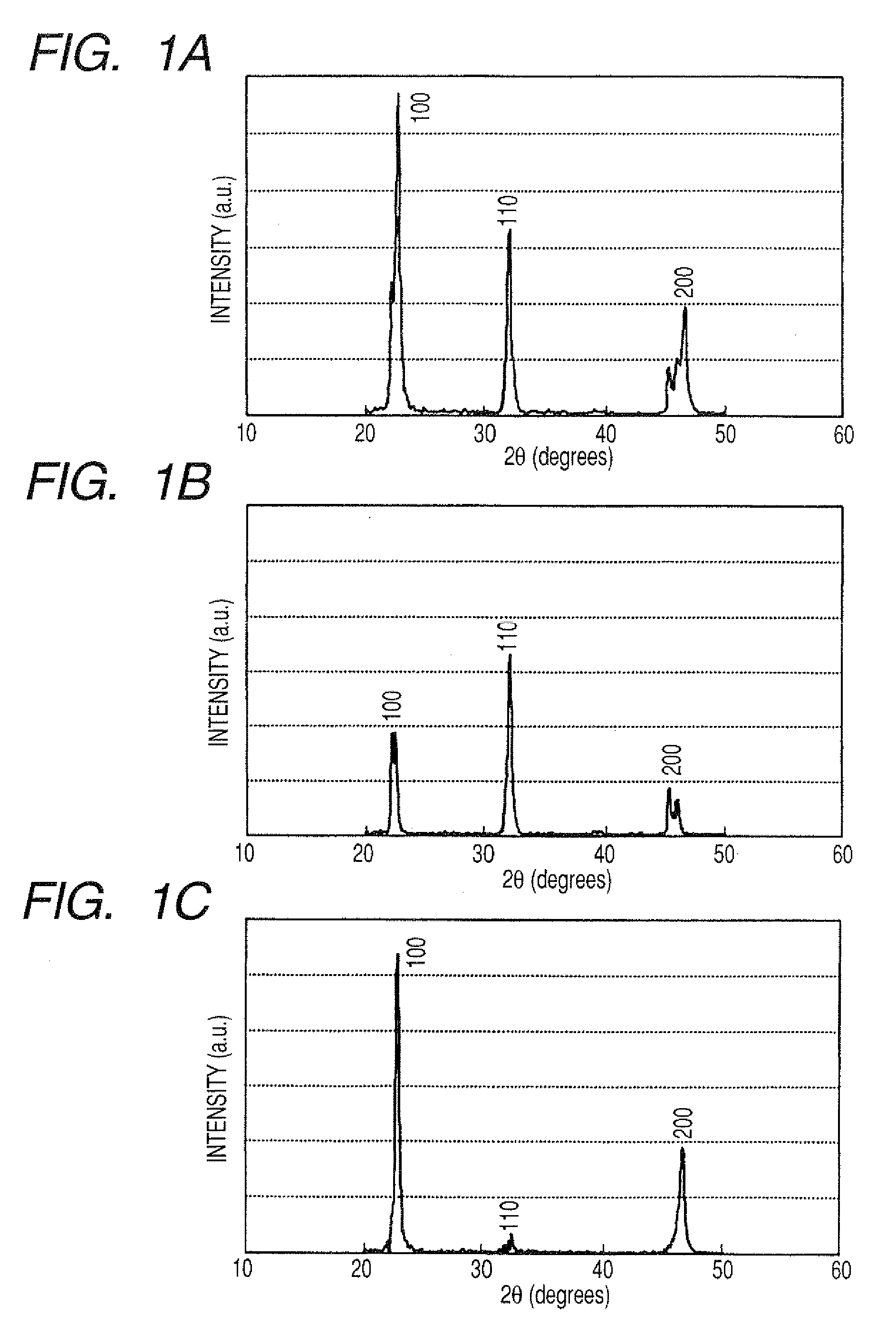

Method of manufacturing crystal oriented ceramics

InactiveUS20090121374A1Excellent piezoelectric propertiesIncreased Curie temperatureRocking curveFull width at half maximum

A method of manufacturing a crystal oriented ceramics is disclosed. The method comprises preparing step, mixing step, shaping step and sintering method. At least one of anisotropically shaped powder, used as raw material, and a compact, formed by shaping step, is selected to have an orientation degree of 80% or more with a full width at half maximum (FWHM) of 15° or less according to a rocking curve method. A microscopic powder, having an average grain diameter one-third or less that of anisotropically shaped powder, is prepared for mixing therewith to prepare raw material mixture. The raw material mixture is shaped into the compact so as to allow oriented planes of anisotropically shaped powder to be oriented in a nearly identical direction. In a sintering step, anisotropically shaped powder and microscopic powder are sintered with each other to obtain the crystal oriented ceramics.

Owner:DENSO CORP

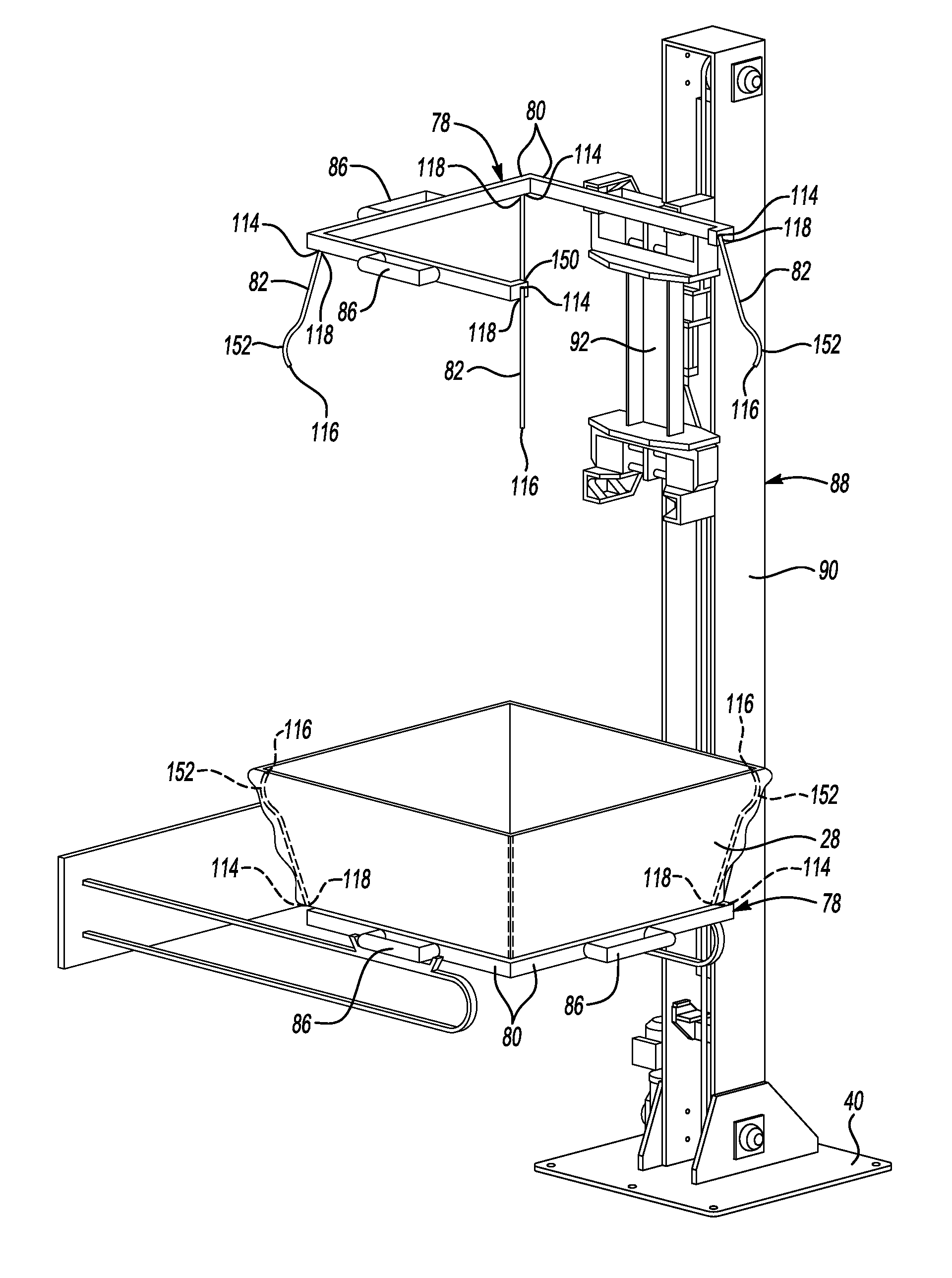

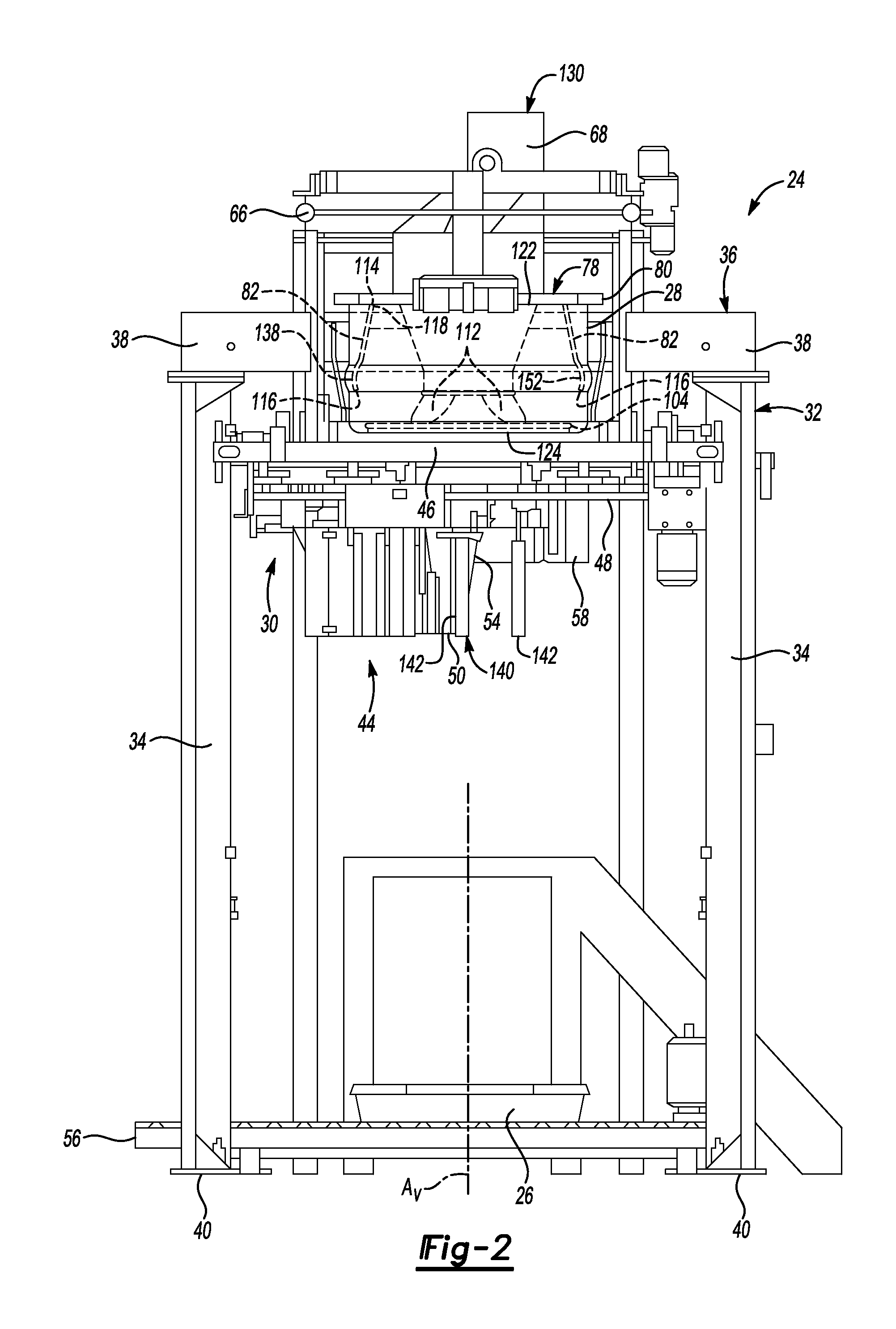

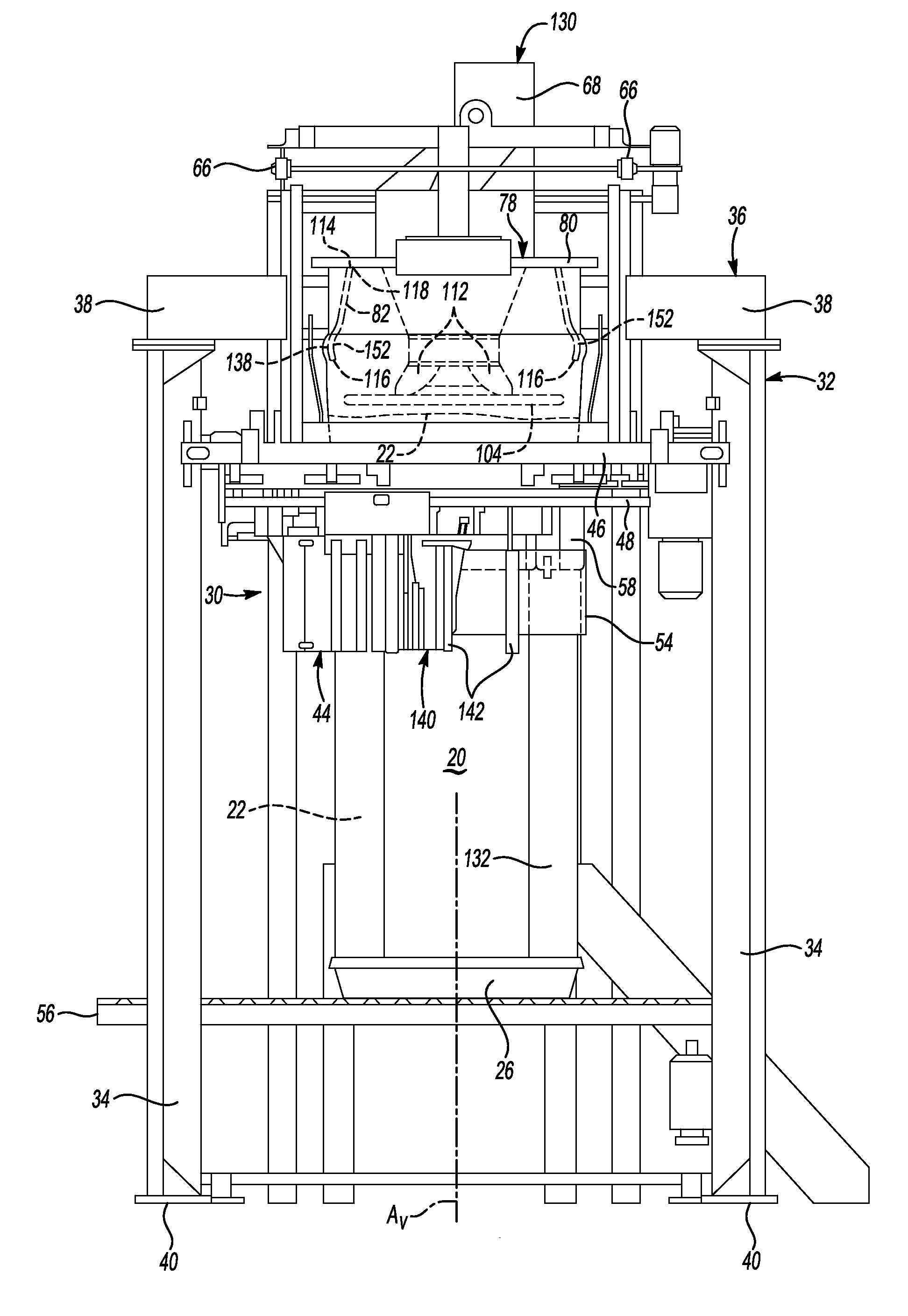

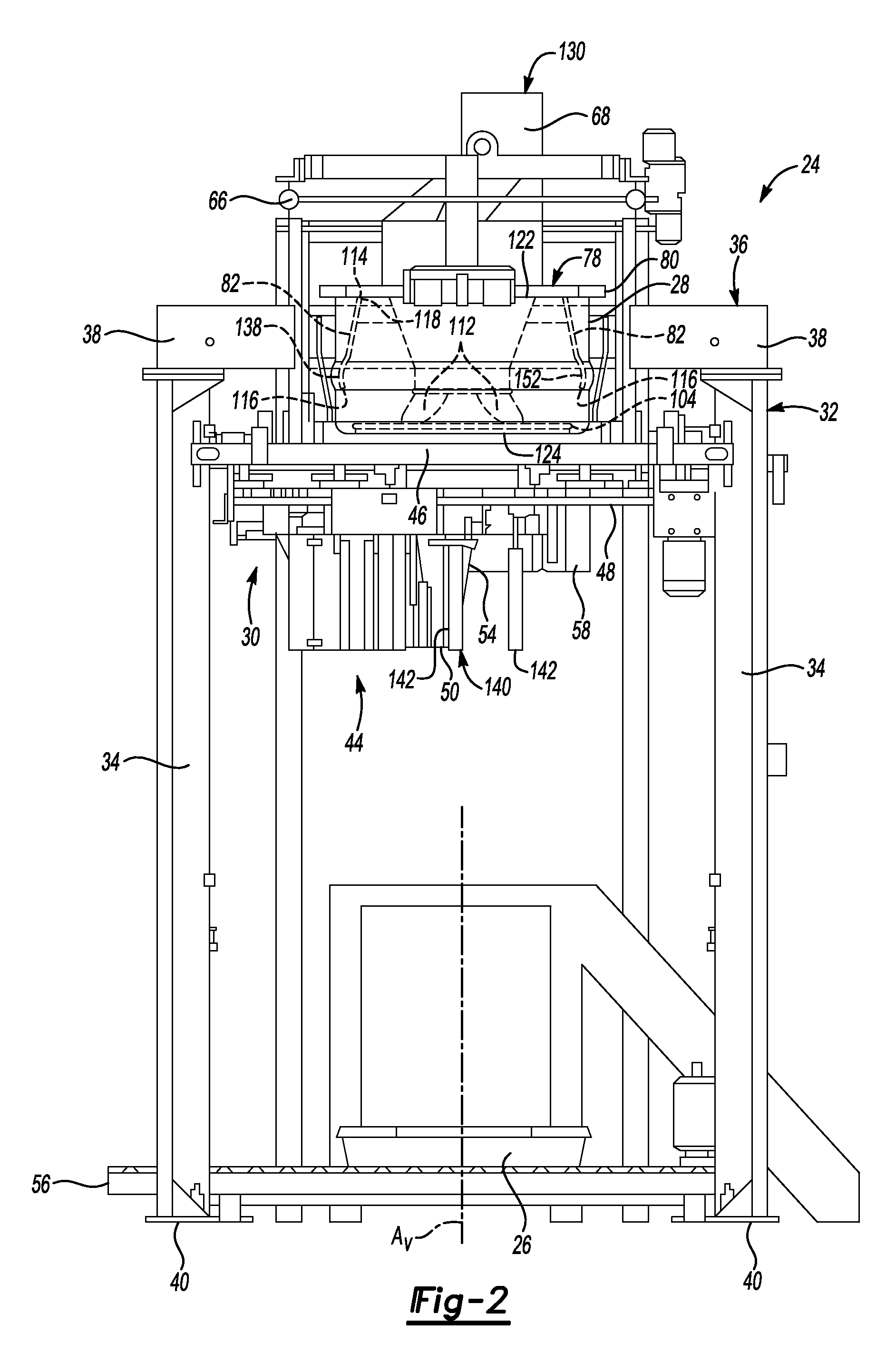

Transportable container for bulk goods and method for forming the same

ActiveUS20120137636A1Cost reductionImprove reliabilityWrappers shrinkagePrestretching mechanismTruckEngineering

The packaging system forms a transportable container for bulk goods having stretch wrap that is spirally wrapped about a bottom support and bulk goods to define the transportable container. The stretch wrap contacts at least a portion of the bulk goods to squeeze and lock together the bulk goods. During filling, the bottom support of the transportable container lowers as the transportable container is formed to accommodate additional bulk goods. The stretch wrap is prestretched from a non-stretched state to a stretched state prior to disposing the wrap about a slip frame former in the stretched state. The wrap returns to its non-stretched state as it is disengaged from the slip frame former to squeeze and lock together the bulk goods disposed therein. The packaging system results in a transportable container that is optimally packed and shaped for the efficient filling of a truck for shipping.

Owner:KELLOGG CO

High manganese cobalt-modified zinc phosphate conversion coating

InactiveUS20080314479A1Low nickel concentrationPoor coatingSolid state diffusion coatingWelding/cutting media/materialsZinc cationChemistry

Owner:HENKEL KGAA

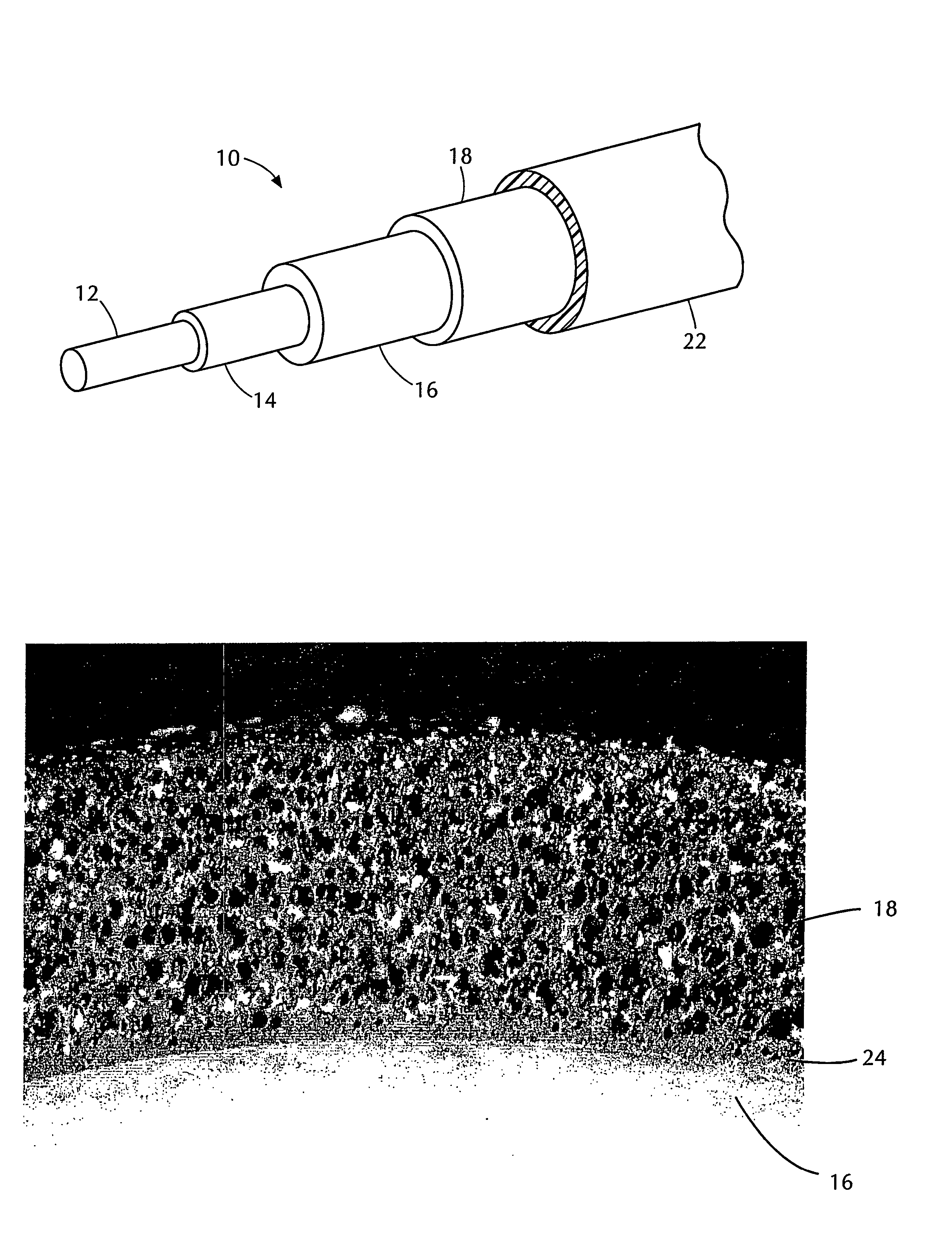

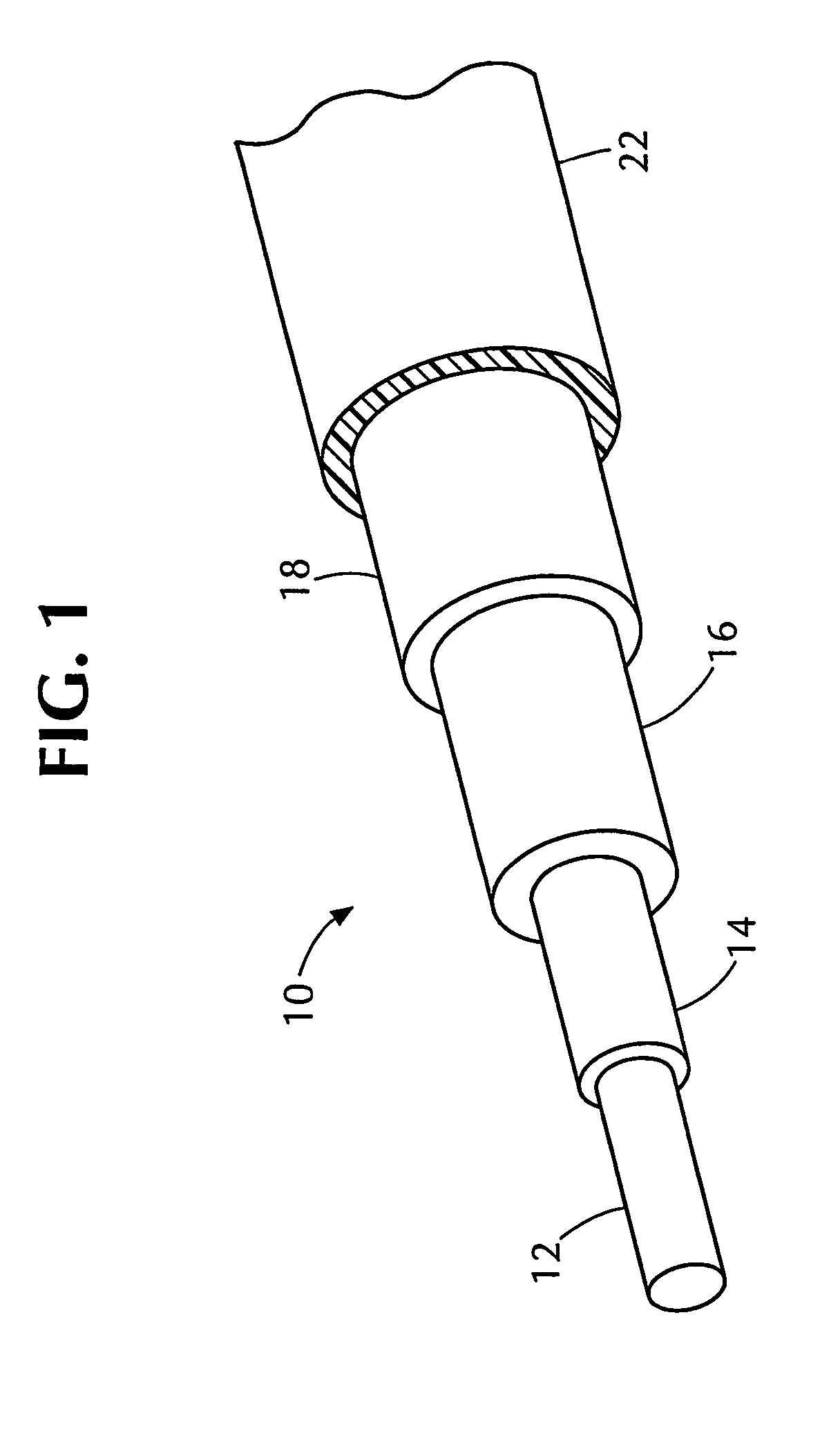

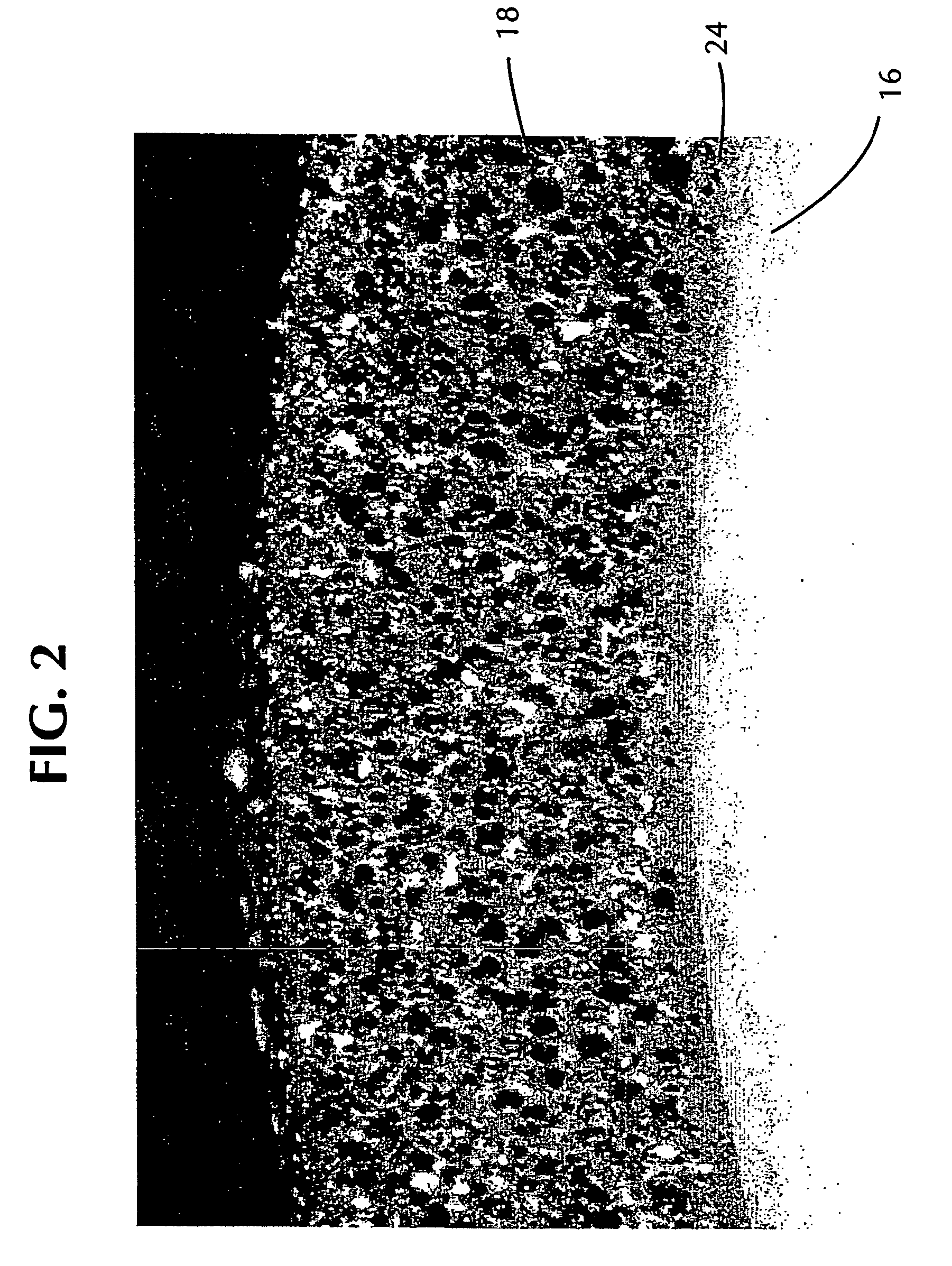

Electrical cable with foamed semiconductive insulation shield

InactiveUS7208682B2Few voidEasy to fillPlastic/resin/waxes insulatorsInsulated cablesPower cableEngineering

An electrical power cable with a foamed, compressible, semiconductive insulation shield which serves as both a cushioning layer and an electrical shield.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Conductive film-forming composition and conductive film producing method

ActiveUS20160024316A1Dispersion stability can be increasedFew voidRadiation applicationsConductive materialVolume averageCopper oxide

In a conductive film-forming composition including copper oxide particles, water and a dispersant selected from the group consisting of a water-soluble polymer and a surfactant, the copper oxide particles have a volume average secondary particle size of 20 to 240 nm, and the copper oxide particles are contained in an amount of 10 to 70 wt % with respect to a total weight of the conductive film-forming composition.

Owner:FUJIFILM CORP

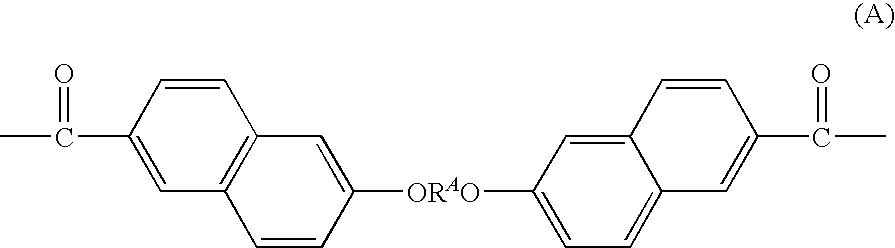

Soldering Method, Solder Pellet for Die Bonding, Method for Manufacturing a Solder Pellet for Die Bonding, and Electronic Component

InactiveUS20080246164A1Avoid environmental pollutionImprove wettabilityCooking-vessel materialsSemiconductor/solid-state device detailsSemiconductor chipSoldering

A pellet for use in die bonding of an electronic chip and a substrate in an electronic component generates minimized voids in spite of the pellet being made of a lead-free solder. The pellet forms a colorless transparent protective film comprising Sn-(30-50 at % 0)-(5-15 at % P) or Sn-(10-30 at % In)-(40-60 at % O)-(5-15 at % P) when heated for soldering, has a thickness of 0.05-1 mm, and has generally the same shape as the semiconductor chip to be bonded to the substrate.

Owner:SENJU METAL IND CO LTD

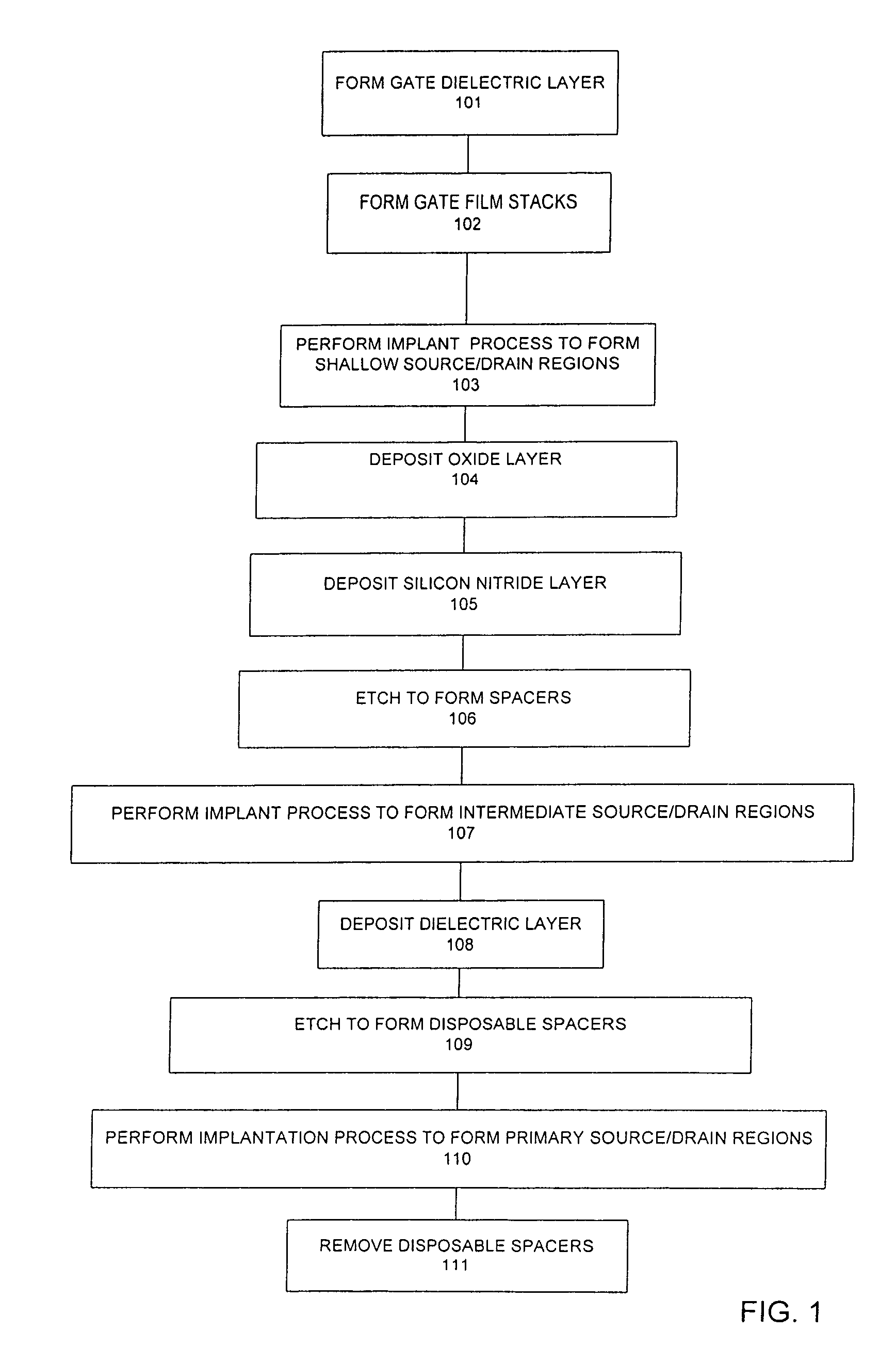

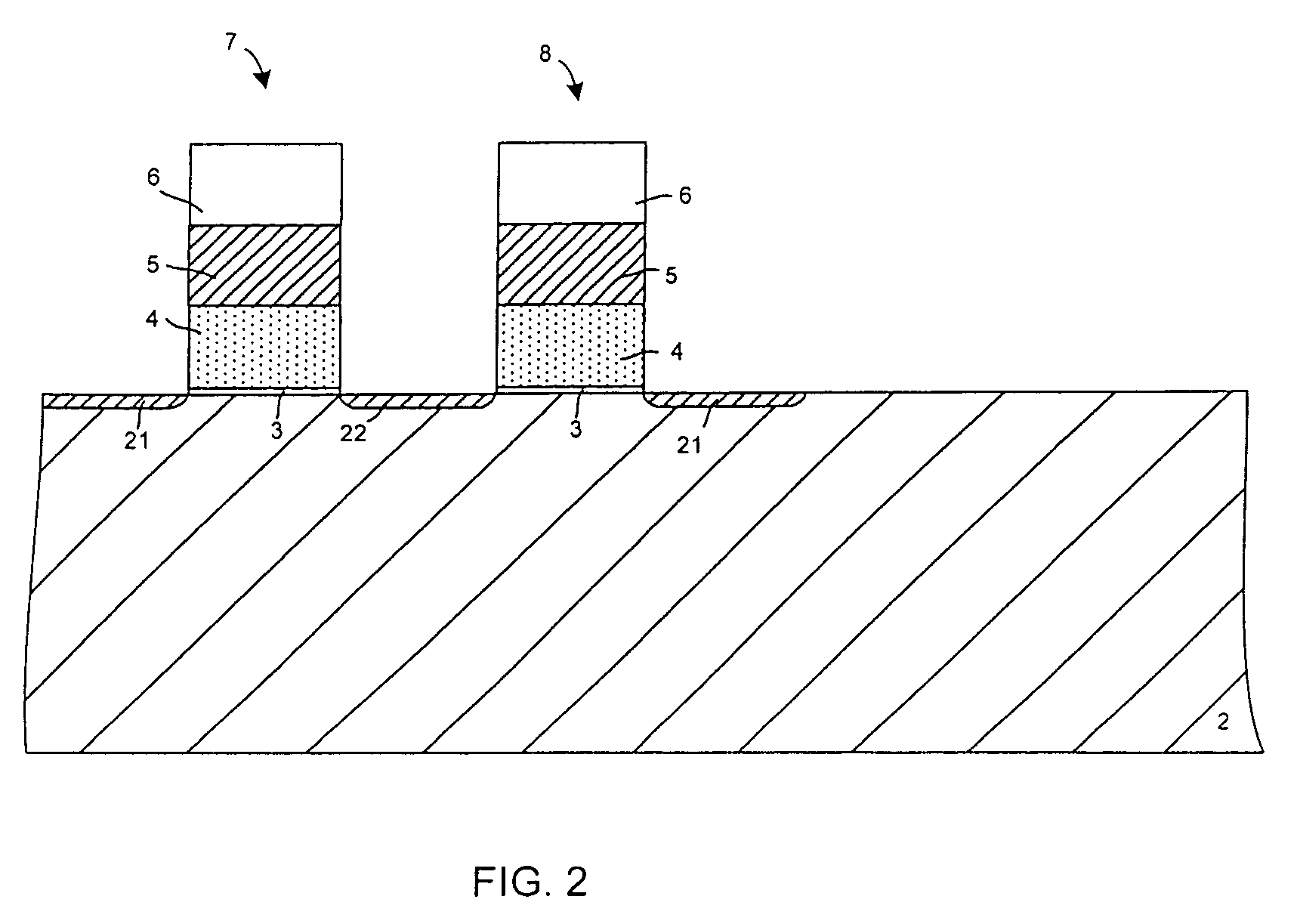

Process for forming CMOS devices using removable spacers

InactiveUS7544556B1CharacteristicReduce generationSemiconductor/solid-state device manufacturingCMOSBiomedical engineering

A process for forming CMOS devices is disclosed in which disposable spacers are used to obtain a structure having improved gap-fill characteristics. First, gate film stacks are formed on the substrate. A shallow implant process is performed so as to form shallow source / drain implant regions. A layer of oxide and a layer of silicon nitride are deposited and etched to form a first set of spacers that extend on opposite sides of the gate film stacks. A second implant is performed so as to form intermediate source / drain implant regions. A set of disposable spacers are then formed that extend on opposite sides of each of the gate film stacks. A third implant process is performed so as to form deep source / drain implant regions. The disposable spacers are then removed, providing more space for the subsequently-formed contact to land.

Owner:INTEGRATED DEVICE TECH INC

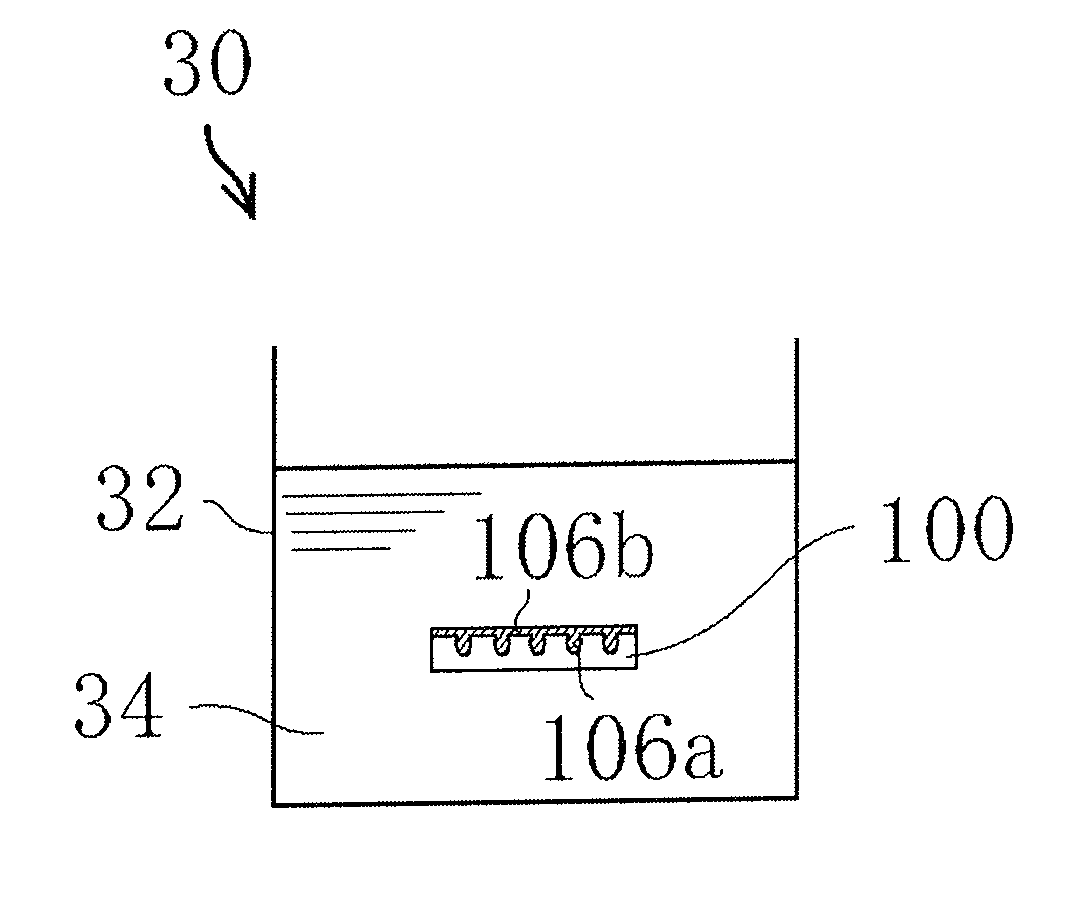

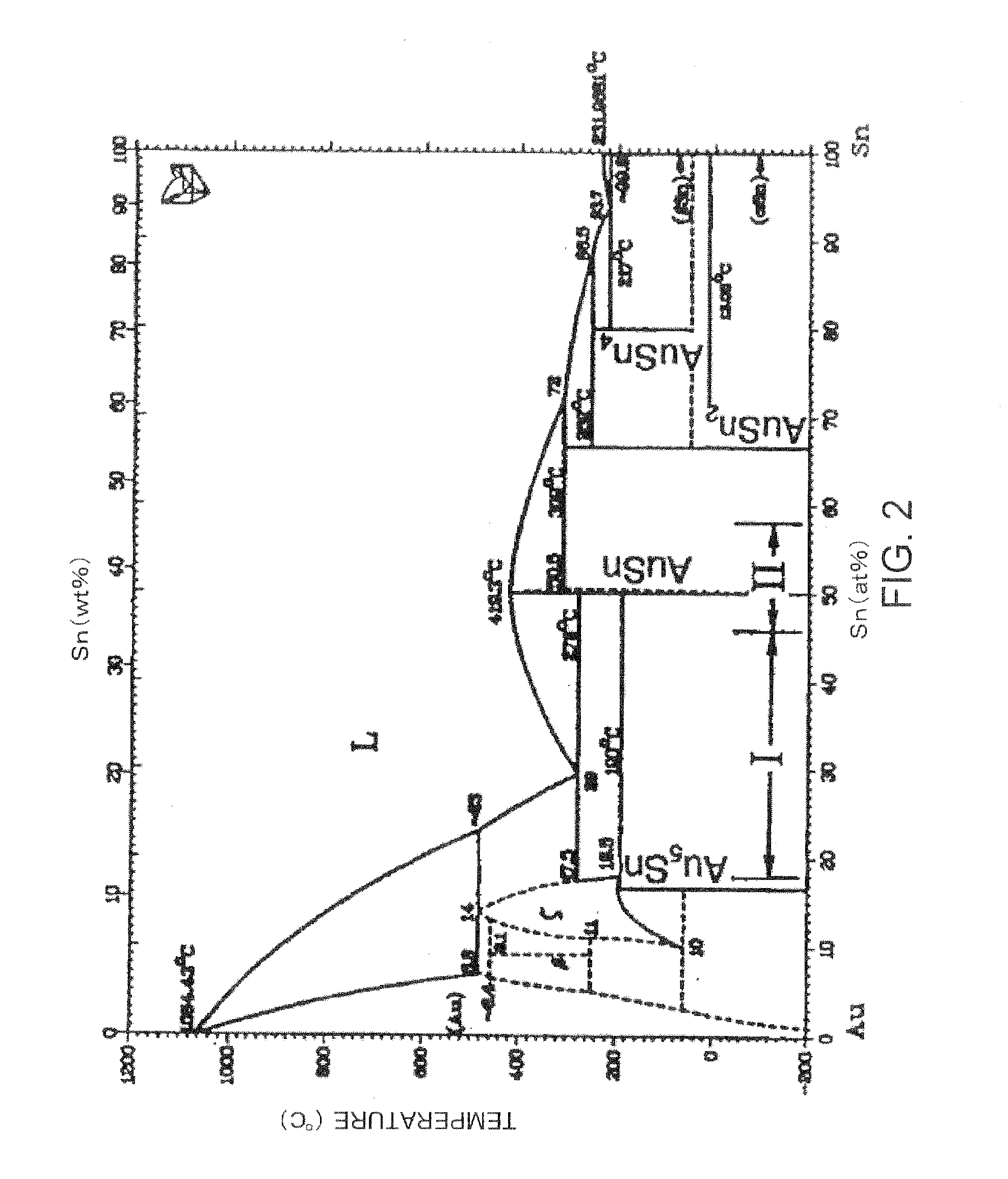

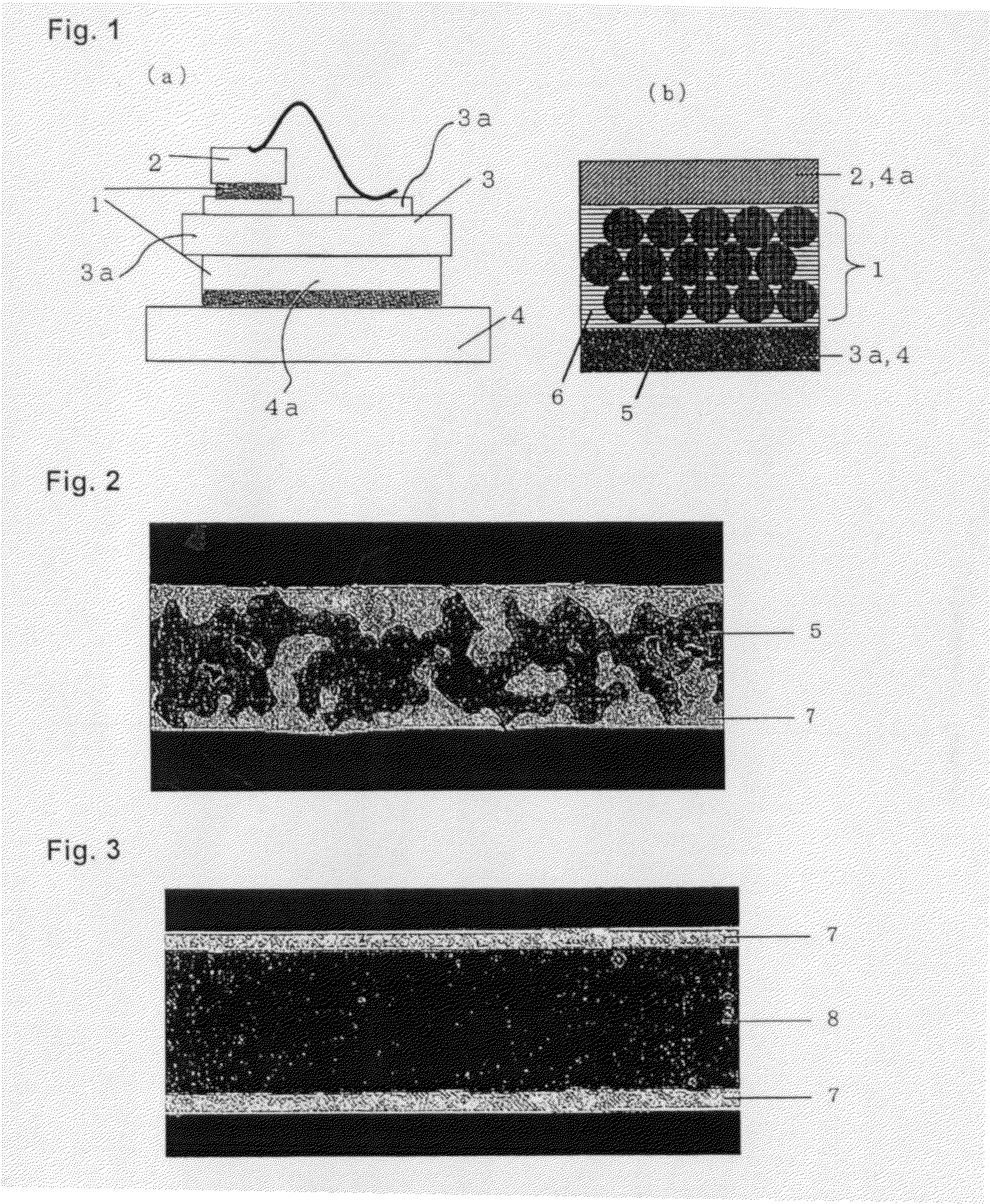

Compound material, method of producing the same and apparatus for producing the same

InactiveUS20110117373A1Few voidImprove adhesionPretreated surfacesSemiconductor/solid-state device manufacturingSurface layerAlloy

Proposed are a composite material having a high adhesiveness, wherein non-penetrating pores that are formed in a silicone surface layer are filled up with a metal or the like without leaving any voids by using the plating technique and the silicone surface layer is coated with the metal or the like, and a method of producing the composite material. A composite material, which has a high adhesiveness between a second metal or an alloy of the second metal (106a, 106b) and a silicone surface, can be obtained by filling up non-penetrating pores that are formed in the surface of a silicone substrate (100) substantially with a second metal or an alloy of the second metal (106a) with the use of the autocatalytic electroless plating technique wherein a first metal located at the bottom of the non-penetrating pores as described above serves as the starting point, and coating the surface of the silicone substrate (100) with the second metal (106b).

Owner:JAPAN SCI & TECH CORP

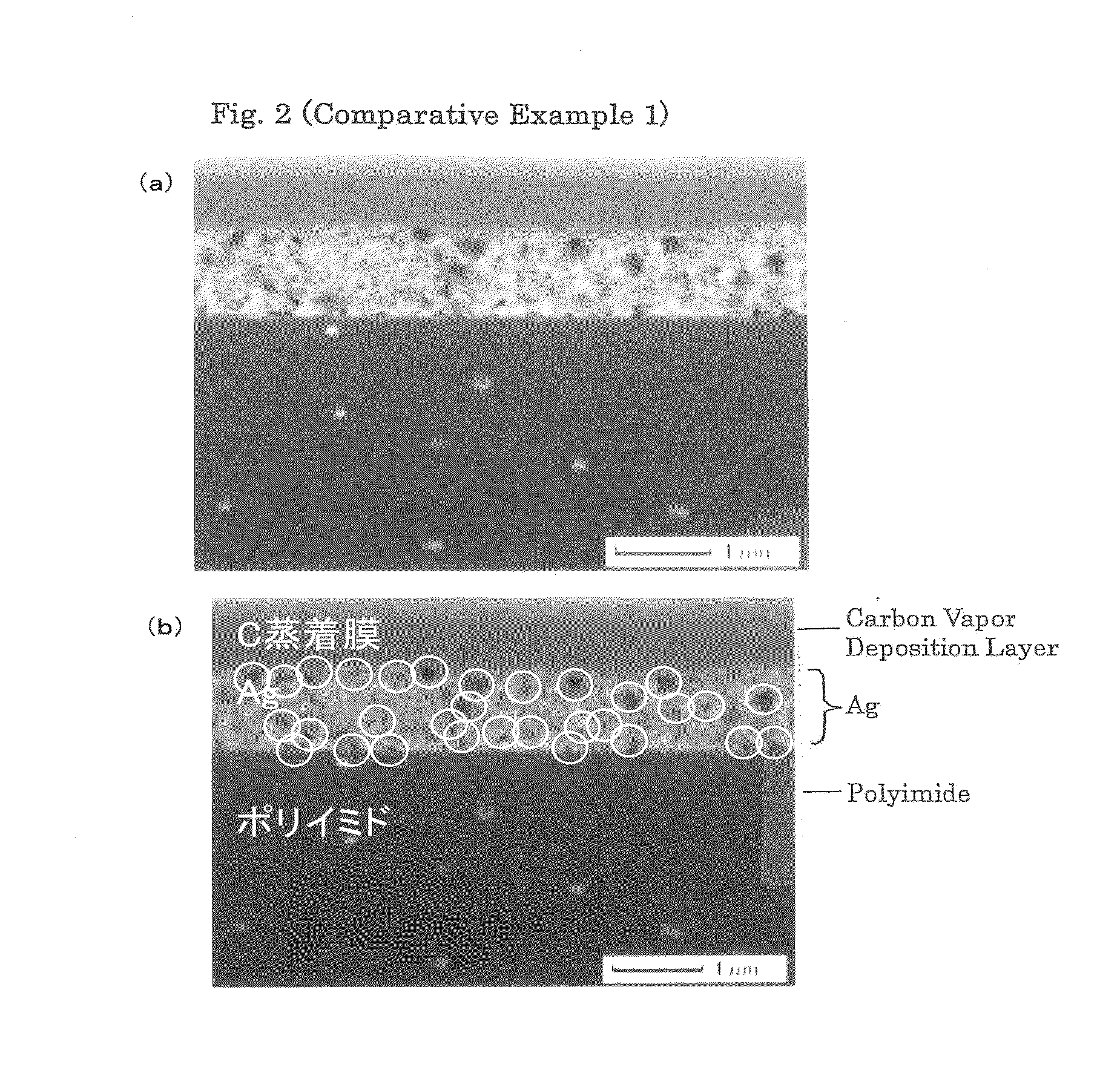

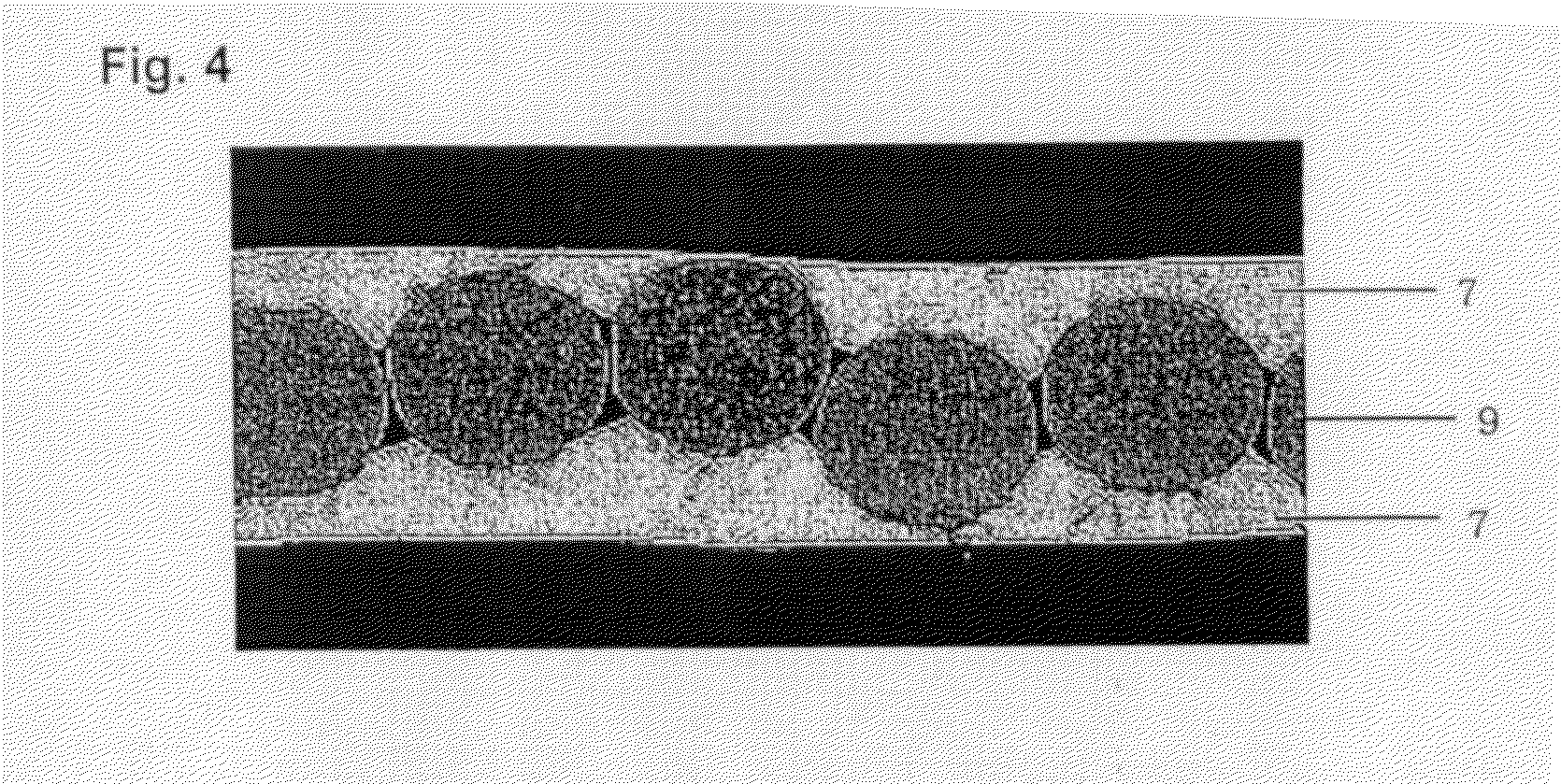

Silver conductive film and production method thereof

InactiveUS20120045573A1Lower resistanceFew voidConductive layers on insulating-supportsPretreated surfacesBoiling pointSurface roughness

Provided is a silver conductive film, a thin film of silver comprising a sintered layer of silver particles having a mean particle size DTEM of at most 100 nm. Its specific resistance is at most 5 μΩ·cm, the ratio of the voids in the sintered layer is at most 3 / μm2, and the film has a texture structure with a surface roughness Ra of from 10 to 100 nm. The silver conductive film having such a texture structure may be produced according to a production process comprising a step of applying a silver particle dispersion of silver particles having a mean particle size DTEM of at most 100 nm dispersed in a non-polar or poorly-polar liquid organic medium having a boiling point of from 60 to 300° C., onto a substrate to form a coating film thereon, and thereafter baking the coating film.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

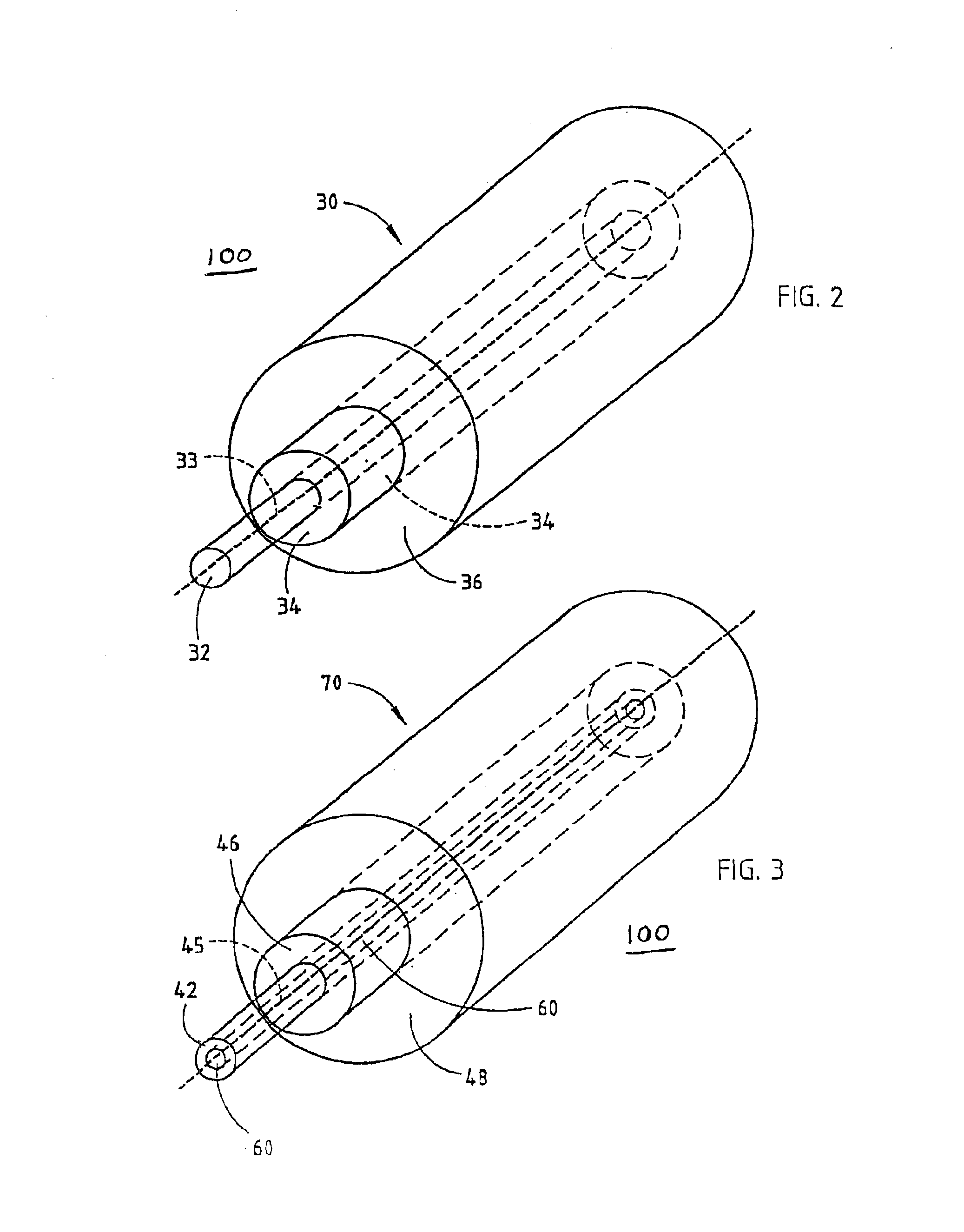

Method for fabricating a low polarization mode dispersion optical fiber

InactiveUS6883351B2Small sizeEnlarge regionGlass making apparatusOptical light guidesFiberPolarization mode dispersion

The method of fabricating an optical waveguide fiber from a preform having a centerline aperture which includes reducing the pressure in the centerline aperture, then increasing the pressure in the centerline aperture to a pressure in order to improve uniformity, circularity, and / or symmetry around the centerline aperture region.

Owner:CORNING INC

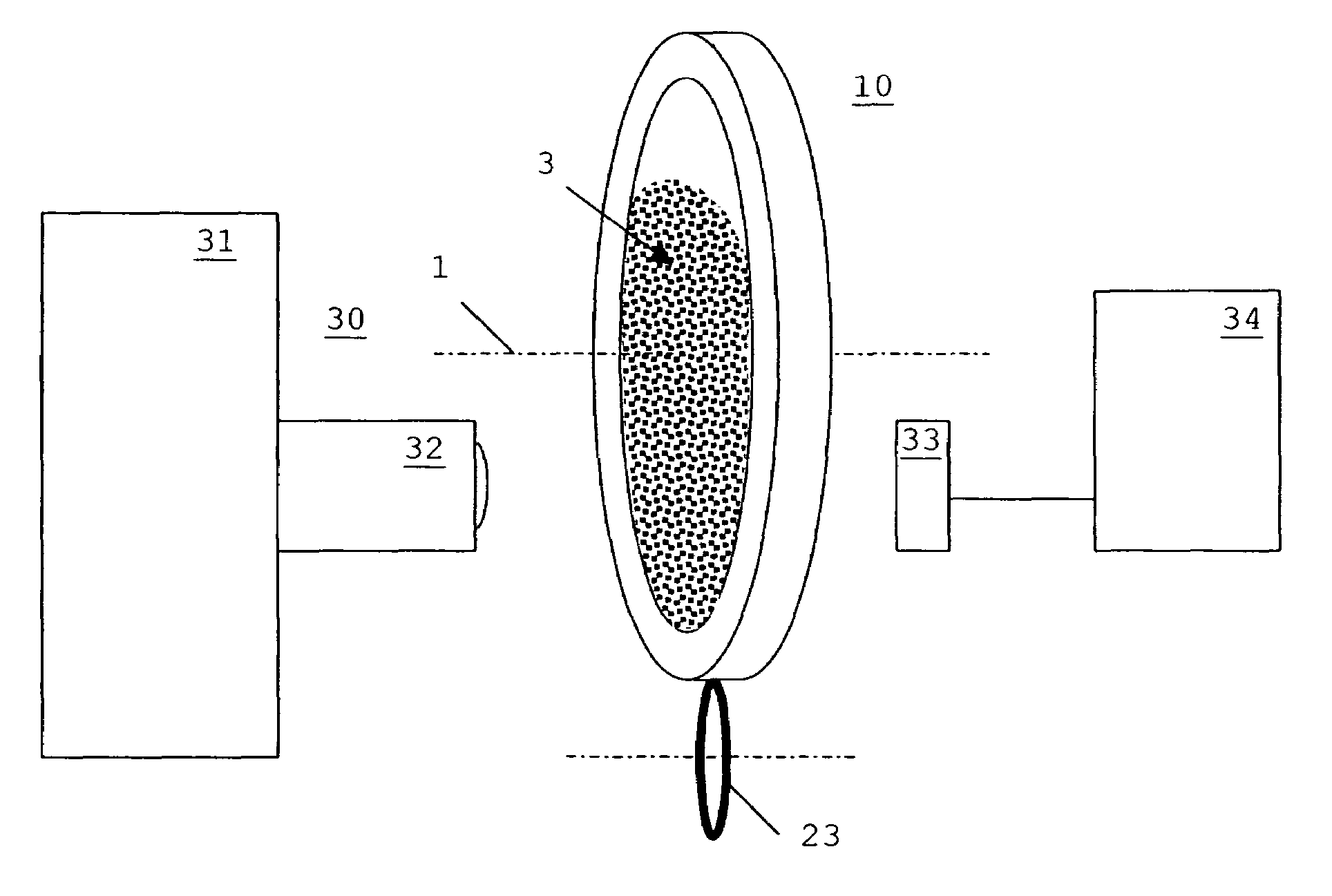

Measuring device, particularly for conducting spectroscopic measurements

InactiveUS7256889B2Easy for statistical analysisReproducibility of measurement is improvedRadiation pyrometrySpectrum investigationCuvetteParticulates

A measuring arrangement, in particular for spectroscopic measurements on particulate samples, is described, having a measuring cuvette (10) for sampling which has at least one window (11) through which the sample (3) can be irradiated and including a rotating mount (20) with which the measuring cuvette (10) can be rotated about a predetermined axis of rotation (1), whereby the alignment of the axis of rotation (1) deviates from a vertical reference direction.

Owner:BRUINS HANS JOACHIM

Methods for forming a metallic damascene structure

ActiveUS7319071B2Compromise reliabilityMinimize exposureSemiconductor/solid-state device manufacturingCopper oxideMaterials science

In damascene process integration, a reducing plasma is applied after the etch stop or barrier layer is opened over a copper layer. Currently known methods for opening barrier layers suffer from the disadvantage that they cause at least some of the underlying copper to oxidize to copper oxide. Because copper oxide is selectively removed by subsequent wet cleaning, voids can form where damaged copper (e.g., copper oxide) is removed, thus compromising the reliability of metal-to-metal contact in vias. The present invention advantageously overcomes this and other disadvantages of the prior art through the use of a hydrogen plasma following the barrier layer opening step, which repairs damaged copper (e.g., reduces copper oxide to copper), thus preventing and / or diminishing defects in metal-to-metal contacts in vias and concomitantly improving the reliability of the same.

Owner:MICRON TECH INC

Electrolytic copper plating bath compositions and a method for their use

The present invention relates to aqueous acidic plating baths for copper and copper alloy deposition in the manufacture of printed circuit boards, IC substrates, semiconducting and glass devices for electronic applications. The plating bath according to the present invention comprises at least one source of copper ions, at least one acid and at least one guanidine compound. The plating bath is particularly useful for plating recessed structures with copper and build-up of copper pillar bump structures.

Owner:ATOTECH DEUT GMBH

Method for producing an oxymethylene copolymer

Provided is a method for producing an oxymethylene copolymer having excellent extrusion moldability and reduced voids in a molded article without lowering the inherent performance of an oxymethylene copolymer. Provided is a method for producing an oxymethylene copolymer, including: a step for copolymerizing a monomer raw material containing trioxane and 5-7 mass % of 1,3-dioxolane relative to the trioxane, in the presence of 0.025-0.07 mmol of boron trifluoride per mol of trioxane and 0.006-2.0 mass % of sterically hindered phenol relative to the trioxane; a step for adding a polymerization terminator to the reaction system when the polymerization yield of this copolymer has reached 92% or higher, and terminating polymerization; and a thermal stabilization step for heating and melting the crude oxymethylene copolymer in the presence of 0.05-5 mass % of an antioxidant and 0.005-5 mass % of a nitrogen-containing compound relative to the crude oxymethylene copolymer.

Owner:MITSUBISHI GAS CHEM CO INC

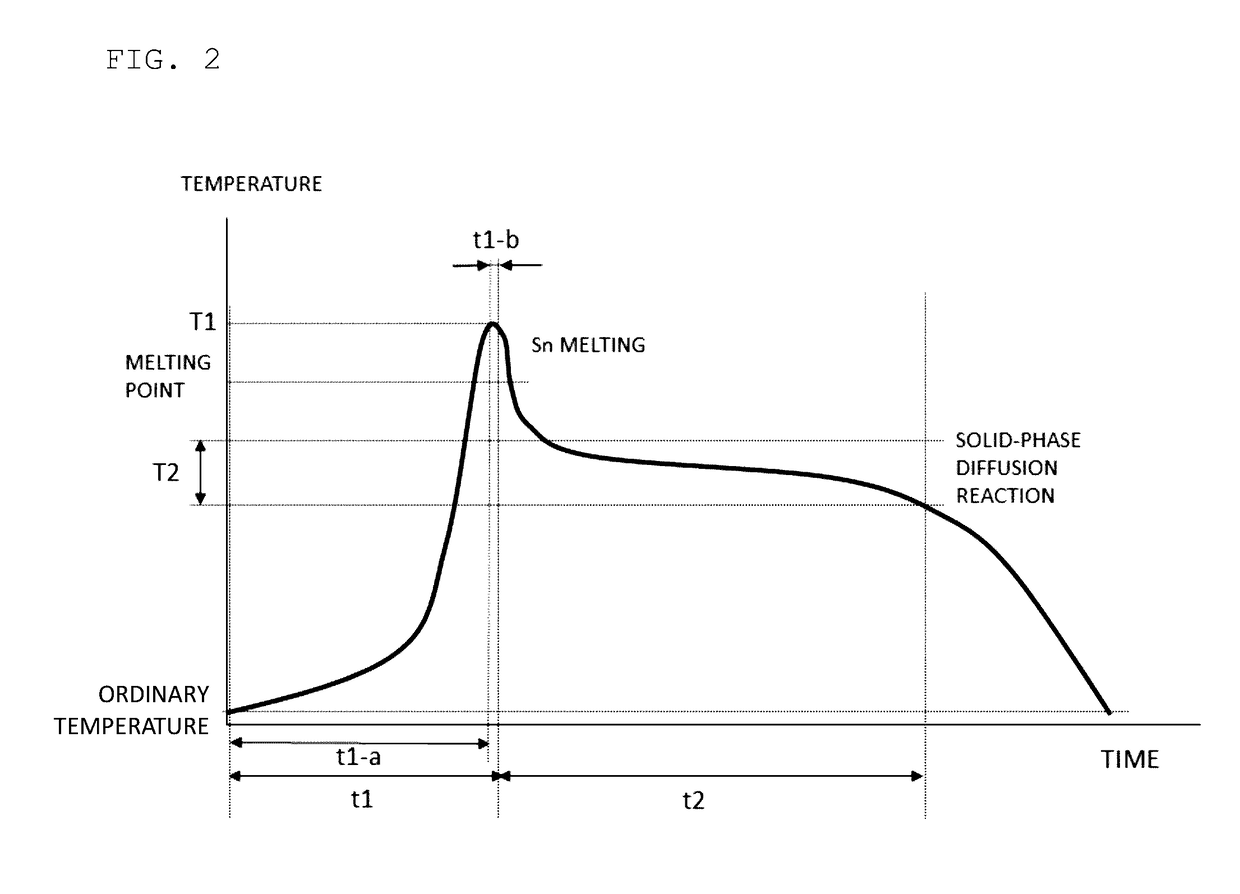

Method for producing intermetallic compound

PendingUS20170159154A1Improve heat resistanceImprove responsePrinted circuit manufactureWelding/cutting media/materialsCompound aAlloy

A metal paste that includes a metal component and a flux. The metal component includes a first metal powder and a second metal powder. The first metal powder is Sn. The second metal powder is a CuNi alloy. The metal paste is heated for a time t1 to a temperature T1 where the first metal powder is melted. Next, the metal paste is heated for a time t2 longer than the time t1 at a temperature T2 lower than the temperature T1 to produce an intermetallic compound from the first metal Sn and the second metal CuNi alloy.

Owner:MURATA MFG CO LTD

Transportable container for bulk goods and method for forming the same

ActiveUS9126705B2Easy to fillEasy to shapeWrappers shrinkagePrestretching mechanismStretch wrapEngineering

The packaging system forms a transportable container for bulk goods having stretch wrap that is spirally wrapped about a bottom support and bulk goods to define the transportable container. The stretch wrap contacts at least a portion of the bulk goods to squeeze and lock together the bulk goods. During filling, the bottom support of the transportable container lowers as the transportable container is formed to accommodate additional bulk goods. The stretch wrap is prestretched from a non-stretched state to a stretched state prior to disposing the wrap about a slip frame former in the stretched state. The wrap returns to its non-stretched state as it is disengaged from the slip frame former to squeeze and lock together the bulk goods disposed therein. The packaging system results in a transportable container that is optimally packed and shaped for the efficient filling of a truck for shipping.

Owner:KELLOGG CO

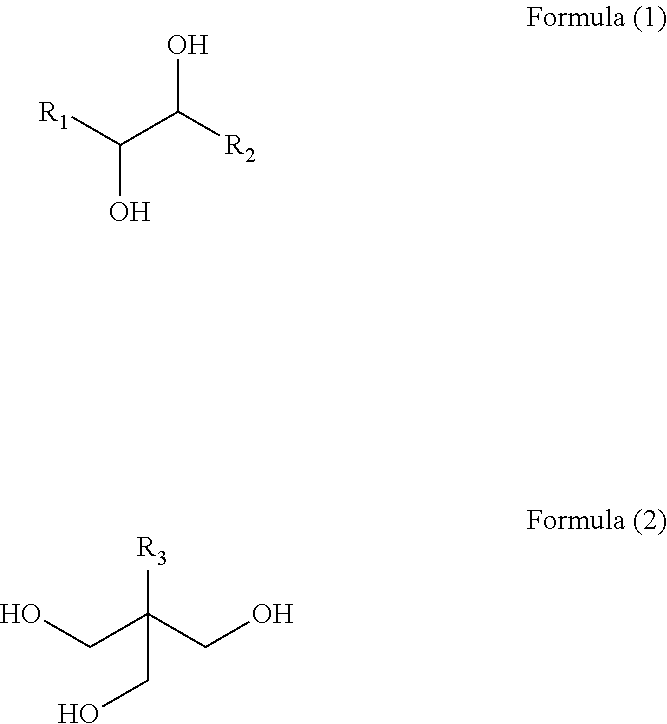

Electroconductive-film-forming composition and method for producing electroconductive film

ActiveUS20160137855A1Improve conductivityFew voidConductive materialNon-conductive material with dispersed conductive materialPtru catalystCopper oxide

An electroconductive-film-forming composition capable of forming an electroconductive film having excellent conductivity and few voids and a method for producing an electroconductive film using the same. The electroconductive-film-forming composition contains copper particles having an average particle diameter of 1 nm to 10 copper oxide particles having an average particle diameter of 1 nm to 500 nm, a reducing agent having a hydroxy group, a metal catalyst including metals other than copper, and a solvent, in which the content of the copper oxide particles is 50% by mass to 300% by mass with respect to the content of the copper particles, the content of the reducing agent is 100 mol % to 800 mol % with respect to the content of the copper oxide particles, and the content of the metal catalyst is 10% by mass or less with respect to the content of the copper oxide particles.

Owner:FUJIFILM CORP

Resist underlayer composition and method for forming pattern using same

ActiveUS20160053132A1Improve thermal stabilityExcellent gap fillingDecorative surface effectsSemiconductor/solid-state device manufacturingResistPolycyclic aromatic hydrocarbon

An under-layer composition of resist having superior thermal stability, etching resistance, gap-filling property and void-preventing property, and a method for forming pattern using the same are disclosed. The under-layer composition of resist comprises: an aromatic ring containing polymer having the repeating unit of the following Formula 1; a compound of the following Formula 4; and an organic solvent.in Formula 1, R1 is a monocyclic or polycyclic aromatic hydrocarbon group having 5 to 20 carbon atoms, R2 and R3 is independently a monocyclic or polycyclic aromatic hydrocarbon group having 4 to 14 carbon atoms, a is an integer of 1 to 3, and b is an integer of 0 to 2.in Formula 4, n is an integer of 1 to 250.

Owner:DONGJIN SEMICHEM CO LTD

Biaxially oriented laminated film

ActiveUS8216704B2Good dimensional stabilityFew voidMagnetic materials for record carriersBase layers for recording layersPolymer scienceBoPET

A biaxially oriented laminated polyester film which has excellent dimensional stability to environmental changes such as temperature and humidity variations and excellent flatness and windability. A biaxially oriented laminated polyester film comprising a film layer B on one side of a film layer A and having a surface roughness (RaB) on the film layer B side which is 1.0 nm or more larger than the surface roughness (RaA) on the film layer A side, wherein at least one of the film layers comprises an aromatic polyester (I) composed of a glycol component and a dicarboxylic acid component containing 5 mol % or more and less than 80 mol % of a recurring unit represented by the following formula (A):wherein RA is an alkylene group having 1 to 10 carbon atoms.

Owner:TEIJIN LTD

Method of manufacturing semiconductor element

ActiveUS20130244361A1Increase productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface layerSemiconductor components

A method of manufacturing a semiconductor element includes forming an element structure layer having a semiconductor layer, on a first substrate. The method also includes forming a first bonding layer on the element structure layer. The method also includes forming a second bonding layer on a second substrate. The method also includes performing heating pressure-bonding on the first and second bonding layers, with the first and second bonding layers facing each other. One of the first bonding layer and the second bonding layer is an AU layer, and the other is an AuSn layer. The AuSn layer has a surface layer having an Sn content of between 85 wt % (inclusive) and 95 wt % (inclusive).

Owner:STANLEY ELECTRIC CO LTD

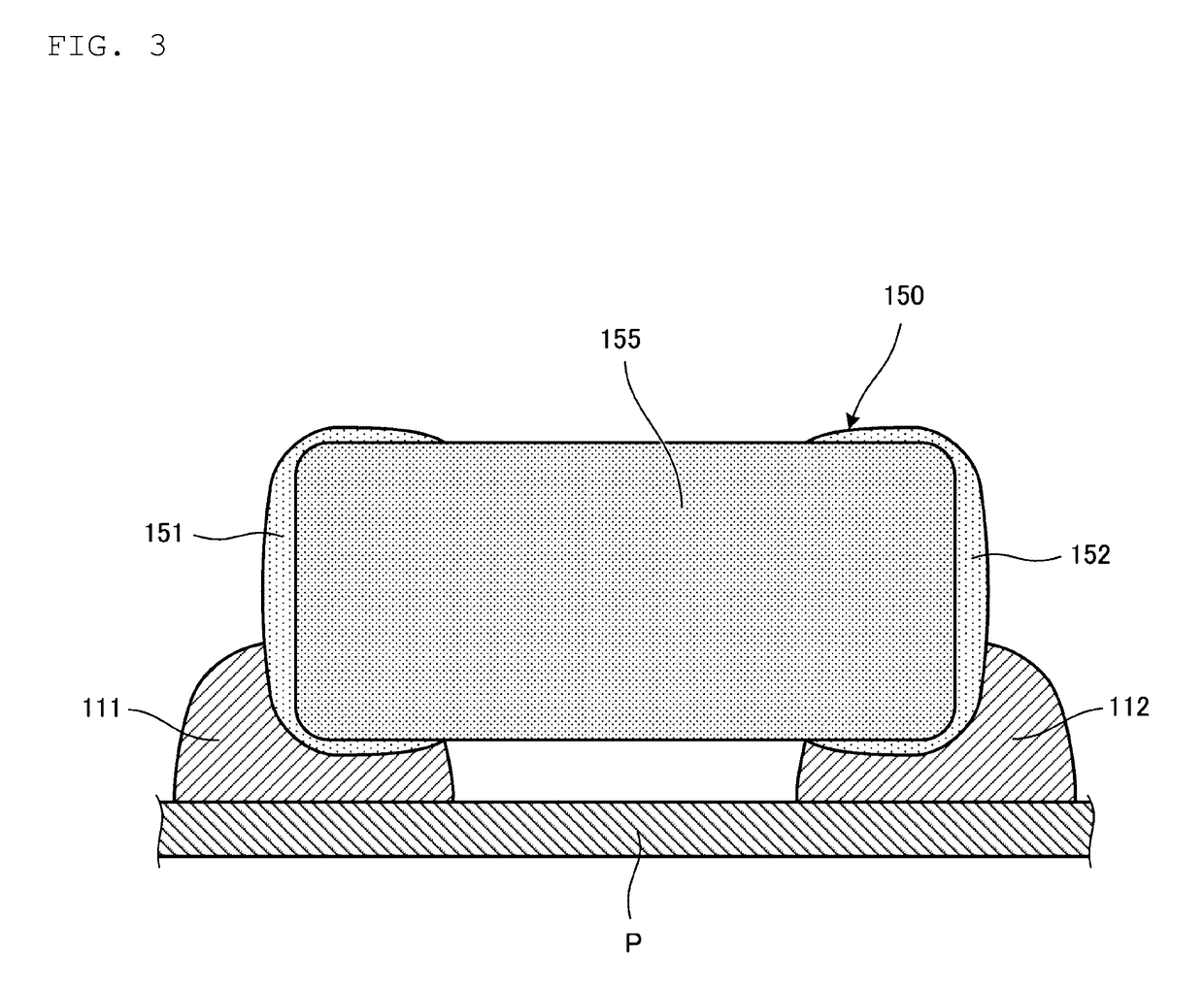

Bonding material for semiconductor devices

ActiveUS8896119B2Improve reliabilityFew voidPorous dielectricsPrinted circuit assemblingMetallurgyInternal bond

A semiconductor device is provided which has internal bonds which do not melt at the time of mounting on a substrate. A bonding material is used for internal bonding of the semiconductor device. The bonding material is obtained by filling the pores of a porous metal body having a mesh-like structure and covering the surface thereof with Sn or an Sn-based solder alloy.

Owner:SENJU METAL IND CO LTD

A liquid composition for a fiber reinforced plastic intermediate base material, a fiber reinforced plastic intermediate base material, and a method of producing the fiber reinforced plastic intermediate base material

PendingUS20220169776A1Small shrinkageExcellent impregnationPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The objective of the present invention is to provide a liquid composition which is for a fiber reinforced plastic intermediate base material, and which imparts excellent FRP mechanical properties and can suppress voids as much as possible.The liquid composition for a fiber reinforced plastic intermediate base material according to the present invention is characterized by being obtained by mixing (A) and (B). (A): a composition including a compound (a) having at least two isocyanate groups, and (B): a composition which includes (b1) as an essential component and may include (b2) and (b3).(b1): a monoalcohol compound having an ethylenically unsaturated group,(b2): a compound having at least two reactive groups with isocyanate groups, and (b3): a polymerization inhibitor.

Owner:JAPAN U PICA COMPANY

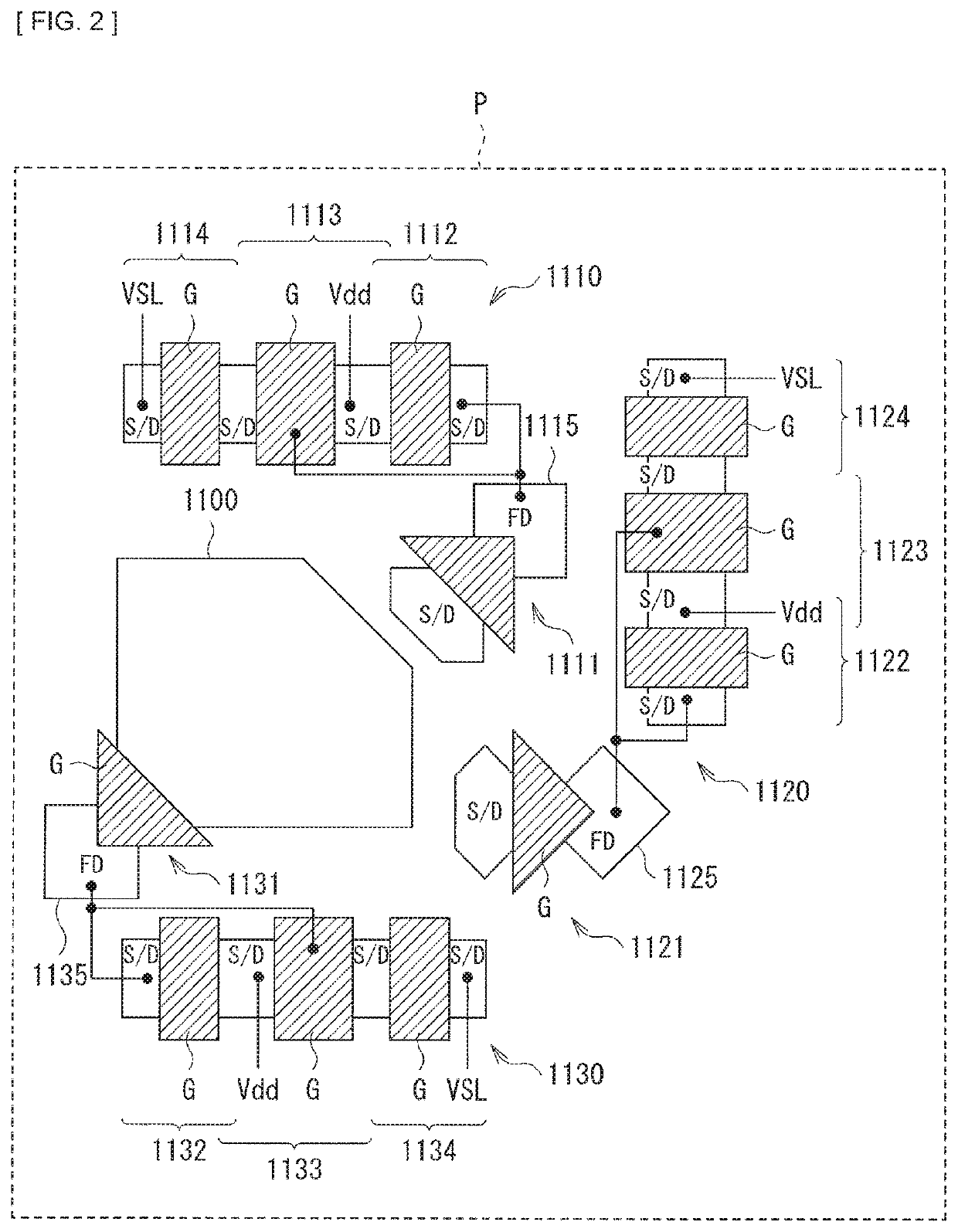

Photoelectric conversion element and solid-state imaging apparatus

ActiveUS11322703B2Improve reliabilityFew voidSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotoelectric conversion

A photoelectric conversion element according to an embodiment of the present disclosure includes: a first electrode; a second electrode opposed to the first electrode; and an organic photoelectric conversion layer provided between the first electrode and the second electrode and formed using a plurality of materials having average particle diameters different from each other, the plurality of materials including at least fullerene or a derivative thereof.

Owner:SONY SEMICON SOLUTIONS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com