Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Lower growth rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

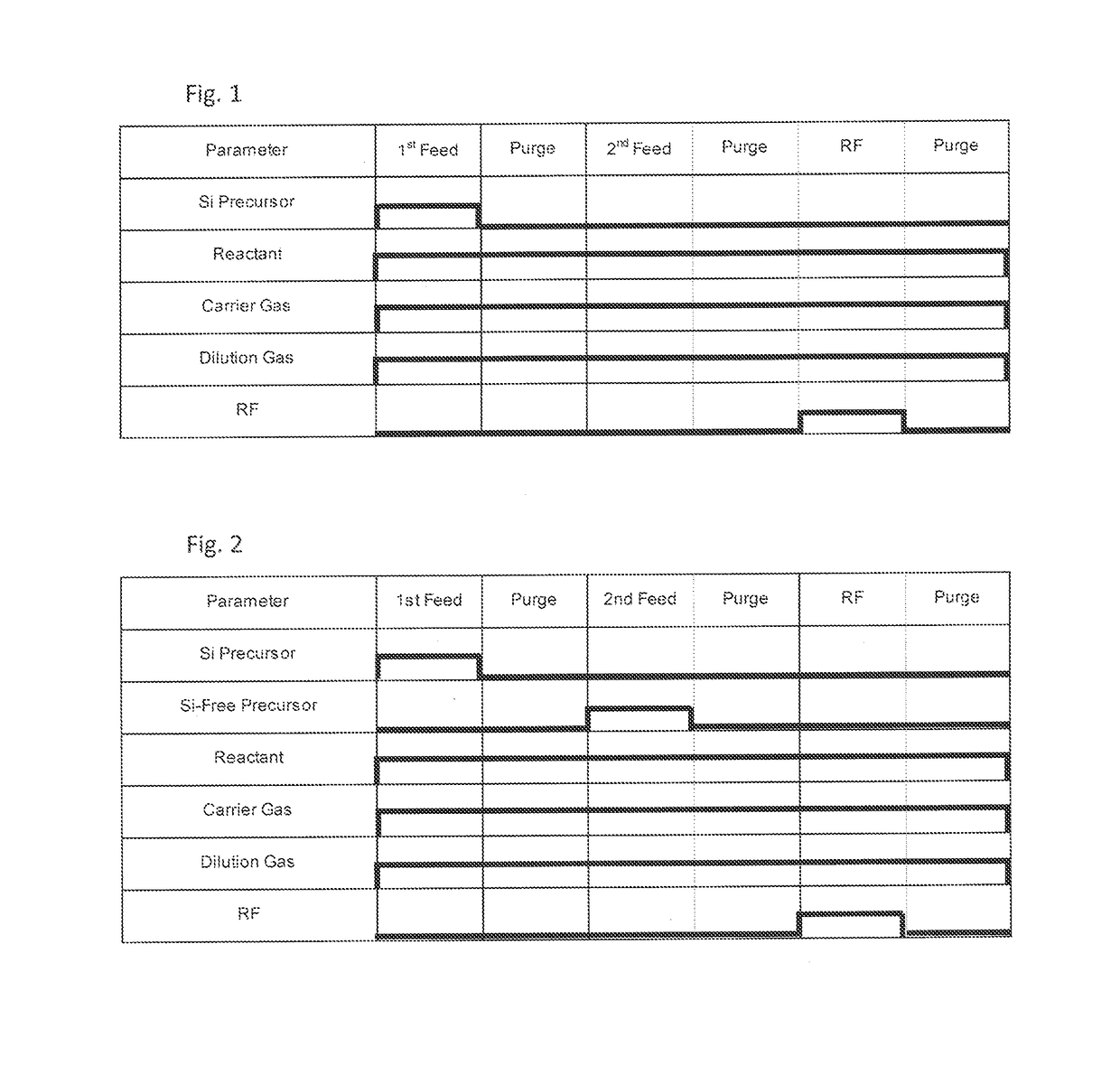

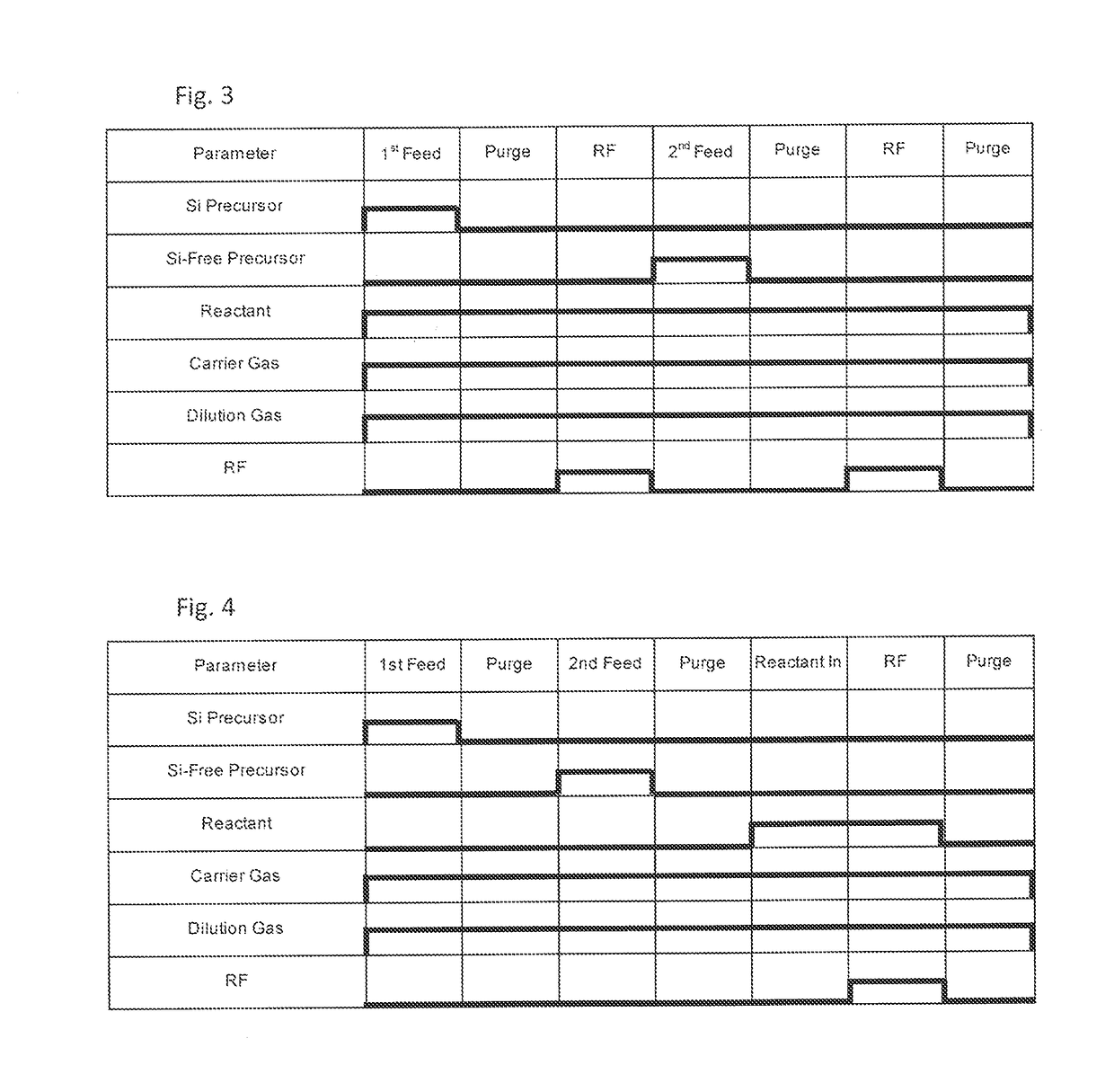

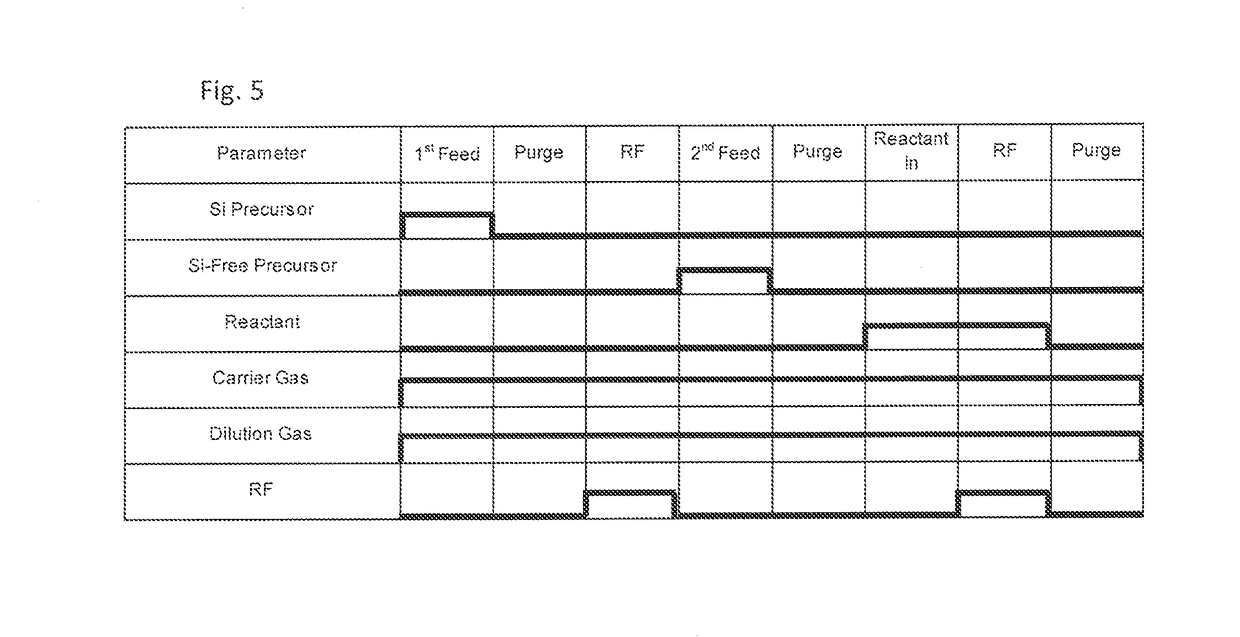

Method for forming conformal nitrided, oxidized, or carbonized dielectric film by atomic layer deposition

ActiveUS10179947B2Easy to oxidizeEasily and nitridedChemical vapor deposition coatingPlasma techniqueDielectric membraneThin membrane

A method for forming a film on a patterned surface of a substrate by atomic layer deposition (ALD) processing includes: adsorbing onto a patterned surface a first precursor containing silicon or metal in its molecule; adsorbing onto the first-precursor-adsorbed surface a second precursor containing no silicon or metal in its molecule; exposing the second-precursor-adsorbed surface to an excited reactant to oxidize, nitride, or carbonize the precursors adsorbed on the surface of the substrate; and repeating the above cycle to form a film on the patterned surface of the substrate.

Owner:ASM IP HLDG BV

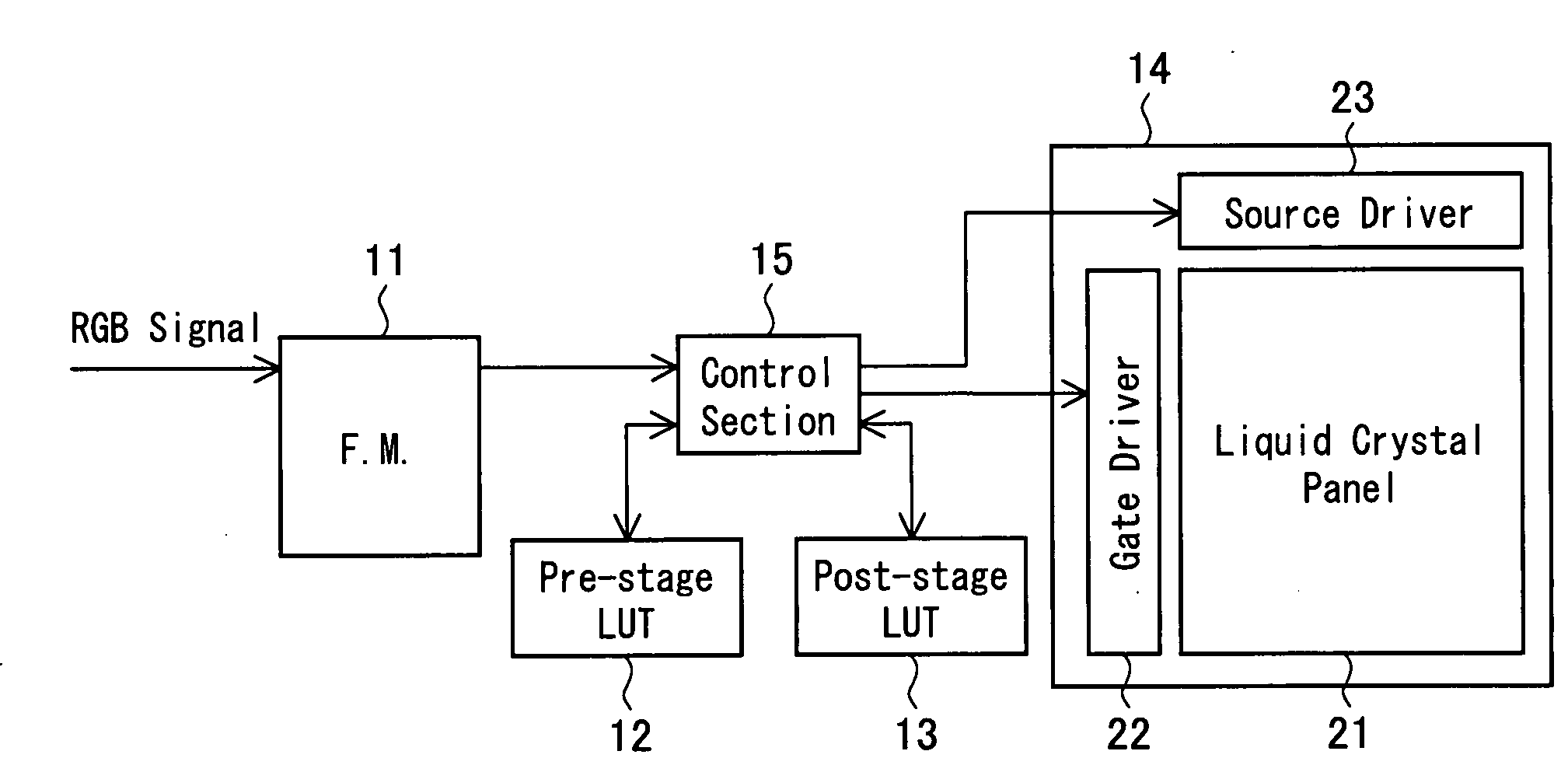

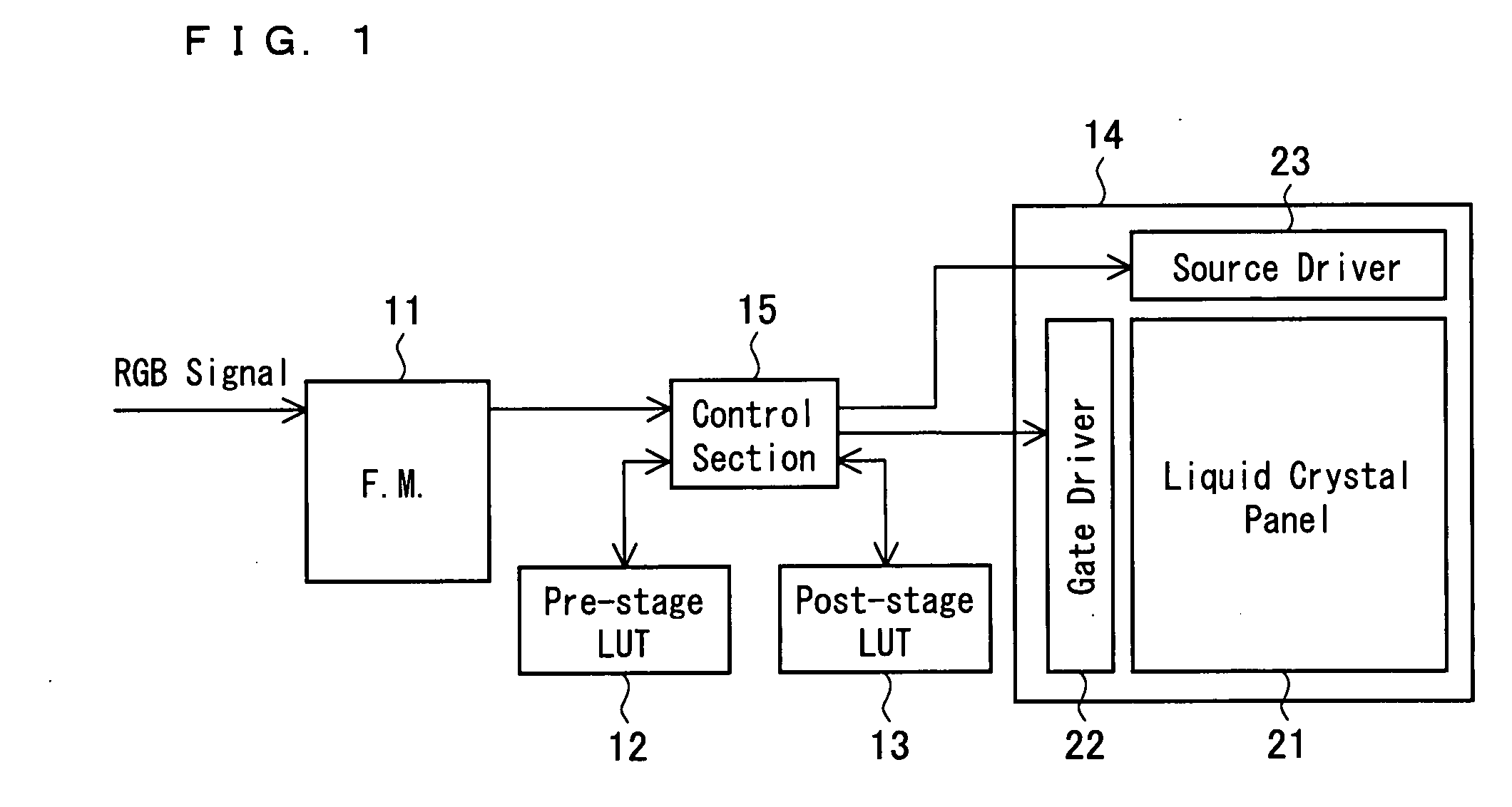

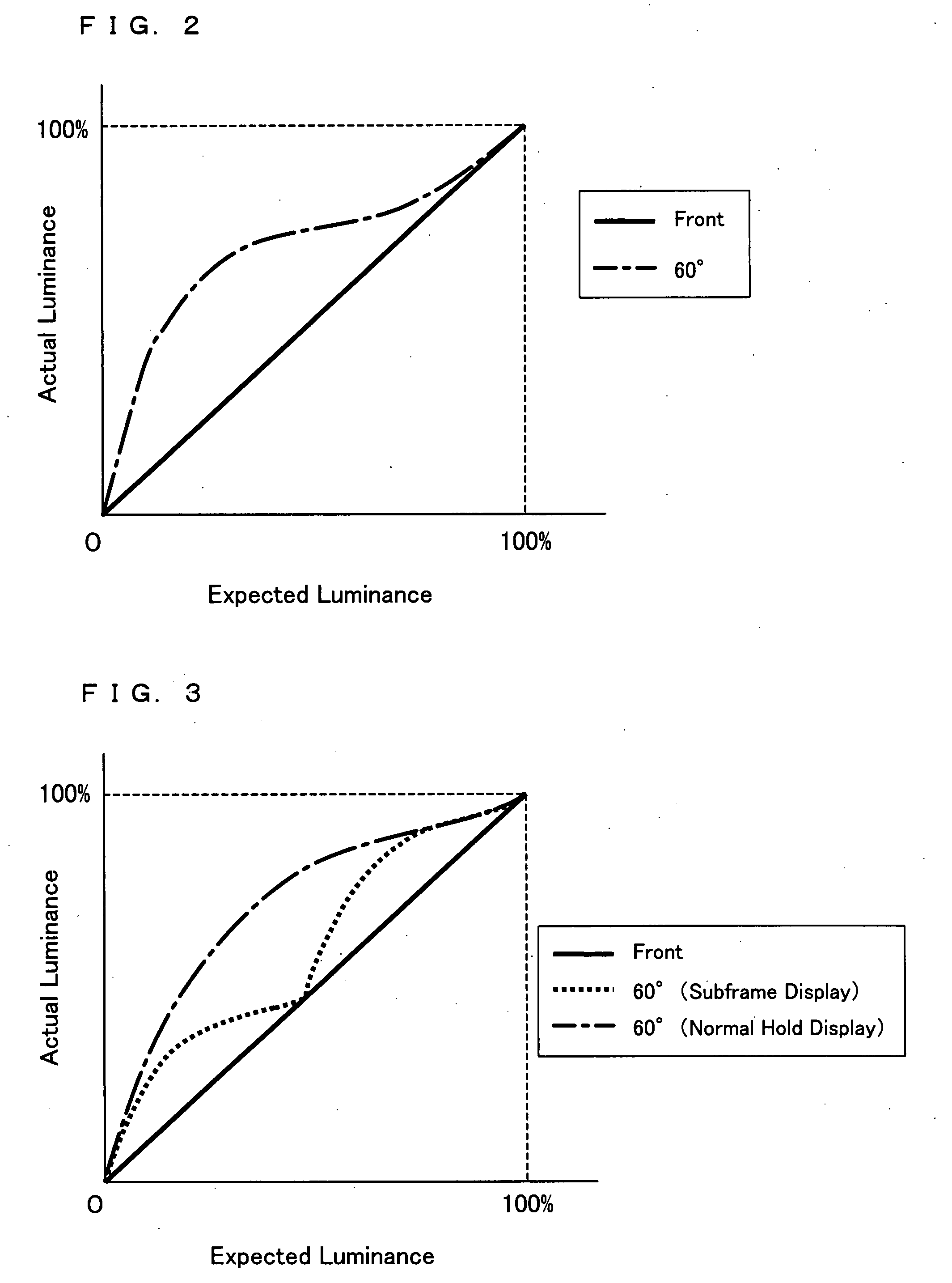

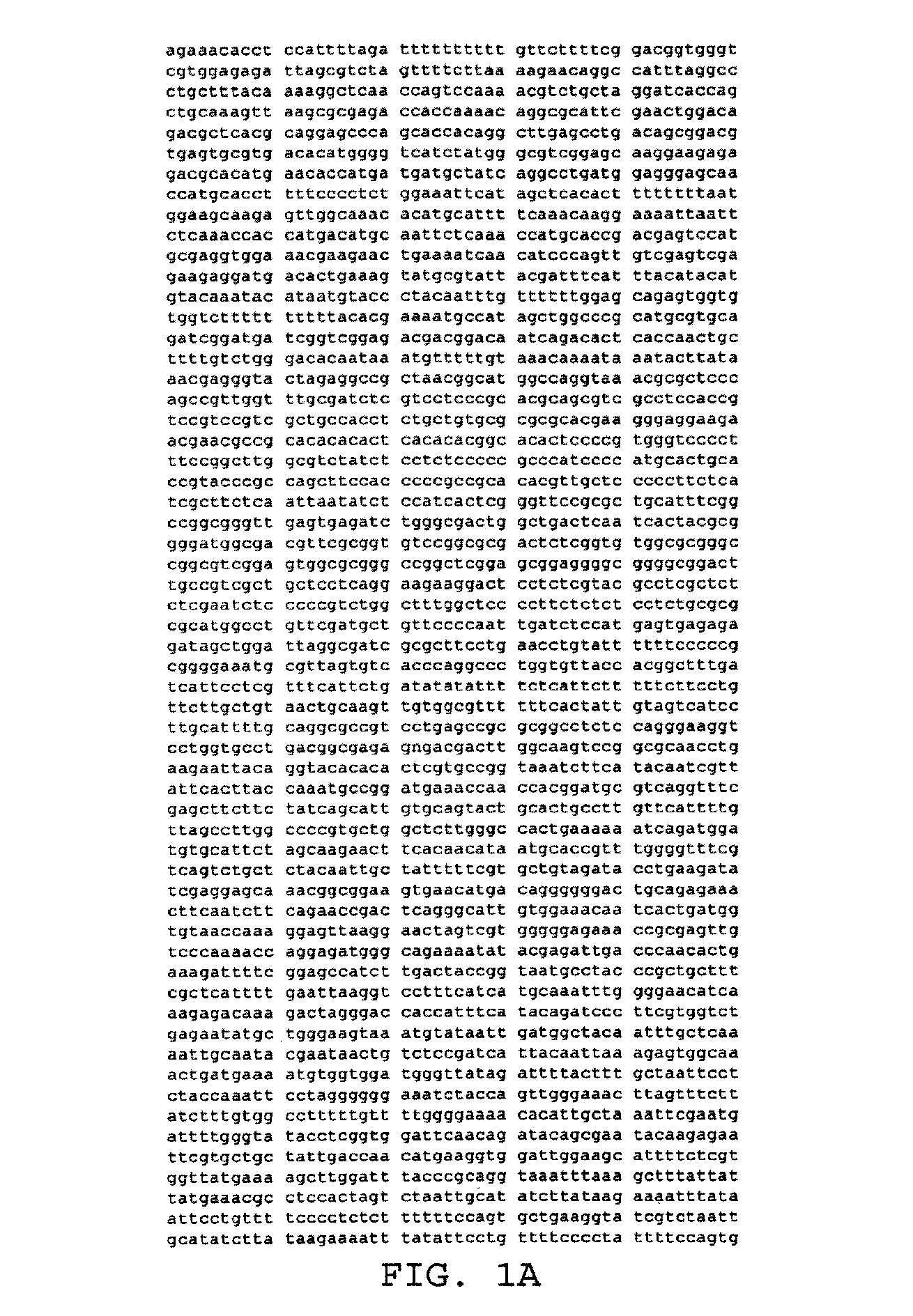

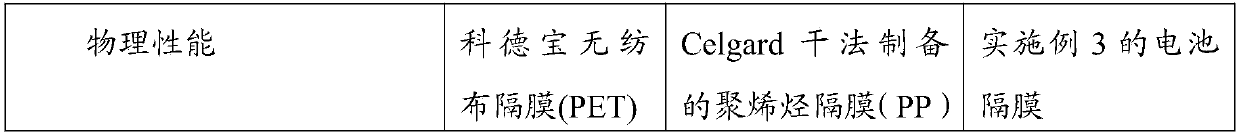

Display Device, Liquid Crystal Monitor, Liquid Crystal Television Receiver, and Display Method

InactiveUS20090121994A1Avoid Brightness DifferencesMitigating excess brightness phenomenonCathode-ray tube indicatorsInput/output processes for data processingTelevision receiversDisplay device

In one embodiment of the present invention, a display device is disclosed wherein if a frame luminance is less than a maximum value, the device creates a difference between luminance outputs in the two subframes and sets the luminance difference to a value less than a sub-maximum luminance which is a maximum luminance output in one subframe. With the arrangement, no complete switching of the subframes in which luminance outputs are made occurs at a grayscale level where low luminance replaces high luminance or vice versa. Thus, the grayscale level-luminance curve continues smoothly.

Owner:SHARP KK

Method and means for improving bowel health

ActiveUS7993686B2Improve blood sugar controlLow in carbsBiocideOrganic active ingredientsAnimal scienceMetabolic health

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30%.

Owner:ARISTA CEREAL TECH

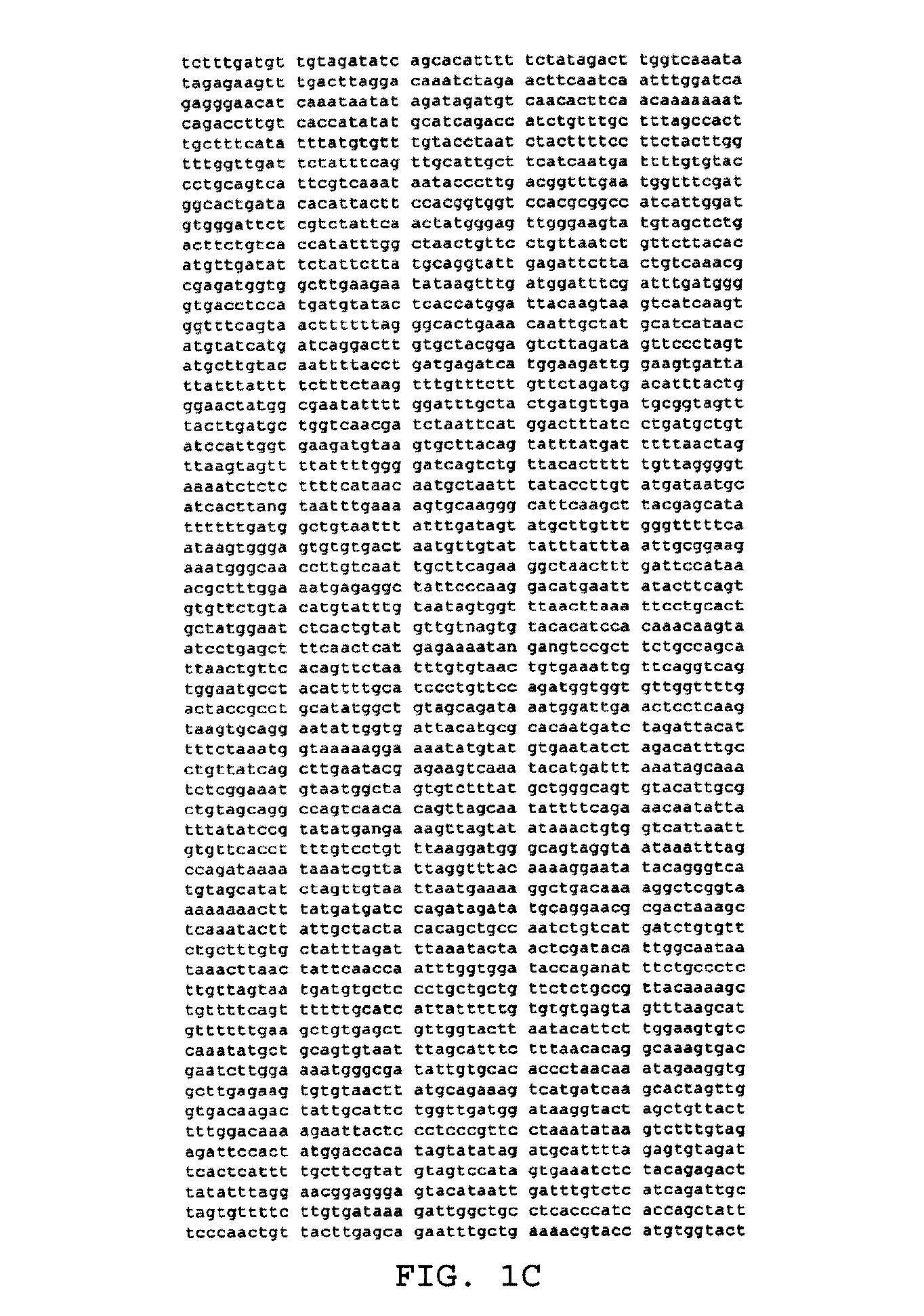

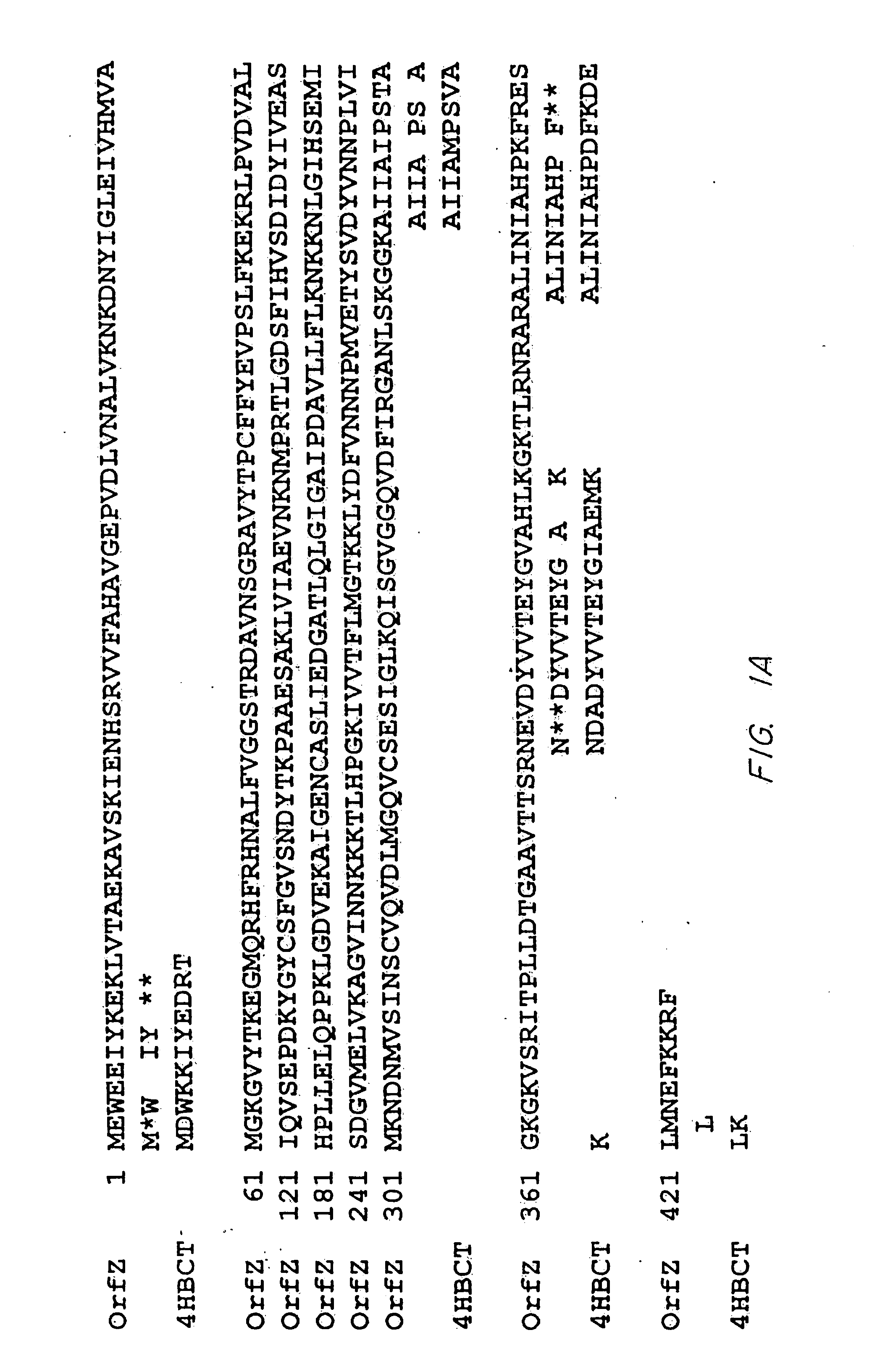

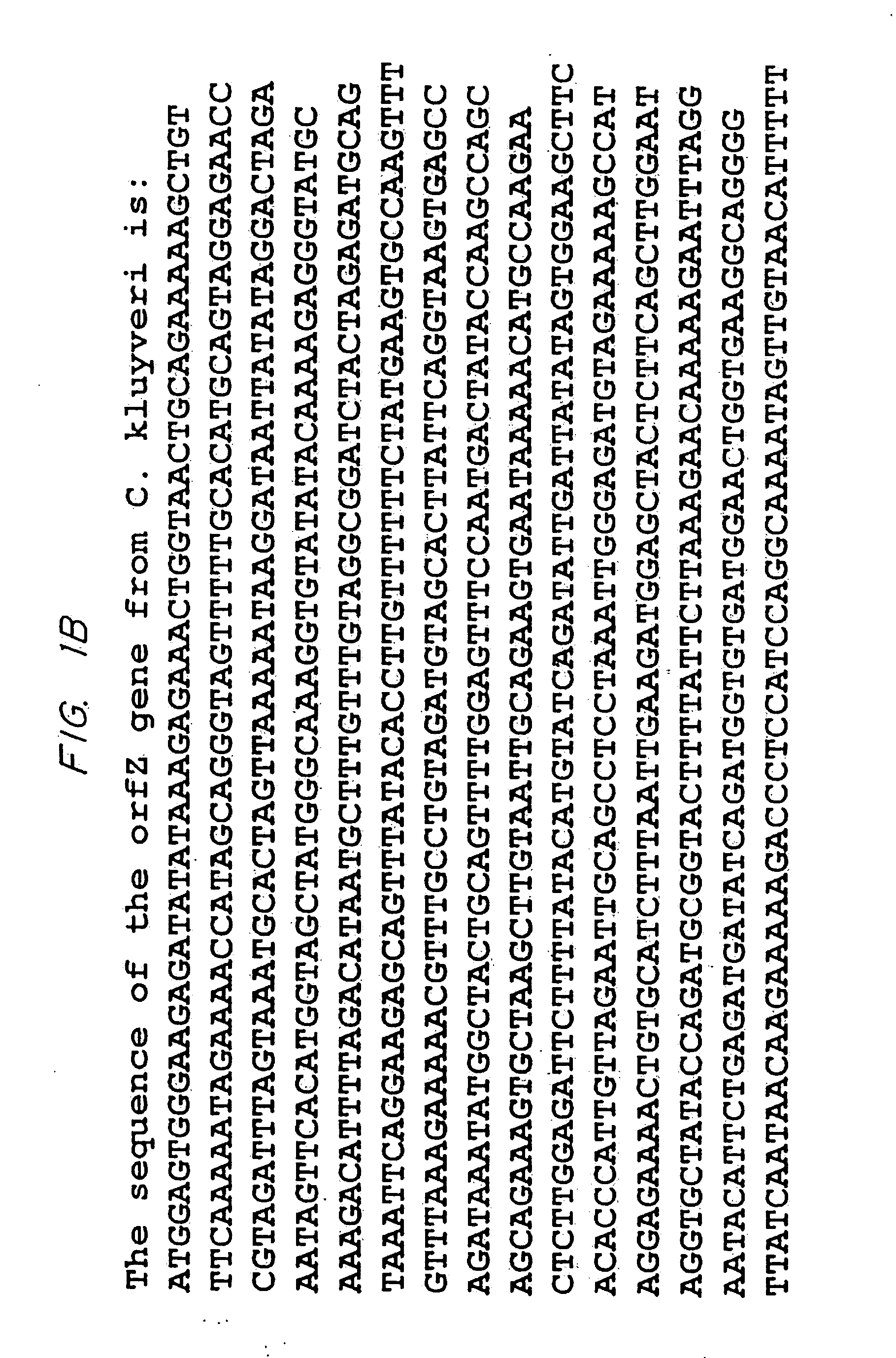

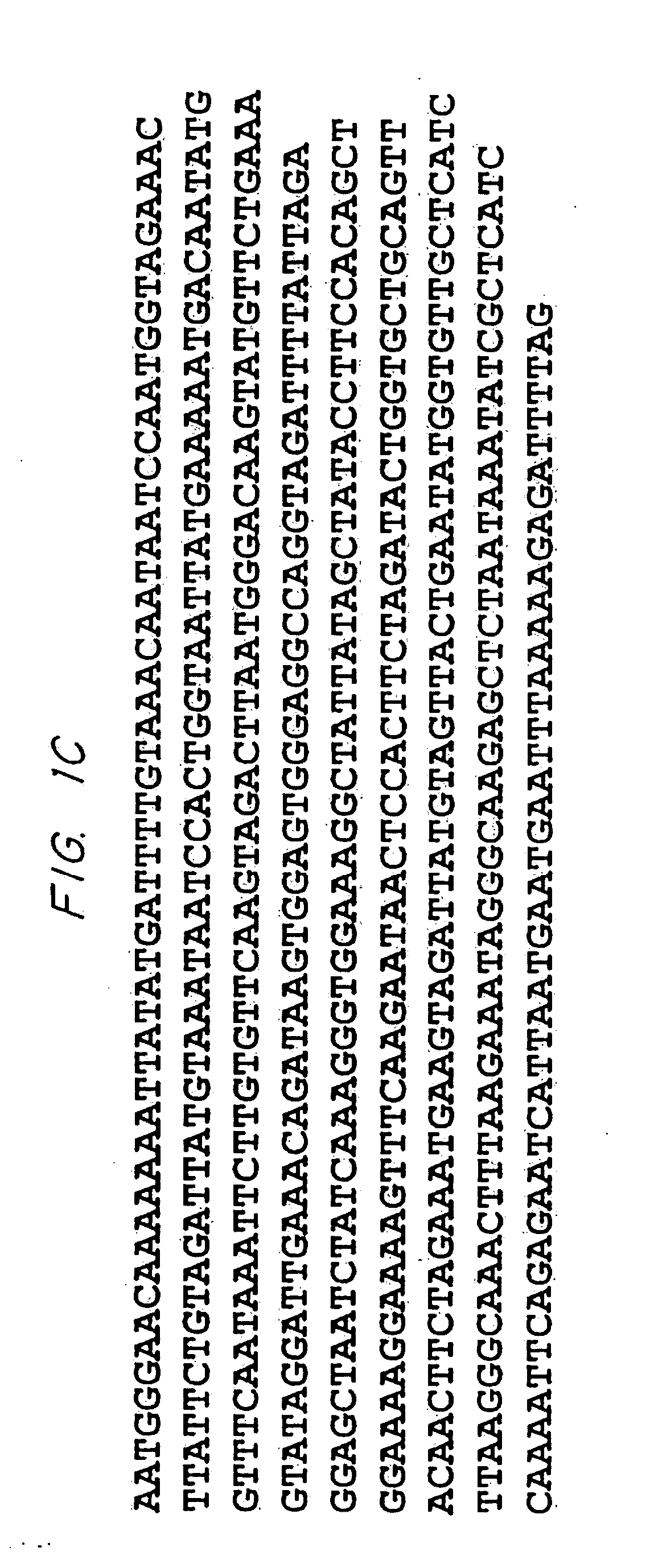

Biological systems for manufacture of polyhydroxyalkanoate polymers containing 4-hydroxyacids

InactiveUS20060084155A1Increase productionHigh activitySugar derivativesBacteriaBiotechnologyDegradation pathway

The gene encoding a 4-hydroxybutyryl-Co A transferase has been isolated from bacteria and integrated into the genome of bacteria also expressing a polyhydroxyalkanoate synthase, to yield an improved production process for 4HB-containing polyhydroxyalkanoates using transgenic organisms, including both bacteria and plants. The new pathways provide means for producing 4HB containing PHAs from cheap carbon sources such as sugars and fatty acids, in high yields, which are stable. Useful strains are obtaining by screening strains having integrated into their genomes a gene encoding a 4HB-CoA transferase and / or PHA synthase, for polymer production. Processes for polymer production use recombinant systems that can utilize cheap substrates. Systems are provided which can utilize amino acid degradation pathways, α-ketoglutarate, or succinate as substrate.

Owner:CJ CHEILJEDANG CORP

Method for producing group III nitride single crystal and apparatus used therefor

InactiveUS20060169197A1Reduce dislocation densityNon-uniform nitrogen distributionPolycrystalline material growthFrom normal temperature solutionsIndiumBulk crystal

A production method is provided in which Group-III-element nitride single crystals that have a lower dislocation density and a uniform thickness and are transparent, high quality, large, and bulk crystals can be produced with a high yield. The method for producing Group-III-element nitride single crystals includes: heating a reaction vessel containing at least one metal element selected from the group consisting of an alkali metal and an alkaline-earth metal and at least one Group III element selected from the group consisting of gallium (Ga), aluminum (Al), and indium (In) to prepare a flux of the metal element; and feeding nitrogen-containing gas into the reaction vessel and thereby allowing the Group III element and nitrogen to react with each other in the flux to grow Group-III-element nitride single crystals, wherein the single crystals are grown, with the flux being stirred by rocking the reaction vessel, for instance.

Owner:OSAKA UNIV

Method and means for improving bowel health

ActiveUS20060204597A1Reduces excessive insulin responseReduce probabilityBiocideAntipyreticAnimal scienceWild type

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30% and / or the grain comprises a reduced level of SBEIIa enzyme activity and / or protein relative to wild-type grain.

Owner:ARISTA CEREAL TECH

Method and means for improving bowel health

ActiveUS20060286186A1Improve blood sugar controlLow in carbsOrganic active ingredientsBiocideMetabolic healthWheat starch

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30%.

Owner:ARISTA CEREAL TECH

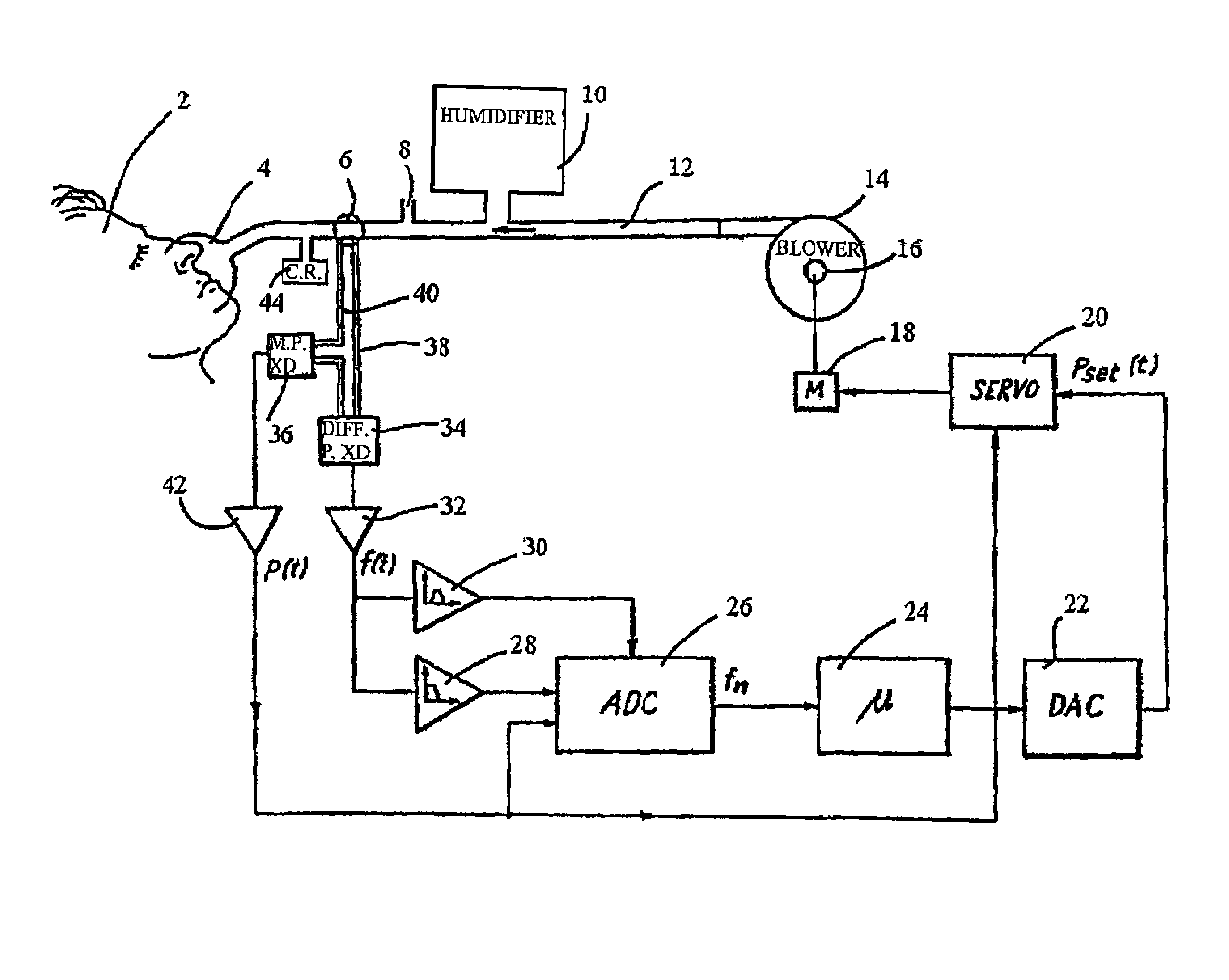

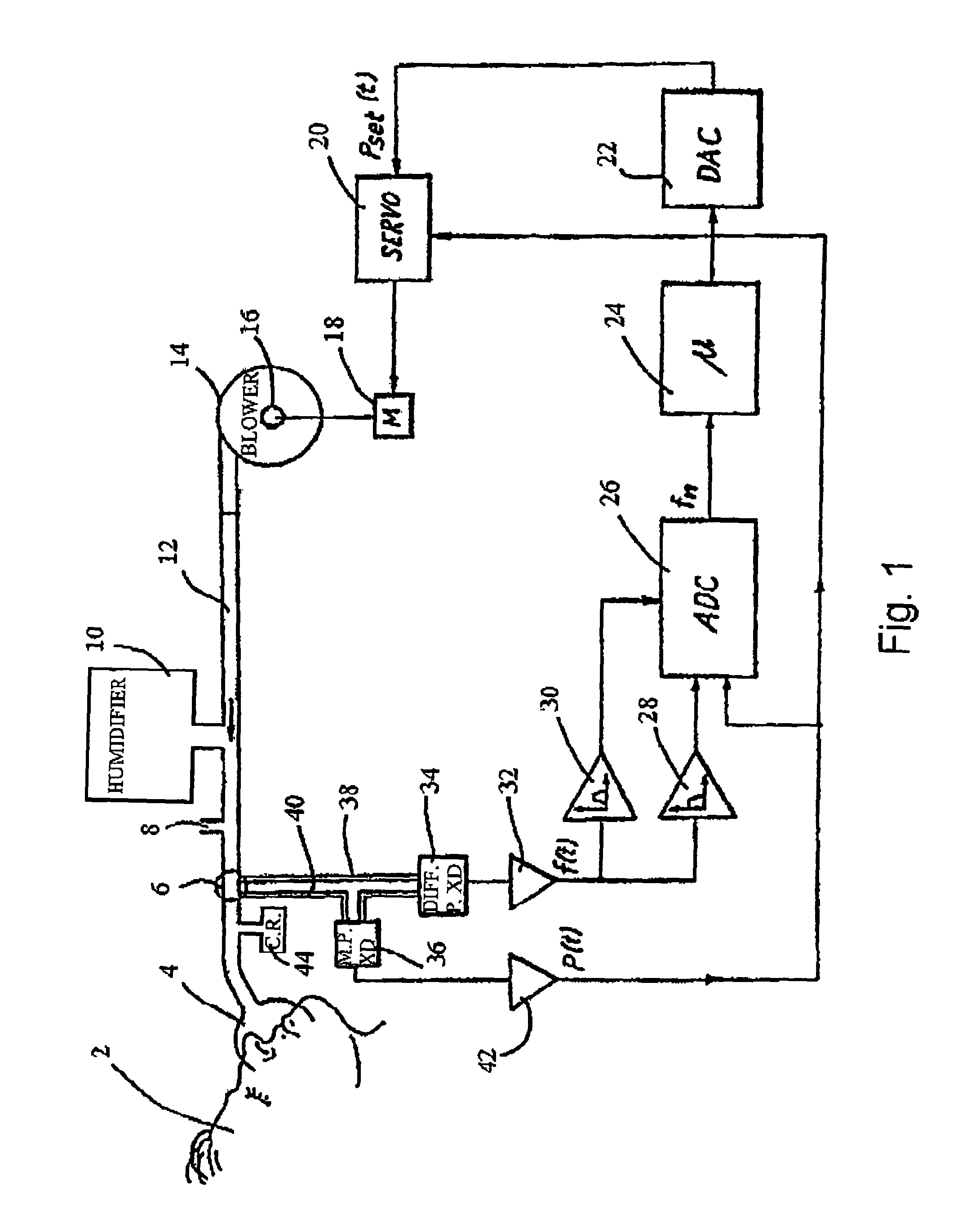

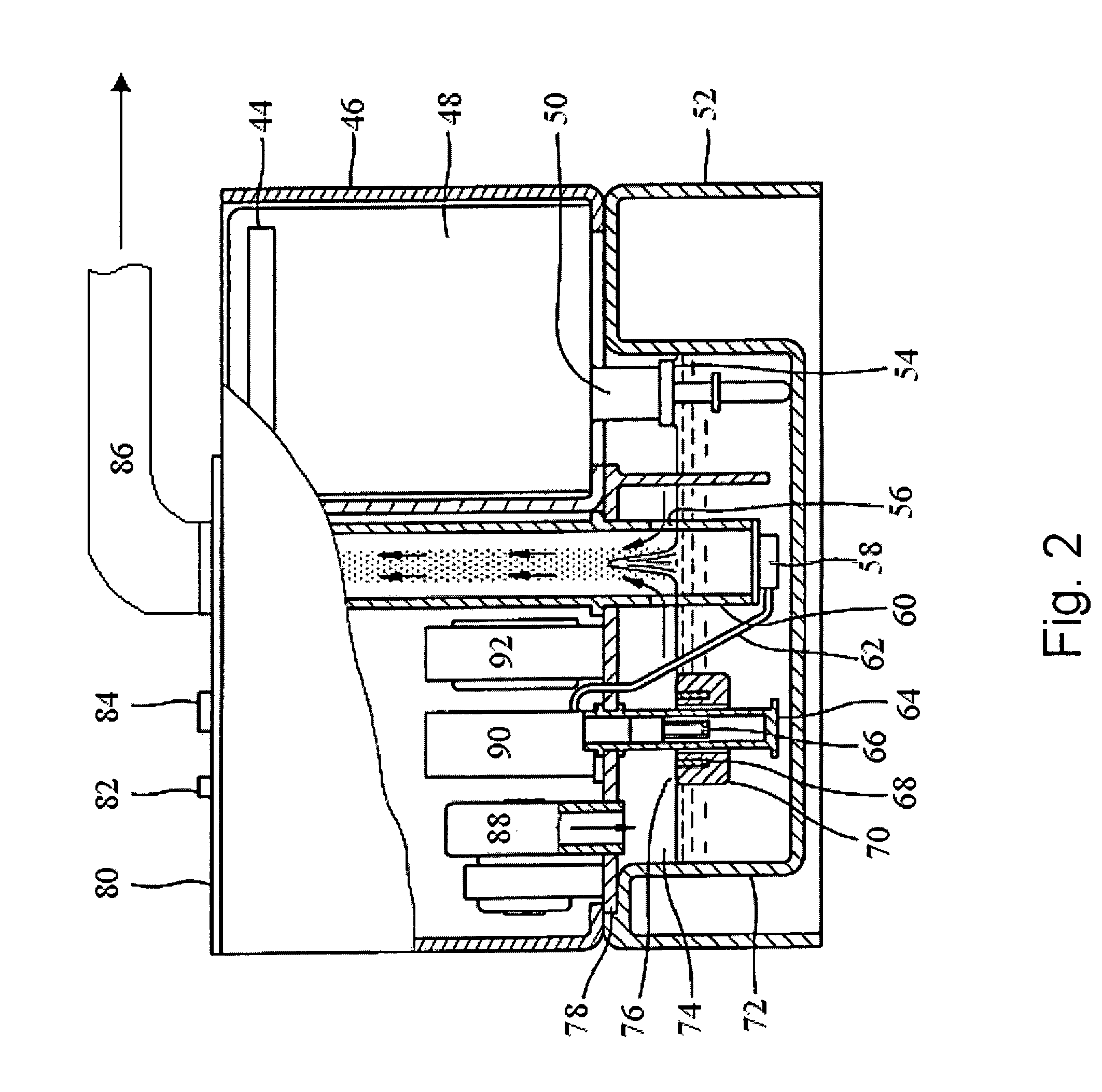

Humidification for continuous positive airway pressure systems

InactiveUS8720439B1Increase humidityGood for healthRespiratorsOperating means/releasing devices for valvesPositive pressureEngineering

The present invention encompasses the inclusion of non-heat, active-force humidifiers into CPAP devices. These humidifier modules use for example ultrasonics, atomization, and nebulization to increase the relative humidity of the air being delivered to the patient. Humidity is important in CPAP devices because it is vital to patient comfort and optimum health. All of these various, non-heat active humidifier modules are components or attachments to a CPAP device, and all optionally employ various procedures and devices for dealing with excess condensation. Most importantly, these humidification modules avoid the main problems associated with heat-requiring humidifiers, such as the added cost and time needed to operate these humidifiers, the excess condensation produced, and the increased likelihood of microbial growth.

Owner:CLEVELAND MEDICAL DEVICES +1

Method and means for improving bowel health

ActiveUS20110212916A1Improve blood sugar controlLow in carbsOrganic active ingredientsBiocideAnimal scienceWild type

A method and composition for improving one or more indicators of bowel health or metabolic health in a mammalian animal. This comprises the delivering to the gastrointestinal tract of the animal an effective amount of an altered wheat starch in the form of or derived from the grain of a wheat plant. The proportion of amylose in the starch of the grain is at least 30% and / or the grain comprises a reduced level of SBEIIa enzyme activity and / or protein relative to wild-type grain.

Owner:ARISTA CEREAL TECH

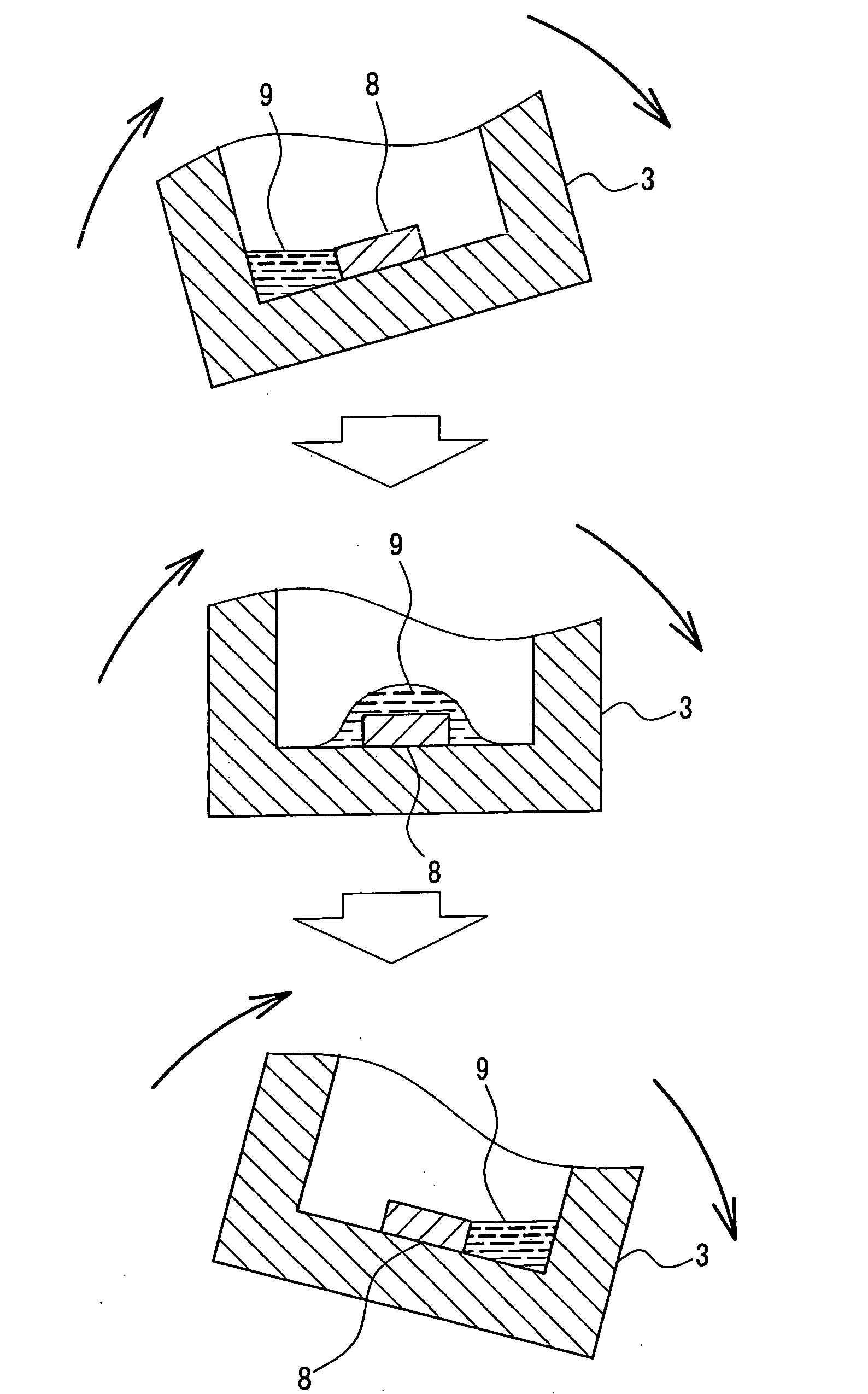

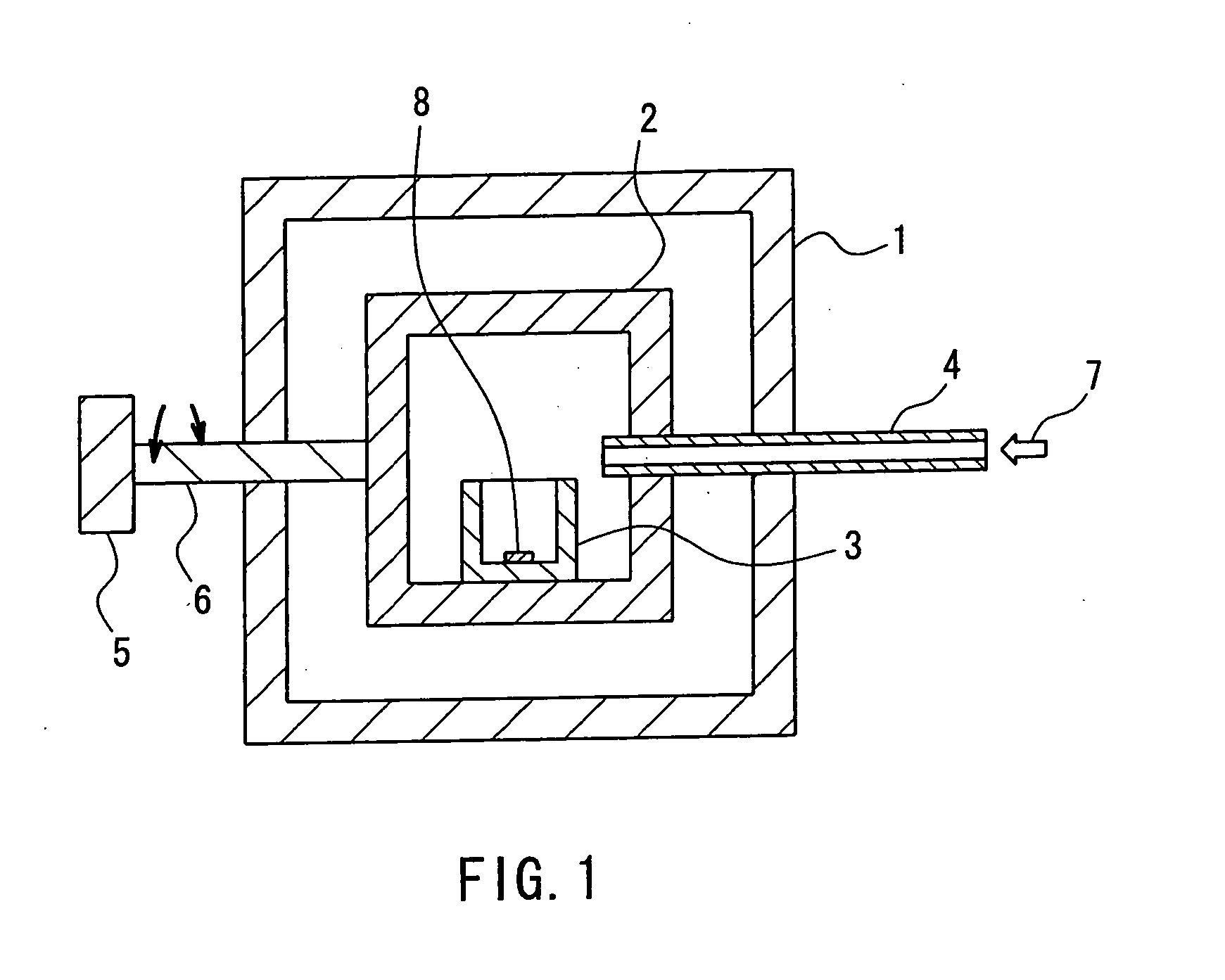

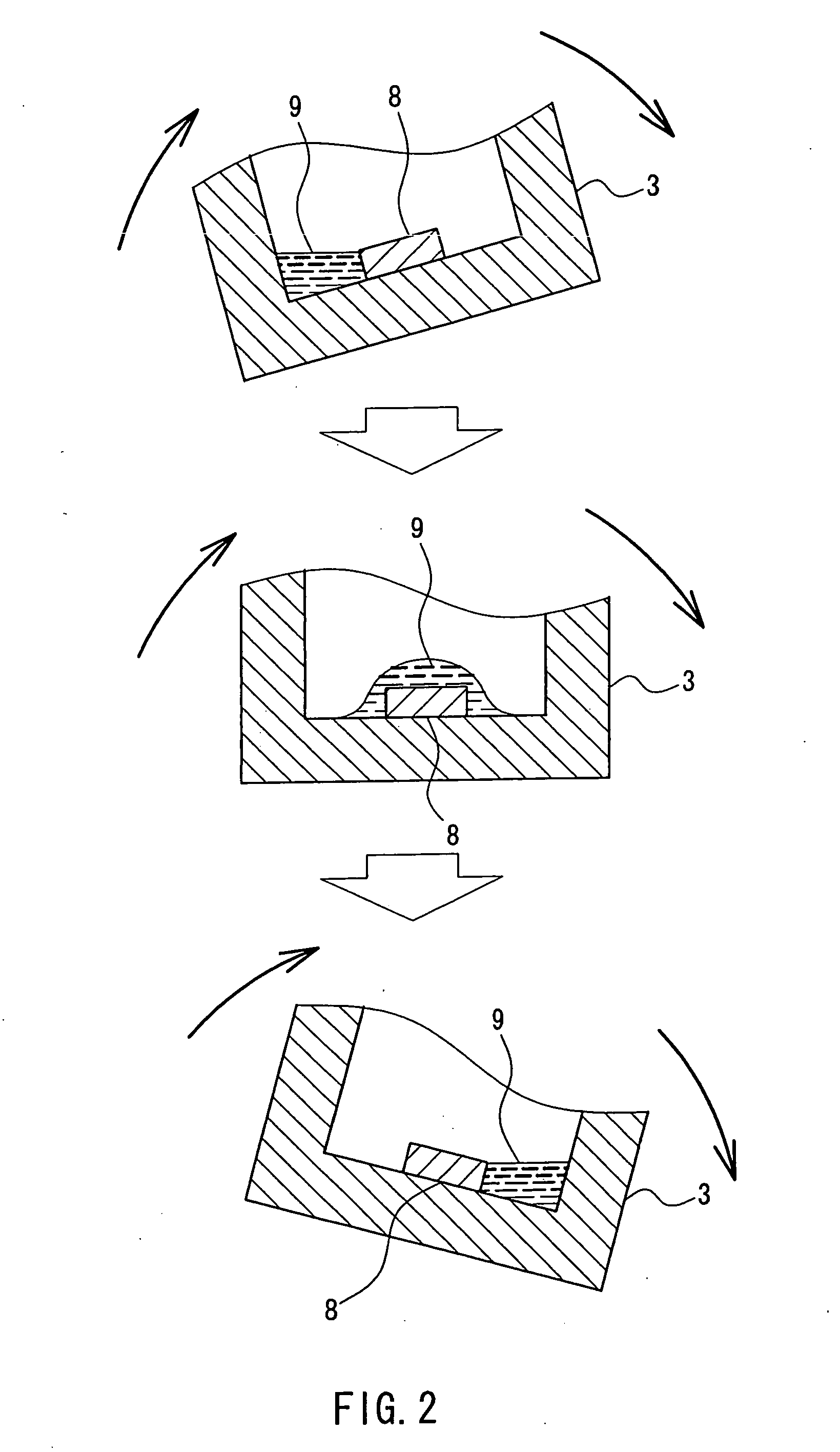

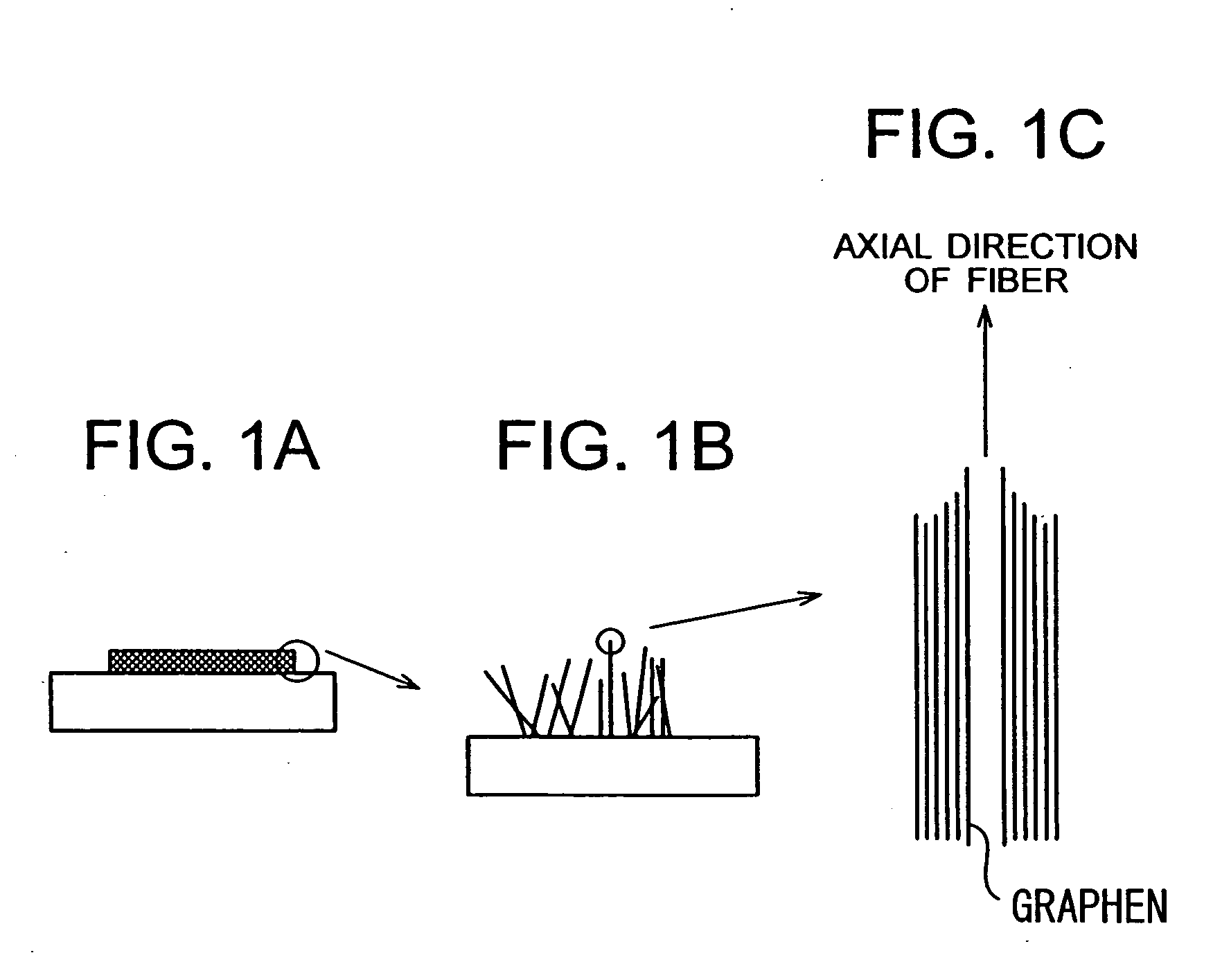

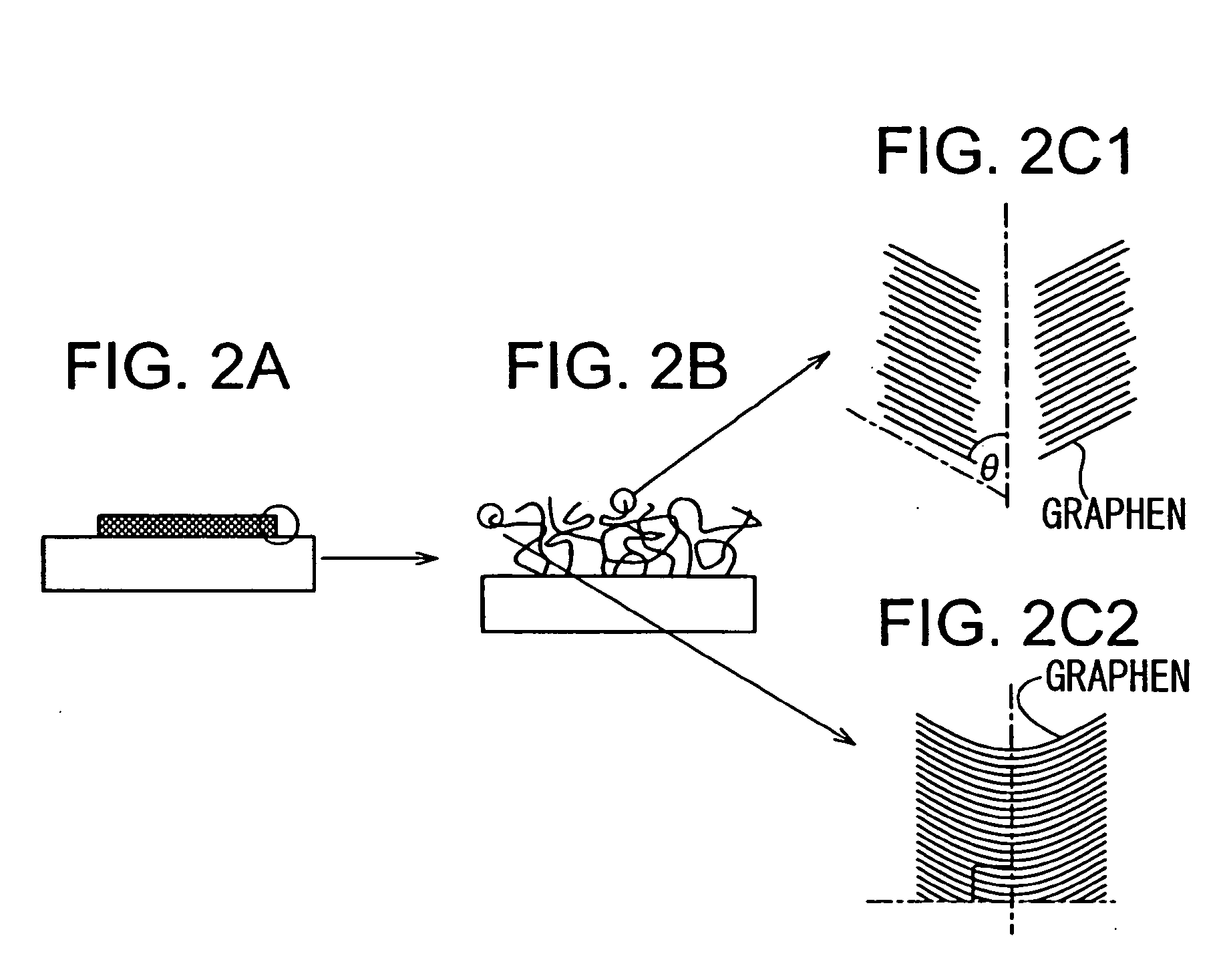

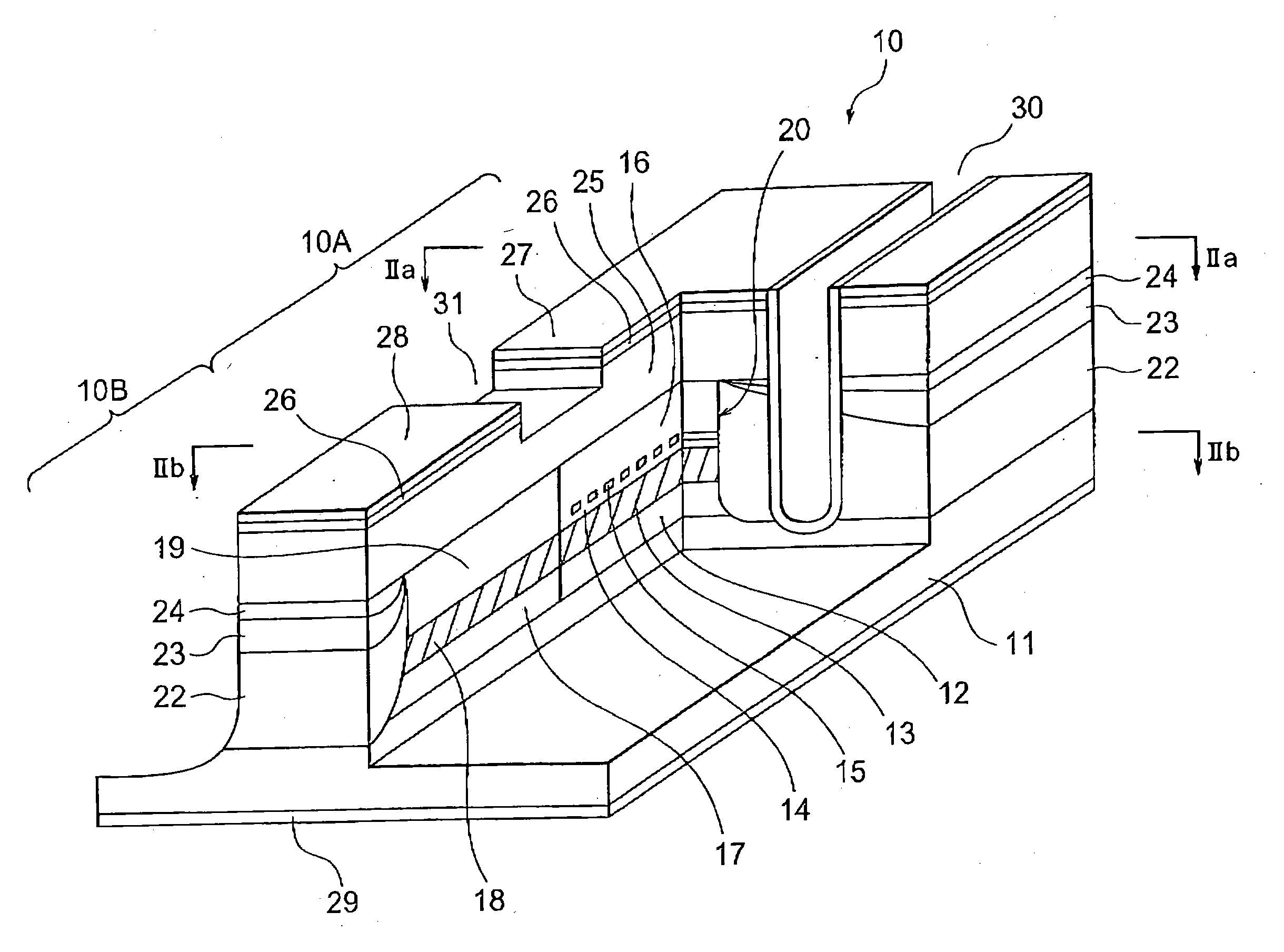

Fiber containing carbon, substrate and electron emission device using fiber containing carbon, electron source using the electron emission device, display panel using the electron source, and information displaying/playing apparatus using the display panel, and a method of manufacturing thereof

InactiveUS20050134161A1Improve evenlyShort timeMaterial nanotechnologyNanostructure manufactureFiberCarbon fibers

The invention provides a fiber containing carbon which is less deteriorated in terms of electron emission characteristic, is excellent in terms of reproducibility, and can in addition be formed at a low cost, a substrate and electron emission device using the fiber containing carbon, an electron source using the electron emission device, a display panel using the electron source, and an information displaying / playing apparatus using the display panel, and a method of manufacturing these. The manufacturing method comprises a first step of preparing a substrate (substrate 1) equipped with a catalyst (catalyst layer 3) on its surface; and a second step of causing the fiber containing carbon (carbon fiber 4) to grow using the catalyst, whereby the second step comprises, in order to decrease, from a midway point of time in this step, the growth rate at which the fiber containing carbon grows, a sub-step of controlling the growth conditions for the fiber containing carbon.

Owner:CANON KK

Oxygen Controlled PVD Aluminum Nitride Buffer for Gallium Nitride-Based Optoelectronic and Electronic Devices

ActiveUS20140264363A1Low rate-of-riseUniform depositionCellsElectric discharge tubesSputteringGas phase

Oxygen controlled PVD AlN buffers for GaN-based optoelectronic and electronic devices is described. Methods of forming a PVD AlN buffer for GaN-based optoelectronic and electronic devices in an oxygen controlled manner are also described. In an example, a method of forming an aluminum nitride (AlN) buffer layer for GaN-based optoelectronic or electronic devices involves reactive sputtering an AlN layer above a substrate, the reactive sputtering involving reacting an aluminum-containing target housed in a physical vapor deposition (PVD) chamber with a nitrogen-containing gas or a plasma based on a nitrogen-containing gas. The method further involves incorporating oxygen into the AlN layer.

Owner:APPLIED MATERIALS INC

Optical device having a carrier-depleted layer

InactiveUS20040048406A1Avoid structureLower growth rateOptical wave guidanceLaser detailsCharge carrierParasitic capacitance

An EA-DFB module including a DFB laser diode and an EA modulator formed on an InP first-conductivity-type substrate has a mesa stripe, a current blocking structure formed on both side surfaces of the mesa strip and a second InP cladding layer formed on top of the mesa stripe and the current blocking structure. The current blocking structure includes a Fe-doped semi-insulating film, a first conductivity-type buried layer and a carrier-depleted layer. The carrier-depleted layer reduces the parasitic capacitance at the boundary between the first-conductivity-type buried layer and the second InP cladding layer.

Owner:FURUKAWA ELECTRIC CO LTD

Fiber containing carbon, substrate and electron emission device using fiber containing carbon, electron source using the electron emission device, display panel using the electron source, and information displaying/playing apparatus using the display panel, and a method of manufacturing thereof

InactiveUS7528538B2Low costLower growth rateMaterial nanotechnologyNanostructure manufactureFiberElectron source

The invention provides a fiber containing carbon which is less deteriorated in terms of electron emission characteristic, is excellent in terms of reproducibility, and can in addition be formed at a low cost, a substrate and electron emission device using the fiber containing carbon, an electron source using the electron emission device, a display panel using the electron source, and an information displaying / playing apparatus using the display panel, and a method of manufacturing these. The manufacturing method comprises a first step of preparing a substrate (substrate 1) equipped with a catalyst (catalyst layer 3) on its surface; and a second step of causing the fiber containing carbon (carbon fiber 4) to grow using the catalyst, whereby the second step comprises, in order to decrease, from a midway point of time in this step, the growth rate at which the fiber containing carbon grows, a sub-step of controlling the growth conditions for the fiber containing carbon.

Owner:CANON KK

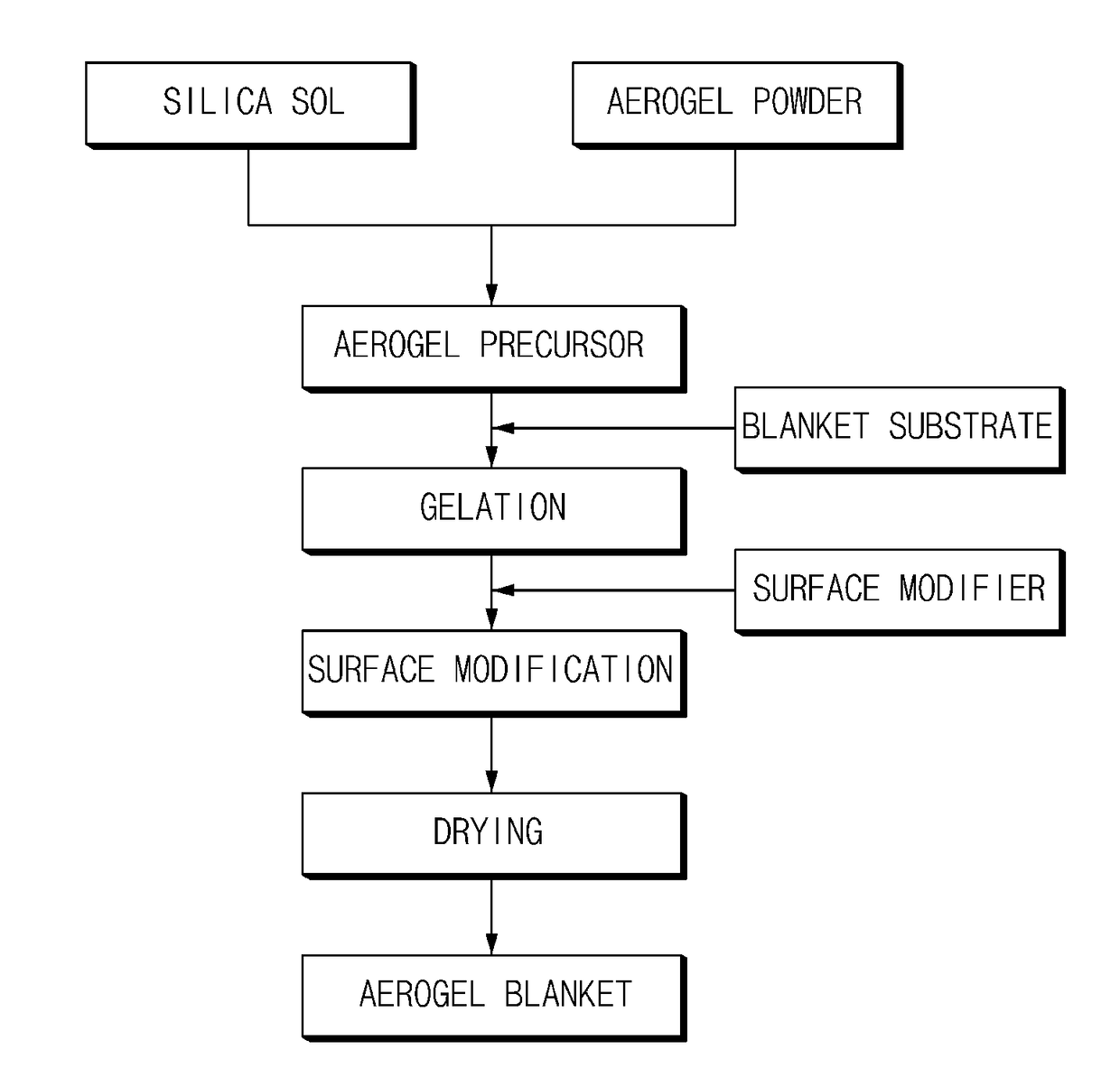

Method for producing aerogel blanket and aerogel blanket produced thereby

ActiveUS20180134566A1Improve hydrophobicityImprove retentionGeneral water supply conservationDrying solid materials without heatSilicon dioxideMaterials science

The present invention relates to a method for producing an aerogel blanket exhibiting excellent hydrophobicity at high temperatures and an aerogel blanket produced thereby. The present invention uses a mixture of silica sol and a hydrophobic aerogel powder as an aerogel precursor and thus can achieve hydrophobicity in the internal structure as well as on the surface of the aerogel included in the aerogel blanket. Accordingly, the aerogel blanket can attain high hydrophobicity and thus can exhibit excellent hydrophobicity retention ability even in high-temperature applications.

Owner:LG CHEM LTD

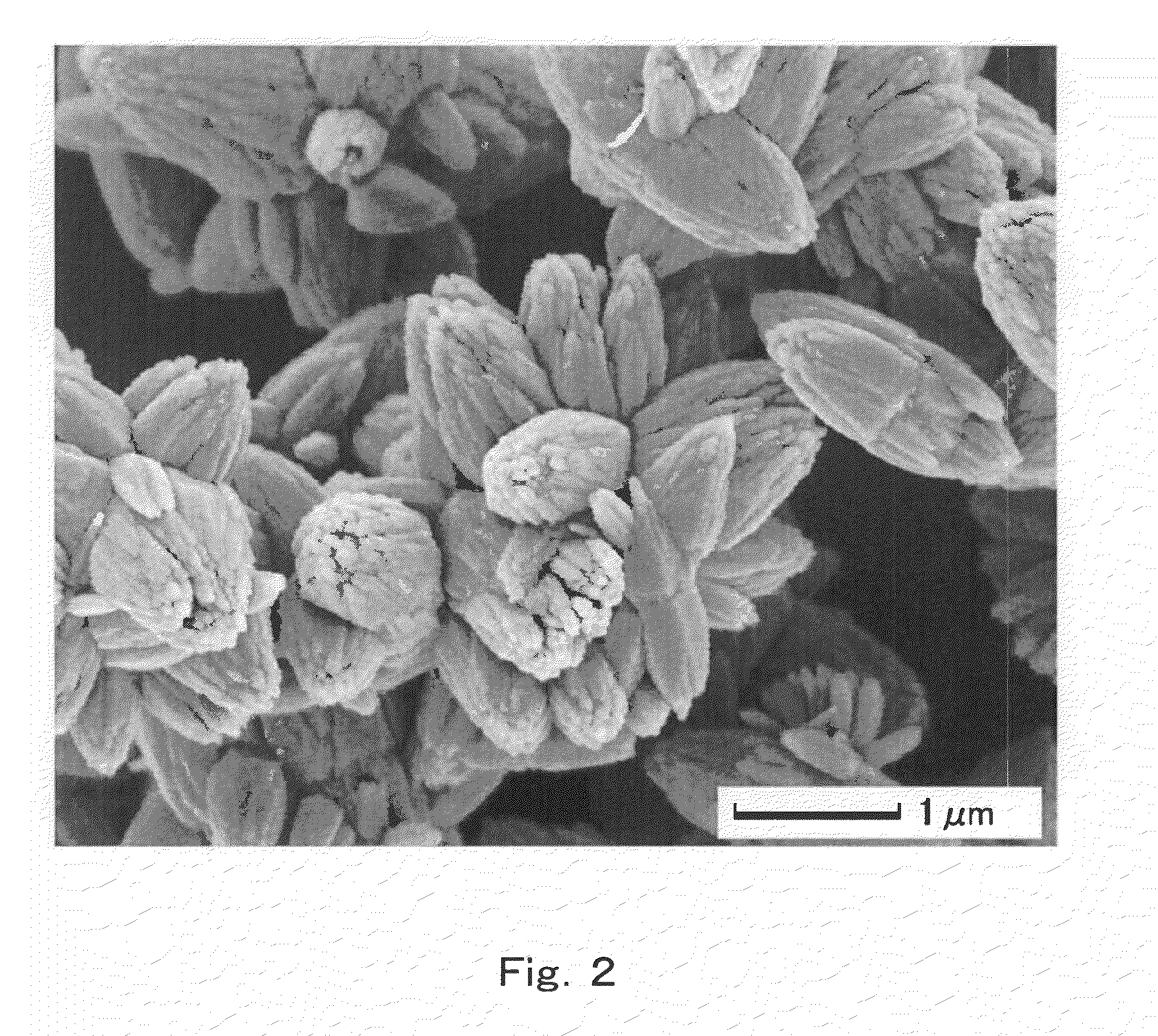

Zinc oxide particle, zinc oxide particle film, and processes for producing these

InactiveUS20100028254A1Degree of supersaturation is loweredHigh degreeMaterial nanotechnologyPolycrystalline material growthZincCrystal growth

The present invention provides zinc oxide particles having a large specific surface area, and a zinc oxide composite material, and processes for producing these, and the invention is zinc oxide particles formed by crystal growth into a multi-needle shape and having a larger specific surface area than hexagonal columnar particles; to a zinc oxide composite material comprising the zinc-containing thin film and the zinc oxide particles; to processes for producing the zinc oxide particles and the composite material, and an advantage of the present invention is that a larger specific surface area can be obtained than with hexagonal columnar particles, and a particle film of a specified thickness with fewer grain boundaries can be formed, thereby achieving less reduction in dielectric constant due to grain boundaries.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Rectification speed increasing tower used for vertical axis wind turbine

InactiveCN101749179AIncrease speedLower growth rateFinal product manufactureMachines/enginesStress conditionsVertical axis wind turbine

The invention relates to a rectification speed increasing tower used for a vertical axis wind turbine. The appearance of the rectification speed increasing tower is a layer or multiple layers of tower-shaped structures. The rectification speed increasing tower comprises a tower base (1), a fairing (2), a tower brim (3) and a tower top (4). The center of the tower is provided with a hollow columnar chamber, and the inside of the chamber is used for installing a vertical axis wind turbine set. The invention has the advantages that the speed increasing ratio of a speed increaser is reduced, the stress condition and the working condition of the vertical axis wind turbine are improved, the stability of the wind turbine is increased, the service life thereof is prolonged, the design difficulty of the wind turbine is lowered, the manufacture and transportation costs of the wind turbine are reduced, the environment is protected, the appearance is beautiful and the like.

Owner:HARBIN INST OF TECH

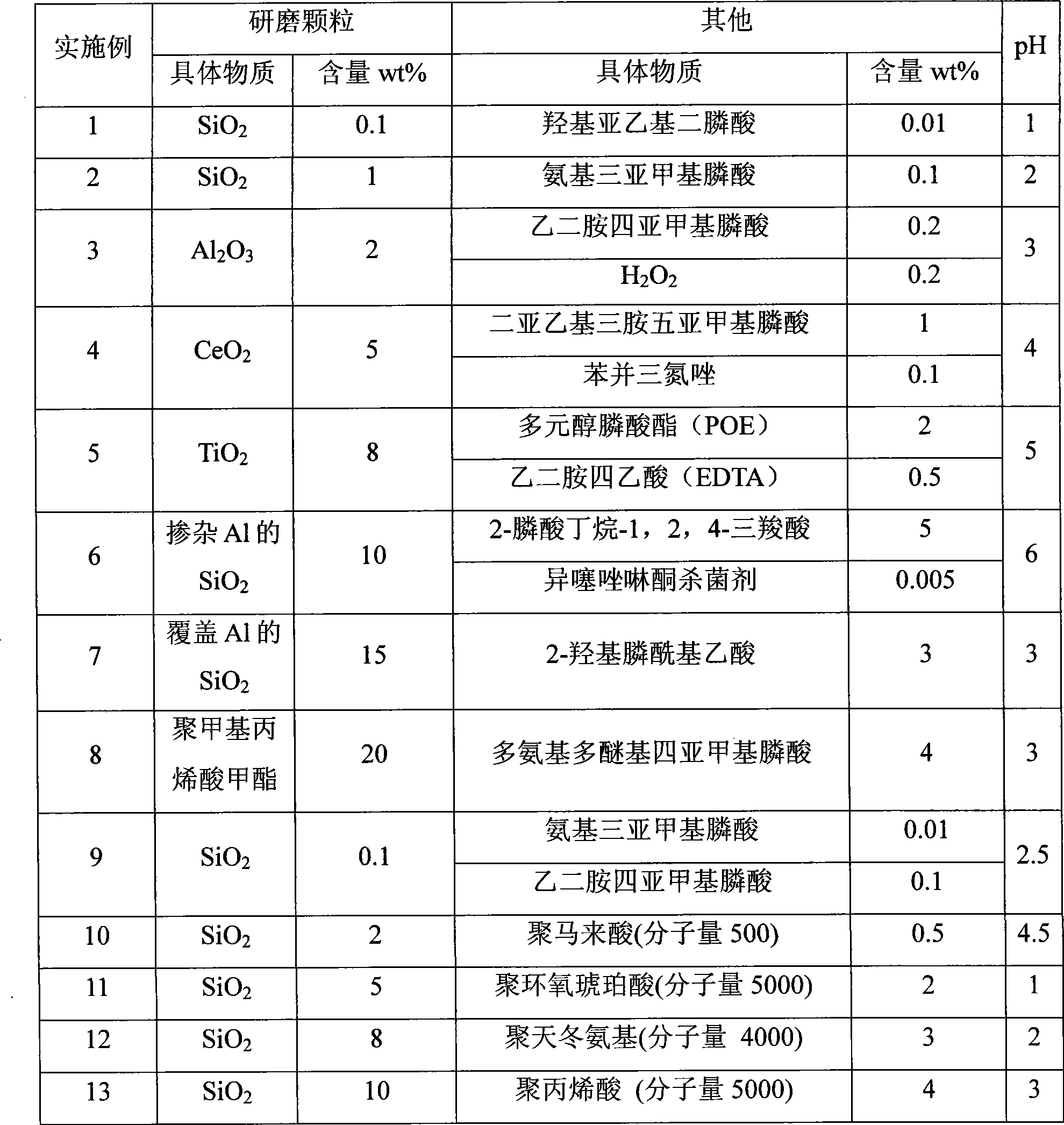

Chemico-mechanical polishing liquid

ActiveCN101451044ALong storage timeExtended service lifeOther chemical processesSemiconductor/solid-state device manufacturingLower gradeLow graded

The present invention discloses a chemical and mechanical polishing liquid, which comprises grinding particles and water. The polishing liquid also comprises one or more of the following components: organic phosphonic acid, polycarboxylic acid compounds, low-grade alkyl ethanol and carbohydrate. The growth rate of the particle size of the grinding particles along with the extension of time in thepolishing liquid is low. The chemical and mechanical polishing liquid has the advantages of higher stability and longer storing time and service life.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

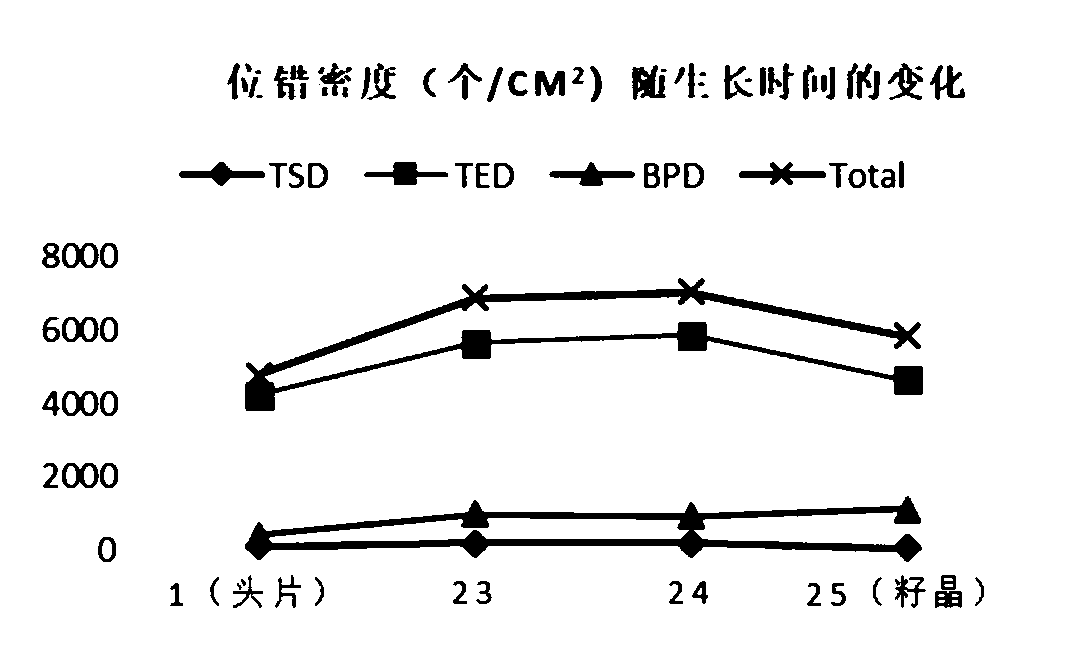

Method for manufacturing large-size low-defect silicon carbide single crystal

ActiveCN110578171AAvoid secondary damageDifficult to solvePolycrystalline material growthFrom condensed vaporsIngotSingle crystal growth

In order to solve the problem that dislocation and other defects are greatly increased during seed crystal growth, the invention provides a SiC single crystal growth method capable of obviously reducing the dislocation density from the initial growth stage, thereby manufacturing SiC single crystals with lower dislocation density from the initial growth stage to the final growth stage. The invention relates to a manufacturing method of a silicon carbide single crystal block. According to the manufacturing method of the silicon carbide single crystal block, the silicon carbide single crystal block is prepared by growing the silicon carbide single crystals by using a sublimation recrystallization method on the growth surface of seed crystals generated by the silicon carbide single crystals, in the initial growth stage of the silicon carbide single crystals, a temperature range of 1200 DEG C to 2000 DEG C is adopted, and maintained for more than 10 minutes, then, the pressure is controlledto be between 100 Pa and 10 Kpa; and the pressure of a furnace body is kept constant, a certain flow of hydrocarbon gas is introduced into a growth furnace to enable the surface of the seed crystalsto grow homogeneously at a speed of less than 50 mu / h, and after growing for a period of time, the temperature and the pressure are adjusted to conventional growth conditions at a certain speed to obtain a SiC single crystal ingot with a target thickness.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD +3

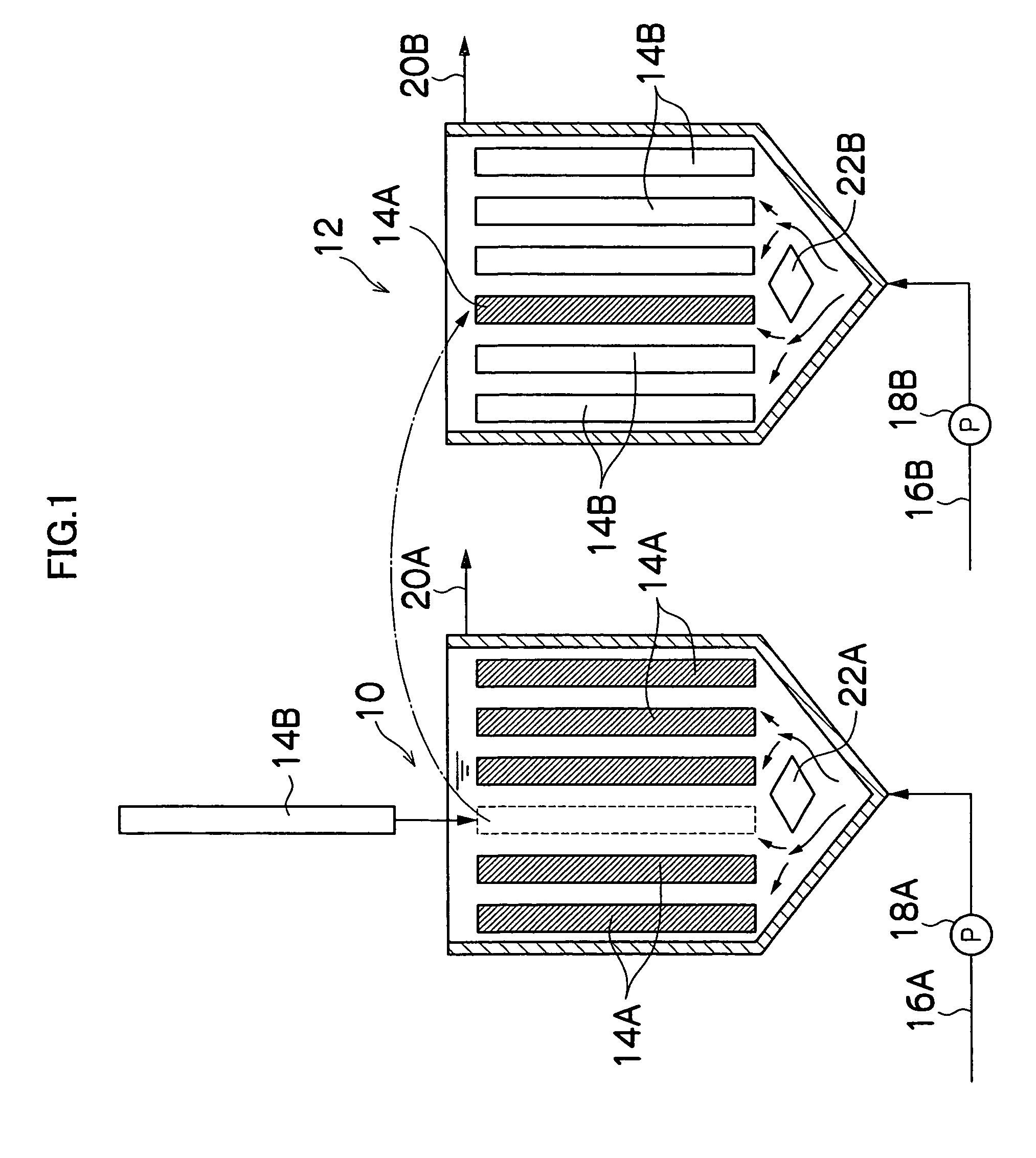

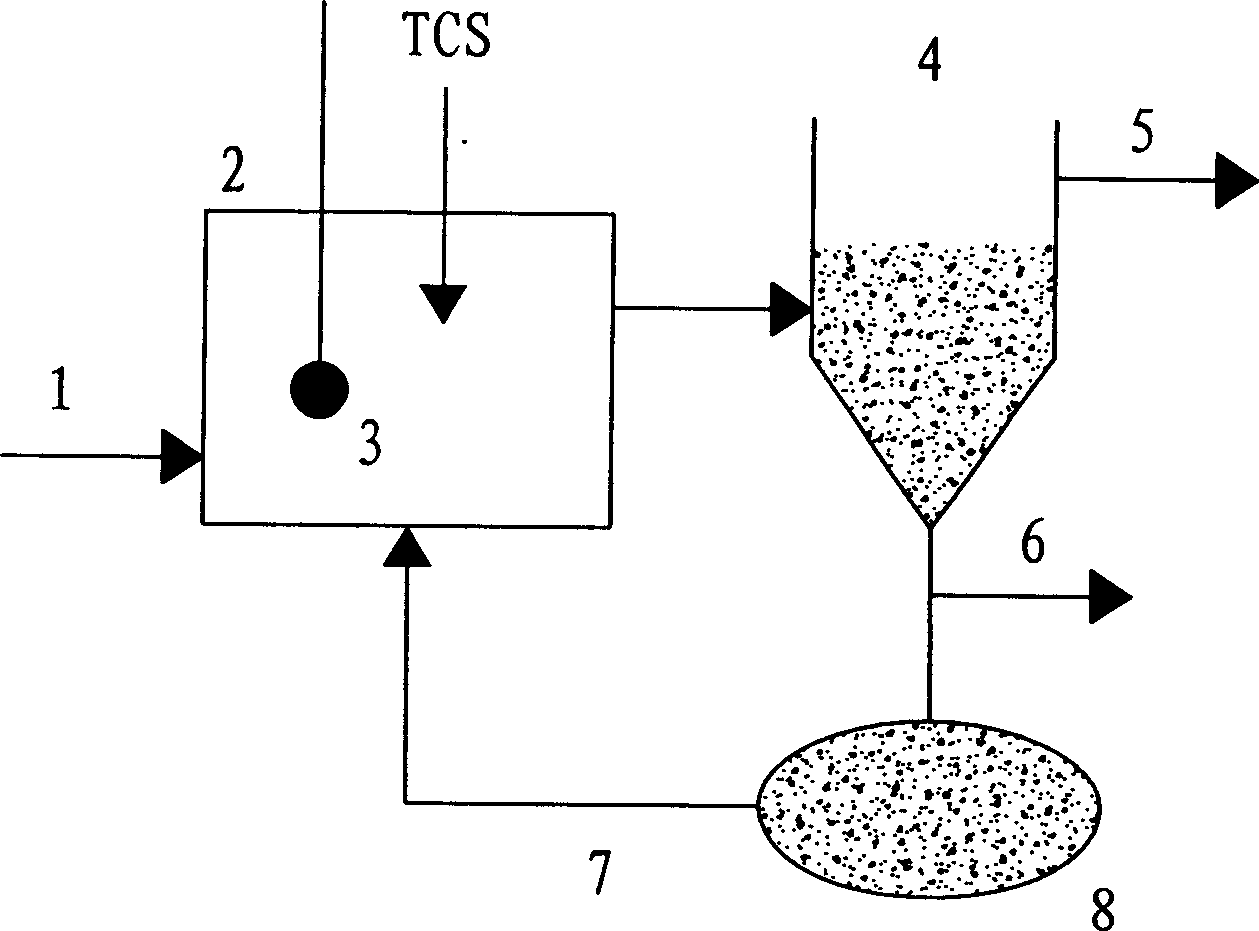

Method for operating anaerobic ammonium oxidation vessel and anaerobic ammonium oxidation equipment

A method for operating an anaerobic ammonium oxidation vessel in anaerobic ammonium oxidation in which ammonium and nitrite in water to be treated are simultaneously denitrified by anaerobic ammonium oxidizing bacteria, the method comprising the steps of:withdrawing a part of the anaerobic ammonium oxidizing bacteria from one anaerobic ammonium oxidation vessel in which the anaerobic ammonium oxidizing bacteria have been acclimatized, andintroducing the withdrawn anaerobic ammonium oxidizing bacteria into another anaerobic ammonium oxidation vessel in which acclimatization is to be carried out to perform start-up operation,wherein the anaerobic ammonium oxidizing bacteria having been acclimatized in the one anaerobic ammonium oxidation vessel are provided as microbe-immobilized materials in which the bacteria are attached to and immobilized on immobilizing materials or entrapped and immobilized in immobilizing materials.

Owner:HITACHI LTD

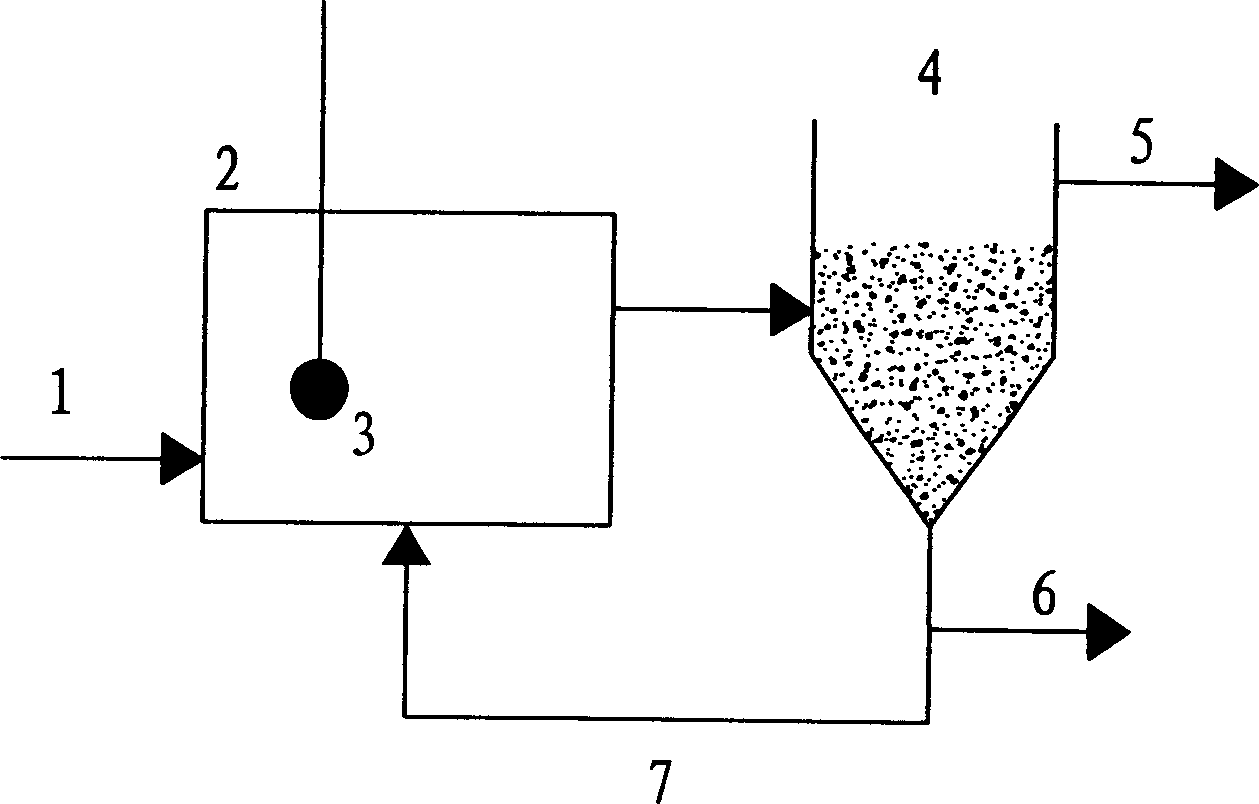

Novel active sludge process with reduced excess sludge

InactiveCN1803664AReduce outputPollution controlTreatment using aerobic processesSustainable biological treatmentActivated sludgeSewage

The activated sludge new technique for reducing residual sludge comprises: adding the sludge and sewage into aeration pond for continual aerating; depositing in deposition pond, and reflowing the sludge to aeration pond; when the sludge concentration over given value, reflowing part sludge to aeration pond and discharging other out; putting decouple agent into the aeration pond as sludge ratio, then aerating with sewage, and leading the decoupled mixed liquid into deposition pond; taking anoxybiotic treatment to some sludge in storage container for 4~6h and reflowing to aeration pond for aeration and decoupling with sewage. This invention can reduce 40-50% residual sludge with small investment and simple device.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

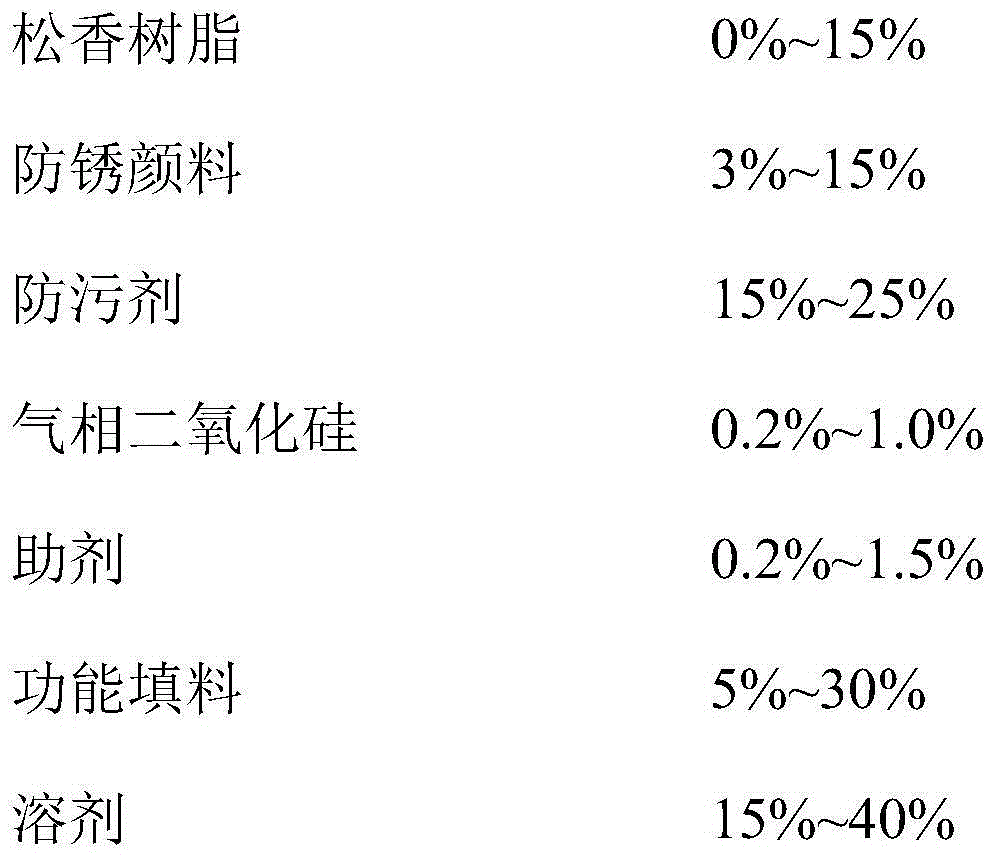

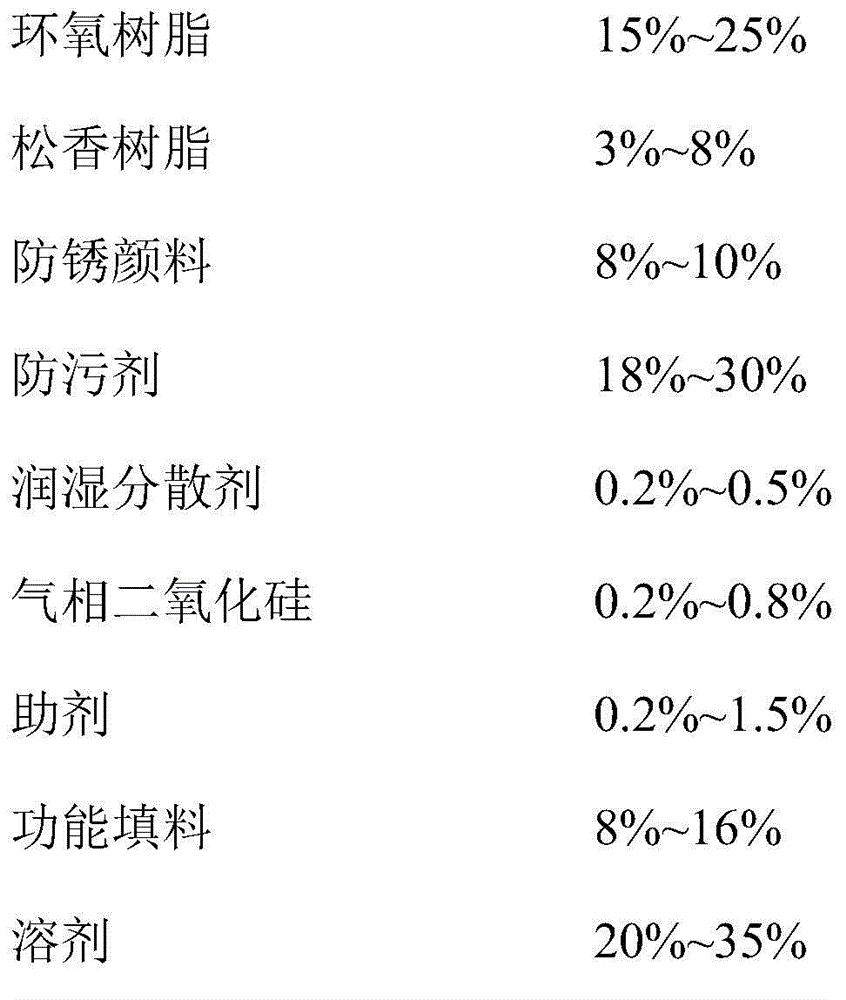

Contact type inshore fishing boat anti-fouling paint and preparation method thereof

InactiveCN104693970AGood antifouling performanceGood anti-corrosion performanceAntifouling/underwater paintsRosin coatingsSolventPesticide

The invention discloses contact type inshore fishing boat anti-fouling paint and a preparation method thereof. The contact type inshore fishing boat anti-fouling paint comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 10%-30% of epoxy resin, 0-15% of rosin resin, 3%-15% of anti-rusting pigments, 15%-25% of an anti-fouling agent, 0.2%-1.0% of fumed silica, 0.2%-1.5% of an aid, 5%-30% of functional pigments and 15%-40% of a solvent; the component B comprises the following components in percentage by weight: 60%-100% of an epoxy curing agent and 0-40% of a solvent. The contact type inshore fishing boat anti-fouling paint has the advantages that the anti-fouling paint does not contain internationally forbidden pesticide poisons such as organic tributyltin (TBT) and dichlorodiphenyltrichloroethane (DDT); the manufacturing and construction environments are relatively good, the poisons and resin emitted to ocean are reduced; the contact type inshore fishing boat anti-fouling paint is environmentally friendly and is non-toxic to the environment.

Owner:上海华谊精细化工有限公司上海开林造漆厂

Clamping device for injection-molding machine

InactiveUS6893246B2Increase speedWithout wasting valuable timeConfectionerySweetmeatsInjection molding machineHigh pressure

A clamping device for injection-molding machine includes a high-speed screw rod unit having a nut element screwed thereto and a movable mold holder connected to a front end thereof, a clamping screw rod unit screwed to a rear end of the nut element and connected to a transmission assembly, a pre-pressing unit adjustably tightened to the clamping screw rod unit for the latter to generate a pre-pressure against the nut element, and a braking unit adapted to brake the nut element. When the nut element is not braked, the high-speed screw rod unit is driven by the transmission assembly to move forward at high speed for closing mold. And, when the nut element is braked and the clamping screw rod unit is driven by the transmission assembly to rotate relative to the nut element, the nut element is linearly pushed forward to generate a high-pressure clamping force during closing mold.

Owner:IND TECH RES INST

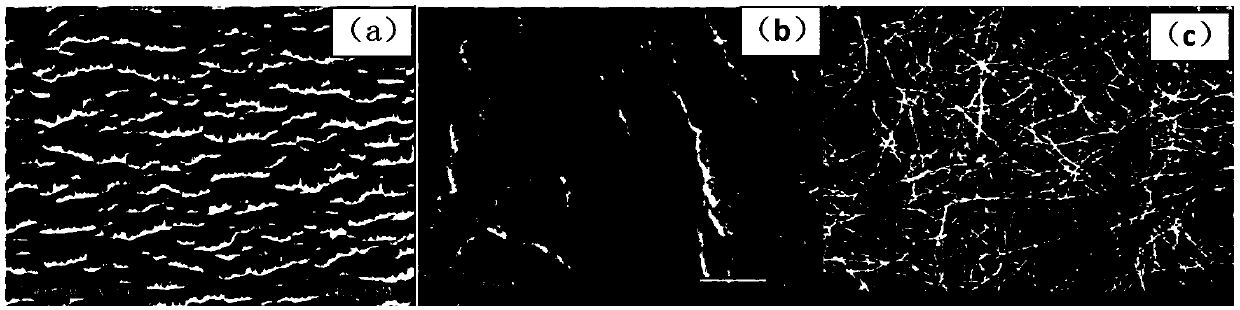

Battery diaphragm and preparation method thereof

InactiveCN109524598AIncrease specific energyGood cycle performanceCell component detailsCharge and dischargeLithium electrode

The invention belongs to the technical field of lithium ion batteries and particularly relates to a battery diaphragm and a preparation method thereof. The preparation method of the battery diaphragmcomprises the steps of putting battery diaphragm fiber filaments into a textile machine, and weaving by virtue of the textile machine, so as to obtain the battery diaphragm, wherein the battery diaphragm fiber filaments are electronically insulated battery diaphragm fiber filaments which do not react with electrolyte, and the diameters of the battery diaphragm fiber filaments are 5-40 microns. Theinvention aims at providing the battery diaphragm with uniform small pore diameter and high porosity, so that dendritic crystals are produced in the charging and discharging processes of the battery,and the cycle performance of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

Component Having Enhanced Efficiency and Method for Production Thereof

ActiveUS20200119228A1Improve efficiencyBetter energizedSemiconductor devicesCharge carrierSemiconductor

A component having an enhanced efficiency and a method for producing a component are disclosed. In an embodiment, a component includes a semiconductor layer sequence comprising a p-conducting semiconductor layer, an n-conducting semiconductor layer and an active zone located therebetween, wherein the active zone comprises recesses on a side of the p-conducting semiconductor layer, each recess having facets extending obliquely to a main surface of the active zone, and wherein the p-conducting semiconductor layer extends into the recesses, and a barrier structure, wherein the active zone is arranged between the barrier structure and the n-conducting semiconductor layer so that an injection of positively charged charge carriers into the active zone via the main surface is hindered in a targeted manner so that an injection of positively charged charge carriers into the active zone via the facets is promoted.

Owner:OSRAM OLED

Methods for producing fish with high lipid content

InactiveUS20110239318A1Increase contentInhibition of maturationPeptide/protein ingredientsDepsipeptidesLipid formationWild type

The invention provides methods for producing biofuel from algae, that use fish which have a high capacity of producing and / or accumulating lipids to harvest algae from an algal culture. The invention also provides methods for growing fish that result in a high lipid content. The invention also provides methods for creating fish that have a high capacity of producing and accumulating lipids by breeding and / or recombinant DNA techniques. Also included are transgenic fish that have a higher lipid content than wild-type fish.

Owner:LIVEFUELS

Method for selective breeding of fast-growing strain of lined seahorse

InactiveUS20170105392A1Quality improvementHigh yieldClimate change adaptationPisciculture and aquariaVitalityBase population

An method for selective breeding of a fast-growing strain of lined seahorse, including: (1) selecting high-quality lined seahorse parents as a base population for selective breeding; (2) performing prenatal intensified breeding; (3) performing pairing and mating, and rearing the juveniles thereof; (4) performing selective breeding in three junctures with different selection proportions; (5) pairing the saved adult lined seahorses, wherein those with low vitality, having injuries on the body surface, or having a dysplastic brood pouch or gonad are culled, and a selection proportion of 10% for every generation is maintained thereafter; (6) repeating steps (2) through (5) for at least four times to obtain a high-quality strain of lined seahorse with improved weight and body length and stable growth. The method can be used for selective breeding of a new strain with high quality and high yield.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

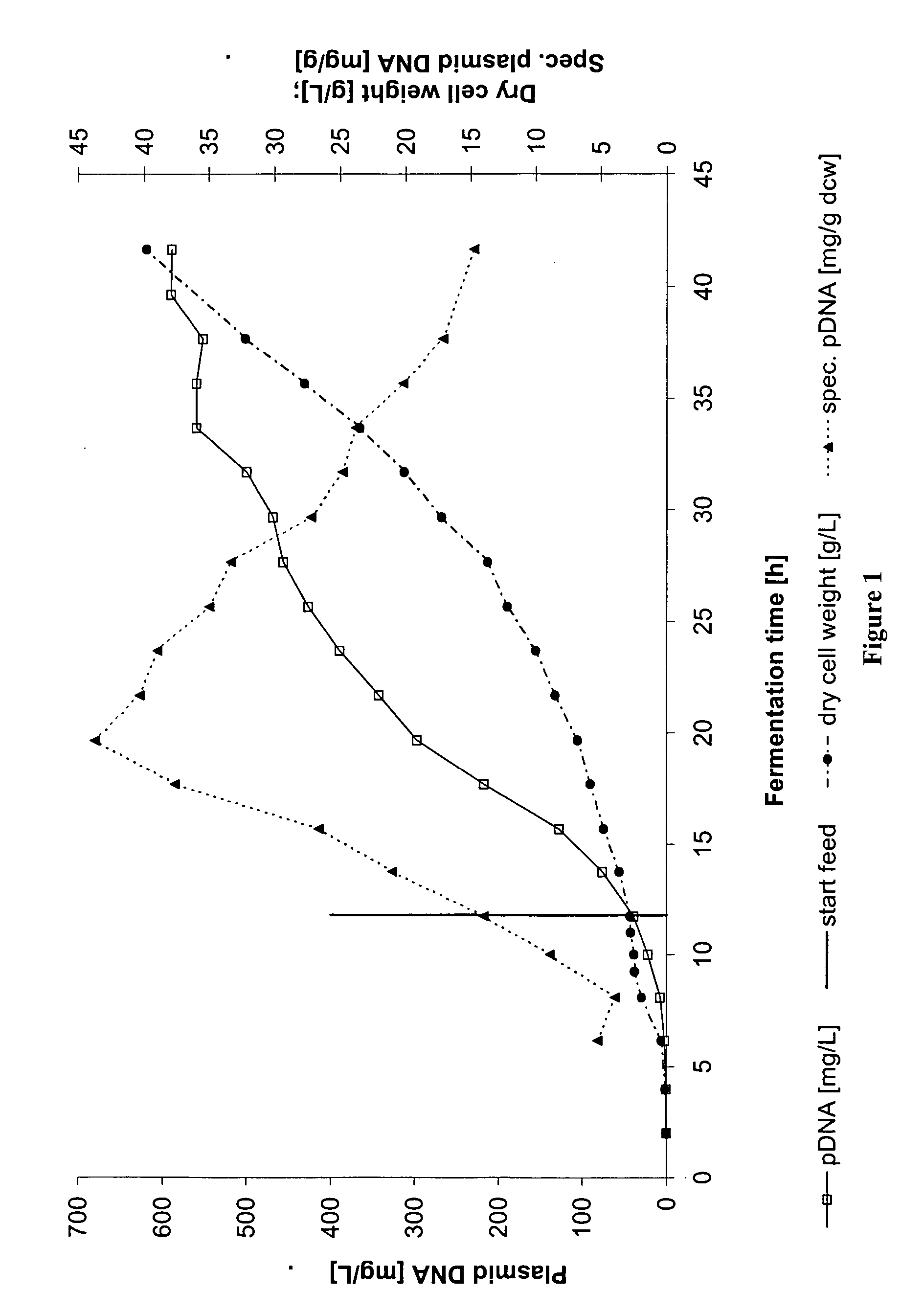

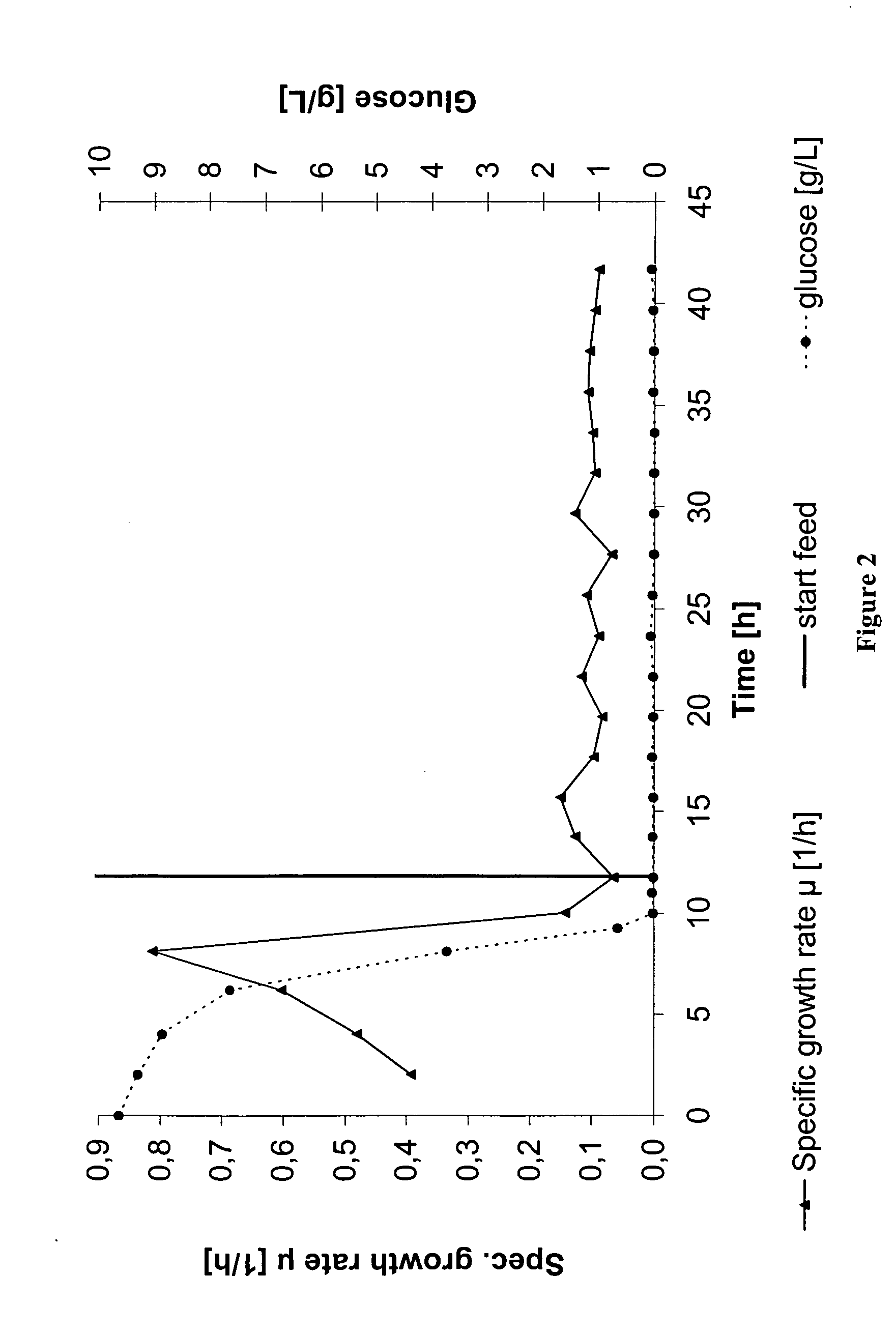

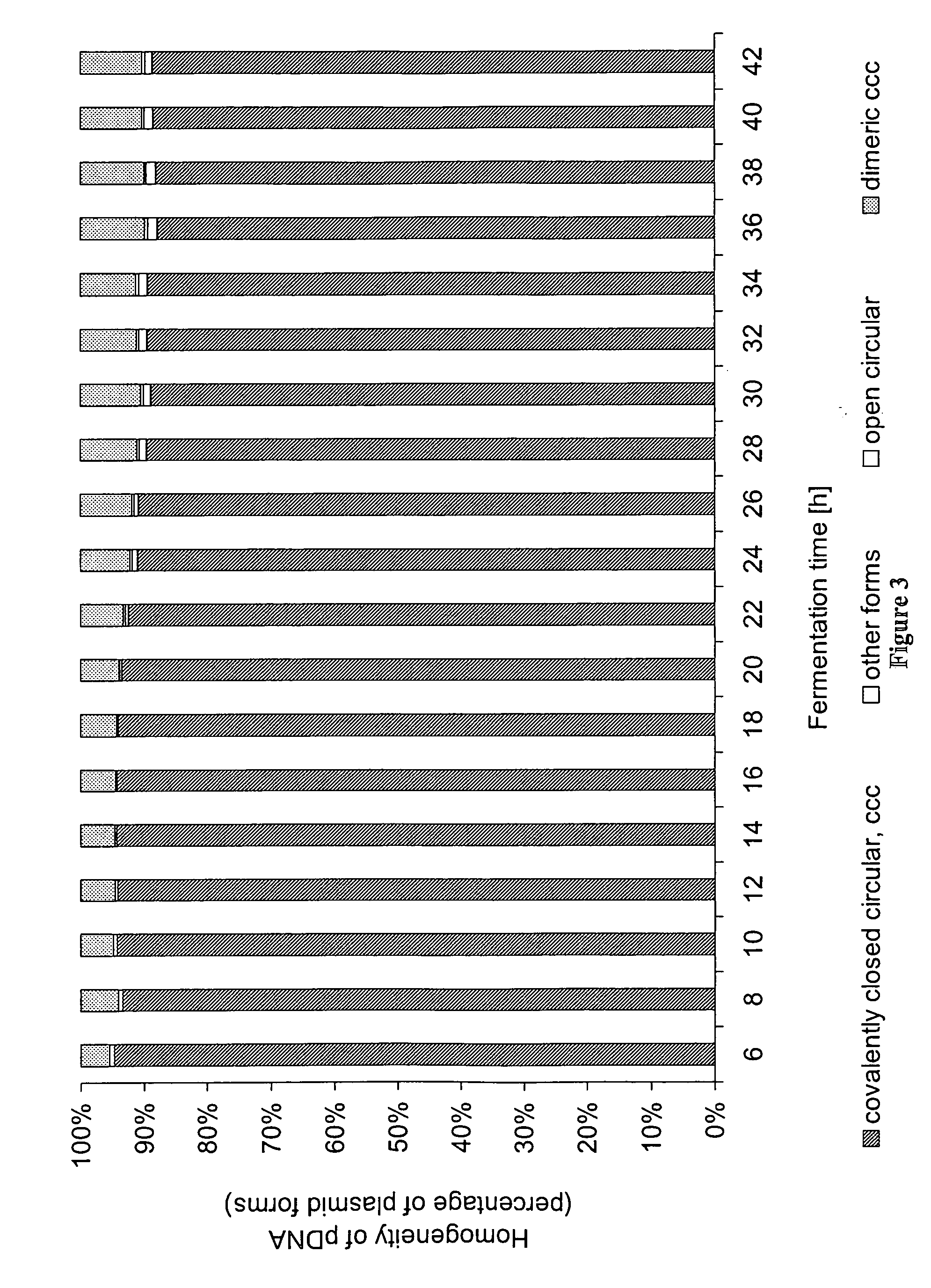

Fed-batch fermentation process and culture medium for the production of plasmid DNA in E. coli on a manufacturing scale

InactiveUS20050233421A1Enhance replicationIncreased yieldBacteriaFermentationCulture mediumsBiotechnology

A process for producing plasmid DNA E. coli cells comprises a pre-culture and fed-batch process. The culture media of the batch phase and the culture medium added during the feeding phase are chemically defined. The culture medium of the feeding phase contains a growth-limiting substrate and is added, for at least a fraction of the feeding phase, at a feeding rate that follows a pre-defined exponential function, thereby controlling the specific growth rate at a pre-defined value. The process results in high yield and homogeneity of plasmid DNA.

Owner:BOEHRINGER INGELHEIM RCV GMBH & CO KG

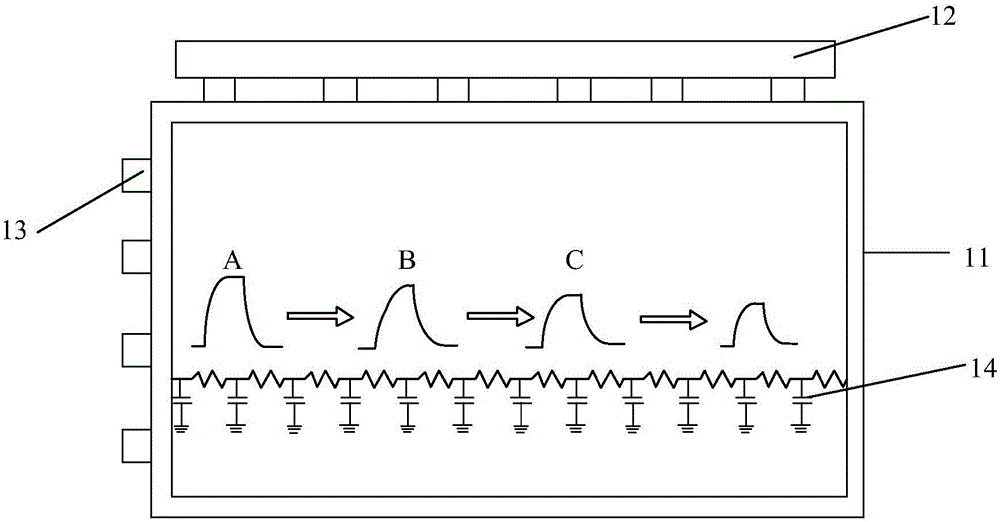

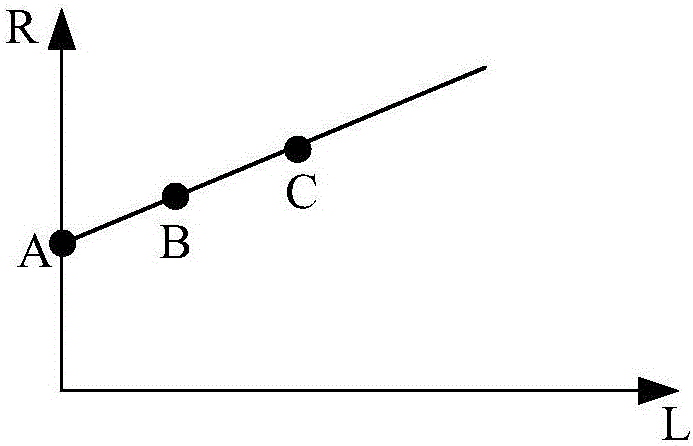

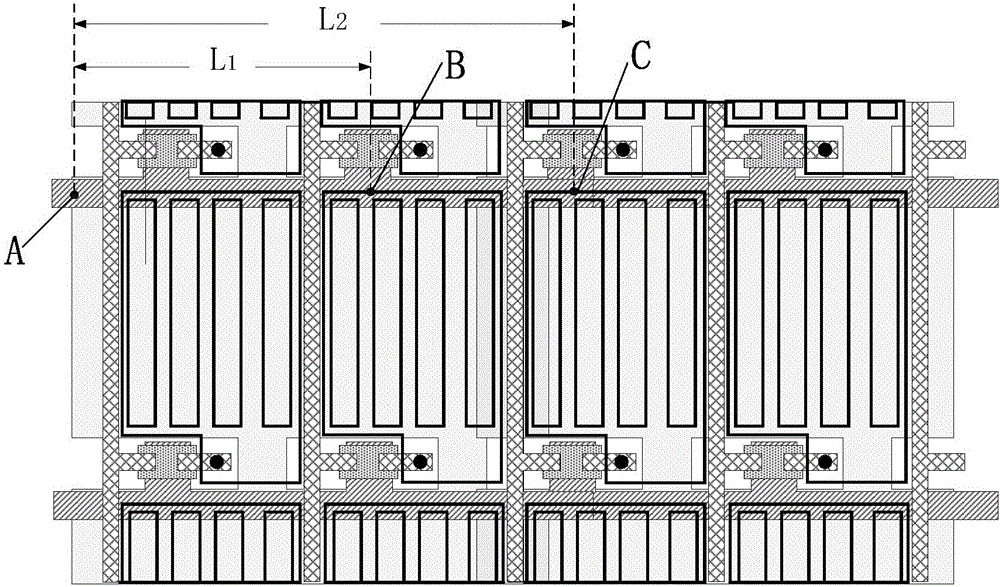

Array substrate and preparation method thereof, display device

InactiveCN106783890AThe growth rate of the resistance decreasesImprovement in reductionSolid-state devicesSemiconductor/solid-state device manufacturingResistance capacitanceDisplay device

The invention provides an array substrate and a preparation method of the array substrate, and a display device, and relates to the technical field of display. The invention can reduce the influence of resistance-capacitance delay of a grid line. The array substrate comprises the grid line arranged on the substrate, wherein one end of the grid line is a scanning signal input end, and moves along the direction far from the input end of the scanning signal; area of the cross section of the grid line is gradually increased; or both ends of the grid line are scanning signal input ends, and moves along the middle position of the input end of the scanning signal and the grid line; the area of the cross section of the grid line is gradually increased, wherein the cross section of the grid line is the section face on the grid line perpendicular to the extension direction of the grid line.

Owner:BOE TECH GRP CO LTD +1

Pickling method of cabbages

InactiveCN104381930AIncrease the rate of acidificationPromote early emergenceFood preparationMathematical CalculusNitrite

The invention relates to the field of pickling of foods and particularly relates to a pickling method of cabbages. The pickling method comprises the following steps: carrying out hot blanching, carrying out early-stage fermentation, carrying out middle-stage fermentation and carrying out post-stage fermentation. The cabbages pickled by adopting the raw materials and the method provided by the invention is unique in taste, short in pickling time and low in nitrite content; and the potential safety hazard to consumers, caused by the fact that calcium oxalate is crystallized and deposited in a urinary system to form calculus, is not caused.

Owner:南宁市绿宝食品有限公司

Interplanting method for plum trees and loquat trees

InactiveCN105010066AReduce management costsSimple structureCultivating equipmentsFruit treeLoquat Tree

The invention relates to the technology field of fruit tree plantation, especially an interplanting method for plum trees and loquat trees. The interplanting method comprises: reasonable planting distribution for plum trees and loquat trees; reasonable management of plum trees and loquat trees, especially fertilization control after planting to improve the soil structure; and annual fertilization treatment contributing to little weeds in interplanting field, loose soil and sufficient nutrient for energy requirement for plum trees and loquat trees. By use of the interplanting method, quality and taste of plums and loquats are improved. The method is labor-saving and cost-saving in tree management such as weeding and loosing the soil and increases profit for fruit growers.

Owner:ZUNYI HONGCHENG AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com