Method for manufacturing large-size low-defect silicon carbide single crystal

A silicon carbide single crystal and manufacturing method technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as large pressure control range, difficult growth speed, and aggravated dislocation increase rate, so as to avoid Effects of secondary damage, cost reduction, and avoidance of seed crystal ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] After charging the furnace according to the normal sublimation recrystallization method, under the vacuum state, when the temperature reaches 1580°C, feed SiH at a flow rate of 50 mL / min into the crucible through the graphite pipeline. 4 The gas stays at this temperature for 20 minutes;

[0053] Subsequently, the vacuum was stopped, Ar gas was introduced into the furnace body, the pressure was controlled at 5Kpa, and the C 3 h 8 Gas, perform low-speed homoepitaxial growth, and keep it for 10 hours;

[0054] Then, fill the Ar gas quickly to 30,000 Pa and stop filling the C 3 h 8 . After that, raise the temperature to 2200°C and lower the Ar gas pressure to 2000Pa to carry out normal SiC single crystal growth.

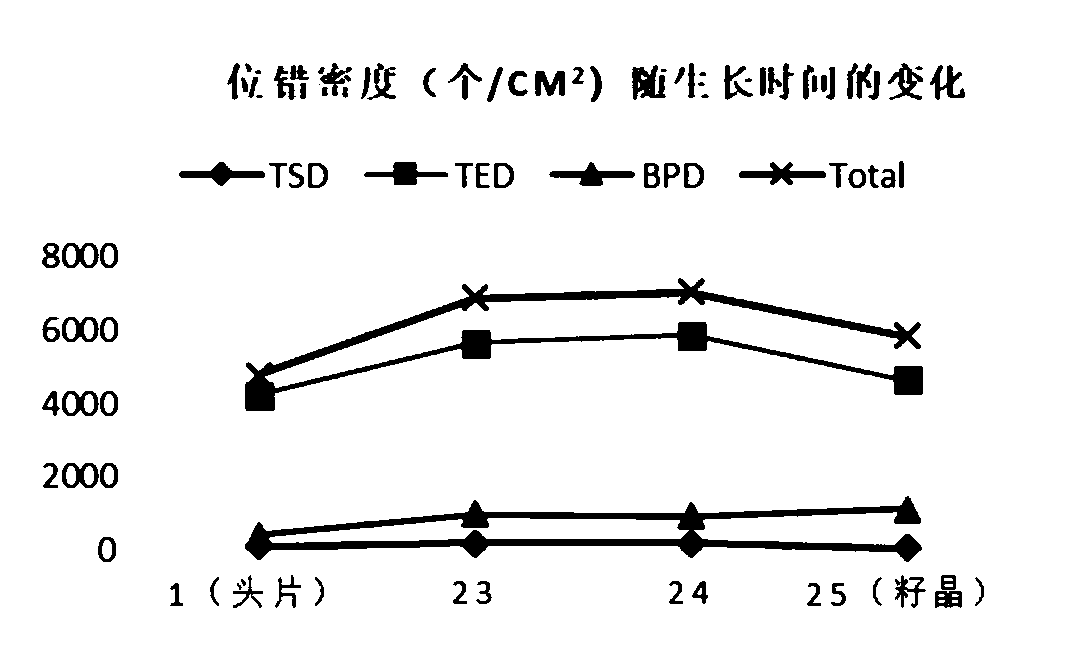

[0055] For silicon carbide single crystal ingots grown by this process, the dislocation density of the initial extended wafer is 1.1 times that of the seed crystal, and the dislocation density of the wafer at the end of growth is 5200 / cm 2 . The SiC single ...

Embodiment 2

[0057] After charging the furnace according to the normal sublimation recrystallization method, under the vacuum state, when the temperature reaches 1640°C, stay at this temperature for 15 minutes;

[0058] Subsequently, the vacuum was stopped, Ar gas was introduced into the furnace body, the pressure was controlled at 4KPa, and the C 3 h 8 Gas, perform low-speed homoepitaxial growth, and keep it for 8 h;

[0059] Then, fill the Ar gas quickly to 30,000 Pa and stop filling the C 3 h 8 . Afterwards, the temperature was raised to 2200° C., and the Ar gas pressure was lowered to 2000 Pa to perform normal SiC single crystal growth.

[0060] For silicon carbide single crystal ingots grown by this process, the dislocation density of the extended wafer at the initial stage is 1.2 times the dislocation density of the seed crystal, and the dislocation density of the wafer at the end of growth is 4800 pieces / cm 2 . The SiC single crystal ingot grown with this embodiment changes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com