Battery diaphragm and preparation method thereof

A battery separator and electrolyte technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of reducing battery energy density, poor tensile mechanical properties, uneven current density distribution, etc., to improve energy density, The effect of high mechanical strength and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

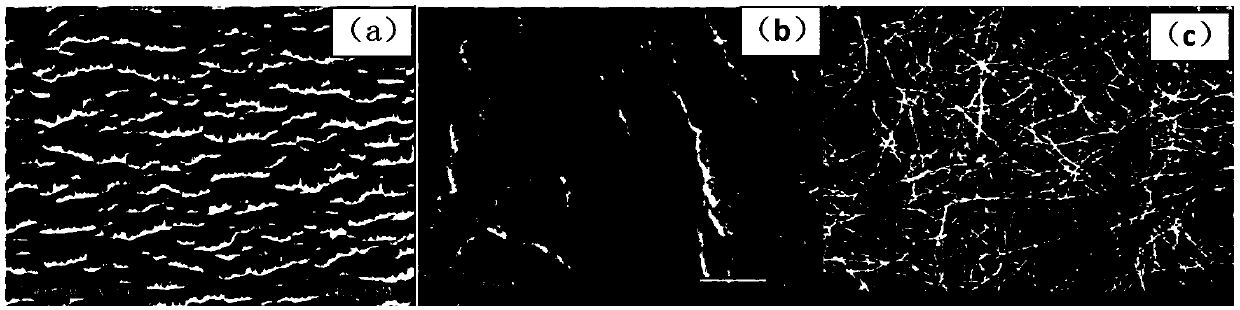

[0066] This embodiment provides the first battery separator, and the specific preparation method is as follows:

[0067] 1. Dry polyvinylidene fluoride (PVDF) at 80°C for 10 hours in a vacuum environment, then dissolve PVDF powder in N-methylpyrrolidone (NMP) solution to obtain transparent, uniform and stable PVDF / NMP The battery separator spinning solution, wherein the solid content of the battery separator spinning solution is 21 wt%.

[0068] 2. The prepared PVDF / NMP battery separator spinning solution is made into PVDF battery separator fiber by electrospinning. The injection needle is 12# (the inner diameter of the needle is 1.2mm), the spinning voltage is 13.5KV, the advancing speed of the metering pump is 0.065mm / min, the distance between the syringe needle and the receiving plate is 20cm, the spinning time is 0.5h, and the spinning temperature is 25°C. The air humidity is 45%, the carbon paper is bent and spread on the receiving roller, and the yarn is collected at a...

Embodiment 2

[0071] This embodiment provides the second battery separator, and the specific preparation method is as follows:

[0072] 1. Polyetherimide (PEI) was dried at 80°C for 6 hours in a vacuum environment, and then the PEI particles were dissolved in N-methylpyrrolidone (NMP) solution at 90°C to obtain transparent, uniform and stable PEI battery separator spinning solution, wherein, the solid content of PEI battery separator spinning solution is 25wt%.

[0073] 2. The prepared transparent PEI battery separator spinning solution is prepared into PEI battery separator fiber filaments by an electrospinning method. The injection needle adopts 12# (the inner diameter of the needle is 1.2mm), the spinning voltage is 14KV, the advancing speed of the metering pump is 0.05mm / min, the distance between the syringe needle and the receiving plate is 20cm, the spinning time is 0.5h, and the spinning temperature is 25°C. The air humidity is 45%, the carbon paper is bent and spread on the receiv...

Embodiment 3

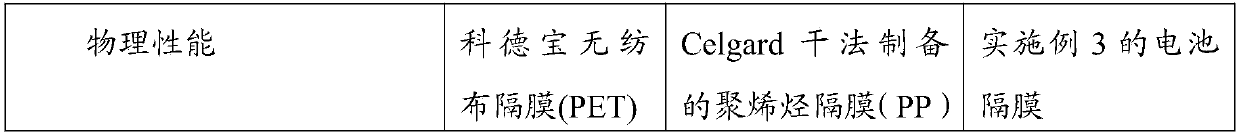

[0076] This embodiment provides the third battery separator, the specific preparation method is as follows:

[0077] 1. Dry polypropylene (PP) at 80°C for 6 hours in a vacuum environment, and then dissolve PP particles in N-methylpyrrolidone (NMP) solution at 90°C to obtain a transparent, uniform and stable PP battery Separator spinning solution, wherein the solid content of the PEI battery separator spinning solution is 25wt%.

[0078] 2. The prepared transparent PP battery separator spinning solution is made into PP battery separator fiber by electrospinning. The injection needle adopts 12# (the inner diameter of the needle is 1.2mm), the spinning voltage is 14KV, the advancing speed of the metering pump is 0.055mm / min, the distance between the syringe needle and the receiving plate is 20cm, the spinning time is 0.5h, and the spinning temperature is 25°C. The air humidity is 45%, the carbon paper is bent and spread on the receiving roller, and the yarn is collected at a lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com