Method for manufacturing lead-carbon ultracapacitor battery cathode

A battery negative electrode and supercapacitor technology, which is applied in the direction of electrode manufacturing, circuits, electrical components, etc., can solve the problems of difficult energy storage systems such as wide application, poor high current acceptance capacity, narrow operating temperature range, etc., to achieve wide application prospects and improve Effect of discharge capacity and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

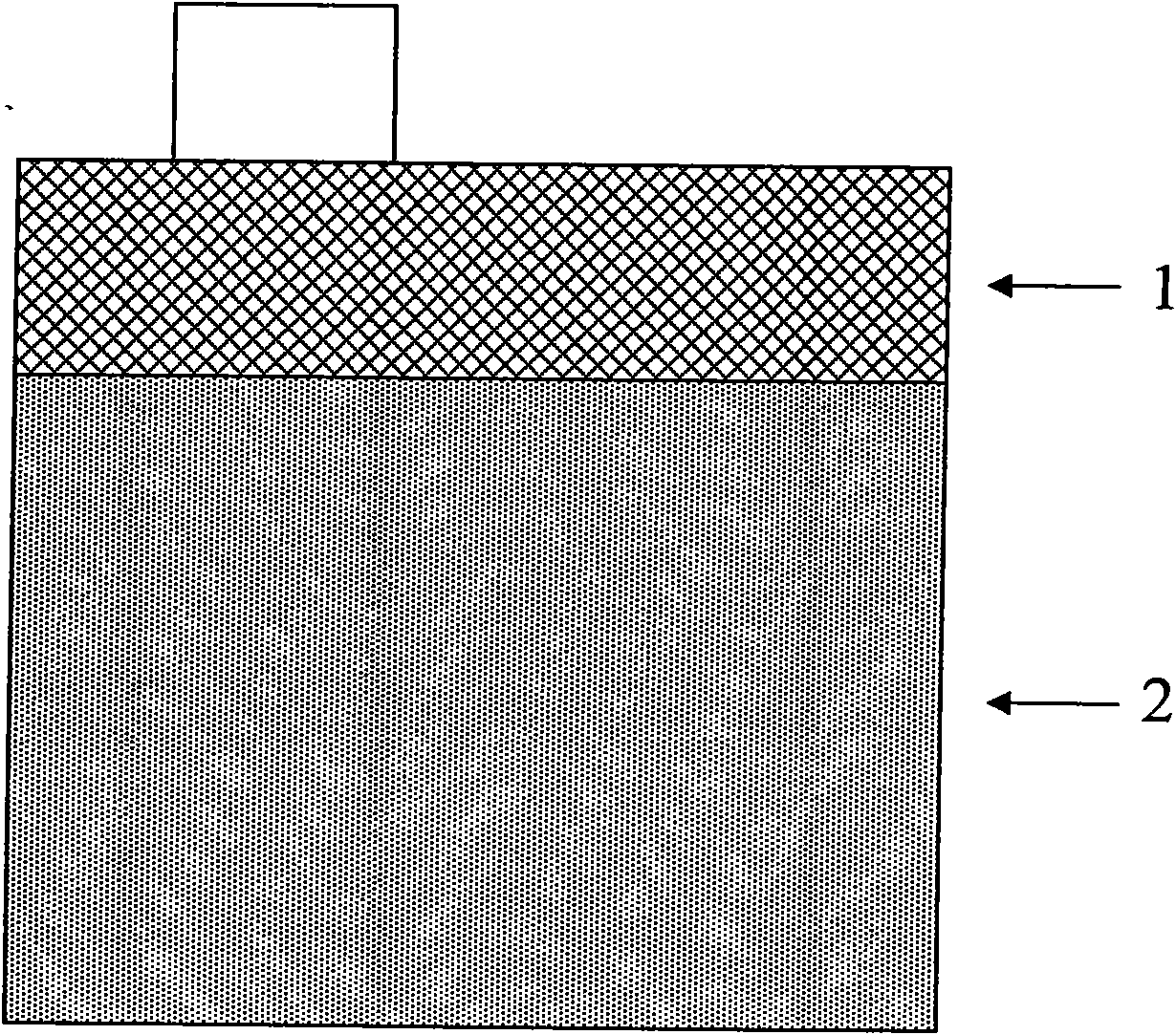

[0020] 20Kg of lead powder, 0.08Kg of short fibers, 0.5Kg of conductive carbon black, 0.28Kg of sodium lignosulfonate, and 0.4Kg of barium sulfate were uniformly dry-mixed, and then wet-mixed by adding deionized water with a raw material weight ratio of 8 to 10Kg. Then add 2Kg density of 1.4g / cm 3 sulfuric acid solution; these lead pastes are then double-coated on a 0.5 mm thick lead strip substrate near the lug area (see figure 1 ), curing and drying at 60°C to 70°C.

[0021] Then dry mix 70Kg activated carbon and 1.6Kg conductive carbon black evenly, add 1.5KgCMC, 3.5Kg LA132 dissolved in aqueous solution, and then apply the mixed paste on both sides outside the 0.5mm thick lead tape matrix lead paste area, and drying at a temperature of 50-80°C, the negative electrode of lead-carbon supercapacitor battery can be made.

[0022] The prepared lead-carbon supercapacitor battery negative electrode is coated with AGM separator U-shaped, and pure lead is used as the substrate to...

Embodiment 2

[0025] 30Kg of lead powder, 0.1Kg of short fibers, 0.55Kg of conductive carbon black, 0.3Kg of sodium lignosulfonate, and 0.5Kg of barium sulfate were uniformly dry-mixed, and then wet-mixed by adding deionized water with a raw material weight ratio of 10 to 12Kg. Then add 2.5Kg density of 1.4g / cm 3 sulfuric acid solution; these lead pastes are then double-coated on a 0.5 mm thick lead strip substrate near the lug area (see figure 1 ), curing and drying at 60°C to 70°C.

[0026] Then dry mix 60Kg activated carbon and 1.2Kg conductive carbon black evenly, add 1.2KgCMC and 3Kg PTFE dissolved in aqueous solution, and then apply the mixed paste on both sides of the 0.5mm thick lead tape matrix outside the lead paste , and dried at a temperature of 50-80°C, the negative electrode of the lead-carbon supercapacitor battery can be made.

[0027] The prepared lead-carbon supercapacitor battery negative electrode is coated with AGM separator U-shaped, and pure lead is used as the subs...

Embodiment 3

[0030] 40Kg of lead powder, 0.12Kg of short fibers, 0.6Kg of conductive carbon black, 0.3Kg of sodium lignosulfonate, and 0.5Kg of barium sulfate were uniformly dry-mixed, and then wet-mixed by adding deionized water with a raw material weight ratio of 10 to 12Kg. Then add 3.2Kg density of 1.4g / cm 3 sulfuric acid solution; these lead pastes are then double-coated on a 0.5 mm thick lead strip substrate near the lug area (see figure 1 ), curing and drying at 60°C to 70°C.

[0031] Then dry mix 50Kg of activated carbon and 1.0Kg of conductive carbon black evenly, add an aqueous solution dissolved in 1.0Kg of CMC and 2.5Kg of PTFE, and then apply the mixed paste on both sides of the 0.5mm thick lead tape matrix lead paste area, and drying at a temperature of 50-80°C, the negative electrode of lead-carbon supercapacitor battery can be made.

[0032] The prepared lead-carbon supercapacitor battery negative electrode is coated with AGM separator U-shaped, and pure lead is used as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com