Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205results about How to "Fine grain structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High purity tantalum, products containing the same, and methods of making the same

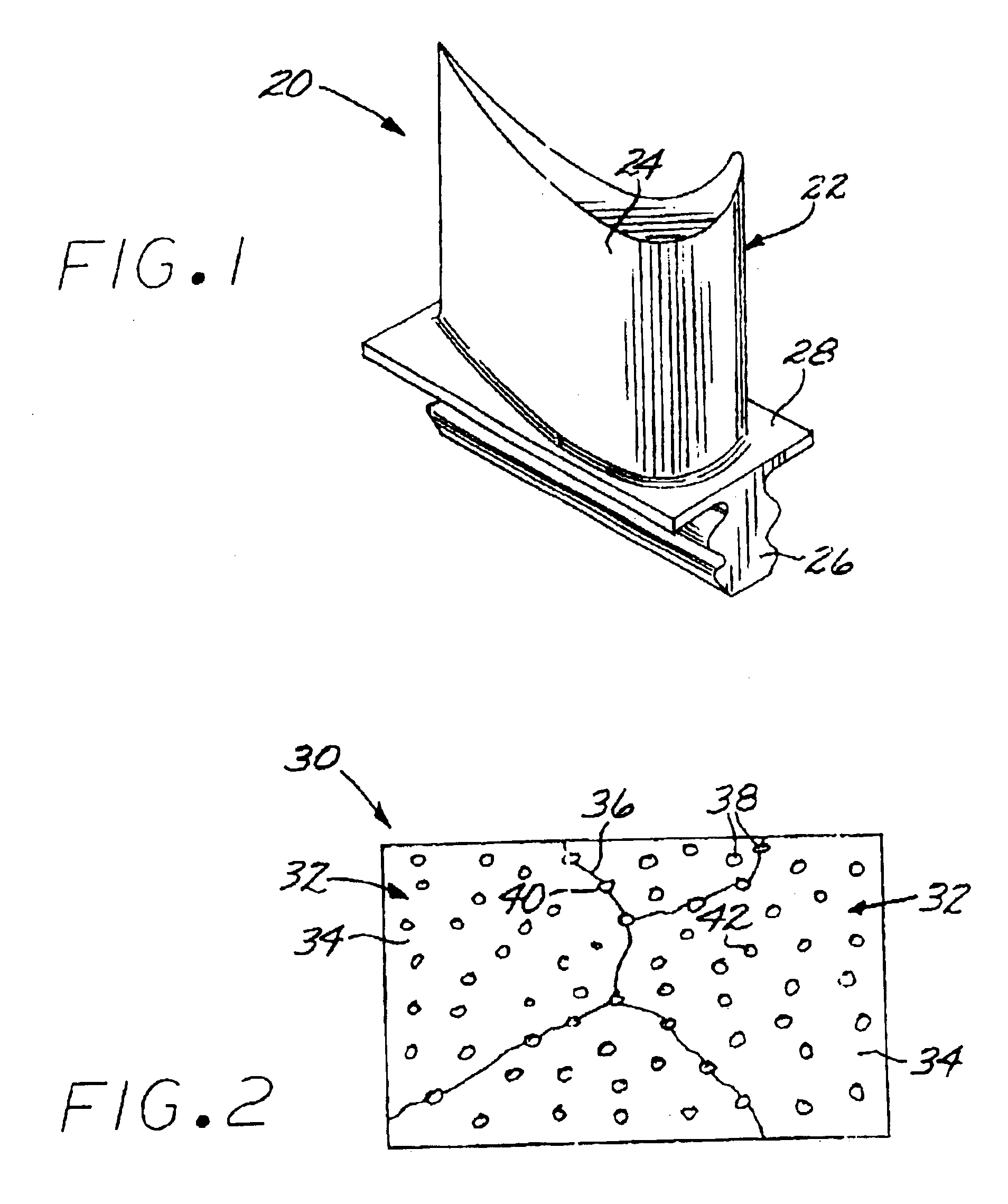

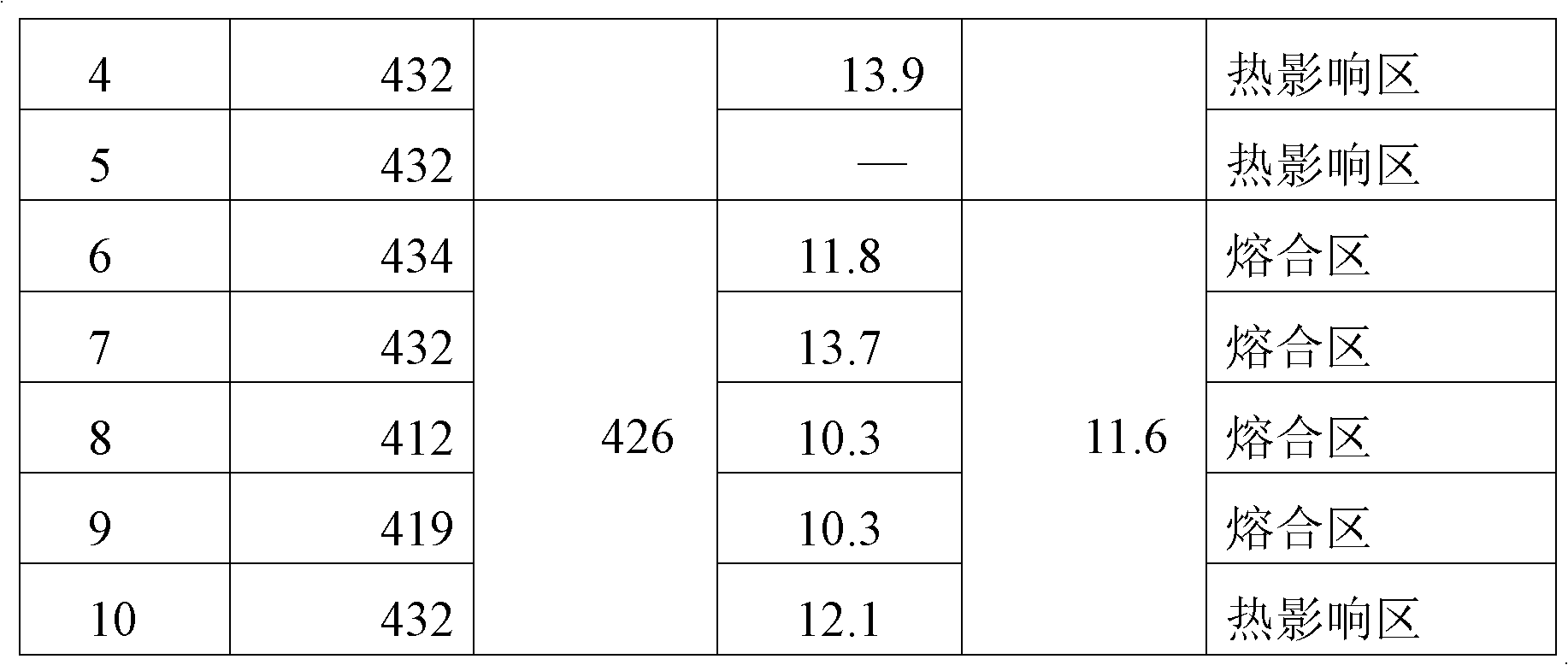

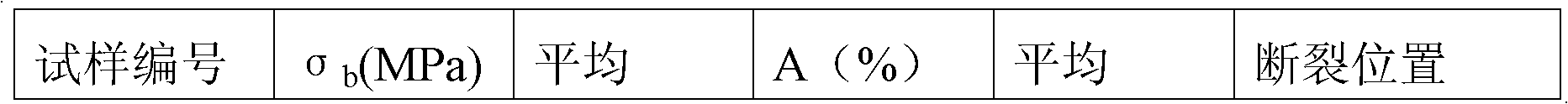

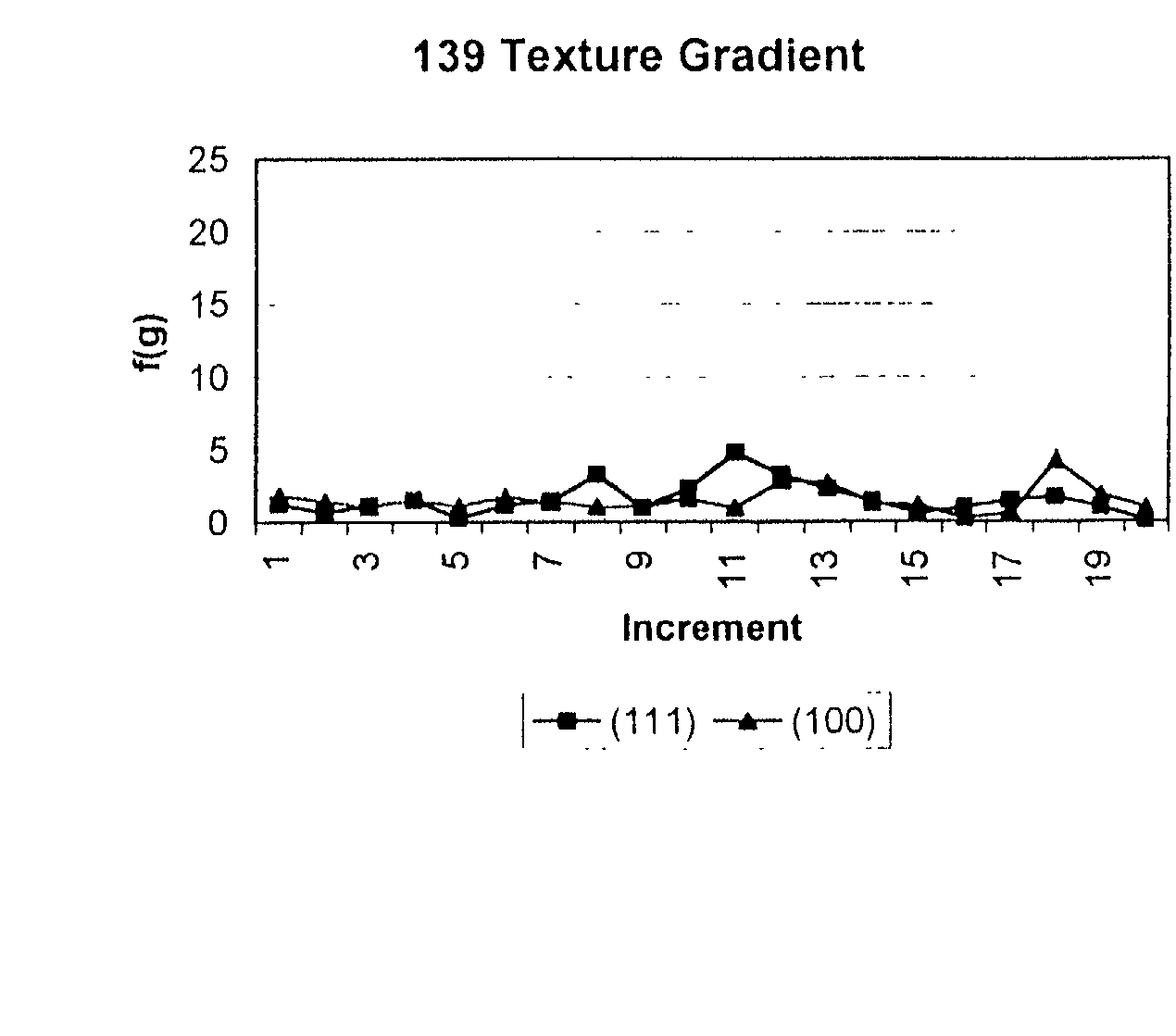

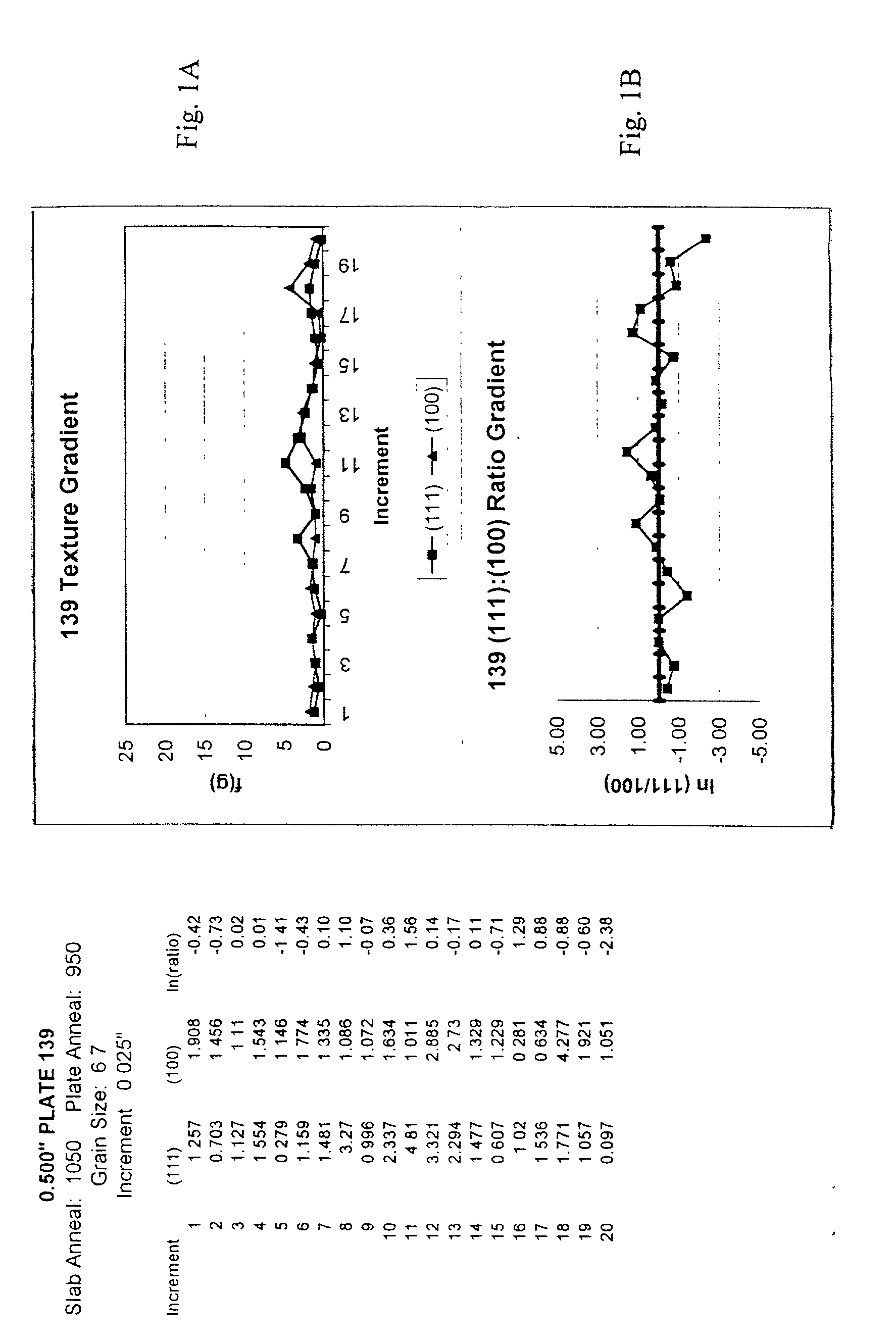

InactiveUS6348113B1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingMetallic materialsUltimate tensile strength

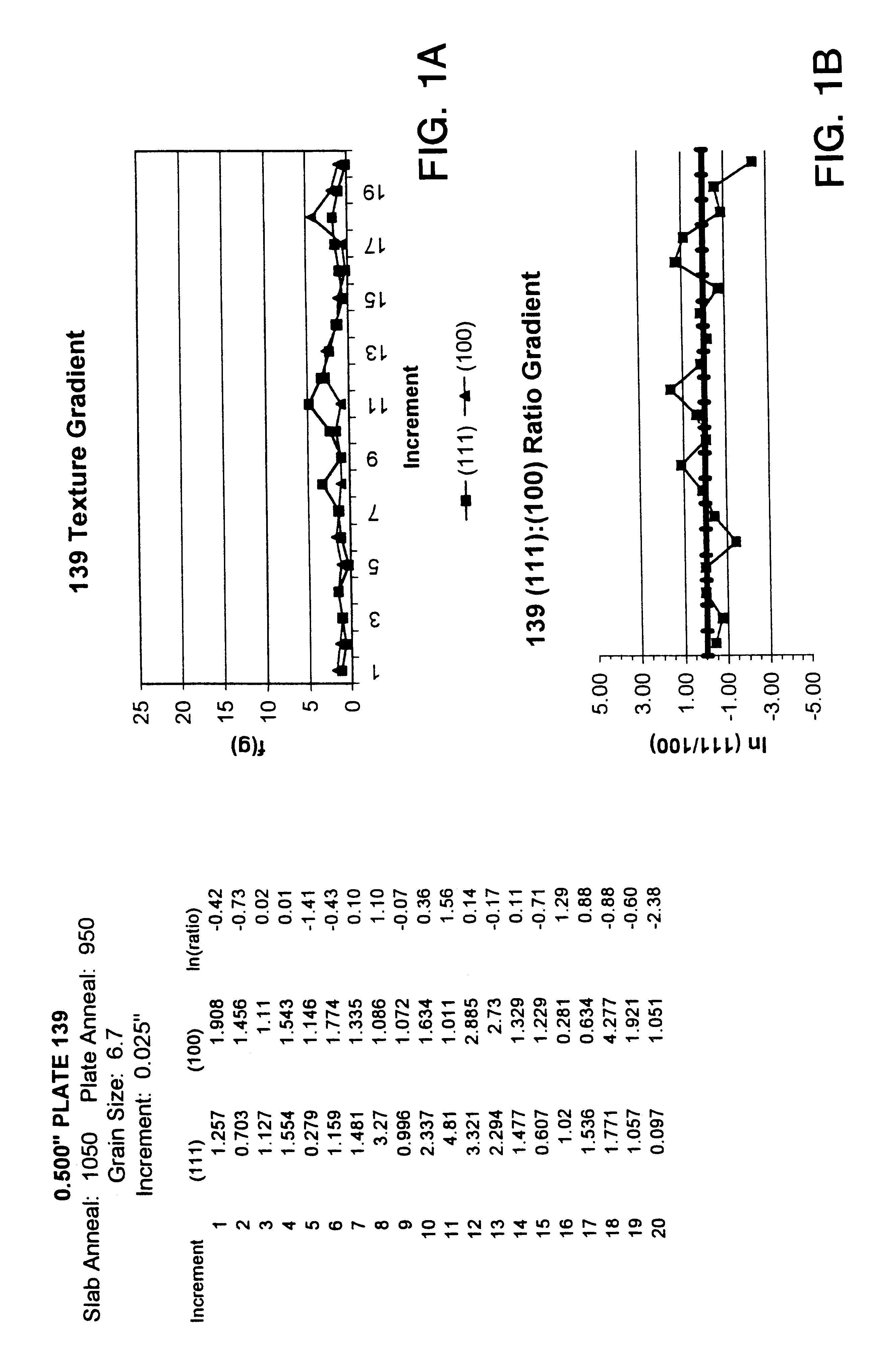

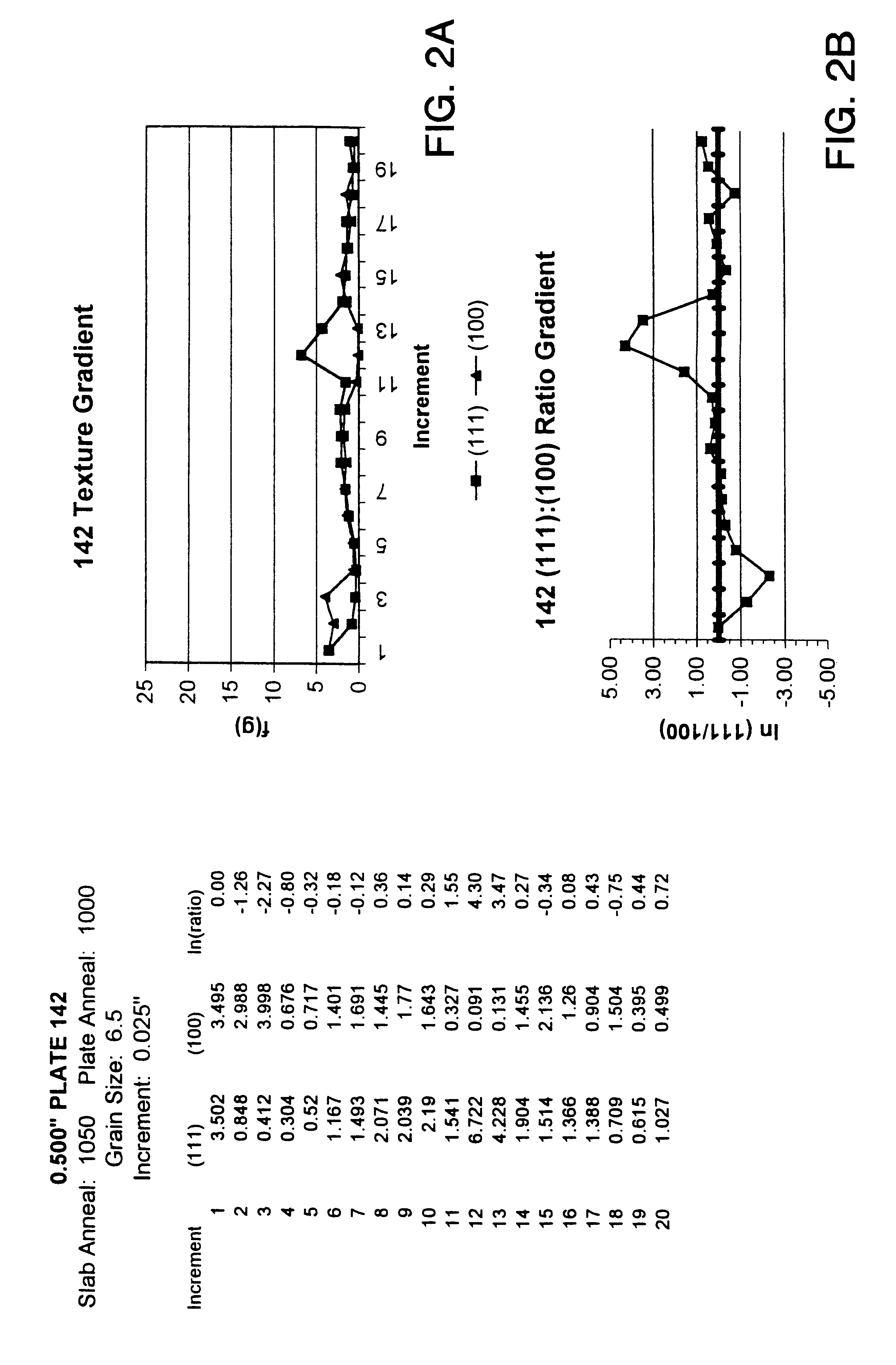

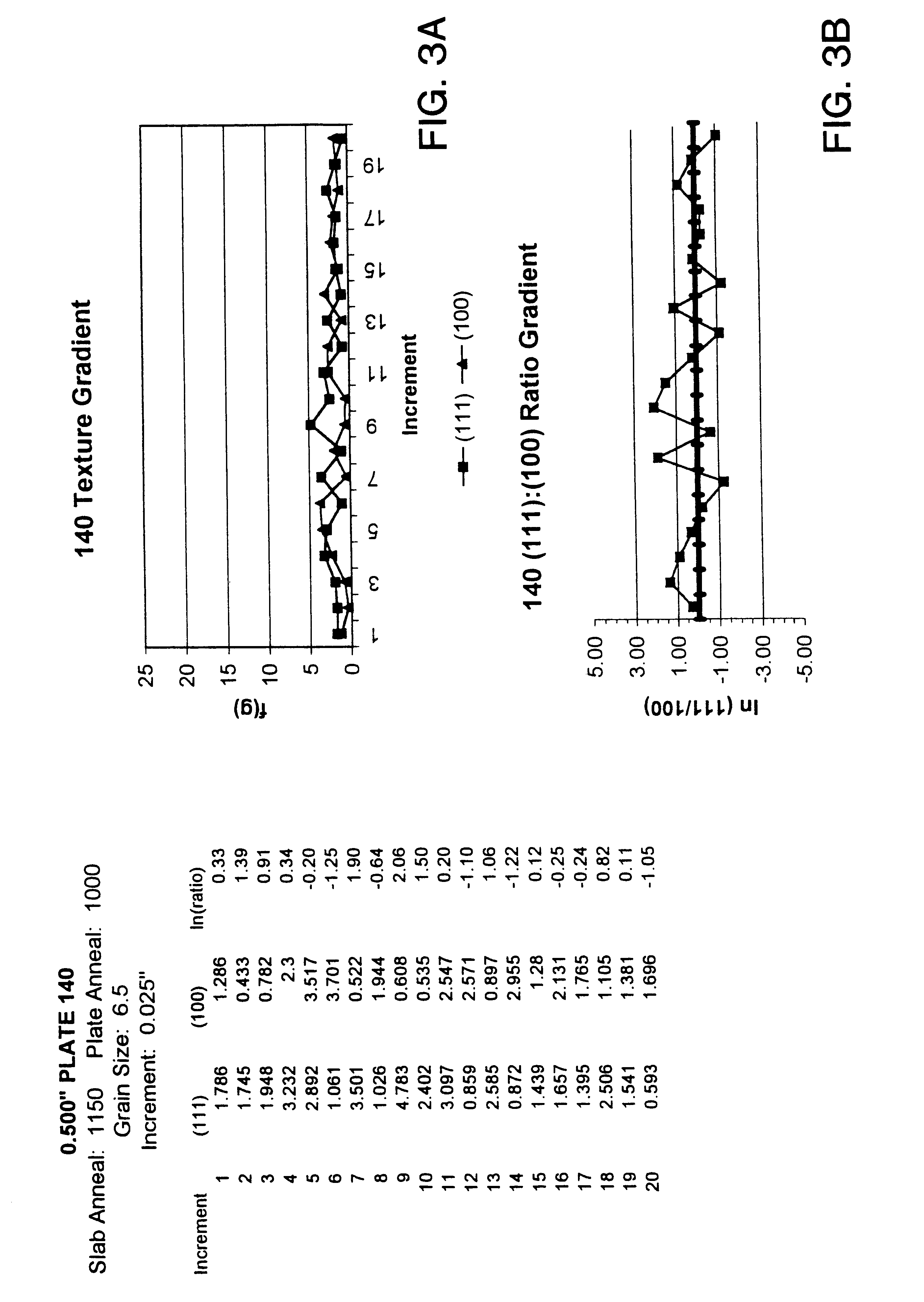

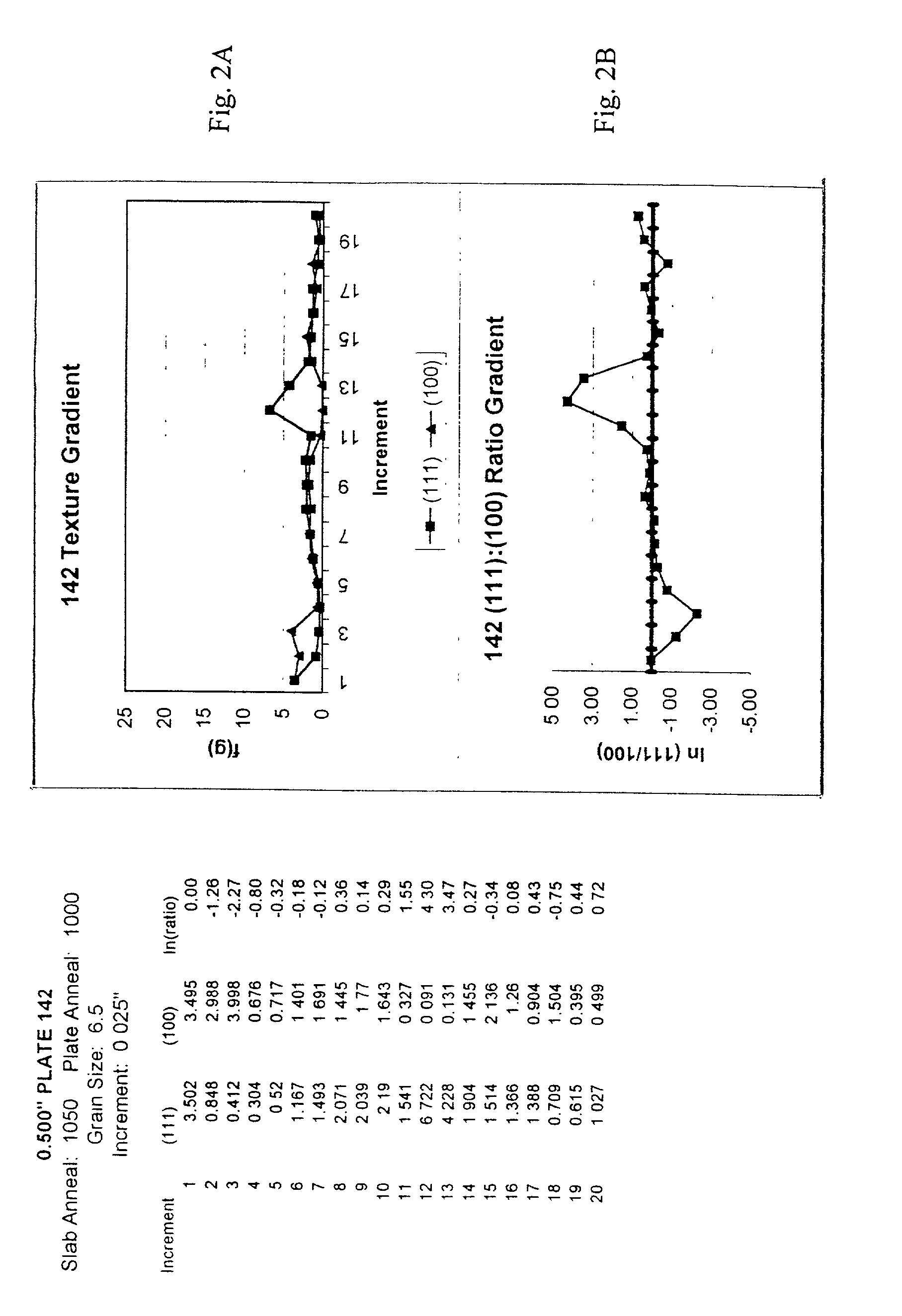

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995% and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

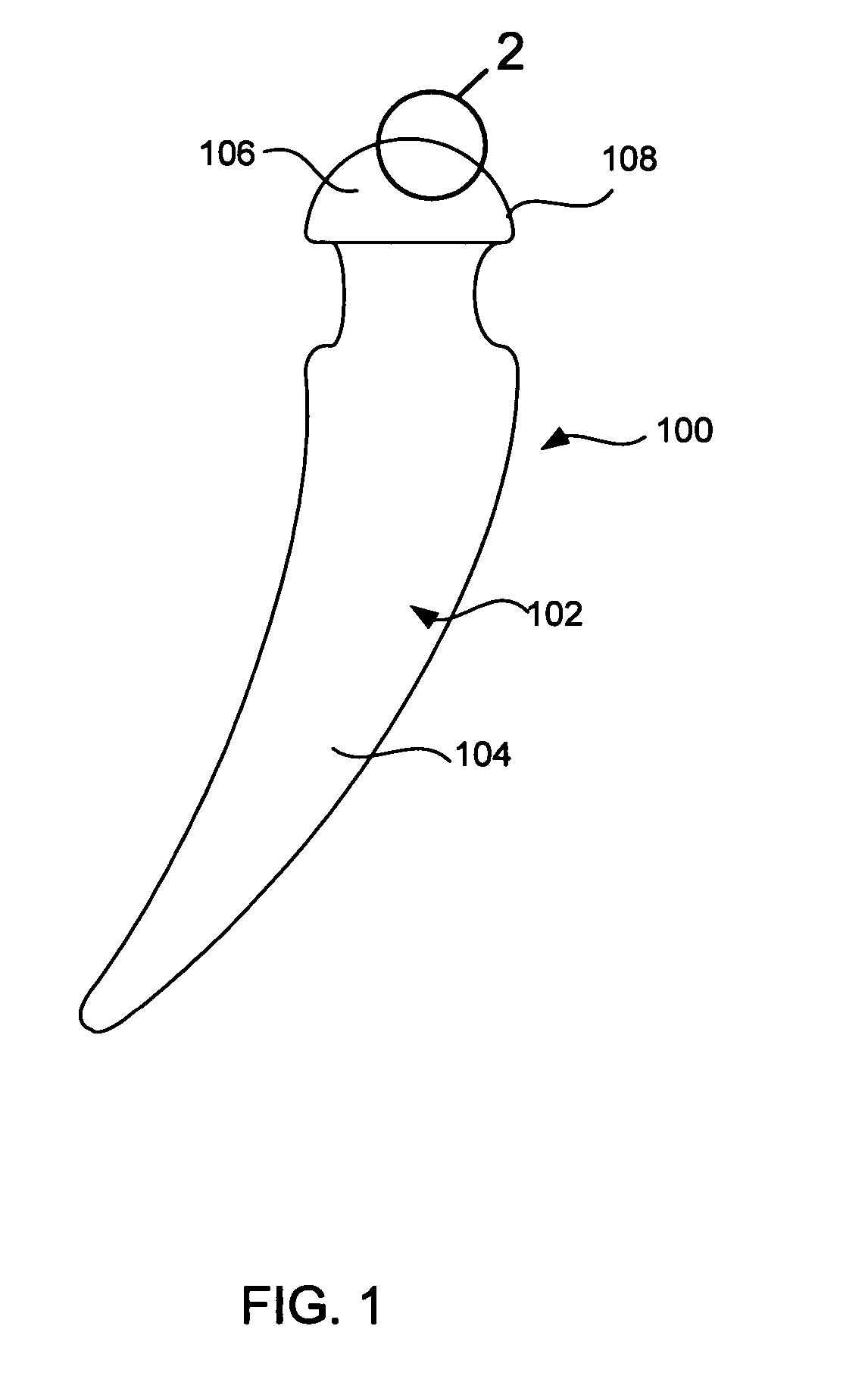

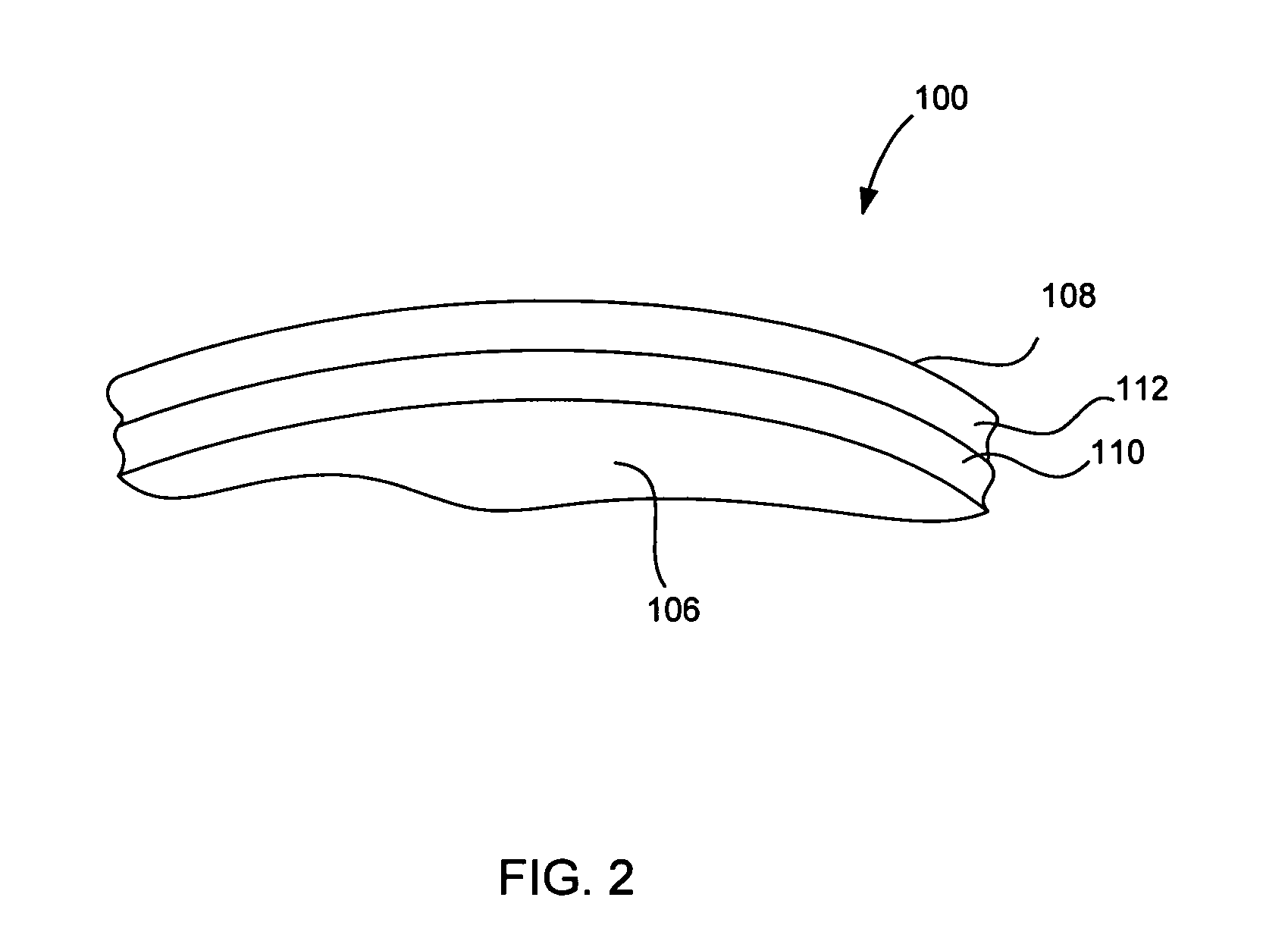

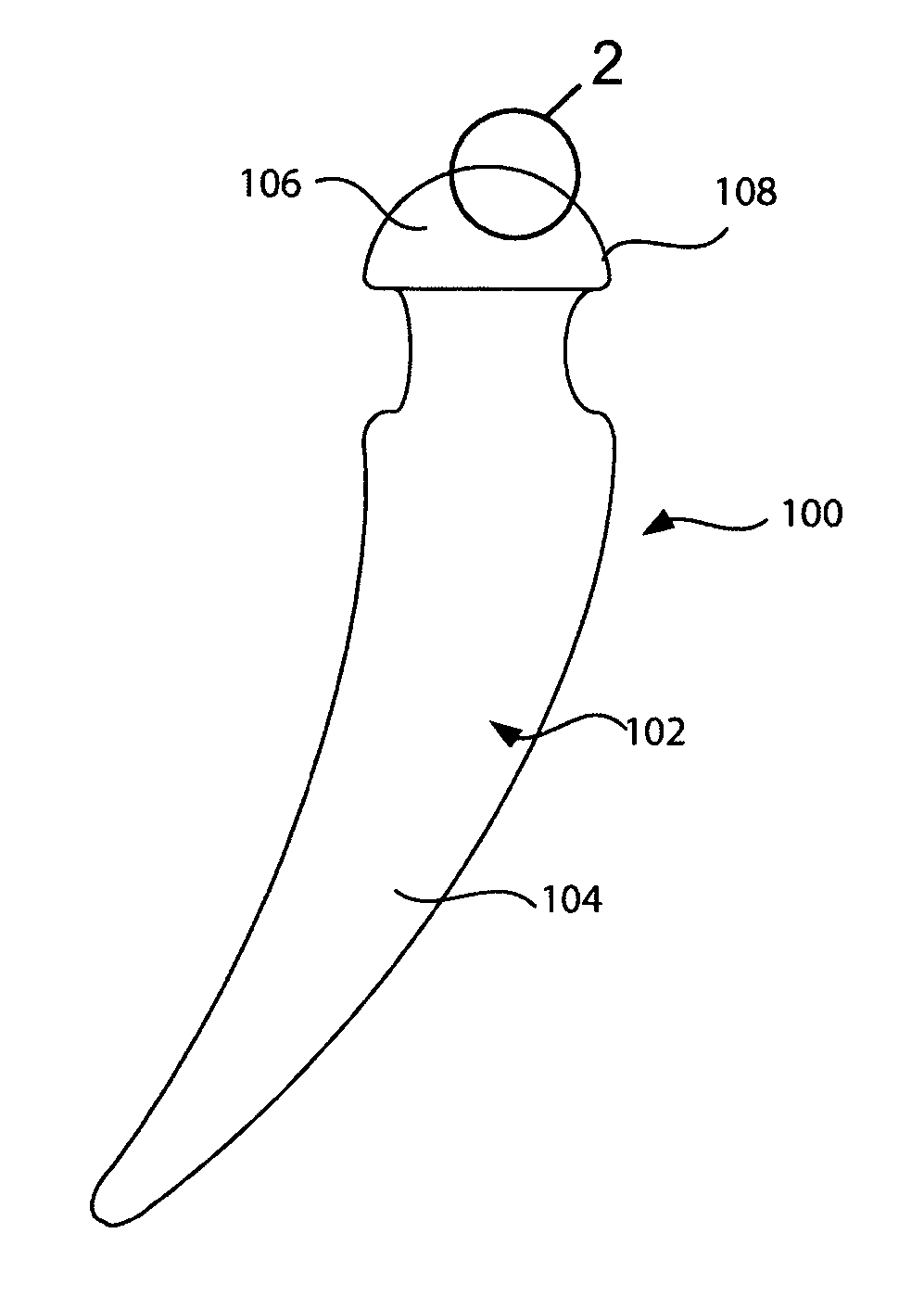

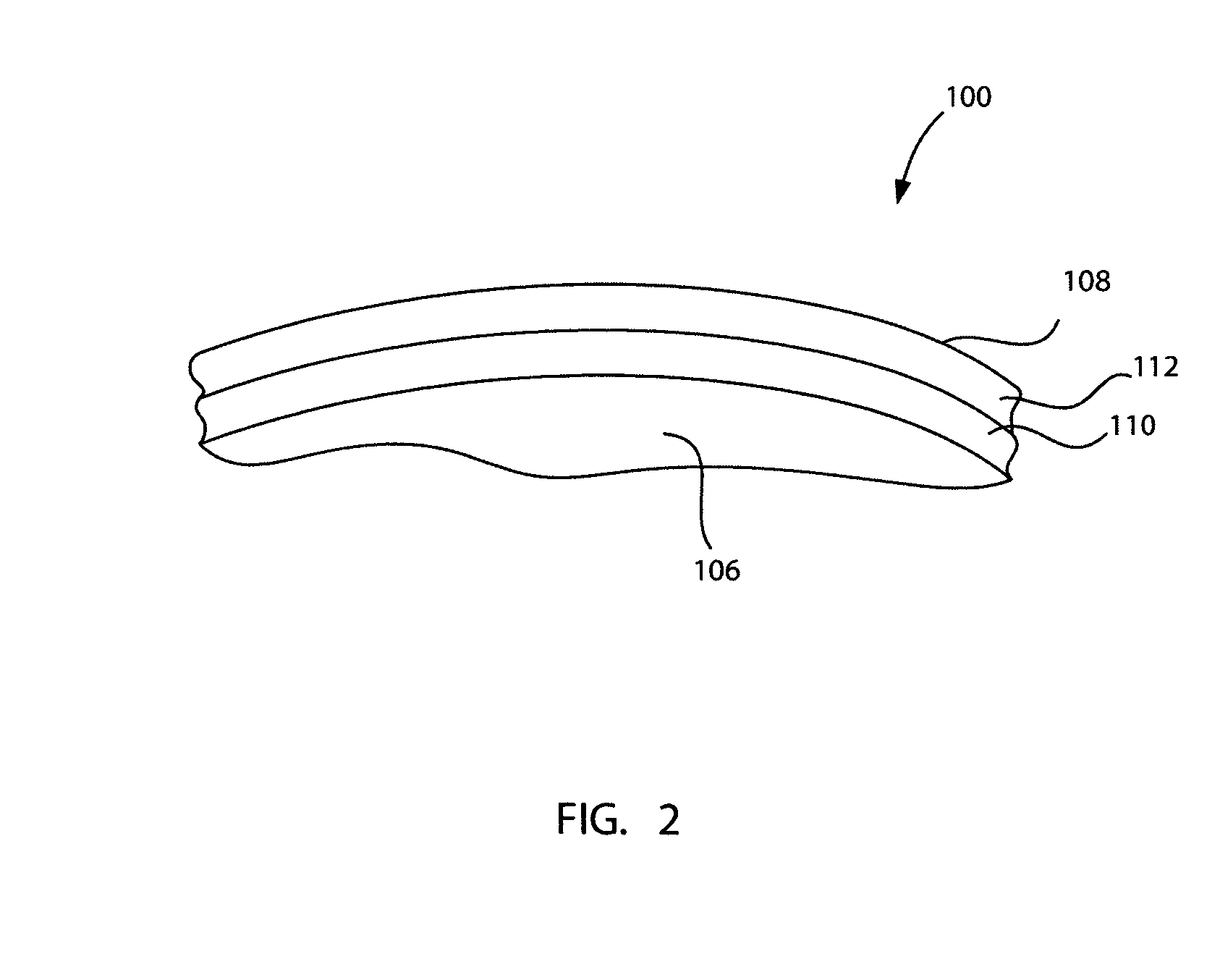

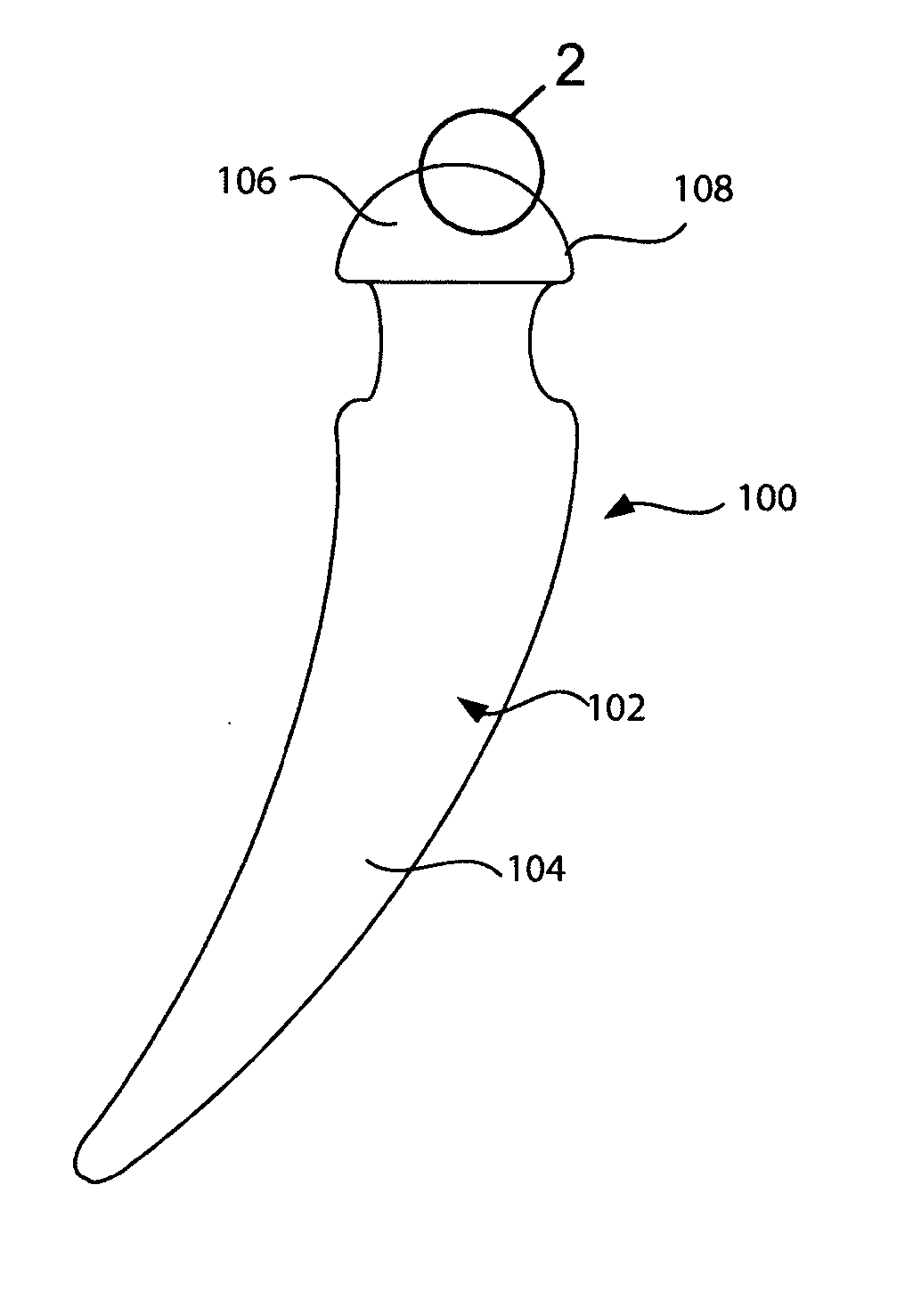

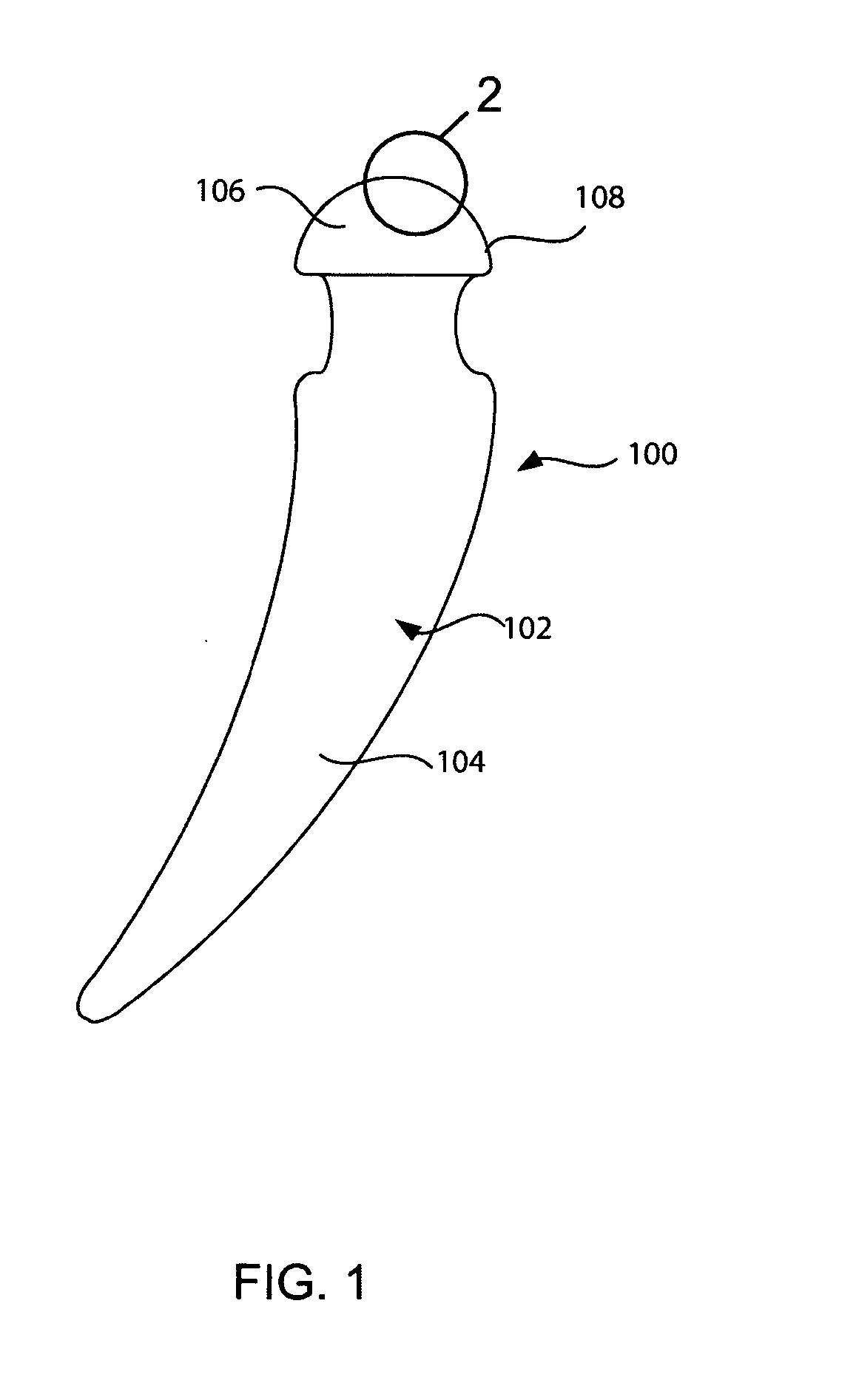

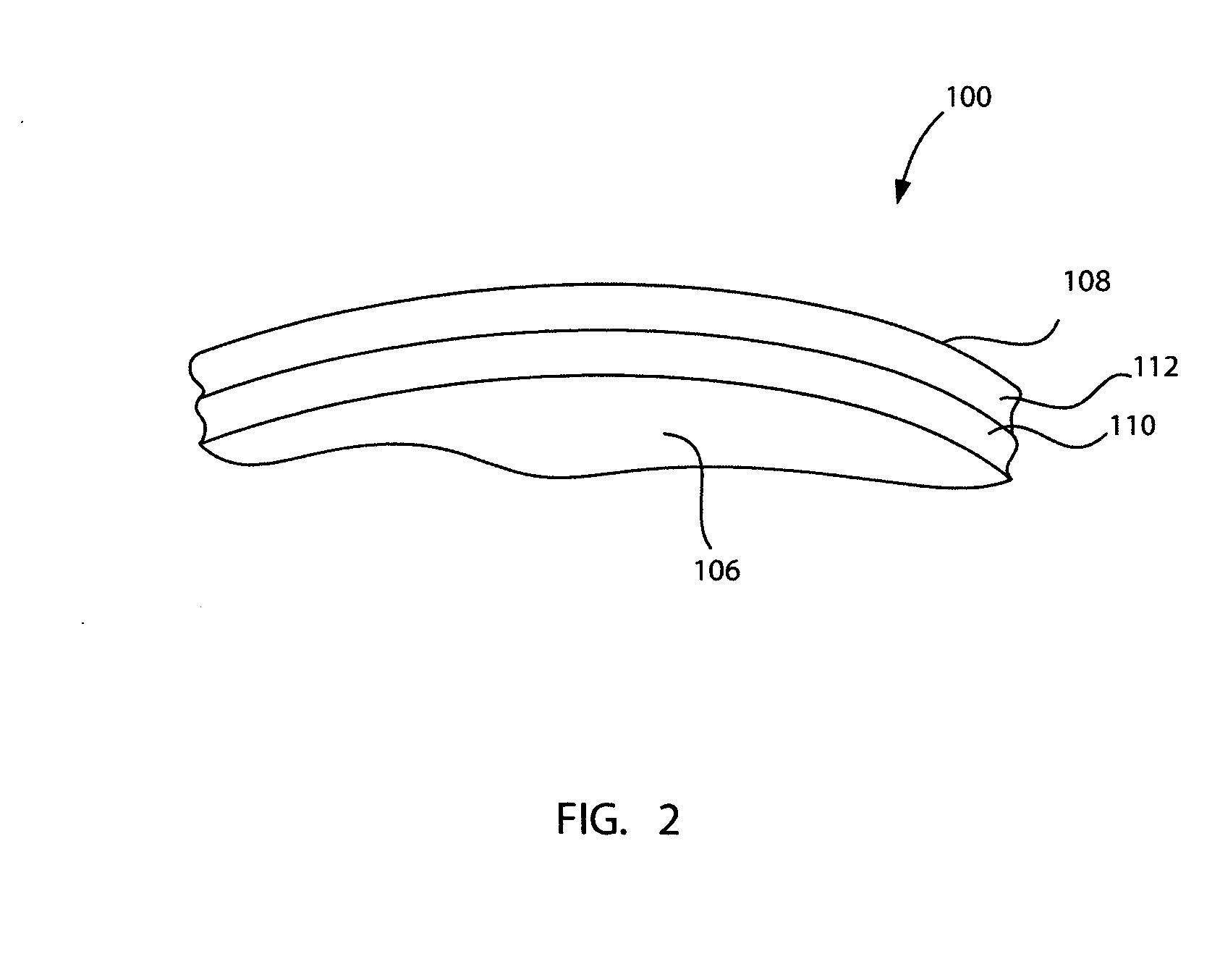

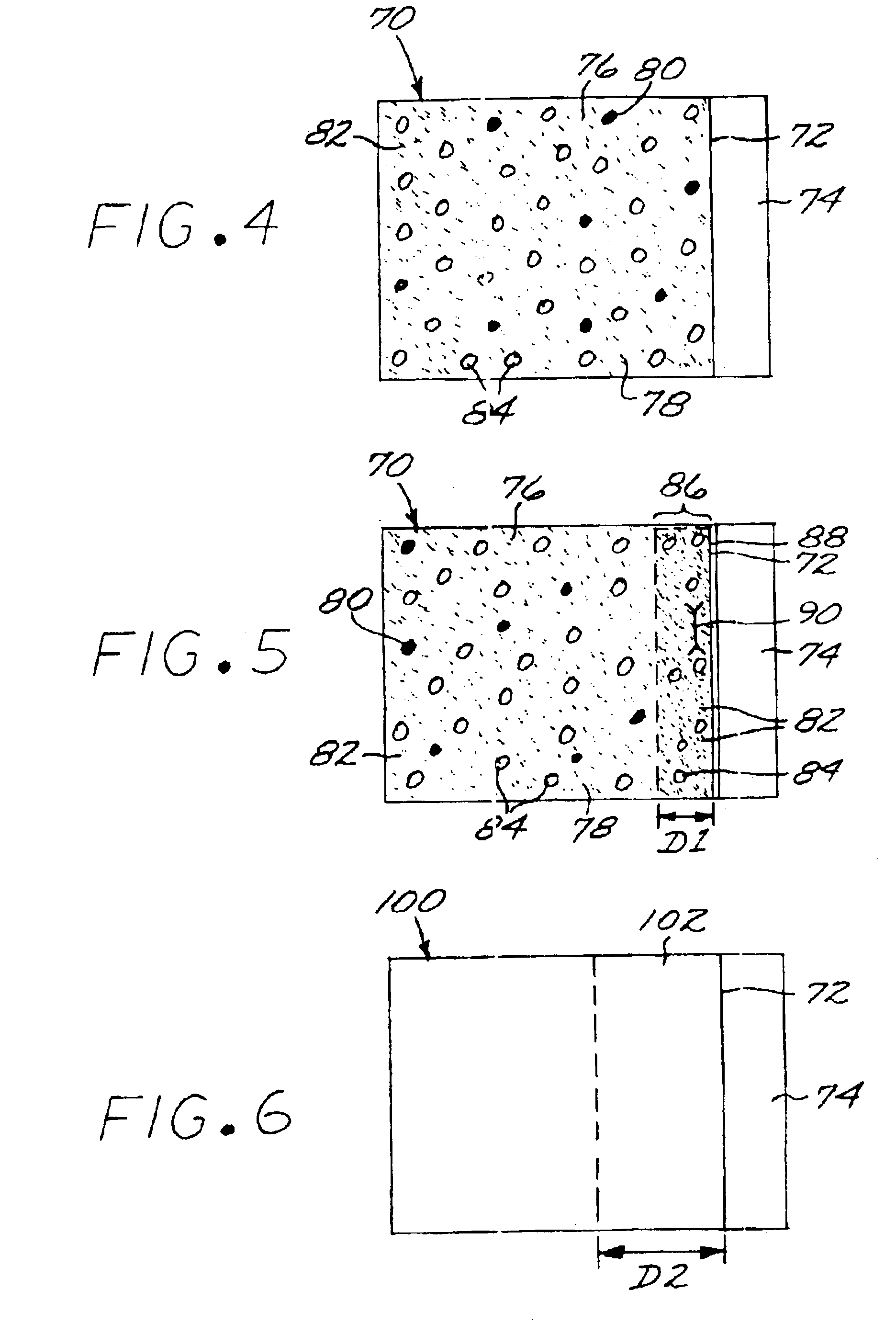

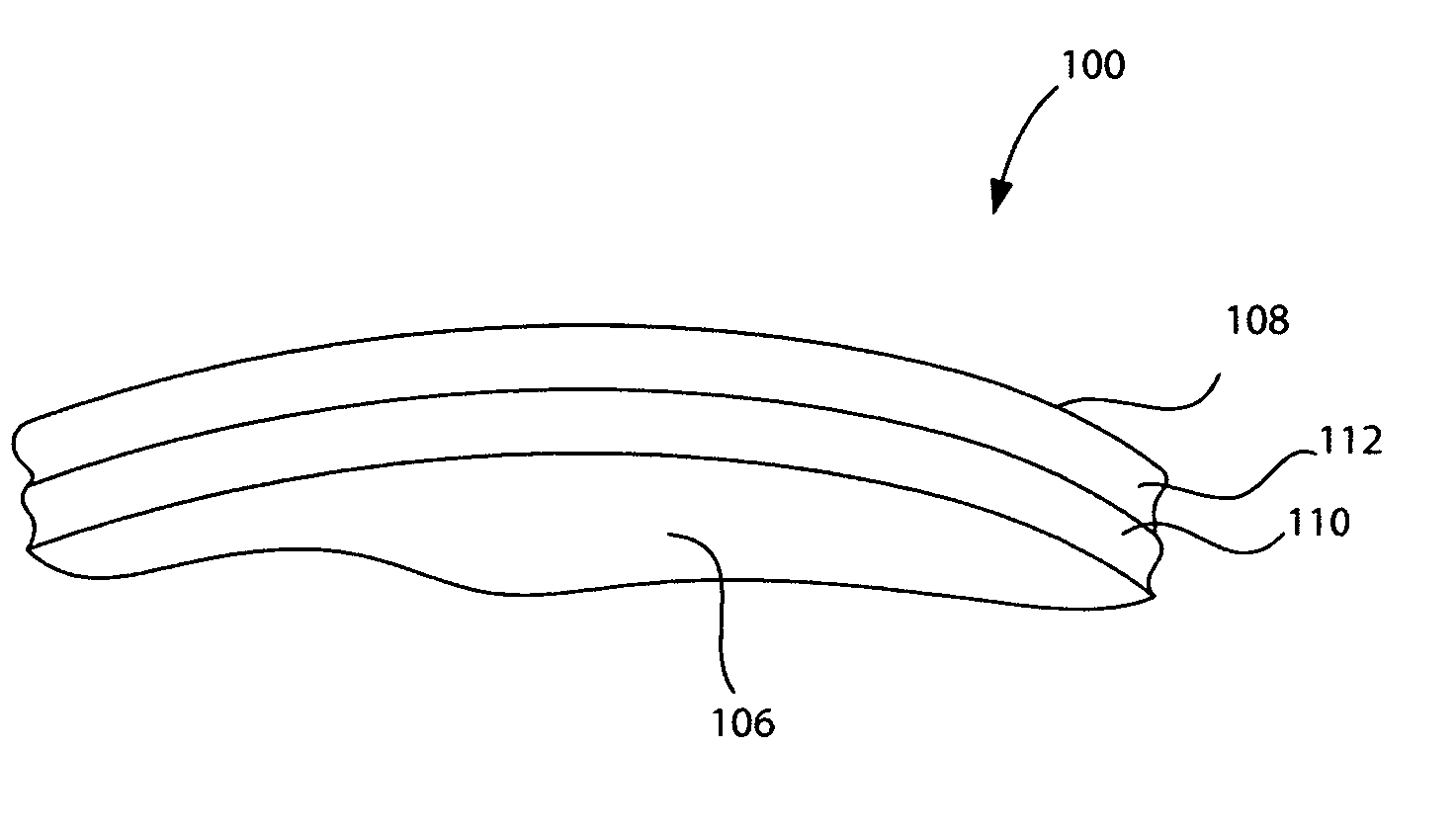

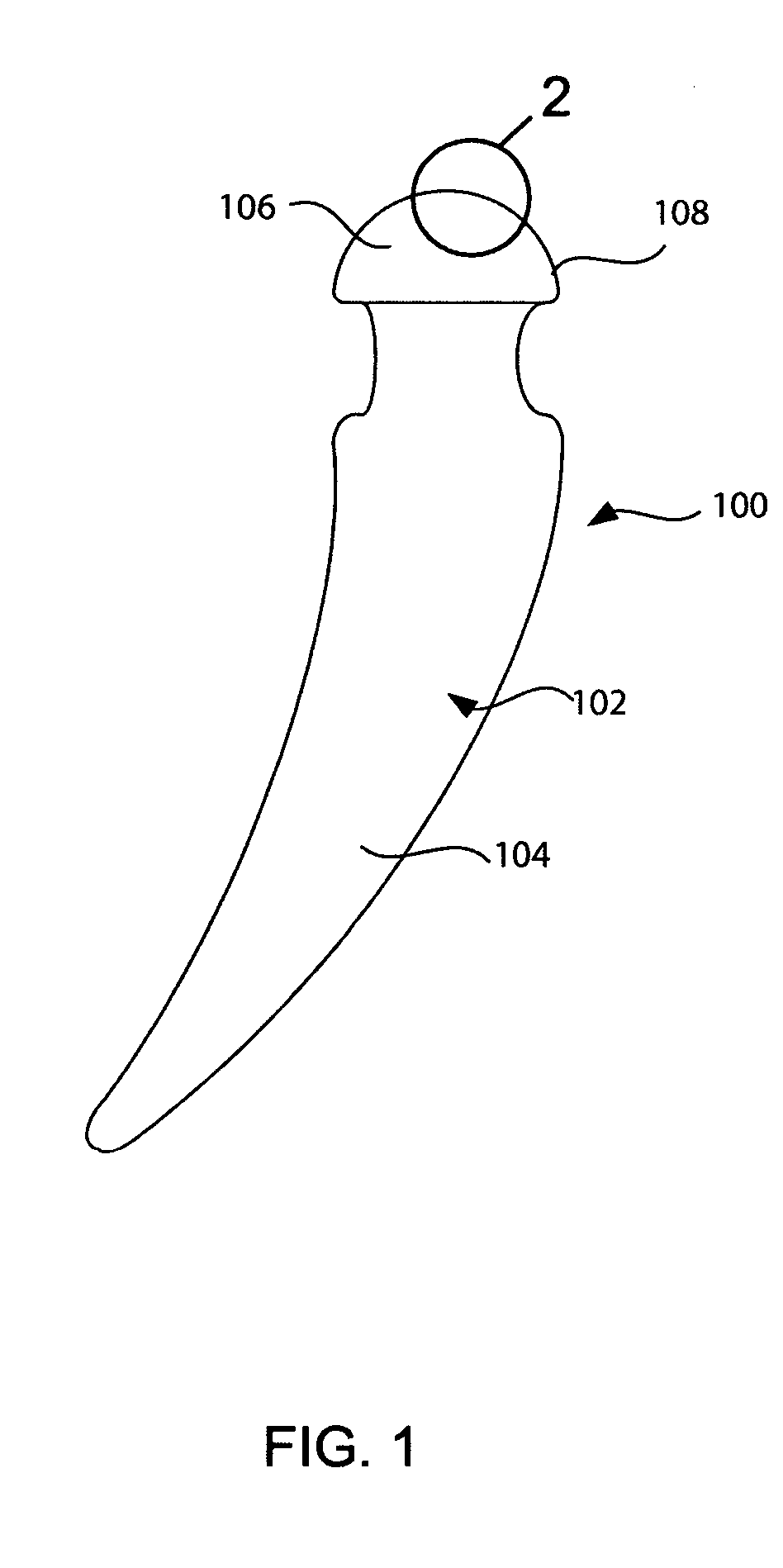

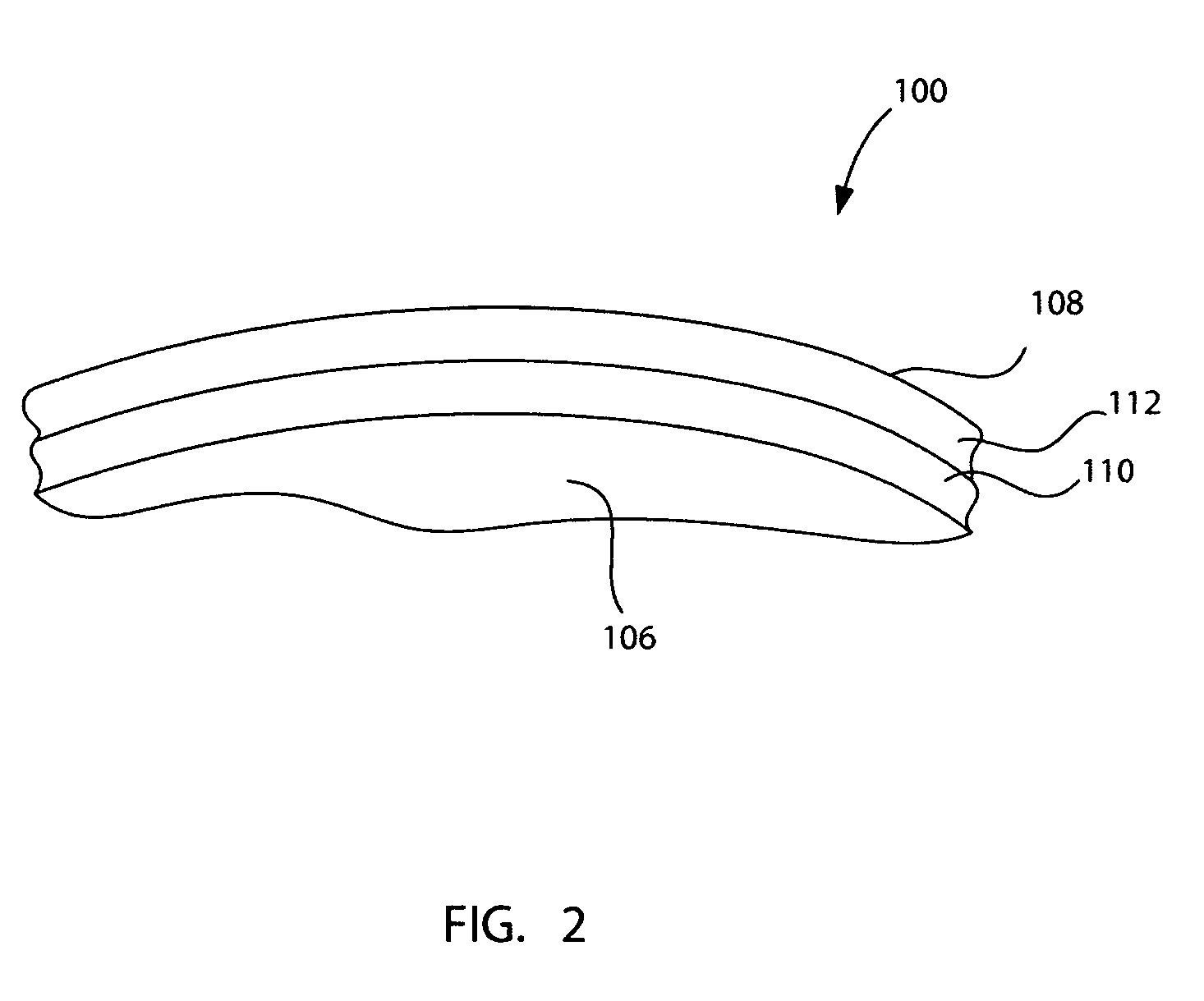

Laser based metal deposition of implant structures

InactiveUS7001672B2Minimize adverse effectsFine grain structureFinger jointsDental implantsArtificial jointsWear resistant

Owner:MEDICINELODGE

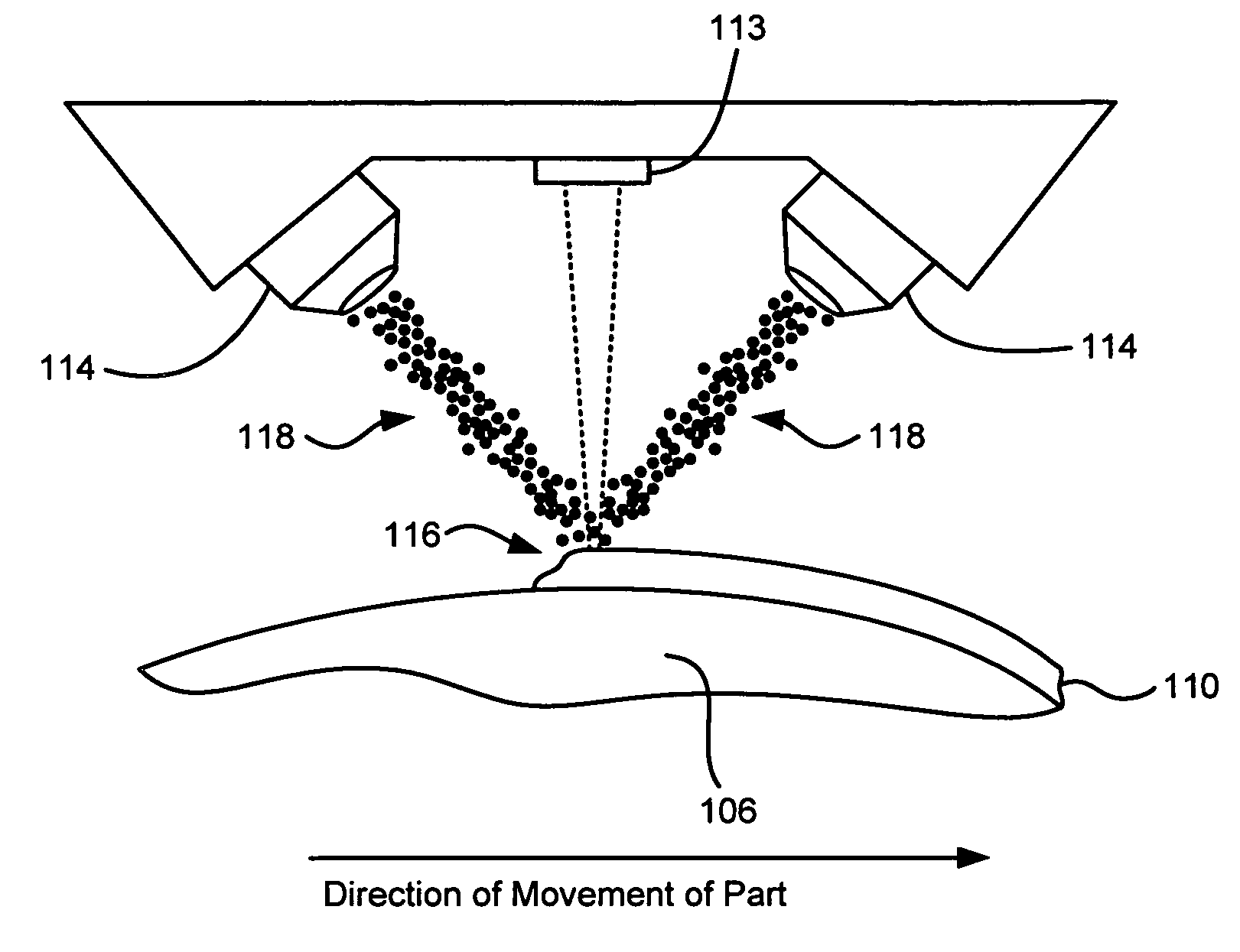

Laser based metal deposition (LBMD) of implant structures

InactiveUS7666522B2Minimize adverse effectsFine grain structureFinger jointsDental implantsWear resistantBone ingrowth

Owner:IMDS CORPORATION

Laser based metal deposition (LBMD) of implant structures

InactiveUS20070202351A1High porosityMinimize adverse effectsFinger jointsDental implantsArtificial jointsWear resistant

A method is provided for depositing a hard wear resistant surface onto a porous or non-porous base material of a medical implant. The wear resistant surface of the medical implant device may be formed by a Laser Based Metal Deposition (LBMD) method such as Laser Engineered Net Shaping (LENS). The wear resistant surface may include a blend of multiple different biocompatible materials. Further, functionally graded layers of biocompatible materials may be used to form the wear resistant surface. Usage of a porous material for the base may promote bone ingrowth to allow the implant to fuse strongly with the bone of a host patient. The hard wear resistant surface provides device longevity, particularly when applied to bearing surfaces such as artificial joint bearing surfaces or a dental implant bearing surfaces.

Owner:IMDS CORPORATION

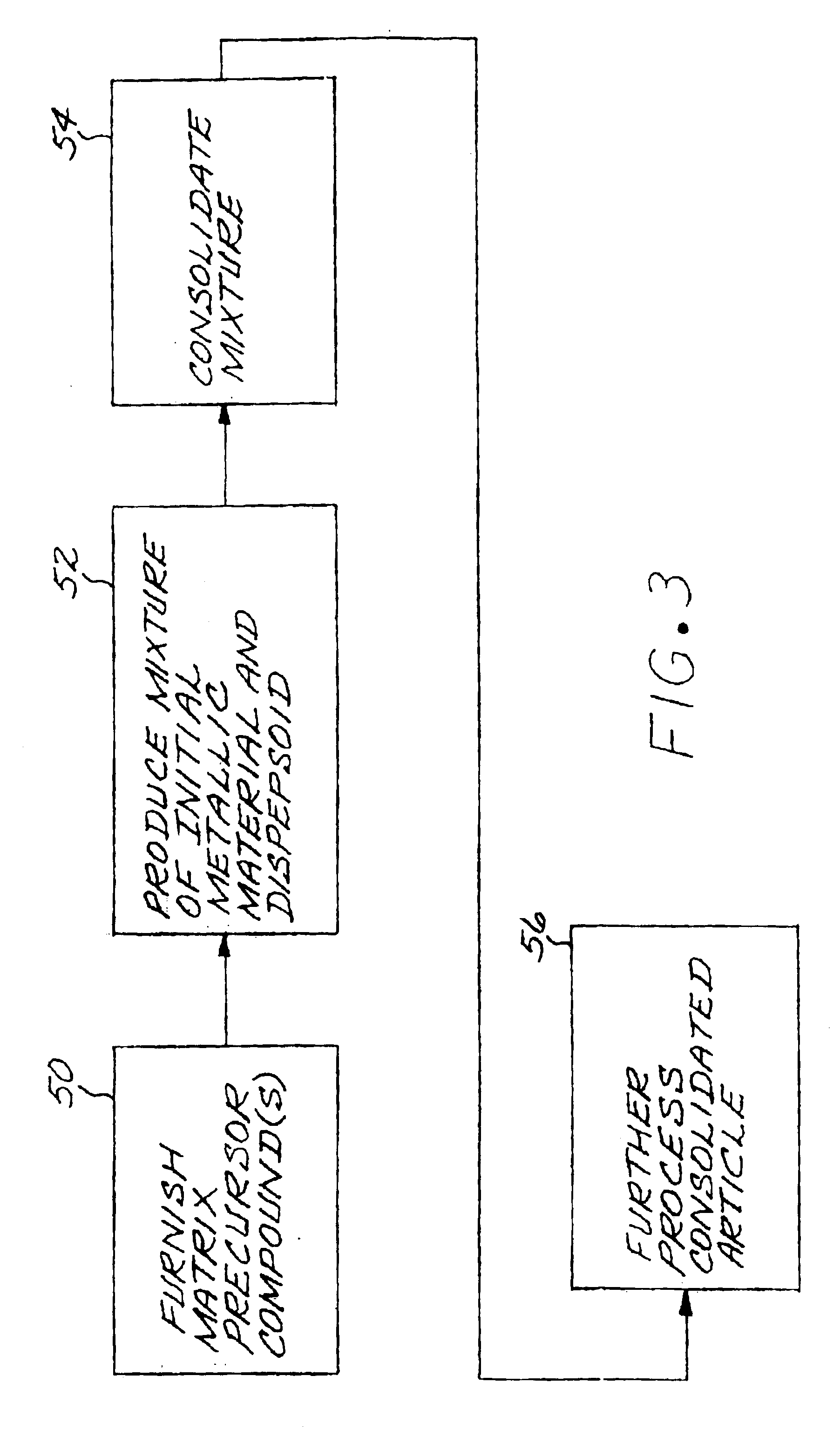

Method for preparing an article having a dispersoid distributed in a metallic matrix

Owner:GENERAL ELECTRIC CO

Method for preparing nano oxide dispersion reinforced superfine crystal tungsten-based composite material

The invention provides a method for preparing a nano oxide dispersion reinforced superfine crystal tungsten-based composite material. The method comprises the following steps of: taking 0.1 to 1 weight percent of micro tungsten powder, nano yttrium oxide powder or yttrium metal powder and 0 to 2 weight percent of titanium metal powder or molybdenum powder or tantalum powder, blending the materials, mechanically alloying the materials, sintering discharge plasma and the like to prepare the superfine crystal tungsten composite material. The method has the following advantage that: the nearly full-densification superfine crystal tungsten-based composite material can be obtained by the method for preparing the nano oxide dispersion reinforced superfine crystal tungsten-based composite material. Complex phase doping of yttrium oxide or yttrium metal and titanium metal, molybdenum or tantalum powder not only realizes sintering densification of tungsten at a lower temperature, but also inhibits grain growth of tungsten crystals during sintering. The tungsten crystal grain size of the yttrium oxide reinforced superfine crystal tungsten-based composite material prepared by adopting the method is less than or equal to 3 microns, and the composite material has good mechanical property and thermal shock resistance.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing tungsten-copper composite material with fine grain

The invention relates to the field of powder metallurgy technology characterized in that, forming the powder with 200 MPa-500 MPa and feeding into sintering furnace, elevating the temperature to 400-700 deg. C. at the speed of 5-20 deg. C per minutes, heat preserving for 15-120 mins, elevating the temperature to sintering temperature of 1150-1350 deg. C. at the speed of 20-60 deg. C per minutes, heat preserving for 30-120 mins.

Owner:CENT SOUTH UNIV

High-strength high-conductivity copper alloy contact wire for rapid transit railway

ActiveCN1811998AExcellent thermal stability and corrosion and wear resistanceFine grain structureSingle bars/rods/wires/strips conductorsCable/conductor manufactureCrystalliteChromium

Owner:郑茂盛 +1

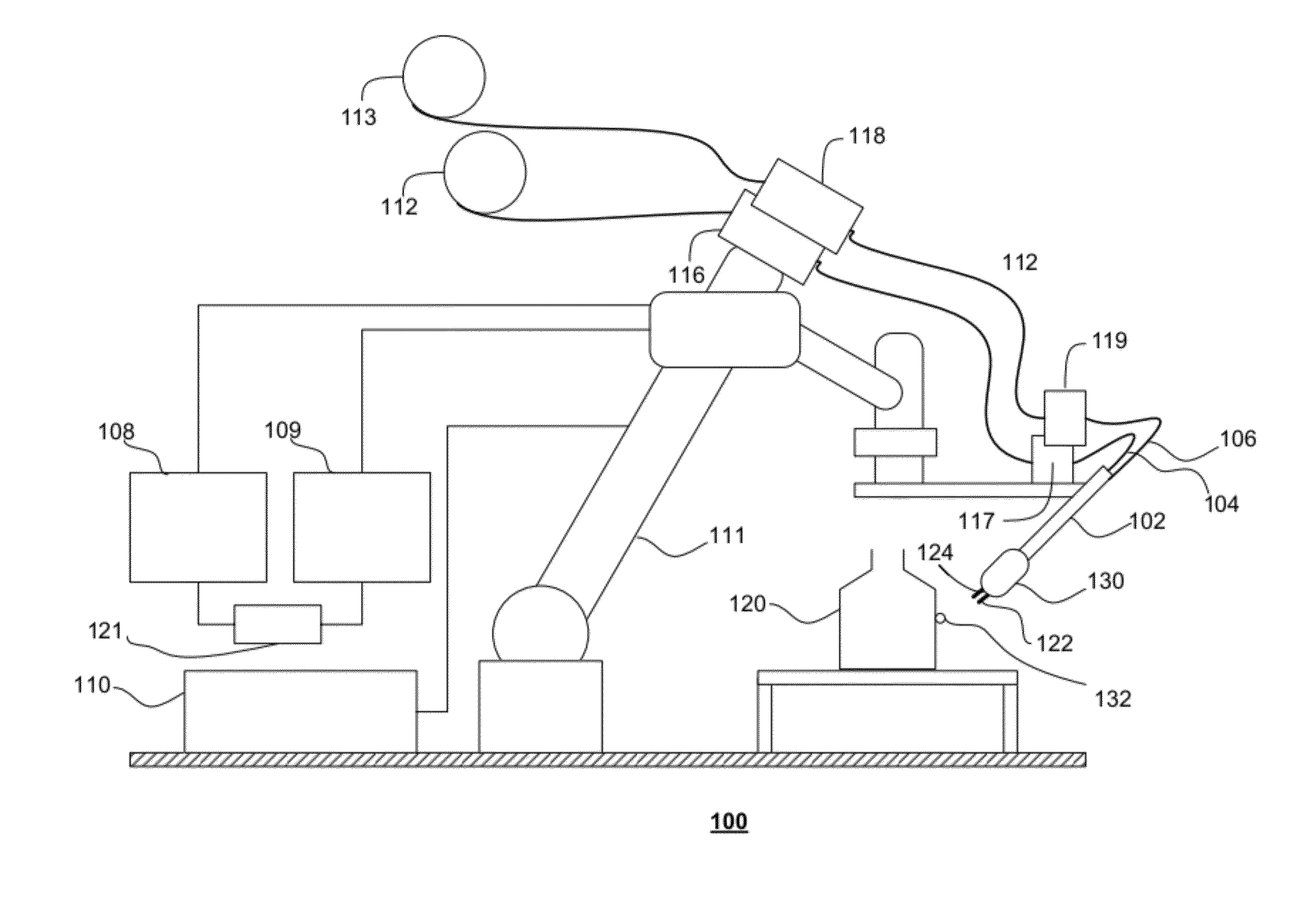

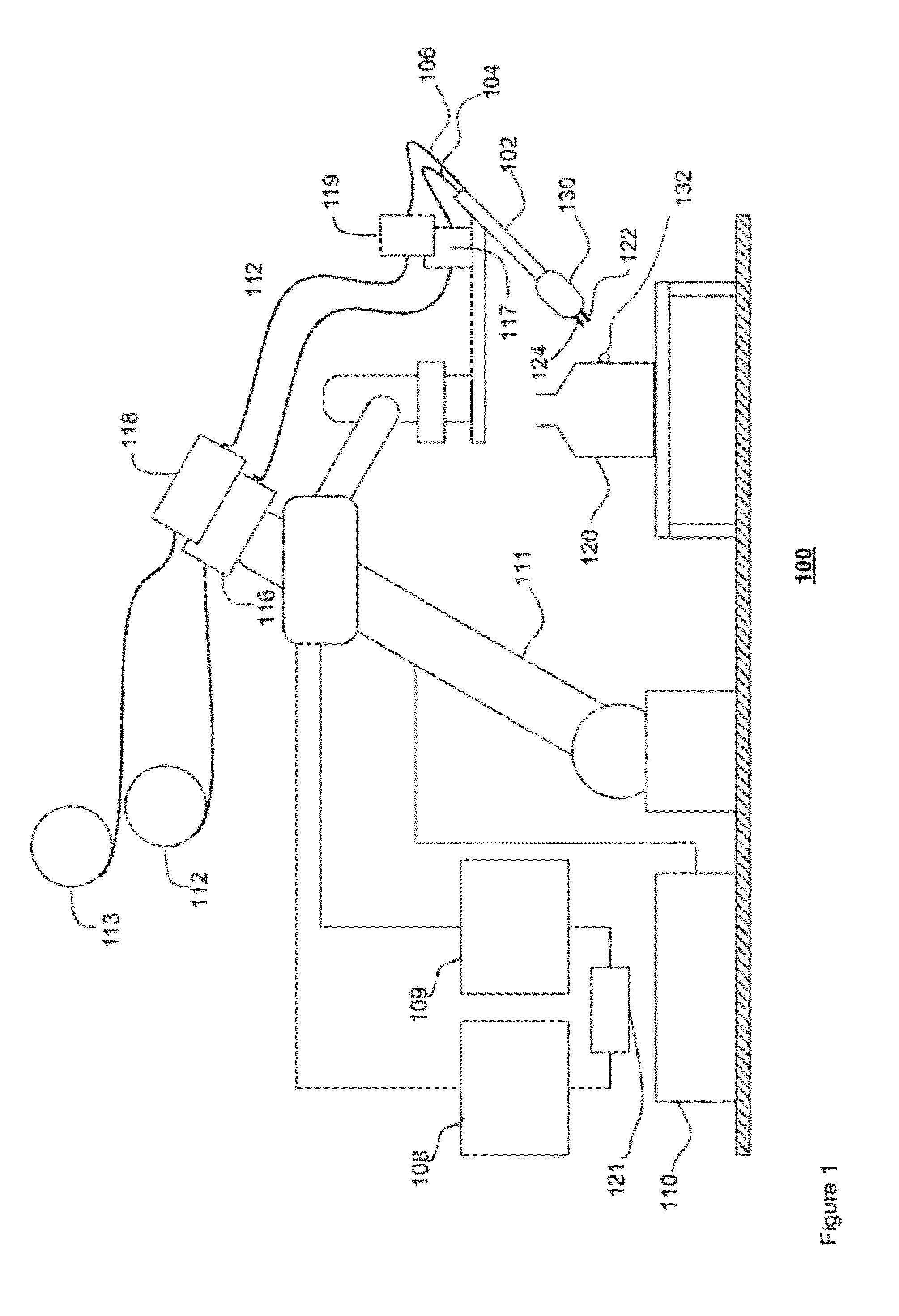

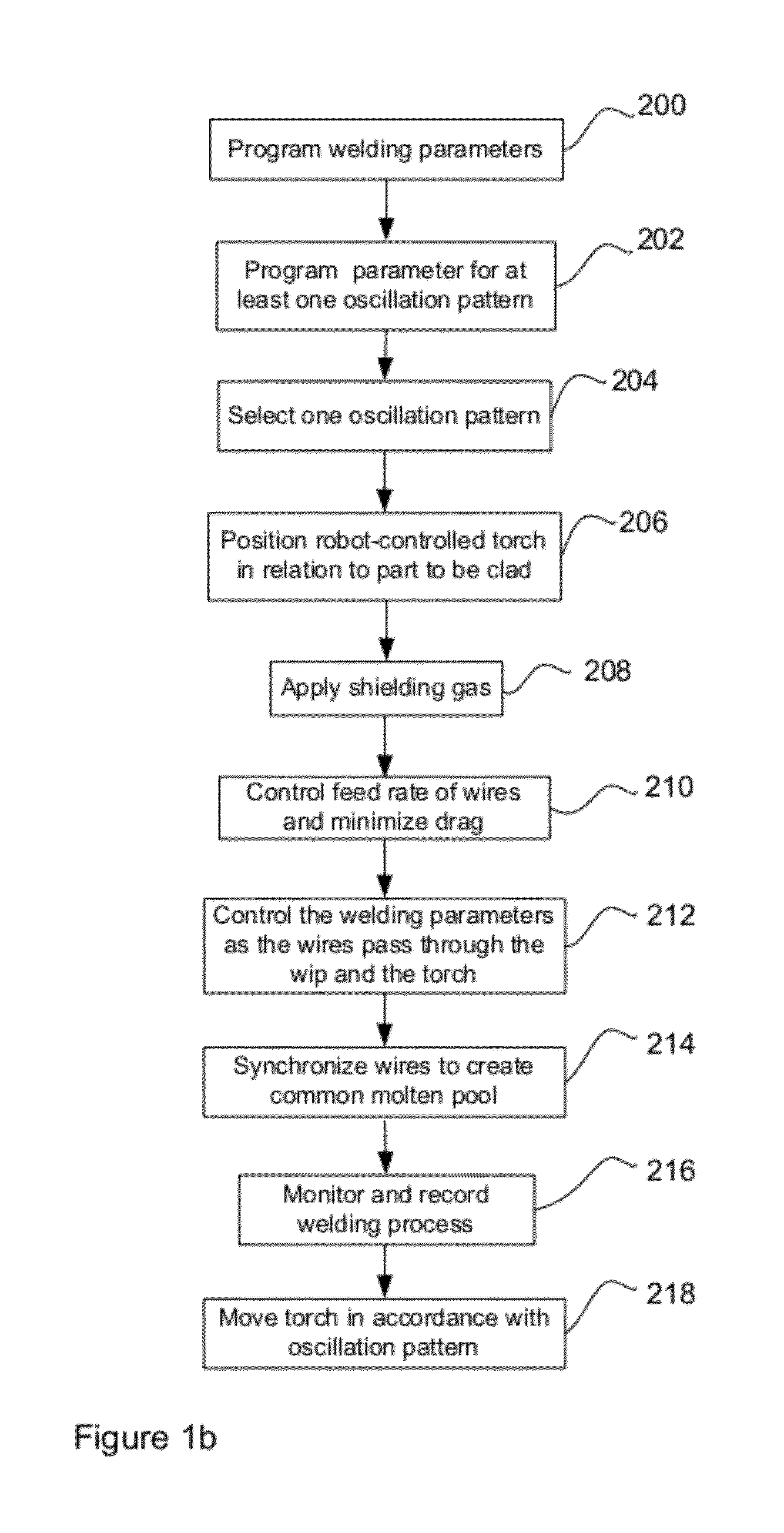

System and Method for High-Speed Robotic Cladding of Metals

A metal cladding process using an automated welding tool, the tool comprising at least one torch for receiving two weld wires to produce a molten pool on the metal, the process having the steps of providing a set of instructions in a non-transitory computer readable medium, the instructions executable by a processor to control the travel speed of the at least one torch; and control the oscillation pattern and frequency of the at least one torch, the oscillation pattern comprising a pause at each of a center position, a lateral left position and a lateral right position relative to a weld reference line.

Owner:TECHN & AUTOMATION HELP CORP

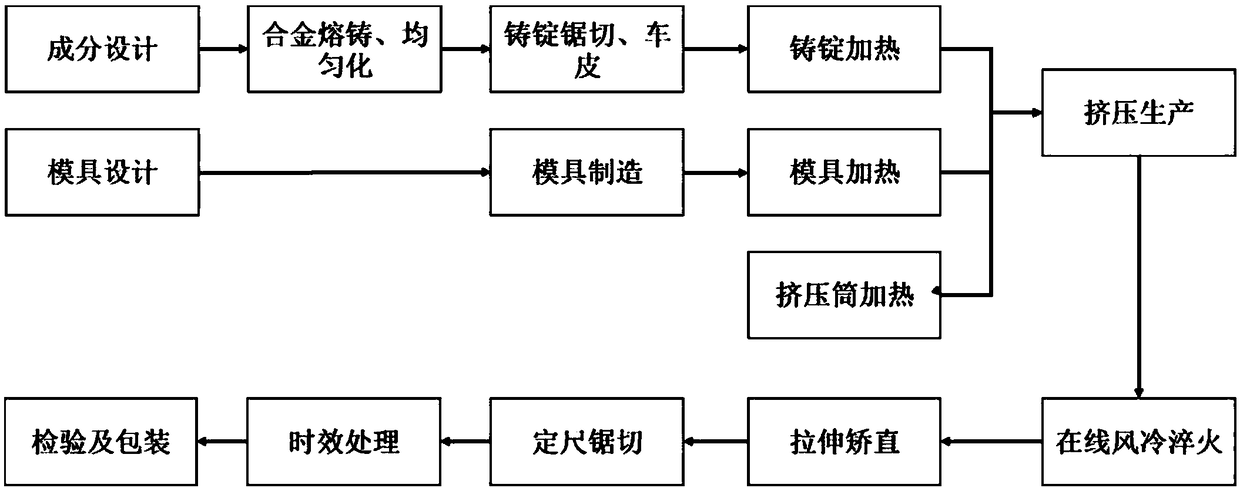

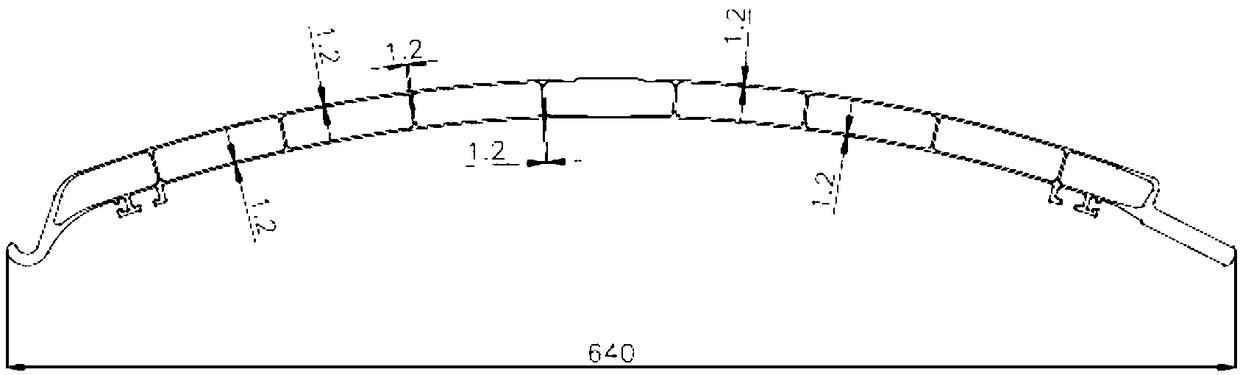

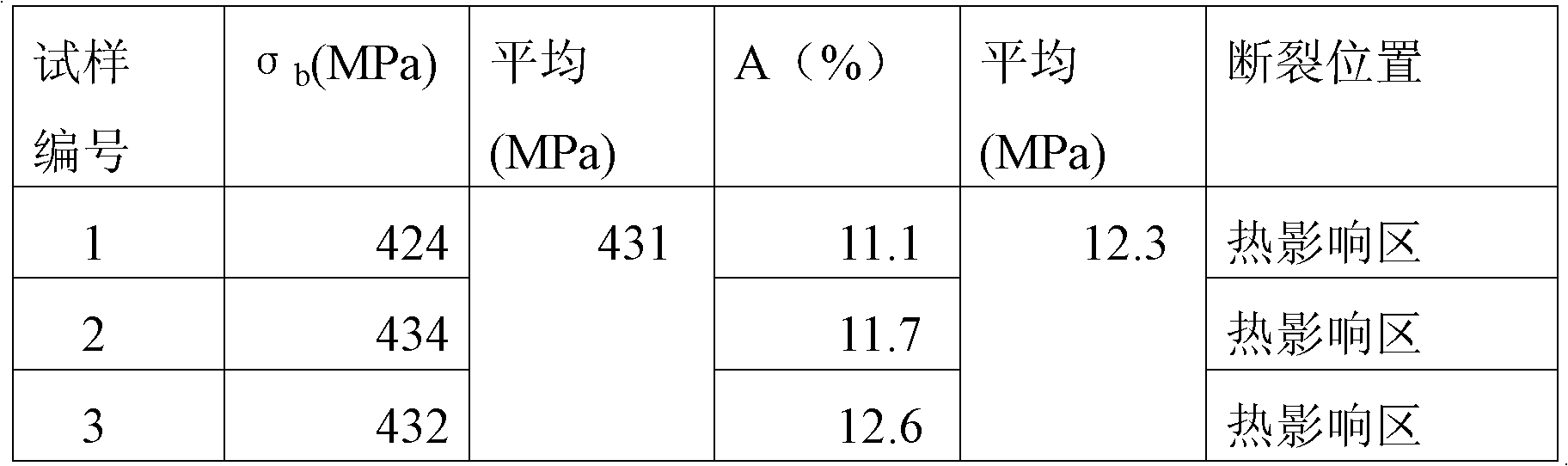

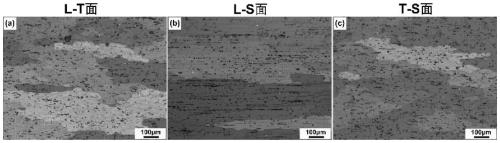

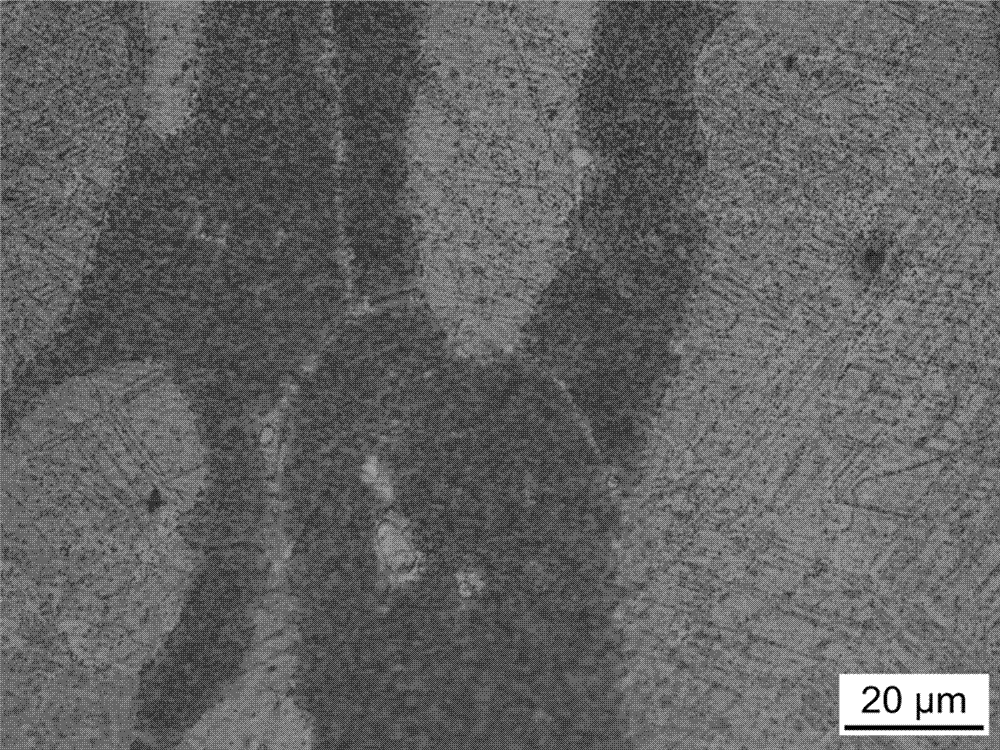

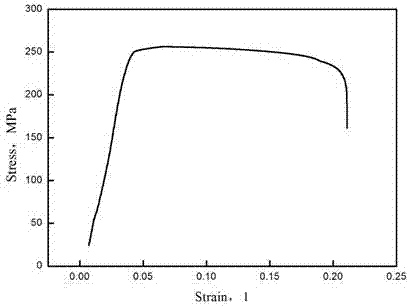

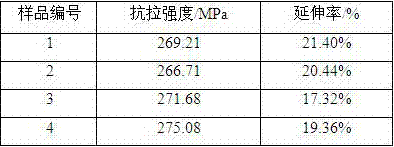

Wide-range thin-wall series-6 aluminum alloy section for high speed train and preparation method of wide-range thin-wall series-6 aluminum alloy section

ActiveCN108893661AHigh extrusion force per unit areaReduce deformation resistanceIngot castingUltimate tensile strength

The invention belongs to the technical field of preparation of aluminum alloy sections, and relates to a wide-range thin-wall series-6 aluminum alloy section for a high speed train and a preparation method of the wide-range thin-wall series-6 aluminum alloy section. Aluminum alloy comprises the following elements in percentages by weight: 0.50-0.65% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.10% of Cu, 0.03-0.15% of Mn, 0.45-0.55% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.10% of Ti, less than or equal to 0.05% ofa single impurity, less than or equal to 0.15% of total impurities and the balance of Al. Deformation resistance and friction resistance in an extruding process are reduced by reasonably controllingthe temperature relationship of an ingot casting, an extrusion barrel and a die, the extruding speed is increased to be 8-13 m / min, the quenching temperature of the product is ensured, thus, any coarse grain rings are not generated when a thin-walled apron board is extruded at high speed, after being subjected to on-line quenching, the product is directly subjected to artificial ageing at the temperature of 175+ / - 5 DEG C for 4-8 hours, the mechanical property of the product can meet requirements in TB / T.3260.4-2011 TO 1.2 mm thin-walled sections, the actual tensile strength reaches 250-270 MPa, the yield strength reaches 210-230 MPa, the specific elongation is 8-10%, and the grade of the grain size of an aluminum section microscopic structure reaches and even exceeds 4.

Owner:中铝特种铝材(重庆)有限公司

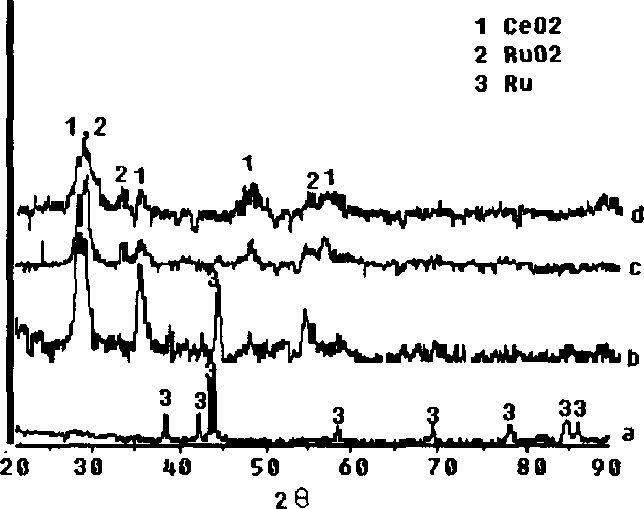

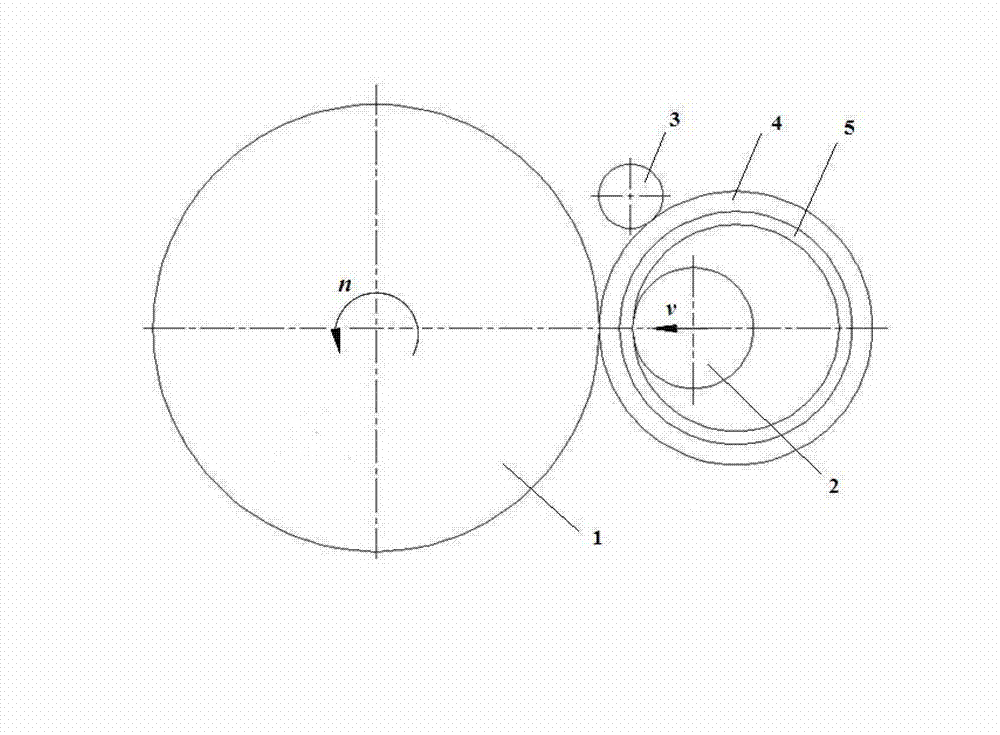

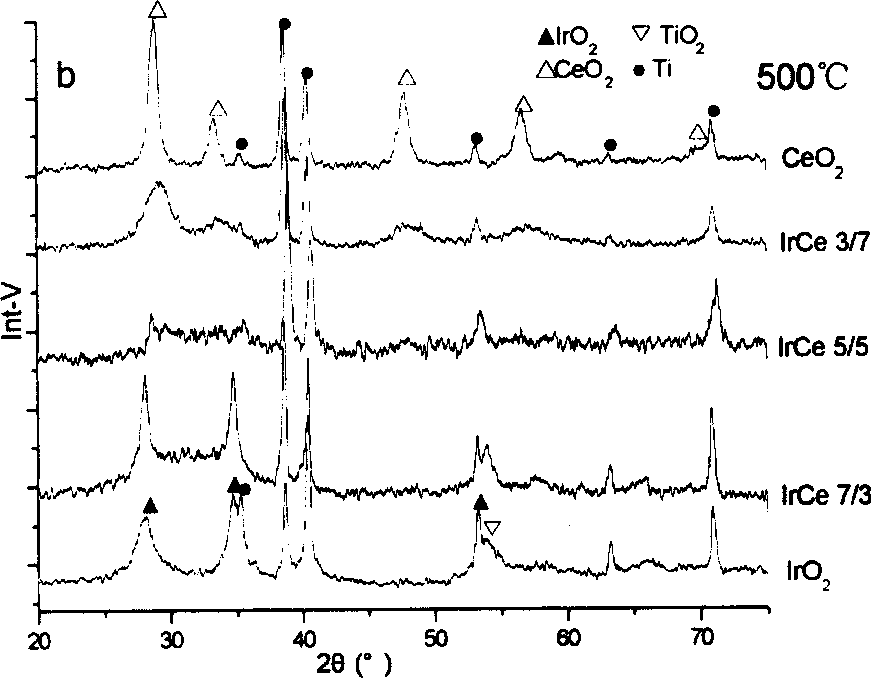

Titanium anode containing ruthenium coating of high cerium content and its preparing method

The present invention provides a high cerium content ruthenium coating contained titanium anode preparation method. Said ruthenium coating containing titanium anode includes titanium basal body, featuring said titanium basal body surface coating RuO 2 and CeO 2 ratio as 1 : 3-3 :1.Said preparation method includes using RuCl 3 H2 O, Ce(No3)3 as source substance, including titanium base preprocessing, unit coating liquid preparation, multielement coating liquid preparation and coating preparation. The present invention has simple technology, convenient operating, fine coated grain structure, and low chlorine separating potential.

Owner:FUZHOU UNIV

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122AImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

High purity tantalum, products containing the same, and methods of making the same

InactiveUS20020026965A1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingUltimate tensile strengthCapacitor

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995 % and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

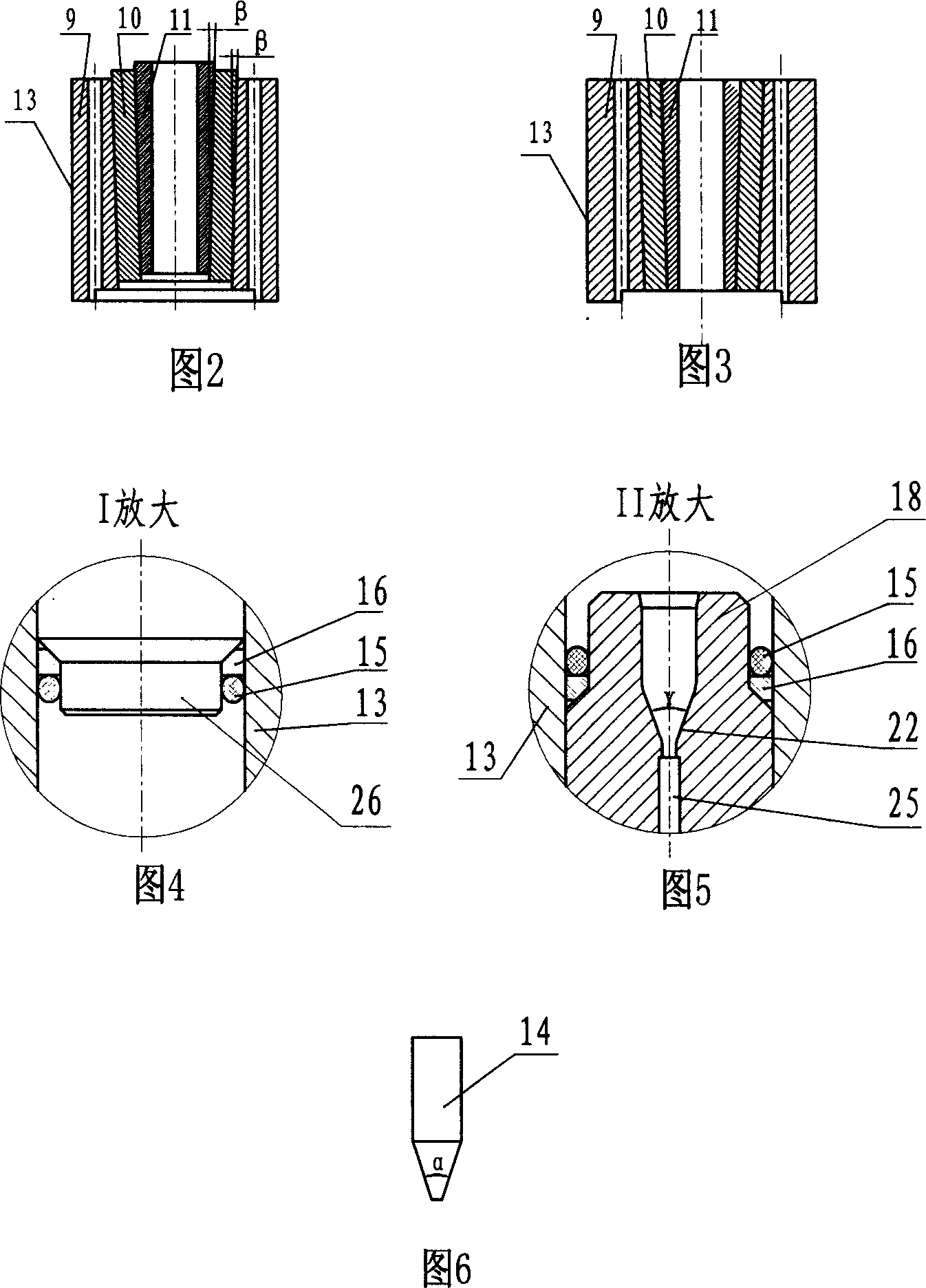

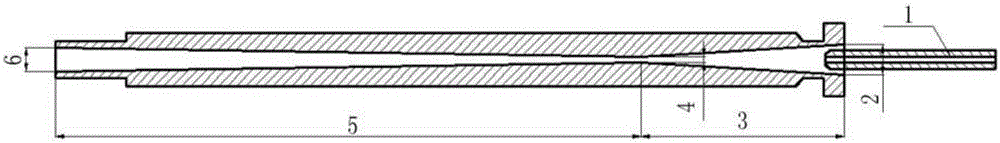

Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

InactiveCN101015841ASpeed up heat dissipationSlow down heat dissipationExtrusion diesExtrusion control devicesTemperature controlPhysical property

The invention relates to a hydraulic extruding method for producing magnesium alloy wire or rod, and relative specific extruding mould, which can avoid crack and high cost or the like. The inventive method comprises that processing magnesium alloy blank, coating lubricant, and heating with era oil, heating hydraulic extruding mould and controlling temperature, arranging magnesium alloy blank, filling era oil, arranging movable convex mould, pressurizing and extruding. The inventive mould comprises a movable convex mould (26), under a convex mould (6) and coaxial with the convex mould (6), wherein the lower end of the convex mould (26) is through a convex mould through hole (8) at the middle of a convex mould press plate (17) to be mounted on the upper part of an extruding barrel (13), and the extruding barrel (13) is a multilayer cold press extruding one. The invention can obtain better physical property and surface quality, or the like.

Owner:HARBIN INST OF TECH

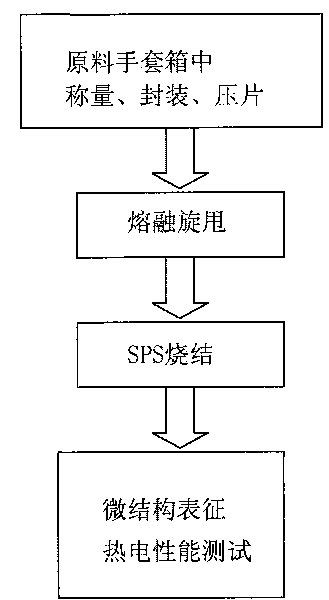

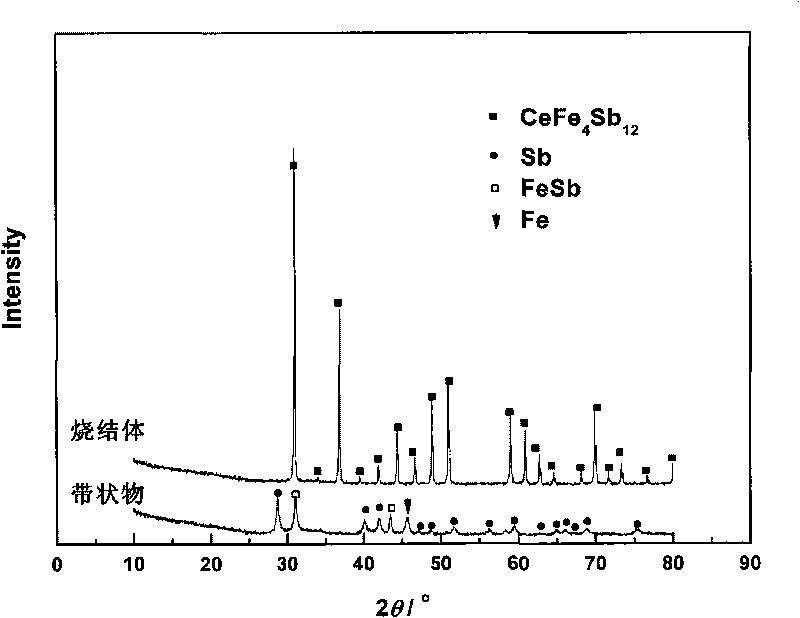

Method for preparing p-type filling type skutterudite compound thermoelectric material

InactiveCN101693962AOmit premeltingPrevent deviationThermoelectric device junction materialsSkutteruditeArgon atmosphere

The invention belongs to the field of new energy materials, and particularly relates to a method for preparing filling type skutterudite thermoelectric compound. A method for preparing the p-type filling type skutterudite compound thermoelectric material comprises the following steps: firstly, taking high-purity granule type M, Fe, Co and Sb as starting reaction materials, weighing reaction raw materials in an Ar gas glove box according to the chemical formula MFe4-xCoxSb12+y, wherein 0<=x<=3, 0<=y<=1.0, mixing the high purity granule type M, Fe, Co and Sb, then, pressing into columnar blocks under the pressure of 300 to 400MPa, secondly, melting columnar blocks, swinging melted welding flux in argon atmosphere, obtaining belt-shaped products, thirdly, sintering in vacuum through a discharge plasma sintering method after coarsely grinding and pressing the belt-shaped products tightly, and obtaining single-phase compact p-type filling type skutterudite compound thermoelectric material. The method for preparing p-type filling type skutterudite compound thermoelectric material has the characteristics of simple technique, short reaction time, low energy consumption, excellent repeatability, and the like.

Owner:WUHAN UNIV OF TECH

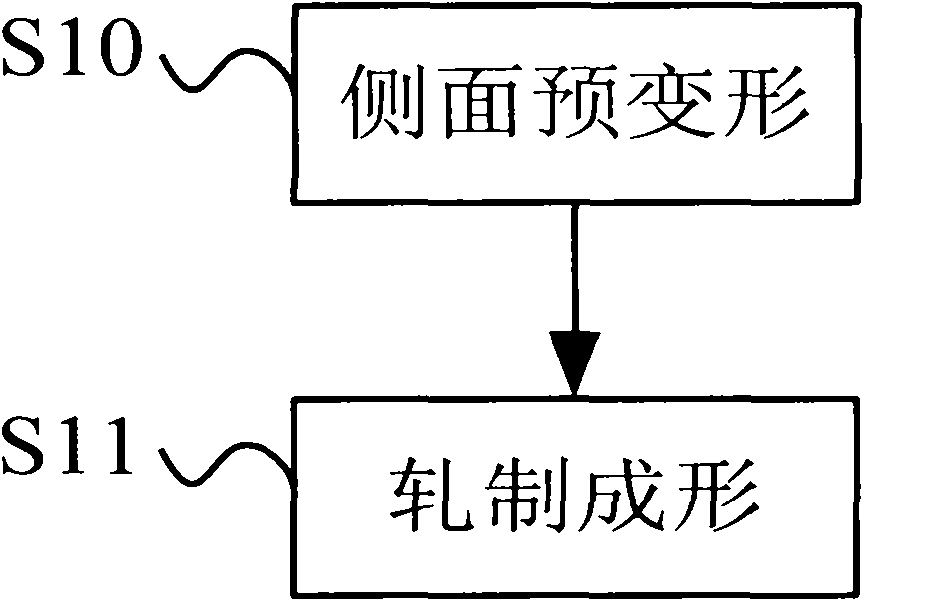

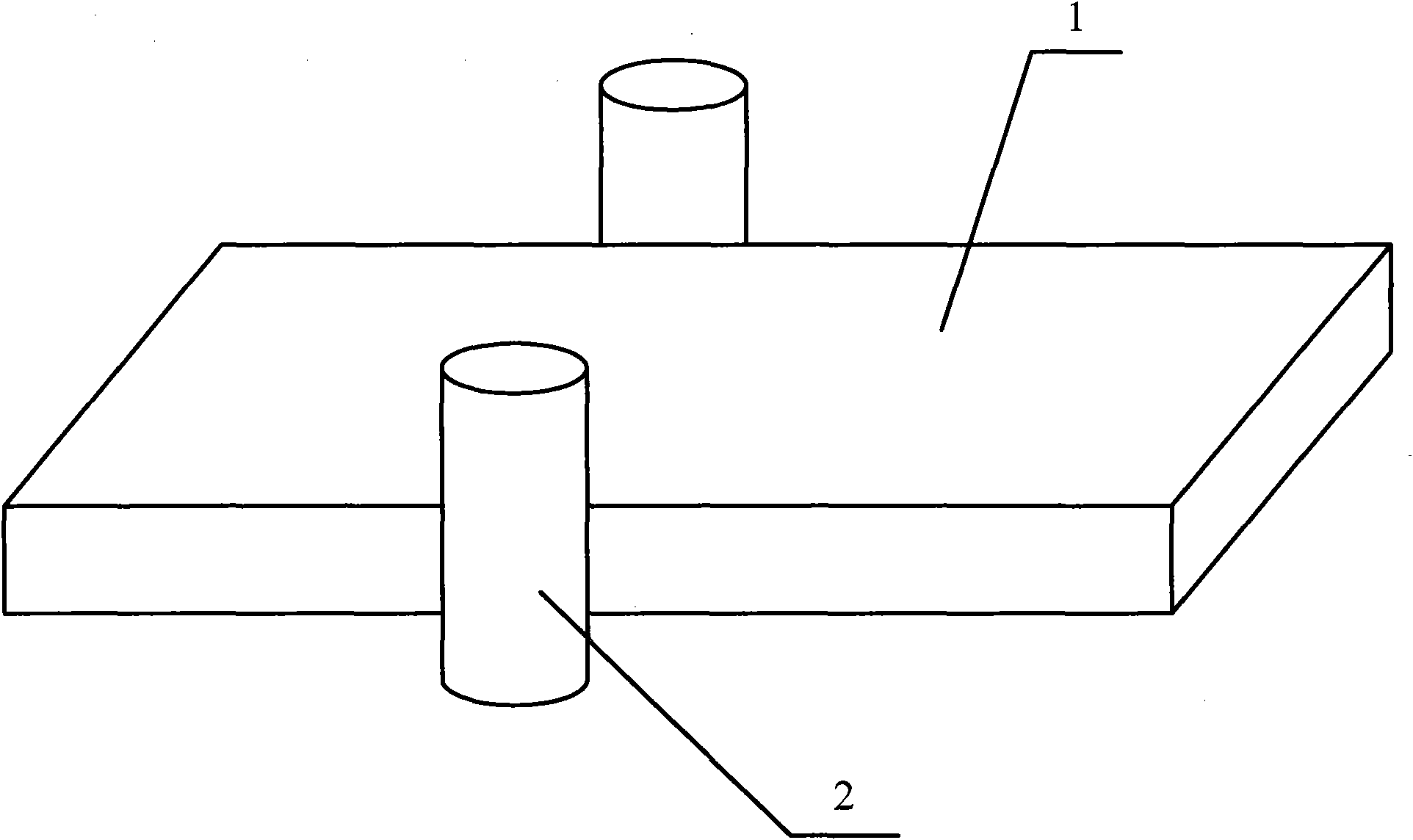

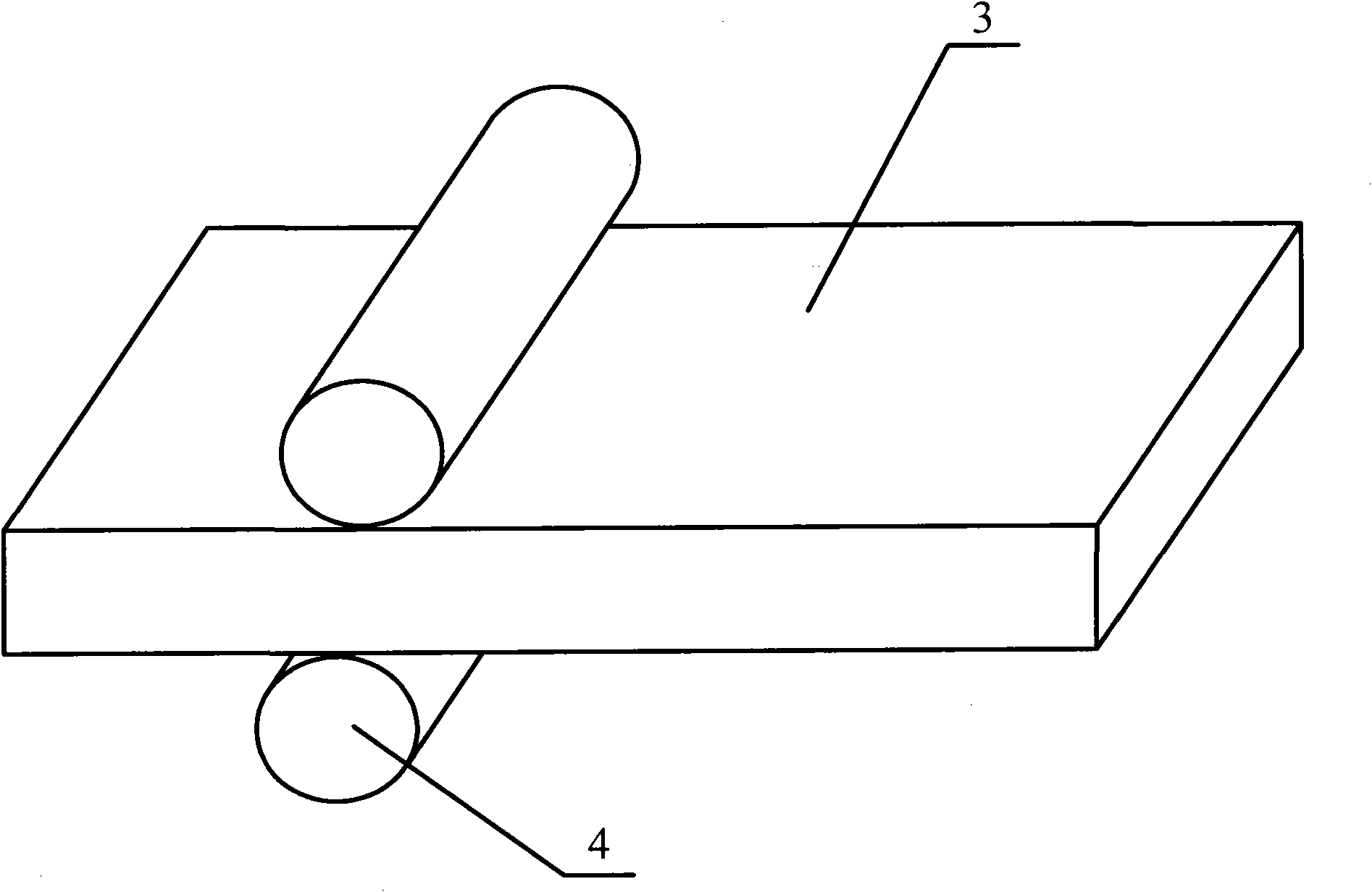

Rolling method of magnesium alloy plate and auxiliary rolling method thereof

InactiveCN102039308AReduce processing costsReasonable cost controlMetal rolling arrangementsCrystallitePre treatment

Owner:CHONGQING UNIV

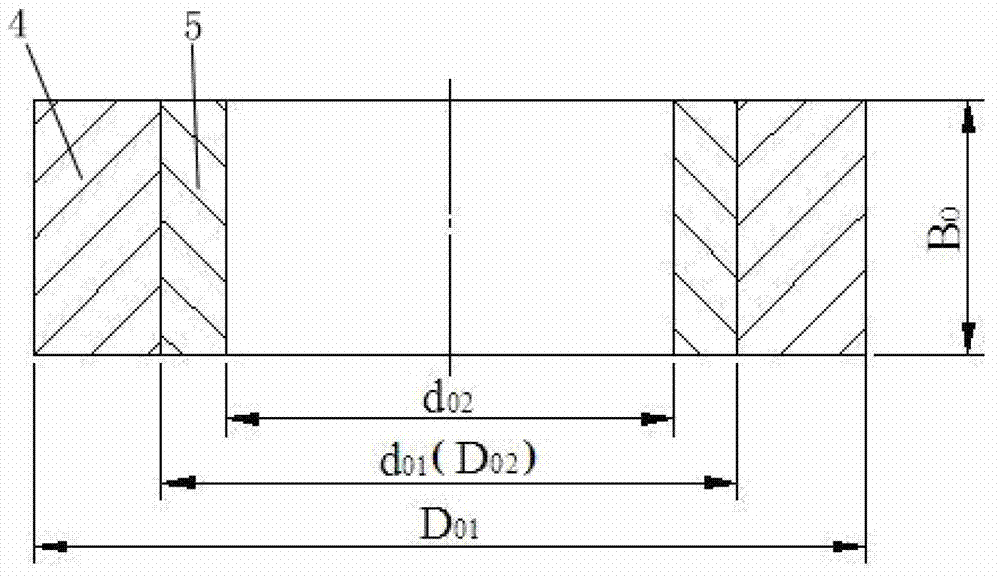

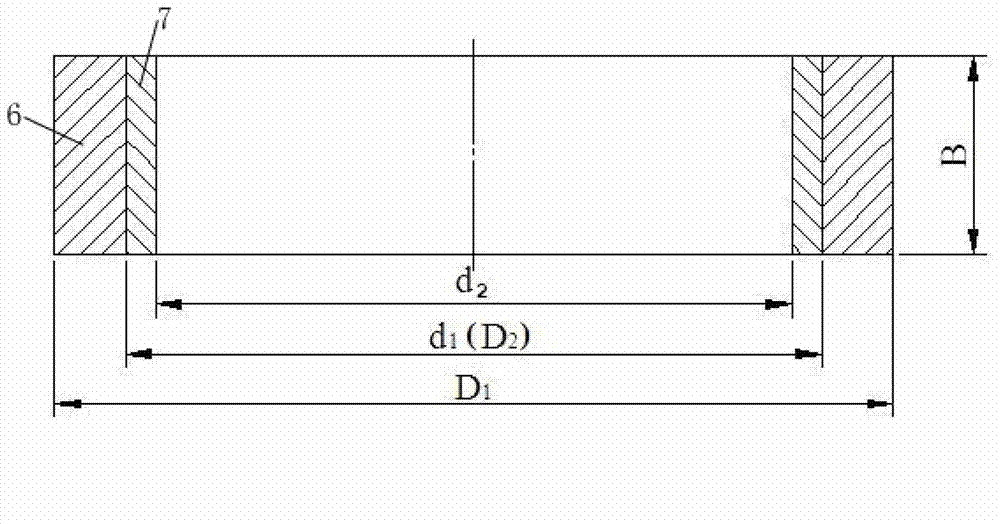

Precise roll forming method for bimetallic rings

ActiveCN103042142ASignificant energy saving and material savingReduce manufacturing costMetal rollingProduction rateRoll forming

The invention relates to a precise roll forming method for bimetallic rings. The method comprises: S1, obtaining an outer ring blank and an inner ring blank; S2, assembling the outer ring blank and the inner ring blank; S3, placing a core roller in the inner ring blank; S4, placing a drive roller outside the outer ring blank; S5, driving the drive roller to rotate through a drive device and driving the core roller to perform linear feed movement radially, wherein the outer ring blank and the inner ring blank are attached closely constantly to produce continuous local plastic deformation with the wall thickness reducing and the diameter expanding; and S6, stopping feed of the core roller and getting the core roller back when the outer diameter of the outer ring blank reaches a preset value of the outer diameter of a bimetallic ring. According to the precise roll forming method, the bimetallic ring is formed integrally through one step through continuous local plastic deformation, so that the method has the advantage that energy and materials are saved, the production cost is reduced, and the yield is improved. The bimetallic ring interface contact quality is good, the connection strength is high, and requirements of service performances and service lives of high-performance bimetallic rings can be met.

Owner:WUHAN UNIV OF TECH

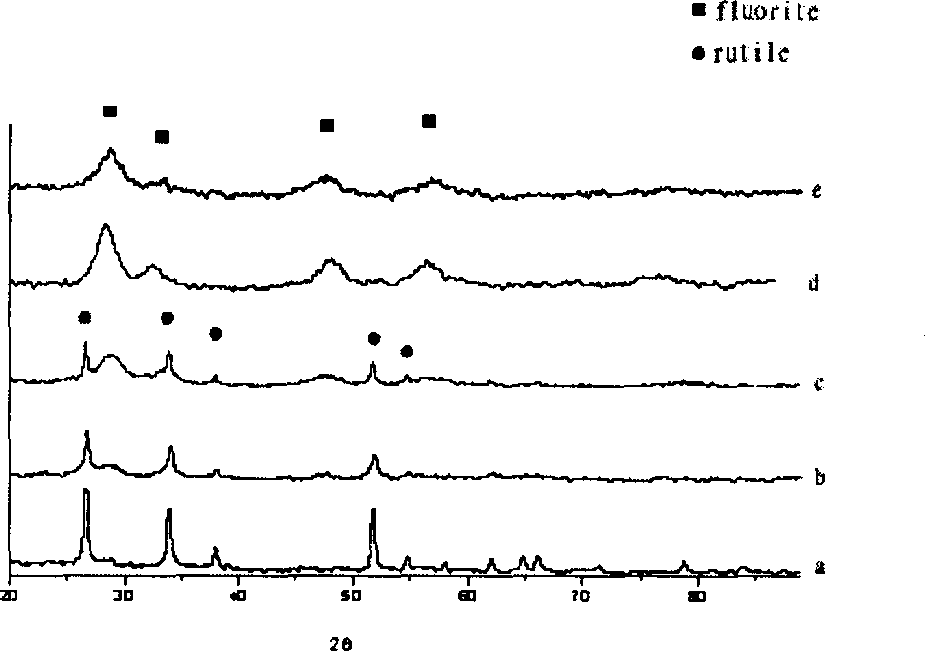

Titanium anode coated with iridium possessing high cerium content and high oxygen separated activity

the invention discloses a Ti anode of Ir coating layer with high-oxygen active high- Ce content at 1:3-3:1 for IrO2:CeO2, which comprises the following steps: adopting H2IrO6 and Ce (NO3)3 .6H2O as source material; predisposing Ti base; allocating the coating liquid; preparing coating layer; making CeO2 as electric catalyst carrier material and IrO2 as electric catalyst center.

Owner:FUZHOU UNIV

Preparing method of Ti Al-based alloy plate

InactiveCN101758236AOvercome the defect of poor deformability during cold and hot processingLow melting pointTension/compression control deviceMetal rolling arrangementsRoom temperatureTitanium

The present invention discloses a preparing method of a Ti Al-based alloy plate, which relates to a preparing method of an alloy plate. The present invention solves the problems that the existing Ti Al-based alloy is not easy to process into to form at room temperature; Ti Al-based alloy plates prepared by powder metallurgy technique are easy to pollute by interstitial elements with many impurities containing oxygen; and Ti Al-based alloy plates prepared by casting metallurgy technique and precision casting art have the disadvantages of crude grain structure, low strength and loose structure. In the method, pure titanium grains are piled in a steel module to obtain a multi-hole titanium prefabricated body; an Al-Si alloy casting wire is cut into block bodies; the block bodies are arranged on the multi-hole titanium prefabricated body to be sintered to obtain a Ti - Al double alloy complex body; the Ti - Al double alloy complex body is coldrolled to obtain a Ti - Al double alloy complex plate; the Ti - Al double alloy complex plate is sintered again, and is cooled to room temperature; the Ti - Al double alloy complex plate is retreated from the steel module to obtain the Ti Al-based alloy plate. The Ti Al-based alloy is processed to be formed at the room temperature, so the Ti Al-based alloy plate has the advantages of compaction, even structure, thin grain structure and high strength, and the negative effect of oxidation and impurities is reduced.

Owner:HARBIN INST OF TECH

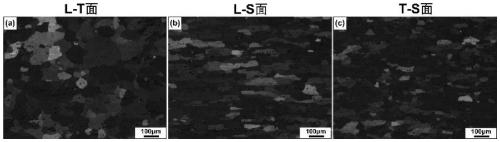

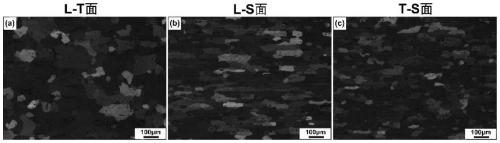

Rolling process for improving surface corrosion resistance of 6061 aluminum alloy

ActiveCN111334677AImprove corrosion resistanceImprove mechanical propertiesAnodisationTemperature controlThick plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a rolling process for improving surface corrosion resistance of 6061 aluminum alloy. The aluminum alloy comprises, by weight, 0.50%-0.65% of Si, less than or equal to 0.2% of Fe, 0.25%-0.35% of Cu, less than or equal to 0.10% of Mn, 0.9%-1.1% of Mg, 0.13%-0.26% of Cr, less than or equal to 0.05% of Ni, less than or equal to 0.04% of Zn, less than or equal to 0.15% of Ti, less than or equal to 0.05% of single impurities while less than or equal to 0.15% of the total impurities, and the balance Al. In the hot rolling procedure, the hot rolling process combining large-deformation rolling and small-deformation temperature control rolling is adopted, a 6061-T651 alloy thick plate with the excellent corrosion resistance is prepared, the grain structure of the plate is fine and uniform, and under the condition that the mechanical property is not lost, the corrosion resistance of the plate in the acidenvironment is greatly improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Low-Li high-plasticity high-strength Mg-Li alloy and preparation method of Mg-Li alloy plate

The invention discloses a low-lithium high-plasticity high-strength Mg-Li alloy prepared from the following components in percentage by mass: 4-7% of Li, 2-6% of Al, 0.5-3% of Zn, 0.2-1% of Mn, 0.1-1% of RE, 0-0.05% of Ti+B, less than 0.3% of impurities and the balance of Mg. The invention also discloses a preparation method of an Mg-Li alloy plate. The preparation method comprises the following steps: proportioning, smelting, casting, homogenizing, extruding, rolling and annealing. The Mg-Li alloy related to the invention is relatively low in Li content and relatively high in strength and corrosion resistance; meanwhile, due to the addition of Li, a close-packed hexagonal crystal structure of Mg is changed, the alloy has relatively high plasticity and can be subjected to cold-rolling deformation; and the adopted extrusion rolling process is simple in operation, the finished product rate is relatively high, and the obtained plate has favorable overall performances.

Owner:郑州轻研合金科技有限公司

Aluminum alloy band for jalousie and manufacturing method thereof

ActiveCN101144133AImprove the distribution patternSimple structureLight protection screensBase framesArc stabilityRare earth

The present invention discloses an aluminum alloy strip steel rolled stock used for a window blind and the production method thereof. The present invention is characterized in that the strip steel rolled stock includes the components and the weight mixing proportions of the material that iron is 0.26-0.34 percent, silicon is 0.05-0.15 percent, copper is 0.005-0.04 percent, manganese is 0.005-0.04 percent, chromium is 0.21-0.28 percent, magnesium is 2.20-2.48 percent, titanium is 0.025-0.045 percent, rare earth metal is 0.10-0.20 percent, and the residual is aluminum; the production method of the aluminum alloy strip used for the window blind comprises smelting, casting, head cutting and surface milling, homogenization annealing, hot rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling, draw bending and straightening, stabilizing treatment, and vertical cutting and strip separating. Compared with the prior art, the present invention has the remarkable advantages that the surface quality is good, the size accuracy is high, the shape of strip steel rolled stock is smooth, and the tensile strength, the product forming performance, and the arc stability better conform to the demand to the window blind.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

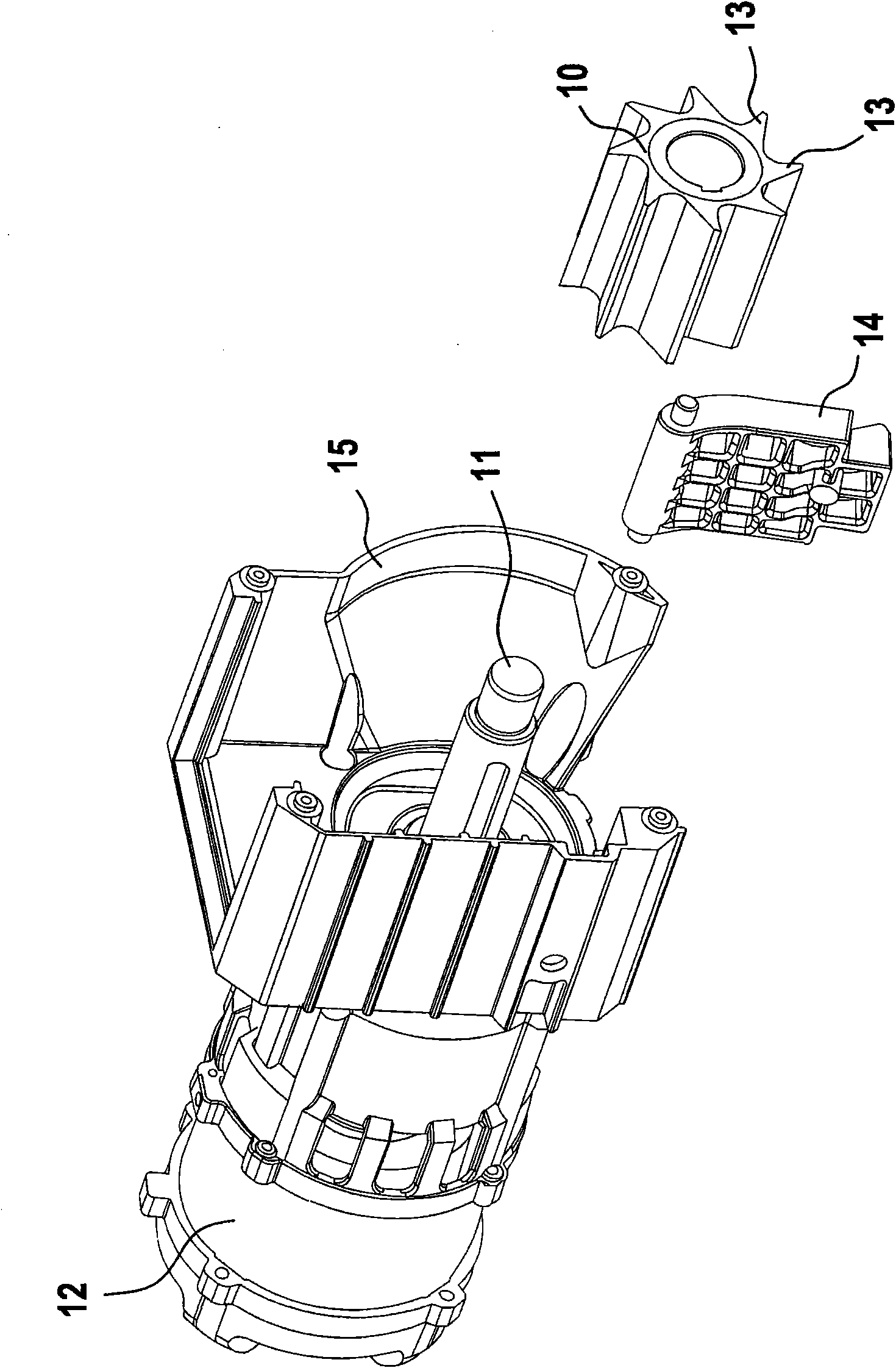

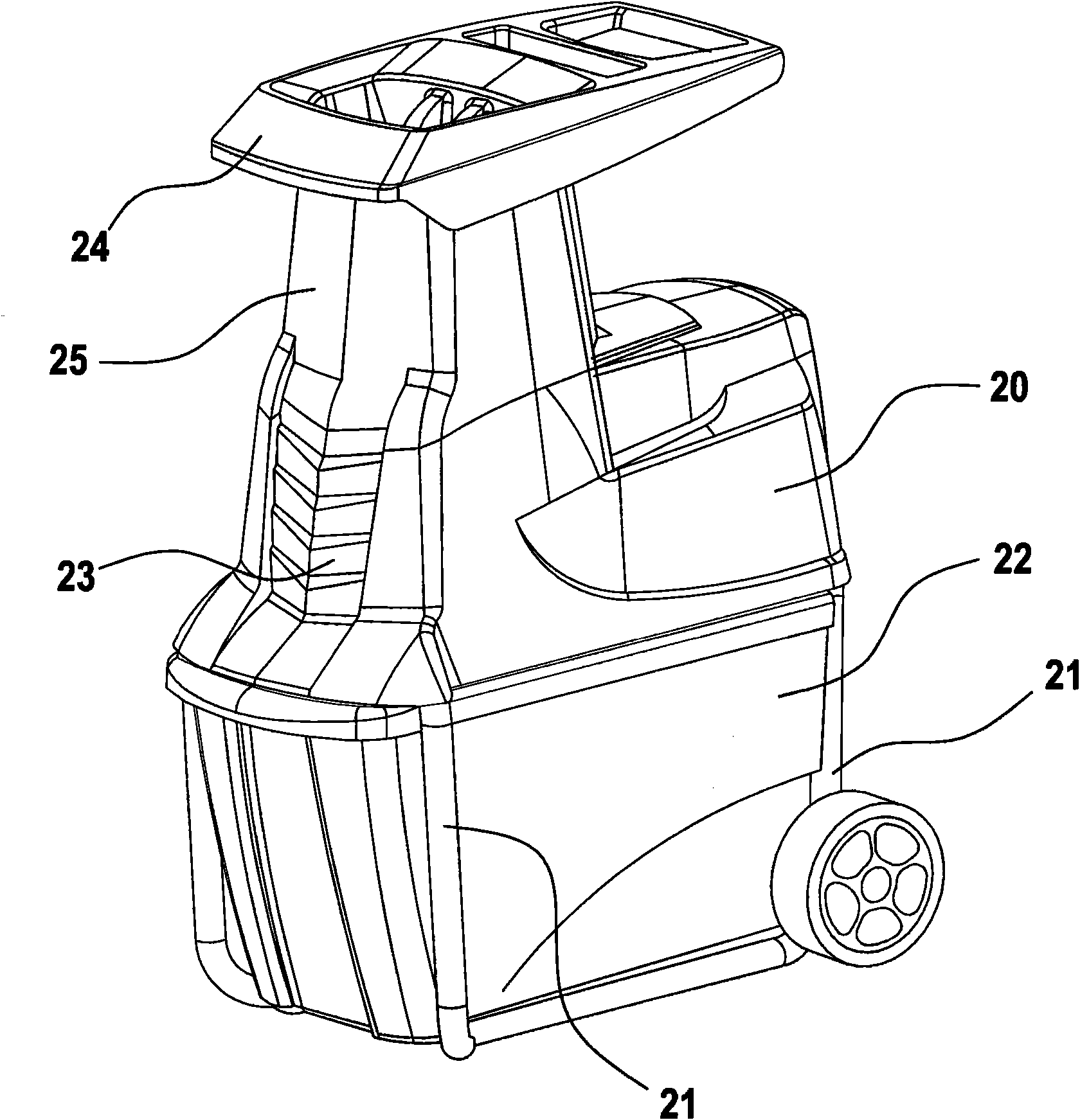

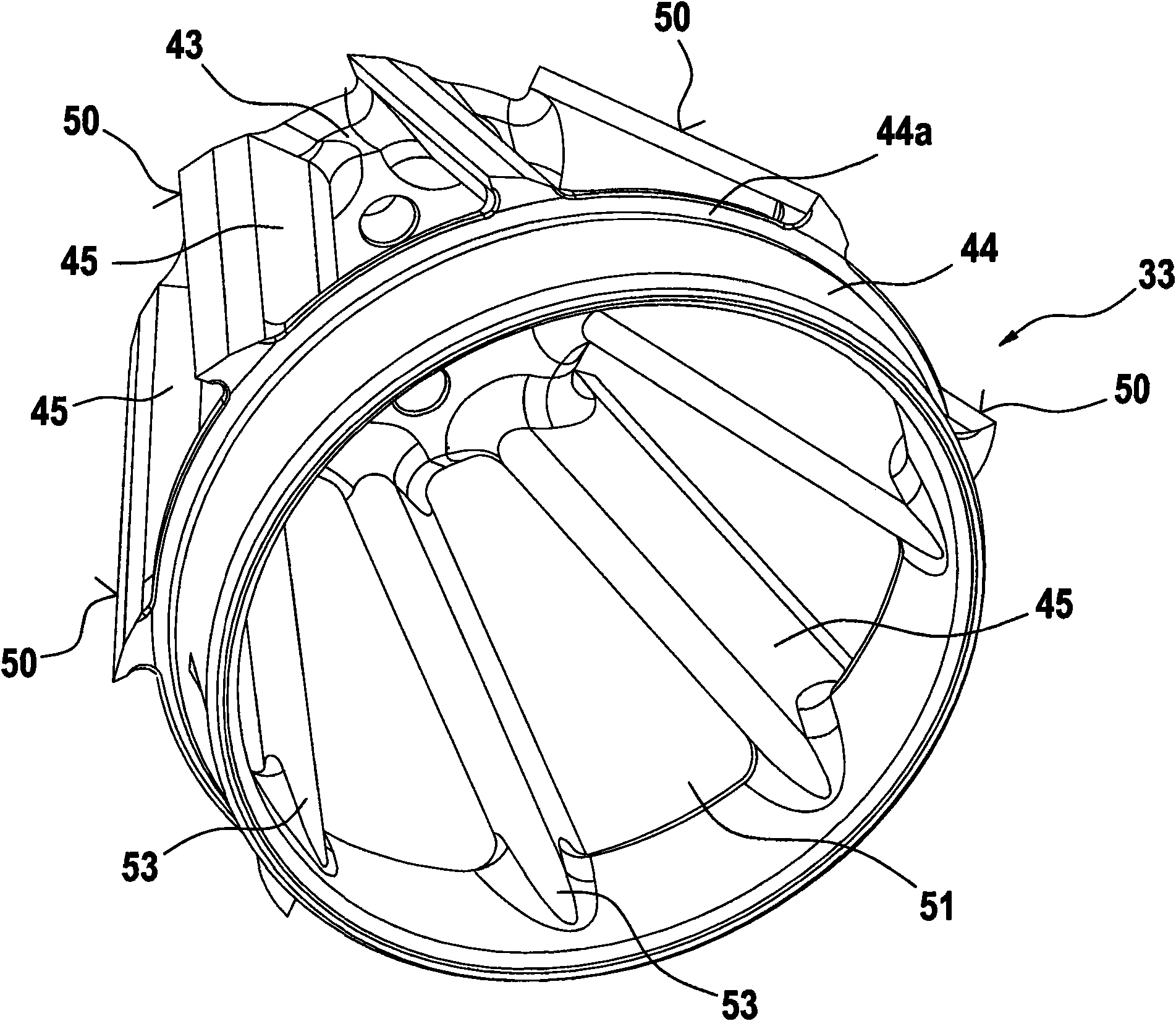

Improvements in or relating to shredder cutters

InactiveCN101903108AFine grain structurePlant waste comminutingCuttersConical formsInvestment casting

The present invention relates to improvements in or relating to cutters for shredders, in particular to cutters for shredders, in particular for vegetation shredders, suitably of the type used for shredding tree branches and garden waste. The present invention relates to a cutter (33) and method for manufacturing the cutter by means of investment casting. We describe a cutting element (33) for a vegetation shredder, the cutting element being a hollow unitary element comprising a plurality of elongate blades (45) arranged in a generally cylindrical configuration between a proximal and distal support elements (43, 44). The cylindrical configuration has a generally frusto-conical form, the distal support element (44) forming a base of said frusto-conical form. The cutting element is formed with elongate apertures (51) between adjacent blades (45).

Owner:ROBERT BOSCH GMBH

Preparation method of nano zirconia-toughened high-chromium refractory material

The invention discloses a preparation method of a nano zirconia-toughened high-chromium refractory material, which can produce a high-chromium material which has the advantages of favorable thermal shock resistance and low cracking tendency and can stably operate inside the kiln for a long time. The method comprises the following steps: by using 91-97 wt% of pigment-grade chrome oxide micropowder as a base, 1-6 wt% of nano zirconia powder as an additive and 3 wt% of titanium dioxide micropowder as a combustion assistant, dispersing by ball milling to form a uniformly dispersed slurry, drying the slurry to obtain powder, and carrying out binding molding to obtain the Cr2O3-ZrO2-TiO2 material. The Cr2O3-ZrO2-TiO2 high-chromium refractory material is a fine crystalline structure formed by distributing nano zirconia powder among the chrome oxide crystal grains or coating the nano zirconia powder among the chrome oxide crystal grains; and after the refractory material is sintered, the volume density is 3.52-4.68 g / cm<3>, and the porosity is 9.8-33.2%. The high-chromium refractory material has the advantages of higher compactness and higher thermal shock resistance.

Owner:TIANJIN UNIV

Method for producing 3004 grade aluminium alloy material used for Venetian blind

InactiveCN101434027AImprove surface qualityMeet needsMetal rolling arrangementsVenetian blindsSuperficial mass

The invention provides a method for manufacturing a No. 3004 aluminum alloy material used for a shutter, which maintains good surface quality of an aluminum strip, fine grain structure, leveled profile shape of a finished product, uniform thickness and high dimension precision through optimized casting, cold rolling and intermediate annealing. Moreover, the forming property and the camber stability accord with the requirements of the shutter product, and simultaneously the method has simple manufacturing technique, short production period, low cost and obvious productivity effect, and can use a cast and rolled plate blank to produce the aluminum material with good mechanical property, profile shape and surface quality for the shutter to meet the user requirements.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

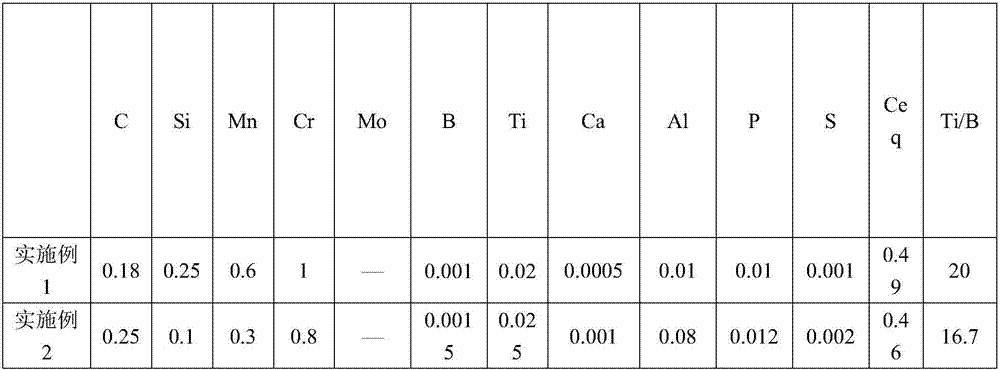

Oil sleeve resistant to hydrogen sulfide stress corrosion cracking and manufacturing method thereof

ActiveCN108004462AExcellent resistance to hydrogen sulfide stress crackingFulfil requirementsChemical elementStress corrosion cracking

The invention discloses an oil sleeve resistant to hydrogen sulfide stress corrosion cracking. The microstructure of the oil sleeve is tempered sorbite, and chemical elements of the oil sleeve comprise, by mass, 0.18-0.28% of C, 0.1-0.5% of Si, 0.3-0.6% of Mn, 0.5-1% of Cr, 0.01-0.05% of Ti, 0.01-0.08% of Al, 0.0005-0.005% of Ca, 0.001-0.003% of B, and the balance Fe and other inevitable impurities; the carbon equivalent Ceq of the oil sleeve is less than or equal to 0.5, wherein the Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15+Si / 24. Correspondingly, the invention further discloses a manufacturing method of the oil sleeve resistant to the hydrogen sulfide stress corrosion cracking. The oil sleeve is high in strength and good in hydrogen sulfide stress corrosion cracking resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Laser based metal deposition (LBMD) of implant structures

InactiveUS20060073356A1Minimize adverse effectsFine grain structureDental implantsFinger jointsArtificial jointsWear resistant

Owner:OPTIMOTION IMPLANTS LLC +1

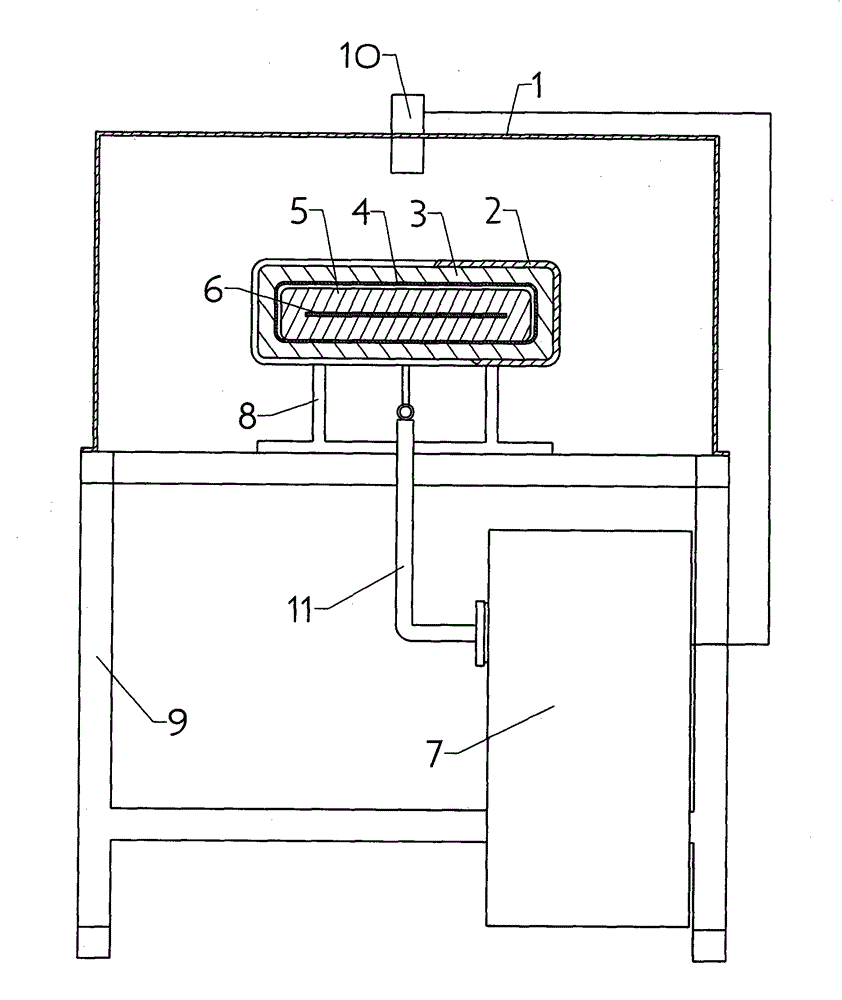

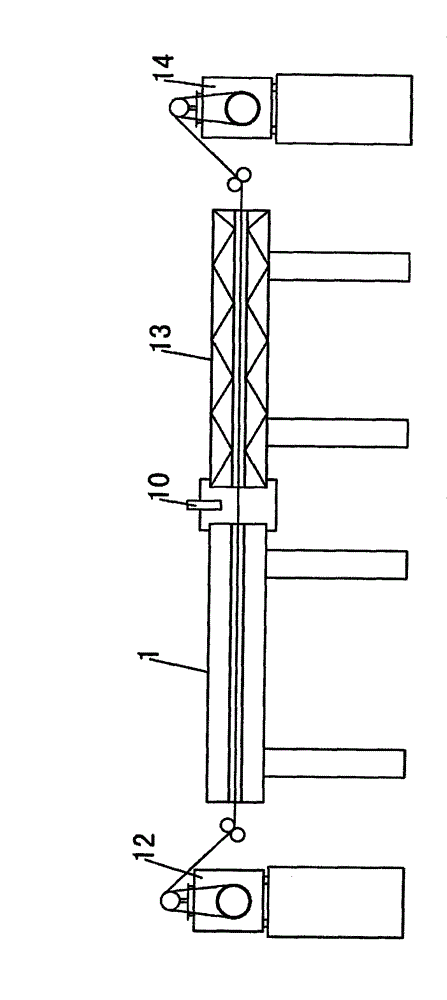

Inducing heating device for thin steel strip coil and heat treatment process thereof

InactiveCN102747204ACompact structureReasonable designFurnace typesIncreasing energy efficiencyFiberGraphite

The invention relates to an inducing heating device for a thin steel strip coil and a heat treatment process of the inducing heating device. An expanding bright annealing device is used for carrying out tension-free annealing to the thin steel strip coil, and the residual stress of the annealed product is eliminated. In addition, the heating mode is changed, and the reliability of the annealing device is improved. The temperature uniformity of the thin steel strip coil product is controlled in the temperature range of 2 DEG C, the heat treatment efficiency and the product quality are improved significantly, and a large amount of energy and time is saved. The inducing heating device for the thin steel strip coil comprises a furnace shell, an inducing heating coil, a high-temperature resistant fiber isolation furnace lining, a quartz tube, a graphite lining, a graphite inner cavity, a power supply device, a bracket, a base, a temperature measuring device and a water-cooled cable device. The base is correspondingly arranged below the furnace shell of the inducing heating device. The bracket is arranged in the middle part above the base. The rectangular inducing heating coil on the bracket is arranged in the furnace shell of the inducing heating device and internally provided with the high-temperature resistant fiber isolation furnace lining with a rectangular section.

Owner:洛阳用功感应加热设备有限公司

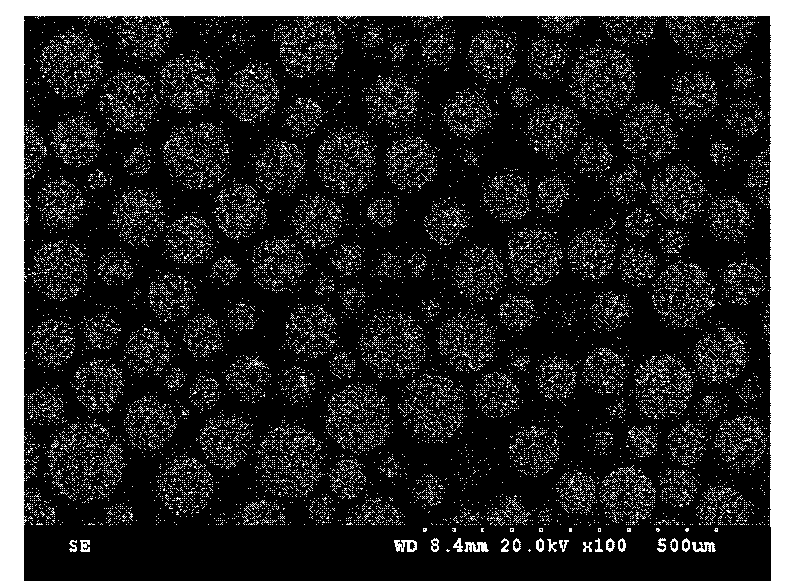

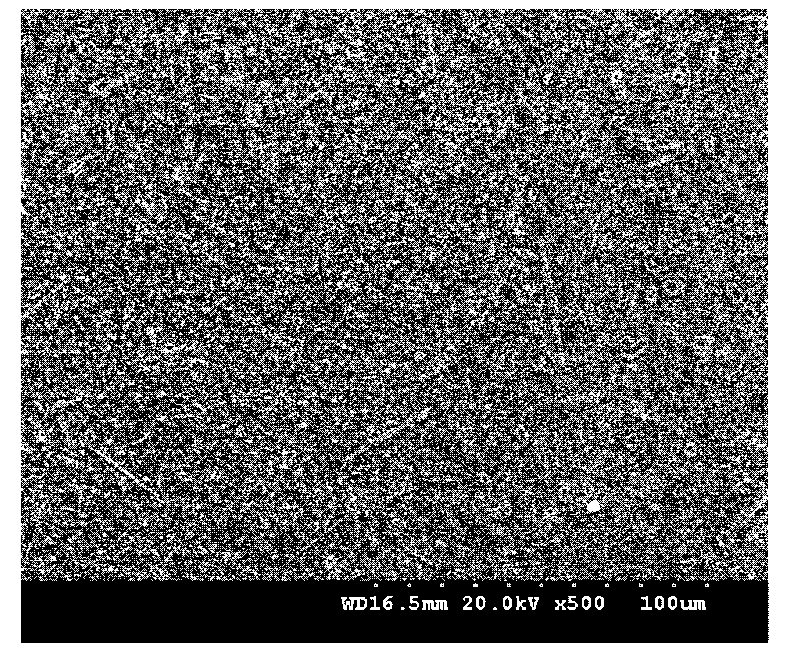

Preparing method of high-density and high-purity sputtering rotation silver target material

InactiveCN105039920AHigh speedSimple processVacuum evaporation coatingSputtering coatingHigh densitySand blasting

The invention discloses a preparing method of a high-density and high-purity sputtering rotation silver target material. Firstly, stainless steel is machined according to the requirement of customers, secondly, sand blasting is carried out through brown aluminium oxide, and thirdly, Cu-Al wires are used for bottoming, wherein the thickness of a bottoming layer is 0.5 mm. A laval spraying pipe manufactured through carbon tungsten alloy is used for spraying silver powder, and the structure of the spraying pipe designed through carbon tungsten is shown as the graph 1. The silver powder is spherical powder, the granularity ranges from 5 microns to 45 microns, the pressure of nitrogen ranges from 3 Mpa to 5 Mpa, the heating temperature of nitrogen ranges from 400 DEG C to 500 DEG C, and the powder conveying rotating speed is 6 RPM. Secondary acceleration is carried out on particles through the laval spraying pipe, and the particle speed is increased to range from 600 m / s to 800 m / s. By means of the method for preparing the silver target material through cold spraying, the beneficial effects of the simple technology and the compact structure are achieved. The relative density of the target material can reach more than 99.8%, the grain structure in the target material is uniform and fine, and the defective structure is avoided. The deposition efficiency is high, and the production cost is reduced.

Owner:WUHU YINGRI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com