Titanium anode containing ruthenium coating of high cerium content and its preparing method

A titanium anode and content technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult control of oxide non-stoichiometric ratio, unclear contribution of electrocatalytic performance, uneven structure of coating, etc., to achieve operation Convenience, low electrode potential for chlorine evolution, and fine grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method steps of the ruthenium-containing coated titanium anode with high cerium content of the present invention are as follows:

[0023] e. Titanium-based pretreatment, that is, the titanium substrate is deesterified, degreased, pickled and etched with a cleaning agent;

[0024] f. Preparation of unit coating solution, including: preparation of CeO 2 Sol: Ce(NO 3 ) 3 ·6H 2 In the absolute ethanol solution of O, add the mixed solution of non-precipitating citric acid and ethylene glycol drop by drop, stir well; prepare RuO 2 Sol: heating, stirring RuCl without precipitation 3 ·3H 2 O ethanol solution, and at the same time, drop by drop the mixed solution of citric acid and ethylene glycol without precipitation, and keep it warm for more than 3 hours under the environment of 50~80°C;

[0025] g. Multi-component coating solution preparation, the CeO prepared in the above step b 2 and RuO 2 Mix the unit coating solution, continue to stir for more th...

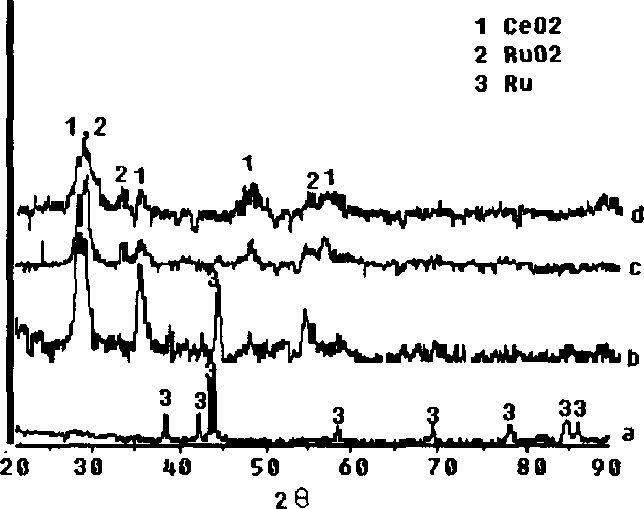

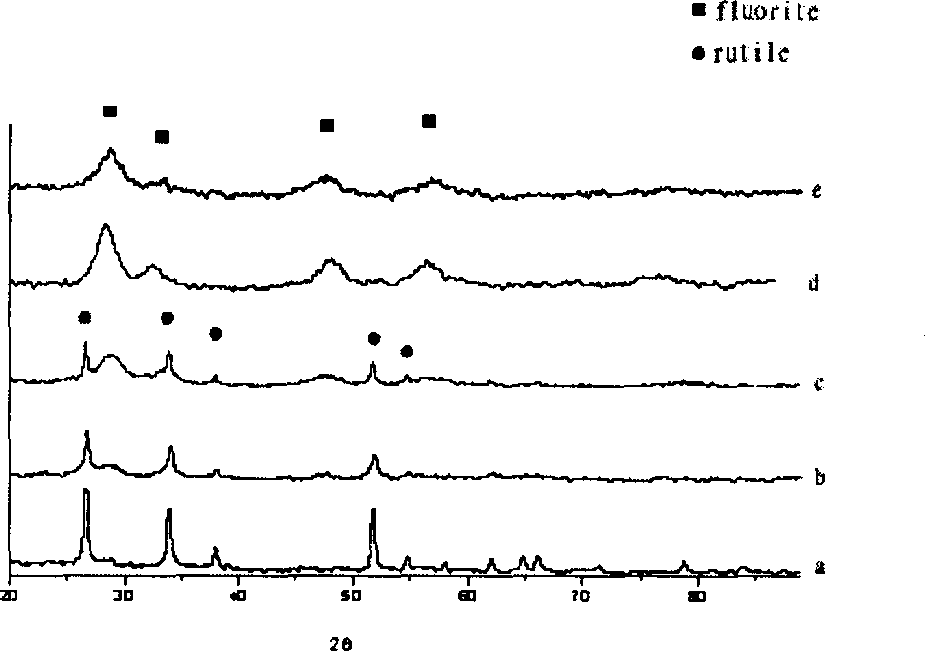

Embodiment 1

[0031] A 20mm×40mm titanium plate (Tal) was degreased by alkaline washing powder, put into 10% (mass fraction) oxalic acid solution, boiled for 2 hours, taken out, rinsed with distilled water and dried, then put into ethanol solution for later use. Weigh a certain amount of Ce(NO 3 ) 3 ·6H 2 O was dissolved in an appropriate amount of absolute ethanol, and a mixed solution of citric acid and ethylene glycol was added drop by drop, fully stirred; a certain amount of RuCl was weighed 3 ·3H 2 O was put into a beaker, diluted with an appropriate amount of ethanol immediately, heated and stirred, and at the same time, a mixed solution of citric acid, ethylene glycol and nitric acid was dropped at a rate of 1 drop / second, and kept at 60°C for more than 3 hours. Form the above into CeO 2 and RuO 2 The solutions were mixed according to the required molar ratio (see Table 1), continued to stir for more than 3 hours, and stood still for 24h. The above-mentioned coating solution wa...

Embodiment 2

[0034] A 20mm×40mm titanium plate (Tal) was degreased by alkaline washing powder, put into 10% (mass fraction) oxalic acid solution, boiled for 2 hours, taken out, rinsed with distilled water and dried, then put into ethanol solution for later use. Weigh a certain amount of Ce(NO 3 ) 3 ·6H 2 O was dissolved in an appropriate amount of absolute ethanol, and a mixed solution of citric acid and ethylene glycol was added drop by drop, fully stirred; a certain amount of RuCl was weighed 3 ·3H 2 O was put into a beaker, diluted with an appropriate amount of ethanol immediately, heated and stirred, and at the same time, a mixed solution of citric acid, ethylene glycol and nitric acid was dropped at a rate of 1 drop / second, and kept at 60°C for more than 3 hours. Weigh a certain amount of SnCl 2 2H 2 O was dissolved in an appropriate amount of absolute ethanol, and the mixed solution of citric acid and ethylene glycol was added drop by drop, and fully stirred. Form the above int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com